OPERATING INSTRUCTIONS

c5-2

E

Item no. : Cafina - 2954079

Item no. : Melitta SystemService - 2954085

OI c5-2 eng V1 / 08.12.2004 © Cafina / Melitta

E

OPERATING INSTRUCTIONS

RETAIN FOR FUTURE USE!

The copyright of these Operating Instructions, which are entrusted to the recipient personally, remains with the Cafina / Melitta company.

The content may not be disclosed or made available to any third party without the express

consent of the Cafina / Melitta company.

These Operating Instructions must be read and applied by anyone performing work with or

on this equipment.

In particular, it is imperative that all such persons familiarise themselves with the safety

instructions.

© Cafina / Melitta OI c5-2 eng V1 / 08.12.2004

TABLE OF CONTENTS

1 Description

1.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

1.1.1 External parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

1.2 Mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.2.1 c5-2 boiler element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.2.2 "Temperature probe" option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.3.1 Boiler element types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

1.3.2 Machine identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

1.3.2.1 Switzerland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

1.3.2.2 Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

1.3.3 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.3.4 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.3.4.1 Temperature and humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.3.4.2 Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

E

2 Safety instructions

2.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

2.1.1 Warning symbols used (depending on nationality) . . . . . . . . . . . . . . 2 - 1

2.1.2 Places where warning symbols

are affixed (depending on nationality) . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

2.1.3 Safety information in these Operating Instructions . . . . . . . . . . . . . . 2 - 1

2.2 Basic safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.2.1 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.2.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.2.1.2 c5-2 boiler element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

2.2.2 Specific hazards and instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

2.2.2.1 c5-2 boiler element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

2.2.3 Personal safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

2.3 Safety mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.3.1 Power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.3.2 Relief pressure valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.4 Authorised persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.4.2 Areas of responsibility of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.4.2.1 Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

2.4.2.2 User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

2.4.2.3 Maintenance personnel (service technician) . . . . . . . . . . . . . . 2 - 6

OI c5-2 eng V1 / 08.12.2004 i © Cafina / Melitta

E

TABLE OF CONTENTS

2.4.3 Minimum training and qualifications of authorised personnel . . . . . . 2 - 6

2.4.3.1 Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

2.4.3.2 User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

2.4.3.3 Maintenance personnel (service technician) . . . . . . . . . . . . . . 2 - 6

2.5 Maintenance duty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

2.6 Availability of these Operational Instructions . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

3 Controls and indicators

3.1 Key-operated switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.2 Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.3 Indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.4 Grip elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.5 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

3.6 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

4 Initial start-up

4.1 Normal initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

4.2 Return to service after the machine

has been out of service for a limited time . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

4.3 Return to service after a fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

5 Operation

5.1 Power supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.2 Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.2.1 Water intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.2.2 Water drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.3 Switching on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.4 Dispensing beverages and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.4.1 Drawing hot water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.4.2 Heating milk (manually) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

5.4.3 Heating milk (automatically) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

5.4.4 Frothing milk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

5.4.5 Routine work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

5.4.5.1 Cleaning the drip tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

© Cafina / Melitta ii OI c5-2 eng V1 / 08.12.2004

TABLE OF CONTENTS

5.5 System work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

5.5.1 Control panel and button layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

5.5.2 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

5.5.2.1 Hot water quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

5.5.2.2 Final milk temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

6 Maintenance

6.1 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

6.1.1 Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

6.1.1.1 Cleaning intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

6.1.1.2 Intervals between services . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

6.2 Periodic checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

6.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

6.3.1 Cleaning work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

6.4 "Operator" maintenance log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

E

7 Troubleshooting

7.1 Checklist for fault diagnosis and troubleshooting . . . . . . . . . . . . . . . . . . . . . 7 - 1

7.1.1 Troubleshooting of specific conditions . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

7.1.2 Troubleshooting on the basis of the LED light intervals . . . . . . . . . . . 7 - 2

8 Taking out of service and storage

8.1 Taking out of service for a

limited time / taking out of service for good . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

8.2 Storage for a limited period / permanent storage . . . . . . . . . . . . . . . . . . . . . 8 - 1

9 Packing and transportation

10 Disposal

11 Guarantee, consumable materials, spare parts, ordering

12 "Service Technician" maintenance log

OI c5-2 eng V1 / 08.12.2004 iii © Cafina / Melitta

E

TABLE OF CONTENTS

© Cafina / Melitta iv OI c5-2 eng V1 / 08.12.2004

1 Description

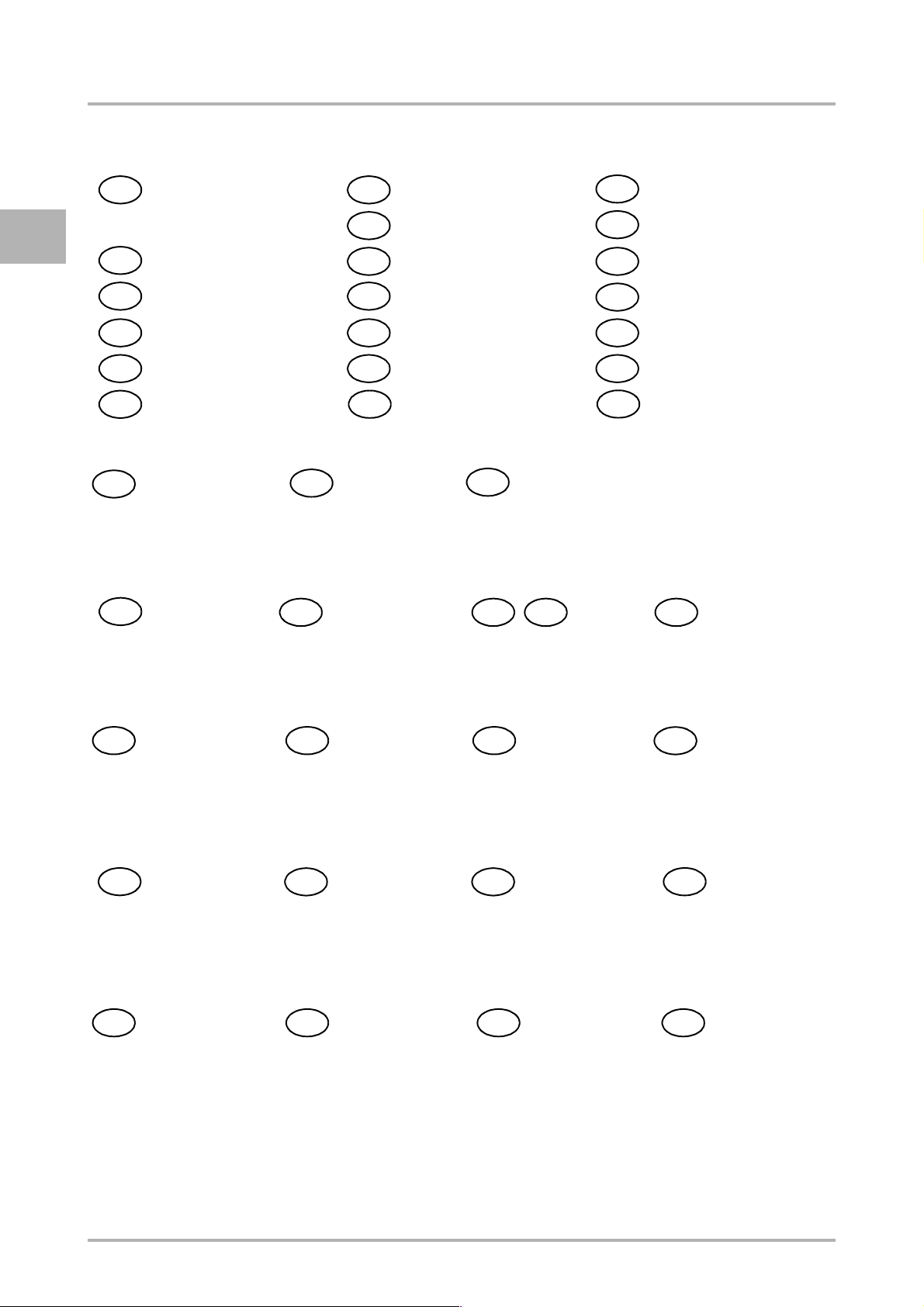

1.1 Design

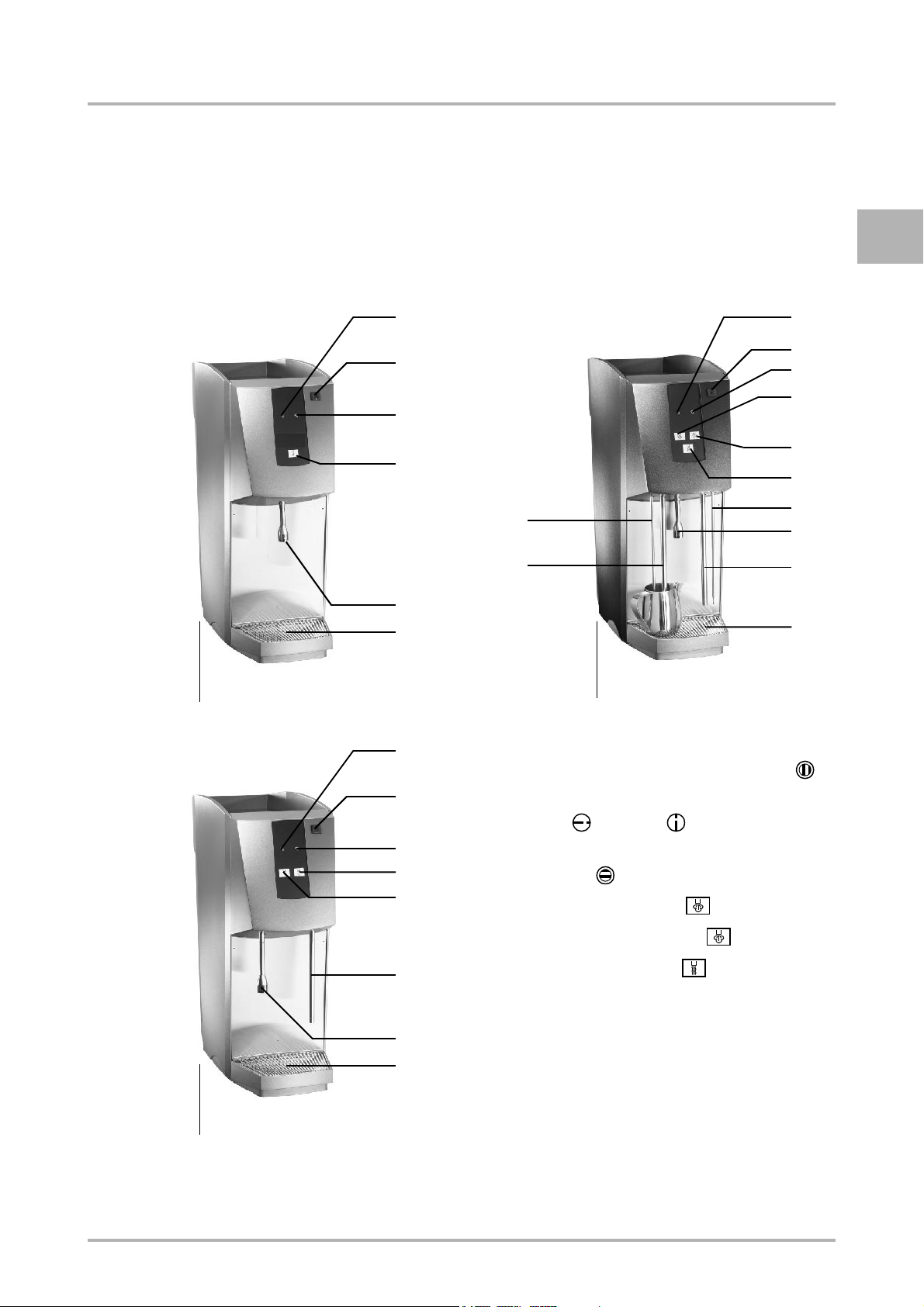

1.1.1 External parts

DESCRIPTION

E

«Type: c5-2 self»

1

2

3

5

6B

8B

7

9

«Type: c5-2C»

1

1 Operating status indicator Red [ ]

1

2

3

4A

4B

5

6A

7

8A

9

«Type: c5-2»

2

3

4B

5

8A

7

9

2 Key-operated switch (power switch)

ON [ ], OFF [ ]

3 Operating status indicator

Green [ ]

4A Steam button left [ ]

4B Steam button rights [ ]

5 Hot water button [ ]

6A Optional: temperature probe right

6B Optional: temperature probe left

7 Hot water outlet

8A Steam outlet right

8B Steam outlet left

9 Drip grille

OI c5-2 eng V1 / 08.12.2004 1-1 © Cafina / Melitta

DESCRIPTION

E

1.2 Mode of operation

1.2.1 c5-2 boiler element

The c5-2 boiler element is an autonomous

hot water/steam module with a large-volume boiler, enabling a high throughput of

beverages.

The c5-2 boiler element is normally connected directly to the water mains, but it

can also be operated with canisters.

1.2.2 "Temperature probe" option

In combination with an additionally installed

temperature probe, the final temperature

of the medium to be heated by the c5-2 /

c5-2C can be monitored.

Once the final temperature is achieved, the

supply of steam is automatically stopped.

1.3 Technical data

1.3.1 Boiler element types

n Self-service version (c5-2 self)

1 hot water outlet (fixed)

n Standard version (c5-2)

1 steam outlet (movable)

1 hot water outlet (movable)

"Temperature probe" option (movable)

n Advanced design (c5-2C)

2 steam outlets (movable)

1 hot water outlet (fixed)

"Temperature probes" option

(movable)

© Cafina / Melitta 1-2 OI c5-2 eng V1 / 08.12.2004

DESCRIPTION

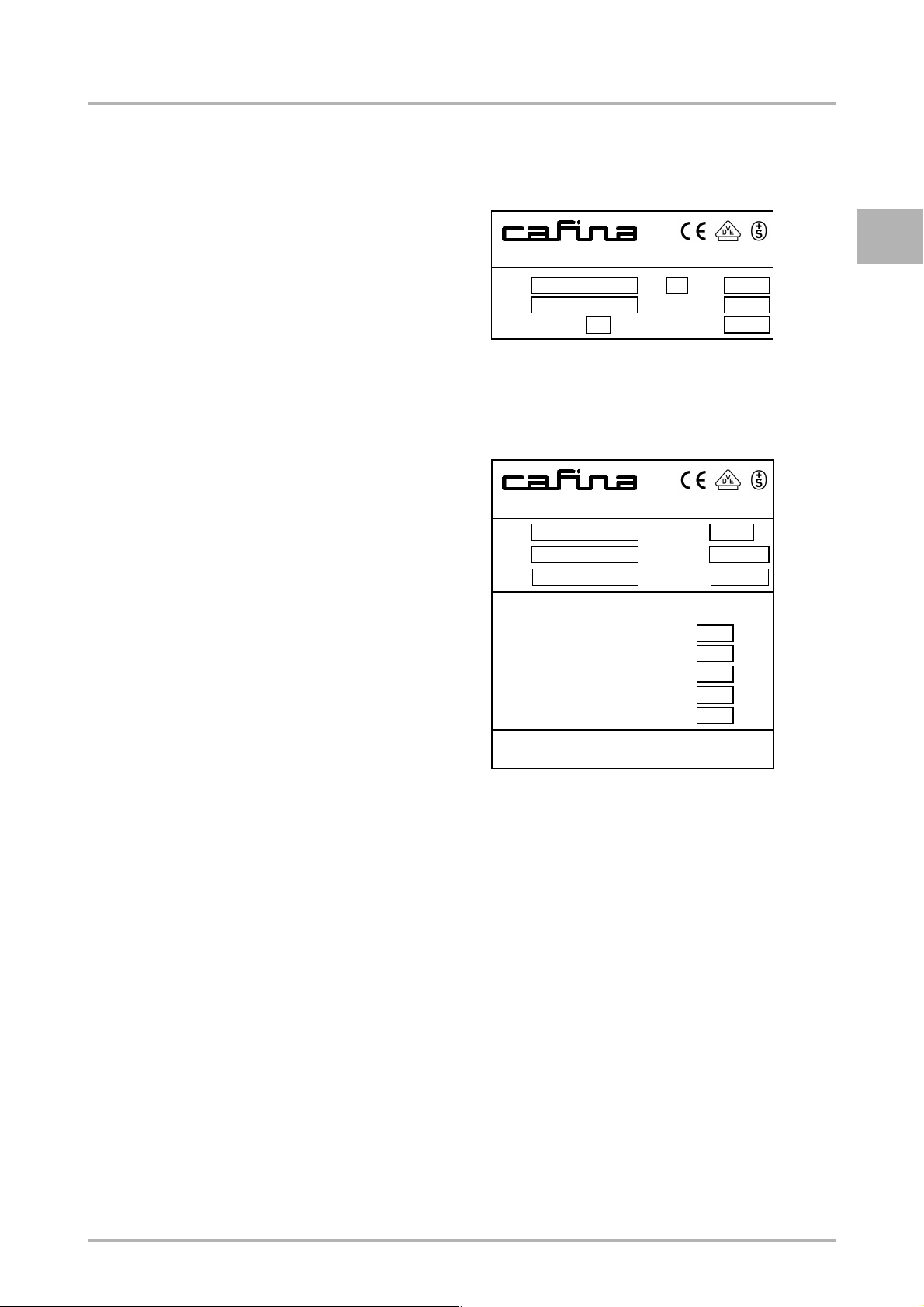

1.3.2 Machine identification

Position of identification plate:

• Switzerland, exports (e.g. EU, USA):

In two places ...

Inside at the top of the back of the machine

Outside, underneath the machine

1.3.2.1 Switzerland

CH-5502 HUNZENSCHWIL

V

Type

Instr. sheet

Hz

Serial-No.

Model year

1.3.2.2 Export

CH-5502 HUNZENSCHWIL

V

Type

Water lowest level

Max. temperature

Max. overpressure

Heater power

Serial-No.

W

Serial-No.

Model year

E

W

Boiler

litres

°C

bar

kW

Test overpressure and design comply with

the Ordinance on Steam Boilers

OI c5-2 eng V1 / 08.12.2004 1-3 © Cafina / Melitta

DESCRIPTION

1.3.3 Characteristics

E

Version c5-2 c5-2 c5-2 c5-2 c5-2 (USA)

Mains power supply [ V ] 1N AC

230

Heater element [ kW ] 3.4 4.0 6.0 3.78 4.92

Fuse protection [ A ] 16 16 16 20 30

Power consumption [ kW ] 3.45 4.05 6.05 3.83 4.97

"Pressureless" power consumption

(= built-in water pump) [ kW ]

Boiler capacity [ litres ] 7.7 7.7 7.7 7.7 7.7

Hot water throughput [ litres/h ] 30 36 50 34 44

Dimensions (W x H x D) [ mm ] 250 x 680 x 600

Empty weight [ kg ] 27.5 27.5 27.5 27.5 31.5

"Pressureless" empty weight

(= built-in water pump) [ kg ]

Fresh water connection (by the customer) R 3/8" A ; 2-4 bar

Waste water connection (by the customer) 2“

Fresh water canister (optional) [ litres ] 20

Waste water canister (optional) [ litres ] 10

3.57 4.17 6.17 3.95 5.09

32 32 32 32 36

3N AC

400

3N AC

400

3 AC

200

2 AC

208

Raised feet (optional) [ mm ] 25.4 (1“) / 50.8 (2“) / 76.2 (3“) / 101.6 (4“)

1.3.4 Environmental conditions

1.3.4.1 Temperature and humidity

n Operating and storage temperatures:

min. + 5 °C

max. + 30 °C

n Operating and storage humidity:

max. 80 %

1.3.4.2 Space requirements

n Minimum space required for operation:

Sufficient space must be kept clear around the c5-2 boiler element so as to ensure that

there is no danger while drinks are being prepared.

© Cafina / Melitta 1-4 OI c5-2 eng V1 / 08.12.2004

SAFETY INSTRUCTIONS

2 Safety instructions

2.1 Warnings

2.1.1 Warning symbols used (depending on nationality)

The following warning symbols can be affixed.

Low voltage

• Warning of dangerous elec-

trical voltage.

• Electric shocks can lead to

serious injury or death.

• Only authorised technical

personnel may perform

work on electrical installations.

• The technical safety instruc-

tions must be followed.

2.1.2 Places where warning

symbols are affixed (depending on nationality)

E

NOTE

• The equipment comes sup-

plied with warning symbols

(stickers) affixed wherever

appropriate.

• If any of the warning sym-

bols should fall off during

operation or following cleaning work, the operator must

stick these warning symbols

back again immediately.

2.1.3 Safety information in

these Operating Instructions

• Unplug c5-2 boiler element

from the mains before carrying out any work on electrical installations.

Hot surface / hot internal components

• Warning of heat which could

lead to injury.

• Allow hot surfaces and components to cool before carrying out any work on these

component parts.

• If necessary, wear heat-resistant gloves.

In these Operating Instructions, you will

find the following three levels of safety information:

n Level 1

WARNING

• A warning refers to signifi-

cant hazards. Failure to follow the relevant safety

instruction could lead to injury or death.

OI c5-2 eng V1 / 08.12.2004 2-1 © Cafina / Melitta

SAFETY INSTRUCTIONS

E

Depending on the type of danger, instead of

STOP, one of the following symbols could

be combined with the word WARNING.

WARNING

• Warning of electric shock.

WARNING

• Warning of heat.

n Level 2

CAUTION

• The CAUTION symbol

stresses important instructions. Failure to observe

these instructions could

lead to damage to the equipment or to other material assets.

n Level 3

NOTE

• Notes contain additional in-

formation aimed at raising

the general level of safety

and at lightening the user’s

workload.

2.2 Basic safety instructions

2.2.1 Proper use

2.2.1.1 General

Proper use includes, in addition to the specific provisions set out below, observing

these Operating Instructions and complying with the supplier’s obligatory maintenance and repair instructions.

2.2.1.2 c5-2 boiler element

The c5-2 boiler element is used solely to

output hot water or steam and to heat and

froth milk.

No other use of the c5-2 boiler element will

be deemed to be proper.

© Cafina / Melitta 2-2 OI c5-2 eng V1 / 08.12.2004

2.2.2 Specific hazards and instructions

2.2.2.1 c5-2 boiler element

WARNING

• Hot air comes out from the

bottom of the steam outlet.

There is a danger of scalding.

• The bottom of the steam

outlet is hot after it has been

giving off steam. There is a

danger of burns.

• Hot liquid comes out from

the bottom of the hot water

outlet. There is a danger of

scalding.

• The bottom of the hot water

outlet is hot after it has been

dispensing liquid. There is a

danger of burns.

WARNING

• Never interfere with the

electricity supply connection

or modify it. This could result

in fatal injury.

• Never remove the screw-

mounted covers. There is a

danger of fatal injury upon

contact with live components.

SAFETY INSTRUCTIONS

CAUTION

• Never interfere with the wa-

ter mains connection or

modify it. There is a danger

of flooding.

• Only operate the c5-2 boiler

element in covered locations, avoid places where

there is a risk of water

splash. There is a risk of

damage.

• Never spray the c5-2 boiler

element with a water hose

during cleaning. There is a

risk of damage.

• Never lift the c5-2 boiler element by the drip tray.

• If the internal relief pressure

valve is actuated due to improper increase of pressure,

switch the c5-2 boiler element off immediately. Secure the c5-2 boiler element

against unintentional

switching on and report to

Customer Support.

• The c5-2 boiler element

must be disconnected from

the water supply after it has

been switched off, e.g. for

the overnight period of inactivity, i.e. it is imperative that

the tap is closed.

E

OI c5-2 eng V1 / 08.12.2004 2-3 © Cafina / Melitta

SAFETY INSTRUCTIONS

2.2.3 Personal safety

E

NOTE

• Regardless of type configu-

ration, the c5-2 boiler element should not be used in

large kitchens.

• Electrical equipment which

does not have adequate

electro-magnetic protection

should not be operated

close to the c5-2 boiler element.

• The drip tray serves solely

to collect drip water. It must

not be used as a sink.

• Ideally, do not leave the key

in the key-operated switch.

WARNING

If handled improperly, the c5-2

boiler element could cause serious or fatal injury.

Anyone using and maintaining

the c5-2 boiler element must be

trained in the correct handling of

the c5-2 boiler element and

must have read and understood

the safety instructions in these

Operating Instructions before

starting to use or maintain the

c5-2 boiler element.

WARNING

Never operate the c5-2 boiler element in a damaged condition.

WARNING

Never modify or remove any

safety mechanisms.

Do not disable any safety mechanisms by modifying the c5-2

boiler element.

If there are any warning symbols

affixed to the c5-2 boiler element

(dependent on nationality), never remove these. Replace any

lost or defective warnings symbols immediately.

Report any irregularities to your

superior immediately, especially

if they affect safety.

© Cafina / Melitta 2-4 OI c5-2 eng V1 / 08.12.2004

SAFETY INSTRUCTIONS

2.3 Safety mechanisms

As well as the warning symbols (dependent

on nationality) affixed to the c5-2 boiler element, the c5-2 boiler element also has several active safety mechanisms.

2.3.1 Power switch

- c5-2 boiler element key-operated

switch

- Black grip protection

2.4 Authorised persons

2.4.1 General

Only persons who are authorised to do so

may work on or with the c5-2 boiler element.

A person is deemed to be authorised if he/

she satisfies the minimum training and

knowledge requirements listed in this section and has been assigned a fixed area of

responsibility.

2.4.2 Areas of responsibility of personnel

2.4.2.1 Operator

As the most senior person from the legal

point of view, the operator is responsible for

the proper use of the c5-2 boiler element

and for the training and deployment of authorised personnel.

E

2.3.2 Relief pressure valve

The c5-2 boiler element is fitted with an internal relief pressure valve which monitors

the boiler pressure.

He records the competencies and of authorised persons, including whether they have

the authority to give orders, for his business.

His tasks include the following:

- He sets or resets the c5-2 boiler ele-

ment to the beverages that are currently to be dispensed, if he wishes to

dispense different beverages than

those that the supplier configured upon

delivery or installation of the c5-2 boiler

element.

OI c5-2 eng V1 / 08.12.2004 2-5 © Cafina / Melitta

SAFETY INSTRUCTIONS

E

2.4.2.2 User

He is responsible for the following tasks:

- He starts up the c5-2 boiler element and

monitors it.

- He adjusts the c5-2 boiler element to

the beverages currently to be dispensed.

- He sets the c5-2 boiler element to the

products to be processed.

- He cleans and services the c5-2 boiler

element in accordance with the work

described in chapters «6 Maintenance,

6 - 1» and «7 Troubleshooting, 7 - 1».

- He pinpoints problems and organises

problem rectification.

2.4.2.3 Maintenance personnel (ser-

vice technician)

2.4.3.2 User

This is a person who has been instructed in

how to use the c5-2 boiler element and is

aware of the hazards that exist.

2.4.3.3 Maintenance personnel (service technician)

These are people who have completed specialist vocational training, are familiar with

maintenance of the c5-2 boiler element and

through their work they have acquired the

skills needed.

Maintenance work on the mechanical and

electrical aspects of the c5-2 boiler element

may only be carried out by Customer Support.

2.5 Maintenance duty

He is responsible for the following tasks:

- He maintains and repairs the c5-2

boiler element in accordance with

the work described in chapters

«6 Maintenance, 6 - 1» and «7 Troubleshooting, 7 - 1».

- He takes the c5-2 boiler element apart,

stores it and disposes of it.

2.4.3 Minimum training and

qualifications of

authorised personnel

2.4.3.1 Operator

- He has a commercial background and

performs a managerial function.

- He has specialist experience in risk assessment and staff management.

- He has read and understood chapter

«2 Safety instructions, 2 - 1».

The operator has an obligation to maintain

and clean the c5-w boiler element at regular

intervals.

- To operate the c5-2 boiler element only

in a fully operational and undamaged

condition.

- To use only OEM consumables and

spare parts.

- To test the security mechanisms to

ensure that they are working properly

following any maintenance or repair

work (see section «2.3 Safety mechanisms, 2 - 5»).

2.6 Availability of these

Operational Instructions

A copy of these Operational Instructions in

the vicinity of the c5-2 boiler element must

be available to staff using the equipment at

all times.

© Cafina / Melitta 2-6 OI c5-2 eng V1 / 08.12.2004

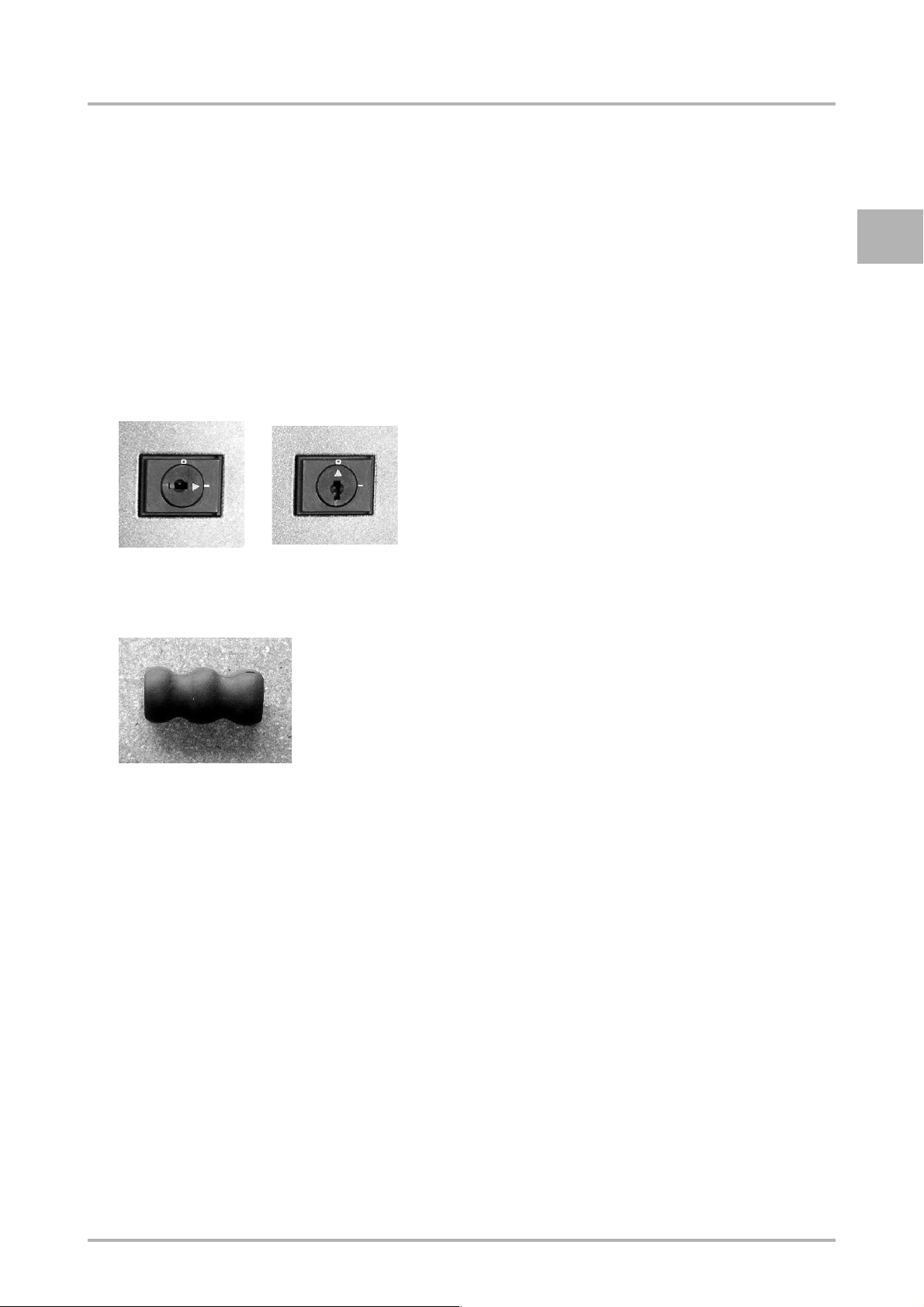

CONTROLS AND INDICATORS

3 Controls and indi-

cators

3.1 Key-operated switch

n Power switch

ON OFF

3.2 Pushbuttons

The piezo-pushbuttons are sealed, resistant to wear and respond to the application

of pressure, preferably in the centre.

3.3 Indicator lamps

n Operating status indicator Green

E

n Operating status indicator Red

n Hot water button

n Steam button

3.4 Grip elements

n Grip protection

3.5 Covers

n Drip grille

OI c5-2 eng V1 / 08.12.2004 3-1 © Cafina / Melitta

E

CONTROLS AND INDICATORS

3.6 Operating modes

Operating mode Description

In operation (free of faults,

power supply switched on)

In this condition, the c5-2 boiler element is connected to the power supply and water mains or to the canisters.

Key-operated switch "ON"

Out of service

(power supply switched off)

Key-operated switch "OFF"

In operation (with fault,

power supply switched on)

Operating status indicator Red

(flashing at regular intervals)

In operation (Programming mode,

power supply switched on)

There are no restrictions on the dispensing of beverages.

In this condition the c5-2 boiler element is disconnected from the power

supply and water mains but is still connected to the canisters.

It is not possible to dispense any beverages.

In this condition, the c5-2 boiler element is connected to the power supply and water mains or to the canisters.

There may be restrictions on the dispensing of beverages.

In the "Programming" state, the c5-2 boiler element is connected to the

power supply and water mains or to the canisters.

Operating status indicator Red

(flashing rapidly)

It is not possible to dispense any beverages.

© Cafina / Melitta 3-2 OI c5-2 eng V1 / 08.12.2004

INITIAL START-UP

4 Initial start-up

4.1 Normal initial start-up

Normal initial start-up assumes that the

c5-2 boiler element is connected to the

mains power supply.

Once the water connection has been

checked, the c5-2 boiler element can be

switched on.

4.2 Return to service after the machine has been out of service for a limited time

Initial start-up after the machine has been

out of service for a limited time assumes

that the c5-2 boiler element will normally

have been disconnected from the mains.

4.3 Return to service after a fault

Normal initial start-up after a fault assumes

that the c5-2 boiler element has not been

disconnected from the mains.

Before the c5-2 boiler element can be

operational again, the fault must have

been cleared in accordance with chapter

«7 Troubleshooting, 7 - 1».

E

Once the water connection has been

checked and the c5-2 boiler element has

been plugged in to the mains, it can be

switched on.

OI c5-2 eng V1 / 08.12.2004 4-1 © Cafina / Melitta

E

INITIAL START-UP

© Cafina / Melitta 4-2 OI c5-2 eng V1 / 08.12.2004

OPERATION

5 Operation

5.1 Power supply connection

Connection to the power supply is a matter

for the installation company and is taken for

granted below.

The equipment is connected to the power

supply either via a mains plug or a permanent connection.

5.2 Water connection

Connection to the water mains is a matter

for the installation company and is taken for

granted below.

CAUTION

• Combining a permanent

connection to the mains water supply and the use of a

waste water canister is not

recommended.

5.2.1 Water intake

The c5-2 boiler element is supplied with

water from ...

n ... the mains water supply, with perma-

nent connection to the pipe system

or

n ... from a fresh water canister with de-

tachable hose coupling.

5.2.2 Water drainage

Water is drained from the c5-2 boiler element ...

n ... into the waste water system, with

permanent connection to the pipe system

or

n ... into a waste water canister fitted with

a perforated cap.

E

• The use of a waste water

canister can cause flooding.

• Ideally, "permanent connec-

tion to permanent connection" should be the

operating mode.

OI c5-2 eng V1 / 08.12.2004 5-1 © Cafina / Melitta

OPERATION

E

5.3 Switching on and off

Switching on

1. Make sure that the c5-2 boiler element

has a water supply:

4 Turn on the tap.

2. Switch the c5-2 boiler element on by

pressing the key-operated switch

(power switch):

4 Key-operated switch "ON"

4 The operating status indicator

Green will be permanently illuminated.

4 The operating status indicator Red

lights up briefly (lamp check).

5.4 Dispensing beverages and handling

5.4.1 Drawing hot water

CAUTION

• Water outlet is hot.

• Danger of burns and scald-

ing.

• Only touch hot water outlet

by the black grip protection.

1. To the extent that it can be moved,

align hot water outlet vertically.

2. Place receptacle under hot water out-

let.

3. Press hot water button [ ].

The preprogrammed volume of hot water will be dispensed.

4 The c5-2 boiler element heats up to

operating temperature, following

which it is ready for operation.

Switching off

1. Switch the c5-2 boiler element off by

pressing the key-operated switch

(power switch):

4 Key-operated switch "OFF"

4 The operating status indicator

Green slowly darkens.

2. Disconnect the water supply to the

c5-2 boiler element:

4 Turn off the tap.

© Cafina / Melitta 5-2 OI c5-2 eng V1 / 08.12.2004

OPERATION

5.4.2 Heating milk (manually)

CAUTION

• Steam outlet is hot.

• Danger of burns and scald-

ing.

• Only touch hot steam outlet

by the black grip protection.

1. Align steam outlet vertically.

2. Press steam button [ ] twice to al-

low condensed water to run out of the

steamer outlet into the drip tray, following which only steam should come out

of the steamer outlet.

3. Rotate the steam outlet forwards and

dip it into the drink that is to be heated.

With larger receptacles, move the

steam outlet together with the receptacle towards the c5-2 boiler element and

then place the receptacle on the drip

grille.

4. Press steam button [ ] and wait un-

til the drink has reached the desired

temperature.

5. To terminate the operation, press

steam button [ ].

6. Pull receptacle forwards and put aside.

7. Wipe steam outlet clean with a moist

cloth.

8. Align steam outlet vertically.

9. Press steam button [ ] twice so as

to allow the residual fluid that is still in

the steam outlet to run off into the drip

tray.

5.4.3 Heating milk (automatically)

CAUTION

• Steam outlet is hot.

• Danger of burns and scald-

ing.

• Only touch hot steam outlet

by the black grip protection.

• Only move steamer outlet

temperature probe unit by

the steam outlet.

1. The steam outlet and the temperature

probe are mechanically linked. Align

steam outlet temperature probe unit by

moving the steam outlet vertically.

2. Press steam button [ ] twice to al-

low condensed water to run out of the

steamer outlet into the drip tray, following which only steam should come out

of the steamer outlet.

3. Rotate the steam outlet temperature

probe unit forwards and dip it into the

drink that is to be heated.

With larger receptacles, move the

steam outlet temperature unit together

with the receptacle towards the c5-2

boiler element and then place the receptacle on the drip grille.

4. Press steam button [ ] and wait un-

til the operation automatically finishes.

5. Pull receptacle forwards and put aside.

6. Wipe steam outlet and temperature

probe clean with a moist cloth.

7. Align steam outlet temperature probe

unit vertically.

8. Press steam button [ ] twice so as

to allow the residual fluid that is still in

the steam outlet to run off into the drip

tray.

E

OI c5-2 eng V1 / 08.12.2004 5-3 © Cafina / Melitta

OPERATION

E

5.4.4 Frothing milk

CAUTION

• Beware hot steam outlet

and/or splash from hot milk.

• Danger of burns and scalding.

• Only touch hot steam outlet

by the black grip protection.

Observe distance between

end of steam nozzle and the

surface of the liquid.

NOTE

• If the c5-2 boiler element is

fitted with the "Temperature

probe" option, then the

steam outlet temperature

probe unit must only be

moved by the steam outlet.

• If the c5-2 boiler element

is fitted with the "Temperature probe" option, it is only

possible to froth milk if the

depth to which the temperature probe is plunged was

specifically set by Customer

Support on the occasion of

first-time installation.

1. Align steam outlet vertically.

2. Press steam button [ ] twice to al-

low condensed water to run out of the

steamer outlet into the drip tray, following which only steam should come out

of the steamer outlet.

3. Rotate steam outlet forwards and dip

the end of the steam nozzle into the

drink to be frothed right down to the

bottom of the receptacle.

4. Press steam button [ ].

Then lower the receptacle so that the

end of the steam nozzle is just above

the surface of the liquid.

During the frothing operation, watch

the formation of froth and continually

adjust the distance between the end of

the steam nozzle and the surface of the

liquid (this will differ according to the

physical properties of the steam nozzle).

5. When the desired degree of froth has

been achieved, press the steam button

[ ] to terminate the operation.

6. Pull receptacle forwards and put aside.

7. Wipe steam outlet (temperature probe)

clean with a moist cloth.

8. Align steam outlet vertically.

9. Press steam button [ ] twice so as

to allow the residual fluid that is still in

the steam outlet to run off into the drip

tray.

© Cafina / Melitta 5-4 OI c5-2 eng V1 / 08.12.2004

OPERATION

5.4.5 Routine work

5.4.5.1 Cleaning the drip tray

The drip grille and drip tray must be

cleaned at regular intervals.

CAUTION

• Never lift the c5-2 boiler ele-

ment by the drip tray.

1. Press the drip grille at the back right or

back left corner downwards a little.

2. Remove drip grille and clean.

3. Clean drip tray and clean out the drain

holes if they are blocked.

4. Place the drip grille in the correct position on the drip tray, i.e. with the transverse rods underneath.

5.5 System work

5.5.1 Control panel and button layout

In Programming mode, the control buttons

work as follows:

[ ] "Final milk temperature" function

[ ] "Hot water quantity" function

[ ] Operating status indicator Green

[ ] Operating status indicator Red

and Programming mode

5.5.2 Programming

It is essential to stick to the sequence of operating steps for successful programming.

E

OI c5-2 eng V1 / 08.12.2004 5-5 © Cafina / Melitta

OPERATION

E

5.5.2.1 Hot water quantity

CAUTION

• Water outlet is hot.

• Danger of burns and scald-

ing.

• Only touch hot water outlet

by the black grip protection.

1. Switch on c5-2 boiler element [ ].

Wait until the boiler has heated up.

2. To the extent that it can be moved,

align hot water outlet vertically.

3. Place receptacle under hot water outlet.

4. Switch off c5-2 boiler element [ ].

Wait until the operating status indicator

Green [ ] has gone out totally.

5. Switch on c5-2 boiler element [ ]

again.

6. While the operating status indicator

Red [ ] lights up for approx. 2 seconds, press any button hard three

times in quick succession.

The operating status indicator Red

[ ] will flash rapidly, indicating that

the machine is in Programming mode.

7. Press hot water button [ ], and al-

low hot water to keep flowing into the

receptacle until the desired quantity of

hot water has been reached.

8. To terminate the dispensing of hot water, press steam button [ ].

NOTE

• The hot water dispensing

operation can last a maximum of 50 seconds. If the

operation is not stopped within this time, then

"50 sec." is automatically

stored as the outflow time.

The operating status indicator Red

[ ] goes dark and the hot water dispensing volume and outflow time are

stored.

9. Press the hot water button [ ] so

that the programmed quantity of hot

water can be dispensed.

NOTE

• The hot water dispensing

volume can vary slightly due

to fluctuations in the mains

water pressure or the boiler

pressure.

© Cafina / Melitta 5-6 OI c5-2 eng V1 / 08.12.2004

5.5.2.2 Final milk temperature

OPERATION

NOTE

• The final milk temperature

can only be programmed if

your c5-2 boiler element has

the "Temperature probe"

option!

• If the c5-2 boiler element is

fitted with two "Temperature

probe" options (right and

left), the final milk temperature can be separately programmed for each side.

• For each temperature

probe, the final milk temperature can be programmed

within the limits 55 °C and

80 °C. If the temperature of

the liquid is outside the limits

while the program is running, the operating status indicator Red [ ] flashes

four times, repeated periodically.

CAUTION

• Steam outlet is hot.

• Danger of burns and scald-

ing.

• Only touch hot steam outlet

by the black grip protection.

1. Switch on c5-2 boiler element [ ].

Wait until the boiler has heated up.

2. Rotate steam outlet and temperature

probe forwards and then dip into the

liquid to be heated: approx. 1 litre of

water.

Move steam outlet and temperature

probe together with the receptacle towards the c5-2 boiler element and then

place the receptacle on the drip grille.

NOTE

• Ideally, place a thermometer

in the liquid.

E

• The temperature is recorded

via the submerged temperature probes, with a slight

time delay. As a result, small

volumes of liquid could be

heated slightly higher and

large volumes slightly lower

(200 ml with approx. + 2 °C,

1 litre with approx. - 2 °C).

This anomaly can be compensated through appropriate warming of the

calibration liquid.

3. Press steam button [ ] and wait un-

til the operation automatically finishes.

Repeat this process until the liquid has

reached the desired temperature.

OI c5-2 eng V1 / 08.12.2004 5-7 © Cafina / Melitta

E

OPERATION

4. Switch off c5-2 boiler element [ ].

Wait until the operating status indicator

Green [ ] has gone out totally.

5. Switch on c5-2 boiler element [ ]

again.

6. While the operating status indicator Red [ ] lights up for approx.

2 seconds, press any button hard

three times in quick succession.

The operating status indicator Red

[ ] will flash rapidly, indicating that

the machine is in Programming mode.

7. Press steam button [ ].

The operating status indicator Red

[ ] will go out.

The final liquid temperature has now

been stored.

8. If necessary, go through the heating

operation for both a small quantity

of milk and a large quantity, following the procedure described in section «5.4.3 Heating milk (automatically), 5 - 3».

NOTE

• If necessary, check the final

liquid temperature using a

thermometer.

© Cafina / Melitta 5-8 OI c5-2 eng V1 / 08.12.2004

MAINTENANCE

6 Maintenance

This chapter deals exclusively with preventive maintenance of the c5-2 boiler element. In case of problems, please consult chapter «7 Troubleshooting, 7 - 1».

6.1 Maintenance schedule

6.1.1 Intervals

6.1.1.1 Cleaning intervals

Cleaning area Daily Weekly Monthly

E

Outside of c5-2 boiler element

(Stainless steel surface: chrome cleaner spray can order no. 2150024)

Control buttons

Operating status indicators

Steam outlets

Hot water outlets

Temperature probes

Drip grille

Drip tray

6.1.1.2 Intervals between services

NOTE

• The equipment must be serviced once a year, including a check of all safety

mechanisms.

n

n

n

n

n

n

n

n

OI c5-2 eng V1 / 08.12.2004 6-1 © Cafina / Melitta

E

MAINTENANCE

6.2 Periodic checks

Product dispensed Daily Weekly Monthly

Steam nozzles (check for

clogging, incrustation, deposits)

n

Hot water outlet

(check for clogging, lime)

If the equipment is used only

to dispense steam, then at

least one litre of hot water

should be passed through it

regularly (as a precaution

against the formation of

deposits)

6.3 Cleaning

6.3.1 Cleaning work

CAUTION

• Only use non-corrosive, non-abrasive household cleaners.

• Only use non-abrasive cloths.

n

n

• Use standard (rapid-action) decalcifying agent exclusively for the unscrewed

hot water outlet (filter use).

6.4 "Operator" maintenance log

The service technician from Customer Support maintains the maintenance log for the installation and subsequent maintenance work.

For this purpose he enters the necessary data into the table cells in chapter

«12 "Service Technician" maintenance log, 12 - 1».

© Cafina / Melitta 6-2 OI c5-2 eng V1 / 08.12.2004

TROUBLESHOOTING

7 Troubleshooting

7.1 Checklist for fault diagnosis and troubleshooting

7.1.1 Troubleshooting of specific conditions

Fault Cause of fault Troubleshooting measure(s)

E

c5-2 boiler element

does not respond

(not working)

Operating status indicator

Green [ ] does not light up.

No steam output, but

cold water is coming out.

The machine will not

produce any hot water.

Loud hissing noise is

audible and steam is

coming out of all the joints.

No electrical supply

voltage present.

Boiler temperature

too low.

Boiler:

water level too low.

Tap is turned off.

Relief pressure valve has

been activated due to

rise in pressure / temperature beyond permissible

limits

Switch c5-2 boiler element off

and then on again.

Check key-operated switch.

Check fuses in the electrical

mains connection.

Switch boiler element off and

then on again. Wait until the

boiler has heated up.

If the c5-2 boiler element is not

working normally 15 minutes

after switching on, switch off

the c5-2 boiler element and

notify Customer Support.

Turn the tap full on.

Notify Customer Support.

Switch off the c5-2 boiler element immediately and notify

Customer Support.

Ensure that the c5-2 boiler element cannot be unintentionally switched on.

OI c5-2 eng V1 / 08.12.2004 7-1 © Cafina / Melitta

E

TROUBLESHOOTING

7.1.2 Troubleshooting on the basis of the LED light intervals

During operation, the control system monitors the operating status continually. Any faults are

indicated by the operating status indicator Red [ ]. In case of malfunction, the user can

intervene and attempt to troubleshoot the problem in accordance with the procedures described in this chapter. Faults are indicated by the operating status indicator Red [ ]

(periodically recurring): flashing interspersed with darkness.

Flashing of operating

status indicator Red [ ]

Only applicable if the

"Temperature probe 1"

option is installed.

Only applicable if the

"Temperature probe 2"

option is installed.

Cause of fault Troubleshooting measure(s)

Temperature probe 1

(right-hand side) is faulty,

control system cannot

measure temperature.

Temperature probe 2

(left-hand side) is faulty,

control system cannot

measure temperature.

Boiler:

water level too low.

Manual heating of milk is not

possible. For safety reasons,

steam cannot be output for

more than ten seconds.

Notify Customer Support.

Manual heating of milk is not

possible. For safety reasons,

steam cannot be output for

more than ten seconds.

Notify Customer Support.

Turn the tap full on.

Switch c5-2 boiler element off

and then on again.

Dispensing of steam is not

possible, but should be restricted to a minimum so as to

avoid overheating the boiler.

Notify Customer Support.

Programming: incorrect sequence or sequence not followed consistently during

programming.

Temperature of "calibration

liquid" is below 55°C or

above 80°C.

© Cafina / Melitta 7-2 OI c5-2 eng V1 / 08.12.2004

Perform correct programming.

Use correctly warmed up "calibration liquid".

TAKING OUT OF SERVICE AND STORAGE

8 Taking out of

service and storage

8.1 Taking out of service for a limited time / taking out of service for good

If the c5-2 boiler element is to be taken out

of service for only a limited time (over an

extended period) and also when it is taken

out of service for good, the c5-2 boiler element must be disconnected from the power

supply.

All the components must be cleaned thoroughly.

If the c5-2 boiler element is to be out of service for an extended period, to avoid (frost)

damage, it should be expertly drained by

Customer Support.

8.2 Storage for a limited period / permanent storage

E

Whether the c5-2 boiler element is to be

taken out of service for a limited period or

for good, it is essential that this is done in

the proper fashion - see requirements on

the left.

When storing the equipment, the requirements specified in section «1.3.4 Environmental conditions, 1 - 4» must be observed.

OI c5-2 eng V1 / 08.12.2004 8-1 © Cafina / Melitta

E

TAKING OUT OF SERVICE AND STORAGE

© Cafina / Melitta 8-2 OI c5-2 eng V1 / 08.12.2004

PACKING AND TRANSPORTATION

9 Packing and

transportation

WARNING

• Only persons with experi-

ence of haulage and transportation are authorised to

pack and transport the c5-2

boiler element.

• The requirements set out in

chapter «2 Safety instructions, 2 - 1» must be strictly

observed!

CAUTION

• When securing the c5-2

boiler element (... in the original packaging) on the transport base, take care not to

cause any chafe marks.

When packing and transporting the equipment, the following requirements must be

observed:

E

1. Disconnect c5-2 boiler element from

the power and water mains.

2. Empty hoses and drain. This is a matter

for Customer Support.

3. Clean c5-2 boiler element.

4. If possible, pack c5-2 boiler element in

the original packaging.

5. Place the c5-2 boiler element (... in the

original packaging) on a suitable transport base in an upright position and attach to the transport base.

OI c5-2 eng V1 / 08.12.2004 9-1 © Cafina / Melitta

E

PACKING AND TRANSPORTATION

© Cafina / Melitta 9-2 OI c5-2 eng V1 / 08.12.2004

DISPOSAL

10 Disposal

WARNING

• Disassembly and disposal

of the c5-2 boiler element

may only be carried out by

persons who satisfy the necessary qualification and

training requirements.

• The requirements set out in

chapter «2 Safety instructions, 2 - 1» must be strictly

observed!

NOTE

The following requirements must be observed in the case of disposal:

1. Disconnect c5-2 boiler element from

the power and water mains.

2. Empty hoses and drain.

3. Take c5-2 boiler element apart.

4. Recycle individual parts according to

material type.

5. Dispose of non-recyclable materials

according to type.

E

• Information on disposal or-

ganisations and collection

points can be obtained from

your local administrative authority.

• During disposal, it is necessary in any case to comply

with the pertinent national

and regional laws and directives.

• The c5-2 boiler element

does not contain any materials whose disposal requires

special approval.

OI c5-2 eng V1 / 08.12.2004 10 - 1 © Cafina / Melitta

E

DISPOSAL

© Cafina / Melitta 10 - 2 OI c5-2 eng V1 / 08.12.2004

GUARANTEE, CONSUMABLE MATERIALS, SPARE PARTS, ORDERING

11 Guarantee,

consumable

materials, spare

parts, ordering

Guarantee

This machine is guaranteed for a guarantee period

of 12 months. The guarantee period commences

the day that the equipment is installed.

During the guarantee period, any problems with materials and any defects attributable to defective design or construction will be rectified free of charge by

us or by our authorised subcontractor. It is a requirement that the machine has been used as directed

and properly handled in accordance with the pertinent sections of these Operating Instructions.

Accordingly, we shall not be held liable in the following cases:

- faults due to dirt accumulation as a result of im-

proper cleaning (e.g. blocked valves)

- faults due to calcification or other deposits dur-

ing operation with water softening equipment

(e.g. boiler, water pumps)

- faults due to mains overvoltage (e.g. blown

print circuit boards)

We accept no responsibility for damage to any

equipment that arises as a result of improper servicing and maintenance by the customer.

We accept no responsibility for any defects in our

equipment which are due to improper repairs or to

the installation of non-original spare parts.

Normal wear and tear of parts which are subject to

natural wear and tear is specifically excluded from

this guarantee.

Such parts include:

- seals

- filters

- paintwork

To make a claim under the guarantee, the defective

part must be returned to the manufacturer. The

manufacturer reserves the right to refuse a claim under guarantee after inspecting the returned part, if

one of the conditions mentioned above applies.

Acknowledgement of damage which falls within the

terms of the guarantee is only possible after a written report from the manufacturer.

Any adjustments of quality which are not carried out

due to a malfunction are excluded from the guarantee.

The fact that work is carried out during the guarantee period will not extend this period.

Consumable materials, spare parts, ordering

Normally concerns service technicians, third-party

customers and resellers:

To avoid misunderstandings over the ordering of

consumable materials or spare parts, we would ask

you to always specify the following information in

your order:

n machine ID as per type plate.

n name and, if appropriate, article number of the

consumable item or spare part.

n number of consumable materials or spare parts

required.

Equipment-specific consumable materials and

spare parts must be obtained from the customer

service address for the relevant country.

Only equipment-specific spare parts supplied by the

manufacturer may be used.

The manufacturer does not accept any liability in

cases where it turns out that non equipment-specific

spare parts from the manufacturer have been installed in the relevant machine.

E

OI c5-2 eng V1 / 08.12.2004 11 - 1 © Cafina / Melitta

GUARANTEE, CONSUMABLE MATERIALS, SPARE PARTS, ORDERING

A Adresses of service AUS Adresses of service B Serviceadressen

E

CH Adresses of service D Adresses of service

DK Serviceadresser E Servico Tecnicos F Services Techniques

FIN Huoltopisteiden osoitteita GB Customer Support addresses J Adresses of service

N Serviceadresser NL Serviceadressen RC Adresses of service

RUS Service S Serviceadresser TH Adresses of service

USA Adresses of service KR Adresses of service TW Adresses of service

A

MELITTA System Service

International GmbH

Ziegeleistrasse 31

5020 Salzburg

Tel. +43-662 / 88 28 88-33

Fax +43-662 / 88 28 88-99

CH

CAFINA AG

Römerstrasse 2

5502 Hunzenschwil

Phone +41-62 / 889 42 42

Fax +41-62 / 889 42 89

Instruktionsnummer: 17098

AUS

National Coffee

Distributors

PO Box 201

Fairy Meadow NSW 2519

Phone +61-2 / 95 71-44 44

Fax +61-2 / 42 84-60 99

D

MELITTA System Service

GmbH & Co. KG

Zechenstrasse 60

32429 Minden-Dützen

Phone +49-571 / 50 49-0

Fax +49-571 / 50 49-233

B

MELITTA System Service Benelux

Bijkantoor MELITTA Syst. Service

Brandstraat, 8

9160 Lokeren

Phone +32-9 / 331 52 30

Fax +32-9 / 331 52 35

DK N

aromateknik a/s

Industrivej 44

4000 Roskilde

Phone +45-46 / 75 33 66

Fax +45-46 / 75 38 10

E

Tecnimel Hosteleria, S.L.

Avda. Esparteros, 15

Pol. S. J. de Valderas Sanahuja

28918 Leganés (Madrid)

Phone +34-91 / 644 81 30

Fax +34-91 / 644 81 31

F

MELITTA System Service

France SA

16 Rue P.H. Spaak

Saint Thibault des Vignes

77462 LAGNY sur Marne Cedex

Phone +33-1 / 6430 32 95

Fax +33-1 / 6430 33 40

KR

Edward Keller (Korea) Ltd.

3F. Nasan Bldg. 1024

Daechi-dong

Kangnam-gu

Seoul 135-173

Phone +82-2 / 2192-9541

Fax +82-2 / 2192-9590

S

aromateknik A/S

Radiovägen 2

Box 662

13526 Tyresö

Phone +46-8 / 7 98 77 88

Fax +46-8 / 7 98 90 18

FIN

Hackman

Metos Oy AB

Ahjonkaarre

04220 Kerava

Phone +358-204 / 39 13

Fax +358-204 / 39 44 33

NL

MELLITA

System Service Benelux BV

Industriestraat 6

3371 XD HARDINXVELD

GIESSENDAM

Phone +31-18 467 / 16 60

Fax +31-18 461 / 04 14

TH

Great Earth International Co., Ltd.

5th Floor, M Thai Tower,

All Seasons Place

87 Wireless Road, Patumwan

Bangkok 10330

Phone +66-2 / 654-1118

Fax +66-2 / 654-1119

GB

M.S.S. (UK) Limited

21 Grove Park

White Waltham

Maidenhead Berkshire

SL6 3LW

Phone +44-1628 / 82 98 88

Fax +44-1628 / 82 51 11

RC

Edward Keller

21/F Southmark

11 Yip Hing St.

Wong Chuk Hang

Hongkong / China

Phone +852 / 28 95-96 20

Fax +852 / 28 95-00 39

USA

Michaelo Espresso, Inc.

3801 Stone Way N.

Seattle, WA 98 103

Phone +1-206 / 548-9000

Fax +1-206 / 695-4951

J

MELITTA Japan Ltd.

9F abc Kaikan

2-6-3, Shiba-koen, Minato-ku

Tokyo 105-0011 Japan

Phone +81-3 / 5470-2770

Fax +81-3 / 5470-2774

RUS

MELITTA Russland

Sofiskaya 14 of. 805

192236 St. Petersburg

Phone +7-812 / 3 26 65 56

Fax +7-812 / 3 26 65 57

TW

JAS Corporation

B1, No. 17, Lane 28

Sec. 1, Huan Shan Rd.,

Nei Hu Area

Taipei

Phone +886-2 / 2727-0630

Fax +886-2 / 2727-0640

© Cafina / Melitta 11 - 2 OI c5-2 eng V1 / 08.12.2004

"SERVICE TECHNICIAN" MAINTENANCE LOG

12 "Service Technician" maintenance log

Installation Serial no.:

Date: Installed water filter type:

Key:

[ A ] = Service of whole system

[ S ] = Annual check of safety mechanisms

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Signature: GH°:

... OUT

2)

[ F ] = Water filter replaced

* = Check applicable fields

1)

= Untreated water before the filter

2)

= Water at the beverage outlet

Water measured values

on ...

1)

... IN

kH°:

pH:

... OUT

2)

E

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

... OUT

... OUT

2)

2)

OI c5-2 eng V1 / 08.12.2004 12 - 1 © Cafina / Melitta

E

"SERVICE TECHNICIAN" MAINTENANCE LOG

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

... OUT

... OUT

2)

2)

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

... OUT

... OUT

2)

2)

kH°:

pH:

© Cafina / Melitta 12 - 2 OI c5-2 eng V1 / 08.12.2004

"SERVICE TECHNICIAN" MAINTENANCE LOG

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

... OUT

... OUT

2)

2)

E

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

... OUT

... OUT

2)

2)

kH°:

pH:

OI c5-2 eng V1 / 08.12.2004 12 - 3 © Cafina / Melitta

E

"SERVICE TECHNICIAN" MAINTENANCE LOG

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

... OUT

... OUT

2)

2)

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

kH°:

pH:

Date: Service * Water values Notes:

[ A ] [ S ] [ F ]

Service Technician no.:

Water measured values

on ...

1)

... IN

Signature: GH°:

... OUT

... OUT

2)

2)

kH°:

pH:

© Cafina / Melitta 12 - 4 OI c5-2 eng V1 / 08.12.2004

INDEX

Page Page

B

Basic safety instructions . . . . . . . . . 2 - 2

C

Characteristics . . . . . . . . . . . . . . . . 1 - 4

Cleaning work . . . . . . . . . . . . . . . . . 6 - 2

Consumable materials . . . . . . . . . 11 - 1

Control elements . . . . . . . . . . . . . . 3 - 1

Customer Support addresses . . . . 11 - 2

D

Description . . . . . . . . . . . . . . . . . . . 1 - 1

Disposal . . . . . . . . . . . . . . . . . . . . 10 - 1

G

P

Packing . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Periodic checks . . . . . . . . . . . . . . . . 6 - 2

Physical construction . . . . . . . . . . . . 1 - 1

S

Safety instructions . . . . . . . . . . . . . . 2 - 1

Safety mechanisms . . . . . . . . . . . . . 2 - 5

Service Technician

maintenance log . . . . . . . . . . . . . . . 12 - 1

Spare part . . . . . . . . . . . . . . . . . . . 11 - 1

Specific hazards

and instructions . . . . . . . . . . . . . . . . 2 - 3

Storage . . . . . . . . . . . . . . . . . . . . . . 8 - 1

E

Guarantee . . . . . . . . . . . . . . . . . . . 11 - 1

I

Indicators . . . . . . . . . . . . . . . . . . . . 3 - 1

Initial start-up . . . . . . . . . . . . . . . . . 4 - 1

M

Maintenance . . . . . . . . . . . . . . . . . . 6 - 1

Mode of operation . . . . . . . . . . . . . . 1 - 2

O

Operating modes . . . . . . . . . . . . . . 3 - 2

Operation . . . . . . . . . . . . . . . . . . . . 5 - 1

Operator maintenance log . . . . . . . 6 - 2

T

Taking out of service . . . . . . . . . . . . 8 - 1

Technical data . . . . . . . . . . . . . . . . . 1 - 2

Transportation . . . . . . . . . . . . . . . . . 9 - 1

Troubleshooting . . . . . . . . . . . . . . . . 7 - 1

W

Warnings . . . . . . . . . . . . . . . . . . . . . 2 - 1

Ordering . . . . . . . . . . . . . . . . . . . . 11 - 1

OI c5-2 eng V1 / 08.12.2004 I © Cafina / Melitta

E

INDEX

© Cafina / Melitta II OI c5-2 eng V1 / 08.12.2004

Loading...

Loading...