Page 1

AUTOMATION FOR STREET BARRIERS

GARD 4 SERIES

INSTALLATION MANUAL

G4040 - G4040I

Page 2

“IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLATION”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL INSTALLERS OR QUALIFIED PERSONS”

1 Legend

This symbol indicates sections to be read with particular care.

This symbol indicates sections concernig safety

This symbol indicates notes to communicate to users.

ENGLISH

2 Destination and limits of use

2.1 Destination

The GARD 4 automatic barrier was designed for use in private or public carparks, in residential areas or in highly traffi cked

areas.

The use of this product for purposes other than as described above and installation executed in a manner other than as

instructed in this technical manual are prohibited.

2.2 Limits of use

Passage width of up to 3.75 meters with a 2- to 6-second aperture time.

3 Standard followed

The following standard were complied with for this product: EN 12978, UNI EN 954-1, CEI EN 60335-1, UNI EN 12453.

4 Description

4.1 Gearmotor

GARD 4 was designed and manufactured by CAME CANCELLI AUTOMATICI S.p.A. and is compliant with safety regulations in

force. Guaranteed 24 months if not tampered with.

The cabi ne t is ma de o f 2.5 mm pa in ted g al v ani zed s t eel or 2 mm A ISI 304 sat in -fi nish s t ai nles s s te el. Ins ide t he c ab ine t, t he

electr omechanic al gearmo tor operate s with a con tainer for el ectri c board and tr ansformer. Built wi th a anti- shearing s afet y

system, it includes a safety contact in the inspection hatch lock and in the emergency release lock.

There are two versions of the GARD 4 model:

G4040 - painted galvanized steel automatic barrier with a 24V DC gearmotor and container for board and transformer;

G404 0I - satin -finish A ISI 30 4 st ainle ss st eel au tomat ic bar rier w it h 24V DC gearmo tor and c ont ainer f or boar d and tr ans former;

The GARD 4 automation system is supplied with the following accessories:

001 G03750 – L. 4m semioval aluminium bar, painted white, with slot cover and shock-resistant profi le;

001 G03752 – L. 4m oval aluminium bar, painted white, with slot cover;

001 G02040 – Ø 40 (yellow) balancing spring;

001 G04060 – Ø 50 (green) balancing spring;

001 G06080 – Ø 55 (red) balancing spring;

003 ZL38 - Electric board designed to accommodate radio board coupling;

002 LB38 – Board for the connection of three 12V-6Ah emergency batteries;

The following accessories are optional to the GARD 4 automation system:

001 G02801 – Flashing dome lamp;

001 G028 02 - Suppor t fo r moun t in g t he p ho to e l e c t r i c c e ll (DIR) onto the cabinet ( n o t ap pli cable to bar riers wi t h b a r an d rack

and/or mobile foot);

001 G03751 - Emergency battery housing support;

001 G02803 - Luminous cord for movement signalling;

001 G02804 - Luminous cord connecting cable;

001 G02807 - Fixed barrier support;

001 G02808 – Mobile barrier support;

001 G02809 – Red reflector strips (package of 20);

001 G0465 - Painted aluminium rack in 2m modules;

Importan t! Check that the safety equipment and accessories are CAME originals; this is a guarantee that also makes the system

easy to set up and upkeep.

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

2

Page 3

4.2 Technical information

GEARMOTOR

Power supply: 230V A.C. 50/60Hz

Motor power supply: 24V D.C. 50/60Hz

Max. absorption: 1.3A (230V) / 15A (24V)

Rated power: 300W

Max. torque: 600 Nm

Reduction ratio: 1/202

Opening time: 2÷6 s

Operative intermittence: intensive operation

Protection level: IP54

Weight: 54 kg

Insulation class: I

#

#

ENGLISH

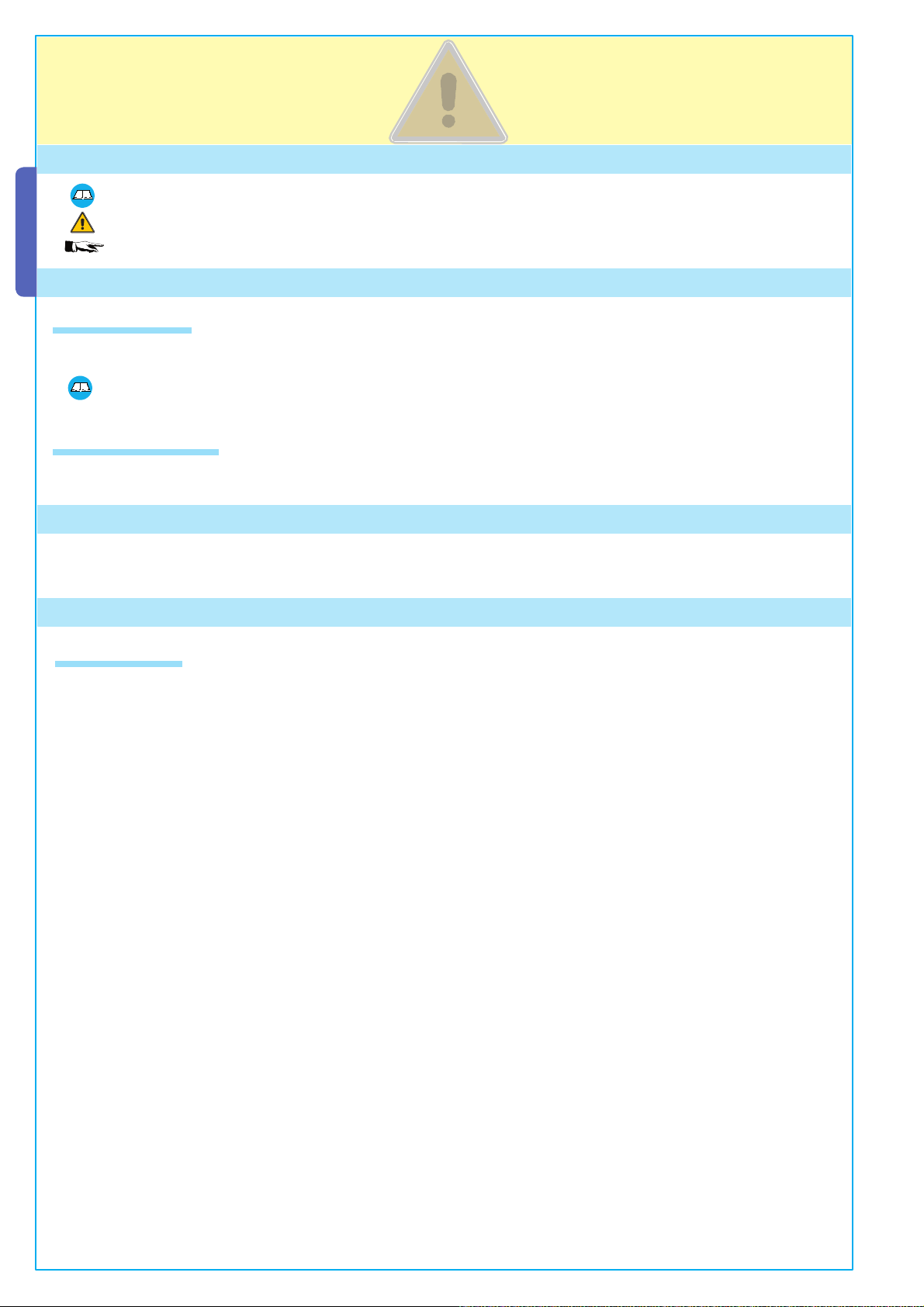

4.3 Parts description

AUTOMATION UNIT

1)

Upper dome

2)

Bar beam plate

3)

Bar fitting intermediate plate

4)

Cover for semioval aluminium bar

5)

Anti-shearing protection cover

6)

Sheet-steel or stainless steel cabi-

net with galvanized and painted finish

7)

Inspection hatch

8)

Gearmotor

9)

ABS container for electric

board with transformer

VIEW FROM THE BAR

SUPPORT BRACKET

1

7

2

3

4

5

VIEW FROM INSPECTION

HATCH

9

8

ACCESSORIES

1)

2)

3)

4)

5)

6)

7)

8)

9)

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

10)

11)

12)

13)

14)

15)

6

G03750 - Semioval aluminium bar, painted white L = 4 m.

G03752 - Oval aluminium bar, painted white L = 4 m.

G02040 - Ø40 (yellow) balancing spring

G04060 - Ø50 (green) balancing spring

G06080 - Ø55 (red) balancing spring

G0465 - Rack

G02802 - Support for DIR photoelectric cells

G02803 - Luminous cord

G02807 - Fixed barrier support

G02808 - Mobile barrier support

G02809 - Adhesive reflector strips

G02801 - Flashing dome lamp

G03751 - Emergency battery housing support

ZL38 - Electric board designed to accommodate radio board coupling

G03753 - cover for oval aluminium bar

13

6

11

10

14

CAME

CAME

CAME

CAME

15

3

4

5

9

:,

7

12

8

1

2

3

Page 4

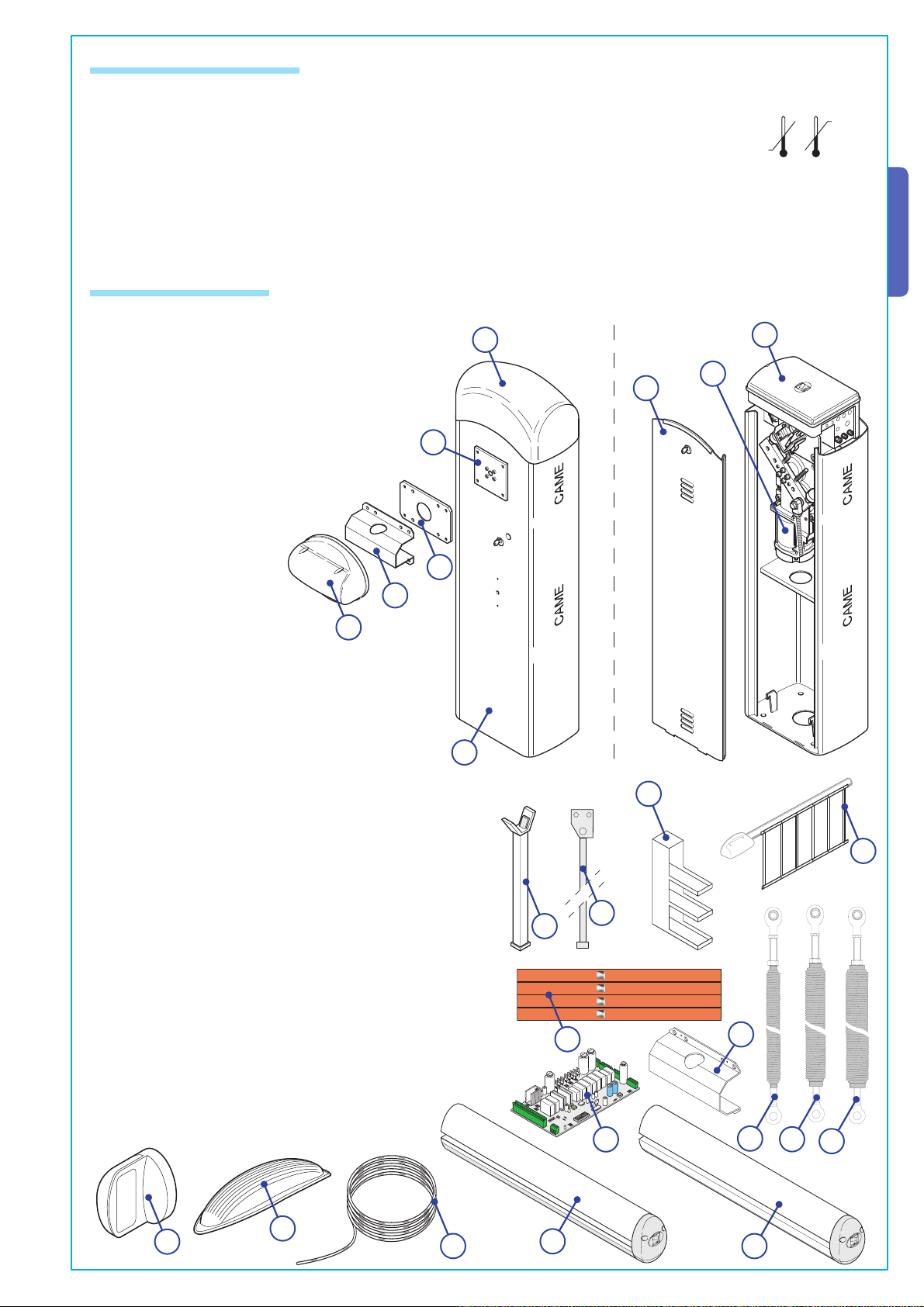

4.4 Size measurements

ENGLISH

MAX

Measurements in mm

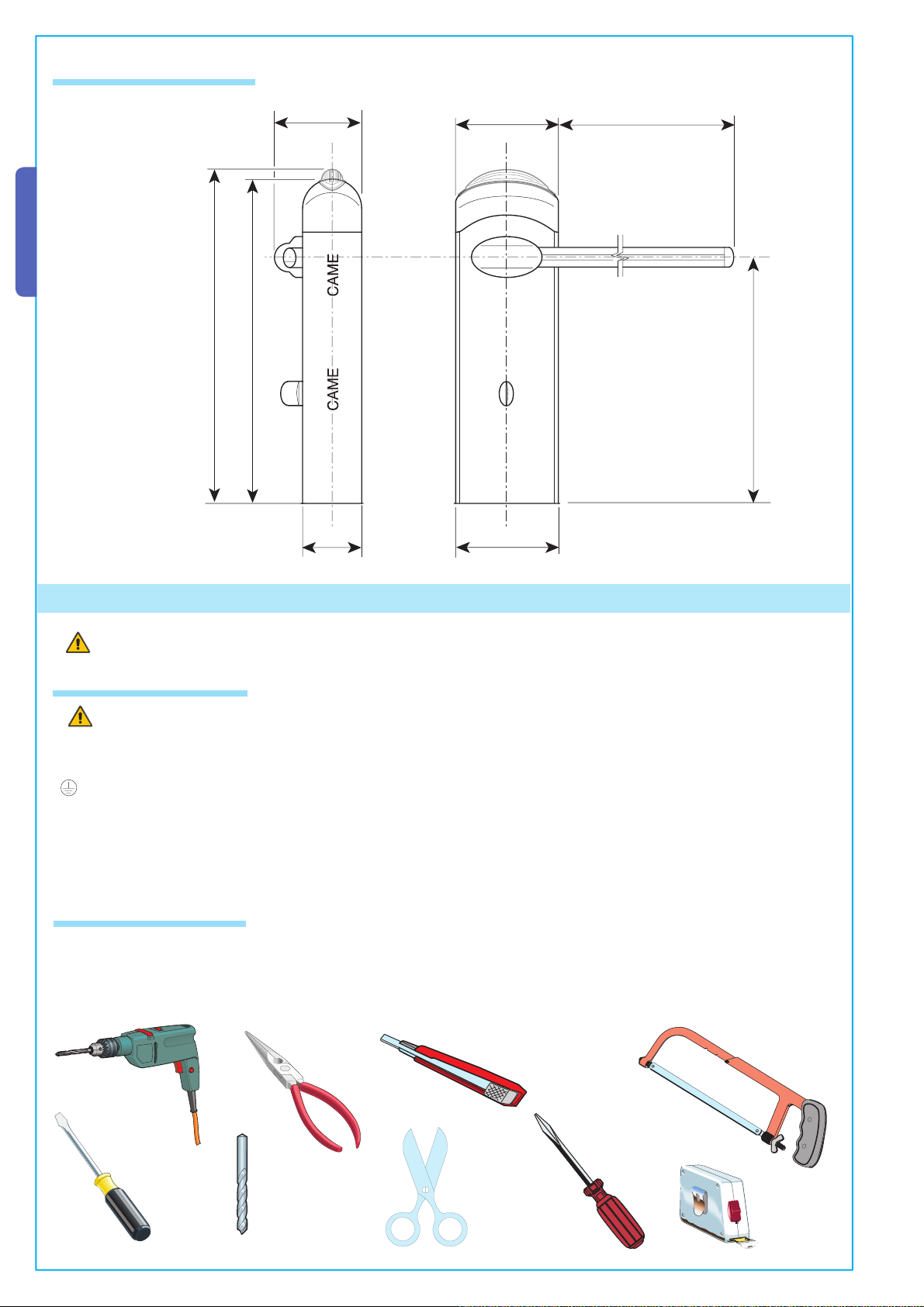

5 Installation

Installation must be carried out by expert qualified personnel and in full observance of regulations in force.

5.1 Preliminary checks

Before proceeding with the installation, it is necessary to:

• Make sure the area selected for the mounting of the base and for the unit itself presents no hazards;

• Provide for suitable omnipolar disconnection device with more than 3 mm between contacts to section power supply.

• Connections inside the case made for protection circuit continuity are allowed as long as they include additional insulation

with respect to other internal drive parts.

• Install suitable tubes and ducts for electric cable passage to guarantee protection against mechanical damage.

5.2 Tools and materials

Make sure all tools and materials necessary are within reach to install the edge in maximum safety, according to regulations in

force. The following figure illustrates the minimum equipment for the installer.

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

4

Page 5

5.3 Cable list and minimun thickness

Connections Type of cable Length of cable 1 < 10 m Length of cable 10 < 20 m Length of cable 20 < 30 m

230V 2F power supply

3G x 1,5 mm

24V motor power supply 2 x 1 mm

24V - 230V flashing lamp 2 x 0,5 mm

Photoelectric cells TX 2 x 0,5 mm

Photoelectric cells RX 4 x 0,5 mm

24V power supply accessory 2 x 0,5 mm

FROR CEI

20-22

CEI EN

50267-2-1

Control button 2 x 0,5 mm

End stop 3 x 0,5 mm

2

2

2

2

2

2

2

2

3G x 2,5 mm

2 x 1,5 mm

2 x 1 mm

2 x 0.5 mm

4 x 0,5 mm

2 x 0,5 mm

2 x 0,5 mm

3 x 1 mm

Antenna connection RG58 max. 10 m

Metallic mass detector (see documents provided with product)

N.B.: An evaluation of the size of the cables with lengths other than the data in the table must be made based on the effective

absorption of the connected devices, according to the instructions indicated by the CEI EN 60204-1 standards.

For connections that require several loads on the same line (sequential), the size given on the table must be re-evaluated based

on actual absorption and distances.

2

2

2

2

2

2

2

2

3G x 4 mm

2 x 2,5 mm

2 x 1,5 mm

2 x 0,5 mm

4 x 0,5 mm

2 x 1 mm

2 x 0,5 mm

3 x 1,5 mm

2

2

2

2

2

2

2

2

ENGLISH

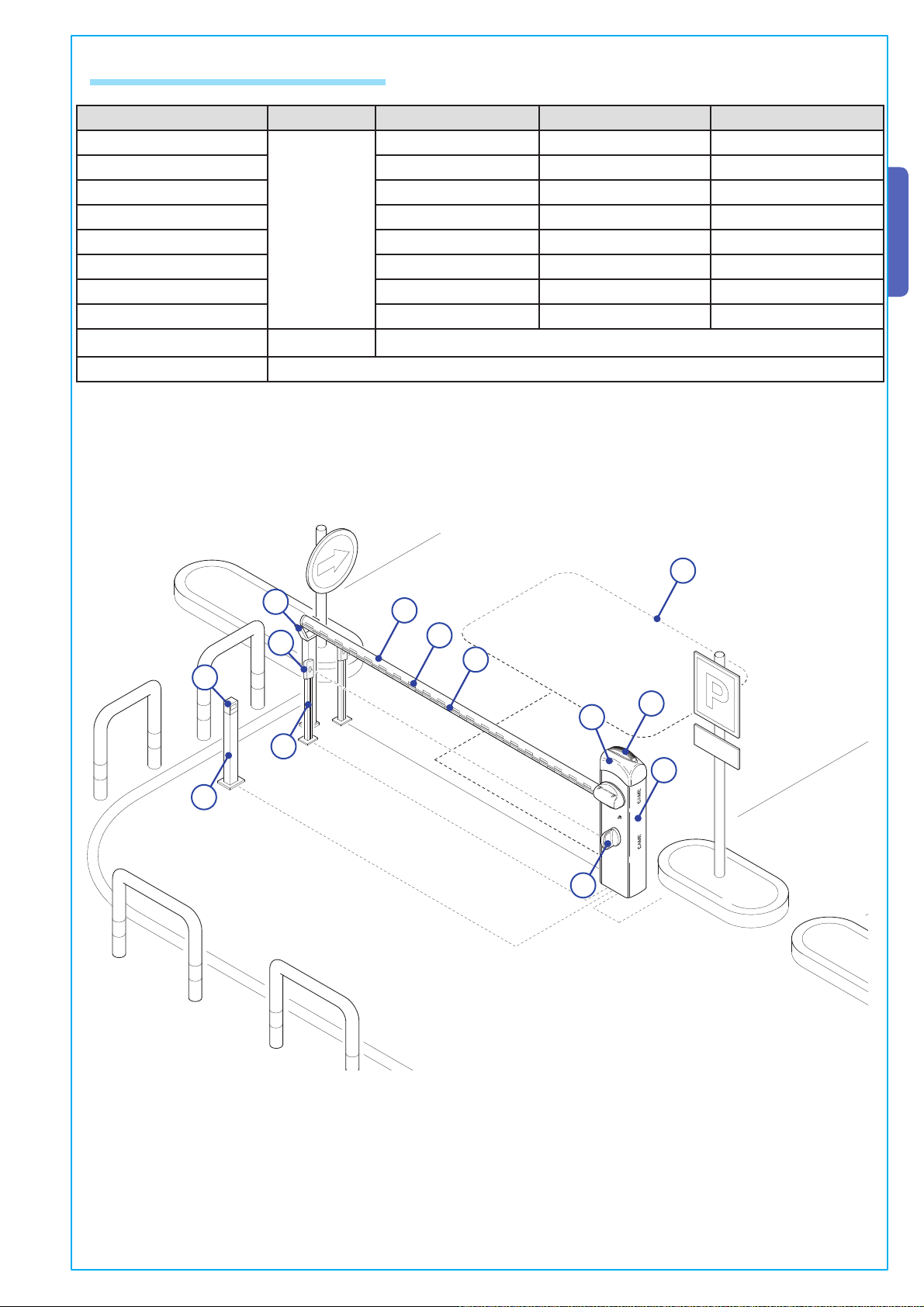

10

9

8

3

4

5

12

6

2

7

1

13

11

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

1 - GARD unit

2 - Control panel

3 - Aluminium bar

4 - Red phosphorescent strips

5 - Luminous cord

6 - Movement-indicating flashing lamp

7 - Column for photoelectric cells

8 - Photoelectric cells

9 - Fixed barrier support

10 - Magnetic sensor

11 - Photoelectric cell support

12 - Magnetic reader

13 - Column for reader

5

Page 6

5.4 Fitting for unit base

The following applications are only examples, as the space required for unit installation and the accessories vary

depending on dimensions and therefore it is up to the installer to select the best solution.

ENGLISH

1) Prepare a hole to house the fixing base and prepare

sheath tubes from the branch pit for the connections.

2) Assemble the four anchoring clamps at the base.

3) Fill the hole with concrete and immerge the clamps and the

fixing base, paying particular attention to the sheath tube which

must go through the hole at the base. The base must be perfectly

level, clean and with the screw threads fully on the surface.

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

4) Remove the nuts and washers from the threaded screws, position the cabinet

on the base in correspondence with the 4 threaded screws and secure with the

nuts and washers.

Note: We recommend installing the cabinet with the inspection hatch facing the

internal area.

6

Page 7

5.5 Installation of the Unit

1) Remove the two screws at the upper dome’s

side and lift it.

Insert the customised key in the lock, turn it

counter-clockwise and remove the hatch from the

cabinet.

ENGLISH

DX

SX

3) Should installation on the right be required, the direction of the bar’s

opening must be inverted. Proceed in the following manner:

- remove the anchor bolt for springs from the transmission arm;

- release the gearmotor with the key;

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

- turn the transmission arm around;

- secure the gearmotor again;

- secure the anchor bolt to the transmission arm’s opposite hole;

- invert the motor phase on terminals M and N;

- invert the end stop wires on terminals FA and FC.

2) The barrier is designed to be installed on the left of

the gateway as seen from inside.

38

$8

04 & &#

&!

-

.

7

Page 8

Bar beam plate

Bar fi tting intermediate plate

Bar fi tting cover

ENGLISH

5) Insert the bar in the fitting cover and secure

it with UNI 5931 M8x20 and M8x12 screws.

4) Position the middle plate between the fitting plate and the

bar-fitting cover, and put in one UNI 5931 M8x20 screw without

tightening it to facilitate bar assembly.

UNI5931 M8x12

UNI5931 M8x20

UNI5931 M8x12

UNI6954 ø2,9x13

6) Measure the length of the bar, cut the bar slot to

,

the same length and insert it in the bar’s conduit, a

procedure that should be carried out on both sides.

Insert the shock-resistant profile and cut excess

length. Lastly, secure the bar end plug with the

screws provided.

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

8

Page 9

7) Tighten the anti-shearing protection cover to the bar fitting

with UNI6954 Ø3.9x19 screws.

5.6 Bar balancing

ENGLISH

1) Prior to bar balancing, select a suitable spring depending on the situation at hand.

See table below.

PASSAGE CLEARANCE LAMP (max. 3.75 m)

Passage clearance lamp (m) 1.5

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

1.75

Bare bar* + shock-resistant profile

Bare bar* + shock-resistant profile and luminous cord

Bare bar* + rack

Bare bar* + luminous cord and rack

Bare bar* + shock-resistant profile and mobile barrier support

Bare bar* + shock-resistant profile, luminous cord and mobile barrier support

Bare bar* + rack and mobile barrier support

Bare bar* + luminous cord, rack and mobile barrier support

G02040 spring Øe = 40 mm

G04060 spring Øe = 50 mm

G06080 spring Øe = 55 mm

2.0

2.25

2.5

2.75

3.0

3.25

3.5 3.75

* By Bare bar we mean a bar complete with the transparent slot cover and end plug.

9

Page 10

2) Release the gearmotor and position the bar vertically, and then refasten the gearmotor.

WARNING! The release procedure may

constitute a hazard for the user when, for whatever

reason – the bar is fixed improperly to the housing

during assembly, or the bar is cracked or broken

ENGLISH

in an accident, and so on – the tension springs no

longer provide balance! These can thus cause a

brusque rotation of the bar attachment and/or of

the bar itself.

3) Tighten the tie rod to the spring and then the top part of the

spring to the anchor bolt with an anchor nut.

4) Hook the tie rod to the

anchoring bracket, release

the gearmotor and manually

turn the spring to increase or

decrease traction until the bar

rests at 45°.

10

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

Page 11

5.7 ZL38 Electric board installation

5) Tighten the blocking nut and refasten the gearmotor.

Note: make sure the spring functions properly:

- the spring is loose when the bar is in the vertical position (at rest)

- the spring is tight when the bar is in the horizontal position (tense).

ENGLISH

1) Loosen the three screws in the container cover located in the

upper part of the unit.

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

2) Insert the board in the container and fasten it with the screws provided; carry out all the

electrical connections (see the dedicated technical documentation enclosed with the board).

11

Page 12

5.8 End stop adjustment

Power up the ele ct ri c boar d, c arry out a s eri es of s tep s to ma ke sure of t he ba r’s cor re ct o penin g and cl osing p osi tio ns, an d

then, if necessary, proceed to the adjustment of the dampers.

Warning! For greater safety and better unit performance, the bar’s opening and closing operations should be carried out with

the inspection hatch closed!

1) Execute the closing operation, adjust the open bar’s position

by turning the free damper clockwise (to increase the bar’s

ENGLISH

run) or counter-clockwise (to decrease the run). Adjustment

of the position with a ~89° aperture from the closed position is

recommended.

Warning! The bar’s stop position is preceded by the slowing

phase by means of a tab and spring system that activates the

slowing-down microswitch prior to the bar’s total stop.

^

^

2) The procedure is similar for the bar’s opening position. Adjust the closure

damper screw until a position parallel to the road surface is reached.

^

^

12

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

Page 13

3) After bar opening and closing adjustment, tighten the locking nuts

under the dampers.

4) After making adjustments and settings from the control panel, put

the container lid in place and secure with screws.

ENGLISH

5) Insert the inspection hatch and close it.

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

6) Insert the protection dome on the upper part of the unit

and secure with the two UNI6954 Ø3.9x13 screws provided.

13

Page 14

6 Maintenance

6.1 Periodic maintenance

The unit does not require specifi c maintenance. Only as a precautionary measure and in case of intensive use, we recommend periodic checks (every 6 months) on the state of the electric wire connected to the motor, the spring-bar balance, the

tightness of the nuts and the proper oiling of the sliding points between fi xed and mobile parts.

All checks must be recorded (in a dedicated record-book).

6.2 Problem solving

MALFUNCTIONS REFERENCES CHECKS

ENGLISH

The unit neither opens nor shuts 1-2-3-4-6-8-18 1 – Close the inspection hatch with the key and check the

release lock

The unit opens but does not close 4-7-10 2 - Disable “steady movement” with dipswitch

The unit shuts but does not open 4-7-9 3 – Check power supply and fuses

No automatic closure 11-12-13 4 - N.C. safety contacts open (1-2 / 2-C1 / 2-C5)

The unit does not work if the remote control

is used

The unit inverts direction 7-18 7 – Check spring tension and balancing

The unit works only with remote control 22 8 – Disable obstacle detection with dipswitch

The photoelectric cell does not react 12-23-24 9 – Check if end stop opens

The signalling LED indicator flashes rapidly 4 10 – Check if end stop closes

The signalling LED indicator remains on 13 11 - Activate “automatic closure” dip switch

The unit does not end its run 7 12 – Check the correct direction of movement

The bar is not properly balanced 7-15 13 - (2-3 / 2-4 / 2-7) command button

The unit does not slow down 7-15 14 –Check jumper on AF43S, turn on/off power

The unit does not work with the back-up

batteries

The unit is slow to respond 7 16 – Re-save radio code

2-14-16 6 - Disable master-slave function

8-25-26 15 – Check the bar length ratio with mountable accesso-

ries

18 – Adjust sensitivity

22 - Enter or duplicate the same code in all the remote

controls

23 – Activate the photoelectric cell with the dipswitch

24 – Connect the photoelectric cells in a series, not in

parallel

25 – Dead batteries

26 –Respect the photoelectric cells’ polarity

7 Demolition and disposal

In its premises, CAME CANCELLI AUTOMATICI S.p.A. implements an Environmental Management System certifi ed in

compliance with the UNI EN ISO 14001 standard to ensure environmental protection.

Please continue our efforts to protect the environment—which CAME considers one of the cardinal elements in the development

of its operational and market strategies—simply by observing brief recommendations as regards disposal:

DISPOSAL OF PACKAGING – The packaging components (cardboard, plastic, etc.) are all classifi able as solid urban waste

products and may be disposed of easily, keeping in mind recycling possibilities.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of installation.

PLEASE DISPOSE OF PROPERLY!

PRODUCT DISPOSAL – Our products are made up of various types of materials. Most of them (aluminium, plastics, iron,

electrical wires, etc.) may be disposed of in normal garbage collection bins and can be recycled by disposing of in specifi c recyclable material collection bins and disposal in authorized centres. Other components (electrical boards, remote control batteries,

etc.), however , may contain polluting substances. They should therefore be removed and given to qualifi ed service companies for

proper disposal.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

14

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

Page 15

8 Manufacturer’s warranty

MANUFACTURER’S DECLARATION OF CONFORMITY

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030 Dosson di Casier - Treviso - ITALY

tel (+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Declares under its own responsibility that the equipments for automatic garage doors and

gates listed below:

AUTOMATION FOR STREET BARRIERS

CONTAINING SOME OF THE FOLLOWING ACCESSORIES

G4040 - G4040I

Pursuant to annex II B of the Machinery Directive 98/37/EC

G03750 - G03751 - G03752 - G02040 - G04060 - G06080

G02801 - G02802 - G02803 - G02804 - G02807 - G02808 - G02809 - G0465

… comply with the National Law related to the following European Directives and to the

applicable parts of the following Standards.

98/37/CE - 98/79/CE M

98/336/CEE - 92/31/CEE E

73/23/CEE - 93/68/CE LOW VOLTAGE DIRECTIVE

89/106/CEE CONSTRUCTION PRODUCTS DIRECTIVE

EN 13241-1 EN 12635 EN 61000-6-2

EN 12453 EN 12978 EN 61000-6-3

EN 12445 EN 60335-1 EN 60204-1

Reference code to request a true copy of the original: DDF B EN G001 ver.1.0

ACHINERY DIRECTIVE

LECTROMAGNETIC COMPATIBILITY DIRECTIVE

Do not use the equipment specifi ed here above, before completing the full installation

In full compliance with the Machinery Directive 98/37/EC

IMPORTANT W ARNING!

MANAGING DIRECTOR

Mr. Andrea Menuzzo

ENGLISH

All the data and informati on contained herein is c onsidered su b ject to change at any time and at our di scretion

15

Page 16

CAME UNITED KINGDOM LTD

UNIT 3, ORCHARD BUSINESS PARK TOWN

STREET, SANDIACRE

NOTTINGHAM - NG10 5BP - U.K.

Tel 0044 115 9210430

Fax 0044 115 9210431

Cod. 119GT80 ver.0.2 06/06 © CAME CANCELLI AUTOMATICI

Loading...

Loading...