Bushnell LS1440 User Manual

ENGLISH

Miter Saw

MODEL LS1440

DOUBLE

INSULATION

INSTRUCTION MANUAL

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

002146

SPECIFICATIONS

Blade diameter.................................................................................................................................................... 355 mm

Hole diameter.................................................................................................................................. 25 mm and 25.4 mm

Max. Miter angle ................................................................................................................................Left 45° , Right 45°

Max. Cutting capacities (H x W)

Miter angle

0° 45° (left and right)

122 mm x 152 mm 122 mm x 115 mm

-1

No load speed (min

Dimensions (L x W x H) .....................................................................................................530 mm x 596 mm x 610 mm

Net weight............................................................................................................................................................... 34 kg

Safety class............................................................................................................................................................... /II

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

SYMBOLS

The following show the symbols used for the tool. Be

sure that you understand their meaning before use.

...................Read instruction manual.

...................DOUBLE INSULATION

Intended use

The tool is intended for accurate straight and miter cutting in wood. With appropriate saw blades, aluminum

can also be sawed.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and

can only be operated on single-phase AC supply. They

are double-insulated in accordance with European

Standard and can, therefore, also be used from sockets

without earth wire.

) ............................................................................................................................................. 3,200

END201-1

2

GENERAL SAFETY RULES GEA001-3

WARNING:

Read all instructions. Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury. The term “power tool” in all of the

warnings listed below refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

SAVE THESE INSTRUCTIONS

Wor k area sa fe ty

1. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

2. Do not operate power tools in explosive atmos-

pheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while oper-

ating a power tool. Distractions can cause you to

lose control.

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the

risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

Personal safety

9. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

10. Use safety equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the switch is

in the off-position before plugging in. Carrying

power tools with your finger on the switch or plugging in power tools that have the switch on invites

accidents.

12. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

13. Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

14. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

15. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

Power tool use and care

16. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the rate

for which it was designed.

17. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

18. Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

3

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

19. Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

20. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused

by poorly maintained power tools.

21. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

22. Use the power tool, accessories and tool bits

etc. in accordance with these instructions and in

the manner intended for the particular type of

power tool, taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

23. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

24. Follow instruction for lubricating and changing

accessories.

25. Keep handles dry, clean and free from oil and

grease.

ADDITIONAL SAFETY RULES FOR TOOL ENB040-3

1. Wear eye protection.

2. Keep hands out of path of saw blade. Avoid con-

tact with any coasting blade. It can still cause severe

injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly. Never

clamp or tie the blade guard into the open position.

4. Do not perform any operation freehand. The

workpiece must be secured firmly against the turn

base and guide fence with the vise during all operations. Never use your hand to secure the workpiece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing settings.

7. Unplug tool before changing blade or servicing.

8. Don’t use the tool in the presence of flammable liq-

uids or gases.

9. Check the blade carefully for cracks or damage

before operation.

Replace cracked or damaged blade immediately.

10. Use only flanges specified for this tool.

11. Be careful not to damage the arbor, flanges (espe-

cially the installing surface) or bolt. Damage to

these parts could result in blade breakage.

12. Make sure that the turn base is properly secured so

it will not move during operation.

13. For your safety, remove the chips, small pieces, etc.

from the table top before operation.

14. Avoid cutting nails. Inspect for and remove all nails

from the workpiece before operation.

15. Make sure the shaft lock is released before the

switch is turned on.

16. Be sure that the blade does not contact the turn

base in the lowest position.

17. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and stopping.

18. Make sure the blade is not contacting the workpiece

before the switch is turned on.

19. Before using the tool on an actual workpiece, let it

run for a while. Watch for vibration or wobbling that

could indicate poor installation or a poorly balanced

blade.

20. Wait until the blade attains full speed before cutting.

21. Stop operation immediately if you notice anything

abnormal.

22. Do not attempt to lock the trigger in the on position.

23. Be alert at all times, especially during repetitive,

monotonous operations. Don't be lulled into a false

sense of security. Blades are extremely unforgiving.

24. Always use accessories recommended in this manual. Use of improper accessories such as abrasive

wheels may cause an injury.

25. Do not use the saw to cut other than aluminum,

wood or similar materials.

26. Connect miter saws to a dust collecting device

when sawing.

4

27. Select saw blades in relation to the material to

be cut.

28. Take care when slotting.

29. Replace the kerf board when worn.

30. Do not use saw blades manufactured from high

speed steel.

31. Some dust created from operation contains

chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based-painted material

• arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

SAVE THESE INSTRUCTIONS

reduce your exposure to these chemicals: work

in a well ventilated area and work with approved

safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

32. To reduce the emitted noise, always be sure that

the blade is sharp and clean.

33. The operator is adequately trained in the use,

adjustment and operation of the machine.

34. Use correctly sharpened saw blades. Observe

the maximum speed marked on the saw blade.

35. Refrain from removing any cut-offs or other

parts of the workpiece from the cutting area

whilst the machine is running and the saw head

is not in the rest position.

5

INSTALLATION

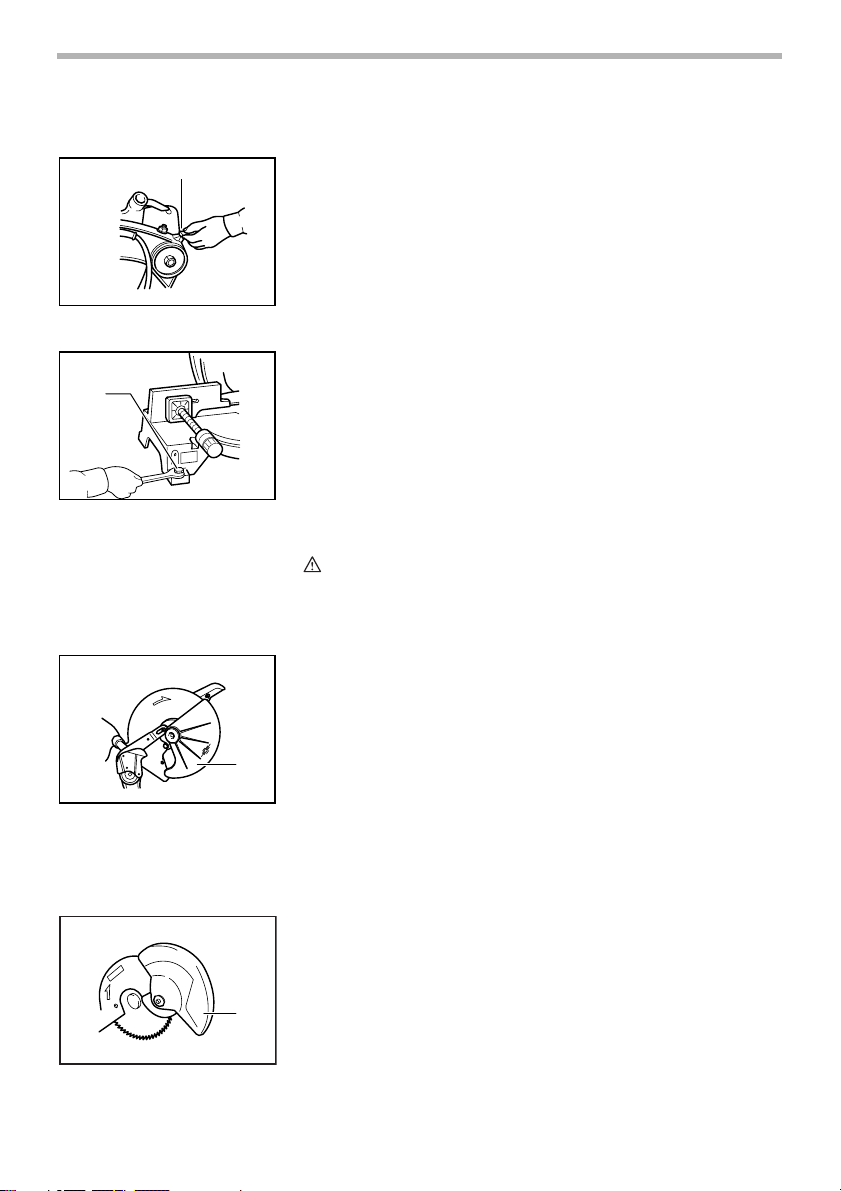

1

1. Handle latch

1

1. Bolt

Bench mounting

002147

When the tool is shipped, the handle is locked in the lowered position by the

handle latch. Release the handle latch by lowering the handle slightly and turn

the handle latch to the released position.

003638

This tool should be bolted with four bolts to a level and stable surface using the

bolt holes provided in the tool’s base. This will help prevent tipping and possible injury.

FUNCTIONAL

DESCRIPTION

1. Blade guard

1. Blade guard

6

002149

1

001782

1

CAUTION:

• Always be sure that the tool is switched off and unplugged before

adjusting or checking function on the tool.

Blade guard

When lowering the handle, the blade guard rises automatically. The guard is

spring loaded so it returns to its original position when the cut is completed

and the handle is raised. NEVER DEFEAT OR REMOVE THE BLADE GUARD

OR THE SPRING WHICH ATTACHES TO THE GUARD.

In the interest of your personal safety, always maintain the blade guard in good

condition. Any irregular operation of the blade guard should be corrected

immediately. Check to assure spring loaded return action of guard. NEVER

USE THE TOOL IF THE BLADE GUARD OR SPRING ARE DAMAGED,

FAULTY OR REMOVED. DOING SO IS HIGHLY DANGEROUS AND CAN

CAUSE SERIOUS PERSONAL INJURY.

If the see-through blade guard becomes dirty, or sawdust adheres to it in such

a way that the blade is no longer easily visible, unplug the saw and clean the

guard carefully with a damp cloth. Do not use solvents or any petroleum-based

cleaners on the plastic guard.

If the blade guard is especially dirty and vision through the guard is impaired,

use the supplied socket wrench to loosen the hex bolt holding the center cover.

Loosen the hex bolt by turning it counterclockwise and raise the blade guard

and center cover. With the blade guard so positioned, cleaning can be more

completely and efficiently accomplished. When cleaning is complete, reverse

procedure above and secure bolt. Do not remove spring holding blade guard.

If guard becomes discolored through age or UV light exposure, contact a Makita service center for a new guard. DO NOT DEFEAT OR REMOVE GUARD.

Loading...

Loading...