Page 1

MAKER’S WARRANTY

Cannon

FREESTANDER MODELS

CANT, CANTLP

USER INSTRUCTIONS

INSTALLATION INSTRUCTIONS

SERVICE INSTRUCTIONS

This heater is approved for use with Natural and Propane gases.

Please leave instructions with the owner

Page 2

Contents

Contents 2

Warranty 3

Safety warnings 4

❍ What to do if you smell gas

❍ Warnings

❍ Standards

User instructions 6

❍ Operating instructions

❍ Cleaning

Heater specifications 9

❍ Alternative flue

Installation instructions 10

❍ Clearances

❍ Installation

❍ Gas connection

❍ Fuel bed & log installation

❍ Gas pressure point

Flue installation 14-15

❍ Flue kit

❍ Alternative double skin flue installation

❍ Alternative flue kit

Service instructions 18-20

❍ General

❍ Access to components

To replace the gas control

To replace the fan

To replace the electronic controller

To check or change fuse

To remove the burner and electrodes

❍ Trouble shooting

❍ Wiring diagram

❍ Authorised service agents

2

Page 3

Warranty

The Cannon appliance is warranted against defects in materials

and workmanship for a period of one, (1) year from its date of

original purchase, for residential use in Australia.

Warranty service, which includes parts and labour for the replacement or repair of defective parts, is available through Cannon

Authorised Service Agencies. (Please refer to the list of authorised

service agents in this manual.)

Consumers are responsible for service person’s travel outside normal service areas (approximately seventy (70k) radius from the

nearest Cannon dealer’s location), local cartage, and normal maintenance as described in this manual.

Any product subjected to misuse, abuse, negligence, accident or

alteration will have its warranty voided. The defacement of serial

plate will have it’s warranty voided.

If installation is not carried out in accordance with manufacturer’s

instructions, this warranty may be void.

The customer must keep their “Tax Invoice” as proof of purchase of

this product, and compliance certificate as proof of required installation.

Model number: ______________________________________

Serial number: _______________________________________

Date of manufacture: _________________________________

Date installed: _______________________________________

Compliance Certificate No: ____________________________

Don’t risk your appliance warranty

Only a licensed person will give you a Compliance Certificate, showing that the work complies with all the relevant

standards.

And only a licensed person will have insurance protecting

their workmanship for 6 years.

So make sure you use a licensed person to install this appliance and ask for your Compliance Certificate to ensure the

manufacturers appliance warranty will be honoured.

3

Page 4

Safety Warnings

Please read this manual before installing and using the heater.

What to do if you smell

gas

Warnings

1. Turn OFF the main gas supply.

2. Extinguish any open flame.

3. Open windows.

4. Do not touch electrical switches.

5. Do not use your telephone.

6. Call your gas supplier immediately from a neighbour’s phone.

1. Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to other

sections of this manual for correct procedures, or consult with

place of purchase, a licensed plumber, a gas supplier or

service agent listed in this manual.

2. Due to high temperatures the room heater should be located

out of traffic and away from:

• Furniture and draperies,

• Combustible materials,

• Gasoline and other flammable liquids,

Do not place clothing or other flammable material on or near

the heater.

3. Keep curtains*, clothing, furniture and other flammable materials at least 900mm from front, rear and sides of the heater.

* At the owner’s discretion curtain clearance can be less than

900mm as long as they are restrained from the front, top and

sides of the heater. The manufacturer takes no responsibility if

curtain clearance is less than 900mm and not restrained.

4. Children and adults should be alerted to the hazard of high

surface temperature and should take care to avoid burns or

clothing ignition.

Young children should be carefully supervised when they are

in the same room as the heater.

5. Never attempt to burn paper or any other material in the

heater.

6. Do not spray aerosols in the vicinity of this appliance while it

is in operation.

7. If removed the glass window must be put back onto the unit

prior to operating the heater.

8. Installation and repairs should be performed by a licensed

service person only, refer to back of brochure for service

number.

4

Page 5

9. The appliance should be inspected prior to use, with regular

inspections (annually) to be made by a licensed service person. It is important that circulating air passageways of the

appliance be kept clean, dirt and lint free, for a safe and

efficient operation of the heater.

10. On first lighting your heater a smell may occur due to it’s new

condition. This is quite normal and will disappear after a few

hours use at the maximum control position.

Important:

WHEN THIS HEATER IS OPERATING, THE GLASS FRONT IS HOT.

A safety guard conforming to AGA requirements is available for

this heater. It is an optional extra, which may be fitted to the heater

to reduce the risk of fire or injury from burns. Its fitting is recommended when there are children present. For permanent protection

of young children or the infirm, an optional mesh guard is recommended. Call your retailer or authorised service agent for further

details.

Standards

This appliance meets the following standards:

Standards Australia: AS 3100

AS 5601/AG 601

AS 4553/AG 103

5

Page 6

User instructions

Operating instructions

The Australian Gas Association: AG 103

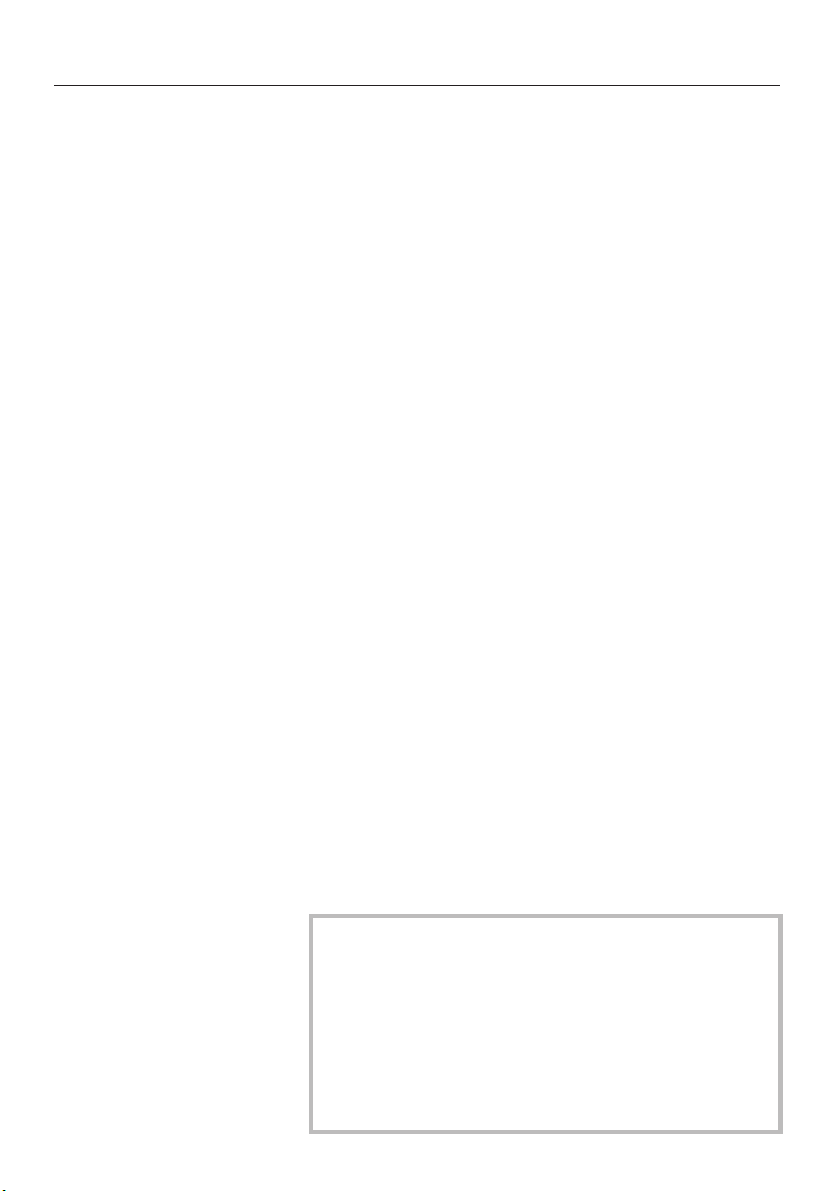

1. Plug the power cord into the wall socket and turn on the power

to the heater, see figure 1. Use of an extension cord is not

recommended

1

2. For control lay-out refer to figure 2

2

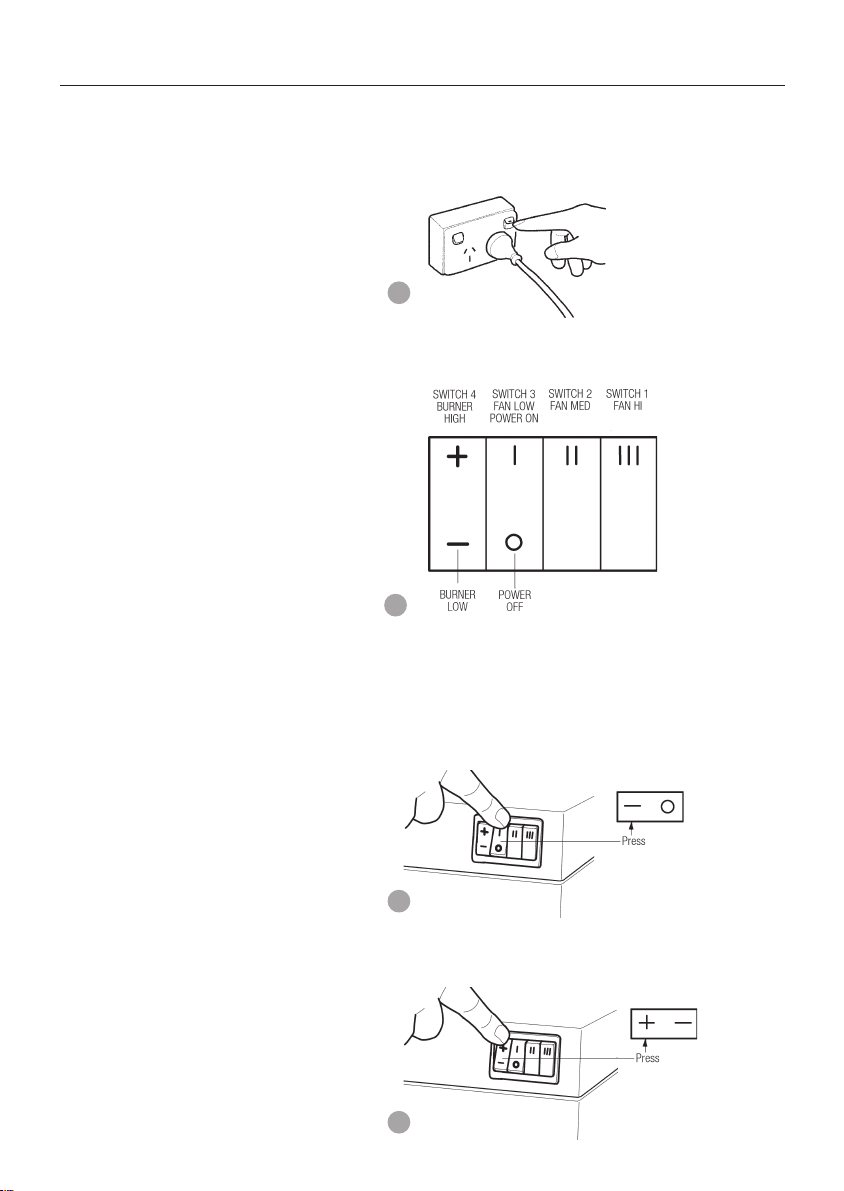

3. To turn heater on press switch to POWER ON position. There

is a 5 second delay before the burner ignites. At this setting the

burner is on LOW and the fan speed is on LOW. Refer

figure 3.

The burner will ignite on both HIGH and LOW settings.

3

4. To turn burner to HIGH setting, press switch for HIGH setting.

Refer figure 4.

4

6

Page 7

5. To increase the fan speed to MED, press switch for MED setting. Refer figure 5.

5

6. To increase the fan speed to HIGH, press switch for HIGH

setting. Refer figure 6.

6

7. To turn the burner to LOW setting, press switch for LOW setting. Refer figure 7.

On low burner setting it is more efficient to operate the fan

speed on LOW.

7

8. If the burner fails to ignite, wait 20 seconds and repeat the

ignition porcedure. See below.

To turn burner OFF To turn burner ON

7

Page 8

User instructions continued

Cleaning.

All cleaning should be carried out when the heater is cold. Normally the heater should only need wiping with a lint - free damp

cloth. Any stubborn stains can be removed with a non-abrasive

spray on cleaner. If an abrasive cleaner is used the paint finish will

be damaged.

Internally the heater should only be cleaned by a licensed service

person listed in this manual.

If your heater requires attention contact your supplier or licensed

service person listed in this manual.

Important:

The appliance should be inspected before use and at least annually by an authorised service person. More frequent cleaning may

be required due to excessive lint build-up from carpeting, bedding

materials, pet hair, etc.

It is imperative that control compartments, burners and circulating

air passage ways of the appliance be kept clean.

Do not use this fire if the glass is cracked or with the glass safety

screen removed.

Do not use fire with broken or missing logs.

8

Page 9

Page 10

Installation Instructions

1. This appliance is to be installed by a licensed service person

only.

2. This appliance is to be installed in accordance with the

manufacturer’s installation instructions, AS 5601/AG601,

Municipal Building Codes, Electrical Wiring Regulations and

any other statutory regulations.

Clearances

3. Ensure the minimum clearances to combustible construction are

maintained during installation, including adequate space for

the proper operation and servicing of the heater.

For clearances to curtains and furnishing refer to warning 3 on

page 4

For minimum clearances refer fig 9 and 10.

Installation

10

9

4. Remove the carton from the heater and lift from pallet. Check

the heater is suitable for gas available.

(Please dispose of packaging appropriately, keep away from

children).

5. Prepare electrical and gas connections, a 10 Amp wall socket

needs to be located within 1.5m of the heater.

6. Fit rear spacers as per figure 10.

7. Place heater in position. (Check flue and gas connection posi-

tions. Refer to gas connection instructions on page 11 and flue

installation instructions on pages 14 & 15 and 16 & 17).

8. Remove the pedestal front by unscrewing two screws either

side. Refer figure 11.

Remove the heater front securing screws, one either side. Refer

figure 12.

10

Page 11

11

12

9. Remove the front glass surround by holding it firmly on either

side and pulling it towards yourself, see figure 13.

13

10.Remove the inner glass. Slacken off screws in top clamp and

remove side clamps. Refer figure 14.

14

Gas connection

11. Connect incoming gas supply pipe to compression fitting at

rear of appliance. For inlet position see figure 15.

15

11

Page 12

Installation instructions continued

Fuel bed and log

installation

12. The fuel bed is contained within the burner chamber. Remove

the fuel bed transit packaging. Refer figure 16.

The fuel bed is retained by a spring clip fixed to the rear of the

burner chamber

FUEL BED MUST BE HARD UP AGAINST REAR OF BURNER

16

13. Carefully unpack the log set. Logs are numbered as follows:

No 1 - Left front log

No 2 - left back log

No 3 - Right front log

No 4 - Right back log

Position the four individually numbered logs in the following

order on the fuel bed as shown in figures 17-20. The male

locating pins in fuel bed must engage with corresponding

holes in the individual logs.

a) Place log No.1 onto the 2 front left pins on the fuel bed,

see figure 17.

12

17

b) Place log No.2 onto the 2 left back pins. Refer figure 18.

18

c) Place log No.3 on single right front pin, ensure fork

locates over log No. 2, see figure 19.

19

Page 13

d) Place log No. 4 on single right back pin, ensure left side

of log rests on depression in No. 3 log, see figure 20.

20

14. Refit the inner glass, but do not overtighten the screws.

15. Refit the front glass surround. Ensure that the glass surround is

replaced the correct side up. The rearward sloping frame must

be at the top and the vertical ledge must be at the bottom.

Refer figure 21.

21

Gas pressure point

16. Using an 8mm spanner remove the pressure point cover and

check the outlet pressure of the gas regulator. It should be 1.0

kPa for NG, 2.75 for LP gas. Adjustment for LP gas is at the

gas bottle regulator. The outlet pressure point is situated on the

RHS top of the gas control. Refer figure 22

22

17. Refit the pedestal cover.

18. Follow User Instructions to turn on heater.

Important:

To achieve the correct visual flame effect:

On Propane the gas pressure must be set at 2.75 kPa

with burner operating on maximum setting.

On Natural Gas the gas pressure must be set at 1.0 kPa.

13

Page 14

Flue installation

This heater is a flued appliance. It must be properly connected to a

flue system in accordance with the latest edition of the Gas Installation Code, AS 5601/AG 601.

If elbows are needed, the total horizontal length depends on the

number of elbows used. Venting should never slope down. A 6mm

per 500mm horizontal rise is recommended.

If practical locate the heater in a position to minimise the use of

horizontals and elbows.

The flue rise should be a minimum of 1.8m before any horizontal

run is used.

If placed against a combustible wall the 40mm rear spacers locate

against the wall.

1. Ensure clearances to combustible have been observed. For

clearances refer page 10.

2. The centre line of the flue is 75mm to rear of appliance (ex

cluding rear spacers).

3. Carry out installation as per figure 23 (ceiling plate installation)

and figure 24 (flue installation).

Cut a hole 180mm ø in the ceiling in line with the flue position.

Secure ceiling plate against the ceiling by bending out the tabs

above the ceiling.

Note: If the ceiling has an incline, the ceiling box will need to

be fitted. Installation instructions are supplied with the ceiling

box.

20

Flue kit

14

23

The flue kit contains:

3 x 900mm lengths of 125mm ø painted flue.

1 x 900mm length of 125mm ø plain flue.

1 x ceiling plate

1 x 900mm painted bottom flue spigot.

Page 15

24

15

Page 16

Installation instructions continued

Alternative double skin

flue installation

This heater is a flued appliance. It must be properly connected to a

flue system in accordance with the latest edition of the Gas Installation Code, AS 5601/AG 601.

If elbows are needed, the total horizontal length depends on the

number of elbows used. Venting should never slope down. A 6mm

per 500mm horizontal rise is recommended.

If practical locate the heater in a position to minimise the use of

horizontals and elbows.

The flue rise should be a minimum of 1.8m before any horizontal

run is used.

1. Ensure clearances to combustible have been observed. For clearances refer page 10.

2. The centre line of the flue is 75mm to rear of appliance (excl.

rrear spacers)

3. Carry out installation as per figure 25 (ceiling plate installation)

and figures 27 & 28 (flue installation).

Cut a hole 195 x 185mm in the ceiling in line with the flue

position.

4. One large and two small holes in the bottom end of the lower

outer flue cover locate around the flue spigot and two locating

pins. Refer figure 26.

Note: If the ceiling has an incline refer to installation leaflet en-

20

closed with ceiling plate package.

Alternative flue kit

16

25

The flue kit contains:

4 x 900mm lengths of 75mm ø inner galvanised flue.

1 x 850mm length of 170mm wide lower outer flue cover.

2 x 850mm length of 170mm wide upper flue cover.

1 x ceiling plate.

1 x 75mm ø flue cowl

Page 17

27

28

26

17

Page 18

Service Instructions

General

Access to components

1. Service work to be carried out by a licensed service person

only.

2. Unplug from wall socket.

3. Always shut off the gas supply and ensure that the heater is cool

before commencing any service operations.

4. Always check for gas soundness after servicing.

Remove the pedestal front by unscrewing two screws. Refer

figure 11.

To replace the gas control

1. Disconnect the gas regulator connector from the electronic

module.

2. Undo the inlet and outlet compression nuts.

3. Unscrew the four M3 retaining screws adjacent to the gas inlet

at the rear of the appliance, releasing the control.

4. Replace in reverse order.

To replace the fan

1. Disconnect the fan plug from the electronic controller.

2. Undo the two M5 wing nuts fixing the fan to the burner chamber

underside.

3. Replace in reverse order.

18

To replace the electronic controller

1. Disconnect the three earth leads by unscrewing the M5 nut at

the base of the unit.

2. Disconnect the fan plug from the electronic controller.

3. Disconnect the gas regulator connector from the electronic controller.

4. Unscrew the M5 wing nut holding the electronic controller in

place.

5. Replace in the reverse order ensuring that the earth leads are

fitted correctly.

To check or change fuse

1. Using a small flat screwdriver turn the fuse holder anticlockwise

untill it pops out.

2. replace with 1A fuse

To remove the burner and electrodes

1. Follow steps 11 and 14 of the installation instructions.

Page 19

2. Remove the logs and the fuel bed from the burner chamber.

3. Disconnect the compression nut at the back of the burner now

visible through the primary baffle.

4. Remove lower front panel.

5. Remove the four M5 screws fixing the burner chamber fascia in

position and slide out taking a note of the “P” clip position

through which the thermocouple leads are passed.

6. Remove the two M5 screws fixing the burner to the burner chamber fascia.

7. Remove the two 8G self tapping screws fixing the electrodes in

position.

8. Replace in reverse order.

Troubleshooting

Item No Check Action

1 Check 240V power to heater. Use a multimeter to confirm presence of 240V.

2 Confirm spark is produced A blue spark can be seen when the heater

when heater is turned on. ignition process starts. Ensure spark is present

between electrode and burner. Listen for cracking

sound when spark is produced.

3 If no spark is produced. • Ensure spark electrode is OK.

• Check fuse in heater.

• Check 240V power is present at spark box

when heater switch is ON. Terminal 1 is active

in. Terminal 2 is neutral.

• Check that all terminals on the module are

clean and firm.

4 Spark is heard but no flame • Check that solenoid valves are opening.

starts. • Check that gas supply is on.

• Terminal 5 is active to valve 1.

• Terminal 7 is active to valve 2.

• Check that spark gap is as specified. Refer

figure 29 on page 20.

5 If flame lights and goes out. • Check that the wall socket to the appliance

has correct polarity.

• Check polarity in the lead to the appliance. (Do

not use extension cord).

• Check that the sense probe is in the flame.

• Check that the appliance is earthed correctly.

A multi meter between the lead earth plug and

the appliance parts should see a resistance of

0.1 Ohms. The burner earth should be

checked.

6 Fan does not work • Check for clogging with dust.

Check all fan speeds for correct operation.

•

• Check fuse.

19

Page 20

Service instructions continued

29

Wiring diagram

Authorised service agents

For further information or spare parts contact the CANNON distributor in your

state.

Sampford & Staff Pty Ltd

421 Smith Street.

Fitzroy, Vic, 3065

Vic/Tas: (03) 9418 5800

NSW: (02) 9331 8888

SA/NT: (08) 8212 7000

Qld: (07) 3358 3000

WA: (08) 9242 5333

ACT: (02) 6280 4177

Elsewhere: 1800 334 887

email: service@sampford.com.au

20

Part No: F2574

Revision G

Loading...

Loading...