Campbell Hausfeld WS0900, WS0950, WS1000, WS1020 User Manual

D

E

C

R

E

A

S

E

I

N

C

R

E

A

S

E

1

2

3

4

5

6

1

2

4

5

6

3

1

Operating Instructions & Parts Manual Models WS0900, WS0950, WS1000 and WS1020

CAMPBELL

HAUSFELD

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It also may mean a

hazard that will only cause damage to

property.

NOTE: Note means any additional

information pertaining to the product

or its proper usage.

1/16 15 amp

5/64 20 amp

Q

U

A

L

I

T

Y

A

S

S

U

R

A

N

C

E

P

R

O

G

R

A

M

Need

Assistance?

Call Us First!

1-800-746-5641

Description

General Safety

IN198903AV 4/97

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Shielded Metal

Arc Welder

This line of Campbell Hausfeld Arc

Welders is designed to be used on

standard 115V household current. These

welders are equipped with infinite

amperage control to accurately select the

proper current needed for various

welding conditions. Internal components

are thermostatically protected.

This welder can weld up to 1/8” steel in

a single pass. Recommended electrode

size is 1/16” diameter for 15 amp

circuits, up to 5/64” diameter for 20

amp circuits. For replacement

electrodes, call (800) 746-5641 for the

nearest dealer.

MODEL

WS1020

ONLY

Unpacking

When unpacking, inspect carefully for

any damage that may have occurred

during transit. Report any damaged or

missing items by calling 1-800-746-5641.

Circuit Requirements

dedicated 115 volt circuit. Refer to the

following chart for the correct circuit

breaker or fuse rating. Do not run

other appliances, lights, or tools on

this circuit while operating this

equipment. Extension cords are not

recommended. Blown fuses or tripped

circuit breakers can result from failure

to comply with this recommendation.

Electrode Circuit Breaker or

Diameter Slow Blow Fuse

This equipment

requires a

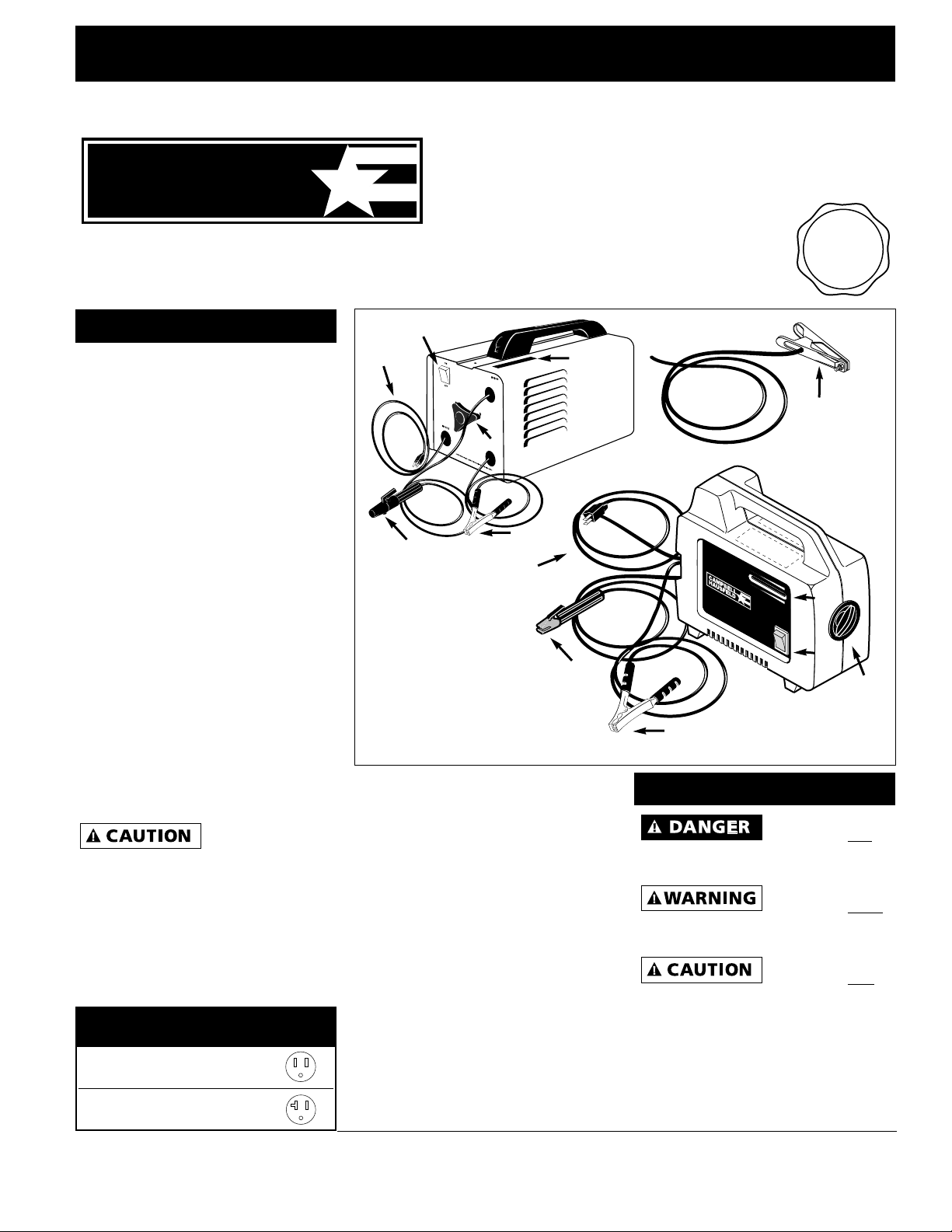

Figure 1 - Welder Components

and Controls

Components and Controls

1. Work Clamp - connect to work piece

2. Electrode Holder - holds electrode

welding rod

3. Power Cord - plug into 115 volt outlet.

4. On/Off Switch - lights if thermostat

has automatically shut unit off.

5. Infinite Amperage Control Knob turns clockwise to increase amperage

and counterclockwise to decrease

amperage.

6. Welding Amp Indicator - as the

amperage control knob (5) is rotated,

the amperage indicator moves

displaying approximate weld amps.

1

MODEL WS0900

Danger means a

hazard that will

Shielded Metal Arc Welder

Always keep a fire

extinguisher accessible

while performing arc

welding operations.

General Safety (Con’t)

● Before starting or servicing any

electric arc welder, read and

understand all instructions. Failure

to follow safety precautions or

instructions can cause equipment

damage and or serious personal

injury or death.

● All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Improper use of electric

arc welders can cause

electric shock, injury,

and death! Take all

precautions described in

this manual to reduce the possibility of

electric shock.

● Verify that all components of the

arc welder are clean and in good

condition prior to operating the

welder. Be sure that the insulation

on all cables, electrode holders, and

power cords is not damaged.

Always repair or replace damaged

components before operating the

welder. Always keep welder panels,

shields, etc. in place when operating

the welder.

● Always wear dry protective clothing

and welding gloves, and insulated

footwear.

● Always operate the welder in a

clean, dry, well ventilated area. Do

not operate the welder in humid,

wet, rainy, or poorly ventilated

areas.

● Be sure that the work piece is

properly supported and grounded

prior to beginning any electric arc

welding operation.

● Coiled welding cable should be spread

out before use to avoid overheating

and damage to insulation.

Never immerse the

electrode or

electrode holder in water. If the welder

becomes wet for any reason, be

absolutely certain that it is completely

clean and dry prior to attempting use!

● Always shut the equipment off and

unplug the power prior to moving

the unit.

● Always attach the work lead first.

● Verify that the work piece is

securely grounded.

● Always shut off electric arc welding

equipment when not in use and, and

remove the electrode from the holder.

● Never allow any part of the body to

touch the electrode and ground or

grounded work piece at the same time.

● Awkward welding conditions and

positions can be electrically hazardous.

When crouching, kneeling or at

elevations, be sure to insulate all

conductive parts, wear appropriate

protective clothing, and take

precautions to prevent injury from falls.

● Never attempt to use this

equipment at current settings or

duty cycles higher than those

specified on the equipment labels.

● Never use an electric arc welder to

thaw frozen pipes.

Flying sparks and hot

metal can cause injury.

As welds cool, slag can

be thrown off. Take all

precautions described in

this manual to reduce the possibility of

injury from flying sparks and hot metal.

● Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

● Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

Electric arc welding

operations produce

intense light and heat

and ultraviolet (UV)

rays. This intense light

and UV rays can cause injury to eyes

and skin. Take all precautions described

in this manual to reduce the possibility

of injury to eyes and skin.

● All persons operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including:

welding helmet or shield with at

least shade 10, flame resistant

clothing, leather welding gloves,

and full foot protection.

Never look at arc

welding operations

without eye protection as described

above. Never use a shade filter lens

that is cracked, broken, or rated below

number 10. Warn others in the area not

to look at the arc.

Electric arc welding

operations cause sparks

and heat metal to

temperatures that can

cause severe burns! Use protective

gloves and clothing when performing

any metal working operation. Take all

precautions described in this manual to

reduce the possibility of skin and

clothing burns.

● Make sure that all persons in the

welding area are protected from

heat, sparks, and ultraviolet rays.

Use additional face shields and

flame resistant barriers as needed.

● Never touch work pieces until

completely cooled.

Heat and sparks

produced during electric

arc welding and other

metal working

operations can ignite

flammable and explosive materials!

Take all precautions described in this

manual to reduce the possibility of

flames and explosions.

● Remove all flammable materials

within 35 feet (10.7 meters) of

welding arc. If removal is not

possible, tightly cover flammable

materials with fire proof covers.

● Do not operate any electric arc

welder in areas where flammable or

explosive vapors may be present.

2

Models WS0900, WS0950, WS1000 and WS1020

should consult with their physician

prior to performing any electric arc

welding operations.

● Route the electrode and work

cables together and secure with

tape when possible.

● Never wrap arc welder cables

around the body.

● Always position the electrode and

work leads so that they are on the

same side of the body.

● Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

that the welding

area is secure and free of hazards

(sparks, flames, glowing metal or slag)

prior to leaving. Be sure that

equipment is turned off and electrode

is removed. Be sure that cables are

loosely coiled and out of the way. Be

sure that all metal and slag has cooled.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from

Superintendent of Documents, U.S.

Government Printing Office,

Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed

Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA

22202

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

Park, Quicy, MA 02269

Installation

Assembly

General Safety (Con’t)

WS1000

GROUND

ELECTRODE

INFINITE

AMPERAGE SELECTOR

115 VOLT

OUTPUT 70 AMPS AC @ 23 V • 20% DUTY CYCLE • MAX OCV: 38 VOLTS • SINGLE PHASE

D

E

C

R

E

A

S

E

I

N

C

R

E

A

S

E

ON

60HZ 23A

OFF

Figure 2 - Handle Assembly

● Take precautions to be sure that

flying sparks and heat do not cause

flames in hidden areas, cracks,

behind bulkheads, etc.

Fire hazard! Do not

weld on containers or

pipes that contain or

have contained

flammable materials or

gaseous or liquid combustibles.

Arc welding closed

cylinders or containers

such as tanks or drums

can cause explosion if

not properly vented! Verify that any

cylinder or container to be welded has

an adequate ventilation hole, so that

expanding gases can be released.

Do not breathe fumes

that are produced by

the arc welding

operation. These fumes

are dangerous. If the welding area

cannot be adequately ventilated, be

sure to use an air-supplied respirator.

● Keep the head and face out of the

welding fumes.

● Do not perform electric arc welding

operations on metals that are

galvanized or cadmium plated, or

contain zinc, mercury, or beryllium

without completing the following

precautions:

a. Remove the coating from the

base metal.

b.Make sure that the welding area

is well ventilated.

c. Use an air-supplied respirator.

Extremely toxic fumes are created

when these metals are heated.

The electromagnetic

field that is generated

during arc welding may

interfere with the

operation of various electrical and

electronic devices such as cardiac

pacemakers. Persons using such devices

3

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to the Material Safety Data

Sheets and the manufacturers

instructions for metals, electrodes,

coatings and cleaners.

Location

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

● For best results locate the welder in

an environment that is clean and

dry. Dust and dirt in the welder

retain moisture and increase wear

of moving parts.

● Store electrodes in a clean, dry

location with low humidity to

preserve the flux coating.

● The receptacle used for the welder

must be properly grounded and the

welder must be the only load on the

power supply circuit. Refer to the

Circuit Amps chart on page 1 for

correct circuit capacity.

● The use of an extension cord is not

recommended for arc welding

machines. Extension cord use will

significantly degrade the

performance of the welder.

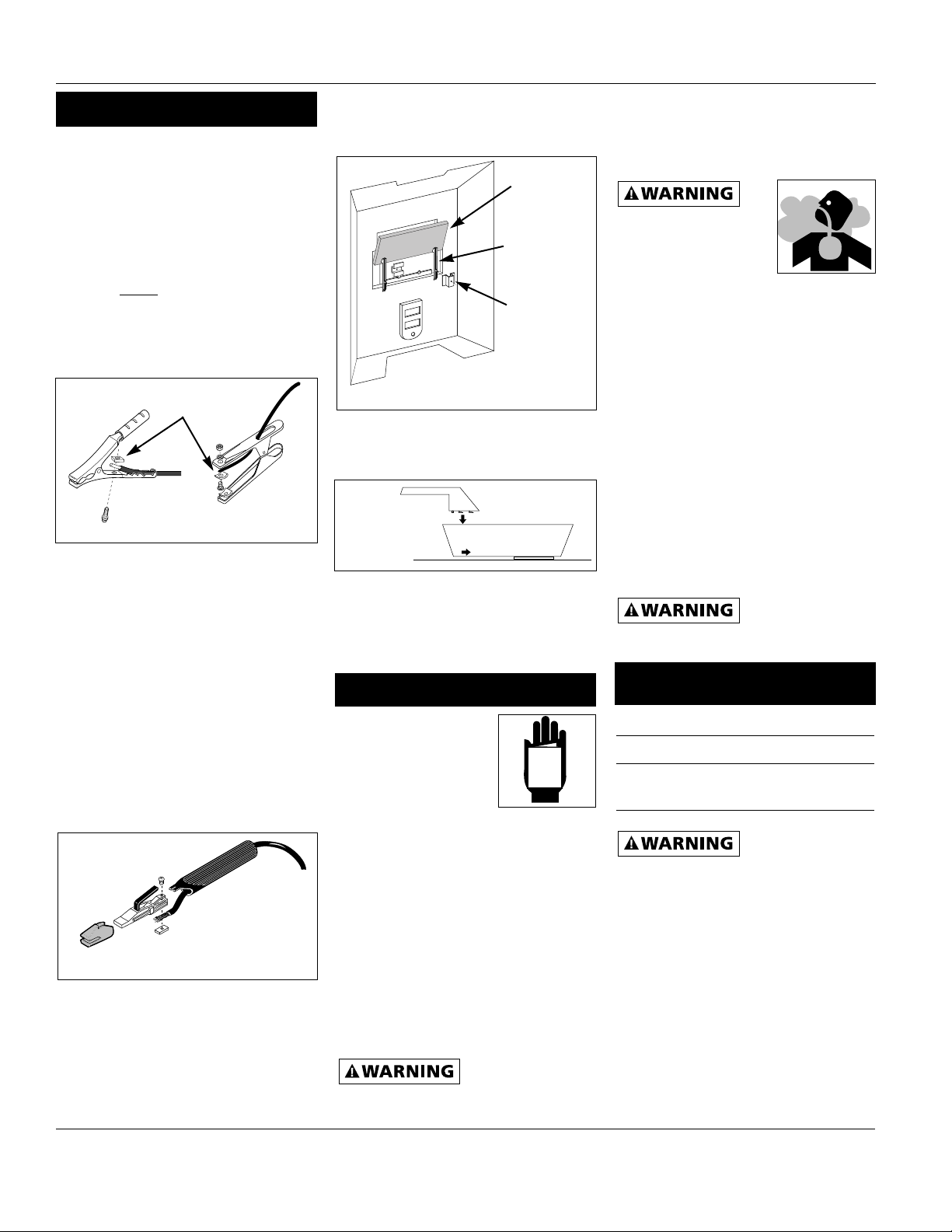

HANDLE ASSEMBLY-MODELS

WS0950, WS1000 AND WS1020 ONLY

1. Slide handle in slot toward rear of

unit.

Shielded Metal Arc Welder

2. Push forward and snap front of

handle in cutout in cabinet.

3. Fasten screw through handle and

into cabinet (See Figure 2).

WORK CLAMP (ALL MODELS)

1. Loosen hex bolt or nut on work

clamp.

2. Insert either

cable from the welder

through the clamp handle and slide

bare wire under the clamp block.

Tighten hex bolt or nut making sure

bare wire is clamped securely.

ELECTRODE HOLDER (ALL MODELS)

1. Remove insulation handle from the

holder body by pulling the two

pieces apart.

2. Slide the other weld cable through

the handle.

3. Loosen the wire clamping screw and

slide the bare cord wire under the

clamp block. Tighten the clamping

screw making sure the wire is secure.

4. Slide the handle over the electrode

holder body and press to stop. Make

sure the handle is secure and there

is no exposed metal on the holder.

HANDSHIELD (ALL MODELS EXCEPT

WS1020)

1. Cut retainer stiffeners and

detachable handle away from shield.

Trim the excess plastic to remove

sharp edges.

protective welding gear including: eye

protection with proper shade as

specified in the following chart, flame

resistant clothing, leather welding

gloves, and full foot protection.

If heating, welding, or

cutting materials that

are galvanized, zinc

plated, lead, or

cadmium plated refer to the General

Safety Information Section for

instructions. Extremely toxic fumes are

created when these metals are heated.

4. Connect the work clamp to the

work piece. Make sure the contact is

on bare metal and not obstructed

by paint, varnish, corrosion, or nonmetallic materials.

5. Insert the exposed part of the

electrode rod (the end with no flux)

into the jaws of the electrode holder.

6. Set the amperage adjustment knob

to the proper amperage for the

electrode rod diameter. Refer to

the following chart for proper

electrode current settings.

The electrode

holder and rod are

electrically “live” (current potential)

when the welder is on.

Grounding against

any metallic

surface may produce an arc which

could cause sparks and damage

eyesight.

7. Hold the electrode rod away from

the grounded work piece or

workbench. Turn on the welder.

8. Position the electrode to begin weld,

lower the welding helmet or position

the hand shield, and strike an arc.

Adjust weld amperage as needed.

9. When finished welding, turn welder

off and store properly.

Clamping

block

Figure 3 - Work Clamp Assemblies

Figure 4 - Electrode Holder Assembly

Operation

MANUAL

Electrode Current

Diameter Setting (Amps)

1/16" (1.6 mm) 35-80

5/64" (2 mm) 45-100

For specific settings, see weld guide

marked on welder

Assembly (Con’t)

Lens

Lens

Retainer

Retainer

Stiffener

Figure 5

Figure 6

2. Insert filter lens.

3. Attach the stiffeners over the pins on

the lens retainers (See Figure 5).

4. To attach the handle, place shield on

a flat surface and press handle into

place (See Figure 6).

NOTE: If you have never welded before

or have little experience, a full face

helmet is recommended. Both hands

are needed to stabilize and control the

angle and arc length of the electrode.

1. Be sure to read,

understand, and

comply with all

precautions in the

General Safety

Information section.

Be sure to read the entire section

entitled Welding Guidelines prior to

using this equipment.

2. Turn welder off and plug into

appropriate receptacle:

115v-15 amp - 1/16 electrodes

115v-20 amp - 5/64 electrodes

3. Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other contaminants.

These contaminants make welding

difficult and cause poor welds.

All persons

operating this

equipment or in the area while

equipment is in use must wear

4

Loading...

Loading...