Page 1

INSTALLATION

AND

Price

-

$3.00

OPERATING

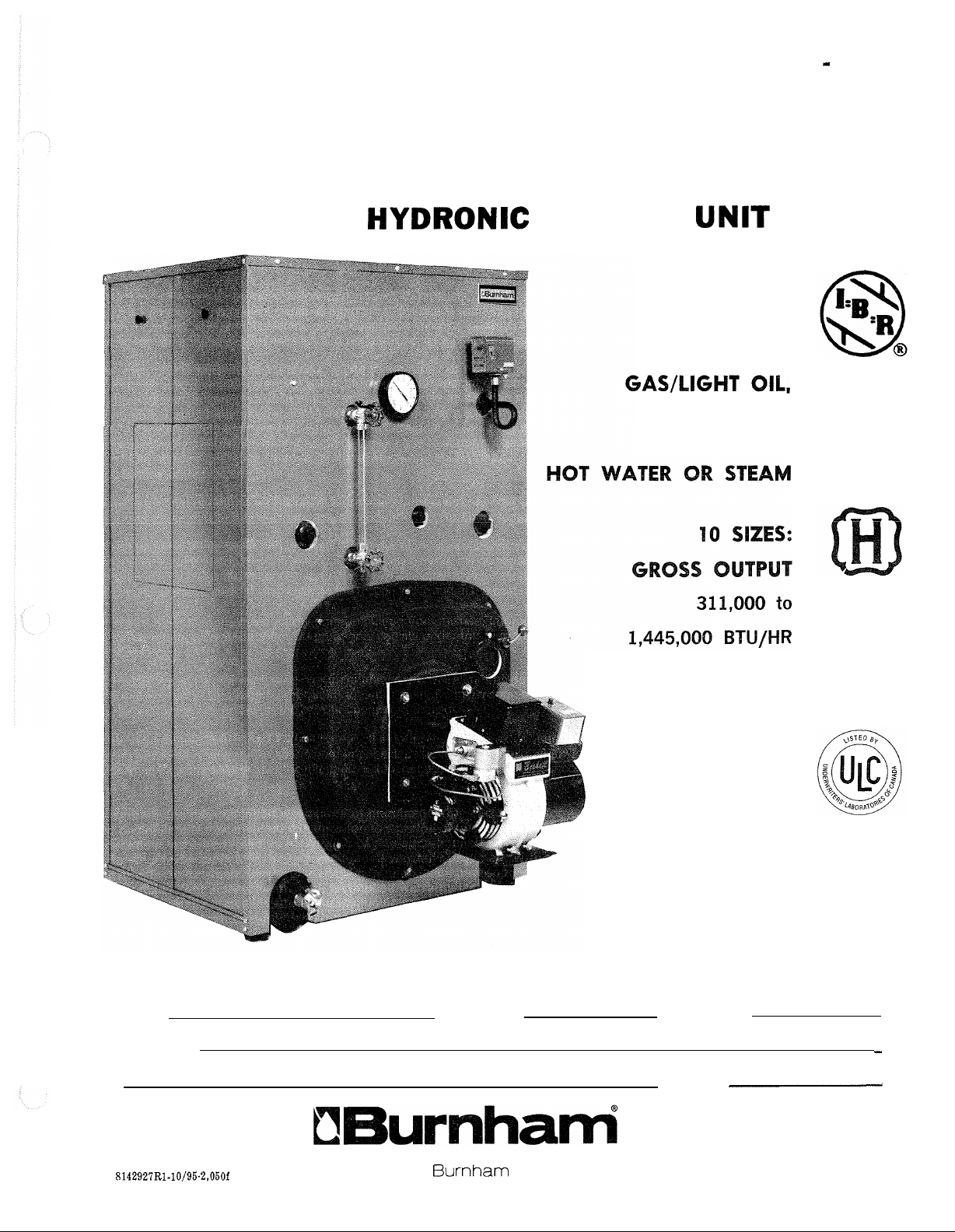

V-9

CAST

IRON HYDRONIC

INSTRUCTIONS

FOR

SERIES

HEATING

FORCED DRAFT

UNIT

LIGHT

OR GAS

FOR

OIL,

These Instructions have been

reviewed

suitable for use

Installation of

V-9

The ULC label or listed

marking on a product

only evidence provided

Underwriters' Laboratories

of Canada to identify products

which have been produced

under the listing and follow

service.

For service and repairs to the heating plant, call your Heating Contractor.

provide series and size designation shown on rating plate.

Boiler Number Type Firing Type System

Heating Con tractor

Address

Part

No.

8142927Rl-10/95-2,050f

AMERICA'S

Burnham Corporation

BOILER

Lancaster,

PA

17604-3079

When seeking information on the boiler,

COMPANY

by

ULC and found

in

Series Boilers.

ULC

.Phone No

the

labeled

is

the

by

-

up

-

Page 2

Page 3

IMPORTANT INFORMATION

PLEASE READ THIS PAGE CAREFULLY

1.

READ THIS MANUAL AND BURNER INSTALLATION MANUAL CAREFULLY BEFORE INSTALL

ING, OPERATING, OR SERVICING THIS UNIT.

ED AND PACKED IN THE BURNER CARTON.

BURNHAM AND ASK FOR APPROPRIATE BURNER MANUAL.

TO

BLE CONDITION AND POSTED NEAR HEATING UNIT FOR REFERENCE BY OWNER AND SERV

ICEMAN.

2.

ALL BOILERS MUST BE INSTALLED IN ACCORDANCE WlTH NATIONAL, STATE AND LOCAL

PLUMBING, HEATING AND ELECTRICAL CODES AND THE REGULATIONS OF THE SERVING

UTILITIES.

AUTHORITIES HAVING JURISDICTION SHOULD BE CONSULTED BEFORE INSTALLA

TIONS ARE MADE.

IN ALL CASES, REFERENCE SHOULD BE MADE TO THE FOLLOWING STANDARDS:

USA BOILERS

A.

Current edition of American National Standard ANSWNFPA 31, "Installation of Oil Burning Equipment", for clearances

between boiler, vent connector and combustible material.

B. Current Edition of American National Standard

Appliances

tible materials.

C. Current Edition of American Society of Mechanical Engineers ASME CSD

ally Fired Boilers", for assembly and operations of controls and safety devices.

A. Current Edition of Canadian Standards Association CSA

mended Installation Practices.

B. The equipment shall be installed in accordance with the current installation code for gas burning appliances and equip

ment, CGA B149, and applicable provincial regulations for t%e class; which should be carefully followed in all cases. Auth

orities having jurisdiction should be consulted before installations are made.

"

, For Chimney requirements, type of venting material and clearances between vent connector pipe and combus

ANSI/NFPA 211, "Chimneys, Fireplaces, Vents, and Solid Fuel Burning

CANADA BOILERS

THE BURNER MANUAL FOR THIS UNIT IS PROVID

IF

YOU DO NOT HAVE A BURNER MANUAL, WRITE

KEEP INSTRUCTIONS IN LEGI

-

1, "Controls and Safety Devices for Automatic

B139, "Installation Code for Oil Burning Equipment", for recom

-

-

-

-

-

-

-

-

-

-

3.

ALL HEATING SYSTEMS SHOULD BE DESIGNED BY COMPETENT CONTRACTORS AND ONLY PER

SONS KNOWLEDGEABLE IN THE LAYOUT AND INSTALLATION OF HYDRONIC HEATING SYS

TEMS SHOULD ATTEMPT INSTALLATION OF ANY BOILER.

4.

THE BOILER MUST BE PROPERLY VENTED IN ACCORDANCE WITH NATIONAL AND LOCAL

CODES. SERIOUS PROPERTY DAMAGE COULD RESULT IF THE BOILER IS NOT PROPERLY

VENTED.

5.

READ THE LITERATURE ENCLOSED BY THE MANUFACTURER WITH THE VARIOUS ACCESS

ORY DEVICES.

THESE ACCESSORY DEVICES MIJST BE INSTALLED AND USED ACCORDING TO

THE RECOMMENDATIONS OF THE MANUFACTURER.

6.

IT IS THE RESPONSIBLJTY OF THE INSTALLING CONTRACTOR TO SEE THAT ALL CONTROLS

ARE CORRECTLY INSTALLED AND ARE OPERATING PROPERLY WHEN THE INSTALLATION IS

COMPLETED.

7. DO NOT TAMPER WITH THE UNIT OR CONTROLS. RETAIN A COMPETENT SERVICEMAN TO

SURE THAT THE UNIT

8.

FOR OPTIMUM PERFORMANCE FROM THIS UNIT FOLLOW SERVICE INSTRUCTIONS

IS

PROPERLY ADJUSTED AND MAINTAINED.

AS

SPECIFI

ED IN SECTION V OF THIS MANUAL.

9.

PROBE AND FLOAT TYPE LOW WATER CUTOFF DEVICES REQUIRE ANNUAL INSPECTION AND

299

MAINTENANCE. REFER TO INSTRUCTIONS ON PAGE

ITEM 4 FOR STEP BY STEP IN

SPECTION AND CLEANING INSTRUCTIONS.

10.

ALL FLAMMABLE DEBRES, RAGS, PAPER, WOOD SCRAPS, ETC., SHOULD BE KEPT CLEAR OF

THE BOILER AT ALL TIMES. KEEP THE BOILER AREA CLEAN AND FREE OF FIRE HAZARDS.

-

-

-

A$-

-

-

HIGH WATER TEMPERATURES INCREASE THE RISK OF BURNS OR SCALDING INJURY. INSTALL AN

AUTOMATIC MIXING VALVE AT THE

TANKLESS HEATER OUTLET TO AVOID EXCESSIVELY

HOT

WATER AT THE FIXTURES.

Page 4

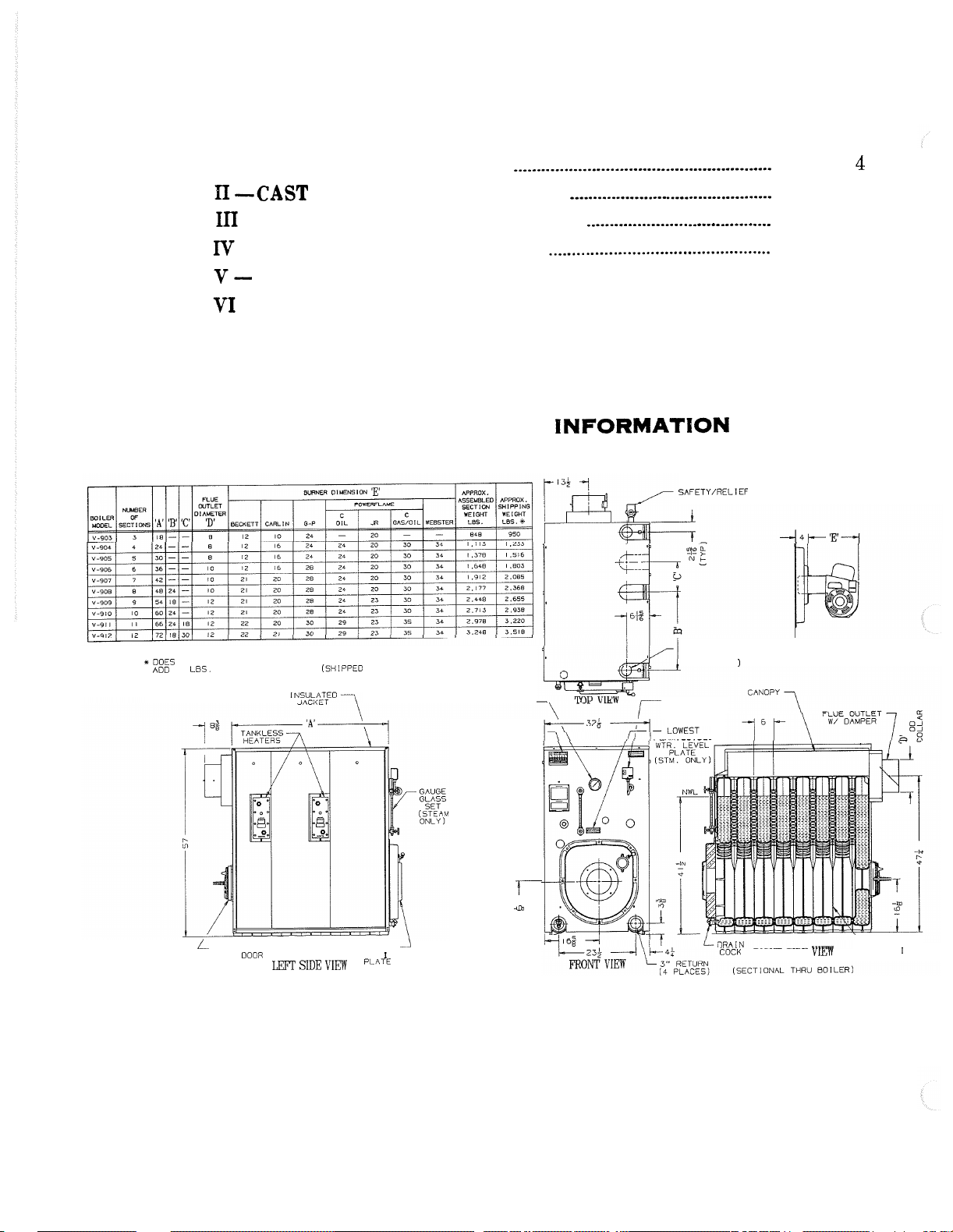

TABLE

OF CONTENTS

SECTION I - GENERAL INFORMATION

SECTION

SECTION

SECTION

SECTION

SECTION

PI

--CAST IRON BLOCK ASSEMBLY

111

-

INSTALLATION INSTRUCTIONS

IV

-

OPERATING INSTRUCTIONS

V

--

SERVICE INSTRUCTIONS

VI

-

REPAIR PARTS

SECTION

.............................................................................

I

GENERAL INFORMATlON

........................................................

............................................

........................................

..............................................

........................................................

SAFETY/RELIEF

VALVE

Page

Page

Page

Page

Page

Page

4

7

12

24

27

29

+DOES NOT INCLUDE BURNER MOUNTING PLATE.

ADO

45

LBS.

FOR

M

O

U

N

T

I

NG PLA

T

E

(SHIPPED

L

PRESSURE

DOOR MOUNT I NG

RELIEF

ASSEMBLY

LEFT

SIDE

vlmy

SEPARATELY

BURNER

PLATE

-3"

TAPPING

(TYPICAL ALL

S

U

P

PLI

E

S

).

GAUGE

RATING

PLATE

-

-

PRESSURETROL

(STEAM ONLY)

PERMISSIBLE

)

BURNER

DETAIL

t

-im

in

a

COCK

RIGHT SIDE VIEW

CAST IRON

SECT l ONS

Fig.

1

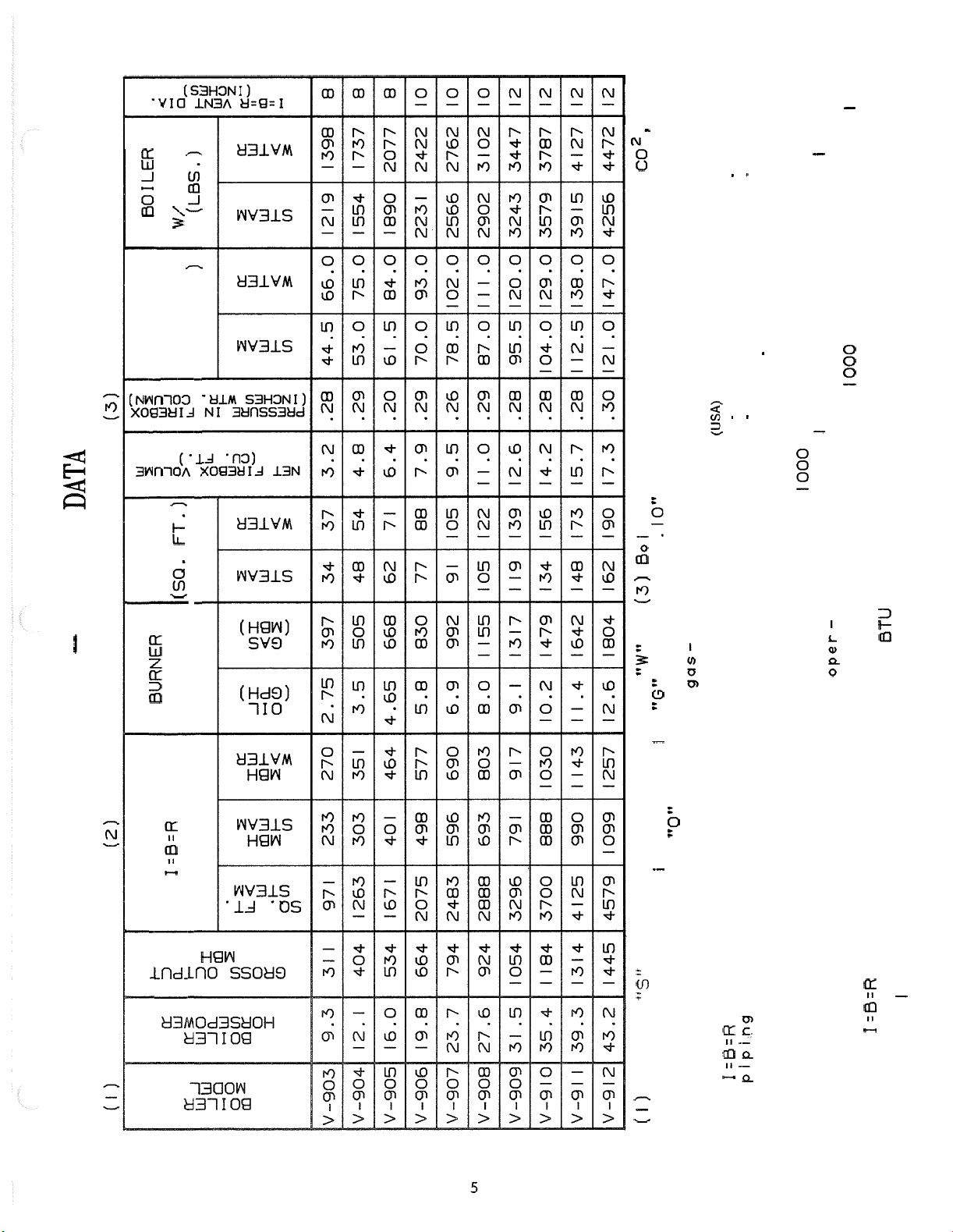

Page 5

.

l

)

GHT

I

WATER

BOILER

(LBS.

WE

W/

I

)

S

N

O

LL

FULL

WATER

RATINGS

-

I

TABLE

A

G

CONTENT

(

NG

I

FT.)

HEAT

SURFACE

(SQ.

T

U

P

N

I

BURNER

CO',

12.5%

.lo" water column pressure at boiler

+

£301 ler ratings are based on

flue outlet.

MAXIMUM ALLOWABLE WORKING PRESSURE:

(3)

-

"W"

,

"G"

x

l

PSI

45

15 PSI

-

-

WATER

PSI

70

-

PSI

15 PSI STEAM

50

-

-

(USA) (CANADA)

STEAM

WATER

OPTIONAL SPECIAL ORDER

cated,

I

nd

i

feet on

2000

feet above sea leve

1000

tudes above those

i

t

l

feet on oil and

1000

for each

4%

the ratings should be reduced at the rate

gas. For a

up to

-

of

Ratings shown above apply at altitudes

BTU

based

is

140,000

GPH

RATING

I=B=R

NET

indicates oil

Suf f

.

"0"

ler

i

fired,

-

indicates steam boi ler

indicates comblnat ion gas-

"

'5**

Suffix

)

(I

GO

"

indicates gas

indicates water bo

fired,

oil fired.

net ratings shown are based on

I=B=R

(2)

piping and pickup allowances which vary

for water.

from 1.333 to 1.315 for steam and 1.15

burner capacity in

on.

l

I=B=R

ments, such as intermittent system oper-

Consult manufacturer for installations

having unusual piping and pickup require

at ion, extensive piping systems, etc.

per gal

The

on oil having a heat value of

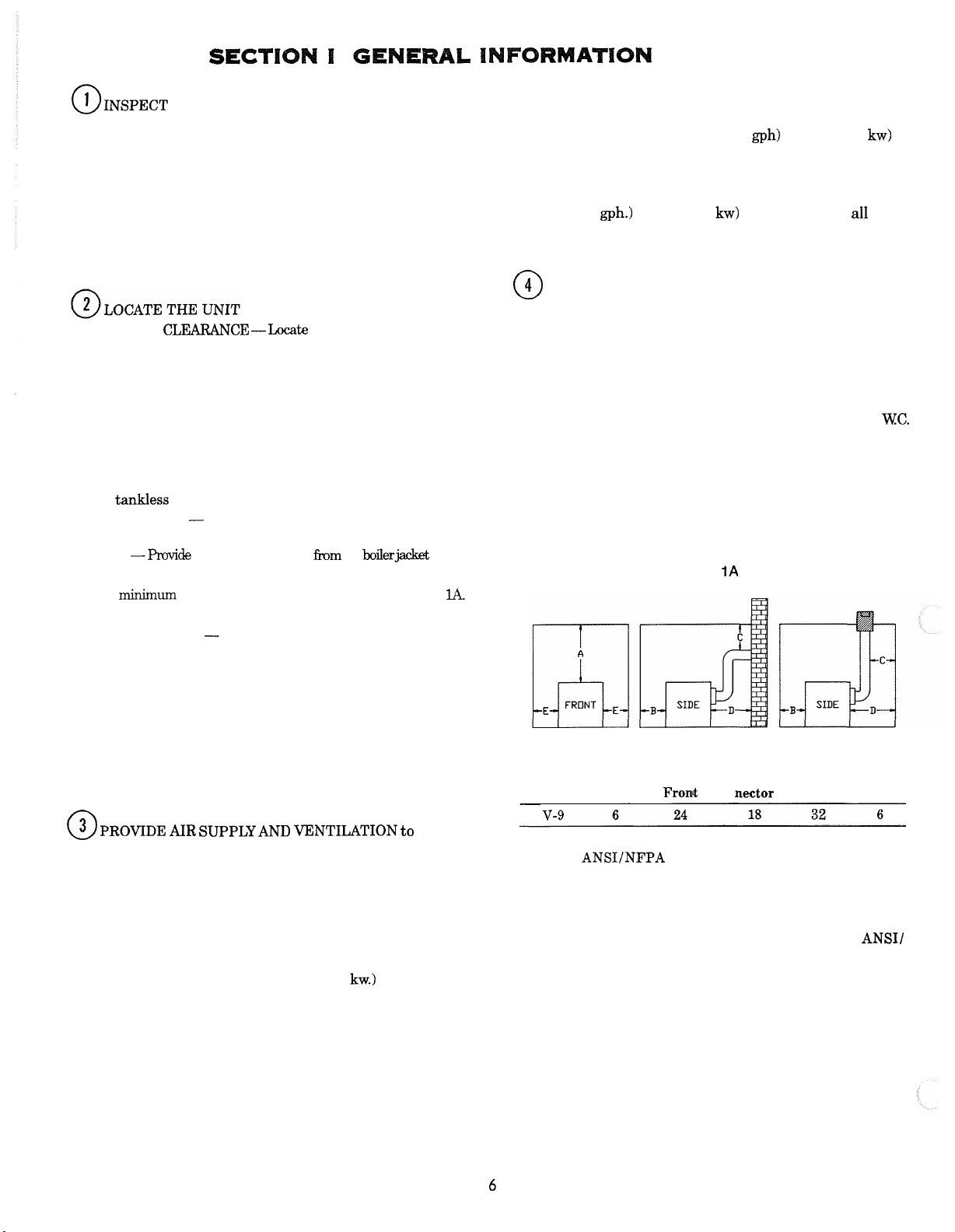

Page 6

@INSPECT SHIPMENT carefully for any signs of damage.

A. ALL EQUIPMENT is carefully manufactured, inspected

and packed. Our responsibility ceases upon delivery of

crated Boiler to the carrier in good condition.

B.

ANY

CLAIMS for damage or shortage in shipment must be

filed immediately against the carrier by the consignee. No

claims for variances from, or shortage in orders, will be

allowed by the manufacturer unless presented within sixty

(60) days after receipt of goods.

A. PROVIDE

so

as

CLEARANCE -Locate the unit in the boiler room

to

provide

ease

of venting and adequate clearance for

maintenance, serviceability, and installation of piping.

-

FRONT

Provide 48" service clearance for removal, main

tenance, and servicing or burner and controls.

REAR

-

jacket of 36

Provide a minimum clearance from the boiler

"

for access to pressure relief door, flame ob

servation, port and flue damper.

LEFT SIDE

boiler jacket of 35

-

Provide a minimum clearance from the

"

for installation and removal of the

tankless heaters and for cleaning of flueways.

RIGHT SIDE

boiler jacket of

TOP

-

Refer to Figure

B.

For

minimum

C.

PROVIDE ADEQUATE FOUNDATION for the unit.

1.

CAUTION

PETING.

-

Provide a minimum clearance from the

9.

F'rovide a minimum

1

for boiler dimensional data.

clearances

to

-

DO NOT INSTALL BOILER ON CAR

Boiler is suitable for installation on com

clearance

from the boilerpcket of 21".

combustible materials,

See

Figure

Ik

bustible floors.

2. Floor construction should have adequate load bear

ing characteristics to bear the weight of the boiler

filled with water (see Table

1).

A boiler foundation

similar to the one shown in Figure 2 is recommended

if the boiler room floor is weak or uneven or if a wa

ter condition exists.

"r

1.

Where communicating by means of vertical ducts, each

opening shall have a free area of not less than

per 4,000 Btuh (35 sq in. per

(

CONTINUED

)

1

sq in.

gph) (5.5 cm2 per kw) of

total input rating of all appliances in the enclosure.

2. If horizontal ducts are used, each opening shall have

free area of not less than 1 sq in per 2,000 Btuh

gph.) (11 cm2 per kw) of total input of all appli

in per

(70

a

sq.

-

ances in the enclosure.

@

CHIMNEY OR VENT

V-9

The

Series boiler is designed for forced draft firing and

may be used with a conventional natural draft stack or a stub

vent, sometimes called a diesel stack (see Figure 3). See Table

1

for the proper vent size. Draft controls are not normally

-

required, although they may be used on installations where a

natural draft stack is used or on multiple boiler installations

with a common stack. The boiler is provided with a breeching

"

-

pressure in the vent connector box during burner operation.

Figure

1A

damper which should be adjusted to maintain a positive 0.1

WC.

-

-

-

-

Boiler Above Fronk nector Rear Sides

A

B

C

Chimney

Con

-

D

E

@

PROVIDE AIR SUPPLY

Am

vENTILATIoN to accom

modate proper combustion.

For commercial and industrial equipment, permanent

facilities for supplying an ample amount of outside air shall

be provided in accordance with the following.

For boiler rooms adjacent to outside walls, and where

combustion air is provided by natural ventilation from the

outside, there shall be a permanent air supply inlet having

a total free area of not less than

hr.

(35 sq. in. per gal. per hr.) (5.5 cm2per kw.) of total input

rating of the burner or burners and in no case less than 35

sq. in. (0.425 m

2

).

1

sq. in. per 4,000 Btu per

For boiler rooms not adjacent to outside walls, the com

bustion air shall be supplied in a manner acceptable to the

authority having jurisdiction.

A. In the absence of local requirements, the confined space

shall be provided with two permanent openings, one in or

near the top of the room and one near the bottom. The

openings shall communicate by means of ducts, with the

outdoors or to such spaces (crawl or attic) that communi

cate with the outdoors.

-

1:

NOTE

Standard

ment.

NOTE

clearances from combustible material as listed above. Listed

clearances can not be reduced for alcove or closet installations.

NOTE

protection must

NFPA 31

Listed clearances comply with American National

ANSIINFPA 31, Installation

2:

V-9

Series boilers can be installed in rooms with

3:

For reduced clearances to combustible material,

be

standard.

provided as described

of

oil burning equip

in

the above ANSI/

-

-

-

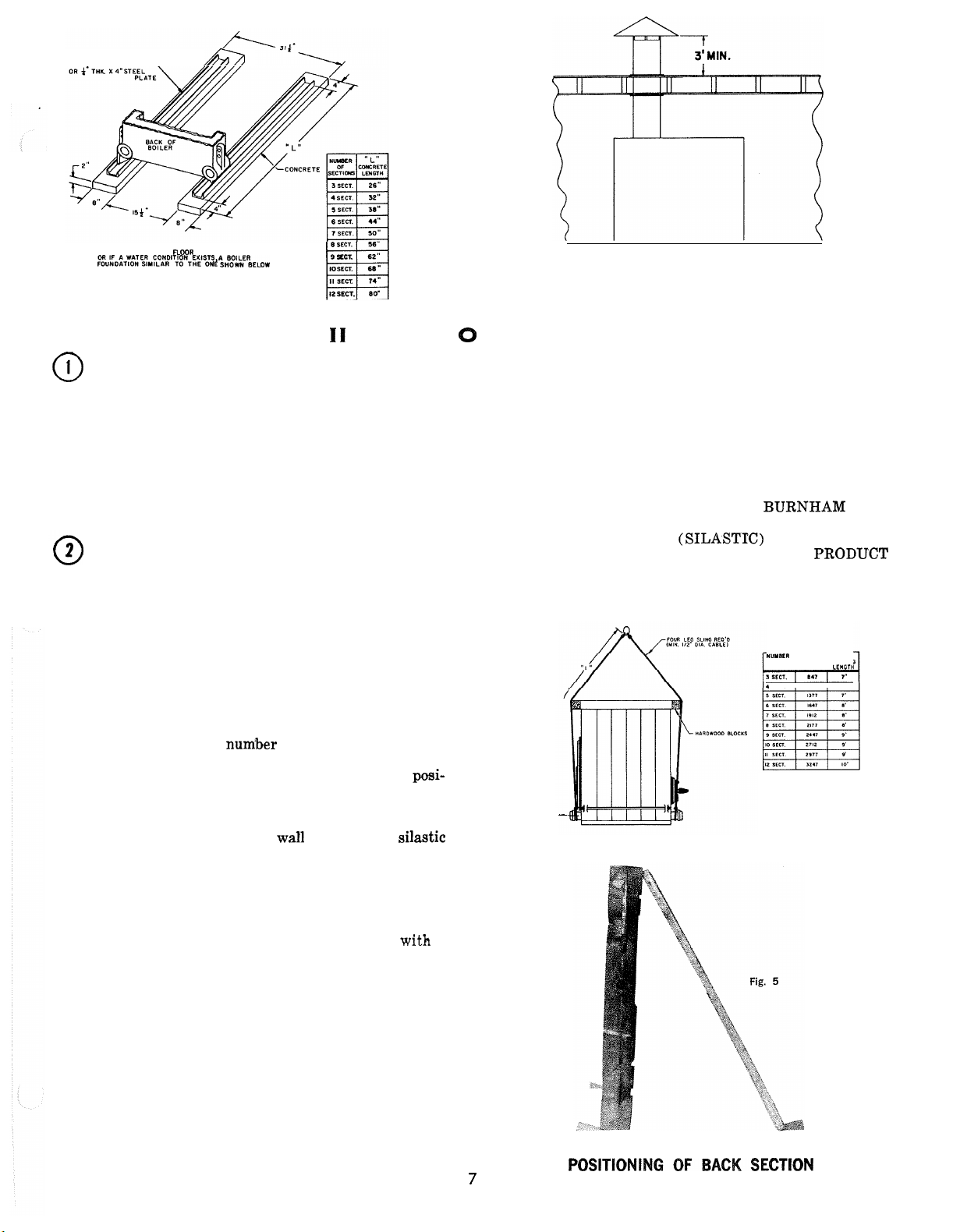

Page 7

6

U8.2 STEEL CHANNEL

-

h-2

NOTE: IF THE BOILER ROOM FLOOR IS WEAK OR UNEVEN

EJL0iz6H'?MFL"fR"1T;:NT5":"01t

IS

RECOMMENDED.

~%'G~RSE~

Fig.

2

SECTION

@

FACTORY ASSEMBLED SECTIONS - If the boil

9

SECT.

I1

CAST

er was ordered with factory assembled sections, the assem

blage should be set in the proper location as outlined in

'Section

Figure

1.

Lifting arrangement and weights are given in

4.

The tie-rod nuts should then be loosened until finger

tight. Now proceed to part

"

HYDROSTATIC TEST.

3

of this section on page 12,

"

FIELD ASSEMBLED SECTIONS - If the boiler

was ordered to be field assembled, follow the assembly

procedure outlined on the following pages.

-

A. Assembly of Sections (Manual Draw

Up)

WHEN ASSEMBLING SECTIONS WITHOUT HY

DRAULIC DRAW-UP EQUIPMENT, NEVER AS

SEMBLE MORE THAN ONE 'SECTION AT A

TIME.

IR

-

-

-

-

1

TYPICAL

FOR

N

BLOCK ASSEMBLY

IMPORTANT

-

AS DIRECTED TO INSURE TIGHT JOINTS.

MOST NIPPLE LEAKS ARE CAUSED

ED OR COCKED NIPPLES.

6. IMPORTANT

-

FIRED BOILER AND SEALANT MUST BE AP

PLIED WHERE SPECIFIED FOR PROPER AND

SAFE PERFORMANCE. THE

PORATION HAS APPROVED A SECTION

JOINT SEALANT

ED BY DOW-CORNING UNDER THE PRODUCT

NUMBERS OF 732-RTV, 732-BLll AND 781. ALL

THREE NUMBERS ARE THE SAME MATER

IAL.

ARRANGEMENT

STUB

VENT

Fig.

3

NIPPLES MUST

BE

BY

DRIVEN

TILT

THIS IS A FORCED DRAFT

BURNHAM COR

(SILASTIC) MANUFACTUR

WUYWR

SECTIONS

4

SECT

LENOTH

-

-

-

-

-

A

"

Manual Draw-Up Kit" is available through Burn

ham

by

ordering part num'ber 6082901.

1.

Place the rear section in its approximate final posi-

tion,

as

suitable prop. 'See Figure

outlined in 'Section 1, and support it with a

5.

903 ONLY - Open target wall carton, apply silastic

to back of target wall and secure target wall to rear

section.

2.

Open the Boiler Assembly Carton (s)

3.

Clean nipples and nipple ports thoroughly

.

degreasing solvent and apply nipple lubricant pro

vided.

4.

Drive nipples squarely into section using block of

wood and hammer, or preferably an aluminum

headed hammer, if available.

5.

A special nipple setting gauge is provided for the

nipples.

Gauge nipple in both directions to insure

that it is driven to the proper depth into the nipple

opening. Cut

-

out in gauge must rest on nipple, with

legs of gauge touching finished face of section,

when nipple is properly driven. See Figure 6.

with

-

Fig.

4

LIFTING INSTRUCTIONS

a

-

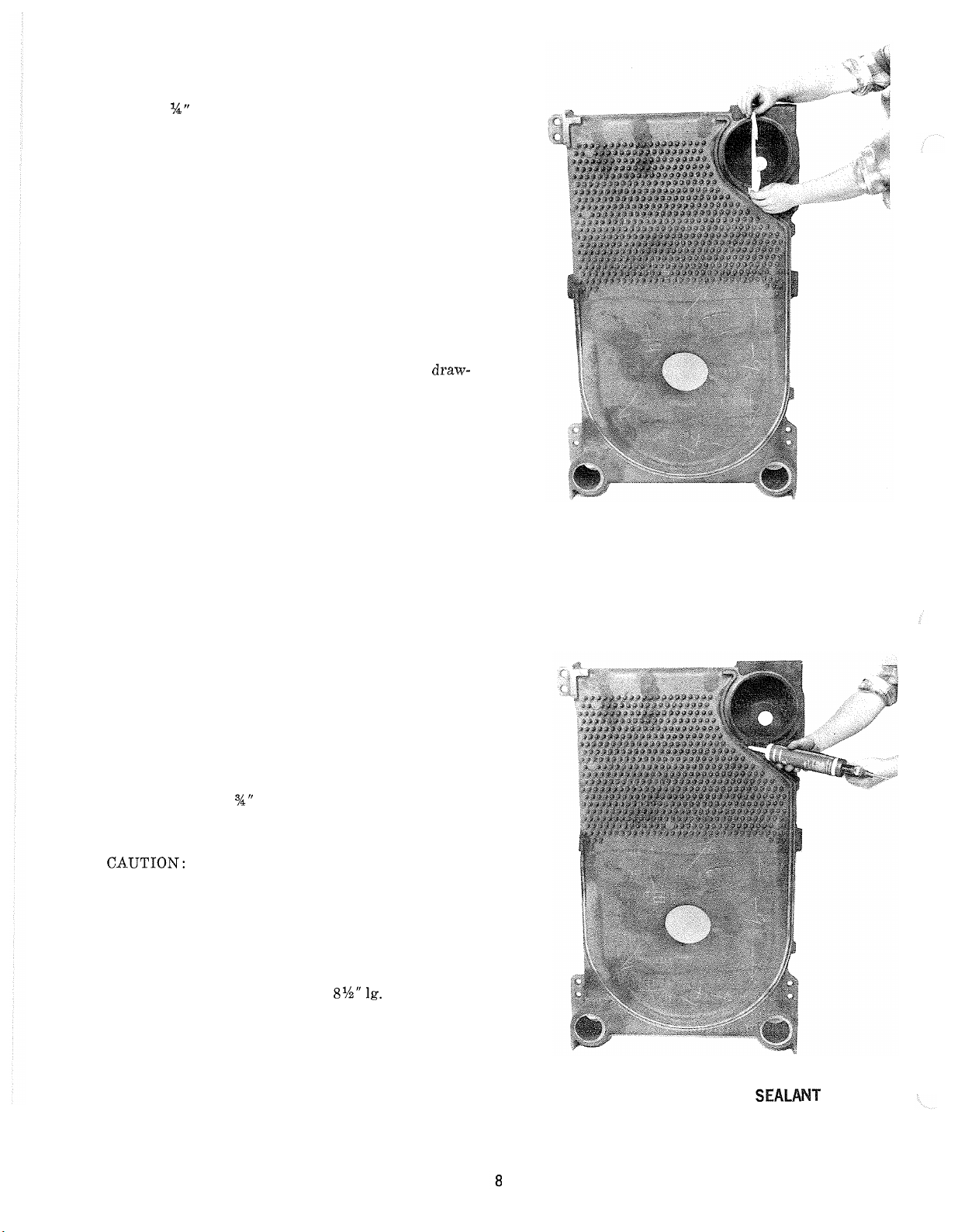

Page 8

The grooves in the gound joint along the edge

the section should be cleaned with a wire brush.

Then using a cartridge of sealant in a caulking gun,

apply

Y4"

bead of Silastic to one side of each joint

to be mated. Touch up any missed spots before

-

up. Touch-up after draw-up has no value. See

draw

Figure

All sections must be drawn-up iron-to-iron at all

three nipple ports.

7.

of

SECTION'S MUST BE DRAWN

WITHIN FOUR HOURS OF THE TIME WHEN

SILASTIC IS FIRST APPLIED. SILASTIC

CURES IN FOUR HOURS AND WILL NOT

FLOW INTO SEAL GROOVES AFTER FOUR

HOURS FROM APPLICATION, REGARDLESS

OF THE PRESSURE APPLIED.

Tie bolts must be applied immediately after

up. If any joint springs apart it must be re-drawn

tight within four hours of the time of application

of the 'Silastic to that joint.

On long boiler assemblies, it may be necessary to

draw

-

up a partial block if the entire boiler is not

ready to be drawn

first application of Silastic. If the block assembly

time extends overnight, the partial block completed

must be drawn

overnight. If a joint springs out, it must be re

drawn tight within four hours of first application

of Silastic to the joint.

7.

From arrangement of sections chart (see Figure

select next section according to code letters on sec

tion.

IMPORTANT

BLED IN PROPER ORDER.

-

up tight within four hours of the

-

up tight before leaving the boiler

-

SECTIONS MUST BE ASSEM

-

UP TIGHT

draw-

8)

-

-

-

SETTING

OF

Fig.

NIPPLES

6

Clean nipple ports and place section on nipples in

rear section. To facilitate assembly, it is advisable

to enter the upper nipple first in its port, then enter

the lower nipples in their respective ports.

8.

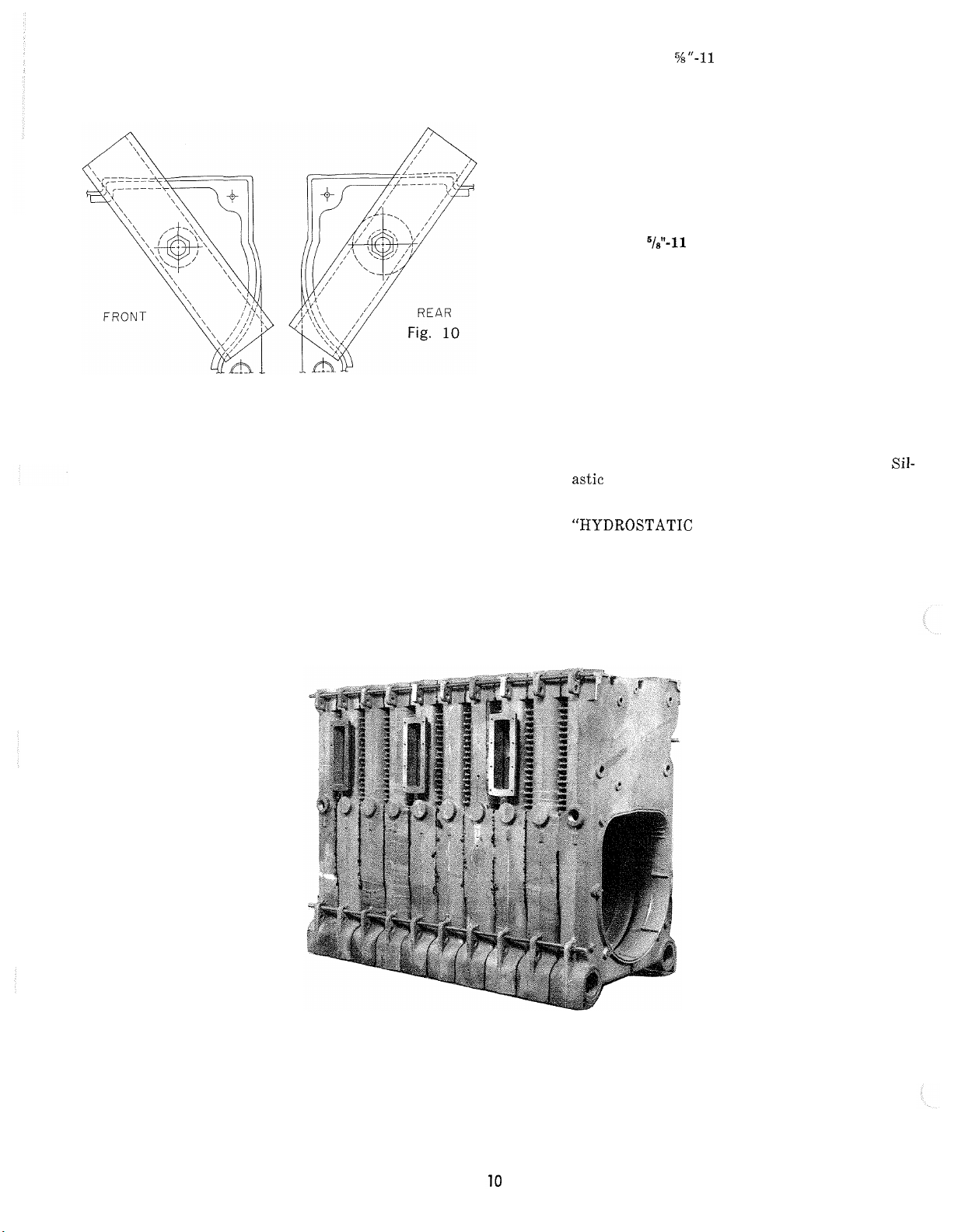

Insert the three

ports in the intermediate section extending them

through the tapped holes in the rear section.

CA.UTION: Care must be exercised to avoid applying

pressure directly on threaded tappings on front and

rear sections with Draw

bly procedures.

Refer to figs.

channel block during assembly procedures.

Place a

upper draw

on each end of the lower draw

nuts and washers. These items are all located in the

Draw

9.

Drive

striking blows as squarely as possible over nipples.

3

"

-

Up Kit. See Figures 9 and 10.

section in place with a heavy block of wood,

%"

draw-up rods through the nipple

-

up channels during assem

9

and 10 for proper placement of

x

12

"

Ig. steel channel on each end of the

-

up rod and an

3

"

x

8%"

1g. steel channel

-

up rods along with

-

APPLICATION

Fig.

OF

7

SEAM

Page 9

V9

SECTION ARRANGEMENT

F - FRONT SECTION w/3"TOP SUPPLY TAPPING

C

-

CENTER SECTION

CT

-

CENTER SECTION w/HEATER OPENING

CX

-

CENTER SECTION w/3"TOP SUPPLY TAPPING

B

-

BACK SECTION w/3" TOP SUPPLY TAPPING

10. DRAW

tightening each draw

that sections are equally spaced, starting with

UP

SECTION SLOWLY AND EVENLY,

-

up rod a little at a time so

low-

draw-up rods.

KEEP NIPPLES A'LIGNED WITH NIPPLE

PORTS. If necessary, tap nipples lightly with

a

!blunt tool or rod to keep nipples from cocking while

-

section are being drawn

SECTION WHEN NIPPLES ARE COCKED. Con

up. DO NOT DRAW UP

tinue tightening draw-up rods equally, periodically

bumping the section with the heavy block of wood

to relieve tension on

meet iron

-to-

11. KEEP DRAW

iron on the ground surfaces.

the draw-up rods, until sections

-

UP ROD THREADS, NUTS AND

WASHERS LUBRICATED with grease or heavy

oil to prevent damage to rods and threads and to

make assembling easier.

12. CONTINUE ASSEMBLING SECTIONS IN

THEIR RESPECTIVE ORDER.

Fig.

8

1.

FOR BOILERS LESS TANKLESS HEATER, REPLACE THE "CT" SECTIONS

NOTES:

WlTH

"C"

2.

3.

SECTIONS.

THE SECTIONS MUST

SHOWN TO INSURE PROPER OPERATION AND ALIGNMENT OF PIPING

WlTH JACKET KNOCKOUTS.

WATER BOILER ONLY. REPLACE "CX" SECTION WlTH

BE

ASSEMBLED ACCORDING TO THE ARRANGEMENT

"C"

SECTION

Be sure to apply the sealant to the groove joints

between adjacent sections as the boiler operates

with a positive pressure in the firebox and products

of combustion will escape between sections unless

the sections are properly sealed. The sealant should

be applied before each section is placed on the

as-

sem'blage.

CHANNEL BLOCK IN POSITION

Fig.

9

Page 10

a. Locate

Boiler Assembly Carton

b.

Locate the Tie-Rod Bundle.

c. Insert tie

V-911

rods must be assembled with tie-rod couplings to

achieve the proper length tie

the coupling is too large to fit through the lugs

on the sections, insert the (2) tie

the lugs before joining with the coupling.

d.

Place a %"-11 hex nut and washer on

of

e. Remove draw-up rods from the section assem

blage.

f. Excess length of tie

they will not extend beyond front and rear

sections. Rods should project equally at each end

to insure proper fit of the jacket.

See Figure

blage. Illustration shows 'boiler equipped with

sections for built

(8)

%"-I1 hex nuts and washers in the

(s)

.

-

rods through lugs on sections. On the

and the V-912, (2) different length tie

-

rod assembly. Since

-

rods through

the tie-rods and

11

turn

until finger tight.

-

rods must be sawed off so

for complete boiler section assem

-

in water heaters.

each

end

-

-

-

13.

After all sections have been drawn up, but before

removing draw

stalled.

-

up rods, the tie-rods must be in

14. If any joint springs apart it must be redrawn with

in four hours of the time of application of the Sil-

astic to that joint.

-

15. Now proceed to part

'%HYDROSTATIC TEST.

3

of this section on page

"

-

12,

SECTION

Fig.

ASSEMBLAGE

11

Page 11

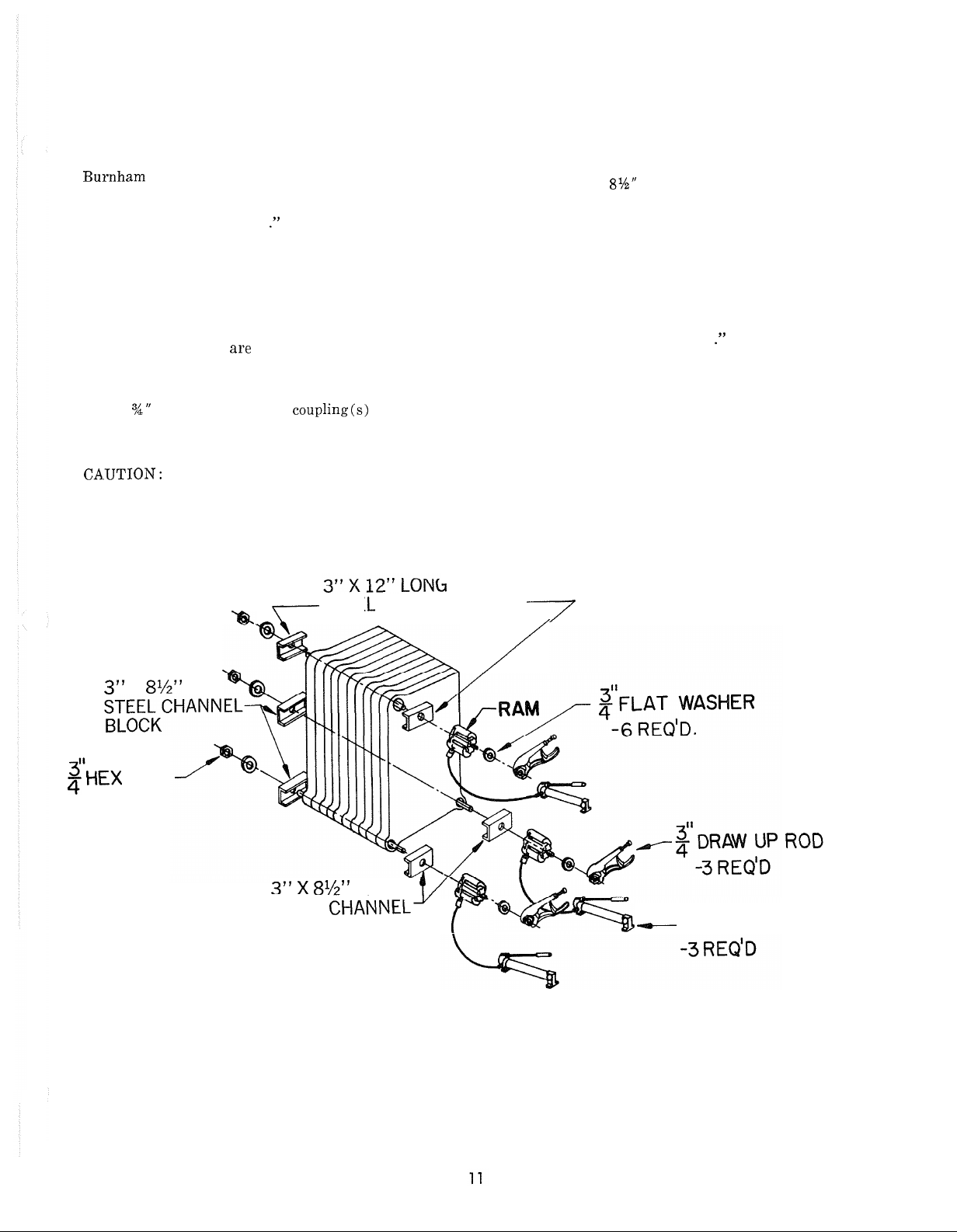

B. Assembly of Sections (Hydraulic Draw-Up)

The entire assemblage may be drawn up at one time

using hydraulic draw

eration is completed within four hours after applica

tion of the sealant.

"

Hydraulic Draw-Up Equipment" is available through

Burnham by ordering part number 6196008.

1.

Repeat steps 1 through 7 under "Assembly of Sec

tions (Manual Draw-Up)

2. Continue assembling sections in their respective or

der until all sections are in the assemblage. Be sure

to apply the sealant to the groove in the ground

joints 'between adjacent sections as the boiler op

erates with a positive pressure in the firebox and

products of combustion will escape between sections

unless the sections

should be applied before each section is placed on

the assemblage.

%"

3. Use

the sections (extra rods and couplings are provided

with hydraulic draw

CA-UTION: Care must be exercised to avoid applying

pressure directly on threaded tappings on front and

rear sections with Draw

bly procedures.

diameter rod (s) and coupling(s) to draw-up

-

up equipment providing the op

."

are properly sealed. The sealant

-

up equipment).

-

up channels during assem

Refer to figs. 9 and 10 for proper placement of

-

-

-

-

-

-

channel block during assembly procedures.

4.

Use two

rod, which is inserted through the upper tappings

and nipple ports. See Figure 12.

5.

Use four

rods, which are inserted through the lower tappings

and nipple ports.

6.

Use hydraulic rams to draw up sections by applying

pressure alternately on the draw

to draw

ground joints.

7.

Repeat steps 13 through 15 under "Assembly of Sec

tions (Manual Draw

12

"

lg. steel channel blocks for the upper

8%"

lg. steel channel blocks for the lower

-

up rods. Continue

-

up until all sections make contact at the

-

Up) ."

-

"HEX

T

-

6

3"

R

X

NUT

E

Q

8l/2"

'D.

LG.

a.

s-

STEE

3"

X

8%''

S

T

E

E

L

CHANNEL^

BLOCK

LL

LVI*J

.L CHANNEL BLOCK

/'

LONG

7

/

-/

ROD

CLAMP

-

PUMP AND

RAM

SET

HYDRAULIC DRAW-UP

Fig.

12

OF

SECTIONS

Page 12

@

HYDROSTATIC TEST -After the boiler sections have

2.

been assembled, it is essential that the boiler be hydrostati-

cally tested before platework, jacket, or piping is installed.

A.

Tankless Heater Installation

If boiler is ordered with

with the gaskets provided. Table

maximum number of heaters permissible per assemblage

and the heater ratings.

tankless heaters, install heaters

I1 on page

13

gives the

D. EXAMINE BOILER CAREFULLY, INSIDE AND OUT

SIDE, to insure against leaks from cocked nipples or

through concealed breakage caused in shipping and han

B. Plug all boiler tappings and fill entirely with cold water. To

protect and safeguard the accuracy of steam or water gauge

supplied, DO NOT INSTALL GAUGE UNTIL AFTER

dling. This precaution is for your protection and will sim

plify handling of necessary replacements and adjustment

claims.

TESTING OF BOILER.

E. After making certain that there are no leaks, drain boiler

C. All completed boilers shall satisfactorily pass the prescribed

and remove plugs for boiler trim and other connections.

hydrostatic test.

1.

STEAM BOILERS: The assembled boiler shall be sub

jected to a hydrostatic test of not less than

@

For boilers with no tankless heaters. proceed to Step

.

-

45

psig.

-

@

4,~oiler Piping. Figure

Hot Water Boiler: The assembled boiler shall be sub-

jected to a hydrostatic test of not less than 1% times the

maximum allowable working pressure.

a. 45 psi mawp

b. 50 psi mawp

c. 70 psi mawp

minimum test pressure is

-

minimum test pressure is 75 psig.

-

minimum test pressure is 105 psig.

68

psig.

-

Install the tankless heater manifolds according to

13.

-

-

-

TWO HEATER MANIFOLD

MINIMUM PIPING RECOMMENDATION FOR

TANKLESS WATER HEATER MANIFOLDS

TYP.

THREE HEATER MANIFOLD

V9

DESCRIPTION

FOUR HEATER MANIFOLD

Fig.

13

FOR JACKET

REMOVAL

NOTES:

1.

IT IS IMPORTANT THAT WATER HEATERS BE CENTRALLY

LOCATED IN BOILER. REFER TO PROPER SECTION

ARRANGEMENT PER FIG.

PRESSURE DROP ACROSS EACH V9-2 TANKLESS

2.

HEATER = 5.25

PSI

(8).

AT

7.5

GPM, FLOW RATE.

Page 13

CONNECT TANKLESS HEATER PIPING AS

SHOWN IN Fig.

Ratings.

THE FOLLOWING GUIDELINES SHOULD BE FOL

LOWED WHEN PIPING THE TANKLESS HEATER:

A. Flow Regulation

If flow through the heater is greater than its rating,

the supply of adequate hot water may not be able to

keep up with the demand. For this reason a FLOW

REGULATOR matching the heater rating should be

installed in the cold water line to the heater. Refer

to Figure

regulator should preferably be located below the inlet

to the heater and a minimum of

inlet so that the regulator is not subjected to excess

temperatures that may occur during

when it is possible for heat to be conducted back

through the supply line. The flow regulator also limits

the flow of supply water regardless of inlet pressure

variations in the range of

B.

Tempering of Hot Water

14.

See Table

14

for piping recommendations. The flow

20

I1

for Tankless Heater

12

"

away from the

"

off" periods

to

125

psi.

required by dishwashers and automatic washers is

possible by piping the hot water from the heater prior

to entering the mixing valve.

be

"

-

C.

D. Hard Water

trapped" by installing it below the cold water

inlet to heater to prevent lime formation in the valve.

Flushing of Heater

All water contains some sediment which settles on the

inside of the coil.

periodically backwashed.

stalling hose bibs as illustrated in Figure

lowing water at city pressure to run into hose bib A,

through the heater, and out hose bib

charge is clear. The tees in which the hose bibs are

located should be the same size as heater connections

to minimize pressure drop.

This is applicable to some city water and particularly

to well water.

cautions are necessary. A water analysis is necessary

and an appropriate water softener installed. This is

not only beneficial to the heater but to piping and fix

tures plus the many other benefits derived from soft

water.

Consequently, the heater should be

This should not be a deterent but pre

The mixing valve should

This is accomplished by in

14

B

until the dis

and al

-

-

-

-

-

Install a mixing valve at the

to avoid risk of burns or scalding due to excessively

hot water at the fixtures.

ing recommendations.

ing valve in accordance with manufacturers instruc

tions.

Installation of a tempering or mixing valve will also

lengthen the delivery of the available hot water by

mixing some cold water with the hot. In addition, sav

ings of hot water will be achieved since the user will

not waste as much hot water while seeking water tem

peratures to his liking. Higher temperature hot water

TANKLESS

BO

I

LER

MODEL

NUMBER OF

I

Adjust and maintain the mix

HEATER RATINGS*

HEATERS INSTALLED

2

tankless heater outlet

Refer to Figure

V9-2

TANKLESS

3

14

for pip

4

3'

FEET

TANKLESS

HEATER

3

I

INLET

1

@

-

-

-

-

-

-

SCHEMATIC

COLD

WATER

SUPPLV

TANKLESS

TEMPERED

HOT WATER

TO FAUCETS

AND SHOWERS

RELIEF LINE AT LEAST

VALVE

HEATER

HIGH TEMP.

WATER FOR

AUTOMATIC

,

FLO~

IN COLD WATER

AHEAD

HEATER

Fig.

14

PIPING

R

E

OF TANKLESS

G

U

L

A

TOR

Ratings are given

continuous

40°F to 140°F with 200°F bol ler water.

in

flow of water heated from

TABLE

gallons per minute

I1

Page 14

@

BOILER PIPING

CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM.

B.

With STEAM HEATING, see Figure

I=B=R Installation and Piping Guide No.

15,

200.

consult

-

CAUTION

IT IS IMPORTANT THAT THE MINI

MUM PIPING REQUIREMENTS AND ARRANGE

MENT'S BE COMPLIED WITH IN ORDER TO IN

SURE MAXIMUM RELIABILITY PERFORMANCE.

-

A. CLEARANCES

have clearances of at least

All steam and hot water pipes shall

%"

from all combustible

construction.

REAR

OF

BOILER

-

-

-

CAUTION- PARTICULAR ATTENTION SHOULD

BE GIVEN TO THE CONSTRUCTION OF THE

HARTFORD LOOP ON STEAM BOILERS. FIGURE

16

ILLUSTRATES THE RIGHT AND WRONG WAY

TO CONSTRUCT THE STEAM HEADER.

V-903 AND V-904

V

-

911 AND V-912

V

-

905 THRU V-907

I

BOILER

MINIMUM PIPING REQUIREMENTS

STEAM BOILERS

V

-

908 THRU V-910

I

PIPE

SIZE

I

RISER

1

Fig.

15

Page 15

HORIZONTAL

ON RISERS

AL SECONDARY SUPPLV

USE REDUCING ELBOW

OR ATTACH EQUALIZER

TO BOTTOM

OF HEADER

EQUAL12

CORRECT PHYSICAL ARRANGEMENT FOR STEAM HEADERS

4

I

ER

HORIZONTALLY

TO EQUALIZER

IN

*

Optional Secondary Supply connections illustrated in dotted lines are to be used only in addition to supply connections shown in

solid lines not in lieu of.

Fig.

16

T

FOR STEAM HEADERS

Page 16

V-908

AND V-

909

k

"--REAR

O

F

V-910

THRU

\

V-912

MINIMUM PIPING REQUIREMENTS WATER

C.

With forced circulation HOT WATER HEATING, see

Figure

Guide No.

1.

17, consult I=

200.

If this boiler is used in connection with refrigeration systems, the boiler must be installed so that

the chilled medium is piped in parallel with the

heating boiler using appropriate valves to prevent

the chilled medium from entering the boiler, see

Figure

Piping Guides.

18.

Also, consult

B

=

R Installation and Piping

I=B=R

Installation and

Fig.

17

BOILER

MODEL

BOILERS

Y&@'

ARE CLOSED

t%kf

AM

-

OFF SHUT- OFF

SHUT

tN

OPEN

WINTER AND OPEN IN mR

CI

WMTER AND CLOSED IN SUMMER

HEATING

BOILER

WATER

CHILLER

r

VALVE

S%P$&Y

RETURN

7

SpRdzh%

n,y

I

1

2.

If this boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air, the boiler piping must be equipped with flow control valves to prevent gravity

circulation of boiler water during the operation of

the cooling system.

3.

If tankless heater is not used and if the boiler is to

be operated in a system which has a large volume

or excessive radiation where low boiler water temperatures may be encountered

ty circulation system, etc.) the use of a boiler water

bypass is recommended to maintain optimum oper

ation.

(i.e. converted gravi-

1

SUPPLY MAIN

TO COMBINED

HEATING

COOLING

SYSTEM

8

[AIR CUSHION TANK

CIRCULATOR

I

RETURN MAIN

FROM

COMBINED

HEATING

COOLING

4

SYSTEM

8

RECOMMENDED PIPING FOR COMBINATION

HEATING

&

COOLING (REFRIGERATION) SYSTEMS

WATER BOILERS

-

Fig.

18

Page 17

Install a pipe tee between the circulator and boiler

return along with a second tee in the supply piping

as shown in Figure 19. The bypass should be the

same size as the supply and return lines with valves

located in the bypass and supply outlet as illustrated

in Figure 19 in order to regulate water flow for

maintenance of higher boiler water temperature.

Adjust the valves to provide 180°F to 200°F water

temperature when the system water temperature is

at normal operating range.

4.

A hot water boiler installed above radiation level

must be provided with a low water cutoff device

as part of the installation.

@

CANOPY/FLUE OUTLET ASSEMBLY

The parts necessary for items A-C are located in the

canopy carton.

CIRCULATOR

TO

SYSTEM

.

DRAIN

COCK

A. Attach the

end of the canopy with

(2)

canopy mounting brackets to the front

(8)

#I0

x

1/2"

hex washer head

sheet metal screws.

B.

Along the groove provided on top of the sections and

across the top of the front section, place

2

"

wide cera-

felt strips and overlap at corners. See Figure 20.

RECOMMENDED BYPASS PIPING

WATER BOILERS

Fig.

19

GROOVES ON SECTION ASSEMBLAGE FOR CANOPY ATTACHMENT

Fig.

20

Page 18

C.

Loosely attach the canopy to the lugs on the front of

the section assembly with the

nuts, and washers. See Figure

D.

Open the flue outlet carton.

E.

Attach the

the flue outlet assembly that mounts against the back cast

ing and canopy.

F.

Secure the flue outlet to the canopy with the

brass hex nuts and flat washers. Attach the flue out

let to the section assembly with the

and flat washers as shown in Figure

G.

Tighten canopy carriage bolts until canopy is secure.

'18"

x

1" adhesive fiber gasket to the surface of

A"

carriage bolts, lock

21.

(4)

&

"

cap screws

22.

(4)

-

-

A"

-

CANOPY SECURED AND SEALED

TO SECTIONS

Fig.

21

@INSTALL FLUE COVER PLATES over cleanout

openings on left side of boiler as shown in Figure

23.

FLUE OUTLET SECURED AND SEALED

TO CANOPY

CLEANOUT COVER

W/

INSULATION

AND REAR SECTION

Fig.

22

7

C.I. SECTION

/

-

A. Locate the cover plates, carriage bolts, nuts aild wash

ers in the 'boiler assembly carton.

B.

Attach the carriage bolts to the top and bottom of the

flue openings with washers and hex nuts to provide

a

fixed stud.

C.

Install flue cover plates over studs with insulation

against boiler and secure with washers and nuts.

-

CLEANOUT COVER ASSEMBLY

Fig.

23

Page 19

Page 20

@

ASSEMBLY OF JACKET

A.

Open jacket carton and jacket hardware package. Unless otherwise stated, all jacket components are fasten

ed with #8

drive sheet metal screws tight until jacket assembly is

complete.

B.

Attach jacket front panel to front section and jacket

back panel to rear section using the (8)

ping screws. See Figure

ing.

C.

Attach each jacket

channels as shown in the jacket detail on the jacket

assembly drawing.

D.

Attach each 'U/J' channel assembly to the bottom of

the front and back panels using

E.

Attach each remaining 'U' channel to the top of the

front and back panel

metal screws.

F.

Attach the jacket top panel to the front panel, back

panel, and upper

x

.%

"

hex head sheet metal screws.

24

for jacket assembly draw-

'J'

channel to one of the jacket 'U'

(4)

('U'

side down) using

'U'

channels.

#10

sheet metal screws.

(2)

Do not

self tap-

sheet

G.

Fasten the black knobs onto the jacket side panels

#

10

-

using the

H.

Use Figure

left side panels.

I.

Install each panel into position by inserting top of pan

el into upper

towards boiler, and sliding panel down into

J.

Remove the knockouts necessary for tankless heater

operation.

K.

Install the remaining side panels on the right side of

the boiler (order is not important).

L.

Attach the 'D4A' Rating Plate and Water Treatment

Caution Plate (both are in the instructions envelope)

to the front panel using sheet metal screws.

M.

Tighten all sheet metal screws.

machine screws.

25

to determine the correct positions of the

'U'

channel, pushing bottom of panel in

'J'

channel.

-

V-9

JACKET

LEFT

SIDE PANEL ARRANGEMENT

Fig.

25

-C

FRONT

I30

I

60

I

OF

LER

LER

Page 21

@

INSTALL BURNER MOUNTING PLATE

A.

With the use of Silastic, secure the rope gasket to the

groove along the mounting plate opening in the front

section.

B. Mount the burner mounting plate assembly to the front

(8)

section with the

&"-I8 x 1" cap screws and flat

washers located in the burner mounting plate carton.

'See Figure

26.

Refer to Oil Burner Installation Instructions and

Burner Specification Manual, for proper installation, fuel

piping, wiring, burner adjustment and service instruc

tions. Using a hacksaw blade or knife, cut hole to the

proper size in the burner plate insulation for receipt of

burner air tube. Burner is mounted on burner mounting

plate using the

(4)

%"-I6

hex nuts and flat washers lo

cated in the burner mounting plate carton.

BURNER MOUNTING PLATE

Fig.

26

A. Apply a

Y4"

bead of Silastic along the groove on the

inside face of the pressure relief door.

B. Mount the pressure relief door onto the rear section

using the

(4)

$6"-18

x

1"

cap screws and washers locat

ed in the canopy carton.

@

INSPECT SEAL

After the platework is in place, a visual inspection

should be made of all sealed joints and repairs made if

necessary.

A

darkened boiler room with a light source in

the combustion space and canopy 'will aid this inspection.

REAR

FRONT

moN

v-9

SERE3

PURPOSE

PING

LOCAT I ON I NCHES

-

I

1

I

(A)

1

(B)

1

(I)

I

(K)

1

V-9

PURPOSE

SIZE

I

I

STEAM

3

1

3

1

14

I

SAFETY VALVE I RELIEF VALVE

I

AUXILIARY TAPPINGS AUXILIARY TAPPINGS

SERIES BOILER

OF

TAPPINGS

Fig.

27

OF

TAPPINGS

I

S

U

P

P

L

Y

RETURN

Born

LER

m0N

I

WATER BOILER

SUPPLY

RETURN

CROWN INSPECTION/WASH-

OUT (SPECIAL ORDER ONLY

FLOAT L.W.C.O.

L.W.C.0

PROBE

TEMP. LIMIT CTRL.

NOT USED

TEMPERATURE/

PRESSURE GAUGE

SUPPLY

I

I

Page 22

@

STEAM BOILERS - INSTALL STEAM TRIM

Items for steam trim are located in the steam trim

ton (except for the separately ordered low water cutoff

and tankless heater control). Figure

tappings for each item. Figure 29 shows front view of an

assembled steam boiler.

A.

Install the gauge glass set.

27

shows the proner

car-

H.

Plug extra tappings.

I.

Attach the Lowest Permissible Water Level Plate to the

jacket front panel as shown in Figure

x

Yz"

sheet metal screws.

SAFETY

24

with the

VALVE

#8

B. Install the low water cut

C.

Install the Pressuretrol to the boiler using the

(2%") syphon and the

ing.

D.

Install the

hex bushing.

E.

Install the steam gauge using the

hex bushing.

F.

Install the safety valve to the back section as shown

in Figure

provided for blow

G.

For boilers with tankless heaters, install the operating

control in an unused tapping through one of the heater

plates.

%"

drain cock using the

28.

The safety valve is installed in the tee

-

off.

%"

-

off piping.

NPT x

%"

FPT hex bush

3"

NPT

%"

NPT

x

94''

x

%"

%"

x

90

-

FPT

FPT

---

I

11

BLOW-OFF

CONNECTION

IBACK

STEAM BOILER-SAFETY VALVE HOOK-UP

Fig.

28

OF

I I

STEAM BOILER - FRONT VIEW

Fig.

29

Page 23

@

WATER BOILERS - INSTALL WATER TRIM

Items for water trim are located in the water trim car

ton (except for the separately ordered low water cutoff).

Figure

ure

A. Install the temperature pressure gauge.

B.

C.

D. Install the

E.

F.

CAUTION:

sion of the iron and steel boiler components, which

to

oxygen absorption in the

ing the boiler. Problems caused by oxygen contamination of

boiler water are not covered by

such as:

27

shows the proper tappings for each item. Fig

31

shows front view of

Install the low water cutoff.

Install the immersion well and mount the aquastat on

to the well.

%"

hex bushing.

Install the pressure relief valve as shown in Figure

Plug extra tappings.

drain cock using the

an

assembled water boiler.

3"

NPT x

%"

FPT

OXYGEN CORROSION

Oxygen contamination of the boiler water

failure.

There are many

1. Addition of excessive make

2.

3.

As

such, any system must be designed to prevent

tem leaks.

Absorption through open tanks and fittings.

Oxygen permeable materials in the distribution system.

fnst place or prevent it from reach

Burnham's standard warranty.

possible causes of oxygen contamination

-

up water as a result of sys

will

cause corro

can

30.

lead

-

-

/-PRESSURE RELIEF

VALVE

-

PtPED

-

-

PRESSURE SAFETY RELIEF

-

-

WATER BOILER

VA

Fig.

30

In order to insure long product life, oxygen sources should

be eliminated. This

ing measures:

1.

Repairing system leaks to eliminate the need for addi

tion of make-up water.

2.

Eliminating open tanks from the system.

3.

Eliminating andlor repairing fittings which allow oxy

gen absorption.

4.

Use of non-permeable materials in the distribution.

@

INSTALL ELEICTRIC WIRING in accordance with

~itional Electric Code and local regulations. A separate

ELECTRICAL CIRCUIT should be run from meter with

a Fused Disconnect Switch in this Circuit.

CANADA

Electrical features of Fuel Burning Equipment

oil).

-

can

be accomplished by taking the follow

Refer to CSA Standard

C22.2

Part

1,

(gas

1990,

and

-

-

-

WATER BOILER

Fig.

-

31

FRONT

VIEW

Page 24

SECTION

IV

OPERATING INSTRUCTIONS

NOTE: It is important, especially in a steam system,

to properly remove the oil and dirt from the system. Fail

ure to clean the system can result in erratic water lines

and surging.

CLEAN HEATING SYSTEM IF boiler water or con

densate return water is dirty or if erratic water lines or

surging exist after a few days of boiler operation.

to step 6 for proper cleaning instructions for steam and

water boilers.

-

A. STEAM BOILERS

As shown in Figure 1, the normal water line is

from the floor. At the start of each heating season

and once or twice during the season try 'SAFETY

VALVE to be sure it is in working condition.

this, fasten wire or cord to lever of valve and pull

-

lever

B. HOT WATER BOILERS. Fill entire heating system

with water and vent air from system. Use the follow

ing procedure on a Series Loop 'System installed as per

Figure 17

1.

standing safe distance away from valve.

:

Close all but one zone valve.

Fill boiler to normal water line.

Refer

41%"

To do

ED. EXCESS PRESSURE

TION, COULD CAUSE DAMAGE TO HEATING 'SYS

TEM.

DO NOT draw water from boiler while in use. When

adding water while boiler is in operation, do not open

supply valve fully but add water slowly.

-

-

-

@SET CONTROLS with burner service switch turned

A. PRESS RED RESET BUTTON on

relay and release.

B. On STEAM BOILERS set cut-in pressure on PA404

Pressuretrol for three

pressure for two (2) pounds. These pressures may be

varied to suit individual ,requirements of installation.

C. On STEAM BOILERS WITH

TIC WATER HEATER'S, set boiler water tempera

ture dial on low limit operating control at 160°F

(max.). Set differential at 10".

D. ON WATER BOILERS WITHOUT

HEATERS, set high limit dial on 'L4006A at 210°F.

This temperature may be varied to suit requirements

of installation.

E. ON WATER BOILERS WITH TANKLES'S HEAT

ERS, set low limit operating control dial

high limit dial 210°F.

minimum of 20 below .high limit setting.

ential at

25".

I'S DANGEROUS, IN ADDI-

R8184 Protecto

(3)

pounds and differential

TANKLESS DOMES

TANKLESS

at

Operating control must

160°F and

,be a

Set differ

-

-

-

-

-

-

2.

Open drain valve on purge fitting.

3.

Open fill valve.

4. Close purge valve.

5.

Open relief valve on boiler.

6. Allow water to run out of purge fitting drain valve

until zone has been purged of air and filled with

water.

7.

Open zone valve to the second zone to be purged,

then close the first. Repeat

zones have been purged but always have one zone

open. At completion open all zone valves.

8.

Close drain valve on purge fitting.

9.

When water discharges from relief valve, release

the lever on the top of the relief valve, allowing

it to close.

10. Continue filling the system until the pressure

gauge is at desired working pressure.

11.

Open purge valve.

A

ON

MUST NOT EXCEED

BOILER IS EQUIPPED ESPECIA'LLY FOR 70

POUNDS MAXIMUM WORKING PRESSURE. IF

BOILER PRESSURE

OF SAFETY RELIEF VALVE, IT MUST BE,RELIEV-

ED TMMEDIATELY AND THE CAUSE OF RELIEF

VALVE FAILURE INVESTIGATED AND 'CORRECT-

HOT WATER SYSTEM THE PRESSURE

50

POUNDS UNLESS THE

EX.CEED'S 'PRESSURE SETTING

th,is step until all

@

ADJUST BURNER according to the Burner Manual.

A. FLAME FAILURE

The V-9 boiler controls operate the burner automatic

ally. If for unknown reasons the burner ceases to

fire and the reset button on the primary control is

tripped, the burner has experienced ignition failure.

Before pressing the reset button, call your service

man immediately.

CAUTION: Do not attempt to start the burner when

excess oil or gas has accumulated in the combustion

chamber, when the unit is full of vapor, or when the

combustion chamber is very hot.

@

TEST CONTROLS

Before installation of the boiler is considered complete

the

operation of the boiler controls should be checked,

particularly the low water cutoff and the high limit con

trol.

A. CHECK OPERATING CONTROL OPERATION.

Raise and lower operating control setting as required

to start and stop burner.

B.

WARNING - CHECK HIGH LIMIT CONTROL

Jumper Operating Control Terminals. Allow burner

to operate until shutdown

considered complete until this check has been made.

REMOVE JUMPER.

by

limit. Installation is not

-

-

-

-

Page 25

C. OHECK LOW WATER CUTOFF control with water

level at normal water line (see Figure 1). Raise operat

ing control setting to allow burner to operate. Open

boiler drain to allow water level to drop to bottom of

sight glass until burner operation is shut down by low

water cutoff.

Close boiler drain and refill to normal water line.

Burner should automatically restart during fill. Reset

operating control.

PROBE AND FLOAT TYPE LOW WATER CUT

OFF DEVICES REQUIRE ANNUAL INSPECTION

AND MAINTENANCE. Refer to step

Instructions for proper cleaning instructions.

D.

CHECK OPERATING CONTROL on boiler equipped

tankless heaters. With burner off, draw hot

with

water until burner starts, then turn off hot water and

check burner shutdown.

0

BOILER AND SYSTEM CLEANING INsTRuc-

TIONS FOR TROUBLE FREE OPERATION.

A

qualified

be

consulted for recommendations

water treatment chemical specialist should

regarding

4

of Service

appropri

ate chemical compounds and concentrations which are

compatible with local environmental regulations.

A. Steam Boilers

the surface

-

-

-

boiling and trickle of overflow for several hours

until the water coming from the overflow is

clear.

d. Stop 'burner and drain boiler in a manner and to

a location that hot water can be discharged with

safety.

e. Refill boiler to normal water line. If water in

gauge glass does not appear to be clear, repeat

steps (a.

longer time.

2.

Low pressure steam boilers such

be maintained with appropriate water treatment com

pounds. Add suitable water treatment compounds

ommended by your qualified water treatment company.

3.

Remove temporary surface blowoff piping, plug tap

ping and reinstall safety valve. Boil or bring

water temperature to 180°F promptly in order to

drive off the dissolved gases in the fresh water.

4.

If unsteady water line, foaming or priming persist,

install gate valve in Hartford Loop'and drain valves

in return main and at boiler and proceed as follows

a.

Connect hoses from drain cocks to floor drain.

Close gate valve in Hartford Loop and open drain

cock in return main. Fill boiler to normal water

level, turn on oil burner and operate boiler

this water level for at least 30 minutes after the

condensate begins to run hot, then turn off burn

er.

Close all radiator valves. Remove all supply

main air valves and plug the openings in supply

main.

blowoff pipe. Continue this slow

thru c.) and boil out the boiler for a

as

the

V-9

series should

as

rec

-

:

at

-

-

-

1.

Oil, greases & sediments which accumulate in a

new boiler and piping must be removed from the

system in order to prevent an unsteady water line

and carry over of the water into the supply main

above boiler. Operate the boiler with steam in the

entire system for a few days allowing the conden

sate to return to the boiler. If the condensate can

temporarily be wasted, operate boiler only for the

length of time it takes for condensate to run clear.

If the latter cannot be achieved or if the condensate

is returned to the boiler, boil out the boiler using

the SURFACE

28.

a. Drain boiler until water is just visible in gauge glass.

Run temporary

connection to

where hot water may be discharged safely. Do not

install valve in this line.

b. Add an appropriate amount of recommended boil out

compound.

c. Start burner and operate sufficiently to boil the

water without producing steam pressure. Boil

for about

ciently to permit a steady trickle of water from

BLOWOFF connection. See Figure

1

W'

pipe line from the surface blowoff

an

open drain or some other location

5

hours. Open boiler feed pipe suffi

b. Draw about

into a container and dissolve into it the appropriate amount of a recommended

pound. Remove safety valve from boiler and

-

-

pour this solution into boiler, then reinstall

safety valve.

c. Turn on burner and keep operating while feeding

water to boiler slowly. This will raise water

level in boiler slowly into supply main and back

through return main, flowing from drain hose at

about 180°F. Continue until water runs clear

from drain hose for at

d.

Stop feeding water to boiler but continue operat

ing burner until excess water in boiler flows out

through supply main and water lowers

steaming) until it reaches normal leveljn boiler.

5

gallons of hot water from boiler

boilout com-

least 30 minutes.

-

(by

Page 26

Turn off burner. Drain boiler. Open all radiator

valves. Reinstall all supply main air valves. Open

gate valve in Hartford Loop.

e. When boiler has cooled down sufficiently

(crown-sheet of

secti0n.s are not too hot to

touch), close the drain cocks at boiler and in re

turn main and feed water slowly up to normal

level in boiler. Turn on burner and allow 'boiler

to steam for 10 minutes, then turn off burner.

Draw off one quart of water from bottom gauge

glass fitting and discard. Draw off another quart

sample and if this sample is not clear, repeat the

cycle of draining the boiler and return main and

refilling the boiler until sample is clear.

f. If the boiler water becomes dirty again at a later

date due to additional sediment loosened up in

the piping, close gate valve in Hartford Loop,

open drain cock in return main, turn on burner

and allow condensate to flow to drain until it

has run clear for at least 30 minutes while feed-

ing water to boiler so as to maintain normal

water level. Turn off burner, drain boiler, open

gate valve in Hartford Loop, then repeat step

above.

5.

Make pH or Alkalinity Test.

'boiler and system have been cleaned and re-

After

filled as previously described, test the pH of the

water in the system. This can easily be done by

drawing a small sample of boiler water and testing

hydrion paper which is used in the same manner as

litmus paper, except it gives specific readings. A

color chart on the side of the small hydrion dispenser gives the reading in pH. Hydrion paper is

inexpensive and obtainable from

gny chemical sup-

ply house or through your local druggist.

should be higher than 7, but lower than

appropriate water treatment chemicals,

to bring the pH within the specified range.

6.

Boiler is now ready

to

be put into service.

B. Water Boilers

1. Filling of Boiler and System

-

General - In a hot

water heating system, the boiler and entire system

(other than the expansion tank) must be full of

water for satisfactory operation. Water should be

added to the system until the boiler pressure gauge

registers normal system design operating pressure.

To insure that the system is full, water should come

out of all

2.

Boiling Out of Boiler and System. The oil and

grease which accumulate in

can

,air vents when opened.

a

new hot water boiler

,be washed out in the following manner.

a. Remove safety relief valve using extreme care to

avoid damaging it.

an

b. Add

appropriate amount of recommended boil out

compound.

c. Reinstall safety relief valve.

d. Fill the entire system with water.

e. Start firing the 'boiler.

f. Circulate the water through the entire system.

g. Vent the system, including the radiation.

h. Allow boiler water to reach operating tempera-

ture, if possible.

i. Continue to circulate the water for a few hours.

j.

Stop firing the boiler.

The pH

11.

if

necessary,

Add

k. Drain the system in a manner and to a location

that hot water can be discharged with safety.

1. Remove plugs from all available returns and

wash the water side of the boiler as thoroughly

as possible, using a high-pressure water stream.

-

m. Refill the system with fresh water.

3.

Add appropriate boiler water treatment compounds

as

recommended by your qualified water treatment company

4.

Make pH or Alkalinity Test.

After boiler and system have been

cIeaned and re

filled as previously descri'bed, test the pH of the

water in the system. This can easily be done by

drawing a small sample of boiler water and testing

with hydrion paper which is used in the same man

ner as litmus paper, except it gives specific read

-

ings. A color chart on the side of the small hydrion

dispenser gives the reading in pH. Hydrion paper is

inexpensive and ,obtainable from any chemical sup

-

ply house or thru your local druggist. The pH

should be higher than 7 but lower than

1

appropriate water treatment chemicals, if necessary,

to bring the pH within the specified range. With

'this lower level of protection, care must be exer

11.

Add

-

cised to eliminate all of the free oxygen in the

system.

5.

Boiler is now ready to be put into service.

If, during normal operation, it is necessary to add

water to this boiler more frequently than once a month

consult a qualified service technician to check your system

for leaks. A leaky system will increase the volume of

make

-

up water supplied to the boiler which can signifi

cantly shorten the life of the boiler. Entrained in make

-

up water are dissolved minerals and oxygen. When the

fresh, cool make

-

up water is heated in the boiler the

minerals fall out as sediment and the oxygen escapes as

a

gas. Both can result in reduced boiler life. The accumu

lation of sediment can eventually isolate the water from

contacting the cast iron. When this happens the cast iron

in that area gets extremely hot and eventually cracks.

The presence of free oxygen in the boiler creates a corro

-

sive atmosphere which, if the concentration becomes high

enough, can corrode the cast iron through from the in

side. Since neither of these failure types are the result

of a casting defect the warranty does not apply. Clearly

it is in everyone's interest to prevent this type of failure.

The maintenance of system integrity is the best method

to achieve this.

Page 27

SECT1

@IMPORTANT

structions if it becomes necessary to add water to the

boiler more frequently than once a month.

(?)GENERAL

nually. Service as frequently as specified in paragraphs

below. While service or maintenance is being done electri

cal power to the boiler must be "off".

FLUE at least once each year, preferably at the end of

the heating season.

CLEAN THE VENT SYSTEM

be checked annually for

Obstructions.

Accumulations of soot.

Deterioration of vent pipe or vent accessories due

to condensation or other reasons.

Proper support

tal runs.

-

See Item

-

Inspection should be conducted an-

:

-

no sags, particularly in horizon-

'7

under Operating In

-

Vent system should

V

SERVICE INSTRUCTIONS

2.

-

-

Using wire or fibre bristle brush clean crown of

boiler and inside of water legs.

E

.

REASSEMBLE BOrLER

CAUTION: DO NOT START THE BURNER UN

LESS CANOPY, SMOKEPIPE, BURNER MOUNT

ING PLATE AND ALL FLUE PLATE'S ARE SEC

URED IN PLAICE.

Install the canopy taking care to align the cerafelt

strips. If strips are damaged replace as needed.

Reinstall the flue outlet onto the canopy and rear

section. Replace adhesive fiber gasket if damaged.

Reinstall smokepipe on flue outlet and secure to

collar with sheet metal screws.

Reinstall burner mounting plate to front section

making sure Flextex rope gasket is in place and

forms gas tight seal. If gasket is damaged, replace.

Bolt burner to burner mounting plate. Inspect gas

ket to assure adequate seal, replace if damaged.

Connect oil line (s) and/or gas line (s)

Reinstall flue plates making sure gasket on each

is in place and forms gas tight seal. If damaged,

all edges of the

Silastic sealant when reinstalled until insulation

can be replaced.

cleanout plates should be sealed with

.

-

-

-

-

Tightness of joints.

Remove all accumulations of soot with wire brush and

vacuum. Remove all obstructions. Replace all deter

iorated parts and support properly. Seal all joints.

CLEAN THE BOILER

1.

Remove the smokepipe as necessary to gain access

to the boiler flue outlet.

2.

Remove the flue outlet from the canopy and rear

section being careful not to damage the adhesive

fiber gasket on the flue outlet.

3. Remove the jacket top and left side panels.

4.

Remove the canopy being careful not to damage the

cerafelt gasket.

5.

Loosen nuts securing the flue cleanout plates and

remove the plates. The insulation should be remov

ed with the plates taking care not to damage the

insulation.

6.

Using a

(36

top and side using horizontal and diagonal strokes

for best results.

CLEAN TOP OF BOILER SECTIONS.

Brush and vacuum the tops of the boiler sections.

1%"

"

handle) clean the flueways. Brush from the

diameter wire or fibre bristle brush

FLUEWAYS

WMAINTENANCE OF LOW WATER CUTOFF

VICES.

PROBE AND FLOAT TYPE LOW WATER CUTOFF

DEVICES REQUIRE ANNUAL INSPECTION AND

MAINTENANCE.

A. PROBE 'TYPE LOW WATER CUTOFF

Although these devices are

tion, the probe is exposed to possible contamination

in the boiler water and subject to fouling.

It

is important to physically remove the probe from

the boiler tapping annually and inspect that probe for

accumulation of scale or sediment.

Follow these steps to ,inspect, clean and/or replace the

probe

:

-

Turn off electric service to the boiler.

Drain boiler water to a level below the tapping for

the probe.

Disconnect the low water cutoff control from the

probe.

Dismount the low water cutoff control from the

probe.

sol.id state in their opera

DE-

-

CLEAN THE FIREBOX

1.

Disconnect fuel line(s) and remove burner and

burner mounting plate.

Unscrew the probe from the boiler tapping.

Inspect that portion of the probe that is exposed

to the boiler water for a scale or sediment buildup.

Page 28

7.

Light deposits may 'be removed by wiping the probe

with a damp cloth. Wiping the probe with a cloth

soaked in vinegar will remove more tenacious lime

deposits. The most stubborn deposits may be re

moved from the probe by using a diluted amount

(3

parts of water to

(H,

PO4

1.

Exercise caution when handling phosphoric acid and

follow the instruction label on its container.

1

part) of phosphoric acid

@Check burner and control at least once a year. See

Item 5 under Operating Instructions for control checks.

See V

-

9 Burner Manual for burner tests and adjustments.

-

@LUBRICATE BOILER COMPONENTS according

to manufacturer's instructions. Generally, this involves

the oil burner and circulator. This

lubricant to use, frequency of lubrication, and points to

lubricate.

'includes the type of

Wire brushing of the probe is not recommended as

the soft platinum guard ring sandwiched between

the ceramic insulators may be damaged. Care must

'be taken not to damage this ring in any way or the

useful life of the probe may be shortened.

Clean the pipe threads of the probe to remove old,

hardened pipe dope and other foreign matter.

Apply a moderate amount of good quality pipe dope

to the pipe threads on the probe. Leaving the two

end threads bare. Do not use PTFE (Teflon) tape.

Screw the probe into the boiler tapping.

Mount the low water cutoff control on the probe.

Reconnect the control to probe wiring.

Fill the boiler to its normal waterline.

Add boiler water treatment compound as needed.

Restore electric service to the boiler.

Fire burner to bring the water in the boiler to a

boil to drive off free oxygen.

:

-

WARNING

TO SERVICE: Follow the low water cutoff check

out procedure on page 25.

BEFORE RETURNING BOILER

@

GENERAL MAINTENANCE CONSIDERATIONS

Keep radiators and convectors clean.

If a hot water radiator is hot at the bottom but not at

the top, it indicates that air has accumulated inside

and should be vented. To vent radiator, hold small

cup under air vent (located near top of radiator), open

vent until water escapes and then close.

If much water is added to system, it is advisable to

heat system to a high temperature and vent again.

This will make less venting necessary during the

winter.

Where an expansion tank is used, make sure that

neither the tank nor its drain pipe is exposed to freez

ing temperatures. Never place valves in piping leading

to or from expansion tank.

Boiler and system cleaning will help assure trouble

free operation. See Item

tions for procedure.

6

under Operating Instruc

-

-

B. FLOAT TYPE LOW WATER CUTOFF

During the heating season, if an external low water

cutoff is on the boiler, the blow off valve should be

opened once a month (use greater frequency where

conditions warrant), to flush out the sediment chamb

er so the device will be free to function properly.

Low water cutoffs and water feeders should be dis

mantled annually 'by qualified personnel, to the extent

necessary to insure freedom from obstructions and

proper functioning of the working parts. Inspect

connecting lines to boiler for accumulation of mud,

scale, etc., and clean as required. Examine all visible

wiring for brittle or worn insulation and make sure

electrical contacts are clean and that they function

properly. Give special attention to solder joints on bel

lows and float when this type of control is used. 'Check

float for evidence of collapse and check mercury bulb

(where applicable) for mercury separation or dis

coloration. DO NOT ATTEMPT TO REPAIR MECH

ANISMS IN THE FIELD. Complete replacemsent

mechanisms, including necessary gaskets and installa

tion instructions, are available from the manufacturer.

IF

BOILER IS NOT USED DURING WINTER

TIME, IT MUST BE FULLY DRAINED TO PRE

VENT FREEZE DAMAGE.

-

-

-

-

-

-

Spray inside surfaces with light lubricating or crank

case oil using gun with extended stem so as to reach

all corners.

With steam boilers, at end of season add sufficient

water to fill boiler to top of water column and leave it

that way until fall when water

to proper level. If at this time boiler water is dirty,

drain water, flush out boiler, and refill with clean

water to prescribed water level.

Always keep the manual fuel supply valve shut off if

the burner is shut down for an extended period of

time.

To recondition the heating system in the fall season

after a prolonged shut down, follow the instructions

outlined in Section IV

2

through

5.

-

shouId ,be drained again

Operating Instructions, Items

-

-

Page 29

SECTION

All

V9

for delivery from Lancaster.

These offices can advise as to the availability of their products and repair parts from a more local source.

Series Repair Parts can be ordered through the nearest Burnham Regional Sales office or Manufacturer's Representative

VI

REPAIR PARTS

BURNHAM CORPORATION - REGIONAL OFFllCE

A.

Burnham Corporation - Central and Western Region C. Hurnham Corporation - Metropolitan Region

E

0.

Box

Lancaster,

(717) 293

Fax:

B.

Burnham Sales Corporation - Northeast Region

19

-

27 Mystic Avenue

Somerville, MA 02145

(617) 625-9735

Fax

PA

-

5836

293-5832

:

625-9736

17604-3079

3079

100 Davidson Avenue

Somerset, NJ 08873

(908) 560

Fax

D.

Burnham Corporation - Mid Atlantic Region

P.O. Box 3079

Lancaster, PA 17604

(71'7) 293-5861

Fax

:

560-9814

:

293-5855

-

9800

Contact Regional Office Indicated for your State

Alabama

Alaska

Arizona

Arkansas

California

Colorado

Connecticut

Delaware

Florida

Georgia

Hawaii

Idaho

Illinois

Indiana

Iowa

Kansas

Kentucky

Louisiana

Maine

Maryland

Massachusetts

Michigan

Minnesota

Mississippi

Missouri

Montana

Nebraska

Nevada

New Hampshire

New Jersey

Mercer County

All other Counties

:

New Mexico

New York

Albany, Fulton, Montgomery, Rensselear,

Saratoga, Schenectady, Schoharie, Warren,

Washington Counties B

Sullivan County

All other Counties C

North Carolina

North Dakota

Ohio

Athens, Belmont, Gallia, Jefferson, Lawrence,

Meigs, Monroe, Washington Counties

All other Counties

Oklahoma

Oregon

Pennsylvania

Rhode

South Carolina

South Dakota

Tennessee

Texas

Utah

Vermont

Virginia

Washington

Washington, D.C.

West Virginia

Wisconsin

Wyoming

Canada

Island