Page 1

G2081Z

GARD 8 SERIES

INSTALLATION MANUAL

AUTOMATION

FOR STREET BARRIERS

English

EN

119GU44EN

Page 2

Pag.

2

- Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

1 Legend of symbols

G2081Z was designed and manufactured by CAME CANCELLI AUTOMATICI S.p.A. and is compliant with safety regulations in force.

The cabinet is made of 2.5 mm painted galvanized steel. Inside the cabinet, the electromechanical gearmotor operates with a con-

tainer for electric board and transformer.

Built with a anti-shearing safety system, it includes a safety contact in the inspection hatch lock.

The GARD 8 automation system is supplied with the following accessories:

G02000 - White-painted tubular aluminium rod, 2m (Ø 100 mm) complete with transparent slot cover;

G04000 - White-painted tubular aluminium rod, 4m (Ø 100 mm) complete with transparent slot cover;

G06000 - White-painted tubular aluminium rod, 6m (Ø 100 mm) complete with transparent slot cover;

G02040 - Ø 40 (yellow) balancing spring;

G04060 - Ø 50 (green) balancing spring;

G06080 - Ø 55 (red) balancing spring;

G06802 - Reinforcement for boom

G06803 - Telescopic joint and additional insert to attach the bar (this is obligatory for accesses of over 3.6m);

The following accessories are optional to the GARD 8 automation system:

RSE - Board for combined battery operation control and/or compass;

G02801 - Flashing dome lamp;

G02802 - Support for mounting the photoelectric cell (DIR) onto the cabinet (not applicable to barriers with bar and rack and/or

mobile foot);

G028401 - Luminous cord for movement signalling;

G028402 - Luminous cord connecting cable;

G02807 - Fixed barrier support (obligatory for accesses of over 4m);

G02808 - Mobile barrier support (obligatory for accesses of over 4m);

G02809 - Red reflector strips (package of 20);

G0465 - Aluminium skirt (2 m modules);

G028011 - Door break-out bar bracket.

WARNINGS!

001G02802 Not for barriers fitted with 001G0465 skirt or 001G02808 swing-leg.

001G02808 For passage widths of max 7 m.

001G02807 For passage widths of over 7 m the swing-leg is mandatory.

001G0465 - 001G02808 cannot be used together.

Important! Check that the safety equipment and accessories are CAME originals; this is a guarantee that also makes the system easy to

set up and upkeep.

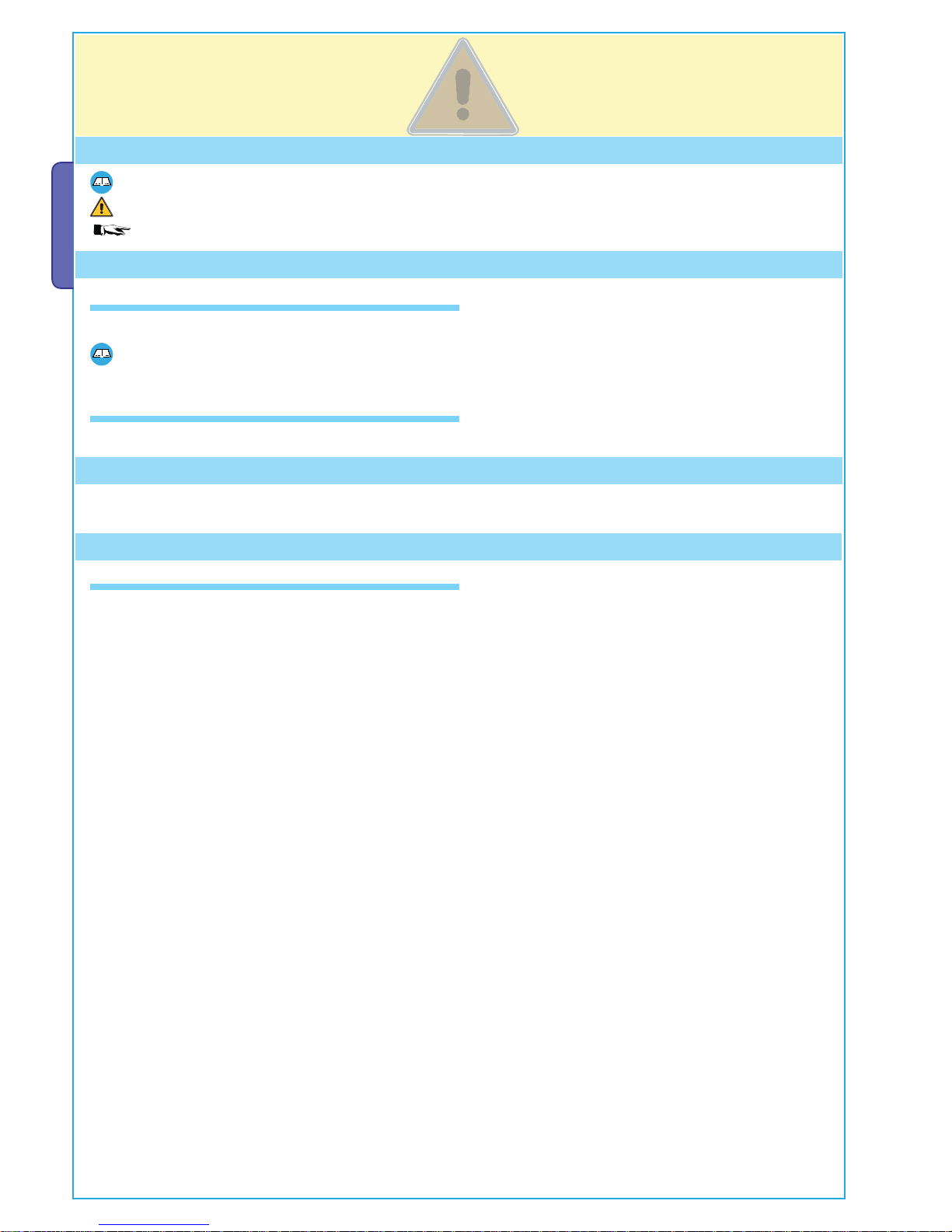

4 Description

“IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLATION”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL INSTALLERS OR QUALIFIED PERSONS”

4.1 Gearmotor

2.1 Destination

2 Destination and limits of use

The GARD 8 automatic barrier was designed for use in private or public carparks, in residential areas or in highly tra cked areas.

The use of this product for purposes other than as described above and installation executed in a manner other than as in-

structed in this technical manual are prohibited.

2.2 Limits of use

Passage width of up to 7.60 meters with a 4 second aperture time.

Came Cancelli Automatici is ISO 9001:2000 and ISO 14Quality and Environmentally certified. Came entirely designs and manufactures its products in Italy. The product in question compliant to the following legislation: see Declaration of Compliance.

3 Standard followed

This symbol indicates sections to be read with particular care.

This symbol indicates sections concernig safety.

This symbol indicates notes to communicate to users.

Page 3

#

#

CAME

CAME

CAME

CAME

6

11

10

7

8

9

1

2

3

5

4

12

1

2

3

4

6

7

5

11

8

10

9

14

13

12

Pag.

3

-

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

4.2 Technical information

GEARMOTOR

Power supply: 230V A.C. 50/60Hz

Motor power supply: 230V A.C. 50/60Hz

Max. absorption: 2.8A

Condenser: 35μF

Rated power: 330W

Max. torque: 250 Nm

Reduction ratio: 1/202

Opening time: s

Operative intermittence: 30%

Protection level: IP54

Weight: 91 kg

Insulation class: I

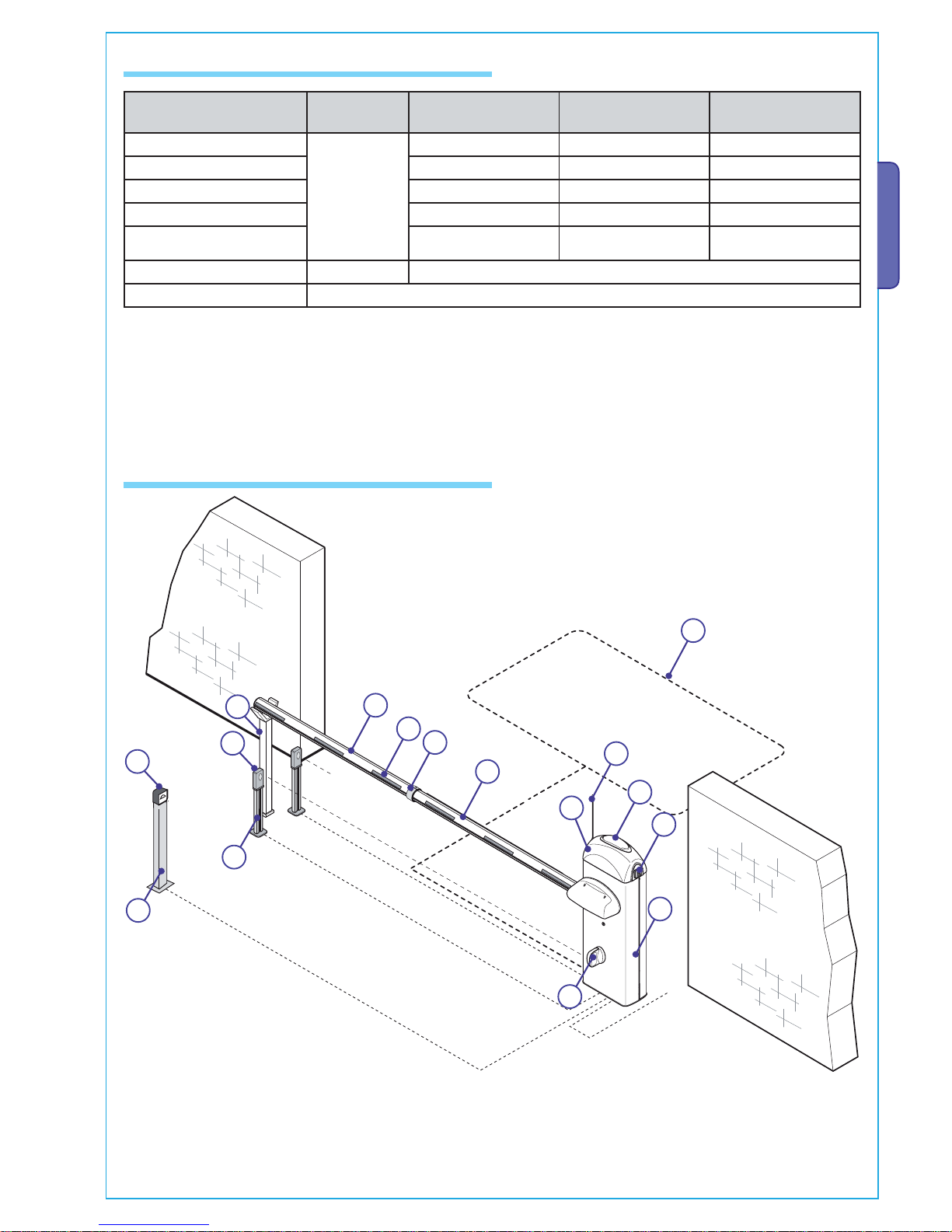

4.3 Parts description

AUTOMATION UNIT

VIEW FROM THE BAR

SUPPORT BRACKET

VIEW FROM IN-

SPECTION HATCH

ACCESSORIES

1) G02000/G04000 - Aluminium bar, painted white, Ø 100 mm

2) G02040 - Ø40 (yellow) balancing spring

3) G04060 - Ø50 (green) balancing spring

4) G06080 - Ø55 (red) balancing spring

5) G02806 - Rack

6) G02802 - Support for DIR photoelectric cells

7) G028401 - Luminous cord

8) G02807 - Fixed barrier support

9) G02808 - Mobile barrier support

10) G02809 - Adhesive reflector strips

11) G02801 - Flashing dome lamp

12) G06803 - Telescopic joint and additional insert to attach the

bar.11 -

1) Upper dome

2) Bar beam plate

3) Bar fitting intermediate plate

4) Cover for aluminium bar

5) Anti-shearing protection cover

6) Galvanized steel cabinet

7) Features for housing accessories

8) End-stop assembly

9) Lever arm

10) Transmission rod

11) Inspection hatch

12) Bar position adjustment

bu ers

13) Gearmotor

14) Control panel

Page 4

MAX

Pag.

4

- Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

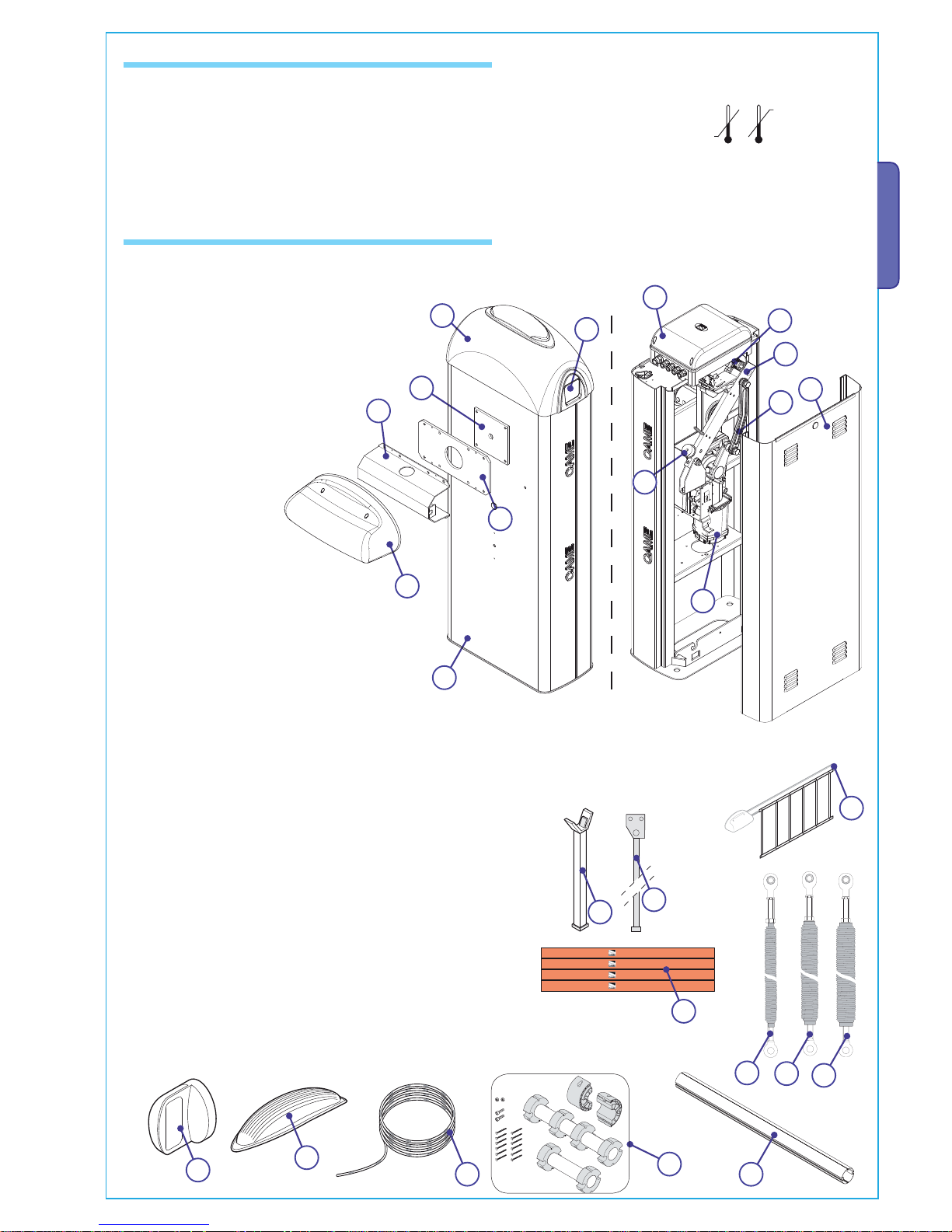

Make sure all tools and materials necessary are within reach to install the edge in maximum safety, according to regulations in

force. The following figure illustrates the minimum equipment for the installer.

Before proceeding with the installation, it is necessary to:

• Make sure the area selected for the mounting of the base and for the unit itself presents no hazards;

• Provide for suitable omnipolar disconnection device with more than 3 mm between contacts to section power supply;

•

Connections inside the case made for protection circuit continuity are allowed as long as they include additional insulation with

respect to other internal drive parts;

• Install suitable tubes and ducts for electric cable passage to guarantee protection against mechanical damage;

Installation must be carried out by expert qualified personnel and in full observance of regulations in force.

5 Installation

4.4 Size measurements

Measurements in mm

5.1 Preliminary checks

5.2 Tools and materials

Page 5

RX

TX

C

A

ME

CAM

E

2

1

7

3

4

5

6

8

9

10

11

12

13

14

15

16

Pag.

5

-

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

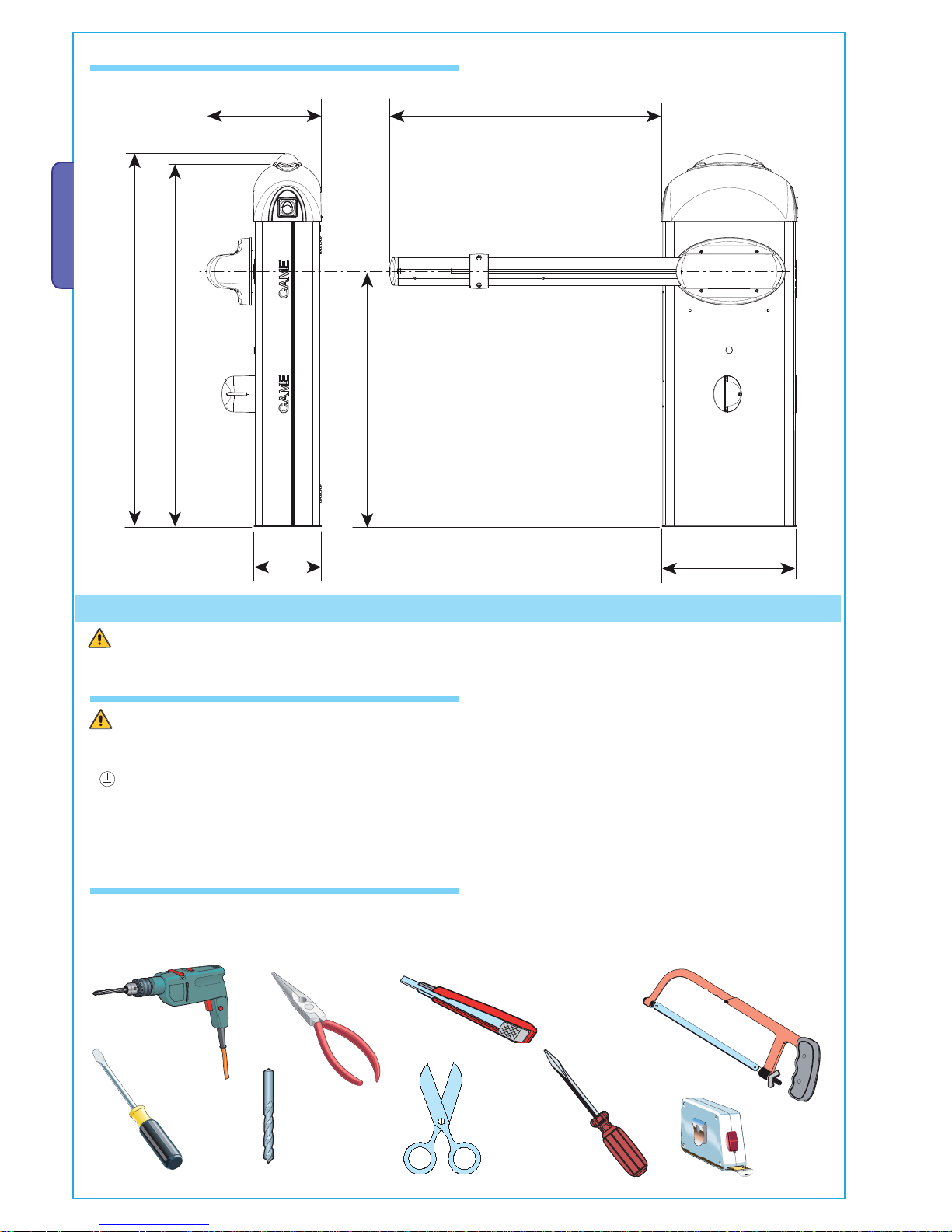

N.B.: An evaluation of the size of the cables with lengths other than the data in the table must be made based on the e ective

absorption of the connected devices, according to the instructions indicated by the CEI EN 60204-1 standards.

For connections that require several loads on the same line (sequential), the size given on the table must be re-evaluated based on

actual absorption and distances.

12 - Command divices (Keyboard, magnetic key, card, etc.)

13 - Column for reader

14 - Joint for rod

15 - Antenne

16 - Key-operated selector switch

5.3 Cable list and minimun thickness

Connections Type of cable

Length of cable

1 < 10 m

Length of cable

10 < 20 m

Length of cable

20 < 30 m

Alimentazione 230V

FROR CEI 20-22

CEI EN

50267-2-1

3G x 1,5 mm

2

3G x 2,5 mm

2

3G x 4 mm

2

Photoelectric cells TX 2 x 0,5 mm

2

2 x 0.5 mm

2

2 x 0,5 mm

2

Photoelectric cells RX 4 x 0,5 mm

2

4 x 0,5 mm

2

4 x 0,5 mm

2

24V power supply accessory 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 1 mm

2

Safety and control divices 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Antenna connection RG58 max. 10m

Metallic mass detector (see documents provided with product)

5.4 Standar installation

1 - GARD unit

2 - Control panel

3 - Aluminium bar

4 - Red phosphorescent strips

5 - Luminous cord

6 - Movement-indicating flashing lamp

7 - Column for photoelectric cells

8 - Photoelectric cells

9 - Fixed barrier support

10 - Magnetic sensor

11 - Photoelectric cell support

Page 6

Pag.

6

- Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

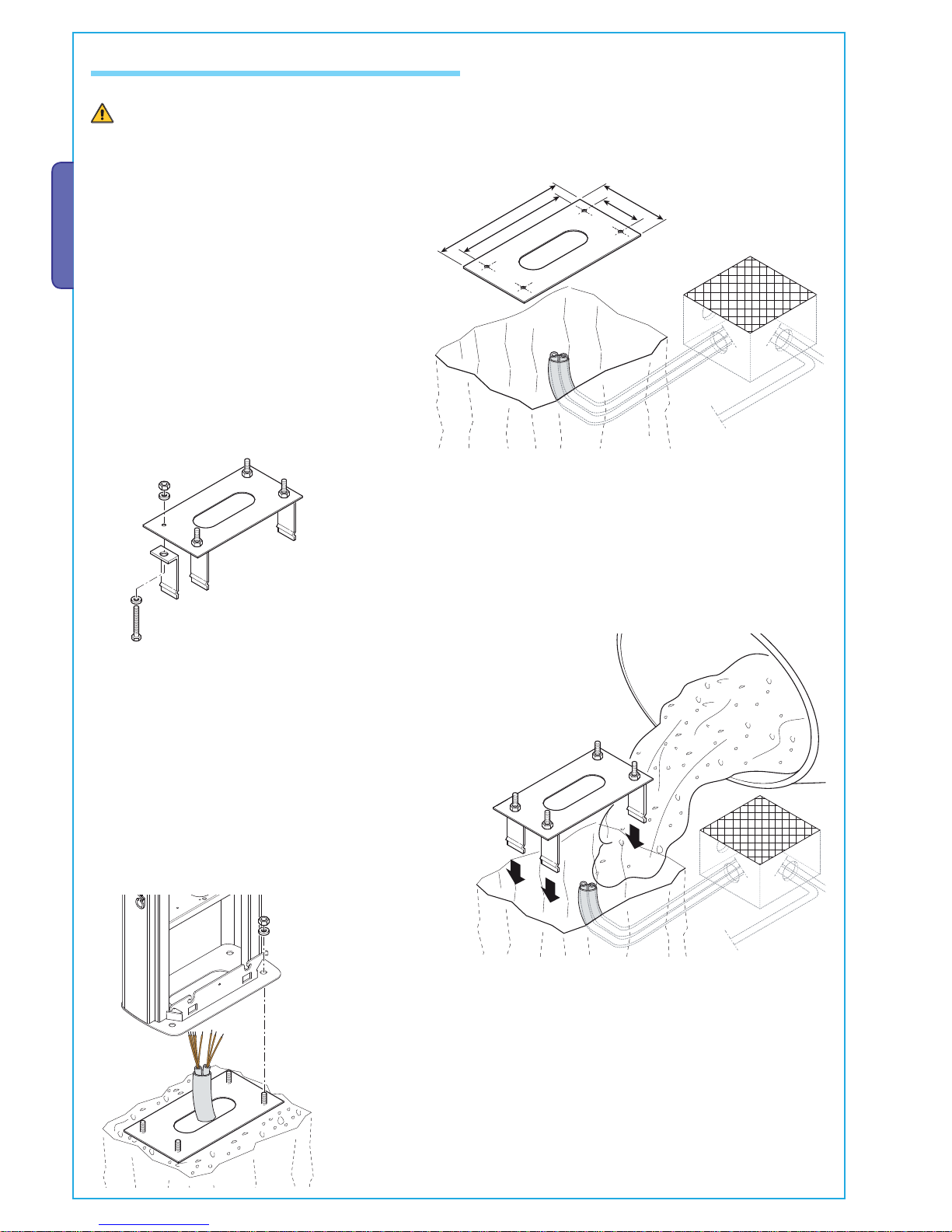

5.5 Fitting for unit base

The following applications are only examples, as the space required for unit installation and the accessories vary depending

on dimensions and therefore it is up to the installer to select the best solution.

- Assemble the four anchoring clamps at the base.

- Prepare a hole to house the fixing base and prepare

sheath tubes from the branch pit for the connections.

N.B. the number of tubes depends on the type of system

and the accessories you will hook up.

- Remove the nuts and washers from the threaded screws, position the cabinet on

the base in correspondence with the 4 threaded screws and secure with the nuts and

washers.

Note: We recommend installing the cabinet with the inspection hatch facing the internal

area.

- Fill the hole with concrete and immerge the clamps and the fixing

base, paying particular attention to the sheath tube which must

go through the hole at the base. The base must be perfectly level,

clean and with the screw threads fully on the surface.

Page 7

SX

DX

1

2

3

4

5

67

&#

&! &

Pag.

7

-

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

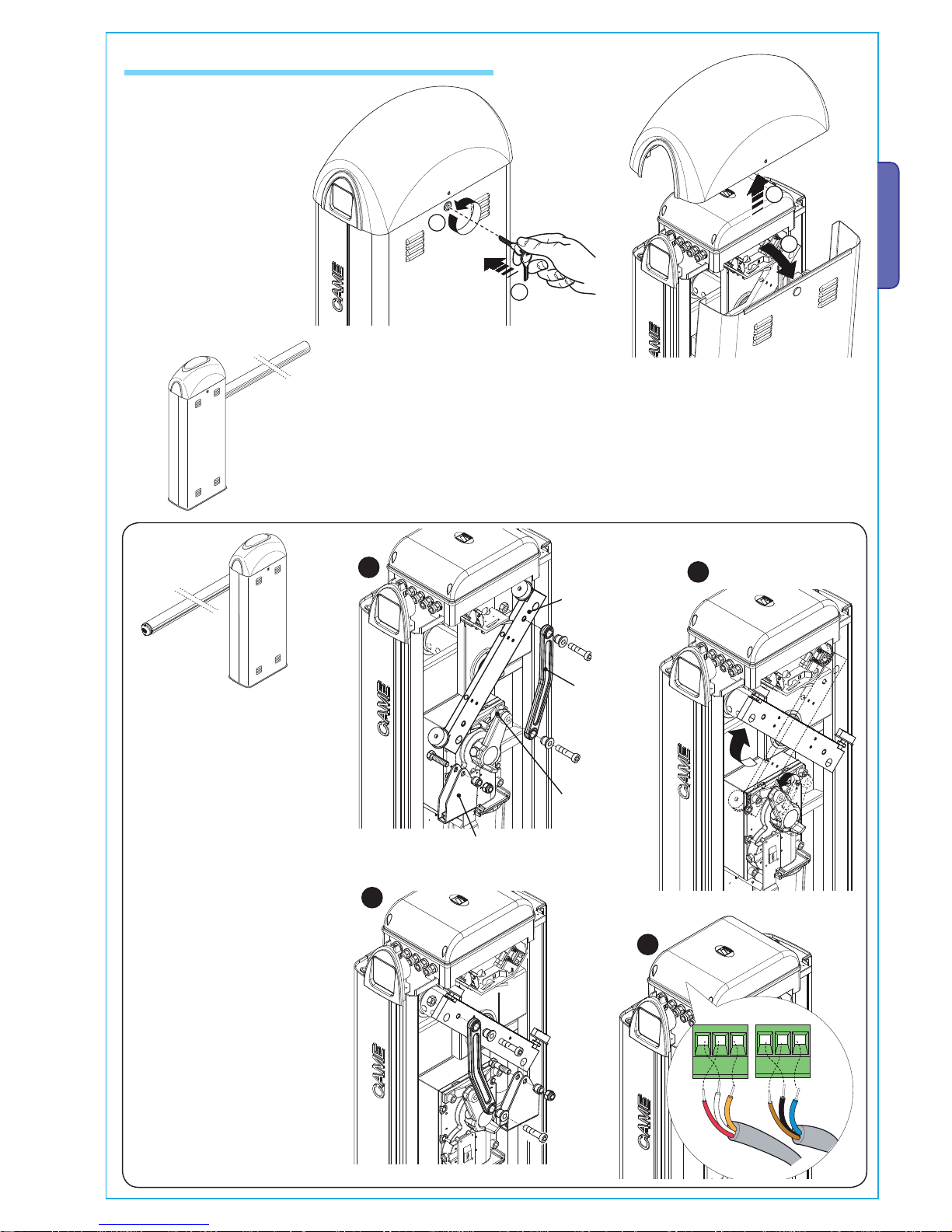

5.6 Installation of the Unit

- Remove the two screws

at the upper dome’s side

and lift it.

Insert the customised key

in the lock, turn it counter-

clockwise and remove the

hatch from the cabinet.

- The barrier is designed to be installed on the left of the gateway as

seen from inside.

Lever arm

Transmission rod

Spring securing bracket

Should installation on the right be

required, the direction of the bar’s

opening must be inverted. Proceed

in the following manner:

- remove the spring securing

bracket and the transmission rod

from the lever arm;

- loosen the motor support grub

screw;

- rotate the lever arm by 90°;

- Fix the spring securing bracket

and the transmission rod on the side

opposite that of lever arm;

- tighten the grub screw;

- invert the motor’s U-V phases and

the FA and FC endstop wires on the

control panel terminal.

Grub

Page 8

UNI5931 M8x20

UNI5931 M8x12

UNI6954 Ø2.9x13

UNI5931 M8x12

Pag.

8

- Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

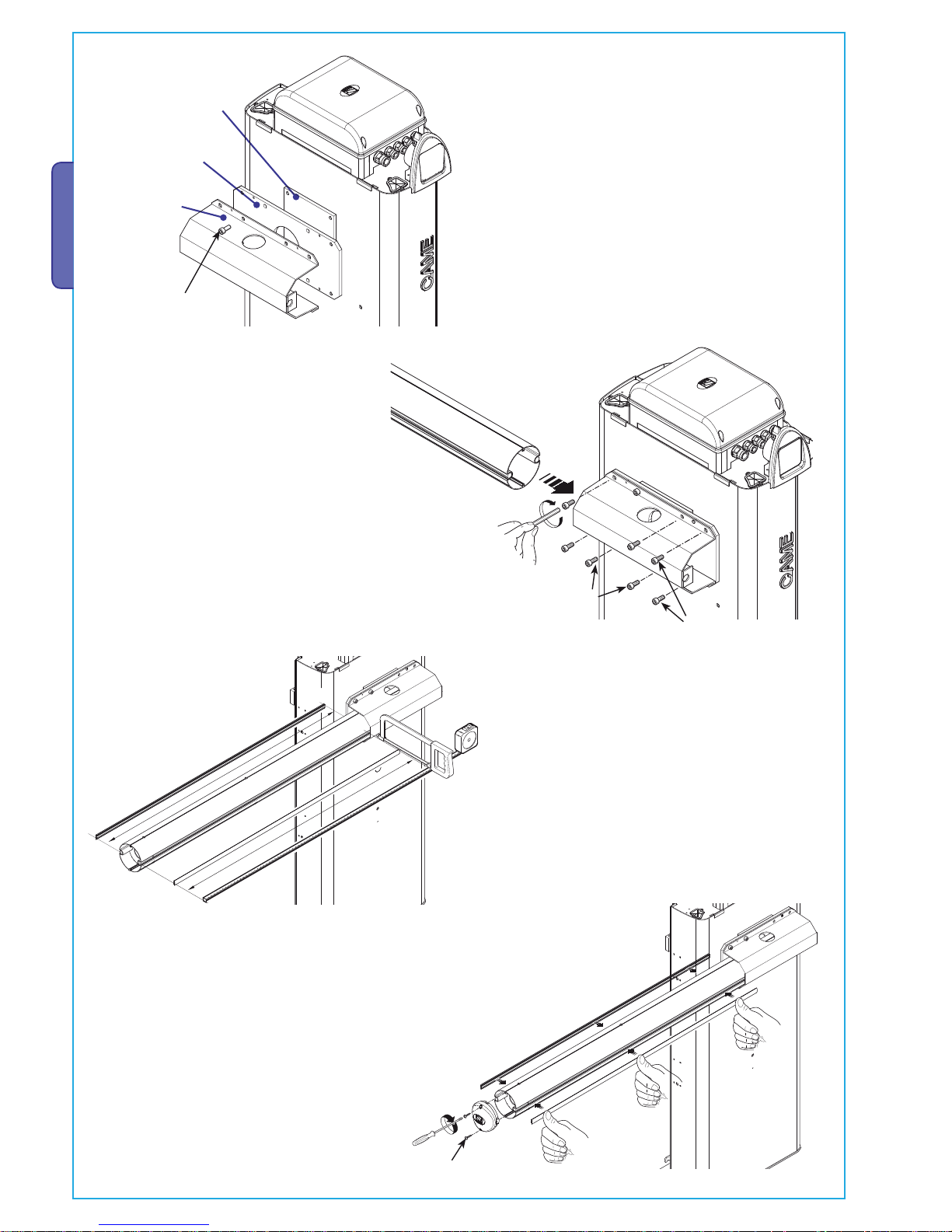

- Measure the length of the bar, cut the bar slot to the

same length.

- Position the middle plate between the fitting plate and the

bar-fitting cover, and put in one UNI 5931 M8x20 screw without tightening it to facilitate bar assembly.

Bar beam plate

Bar fi tting intermediate

plate

Bar fi tting cover

- Insert it in the bar’s conduit, a procedure that should be carried

out on both sides.

Insert the shock-resistant profile and cut excess length. Lastly,

secure the bar end plug with the screws provided.

- Insert the bar in the fitting cover and secure it with

screws.

Page 9

400 mm

UNI6954 Ø3.9x19

Pag.

9

-

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

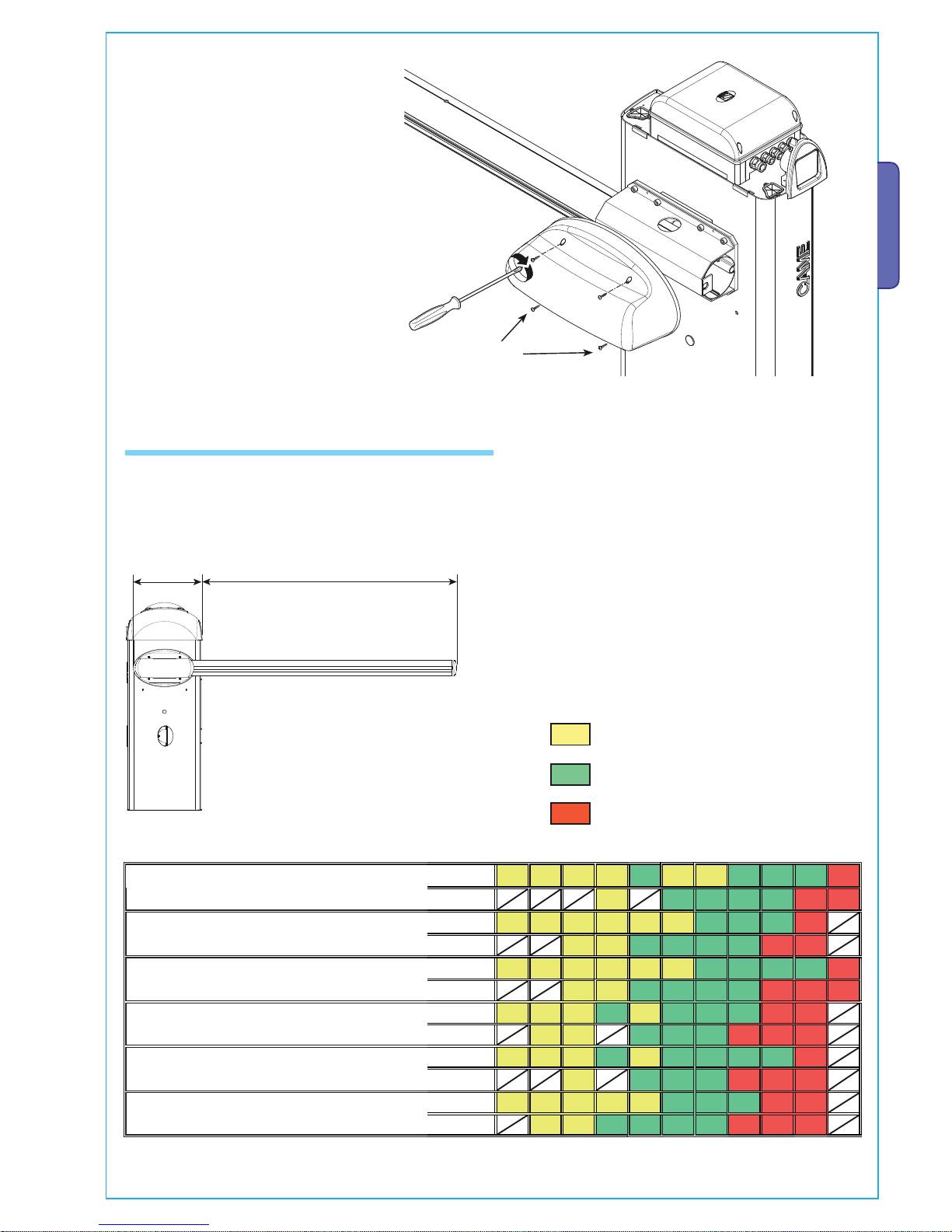

- Prior to bar balancing, select a suitable spring depending on the situation at

hand. See table below:

5.7 Bar balancing

PASSAGE CLEARANCE LAMP (max. 7.60 m)

SPRING TYPES

Spring G02040 Ø

e = 40 mm

Spring G04060 Ø

e = 50 mm

Spring G06080 Ø

e = 55 mm

- Tighten the anti-shearing protection cover

to the bar fitting with UNI6954 Ø3.9x19

screws.

* By Bare bar we mean a bar complete with the transparent slot cover and end plug.

Passage clearance lamp (m) 2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7. 6

Bare bar*

first spring

second spring

Bare bar* + mobile barrier support

first spring

second spring

Bare bar* + luminous cord

first spring

second spring

Bare bar* + luminous cord + mobile barrier support

first spring

second spring

Bare bar* + rack

first spring

second spring

Bare bar* + rack + luminous cord

first spring

second spring

Page 10

Pag.

10

10 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

- Release the gearmotor and position the bar vertically, and then refasten

the gearmotor.

- Hook the tie rod to the anchoring racket.

Perform the same procedure if there is a second screw.

- Insert the UNI5739

M12X70 screw into the

spring securing bracket and

tighten the UNI5588 M12

nut to the screw (1-2).

Tighten the screw to spring

(2) and the tie rod to the

part underneath (3-4).

Page 11

Pag.

11

11 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

- Release the gearmotor and

manually turn the spring to

increase or decrease traction until

the bar rests at 45°.

- Tighten the blocking nut and refasten the gearmotor.

Note: make sure the spring functions properly:

- the spring is loose when the bar is in the vertical position (at rest)

- the spring is tight when the bar is in the horizontal position (tense).

- Perform any electrical connections to the control panel (see electrical

connections paragraph).

Page 12

^

^

Pag.

12

12 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

5.8 End stop adjustment

Similarly, open the bar and adjust the free damper, to regulate the horizontal position (= closing).

If any adjustment of the vertical position (= opening) is needed, open the inspection

door and rotate the free damper clockwise (to increase the bar’s run) or counterclockwise (to decrease the run).

N.B.: perform this procedure after fi nishing the electrical connections.

Close the door and power up the system, activate the barrier to make sure it is parallel with the closed and at about 89° when open.

Warning! For greater safety and better unit performance, the bar’s opening and closing operations should be carried out with

the inspection hatch closed!

Page 13

:,

Pag.

13

13 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

- After bar opening and closing adjustment, tighten the

locking nuts under the dampers.

- ...place back the inspection door and the upper dome. Lock the door with the key.

- After making adjustments and settings from the control

panel, put the container lid in place and secure with

screws....

Page 14

Pag.

14

14 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

WARNING! The release

procedure may constitute a

hazard for the user when,

for whatever reason – the

bar is fixed improperly to

the housing during assembly, or the bar is cracked or

broken in an accident, and

so on – the tension springs

no longer provide balance!

These can thus cause a

brusque rotation of the

bar attachment and/or of

the bar itself.

5.9 Manual release of the barrier

- Insert the key in the lock and turn it clock wise. Manually lift the bar and relock it by turning the key

counterclockwise.

6 Description control panel

This product is engineered and manufactured by CAME cancelli

automatici s.p.a. and complies with current safety regulations.

The control panel works on 230V a.c. of power, 50/60Hz

frequency.

Both command and control devices and accessories are 24V

powered.

Warning! Accessories must not exceed 40 W overall.

In case the endpoint assembly does not intervene, the card

nevertheless guarantees 20 seconds of operation. The card

autonomously handles the Encoder (obstacle sensitive) safety

function, which:

- when opening: the bar inverts the direction of travel until completely closed;

- when closing: the bar inverts the direction of travel until completely open.

Caution! after three consecutive direction reversals, the bar will

remain up and automatic closure will be discontinued. To close the

gate, use the radio remote control or the push-button.

All connections are protected by quick fuses, see table.

The card provides and controls the following functions:

- automatic closing after an open-command;

- immediate closure;

- pre-fl ashing by the motion indicator;

- obstacle detection when bar is still in any position.

The following command modes are possible:

- open/close;

- open/close and maintained action;

- Opening;

- Total stop.

Apposite trimmer regulate:

- the automatic closing run time;

Optional accessories:

- fl ashing crown and luminous band.

- bar open light marks the position of opening of the bar; it turns

o after the closing operation;

- the RSE card, in order to activate the compass function or

coupled through Dipswitches, see the relative technical literature.

Warning! Before acting on the machinery, cut off the main power

supply and disconnect any emergency batteries.

TECHNICAL FEATURES

Power supply 230 V - 50/60 Hz

max. rated power 400 W

Power draw when idling 25 W

Max power of 24V accessories 40 W

Insulation rating II

Material ABS

FUSES

protection: fuse type:

Electroblock

1.6 A-F

Electronic board

(power supply line)

5 A-F

Accessories 2 A-F

Control devices 630 mA-F

Page 15

5

67

&#

&!&

/.

%"

%"

63 #4 ,4

,4

).4%2",/##/

.

,

'.$

"!

$

%

6"

%

%

43

0

#

#

16

8315

18

9

1

13

12

11

10

17

14

2

6

5

19

4

6

20

7

21

5

67

&#

&!&

$

%

COM

NC

NC

COM

Pag.

15

15 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

Blue

Violet

Orange

White

Red

Brown

Black

Grey

6.1 Main components

6.2 Electrical connections

230V (a.c.) Motor

Gearmotor, mechanical stops

Opening-microswitch

Orange

Orange

Red

White

Blue

Black

Closing-microswitch

1 - Line fuse

2 - Control unit fuse

3 - Accessories fuse

4 - Electroblock fuse

5 - Powersource Terminals

6 - Transformer Terminals

7 - Electroblock Terminals

8 - Endpoint assembly Terminals

9 - Coupled Barrier Terminals

10- Encoder Terminals

11- Connections Terminals

12- Radiofrequency Card input (see table on page 20)

13- RSE serial card input (optional for connection coupled

barriers and/or compass)

14- TCA Trimmer: adjusts automatic closing time

15- Function selector Dip switch

16- Radio code storing buttons

17- Signalling LEDs for radio codes/automatic closing

18- Gate run counter

19- Motor Terminals

20- Transformer

21-Condenser

Brown

Red

Black

Condenser

Description of required electrical connections. If installing

on the right side, see page 7.

Page 16

%%430#

#

).4%2",/##/

.

,

%%43

+

-

%"

%"

6"

6

6"

6

Pag.

16

16 - Manual co de:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

Terminals for powering the following accessories:

- 24V A.C. normally;

- 24V D.C. when the emergency batteries are working;

Maximum allowed power: 40W

Power supply for accessories

230V (a.c.) Power, 50/60Hz frequency

Cable lug with bolt and washer for

connecting to earth

Open barrier warning light (contact rating: 24V – 3W max.)

– Signals when bar is in ‘up’ position, turns o once bar is down

Luminous band (Contact rating: 24V-24W max.)

– Flashes when bar is closed or moving.

Warning devices

Flashing Crown (Contact rating: 24V – 8W max.)

– Flashes when bar is opening and closing.

Power out socket for electroblock, activated with opening command.

- VB2 , 24V electroblock powering (preset connection)

- VB1, 12V electroblock powering

Page 17

%%430#

#

%%430#

#

TX

RX

%%430#

#

Pag.

17

17 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

DIR photocells

Safety devices

Command devices

Stop button (N.C. Contact) - Bar stop barrier.Excludes automatic closing.

For movement to resume, press the command button or transmitter button. If unused,

set Dipswitch 6 to ON.

Opening button (N.O. contact) – Bar opening command.

Opening button (N.O. contact) - Opening command of the MASTER bar with coupled or

compass connection.

Closing button (N.O. contact) - Bar closing command. Obligatory in case of “maintained action” function.

Command button (N.O. contact) - Bar opening and closing command. By pushing the

button, the bar opens or inverts its movement depending on the selection made on

Dipswitch 2.

(N.O. contact) for “immediate closing”

- Automatic closing of the bar when obstacle passes in the

detection range of the safety devices.

(N.C.) contact for «re-open during closing phase»

- Input for EN 12978 standard-compliant safety devices

such as photocells. If contact is opened, while bar is

closing, the bar inverts its direction.

If unused, set DIP 7 switch to ON.

Page 18

5

67

%"

63 #4 ,4

,4

).4%2",/##/

.

,

'.$

"!

$

%

6"

/.

%%430#

#

&53)"),%M!

48

48

48

#

.#

(DIR)

Pag.

18

18 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

6.4 Motor torque limiter

6.3 Electrical connection to operate the photocells’ safety test

To manage the performance surge, position dip switches n. 1 and n. 3 to ON: all 8 led indicator lights on the performance counter

light up.

Reset Dipswitch 3 to OFF and leave Dipswitch 1 in the ON mode, if you want to activate the automatic closing function.

6.5 Managing operational surge

Allows the control assembly to check the e ciency of the safety devices (photoelectric cells) after each opening or closing command.

A possible photoelectric cell malfunction is identifi ed with via LED

indicator fl ashing on the control panel, consequently cancelling any

remote control or pushbutton commands.

Electrical connection for safety test activation:

- photoelectric cell transmitters and receivers must be connected in

the following way (see scheme)

- turn dip-switch 8 to ON to carry out the test.

IMPORTANT:

When carrying out the safety test function, contacts N.C. if not used,

on the relative dip switches (see “functions selection” c. 6.9).

To vary the motor torque, move the shown faston (the one with

the black wire) to one of the 4 positions: 1 min – 4 max.

Page 19

/.

/.

/.

ON

OFF

/.

Pag.

19

19 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

6.8 Settings

- «A.C.T.» Sets the waiting time while open. Once this time has elapsed, closing automatically takes place. The waiting time

may be set from 1 to 120 seconds.

6.6 Operation counter

Led n°1 = 5000 operation

Led n°2 = 10000 operation

Led n°3 = 25000 operation

Led n°4 = 50000 operation

Led n°5 = 100000 operation

Led n°6 = 250000 operation

Led n°7 = 500000 operation

Led n°8 = 1000000 operation

6.7 Function selector

Default Setting

Visual count of the number of gate runs through the 8 LEDs, to zero-set the count, set Dipswitch 1 to OFF (if it is set to ON) and

Dipswitch 3 to ON, press CH1 button and wait for all LEDs to turn o . Once zeroed out, reset Dipswitch 1 to ON (if selected) and

Dipswitch to OFF.

1 ON - Automatic Closing - The automatic closing timer activates at the end of the opening gate run. The pre-set time is adjustable,

and is in any case conditioned by the activation of any safety devices, and does not activate after a total safety “stop” or

during a blackout (1 OFF - deactivated);

2 OFF - "Open-close" function with [2-7] button and radio transmitter ((fi tted with inserted radiofrequency card).

2 ON - "Open only" function with radio transmitter ((fi tted with inserted radiofrequency card).

3 ON - Maintained Action – barrier works by keeping the button pressed, one button 2-3 for opening, and one 2-4 for closing

(this excludes functioning of the radio transmitter).

4 ON - Pre-fl ashing while opening and closing – Following an opening or closing command, the fl asher and/or luminous crown

connected on [10-E7-/10-E6], fl ashes for 5 seconds before beginning its action.

5 ON - Obstacle detected - When motor is stopped (bar closed or after a total stop command) it prevents any movement if safety

devices, such as photocells, detect any obstacles.

6 OFF - Total stop - This function stops the bar and consequently excludes any automatic closing cycle; to set in motion again, use

either the keypad or transmitter. Insert the safety device in [1-2]; If unused, set DIP switch to ON.

7 OFF - Opening during closing - If the photocells detect an obstacle during bar is closing, gate motion is inverted until fully opened;

connect the safety device to terminals [2-C1]; if unused, set DIP switch to ON;

8 ON - Functioning of the photocells’ safety test - Allows the card to check the efficiency of any safety devices (i.e. photocells)

after every opening or closing command; (8 OFF deactivated).

9 OFF - Encoder activated – to detect obstacles; (9 ON deactivated)

10 - If unused, set the DIP switch to OFF.

Page 20

/.

Pag.

20

20 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

7 Activating the radio command

AF Card

Connect the antenna’s RG58 cable to the apposite terminals.

Antenna

Insert the radio frequency card into the electronic card AFTER DISCONNECTING THE POWER (and disconnecting any batteries).

N.B.: the electronic card picks up the radiofrequency card on when it is running on power.

Radiofrequency card

Frequency-MHz radiofrequency

card

Series of

transmitters

FM 26.995 AF130 TFM

FM 30.900 AF150 TFM

AM 26.995 AF26 TOP

AM 30.900 AF30 TOP

AM 40.685 AF40 TOUCH

AF43 S / AF43 SM TAM / TOP

AF43SR ATOMO

AF43S / AF43TW TWIN

AM 868.35 AF868 TOP

Page 21

CAME

CAME

CAME

CAME

CAME

CAME

TOUCH

TCH 4024 • TCH 4048

TOP

TOP-432NA • TOP-434NA

TOP-432S

TOP

TOP-302A • TOP-304A

TOP

TOP-432A • TOP-434A

TAM

T432 • T434 • T438

TAM-432SA

TFM

T132 • T134 • T138

T152 • T154 • T158

CAME

CAME

CA

ME

ATOMO

AT01 • AT02

AT04

TWIN

TWIN2 • TWIN4

CAME

CAME

CAME

CAME

CAME

CAME

CAME

Pag.

21

21 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

Transmitters

See instruction sheet in AF43SR radiofrequency card box

See attached instructions

Page 22

CH1

CH2

T1

T2

Pag.

22

22 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

AF Card

- Keep the “CH1” button on the electronic card pressed. The LED fl ashes.

- Press the transmitter button you wish to memorise. The LED will stay on to show memorisation has been successful.

LED flashing

Memorisation

CH1 = Channel for direct command to a function of the the gearmotor’s card, (“open only / “open-close” command, depending on

the choice made on DIP switch 2).

CH2 = Channel for direct commands with an accessory device (radio control with combined barrier connection or with bush).

- Repeat the points 1 and 2 procedures for the “CH2” button associating this to another button on the transmitter.

LED on

Page 23

28

#

!

-

%

#!-

%

48

Pag.

23

23 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

8 Safety instructions

This product must only be employed for its originally intended use. Any other use is wrong and potentially dangerous. The manufacturer cannot be held liable for any damages resulting from wrongful, erroneous or negligent uses.

Avoid using near mechanical moving parts. Stay out of the opening/closing arc when operator is in motion.

Do not exercise force against the motion of the operator as this could result in potentially dangerous situations.

Do not allow children to play or loiter within the opening/closing arc of the operator. Keep remote controls and any other command

device out the reach of children, to prevent operator from being activated by accident.

In the event of anomalous behaviour, stop using the operator immediately.

Important safety instructions

9 Maintenance

9.1 Periodic maintenance

Periodic maintenance to be carried out by the end-user is as follows: wipe clean

the glass surface of the photocells; check that the safety devices work properly; remove

any obstructions.

We suggest checking the state of lubrication and tightness of the anchoring screws on

the operator.

-To check the efficiency of the safety devices, move an object in front of the photocells

when gate is closing. If the operator inverts the motion or stops, the photocells are

working properly.

This is the only maintenance procedure to be carried out with the power source connected.

-Before performing any maintenance procedures, cut off the main power, to prevent possible accidents due to gate movement.

-To clean the photocells use a water dampened cloth. Do not use solvents or other chemical products which may ruin the devices.

-In the event of any strange vibrations or squeaking, lubricate the joints with grease, as

shown in the diagram.

Danger of crushing hands Danger! High voltage No transit during operation

Page 24

Pag.

24

24 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

Periodic maintenance log for end-user (every 6 moths)

Date Notes

Signature

Page 25

Pag.

25

25 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

9.2 Extra-ordinary maintenance

The following table serves to note down any extraordinary maintenance, repairs or improvements performed by specialised

firms.

N.B.: Any extraordinary maintenance must be performed by specialised technicians.

Extra-ordinary maintenance log

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed ________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed ________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed ________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed ________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed ________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed ________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Page 26

Pag.

26

26 - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

MALFUNCTIONS REFERENCES CHECKS

The unit neither opens nor shuts 1-2-3-4-6-8-20 1 - Use key to lock trap door

The unit opens but does not close 4-7-10 2 - Disable “steady movement” with dipswitch

The unit shuts but does not open 4-7-9 3 – Check power supply and fuses

No automatic closure 11-12-13 4 - N.C. safety contacts open (1-2 / 2-C1)

The unit does not work if the remote control is

used

2-14-16 6 - Disable master-slave function

The unit inverts direction 7 7 – Check spring tension and balancing

The unit works only with remote control 22 8 – Disable obstacle detection with dipswitch

The photoelectric cell does not react 12-23-24 9 – Check if end stop opens

The signalling LED indicator flashes rapidly 4 10 – Check if end stop closes

The signalling LED indicator remains on 13 11 - Activate “automatic closure” dip switch

The unit does not end its run 7 12 – Check the correct direction of movement

The bar is not properly balanced 7-15 13 - (2-3 / 2-4 / 2-7) command button

14 -Check jumper on AF43S, turn on/off power

15 – Check the bar length ratio with mountable accessories

16 – Re-save radio code

20 - Raise the motor torque

22 - Enter or duplicate the same code in all the remote

controls

23 - Activate the photoelectric cell with the dipswitch

24 - Connect the photoelectric cells in a series, not in

parallel

9.3 Problem solving

In its premises, CAME CANCELLI AUTOMATICI S.p.A. implements an Environmental Management System certifi ed in com-

pliance with the UNI EN ISO 14standard to ensure environmental protection.

Please continue our e orts to protect the environment—which CAME considers one of the cardinal elements in the development of

its operational and market strategies—simply by observing brief recommendations as regards disposal:

DISPOSAL OF PACKAGING

I The packaging components (cardboard, plastic, etc.) are all classifi able as solid urban waste products and may be disposed of

easily, keeping in mind recycling possibilities.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of installation.

PLEASE DISPOSE OF PROPERLY!

PRODUCT DISPOSAL

IOur products are made up of various types of materials. Most of them (aluminium, plastics, iron, electrical wires, etc.) may be disposed of in normal garbage collection bins and can be recycled by disposing of in specifi c recyclable material collection bins and

disposal in authorized centres. Other components (electrical boards, remote control batteries, etc.), however, may contain polluting

substances. They should therefore be removed and given to qualifi ed service companies for proper disposal.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

10 Demolition and disposal

Page 27

Pag.

27

27 -

Manual code

:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012

© CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

CE Compliance statement

Page 28

CAME

CAME

Fra nce

France

S.a.

S.a. FRANCE

7, Rue Des Haras

Z.i. Des Hautes Patures

92737

Nanterre Cedex

Nanterre Cedex

(+33) 0 825 825 874

(+33) 1 46 13 05 00

GERMANY

CAME Gmbh Seefeld

CAME Gmbh Seefeld

Akazienstrasse, 9

16356

Seefe ld

Seefeld Bei Berlin

(+49) 33 3988390

(+49) 33 39883985

CAME Automatismes S.a.

CAME Automatismes S.a. FRANCE

3, Rue Odette Jasse

13015

Marse ille

Marseille

(+33) 0 825 825 874

(+33) 4 91 60 69 05

U.A.E.

CAME Gulf Fze

CAME Gulf Fze

O ce No: S10122a2o210

P.O. Box 262853

Jebel Ali Free Zone -

Dubai

Dubai

(+971) 4 8860046

(+971) 4 8860048

CAME Automatismos S.a.

CAME Automatismos S.a. SPAIN

C/juan De Mariana, N. 17-local

28045

Madr id

Madrid

(+34) 91 52 85 009

(+34) 91 46 85 442

RUSSIA

CAME Rus

CAME Rus

Umc R us Llc

Umc Rus Llc

Ul. Otradnaya D. 2b, Str. 2, o ce 219

127273,

Mosco w

Moscow

(+7) 495 739 00 69

(+7) 495 739 00 69 (ext. 226)

CAME United King dom Ltd .

CAME United Kingdom Ltd. GREAT BRITAIN

Unit 3 Orchard Business Park

Town Street, Sandiacre

Notti ngham

Nottingham - Ng10 5bp

(+44) 115 9210430

(+44) 115 9210431

PORTUGAL

CAME Portugal

CAME Portugal

Ucj Portug al Unip esso al Lda

Ucj Portugal Unipessoal Lda

R

ua Liebig, nº 23

2830-141

Barre iro

Barreiro

(+351) 21 207 39 67

(+351) 21 207 39 65

CAME Group B enel ux S. a.

CAME Group Benelux S.a. BELGIUM

Zoning Ouest 7

7860

Le ssin es

Lessines

(+32) 68 333014

(+32) 68 338019

INDIA

CAME Indi a

CAME India

Aut omation S oluti ons P vt. Ltd

Automation Solutions Pvt. Ltd

A - 10, Green Park

110016 -

New D elhi

New Delhi

(+91) 11 64640255/256

(+91) 2678 3510

CAME Americas Aut omati on Ll c

CAME Americas Automation Llc U.S.A

11345 NW 122nd St.

Medle y

Medley, FL 33178

(+1) 305 433 3307

(+1) 305 396 3331

ASIA

CAME Asia Pacif ic

CAME Asia Pacific

60 Alexandra Terrace #09-09

B

lock C, The ComTech

118 502

Singa pore

Singapore

(+65) 6275 0249

(+65) 6274 8426

CAME Gmbh

CAME Gmbh GERMANY

Kornwestheimer Str. 37

70825

Korn tal

Korntal Munchingen Bei Stuttgart

(+49) 71 5037830

(+49) 71 50378383

CAME Cancell i Autom atici S.p.a.

CAME Cancelli Automatici S.p.a. ITALY

Via Martiri Della Libertà, 15

31030

Doss on Di Casier

Dosson Di Casier (Tv)

(+39) 0422 4940

(+39) 0422 4941

Informazioni Commerciali 800 848095

ITALY

CAME Sud s.r. l.

CAME Sud s.r.l.

Via F. Imparato, 198

Centro Mercato 2, Lotto A/7

80146

Napo li

Napoli

(+39) 081 7524455

(+39) 081 7529190

CAME Service I talia S.r.l.

CAME Service Italia S.r.l. ITALY

Via Della Pace, 28

31030

Doss on Di Casier

Dosson Di Casier (Tv)

(+39) 0422 383532

(+39) 0422 490044

Assis ten za Tecnica 800 295830

Assistenza Tecnica 800 295830

ITALY

CAME Global Util itie s s.r.l.

CAME Global Utilities s.r.l.

V

ia E. Fermi, 31

20060

Gessa te

Gessate (Mi)

(+39) 02 95380366

(+39) 02 95380224

09_2011

www.came.com www.came.it

Engli sh

English - Manual code:

119G U44

119 GU 44 ver.

0.4

0.4 01/2012 © CAME cancelli automatici s.p.a.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Loading...

Loading...