Page 1

h

BX SERIES

AUTOMATION SYSTEMS FOR SLIDING GATES

INSTALLATION MANUAL

BX-246

nglis

Page 2

“IMPORTANT INSTALLATION, SAFETY INSTRUCTIONS”

2

119B U 50

1.0

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL OR QUALIFIED INSTALLERS”

1 Legend of symbols

This symbol tells you to read the section with particular care.

This symbol tells you that the sections concern safety issues.

This symbol tells you what to say to the end-users.

ENGLISH

2 Conditions of use

2.1 Intended use

The BX246 operator is designed to power sliding gates in residential and condominium settings.

Do not install or use unless as otherwise shown in this manual.

2.2 Limitations to use

For intensive or condominium use: max gate weight 600kg with max gate length 18 m.

3 Reference standards

The company CAME cancelli automatici is ISO 9001:2000 quality certified; it has also obtained the ISO 14001 environmental safeguarding certification. CAME engineers and manufactures all of its products in Italy.

This product complies with the following legislation: see declaration of compliance.

4 Description

4.1 Operator

This product is engineered and manufactured by CAME CANCELLI AUTOMATICI S.p.A. in compliance with current safety standards.

Guaranteed 24 months if not tampered with.

The operator is made of a cast aluminium part inside of which operates the irreversible, electromechanical gearmotor and an ABS

plastic lining which holds the electronic card, transformer and the clamp to house 2 emergency batteries.

4.2 Technical features

BX246 OPERATOR

Control panel power supply: 230V A.C. 50/60Hz

Operator power supply: 24V D.C.

Draw: 10 A

Power: 400 W

Reduction ratio: 1/33

Thrust: 700 N

Max speed.: 10 m/min max.

Duty cycle: intensive use

Protection rating: IP54

Insulation class: I

Weight: 15 kg

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

#

#

119 BU 50 ver.

2 - Manual code:

Pag.

Page 3

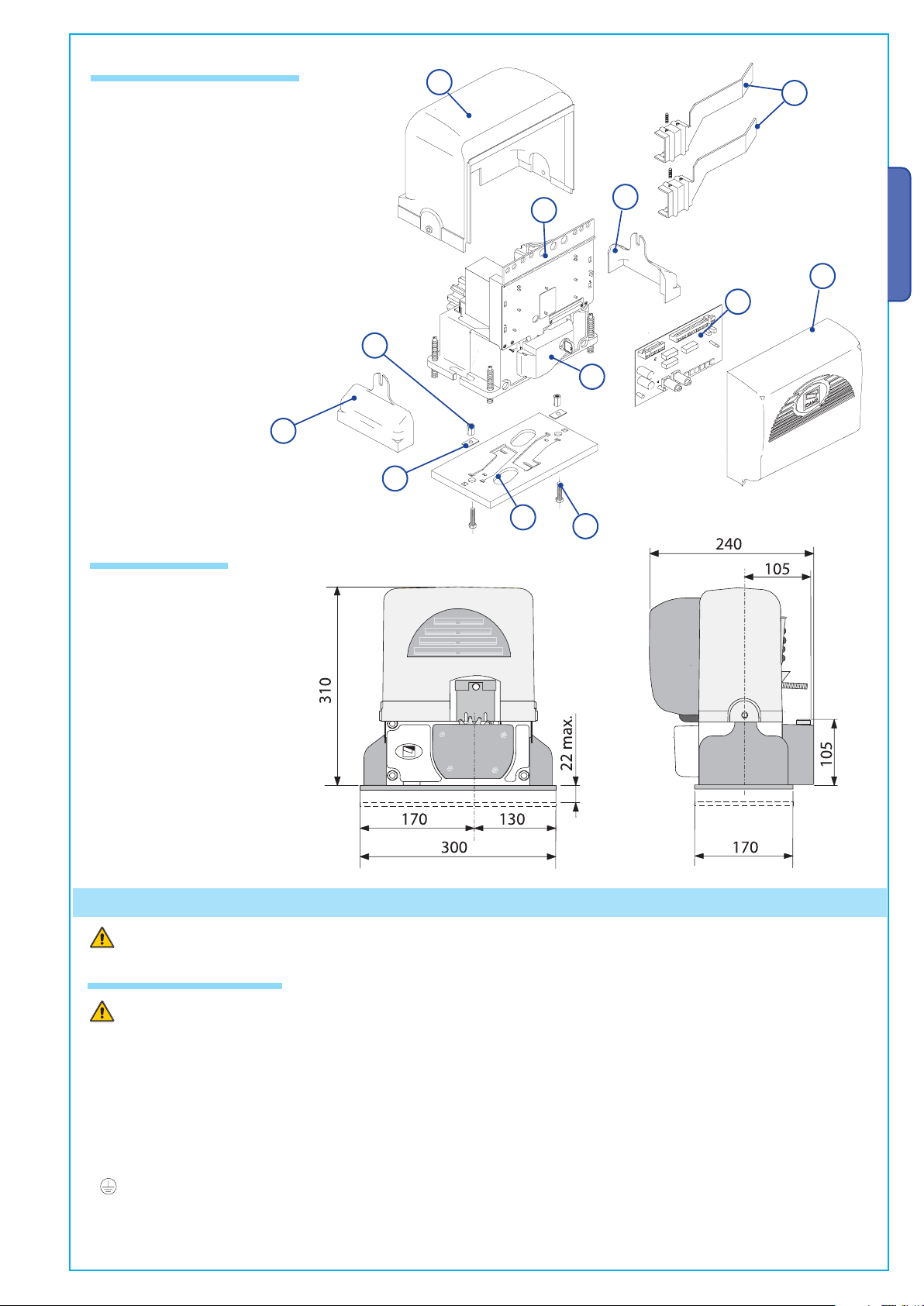

4.3 Description of parts

3

119B U 50

1.0

1 - Top cover

2 - Settings casing

3 - Control board support

4 - Endstop fins

5 - ZD2 electronic card

6 - Front cover to control panel

7 - Gearmotor release door

8 - Securing plate

9- Securing bolt

10- Securing screw plate

11- Nut

1

4

2

3

6

ENGLISH

5

11

7

2

10

8

9

4.4 Dimensions

(mm)

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

5 Installation

Installation must be carried out by expert qualified personnel and in full compliance with current regulations.

5.1 Preliminary checks

Before installing, do the following:

• Make sure that the gate is stable, and that the castors are in good working order and properly greased.

• The ground rack must be well secured to the ground, entirely above the surface and free of any irregularities that may obstruct the

gate’s movement.

• The upper guide rails must not create any friction.

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

• Make sure that there is a closing and an opening endstops.

ver.

• Make sure that the operator is attached to a solid surface and protected from any impacts;

• Make sure you have a suitable omnipolar cut-off device with contacts more than 3 mm apart, and independent (sectioned off) power

supply;

119 BU 50

:

• Check that any connections inside the container (that provide continuity to the safety circuit) are fitted with additional insulation

compared to other internal live parts;

• Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical

Manual code

damage.

3 -

Pag.

Page 4

5.2 Tools and materials

4

119B U 50

1.0

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance

with the current standards and regulations. The following figure illustrates the minimum equipment needed by the installer.

ENGLISH

5.3 Cable list and minimum thickness

Connection Type of cable Length of cable 1 < 10 m Leng. cable 10 < 20 m Leng. cable 20 < 30 m

Control panel power supply 230V

3G x 1,5 mm

Flashing light 2 x 0,5 mm

Photocell transmitter 2 x 0,5 mm

Photocell receiver 4 x 0,5 mm

Accessories power supply 2 x 0,5 mm

FROR CEI

20-22

CEI EN

50267-2-1

2

2

2

2

2

3G x 2,5 mm

2 x 1 mm

2 x 0.5 mm

4 x 0,5 mm

2 x 0,5 mm

2

2

2

2

2

3G x 4 mm

2 x 1,5 mm

2 x 0,5 mm

4 x 0,5 mm

2 x 1 mm

2

2

2

2

2

Safety and control devices 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Antenna connection RG58 max. 10 m

N.B.: If the cable length differs from that specified in the table, then you must determine the proper cable diameter in the basis of

the actual power draw by the connected devices and depending on the standards specified in CEI EN 60204-1.

For connections that require several, sequential loads, the sizes given on the table must be re-evaluated based on actual power

draw and distances. When connecting products that are not specified in this manual, please follow the documentation provided

with said products.

4

3

5.4 Standard installation

1) BX246 Assembly

5

6

2) Rack

3) Reception Antenna

4) Flashing light

5) Keyswitch selector

6) Safety photocells

7) Electric cable junction box

8) Mechanical endstops

9) Guide rails

9

6

8

10) Endstop fi ns

10

10

1

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

2

7

119 BU 50 ver.

4 - Manual code:

Pag.

Page 5

5.5 Securing the plate and installing the assembly

5

119B U 50

1.0

The following applications are only examples, as the space for installing the ratiomotor and accessories varies according to

obstructions. It is thus up to the system installer to select the most suitable solution.

- Dig a pit to the side of the gate (see measurements from diagram).

Prepare the corrugated tubes you will need when making connections coming from the shunt pit.

N.B. the number of tubes depends on the type of system and the accessories you will hook up.

Conduits for electric

cables

Shunt pit

ENGLISH

- Prepare a form box that is larger in size than the securing plate and insert it into the pit. The form box should jut 50mm above

ground level.

Insert an iron grid inside the from box to reinforce the concrete.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

-Prepare the securing plate, insert the bolts into the holes and lock them using the supplied nuts and washers. Extract the preformed

brackets using a screw driver or a set of pliers.

- Position the plate on top of the grid. Careful! The tubes need to pass through the apposite holes.

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Manual code

5 -

Pag.

Page 6

- To position the plate in relation to the rack please see the measurements on the diagram.

6

119B U 50

1.0

Fill the form box with cement and wait for at least 24 hours for it to solidify.

ENGLISH

- Remove the form box, fi ll the pit around the cement block with soil.

H

- Unbolt the nuts and washers from the bolts. The securing plate must be clean, perfectly aligned and with the bolt threads completely

on the surface.

Insert the electric cables into the tubes until they exit about 400mm.

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

6 - Manual code:

Pag.

Page 7

- Remove the cover from the gearmotor by loosening the side bolts, perforate the cable shafts using a screwdriver or a pair of

7

119B U 50

1.0

scissors and position the gearmotor atop the plate. Careful! The electric cables must pass through the cable shafts.

- Lift the gearmotor from the securing plate by about 5 to 10mm by using the threaded steel-levelling feet to allow any later

adjustments between the pinion and the rack.

ENGLISH

- The following illustrations for the securing the rack, are just examples of applications. It is up to the installer to choose the best

solution.

Releasing the gearmotor (see paragraph on manual release). Rest the rack on the gearmotor pinion.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Weld or secure the rack to the gate along its entire length.

To assemble the rack modules, use an excess piece of rack and place it under the joining point, then block it using two C-clamps.

Note: if a rack is already in place, then just adjust the pinion-to-rack distance.

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Manual code

7 -

Pag.

Page 8

- Open and close the gate manually and register the pinion-to-rack distance using the threaded steel-levelling feet (for vertical

8

119B U 50

1.0

adjusting) and the slotted holes (horizontal adjusting). This prevents the weight of the gate from bearing on the operator.

Rack

Rack

ENGLISH

Levelling feet

Pinion

vertical adjusting

Pinion

Slotted holes

horizontal adjusting

Once adjustments are fi nished, secure the assembly using the nuts and washers.

Insert the cover after performing the adjustments and settings on the electronic card.

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

8 - Manual code:

Pag.

Page 9

5.6 Mounting the endstop fins

9

119B U 50

1.0

Place the endstop fi ns onto the rack and secure them using a 3 mm Allen wrench. Their positioning limits the gate run.

Note: the gate schould not slam against the mechanical stop, when opening or closing.

Mechanical stop

5.7 Manually releasing the gearmotor

ENGLISH

- Insert the trilobed key into the lock, push it in and turn it clockwise ....

Trilobed key

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

..... open the small door and turn the release handle clockwise.

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Manual code

9 -

Pag.

Knob

WARNING: opening the door will

disengage the motor (i.e. it will not

function).

To opera te the motor the release mechanism must be fi rmly fastened.

Page 10

6 Control board

10

119B U 50

1.0

6.1 General description

Use 230V A.C. to power the electronic card using the L-N

terminals, at a max 50/60Hz frequency.

Use 24V to power the command devices and accessories.

Careful! The accessories cannot exceed 37W of overall power.

The card is fi tted with an amperometric device which constantly

monitors the motor’s drive. When the gate runs into an obstacle,

the amperometric sensor immediately detects the overload on

the drive and so inverts the gate’s movement:

ENGLISH

- opens it if it is closing

- closes it if it is opening

Warning: after 3 obstacle detections, the gate stops when

in opening-mode and excludes automatic-closing mode; to

regain movement press the command button or use the remote

control.

All connections are protected by quick-fuses – see table.

The card handles the following functions:

- Automatic closing after an opening command;

- Warning light pre-fl ashing;

- Obstacle detection when gate is still at any point;

- Constant monitoring of photocell operations.

- Opening/closing;

- Opening/closing in maintained action mode;

- partial opening;

- total stop.

Apposite trimmers regulate:

- The automatic closing’s running time;

- The partial opening;

- The amperometric device’s detection sensitivity, in both normal

and brake modes;

- the speed of both the normal gate run and the brake mode run.

Warning! Before acting on the machinery, cut off the main power

supply and disconnect any emergency batteries.

TECHNICAL INFORMATION

Power supply 230V - 50/60 Hz

Maximum power allowed 400 W

Absorption at rest 100 mA

Maximum power for 24V accessories 35 W

Insulation rating II

FUSE TABLE ZD2

To protect: fuse:

Motor 10A-F

Control board (line) 1,6A-F

Accessories 1.6A-F

Command devices 1A-F

6.2 Main components

1) Power supply terminals

2) Endstop terminals

3) Motor terminals

4) Encoder terminals

5) Accessory fuse

6) Card fuse

7) Button for memorising the radio code

8) Radio-code signalling LED indicator

9) 230V-power signalling LED

10) Control and signalling LED group

11) Function selector DIP switch

12) Socket for connecting the remote control’s

radiofrequency card

13) Antenna terminal

14) Accessories’ and command device’s terminals

15) Motor fuse

16) Line fuse

17) Setting trimmer

18) Battery charger (LBD2) connecting terminal boards

19) Transformer-connecting terminal board

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

10 - Manual code:

Pag.

Page 11

19

11

119B U 50

1.0

3

14

14

2

4

13

16

15

18

1

9

8

6

5

12

ENGLISH

10

7

/.

11

17

6.3 Electrical connections

Gearmotor, endstop and encoder

Description of the standard electrical connections for left-hand installations

COM

NC

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Opening microswitch

Closing microswitch

Modifications to the electrical connections for right-hand installations

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Invert the gearmotor (M-N) and (FA-FC)

Manual code

11 -

Pag.

endstop phases.

COM

NC

Orange

White

Orange

Red

Orange

White

Red

%$&#&!&

&#&!&

Black

Red

Brown

Blue

24V (d.c.) motor

with encoder

-.

Brown

Blue

-.

Page 12

Power supply for accessories

12

119B U 50

1.0

Terminals for powering the following accessories:

- 24V A.C. normally;

- 24V D.C. when the emergency batteries are

working;

Maximum allowed power: 35W

ENGLISH

230V (a.c.) Power, 50/60Hz

frequency

Warning devices

Movement fl ashing light (Contact range: 24V – 25W max) -

Flashes during the gate’s opening and closing phases.

Cable lug with bolt and washer for connecting to earth.

+

-

.

,

Open-gate status light (contact range: 24V – 3W max)

- Signal that gate is open; turns off when gate is closed.

Command and control devices

Stop button (N.C. contact)

- Gate stop button. Excludes automatic closing. For motion to resume,

press the command button or the remote control button.

Key selector and/or partial opening button (N.O. contact)

- Partial gate opening for pedestrian access.

Key selector and/or command button (N.O. contact)

- Gate opening and closing command.

By pressing the button or turning the selector key, the gate inverts its movement or stops depending on which the settings on the

DIP switches.

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

12 - Manual code:

Pag.

Page 13

Safety devices

13

119B U 50

1.0

«partial stop» (N.C.) contact

- Input for EN 12978 standard-compliant safety

devices such as photocells. Gate stops if moving and

automatically shuts (if this functions has been selected).

RX

DIR photocells

TX

ENGLISH

(N.C.) contact for «re-open during closing phase»

- Input for EN 12978 standard-compliant safety

devices such as photocells. If contact is opened, while

gate is closing, the gate inverts its direction.

«partial stop» (N.C.) contact

RX

RX TX

./ # .#

DIR photocells

DOC photocells

TX

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

«Open while closing» (N.C.) contact

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Manual code

13 -

Pag.

RX

./ # .#

DOC photocells

TX

Page 14

«Open while closing»(N.C.) contact

14

119B U 50

1.0

- input for EN 12978 compliant safety

devices such as sensitive edges. During

gate closing, opening the contact

causes inversion of movement until

gate is fully open; if not used, short

circuit contact 2-C7.

ENGLISH

DF

#./.#

6 6 .#./#6

DF with DFI connections monitor

card

#./.#

DF

«Close while opening» (N.C.)contact

- input for EN 12978 compliant safety

devices such as sensitive edges. During

gate opening, opening the contact

causes inversion of movement until gate

is fully close; if not used, short circuit

contact 2-C8.

6.4 Electrical connection to operate the photocells’ safety test

(DOC)

(DIR)

6 6

6

DF with DFI connections monitor

card

./

.#

#

#./.##./.#

./

#

.#

#

48

.#

At each open/close command, the card check the photocells’ effi ciency. Any

problems with the photocells will cause the (PROG) Led to fl ash on the electronic

card, which cancels any commands from the radio transmitter or push-button.

Electrical connection to operate the photocells’ safety test:

- The transmitter and receiver, must be connected as shown in the diagram;

- Set DIP switch 7 to ON to activate the test.

IMPORTANT:

When the safety test function is activated, the N.C. contacts:

- If unused – are to be excluded on their relative DIP switches (see chapter “selecting functions”)..

&53)"),%M!

48

48

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

14 - Manual code:

Pag.

Page 15

/.

7 Function selector

15

119B U 50

1.0

1 ON - Automatic Closing -

DIP-SWITCH

ON

OFF

The automatic closing timer activates at the end of the opening gate run. The pre-set time is adjustable,

Default Setting

/.

and is in any case conditioned by the activation of any safety devices, and does not activate after a total safety “stop” or

during a blackout.

2 ON - "Open-stop-close-stop" function with [2-7] button and radio transmitter (fi tted with inserted radiofrequency card).

2 OFF - "Open-close" function with [2-7] button and radio transmitter ((fi tted with inserted radiofrequency card).

3 ON - "Open only" function with [2-7] button and radio transmitter ((fi tted with inserted radiofrequency card).

4 ON - Pre-Opening and closing fl asher - Following and opening and closing command, the fl asher connected to [10-E1], fl ashes

for 5 seconds before motion begins.

5 ON - Obstacle detected - When motor is stopped (gate closed or after a total stop command) it prevents any movement if safety

devices, such as photocells, detect any obstacles.

6 ON - Maintained action - The gate works by keeping button pressed (one 2-3P opening button , and one closing button).

7 ON - Functioning of the photocells’ safety test - Allows the card to check the efficiency of any safety devices (i.e. photocells)

after every opening or closing command.

8 OFF - Total stop - This function stops the gate and then excludes any automatic closing cycle; to set in motion again, use either

the keypad or transmitter. Insert the safety device in [1-2]; If unused, set DIP switch to ON.

ENGLISH

9 OFF - Opening during closing - If th e p ho to ce ll s d et e ct an o bs t ac le du ri ng ga te ’s cl os in g, ga te mo ti on is in ve rt e d u nt il ful ly op en ed ;

connect the safety device to terminals [2-C1]; if unused, set DIP switch to ON.

10 OFF - Partial stop - Gate stop when obstacle is detected by the safety device; once obstacle is removed, the gate remains still

or closes if automatic closing is activated. Connect the safety device to terminal [2-C3]; if unused, set the DIP switch to

ON.

8 Settings

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

A.C.T. PAR.OP. SLOW V.RUN S. RUN V.SLOW S.

SETTING TRIMMER LIST:

- «A.C.T.» Sets the waiting time while open. Once this time has elapsed, closing automatically takes place. The waiting time

may be set from 1 to 150 seconds.

- «PAR.OP.» Sets the gate’s partial opening. By pushing the partial opening button connected at 2-3P, the gate opens depending

on the length of the gate.

- «SLOW S.» Sets the amperometric sensitivity that controls the force generated by the motor during slow down; if the force

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

exceed the set level, the system intervenes by inverting the direction of motion.

- «RUN S.» Sets the amperometric sensitivity that controls the force generated by the motor during movement; if the force

119 BU 50

:

exceeds the set level, the system intervenes by inverting the direction of motion.

- «SLOW V.» Sets the gate’s fi nal opening/closing phase slow-down speeds.

- «RUN V.» Sets the gate’s opening/closing motion speed.

Manual code

15 -

Pag.

Page 16

9 Warning Led

16

119B U 50

1.0

Led PWR

Led 1

ENGLISH

Led 3p Led 7

Led C1 Led C3

Led C7

LIST WARNINGS OF THE COMMAND AND SAFETY DEVICES’ CONTROL LEDs:

- «PROG» Red Led. Normally off.

When the transmitter is activating, it turns on or fl ashes.

- «PWR» Green led. Normally on.

Shows that card is properly powered;

- «1» Yellow led. Normally off.

Shows activation of the PARTIAL STOP button.

- «3p» Yellow Led indicator. Normally off.

Indicates that the PARTIAL OPENING button has been activated.

- «7» Yellow Led indicator. Normally off.

Indicates that the OPENING and CLOSING button has been activated.

- «C1» Yellow led. Normally off.

Shows that there are obstacles between the photocells (which are in OPEN WHILE CLOSING mode).

- «C3» Yellow Led. Normally off.

Shows that there are obstacles between the photocells (which are in PARTIAL STOP mode).

- «C6» Yellow Led. Normally off.

Show obstacles detected by the sensitive edge (which are in OPEN WHILE CLOSING mode).

- «C7» Yellow Led. Normally off.

Shows obstacles detected by sensitive edge (which are in CLOSE WHILE OPENING mode).

Led PROG

Led C8

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

16 - Manual code:

Pag.

Page 17

/.

/.

/.

10 Programmation to save gate-run and decelerations adjustments

17

119B U 50

1.0

Do the adjustment by making the operator execute a complete opening/closing manoeuvre

The control board automatically registers the gate-run adjustments with opening and closing decelerations.

ENGLISH

To save the adjustment, position dip 6 in ON and press CH1 button until the signalling led stays on.

Re-position the dip in OFF

Note: you need to reposition the dip in OFF so to avoid that the reactivation of power supply after a blackout provokes a new adjustment while executing the first manoeuvre.

LED acceso

CH1

Dip 6 in ON

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Manual code

17 -

Pag.

Dip 6 in OFF

Page 18

11 Activating the radio command

18

119B U 50

1.0

Antenna

Possible output of the radio receiver’s

second channel (N.O. socket).

Socket rating: 5A-24V (d.c.).

""

ENGLISH

Radiofrequency card

Insert the radio frequency card into the electronic card AFTER DISCONNECTING THE POWER (and disconnecting any batteries).

N.B.: the electronic card picks up the radiofrequency card on when it is running on power

Connect the antenna’s RG58 cable to

the apposite terminals.

Electronic card

Transmitters

CAME

CAME

TOP

TOP-432A • TOP-434A

CAME

ATOMO

AT01 • AT02

AT04

See instruction sheet in AF43SR radiofrequency

TOP

TOP-302A • TOP-304A

AF Card

card box

TOP

TOP-432NA • TOP-434NA

TOP-432S

E

M

A

C

TAM

T432 • T434 • T438

TAM-432SA

CAME

CAME

E

M

A

C

E

CAM

E

AM

C

TOUCH

TCH 4024 • TCH 4048

TWIN

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

TWIN2 • TWIN4

119 BU 50 ver.

See instructions on packaging

E

M

A

C

18 - Manual code:

Pag.

Page 19

Memorisation

19

119B U 50

1.0

- Keep the CH1 button on the electronic card pressed. The led fl ashes.

LED flashing

CH1 = Channel for direct

command to a function

of the gearmotor’s card,

(“open only/”openclose-invert” or ”openstop-close-stop”

vommand, depending on

the choice made on DIP

switches 2 and 3).

/.

CH1

- Press the transmitter button you wish to memorise. The LED will stay on to show memorisation has been successful.

ENGLISH

LED on

CH1

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

- Repeat the points 1 and 2 procedures “CH2” button associating this to another button on the transmitter.

CH2 = Channel for

direct command an

accessory device

connected to B1-B2.

/.

T1

AF card

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

ver.

119 BU 50

:

Manual code

19 -

Pag.

CH2

/.

T2

Page 20

12 Safety instructions

20

119B U 50

1.0

Important safety instructions

This product must only be employed for its originally intended use. Any other use is wrong and potentially dangerous. The

manufacturer cannot be held liable for any damages resulting from wrongful, erroneous or negligent uses.

Avoid working close to the hinges or other moving mechanical parts. Stay out of the opening/closing arc when operator is in

motion.

Do not exercise force against the motion of the operator as this could result in potentially dangerous situations.

ENGLISH

Do not allow children to play or loiter within the opening /closing arc of the operator. Keep remote controls and any other command

device out the reach of children, to prevent operator from being activated by accident.

In the event of anomalous behaviour, stop using the operator immediately.

Danger of crushing hands

Danger of crushing feet

Danger! High voltage

No transit during operation

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

119 BU 50 ver.

20 - Manual code:

Pag.

Page 21

13 Maintenance

21

119B U 50

1.0

13.1 Periodic maintenance

Periodic maintenance to be carried out by the end-user is as follows: wipe clean the glass surface of the photocells;

check that the safety devices work properly; remove any obstructions.

We suggest checking the state of lubrication and tightness of the anchoring screws on the operator.

-To check the efficiency of the safety devices, move an object in front of the photocells when gate is closing. If the operator

inverts the motion or stops, the photocells are working properly.

This is the only maintenance procedure to be carried out with the power source connected.

-Before performing any maintenance procedures, cut off the main power, to prevent possible accidents due to gate movement.

-To clean the photocells use a water dampened cloth. Do not use solvents or other chemical products which may ruin the

devices.

-In the event of any strange vibrations or squeaking, lubricate the joints with grease, as shown in the diagram.

ENGLISH

-Make sure there are no plants within the photocell’s beam, and that the gate motion is free of any obstacles.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

13.2 Trouble shooting

MALFUNCTIONS POSSIBLE CAUSES CHECK AND REMEDIES

The gate will not

open nor close

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

The gate opens

ver.

but will not close

The gate closes

119 BU 50

:

but will not open

• There is no power

• The gearmotor is in release mode and the release door is open

• The transmitter’s batteries are run down

• The transmitter is broken

• The stop button is either stuck or broken

• The opening/closing button or the key selector are stuck

• Fhotocells in partial stop mode

• The photocells are engaged

• Check that the power is up

• Call assistance

• Replace batteries

• Call assistance

• Call assistance

• Call assistance

• Call assistance

• Check that photo cells are clean and

in good working order

• Sensitive edge triggered

• Call assistance

• Sensitive edge triggered • Call assistance

The flasher does

Manual code

not work

21 -

Pag.

• The bulb is burnt • Call assistance

Page 22

Periodic maintenance log for end-user (every 6 moths)

22

119B U 50

1.0

ENGLISH

Date Notes

Signature

13.3 Extra-ordinary maintenance

The following table serves to note down any extraordinary maintenance, repairs or improvements performed by specialised firms.

N.B.: Any extraordinary maintenance must be performed by specialised technicians.

Extra-ordinary maintenance log

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

1.0 10/2007 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Date of job

Technician’s signature

Requester’s signature

119 BU 50 ver.

Job performed________________________________________________________________________________________

__________________________________________________________________________________________________

22 - Manual code:

Pag.

Page 23

Installer’s stamp Operator name

23

119B U 50

1.0

Date of job

Technician’s signature

Requester’s signature

Job performed________________________________________________________________________________________

__________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed________________________________________________________________________________________

__________________________________________________________________________________________________

14 Phasing out and disposal

CAME CANCELLI AUTOMATICI S.p.A. employs a UNI EN ISO 14001 certified and compliant environmental protection system at its plants, to ensure that environmental safeguarding.

We ask you to keep protecting the environment, as CAME deems it to be one of the fundamental points of its market operations

strategies, by simply following these brief guidelines when disposing:

DISPOSING THE PACKING MATERIALS

The packing components (cardboard, plastic, etc.) are solid urban waste and may be disposed of without any particular difficulty,

by simply separating them so that they can be recycled.

Before actions it is always advisable to check the pertinent legislation where installation will take place.

DO NOT DISPOSE OF IN NATURE!

ENGLISH

DISPOSING OF THE PRODUCT

Our products are made using different types of materials. The majority of them (aluminium, plastic, iron, electric cables) can be

considered to be solid urban waste. They may be recycled at authorised firms.

Other components (electrical circuit board, remote control batteries etc.) may contain hazardous waste.

They must, thus, be removed and turned in to licensed firms for their disposal.

Before acting always check the local laws on the matter.

DO NOT DISPOSE OF IN NATURE!

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

15 Conformity declaration

MANUFACTURER’S DECLARATION OF CONFORMITY

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030 Dosson di Casier - Treviso - ITALY

tel (+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Declares under its own responsibility that the equipments for automatic garage doors and gates listed below:

BX-246

… comply with the National Law related to the following European Directives and to the applicable parts of the

1.0 10/2007 © CAM E cancelli automatici s.p.a. -

following Standards.

ver.

98/37/CE - 98/79/CE M

98/336/CEE - 92/31/CEE ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

73/23/CEE - 93/68/CE LOW VOLTAGE DIRECTIVE

89/106/CEE CONSTRUCTION PRODUCTS DIRECTIVE

119 BU 50

:

ACHINERY DIRECTIVE

Pursuant annex II B of the Machinery Directive 98/37/EC

Do not use the equipment specifi ed here above, before completing the full installation

IMPORTANT WARNING!

In full compliance with the Machinery Directive 98/37/EC

MANAGING DIRECTOR

Mr. Andrea Menuzzo

EN 13241-1 EN 12635 EN 61000-6-2

EN 12453 EN 12978 EN 61000-6-3

EN 12445 EN 60335-1 EN 60204-1

Manual code

23 -

Reference code to request a true copy of the original: DDF B EN B001c

Pag.

Page 24

CAME F ra nce S.a.

Nanter re Cedex -

CAME G mbh See feld

Seefel d

CAME Automat ismes S.a.

Marsei lle -

CAME G mbh

Korntal

CAME Automat ismos S.a.

Madri d -

CAME America s Auto mation Llc

Sunris e

CAME Automat ismos C ataluny a S. a.

Sant Vicenc Del Ho rts -

CAME M iddle E ast Fzc o

Dubai -

Paf - CAME

Rio D e Mouro -

CAME P olska S p. Zo.o

War szawa -

CAME U nited K ingdom Ltd.

Nottin gham

S.c. CAME Romani a S. r.l.

Bucare st -

CAME B elgium Sprl

Lessi nes -

CAME R ussia

Moskva

CAME C ancelli Autom atici S.p.a.

Dosso n Di Ca sier

CAME N ord s.r.l .

Colog no Monz ese

CAME S erv ic e Ita li a S. r.l.

Dosso n Di Ca sier

Assist enza Tecnic a 800 2 95830

CAME S ud s.r.l.

Napol i

Engl is h

119B U 50

1.0

CAME France S.a.

7, Rue Des Haras

Z.i. Des Hautes Patures

92737

Nanterre Cedex - FRANCE

(+33) 1 46 13 05 05

(+33) 1 46 13 05 00

CAME Automatismes S.a.

3, Rue Odette Jasse

13015

Marseille - FRANCE

(+33) 4 95 06 33 70

(+33) 4 91 60 69 05

CAME Automatismos S.a.

C/juan De Mariana, N. 17-local

28045

Madrid - SPAIN

(+34) 91 52 85 009

(+34) 91 46 85 442

CAME Automatismos Catalunya S.a.

P.i. Moli Dels Frares N. 23 C/a

08620

Sant Vicenc Del Horts - SPAIN

(+34) 93 65 67 694

(+34) 93 67 24 505

Paf - CAME

Estrada Nacional 249-4 Ao Km 4,35

Cabra Figa - Trajouce

2635-047

Rio De Mouro - PORTUGAL

(+351) 219 257 471

(+35) 219 257 485

CAME Gmbh Seefeld

Akazienstrasse, 9

Bei Berlin - DEUTSCHLAND

(+49) 33 3988390

(+49) 33 39883985

Kornwestheimer Str. 37

Munchingen Bei Stuttgart - DEUTSCHLAND

(+49) 71 5037830

(+49) 71 50378383

CAME Americas Automation Llc

1560 Sawgrass Corporate Pkwy, 4th Floor

Sunrise, FL 33323 - U.S.A

(+1) 305 433 3307

(+1) 305 396 3331

CAME Middle East Fzco

Po Box 17131 Warehouse N. Be02

South Zone - Jebel Ali Free Zone -

(+971) 4 8860046

(+971) 4 8860048

CAME Polska Sp.Zo.o

01-237

Warszawa - POLAND

(+48) 22 8365076

(+48) 22 8363296

16356

Seefeld

CAME Gmbh

70825

Korntal

Dubai - U.A.E.

Ul. Ordona 1

CAME United Kingdom Ltd.

Unit 3 Orchard Business Park

Town Street, Sandiacre

Nottingham - Ng10 5du - UNITED KINGDOM

Buftea, Judet Ilfov

(+44) 115 9210430

1.0 10/2007 © CAME cancelli automatici s.p.a.

119 BU 50 ver.

(+44) 115 9210431

CAME Belgium Sprl

Zoning Ouest 7

7860

Lessines - BELGIUM

(+32) 68 333014

(+32) 68 338019

S.c. CAME Romania S.r.l.

B-dul Mihai Eminescu, Nr. 2, Bloc R2

Scara A, Parter, Ap. 3

Bucarest - ROMANIA

(+40) 21 3007344

(+40) 21 3007344

CAME Russia

Leningradskij Prospekt, Dom 80

Pod’ezd 3, offi ce 608

125190,

Moskva - RUSSIA

(+7) 495 937 33 07

(+7) 495 937 33 08

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

English - Manual code:

CAME Cancelli Automatici S.p.a.

Via Martiri Della Libertà, 15

31030

Dosson Di Casier (Tv)

(+39) 0422 4940

(+39) 0422 4941

20093

CAME Nord s.r.l.

Piazza Castello, 16

Cologno Monzese (MI)

(+39) 02 26708293

(+39) 02 25490288

Informazioni Commerciali 800 848095

www.came.it

CAME Service Italia S.r.l.

Via Della Pace, 28

31030

Dosson Di Casier (Tv)

(+39) 0422 383532

(+39) 0422 490044

Assistenza Tecnica 800 295830

CAME Sud s.r.l.

Via F. Imparato, 198

Cm2 Lotto A/7

80146

Napoli

(+39) 081 7524455

(+39) 081 7529109

Loading...

Loading...