Page 1

The Ultimate Portable

Garage Air Compressor

Operating Instructions and Parts Manual

WL6700 Series

FRANÇAISE: Page FR-1

ESPAÑOL: Página SP-1

MAKES IT EASY TO DO IT LIKE A PRO

Visit us at chpower.com

© 2009 Campbell Hausfeld/Scott Fetzer IN629500AV 4/09

Page 2

Table of Contents

Description. . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Guidelines . . . . . . . . . . . . . . . . . . . . 4

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . 4

Important Safety Information. . . . . . . . . 4

Instructions Pertaining to a Risk of

Fire, Electric Shock, or Injury to

Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

California Proposition 65 . . . . . . . . . . . . .4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . .5

Personal Safety . . . . . . . . . . . . . . . . . . . . . .5

Electrical Safety. . . . . . . . . . . . . . . . . . . . . .5

Use and Care. . . . . . . . . . . . . . . . . . . . . . . .5

Spraying Precautions . . . . . . . . . . . . . . . .6

Air Source. . . . . . . . . . . . . . . . . . . . . . . . . . .6

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contents in the Carton . . . . . . . . . . . . . . .7

Additional Items not Included . . . . . . . .7

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

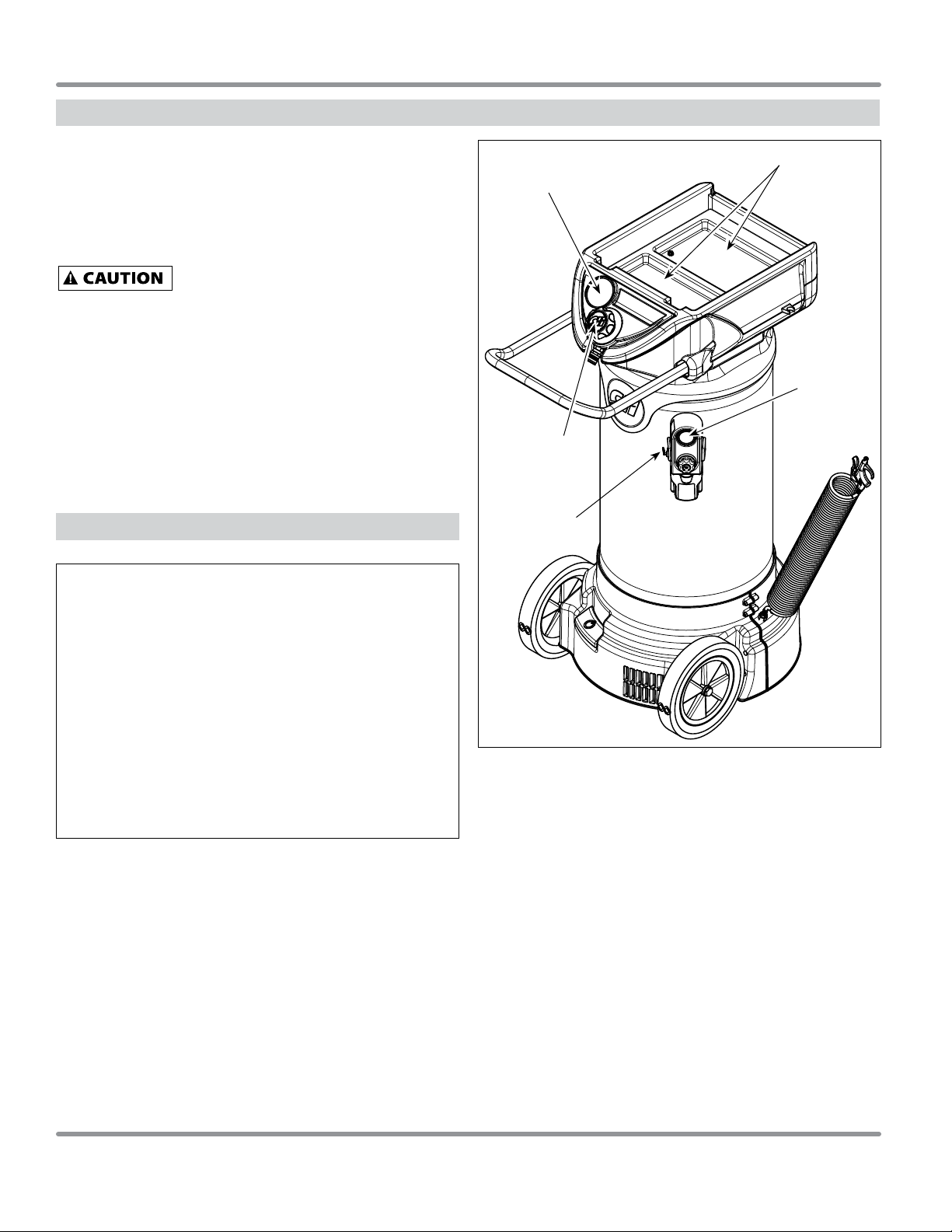

Getting To Know Your Compressor. . . . 9

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Recommended Uses for this

Compressor. . . . . . . . . . . . . . . . . . . . . . . . .9

Tool Recommendation for this

Compressor. . . . . . . . . . . . . . . . . . . . . . . . .9

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tools Required for Assembly. . . . . . . . 10

Handle Assembly . . . . . . . . . . . . . . . . . . 10

Inflation Hose Assembly. . . . . . . . . . . . 10

Installation. . . . . . . . . . . . . . . . . . . . . . . . . 11

Location . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wheel Lock/Foot Brake . . . . . . . . . . . . 11

Electrical Installation. . . . . . . . . . . . . . . 11

Grounding Instructions . . . . . . . . . . . . 11

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lubrication . . . . . . . . . . . . . . . . . . . . . . . 12

ASME Safety Valve . . . . . . . . . . . . . . . . . 13

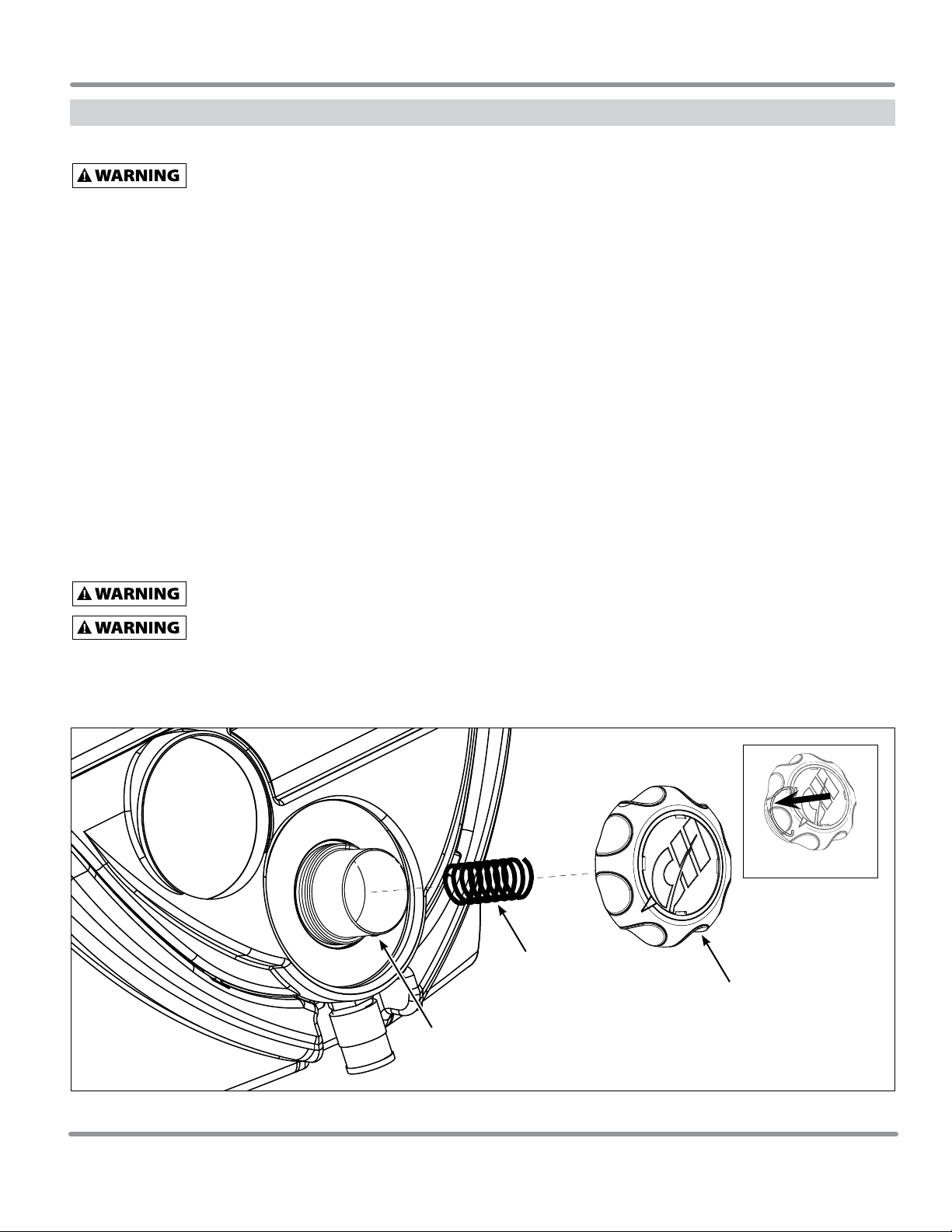

Click-To-Set Regulator Knob. . . . . . . . 13

Reassembly. . . . . . . . . . . . . . . . . . . . . . 13

Outlet (Tool) Pressure Gauge . . . . . . . 13

Tank Pressure Gauge. . . . . . . . . . . . . . . 13

Storage Top . . . . . . . . . . . . . . . . . . . . . . . 13

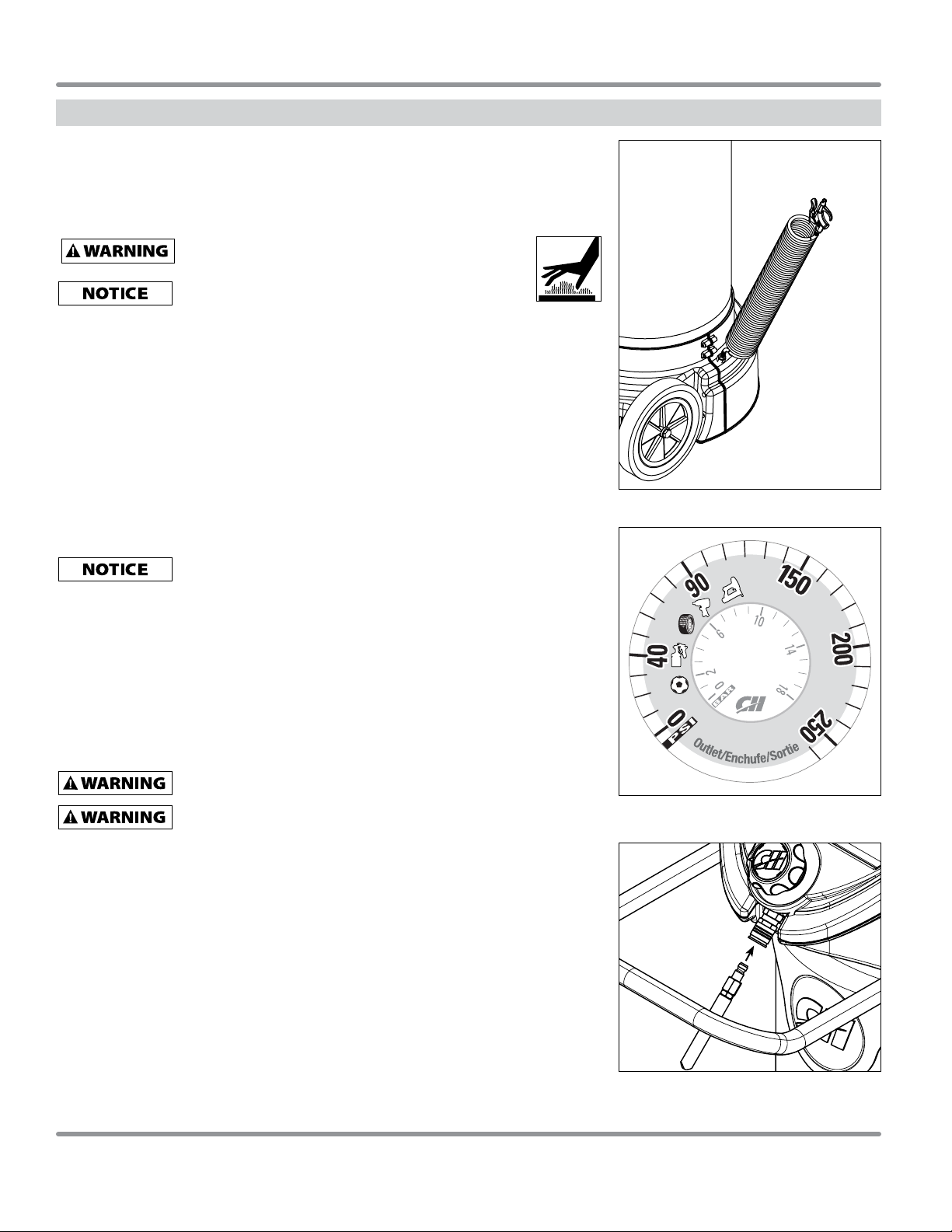

Rapid Inflation Technology™ (RIT) . 14

To Use Compressor For Inflation: . . . 14

To Use Compressor For Air Tool

Usage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

End of Operation/Storage . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . 15

ASME Safety Valve . . . . . . . . . . . . . . . . . 15

Drain Tank. . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Air FIlter . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Lubrication . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal Overload Protector . . . . . . . . 16

Torque Requirements . . . . . . . . . . . . . . 16

Technical Service . . . . . . . . . . . . . . . . . . 16

Service Record. . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting Guide . . . . . . . . . . . . . . 18

Replacement Parts List for Pump,

Model WL390100. . . . . . . . . . . . . . . . . . . . 19

Torque Requirements . . . . . . . . . . . . . . 19

Replacement Parts List for The

Ultimate Portable Garage Air

Compressor . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

For parts, product and service information

Visit: www.chpower.com

Call: Customer Service at 1-800-543-6400

Address any correspondence to: Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Page 3

Operating Instructions and Parts Manual

The Ultimate Portable

Garage Air Compressor

Description

Oilless compressors are designed for do-it-yourselfers with a variety of home and

automotive jobs. These compressors power spray guns, impact wrenches and other

tools. These units operate without oil.

Specifications

WL6700 Series

Running HP: 1.7 (ISO 1217)

Free Air CFM: 3.8 @ 90 psi (ISO 1217)

Free Air CFM: 5.6 @ 40 psi (ISO 1217)

Tank Capacity (gallons):

18, 22, 26, or 30

Volts, Phase: 120 V, single

Amp Draw: 15

Max. Duty Cycle: 50%

Figure 1 - WL6700 Series

Record the model number and serial

number, located on the back of the tank,

and date of purchase in the space below.

Model #: ____________________________

Serial #: _____________________________

Date of Purchase: ____________________

Retain these numbers for future reference.

www.chpower.com

3

Page 4

Operating Instructions and Parts Manual

Important Safety Information

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially

hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates

a potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

IMPORTANT: Information that

requires special attention.

Safety Symbols

The following Safety Symbols appear

throughout this manual to alert you

to important safety hazards and

precautions.

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS

This manual contains important safety, operational and maintenance information. If

you have any questions, please call 1-800-543-6400 for customer assistance.

Since the air compressor and other components (material pump, spray guns, filters,

lubricators, hoses, etc.) used, make up a high pressure pumping system, the following

safety precautions must be observed at all times:

CALIFORNIA PROPOSITION 65

This product or its power cord may contain chemicals, including lead,

known to the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

You can create dust when you cut, sand, drill or grind

materials such as wood, paint, metal, concrete, cement, or

other masonry. This dust often contains chemicals known to cause cancer, birth

defects, or other reproductive harm. Wear protective gear.

Breathable Air Warning

This compressor/pump is not equipped and should not be used “as is” to supply

breathing quality air. For any application of air for human consumption, the air

compressor/pump will need to be fitted with suitable in-line safety and alarm

equipment. This additional equipment is necessary to properly filter and purify

the air to meet minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1 - 1966, OSHA 29 CFR

1910. 134, and/or Canadian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air application

and proper in-line safety and alarm equipment is not simultaneously used,

existing warranties shall be voided, and Campbell Hausfeld disclaims any liability

whatsoever for any loss, personal injury or damage.

Wear Eye and

Mask Protection

Wear Eye and

Ear Protection

Risk of

Electrocution

4

Read Manual

First

Hot Parts

Risk of

Explosion

www.chpower.com

Risk of Fire

Risk of Falling

Risk of Fumes

GENERAL

a. To reduce the risks of electric shock, fire, and injury to persons, read

all the instructions before using the tool. Failure to follow warnings,

dangers, and cautions could result in DEATH or SERIOUS INJURY.

b. Be thoroughly familiar with the controls and the proper use of the

equipment. Follow all instructions. Contact your Campbell Hausfeld representative

if you have any questions.

c. Follow all local electrical and safety codes as well as in the US, National Electrical

Codes (NEC) and Occupational Safety and Health Act (OSHA).

d. Only persons well acquainted with these rules of safe operation should be

allowed to use the unit.

Page 5

Important Safety Information (Continued)

WL6700 Series

WORK AREA

a. Keep the work area clean and well lighted. Cluttered

benches and dark areas increase the risks of electric shock,

fire, and injury to persons.

b. Keep bystanders, children, and visitors away while

operating. Distractions are able to result in the loss of

control. NEVER allow children in the work area.

Motors, electrical equipment

and controls can cause electrical

arcs that will ignite a flammable gas or vapor. Never

operate or repair in or near a flammable gas or vapor.

Never store or spray flammable liquids or gases in the

vicinity of the compressor.

c. To reduce fire hazard, keep engine/motor exterior free of

oil, solvent, or excessive grease.

PERSONAL SAFETY

a. Stay alert. Watch what you are doing and use common

sense when operating the tool. Do not use the tool

while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating the

tool increases the risk of injury to persons.

Ensuring that the tool is used

only when the operator and all

other personnel in the work area are wearing ANSI Z87

eye protection equipment, and when required, other

appropriate protection equipment such as head, hearing

and foot protection equipment. Serious eye or permanent hearing loss

could result.

b. Always wear hearing protection when using the tool.

Prolonged exposure to high intensity noise is able to cause

hearing loss.

c. Always work in a well-ventilated area. Wear OSHA-

approved dust mask.

d. Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair

increases the risk of injury to persons as a result of being

caught in moving parts.

Compressor parts may be hot even if

the unit is stopped.

e. Keep fingers away from a running compressor;

fast moving and hot parts will cause injury and/or

burns.

f. Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

ELECTRICAL SAFETY

Risk of electrical shock. Always

disconnect from power source before

servicing. Servicing should be performed by authorized

service center.

USE AND CARE

Never use plastic (PVC) pipe for

compressed air. Serious injury or

death could result.

a. Before each use, inspect compressed air

system and electrical components for signs of damage,

deterioration, weakness or leakage. Repair or replace

defective items before using.

b. Check all fasteners at frequent intervals for proper

tightness.

c. Check air hoses for weak or worn condition before each

use. Make sure all connections are secure.

d. Do not stand on or use the pump or unit as a handhold.

e. If the equipment should start to abnormally vibrate, STOP

the engine/motor and check immediately for the cause.

Vibration is generally a warning of trouble.

Never remove or attempt to adjust safety valve.

Keep safety valve free from paint and other

accumulations.

f. Do not alter or tamper with the safety relief valve. In the

event that the safety relief valve is tampered with, existing

warranties shall be voided and Campbell Hausfeld disclaims

any liability whatsoever for any loss, personal injury or

damage.

Never attempt to repair or modify

a tank! Welding, drilling or any

other modification will weaken the tank resulting in

damage from rupture or explosion. Always replace worn or

damaged tanks.

Drain liquid from tank daily.

g. Make sure to drain tank regularly and inspect periodically

for unsafe conditions such as rust formation and

corrosion. Tanks rust from moisture build-up, which

weakens the tank.

h. Release air slowly when draining moisture or

depressurizing the compressor system. Fast moving air will

stir up dust and debris which may be harmful.

i. Do not remove any warning labels from the unit.

j. Store inside. Do not store outside or in direct sunlight.

www.chpower.com

5

Page 6

Operating Instructions and Parts Manual

Important Safety Information (Continued)

SPRAYING PRECAUTIONS

Do not spray flammable materials in vicinity of open flame

or near ignition sources including the compressor unit.

a. Do not smoke when spraying paint, insecticides, or other flammable

substances.

b. Use a face mask/respirator when spraying and spray in a well

ventilated area to prevent health and fire hazards.

c. Do not direct paint or other sprayed material at the compressor.

Locate compressor as far away from the spraying area as possible to

minimize overspray accumulation on the compressor.

d. WHEN SPRAYING OR CLEANING WITH SOLVENTS OR TOXIC CHEMICALS,

FOLLOW THE INSTRUCTIONS PROVIDED BY THE CHEMICAL

MANUFACTURER.

AIR SOURCE

Air compressors providing air to the tank should follow the requirements

established by the American National Standards Institute Standard

B19.3-1991; Safety Standard for Compressors for Process Industries. Contact your air

compressor manufacturer for information.

SERVICE

a. Release air pressure from air tank by pulling safety relief ring before servicing or

replacing parts.

b. Service must be performed only by qualified repair personnel.

Never attempt to repair or modify a tank! Welding, drilling or any other

modification will weaken the tank resulting in damage from rupture or

explosion. Always replace worn or damaged tanks.

c. When servicing a tool, use only identical replacement parts. Use only authorized

parts.

NOTE: The DANGER, WARNING, CAUTION, and NOTICE notifications and instructions

in this manual cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which cannot be built

into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

6

www.chpower.com

Page 7

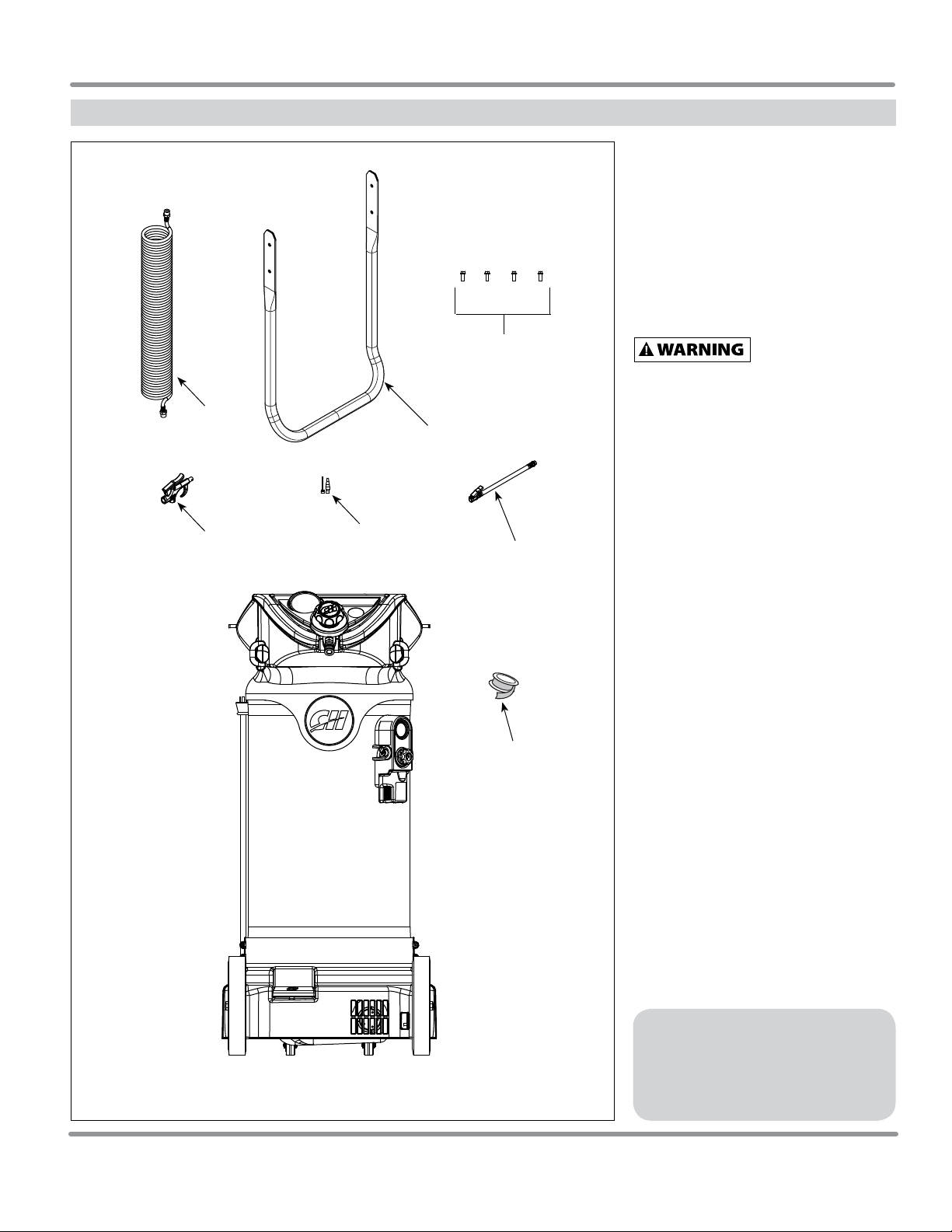

Unpacking

Nylon

recoil hose

Blow gun

Blow gun

accessories

Self-tapping

screws

Handle

Tire

inflation

valve

Thread

tape

WL6700 Series

After unpacking the unit, inspect carefully

for any damage that may have occurred

during transit. Check for loose, missing

or damaged parts. Make sure to tighten

fittings, bolts, etc., before putting unit

into service. Check to be sure all supplied

accessories are enclosed with the unit. In

case of questions, damaged or missing

parts, please call 1-800-543-6400 for

customer assistance.

u Do not operate unit if damaged during

shipping, handling or use. Damage may

result in bursting and cause injury or

property damage.

u For your own safety, never operate unit

until all assembly steps are complete and

until you have read and understood the

entire operator’s manual.

u To reduce the risk of injury, if any parts are

missing, do not attempt to assemble the

air compressor until the missing parts are

obtained and installed correctly.

CONTENTS IN THE CARTON

u Blow gun accessories

u Handle

u Blow gun

u Nylon recoil hose

u (4) Self-tapping screws

u Tire inflation valve

u Thread tape

u Operating Instructions and Parts

Manual

u Product Registration Card

Figure 2 - Unpacking

ADDITIONAL ITEMS NOT INCLUDED

u Air Hose

u ANSI Z87 Eye Protection

u Hearing Protection

u Other Personal Protective Gear as

required

Read & Follow All Instructions

Save These Instructions

Do Not Discard

www.chpower.com

7

Page 8

Operating Instructions and Parts Manual

Glossary

Become familiar with these terms before operating the unit.

AIR DELIVERY - A combination of psi and SCFM. The air delivery required by

a tool is stated as (number) SCFM at (number) psi. The combination of these

figures determines what size unit is needed.

AIR TANK CAPACITY - The volume of air stored in the tank and available for

immediate use. A large tank allows the intermittent use of an air tool with an air

requirement higher than the compressor’s rated delivery.

ASME SAFETY VALVE * - This valve automatically releases air if the tank pressure

exceeds the preset maximum.

CLICK-TO-SET REGULATOR - The regulator controls the amount of air pressure

released at the hose outlet to the proper amount needed to operate an air tool or

spray gun.

CUT-IN/CUT-OFF PRESSURE - Specific psi at which a compressor starts and

stops while refilling the air tank.

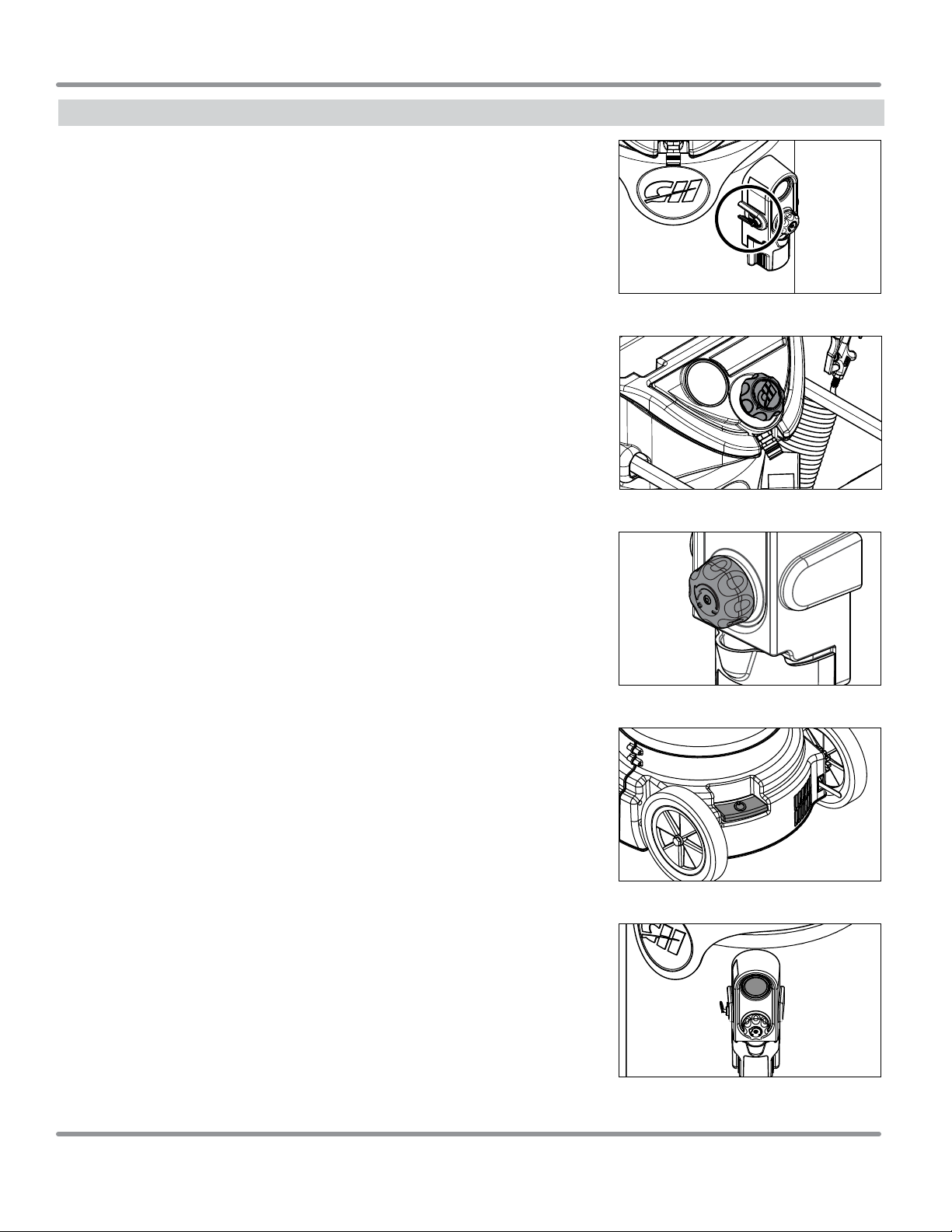

Figure 3 - ASME Safety Valve

EASY DRAIN KNOB - This knob is used to drain moisture from the tank daily to

reduce the risk of corrosion.

FOOT PEDAL ON/OFF SWITCH - Used to turn the compressor on and off. Press

firmly.

MOTOR PROTECTION - If the unit is over worked, a thermal switch will shut

unit off. If this happens, turn unit OFF the ON/OFF Switch, wait 30 minutes to

cool, turn ON the ON/OFF Switch again to resume work.

OUTLET (TOOL) PRESSURE GAUGE - Displays the current outlet pressure to the

tool in psi. It is regulated by the regulator knob.

PRESSURE SWITCH -Shuts the compressor off automatically when tank

pressure reaches the maximum preset pressure. The compressor will

automatically restart when it reaches the minimum preset pressure.

PSI (POUNDS PER SQUARE INCH) - Measurement of the pressure exerted by

the force of the air. The actual psi output is measured by a pressure gauge on the

compressor.

SCFM (STANDARD CUBIC FEET PER MINUTE) - Sometimes called CFM (Cubic

Feet per Minute). Measurement of air volume delivered by the compressor.

TANK PRESSURE GAUGE - Indicates tank pressure in psi.

Figure 4 - Click-To-Set Regulator

Figure 5 - Easy Drain Knob

Figure 6 - Foot Pedal ON/OFF Switch

TOOL STORAGE - The open space on top of compressor is designed for tool

storage. Specific Campbell Hausfeld tool kits will fit in this storage area.

* ASME: American Society of Mechanical Engineers. ASME tanks are

manufactured to ASME requirements.

8

www.chpower.com

Figure 7 - Tank Pressure Gauge

Page 9

Unpacking

Getting To Know Your Compressor

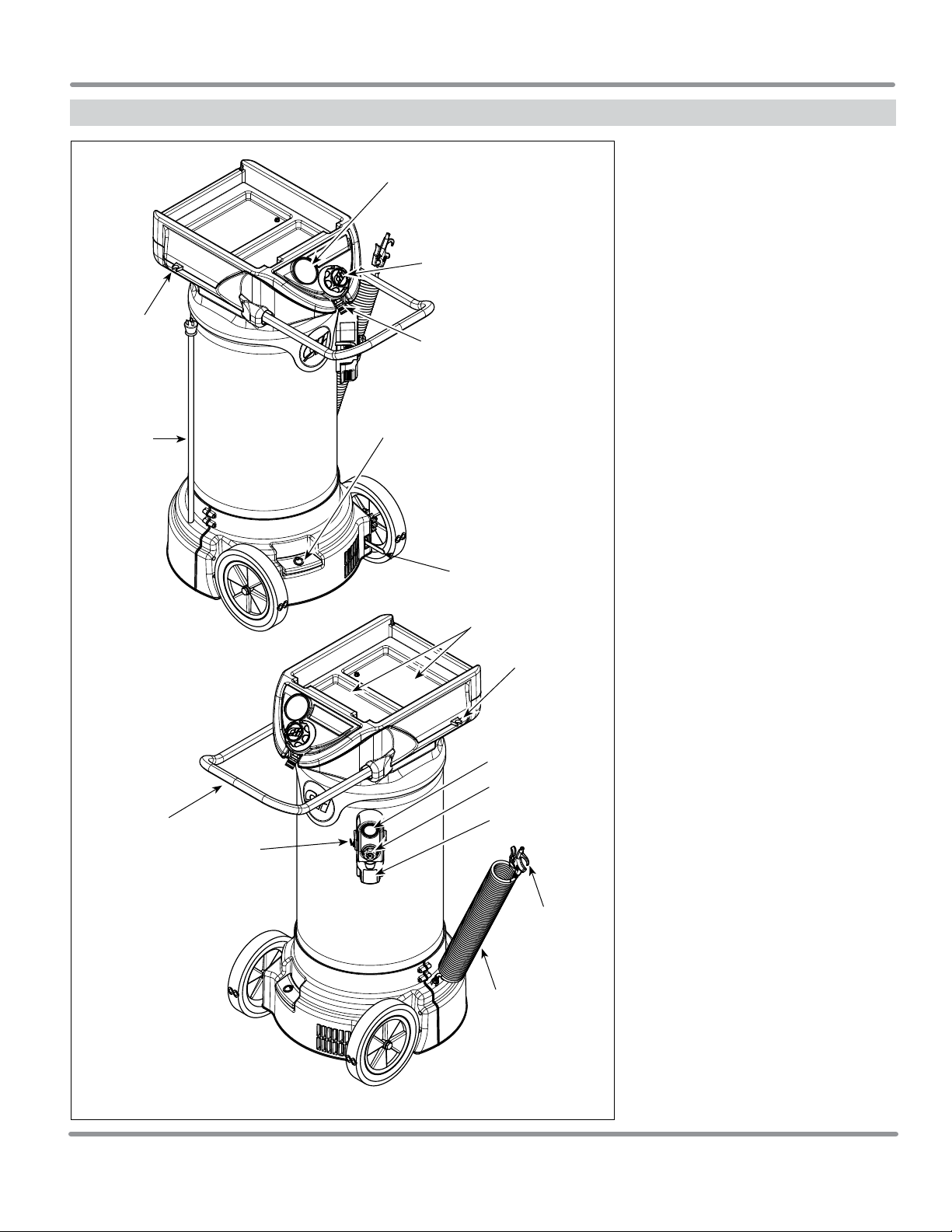

Power

cord clip

Power

cord

Outlet (tool)

pressure gauge

Click-to-set

regulator

Coupler

Foot pedal ON/OFF switch

Wheel lock /

foot brake

Storage trays

WL6700 Series

RECOMMENDED USES FOR THIS COMPRESSOR

u Auto maintenance

u Auto restoration

u Fastening

u Home maintenance

u Inflation

u Woodworking

TOOL RECOMMENDATION FOR THIS COMPRESSOR

Continuous Use —

Inflation accessories

Airbrush

Air screwdrivers

Brad nailers and Staplers

Caulk guns

Engine cleaners

Finish nailers

Grease guns

Home spray guns

Impact wrench

Ratchets

Reciprocating saws

Roofing and Framing nailers

Pull handle

ASME

Safety

valve

Figure 8 - Components of the compressor

Blow gun

clip

Tank pressure

gauge

Easy-drain knob

Easy-drain cup

Safety

blow gun

Instant-air

hose

Intermittent Use

(Short powerful bursts) —

Air chisels

Air drills

Automotive spray guns

Die grinders

Tools Not Recommended —

Cut-off tools

Dual action sanders

Highspeed sanders

Jitterbug sanders

Straight line sanders

www.chpower.com

9

Page 10

Operating Instructions and Parts Manual

Assembly

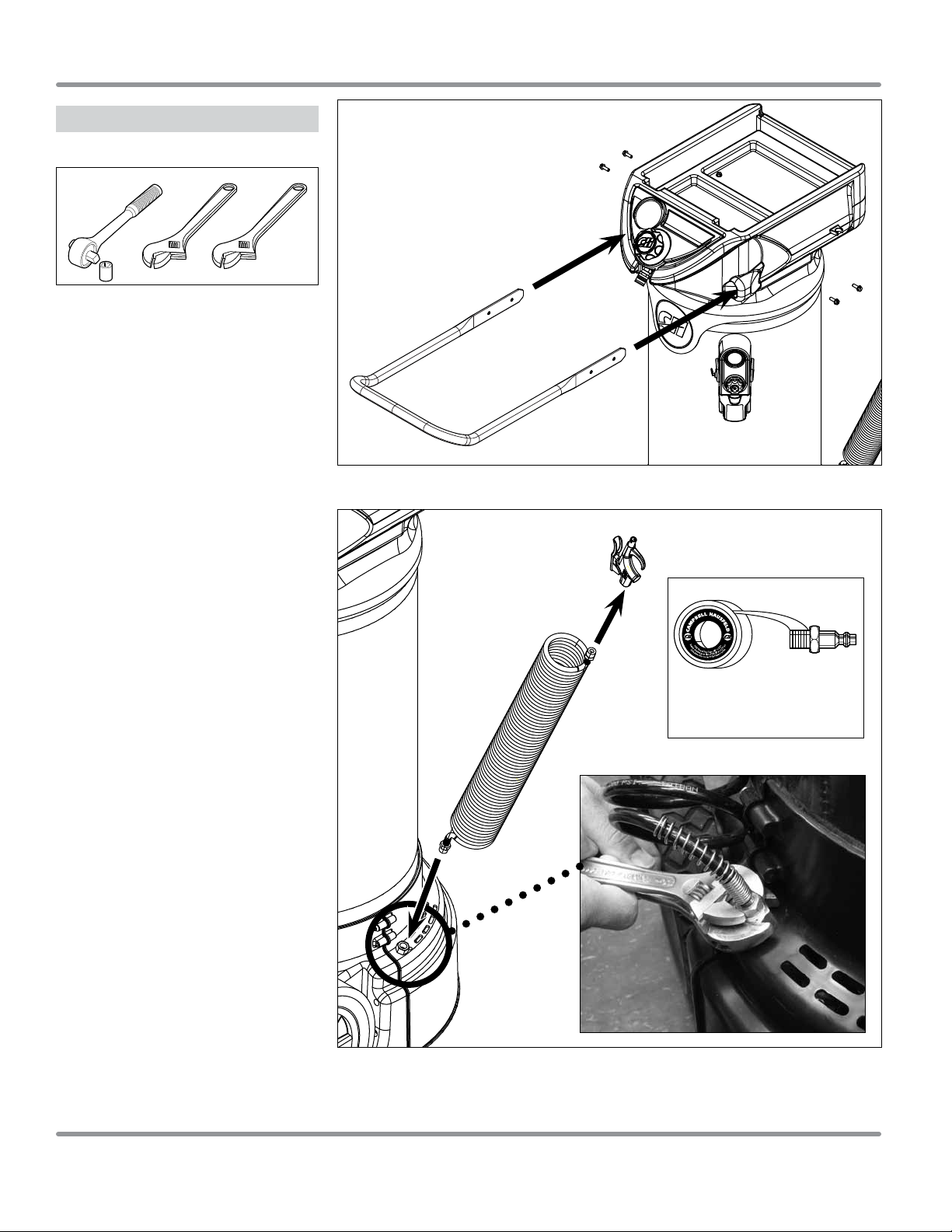

TOOLS REQUIRED FOR ASSEMBLY

u Ratchet with 3/8 inch Socket

u (2) Wrenches

HANDLE ASSEMBLY

1. Slide handle into shroud holes,

making sure handle is on the outside

of the bracket and the holes of the

handle line up with the holes of the

tank bracket.

2. Insert screws through handle and then

the bracket. Using a ratchet with 3/8

inch socket, tighten screws to hold the

handle in place.

Figure 9 - Handle assembly

INFLATION HOSE ASSEMBLY

1. Apply thread tape to both ends of the

recoil hose to prevent leaks.

2. Thread the coil hose into the fitting on

the shroud. Use 2 adjustable wrenches

to tighten the connection by holding

the bottom wrench steady and

tightening with the top wrench (See

Figure 10).

3. Screw blow gun onto the end of the

coil hose. Use 2 adjustable wrenches

to tighten the connection by holding

the bottom wrench steady and

tightening with the top wrench.

Once the recoil hose and blow gun are

attached, make sure no pressure is in

tank before replacing. Recoil hose and

blow gun must be installed for unit to

operate properly.

Apply thread tape to both

ends of the recoil hose to

prevent leaks

10

Figure 10 - Inflation hose assembly

www.chpower.com

Page 11

Installation

LOCATION

When assembled, the tank must sit level to allow the tank to drain properly.

It is extremely important to install the compressor in a clean, well ventilated area where

the surrounding air temperature will not be more than 100°F.

A minimum clearance of 18 inches between the compressor and a wall is required

because objects could obstruct air flow.

Do not locate the compressor air inlet near steam, paint spray, sandblast

areas or any other source of contamination. This debris will damage the

motor.

WHEEL LOCK/FOOT BRAKE

To move the compressor, use your foot to lift the foot brake lever to disengage the

brake.

Once the compressor is at the desire location, use your foot to push down on the foot

brake lever to engage the brake.

WL6700 Series

Disengaged

Engaged

Figure 11 - Wheel Lock/Foot Brake

ELECTRICAL INSTALLATION

All wiring and electrical connections should be performed by a qualified

electrician. Installation must be in accordance with local codes and

national electrical codes.

Never use an extension cord with this product. Use additional

air hose instead of an extension cord to avoid power loss and

permanent motor damage.

STOP!

GROUNDING INSTRUCTIONS

1. This product is for use on a nominal 120 volt circuit and has a grounding plug that

looks like the plug illustrated in Figure 12. Only connect the product to an outlet

having the same configuration as the plug. Do not use an adapter with this product.

In the event of an electrical short circuit, grounding reduces risk of electrical shock

by providing an escape wire for electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug. Plug must be

plugged into an outlet that is properly installed and grounded in accordance with

all local codes and ordinances.

Improper use of grounding plug can result in a possible risk

of electrical shock!

Do not use a grounding adapter with this product!

2. If repair or replacement of cord or plug is necessary, do not connect grounding wire

to either flat blade terminal. The wire with insulation having an external surface

that is green (with or without yellow stripes) is the grounding wire.

Figure 12 - Grounding method

TEST

RESET

Never connect green (or green and yellow) wire to a live terminal.

3. Check with a qualified electrician or serviceman if grounding instructions are not

completely understood, or if in doubt as to whether product is properly grounded.

Do not modify plug provided; if it will not fit outlet, have proper outlet installed by a

qualified electrician.

www.chpower.com

11

Page 12

Operating Instructions and Parts Manual

Installation (Continued)

WIRING

1. Local electrical wiring codes differ from area to area. Source

wiring, plug and protector must be rated for at least the

amperage and voltage indicated on motor nameplate, and

meet all electrical codes for this minimum.

2. Use a slow blow fuse or a circuit breaker.

Overheating, short circuiting and fire damage

will result from inadequate wiring, etc.

NOTE: 120 volt, 15 amp units can be operated on a 120 volt

circuit under the following conditions:

a. No other electrical appliances or lights are connected to

the same branch circuit.

b. Voltage supply is normal.

c. Circuit is equipped with a 15 amp circuit breaker or a 15

amp slow blow fuse.

3. If these conditions cannot be met or if nuisance tripping

of current protection device occurs, it may be necessary to

operate compressor from a 120 volt, 20 amp circuit.

Operation

Outlet (Tool)

Pressure Gauge

Click-to-set

regulator

ASME

Safety Valve

Storage Trays

Tank

Pressure

Gauge

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it

comes from an air compressor pump. When humidity is

high or when a compressor is in continuous use for an

extended period of time, this moisture will collect in the

tank. When using a paint spray or sandblast gun, this water

will be carried from the tank through the hose, and out of

the gun as droplets mixed with the spray material.

IMPORTANT: This condensation will cause water spots

in a paint job, especially when spraying other than water

based paints. If sandblasting, it will cause the sand to cake

and clog the gun, rendering it ineffective. A filter in the air

line (MP3105), located as near to the gun as possible, will

help eliminate this moisture.

This compressor can be used for general inflation as well as

intermittent duty air tool usage. For inflation purposes, this

compressor utilizes a new technology called Rapid Inflation

Technology (RIT).

IMPORTANT: Make sure the Wheel Lock/Foot Brake is engaged

before operating the unit (See Figure 11).

LUBRICATION

This is an oilless product and DOES NOT require lubrication to

operate.

Figure 13

12

www.chpower.com

Page 13

Operation (Continued)

WL6700 Series

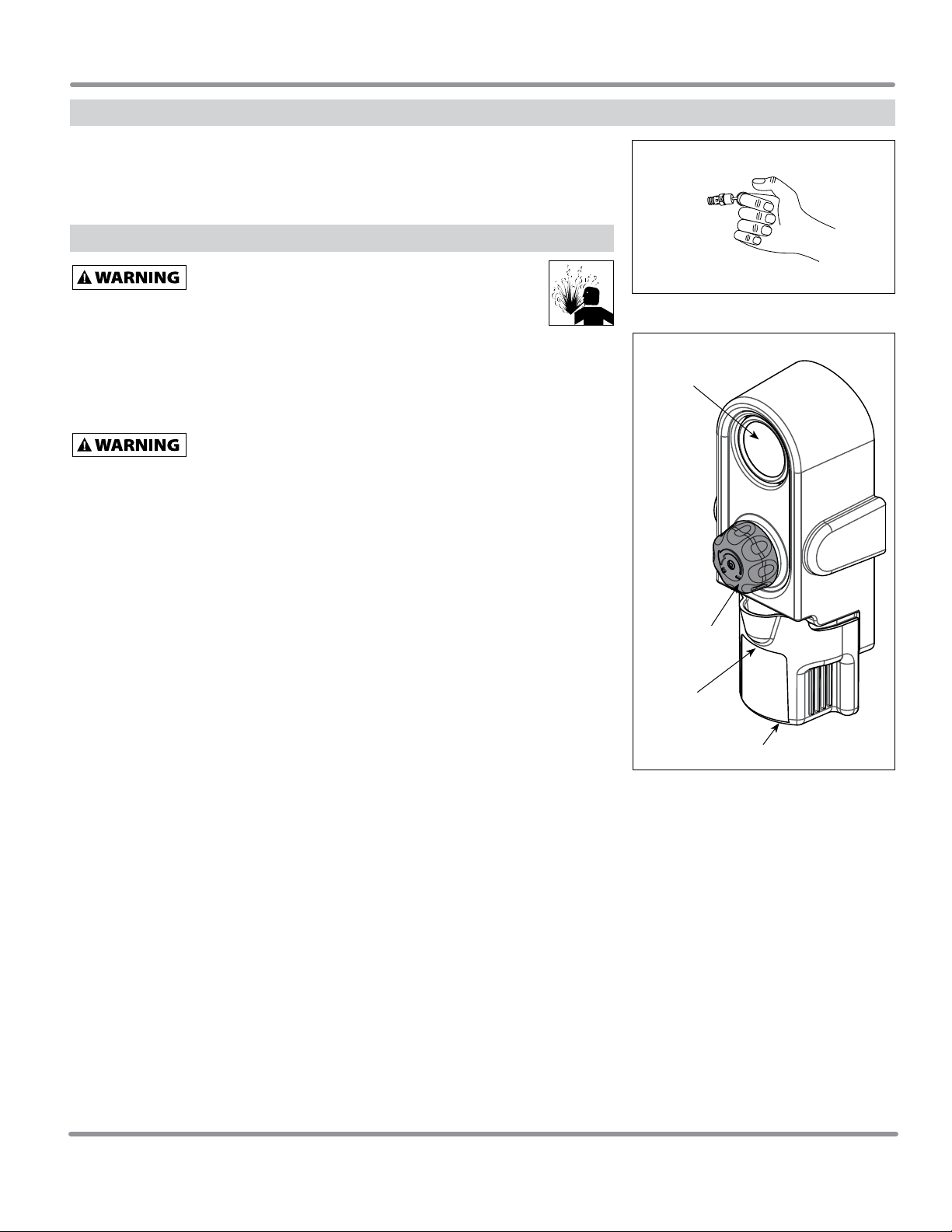

ASME SAFETY VALVE

Do not remove or attempt to adjust the safety

valve!

This valve should be checked under pressure occasionally by

pulling the ring by hand (See Figure 13). If air leaks after ring has

been released, or valve is stuck and cannot be actuated by ring, it

MUST be replaced.

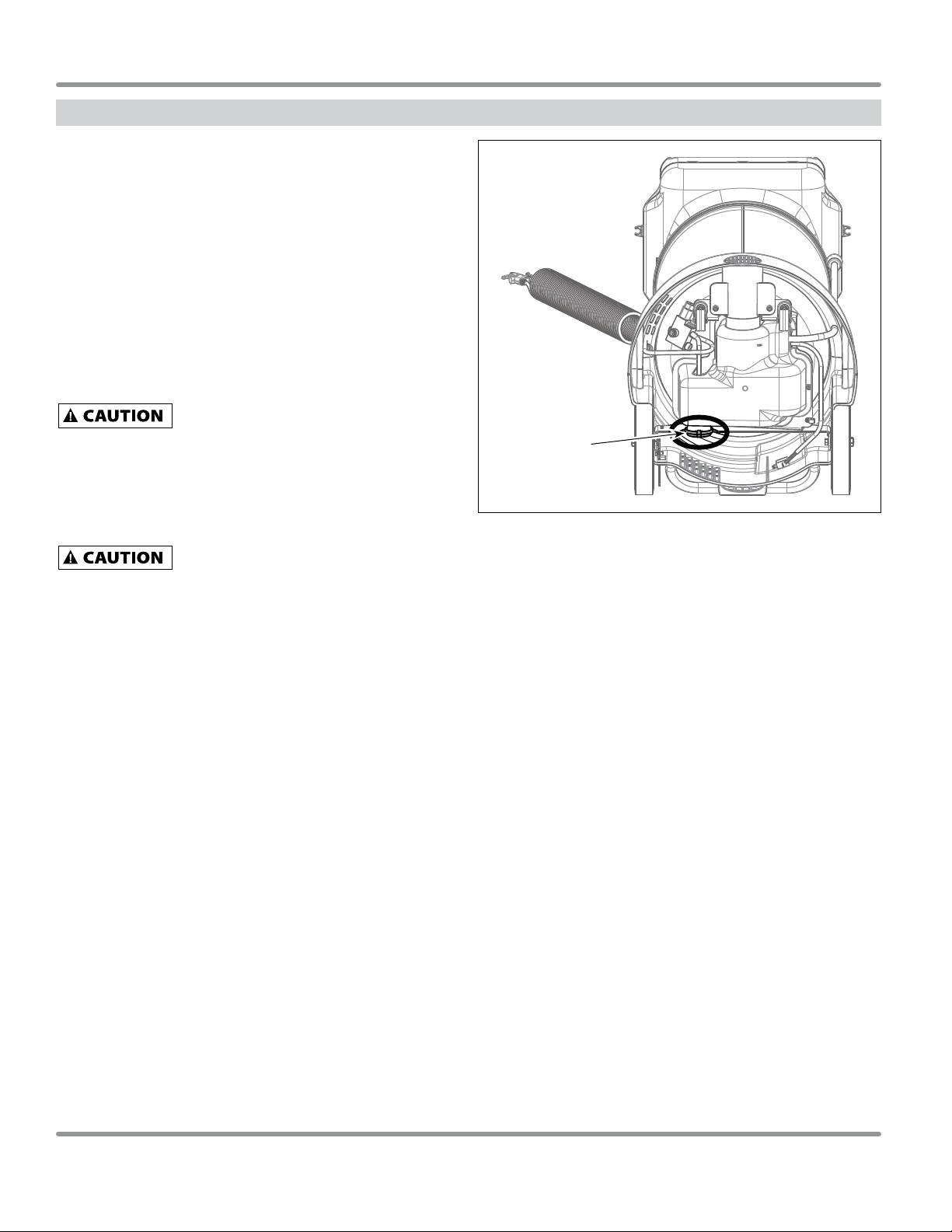

CLICK-TO-SET REGULATOR KNOB

u This knob controls air pressure to an air operated tool, or

paint spray gun.

u Turning knob clockwise increases air pressure at outlet.

u Turning counterclockwise will lower air pressure at outlet.

u Fully counterclockwise will shut off flow of air completely.

This regulator knob is designed to rotate approximately 270

degrees for all feature settings. If the knob is rotated past

minimum operation setting (counterclockwise), the knob will

no longer “click” as designed to indicate that the regulator has

been placed in a specific setting. The outlet pressure will read

zero (0 psi) once the knob is at the minimum operation setting.

Continuous turning of the regulator knob past minimum

operation setting (counterclockwise) could result in the

regulator knob coming loose and detaching.

If outlet pressure gauge is at zero (0) psi,

DO NOT turn knob counterclockwise.

If regulator knob is turned and a “click”

is no longer heard, DO NOT turn knob counter

clockwise.

Reassembly

If you do turn the regulator knob too far past minimum

operation setting ( counterclockwise) and the knob does come

off, use these steps to reassemble the regulator:

1. Align the spring into central position.

2. Locate retaining latch on inside of regulator knob.

3. Align retaining latch to the aluminum threads of the

regulator body.

4. Attach at an angle, catching the retaining latch under the

beginning of the aluminum threads.

5. Apply pressure to align knob to regulator body.

6. Turn clockwise until the knob clicks.

For further assistance or questions, please call 1-800-543-6400.

OUTLET (TOOL) PRESSURE GAUGE

1. This gauge shows at-a-glance, air pressure at outlet. Air

pressure is measured in pounds per square inch (psi).

2. Be sure this gauge reads ZERO before changing air tools or

disconnecting hose from outlet.

TANK PRESSURE GAUGE

Gauge shows pressure in tank indicating compressor is building

pressure properly.

STORAGE TOP

The storage tray compartments, located on the top of the

compressor, are designed for easy tool storage. Unique tool kits,

available at your local retailer or on www.chpower.com, store

easily on top of the unit.

Figure 14

Regulator Body

Regulator Spring

Retaining Latch

Regulator Knob

www.chpower.com

13

Page 14

Operating Instructions and Parts Manual

Operation (Continued)

RAPID INFLATION TECHNOLOGY™ (RIT)

When the compressor is used in the RIT mode, the air being produced from the

compressor pump will go directly to the recoil hose which is attached to the bottom of

the compressor (See Figure 15). This will eliminate waiting for the compressor tank to

fill up, allowing for significantly faster inflation.

Instant air hose will get hot while the compressor is

on and during the inflation process.

Drain water from tank prior to inflation.

TO USE COMPRESSOR FOR INFLATION:

1. Connect recoil hose to open port located on the bottom of compressor (See Figures

10 and 15). The coil hose and blow gun must remain attached so that the unit

operates properly.

2. Attach blow gun to the other end of the recoil hose. The blow gun should ALWAYS

be connected to the recoil hose.

3. To inflate balls, rafts, etc. attach inflation needle or nozzle to the end of blow gun.

4. To inflate tires, attach tire inflation valve to the end of blow gun.

5. Attach the appropriate inflation device to object needing inflation.

6. Turn on compressor by firmly pressing down the red power foot switch and inflate

by squeezing the trigger.

Use caution to avoid over inflation.

7. When inflation is complete, blow gun can be attached to the clip that is molded on

the side of the top shroud for convenient storage.

Figure 15 - Rapid Inflation Technology

TO USE COMPRESSOR FOR AIR TOOL USAGE:

1. Connect 1/4 inch industrial plug to separate hose (plug and hose not included).

2. Connect separate hose to the coupler located below pressure regulator by pulling

the sleeve on coupler all of the way back, then push hose into coupler and release

sleeve (See Figure 17).

3. Close regulator (turn knob fully counterclockwise to the left). Do not over tighten.

If outlet pressure gauge is at zero (0) psi, DO NOT turn knob

counterclockwise.

If regulator knob is turned and a “click” is no longer heard, DO NOT turn

knob counterclockwise.

4. Turn compressor on by firmly pressing down the red power foot switch and allow it

to fill tank until it reaches automatic shut off pressure.

5. Attach air tool, paint gun, nailer, etc. to end of air hose.

6. Adjust regulator for desired application. Regulator has preset “click-to-set” feature

which should closely match application pictures on outlet pressure gauge.

7. Use compressor for desired application.

END OF OPERATION/STORAGE

1. Turn compressor OFF at foot pedal ON/OFF switch.

2. Unplug power cord from wall outlet and attach to clip that is molded on the side of

the top shroud.

3. Drain tank of condensation as outlined in the Drain Tank section below.

Figure 16

Figure 17 - Attach hose to coupler

14

www.chpower.com

Page 15

Operation (Continued)

4. Wearing safety glasses, drain tank of any remaining air pressure by pulling the

ring on the safety valve. Use other hand to deflect any fast moving air that may be

directed towards your face.

5. Store compressor in a cool, dry place.

Maintenance

Disconnect power source then release all pressure from the

system before attempting to install, service, relocate or

perform any maintenance. Service should be performed by an authorized service

representative.

The compressor should be checked often for any visible problems and the

following maintenance procedures should be performed each time the compressor is

used.

ASME SAFETY VALVE

Do not remove or attempt to adjust the safety valve!

Check the safety valve by performing the following steps:

1. Plug the compressor in and run until shut off pressure is reached (see Operating

Procedure).

2. Wearing safety glasses, pull the ring on the safety valve to release pressure from

compressor tank. Use your other hand to deflect fast-moving air from being

directed toward your face.

3. The safety valve should automatically close at approximately 40-50 psi. If the safety

valve does not allow air to be released when you pull on the ring, or if it does not

close automatically, it MUST be replaced.

WL6700 Series

Figure 18 - Safety valve

Tank Pressure

Gauge

Easy-Drain

Knob

DRAIN TANK

1. Turn compressor off at foot pedal switch.

2. Check air pressure in tank. To properly drain tank of condensation, tank pressure

should be between 20-60 psi. Drain system will not work if there is no pressure in

the tank. If tank pressure is above 60 psi, decrease pressure in tank by pulling the

ring on the safety valve. Burst of air will be audible.

3. Slowly turn easy drain knob, located below the tank gauge, to the left

(counterclockwise) until fluid begins to fill drain cup. Watch draining to make sure

drain cup does not overflow. If there is a lot of fluid in the tank, you may need to

close drain knob by turning fully to the right (clockwise) then remove the drain cup

to dispose of fluid.

4. When fluid stops draining, close drain knob by turning all the way to the right

(clockwise).

5. Lift cup up and pull out to dispose of drained fluid. Reinsert cup, making sure to

secure in place.

CLEANING

Turn power OFF and clean dust and dirt from motor, tank, and air lines.

Fill Line

Easy-Drain Cup

Figure 19 - Draining tank

www.chpower.com

15

Page 16

Operating Instructions and Parts Manual

Maintenance (Continued)

IMPORTANT: Unit should be located as far from spraying area

as hose will allow to prevent over-spray from entering the pump.

AIR FILTER

Check air filter to be sure it is clean. To service the air filter, tip

the unit back, resting the wheels and handle on the floor (See

Figure 20). Remove the filter housing cover. Remove filter and

blow off dirt. Replace air filter if it can not be cleaned. Place filter

back in the housing base. Replace cover.

LUBRICATION

This is an oilless type compressor requiring no lubrication.

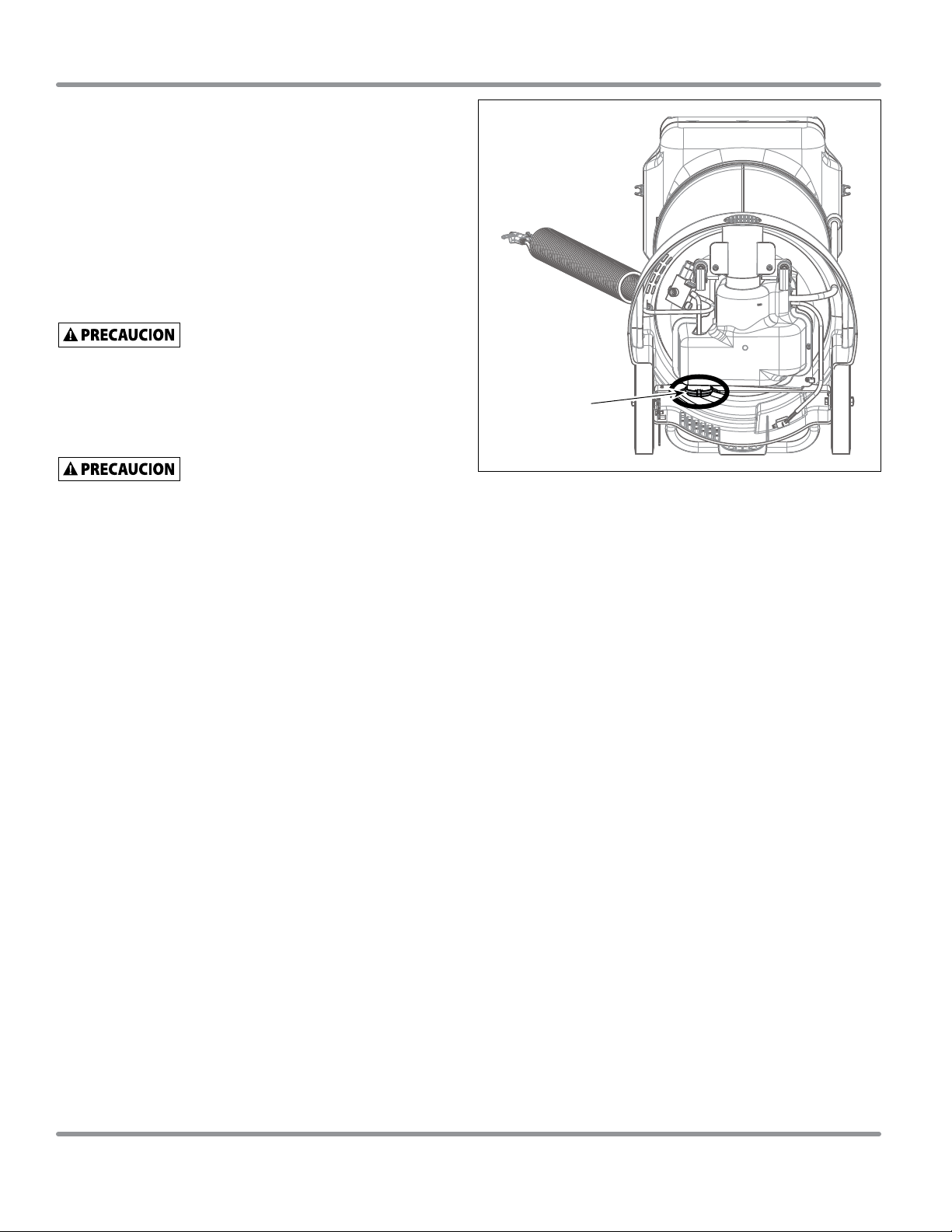

THERMAL OVERLOAD PROTECTOR

This compressor is equipped with an automatic

reset thermal overload protector which will shut

off motor if it becomes overheated.

If thermal overload protector shuts motor OFF frequently look

for the following causes:

1. Low voltage

2. Lack of proper ventilation

If the thermal overload protector is actuated,

the motor must be allowed to cool down before

startup is possible. The motor will automatically restart without

warning if left plugged into electrical outlet and unit is turned on.

Air Filter

Figure 20 - Air Filter

TORQUE REQUIREMENTS

Piston Bolt. . . . . . . . . . . . . . . . . . . . . . . 350 - 450 in. Ibs.

Head Bolts . . . . . . . . . . . . . . . . . . . . . . .90 - 120 in. Ibs.

TECHNICAL SERVICE

For information regarding the operation or repair of this

product, please call 1-800-543-6400.

16

www.chpower.com

Page 17

WL6700 Series

Service Record

DATE MAINTENANCE PERFORMED REPLACEMENT COMPONENTS REQUIRED

www.chpower.com

17

Page 18

Operating Instructions and Parts Manual

Troubleshooting Guide

SYMPTOM CAUSE SOLUTION

Compressor will not run 1. No electrical power 1. Plugged in? Switch on? Check fuse/breaker

2. Breaker open 2. Reset, determine cause of problem

3. Pressure switch bad 3. Replace

4. Motor over worked 4. Turn off, let cool, turn on.

5. Tank pressure above cut-in 5. Bleed tank pressure down to cut-in.

Fuses blow/circuit breaker

trips repeatedly

Tank pressure drops when

compressor shuts off

Air output lower than

normal/low discharge

pressure

Excessive moisture in

discharge air

Compressor runs

continuously

Motor runs but no air output Belt worn Replace belt

1. Incorrect size fuse, circuit overloaded 1. Check for proper fuse, use time-delay fuse.

Disconnect other electrical appliances from circuit

or operate compressor on its own branch circuit

2. Worn check valve 2. Replace

Do not disassemble check valve with

air in tank; bleed tank

1. Loose connections (fittings, tubing,

etc.)

2. Open tank drain 2. Close drain

1. Air leaks in piping (on machine or in

outside system)

2. Piston ring worn 2. Replace

3. Excessive air usage 3. Decrease air usage; compressor not large enough

4. Open tank drain 4. Close tank drain

1. Excessive water in tank 1. Drain tank

2. High humidity 2. Move to area of less humidity; use air line filter

1. Defective pressure switch 1. Replace switch

2. Excessive air usage 2. Decrease air usage; compressor not large enough

1. Check all connections with soap and water

solution. Tighten; or remove and apply pipe dope

or pipe tape to the threads, then reassemble.

1. Check all connections with soap and water

solution. Tighten; or remove and apply pipe dope

or pipe tape to the threads, then reassemble.

for air requirement

for air requirement

18

www.chpower.com

Page 19

For Replacement Parts or Technical Assistance, Call 1-800-543-6400

Please provide following information: Address any correspondence to:

- Model number Campbell Hausfeld

- Serial number (if any) Attn: Customer Service

- Part description and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

WL6700 Series

12

11

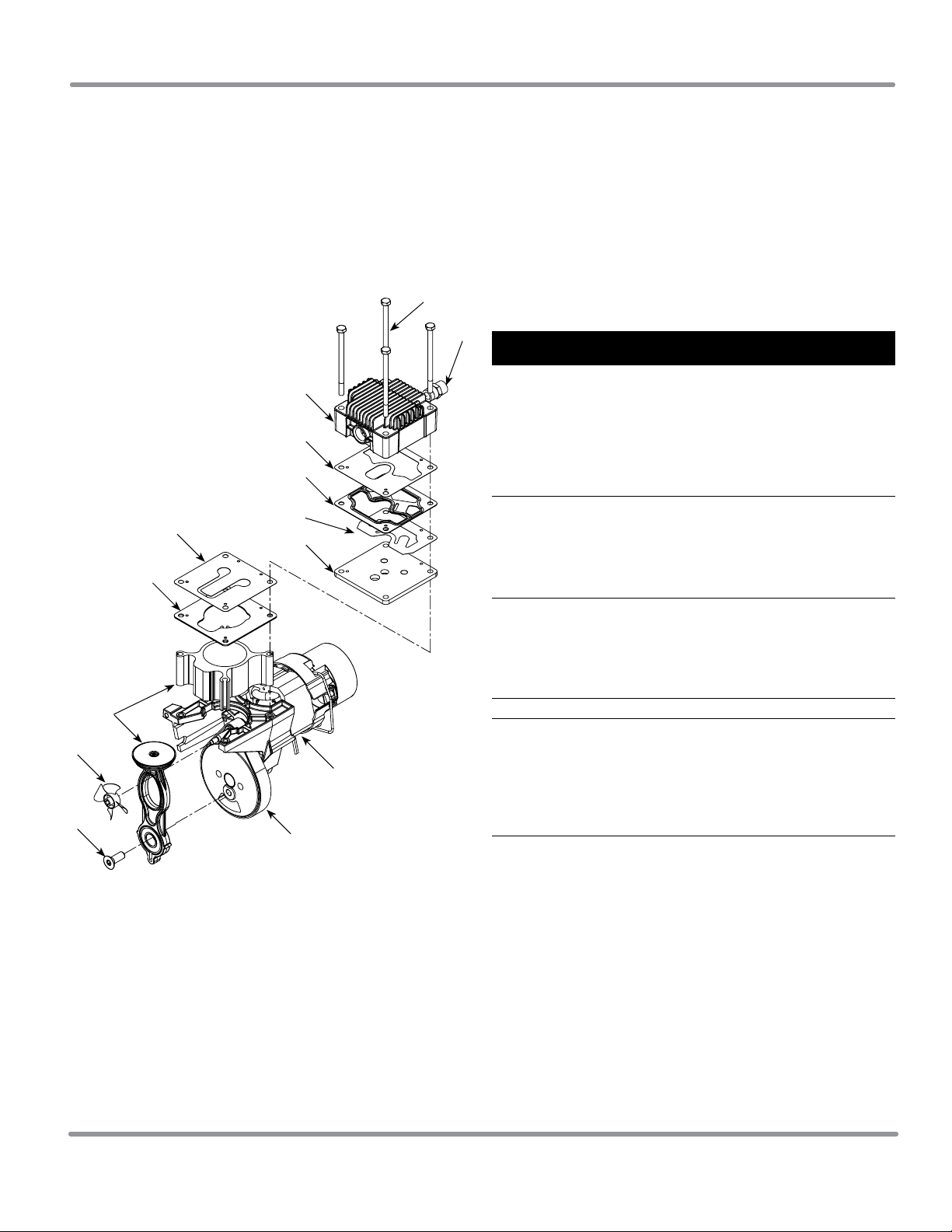

Replacement Parts List for Pump, Model WL390100

13

Ref. Part

No. Description No. Qty.

8

7

6

5

3

4

2

9

1

1 Motor assembly kit

(Includes #2, 3, 6, 7, 10, 12, & 14) WL019100SJ 1

2 Cylinder gasket ▲ 1

3 Intake valve ▲ 1

4 Valve plate ▲ 1

5 Exhaust valve ▲ 1

6 Head gasket ▲ 1

7 Exhaust valve gasket ▲ 1

8 Head WL010500AV 1

9 Piston assembly (Includes #10) WL211000SJ 1

10 Piston bolt ST071804AV 1

11 Head bolt ● 4

12 Fan WL008400AV 1

13 Compression connector ST159001AV 1

14 Belt kit (Includes #10, 12,

check valve, & ferrules) WL015303SJ 1

REPLACEMENT PARTS KITS

● Head bolt kit

(Set of 4 ea., part #11) WL211100AJ 1

▲ Valve plate kit (Includes #2-7) WL211201SJ 1

10

14

Figure 21 – Repair Parts Illustration for pump, model WL390100

TORQUE REQUIREMENTS

Piston Bolt. . . . . . . . . . . . . . . . . . . . . . . 350 - 450 in. Ibs.

Head Bolts . . . . . . . . . . . . . . . . . . . . . . .90 - 120 in. Ibs.

www.chpower.com

19

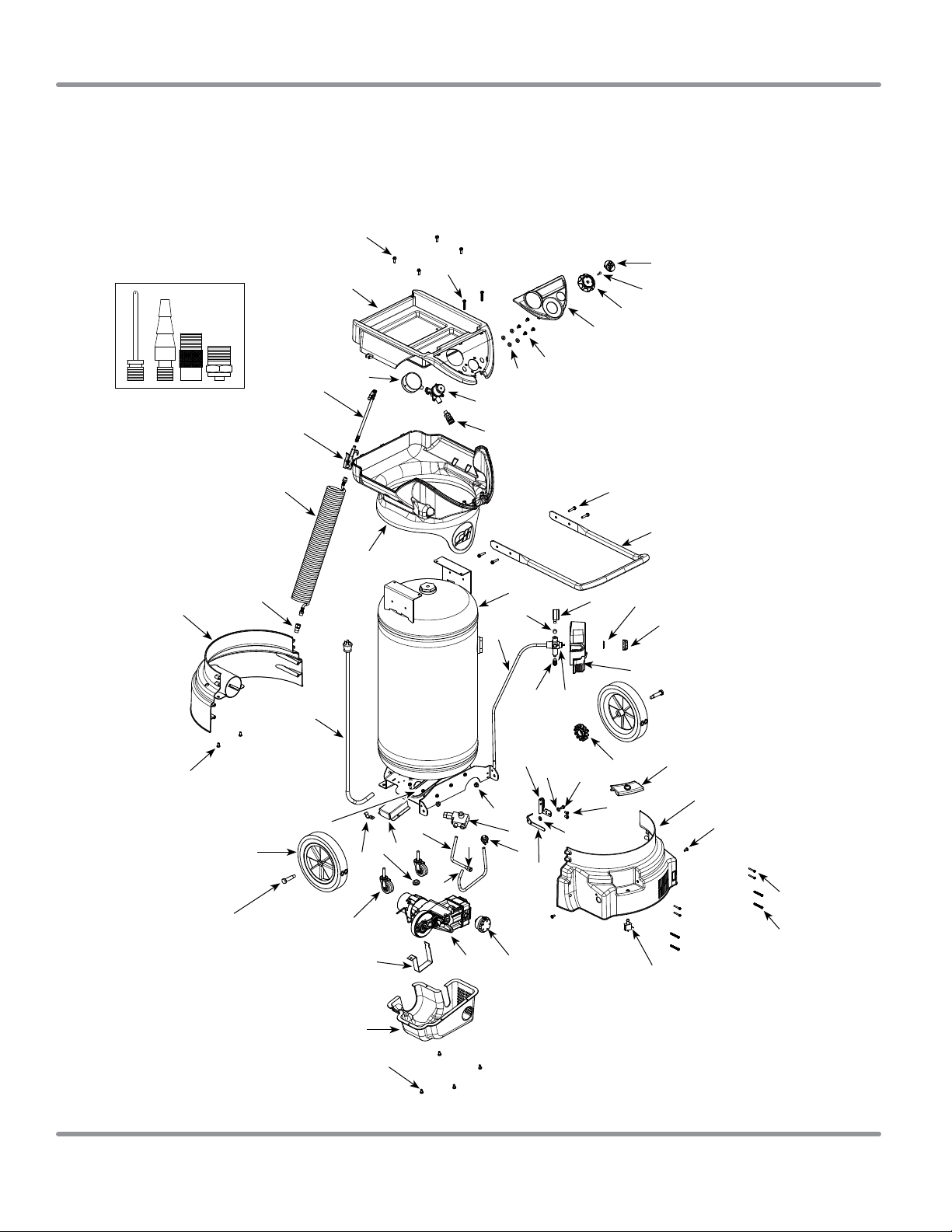

Page 20

Operating Instructions and Parts Manual

For Replacement Parts or Technical Assistance, Call 1-800-543-6400

Please provide following information: Address any correspondence to:

- Model number Campbell Hausfeld

- Serial number (if any) Attn: Customer Service

- Part description and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

20

19

16

56

18

25

17

21

26

50

48

1

27

51

29

28

47

44

57

55

53

52

4

24

23

22

31

30

45

46

49

39

43

7

14

27

27

8

40

28

20

36

37

Figure 22 – Repair Parts Illustration for The Ultimate Portable Garage Air Compressor, model WL6701

20

www.chpower.com

15

6

35

9

10

12

2

34

11

13

5

38

54

28

33

3

28

41

42

32

Page 21

Replacement Parts List for The Ultimate Portable Garage Air Compressor

WL6700 Series

Ref. Part

No. Description No. Qty.

1 26 Gallon Tank AR062700CG 1

2 Rubber Grommet WL008000AV 1

3 Bottom Front Shroud WL045000AV 1

4 Lower Caster Side Shroud WL044900AV 1

5 Millenium Pump/Motor Assembly WL212000SJ 1

6 Caster Swivel Wheel -

2 in. Diameter ▲ 2

7 Check Valve CV309100AV 1

8 Pressure Switch CW218300AV 1

9 Pump/Motor Shroud n 1

10 #8 X .375 Self-Tapping Screw n 4

11 Push Type - Straight Tube Fitting ST119305AV 1

12 Exhaust Tube ● 1

13 Instant Air Tube u 1

14 Filter WL026100AV 1

15 Strain Relief WL012700AV 1

16 Power Cord EC012601AV 1

17 Top Skirt WL044700AV 1

18 Top Shroud WL044600AV 1

19 1/4 in. X 1.50 in. Plastic Screw t 2

20 1/4-20 X .75 Self-Tapping Screw t 12

21 Regulator Assembly RE300200AV 1

22 Regulator Knob w 1

23 #10 X .75 Self-Tapping Screw w 1

24 Regulator Knob Cover w 1

25 3 in. Outlet Gauge GA032700AV 1

26 1/4” NPT Male Universal Coupler HF203300AV 1

27 Washer - Plain Type “A” t H 6

28 Torx Button Head Screw t m H 10

29 Control Panel without Switch WL042200AV 1

30 Handle o 1

31 1/4-20 X 1.25 Self-Tapping Screw o 4

32 On/Off Switch ST196400AV 1

33 On/Off Pedal WL044500AV 1

34 Eccentric Cover WL044400AV 1

35 Motor Bracket BA018300AV 1

Ref. Part

No. Description No. Qty.

36 Wheel - 10” OD Black Hub WA004000AV 2

37 Axle Bolt ST033400AV 2

38 Wheel Cog Gear H 1

39 Brake Bracket Mount H 1

40 Brake Locking Arm H 1

41 #8 X 1.50 in. Plastic Screw m 4

42 #12 X 1.75 in. Plastic Screw m 4

43 Hex Keps Nut ▲ 2

44 Drain Valve D-140700AV 1

45 Jam Nut and Washer Set 6 1

46 Drain Knob and Screw WL046100AV 1

47 Pressure Gauge, 1.5 in. Diameter GA032900AV 1

48 1/4 - 18 Pipe Plug † 1

49 Drain Shroud and Cup 6 1

50 Drain Tube with Weight WL046300AV 1

51 Safety Valve V-215106AV 1

52 Tube to Hose Fitting ST196000AV 1

53 50 ft. Recoil Hose MP287400AV 1

54 Screw - Hex Head Machine H 1

55 Lever Safety Blow Gun MP216700AV 1

56 Tire Inflation Valve with

Whip Hose HF229900AV 1

57 Blowgun Inflator Kit MP211600AV 1

REPLACEMENT PARTS KITS

▲ Caster Wheel Kit WA005900AJ

n Shroud kit WL042900AJ

● Exhaust Tube Kit

(includes nuts and ferrules) WL046600AJ

u Instant Air Tube Kit

(includes nuts and ferrules) WL046900AJ

t Upper Shroud Hardware Kit ST172200AJ

w Regulator Knob Kit RE300300AJ

o Handle Kit HL037700AJ

m Lower Shroud Hardware Kit ST172300AJ

H Brake Assembly WL047000AJ

6 Shroud And Drain Cup Assembly WL046200AJ

† Standard Hardware Item

www.chpower.com

21

Page 22

Operating Instructions and Parts Manual

Reminder: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: One Year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool, spray gun, inflator or

air accessory supplied or manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial, industrial or

rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States do not allow limitation

on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser’s abuse, neglect or failure to

operate products in accordance with instructions shall also include the removal or alteration of any safety devices. If such

safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs, bumpers, debris shields, driver

blades, fuses, batteries, gaskets, packings or seals, fluid nozzles, needles, sandblast nozzles, lubricants, material hoses, filter

elements, motor vanes, abrasives, blades, cut-off wheels, chisels, chisel retainers, cutters, collets, chucks, rivet jaws, screw

driver bits, sanding pads, back-up pads, impact mechanism, or any other expendable part not specifically listed. These

items will only be covered for ninety (90) days from date of original purchase. Underlined items are warranted for defects in

material and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service Center.

Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will

be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights. You may also have

other rights which vary from state to state or country to country.

22

www.chpower.com

Page 23

L’ultime compresseur

d’air de garage portable

Instructions d’Utilisation et Manual de Pièces

Série WL6700

ENGLISH: Page 1

ESPAÑOL: Página SP-1

MAKES IT EASY TO DO IT LIKE A PRO

Visit us at chpower.com

© 2009 Campbell Hausfeld/Scott Fetzer IN629500AV 4/09

Page 24

Table des Matières

Description. . . . . . . . . . . . . . . . . . . . . . . .Fr-3

Spécifications. . . . . . . . . . . . . . . . . . . . . .Fr-3

Directives de sécurité. . . . . . . . . . . . . . .Fr-4

Symboles de sécurité . . . . . . . . . . . . . . .Fr-4

Importantes instructions de

sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . .Fr-4

Instructions portant sur un risque

d’incendie, un choc électrique ou

des blessures aux personnes . . . . . . .Fr-4

Proposition 65 de Californie . . . . . . .Fr-4

Généralité :. . . . . . . . . . . . . . . . . . . . . . .Fr-4

Aire de travail . . . . . . . . . . . . . . . . . . . .Fr-5

Sécurité personnelle . . . . . . . . . . . . . .Fr-5

Sécurité électrique . . . . . . . . . . . . . . . .Fr-5

Utilisation et entretien . . . . . . . . . . . .Fr-5

Précautions de pulvérisation. . . . . . .Fr-6

Source d’air . . . . . . . . . . . . . . . . . . . . . .Fr-6

Service. . . . . . . . . . . . . . . . . . . . . . . . . . .Fr-6

Déballage . . . . . . . . . . . . . . . . . . . . . . . . .Fr-7

Contenu de la boîte . . . . . . . . . . . . . . .Fr-7

Autres articles non inclus. . . . . . . . . .Fr-7

Glossaire . . . . . . . . . . . . . . . . . . . . . . . . . .Fr-8

Apprendre à connaître votre

compresseur. . . . . . . . . . . . . . . . . . . . . . .Fr-9

Utilisations recommandées pour

ce compresseur. . . . . . . . . . . . . . . . . . .Fr-9

Outils recommandés pour ce

compresseur d’air . . . . . . . . . . . . . . . .Fr-9

Assemblage. . . . . . . . . . . . . . . . . . . . . . Fr-10

Outils requis pour l’assemblage . . .Fr-10

Assemblage de poignée . . . . . . . . . .Fr-10

Assemblage du tuyau de

gonflement. . . . . . . . . . . . . . . . . . . . . .Fr-10

Installation. . . . . . . . . . . . . . . . . . . . . . Fr-11

Endroit . . . . . . . . . . . . . . . . . . . . . . . . .Fr-11

Verrou de roue/frein à pied. . . . . . .Fr-11

Installation électrique. . . . . . . . . . . .Fr-11

Instructions de mise à la terre. . . . .Fr-11

Installation de fils. . . . . . . . . . . . . . . .Fr-12

Fonctionnement. . . . . . . . . . . . . . . . . Fr-12

Lubrification . . . . . . . . . . . . . . . . . . . .Fr-12

Soupape de sûreté ASME . . . . . . . . .Fr-13

Bouton Régulateru « Cliquer-pour-

régler ». . . . . . . . . . . . . . . . . . . . . . . . . .Fr-13

Remontage . . . . . . . . . . . . . . . . . . . .Fr-13

Manomètre de sortie (outil). . . . . . .Fr-13

Manomètre du réservoir. . . . . . . . . .Fr-13

Dessus de rangement . . . . . . . . . . . .Fr-13

Technologie de gonflement rapide

[Rapid Inflation Technology™

(RIT)]. . . . . . . . . . . . . . . . . . . . . . . . . . .Fr-14

Pour utiliser le compresseur

pour le gonflement : . . . . . . . . . . . . .Fr-14

Pour utiliser le compresseur

pour un outil pneumatique :. . . . . .Fr-14

Conclusion du travail/

entreposage. . . . . . . . . . . . . . . . . . . . .Fr-14

Entretien . . . . . . . . . . . . . . . . . . . . . . . . Fr-15

Soupape de sûreté ASME . . . . . . . . .Fr-15

Purger le réservoir . . . . . . . . . . . . . . .Fr-15

Nettoyage. . . . . . . . . . . . . . . . . . . . . . .Fr-15

Filtre d’air. . . . . . . . . . . . . . . . . . . . . . .Fr-16

Graissage . . . . . . . . . . . . . . . . . . . . . . .Fr-16

Protecteur de surcharge

thermique . . . . . . . . . . . . . . . . . . . . . .Fr-16

Couple. . . . . . . . . . . . . . . . . . . . . . . . . .Fr-16

Service technique. . . . . . . . . . . . . . . .Fr-16

État de service . . . . . . . . . . . . . . . . . . . Fr-17

Guide de dépannage . . . . . . . . . . . . . Fr-18

Liste de pièces de rechange pour la

pompe, modèle WL390100. . . . . . . . Fr-19

Couple. . . . . . . . . . . . . . . . . . . . . . . . . .Fr-19

Liste de pièces de rechange pour

l’ultime compresseur d’air de

garage portable . . . . . . . . . . . . . . . . . . Fr-21

Garantie Limitée . . . . . . . . . . . . . . . . . Fr-22

Pour de renseignements sur pièces de rechange, produits et entretien

Adresser toute correspondance à : Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Appeler :

Service à la clientèle au 1-800-543-6400

Page 25

Instructions d’Utilisation et Manual de Pièces

L’ultime compresseur

d’air de garage portable

Description

Les compresseurs sans huile sont conçus pour les bricoleurs avec projets domestiques

et d’automobile. Ces compresseurs servent à faire fonctionner les pistolets à peinture,

clés à chocs et autres outils. Ces modèles fonctionnent sans huile.

Spécifications

Modèle WL6700

HP de marche : 1,7 (ISO 1217)

m³/min (pi³/min) d’air libre :

0,107 m³/min @ 621 kPa

(3,8 @ 90 lb/po²) (ISO 1217)

m³/min (pi³/min) d’air libre :

158 m³/min @ 276 kPa (5,6 @ 40 lb/

po²) (ISO 1217)

Capacité de réservoir :

68,13 L, 83, 27 L, 98,41 L, 113,55

L(18, 22, 26, or 30 gallons)

Figure 1 - Série WL6700

Volts, phase : 120 V, monophase

Tirage d’ampères : 15

Cycle de service max. : 50%

Enregistrer les numéros de modèle et de

série qui se trouvent à l’arrière du réservoir

et la date d’achat dans l’espace plus bas.

No. de Modèle : ______________________

No. de Série : ________________________

Date d’Achat : _______________________

Garder ces numéros pour référence.

Fr-3

Page 26

Instructions d’Utilisation et Manual de Pièces

Importantes instructions de sécurité

Directives de sécurité

Ce manuel contient de l’information

très importante qui est fournie

pour la SÉCURITÉ et pour ÉVITER

LES PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger indique

dangereuse imminente qui MÈNERA à la

mort ou à des blessures graves si elle n’est

pas évitée.

Avertissement

situation potentiellement dangereuse qui,

si elle n’est pas évitée, POURRAIT mener à

la mort ou à de graves blessures.

Attention indique

potentiellement dangereuse qui, si elle n’est

pas évitée, PEUT mener à des blessures

mineures ou modérées.

Avis indique

importante qui pourrait endommager

l’équipement si elle n’est pas respectée.

une situation

indique une

une situation

de l’information

IMPORTANT : Information qui exige

une attention spéciale.

Symboles de sécurité

Les symboles de sécurité suivants

apparaissent dans l’ensemble de ce

manuel pour vous aviser des dangers et

précautions importants de sécurité.

Porter une

protection

oculaire et un

masque.

Porter une

protection

des yeux et

des oreilles

Lire le manuel

d’abord

Pièces

chaudes

Risque

d’incendie

Risque de

tomber

INSTRUCTIONS PORTANT SUR UN RISQUE D’INCENDIE, UN CHOC ÉLECTRIQUE OU DES BLESSURES AUX PERSONNES

Ce manuel contient des informations concernant la sécurité, le fonctionnement et

l’entretien. Si vous avez des questions, appeler le 1-800-543-6400 pour le service à la

clientèle.

Puisque le compresseur d’air et les autres pièces détachées (pompe, pistolets, filtres,

graisseurs, tuyaux, etc.) font partie d’un système de pompage de haute pression, il est

nécessaire de suivre les précautions suivantes:

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son cordon peuvent contenir des produits chimiques,

y compris du plomb, relevés par l’État de Californie comme cause de

cancer, d’anomalies congénitales ou d’autres problèmes reproductifs. Lavez-vous les mains

après toute manipulation.

Vous pouvez créer de la poussière en coupant, ponçant,

perçant ou meulant les matériaux tels que le bois, la

peinture, le métal, le béton, le ciment ou autre maçonnerie. Cette poussière contient

souvent des produits chimiques reconnus pour causer le cancer, les déformations

congénitales

Avertissement D’Air Respirable

Ce compresseur/pompe n’est pas équipé pour et ne devrait pas être utilisé

“comme soi” pour fournir de l’air respirable. Pour les applications d’air pour la

consommation humaine, il est nécessaire d’équiper le compresseur d’air/pompe

avec de l’équipement de sécurité en canalisation et d’alarme. Cet équipement

additionnel est nécessaire pour filtrer et purifier l’air afin d’atteindre les

spécifications minimales pour la respiration Grade D décrite dans le Compressed

Gas Association Commodity Specification G 7.1 - 1966, OSHA 29 CFR 1910. 134,

and/or Canadian Standards Associations (CSA).

DÉNÉGATION DES GARANTIES

Si le compresseur est utilisé pour les applications d’air respirable et l’équipement

de sécurité en canalisation et d’alarme n’est pas utilisé simultanément, les

garanties en existance seront annulées, et Campbell Hausfeld dénie toute

responsabilité pour n’importe quelle perte, blessure ou dommage.

GÉNÉRALITÉ :

a. Pour réduire les risques de chocs électriques, d’incendie ou de

blessures aux personnes, lire toutes les instructions avant d’utiliser

l’outil. Ne pas suivre les avertissements, les dangers et les mises en

garde pourrait causer la MORT ou de GRAVES BLESSURES.

b. Se familiariser avec ce produit, ses commandes et son utilisation. Suivez toutes

les instructions. Contacter votre représentant Campbell Hausfeld si vous avez des

questions.

c. Suivre tous les codes de sécurité locaux ainsi que les National Electrical Codes

(NEC) and Occupational Safety and Health Act (OSHA) des É-U.

d. Seules les personnes familières avec ces règles d’utilisation sans danger

devraient utiliser cette unité.

Risque de choc

électrique

Fr-4

Risque

d’explosion

Pièces

chaudes

Page 27

Importantes instructions de sécurité (Suite)

Série WL6700

AIRE DE TRAVAIL

a. Garder l’aire de travail propre et bien éclairée. Les établis

encombrés et les coins sombres augmentent les risques de

chocs électriques, d’incendie et de blessures aux personnes.

b. Garder les spectateurs, les enfants et les visiteurs loin

en utilisant l’unité. Les distractions peuvent faire perdre

le contrôle de l’unité. NE JAMAIS permettre aux enfants

d’avoir accès à l’aire de travail.

Les moteurs, l’équipement et

les commandes électriques peuvent

produire des arcs électriques qui peuvent allumer les gaz

ou vapeurs inflammables. Ne jamais faire fonctionner

ni réparer près des gaz ou vapeurs inflammables. Ne

jamais ranger ni pulvériser des liquides ou gaz inflammables près du

compresseur.

c. Pour réduire le risque d’incendie, garder l’extérieur du

moteur libre d’huile, de solvant ou de graisse excessive.

SÉCURITÉ PERSONNELLE

a. Rester vigilant. Il faut regarder ce que vous faites et utiliser

son sens commun en faisant fonctionner un outil. Ne

pas faire fonctionner l’appareil si vous êtes fatigué ou

sous l’influence de drogues, d’alcool ou de médicaments.

Un moment d’inattention en faisant fonctionner l’outil

augmente le risque de blessures.

S’assurer que l’outil est utilisé

seulement lorsque l’opérateur

et tout autre personnel dans l’aire de travail portent un

équipement de protection oculaire ANSI Z87 et, s’il y a lieu,

d’autre équipement de protection approprié tel que de

l’équipement de protection pour la tête, les oreilles et les

pieds. Il pourrait y avoir de graves lésions oculaires ou perte auditive.

b. Toujours porter une protection auditive en utilisant l’outil.

Toute exposition prolongée à des bruits de forte intensité

pourrait provoquer une perte auditive.

c. Toujours travailler dans un endroit bien ventilé. Porter un

masque anti-poussières homologué OSHA.

d. Il faut s’habiller correctement. Ne pas porter de bijoux ou

de vêtements amples. Attacher les cheveux longs. Garder

les cheveux, les vêtements et les gants loin des pièces

mobiles. Les vêtements amples, les bijoux ou les cheveux

longs augmentent le risque de blessures si quelque chose se

prend dans les pièces mobiles.

Les pièces du compresseur peuvent

être chaudes, même si le modèle est

hors circuit.

e. Garder les doigts à l’écart du compresseur; les

pièces mobiles et chaudes peuvent causer des

blessures et/ou des brûlures.

f. Ne pas trop se pencher. Garder bon pied et bon

équilibre en tout temps. Ceci permet d’avoir un

meilleur contrôle de l’outil dans les situations

imprévues.

SÉCURITÉ ÉLECTRIQUE

Risque de secousse électrique :

Toujours débrancher de la source

d’énergie avant de faire l’entretien. L’entretien doit être

réalisé seulement par un centre de service autorisé.

UTILISATION ET ENTRETIEN

Ne jamais utiliser les tuyaux

plastiques (CPV) pour l’air

comprimé. Ceci peut causer des blessures graves ou la

mort.

a. Inspecter le système d’air comprimé et pièces

détachées électriques pour toute indication de dommage,

détérioration, faiblesse ou fuites avant chaque utilisation.

Réparer ou remplacer toutes pièces défectueuses avant

l’utilisation.

b. Inspecter le degré de serrage de toutes attaches par

intervalles régulières.

c. Vérifier les tuyaux d’air pour rechercher tout signe de

faiblesse ou d’usure avant chaque utilisation. S’assurer que

tous les branchements soient bien serrés.

d. Ne pas se tenir debout sur/ni utiliser le modèle comme

une prise à main.

e. Si l’équipement vibre anormalement, ARRÊTER le

moteur et l’inspecter immédiatement. La vibration est

généralement une indication d’un problème.

Ne jamais enlever ou essayer d’ajuster la

soupape de sûreté. Garder la soupape de sûreté

libre de peinture et d’autres accumulations.

f. Ne pas modifier ou altérer la soupape de sûreté. Si la

soupape de sûreté est altérée, les garanties en cours seront

annulées et Campbell Hausfeld dénie toute responsabilité

quelconque pour toute perte, blessure personnelle ou

dommage.

Ne jamais essayer de réparer

ou de modifier un réservoir! Le

soudage, perçage ou autre modifications peuvent affaiblir

le réservoir et peuvent résulter en dommage de rupture ou

d’explosion. Toujours remplacer un réservoir usé, fendu ou

endommagé.

Purger le liquide du réservoir

quotidiennement.

g. Purger le réservoir quotidiennement et l’inspecter

périodiquement pour n’importe quel état d’entretien

dangereux tel que la rouille et la corrosion ou autre

dommage. L’accumulation d’humidité cause la rouille qui

peut affaiblir le réservoir.

h. Lâcher l’air lentement en purgeant l’humidité ou pendant

la dépressurisation du système du compresseur. L’air

mouvante peut agiter la poussière et le débris qui peut être

dangereux.

i. Ne pas retirer les étiquettes d’avertissement de l’appareil.

j. Rangez à l’intérieur. Ne rangez pas à l’extérieur ou dans les

rayons du soleil.

Fr-5

Page 28

Instructions d’Utilisation et Manual de Pièces

Importantes Instructions De Sécurité (Suite)

PRÉCAUTIONS DE PULVÉRISATION

Ne pas pulvériser les matériaux inflammables dans

d’allumage y compris le compresseur.

a. Ne pas fumer pendant la pulvérisation de la peinture, d’insecticides ou

autres matières inflammables.

b. Utiliser un masque/respirateur pendant la pulvérisation et pulvériser

dans un endroit bien ventilé pour éviter le risque de blessures et

d’incendie.

c. Ne pas diriger la peinture ou autre matériel pulvérisé vers le

compresseur. Situer le compresseur aussi loin que possible de l’endroit de

pulvérisation pour réduire l’accumulation de surpulvérisation sur le compresseur.

d. EN PULVÉRISANT OU NETTOYANT AVEC DES SOLVANTS OU DES PRODUITS

CHIMIQUES TOXIQUES, SUIVRE LES INSTRUCTIONS FOURNIES PAR

LE FABRICANT DES PRODUITS CHIMIQUES.

SOURCE D’AIR

Le compresseur d’air utilisé avec cette cloueuse doit conformer aux

Standard B19.3-1991; Safety Standard for Compressors for Process Industries. Contacter le

fabricant du compresseur pour plus d’informations.

un endroit de flamme ouverte ni près d’une source

exigences établies par l’American National Standards Institute

SERVICE

a. Dissiper la pression d’air du réservoir à air en tirant sur l’anneau de sûreté avant

le service ou le remplacement de pièces.

b. Tout le travail d’entretien et de réparation doit être effectué seulement par un

personnel de réparation qualifié.

Ne jamais essayer de réparer ou de modifier un réservoir! Le soudage,

résulter en dommage de rupture ou d’explosion. Toujours remplacer un réservoir usé, fendu ou

endommagé.

perçage ou autre modifications peuvent affaiblir le réservoir et peuvent

c. En réparant ou faisant l’entretien d’un outil, utiliser seulement des pièces de

rechange identiques. Utiliser seulement des pièces autorisées.

NOTE: Les symboles DANGER, AVERTISSEMENT, ATTENTION ET AVIS ainsi que les

instructions de ce manuel ne peuvent pas couvrir toutes les conditions et situations qui

pourraient se produire. L’opérateur doit comprendre que le bon sens et des précautions sont

des facteurs qui ne peuvent pas être inclus dans ces produits, mais doivent être fournis par

l’opérateur.

CONSERVER CES INSTRUCTIONS

NE LES JETEZ PAS

Fr-6

Page 29

Déballage

Tuyau de

rappel de

nylon

Soufflette

Poignée

Accessoires

de soufflette

Vis autotaraudeuses

Valve de

gonflement

de pneu

Série WL6700

Dès que l’appareil est déballé, l’inspecter

attentivement pour tout signe de

dommages en transit. Vérifier s’il y a

des pièces desserrées, manquantes ou

endommagées. S’assurer de resserrer

tous les raccords, boulons, etc. avant

de le mettre en service. Vérifier pour

s’assurer que tous les accessoires fournis

sont inclus avec l’appareil. Pour toutes

questions, pièces endommagées ou

manquantes, appeler le 1-800-543-6400

pour le service à la clientèle.

u Ne pas faire fonctionner l’appareil s’il

est endommagé pendant l’expédition,

la manipulation ou l’utilisation. Des

dommages peuvent mener à l’éclatement

et provoquer des blessures ou des

dommages à la propriété.

u Pour votre propre sécurité, ne jamais faire

fonctionner l’appareil avant de terminer

toutes les étapes d’assemblage et d’avoir lu

et compris tout le manuel de l’opérateur.

u Pour réduire les risques de blessure, s’ils

manquent des pièces, ne pas essayer

d’assembler le compresseur d’air avant

d’avoir obtenu les pièces manquantes et de

les avoir installées.

Figure 2 - Déballage

Ruban

de

filetage

CONTENU DE LA BOÎTE

u Accessoires de soufflette

u Poignée

u Soufflette

u Tuyau de rappel de nylon

u (4) Vis autotaraudeuses

u Valve de gonflement de pneu

u Ruban de filetage

u Instructions d’utilisation et manual de

pièces

u Carte d’enregistrement de produit

AUTRES ARTICLES NON INCLUS

u Tuyau à air

u ANSI Z87, Protection oculaire

u Protection auditive

u Autre équipement de protection

personnelle, si nécessaire

LIRE ET SUIVRE TOUTES LES

INSTRUCTIONS.

Conserver ces instructions

ne pas les jeter.

Fr-7

Page 30

Instructions d’Utilisation et Manual de Pièces

Glossaire

Familiarisez-vous avec ces termes avant d’utiliser l’appareil.

SOUFFLAGE D’AIR - Une combinaison de kPa (lb/po²) ou m³/min (PCNM). Le

soufflage d’air requis par un outil est indiqué sous forme de (nombre) m³/min

(PCNM) à (nombre) kPa (lb/po²). Le mélange de ces chiffres détermine la taille

d’appareil nécessaire.

CAPACITÉ DE RÉSERVOIR À AIR - Le volume d’air stocké dans le réservoir et

disponible pour une utilisation immédiate. Un large réservoir permet l’utilisation

intermittente d’un outil pneumatique exigeant de l’air à un niveau plus élevé

que la valeur nominale du compresseur.

SOUPAPE DE SÛRETÉ ASME* - Cette soupape dégage automatiquement l’air si

la pression du réservoir dépasse le maximum préétabli.

RÉGULATEUR « CLIQUER-POUR-RÉGLER » - Le régulateur contrôle la

quantité de pression d’air dégagée à la sortie du tuyau à la quantité appropriée

et nécessaire pour faire fonctionner un outil pneumatique ou un pistolet

de pulvérisation.

PRESSION DE FERMETURE/D’OUVERTURE - kPa ou lb/po² précis où un

compresseur démarre et s’arrête en remplissant le réservoir d’air.

BOUTON DE VIDANGE FACILE - Ce bouton est utilisé pour vidanger chaque

jour l’humidité du réservoir pour réduire le risque de corrosion.

Figure 3 - Soupape de sûreté ASME

Figure 4 - Régulateur « cliquer-pour-régler »

INTERRUPTEUR MARCHE/ARRÊT DE LA PÉDALE AU PIED - Utilisé pour

mettre le compresseur en marche et l’arrêter. Pressez fermement.

PROTECTION DU MOTEUR - Si l’appareil fonctionne trop, un interrupteur

thermique l’arrêtera. Si ceci se produit, mettre l’interrupteur MARCHE/

ARRÊT à la position OFF (arrêt), attendre 30 minutes pour laisser refroidir,

remettre l’interrupteur à nouveau à ON (marche) pour reprendre le travail.

MANOMÈTRE DE SORTIE (OUTIL) - Affiche la pression de sortie actuelle à

l’outil en Kpa ou lb/po². Il est régulé par le bouton du régulateur.

PRESSOSTAT -Éteint automatiquement le compresseur lorsque la pression du

réservoir atteint la pression maximale préréglée. Le compresseur redémarrera

automatiquement lorsqu’il atteint la pression minimale préréglée.

LB/PO² (KPA) - Mesure de la pression de la force de l’air. La sortie réelle en

lb/po² (kPa) se mesure par un manomètre sur le compresseur.

PCNM (PIED CUBE NORMAL PAR MINUTE) (M³/MIN OU MÈTRE CUBE

PAR MINUTE) - Synonyme à pied cube par minute). Mesure du volume d’air

livré par le compresseur

MANOMÈTRE DU RÉSERVOIR - Indique la pression du réservoir en lb/po²

ou kPa.

RANGEMENT D’OUTILS - L’espace ouvert sur le dessus du compresseur est

conçu pour le rangement des outils. Des trousses d’outils Campbell Hausfeld

précises se rangeront dans cet espace.

Figure 5 - Bouton de vidange facile

Figure 6 - Interrupteur marche/arrêt de

la pédale au pied

* ASME : American Society of Mechanical Engineers. Les réservoirs ASME sont

fabriqués selon les exigences ASME.

Fr-8

Figure 7 - Manomètre du réservoir

Page 31

Apprendre à connaître votre compresseur

Pince de

cordon

d’alimentation

Cordon

d’alimentation

Poignée à

tirer

Soupape

de sûreté

ASME

Manomètre de

sortie (outil)

Régulateur

« cliquer-pour-régler »

Coupleur

Interrupteur marche/arrêt

de la pédale au pied

Verrou de roue /

frein à pied

Plateaux de

rangement

Pince de

soufflette

Manomètre

du réservoir

Bouton de

vidange facile

Godet

d’écoulement

facile

Série WL6700

UTILISATIONS RECOMMANDÉES POUR CE COMPRESSEUR

u Entretien d’automobile

u Restauration d’automobile

u Cloueuses et agrafeuses

u Entretien résidentiel

u Gonflement

u Travail du bois

OUTILS RECOMMANDÉS POUR CE COMPRESSEUR D’AIR

Utilisation continue —

Accessoires de gonflement

Brosse pneumatique

Tournevis pneumatiques

Cloueuses de pointes de vitrier et agrafeuses

Pistolets à calfeutrer

Nettoyeurs à moteur

Cloueuses de finition

Pistolets à graisse

Pistolets de pulvérisation résidentiels

Clés à chocs

Clés à cliquet

Scies alternatives

Cloueuses de toiture et encadrement

Usage intermittent

(Courtes salves puissantes) —

Burins pneumatiques

Perceuses pneumatiques

Pistolets de pulvérisation automobiles

Meules à rectifier

Outils non recommandés —

Machines à tronçonner

Ponceuses à double action

Ponceuses à grande vitesse

Ponceuses à sautillement

Ponceuses alternatives

Figure 8 - Composants du compresseur

Soufflette

de

sécurité

Tuyau d’air

instantané

Fr-9

Page 32

Instructions d’Utilisation et Manual de Pièces

Assemblage

OUTILS REQUIS POUR L’ASSEMBLAGE

u Clé à cliquet avec douille de 9,5 mm

(3/8 po)

u (2) clés

ASSEMBLAGE DE POIGNÉE

1. Glisser la poignée dans les trous

d’épaulement en s’assurant que

la poignée est à l’extérieur de la

fixation et que les trous de la poignée

s’alignent avec les trous de la fixation

du réservoir.

2. Insérer les vis à travers la poignée,

puis la fixation. Utiliser une clé à

cliquet à douille de 9,5 mm (3/8 po),

resserrer les vis pour retenir la poignée

en place.

Figure 9 - Assemblage de poignée

ASSEMBLAGE DU TUYAU DE GONFLEMENT

1. Appliquer du ruban de filetage aux

deux extrémités du tuyau de rappel

pour éviter les fuites.

2. Enfiler le tuyau de rappel dans le

raccord sur l’épaulement. Utiliser

2 clés ajustables pour resserrer la

connexion en tenant la clé inférieure

sans bouger et en resserrant avec la

clé supérieure (voir la figure 10).

3. Visser la soufflette à l’extrémité

du tuyau de rappel. Utiliser 2 clés

ajustables pour resserrer la connexion

en tenant la clé inférieure sans bouger

et en resserrant avec la clé supérieure.

Lorsque le tuyau de rappel et la

soufflette sont attachés, s’assurer qu’il

n’y a aucune pression dans le réservoir

avant de replacer. Le tuyau de rappel et