Campbell Hausfeld IN281600AV Operating Instructions Manual

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Operating Instructions

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Description

This air powered rotary cutting tool is

designed for cutting, sanding and

grinding. This tool may be used with

other brands of cutters, stones, sanding

drums, router bits and grinding points.

Using the correct accessory you can cut,

sand, or grind a large assortment of

materials such as:

Building Material - Acoustical tile,

cement board, ceramic, ceramic wall

tile, drywall, fiberglass, glass,

hardwoods, marble, OSB, plaster,

shell/stone, stucco, underlayment,

wood composites.

Plastic - Acrylic, foam board,

laminates, vinyl siding.

Metals - Aluminum, brass, iron,

steel.

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or

serious injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

C

aution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

NOTICE

!

CAUTION

!

WARNING

!

DANGER

General Safety

Information

CALIFORNIA PROPOSITION 65

You can create dust when

you cut, sand, drill, grind

material such as wood,

paint, metal, concrete,

cement, or other masonry. This dust

often contains chemicals known to

cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

WORK AREA SAFETY

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Avoid

a dangerous environment. Do not

use air tools in the presence

of flammable liquids or

gases. Avoid chemical or

corrosive environments.

This air tool is part of a highpressure air system. Do not

exceed the maximum

pressure rating of this tool

or any component in the

system. Release all pressure from the

system before attempting to install,

service, relocate or perform any

maintenance.

!

WARNING

!

DANGER

IN281600AV 11/02

Keep by-standers, children and visitors

away while operating a power tool.

Distractions can cause you to lose focus

and control.

Safety

glasses

and ear protection must be

worn during operation.

Everyone in the work area

must wear the proper safety

equipment. Grinding and cutting

produces sparks, air borne particles and

accessories can fail during use causing

serious personal injury. Use ANSI/OHSA

approved eye, hearing, breathing, skin

and head protection.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of

the tool in unexpected situations.

Never work around live

electrical wires. If cutting

into existing walls or other

blind areas where electrical

wiring may exist is

unavoidable, disconnect all fuses or

circuit breakers feeding this work area.

PERSONAL SAFETY

Stay alert, pay

attention and use

common sense when operating any

power tool. Do not use tool while tired

!

WARNING

!

WARNING

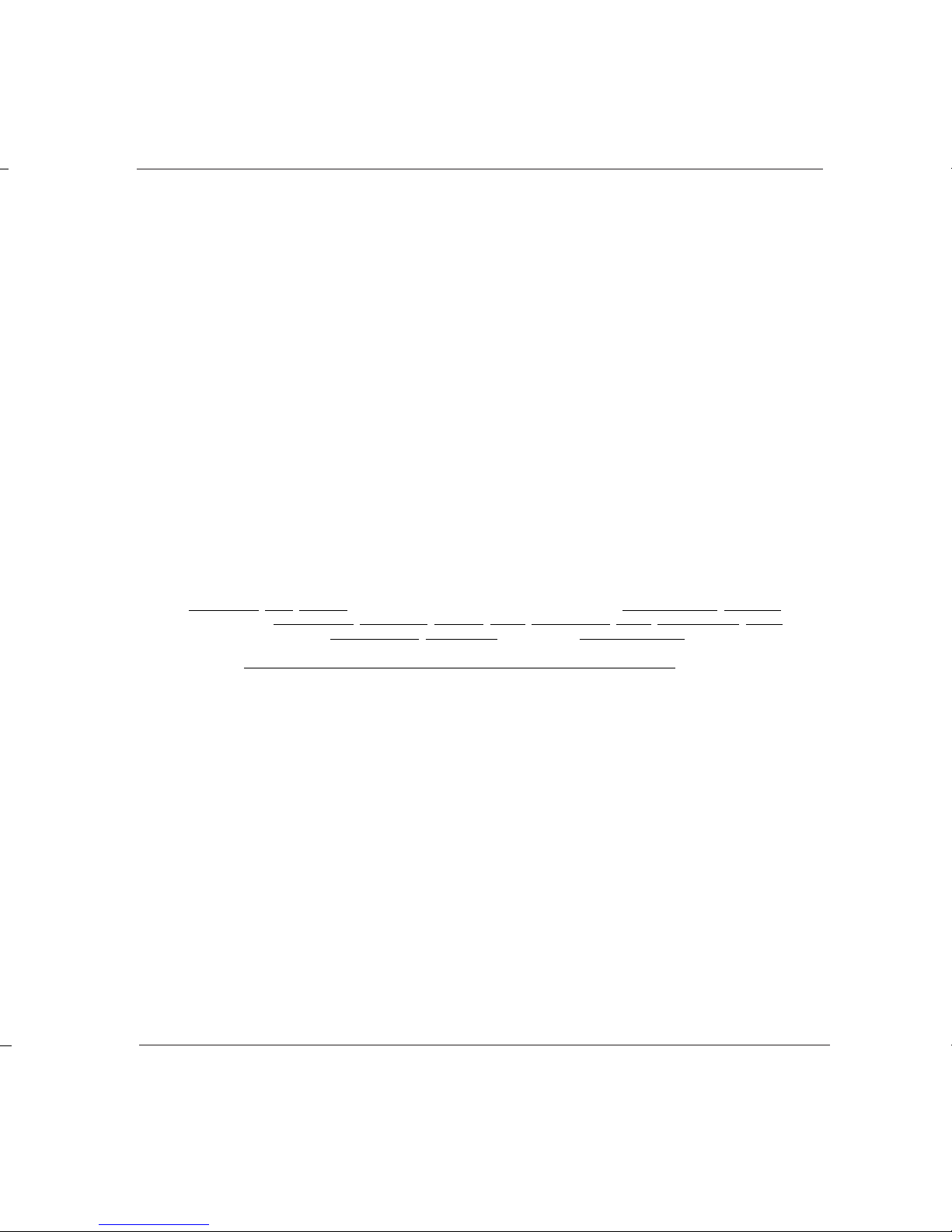

BUILT TO LAST

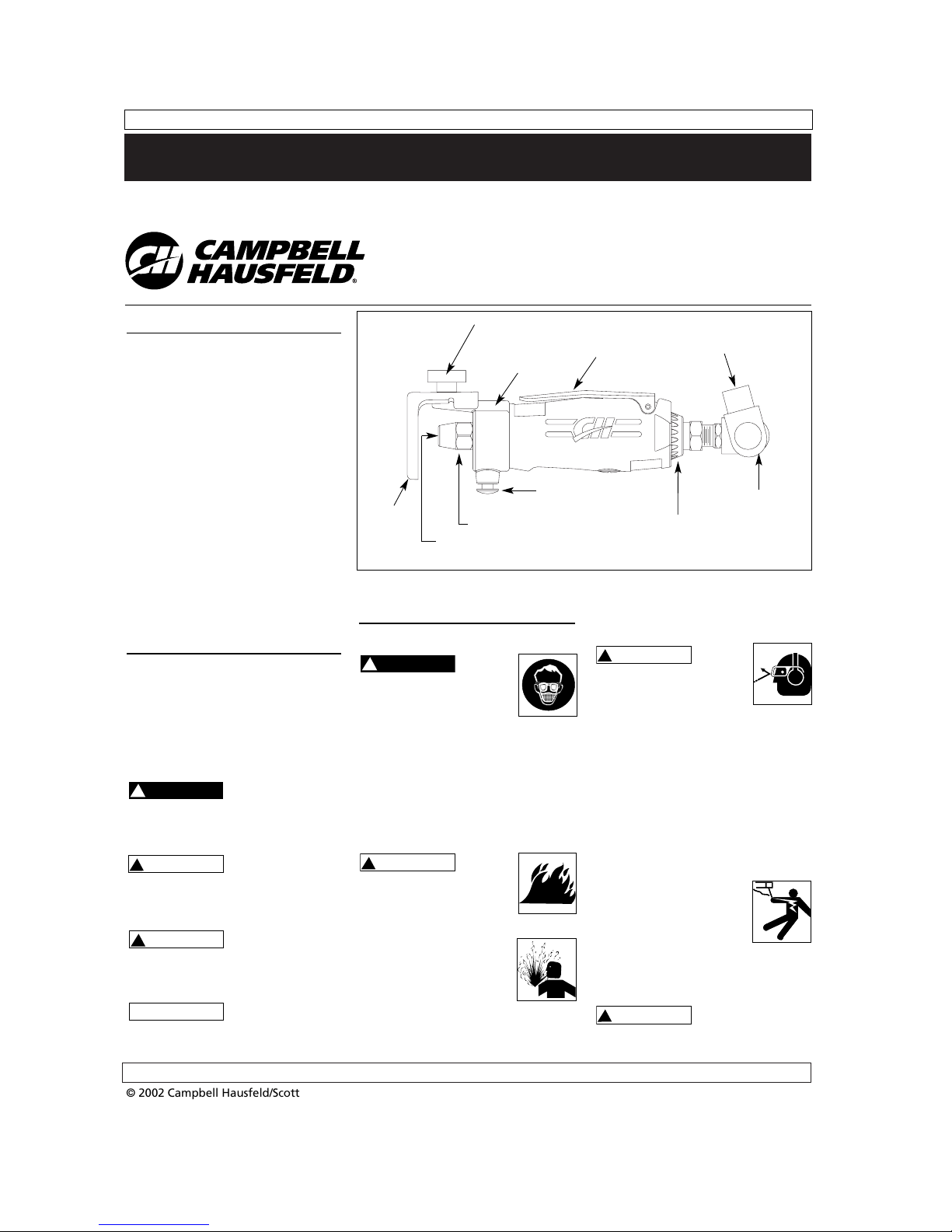

Rotary Cutting Tool

Depth Guide

Locking Knob

Bracket

Trigger

Exhaust

Port

Shaft Lock

Button

Collet Nut

Collet Inside

Depth

Guide

FIgure 1

For parts, product & service information

visit www.chpower.com

Air

Swivel

Air Inlet

Port

© 2002 Campbell Hausfeld/Scott Fetzer

See Warranty on page 5 for important information about commercial use of this product.

Problemas Posibles Causas Acciones a Tomar

La herramienta funciona

lentamente o no funciona

La herramienta expulsa

humedad

Vibración excesiva

Guía de Diagnóstico de Averías

Manual de Instrucciones

2

General Safety

Information (Continued)

or under the influence of drugs,

alcohol or medication. One second of

inattention while operating any power

tool may result in serious personal

injury.

Excessive exposure

to vibration,

working in awkward positions and

repetitive work motions can cause

injury to hands and arms. Stop using

any tool if discomfort, numbness,

tingling or pain occur and consult a

physician.

Do not use tool on

hazardous

materials. Some building materials or

work surfaces may contain known

hazardous materials. If the hazardous

material is touched or particulate

breathed, medical problems could

occur.

Dress properly. Do

not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing and gloves

away from moving parts. Loose

clothing, jewelry or long hair can be

caught in moving parts.

Disconnect the tool from the power

source before making any adjustments,

changing accessories and/or attachments or storing. Such preventive

safety measures will reduce accidents.

TOOL SAFETY AND CARE

Only persons well

acquainted with

these instructions should be allowed to

use this tool. Any persons not wearing

the proper safety equipment or

unfamiliar with this tool’s operation

can become seriously injured.

Do not exceed the

maximum operating

pressure of this tool (90 psig).

Pressures higher than 90 psig will

reduce the life of the tool. Maximum

operating pressure of 90 psig is

measured at the tool air inlet while the

tool is running. Any compensation for

airline pressure drop must be made at

the compressor regulator.

Recommended accessories:

Not all 1/8” or 1/4”

accessories that fit this tool

are recommended. Read the

safety and operating

information provided by the

manufacture of the accessory. Some

accessories with large cutting surfaces

NOTICE

!

WARNING

!

CAUTION

!

DANGER

!

WARNING

might be hard to control due to tool

rotating speed. Do not use 1/4”cutout

bits. The cutting flutes on 1/4” cutout

bits are too aggressive, making it hard

to control this tool.

Do not use

damaged

accessories. Accessory can become

damaged during shipment or after

attachment to the tool. Damaged

accessory can fly apart as the tool

comes up to speed. Inspect accessory

before and after attaching it to the

tool and before each use.

Do not use any accessories that were

not designed for this tool. Use only

accessories with a speed rating higher

than 25,000 RPM’s.

This product is not designed to use cutoff wheels, no guard is provided.

Do not force the

tool. Allow the tool

and accessory to do the work; applying

too much force will damage the

accessory or cause it to break.

Use clamps or other

practical ways to

secure and support the workpiece.

Holding the work-piece in your hand or

against your body is unstable,

dangerous and could cause an

accident, don’t do it.

Always make sure

the workpiece is

free from nails, staples or other

foreign objects. Cutting into a hard

object like a nail can cause the

accessory to break, causing personal

injury.

Use the depth guide when cutting with

bits. The guide, when securely

positioned on the work surface,

improves the stability and control of

the tool.

Do not use dull

accessories. Dull

accessories will require more force to

push the tool, possibly causing the

accessory to break and causing

personal injury.

Never touch the bit during or

immediately after use. The cutting

flutes on bits will cut you if touched

while tool is running. Bits will become

hot to the touch when cutting.

Do not trigger the

tool while the

wrench is on the collet nut or the shaft

lock is engaged. Personal injury can

occur if the wrench is not removed

before turning on the tool.

!

WARNING

!

CAUTION

!

CAUTION

!

WARNING

NOTICE

!

WARNING

Do not engage the shaft lock while the

tool is running. Stopping the tool

quickly with the shaft lock can cause

damage to the tool and a possible

dangerous situation.

After changing the

accessories or

making any adjustments, make sure

the collet nut and other tool parts are

securely tightened. Loose accessories

or parts can cause a loss of control,

which might cause a personal injury.

Never start the tool against the work

surface when a cutting bit is attached.

The bit cutting edge may grab the

material causing loss of control of the

cutter, which might cause personal

injury.

Do not abuse the

hose. Never use the

hose to carry the tool or pull the

compressor. Keep hose away from

heat, oil, sharp edges or moving parts.

Tool service must

be performed only

by qualified repair personnel. Service

or maintenance performed by

unqualified persons could result in

serious personal injury.

Do not use a cut-

off disc mandrel on

this tool unless a safety guard is in

place.

For system setup refer to Instructions

on IN170102AV. Refer to tool diagram

Figure 1 and callouts on front page.

Pre-Operation

Use of a whip hose

prevents accidental

triggering of the tool when pressurized

air is connected to the tool.

Using fittings or air hoses, which are

too small, can create a pressure drop,

which will result in a loss of power in

the tool.

LUBRICATION

Air tools require lubrication throughout the life of the tool. Proper

lubrication is the owner’s responsibility.

Use Campbell Hausfeld airtool oil (Part

No. ST127000AV) to lubricate, clean

and inhibit rust in one step. Failure to

lubricate and maintain an air tool

properly will dramatically shorten the

life of the tool and will void the

warranty. This air tool requires

lubrication before initial use and

before and after each use.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

Operating Instructions

www.chpower.com

MANUAL

Pre-Operation (Cont.)

How to lubricate tool:

1. Disconnect the tool from air supply if

connected.

2. Turn the tool with the air swivel

pointing upward.

3. With the trigger pulled, add a

teaspoon of oil to the air inlet port.

4. Release trigger and connect the air

hose. Cover exhaust port with a rag,

then run tool for approximately 20

seconds.

5. Wipe the tool clean.

Cover tool exhaust

port with a rag and

then apply air pressure. Failure to

cover exhaust port will allow oil mist

to be sprayed from tool, which might

cause damage to work piece and cause

personal injury.

Operation

Follow the previous safety instructions.

Check for proper system setup and

connection of the tool.

INSTRUCTIONS ON USING CUTOUT

BITS

Do not use 1/4”

cutout bits with this

tool. The cutting flutes on 1/4” cutout bits

are too aggressive, making this tool hard

to control.

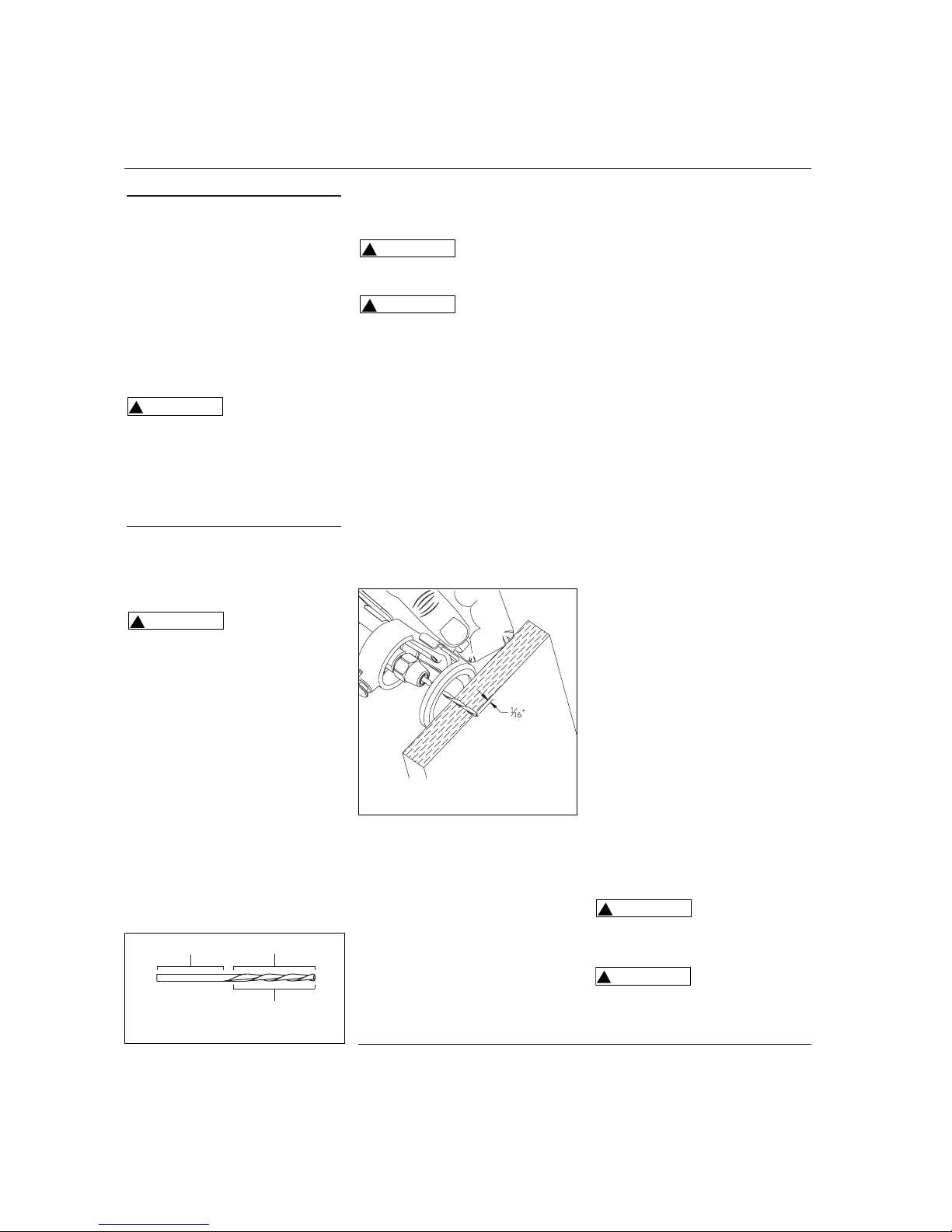

1. With air hose disconnected, install

the cutting bit into the tool by:

A. With the shaft lock button

depressed loosen the collet nut by

turning counter clockwise (CCW)

with a 5/8” wrench. A couple of

rotations CCW are all that is

needed.

B. Insert the bit into the collet

leaving 1/16” to 1/8” of smooth

shank visible above the collet.

NOTE: The bit flutes are sharp,

handle with care.

C. After properly placing the bit into

the collet, depress the shaft lock

button and simultaneously tighten

!

CAUTION

!

WARNING

3

Operating Instructions

the collet nut in a clockwise (CW)

direction. Tighten collet nut by

hand first, then use a wrench until

bit is held securely.

If the bit flutes are

inside the collet

when the collet nut is tightened, the

bit may break.

If the cutting bit is

removed from the

tool for storage, do not tighten the

collet nut. Tightening the collet nut on

an empty collet will cause the collet

hole to become smaller, preventing

you from inserting a bit in the future.

2. Adjust the depth guide. Use the

depth guide to adjust the depth of

the cut. The depth guide assembly

consists of the depth guide, locking

knob and bracket. Loosen the

locking knob by turning counter

clockwise (CCW) enough to enable

the depth guide to slide up or down

to the desired depth of your cut and

retighten the locking knob by

turning clockwise (CW). It is best to

allow the cutting bit to be 1/16”

greater than the material you are

cutting.

3. Check that all parts are tight and

safety equipment is in place before

turning on the tool.

4. Attach the air hose, turn on the tool

while holding tool firmly and apply

to work-piece by inserting the bit

into the material at a 45-degree

angle.

5. Slowly bring it to a 90-degree angle

to begin the cut. The guide should

be firmly touching the work-surface.

For most materials, slide the tool in a

clockwise direction with a slow and

steady pressure to make the cut.

!

CAUTION

!

CAUTION

NOTE: When using a bit and cutting

drywall, use a counter clockwise (CCW)

rotation.

6. After completing your cut, turn off

the tool and carefully remove it from

the work surface.

NOTE: Because of the rotating cutting

action of the bit, there will be a slight

pull when cutting. The slower you cut,

the more control you have. Excessive

force will cause excessive heat and may

shorten the life of the bit.

NOTE: When cutting on a vertical

surface, avoid ending your cut at the

bottom of the hole. If possible, start

and end your cut at the top so scrap

material will not drop onto the

rotating bit.

INSTRUCTIONS ON USING GRINDING

STONES, HIGH-SPEED CUTTERS AND

BURRS

NOTE: This tool is shipped with a 1/8”

collet installed in the tool. If 1/4” bits

are to be used then the 1/8” collet

needs to be removed from the tool.

The 1/8” collet can be removed by

removing the collet nut and pulling out

the 1/8” collet.

Disconnect the air hose.

1. Remove any accessory that is in the

tool.

2. Insert the accessory fully into the

collet, and then pull out

approximately 1/16” before

tightening collet nut.

3. The depth guide may or may not be

used depending on your application.

4. Check that all parts are tight and

safety equipment is in place before

turning on the tool.

5. Attach the air hose and begin

cutting, grinding or sanding.

NOTE: Do not try to use accessories

with 1/32”, 1/16”, or 3/32” diameter

shanks. Some 1/8” shank high-speed

router bits have large cutting edges

and should not be used in this tool.

Do not use wire

brushes, bristle

brushes or polishing wheels in this

tool. These accessories are designed to

work on tools with a low RPM setting.

When using steel

saws, high speed

cutters or tungsten carbide cutters,

always have the work securely

clamped. Never attempt to hold the

!

WARNING

!

CAUTION

Shank Flutes

Cutting

Surface

Figure 2

Figure 3 - Bits can cut material up to

1” thick

www.chpower.com

4

Operating Instructions

Operation (Cont.)

work with one hand while using any of

these accessories. The reason is that

these accessories could grab if they

become slightly canted in the groove

and could kickback or break causing

loss of control, resulting in serious

personal injury. Your second hand

should be used to steady and guide the

hand holding the tool.

Storage

The air tool must be lubricated before

storing. An air motor cannot be oiled

too often.

Technical Service

For information regarding the

operation or repair of this product,

please call 1-800-543-6400.

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Tool runs slowly or will not

operate

Moisture blowing out of tool

Excessive vibration

1. Grit or gum in tool

2. No oil in tool

3. Low air pressure

4. Air hose leaks

5. Pressure drops

6. Worn ball bearing in

motor

1. Water in tank

2. Water in the air

lines/hoses

1. Damaged stone or

burr

2. Collet shaft bent

1. Flush the tool with Campbell Hausfeld air tool oil, gum

solvent, or an equal mixture of SAE 10 motor oil and

kerosene. If Campbell Hausfeld oil is not used, lubricate

the tool after cleaning

2. Lubricate the tool according to lubrication instructions in

Pre-Operation section

3. Adjust the compressor regulator to tool maximum while

the tool is running free

4. Tighten and seal hose fittings if leaks are found

5. Be sure hose is properly sized. Long hoses or tools using

large volumes of air may require a hose with an I.D. of

1/2” or larger depending on total hose length

6. Remove and inspect bearing for rust, dirt, grit or worn

race. Clean and regrease bearing with bearing grease or

replace bearing

1. Drain tank (See air compressor manual). Oil tool and run

until no water is evident. Oil tool again and run 1-2

seconds

2a. Install a water separator/filter (PA2121). NOTE: Separators

work properly only when air steam is cool. Locate

separator/filter as far as possible from compressor

2b. Install an air dryer

2c. Anytime water enters the tool, the tool should be oiled

immediately

1. Replace with new stone or burr

2. Replace shaft or collet

www.chpower.com

Replacement Parts

Information

For information regarding where to

order replacement parts, call toll free

1-800-543-8622. Please provide the

following information:

• Model number

• Stamped-in code

• Part number and description

Address parts correspondence to:

Campbell Hausfeld

Attn: Parts Department

100 Production Drive

Harrison, Ohio 45030 U.S.A.

Manual de Instrucciones

Informaciones

Generales de Seguridad

(Continuación)

Nunca encienda la herramienta contra

la superficie de trabajo cuando está

colocada una mecha de corte. El borde

de la mecha de corte puede asirse al

material, provocando la pérdida de

control de la herramienta lo que puede

causar lesiones personales.

manguera. Nunca use la manguera para

transportar la herramienta o tirar del

compresor. Mantenga la manguera

alejada del calor, aceite, bordes filosos

o piezas móviles.

herramienta debe ser realizado sólo por

personal de reparaciones calificado. El

servicio o mantenimiento realizado por

personas no calificadas puede provocar

graves lesiones personales.

con disco de corte sin haber monta do

una guarda de seguridad

Para la configuración del sistema

consulte las instrucciones en

IN170102AV. Consulte el diagrama de

la herramienta en la Figura 1 y los

nombres en la página delantera.

Pre-Funcionamiento

manguera flexible previene el

accionado accidental de la herramienta

cuando se conecta el aire presurizado a

la misma.

El uso de accesorios o mangueras de

aire demasiado pequeñas puede crear

una caída de presión lo que dará como

resultado una pérdida de la potencia

de la herramienta.

LUBRICACION

Las herramientas neumáticas siempre

requieren lubricación para operar. La

lubricación adecuada es la

responsabilidad del propietario. Utilice

el aceite para herramientas neumáticas

Campbell Hausfeld (ST127000AV) para

lubricar la herramienta, limpiarla e

inhibir el óxido en un solo paso. La

falta de lubricación y mantenimiento

adecuados de una herramienta de aire

reducirá dramáticamente la vida útil de

la herramienta y anulará la garantía.

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

5

Operating Instructions

www.chpower.com

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty Products - One Year, Serious

Duty Products - Two Years, Extreme Duty Products - Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the

Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool, spray gun,

inflator or air accessory supplied or manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED

FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial,

industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States

do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply

to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance

with instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser's abuse, neglect or

failure to operate products in accordance with instructions shall also include the removal or alteration of any safety

devices. If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs, bumpers, debris shields,

driver blades

, fuses, batteries, gaskets, packings or seals, fluid nozzles, needles, sandblast nozzles, lubricants,

material hoses, filter elements, motor vanes, abrasives, blades, cut-off wheels, chisels, chisel retainers, cutters,

collets, chucks, rivet jaws, screw driver bits

, sanding pads, back-up pads, impact mechanism, or any other

expendable part not specifically listed. These items will only be covered for ninety (90) days from date of original

purchase. Underlined items are warranted for defects in material and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability

of replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights. You may

also have other rights which vary from state to state or country to country.

Loading...

Loading...