Burnham V9 Brochure

COMI-4ERCIAL HYDRON I C I'I EAT

PRESSURIZED,

WET

otl,cASOnCollBNATroN

BAsE

IIBWtffi

t

Heatiry

V9

SERlEs@@eao

511

Capacities:

to

1115

tlBil

V9SERIES

HOTWATER

ORSTEAM

Maximum

The

boiler

water

working

commercial

that

fits the

BOILER

Pressure:7o

job.

The

Burnham@ V9

iron

boiler represents

finest

designs in

boilers.

The V9 is

through. It is

draft design which

no

need for

combustion

equipment

proper

forced

optimum draft for

combustion, thus

need for high

rear

smoke

only six and one half feet

clearance from floor

The

V9

boiler

installations

is not

In

addition to being

individual

available with factory-assembled

sections or as

aged unit. The

fastened

lifting

will fit

and

inch

80

serve as the

replacing

pad.

A factory fire-test is

on all

All regular

areas are located

allowing

stalled 9" from

The

tankless

provide

and

are also accessed from

side of the boiler.

Available in

output ratings from

MBH,

combination

quality

a wet base, forced

a special base and

chamber or mechanical

to artificially induce

draft. Because

draft unit, it

chimneys. And with

outlet, the V9 requires

sectional construction

makes it

where

easily accessible.

sections the boiler is

a completely

to a steel skid to facilitate

with a fork

through

doorwav. The

boiier

the need for a

packaged

maintenance

V9

the

hot

ratings

the V9

Series

gas/oil

Series cast

one

of the

commercial

through

means

provides

controlled

eliminating the

to ceiling.

ideal for

the boiler room

packaged

truck or crane

a standard 56 x

foundation,

units.

on the left

boiler to be in-

the right sidewall.

water heaters

of 6.0 to 28.5

ten sizes with

377 to 1445

fires

and can be

and

is

there

the boiler is

of vertical

of the

in

use

shipped as

pack-

unit is

skid can

concrete

available

access

side

GPM

the left

gross

gas,

oilor

a

a

P5l

water,

equipped

trim

energy efficient with

efficiency

exceed the efficiency

of ASHRAE

The

difference.

Each

statically

times rated

make

fl

awless.

sections

half

pressure.

ground

mating,

an

sealant is

guarantee

to

and

forced

is

easily

time

gasket

times longer.

Each

quality

which

used in some

Time-proven cast iron

the life of

and

they

the

Added

ity are

pressure

a

equipment. This will reduce

tial damage to the

with either

and controls. The

of up to 84o/o. All

90.1.

bond that

V9

boiler section is

tested

at two

working

sure that

times

to

elastic sealing

gas-tight

draft operation. The

than

materials

section

cast iron nipples

can deteriorate the

contract along with

join

entire section assembly.

achieved with the

the section is

Factory-assembled

are tested

rated

the

The

sections

insure

smooth

and

sealed

used

on all section

a completely

assembly required

applied and

applying conventional

and lasts many

is

competitors' boilers.

the boiler. They expand

ensuring the integriry

safety and

relief

door as standard

15 PSI Steam

steam or water

product

a combustion

sizes

requirements

makes the

hvdro-

and one half

pressure

at one

and one

working

are surface

surface

gas-tight

compound.

sealed

sealant

takes less

joined

then

which will

lncrease

the

longevity

of the

boiler by

resisting

petroleum

based

chemicals,

including

antifreeze

gaskets

nipples last

the sections

system

addition of

breeching or heat

is

to

with

This

joints

for

with

of

longev-

poten-

exchanger

inadvertent

burner.

CAD/CAE

boiler

The V9 is

because

on

computers

and

CAD/CAE

improving

By modeling

puters,

quickly

every design

configuration

surface

tion

tions

without

of different

Specifying

CSI

Institute)

with

computer

program.

program

the

menu

atmospheric

forced

or hot water;

oil.

or combination

fuels;

packaged;

or

gross,

Optional

in

editing features

customized

Consult

representative

Commitment

For

Burnham.

years

tial and

continuing

and

America

in

the event

delayed ignition

speeds,

design

the firsr

it was

designed

to optimize

minimize

passageways.

permit

(Construction

Burnham'

to specify

draft;

single or lead-lag;

net or

all

experience

excellence has

space requirements.

perfects

quality.

Burnham

able

to see the

decision

of the heat

to the location

design

costly

testing

prototypes.

a heating

format is

sofrware

Use

or

steam

gas,

and output ratings

square feet

equipment

CSI specification.

your

local

for details.

your

boiler needs

Burnham has

commercial

commitment

s Boiler

of an

verifies

of its

kind

completely

efficiency

the design

the boiler

engineers

s

Smartspec

to

producing

Company.

on com-

effects

from

transfer

of

combus-

Such simula-

optimization

and re-testing

system

Specifications

made

easy

knockdown

of steam.

menu

and

you

let

Burnham

quality

over 100

boilers.

to

made

us

create

look

quality

of the

while

were

of

exact

in

in

built-

a

sales

to

residenOur

V9

FEATURES

AND

,i

STANDARD

V9 Series

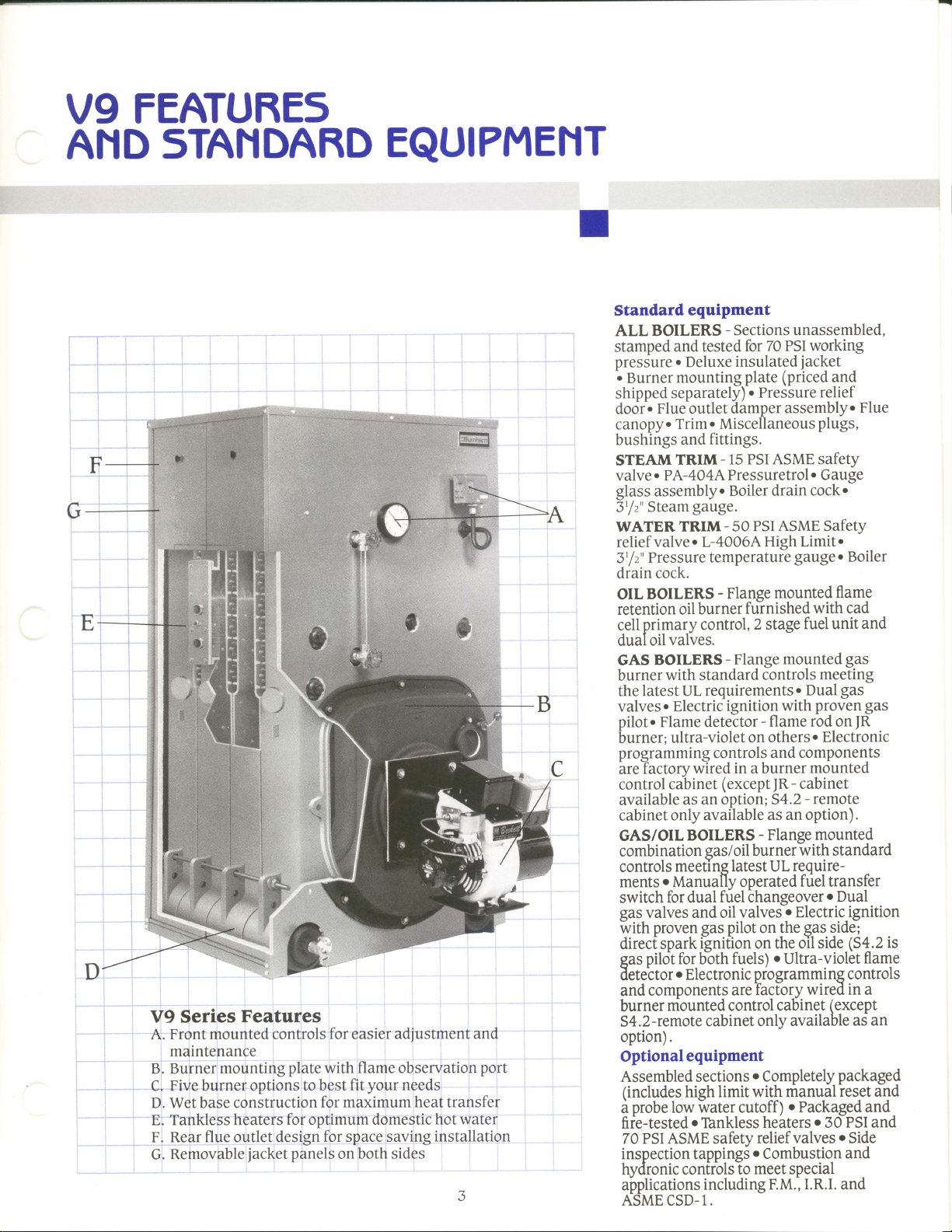

A:'Front

B. Burner

Ci

D. Wet base

E. Tankless

F, Rear flue outlet

G.

Features

mounted

maintenance

mounting

Five

bur"ner

Removable

options:to

construction

heaters for optimum domestic hot

lacket

controls

plate

best

for maximum

design

pa-nels

EQUIPI'4ENT

for

with flame observation

for

space savitrg

onboth

adjustment and

easier

fityour needs

heat

installation

sides

port

transfer

rvater

Standard

ALL BOILERS

stamped and tested

pressure.

i

Burner

shiooed

dooi.

c?noP/

bushings

STEAM

valve

glass

z" Steam

Stf

WATER

relief

31f z"

drain

otl,

retention oil

cell

dual oil valves.

GAS

burner

the

valves.

pilot.

burner, ultra-violet

programming

are Tactorv

control

available

cabinet

GAS/OIL

combination

controls

ments

switch

sas

Vvi*r

direct

gas

ilete^ctor

and

burner

54.2-remote

option).

Optional

Assembled sections

(includes

probe

a

fiie-tested

70

inspection tappingi

nvdronlc controts

a[plications

ASME CSD-1.

equipment

-

Sections unassembled,

Deluxe

mounting

seoaratelv)

Flue outlet

o

Trim.

and

TRIM

.

P A-404A

assembly.

TRIM - 50

valve.

Pressure temperature

cock.

BOILERS

primary

BOILERS

with standard

latest UL

Electric

Flame

cabinet

as an

only

BOILERS

meeting

o

Manuallv operated

fordual

valves and oil

proven

spark

piloi

forbbth

o

Ele

components

niounted control

equlpment

hieh

low fuater cutoff)

ASME

PSI

insulated

lamper assembly.

Miscellaneous

fittings.

-

15 PSI

Pressuretrol.

Boiler drain

gauge.

L-4OO6A

-

Flange

burner

control,2

-

Flange

requirements.

ignition with

detector

controls

in a burner

wired

(except

option; 54.2

available

gas/oil

latest UL

fuel

valvesl

pilot

sas

ienition on the

frlels) o Ultra-violet

n

ctro

are

cabinet only

limit with

o

Tbnkless

safetv

to

including F.M.l

PSI working

70

for

plate (priced

.

PSI

fuinished

on

burner-with

bhaneeover.

ic

o

.

jacket

and

Pressure

ASME safety

High Limit.

stage

controls

-

flame

others.

and

JR

as an option).

-

Flanse

on

pfo

factorv

Completelv

hehters. 5O?SI and

relief valves o Side

Combustio.n

meet

relief

Plugs,

Gauge

cock.

ASME Safety

gauge.

mounted

mounted

the

gram

cabinet

manual

o

specnl

flame

with cad

fuel

unit

meeting

gas

Dual

proven gas

rod

on

Electronic

components

mounted

-

cabinet

-

remote

mounted

standard

require-

fiiel

transfer

Dual

Electric

gas

side]

oil side

nli ng co

wired

(except

available

packaged

reset

Packased and

I.R.I. and

Flue

Boiler

and

gas

fR

ignition

(S4.2

flame

ntrol

in

a

as- an

a-nd

and

is

s

Loading...

Loading...