Page 1

SMA2

English

SERIES R ACCESSORIES

MAGNETIC LOOP

CONTROL DEVICE

SMA2

nglis

h

SERIES R ACCESSORIES

MAGNETIC LOOP

CONTROL DEVICE

Page 2

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

2

2 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

ELECTRIC SPECIFICATIONS

Supply voltage 12/24 V ac/dc

Current draw 20 mA max

Outlet relays Max capacity: 5 A at 230 Vac - Closed contact

Magnetic loop inductance Between 20 and 1000 μH

2. TECHNICAL FEATURES

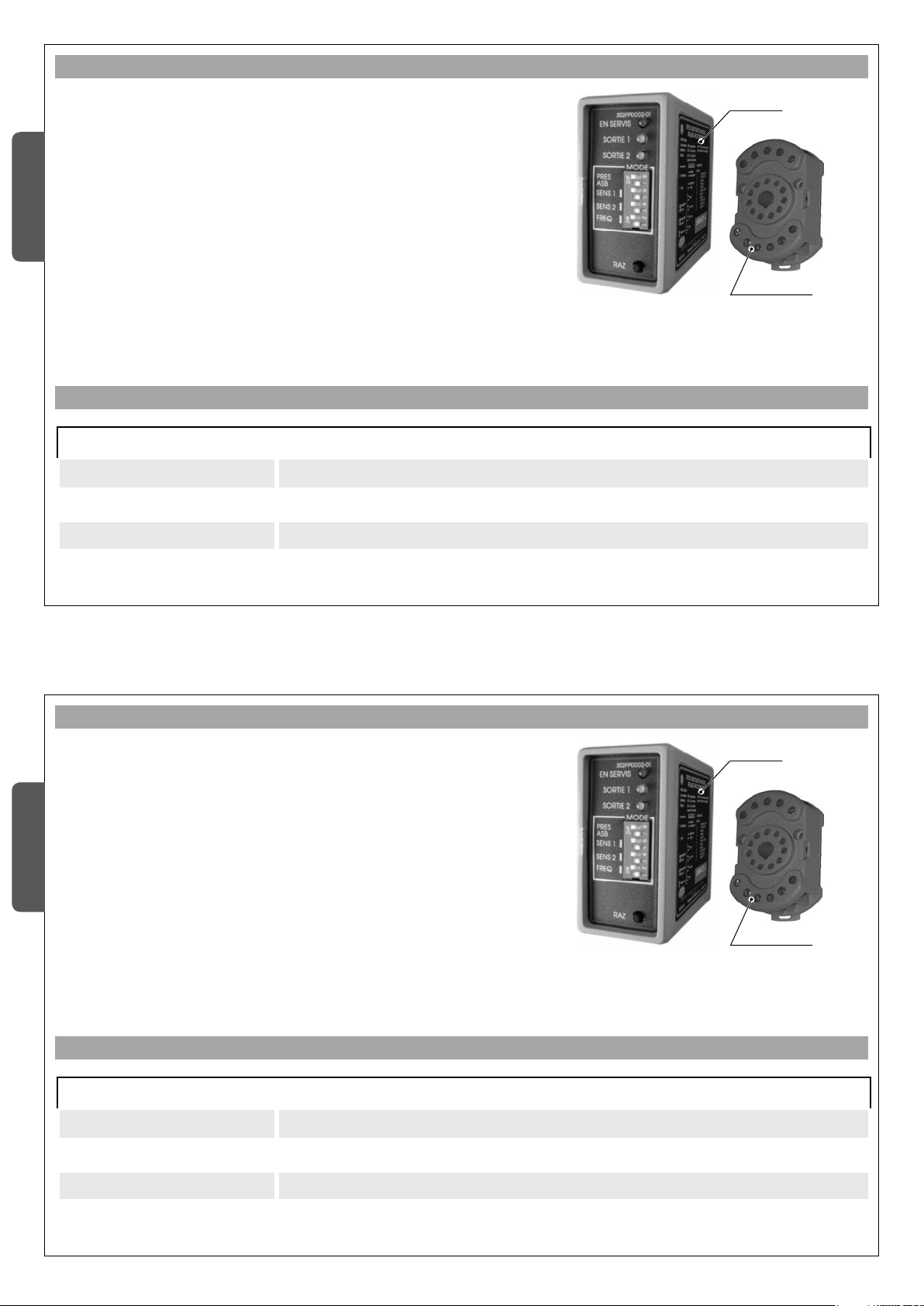

The 1 channel SMA sensor is a vehicle detector using electromagnetic

loops. It is fitted with a microprocessor and has been designed for

access and traffic flow controls

The operating principle involves measuring the inductance variation in

the magnetic loop caused when a vehicle passes over it.

Inside the sensor, the measuring circuits for the two channels are

multiplied to limit oscillations and interference that could be formed

between the magnetic loops.

SMA is complete with an 11-pin support/terminal block for connection

to the loops and the 12 or 24 Vac/dc power supply.

Support

Sensor

1. DESCRIPTION

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

2

2 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

ELECTRIC SPECIFICATIONS

Supply voltage 12/24 V ac/dc

Current draw 20 mA max

Outlet relays Max capacity: 5 A at 230 Vac - Closed contact

Magnetic loop inductance Between 20 and 1000 μH

2. TECHNICAL FEATURES

The 1 channel SMA sensor is a vehicle detector using electromagnetic

loops. It is fitted with a microprocessor and has been designed for

access and traffic flow controls

The operating principle involves measuring the inductance variation in

the magnetic loop caused when a vehicle passes over it.

Inside the sensor, the measuring circuits for the two channels are

multiplied to limit oscillations and interference that could be formed

between the magnetic loops.

SMA is complete with an 11-pin support/terminal block for connection

to the loops and the 12 or 24 Vac/dc power supply.

Support

Sensor

1. DESCRIPTION

Page 3

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

3

3 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

MECHANICAL SPECIFICATIONS

Materials ABS plastic casing

Fastenings Pressure sensor on the connector; connector mounted on DIN guides or screw in place

Measurements LxHxP 42 x 78 x 103 mm (sensor + connector)

Weight 230 g

Operating temperature -40 / +70 °C

Protection rating IP30

FUNCTIONAL SPECIFICATIONS

Sensitivity

4 ranges, selected through 2 dipswitches:

- High sensitivity: 0.02%, L/L

- Medium-high sensitivity: 0.05%, L/L

- Medium-low sensitivity: 0.10% L/L

- Low sensitivity: 0.50% L/L

Working frequency

High or low frequency, selected from a dipswitch; the frequency level depends on the size of the

magnetic loop

Output impulse length 200 ms

Response time 100 ms

Visual indicators

- 1 red power on led

- 2 green leds for sensor activities

Relay outputs 2 “presence” mode outputs

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

3

3 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

MECHANICAL SPECIFICATIONS

Materials ABS plastic casing

Fastenings Pressure sensor on the connector; connector mounted on DIN guides or screw in place

Measurements LxHxP 42 x 78 x 103 mm (sensor + connector)

Weight 230 g

Operating temperature -40 / +70 °C

Protection rating IP30

FUNCTIONAL SPECIFICATIONS

Sensitivity

4 ranges, selected through 2 dipswitches:

- High sensitivity: 0.02%, L/L

- Medium-high sensitivity: 0.05%, L/L

- Medium-low sensitivity: 0.10% L/L

- Low sensitivity: 0.50% L/L

Working frequency

High or low frequency, selected from a dipswitch; the frequency level depends on the size of the

magnetic loop

Output impulse length 200 ms

Response time 100 ms

Visual indicators

- 1 red power on led

- 2 green leds for sensor activities

Relay outputs 2 “presence” mode outputs

Page 4

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

4

4 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

3.1. Operating principles

The inductive loop sensor detects the presence of a vehicle on the

surface marked out by a cabled loop, formed of 2 or more runs of leads

beneath the road surface.

When a vehicle goes over the loop the relative inductance measured by

the sensor is reduced.

This detection activates a relay and its contacts are used to guide the

external devices.

The magnetic loop and the loop tail must be formed of a simple isolated

lead, without any connections, in multithread copper, with a minimum

section of 1.5 mm

2

(16 AWG).

It is not advisable to make connections to the magnetic loop or to the

power pack. However, if it is unavoidable they must be welded and

isolated in a waterproof case.

This is very important to guarantee long lasting detection reliability.

3.2. Operating limits

3.2.1. Use of adjacent SMA sensors

When the magnetic loops are too close to each other, the respective

magnetic fi elds could overlap and disturb the detection or damage the

sensors.

There are various solutions to prevent this:

- use different frequencies for each magnetic loop.

- keep the two groups of loops at least 2 meters away from each

other.

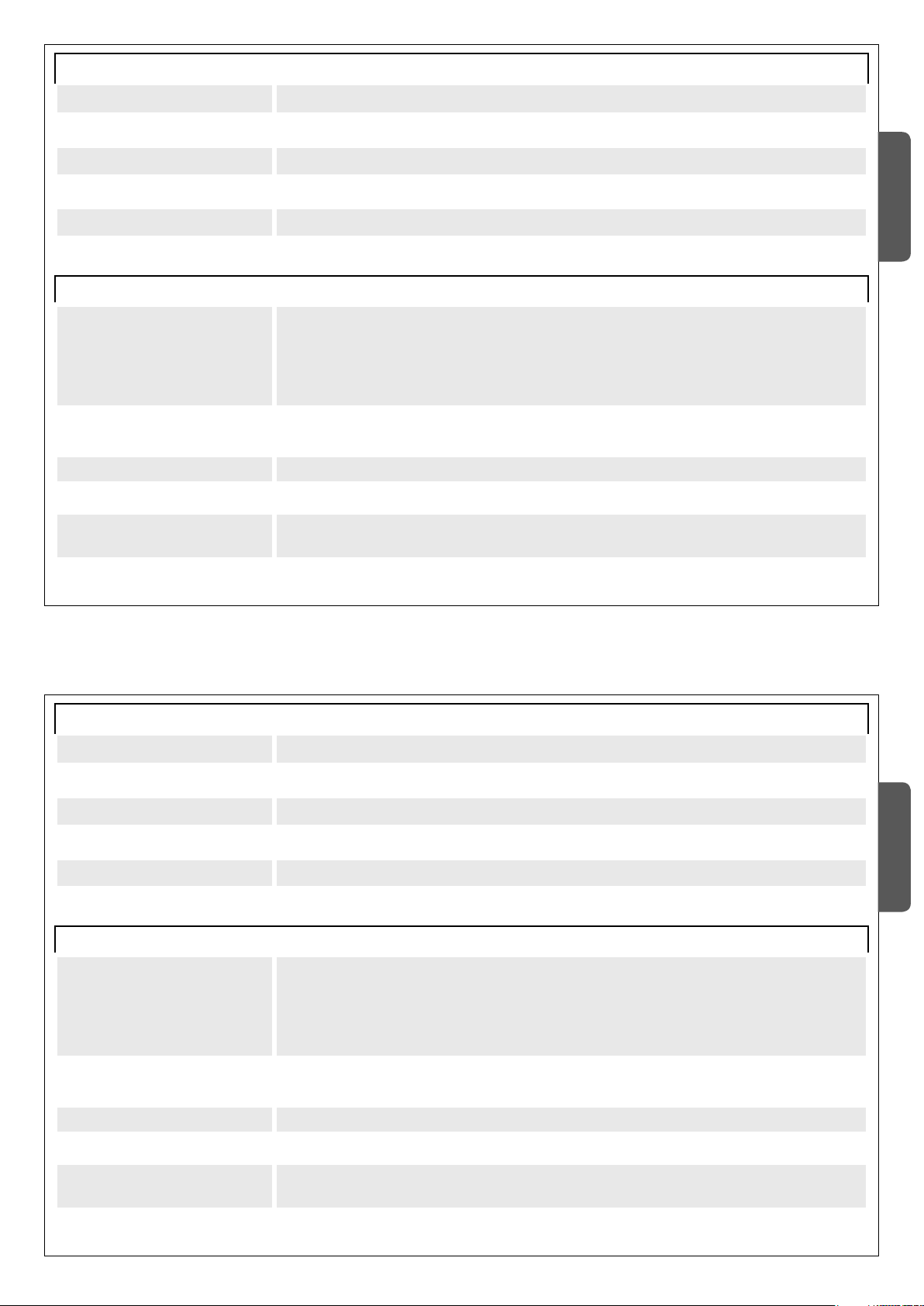

3.2.2. Interference caused by metal masses

If there is any metal under the loops, especially if they are laid in

reinforced concrete, it reduces the impedance and consequently the

sensitivity of the sensor.

To compensate this reduction, two turns can be added to the detection

loop.

Otherwise provide a minimum space of 150 mm between the magnetic

loop and the reinforcing.

If the loop tail is channelled

with other cables, ensure

that they are screened.

Clean and dry the cable duct

before laying the cable.

3. INSTALLING THE MAGNETIC LOOPS

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

4

4 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

3.1. Operating principles

The inductive loop sensor detects the presence of a vehicle on the

surface marked out by a cabled loop, formed of 2 or more runs of leads

beneath the road surface.

When a vehicle goes over the loop the relative inductance measured by

the sensor is reduced.

This detection activates a relay and its contacts are used to guide the

external devices.

The magnetic loop and the loop tail must be formed of a simple isolated

lead, without any connections, in multithread copper, with a minimum

section of 1.5 mm

2

(16 AWG).

It is not advisable to make connections to the magnetic loop or to the

power pack. However, if it is unavoidable they must be welded and

isolated in a waterproof case.

This is very important to guarantee long lasting detection reliability.

3.2. Operating limits

3.2.1. Use of adjacent SMA sensors

When the magnetic loops are too close to each other, the respective

magnetic fi elds could overlap and disturb the detection or damage the

sensors.

There are various solutions to prevent this:

- use different frequencies for each magnetic loop.

- keep the two groups of loops at least 2 meters away from each

other.

3.2.2. Interference caused by metal masses

If there is any metal under the loops, especially if they are laid in

reinforced concrete, it reduces the impedance and consequently the

sensitivity of the sensor.

To compensate this reduction, two turns can be added to the detection

loop.

Otherwise provide a minimum space of 150 mm between the magnetic

loop and the reinforcing.

If the loop tail is channelled

with other cables, ensure

that they are screened.

Clean and dry the cable duct

before laying the cable.

3. INSTALLING THE MAGNETIC LOOPS

Page 5

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

5

5 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

3.3.1. Dimensions

The magnetic loop must be rectangular with the longest side perpendicular

to the circulation direction. There must be a minimum width of 1 m.

The surface must measure at least 1 m

2

and no more than 30 m2. For a

traditional road we advise an area of 1.5 – 2 m2.

Table with indication of the number of turns per surface:

Area m2Number of turns

< 3 4

3 < 5 3

> 5 2

3.3.2. Magnetic loop tail

The tail is the connecting lead between the magnetic loop and the sensor.

It is formed of a twisted, armoured cable, or a pair in isolated multi-pole

copper, with a minimum section of 1.5 mm2 and twisted with 20 turns

per meter.

The tail must not be any longer than 25 m.

3.3. Magnetic loop geometry

Sensor

Loop tail

Magnetic loop

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

5

5 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

3.3.1. Dimensions

The magnetic loop must be rectangular with the longest side perpendicular

to the circulation direction. There must be a minimum width of 1 m.

The surface must measure at least 1 m

2

and no more than 30 m2. For a

traditional road we advise an area of 1.5 – 2 m2.

Table with indication of the number of turns per surface:

Area m2Number of turns

< 3 4

3 < 5 3

> 5 2

3.3.2. Magnetic loop tail

The tail is the connecting lead between the magnetic loop and the sensor.

It is formed of a twisted, armoured cable, or a pair in isolated multi-pole

copper, with a minimum section of 1.5 mm2 and twisted with 20 turns

per meter.

The tail must not be any longer than 25 m.

3.3. Magnetic loop geometry

Sensor

Loop tail

Magnetic loop

Page 6

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

6

6 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

4. CONNECTIONS

1 12 – 24 V ac/dc

2 12 – 24 V ac/dc

3 Loop 1

4 Loop 1

5 Loop 2

6 Loop 2

The relays in contacts 1

and 2 are prepared for

just security purposes

(photocell type).

7 Contact 2 (NC)

8 Contact 2 (COM)

9 Ground

10 Contact 1 (NC)

11 Contact 1 (COM)

Dipswitch OFF

(default)

Dipswitch ON

5. SETTING THE FUNCTIONS

5.1. Description

The leds and dipswitches for setting the functioning parameters

are in the front part of the sensors.

Use a screwdriver for the ON/OFF selection.

All the dipswitches are on OFF for default.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

6

6 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

4. CONNECTIONS

1 12 – 24 V ac/dc

2 12 – 24 V ac/dc

3 Loop 1

4 Loop 1

5 Loop 2

6 Loop 2

The relays in contacts 1

and 2 are prepared for

just security purposes

(photocell type).

7 Contact 2 (NC)

8 Contact 2 (COM)

9 Ground

10 Contact 1 (NC)

11 Contact 1 (COM)

Dipswitch OFF

(default)

Dipswitch ON

5. SETTING THE FUNCTIONS

5.1. Description

The leds and dipswitches for setting the functioning parameters

are in the front part of the sensors.

Use a screwdriver for the ON/OFF selection.

All the dipswitches are on OFF for default.

Page 7

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

7

7 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.2. Setting the parameters

5.2.1. Dipswitches 1 and 2: regulating working frequency

These dipswitches are used to select the

working frequency for the magnetic loop: this

is useful when there is more than one sensor

in a confi ned area. Generally, high frequency

is used for the magnetic loop with the highest

inductance.

Dipswitch 1 and 2 OFF: Frequency is regulated on HIGH

Dipswitch 1 OFF and 2 ON: Frequency is regulated on MEDIUM-HIGH

Dipswitch 1 ON and 2 OFF: Frequency is regulated on MEDIUM-LOW

Dipswitches 1 and 2 ON: Frequency is regulated on LOW

These dipswitches are used to regulate

the detection sensitivity. In areas with low

selection or interference, it is advisable to

lower the sensitivity.

Dipswitches 3 and 4 OFF: MAXIMUM detection sensitivity

Dipswitch 3 OFF and 4 ON: MEDIUM-MAXIMUM detection sensitivity.

Dipswitch 3 ON and 4 OFF: MEDIUM-MINIMUM detection sensitivity

Dipswitch 3 and 4 ON: MINIMUM detection sensitivity

5.2.2. Dip 3 e 4 - CH2 channel sensitivity regulation

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

7

7 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.2. Setting the parameters

5.2.1. Dipswitches 1 and 2: regulating working frequency

These dipswitches are used to select the

working frequency for the magnetic loop: this

is useful when there is more than one sensor

in a confi ned area. Generally, high frequency

is used for the magnetic loop with the highest

inductance.

Dipswitch 1 and 2 OFF: Frequency is regulated on HIGH

Dipswitch 1 OFF and 2 ON: Frequency is regulated on MEDIUM-HIGH

Dipswitch 1 ON and 2 OFF: Frequency is regulated on MEDIUM-LOW

Dipswitches 1 and 2 ON: Frequency is regulated on LOW

These dipswitches are used to regulate

the detection sensitivity. In areas with low

selection or interference, it is advisable to

lower the sensitivity.

Dipswitches 3 and 4 OFF: MAXIMUM detection sensitivity

Dipswitch 3 OFF and 4 ON: MEDIUM-MAXIMUM detection sensitivity.

Dipswitch 3 ON and 4 OFF: MEDIUM-MINIMUM detection sensitivity

Dipswitch 3 and 4 ON: MINIMUM detection sensitivity

5.2.2. Dip 3 e 4 - CH2 channel sensitivity regulation

Page 8

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

8

8 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.2.3. Dip 5 e 6 - CH1 channel sensitivity regulation

These dipswitches are used to regulate

the detection sensitivity. In areas with low

selection or interference, it is advisable to

lower the sensitivity.

Dipswitches 5 and 6 OFF: MAXIMUM detection sensitivity

Dipswitch 5 OFF and 6 ON: MEDIUM-MAXIMUM detection sensitivity.

Dipswitch 53 ON and 6 OFF: MEDIUM-MINIMUM detection sensitivity

Dipswitch 5 and 6 ON: MINIMUM detection sensitivity

5.2.4. Dipswitch 7 – automatically increases ASB sensitivity

This function automatically takes the sensor

sensitivity to maximum, so that irregular

shaped vehicles are recognised as well (e.g.

lorries)

Dipswitch 7 OFF – Automatic sensitivity increase DEACTIVATED

Dipswitch 7 ON – Automatic sensitivity increase ACTIVATED

5.2.5. Dipswitch 8 – Presence length

This dipswitch allows selecting either

permanent or limited detection.

It is advisable to regulate this dipswitch

on “permanent” to ensure access security.

Dipswitch 8 OFF – LIMITED PRESENCE: the sensor activates the output relay for a

preset time, after which the contact is released.

Dipswitch 8 ON – PERMANENT PRESENCE: the sensor leaves the output relay

active for as long as the vehicle is over the magnetic loop.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

8

8 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.2.3. Dip 5 e 6 - CH1 channel sensitivity regulation

These dipswitches are used to regulate

the detection sensitivity. In areas with low

selection or interference, it is advisable to

lower the sensitivity.

Dipswitches 5 and 6 OFF: MAXIMUM detection sensitivity

Dipswitch 5 OFF and 6 ON: MEDIUM-MAXIMUM detection sensitivity.

Dipswitch 53 ON and 6 OFF: MEDIUM-MINIMUM detection sensitivity

Dipswitch 5 and 6 ON: MINIMUM detection sensitivity

5.2.4. Dipswitch 7 – automatically increases ASB sensitivity

This function automatically takes the sensor

sensitivity to maximum, so that irregular

shaped vehicles are recognised as well (e.g.

lorries)

Dipswitch 7 OFF – Automatic sensitivity increase DEACTIVATED

Dipswitch 7 ON – Automatic sensitivity increase ACTIVATED

5.2.5. Dipswitch 8 – Presence length

This dipswitch allows selecting either

permanent or limited detection.

It is advisable to regulate this dipswitch

on “permanent” to ensure access security.

Dipswitch 8 OFF – LIMITED PRESENCE: the sensor activates the output relay for a

preset time, after which the contact is released.

Dipswitch 8 ON – PERMANENT PRESENCE: the sensor leaves the output relay

active for as long as the vehicle is over the magnetic loop.

Page 9

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

9

9 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.3. Signal leds

5.3.1. Red led

• Red led on – signals that the power is turned on. .

5.3.2. Green leds

• During normal functions, each time a vehicle passes over the magnetic loop the green led lights up for

a moment to signal it has detected the vehicle

• Each time the device is turned off (before activating or after the power is turned back on) during

automatic setting, the green led fl ashes for a few moments until the procedure has been completed.

• If the green led fl ashes twice for one second at regular intervals, it shows there is a fault in the

detection loop.

• If the green led remains on and then goes off briefl y when a vehicle passes (opposite to the normal

function), it shows that there has been a fault or malfunction that has been solved independently: in this

case reset the system

5.4. Reset button

SMA automatically starts setting the magnetic loops when the device is turned on.

A new setting could be required manually, for example if the sensor parameters have been reset

(changing the dipswitches): when the reset button is pressed the setting is started up.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

9

9 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.3. Signal leds

5.3.1. Red led

• Red led on – signals that the power is turned on. .

5.3.2. Green leds

• During normal functions, each time a vehicle passes over the magnetic loop the green led lights up for

a moment to signal it has detected the vehicle

• Each time the device is turned off (before activating or after the power is turned back on) during

automatic setting, the green led fl ashes for a few moments until the procedure has been completed.

• If the green led fl ashes twice for one second at regular intervals, it shows there is a fault in the

detection loop.

• If the green led remains on and then goes off briefl y when a vehicle passes (opposite to the normal

function), it shows that there has been a fault or malfunction that has been solved independently: in this

case reset the system

5.4. Reset button

SMA automatically starts setting the magnetic loops when the device is turned on.

A new setting could be required manually, for example if the sensor parameters have been reset

(changing the dipswitches): when the reset button is pressed the setting is started up.

Page 10

Spiraal 2

Spiraal 1

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

10

10 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

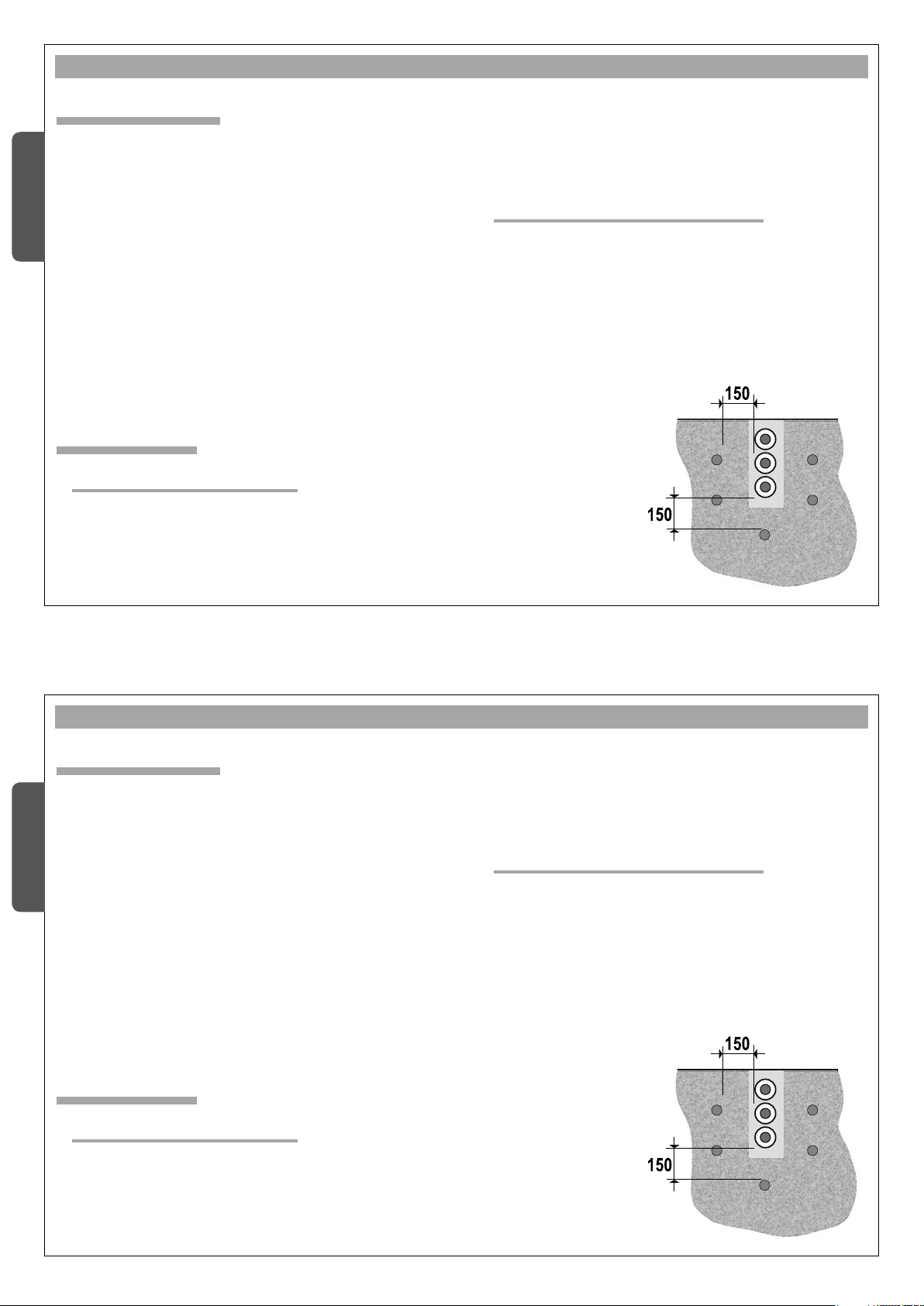

5.5. Driving direction recognition function

5.5.1. “Direction” mode description

When the vehicle magnetic detector is connected to an access control

device, a function could be required that recognises the driving direction

of the vehicle (in/out) to allow managing a vehicle counter, for example.

5.5.2. How the “Direction” mode works

To detect the direction of the vehicle 2 magnetic loops must be installed

in series and close to each other; depending on the direction of the

vehicle, SMA2 will activate one or other of the output relays.

ATTENTION: for the “Direction” mode to work correctly, the two

magnetic loops must be close enough so that the vehicle is detected by

them both at the same time.

The vehicle must not have left the fi rst loop before it meets the second.

Driving direction Relay activated

From loop 1 to loop 2 Relay 1

From loop 2 to loop 1 Relay 2

Spiraal 2

Spiraal 1

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

10

10 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.5. Driving direction recognition function

5.5.1. “Direction” mode description

When the vehicle magnetic detector is connected to an access control

device, a function could be required that recognises the driving direction

of the vehicle (in/out) to allow managing a vehicle counter, for example.

5.5.2. How the “Direction” mode works

To detect the direction of the vehicle 2 magnetic loops must be installed

in series and close to each other; depending on the direction of the

vehicle, SMA2 will activate one or other of the output relays.

ATTENTION: for the “Direction” mode to work correctly, the two

magnetic loops must be close enough so that the vehicle is detected by

them both at the same time.

The vehicle must not have left the fi rst loop before it meets the second.

Driving direction Relay activated

From loop 1 to loop 2 Relay 1

From loop 2 to loop 1 Relay 2

Page 11

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

11

11 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.5.3. How to activate the “Direction” mode

To activate this function, reach the sensor board (see fi gure

A) to change the confi guration of 3 jumpers and alter the

status of the NC to NO contacts, as shown in fi gures B and

C.

fi g.C

fi g. A

Using a fl at screwdriver, carefully force the

point as shown and carefully remove the board,

pressing on the front and pulling at the bottom

(the board slides along a track in the container).

Unsolder and then

re-solder the wires

From J6 to J5

and from J9 to J8

Jumper A = left

engaged

Jumpers B and

C = bridges

engaged

fi g. B

Jumper

Bridge

A

B

C

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Pag.

11

11 - Manual code:

119R V04

119 RV 04 ver.

0.1

0.1 03/2009 © CAME cancelli automatici s.p.a.

ENGLISH

5.5.3. How to activate the “Direction” mode

To activate this function, reach the sensor board (see fi gure

A) to change the confi guration of 3 jumpers and alter the

status of the NC to NO contacts, as shown in fi gures B and

C.

fi g.C

fi g. A

Using a fl at screwdriver, carefully force the

point as shown and carefully remove the board,

pressing on the front and pulling at the bottom

(the board slides along a track in the container).

Unsolder and then

re-solder the wires

From J6 to J5

and from J9 to J8

Jumper A = left

engaged

Jumpers B and

C = bridges

engaged

fi g. B

Jumper

Bridge

A

B

C

Page 12

FRANCE -

CAME France S.a .

CAME France S.a.

7, Rue Des Haras - Z.i. Des Hautes Patures

92737

Nanterre Cedex

Nanterre Cedex - - (+33) 1 46 13 05 05 - (+33) 1 46 13 05 00

CAME GmbH Nord

CAME GmbH Nord - DEUTSCHLAND

Akazienstraße, 9

16356

Seefeld

Seefeld - (+49) 33 3988390 _ (+49) 33 39883985

FRANCE -

CAME Au to ma ti sm es S.a.

CAME Automatismes S.a.

3, Rue Odette Jasse

13015

Marseille -

Marseille - (+33) 4 95 06 33 70 - (+33) 4 91 60 69 05

CAME GmbH Süd

CAME GmbH Süd - DEUTSCHLAND

Kornwestheimer Straße 37

70825

Kor ntal-

Korntal-Münchingen

- (+49) 71 5037830 _ (+49) 71 50378383

SPAIN -

CAME Au to ma ti sm os S.a.

CAME Automatismos S.a.

C/juan De Mariana, N. 17-local

28045

Madrid -

Madrid - (+34) 91 52 85 009 - (+34) 91 46 85 442

CAME Am er ic as Au to mation Llc

CAME Americas Automation Llc - U.S.A

1560 Sawgrass Corporate Pkwy, 4th Floor

Sunrise

Sunrise, FL 33323 - (+1) 305 433 3307 _ (+1) 305 396 3331

SPAIN -

CAME Au to ma ti sm os C at al un ya S.a .

CAME Automatismos Catalunya S.a.

P.i. Moli Dels Frares N. 23 C/a

08620

Sant V ic en c De l Ho rt s

Sant Vicenc Del Horts - - (+34) 93 65 67 694 - (+34) 93 67 24 505

CAME Middle East F zc o -

CAME Middle East Fzco - U.A.E.

Po Box 17131 Warehouse N. Be02 - South Zone, Jebel Ali Free Zone

Dubai

Dubai - (+971) 4 8860046 _ (+971) 4 8860048

PORTUGAL -

Paf - CAME

Paf - CAME

Estrada Nacional 249-4 Ao Km 4,35 - Cabra Figa - Trajouce

2635-047

Rio De Mouro -

Rio De Mouro - (+351) 219 257 471 - (+35) 219 257 485

CAME Polska Sp.Zo.o -

CAME Polska Sp.Zo.o - POLAND

Ul. Ordona 1

01-237

War sz aw a

Warszawa - (+48) 22 8365076 _ (+48) 22 8363296

UNITED KINGDOM -

CAME United King do m Lt d.

CAME United Kingdom Ltd.

Unit 3 Orchard Business Park - Town Street, Sandiacre

Nottingham

Nottingham Ng10 5du - (+44) 115 9210430 - (+44) 115 9210431

S.c. C AM E Ro mania S. r.l. -

S.c. CAME Romania S.r.l. - ROMANIA

B-dul Mihai Eminescu, Nr. 2, Bloc R2 - Scara A, Parter, Ap. 3

Buftea, Judet Ilfov

Bucarest

Bucarest

- (+40) 21 3007344 _ (+40) 21 3007344

BELGIUM -

CAME Belgium Spr l

CAME Belgium Sprl

Zoning Ouest 7

7860

Lessines -

Lessines - (+32) 68 333014 - (+32) 68 338019

CAME Russia

CAME Russia - RUSSIA

Leningradskij Prospekt, Dom 80 - Pod’ezd 3, offi ce 608

125190,

Moskva

Moskva - (+7) 495 937 33 07 _ (+7) 495 937 33 08

ITALIA -

CAME Cancelli A ut om at ic i S.p.a.

CAME Cancelli Automatici S.p.a.

Via Martiri Della Libertà, 15

31030

Dosson Di Casie r

Dosson Di Casier (TV) - (+39) 0422 4940 _ (+39) 0422 4941

Informazioni Commerciali 800 848095 -

www.came.it

www.came.it

CAME Nord s.r.l.

CAME Nord s.r.l. - ITALIA

Piazza Castello, 16

20093

Cologno Monzese

Cologno Monzese (MI)

- (+39) 02 26708293 _ (+39) 02 25490288

ITALIA -

CAME Ser vi ce I ta li a S.r.l.

CAME Service Italia S.r.l.

Via Della Pace, 28

31030

Dosson di Casie r

Dosson di Casier (TV)

- (+39) 0422 383532 _ (+39) 0422 490044

Assistenza Tecnica 800 29583 0

Assistenza Tecnica 800 295830

CAME Sud s.r.l .

CAME Sud s.r.l. - ITALIA

Via F. Imparato, 198 - Cm2 Lotto A/7

80146

Napoli -

Napoli - (+39) 081 7524455 _ (+39) 081 7529109

En glish

English - Manual code:

119RV 0 4

119RV04 ver.

0.1

0.1 03/2009 © C AME cancelli automatici s.p.a.

The data and information reported in this installation manual are susceptible to change at any time and

without obligation on CAME cancelli automatici s.p.a. to notify users.

The declaration de conformit y and other technical documentation are available on our website ww w.came.it

BUY-TO-SELL PRODUCT

FRANCE -

CAME France S.a .

CAME France S.a.

7, Rue Des Haras - Z.i. Des Hautes Patures

92737

Nanterre Cedex

Nanterre Cedex - - (+33) 1 46 13 05 05 - (+33) 1 46 13 05 00

CAME GmbH Nord

CAME GmbH Nord - DEUTSCHLAND

Akazienstraße, 9

16356

Seefeld

Seefeld - (+49) 33 3988390 _ (+49) 33 39883985

FRANCE -

CAME Au to ma ti sm es S.a.

CAME Automatismes S.a.

3, Rue Odette Jasse

13015

Marseille -

Marseille - (+33) 4 95 06 33 70 - (+33) 4 91 60 69 05

CAME GmbH Süd

CAME GmbH Süd - DEUTSCHLAND

Kornwestheimer Straße 37

70825

Kor ntal-

Korntal-Münchingen

- (+49) 71 5037830 _ (+49) 71 50378383

SPAIN -

CAME Au to ma ti sm os S.a.

CAME Automatismos S.a.

C/juan De Mariana, N. 17-local

28045

Madrid -

Madrid - (+34) 91 52 85 009 - (+34) 91 46 85 442

CAME Am er ic as Au to mation Llc

CAME Americas Automation Llc - U.S.A

1560 Sawgrass Corporate Pkwy, 4th Floor

Sunrise

Sunrise, FL 33323 - (+1) 305 433 3307 _ (+1) 305 396 3331

SPAIN -

CAME Au to ma ti sm os C at al un ya S.a .

CAME Automatismos Catalunya S.a.

P.i. Moli Dels Frares N. 23 C/a

08620

Sant V ic en c De l Ho rt s

Sant Vicenc Del Horts - - (+34) 93 65 67 694 - (+34) 93 67 24 505

CAME Middle East F zc o -

CAME Middle East Fzco - U.A.E.

Po Box 17131 Warehouse N. Be02 - South Zone, Jebel Ali Free Zone

Dubai

Dubai - (+971) 4 8860046 _ (+971) 4 8860048

PORTUGAL -

Paf - CAME

Paf - CAME

Estrada Nacional 249-4 Ao Km 4,35 - Cabra Figa - Trajouce

2635-047

Rio De Mouro -

Rio De Mouro - (+351) 219 257 471 - (+35) 219 257 485

CAME Polska Sp.Zo.o -

CAME Polska Sp.Zo.o - POLAND

Ul. Ordona 1

01-237

War sz aw a

Warszawa - (+48) 22 8365076 _ (+48) 22 8363296

UNITED KINGDOM -

CAME United King do m Lt d.

CAME United Kingdom Ltd.

Unit 3 Orchard Business Park - Town Street, Sandiacre

Nottingham

Nottingham Ng10 5du - (+44) 115 9210430 - (+44) 115 9210431

S.c. C AM E Ro mania S. r.l. -

S.c. CAME Romania S.r.l. - ROMANIA

B-dul Mihai Eminescu, Nr. 2, Bloc R2 - Scara A, Parter, Ap. 3

Buftea, Judet Ilfov

Bucarest

Bucarest

- (+40) 21 3007344 _ (+40) 21 3007344

BELGIUM -

CAME Belgium Spr l

CAME Belgium Sprl

Zoning Ouest 7

7860

Lessines -

Lessines - (+32) 68 333014 - (+32) 68 338019

CAME Russia

CAME Russia - RUSSIA

Leningradskij Prospekt, Dom 80 - Pod’ezd 3, offi ce 608

125190,

Moskva

Moskva - (+7) 495 937 33 07 _ (+7) 495 937 33 08

ITALIA -

CAME Cancelli A ut om at ic i S.p.a.

CAME Cancelli Automatici S.p.a.

Via Martiri Della Libertà, 15

31030

Dosson Di Casie r

Dosson Di Casier (TV) - (+39) 0422 4940 _ (+39) 0422 4941

Informazioni Commerciali 800 848095 -

www.came.it

www.came.it

CAME Nord s.r.l.

CAME Nord s.r.l. - ITALIA

Piazza Castello, 16

20093

Cologno Monzese

Cologno Monzese (MI)

- (+39) 02 26708293 _ (+39) 02 25490288

ITALIA -

CAME Ser vi ce I ta li a S.r.l.

CAME Service Italia S.r.l.

Via Della Pace, 28

31030

Dosson di Casie r

Dosson di Casier (TV)

- (+39) 0422 383532 _ (+39) 0422 490044

Assistenza Tecnica 800 29583 0

Assistenza Tecnica 800 295830

CAME Sud s.r.l .

CAME Sud s.r.l. - ITALIA

Via F. Imparato, 198 - Cm2 Lotto A/7

80146

Napoli -

Napoli - (+39) 081 7524455 _ (+39) 081 7529109

En glish

English - Manual code:

119RV 0 4

119RV04 ver.

0.1

0.1 03/2009 © C AME cancelli automatici s.p.a.

The data and information reported in this installation manual are susceptible to change at any time and

without obligation on CAME cancelli automatici s.p.a. to notify users.

The declaration de conformit y and other technical documentation are available on our website ww w.came.it

BUY-TO-SELL PRODUCT

Loading...

Loading...