Page 1

CAME UNITED KINGDOM LTD

UNIT 3

ORCHARD PARK INDUSTRIAL ESTATE,

TOWN STREET, SANDIACRE,

NOTTINGHAM NG10 5BP

TEL: 0115 921 0430

FAX: 0115 921 0431

INTERNET - www.cameuk.com

E-MAIL - enquiries@cameuk.com

TECHNICAL

HELPLINE

0115 921 0430

GARD G6000

Installation Instructions

for swift road barriers

THE GARD KIT CONSISTS OF:

BARRIER UNIT

CONTROL PANEL

ALUMINIUM BARRIER ARM

RED PHOSPHORESCENT STICKERS

SAFETY BEAM POST

SAFETY BEAM

Page 2

INTRODUCTION

THESE INSTRUCTIONS WILL SHOW YOU HOW TO INSTALL A

GARD AUTOMATION SYSTEM FOR SWIFT ROAD BARRIERS.

PLEASE READ THESE INSTRUCTIONS AND DIAGRAMS

CAREFULLY BEFORE STARTING ANY WORK.

UNDER NO CIRCUMSTANCES SHOULD THIS EQUIPMENT BE OPERATED UNLESS FITTED TO AGATE.

FAILURE TO COMPLY WILL INVALIDATE THE GUARANTEE.

1

Page 3

GENERAL SPECIFICATION

DESCRIPTION:

This unit can be used to control entrances up to 6.5 metres wide (with accessories on the barrier up

to 6metres). Designed and constructed by CAME in compliance with current safety standards (UNI

8612) and with an IP54 protecting rating.

Guaranteed for 12 months unless tampered with by unauthorised personnel.

MODELS:

G6000. Barrier with non-reversible 24V DC gear motor, case in galvanised steel with enamel finish,

control panel and internal drive system.

OPTIONAL ACCESSORIES:

G0601 Rectangular cross-section, 100x40x6850mm aluminium barrier with white enamel finish.

G0602 Tubular cross-section, 100mm dia x 6850mm aluminium barrier with white enamel finish

(recommended for areas subject to strong winds)

G0603 Red anti-collision bumper strip with end caps, for G0601 barrier.

G0460 Pack of 6, 24V DC signal lamps with brackets for fitting to G0401 barrier with flash control

circuit board.

G0461 Red phosphorescent stickers for barrier.

G0462 Non-moving support for barrier.

G0463 Moving support for barriers.

G0465 White enamelled aluminium fencing for barriers.

G0467 Joint for G0601 barrier.

G0468 Support for attachment of safety beam to casings.

G0469 Support for attachment of flashing light assembly.

ATTENTION! For ease of installation and conformance to current safety norms, we recommend

installation of CAME safety and control accessories.

2

Page 4

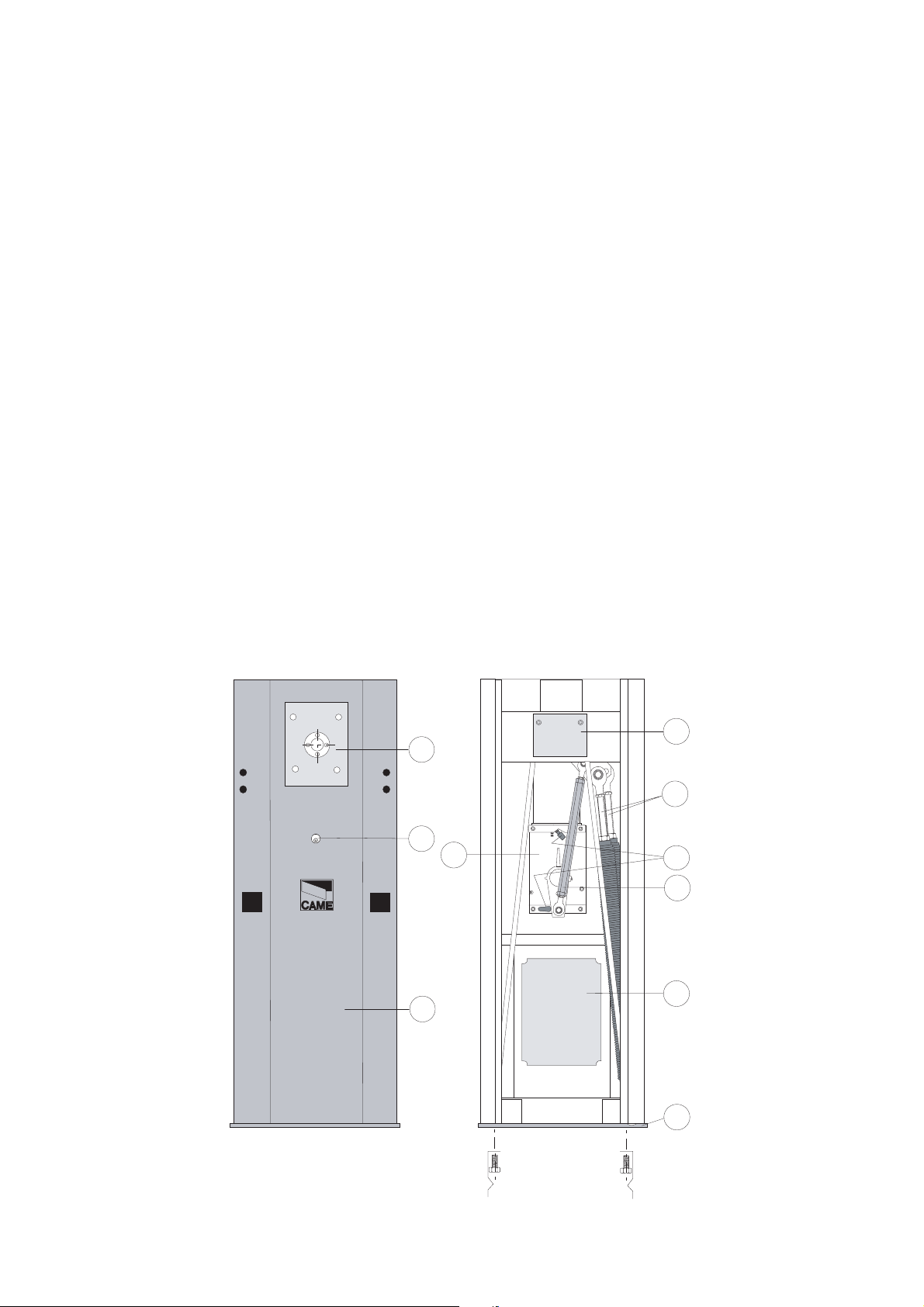

TECHNICAL CHARACTERISTICS

EXTERNAL DIMENSIONS

TYPE WEIGHT POWER CURRENT MOTOR DUTY REDUCTION MAX TIME

KG SUPPLY DRAW POWER CYCLE RATIO TORQUE

G6000 230V AC 1.3A-230V 300W HEA VY

G6001 72 24V DC 15A-24V DUTY 1/202 600Nm 4-8s

3

450

460 240

914

==

1077

295

Page 5

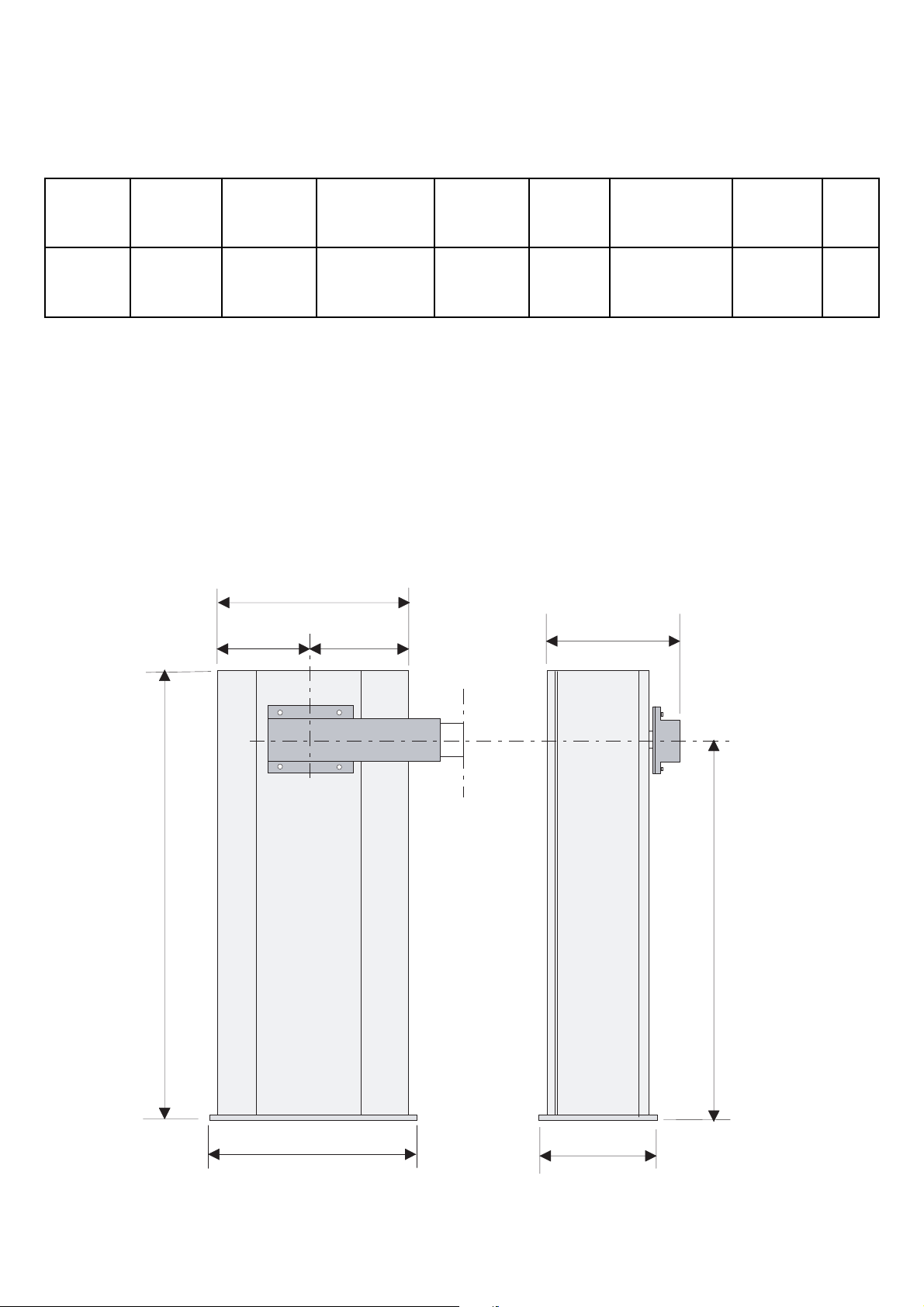

TECHNICAL DESCRIPTION

A Case constructed in 2.5mm galvanised stainless sheet with an enamel finish (G6000), or in 2mm

stainless steel, with a satin finish (G6001), factory configured to accept all required accessories.

The access door for inspection can be locked onto the case with a personal key.

B Mounting base in galvanised steel with anchor stays and bolts for anchoring the case to the

baseplate.

C The flange is in galvanised steel. This holder allows the barrier to be quickly and securely locked.

D Manual release system.

E Motor: 24V DC reduction gear, non-reversible with die-cast aluminium housing and is

permanently lubricated with liquid grease.

F A spring acts as counterbalance for precise uniform movement.

G An internal shock absorber/travel stop is provided.

H Limit switch assembly.

I Control panel (ZL37F)

4

C

D

E

A

I

F

L

B

G

H

#

%

$

s

s

s

Page 6

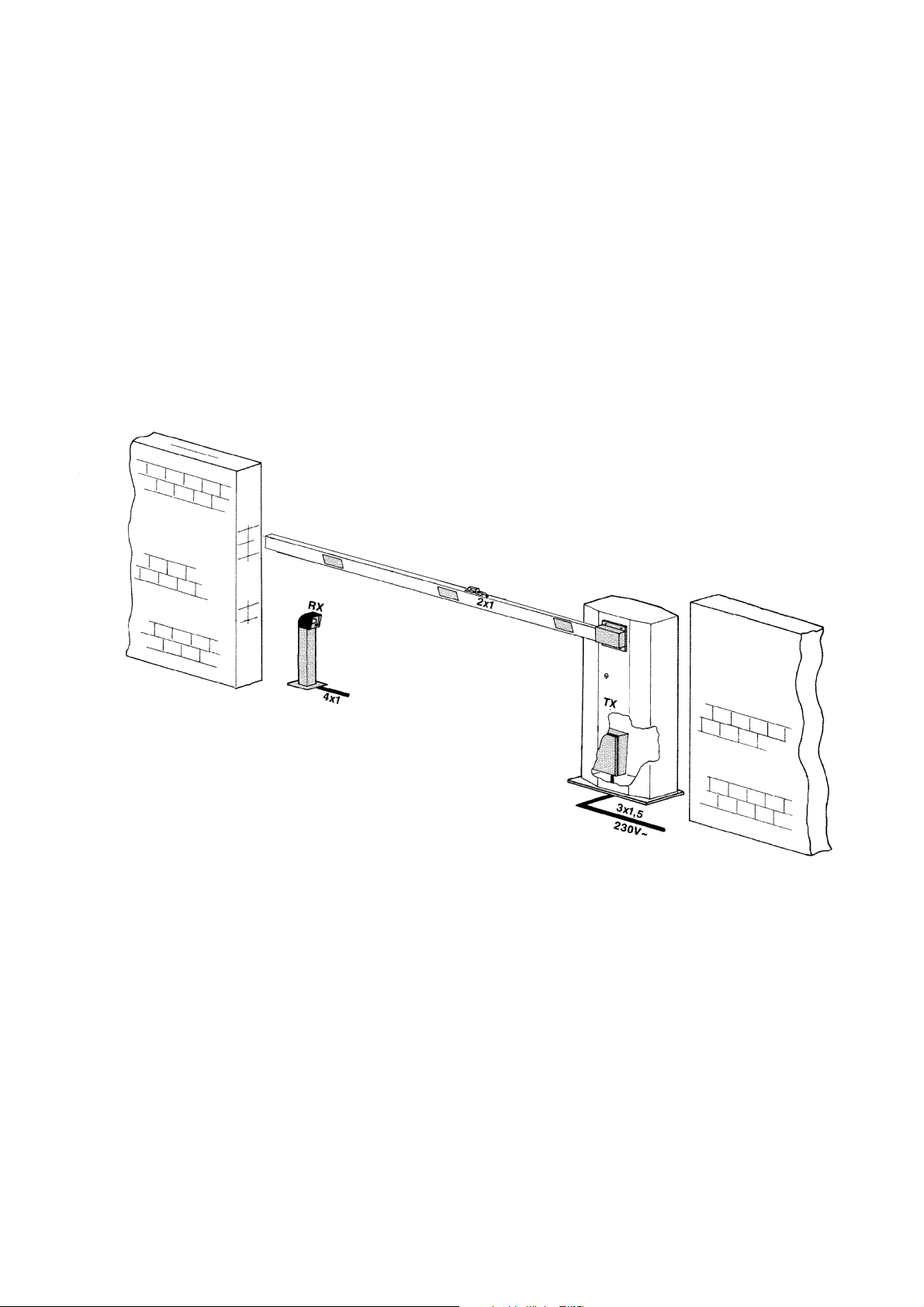

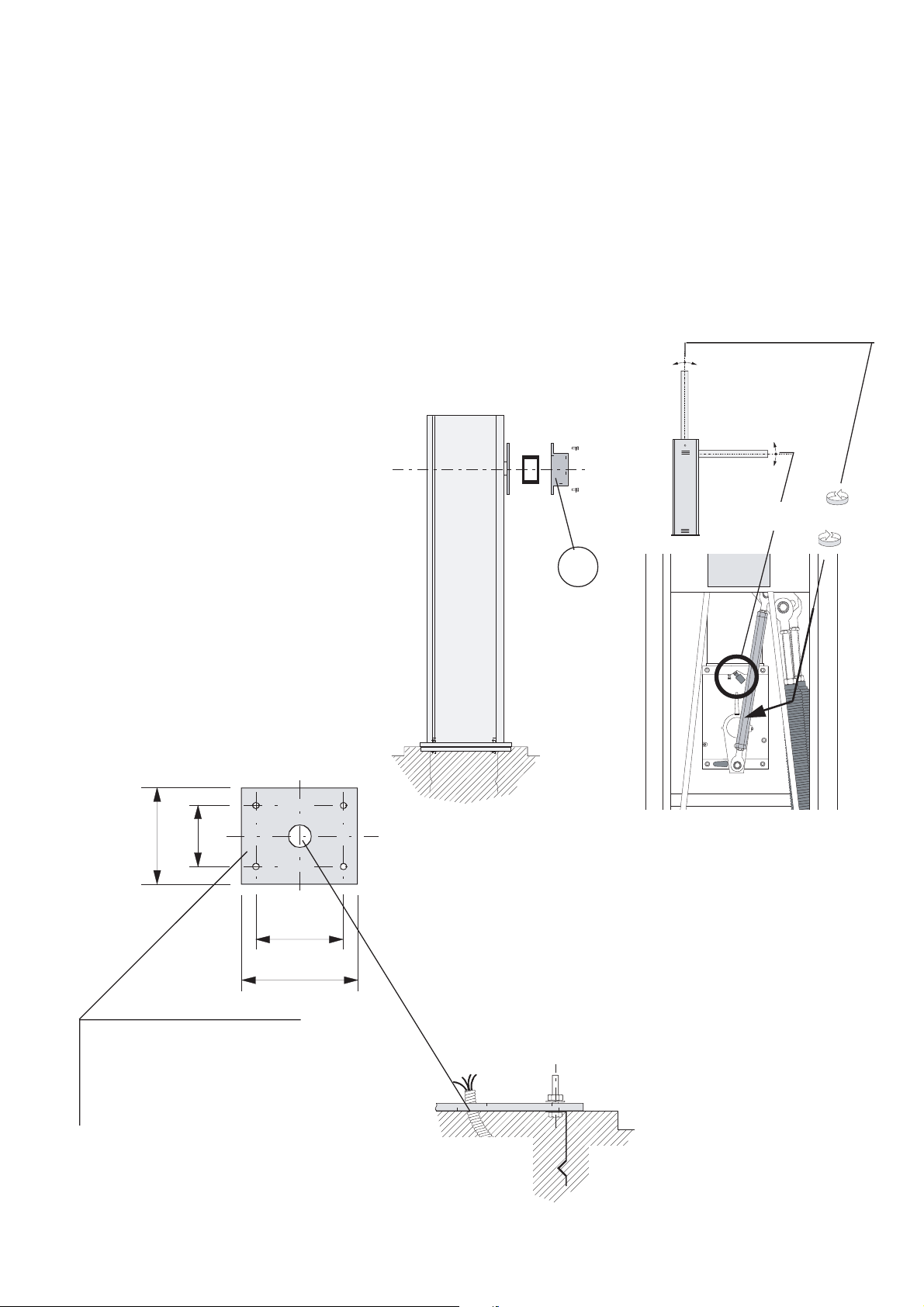

INSTALLATION

Construct an adequate concrete base of the correct size for the installation of the unit. When pouring,

sink the anchoring stays and the mounting base for the unit into the concrete. The concrete base must

be perfectly level and clean from end to end. All screw threads must be completely accessible from

the surface of the concrete base. The electrical cables from the unit must also protrude from the base.

When the concrete is set place the unit on the base. It is good practice to have the inspection door

on the inside of the property .Tighten the unit down and check for level. Fit the barrier arm and adjust

the mechanical stops to stop the arm in the desired position.

5

B

C

A

140

240

380

Mounting base for case

460

Cable exit

Page 7

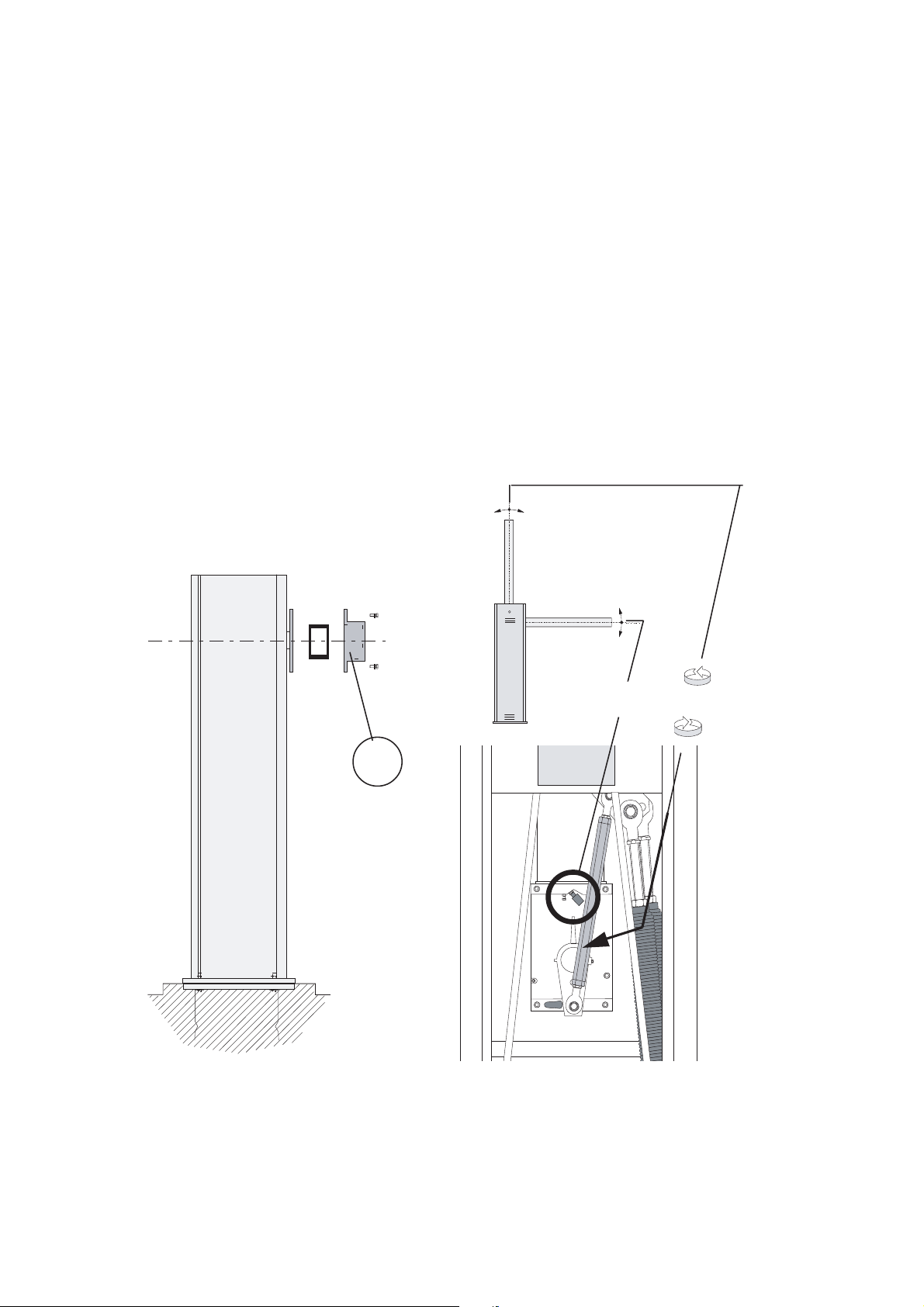

COMMISSIONING

1. Ensure that the barrier is securely fastened to the base plate with the bolts provided. It is good

practice to install the barrier so that the access door is on the inside of the installation.

2. First determine the length of our barrier arm the insert the arm into the holder and secure with the

four allen screws provided. Adjust the mechanical stops B and C to obtain the desired vertical and

horizontal positions. (see figure 1)

6

A

B

C

Page 8

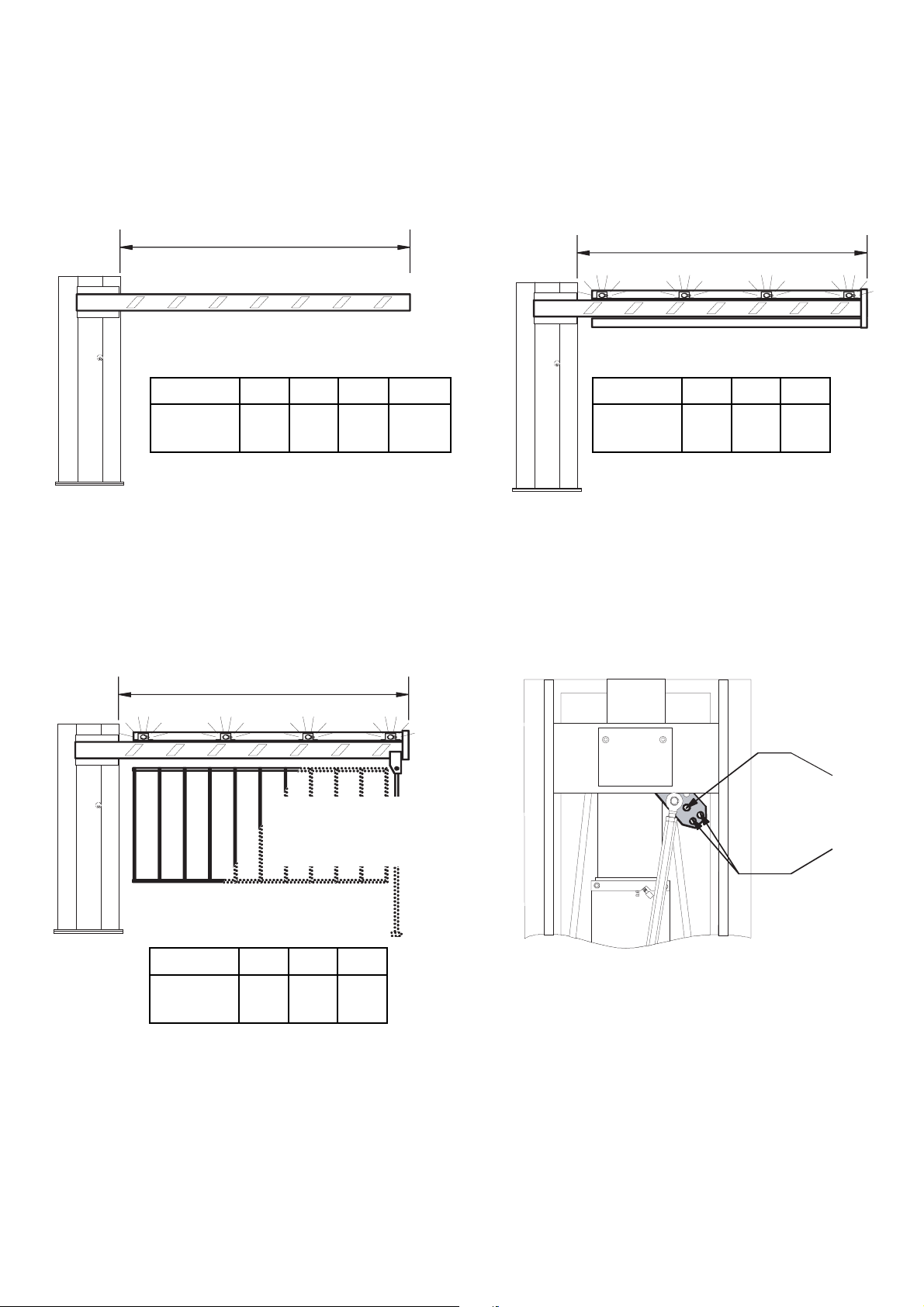

3. The G6000 Barrier is supply with both springs installed in position B. If the final configuration of you

barrier requires a spring change follow the illustrations below.

7

L m <4 <5 <6 <6.5

Spring 1A 1A 1B 1A

Positions 1B

L m <4 <5 <6

Spring 1A 1B 1A

Position 1B

Spring

attachment

Points

With skirts or

Mobile support

L m <4 <5 <6

Spring 1B 1A 2B

Position 1B

L

L

L

A

B

Page 9

4. Unlock the gearmotor and change the position of the springs (do not throw away the spring if not

used)

5. The barrier arm should be balanced at 45º for the barrier to work correctly.

1) Manually release the gear motor by using the manual release key.

2) Loosen locknuts B on the tension rods A.

3) Manually adjust the springs to increase/decrease their tension until the barrier arm is balanced at

45º.

4) Now tighten the locknuts and re engage the gear motor by using the manual release key.

8

200 max80 max

A

B

Page 10

6) Connect mains power to terminals L1 and L2 and connect to a suitable earth.

7) Set all dipswitches off accept 8 and 9 ON for commissioning and insert a wire link between

terminals 2 and C1

8) Set potentiometer SENS to the halfway position for commissioning.

9) Set potentiometer TCA to minimum for commissioning

10) Set the Transformer as follows for commissioning: - SPEED to minimum and DECLERATION to

minimum.

To set the speed and deceleration, move the faston connectors “A” and “B” onto the indicated

terminals

11) Ensure that the barrier arm is locked in the 45° position.

12) Momentarily pulse terminals 2 and 3 and the barrier should move to the open Position. Once the

barrier is in the up position pulse terminals 2 and 7 to make the barrier come down.

13) Prove and adjust the open and closed limit stops to the desired position.

9

Deceleration

Max Min Min Med Max

C

O

M

Speed

Page 11

14) Check the sensitivity of the barrier by physically trying to stop the barrier when it is moving to the

closed position, If the arm is easily stopped the power needs to increased by turning

potentiometer SENS more to the minus position.

TRIMMER SENS

15) If automatic closing is required move dipswitch 1 to the on position and adjust potentiometer TCA

until the desired time is achieved.

16) If safety beams or induction loops are used to prevent the barrier closing onto vehicles, remove

the wire link between terminals 2 and C1. This will give you re-opening during closing.

17) If “Emergency stop” is required insert the safety device (normally closed) into terminals 1 and 2

and move dipswitch 9 to the OFF position.

18) If a closed only button is required move the jump strap that is positioned between the terminal

blocks to the number 4 position. This will give you closed only on terminals 2 and 7.

19) If a full-length barrier arm is fitted with accessories it is advised to use the increased braking facility

by moving dipswitch 10 to the OFF position.

10

Page 12

TROUBLE SHOOTING

Fault Action

Barrier goes up but will not go down If NO safety devices are fitted check that there is

a link fitted between terminals 2 and C1.

If safety devices are fitted check that they are

giving a closed circuit when the are working

normally.

The barrier stalls when moving up or down Check that the barrier is balanced at the 45∞when

the barrier is manually released.

Check that the barrier sensitivity is set correctly

and adjust accordingly.

(minimum sensitivity gives you maximum power)

The barrier arm stalls when a Check all of the above

short arm is fitted Check that the increased braking facility has not

been used (dipswitch 10)

TECHNICAL HELP LINE

0115 9210430

11

Page 13

12

TECHNICAL DESCRIPTION OF ZL37F

CONTROL PANEL

This control board is powered by 230V a.c. across terminals L1 and L2, and is protected by a 3.15A

fuse on the main power line. Control systems are (24) powered by low voltage and protected with by

a 2A fuse. The total power consumption of 24V accessories must not exceed 20 W.

SAFETY

Photocells can be connected to obtain:

a) Re-opening during the closing cycle;

b) Total stop: the movement of the bar is interrupted, and the automatic closure cycle is disactivated.

Use the keyboard or the radio transmitter to resume movement of the bar;

- Amperometric safety device: see

NOTE;

- Fixed operating time of 20 sec.

OTHER FUNCTIONS

- Automatic closing: The automatic closing timer is automatically activated at the end of the opening

cycle. The preset, adjustable automatic closing time is automatically interrupted by the activation of

any safety system, and is deactivated after a total stop command or in case of power failure;

- Immediate closure (the bar is lowered automatically after the vehicle has passed the safety devices,

on the terminals 2-C5 of the control panel;

- "Operator present" function. Bar operates only when the pushbutton is held down (the radio remote

control system is deactivated);

- Obstacle detection: When the motor is stopped (bar is closed, open or half-open after an

emergency stop command), the transmitter and the control pushbutton will be deactivated if an

obstacle is detected by one of the safety devices (for example, the photocells);

- Flashing light activated before opening and closing cycle begins;

- Activation of a 24V output signal during the movement phases and in the closed position;

- "Slave" operation when two motors are used in combination (see page 22);

- Increases the braking action on the barrier;

- Selection of command sequence: open-close, open only.

ACCESSORIES CONNECTED IN SERIES

- Flashing signal light (25W max.), when bar is in motion.

OPTIONAL ACCESSORIES

- Open barrier pilot lamp (3W max.). This is a light that indicates the barrier open position and turns

off when the barrier activates the closing end-stop (terminals 10-5);

- LB35 board, used to power the automation system using battery power in case of a power failure.

When the power supply is restored, the batteries are recharged automatically (refer to instruction

sheet);

ADJUSTMENTS

- Sensitivity of amperometric safety system: min./max.

- Automatic closing time

Page 14

13

ZL37F MOTHERBOARD

MAIN COMPONENTS

1 Terminal block for external connections

2 3.15A line fuse

3 2A accessories fuse

4 "Function selection" dip-switch

5 Radiofrequency board socket (see table)

6 TCA trimmer: automatic closing time adjustment

7 SENS trimmer: amperometric sensitivity adjustment

8 Button for memorizing code numbers

9 Radio code / automatic closing signal LED

10 Connectors for power supply motor

11 Connectors for connection to battery charger (LB35)

12 Jumper for selection of type of control for button in 2-7

L1T

L2T

M

PT

"B"

Min.Max.

Max.Med.Min.

"A"

QU A DRO CO M AND O

ZL 37

21 345678910

Page 15

14

DIPSWITCH SELECTION OF FUNCTIONS

1 ON Automatic closure enabled;

2 ON "Only open" radio control or pushbutton function enabled (with plug-in radiofrequency

board);

2 OFF "Open-close-reverse" radio control or pushbutton function enabled (with plug-in radio

frequency board);

3 ON 24V output voltage on 10-E terminals when the barrier is in motion and in the barrier's

closed position, enabled;

3 OFF 24V output voltage on 10-E terminals when the barrier is in motion, enabled;

4 ON "Operator present" function enabled;

5 ON Pre-flashing (aperture and closure) enabled;

6 ON Obstacle detection device (motor of limit position) enabled;

7 ON "Slave" operation (motor is controlled externally) enabled;

8 OFF Immediate closure function enabled; activate safety device (2-C5);

9 OFF "Stop" button enabled; activate safety device (1-2);

10 ON Function that increases the braking action on the barrier enabled;

ON

2345678910

ON

OFF

L1

QU ADRO COMAND O

ZL 37

L1TL2

PT

L2T

0

Vel.

Rall.

74

21 345678910

Page 16

15

PROGRAMMING THE REMOTE CONTROLS

T432S (MINI-PINK) Remotes

Remove the battery cover off of the remote and change the Factory set code to a unique code for the

installation via the 10 dipswitches.

Insert the frequency card into the control panel (item 5 on motherboard). Identify the little yellow button

on the motherboard and press and hold the little yellow button in and an LED will flash. Then press

the button on the remote control you wish to operate the equipment with and then let go of both

buttons. Make sure any additional remotes are the same code. You do not have to program these into

the board - they should work.

Channel 1

Channel 3

Channels

selection

jumpers

Code selection

dipswitch:

set the same

code

programmed

on receiver

actionning LED

4 pins strip

1st key fixed

on channel 1

2nd key preset on

channel 2; put the

jumpers as shown in

figures to change

Channel 4

Channel 2

Channels Scheme

"AF" BOARD

- T.C.A .

-

OFFON

NS. -

MOTHERBOARD

1ON2345678910

Page 17

16

PROGRAMMING THE REMOTE CONTROLS

Use on existing system

(with TOP at 433.92 MHz)

1. Press the key to encode until, after 7 seconds of

flashing, the red signalling LED remians on. (fig A)

2. Within 10 seconds, bring the existing transmitter

closer from the rear part and press the pushbutton you

want to copy for a few seconds. (fig B)

Once it has been saved, the LED will flash 3 times

and the transmitter will be ready for use.

Repeat 1 and 2 for the other pushbuttons. (NB: the code of

another system can be saved).

Use on new system

Consult the documentation of the electric board to save the first transmitter, then follow the procedure

described above to duplicate it in the quantity desired.

To open battery compartment, press and slide.

Red signalling LED

A

B

Page 18

17

ZL37F

ELECTRICAL CONNECTIONS

11

L1

L2

M

N

10

E

E

+10 - 11 1 2 C 1 C 5

230V (a.c.) power supply

24V (d.c.) motor

Uscita 24V in movimento (es.lampeggiatore - dip 3 OFF)

24V output in motion (e.g. flashing light - Pos. B Jumper)

Sortie 24V en mouvement (ex. branchement clignotant - Jumper Pos. B)

Ausgang 24V in Bewegung (z.B. Blinker-Anschlufl - Jumper Pos. B)

24V output

Salida de 24V en movimento (ej. l· mpara intermitente - Jumper Pos. B)

7

5

3

during movement (e.g. flashing light)

during movement and in the closed position

INTERBLOCCO

FA FC F

PT

MN

DIP 3

OFF

DIP 3

ON

10

5

10

11

1

2

24V -3W max. "bar-opened" signal lamp

Power supply accessories (max. 40W):

24V (a.c.) with power supply at 230V (a.c.)

24V (d.c.) with power supply at 24V (d.c.)

Pushbutton stop (N.C.)

N.B. When connecting the

photocells (TX and RX),

observe the correct

polarities.

TX

RX

NO C NC

101011

Page 19

18

ZL37F

ELECTRICAL CONNECTIONS

2

3

2

7

2

C1

Open pushbutton (N.O.)

Collegamento radio e/o pulsante (N.O.)

per tipo comando, vedi dip-switch 2

Connector (N.O.) radio and/or pushbutton. See DIP 2 for command type

Connector (N.O.) radio and/or pushbutton

see dip-switch 2 for command type

Connection radio et/ou bouton-poussoir (N.O.)

pour commande voir dip-switch 2

Anschlufl Funkkontakt und/oder Taste (N.O.)

Steuerart siehe dip-switch 2

Button operation: closure only

ConexiÛn radio y/o pulsador (N.O.)

para mando mirar dip-switch 2

Contact (N.C.) for ´ re-aperture during closureª

if not used

JUMPER

JUMPER

2-C1

E 10 111 2 3 5 7C1 C

5

2

C5

F

FA

F

FC

Contact (N.C.) of ´ immediate closureª

Connection microswitch deceleration opens

Connection microswitch deceleration closes

if not used

dip 8 ON

Antenna connection

Page 20

19

ZL37

BARRIER SPEED ADJUSTMENT

To set the barrier speed and deceleration, move the faston connectors “A”+”B” onto the indicated

terminals

C

O

M

BA

DECEL

SPEED

ARM

SPEED

Max Min Min Med Max

Page 21

CONNECTION FOR TWO COMBINED MOTORS

CONTROLLED TOGETHER

1) On one of the two control

panels, set Dip 7 to ON in order

to select the motor controlled

externally (slave).

2) Wire the electrical

connections only on the

terminal board for the pilot

motor in the normal.

3) Connect the two control

panels using the interlock

terminals as shown in the

figure.

ad

ad

20

SX DX

CAME

1)

2)

Slave motor 2∞ control panel

Deceleration

SpedVelocit‡

Rallentamento

Vitesse

Ralentissement

Geschw.

Geschw.

Velocidad

Abnahme

DeceleraciÛn

C

O

M

Max.Med.Min.Min.Max.

"B" "A"

0

Vel.

Ral.

line fuse

motor fuse

accessories fuse

74ZL 37

Deceleration

Speed

Rallent amen to

Veloc it ‡

Vitesse

Ralentissement

Geschw.

Geschw.

Abnah m e

Velocidad

DeceleraciÛn

C

O

M

Max.Med.Min.Min.Max.

"B" "A"

PT

L1TL2L1

L2T

0

Vel.

line fuse

motor fuse

CONTROL PANEL

ZL 37

Rall.

74

accessories fuse

21 3 45678910

(pilot) motor 1∞ terminal block

3)

Deceleration

Speeeed

Rallentamento

Velocit‡

Ralentissement

Vitesse

Geschw.

Geschw.

Abnahme

Velocidad

DeceleraciÛn

C

O

M

Max.Med.Min.Min.Max.

"B" "A"

2C1C5

735 INTERBLOCCO

PT

L1TL2L1

L2T

0

Vel.

Rall.

line fuse

motor fuse

accessories fuse

CONTROL PANEL

74

ZL 37

213456 78910

E

+10-11 1 2 C1C5

FAFC F

PT

3

MN

7

5

INTERBLOCCO

Deceleration

Speeeed

Rallentamento

Velocit‡

Ralentissement

Vitesse

Geschw.

Geschw.

Abnahme

Velocidad

DeceleraciÛn

C

O

M

"B" "A"

E

+10 - 1 1 1 2 C1 C 5

PT

L1TL2L1

L2T

0

Vel.

Rall.

line fuse

motor fuse

accessories fuse

CONTROL PANEL

74

ZL 37

FA FC F

Max.Med.Min.Min.Max.

735 INTERBLO CCO

21345678910

Slave motor 2∞ terminal block(pilot) motor 1∞ terminal block

PT

MN

Page 22

21

HANDING THE G6000 BARRIER

SX = With the barrier arm on the outside and the cabinet facing the inside of the property. This unit is

usually positioned on the left.

DX = With barrier arm on the outside and the cabinet facing the inside of the property. This unit is

usually positioned on the right.

OUTSIDE

INSIDE

SX DX

IF THERE ARE ANY PROBLEMS PLEASE CONTACT THE CAME

TECHNICAL HELPLINE:

0115 921 0430

Page 23

22

NOTES

Page 24

CONTACT INFORMATION

CAME UNITED KINGDOM LTD

UNIT 3

ORCHARD PARK INDUSTRIAL ESTATE

TOWN STREET, SANDIACRE, NOTTINGHAM NG10 5BP

TEL: 0115 921 0430

FAX: 0115 921 0431

INTERNET : www.cameuk.com

E-MAIL: enquiries@cameuk.com

THIS INSTALLATION WAS COMPLETED BY:

.........................................................................

NAME..............................................................

ADDRESS........................................................

.........................................................................

.........................................................................

.........................................................................

TEL........................ MOBILE............................

DATE OF INSTALLATION................................

Loading...

Loading...