Page 1

INSTALLATION MANUAL

KR300 - KR302 - KR310 - KR312

KR510 - KR512

GEARMOTOR FOR SWING GATES

FA00290-EN

English

EN

Page 2

p.

2

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

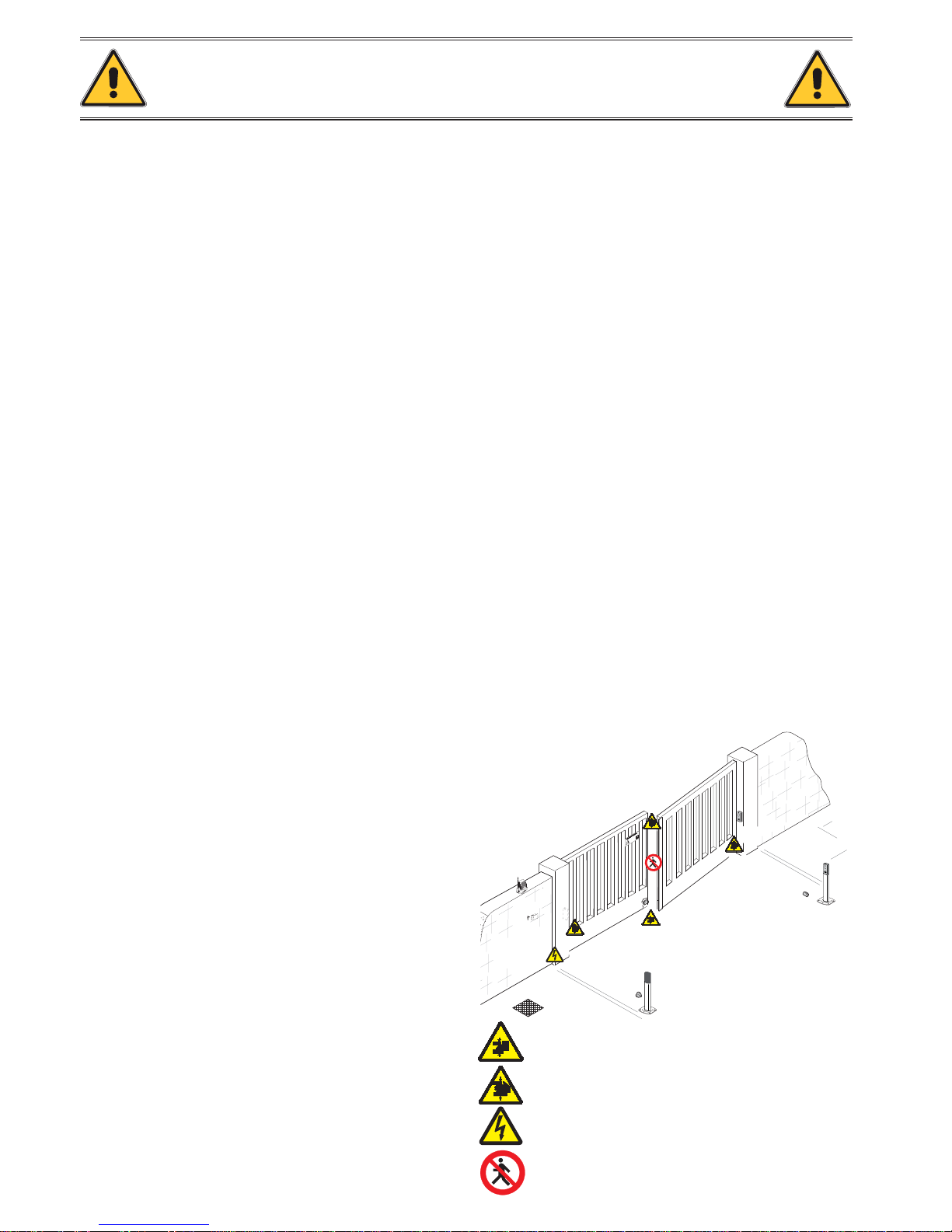

Danger of hand crushing

Danger! High voltage.

No transiting while the barrier is moving

Danger of foot crushing

WARNING!

important safety instructions for people:

READ CAREFULLY!

PREMISE

• THIS PRODUCT SHOULD ONLY BE USED FOR THE PURPOSE FOR

WHICH IT WAS EXPLICITLY DESIGNED. ANY OTHER USE IS DANGEROUS.

CAME S.

P.A. IS NOT LIABLE FOR ANY DAMAGE CAUSED BY

IMPROPER

, WRONGFUL AND UNREASONABLE USE • KEEP THESE WARNINGS

TOGETHER WITH THE INSTALLATION AND OPERATION MANUALS THAT COME WITH

THE OPERATOR

.

BEFORE INSTALLING

(

CHECKING WHAT'S THERE: IF SOMETHING IS MISSING, DO NOT CONTINUE UNTIL

YOU HAVE COMPLIED WITH ALL SAFETY PROVISIONS

)

• CHECK THAT THE AUTOMATED PA RTS ARE IN PROPER MECHANICAL ORDER, THAT

THE OPERATOR IS LEVEL AND ALIGNED, AND THAT IT OPENS AND CLOSES PROPERLY.

M

AKE SURE YOU HAVE SUITABLE MECHANICAL STOPS • IF THE OPERATOR IS TO BE

INSTALLED AT A HEIGHT OF LESS THAN 2.5 M FROM THE GROUND OR OTHER ACCESS

LEVEL, MAKE SURE YOU HAVE ANY NECESSARY PROTECTIONS AND/OR WARNINGS IN

PLACE • IF ANY PEDESTRIAN OPENINGS ARE FITTED INTO THE OPERATOR, THERE

MUST ALSO BE A A SYSTEM TO BLOCK THEIR OPENING WHILE THEY ARE MOVING •

M

AKE SURE THAT THE OPENING AUTOMATED DOOR OR GATE CANNOT ENTRAP PEOPLE

AGAINST THE FIXED PART S OF THE OPERATOR • DO NOT FIT UPSIDE DOWN OR ONTO

ELEMENTS THAT COULD BEND. IF NECESSARY, ADD SUITABLE REINFORCEMENTS TO

THE ANCHORING POINTS • DO NOT INSTALL DOOR OR GATE LEAVES ON TILTED

SURFACES • MAKE SURE ANY SPRINKLER SYSTEMS CANNOT WET THE OPERATOR

FROM THE GROUND UP • MAKE SURE THE TEMPERATURE RANGE SHOWN ON THE

PRODUCT LITERATURE IS SUITABLE TO THE CLIMATE WHERE IT WILL BE INSTALLED

• F

OLLOW ALL INSTRUCTIONS AS IMPROPER INSTALLATION MAY RESULT IN SERIOUS

BODILY INJURY • IT IS IMPORTANT TO FOLLOW THESE INSTRUCTIONS FOR THE SAFETY

OF PEOPLE. KEEP THESE INSTRUCTIONS.

I

NSTALLING

• SUITABLY SECTION OFF AND DEMARCATE THE ENTIRE INSTALLATION SITE TO

PREVENT UNAUTHORIZED PERSONS FROM ENTERING THE AREA, ESPECIALLY MINORS

AND CHILDREN • BE CAREFUL WHEN HANDLING OPERATORS THAT WEIGH OVER

20

KG. IF NEED BE, USE PROPER SAFETY HOISTING EQUIPMENT • ALL OPENING

COMMANDS (THAT IS, BUTTONS, KEY SWITCHES, MAGNETIC READERS, AND SO ON)

MUST BE INSTALLED AT LEAST 1.85 M FROM THE PERIMETER OF THE GATE'S

WORKING AREA, OR WHERE THEY CANNOT BE REACHED FROM OUTSIDE THE GATE.

A

LSO, ANY DIRECT COMMANDS (WHETHER BUTTONS, TOUCH PANELS, AND SO ON)

MUST BE INSTALLED AT LEAST 1.5 M FROM THE GROUND AND MUST NOT BE

REACHABLE BY UNAUTHORIZED PERSONS • ALL MAINTAINED ACTION COMMANDS,

MUST BE FITTED IN PLACES FROM WHICH THE MOVING GATE LEAVES AND TRANSIT

AND DRIVING AREAS ARE VISIBLE • APPLY, IF MISSING, A PERMANENT SIGN SHOWING

THE POSITION OF THE RELEASE DEVICE • BEFORE DELIVERING TO THE USERS, MAKE

SURE THE SYSTEM IS EN 12453 STANDARD COMPLIANT (REGARDING IMPACT

FORCES), AND ALSO MAKE SURE THE SYSTEM HAS BEEN PROPERLY ADJUSTED AND

THAT ANY SAFETY, PROTECTION AND MANUAL RELEASE DEVICES ARE WORKING

PROPERLY • APPLY WARNING SIGNS WHERE NECESSARY AND IN A VISIBLE PLACE,

(

SUCH AS, SUCH AS THE GATE'S PLATE

SPECIAL USER-INSTRUCTIONS AND RECOMMENDATIONS

• KEEP GATE OPERATION AREAS CLEAN AND FREE OF ANY OBSTRUCTIONS. MAKE

SURE THAT THE PHOTOCELLS ARE FREE OF ANY OVERGROWN VEGETATION AND THAT

THE OPERATOR'S AREA OF OPERATION IS FREE OF ANY OBSTRUCTIONS • DO NOT

ALLOW CHILDREN TO PLAY WITH FIXED COMMANDS, OR TO LOITER IN THE GATE'S

MANEUVERING AREA. KEEP ANY REMOTE CONTROL TRANSMITTERS OR ANY OTHER

COMMAND DEVICE AWAY FROM CHILDREN, TO PREVENT THE OPERATOR FROM BEING

ACCIDENTALLY ACTIVATED. • THE APPARATUS MAY BE USED BY CHILDREN OF EIGHT

YEARS AND ABOVE AND BY PHYSICALLY, MENTALLY AND SENSORY-CHALLENGED

PEOPLE, OR EVEN ONES WITHOUT ANY EXPERIENCE, PROVIDED THIS HAPPENS UNDER

CLOSE SUPERVISION OR ONCE THEY HAVE BEEN PROPERLY INSTRUCTED TO USE THE

APPARATUS SAFELY AND TO THE POTENTIAL HAZARDS INVOLVED. CHILDREN MUST

NOT PLAY WITH THE APPARATUS. CLEANING AND MAINTENANCE BY USERS MUST

NOT BE DONE BY CHILDREN, UNLESS PROPERLY SUPERVISED • FREQUENTLY CHECK

THE SYSTEM FOR ANY MALFUNCTIONS OR SIGNS OF WEAR AND TEAR OR DAMAGE

TO THE MOVING STRUCTURES, TO THE COMPONENT PART S, ALL ANCHORING POINTS,

INCLUDING CABLES AND ANY ACCESSIBLE CONNECTIONS. KEEP ANY HINGES, MOVING

JOINTS AND SLIDE RAILS PROPERLY LUBRICATED • PERFORM FUNCTIONAL CHECKS

ON THE PHOTOCELLS AND SENSITIVE SAFETY EDGES, EVERY SIX MONTHS. TO CHECK

WHETHER THE PHOTOCELLS ARE WORKING, WAVE AN OBJECT IN FRONT OF THEM

WHILE THE GATE IS CLOSING; IF THE OPERATOR INVERTS ITS DIRECTION OF TRAVEL

OR SUDDENLY STOPS, THE PHOTOCELLS ARE WORKING PROPERLY. THIS IS THE ONLY

MAINTENANCE OPERATION TO DO WITH THE POWER ON. CONSTANTLY CLEAN THE

PHOTOCELLS' GLASS COVERS USING A SLIGHTLY WATER-MOISTENED CLOTH; DO NOT

USE SOLVENTS OR OTHER CHEMICAL PRODUCTS THAT MAY RUIN THE DEVICES • IF

REPAIRS OR MODIFICATIONS ARE REQUIRED TO THE SYSTEM, RELEASE THE OPERATOR

AND DO NOT USE IT UNTIL SAFETY CONDITIONS HAVE BEEN RESTORED • CUT OFF

THE POWER SUPPLY BEFORE RELEASING THE OPERATOR FOR MANUAL OPENINGS AND

BEFORE ANY OTHER OPERATION, TO PREVENT POTENTIALLY HAZARDOUS SITUATIONS.

R

EAD THE INSTRUCTIONS IF THE POWER SUPPLY CABLE IS DAMAGED, IT MUST

BE REPLACED BY THE MANUFACTURER OR AUTHORIZED TECHNICAL ASSISTANCE

SERVICE, OR IN ANY CASE, BY SIMILARLY QUALIFIED PERSONS, TO PREVENT ANY

RISK • IT IS FORBIDDEN FOR USERS TO PERFORM ANY OPERATIONS THAT ARE NOT

EXPRESSLY REQUIRED OF THEM AND WHICH ARE NOT LISTED IN THE MANUALS.

FOR ANY REPAIRS, MODIFICATIONS / ADJUSTMENTS, AND FOR EXTRA-ORDINARY

MAINTENANCE, CALL TECHNICAL ASSISTANCE • LOG THE JOB AND CHECKS INTO

THE PERIODIC MAINTENANCE LOG .

F

URTHER RECOMMENDATIONS FOR ALL

•

KEEP CLEAR OF HINGES AND MECHANICAL MOVING PAR TS • DO NOT ENTER

THE OPERATOR'S AREA OF OPERATION WHEN IT IS MOVING • DO NOT COUNTER

THE OPERATOR'S MOVEMENT AS THIS COULD RESULT IN DANGEROUS SITUATIONS

• A

LWAY S PAY SPECIAL ATTENTION TO ANY DANGEROUS POINTS, WHICH HAVE TO

BE LABELED WITH SPECIFIC PICTOGRAMS AND/OR BLACK AND YELLOW STRIPES •

W

HILE USING A SELECTOR SWITCH OR A COMMAND IN MAINTAINED ACTIONS, KEEP

CHECKING THAT THERE ARE NO PERSONS WITHIN THE OPERATING RANGE OF ANY

MOVING PA RTS , UNTIL THE COMMAND IS RELEASED • THE GATE MAY MOVE AT

ANY TIME AND WITHOUT WARNING • ALWA YS CUT OFF THE MAINS POWER SUPPLY

BEFORE PERFORMING ANY MAINTENANCE OR CLEANING

.

Page 3

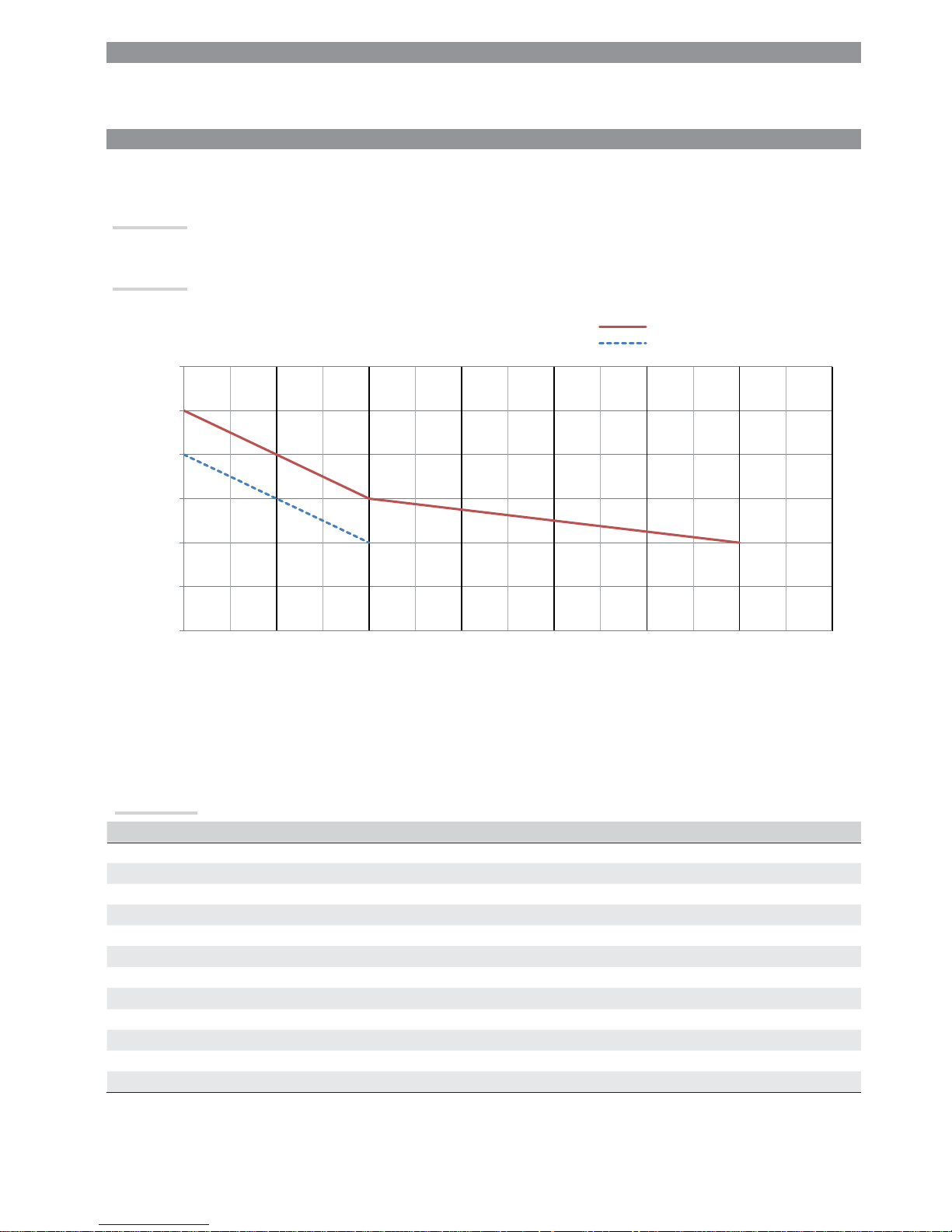

0

200

400

600

800

1000

1200

2 2,5 3 3,5 4 4,5 5 5,25

KR510 - KR512

KR300 - KR302 - KR310 - KR312

p.

3

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Technical data

Type KR300 - KR310 KR302 - KR312 KR510 KR512

Protection rating (IP) 54 54 54 54

Power supply (V - 50/60 Hz) 230 AC 230 AC 230 AC 230 AC

Power supply motor (V) 230 AC 230 AC 230 AC 230 AC

Ma x d r a w ( A) 1.1 1.1 1.1 1.1

Power (W) 130 130 130 130

Thrust (N) 400 ÷ 3000 400 ÷ 3000 400 ÷ 3000 400 ÷ 3000

Opening time at 90° (s) 22 18 34 30

Duty cycle (%) 30303030

Operating temperature (°C) -20 ÷ +55 -20 ÷ +55 -20 ÷ +55 -20 ÷ +55

Condenser (μF) 8 8 8 8

Motor's thermal monitoring (°C) 150 150 150 150

Weight (Kg) 10 10 12 12

DESCRIPTION

KR300 - KR302 Irreversible gearmotor for swing gates with leaves of up to 3 m long.

KR310 - KR312 Irreversible gearmotor for swing gates with leaves of up to 3 m long with opening and closing limit-switch micro switches.

KR510 - KR512 Irreversible gearmotor for swing gates with leaves of up to 5 m long with opening and closing limit-switch micro switches.

Intended use

This gearmotor is designed to power and operate swing gates in private homes and apartment blocks.

Any installation and/or use other than that specifi ed in this manual is forbidden.

Limits to use

LEGEND

This symbol shows which parts to read carefully.

⚠

This symbol shows which parts describe safety issues

☞

This symbol shows which parts to tell users about.

Gate-leaf weight (Kg)

Gate-leaf length (m)

⚠

We suggest you always fi t an electrolock onto swing gates for a more reliable closure.

You must install electrolocks onto irreversible operators with gate leaves exceeding 2.5 m.

Page 4

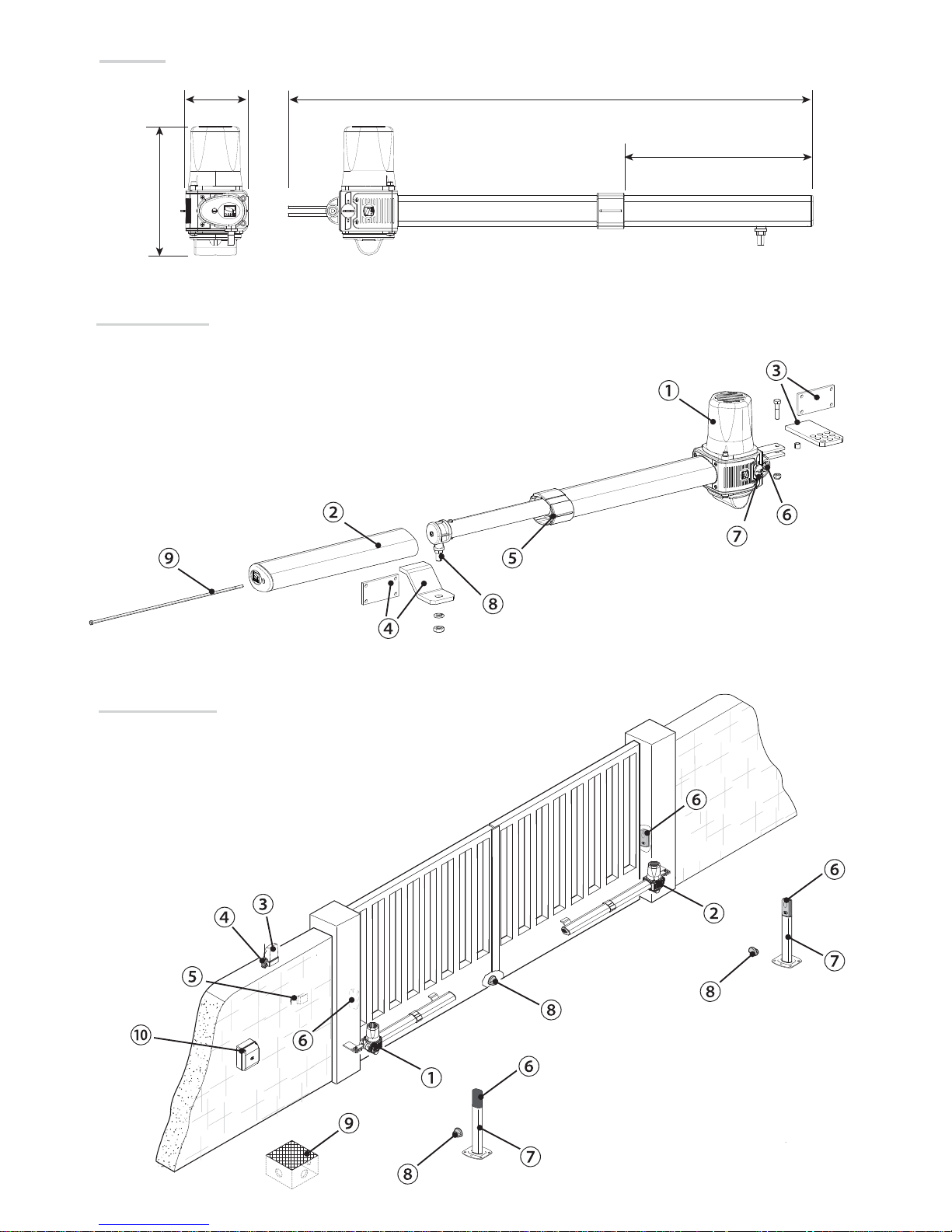

113

234

956 * - 1356 **

304 * - 504 **

*

KR300 - KR302 - KR310 - KR312

**

KR510 - KR512

p.

4

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Standard installation

1. Left-side gearmotor

2. Right-side gearmotor

3. Flashing light

4. Antenna

5. Control device

6. Photocells

7. Photocells post

8. Mechanical gate stop

9. Junction pit

10. Control panel

Description of parts

1. Gearmotor

2. Cover

3. Post braces with bushing, fastening screw and self-locking nut

4. Gates braces with grower elastic washer and self-locking nut

5. Limit-switch adjusting screws

6. Release lock

7. Release lever

8. Pinion

9. Cover-fastening screw

Dimensions

(mm)

Page 5

p.

5

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

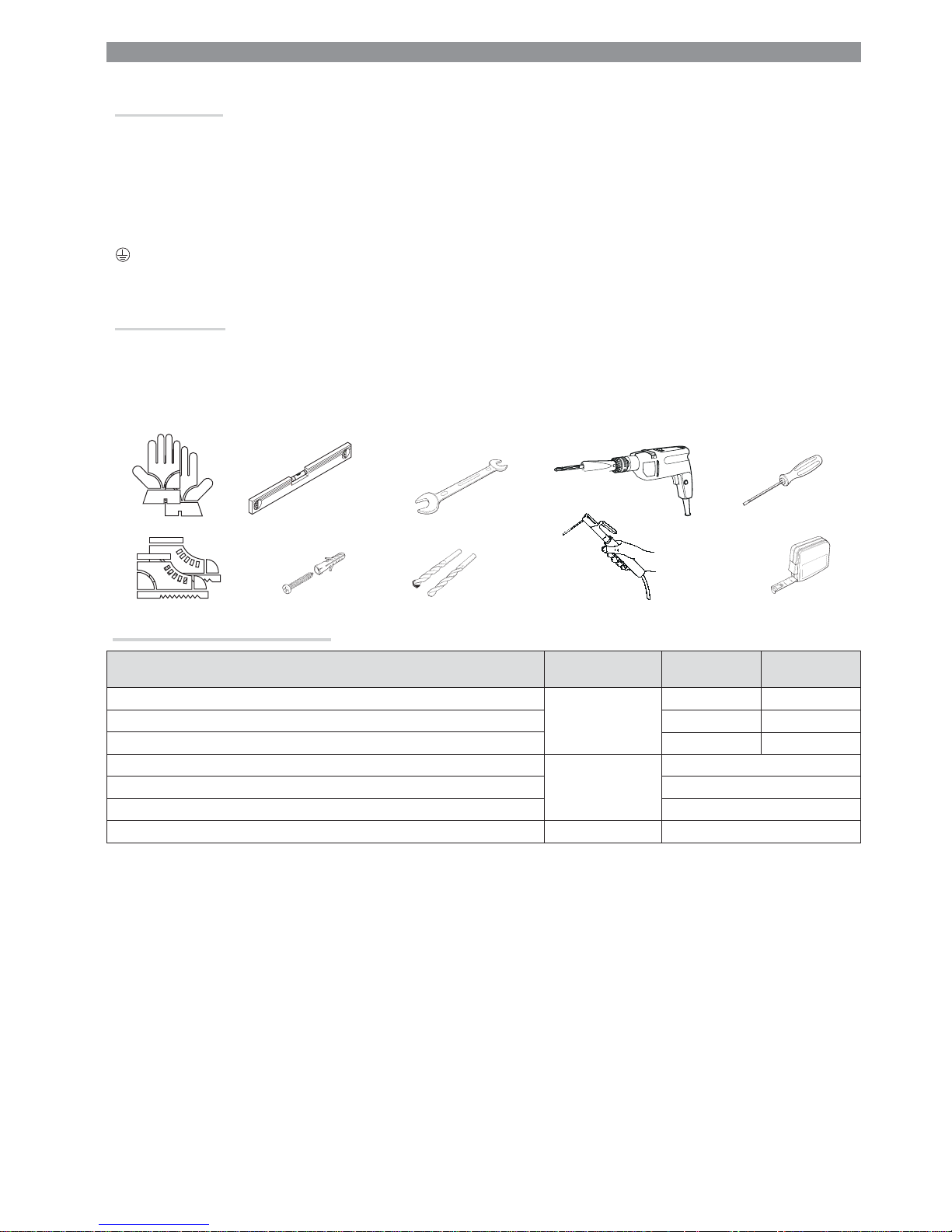

GENERAL INSTALLATION INDICATIONS

⚠

Only skilled, qualified staff must install this product.

Preliminary checks

⚠

Before beginning, do the following:

• check that the gate structure is sturdy enough, the hinges work efficiently and that there is no friction between the fixed and moving parts;

• make sure that measurement C does not exceed the value shown in the reference table;• make sure you have fitted opening and closing

mechanical gate stops;

• make sure that the point where the gearmotor is fastened is protected from any impacts and that the anchoring surface is solid enough;

• make sure you have set up a suitable dual pole cut off device along the power supply that is compliant with the installation rules. It should

completely cut off the power supply according to category III surcharge conditions (that is, with minimum contact openings of 3 mm);

•

make sure that any connections inside the container (ones that ensure continuity to the protection circuit) are fitted with additional insulation

with respect to those of other electrical parts inside:

•set up suitable tubes and conduits for the electric cables to pass through, making sure they are protected from any mechanical damage.

Tools and materials

Make sure you have all the tools and materials you will need for installing in total safety and in compliance with applicable regulations. The figure

shows some of the equipment installers will need.

Cable types and minimum thicknesses

Connection Cable type

Cable length

1 < 15 m

Cable length

15 < 30 m

Control panel power supply 230 V AC

H05RN-F

3G x 1,5 mm

2

3G x 2,5 mm

2

Power supply to motor 230 V AC 4G x 1,5 mm

2

4G x 2,5 mm

2

Flashing light 2 x 0,5 mm

2

Photocell transmitters

FROR CEI 20-22

CEI EN

50267-2-1

2 x 0,5 mm

2

Photocell receivers 4 x 0,5 mm

2

Command and safety device 2 x 0,5 mm

2

Antenna RG58 max 10 m

If cable lengths di er from those specifi ed in the table, establish the cable sections depending on the actual power draw of the connected

devices and according to the provisions of regulation CEI EN 60204-1.

For multiple, sequential loads along the same line, the dimensions on the table need to be recalculated according to the actual power draw and

distances. For connecting products that are not contemplated in this manual, see the literature accompanying said products.

Page 6

E

p.

6

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Fastening the braces

Establish the point the gate and post braces will be fitted, while respecting the quotas shown on the table.

The greater the gate leaf's opening angle, the greater the opening speed and the slower is the gearmotor's thrust.

The smaller the gate leaf's opening angle, the slower the opening speed and the greater is the gearmotor's thrust.

Application dimension (mm)

KR300 - KR302 - KR310 - KR312

Leaf opening arc (°) A B C MAX E

90° 130 130 60 910

120° 130 110 50 910

KR510 - KR512

Leaf opening arc (°) A B C MAX E

90° 200 200 120 1310

130° 200 140 70 1310

INSTALLATION

⚠

The following illustrations are just examples, in that the space available for fitting the operator and accessories varies depending on the overall

dimensions. It is up to the installer to find the most suitable solution.

The drawings refer to the left-side gearmotor. Install the operator on the right, symmetrically.

Corrugated tube laying

Fit junction boxes and corrugates tubes for incoming connections from the junction pit.

The number of tubes depends on the type of system and the accessories you

are going to fit.

Gate bracket

Post bracket

Page 7

p.

7

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Assemble and weld the two parts of the post brace.

Fasten the brace to the established point, using suitable plugs and screws. If the post is metallic, weld the brace.

Weld the gate brace to the leaf following the measurements shown on the table.

On non-metallic leaves, assemble and weld the two parts of the brace - use suitable screws to fasten.

Page 8

W V U W V U

ZA3N - ZA3P

p.

8

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Open the leaf, fit the pinion into the gate brace and fasten it using the supplied washer and nut.

Connecting to the control panel

⚠

Warning! Before working on the control panel, cut off the main current supply and, if present, remove any batteries.

Fastening the gearmotor

Lubricate the bushing and fit into one of the post brace holes (the holes on the brace are for varying the gate's opening angle.

Fasten the joint to the post brace using the bolt and nut.

230 V AC gearmotor fi tted on the left (inside

view), with delayed opening.

230 V AC gearmotor fi tted on the right (inside

view), with delayed closing.

Page 9

p.

9

- Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Establishing the limit-switch points

Before establishing the limit-switch points, you must remove the cover by loosening the fastening screw.

For closing

Release the gearmotor.

Push the leaf to its closing strike position.

Send a (2-4) closing command and turn the threaded rod counter clock-wise until the closing microswitch activates to stop the gearmotor.

Leave the nut loose on the threaded rod.

Do the same procedure for the right-side gearmotor.

The closing microswitches are positioned at the far ends of their travel range.

Page 10

A

B

p.

10

10 - Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

INWARD OPENING CONNECTIONS AND INSTALLING

Fastening the braces

Measure quotas A and B (while respecting the quotas shown on the table) to establish the point where the post brace joined with non-supplied

supplementary brace will be fastened.

Application dimension (mm)

KR300 - KR302 - KR310

Leaf opening arc (°) A B E

90° 130 130 910

KR510 - KR512

Leaf opening arc (°) A B E

90° 200 200 1310

For opening

Release the gearmotor.

Reach the wanted leaf-opening point.

Send a (2-3) opening command and turn the threaded rod clockwise until the microswitch activates to stop the gearmotor.

Leave the nut loose on the threaded rod.

Do the same procedure for the right-side gearmotor.

Page 11

E

p.

11

11 - M anual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Open the gate to 90°, weld or fasten the gate brace using suitable bolts (while respecting quota E as shown in the table).

Assemble and weld the supplementary brace to the post brace. Fasten the supplementary brace to the post.

Fasten the gearmotor to the braces by using the supplied nuts and bolts.

Page 12

ZA3N - ZA3P

W V U W V U

p.

12

12 - Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Establishing the limit-switch points

Carefully follow the previous description.

➡To establish the opening limit-switch point, use the threaded rod .

To establish the closing limit-switch point, use the threaded rod .

230 V AC gearmotor fi tted on the left (inside

view), with delayed opening.

230 V AC gearmotor fi tted on the right (inside

view), with delayed closing.

Connecting to the control panel

⚠

Warning! Before working on the control panel, cut off the main current supply and, if present, remove any batteries.

Page 13

90°

90°

p.

13

13 - Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

RELEASING

LOCKING

RELEASING THE GEARMOTOR

⚠

This procedure must be done with the main power cut o .

⚠

The gearmotor's manual release may cause unwanted movement of the gate, if the latter has any mechanical issues or if it is not balanced.

FINAL OPERATIONS

Proceed with the fi nal steps, only once you have completed all connections and made the gate operational.

Fit the cover and fasten the screw.

Page 14

p.

14

14 - Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

MAINTENANCE

Periodic maintenance

☞ Before doing any maintenance, cut off the power supply, to prevent any hazardous situations caused by accidentally activating the operator.

Periodic maintenance log kept by users (every six months)

Date Notes Signature

TROUBLESHOOTING

TROUBLES POSSIBLE CAUSES FIXES

It neither opens

nor closes

• Power supply missing

• The gearmotor is stuck

• The transmitter's battery is run down

• The transmitter is broken

• The stop button is either stuck or broken

• The opening/closing button or the key-switch selector is stuck

• Check main power supply

• Lock the gearmotor

• Replace the batteries

• Call for assistance

• Call for assistance

• Call for assistance

The gate opens

but does not close

• The photocells are soiled. • Clean and check that the photocells work

properly. Otherwise call for assistance

Page 15

p.

15

15 - Manual code:

FA00 290 -EN

FA00290-EN v.

2

2 - 06/2017 - © Came S.p.A. The contents of this manual may be changed at any time without prior notice.

Extraordinary maintenance

⚠

The following table is for logging any extraordinary maintenance jobs, repairs and improvements performed by specialized contractors.

Any extraordinary maintenance jobs must be done only by specialized technicians.

Extraordinary maintenance log

Fitter's stamp Name of operator

Job performed on (date)

Technician's signature

Requester's signature

Job performed __________________________________________________________________________________________

____________________________________________________________________________________________________

__________________________________________________________________________________________

Fitter's stamp Name of operator

Job performed on (date)

Technician's signature

Requester's signature

Job performed __________________________________________________________________________________________

____________________________________________________________________________________________________

__________________________________________________________________________________________

DISMANTLING AND DISPOSAL

☞

CAME S.p.A. applies a certified Environmental Management System at its premises, which is compliant with the UNI EN ISO 14001 standard

to ensure the environment is safeguarded.

Please continue safeguarding the environment. At CAME we consider it one of the fundamentals of our operating and market strategies. Simply

follow these brief disposal guidelines:

DISPOSING OF THE PACKAGING

The packaging materials (cardboard, plastic, and so on) should be disposed of as solid urban waste, and simply separated from other waste for

recycling.

Always make sure you comply with local laws before dismantling and disposing of the product.

DO NOT DISPOSE OF IN NATURE!

DISMANTLING AND DISPOSAL

Our products are made of various materials. Most of these (aluminum, plastic, iron, electrical cables) is classified as solid household waste. They

can be recycled by separating them before dumping at authorized city plants.

Whereas other components (control boards, batteries, transmitters, and so on) may contain hazardous pollutants.

These must therefore be disposed of by authorized, certified professional services.

Before disposing, it is always advisable to check with the specific laws that apply in your area.

DO NOT DISPOSE OF IN NATURE!

Fitter's stamp Name of operator

Job performed on (date)

Technician's signature

Requester's signature

Job performed __________________________________________________________________________________________

____________________________________________________________________________________________________

__________________________________________________________________________________________

REFERENCE REGULATIONS

The product complies to the reference regulations in effect.

Page 16

www.came.com

www.came.com

Came S.p.A.

Came S.p.A.

Via Martiri Della Libertà, 15 Via Cornia, 1/b - 1/c

31030

Dos son d i Casier

Dosson di Casier

Treviso

Treviso - Italy

33079

Sesto al Reghena

Sesto al Reghena

Pordenone

Pordenone - Italy

(+39) 0422 4940

(+39) 0422 4941

(+39) 0434 698111

(+39) 0434 698434

Engl is h

English - Manual code:

FA00 290 -EN

FA00290-EN v.

2

- 06/2017 - © Came S.p.A.

The contents of this manual may be changed at any time without prior notice.

Loading...

Loading...