Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observ ng all safety

information. Faiiure to comply with instructions could result in personal injury and/or property

damagel Retain instructions for future reference.

Oilless Air

IRONFORCF__ Compressors

@

Description

Oilless compressors are designed for

do-it-yourselfers with a variety of home

and automotive jobs. These

compressors power spray guns, impact

wrenches and other tools. These units

operate without oil.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information isprovided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

hazardous situation which, ff not

avoldee_ WILL resu/f In deafh or serious

Injury.

hazardous situation whlo% if not

avolde_ COULD result In death or

s_Hous injury.

hazardous situation whk_ if nor

avolde_ MAY _lsuif ln mltmr or

moderate InJu_.

t NOTICE t _--._dlcate,

Information, that If not followeeL MAY

cause damage tu equipment.

an Imminently

Wanllng Indicates

a potentially

Carrion Indl¢'.ates a

potenffally

Important

Unpacking

After unpacking the unit, inspect

carefully for any damage that may have

occurred during transit. Make sure to

tighten fittings, bolts, etc., before

putting unit into service. In case of

questions, damaged or missing parts,

please call 1-800-543_o400 for customer

O DO NOT RETURN THE

PRODUCT TO THE

RETAILERI

Breathable Air Warning

This compressor/pump is not

equipped and should not be used

"as is" to supply breathing quality

air. For any application of air for

human consumption, the air

compressor/pump will need to be

fitted with suitable in-line safety

Information '_l_ -- _

Record the Model No, Serial NO. and

date of purchase located on the base

below the pump in the space below.

Model No.

Serial No.

Date of purchase

Retain these numbers for future

reference.

assistance or call the nearest Campbell

Hausfeld Authorized Service Center.

A listing of service center locations is

enclosed, Have the serial number.

model number, and parts list (with

missing parts circled) before calling.

Do not operate

during shipping, handling or use.

cause injury orproper;y damage, included with this

unit If damaged times:

and alarm equipment. This

additional equipment is necessarj

to properly filter and purify the air

to meet minimal specifications for

Grade D breathing as described in

Compressed Gas Association

Commodity Specification G 7.1 -

1966, OSHA 29 CFR 1910. 134,

and/or Canadian Standards

Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used

for the purpose of breathing air

application and proper In-line

safety and alarm equipment Is not

simultaneously used, existing

warranties shall be voided, and

Campbell Hausfeld disdalms any

liability whatsoever for any loss,

personal injury or damage.

precautions must be observed at atl

product carefully. Be

General Safety thoroughlyfamiliar

Information _th the controls and

the proper use of the equipment.

Since the air compressor and other 2. Follow all localelect deal and safety

components (material pump. spray cedes as well as in t_ US, National

guns, filters, lubricators, hoses, etc.) Electrical Codes (NEC) and O¢cupatio_ll

used, make up a high pressure Safety and Health Act (OSHA).

pumping system, the following safety

O 2003 Campbell Hausfeld,Scott Fetzer F_ i_lt_s,product&serviceInforma*tion IN61020OAV 9/03

vkit www.chpower_om

Page 2

Oilless Compressors

General Safety

Information (Continued)

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and use hearing

protection when operating the

pump or unit.

6. Do not stand on or use the pump or

unit as a handhold.

7. Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

_WARNINGI

Motors. efectrkal

equipment and controls

can cause electrical arcs

that will 19nite • flammable gas or

vapor. NeVer operate or repair In or

near a flammable gss or vapor. Never

store or spray flammable liquids or

gases In the vtcin/ty of b'le compressor.

Compressor part: may be

hot even ff the unit is

stoppnd.

g. Keep fingers away from a running

compressor, fast moving and hot

parts will cause injury and/or burns.

t0. If the equipment should start to

abnormally vibrate, STOP the

engine/motor and check

immediately for the cause. Vibration

isgenerally a warning of trouble.

11.To reduce fire hazard, keep

engine/motor exterior free of oil

solvent, or excessive grease.

Ng_r rgm_o_ or

a_npt to a_f._

_ p•int _,d ether a_let_s.

Never ammPt to i_pair

or modify • 1onkl

Welding, drilling or any other.

modiflcltinn will weaken the tank

resulting In damage from nlpture or

expinsinn. Always _plece worn or

dam:gad tenk_

I NOTICE I _.inl_.ld_..

12. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

such as rust formation and corrosion.

t3. Fast moving air will stir up dust and

debris which may be harmful. Release

air slowly when draining moisture or

depressudzil_cJ the compressor system.

SPRAYING PRECAUTIONS

tank dally.

IAWARNINGI

Do not spray flammable

meterfait in vicinity of

open flame or near

ignition sources including the

€ompre_or unlL

14. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

15. Use a face mask/

resplretor when

spraying and spray in

a well ventilated area

to prevent health and

fire hazards.

16. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to

minimize overspray accumulation

on the compressor.

17.When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

Assembly

HANDLE/_SI:MBLY

Compressor handle has a notch (or

detent) at top of handle. This notch

provides a handy place to hang a spray

gun, sandblast gun. or other tool

equipped with a hook.

t. If a handle grip was incioded with

the unit, coat the inside of grip with

a thin film of soapy water. Push grip

onto handle.

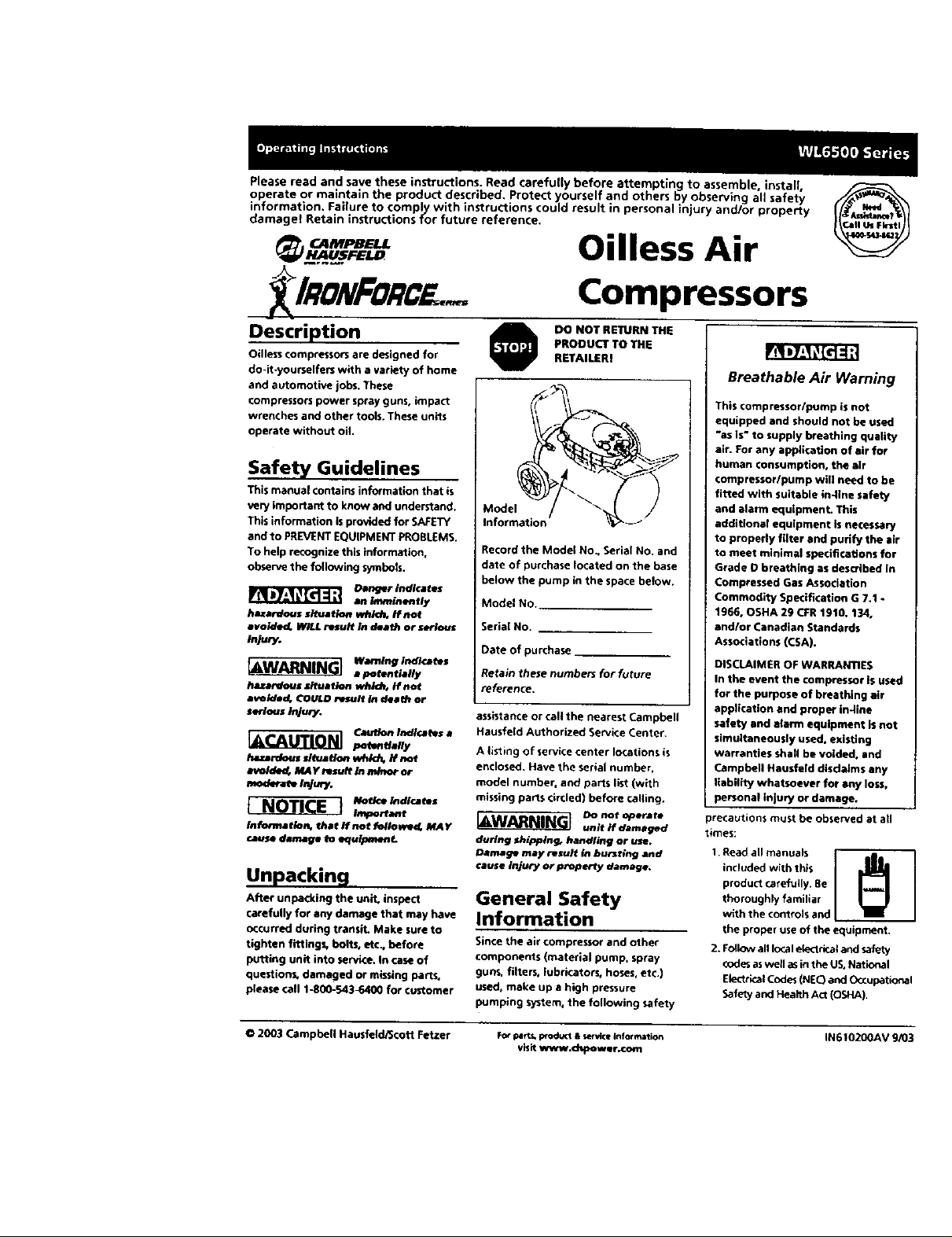

2. Insert handle through shroud and

into baseplate as shown in Figure 1,

Handle must fit into special openings

in baseplate.

3. Place a short piece of wood against

end of handle and tap it with a

mallet or hammer to drive handle

into haseplate until hole in handle

and baseplate line Up.

4. Assemble and tighten 2 screws (from

parts package) through hole in base-

plate ensudng h goeslhrough handle.

Ne vIFr USe t_le

unit completely off the ground. Only

use the hand/e to lift one end so the

wheets may be usecl to movt the unlt

5. Insert threaded post of rubber foot

into hole in ground iron. Tighten

securely with Iocknut.

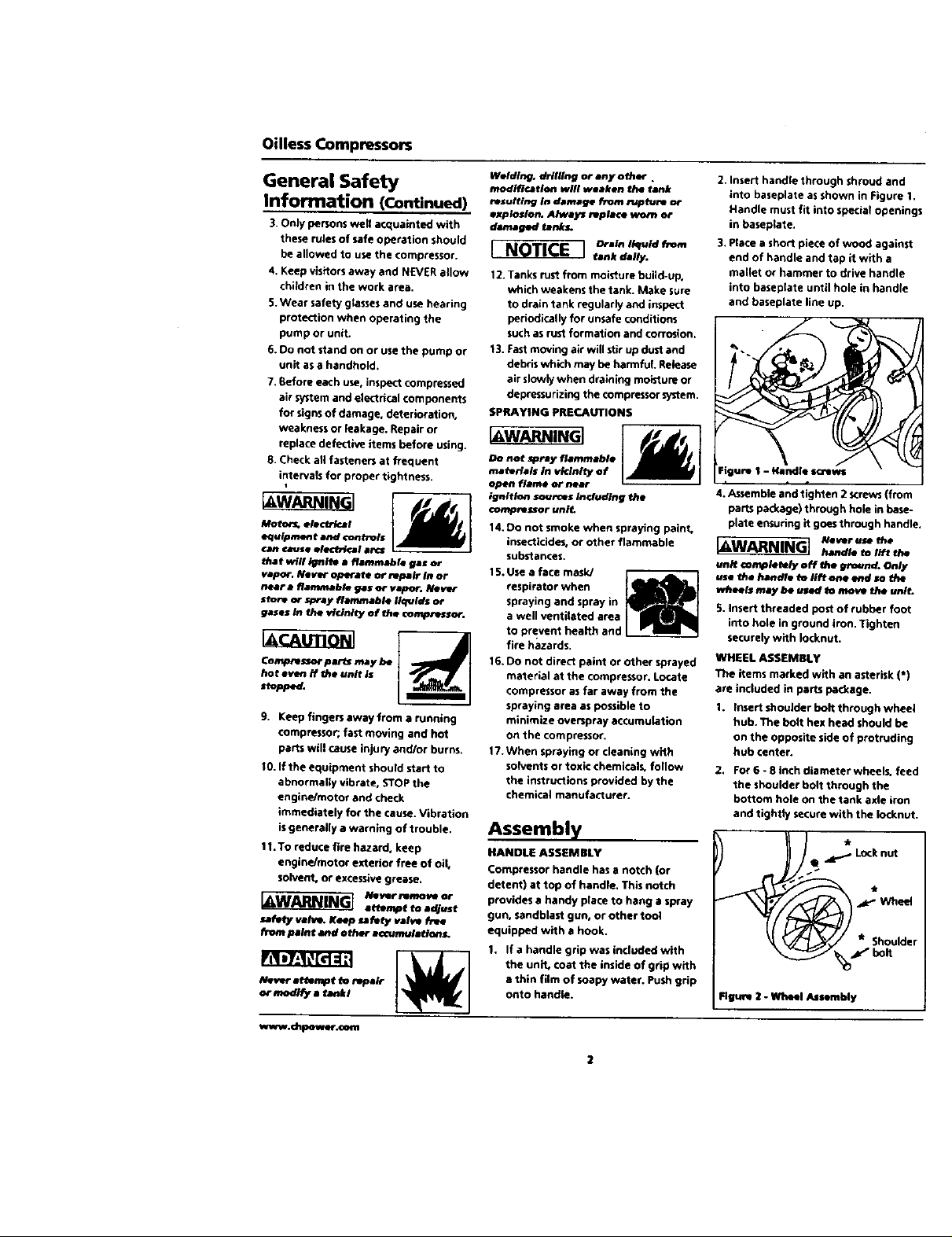

WHEEL ASSEMBLY

The items marked with an asterisk (*)

are included in parts package.

1. Insert shoulder bolt through wheel

hub. The bolt hex head should be

on the opposite side of protruding

hub <:enter.

2. For 6 - 8 inch diameter wheels, feed

the shoulder bolt through the

bottom hole on the tank axle iron

and tightly secure with the iocknut.

handle to lift the

)Q _ Lock nut

a u,der

Figure 2 -wheel Assembly

wvnv.chpower.€om

Page 3

WL6500 Series

Assembly (Con't)

For 10 inch diameter wheels, feed

the shoulder bolt through the top

hole on the tank axle iron and

tightly secure with the Iocknut.

Repeat on the opposite side.

•_ Grip

Figure 3- Optlomll Assembly

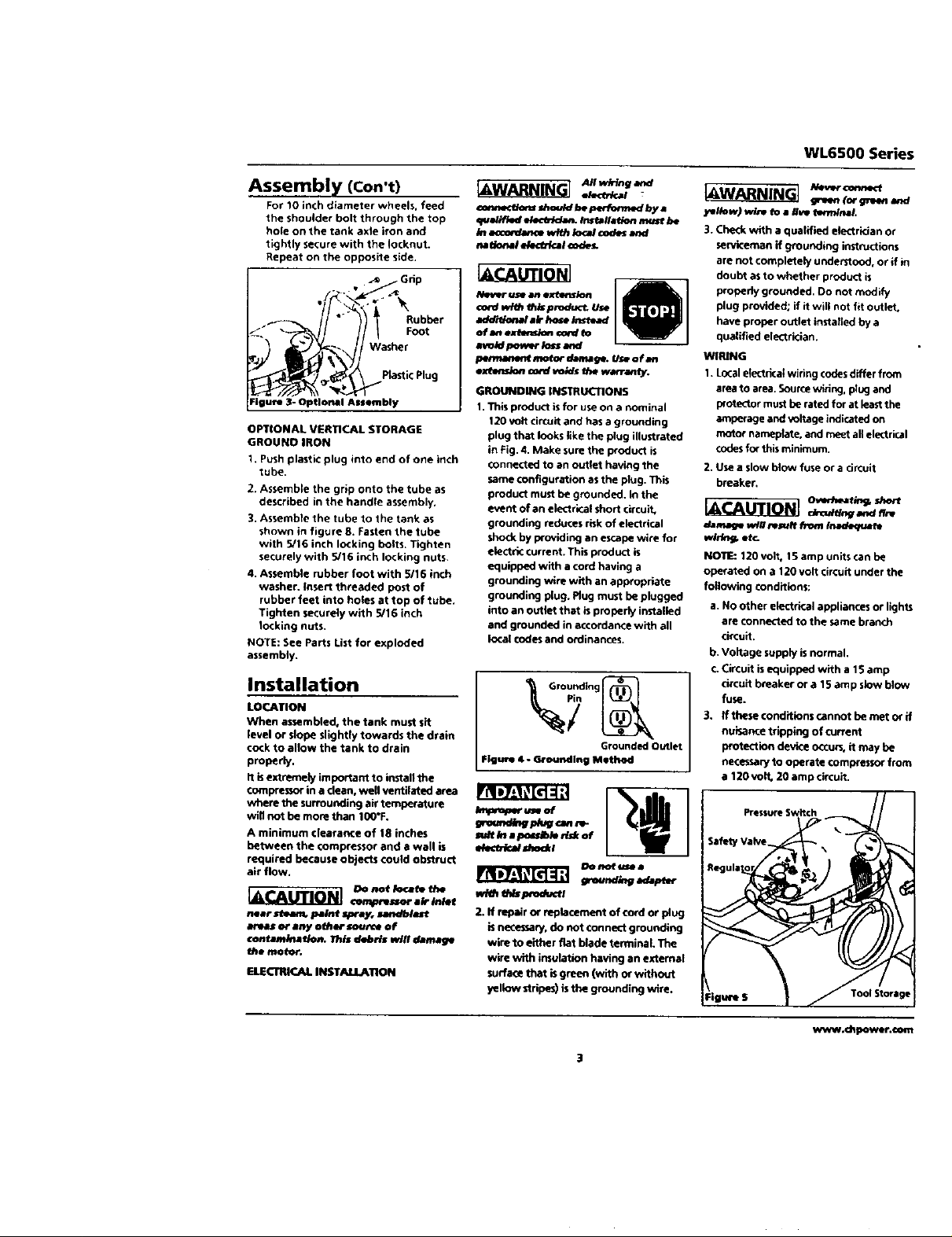

OPTIONAL VERTICAL SIORAGE

GROUND IRON

1. Push plastic plug into end of one inch

tube.

2. Assemble the grip onto the tube as

described in the handle assembly.

3. Assemble the tube to the tank as

shown in figure 8. Fasten the tube

with 5/16 inch locking bolts. Tighten

securely with 5/16 inch locking nuts.

4. Assemble rubber foot with 5/16 inch

washer. Insect threaded pest of

rubber feet into holes at top of tube.

Tighten securely with 5/16 inch

locking nuts.

NOTE: See Parts List for exploded

assembly.

Installation

LOCATION

When assembled, the tank must sit

level or slope slightly towards the drain

cock to allow the tank to drain

properly,

It isextremely important to install the

compressor in a dean. well ventilated area

where the surrounding air temperature

will not be morethan t00*F.

A minimum clearance of 18 inches

between the compressor and a wall is

required because objects could obstruct

air flow.

DO not/ocat_ the

near _ pa/nt spray, sandbtaurt

areas or any oth_ source of

€onMm/flab_n, This debris wilt damage

I_bemotor.

GILECTRIC_L INST,4U.ILATION

IAWARNINGI A,I-_V_R.,_

€oemKl_s lhoutd bt _ by a

qu_//f_d e/ec/rida_ Insf_//ation must be

/n axx_am:e with/oca/€odes and

_l_# mc_-blcat _o_es.

GROUNDING INSTRUCTIONS

1.This product is for use on a nominal

120 volt circuit and has a grounding

plug that looks llke the plug illustrated

in Fig.4. Make sure the product is

connected to an Outlet having the

same COnfiguration as the plug. ThiS

product must be grounded, in the

event of an electrical short circuit,

grounding reduces risk of electrical

shod( by providing an escape wire for

electric current. This product is

equipped with a cord having a

grounding wire with an appropriate

grounding plug. Plug must be plugged

into an outlet that is properly installed

and grounded in accordance with all

local codes and ordinances.

ateOWcal

rR=7_=lt_[d=1;

md_kl i _*m_db/e n_k of

w/_ _p_oduct_

2.it repalror reple©ementof cordor ping

isnecessary,do notconnectgrounding

wire to eitherfiat blade terminal. The

wire with insulationhavingan external

surfacethat isgreen (withor without

yellow stripes)isthe grounding wire.

_WARNINGI _.v,,o_._

yetlow) wlre to a _ve tmmlnaL

3. Che_k with a qualified electrician or

sen*iceman if grounding instructions

are not completely understood, or if in

doubt as to whether product is

properly grounded. Do not mndify

plug provided; if it will not fit outlet.

have proper outlet installed by a

qualified electrician.

WIRING

1. Local electrka_ wiring codes differ from

area to area. Sourcewiring, plug and

p_otect_r must be rated for at least the

amperage and voltage indicated on

motor nameplate, and meet all electrical

codesfor this minimum.

2. Use a slow blow fuse or a circuit

breaker,

IF_n (or g_Nm and

IACAUTION] d._ ._.re

damage wf# result fn_-n/nade<F_ fe

whig. et_

NOTE: 120 volt, 15 amp units can be

operated on a 120 volt circuit under the

following conditions:

a. No other electrical appliances or lights

are connected to the same branch

drcuit.

b. Voltage supply is normal.

r. Circuit is equipped with a 15 amp

circuit breaker or a 15 am p slow blow

fuse.

3. ff tbese €onditions cannot be met or if

nuisance tripping of current

protection device occurs, it may be

necessar/to operate compressor from

a 120volt. 20 amp circuit.

www.d_power,c_m

Page 4

Oilless Compressors

Operation

Pressure Switch - Aut_Off Switch - In

the ON position, the compressor shuts

off automatically when tank pressure

reaches the maximum preset pressure.

The compressor will automatically

restart when it reaches the minimum

preset pressure. In the OFF position.

the compressor will not operate. This

switch should be in the OFF position

when connecting or disconnecting the

power cord from the electrical outlet

or when changing air tools.

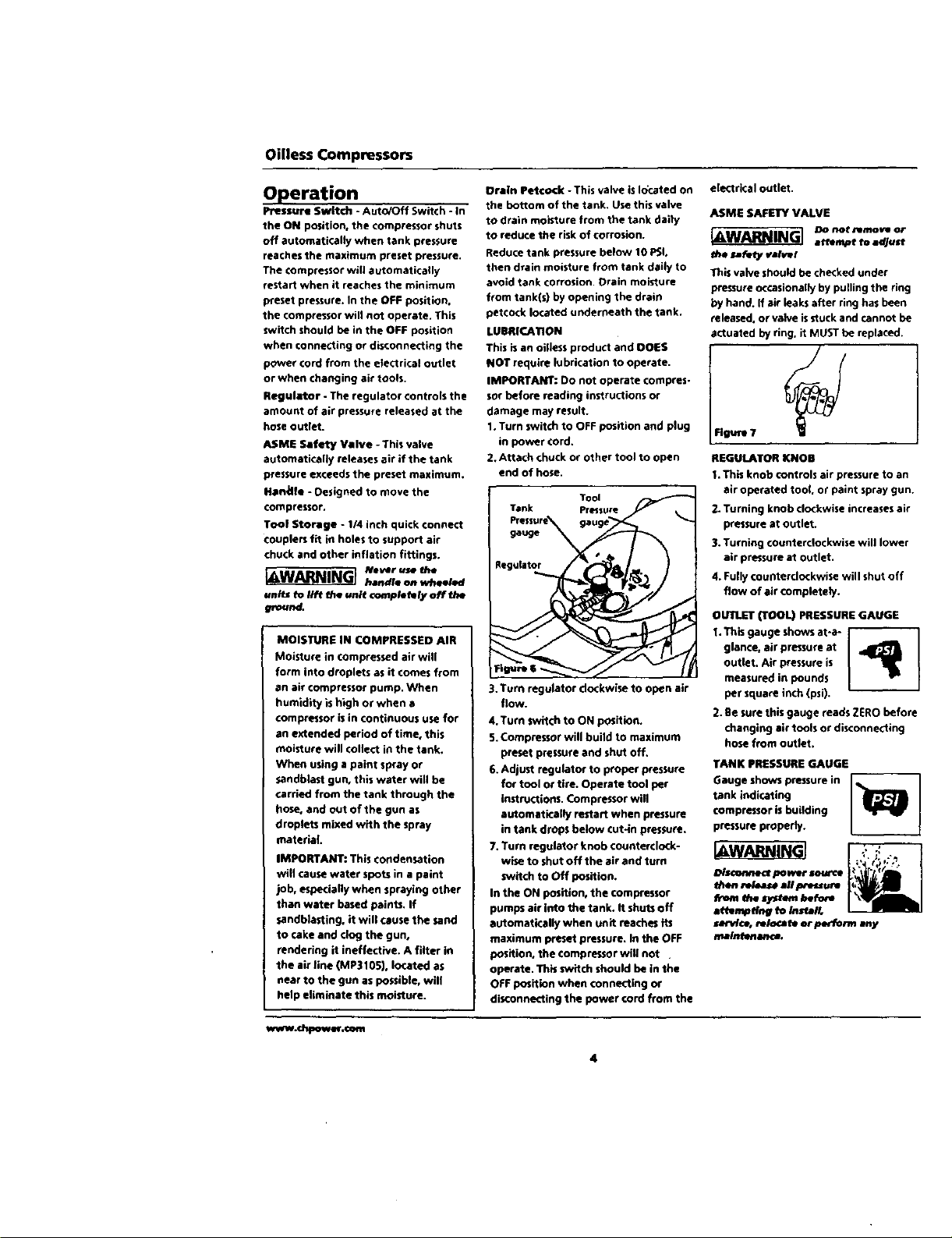

Regulator - The regulator controls the

amount of air pressure released at the

hose outlet.

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Han_lle - Designed to move the

compressor.

Tool Storage - I/4 inch quick connect

couplers fit in holes to support air

chuck and other inflation fittings.

_WARNING] No_,,.,* _

knits to lift b_e unit completely off the

ground.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will

form into droplets as it comes from

an air compressor pump. When

humidity is high Or when a

compressor is in continuous use for

an extended period of time, this

moisture will collect in the tank.

When using a paint spray or

sandblast gun, this water will be

carried from the tank through the

hose, and out of the gun as

droplets mixed with the spray

material.

IMPORTANT: This condensation

will cause water spots in a paint

job, especially when spraying other

than water based paints. If

sandblasting, it will cause the sand

to cake and clog the gun,

rendering it ineffective. A filter in

the air line (MP3105). located as

near to the gun as possible, will

help eliminate this moisture.

handle on wheeled

Oraln Petcock -This valve is located on

the bottom of the tank, Use this valve

to drain moisture from the tank daily

to reduce the risk of corrosion.

Reduce tank pressure below 10 PSI.

then drain moisture from tank daily to

avoid tank corrosion Drain moisture

from tank(s) by opening the drain

petcock located underneath the tank.

LUBRICATION

This is an oi[less product and DOES

NOT require lubrication to operate.

IMPORTANT: Do not operate compres-

sor before reading instructions o¢

damage may result.

1, Turn switch to OFF position and plug

in power cord.

2, Attach chuck or other tool to open

end of hose.

Tank Pressu

Pressure gauge

gauge

_iRegulat°r •_

3. Turn regulator clockwise to open a_r

flow.

4. Turn switch to ON position.

5. Compressor will build to maximum

preset pressure and shut off.

6. Adjust regulator to proper pressure

for tool or tire. Operate tool per

instructions. Compressor will

automatically restart when pressure

in tank drops below cut-in pressure.

7. Turn regulator knob counterclock-

wise to shut off the air and turn

switch to Off position.

In the ON position, the compressor

pumps air into the tank. it shuts off

automatically when unit reaches its

maximum preset pressure. In the OFF

position, the compressor will not .

operate. This switch should be in the

OFF position when connecting or

disconnecting the power cord from the

electrical outlet.

ASME SAFETY VALVE

DO i_Ot _llal_ovg or

the _a_ty valve!

This valve should be checked under

pressure occasionally by pulling the ring

by hand. If air leaks after ring has been

released, or valve is stuck and cannot be

actuated by ring. it MUST be replaced.

REGULATOR KNOB

I. This knob controls air pressure to an

air operated tool, or paint spray gun.

2. Turning knob clockwise increases air

pressure at outlet.

3. Turning counterclockwise will lower

air pressure at outlet.

4, Fully counterclockwise will shut off

flow of air completely,

OUI1LET (TOOL) PRESSURE GAUGE

I. This gauge shows at-a- r ]

glance, air pressure at |

outlet. Air pressure is

measured in pounds [ _

per square inch (psi).

2. Be sure this gauge reads ZERO before

changing air tools or disconnecting

hose from outlet.

TANK PRESSURE GAUGE

Gauge shows pressure in 1

tank indicating

compressor is building

pressure properly.

a_ to _sf.m_

s_rvfce, relocate or perform any

attempt to adjust

J

Page 5

WL6500 Series

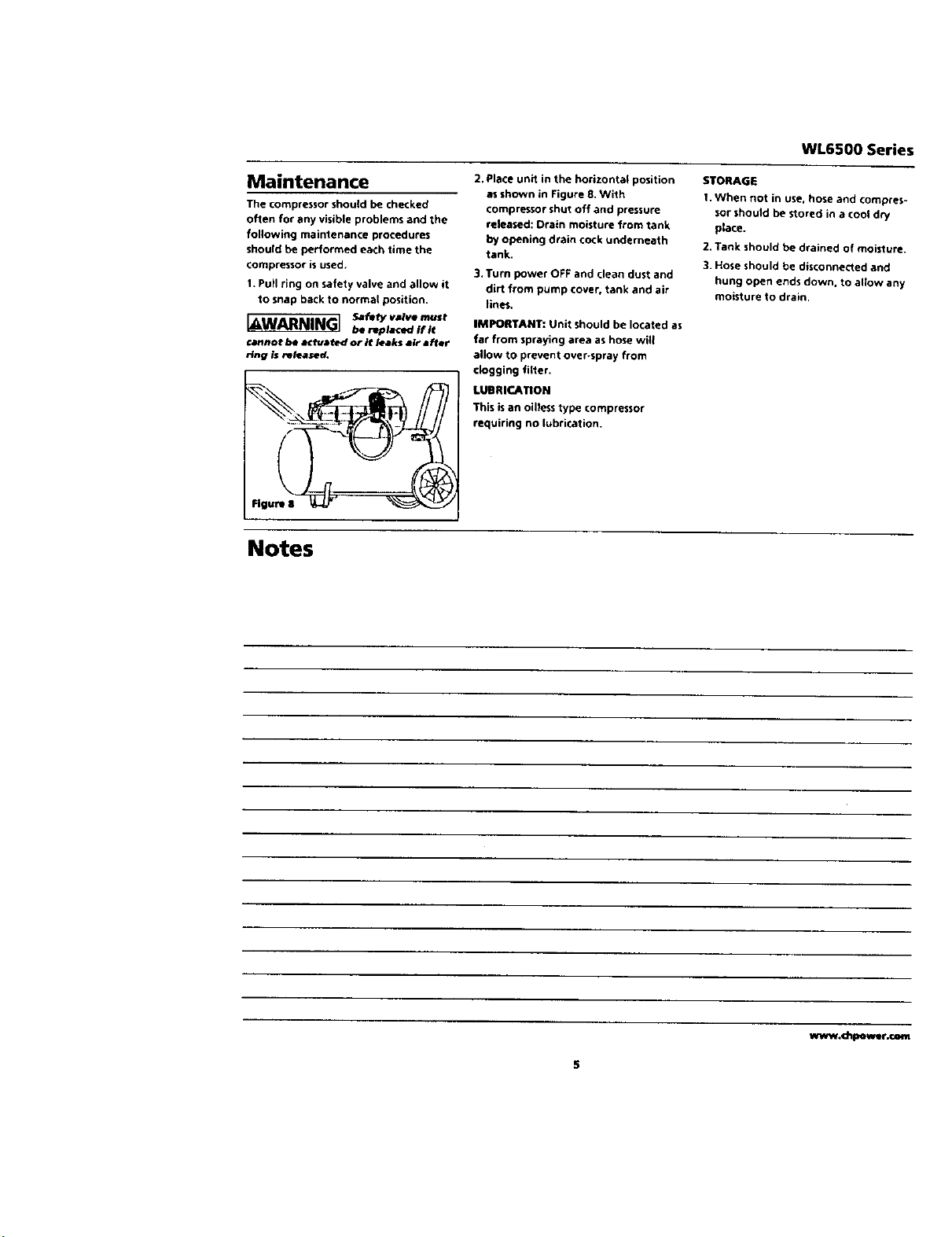

Maintenance

The compressor should be checked

often for any visible problems and the

following maintenance procedures

should be performed each time the

compressor is used,

1. Pull ring on safety valve and allow it

to snap back to normal position.

Safely vJIve must

cannot be actuated or it leaks a(r • fter

rfng is released.

be r_pla(_l If It

2. Place unit in the horizontal position

as shown in Figure 8. With

compressor shut off and pressure

released: Drain moisture from tank

by opening drain co(k underneath

tank.

3. Turn power OFF and clean dust and

dirt from pump cover, tank and air

lines.

IMPORTANT: Unit should be located as

far from spraying area as hose will

allow to prevent over-spray from

clogging filter.

LUBRICATION

This isan oilless type compressor

requiring no lubrication.

STORAGE

t. When not in use, hose and compres-

sor should be stored in a cool dry

place.

2. Tank should be drained of moisture.

3. Hose should be dlsconnected and

hung open ends down, to allow any

moisture to drain.

Page 6

Oilless Compressors

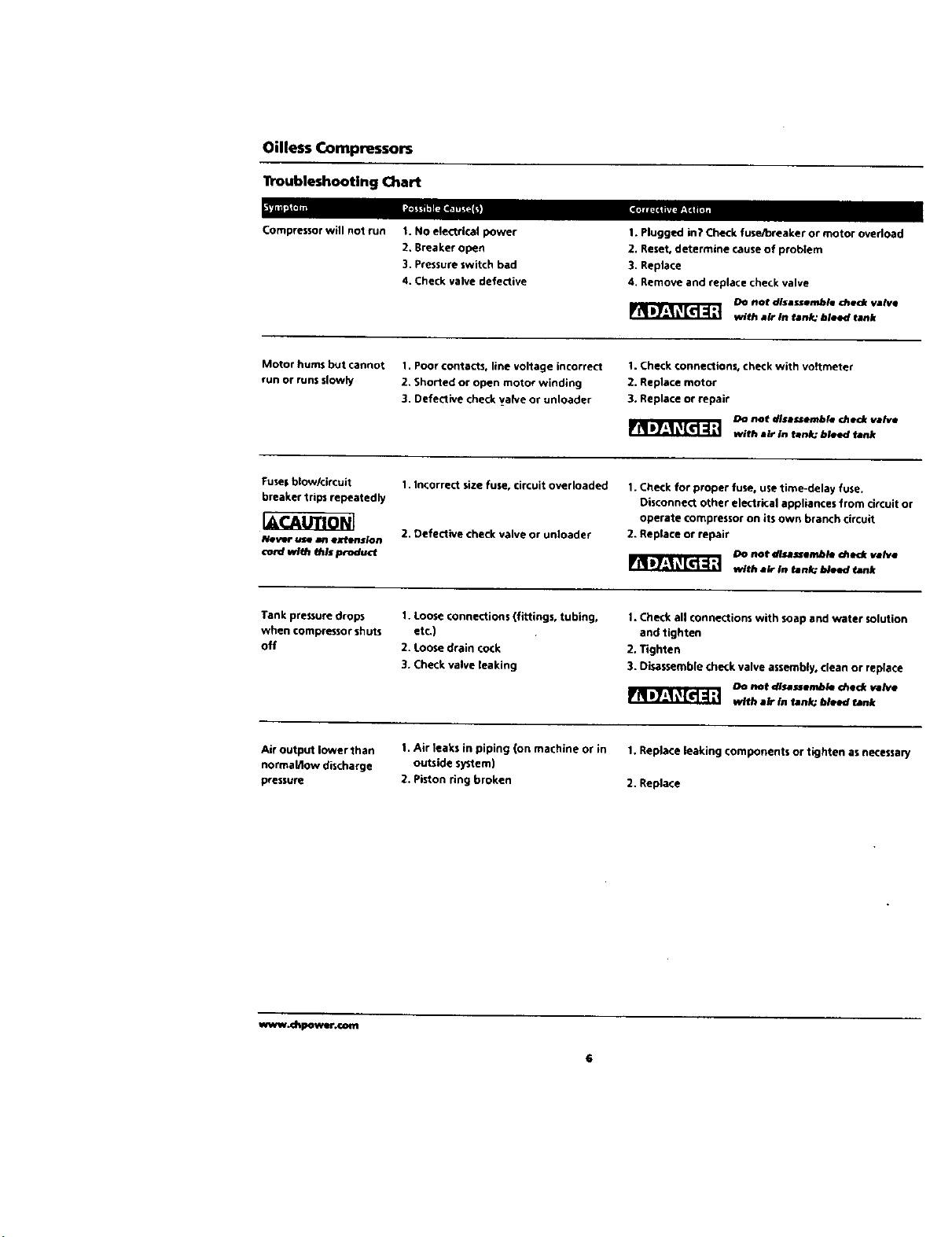

1Youbleshooting Chart

Compressor will not run t. NO electrical power

2. Breaker open

3. Pressure switch bad

4. Check valve defective

Motor hums but cannot

run or runs slowly

Fuse| blow/circult

breaker trips repeatedly

I_CAUTZONI

Nevl_ uJ;e 4MI e_rlsloN

cord with thls produd

Tank pressure drops

when compressor shuts

off

1. Poor contacts, llne voltage incorrect

2. Shorted or open motor winding

3. Defective check Valve or unloader

1. Incorrect size fuse, circuit overloaded

2. Defective check valve or unloader

1. Loose connections (fittings, tubing,

etc.)

2. Loose drain cock

3. Check valve leaking

I. Plugged in? Check fuse/breaker or motor overload

2. Reset, determine cause of problem

3. Replace

4. Remove and replace check valve

Do not dlsa_emble che_k valee

with air in tank_ bleed tank

1. Check connections, check with voltmeter

2. Replace motor

3. Replace or repair

Do not disassemble check valve

with air in tank_ bleed tank

1. Check for proper fuse, use time-delay fuse.

Disconnect other electrical appliances from circuit or

operate compressor on its own branch circuit

2. Replace or repair

Do not disassemble check valve

with air in tank; bleed tank

I. Checkall connectionswith soap and water solution

and tighten

2. Tighten

3. Disassemblecheckvalve assembly,clean or replace

Do not disassemblecheckvalve

with air in tank; bleedtank

Air output lower than I. Air leaks in piping (on machine or in 1. Replace leaking components or tighten as ne<essary

normal/low discharge outside system)

pressure 2. Piston ring broken 2. Replace

_.d_pewer.com

Page 7

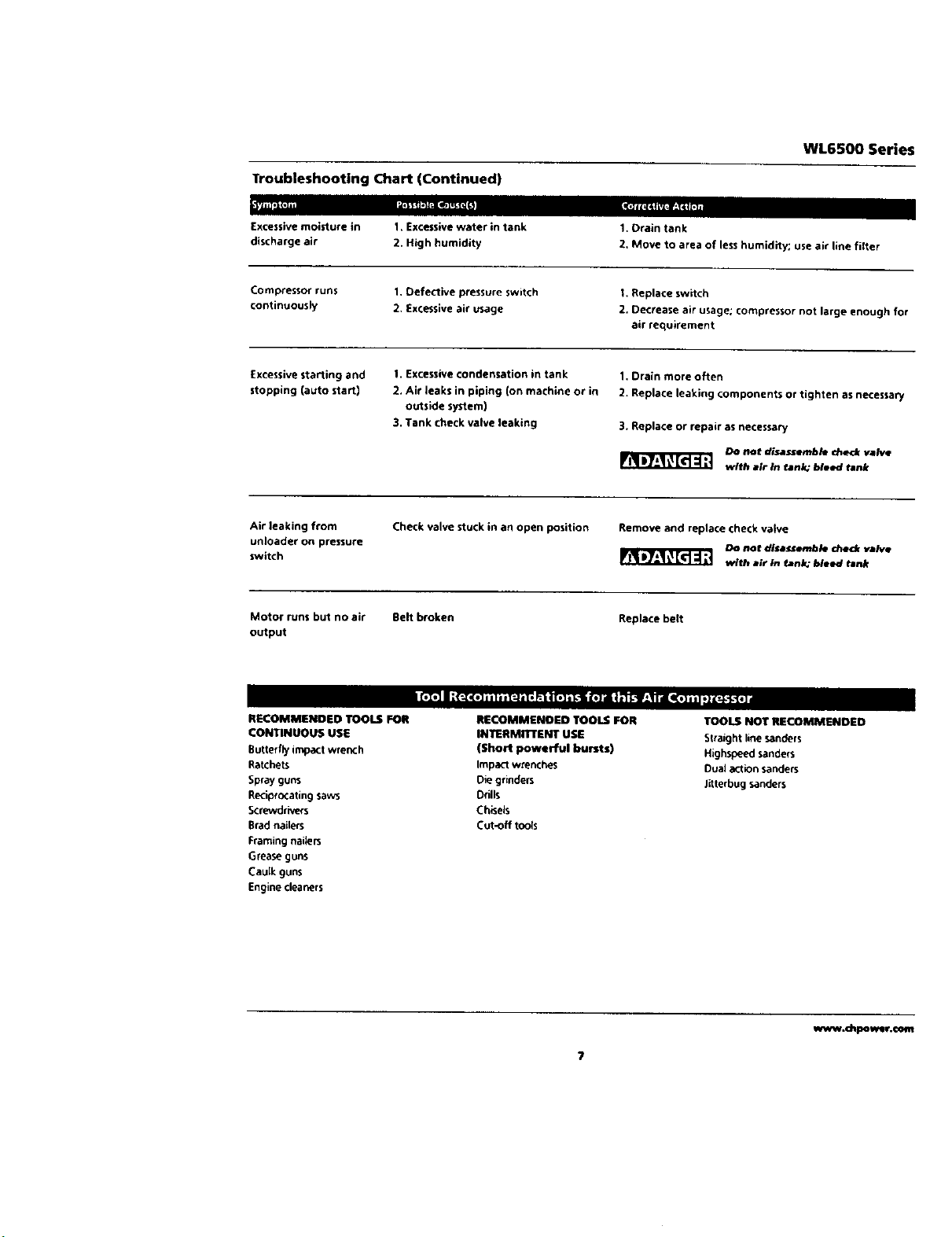

Troubleshooting Chart (Continued)

WL6500 Series

Excessive moisture in

discharge air

Compressor runs

continuously

Excessive starting and

stopping (auto start)

Air leaking from

unloader on pressure

switch

Motor runs but no air Belt broken

output

1. Excessive water in tank

2. High humidity

1, Defective pressure switch

2. Excessive air usage

1. Excessive condensation in tank

2. Air leaks in piping (on machine or in

outside system)

3. Tank check valve leaking

Check valve stuck in an open position

1. Drain tank

2. Move to area of less humidify; use air line filter

l, Replace switch

2. Decrease air usage; compressor not large enough for

air requirement

1, Drain more often

2. Replace leaking components or tighten asnecessary

3. Replace or repair as necessary

Do not disassemble ch@ck valve

with air in tank; bleed tank

Remove and replace check valve

not disassemble check valve

with air in tank." bleed tank

Replace belt

RECOMMENDED TOOLS FOR

CONTINUOUS USE

Butterfly impact wrench

Ratchets

Sprayguns

Reciprocating saws

Screwdrh_rs

Bradnailers

Framing nailers

Grease guns

Caulk guns

Engine cleaners

RECOMMENDED TOOLS FOR

INTERMITTENT USE

(Short powerful bursts)

Impact wrenches

Die grinders

Drills

Chisels

Cut-off took

TOOLS NOT RECOMMENDED

S(raight line sanders

Highsdeed sande(s

Dual action sanders

Jitterbug sanders

www.chpower.com

Page 8

Oilless Compressors WL6500 Series

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty - One Year; Serious Duty - Two

Years; Extreme Duty - Three Years; Maxus Model Series - Five Years.

2. WHO GIVES THIS WARRANTY _VARRANTOR):

Campbell Hausfeid I Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Telephone: (800) $43 -6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the CampbetE

Hausfetd compressor.

4. WHAT PRODUCTS ARE COVERED 8Y THIS WARRANTY: Any Campbell Hausfeid air compressor,

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects due to material and workmanship with the exceptions

noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this compressor i$ used for commercial, industrial or

rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Extreme Duty Contractor

Compressors and Maxus branded compressors are not limited to a ninety (90) day warranty when used in contractor

applications. Four eJllnder slngle-stape and _o-stage _ornpressors are not limited to a ninety (_) day warre_ty when

used in commercial or industrial applications. Some States do not allOW limitations on how long an implied warranty

lasts, so the above limitations may not apply to you.

B, ANY IHCIDENTAL. INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE. OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or

limitations of incidental Or consequential damages, so the above limitation or exclusion may not apply to you.

C, Any failure that results from an accident, purchaser's abuse, neglect or failure to operate products in accordance with

'instructions provided in the owner's manual(s) supplied with compressor.

D. Pre_:lelivery service, i.e. assembly, oil or lubricants, and adiustment.

E. Items or service that are normally required to maintain the product, i.e. lubricants, filters and gaskets, etc,

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser

must comply with the warranty given by the engine manufacturer which issupplied with the product.

G. Additional items not covered under this warranty:

I. All Compressors

a. Any component damaged in shipment or any failure caused by insta}_ing or operating unit under conditions not in

accordance with installation and operation guidelines or damaged by contact with toob or surroundings.

b. Pump or valve failure caused by rain, excessive humidity, corrosive environments or other contaminants.

c. Cosmetic defects that do not interfere with compressor functionality.

d. Rusted tanks, including but not limited to rust due to improper drainage or corrosive environments.

e. Electric motors, check valves and pressure switches after the first year of ownership.

f. Drain cocks.

g. Damage due to incorrect voltage or improper wiring,

h. Other items not listed but considered general wear paris.

_. Pressure switc_.-,s, air governors and safe_y vaives mndified from tactory se_iogs.

2. Lubricated Compressors

a. Pump wear or valve damage caused by using oil not specified.

b. Pump wear or valve damage caused by any oil contamination or by failure to follow proper oil maintenance

guidelines,

3. Belt Drive / Direct Drive / Gas Driven Compressors

a. Behs.

b. Ring wear or valve damage from inadequate filler maintenance.

c. Manually adjusted load/unload and throttle control devices.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Wa_antor's option, ¢omgressor ar

component which isdefective, has malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Portable compressors or components must be delivered or shipped to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any. must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner's manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location° and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other

rights which vary from State to State or country to country.

Page 9

S'il vous plait llre et conserver ces instructions. Life attentivement avant de monter, installer, utiliser ou de

proc_der & I'entretien du produit d_crit. Se protdger ainsi que les autres en observant toutes les instructions de

si_curit6, sinon, il y a risque de blessure et/ou d_g_ts mat6rielsl Conserver ces instructions comme r_f6rence.

Compresseurs

d'Air Sans Huile

Description

Les compres_eurs sans huge sont con_;us

pour les bricoleurs avec projets

domes_iq ues et d'automobile. Ces

comwesseurs servent _ faire fonctionner

les pistolets _ peint ure. cles _ chocset

autres outils. Ces modules

fon(tlonnent sans huile.

Directives De S6curit_

Ce manuel comient de I'information tr_s

importante qui est foumie pour la

SI_CURITIE_et pour _VITE R LESPROBI_MES

D'_QUIPEM ENT. Recherdler les symboles

suivants pour cette information.

ume _tua_n _ _ quI

J_S_LIERA en perb de v_ ou b/e_mmes

graves.

[AAVamSSEM m]

indkl_e une s/_ae/on _

potenb_(te WI PLqff r_h_u/heren p_ree de

vfe ou_ _rm_

me derek W poe_m_e q_d

J,Eiff nk_teer eet _

[ AVIS

de/_nfofmat/on kqF_tarde pa_ 4W_r/e

domm_ der_i_-_

D_ballage

Lots du d_ballage de ce produit,

I'examiner soigneusement pour

rechercher route trace de dommage

susceptible de s'_tre produit en €ours de

transport. Veiller _i setter tous rac_ds,

boulom, etc_ avant de mettre ce pmduit

en secvice. En cas de dommage ou de

pi_ces manquantes, S.V.P. composer le

t-80(}-543_622 pour demander conseil

O NE PAS RENVOYER LE

Renseignements

du module

Enregistrer le No. de ModUle, NO. de

S_rie. et la Date d'Achat s_tu_e sur la base

de la pompe dam I'espace d_lessom.

No. de ModUle

PRODUIT AU

MARCI'IAND!

No. de S_rie

Date d'Achat

Garder ces num#ros pour r_f#rence

ou appoler un Centre De Service Autoris6

Campbell Hausfeld.

Une li_te de centres de servicesest ci-

incluse. FTi_re d'avoir le numdto de s_rie.

nunt_ro de module et llste de piL_ces(avec

les pi_ces manquantes e_cercl_es) avant

d'appeler.

IAAVERTISSEMEN_ ._ ,,,.,

_ ejuf a #Wi endommag_ pendant le

transport, laemamipulafion o_ I'utUisation.

Le dommage _ r4sulter _ exp_odon et

peut _user des blessunes ou d_l_les

maek_

G_n_ralit6s Sur La

Sdcuritd

Puisque le compresseur d'air et les autres

piercesd_ach_s (pompe. pistolets, filtres.

graisseu_, tuyaux, etc.) font partie d'un

WJ Kcl:IR

AverUssementD'_r Respirable

Ce compresseur lpompe n'es_pas

_q_p_pouretnedewaltpas_ze

ul_[|s_"o0mme sol- pour foumlr de fair

resplrable. Pour les appii_ons d'atr

pour la _ humaln_ II est

n_cessaire d'_ulp_ le _

d'air/pompe avec de I'dquipemem de

_curi_ en canalisa'do_ et d'alaeme. Cet

_quipement add'dJonnel est n_ssaire

pour flitter et purifier I'air afin

d'attal_re les sp_Sca_ons minimales

pour _ respka_n Grade D d_rite

d._s le Camp_essed Gas Assode_on

Commodity Spedfica_on G 7.1.19_6.

OSHA 29 CFR 1910.134, and/or

Canadian Standards Associations

(CSA).

DI_N_AllON DESGARANDES

Sile eompresseurestutilis_pour les

appllcatJomd'air_ et

r_qutpernent de s_ari_ en

(an_isa'_onet d'_ne nest pasutUi_

simultaed_ lesgarae_esen

ex_ance _nt _ et Camp_

Hausfeldd_nieroute res_li_

pour nlmporte quellepotte, blessure

oudommag_

syst_me de haute pression, il est

n_cessaire de suivre les precautions

suivantes:

t. Lire a_tentivement tous

manuels compris avec ce

produit. 5e familiariser

avec ce prod uit. ses

commandes et son utillsation.

2, Sulvre tousles codes de S_curit/_

Iocaux ainsi que les National Electr_.al

Codes (NEC) and O<cupational Safety

and Health Act (OSHA) des I_-U.

O 2003 Campbell Hausfeld/Scot_ Fetzer

IN610200AV 9/03

9 Fr

Page 10

Compresseurs Sans Huile

G6n_ralitds Sur La

Ga._for/a _ de _el_l Ji_ _

_bltut_ et _'m _

S_curit_ (suite)

3. Seules lespersonnes bien familiarisLSes

avec ¢esr_JleS d'utilisatlon doivent

_tre autoris_es _ sesen,lf du

oompresseur.

4. Garder les visiteurs ,_Wecartde/et N E

JAMAIS permettre les enfants dans

I'endroit de travail.

5. Utillser des lunettes de r_curit_ et la

protec_K)n audi_ie pendant

I'utilisation du module.

6. Ne passe tenlr debout sur/ni utillser le

module comre_ une prise _ m_m.

7. Inspecter la syst_tmed'ai¢ comprim_ et

pl/_es d_tach_es _le_triques pour

toute indication de dommage,

d_t_rioration, faiblesse ou furies

avant chaque utilisation. R_parer ou

remplacer toutes pi_=cesd_fectueuses

avant Futilisatiofl.

g. Insoecter le deg_ de serrage de

toutes attaches par intervalles

r6guli6ms_ compre_eur.

=u _ medlll_ u_ r_n_rl _ L___

r_JdaS_ p_l/e eu _ mod/_a k

pou_mt affalbllr le r_a_n_lr ef p_m_nt

r_ul_r en dommage de n4p_re _

d"exploslo_ 7oujours rempM_r un

_volr us& fend_ _u _dmnmag_.

I AVIS

quotidiennemen f.

12. L'accumutatlon d'humidit_ cause la

rouille qui paut affaibtir le r_ervoir.

Purger le r_'servoir quotidiennement

et I'inspecter I_riodiquement pour la

rouille et la corroskm ou autre

dommage.

13, Uair mouvante peut agiter la

poussi_m et le d_bris qui peut i_tre

dangemux. L_che¢ I'alr lentement en

purgeant I'humiditd ou pendant la

d_pressurisatlon du syst_me du

/#sen_/r

i_,AVERTISSBVlENI1I--_- _ _._.no.s. _,vms_no.

_ee_-qu_ qul _u_mt _k,_er l_ pz ou

vaf_Na_ lnflammables. Ne Jamals f_ire de _mm_e _uverfe nl pr&s el*_ne s_Jro_

fm_onr,_r nir_r_rlx_ d_s g_z_

vapeur_Inflamnmble_NeJamaisranger

nl pulv4rlser desllquldes ou gaz

Inflammablesp_s du mmpresseur.

g. GarderlesdoigtsitI',_,cart du

comp_sseu_,lespi_cesmobileset

chaudespam_entcauserdesblessures

et/ou desbr01ures.

tO.SiI'_luipement vibreanormalement.

ARR_TERle moteur et rinspecter

i_iatemeut. Lavibretion e_t

g_r_ralement une indic_io_ d'un

probl_ne.

11.Pour_duire lerisquedlncendie,

garderrext_deu(du moteur fibre

d'hui_, desolvantou de gmis_e

excessi_.

[._,AVERTISSEMENI_ _.. _

14. Ne pas fumer pendant la

pulv_ris_tion de la pelnture,

d'insecl_id es ou autres mati6res

inflammables.

1_ Utiliser un masque/

resplrateur pendant la

pulvdris_tion et pulv_rise¢

dans un endroit blen

ventil_ pour _,vlter le risque de

blessures et d'incendie.

16. Ne pa_ diriger la peinture ou autre

mat_rie| pulv_rb_ vers le

compresseur. Situer le comwesseur

aussi loin que possible de rendroit de

pu_ris_'_n pour r_ulre

l°a_'umulation de surpu;v_q_sation su_

le compresseur.

17. S_m _e_instn_ions du fabr_.,_

pendant la pulv_rbation ou le

nettoyage a_ec dessolvants ou

produits chimiques toxiques,

Assemblage

MONTAGE DU MANCHE

L'encoche sur le haut du manche du

compre_eur foumi_ un efldroit

convenable pour ac_rocher un pbtolet

vaporisateur, plstolet pour le d_capage

au sable ou autre outil _uip_ d'un

crochet.

1. Si une poign/_e e_ comp_'ise avec le

module, couvrir I'int/_rleu re de la

poig nde avec une touche mince

d'eau savonneuse. Pousser la

polgn6e sur le manche.

2. Introduire le manche _ travers le

couvercle de protection et dans la

plaque de base tel qu'indiqu/_ sur la

Figure 1. Le manche doit s'aju_ter

dam les ouvertures Sl_¢iaux dens la

plaque de bare.

3. Placer un morceau de bob court contre

le bout du manche et le frappar ave(

un maillet ou un marteau pour

eftfoncer la poig n_=edans la plaque de

base jusqu'& ce que le$trous du

manche et la plaque de base soient

alights.

4. Monter el:serrer 2 vis (du paquet de

pi_es) _1travers le tmu dam la plaque

de base et ,_travers le manche.

I AWERTISSEMEm]

u_l_r M m_ld_ p_r eampM_ment

sou/e_r rapp_ U_i/L_-/e rna_

po_r _/e_r m bo_ et ub_iser Ms ra_es

5. Introduire 1,1place de montage du

pied en caoutchouc dan$ le trou du

fer de mise _ la terre, Bien le serrer

avec I'_crou de serrage.

MONTAGE DIE ROU_.S

Les articles indiqu_s d'un ast_risque (*)

sont indus dans le paquet de pi_ces.

I. Introduire le boulon _ _paulemeut ,_

travers le moyeu de la roue, Lat_e

hexagonale du boulon devrait _ au

sere oppos_ du centre pro_mineut du

moyeu.

10 Fr

Page 11

SdrieWL6500

Assemblage (suite)

2 Pour les roues de diam/zt re de 15,24

cm - 20,32 era, pas_er le bouIon a

_paulement _ travers le trou inf_rieur

de I'axe du r_=servoiret bien le setter

avec I'_¢rou de serrage. Pour lesroues

de dlam_t re de 25.40 cm. passer le

boulon _ _paulement _ trave_ le trou

sup_rieur sur I'axe du rdservoir et bien

le serrer avec I'_crou de setrage.

Rdp_ter au sens oppose.

•_ serrage

_r _ Roue

* Boulon ;I

paulmenl

Figure • - Montage Oe Roues

_RANGEMEINT VERTICAL OFFIONNEL

FER DE MISE A LA TERRE

1. Pousser le bouchon de plastlque

I'extr6mit_ d'un tube de 2,$4 cm.

2. Assembler la poignde dans le tube tel

que d_rlt souS I'assemblage du

manche.

3. Assembler le pied de caoutchouc

avec une rondelle de 7,94 ram.

Assembler le tube au rdservoir tel

qu'indiqu/_ sous la figure 8. Fixer le

tube avec des boutons de serrage de

7.94 ram. Resserrer bien avec le$

_¢rous de serrage de 7.94 ram.

4, Insdrer la piece filet_ du pied de

caoutchouc dans les trous sur le

dessus du tube. Bien resserrer avec

le$ _t'crous de serrage de 7,94 mm.

NOLO: Voire la liste de pi_ces pour la

rue 6dat_e de I'assemblage.

Pied en

caoutchouc

Rondelle

Bouchon de

Installation

ENDROIT

Une fob mont6, le r_,;ervoir doit 6tre

nivel6 ou indin6 un peu vers le robinet de

vidange afin de permettre le vidange

correct.

II est tr6s important d'installer le

compres_eur dans un endroit propre et

blen ventil6 o_ la temperature n'exc/_'dera

pas 3_ (100°F).

Un espace libre minimum de 45.7

centim6t res entre le compresseur et un

tour est exig6 pour 6viter le stoppage d'air

par des objets.

IAATTENTIONI

_ d'_/r du W_ de la

er_lh:l(zd_ d_r_llQ UJ MMe ouauCre

sources de (onl_mTnatJm_/_d_bri_

INSTALLA_ON I_I.EC_RIQUE

I_,AVERTISSEMEN_ _._

qua//fi_ do/t effl_r _//a t_n

IM_pecter _ut_ l_ _ lo_l= et

na_ de r_t_-trld_.

IAA ENTIONI

Ne Jama/_ ue_ un m,_n

_f_ mt fuya_ t_ex_ I a_r_

_lh_r ur,e pe_'e de pu[_4m_ et dommage

d_ m_'. u_ge d'un cordon

I_ang_ur s_t _l_muler la g_,_e,

IN_Rt_-_ONS DE MI_E _ L_ lnERRE

1. Ce produit est (oPt; u pour I'utilbation

d'un drcuit de 120 volts eta une fiche

de mbe & la terre ¢omme celle indiqu6e

sur la Fig. 4. S'a_su_erque |e mod61e solt

brand_ ._ une prise de oourant qui a la

m6me configuration que la fkhe. Ce

produit dolt _tre mis & la terre. Dam

I'd_enement d'un _x_rt-drcuit. la robe &

la terse dimlnue le risque de se¢ousse

_lectrique en fournbsant un fil

d'L_happoment pour le courant

rr "

Prise de Courant Mise de Tetre

Figure 4 - M4thode de mlse i Is terre

61ectrlque. Ce produit est_luip6 d'un

cordon q_(=a un _t de terre ave< une

fiiche de terre. La fiche dolt _tre

brand_e dans une I_Se de courant qut

a _6 installde et raise & la terse

¢orrectement en re_poctant tousles

codes et r_glements Io_aux.

en m _/edxiquet

adaptateur de mbre& la t'erre m_ ce

2. Si la r6paration ou le rempI,xement du

_ordon ou de la fiche est n_k:essaire,ne

pas connecter le fil de terre &ni une ni

I'autre borne plate. Le fil ave< I'bolation

qui a une surf_e exteme verte (avec ou

sans jaunes) est le fil de terre.

[_,AVERTISSEIVIE NT] _,,_

le _l _ (_ _rt et J=une) t=u_ borr_

3. Si vous rm comprenez pasleS

instructions pour la mbe ,_ la te_e ou si

_ous n'_es pas terrains si le proriuit est

mis _ la terre €on_ement, v6rlfier

ave_ un 61ectricien ou une personne

qu alif'_e. Ne pas modifier I_ fiche

foumie; slla fkhe n'est pas la bonne

ta_e pour la prise de courant, contacter

un 61ectricien qualif'_ pour I'installation

d'une nouvelle prise de courant.

INS_rALLAllON DE FII¢

1. Les redes 6k.ctrk;ues d'k_staU_'to_ de

fils sont variables d'un endroit a

rautre. Lesfib d'alimentation, f'.:he et

protecteurs doivent i_tre dasdfi6s pour

au moins I'amp6rage et la tension

indlqu6s surla plaque indicatri_e du

moteur et doivent rdpondre aux codes

_lectrklues pour ce minimum.

2. Utillser une fusde ._ retardement ou un

disjoncteur.

IAATrENTIONI

fib l_ peut N_ul_r en

_rtha_ffag_ o_dmulf _ en

dommaged'inmmll_

REMARQUp"Lesmodulesde 120V, 15A

peuventfonctionnersurun circuitde 120

V souslesconditions suivantes:

a. Au¢un autre apporeil _lectrique ou

lumi_re est Connect6 au m6me

branchement.

11 Fr

Page 12

Compresseurs Sans Huile

b. L'aEmentationentension est

nonnale.

c Lecircuitest_cluip_ avecun

disjoncteurde 15 amperesou une

fus_,_ retardement de 15amperes.

3.S'iln'estpespossibled'atteindre les

conditionsci-dessusou s'ily • un

d_,denchementdu ptotecteurde

courant ,_maintesreprises,il peut _tre

nLt_e_sainede faite fonctionrlerle

compre_eursurun circuit de 120 volts,

ZOamperes.

Fonctionnement

Marlo_&t

Soupape de

VHUMIDITI_ DANS LAIR COMPRIMI_

L'humidit6 dans I'air comprim6

forrne des goutelettes en arrivant de

|a pompe du €ompresseur. Si

I'humidit6 est/zlev_e ou si le

€ompresseur est utilis6

continuellement, cette humidit6

s'accumulera dam le r6servoir. En

utilisant un pistolet ,_peinture ou un

pistolet pour d_capage au sable,

cet_e eau sera transport_e hors du

r_selvoir par moyen du tuyau en

forme de goutelettes m_langdes

avec le materiel utills_.

IMPORTANT: Cette condensation

deut avoir €omme r6suitat des

taches d'eau sur votre travail de

peleture, surtout en pulv_rlsant la

peinture qui n'est pas de base d'eau.

Pendant la d_capage au sable,

(MP3105) cette eau servira E tenir le

sab • ensemble et _ causer une

I obstruction dam le plstolet.

Manostat - Interrupteur Auto/Off. Dans

le position ON, le compresseur se coupe

automatiquement quand la pression du

r_'sen/oir arrive _ le pression maximale

r/_gt6e d'avance. Le ¢ompresseur se

mettra en mar€he •utomatiquement

une fob qu'il atteigne le pression

minimum r_gk!e d'avance, Oans la

position OFF, io compresseur ne

fonctionnera pas. Cet interrupteur

devrait itre dens la position OFF pendant

le branchernent ou ie d6branchement du

cordon d'allmentation de la prise de

courant ou pendant le changement

d'outils pneumatlques.

R/.kjulate ur - Le r6gulateur sert& t_gier

la pression d'air &la sortie du tuyau.

Soupape de SO_'t_ ASME -Cette

soup•de leisse 6chapper I'air si la pression

du r6sen/oir d/=passe la pression

maximum r6glee d'avance.

Manche - Con_ue pour le deplacement

du compresseur,

Rangement d'Outlle - les raccords

rapides d'I/4 po s'ajustent dans les

trous afln de supporter un mandrin et

autres raccords de gonflage.

LAAVamSSEaE

numd:e_-/es _ aw_ n_uesp_Jr

_u/et_'/e meddle.

Roblr,et dlePurge - Cettesoupape est

situdesurla basedu Mservoir.Utiliser

cette soup•pc pour purger r humidit_ du

r_servoirquotidiennement •fin de

r_,duirele risquede corrosion.

Baisr,erb pressiondu r_servoir sous69

kPa,et emuitepurger I'humidit6 du

r_servoir•fin d'_witerle corrosion. Purger

rhumidit_du/desr_servoir(s)en ouwant

le robinet de purge_u_ sur le basedu

rt,setvoiL

LUBRIRCATION

re prnduitest"sans4_t_le"et n'exlge

pm d'huile po_r fonctionner.

IMPORlrANT:Pour Cktiterdu dommage

au _ompcesseur,lire toutesks

instructions•rant de I'utilisen

1.Toumer I'interrupteur_ lapofition OFF

et brancherle cordond'alimentation.

2. F_er un mand_n ou autre o_ti_ au bout

ouvect du twau.

3. Faire toumer le r_gulateur dan$ le

sens des aiguille$ d'une montre pour

ouvrir la drculation d'air.

R6gulateur

4. TournerI'interrup_eur&la positionON.

5. LecompresseuracoJmuleralapression

jusqu'_Cequ'il _ttelnt la pt_ssion

r6gl6ed'avanceet s'arr_tera.

6. Ajustet le r/=gulateur,_la bonne

pression(outil ou pneu). Utiliser

l'outl| conformi_ment aux

instructions.Lecompresseurse

remettra automatiquement en

matche Iorsque la pressiondu

r_servoirtombe sousle pression

d'endenchement.

7.Tournerle boutondur_guleteurau

sensinversedesalguilksd'une montre

•fin de couperrair et ensuitetoumer

I'intemJpteur&la positionOff.

Oansla positionON.le compresseur

pompede _'airda_sle _e_. ttse

coupe automatiquernentquand ilatteint

lapce_ionmaximale r_gk!ed'avance.Le

compresseurne fonctionnera pasdans

ta position OFF.Cetinterrupteur devr,Y_t

6tredansla positionOFFpendantle

branchementet !ed6b_anchernentdu

cordond'alimentationd'une prisede

¢ouranf.

SOUPA._OES0RET_ASME

V_ifier cettesoup•pc Io_que sous

presdondetempsAtempsentlrant

ranneau &la main.LZsoupapeDOlT_tre

remplec_ s'ilya desfuitesd'airunefob

que ranneau soitrel,_ch_ou sila soupape

estgr_pp_ et ne fonct:_n_ebas•vec

i_anneag.

12Fr

Page 13

S_rie WL6500

Fonctionnement

(Suite)

Figure 7

BOUTON DU RL_GU_LAT1EUR

1. Ce bouton r_gie ia pcesslon _ un outil

pneumatlque ou _lun pistolet

vaporisateur.

2. La pression d'air _ la sortie est

augment6e en toumant ie bouton au

sens des aiguilies d'une montre,

3. La pression d'air _ la sortie est r_duite

en tournant le bouton au sens inverse

des aiguilles d'une montre.

4. Pour couper le ddbit d'alr, tourner

compl6tement au sens inverse des

aiguilies d'une montre.

MANOM_rRE DIE SORTIE (OUTIL)

pression d'air de sortie.

La premion d'air est

-I*l

mesur6e en kPa.

2. S'assurer que le marmm_tre est _ ZERO

avant de changer les outils

pneumatiques ou avant de d/_brancher

le tuyau de la sortie.

M/_IOM_:TRE DU RI_ERVOIR

le manom_re indique ie

pression dans le r_servoir ce

qui lodique que le

compresseur fonctionne

bien,

Entretien

lAAVERllSSEMENT] _

eo_'t/m pros/an du _

av_t d'e_ayor d'ks/a//Gr, de NpanJr, de

d_o_w:r ou de pr_X_er A r_t_t_

Inspecter le compresseur souvant et

suivre les proc6d_s d*entretien suivants

pendant chaque utilisatlon du

compresseur.

I. Tirer sur I'anneau de la soupape de

s0ret_ et la lais_er revenir _ sa position

normale.

[_AVERTISSEMEIMI"] _,'_

al_s _/a soupape _t Mch_e ou sl/a

soupape ne fonc_onne pa_ elle devralt

_re reaw_o

2. Placer Yappareil en position

horizontale tel qu'indiqu_ sou$ la

Figure 8. Avec le compresseur hors

drcuit et la pression dissip@e,purger

I'humidit_ du r_servoir en ouvrant le

mbinet de purge sou$ le r_.ervoir.

3. Mettre hor$ circuit (OFF) et nettoyer

la poussi_re et la salet_ du couver¢le

de la pompe, du r_servoir et des

canalisations d'air,

IMPORTANT: Situer le module aussi loin

de I'endroit de pulv_risation que possible

afin d'emp6dler que le flltre deviennent

obstru6 par la surpulv6risation.

GRAISSAGE

Ce mnd_le "sans huile" n'exige pas de

graissage.

ENTREPOSAGE

1. Entreposer les tuyaux et le com-

presseur dam un endroit frai$ et se_

2. Le rdservoi¢ doit _tre porg_ d'humidit_.

3. Letuyau doit _tre d_branch_ et

suspendu avec les pouts ouverts face

en bas pour laisser touter rhumidit_.

Notes

13 Fr

Page 14

Cornpresseurs Sans Huile

Guide de D_pannage

Le compresseuf ne

fonctionne pas

1, Manque de puissance _lectrique

2. Disjoncteur declench6

3. Manostat en panne

4. $oupape de retenue d6fecteuse

Lemoteur ronron mais 1. Contactsg_4s. tendonin_:omecte

ne peut pasfonctionner 2. Boblnnagedu moteurcc_Jrt<i_cuiteou

ou fonctionne ouvert

lentement 3. Soupapede retenueouded_hargement

Fusibles saut_s/le

dlsjoncteur sed_clenche

_l maintes reprises

Ne jamb utillser un

cordon prolongateur

• ve¢ €* prodult

Perte de pression dans 1. Raccordements d_gagds (raccords,

le r_ervoir & air quand tuyaux, etc.)

le compresseur se coupe 2. Robinet de purge degag6

d_-_tueuse

1. Taille de fusible incorrect, surcharge

2. Soupape de i'etenue ou de

dechargement d_fectueuse

3. Fuite du dapet

I, Mod61e branch6? V6rifler le fusible./disjoncteur ou

surcharge du moteur,

2. Rajuster et trouver la source du probl_me

3. Remplacer

4. Enlever et remplacer le clapet

Ne pas d_monter le

€lapet s'll y • de I'_ir

1. Impecterlesbrand_,mlents,v_fier avecunvoltm_tre

Z Remplacerle moteur

3.Remp_'erour_oa_r

Ne pas d4monter le

darts le r4servoir, v_danger le r#servolr

1. V6riEer le type de fudble, utilber un fusible _ mtardement.

Dibrand_r ks au_s appareils e_ du d_ult ou

faire fofK'Eonner le o0m_ surun droJit unklu_

dapet s'll y • de Pair

z Remp_erour_parer

No pas d_monter le

dans le r_servol_, vldanger le _se_olr

1. Verifier tousles raccordements avec de I'eau

savonneuse et les serrer

2. Serrer

3. Demonter I'assemblage du dapet, nettoyer ou

remplarer

€lapet s'H y • de I'alr

Ne pas d_monter le

D6bit d'air plus bas que 1. Fuites d'air dans la tuyauterie (sur le 1. Remplacer les pieces qui ont des fuites ou serrer

norrnal/pression de mod61e ou dans le systt_me extdrieur)

d_charge basse 2. Segment de piston en panne 2. Remplacer

14 Fr

Page 15

Sdrie WL6500

Guide de D_pannage (Suite)

li_T;ll'llll i i_||_.............. ".................... "

Humidit_ excessive dans T. Eau excessive dans le r_servoir 1. Purger le rdservoir

I'air de d_bit 2. Humiditd _lev_e 2. DiSplacer _ un endroit moins humid•; utiliser un filtre

Le ¢ompresseur 1_Manostat d_fectueux I. Remplacer te manostat

fonctionne 2. Utilisatlon d'air excessive 2. Rdduire I'utiJisation d'air; le cornpresseur n'est pas

cofltinuellsment assez large pour la demande d'air

en canaltsation d'air

D_marrage et coupage

excessif (ddmarrage

automatique)

Fuite d'alr de I'appareil

de d_chargement sur le

manostat

Le moteu¢ fonctionne, Courroie bristle

mais il n'y a pas de

d_bit d'air

OUTILS RECOMMANDI_S FOUR UNE

UTIUSATION CONTINUE

Cles a choc papillon

CI_ ,_diquet

Pistoletsde pulv_r_ation

Sclesalternatives

Toumevis

pistolets _ point•

Ck_Jeuts de charpente

pistolets _ g_aisse

Pbtolets ,t calfeut_e(

Nettoyeurs ;_moteur

1. Condensation excessive dans le

r_servoif

2. Fuites d'air dans la tuyauterie (sur le

module ou dans le systizme ext_rieur)

3. Fuite du el•pet de r_servoir

Clapet gripl_ dans la position ouverte Enlever et remplacer le el•pet

1. Purger le r_servoir plus souvant

2. Remplacer ;es pi_ces qui ont des fuites ou sefrer

3. Remplacer ou r_pa_er $i n_cessaire

clans IB r_se_oir; vldanger le r_scrvoir

darts Ic _servoir; vidanger le rLservolr

Remplacer la courroie

OUlnLS RECOMMANO_.S POUR UN

USAGE INTERMIITENT

(impulsions pulssantes et €ourt•s)

Cl_s a chocs

Meules ,_rectifier

Perceuses

Burns pneumatiques

Machines a tron¢onner

Ne pas d_monter lc

€lapet s'il y • de I'air

Ne pas d_monder le

€lapet s'il y • de I'•ir

OUI_LS NON RECOMMANDI_S

Pone•uses alternatives

Ponceuses a grand• vitesse

Ponceuses _ double action

Ponceuses a sautillement

15 Fr

Page 16

Compresseurs Sans Huile S_rie WL6500

Garantle I.imlt_e

1. DUR_E: A partir de la date d'achat par I'acheteur original comme suit : Produits A Service Standard (Standard Duty) - Un

An; Prod uits A Service S_rleux (Serious Duty) ° Deux Ans; Produits A Service Extreme (Extreme Duty) - Trois Ans: Sdrie

ModUle Maxus - Cinq Ans.

2, GARANTIE ACCORD_E PAR (GAP,ANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio,

45030, T_l_phone: (800) 543-6400

3. 81_NI_FICIAIRE DE CETTE GARANTIE (ACHETEUR): L'acheteur original (sauf en cas de revente) du prodult Campbell Hausfeid.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: N'importe quel compresseur d'alr Campbell Hausfeld.

5. COUVERTURE DE LA PRI_SENTEGARANTIE: Ddfauts de mati_re et de fabrication consid_rables avec les exceptions indiqu_es

ci*dessous.

6. LA PRI_SENTEGARANTIE NE COUVRE PAS:

A. Les garanties implicites, y comprls celles de commerclallsabilit_ et D'ADAPTION A UNE FONCTION PARTICULII_RE SONT

LIMITI'ES A PARTIR DE LA DATE D'ACHAT INITIALE TELLE QU'INDIQUI_E DANS LA SECTION DURI_E. Sice compresseur

d'air est utilis6 pour une fonction commerciale ou pour la location, la duroc de la garantie sera quatre-vingt<lix (g0)

jours ;bcompt(_ de la date d'achat, I.es compresseurs d'entrepreneurs de service extreme et les compresseur$ de marque

Maxus ne sont pas limit,s ,_une garantie de quatre-vingt-dix (go) jours Iorsqu'ils sont trtilis_s dans des applications

d'entrepreneurs. Les produit$ ;_quatre cylindres d'un ou de deux _tages ne sont pas limit, s 1_une garantie de quatre-

vingt-dix (90) jours sl utilis_s dans les applications commerciaux ou industrielles. Quelques Provinces (_tats) n'autorisent

pas de limitations de duroc pour les garanties implicites. Les limitations pr_c_dentes peuvent done ne pas s'appliquer.

B. TOUT DOMMAGE, PERTE OU DISPENSE FORTUIT OU INDIRECT POUVANT R_SULTER DE TOUT DI_FAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (l_tats) n'autoritent pas

I'exclusion nl la limitation des dommages fortuits ou iodirects. La limitation ou I'exdusion prdc_dente peut ne done pas

.s'appliquer.

C. Toute panne r_suitant d'un accident, d'une utilisation abusive, de la n_gligence ou d'une utilisation ne respectant pas

les instructions donn_es dans le(s) manuel(s) accompagnant le prodult.

D. Service avant livraison; le montage, I'huile ou la graisse et les r/_glages par exemples.

E. Articles ou services qui sont exig_s pour I'entretien normal du prodult; graisses, flit reset joints d'_tanch_itds par exemples.

F. Les moteurs _ essence et les pi_ces d_tach_es sont express_ment exclus de cette garantie limitde. L'acheteur dolt

observer la garantie du fabricant de moteur qui est fournie avec le produit.

G, Articles suppl_mentaires qui ne sont gas couverts sous cette garantie:

1. Tousles Compresseurs

a. Toutes pi_ces d_tach_es endommag_es pendant I'exp_litlon. n'importe quelle panne caus/_e par un montage ou

fonctionnement du modi_le sous des conditions qui ne conforment pas aux directives de montage et de

fonctionnement ou dommage caus_e par le contact avec les outils ou les alentours.

b. La panne de la pompe ou de la soupape caus_e par la pluie, I'humidit_ excessive, un environnement corrosif ou

autres polluants.

C. Les d_fauts de forme qui n'ont pas d*effet sur le fonctionnement du compresseur.

d, Les r_servolrs rouillds, y compris mais pas llmit_,s _ la rouille caus_ par le vidange incorrect ou par un

environnement corrosif.

e. Les moteurs _fectriques, les clapetso et les manostats suivant la premiere annie de possession.

f. Robinats de vidange.

g. Dommage dO -_ la tension ou installation de fils iocorrecte.

h. Autres articles pas indiqu_s mais consid_r_s pi_ces & fatigue g_n_rales.

i. Manostats. r_gulateurs d*air et soupapes de sOrat_ qui ont _t_s modifies d,apr_.s les r_glages de i.usine,

2. Compresseurs Graiss_s

a, Usure de la pompe ou dommage aux soupapes caus_ par I'utilitation d'huile non-spL_cifi/_e.

b. Usure de 1,1pompe ou dommage aux $oupapes caus/_par route contamination d'huile ou par le manque de suivre

les directives d'e ntretien d'huile.

3. Corn mande par Courroie / Commande Directe I Compresseurs _ Essence

a, Coun'oies

b, Usure de bagues caus_ par I'entretien de filtre imuffisant

c. Appareils manuefs de chargemenUd/_;chargement et appareils de €ommande d'obturateur.

7. RESPONSARILITI_S DU GARANT AUX TERMES DE CET_E GARANTIE: R_paration ou remglacement, au cholx du Garant, d'un

(ompresseur ou d'une piece d_tach£'e qui se sont rival,s d_fectueux ou qui ne se sont pas €onform_s pendant la dur_e de

validit/_ de la garantle.

8. RESPONSABILITI_S DE L'ACHETEUR AUX TERME$ DE cETrE GARANTIE:

A. Fournir une preuve d'acbet dat_.e et un _tat d'entretien.

8. La livraison ou expedition des compresseurs portatifs ou des pi_ces d_tach_es au Centre De Service Autoris_ Campbell

Hausfeld. Taux de frais, si applicab_,s, sont la responsabilit_ de I°acheteut,

C. Utgisation at entratien du produit avec un soin raisonable, aiosi que le d_,cri(vent)t le(s) manuel{s) d'utilisation.

9. RI_PARATION OU REMPLACIEMENT £FFECTUI_ PAR LE GAP,ANT AUX TERMES DE LA PR{_SENTEGARANTIE: La r_paration ou

le remplacement sera pr_v,J et ex_cut_ en fonction de la charge de travail dans le centre de service at d_pendra de la

disponibilit_ des pi_ces de rechange.

Cette Garantie Limit_e s'appfique aux I_.-U., au Canada et au Mexique seulement et vous donne des droits juridiques precis.

L'achateur peut _galement joulr d'autres droits qui varient d'une Province, d'un _tat ou d'un Pays _ I'autre.

16 Fr

Page 17

Sirvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar_ instalar, maneiar o darle

servicio al producto descrito en este manual. Prot_jase Ud.y a los demos observando todas as reg asde

seguridad. El no seguir las instrucciones podria resultar en neridas y/o da_os a su prop edad. Guarde este

manual como referencia.

Compresores

IRONFORcL_

Descripci6n

Loscompresores sin aceite han sido

diserlados para una gran variedad de

trabaios dom_sticos y mecAnica

automotriz. Estoscompresores se utilizan

con pistolas rociadoras. Ilaves de impacto

y otras herramientas neu mcSsicas.Esta$

unldades funcionan sin acelte.

Medidas de Seguridad

Este manual contiene informaci6n que es

muy importante que sepa y comprenda.

E_ta informaci6n se la suminbtramos

como medida de SEGURIDAD y para

EVITAR PROBLEMAS CON ELEQUIPO.

Debe reconocer los siguientes simbolos.

hay una s/tuadd_ kvm_m_ _ LE

OCAS/ONAR/A/a muer te oher fdas de

Wa_

I_,ADVERTENCIA] _ q.

hay una slWad6n quo POONA ocaslonar_

/a mu_r_ o hwfd_s de gra,,_dad,

PRECAUCIONt

hay una dlu_d6n quQ POQR/A oc_dmur_

her_ no n_y ilra_

[ AVISO

/nfomum_n imp_tan_ q_e _ no

_Ma./_ podeia ocasionu dadlosat

Para Desempacar

Cuando desempaque la unidad,

inspeca6nela cuidadosamente para

verific_r si sehan p_ducido dattos

du_ante el transporte. Asegtlrese de

apret_r todos los accesorios, pemos, etc

que est_n suellos antes de porter la

O 2003 Campbell Hausfeld/Scott Fetzer

Sin Aceite

O INO DEVUELVA EL

Regist re en el espacio a continuacibn

el No. del Modelo, el NGmero de Serie

y la Fecha de Compra ubicados en la

base debajo de la bomb,

No. del Modelo

No. de _erie

Fecha de Compta

unidad en servicio. En casode que haya

da_os o fallen pieza_ sirvase Ilamar al

1_00_543-8622 para obtener ayuda o

Ilame al Centro de Se_i¢io Autorizado de

Campbell Hausfeld m_s cercano.

Se incluye una lista de las di_cciones de

los cenlros de servicio. Tenga a mano el

ndmero de serie, el n_me¢o del modelo y

la lista de piezas {con las pieza_ que fallan

marcadi_ con un ¢irculo) antes de Ilamar.

IAADVERTENGAt, , ,.

urddad SiSeh_ de'do dunm_ _ _mv'.o,

€_Jsionar una e_q_os76n y _as;onarfe

hertdas o d.mlos a su pmp,_dad.

PROD UCTO AL

MINORISTA|

Guarde estos nGrneros para

referencia en el futuro.

Adverten¢la sobre

el aire respirable

Es_emmpresorto_ezal no v_ne _s_ode

f_br_ p_ _de _re respir_ble,

Antes de _'lizados mn es_ fir_ debe_

inll_l_rfe un si_tem_desegurk_d y M_ma

Inca_por_o a _ an_. Es_es_m_ _om_

es ne_,sario pam fafrar y p_ffiar elaire

a_men_, para mmp#r con las

_ mln#n_ssobre _r_

re_plrd_le de Gradop de_ enl_

Esped_ad6n de Produ_os G 7.1-19_6 de

_ por el Ar_culo 29 CI_ _910. 134

de I_ Org_d_dn nor_me_Jn_ OSHA

ylo la CanadlanStandard_,e_oda_oas

(CSA_

RENUNOA A I_S GARANTIA5

$i el ownpeesorseuoTizapara lx_udr ake

re_k_Ne _N habede _o _l _t_ma

de _gurided y M_rm_, toabsl_ 91_r_n_sse

anular_n y la compaala C_mpb_l Haulfeld

no a_m_I NINGUNA _,_non_ll_dad por

Informaciones

Generales de Seguridad

Como el compresor de aire y otros

componentes usados (cabezales, pistolas

pulverizadoras, filtros, lubricadores,

mangueras, etc), forman parle de un

sis_ema de bombeo de alia presi6n,

deber_ segulr lassiguientes medidas de

seguridad todo el tiempo:

manuales induidos con e_te

producto. Familiar_ese con

1. Lea con cuidado lodos los

los ¢ontrotes yel uso

adeCuado del equipo.

2. Siga todos Io5 c_digos de seguridad

labo_al y electd¢idad estableddos en

IN610200AV 9/03

_7sp

Page 18

Compresores Sin Aceite

Informaciones

Generales de Seguridad

(Continuacion)

su pals, por ejemplo losde JaNEC y

OSHA en EUA.

3. Este ¢ompresor sblo debe set usado

por per-.onas que es_n bien

familiarizaclas con las reglas de

seguridad y de manejo.

4. Mantenga a los visitantes alejados y

NUNCA permita la presencia de ni_os

en el _trea de trabajo.

5. Siempce I_e ante(_jos de segurldad y

pr0t_jase los oidos para operar el

cabezal o el compresor.

6. No se encarame sobre el cabezal, nl lo

use para sostenerse.

7. Antes de cada uso. inspeccione el

$istema de alre comprimido ylos

cemponentes el_ctricos, para vet si

est_n da_ados, deteriorados.

desgastados o tienen fugas. Repare o

reemplace las piozas da_ldas antes de

usar el equipo.

8. Chequ_e todas lasconexiones

frecuentemente para cerclorarse de

que est6n bien apretadas.

[_,ADVERTENCIA] _

_.scanect_mr o _t_r de _]tart_- Ms vilvuMs

sQ/es ao_nu/e p&_nl u ofn_ n_lfen_/eL

moBg'fi_" el _l $i _ _

podr_ d_K, m,np*m o *_/otK.

I A mO

di,_q_men t_,

12. los tanques se oxldan debido a la

acumulaci6n de humedad y _sto

debillta el tanque. Cercibrese de

drenar el tanque con regularkbd •

insp_ccionelo pedbdicamente para vet

stest_ en malas condiciones, poe

ejemplo si est_ oxidado.

13. La circulad6n r_pida de aire podrla

levantar polvo y desperdidos dal_ioo_

Siemp_e libare el aire lentamente para

drenar el tanque o liberar la presk_

del sistema.

Ensamblaje

ENSAMBLAJE DEL MANGO

El mango del compresor tiene una

protuberancia en la parte superior. _sla te

sirve para colgar las pistolas

pulverizadoras, roaadoras de arena u

otras herramlentas que tengan un

gancho.

1. Si la unidad incluye la agarradera del

mango, moje la parte tnterna de la

agarradera con una capa delgada de

agua jabonosa. Empuje la agartadera

en el mango.

2. Introduzca el mango en la cubierta yen

la platina de base como indicado en la

Figura 1.El mango tiene que ajustarse

en los orificios especiales de la pJatina

de base.

3. Coioque untrozo pequefio de madera

sobre el mango y golp6elo con un

marUIIo hasta que el orifk_o del mango

y la base est6n allneados.

/_O_L'eel'€oml_v_sor€_ de gases o

_ Nunc_ aln_cene nl

Ilq_lldos o g_4s Jnfl_ables _r_lt

del compre_or.

ONJl--/I

_._o_ I._.. I

_ cadien_s.

9. Mantenga losdedosalejadosdel

compresorcuandoest6funcionando;

bs piezasen rnovimientoocalientes,

ieoQ_iona_lanherida_y/o

quemaduras.

10.$i el equipoo0mienzaa vibrar

excesivamente,APAGUEel motor y

cbaqu_eloiomedlatamente para

determinarla razbn.Generalmente,la

vlbra_i6nexcesivasedebea una falla.

1I. Para_dudr el peligrode incendlo,

mantenga d exteriorde[ motor libre

de a(e_e, mlventeso exoesode grasa.

14. NO fume mientras est_ rodando

pintura, insecticldas u otras

substandes inflamables.

15. Use una miscara/

resplrado_ cuando vaya a

roclar y siemp_e rocle en

un _rea bien _ntilada

para evitar peligms de

salud • incendios.

t6. Nunca rode _a pintura y otros

materiales, dlr_-_'tamente hacia el

compresor. Coloque el _ompreso¢ lo

m_s Wjos posible del _ma de trabajo.

para minlmizar la acumulaci6n de

res_uos en el ¢ompreson

17. AI rocia¢ o limpiar con solventes o

quimicos t6_lcos, siga las instrucclones

del fab_icante de dichos qulmicos.

18 Sp

4. Inserte los 2 tornillos (del paquete de

piezas) en los orificios de la base y

apri6telos cercior_lndose de que el

mango es_6 _egur_Jo,

I ADVERTENaA]

r_mgo _ te_me_r/i un/_ld

€omp/efamm_., _ e/mm'_go ,so/,wmm_

p_n _le_x un em_,mo p_n_ que/_s

5. Introduzcaelperno roscadode la pata

decauchoend oriflcloen elIlierro

emlerilado. Aseg0relafirmementecon

latuercade segurided.

PARAENSAMBLAR LAS RUEDAS

LosartIculos marcacloscon un as_erisco

(*) seencuen_ranen el paquete de

piezas,

1.Introduzcael perno a tr_s delcubo

de b rueda.Lacabezahexdel pemo

Page 19

Serie WL6500

Ensamblaje

(Continuation)

debe estat en el lado opuesto a la pieza

sobresaliente del centro del cubo.

2. En lasruedas de 15.24 cm (6") - 20,32

cm (8") de di,_metro, introduzca el

pemo en el orificlo ubicado en la parte

inferior del eje de hierro del tanque y

aseg_relo bien con una tuerca de

seguridad. En las nJedas de 25.4 crn

(10") de all'metro, introduzca el pemo

en el orificio ubicado en la parte

superior del eje de hierro del tanque y

asegt_relo bien con una tuerca de

seguridad. Repita este paso en el otto

lado.

,_v.._Tuercade

seguridad

_Perno

Figure 2 - Para snsamblar las ruedas

ELEMENTO MET_LICO OPaONAL DI

CONEXION A TIERRA PARA

POSICION VERTICAL

I. Presione el tap6n de pl;_stico en el

extremo de tubo de una pulgada.

2. Monte el pu_o en el tubo como

indicado en el motaje del mango.

3. Monte el tub<) en el tanque como se

Indica en la figura 8. Ajuste el tubo

con pernos de segurldad de 7.9 mm

(5/16"). Ajuste firmemente con

tuerca$ de seguridad de 7,9 mm

(5/t6").

4. Monte el pie de caucho con una

arandela de 5/16. Inserte el extremo

roscado del pie de caucho en los

huecos al tope del tubo. Ajuste

firmemente con tuercas de seguridad

de 7.9 mm (5/16").

NOTA: Vea la lista de piezas para la

vista despiezada del montaje.

Pata de

goma

Arandela

Instalaci6n

LRIICAQON

Una vez que Io ensamble, el tanque debe

estar nivelado o un poco indinado haaa

el lado donde e_tl la Ilave de drenaje de

modo que pueda drenado

adecuadamente,

E$de suma impertancia instalar el

compresor en un Ilugar limplo y bien

ventilado donde la temperatura ambiente

no sea mayor de 38" C (100"F).

Se requlere un espacio minimo de 45,7 on

(t8 pulgadas) entre el compresor y la

pared, para evitar obstruc¢iones en el

flujo de aire.

IAPRECAUCIONI

enb_da de akv de/€ompmsor ce_a de

keas _n vapor, vapoms de pinturm,

dmnos de _ma o cualquier otra fuente

de mlnacl6_ Los deq_rdidos

daltar_ e#motor.

INSTALACK)N ELECTRICA

IAADVERTENCIAI

xlones e/_-trlcas y M a/ambrano dsber_m

w l_vados a ca_o por un elecb_sta

pro_s_naI. La k_a_d6n debe estar

€onforme con lose6d_os _a_s y

nadonaJes de ek_'b_dad.

IAPRECAUCIONI

CONEXlON A TIERRA

1. Este producto est& disehado para

citcuitos nominales de 120 vohios y

tiene un enchufe para conexion a tle_a

similar at de la Figura 4. Cerci6rese de

conectado a un _omacorrientes clJya

conf_u raci6n sea similar a la def

enchufe. Esteproducto se debe

conectar a tlerra. En caso de que ocurra

un cortocirculto, dsto evitarla el riesgo

de choque el6ct rico al ofrecerle un

Terminal

Tomacorrlente$ conectado a tlerra

Flguta 4 - M_todo de €onexi6n • t|err_

cable de desvio a lacorrlente el_trica.

Este produc_o tlene uncordbn con un

alambre y terminal de conexi6n a

tlerra, Debe conectar_o a un

toma(orrlentes que est6 instalado

adecuadamente segun los c6digos y

ordenanzas locales.

El u_ InadeoJado de/er_d)u fe

con c_exMn a _'a podrM

e,c_ion_le d_ques eli_o_

_aptador para €onexi_t a b_a €on este

2. 5i ne_esita reparar o reemplazar el

cord6n o e! enchufe, no conecte el

cable de conexi6n a tierra a ninguno de

los terminates pianos. El alamb_e cuya

suped_cie extema del aislante es verde.

con o sin rayas amaritlas, es el cable de

conexibn a tierra.

IAADVERTENCIA] _,

/os cab/es ve_es o verde con riyas

amarllM_ a un termlnal o_ntensi6n.

3. Cons_iltele a un elect ricistacalificado o

a un t6cnico de reparation, en cas de

que no comprenda bien las

instPJcclones o si tlene dudas de que

est6 conectado a tierra

adecuadarnente. No mod_iclue el

enchufe, si _ste no ent_a en el

tomacofTlentes, mande a instalar un

tomacorTlentes adecuado con un

electricista calificado.

AUU_BRADO

1. Los c6digos el_t ricos varian de un ;_rea

a otra. Sin embargo, el alembrado,

enchufe y protectores se deben

seleccionar seg_n las esl:_-ificadones

de amperaje y vokaje indicados en la

plata del motor y cumplir (on las

especificadones mlnimas.

2. Use fusibles de action retardada ripe T

o un cortadrcuito.

t PRECAUCIONI

/oscab;es_uadamen_e p_M/_ber

cor_ kK_X_ sobma_

kmtam/en_ et_

NOTA:Lasunidadesde 120voltios.15

ampse puedenutilizaren cit_uitosde 120

voltio$bajo lassiguientes condicx)ne_

a. NingOnotto artefacto el6ctricoo

lutesest6n€onectadosal mlsmo

drcuito.

b, Elsuministrodevokaje esnormal.

¢. Loscordonesde extensi6nsonlos

19 Sp

Page 20

Compresores Sin Aceite

adecuados y cumplen los requisitos

minimos espedflcados en este

manual de instrucdones,

d. Elcircuito tiene un ¢ortadrcuito de

15 ampedos o on fusible de acrid1

retardada de 15 ampedos.

3. Si no puede satisfa_er las condidones

arriba enumeradas o s_el cortadrcuito

se actlva frecuentemente, q uiza_stenga

que utiliza¢ un cln:uito de 120 voltios.

20 amperios.

Funcionamiento

de herramlentas

ON (efKendldo) el €ompresor se apaga

autom_ticamente cuando la presi6n del

tanque alcanza el nivel m_ximo fijado en

laf_l_ica, El €ompresor se encender_

HUMEDAD EN EL ABE COMPRIMIDO

Lahumeded que seacumela en el ave

comlxk_dese€omlerteeng_asa

medide que saledel r_10ezaldel

coml_esor de aire. Cuan_o el nivel de

I_mneded _ muy alto o cuando el

(ampres_x ha estado en usoconttnuo

pot mud_o tiempo. _a se aoJmularS

en el tanque. AI usar una pbtela

pulverbadora de ptmura o una

rodadora de arena, la h_lad saldr6 a

tTav_sde la ma_g_..ra mezclada con el

material que est,,roclafldo.

IMPORTANTE: Esta_nsaciGn

o_t ma_cbasenlasuixn'l_

_ad_ _ o_de es_

puk_tzando pinturas que no seana

basede agua. AI rodx arena _*ta

ocador_r_l que la arena se aglutine y

obs_r/a lapistola. _ su

efic_a. Para erm_inareste prcd)lema,

tnstaletm filtro en la Ilnea de aire

(MP3105), id re,iscer_ posible de la

- Autom_tico - En b podd6n

autom_ticamente cuando alcance la

presidn minima fijada en la f_bdca. En

la posidbn OFF, el compresor no

funcionar_. Elpresostato debe coidcarse

en OFF (alpagado) para conectar o

desconectar el ¢ord6n eldctdco del

tomacorrientes o para cambiar la

herramienta neum_tica.

Regulador -£1regulador controla la

cantidad de presibn de aire expubada pot

la manguera.

V_llvula de segurldad ASME - Esta

v&lvula automitticamente libera el aire si

la presidn del tanque excede el valor

m&ximo fijado de f_bdca.

Mango - Dise_ado para mover el

¢ompresor.

ComparUmlento para almacenar

herramientas - Los acopladores

r_pldos de 6,4ram (1/4") pueden

utilizarse con manddle$ de aire y otro$

a¢cesorios para inflar.

I ADVERTENCIAI

d_/a_ urddades oo_ ruedas pare/e_am_e_r

Llave de drenaje -Esta v_lvula est_

ubicada debajo del tanque. 0sela para

drenar la humedad del tanque diaria-

mente, para evitar que el tanque se oxide.

Reduzca la presidn del tanque a menos de

0,69 bar, despuds drene la humedad del

tanque diadarnente para evitar que se

oxide. Pata drenar lostanques abra la

Nave ubicada debajo del tanque.

ENGRASE

Esteesunaparato sinaceitey no

I_quiere engrasesparasu

fundonamiento.

IMPOR_rAN/_ No utilk:e el _ompresor dn

haber leido las instrucciones o podrla

daflado.

Presl6n de la

Pres_bndel

Herramle_ta

1. Coloque el presostato en OFF y

conecte el corddn al tomacorriente_

2. Conecte un mandril o herramlenta

neumattica a la manguera.

3. Gire e[ regulador en el sentldo de

las agujas del reloj para abdr el

flujo de aire.

4. Coloque el presostato en ON.

5. El compresor se apagarat

autom,_ticamente al el¢anzar la

presibn m&xima fijada de f&brica.

6. Ajuste el regulador a la presidn

adecuada para una herramlenta o

neum_tico. Maneje la herramienta

segOn las instru¢ciones. El compresor

se reinidar& autom_ticamente

cuando la presidn en el tanque caiga

pot debajo de la presidn de

arranque.

7. Gire la perilla del regulador

¢ompletamente en sentido

¢ontrario al de las agujas del reloj,

para cerrar el flujo de aire y

coloque el presostato en Off.

En la posick_n ON. el compresor

bombea aire hacia el tanque. El

¢ompresor se apaga autom&ticamente

cuando la unidad alcanza una presi_n

mixima fljada de f_brica. En la posick_n

OFF, el comresor no funcionarlt. El

presostato debe estar en OFF cuando

vaya a conectar o d_conectar el cordbn

el_=ctrico del tomacorrlentes.

VALVULA DE SEGURJDAD ASME

I ADVERTENOAI

feo Ir_e de aJustar/a v_fvu/a de

De vez en cuando debe halar el anillo con

la mano para chequear eta v&lvula. Si hay

una fuga de eln_ despuds de haber

seltado el anillo, o si lav&lvula estlt

atascade y no la puede activar _on el

anillo, DEgERA reemplazada.

20 Sp

Page 21

Serie WL6500

Funcionamiento

(Continuadon)

PERILLA DEL REGULADOR

1. Es_a pedlla controla el abe comprimido

que se le suministra alas herramienta$

neurnAti_as o pistolas pulverizadoras.

2, Gire la peritla en el misrno sentido de

Tasagujas del reloi para aumentar la

presi6n de aire sumins_rado.

3. Gire la perilia en sentido contrario al de

las agujas del reloj para disminuir la

presibn de aire suminist rado.

4. Gire la perilla €ompletamente en

sentido contrarlo alas agujas del reloi

para cefcar el suministro de alre

completamente,

MANOMETRO PARA MEDIR LA

PRESION DE SAUDA

(HERRAMIENTA)

1, Este man6mel_o le

perrnite verificar la presi6n

de salida muy i+¢ilmente.