Page 1

Type S020

Insertion fitting

Insertion Fitting

Raccord à insertion

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2012 - 2013

Operating Instructions 1311/4_EU-ML 00565449 ORIGINAL_FR

Page 3

Type S020

Table of Contents

1. ABOUT THESE OPERATING INSTRUCTIONS .................................5

1.1. Symbols used .......................................................................................5

2. INTENDED USE ................................................................................................6

3. BASIC SAFETY INFORMATION ...............................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Manufacturer's address and international contacts .........7

4.2. Warranty conditions ...........................................................................7

4.3. Information on the Internet ............................................................7

5. DESCRIPTION ...................................................................................................8

5.1. Area of application .............................................................................8

6. TECHNICAL DATA ...........................................................................................8

6.1. Conditions of use ................................................................................8

6.2. Available certificates .........................................................................8

6.3. General technical data .....................................................................9

6.3.1. Diameters available ...............................................................9

6.3.2. Materials .................................................................................. 9

6.3.3. Dimensions of T fittings .....................................................10

6.3.4. Dimensions of spigots ........................................................17

6.3.5. Dimensions of the saddles ................................................19

6.3.6. Dimensions of the measurement chamber ....................19

6.4. K factors ................................................................................................ 20

6.4.1. Terms of reference ..............................................................20

6.4.2. Calculation of K factors (in pulse/litre) for

saddles, fusion spigots, welding sockets with

radius or screw-ons ............................................................20

6.4.3. K factors (in pulse/litre) for T fittings used with

a 8041 or 8045 with a G2'' nut .......................................21

6.4.4. K factors (in pulse/litre) for T fittings and welding sockets used with a 8041 or a 8045 with

clamp connection ................................................................23

6.4.5. K factors (in pulse/litre) for T fittings used with

a 8020, 8024, 8025 or 8026 ..........................................23

6.4.6. K factors (in pulse/litre) for saddles ................................25

6.4.7. K factors (in pulse/l) of the fusion spigots and

welding sockets with radius for measuring

devices with a G2'' nut .......................................................26

6.4.8. K factors (in pulse/litre) for screw-ons ...........................28

7. INSTALLATION AND COMMISSIONING ...........................................29

7.1. Safety instructions...........................................................................29

7.2. Installation onto the pipe .............................................................30

7.2.1. Recommandations for installing the S020 fitting

on the pipe ............................................................................30

7.2.2. Installing a T fitting ..............................................................32

English

3

Page 4

7.2.3. Installing saddles .................................................................33

7.2.4. Installing a welding socket with radius, for mea-

suring devices with a G2'' nut ..........................................34

7.2.5. Installing a welding socket, for measuring

devices with a clamp connection ....................................34

7.2.6. Installing a fusion spigot (PE, PP or PVDF) ..................36

7.2.7. Installing a screw-on in plastic (PP, PVC, PE) .............37

7.2.8. Installing the measurement chamber ..............................38

7.2.9. Graph - pipe DN - fluid velocity - flow rate ...................39

8. MAINTENANCE .............................................................................................. 40

8.1. Safety instructions...........................................................................40

8.2. Cleaning ................................................................................................ 40

9. SPARE PARTS AND ACCESSORIES ................................................. 41

10. PACKAGING, TRANSPORT, STORAGE .......................................... 44

11. DISPOSAL OF THE FITTING ................................................................44

English

4

Page 5

Type S020

About these operating instructions

1. ABOUT THESE OPERATING

INSTRUCTIONS

These operating instructions describe the entire life cycle of the fitting.

Please keep these operating instructions in a safe place, accessible to

all users and any new owners.

These operating instructions contains important safety

information.

Failure to comply with these instructions can lead to hazardous

situations.

• These operating instructions must be read and understood.

1.1. Symbols used

danger

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or

even death.

attention

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

note

Warns against material damage.

• Failure to observe this warning may result in damage to the

fitting or system.

Indicates additional information, advice or important

recommendations.

Refers to information contained in this manual or in other

documents.

→ Indicates a procedure to be carried out.

English

5

Page 6

Type S020

Intended use

2. INTENDED USE

Use of insertion fittings that does not comply with the instructions could present risks to people, nearby installations

and the environment.

• The S020 fitting is intended for installation in a pipe, of an

insertion device.

• Use this fitting in compliance with the specifications and conditions of commissioning and use given in the contractual documents, in these operating instructions and in the user manual for

the device which is inserted into it.

• Safe and trouble-free operation of the fitting depends on its

proper transport, storage and installation, as well as careful

operation and maintenance.

• Only use this fitting as intended.

→ Observe any existing restraints when the fitting is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during installation,

use and maintenance of the devices.

• the local safety regulations for which the operating company is res-

ponsible including the staff in charge of installation and maintenance.

Danger due to high pressure in the installation.

Danger due to high temperatures of the fluid.

Danger due to the nature of the fluid.

Various dangerous situations

To avoid injury take care:

• to prevent any unintentional power supply switch-on.

• to ensure that installation and maintenance work are

carried out by qualified, authorised personnel in possession of

the appropriate tools.

• to guarantee a set or controlled restarting of the process, after a

power supply interruption.

• to use the fitting only if in perfect working order and in compliance with the instructions provided in these operating

instructions.

6

English

Page 7

Type S020

General information

4. GENERAL INFORMATION

Various dangerous situations (cont'd)

To avoid injury take care:

• to observe the general technical rules when installing and using

the fitting.

• not to use this fitting in explosive atmospheres.

• not to use fluid that is incompatible with the materials from which

the fitting is made.

• not to use this fitting in an environment incompatible with the

materials from which it is made.

• not to subject the fitting to mechanical loads (by placing objects

on top of it or by using it as a step, for example).

• not to make any internal or external modifications to the fitting.

note

The fitting may be damaged by the fluid in contact with.

• Systematically check the chemical compatibility of the component materials of the fitting and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

4.1. Manufacturer's address and international contacts

To contact the manufacturer of the fitting, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

The addresses of our international branches can be found on the

last pages of these operating instructions.

They can also be found on the Internet at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the S020 in observance of the operating conditions specified in this

manual.

4.3. Information on the Internet

You can find the operating instructions and the technical data sheet

regarding the type S020 at: www.burkert.com

English

7

Page 8

Type S020

Description

5. DESCRIPTION

5.1. Area of application

The S020 fitting simplifies the installation of insertion devices for measuring flow, pH, oxidation reduction potential (REDOX) or conductivity

on DN6 to DN400 pipes.

The fitting S020 is available in various versions for the installation of

measuring devices with a G2'' nut or measuring devices with a clamp

process connection.

The S020 measuring chamber is used:

• on the one hand, to install an insertion device for measuring the

pH, the oxidation reduction potential or the conductivity in a pipe

• and, on the other hand, to guarantee that the measurement sensor

is fully covered by the fluid.

6. TECHNICAL DATA

6.1. Conditions of use

Fluid

temperature

Ambient

temperature

Pressure

class

6.2. Available certificates

• Certificate 3.1, S020 in stainless steel only

• Certificate 2.2

• Surface roughness certificate

• Calibration certificate

• FDA approval (with EPDM seal), S020 in stainless steel only

depends on the device inserted and the material

from which the S020 fitting is made. Refer to the

operating instructions for the device and to the temperature/fluid pressure dependency curve in Fig. 5.

If the ranges are different, use the most restrictive

range.

depends on the device inserted into the S020.

Refer to the related operating instructions.

depends on the device inserted and the material

from which the S020 fitting is made. Refer to the

operating instructions for the device and to the temperature/fluid pressure dependency curve in Fig. 5.

If the pressure classes are different, take the lowest

value into account.

8

English

Page 9

Type S020

Technical data

6.3. General technical data

6.3.1. Diameters available

The diameters available depend on the design of the S020 fitting.

Consult the technical data sheets for the S020 fittings and

the device inserted to determine the appropriate DN.

Table 1: Diameters available depending on the design of the fitting

Design of the S020 DN available

T fittings for measuring devices with

a G2'' nut

T fittings for measuring devices with

a clamp process connection

Welding socket with radius, for measuring devices with a G2'' nut

Plastic fusion spigot DN65 to DN400

Screw-on

1)

Welding socket for measuring

devices with clamp connection

Saddle

1)

1)

Only for the flow measurement.

DN6 to DN65

DN32 to DN100

DN50 to DN350

DN100 to DN400

DN32 to DN100

DN50 to DN200

6.3.2. Materials

Table 2: Materials depending on the design of the S020 fitting

Design of the S020 Materials

Body Adapter Seal

T fittings for measuring devices with a

G2'' nut

T fittings for measuring devices with

a clamp process

connection

Welding socket with

radius, for measuring

devices with a G2''

nut

Fusion spigot

Welding socket

for measuring

devices with clamp

connection

Stainless steel (316L - 1.4404) FKM

Brass Stainless steel

(316L - 1.4404)

or

EPDM

PVC

PP

PVDF

Stainless steel

- -

(316L )

Stainless steel

- -

(316L - 1.4404)

PE - PP - PVDF - -

Stainless steel

- -

(316L )

English

9

Page 10

Type S020

Technical data

Screw-on

PVC - -

PE - -

PP - Saddle PP PVC EPDM

Measurement

chamber

Stainless steel

(316L - 1.4404)

- -

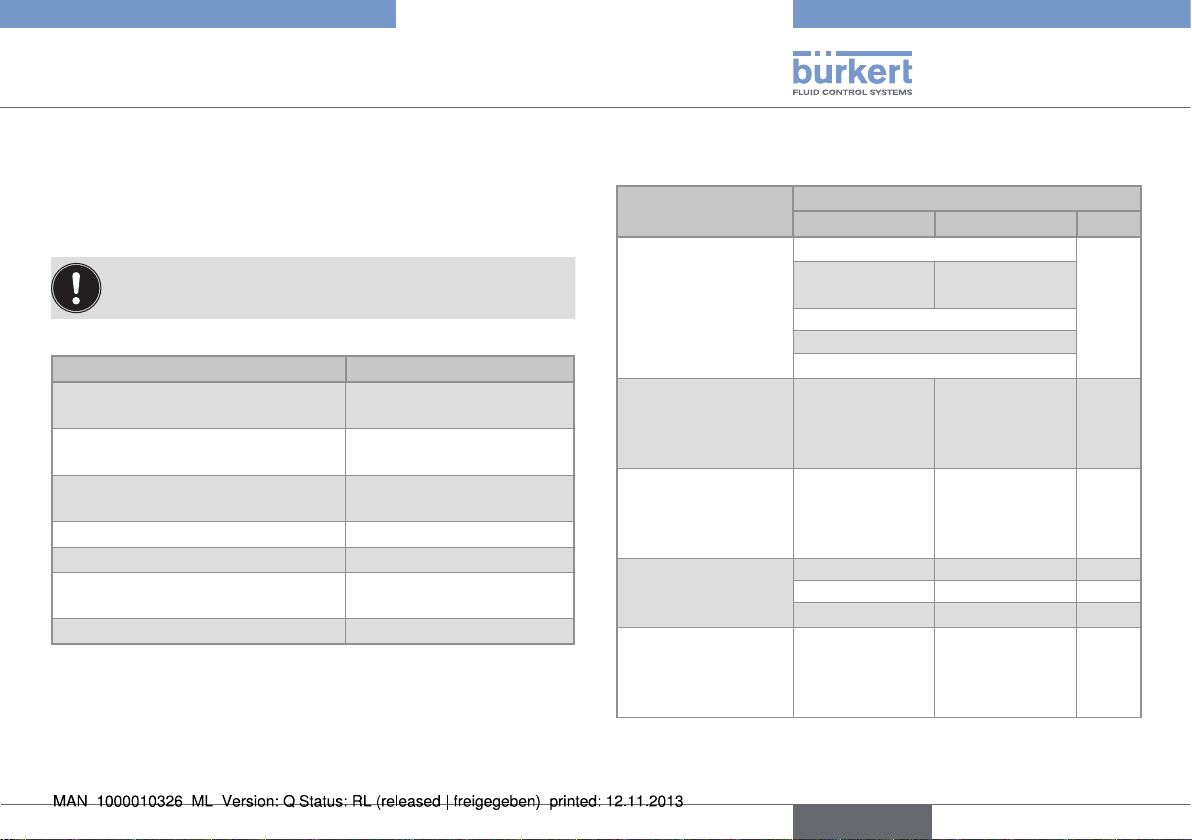

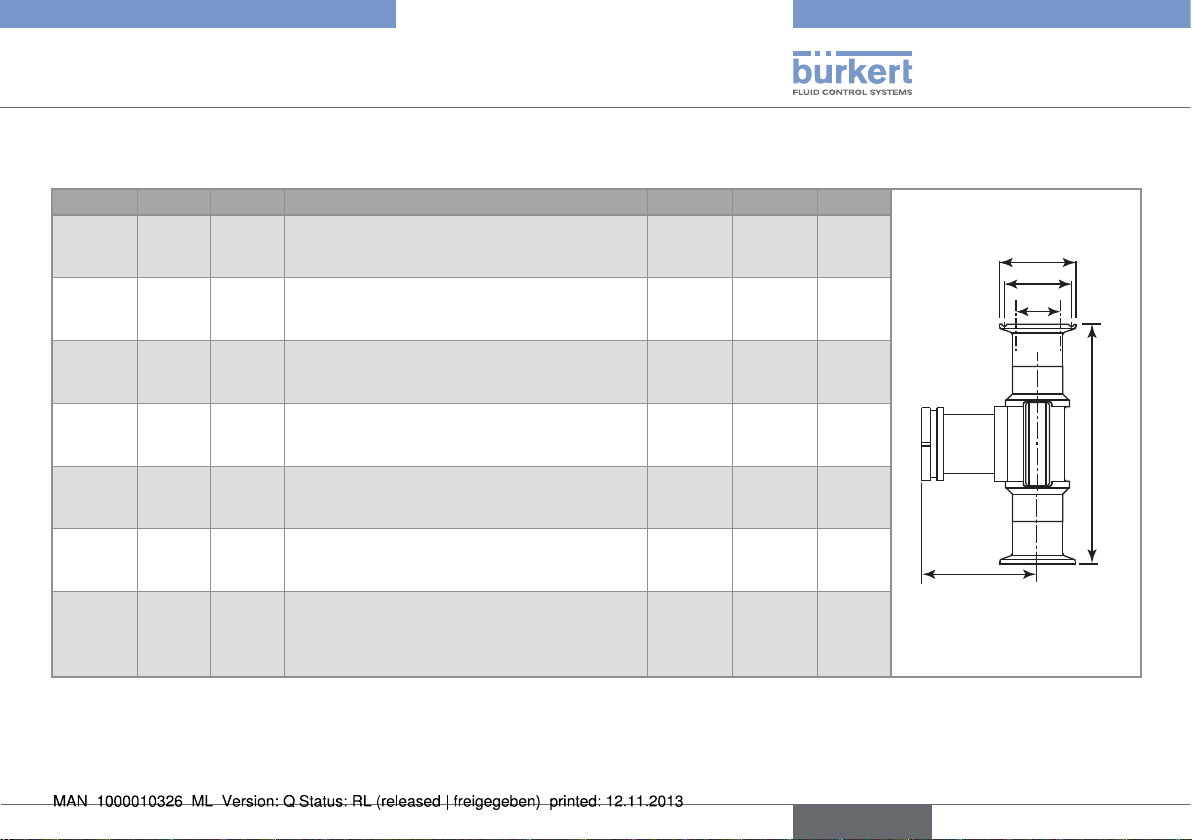

6.3.3. Dimensions of T fittings

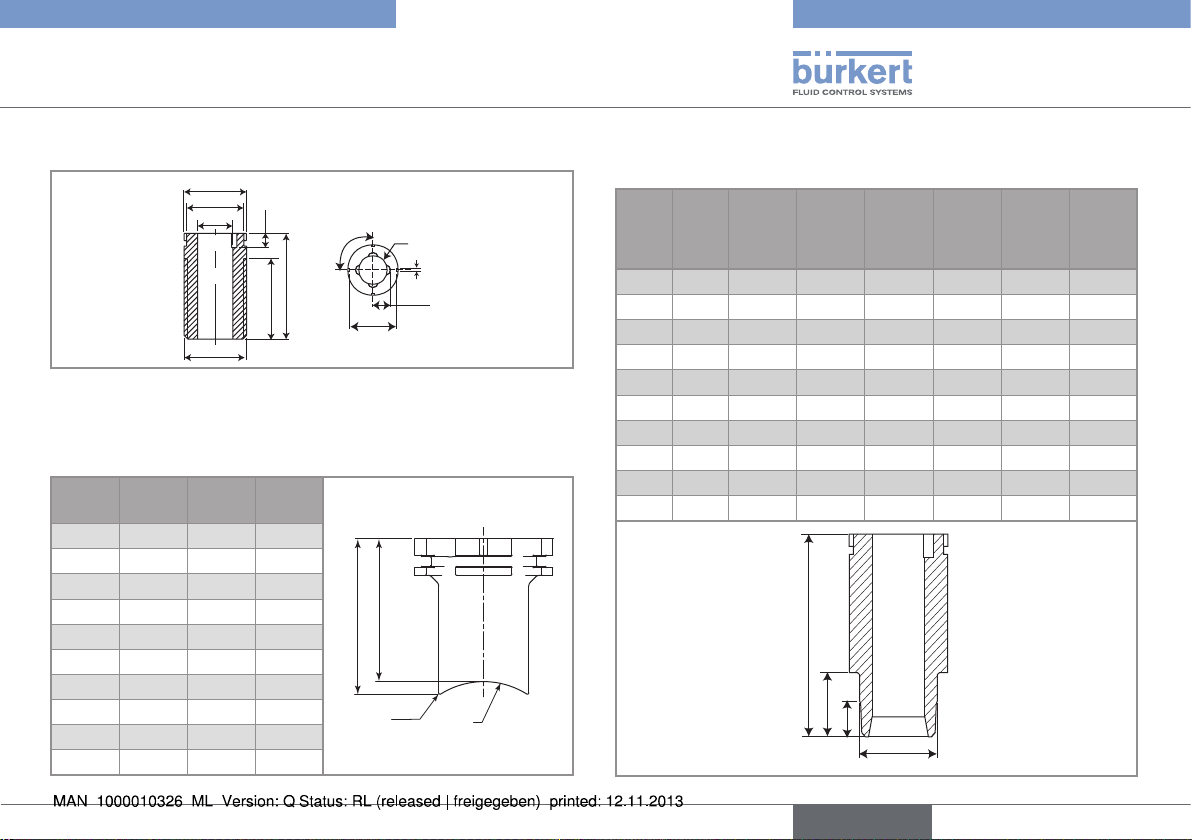

Table 3: Dimensions of the S020 fitting with internal thread

connections acc. to G, Rc or NPT, in stainless steel or

brass, for measuring devices with a G2'' nut

DN [mm] P [mm] A [mm] D [inch] L [mm]

15 80.3 84.0 G 1/2

NPT 1/2

Rc 1/2

20 77.8 94.0 G 3/4

NPT 3/4

Rc 3/4

25 78.0 104.0 G 1

NPT 1

Rc 1

32 81.6 119.0 G 1 1/4

NPT 1 1/4

Rc 1 1/4

40 85.4 129.0 G 1 1/2

NPT 1 1/2

Rc 1 1/2

16.0

17.0

15.0

17.0

18.3

16.3

23.5

18.0

18.0

23.5

21.0

21.0

23.5

20.0

19.0

50 91.5 148.5 G 2

NPT 2

Rc 2

P

L

A

27.5

24.0

24.0

D

10

English

Page 11

Type S020

Technical data

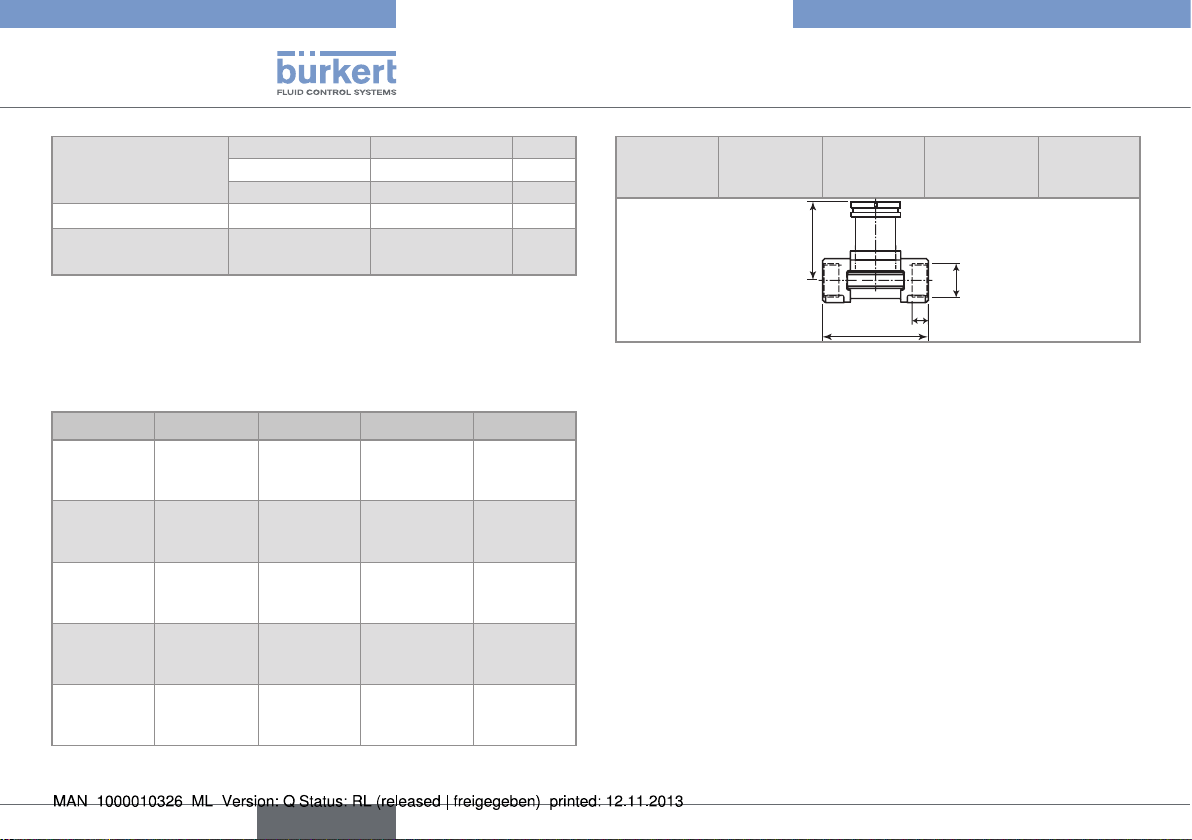

Table 4: Dimensions of the S020 fitting with external thread

connections acc. to G, in stainless steel, brass (DN15 to

50) or PVC (DN6 and 8 only), for measuring devices with

a G2'' nut

DN

[mm]

6 75.3 90.0 G 1/2 14.0

8 75.3 90.0 G 1/2 14.0

15 80.3 84.0 G 3/4 11.5

20 77.8 94.0 G 1 13.5

25 78.0 104.0 G 1 1/4 14.0

32 81.6 119.0 G 1 1/2 18.0

40 85.4 129.0 M55 x 2 19.0

50 91.5 148.5 M64 x 2 20.0

P

[mm]

A

[mm]

D

[inch]

L

[mm]

P

D

L

A

Table 5: Dimensions of the S020 fitting with external thread

connections acc. to SMS 1145, in stainless steel, for

measuring devices with a G2'' nut

DN

[mm]P[mm]

25 77.8 130 Rd40 x 1/6"

40 81.6 164 Rd60 x 1/6"

50 85.4 173 Rd70 x 1/6"

A

[mm]

D

[inch]

P

D

A

English

11

Page 12

Table 6: Dimensions of the S020 fitting with welding end

connections acc. to EN ISO 1127 / ISO 4200, SMS 3008

or BS 4825/ASME BPE, in stainless steel, for measuring

devices with a G2'' nut

DN

[mm]P[mm]A[mm]

15 80.3

-

-

20 77.8

-

83.3

25 78.0

77.8

77.8

32 81.6

-

78.0

40 85.4

81.6

81.6

50 91.5

85.4

85.4

65 -

91.5

91.5

84.0

-

-

94.0

-

84.0

104.0

94.0

94.0

119.0

-

104.0

129.0

119.0

119.0

148.5

128.0

128.0

-

147.0

147.0

Standard D

EN ISO 1127 / ISO 4200

SMS 3008

ASME BPE

EN ISO 1127 / ISO 4200

SMS 3008

ASME BPE

EN ISO 1127 / ISO 4200

SMS 3008

BS 4825 / ASME BPE

EN ISO 1127 / ISO 4200

SMS 3008

BS 4825 / ASME BPE

EN ISO 1127 / ISO 4200

SMS 3008

BS 4825 / ASME BPE

EN ISO 1127 / ISO 4200

SMS 3008

BS 4825 / ASME BPE

EN ISO 1127 / ISO 4200

SMS 3008

BS 4825 / ASME BPE

[mm]s[mm]

21.30

-

-

26.90

-

19.05

33.70

25.00

25.40

42.40

-

32.00

48.30

38.00

38.10

60.30

51.00

50.80

-

63.50

63.50

1.60

-

-

1.60

-

1.65

2.00

1.20

1.65

2.00

-

1.65

2.00

1.20

1.65

2.60

1.20

1.65

-

1.60

1.65

Type S020

Technical data

s

H

P

�A

12

English

Page 13

Type S020

Technical data

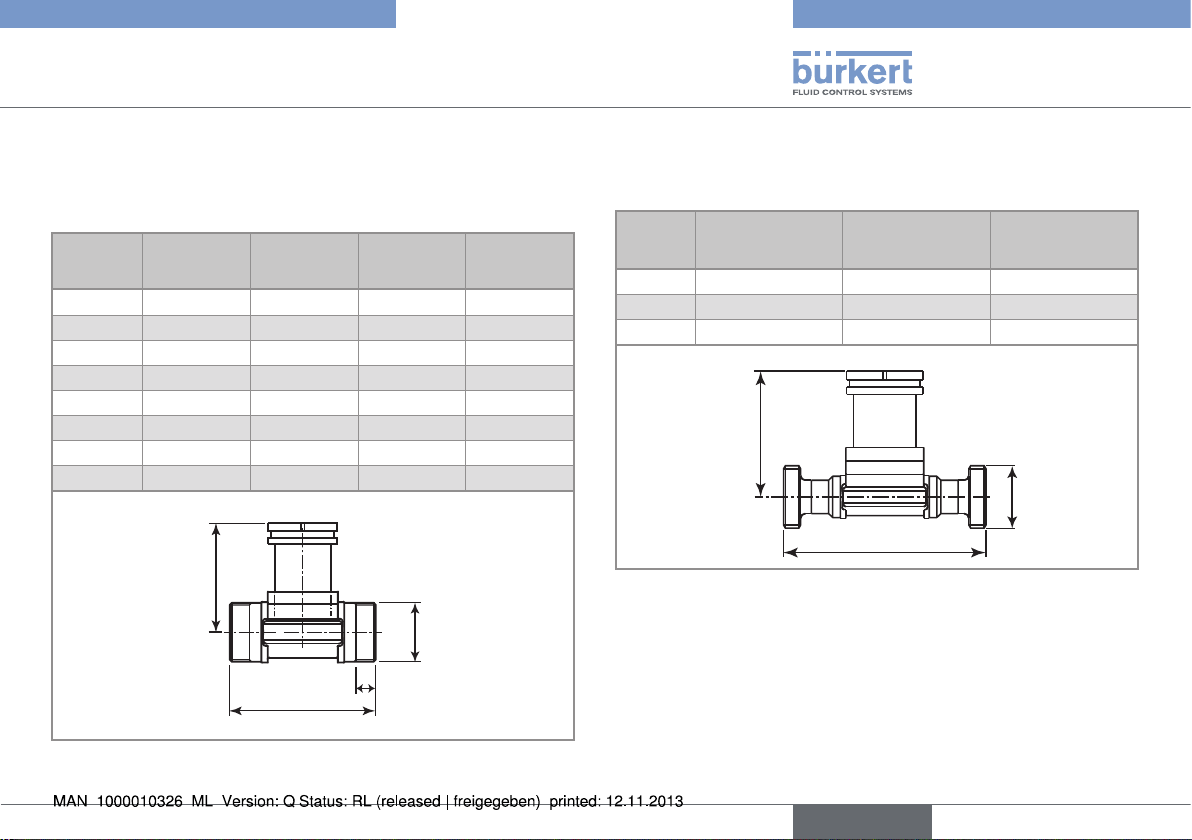

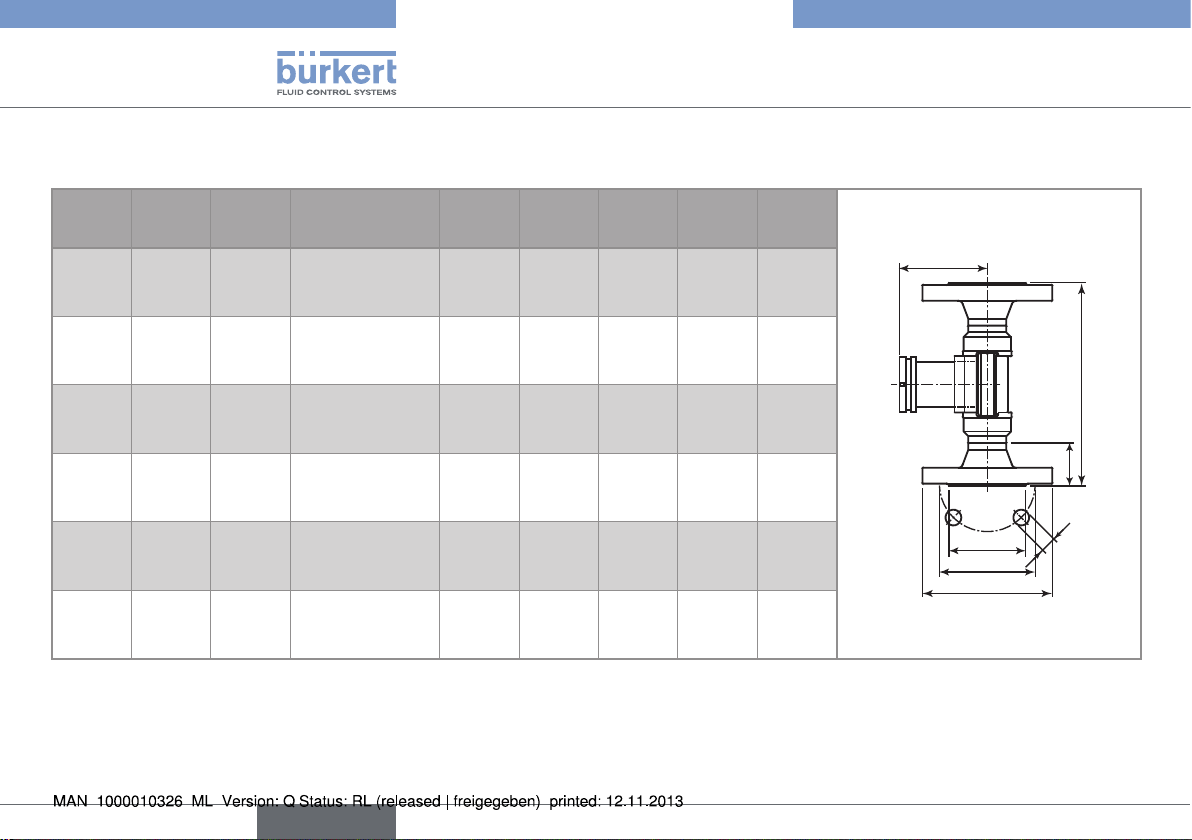

Table 7: Dimensions of the S020 fitting with Clamp connections acc. to ISO (for pipes according to EN ISO 1127 / ISO 4200), SMS 3017/

ISO 2852

DN [mm]

P [mm] A [mm] Standard D2 [mm] D1 [mm] D [mm]

15 80.3

-

-

20 77.8

-

80.3

25 78.0

77.8

77.8

32 81.6

-

-

40 85.4

81.6

81.6

50 91.5

85.4

85.4

65 -

91.5

91.5

1)

Available with an internal roughness of Ra = 0.8 μm

1)

or BS 4825/ASME BPE1), in stainless steel, for measuring devices with a G2'' nut

130.0

-

-

150.0

-

119.0

160.0

129.0

129.0

180.0

-

-

200.0

161.0

161.0

230.0

192.0

192.0

-

216.0

216.0

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

ASME BPE

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

ASME BPE

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

BS 4825 / ASME BPE

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

BS 4825 / ASME BPE

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

BS 4825 / ASME BPE

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

BS 4825 / ASME BPE

ISO (pipe EN ISO 1127 / ISO 4200)

SMS 3017 / ISO 2852

BS 4825 / ASME BPE

18.10

-

-

23.70

-

15.75

29.70

22.60

22.10

38.4

-

-

44.3

35.6

34.8

55.1

48.6

47.5

-

60.3

60.2

27.5

-

-

43.5

-

19.6

43.5

43.5

43.5

43.5

-

-

56.5

43.5

43.5

70.5

56.5

56.5

-

70.5

70.5

34.0

-

-

50.5

-

25.0

50.5

50.5

50.5

50.5

-

-

64.0

50.5

50.5

77.5

64.0

64.0

-

77.5

77.5

D

D1

D2

A

P

English

13

Page 14

Type S020

Technical data

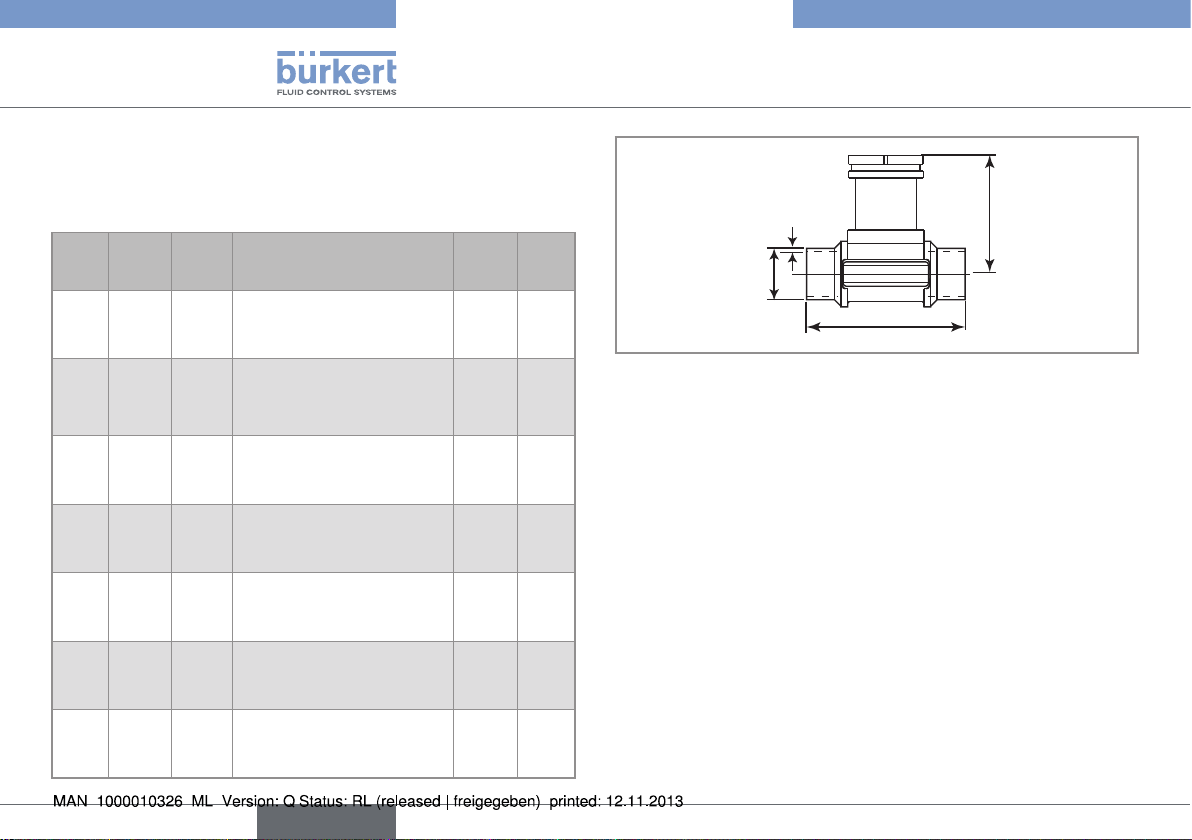

Table 8: Dimensions of the S020 fitting with flange connections acc. to EN1092-1 (ISO PN16), ANSI B16-5-1988 or JIS 10K, in stainless

steel, for measuring devices with a G2'' nut

DN

[mm]P[mm]A[mm]

15 80.3

80.3

80.3

20 77.8

77.8

77.8

25 78.0

78.0

78.0

32 81.6

81.6

81.6

40 85.4

85.4

85.4

50 91.5

91.5

91.5

130.0

130.0

152.0

150.0

150.0

178.0

160.0

160.0

216.0

180.0

180.0

229.0

200.0

200.0

241.0

230.0

230.0

267.0

Standard L

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

[mm]Z[mm]D2[mm]D1[mm]D[mm]

23.5

23.5

23.5

28.5

28.5

28.5

28.5

28.5

28.5

31.0

31.0

31.0

36.0

36.0

36.0

41.0

41.0

41.0

4x14.0

4x15.8

4x15.0

4x14.0

4x15.8

4x15.0

4x14.0

4x15.8

4x19.0

4x18.0

4x15.8

4x19.0

4x18.0

4x15.8

4x19.0

4x18.0

4x19.0

4x19.0

45.0

34.9

51.0

58.0

42.9

56.0

68.0

50.8

67.0

78.0

63.5

76.0

88.0

73.0

81.0

102.0

92.1

96.0

65.0

60.3

70.0

75.0

69.8

75.0

85.0

79.4

90.0

100.0

88.9

100.0

110.0

98.4

105.0

125.0

120.6

120.0

95.0

89.0

95.0

105.0

99.0

100.0

115.0

108.0

125.0

140.0

117.0

135.0

150.0

127.0

140.0

165.0

152.0

155.0

P

A

L

D2

Z

D1

D

14

English

Page 15

Type S020

A

Technical data

Table 9: Dimensions of the S020 fitting with true union connections acc. to DIN 8063, ASTM D 1785/76 or JIS K in PVC, acc. to

DIN 16962 in PP or acc. to ISO 10931 in PVDF, for measuring devices with a G2'' nut

DN

[mm]P[mm]D[mm]ADIN/ISO ASTM JISD1DIN/ISO ASTM JIS

15

15

20

20

25

25

1)

1)

1)

80.4

81.44374

77.8

81.45374

78.0

81.46074

128

148

144

154

160

160

130.0-129

-

145.6-145

-

161.4-161

-

20

20

25

25

32

32

21.3-18.40-90

26.7-26.45-100

33.4-32.55-110

A2

[mm]A1[mm]

11096116

106

110

116

116

110

116

D

D1

A2

A1

A

32 81.4 74 168 170.0 169 40 42.2 38.60 110 116

40 85.2 83 188 190.2 190 50 48.3 48.70 120 127

50 91.5 103 212 213.6 213 63 60.3 60.80 130 136

1)

Specific fitting for analytical sensors

P

Table 10: Dimensions of the S020 fitting with spigot connections acc. to DIN 8063 in PVC, acc. to DIN 16962 in PP or acc. to ISO 10931 in

PVDF, for measuring devices with a G2'' nut

DN

[mm]

15 80.4 17.5 90 85 20 16.5 14

P

[mm]

H

[mm]

A [mm]

DIN 8063 DIN 16962

ISO 10931

D [mm] L [mm]

DIN 8063 DIN 16962

ISO 10931

PH

20 77.8 17.5 100 92 25 20 16

25 78.0 21.5 110 95 32 23 18

D

32 81.4 27.5 110 100 40 27.5 20

40 85.2 31.5 120 106 50 30 23

50 91.5 39.5 130 110 63 37 27

L

English

15

Page 16

Type S020

P

Technical data

Table 11: Dimensions of the S020 fitting with welding end connections acc. to EN ISO 1127 / ISO 4200, SMS 3008, BS 4825/ASME BPE

or DIN 11850 range 2, for measuring devices with a clamp connection

DN [mm] P [mm] A [mm] Standard D [mm] S [mm]

32 - 130 EN ISO 1127 / ISO 4200 42.4 2

40 - 130 EN ISO 1127 / ISO 4200 48.3 2

42.5 110 SMS 3008 38 1.2

43.7 120.6 BS 4825 / ASME BPE 38.1 1.65

- 120 DIN 11850 range 2 41 1.5

50 - 180 EN ISO 1127 / ISO 4200 60.3 2

49.3 164 SMS 3008 51 1.2

S

50.6 146 BS 4825 / ASME BPE 50.8 1.65

- 160 DIN 11850 range 2 53 1.5

D

65 - 220 EN ISO 1127 / ISO 4200 76.1 2

54.4 210 SMS 3008 63.5 1.5

55.4 158.8 BS 4825 / ASME BPE 63.5 1.65

- 210 DIN 11850 range 2 70 2

A

80 - 260 EN ISO 1127 / ISO 4200 88.9 2.3

60.7 220 SMS 3008 76.1 1.6

62 171.5 BS 4825 / ASME BPE 76.2 1.65

- 260 DIN 11850 range 2 85 2

100 73.8

77.1

209.6 BS 4825 / ASME BPE 101.6 2.11

310 DIN 11850 range 2 104 2

16

English

Page 17

Type S020

Technical data

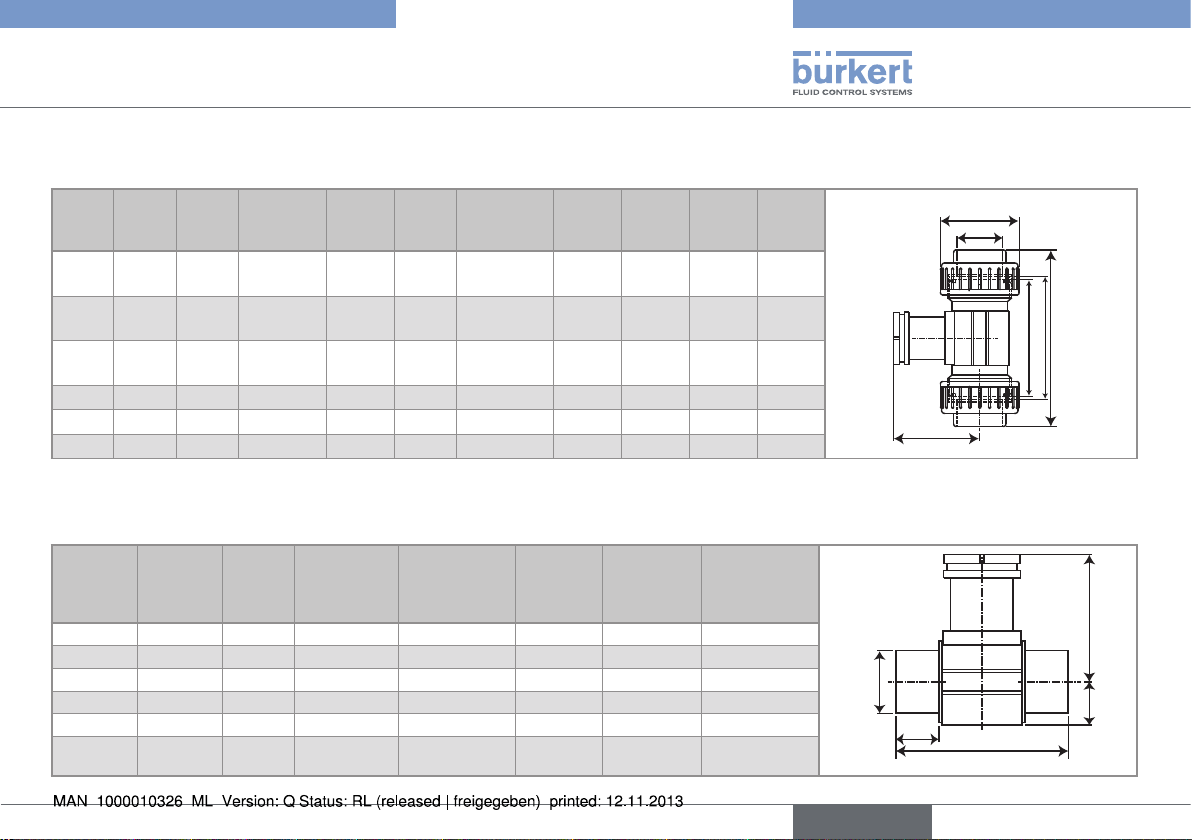

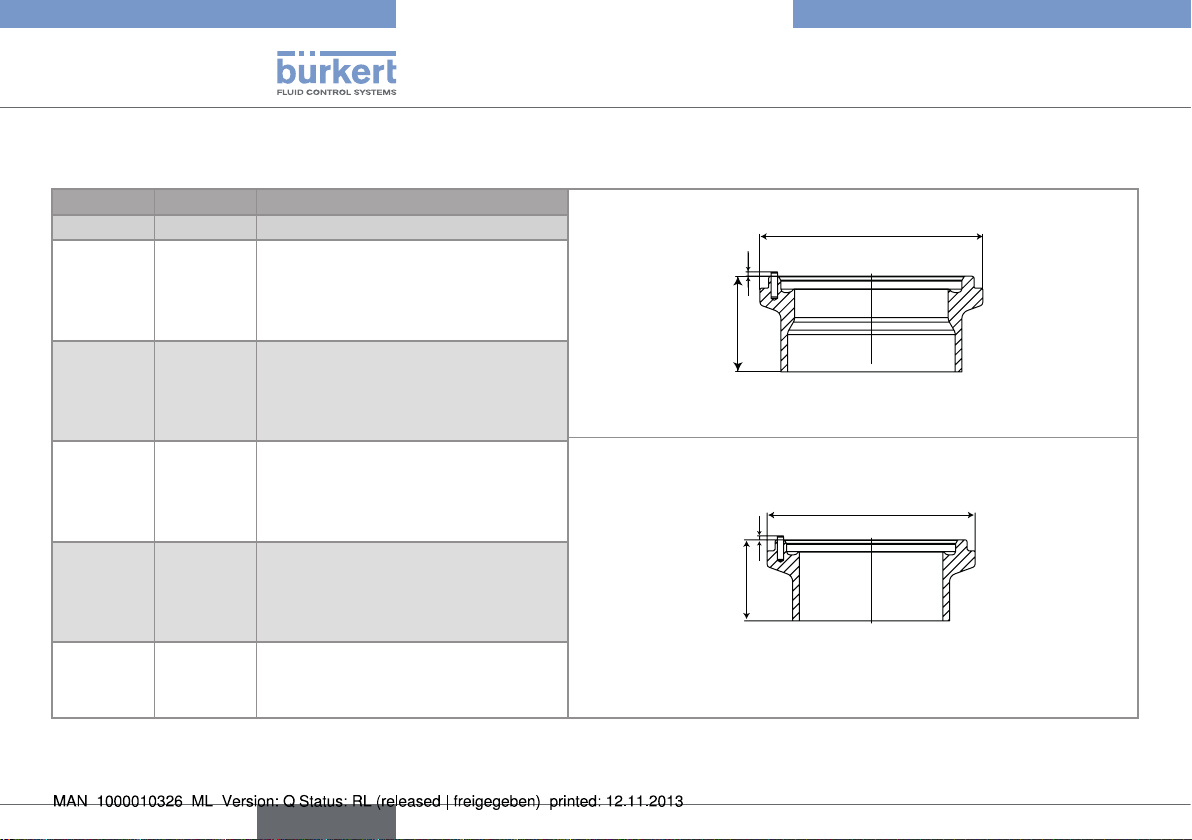

6.3.4. Dimensions of spigots

ø 49

ø 45

ø27.6

G1-1/2"

Fig. 1: Dimensions of screw-ons DN65 to DN400, in PVC, PE or PP

(in mm), for measuring devices with a G2'' nut

Table 12: Dimensions of the welding sockets with radius, in

stainless steel, for measuring devices with a G2" nut

DN

[mm]A[mm]B[mm]R[mm]

50 56.6 61.6 30.2

65 54.5 58.6 36.7

80 53.1 56.4 44.5

100 50.7 53.2 57.2

125 48.2 50.3 70.7

150 45.7 47.4 84.2

200 41.0 42.3 109.6

250 73.6 74.7 136.6

300 67.8 68.7 162.0

350 63.9 64.7 177.8

11.5

73

93

90°

B

45

A +0.1

R4 (4x)

3

16.2

R0.5

R

Table 13: Dimensions of the fusion spigots, in PE, PP or PVDF, for

measuring devices with a G2" nut

DN

[mm]H[mm]PEH1

[mm]

H2

[mm]

PP

H1

[mm]

H2

[mm]

PVDF

H1

[mm]

H2

[mm]

65 72.5 13 - 13 - 10.4 80 72.5 15.6 - 15.6 - 12.5 100 72.5 19 5 19 5 15.2 6

125 102 24.2 8 - - - 150 102 27.7 10 27.7 10 - 200 102 38.9 16 38.9 16 - 250 102 48.4 21 48.4 21 - 300 102 54.5 24 54.5 24 - 350 102 61.3 28 61.3 28 - 400 102 69.1 31.5 - - - -

H

H1

H2

ø39

English

17

Page 18

Type S020

H

Ø

50,5

H

Technical data

Table 14: Dimensions of the welding sockets acc. to EN ISO 1127 / ISO 4200, SMS 3008, BS 4825/ASME BPE or DIN 11850 range 2, for

measuring devices with a clamp connection

DN [mm] H [mm] Standard

32 - ISO 4200

40 21.7 SMS 3008

1

23.7 BS 4825 / ASME BPE

- DIN 11850 range 2

- ISO 4200

50 21.7 SMS 3008

23.7 BS 4825 / ASME BPE

- DIN 11850 range 2

Welding socket acc. to SMS 3008, DIN 11850 Range 2 and ISO 4002

- ISO 4200

65 19.7 SMS 3008

19.7 BS 4825 / ASME BPE

- DIN 11850 range 2

- ISO 4200

1

Ø 50.5

80 19.7 SMS 3008

19.7 BS 4825 / ASME BPE

- DIN 11850 range 2

- ISO 4200

100 19.7 SMS 3008

19.7 BS 4825 / ASME BPE

19.7 DIN 11850 range 2

Welding socket acc. to BS 4825/ASME BPE

18

English

Page 19

Type S020

Technical data

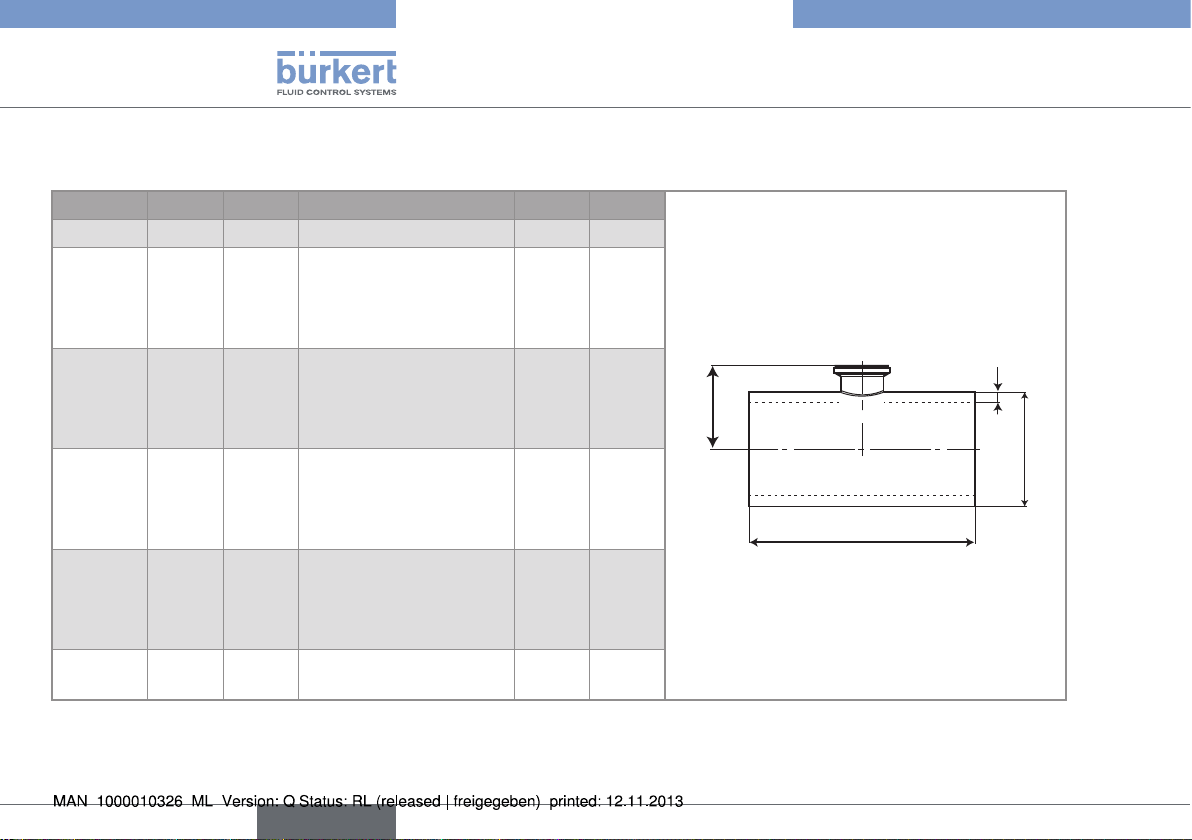

6.3.5. Dimensions of the saddles

Table 15: Dimensions of the saddles in PP/PVC

DN

[mm]D[mm]P[mm]D1[mm]H[mm]

50 116 116.0 63 155.0

65 129 115.0 75 160.0

80 144 119.0 90 171.0

100 166 124.0 110 187.0

110 181 120.0 125 191.0

125 196 127.0 140 205.0

150 216 137.0 160 225.0

180 266 161.0 200 271.0

200 290 173.0 225 297.0

D1

6.3.6. Dimensions of the measurement

chamber

ø 60.3

P

H

62.6

D

17.6

G 1/2

ø 27

G 1/2

118

Fig. 2: Dimensions of the measurement chamber (in mm)

41

ø 33.6

80.2

2.70

ø 60

19

English

Page 20

Type S020

Technical data

6.4. K factors

6.4.1. Terms of reference

The K factors have all been determined under the following terms

of reference: fluid = water, water and room temperatures of 20°C,

minimum upstream and downstream distances respected, appropriate pipe dimensions.

6.4.2. Calculation of K factors (in pulse/

litre) for saddles, fusion spigots,

welding sockets with radius or

screw-ons

The calculation does not apply to T fittings or welding

sockets for measuring devices with a clamp connection.

In addition to the terms of reference mentioned above, the K factors

for saddles, fusion spigots, welding sockets with radius and screwons have been determined as a function of the external diameter

(D

) and the wall thickness (s

material

tables.

) of the pipe given in the

material

→ When the dimensions of the pipe are slightly different from

dimensions D and s given in the tables, recalculate the K factor

using one of the following formulae:

These formulae can only be applied if the dimensions of the

pipe vary by +/-5% compared with the theoretical dimensions given in the tables.

2

d

Kn = Kt x

t

2

d

n

Fig. 3: Fitting used with a paddle-wheel flowmeter

2

d

Kn = Kt x

n

2

d

t

Fig. 4: Fitting used with an electromagnetic flowmeter

Kn = recalculated K factor

= K factor given in the table

K

t

= D

d

t

= internal diameter of the pipe

d

n

material

- 2s

= theoretical internal diameter of the pipe

material

calculated using the values D

s

given in the tables, for each fitting

material

material (D

the pipe and s

pipe)

= external diameter of

material

= thickness of the

material

material

and

20

English

Page 21

Type S020

Technical data

6.4.3. K factors (in pulse/litre) for T fittings used with a 8041 or 8045 with a G2'' nut

We advise not to use a type 8041 or 8045 measuring device in an S020 fitting in brass as drifts in measurement may occur.

If the measuring device does not automatically convert the K factor, use the following conversion formulae before setting the parameters of the device:

• K factor in pulse/US gallon = K factor in pulse/litre x 3.785

• K factor in pulse/UK gallon = K factor in pulse/litre x 4.546

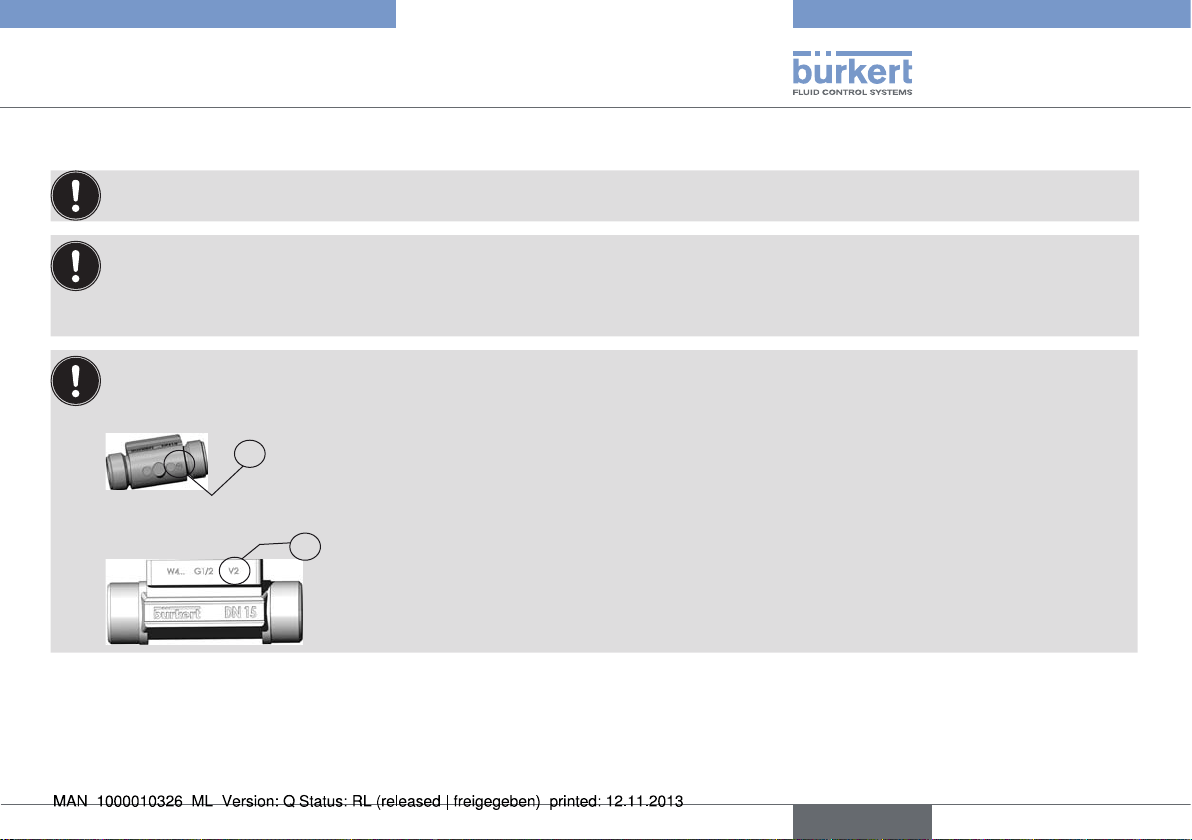

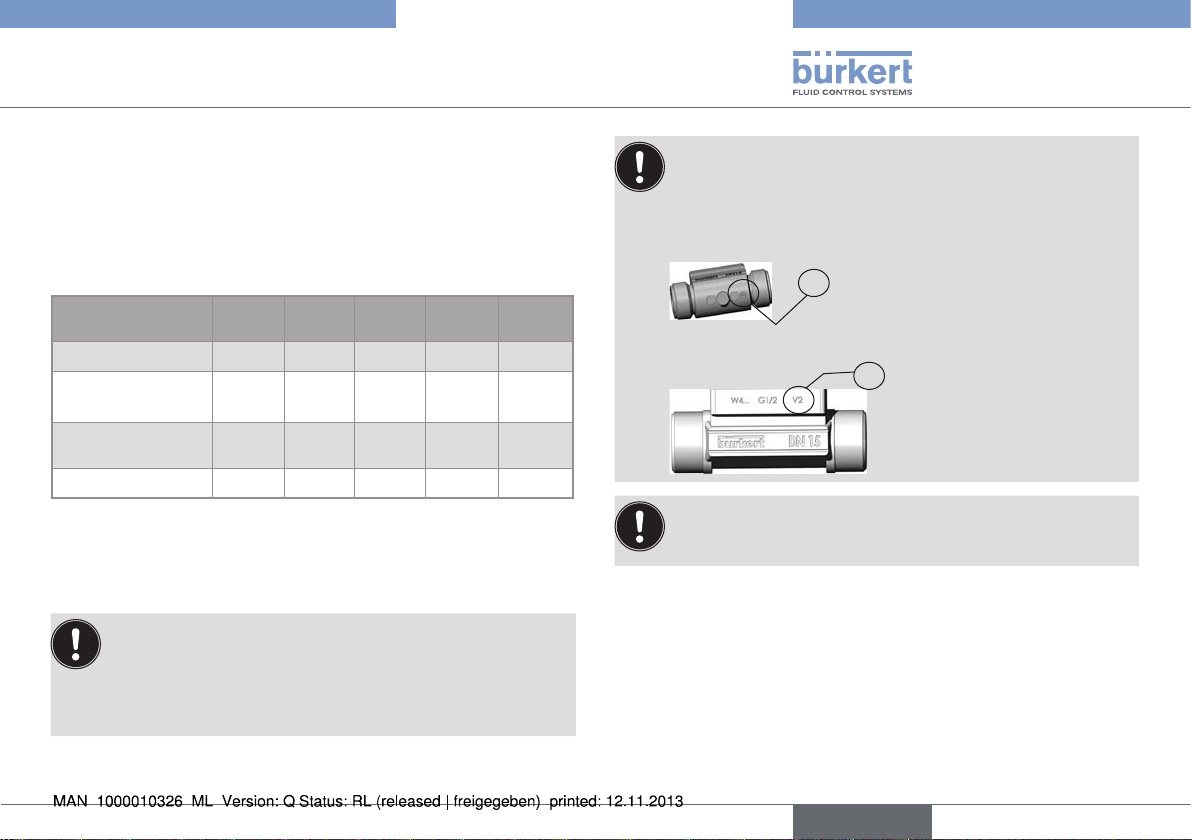

Two versions of the S020 in DN15 and DN20 exist, having different K factors.

Only version 2, identified by the "v2" marking, is available from March 2012. The "v2" marking can be found:

• on the bottom of the DN15 fitting in plastic:

V2

• on the side of the DN15 or DN20 fitting in metal:

V2

English

21

Page 22

Type S020

Technical data

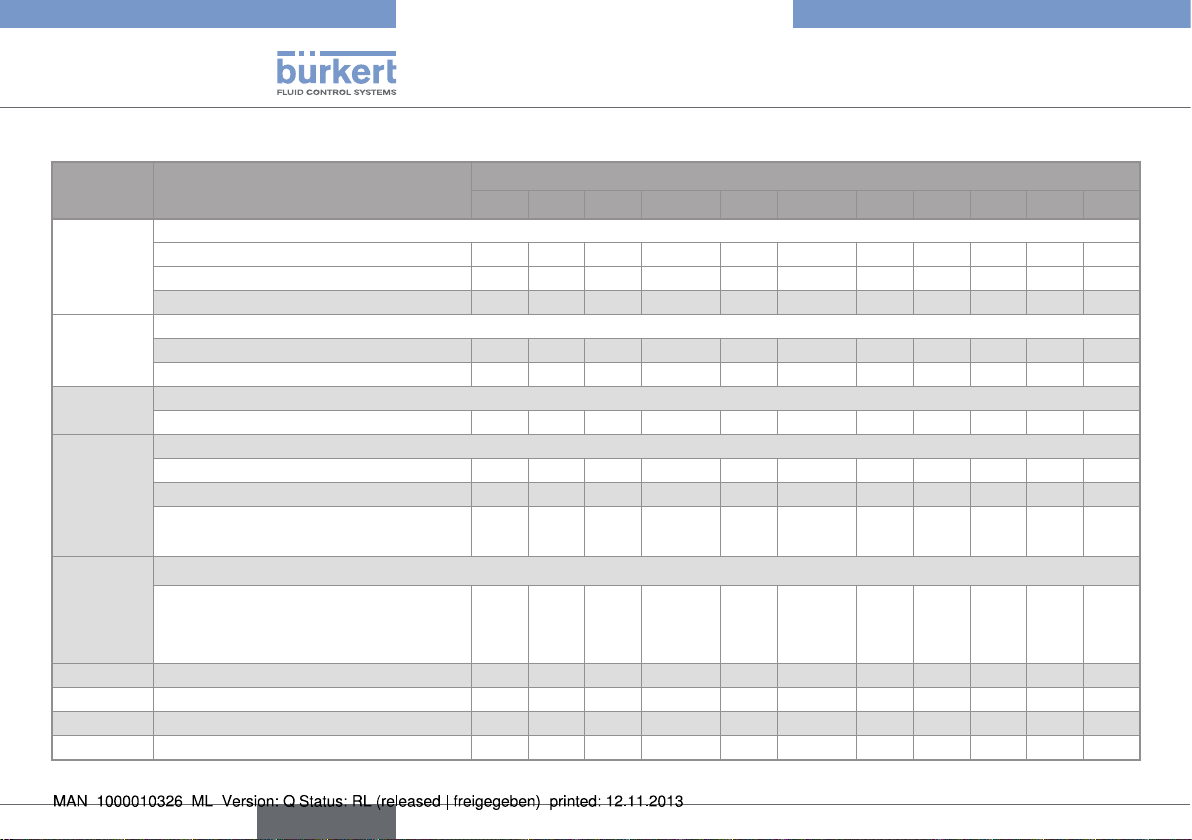

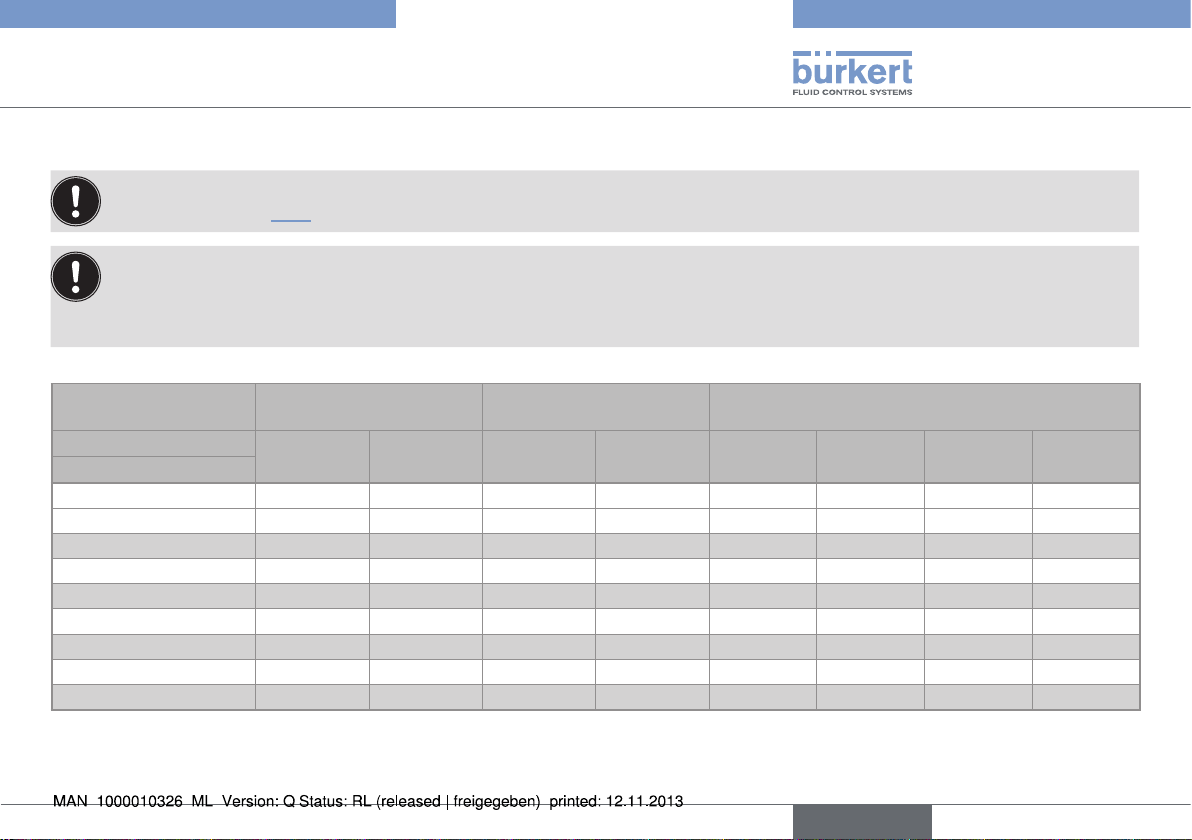

Table 16: K factors depending on the connections and standards and materials of the T fittings used with a 8041 or 8045 with G2" nut

Material Type of connection and standard

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Brass all - - - - 1,98 - 2,85 4,32 6,68 11,3 PVC all 0,310 0,470 1,33 1,33 1,45 - 2,26 4,29 7,30 12,5 PP all - - 1,29 1,37 1,44 - 2,21 4,30 7,16 12,2 PVDF all - - 1,21 1,22 1,37 - 2,04 4,03 6,88 11,5 -

welding ends

• acc. to SMS 3008 - - - - - - 1,98 - 4,32 6,68 11,3

• acc. to BS 4825 / ASME BPE - - - - 1,69 1,75 1,98 2,85 4,32 6,68 11,3

• acc. to EN ISO 1127 / ISO 4200 - - 1,69 1,75 1,98 - 2,85 4,32 6,68 11,3 external threads

• acc. to SMS 1145 - - - - - - 1,98 - 4,32 6,68 -

• G 0,355 0,530 1,69 1,75 1,98 - 2,85 4,32 6,68 11,3 internal threads

• G, Rc, NPT 0,355 0,530 1,69 1,75 1,98 - 2,85 4,32 6,68 11,3 Clamp

• acc. to SMS 3017 / ISO 2852 - - - - - - 1,98 - 4,32 6,68 11,3

• acc. to BS 4825 / ASME BPE - - - - 1,69 1,75 1,98 - 4,32 6,68 11,3

• acc. to ISO (for pipes acc. to

EN ISO 1127 / ISO 4200)

flanges

• acc. to EN1092-1 (ISO PN16)

• acc. to ANSI B16-5-1998

• acc. to JIS 10K

K factor [Pulse/litre]

DN6 DN8 DN15 DN15 v2 DN20 DN20 v2 DN25 DN32 DN40 DN50 DN65

- - 1,69 1,75 1,98 - 2,85 4,32 6,68 11,3 -

- - 1,69 1,75 1,98 - 2,85 4,32 6,68 11,3 -

22

English

Page 23

Type S020

Technical data

6.4.4. K factors (in pulse/litre) for T

fittings and welding sockets used

with a 8041 or a 8045 with clamp

connection

Table 17: K factors of the T fittings for measuring devices with clamp

connection

Type of connection

and standard

acc. to SMS 3008 5.23 10.4 15.9 24.7 acc. to BS 4825 /

ASME BPE

acc. to DIN 11850

range 2

acc. to ISO 4200 - - - - -

DN40 DN50 DN65 DN80 DN100

5.33 10.4 16.7 25.7 50.3

- - - - 52.7

6.4.5. K factors (in pulse/litre) for T fittings

used with a 8020, 8024, 8025 or

8026

If the measuring device does not automatically convert the K

factor, use the following conversion formulae before setting

the parameters of the device:

• K factor in pulse/US gallon = K factor in pulse/litre x 3.785

• K factor in pulse/UK gallon = K factor in pulse/litre x 4.546

Two versions of the S020 in DN15 and DN20 exist, having

different K factors.

Only version 2, identified by the "v2" marking, is available

from March 2012. The "v2" marking can be found:

• on the bottom of the DN15 fitting in plastic:

V2

• on the side of the DN15 or DN20 fitting in metal:

V2

Do not use a fitting S020 in sizes DN6, DN8, DN15, DN15

Version 2 (V2) or DN20 Version 2 (V2) with a paddle-wheel

flowmeter types 8020, 8024, 8025, 8026.

English

23

Page 24

Type S020

Technical data

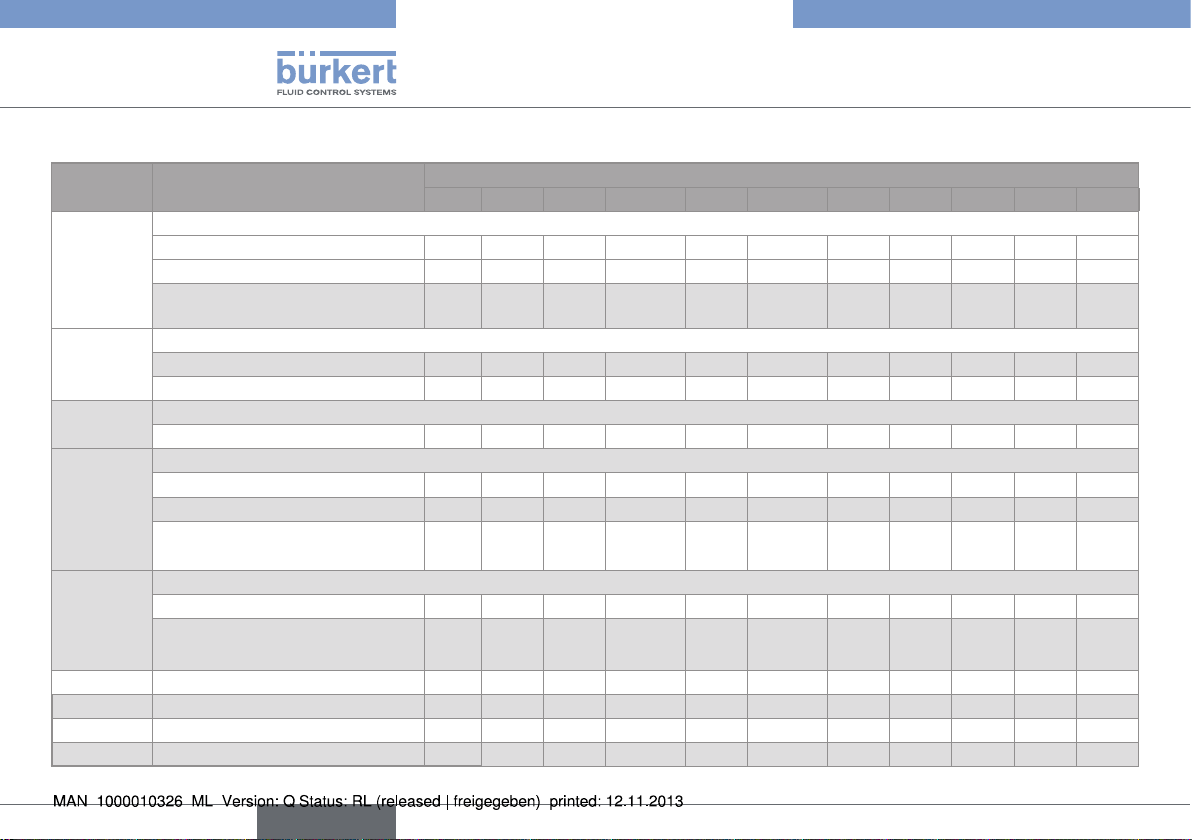

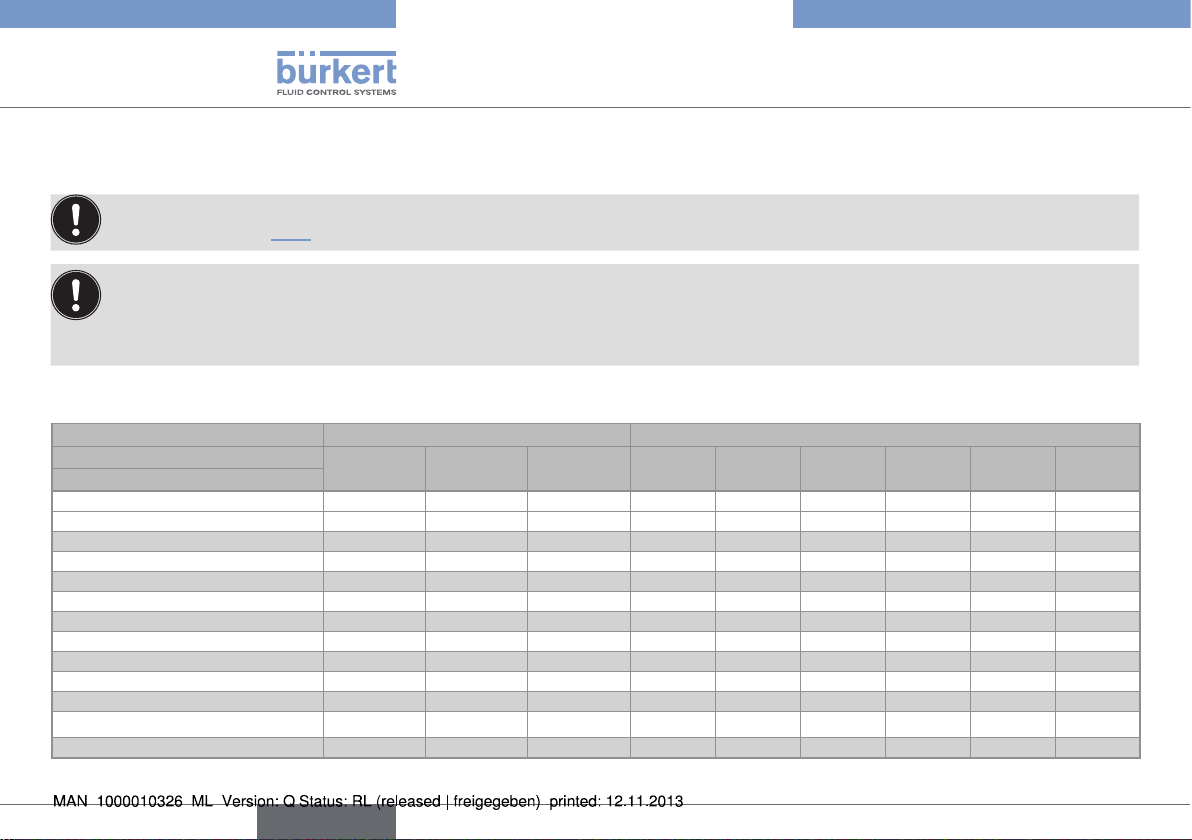

Table 18: K factors depending on the connections and standards and materials of the T fittings used with a 8020, 8024, 8025 or 8026

Material Type of connection and standard

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Brass all - - - - 64,0 - 48,3 30,9 19,5 11,2 PVC all - - - - 81,1 - 56,6 29,9 18,6 10,7 PP all - - - - 75,1 - 53,6 29,0 17,4 10,3 PVDF all - - - - 81,2 - 60,3 31,9 19,4 11,1 -

welding ends

• acc. to SMS 3008 - - - - - - 64,0 - 30,9 19,5 11,2

• acc. to BS 4825 / ASME BPE - - - - - - 64,0 48,3 30,9 19,5 11,2

• acc. to EN ISO 1127 / ISO

4200

external threads

• acc. to SMS 1145 - - - - - - 64,0 - 30,9 19,5 -

• G - - - - 64,0 - 48,3 30,9 19,5 11,2 -

internal threads

• G, Rc, NPT - - - - 64,0 - 48,3 30,9 19,5 11,2 -

Clamp

• acc. to SMS 3017 / ISO 2852 - - - - - - 64,0 - 30,9 19,5 11,2

• acc. to BS 4825 / ASME BPE - - - - - - 64,0 - 30,9 19,5 11,2

• acc. to ISO (for pipes acc. to

EN ISO 1127 / ISO 4200)

flanges

• acc. to EN1092-1 (ISO PN16) - - - - 64,0 - 48,3 30,9 19,5 11,2 -

• acc. to ANSI B16-5-1998

• acc. to JIS 10K

K factor [Pulse/litre]

DN6 DN8 DN15 DN15 v2 DN20 DN20 v2 DN25 DN32 DN40 DN50 DN65

- - - - 64,0 - 48,3 30,9 19,5 11,2 -

- - - - 64,0 - 48,3 30,9 19,5 11,2 -

- - - - 64,0 - 48,3 30,9 19,5 11,2

24

English

Page 25

Type S020

Technical data

6.4.6. K factors (in pulse/litre) for saddles

When the dimensions of the pipe are slightly different from dimensions D and s given in the table, recalculate the K factor using one of

the formulae in chap. 6.4.2.

If the measuring device does not automatically convert the K factor, use the following conversion formulae before setting the parameters of the device:

• K factor in pulse/US gallon = K factor in pulse/litre x 3.785

• K factor in pulse/UK gallon = K factor in pulse/litre x 4.546

Table 19: K factors, external diameters and theoretical cross-sections of saddles

Measuring device

inserted

Material of the pipe

DN

50 14,2 (L) 15,6 (L) 10,4 (L) 9,28 (L) 63 4,7 63 5,8

65 11,2 (L) 12,3 (L) 14,5 (L) 12,9 (L) 75 5,5 75 6,9

80 7,37 (L) 7,80 (L) 21,3 (L) 20,4 (L) 90 6,6 90 8,2

100 4,83 (L) 5,29 (L) 33,0 (L) 30,4 (L) 110 8,1 110 10

110 3,45 (L) - 44,7 (L) - 125 9,2 - 125 2,55 (L) 3,10 (L) 63,7 (L) 52,1 (L) 140 10,3 140 12,8

150 1,67 (L) 2,03 (L) 137 (L) 78,8 (L) 160 6,2 160 14,6

180 1,08 (L) 1,37 (L) 197 (L) 116 (L) 200 9,6 200 18,2

200 0,80 (L) 1,07 (L) 290 (L) 147 (L) 225 8,6 225 20,5

(L): long sensor version

8020, 8024, 8025, 8026 8041, 8045 External diameters and theoretical cross-sections

PVC PE / PP PVC PE / PP

D

PVC

[mm]

s

PVC

[mm]

D

PP

[mm]

s

PP

[mm]

English

25

Page 26

Type S020

Technical data

6.4.7. K factors (in pulse/l) of the fusion spigots and welding sockets with radius for

measuring devices with a G2'' nut

When the dimensions of the pipe are slightly different from dimensions D and s given in the table, recalculate the K factor using one of

the formulae in chap. 6.4.2.

If the measuring device does not automatically convert the K factor, use the following conversion formulae before setting the parameters of the device:

• K factor in pulse/US gallon = K factor in pulse/litre x 3.785

• K factor in pulse/UK gallon = K factor in pulse/litre x 4.546

Table 20: K factors, external diameters and theoretical cross sections of the welding sockets with radius, for measuring devices with a G2''

nut, and of the fusion spigots in plastic, used with a 8020, 8024, 8025 or 8026

Measuring device inserted 8020, 8024, 8025, 8026 External diameters and theoretical cross-sections

Material of the pipe

DN

50 13,0 (C) - - 60,3 2,0 - - - 65 7,86 (C) 8,32 (C) 5,53 (C) 76,1 2,9 75 6,9 75 2,5

80 5,52 (C) 5,49 (C) 3,65 (C) 88,9 3,2 90 8,2 90 2,8

100 3,20 (C) 3,51 (C) 2,34 (C) 114,3 3,6 110 10 110 3,5

110 - - - - - - - - 125 2,00 (C) 2,66 (L) - 139,7 4 140 12,8 - 150 1,32 (C) 2,12 (L) - 168,3 4,5 160 14,6 - 180 - - - - - 200 18,2 - 200 0,72 (C) 0,98 (L) - 219,1 6,3 225 20,5 - 250 0,50 (L) 0,63 (L) - 273 7,7 280 25,5 - 300 0,35 (L) 0,42 (L) - 323,9 9,5 315 28,7 - -

350 0,26 (L) 0,30 (L) - 355,6 10,1 355 32,3 - 400 - 0,23 (L) - - - 400 36,4 - -

Stainless

steel

PE / PP PVDF

D

steel

[mm]

s

steel

[mm]

D

PE/PP

[mm]

s

PE/PP

[mm]

D

PVDF

[mm]

s

PVDF

[mm]

26

English

Page 27

Type S020

Technical data

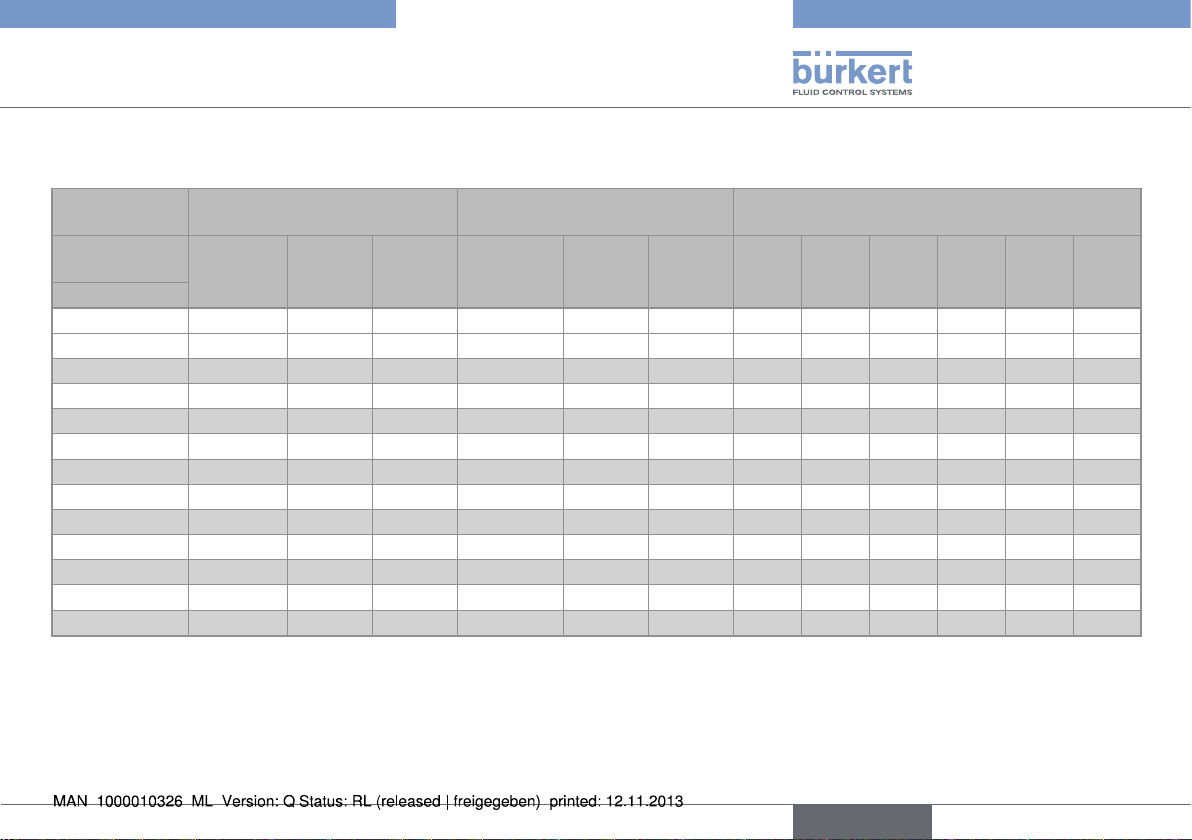

Table 21: K factors, external diameters and theoretical cross-sections of welding sockets with radius and fusion spigots, in plastic, used with a

8041 or a 8045 with G2'' nut

Measuring

device inserted

Material of the

pipe

DN

8041, 8045 with sensor in

stainless steel

Stainless

steel

PE / PP PVDF

8041, 8045 with sensor in PVDF

Stainless

steel

PE / PP PVDF

External diameters and theoretical

cross-sections

D

steel

[mm]

s

[mm]

steel

D

PE/PP

[mm]

s

PE/PP

[mm]

50 11,6 (C) - - 13,8 (C) - - 60,3 2,0 - - - -

65 20,0 (C) 17,8 (C) 24,1 (C) 24,0 (C) 21,3 (C) 28,9 (C) 76,1 2,9 75 6,9 75 2,5

80 28,5 (C) 25,6 (C) 40,8 (C) 33,2 (C) 30,7 (C) 48,9 (C) 88,9 3,2 90 8,2 90 2,8

100 49,2 (C) 38,1 (C) 70,5 (C) 60,5 (C) 45,7 (C) 84,5 (C) 114,3 3,6 110 10 110 3,5

110 - - - - - - - - - - - 125 78,0 (C) 81,7 (L) - 93,6 (C) 81,7 (L) - 139,7 4 140 12,8 - 150 98,4 (C) 103 (L) - 118 (C) 103 (L) - 168,3 4,5 160 14,6 - 180 - - - - - - - - 200 18,2 - 200 210 (C) 224 (L) - 252 (C) 224 (L) - 219,1 6,3 225 20,5 - 250 311 (L) 347 (L) - 311 (L) 347 (L) - 273 7,7 280 25,5 - 300 447 (L) 510 (L) - 447 (L) 510 (L) - 323,9 9,5 315 28,7 - 350 609 (L) 705 (L) - 609 (L) 705 (L) - 355,6 10,1 355 32,3 - 400 - 931 (L) - - 931 (L) - - - 400 36,4 - -

(C): short sensor version

(L): long sensor version

D

PVDF

[mm]

s

PVDF

[mm]

English

27

Page 28

Type S020

Technical data

6.4.8. K factors (in pulse/litre) for screw-ons

When the dimensions of your pipe are slightly different from dimensions D and s given in the table, recalculate the K factor using one

of the formulae in chap. 6.4.2.

If the measuring device does not automatically convert the K factor, use the following conversion formulae before setting the parameters of the device:

• K factor in pulse/US gallon = K factor in pulse/litre x 3.785

• K factor in pulse/UK gallon = K factor in pulse/litre x 4.546

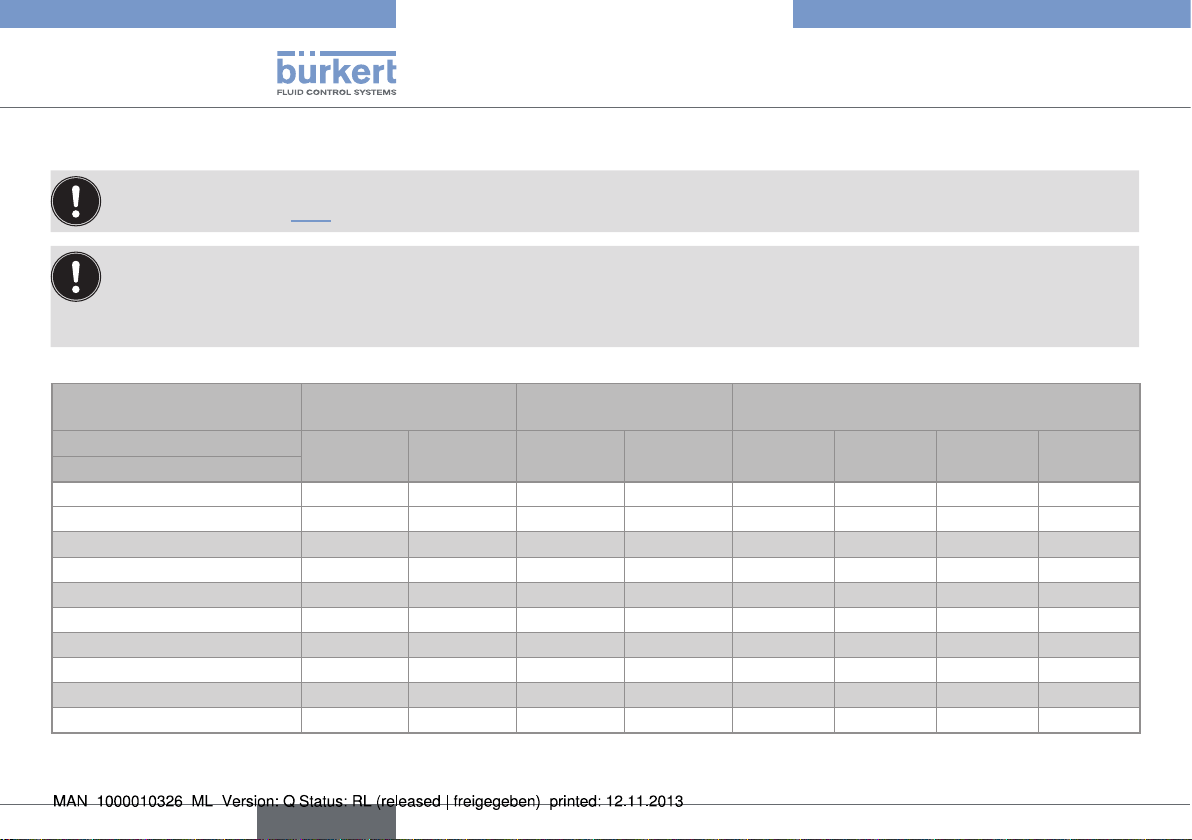

Table 22: K factors, external diameters and theoretical cross-sections of screw-ons

Measuring device inserted 8020, 8024, 8025, 8026 8041, 8045

Material of the pipe

DN

PVC PP / PE PVC PP / PE

100 4,83 (L) 5,29 (L) 33,0 (L) 30,4 (L) 110 8,1 110 10

110 3,45 (L) - 44,7 (L) - 125 9,2 125 11,4

125 2,55 (L) 3,10 (L) 63,7 (L) 52,1 (L) 140 10,3 140 12,8

150 1,67 (L) 2,12 (L) 137 (L) 78,8 (L) 160 6,2 160 14,6

180 1,08 (L) 1,37 (L) 197 (L) 116 (L) 200 9,6 200 18,2

200 0,80 (L) 1,07 (L) 290 (L) 147 (L) 225 8,6 225 20,5

250 - 0,63 (L) - 347 (L) - - 280 25,5

300 - 0,42 (L) - 510 (L) - - 315 28,7

350 - 0,30 (L) - 705 (L) - - 355 32,3

400 - 0,23 (L) - 931 (L) - - 400 36,4

(L): long sensor version

28

English

External diameters and theoretical

cross-sections

D

PVC

[mm]

s

PVC

[mm]

D

PE/PP

[mm]

s

PE/PP

[mm]

Page 29

Type S020

Installation and commissioning

7. INSTALLATION AND

COMMISSIONING

7.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the fitting.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and safety

relating to the use of hazardous products.

Warning

Risk of injury due to non-conforming installation.

• Fluidic installation can only be carried out by qualified and authorised personnel with the appropriate tools.

• Observe the installation instructions for the measuring device

inserted into the fitting.

Risk of injury due to an uncontrolled restart.

• Ensure that the restart of the installation is controlled after any

interventions on it.

Warning

Risk of injury if the fluid pressure / temperature dependency

is not respected.

• Take into account the fluid pressure / temperature dependency

according to the materials from which the fitting is made (see

Fig. 5) and to the measuring device used (see the relevant user

manual).

• Comply with the Pressure Directive 97/23/EC.

Warning

Danger due to non-conforming commissioning.

Non-conforming commissioning may lead to injuries and damage

the fitting and its surroundings.

• Before commissioning, make sure that the staff in charge have

read and fully understood the contents of these operating

instructions.

• In particular, observe the safety recommendations and intended

use.

• The installation must only be commissioned by suitably trained

staff.

English

29

Page 30

Type S020

Installation and commissioning

P (bar)

16

15

14

13

12

PVDF

11

10

9

8

PVC + PP

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +120

1)

Except DN100 for measuring devices with clamp connection

Metal

(PN16)

PVC (PN10)

PP (PN10)

1)

DN100 for measuring

devices with clamp connection

(PN10)

PVDF (PN10)

+150

T (°C)

Fig. 5: Fluid pressure / temperature dependency curves for T

fittings used on their own

7.2. Installation onto the pipe

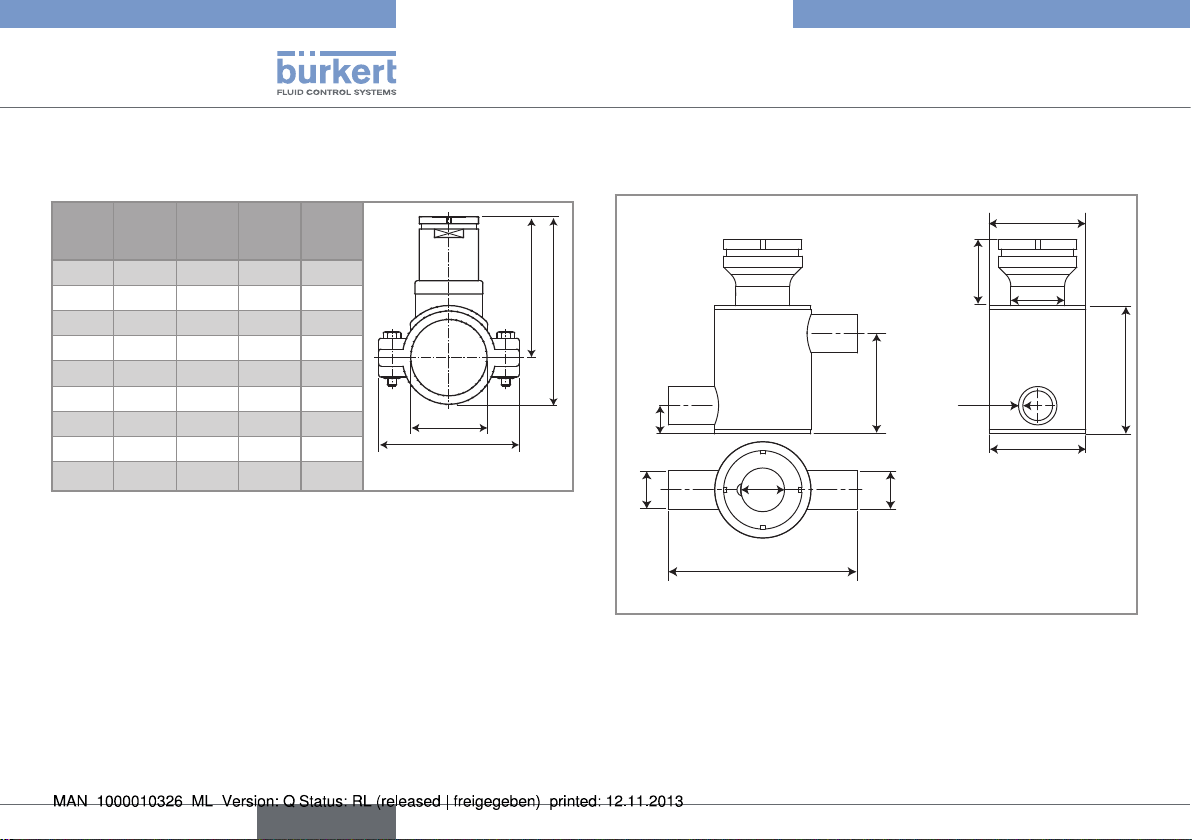

7.2.1. Recommandations for installing the

S020 fitting on the pipe

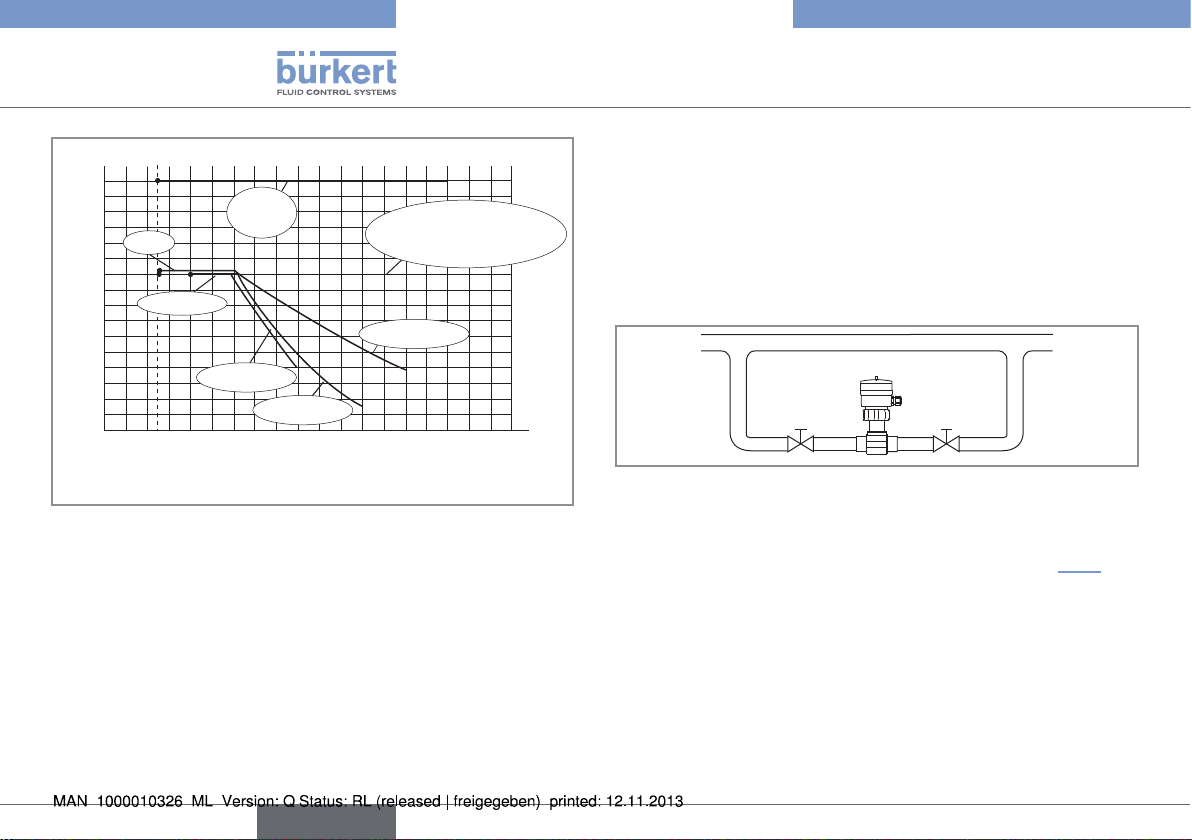

→ To measure the pH or the oxidation reduction potential, install

a U-shaped bypass in order to prevent the electrode drying out

and to allow calibration without stopping the process.

Fig. 6: Bypass installation of the fitting

→ For measuring the flow and depending on the design of the

pipes, respect the minimum distances in accordance with the

standard EN ISO 5167-1, from which the diagrams in Fig. 7 are

excerpted.

30

English

Page 31

Type S020

Installation and commissioning

bubbles in the pipe and the pipe filling system on the measuring

device.

50 x DN 5 x DN

With regulating valve Pipe with 2 elbows at 90° in 3

40 x DN 5 x DN

dimensions

25 x DN 5 x DN 20 x DN 5 x DN

Pipe with 2 elbows at 90° Pipe with 1 elbow at 90° or 1

T-piece

18 x DN 5 x DN 15 x DN 5 x DN

With pipe expansion With pipe reduction

Fig. 7: Upstream and downstream distances depending on the

design of the pipes.

→ To measure the flow, use a flow conditioner, if necessary, to

obtain the best accuracy.

→ For all types of measurement, respect the following additional

assembly conditions to ensure that the measuring device operates correctly (Fig. 8 and Fig. 9) and prevent the formation of air

Correct

Incorrect

Flow direction

Correct

Fig. 8: Additional recommendations on installation

Incorrect

English

31

Page 32

Type S020

Installation and commissioning

7.2.2. Installing a T fitting

Follow the recommendations on installation described in

chap. 7.2.1.

Correct

Flow direction

Flow direction

Correct

Fig. 9: Additional recommendations on installation

32

English

Incorrect

Incorrect

note

The seal on the fitting with welding end connections may be

damaged during welding.

Version for measuring devices with a G2'' nut:

• Before welding the welding ends, remove the adapter from the

fitting by unscrewing the 4 screws and remove the seal.

• After welding, correctly put the seal in the groove and the adapter

on the fitting, tighten the 4 screws, applying a nominal tightening

torque of 2 Nm.

Version for measuring devices with a clamp connection:

• Before welding the welding ends, remove the seal.

• After welding, correctly replace the seal in the groove.

→ Install the fitting by turning one of the polarising slots opposite

the flow direction.

Page 33

Type S020

Installation and commissioning

Polarizing pin for the

8045 with clamp

connection

Pipe

Polarizing slot

for the 8045

with G2" nut

Pipe

7.2.3. Installing saddles

Seal

Screws

32 mm

Nut

Pipe

Fig. 11: Installing saddles

→ Drill a hole 32 mm

in diameter in the

pipe.

→ Insert the seal pro-

vided in the saddle

groove.

→ Fix the saddle to

the pipe.

→ Insert the nuts into

their housing.

→ Insert the screws

into the nuts and

tighten them.

Fig. 10: Installing a T fitting

English

33

Page 34

Type S020

α

α

Installation and commissioning

7.2.4. Installing a welding socket with

radius, for measuring devices with a

G2'' nut

→ Drill a hole 28 mm in

diameter in the pipe.

→ Position the oblong

internal polarising

Internal polarising

slot

External polarising

slots

slot opposite the flow

direction.

→ Align 2 of the 4 external

polarizing slots (a < 3°)

in the axis of the pipe.

→ Weld around the entire

Weld

Fig. 12: Installing a welding socket with radius

circumference of the

welding socket with

radius.

7.2.5. Installing a welding socket, for

measuring devices with a clamp

connection

The welding socket can be installed:

• either on a T fitting with a short branch, installed into the pipe,

• or on the pipe which has previously been drilled and extruded to

shape a T fitting with a short branch.

→ Respect the following dimensions to drill and extrude the pipe:

DN Standard H D

32 ISO4200 38.4

40 SMS 3008 3.0 35.6

BS 4828 / ASME BPE 2.5 34.8

DIN 11850 range 2 3.0 38

ISO4200 38.4

50 SMS 3008 3.0 35.6

BS 4828 / ASME BPE 2.5 34.8

DIN 11850 range 2 3.5 38

ISO4200 38.4

65 SMS 3008 3.0 35.6

BS 4828 / ASME BPE 4.0 34.8

DIN 11850 range 2 4.0 38

ISO4200 38.4

34

English

Page 35

Type S020

Ø

D

Installation and commissioning

80 SMS 3008 4.0 35.6

BS 4828 / ASME BPE 4.5 34.8

DIN 11850 range 2 4.5 38

ISO4200 38.4

100 SMS 3008

1)

BS 4828 / ASME BPE 5.5 34.8

DIN 11850 range 2 6.5 38

±1

H

1)

Depending on the pipe, refer to line BS 4828/ASME BPE or DIN

11850 range 2 of DN100

DN L Standards

32 - ISO 4200

40 23.5 SMS 3008

BS 4825 / ASME

24.6

BPE

- DIN 11850 range 2

- ISO 4200

50 23.8 SMS 3008

BS 4825 / ASME

25.2

BPE

- DIN 11850 range 2

- ISO 4200

65 22.6 SMS 3008

BS 4825 / ASME

23.6

BPE

- DIN 11850 range 2

- ISO 4200

80 23.0 SMS 3008

BS 4825 / ASME

23.9

BPE

- DIN 11850 range 2

- ISO 4200

1)

100

SMS 3008

BS 4825 / ASME

23.0

BPE

25.1 DIN 11850 range 2

→ Make sure length L cor-

responds to the DN and

standard of the socket used,

if not the K factors given in

Table 17 are not correct.

L

English

35

Page 36

Type S020

α

α

Installation and commissioning

Marking of the flow

direction

Polarizing pin

Flow direction

→ Position the pola-

rizing pin opposite

the flow direction.

→ Align the polarizing

pin (a < 3°) in the

α

α

Polarising pin

axis of the pipe.

→ Tip 4 points at 90°

from each other.

→ Weld around the

entire circumference of the fusion

spigot.

Fig. 13: Installing a welding socket, for measuring devices with a

clamp connection

7.2.6. Installing a fusion spigot (PE, PP or

PVDF)

→ Drill a hole 40 mm in dia-

meter in the pipe.

→ Position the oblong

internal polarising slot

Internal polarising slot

External polarising slots

opposite the flow direction.

→ Align 2 of the 4 external

polarizing slots (a < 3°) in

the axis of the pipe.

→ Weld around the entire cir-

Weld

Fig. 14: Installing a fusion spigot (PE, PP or PVDF)

cumference of the fusion

spigot.

36

English

Page 37

Type S020

α

α

Installation and commissioning

7.2.7. Installing a screw-on in plastic (PP,

PVC, PE)

G 1-1/2''

ø 45

→ Drill a hole 45 mm in dia-

meter in the pipe.

→ Thread to G 1 1/2’’.

→ Screw on the spigot until it

L

G 1-1/2"

reaches length L (see Table

23) corresponding to the

DN of the pipe so that the K

factors given in Table 22 are

respected.

→ Use an appropriate sealing

material (PTFE tape, for

example).

→ When L is reached, slightly

unscrew or continue to

Internal polarising slot

External

polarising

slots

screw until 2 of the 4 polarising slots are aligned in

the axis of the pipe and the

oblong internal polarising

slot is positioned opposite

the flow direction.

DN of the screw-on

Length L to be screwed (in mm)

PVC PP / PE

100 69,3

110 57,8 -

125 57,3 57

150 57,3 57

180 61,3 61,3

200 60,8 60,8

250 - 53,6

300 - 47,5

350 - 40,7

400 - 32,9

Table 23: Lengths L to be screwed to insert flowmeters 8020, 8024,

8025, 8026, 8041 and 8045, depending on the material

of the screw-on

Fig. 15: Installing a screw-on (PP, PVC, or PE)

English

37

Page 38

7.2.8. Installing the measurement

chamber

→ Install the measurement

chamber in the main pipe or in

the bypass.

→ Pay attention to the flow

direction of the fluid.

→ Screw the G 1/2'' connections

to the pipe.

Fig. 16: Installing the measurement chamber

Type S020

Installation and commissioning

38

English

Page 39

Type S020

Installation and commissioning

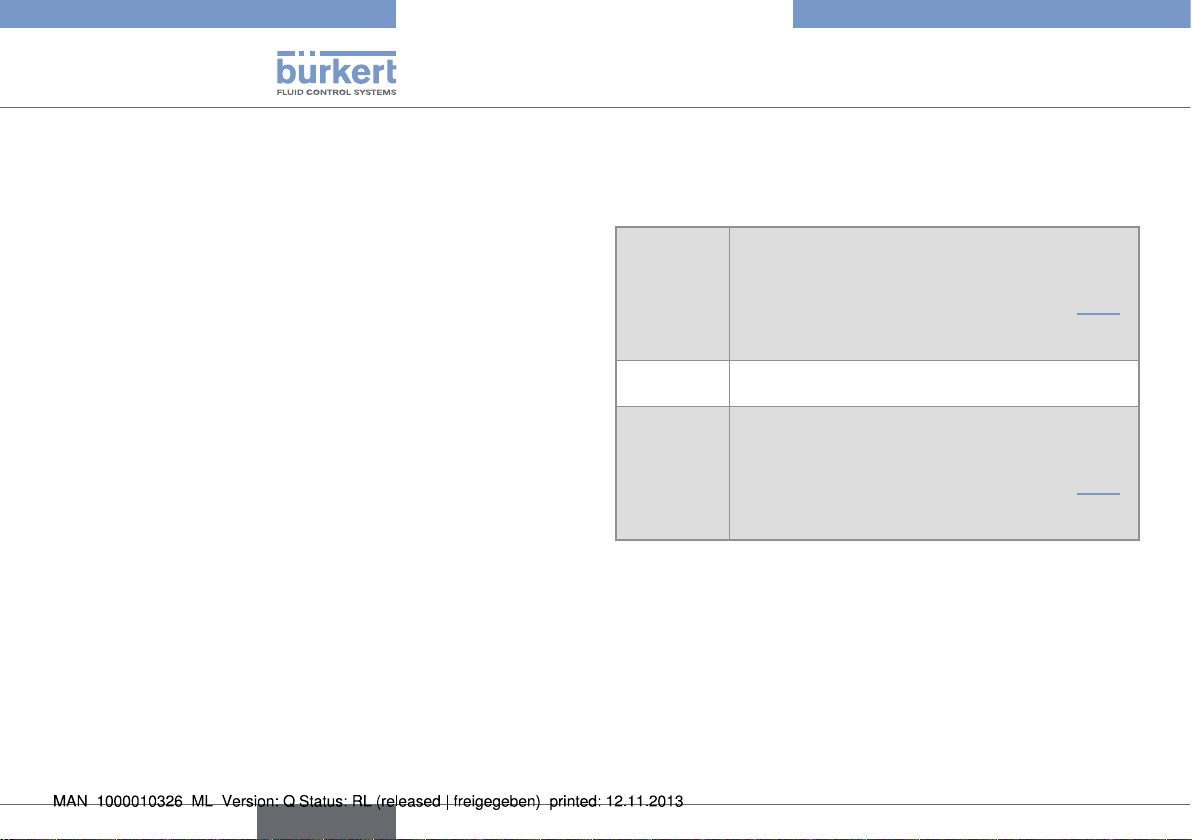

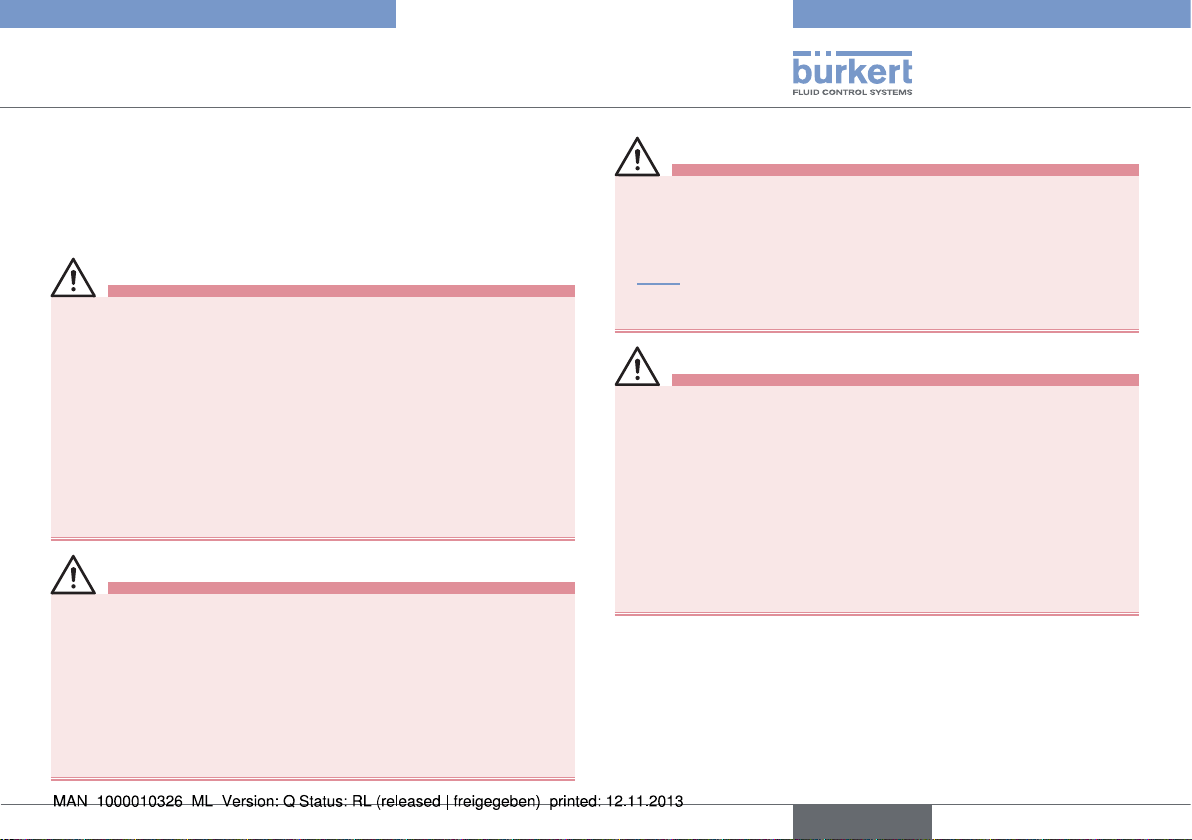

7.2.9. Graph - pipe DN - fluid velocity - flow rate

The graph is used to determine the DN of the pipe and the fitting appropriate to the application, according to the fluid velocity and the flow rate.

m/s

0.01

0.1 0.3 0.5 1 3 5 10

fps

30

Fluid velocity

0.3 0.5 1 3 5 10

DN 400

DN 350

DN 300

DN 250

DN 200

DN 150

DN 125

DN 100

DN 80 (DN100)*

DN 65 (DN80)*

DN 50 (DN65)*

DN 40 (DN50)*

DN 32 (DN40)*

DN 25 (DN32)*

DN 20 (DN25)*

DN 15 (DN15 ou DN20)*

DN 08

DN 06

/h

3

m

5000

2000

1000

500

200

100

50

20

10

5

1

2

0.5

0.2

0.1

0.05

0.02

Flow rate

l/min

100000

US gpm

50000

20000

30000

10000

20000

5000

10000

2000

5000

1000

3000

2000

500

1000

200

500

100

200

50

100

20

50

10

20

10

1

2

5

0.5

0.2

0.5

0.1

0.2

0.05

English

* For the following fittings:

• external thread connections acc. to SMS 1145,

BS 4825 / ASME BPE or DIN 1850 range 2,

• with weld end connections acc. to SMS 3008,

BS 4825 / ASME BE or DIN 32676

• with clamp connections acc. to SMS 3017 / ISO 2852,

39

1

2

5

Page 40

Type S020

Maintenance

8. MAINTENANCE

8.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the fitting.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

• Keep all easily flammable fluid or material away from the fitting.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

Warning

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Ensure that the restart of the installation is controlled after any

interventions.

8.2. Cleaning

note

The fitting may be damaged by the cleaning product.

• Clean the fitting with a cloth dampened with water or a detergent compatible with the materials the fitting is made of.

40

English

Page 41

Type S020

Spare parts and accessories

9. SPARE PARTS AND

ACCESSORIES

attention

Risk of injury and/or damage caused by the use of unsuitable

parts.

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the fitting and the surrounding area.

• Use only original accessories and original spare parts from

Bürkert.

Accessory Order code

Certificate

Certificate 3.1 (S020 in stainless steel)

Certificate 2.2

Surface roughness certificate

Calibration certificate (S020 combined with

the flowmeter inserted)

FDA approval

440790

440789

444898

550676

449788

Spare part Order code

Adapter (with 4 screws) (Fig. 17)

in stainless steel

in PVC

in PP

in PVDF

Set of O-ring seals (DN6 to DN65) for

adapter in stainless steel

FKM (5 parts)

EPDM (5 parts)

Fig. 17: Adapter with 4 screws

555484

561175

561176

561177

428971

428972

English

41

Page 42

Type S020

Spare parts and accessories

Spare part Order code

Set of seals (DN6 to DN65) for adapter in

plastic (Fig. 18)

FKM (1 O-ring seal and 1 flat seal)

EPDM (1 O-ring seal and 1 flat seal)

561043

561044

Fig. 18: Set of seals for adapter in plastic

Spare part Order code

Plug fitted with an O-ring seal in FKM, nut

in PC and snap ring (all DNs) (Fig. 19)

in stainless steel

in PVC

in PP

438755

438754

627614

Plug

O-ring seal in FKM

Snap ring

Nut in PC

Fig. 19: Plug with O-ring seal, nut and snap ring

Spare part Order code

O-ring seal in EPDM with FDA agreement, for

730837

a T fitting or a welding socket for devices with

a clamp connection (see Fig. 20)

O-ring seal in FEP with FDA agreement, for a

730839

T fitting or a welding socket for devices with a

clamp connection (see Fig. 20)

Clamp (see Fig. 20)

Plug for T fittings or welding sockets for mae-

731164

565200

suring devices with a clamp connection (see

Fig. 20)

42

English

Page 43

Type S020

Spare parts and accessories

Plug

Clamp

O-ring seal

Fig. 20: Plug, clamp and seal for an S020 for measuring devices

with a clamp connection

Spare part Order code

Set of 2 O-ring seals for the end pieces +

1 flat seal and 1 O-ring seal for the adapter

(T fittings with true union connection only)

(Fig. 21)

FKM - DN8

FKM - DN15

FKM - DN20

FKM - DN25

448679

431555

431556

431557

Spare part Order code

FKM - DN32

FKM - DN40

FKM - DN50

EPDM - DN8

EPDM - DN15

EPDM - DN20

EPDM - DN25

EPDM - DN32

EPDM - DN40

EPDM - DN50

O-ring

seals

431558

431559

431560

448680

431561

431562

431563

431564

431565

431566

O-ring or flat seal

Fig. 21: Seals for a fitting with true union connection

English

43

Page 44

Type S020

Packaging, Transport, storage

10. PACKAGING, TRANSPORT,

STORAGE

attention

Damage due to transport

Transport may damage an insufficiently protected part.

• Transport the fitting in shock-resistant packaging and away

from humidity and dirt.

• Do not expose the fitting to temperatures that may exceed the

admissible storage temperature range.

Poor storage can damage the fitting.

• Store the fitting in a dry place away from dust.

• Storage temperature -15 to +60°C.

Damage to the environment caused by products contaminated by fluids.

• Dispose of the fitting and its packaging in an environmentallyfriendly way.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

11. DISPOSAL OF THE FITTING

→

Dispose of the fitting and its packaging in an environmentallyfriendly way.

note

Damage to the environment caused by products contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

note

Comply with the national and/or local regulations which

concern the area of waste disposal.

44

English

Page 45

Typ S020

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ...............................................................5

1.1. Darstellungsmittel ..............................................................................5

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ......................................6

3. GRUNDLEGENDE SICHERHEITSHINWEISE ....................................6

4. ALLGEMEINE HINWEISE .............................................................................7

4.1. Herstelleradresse und internationale Kontaktadressen 7

4.2. Gewährleistung ....................................................................................7

4.3. Informationen im Internet ...............................................................7

5. BESCHREIBUNG .............................................................................................8

5.1. Vorgesehener Einsatzbereich ......................................................8

6. TECHNISCHE DATEN ...................................................................................8

6.1. Betriebsbedingungen .......................................................................8

6.2. Verfügbare Zertifikate .......................................................................8

6.3. Allgemeine Technische Daten .....................................................9

6.3.1. Verfügbare Durchmesser .....................................................9

6.3.2. Werkstoffe ..............................................................................9

6.3.3. Abmessungen der T-Fittings ............................................10

6.3.4. Abmessungen der Stutzen ................................................17

6.3.5. Abmessungen der Anschluss-Schellen .........................19

6.3.6. Abmessungen der Messkammer .....................................19

6.4. K-Faktoren ...........................................................................................20

6.4.1. Referenzbedingungen ........................................................20

6.4.2. Berechnung der K-Faktoren (in Pulse/Liter)

der Anschluss-Schellen, Schweißstutzen oder

Einschraubstutzen ...............................................................20

6.4.3. K-Faktoren (in Pulse/Liter) der T-Fittings mit

einem Messgerät Typ 8041 oder 8045 mit

G2''-Überwurfmutter ...........................................................21

6.4.4. K-Faktoren (in Pulse/Liter) der T-Fittings und

der Schweißstutzen mit einem Messgerät 8041

oder 8045 mit Clamp-Anschluss ....................................23

6.4.5. K-Faktoren (in Pulse/Liter) der T-Fittings mit

einem Messgerät Typ 8020, 8024, 8025 oder 8026 23

6.4.6. K-Faktoren (in Pulse/Liter) der Anschluss-Schellen ...25

6.4.7. K-Faktoren (in Pulse/Liter) der Schweißstutzen

für Messgeräte mit G2''-Überwurfmutter .......................26

6.4.8. K-Faktoren (in Pulse/Liter) der Einschraubstutzen ......28

7. INSTALLATION UND INBETRIEBNAHME ........................................29

7.1. Sicherheitshinweise ....................................................................... 29

7.2. Fluidischer Anschluss ................................................................... 30

7.2.1. Empfehlungen für die Montage des Fittings

S020 in die Rohrleitung .....................................................30

7.2.2. Installation eines T-Fittings ................................................32

7.2.3. Installation der Anschluss-Schellen ................................33

deutsch

3

Page 46

7.2.4. Installation eines Schweißstutzen mit Radius,

für Messgeräte mit G2''-Überwurfmutter .......................34

7.2.5. Installation eines Schweißstutzens für Messge-

räte mit Clamp-Anschluss .................................................34

7.2.6. Installation eines Schweißstutzens aus

Kunststoff (PE, PP oder PVDF) .......................................36

7.2.7. Installation eines Einschraubstutzens aus

Kunststoff (PP, PVC, PE) ............................................................37

7.2.8. Installation der Messkammer ............................................38

7.2.9. Ermittlung der DN der Rohrleitung - Fließges-

chwindigkeit - Durchfluss ..................................................39

8. WARTUNG ........................................................................................................40

8.1. Sicherheitshinweise ....................................................................... 40

8.2. Reinigung ............................................................................................. 40

9. ERSATZTEILE UND ZUBEHÖR ............................................................. 41

10. VERPACKUNG, TRANSPORT, LAGERUNG ..................................44

11. ENTSORGUNG DES GERÄTES .......................................................... 44

deutsch

4

Page 47

Typ S020

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Fittings. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer zugänglich ist und jedem neuen Eigentümer des Fittings

wieder zur Verfügung steht.

Diese Bedienungsanleitung enthält wichtige Informationen

zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Diese Bedienungsanleitung muss gelesen und verstanden

werden.

1.1. Darstellungsmittel

Gefahr!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die

Folge.

WarnunG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen oder Tod.

VOrSIChT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere Verletzungen oder leichte

Verletzungen zu Folge haben.

hInWeIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Fitting oder die Anlage beschädigt werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

deutsch

5

Page 48

Typ S020

Bestimmungsgemässe Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz dieses Fittings

können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Das Fitting S020 dient zur Installation eines Insertion-Gerätes in

eine Rohrleitung.

• Für den Einsatz sind die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten, Betriebsund Einsatzbedingungen zu beachten.

• Zum sicheren und problemlosen Einsatz des Fittings müssen

Transport, Lagerung und Installation ordnungsgemäß erfolgen,

außerdem müssen Betrieb und Wartung sorgfältig durchgeführt

werden.

• Achten Sie immer darauf, dieses Fitting auf ordnungsgemäße

Weise zu verwenden.

→ Beachten Sie bei der Ausfuhr des Fittings gegebenenfalls beste-

hende Beschränkungen.

3. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Installations- und Wartungspersonal, der

Betreiber verantwortlich ist.

Gefahr durch hohen Druck in der Anlage!

Gefahr durch hohe Flüssigkeitstemperaturen!

Gefahr aufgrund der Art der Flüssigkeit!

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten,

• dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

• Nach einer Unterbrechung der elektrischen Versorgung ist ein

definierter oder kontrollierter Wiederanlauf des Prozesses zu

gewährleisten.

• Betreiben Sie das Fitting nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung.

6

deutsch

Page 49

Typ S020

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

Allgemeine Gefahrensituationen (Folge).

Zum Schutz vor Verletzungen ist zu beachten,

• Bei der Einsatzplanung und dem Betrieb des Fittings die allgemeinen Regeln der Technik einhalten.

• Dieses Fitting nicht in einem explosionsgefährdeten Bereich

verwenden.

• Keine Flüssigkeit verwenden, die sich nicht mit den Werkstoffen

verträgt, aus denen das Fitting besteht.

• Dieses Fitting nicht in einer Umgebung verwenden, die mit den

Werkstoffen, aus denen es besteht, inkompatibel ist.

• Belasten Sie das Fitting nicht mechanisch (z. B. durch Ablage von

Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen oder innerlichen Veränderungen

am Fitting vor.

hInWeIS!

Das Fitting kann durch die Flüssigkeit beschädigt werden.

• Kontrollieren Sie systematisch die chemische Verträglichkeit der

Werkstoffe, aus denen das Fitting besteht, und der Flüssigkeiten, die mit diesem in Berührung kommen können (zum Beispiel:

Alkohole, starke oder konzentrierte Säuren, Aldehyde, Basen,

Ester, aliphatische Verbindungen, Ketone, aromatische oder

halogenierte Kohlenwasserstoffe, Oxidations- und chlorhaltige

Mittel).

4.1. Herstelleradresse und internationale Kontaktadressen

Sie können mit dem Hersteller des Fittings unter folgender Adresse

Kontakt aufnehmen:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

Die internationale Kontaktadressen finden Sie auf den letzten Seiten

dieser Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des S020 unter Beachtung der im vorliegenden

Handbuch spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ S020 finden Sie im

Internet unter: www.buerkert.de

deutsch

7

Page 50

Typ S020

Beschreibung

5. BESCHREIBUNG

5.1. Vorgesehener Einsatzbereich

Mit dem Fitting S020 können Geräte für die Messung von Durchfluss,

pH, Redoxpotential (REDOX) oder Leitfähigkeit leicht an Rohrleitungen

von DN6 bis DN400 installiert werden.

Das Fitting S020 ist in verschiedenen Ausführungen für die Installation

der Messgeräte mit G2''-Überwurfmutter oder der Messgeräte mit

Sensor mit Clamp-Anschluss verfügbar.

Die Messkammer S020 ermöglicht

• einerseits die Installation eines Sensors zur Messung von pH,

Redoxpotential oder Leitfähigkeit in einer Rohrleitung

• und garantiert andererseits, dass der Messsensor von der Flüssigkeit umspült wird.

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Flüssigkeitstemperatur

UmgebungsTemperatur

Druckklasse

6.2. Verfügbare Zertifikate

• Zertifikat 3.1, nur S020 aus Edelstahl

• Zertifikat 2.2

• Zertifikat bezüglich Rauigkeit

• Kalibrierzertifikat

• FDA-Zulassung (mit EPDM-Dichtung), nur S020 aus Edelstahl

abhängig vom verwendeten Gerät und vom Werkstoff des Fittings S020. Siehe das Handbuch des

Gerätes und die Druck-Temperatur-Kurve der Flüssigkeit in Bild 5. Wenn die Bereiche unterschiedlich

sind, den Bereich, der am meisten einschränkt,

verwenden.

abhängig vom verwendeten Gerät. Siehe das entsprechende Handbuch.

abhängig vom verwendeten Gerät und vom Werkstoff des Fittings S020. Siehe das Handbuch

des Gerätes und die Druck-Temperatur-Kurve der

Flüssigkeit in Bild 5. Wenn die Druck-Grenzwerte

unterschiedlich sind, den geringsten Maximaldruck

nicht überschreiten.

8

deutsch

Page 51

Typ S020

Technische Daten

6.3. Allgemeine Technische Daten

6.3.1. Verfügbare Durchmesser

Die verfügbaren Durchmesser hängen von der Bauform des Fittings

S020 ab.

Siehe die Datenblätter der Fittings S020 und des verwendeten Gerätes, um den passenden DN zu ermitteln.

Tab. 1: Verfügbare Durchmesser je nach Bauform des Fittings

Bauform des S020 Verfügbare DN

T-Fittings für Messgeräte mit

G2''-Überwurfmutter

T-Fittings für Messgeräte mit

Clamp-Anschluss

Schweißstutzen mit Radius, für

Messgeräte mit G2''-Überwurfmutter

Schweißstutzen aus Kunststoff DN65 bis DN400

Einschraubstutzen

1)

Schweißstutzen für Messgeräte mit

Clamp-Anschluss

Anschluss-Schellen

1)

Nur zur Durchflussmessung.

1)

DN6 bis DN65

DN32 bis DN100

DN50 bis DN350

DN100 bis DN400

DN32 bis DN100

DN50 bis DN200

6.3.2. Werkstoffe

Tab. 2: Werkstoffe je nach Bauform des Fittings S020

Bauform des S020 Werkstoffe

Gehäuse Zwischenstutzen Dichtung

T-Fittings für

Messgeräte mit

G2''-Überwurfmutter

T-Fittings für

Messgeräte mit

Clamp-Anschluss

Schweißstutzen

mit Radius, für

Messgeräte mit

G2''-Überwurfmutter

Schweißstutzen

Schweißstutzen

für Messgeräte mit

Clamp-Anschluss

Einschraubstutzen

Anschluss-Schellen PP PVC EPDM

Edelstahl (316L - 1.4404) FKM

Messing Edelstahl (316L

- 1.4404)

oder

EPDM

PVC

PP

PVDF

Edelstahl

- -

(316L )

Edelstahl

- -

(316L

- 1.4404)

PE - PP - -

PVDF - -

Edelstahl

- -

(316L )

PVC - -

PE - PP - -

deutsch

9

Page 52

Typ S020

Technische Daten

Messkammer Edelstahl

- -

(316L

- 1.4404)

6.3.3. Abmessungen der T-Fittings

Tab. 3: Abmessungen des Fittings S020 mit G-, Rc- oder NPT-

Innengewinde-Anschlüssen aus Edelstahl oder Messing,

für Messgeräte mit G2''-Überwurfmutter

DN [mm] P [mm] A [mm] D [Zoll] L [mm]

15 80.3 84.0 G 1/2

NPT 1/2

Rc 1/2

20 77.8 94.0 G 3/4

NPT 3/4

Rc 3/4

25 78.0 104.0 G 1

NPT 1

Rc 1

32 81.6 119.0 G 1 1/4

NPT 1 1/4

Rc 1 1/4

40 85.4 129.0 G 1 1/2

NPT 1 1/2

Rc 1 1/2

50 91.5 148.5 G 2

NPT 2

Rc 2

16.0

17.0

15.0

17.0

18.3

16.3

23.5

18.0

18.0

23.5

21.0

21.0

23.5

20.0

19.0

27.5

24.0

24.0

P

D

L

A

10

deutsch

Page 53

Typ S020

Technische Daten

Tab. 4: Abmessungen des Fittings S020 mit G Außengewinde-

Anschlüssen aus Edelstahl, Messing (DN15 bis 50) oder PVC

(nur DN6 und 8), für Messgeräte mit G2''-Überwurfmutter

DN

[mm]

6 75.3 90.0 G 1/2 14.0

8 75.3 90.0 G 1/2 14.0

15 80.3 84.0 G 3/4 11.5

20 77.8 94.0 G 1 13.5

25 78.0 104.0 G 1 1/4 14.0

32 81.6 119.0 G 1 1/2 18.0

40 85.4 129.0 M55 x 2 19.0

50 91.5 148.5 M64 x 2 20.0

P

[mm]

A

[mm]

D

[Zoll]

L

[mm]

P

D

L

A

Tab. 5: Abmessungen des Fittings S020 mit Außengewinde-

Anschlüssen nach SMS1145 aus Edelstahl, für

Messgeräte mit G2''-Überwurfmutter

DN

[mm]P[mm]

25 77.8 130 Rd40 x 1/6"

40 81.6 164 Rd60 x 1/6"

50 85.4 173 Rd70 x 1/6"

A

[mm]

D