Page 1

Price - $3.00

INSTALLATION,

OPERA TING AND SERVICE

INSTRUCTIONS FOR

V7 SERIES OIL FIRED BOILER

KNOCKDOWN & P ACKAGED

HEA TING UNITS

These instructions have been

reviewed by ULC and found

suitable for use in the

installation of ULC labeled

As an

ENERGY

STAR® Partner,

Burnham Corporation

has determined that the

V73WR (0.60 GPH),

V74WR (0.80 GPH),

V75WR (0.90 GPH),

and V76WR (1.15 GPH)

meet the ENERGY STAR

guidelines for Energy

efficiency established by the

United States Environmental

Protection Agency (EPA).

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide

Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number Boiler Serial Number Installation Date

_V7 ____-____

®

6_ _ _ _ _ _ _

V-7 Series Boilers.

The ULC label or listed

marking on a product is the

only evidence provided by

Underwriters' Laboratories of

Canada to identify products

which have been produced

under the listing and follow-up

service.

Heating Contractor Phone Number

Address

8142711R24-7/99

1

Page 2

IMPORTANT INFORMATION - PLEASE READ THIS PAGE CAREFULLY

1. THIS BOILER HAS LIMITED WARRANTIES, COPIES OF WHICH ARE PRINTED ON THE BACK COVER OF THIS

MANUAL.

2. THIS BOILER IS SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORING. BOILER CANNOT BE INSTALLED ON CARPETING.

3. ALL BOILERS MUST BE INSTALLED IN ACCORDANCE WITH NATIONAL, STATE AND LOCAL PLUMBING,

HEATING AND ELECTRICAL CODES AND THE REGULATIONS OF THE SERVING UTILITIES WHICH MAY

DIFFER FROM THIS MANUAL. AUTHORITIES HAVING JURISDICTION SHOULD BE CONSULTED BEFORE

INSTALLATIONS ARE MADE.

IN ALL CASES, REFERENCE SHOULD BE MADE TO THE FOLLOWING STANDARDS:

USA BOILERS

A. Current Edition of American National Standard ANSI/NFPA 31, “Installation of Oil Burning Equipment”, for clearances between boiler, vent connector and

combustible material.

B. Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances”, For Chimney require-

ments, type of venting material and clearances between vent connector pipe and combustible materials.

C. Current Edition of American Society of Mechanical Engineers ASME CSD-1, “Controls and Safety Devices for Automatically Fired Boilers”, for assembly and

operations of controls and safety devices.

A. Current Edition of Canadian Standards Association CSA B139, “Installation Code for Oil Burning Equipment”, for recommended Installation Practices.

4. ALL HEATING SYSTEMS SHOULD BE DESIGNED BY COMPETENT CONTRACTORS AND ONLY PERSONS

KNOWLEDGEABLE IN THE LAYOUT AND INSTALLATION OF HYDRONIC HEATING SYSTEMS SHOULD

ATTEMPT INSTALLATION OF ANY BOILER.

5. THE BOILER MUST BE CONNECTED TO AN APPROVED CHIMNEY IN GOOD CONDITION. SERIOUS PROPERTY

DAMAGE COULD RESULT IF THE BOILER IS CONNECTED TO A DIRTY OR INADEQUATE CHIMNEY. THE

INTERIOR OF THE CHIMNEY FLUE MUST BE INSPECTED AND CLEANED BEFORE THE START OF THE HEATING SEASON AND SHOULD BE INSPECTED PERIODICALLY THROUGHOUT THE HEATING SEASON FOR ANY

OBSTRUCTIONS. A CLEAN AND UNOBSTRUCTED CHIMNEY FLUE IS NECESSARY TO ALLOW NOXIOUS

FUMES THAT COULD CAUSE INJURY OR LOSS OF LIFE TO VENT SAFELY AND WILL CONTRIBUTE TOWARD

MAINTAINING THE BOILER’S EFFICIENCY.

6. READ THE LITERATURE ENCLOSED BY THE MANUFACTURER WITH THE VARIOUS ACCESSORY DEVICES.

THESE ACCESSORY DEVICES MUST BE INSTALLED AND USED ACCORDING TO THE RECOMMENDATIONS

OF THE MANUFACTURER.

7. IT IS THE RESPONSIBILITY OF THE INSTALLING CONTRACTOR TO SEE THAT ALL CONTROLS ARE CORRECTLY INSTALLED AND ARE OPERATING PROPERLY WHEN THE INSTALLATION IS COMPLETED.

8. FOR OPTIMUM PERFORMANCE AND SERVICEABILITY FROM THIS BOILER ADHERE TO THE FOLLOWING

RECOMMENDATIONS:

A. DO NOT TAMPER WITH THE BOILER OR CONTROLS. Retain your contractor or a competent serviceman to assure that the boiler is properly adjusted and

maintained.

B. Clean flueways at least once a year - preferably at the end of the heating season to remove soot and scale. Inside of firebox should also be cleaned at the same

time.

C. Have oil burner and controls checked at least once a year or as may be necessitated.

CANADA BOILERS

WARNING

This boiler is designed to burn No. 2 fuel oil only. Do not use gasoline, crankcase drainings, or any oil

containing gasoline. Never burn garbage or paper in this boiler. Do not convert to any solid fuel (i.e.

wood, coal) or gaseous fuel (i.e. natural gas, LP/propane). All flammable debris, rags, paper, wood scraps,

etc., should be kept clear of the boiler at all times. Keep the boiler area clean and free of fire hazards.

WARNING

All boilers equipped with burner swing door have a potential hazard which can cause severe property

damage, personal injury or loss of life if ignored. Before opening swing door, turn off service switch to

boiler to prevent accidental firing of burner outside the combustion chamber. Be sure to tighten swing door

fastener completely when service is completed.

WARNING

High water temperatures increase the risk of burns or scalding injury. Install an automatic tempering

(mixing) valve at the tankless heater outlet to avoid excessively hot water at the fixtures.

2

Page 3

IMPOR TANT

p

g

Before star ting to in st a ll t his o i l b o ile r, r e ad t he se inst r uc t io n s ca r efu lly. K e ep ins t r uc t ions i n legible condition and

osted near oil boiler for reference by o w ne r an d s er v i c e tec hn i cian.

TABLE OF CONTENTS

I. General Information ............................. 3

II. Knockdown Boiler Assembly ............... 7

III. Installation Instructions...................... 12

IV. Operating Instructions ........................ 21

V. Boiler Cleaning .................................. 29

VI. Repair Parts ........................................ 31

Burner Specifications ......................... 46

SECTION I: GENERAL INFORMATION

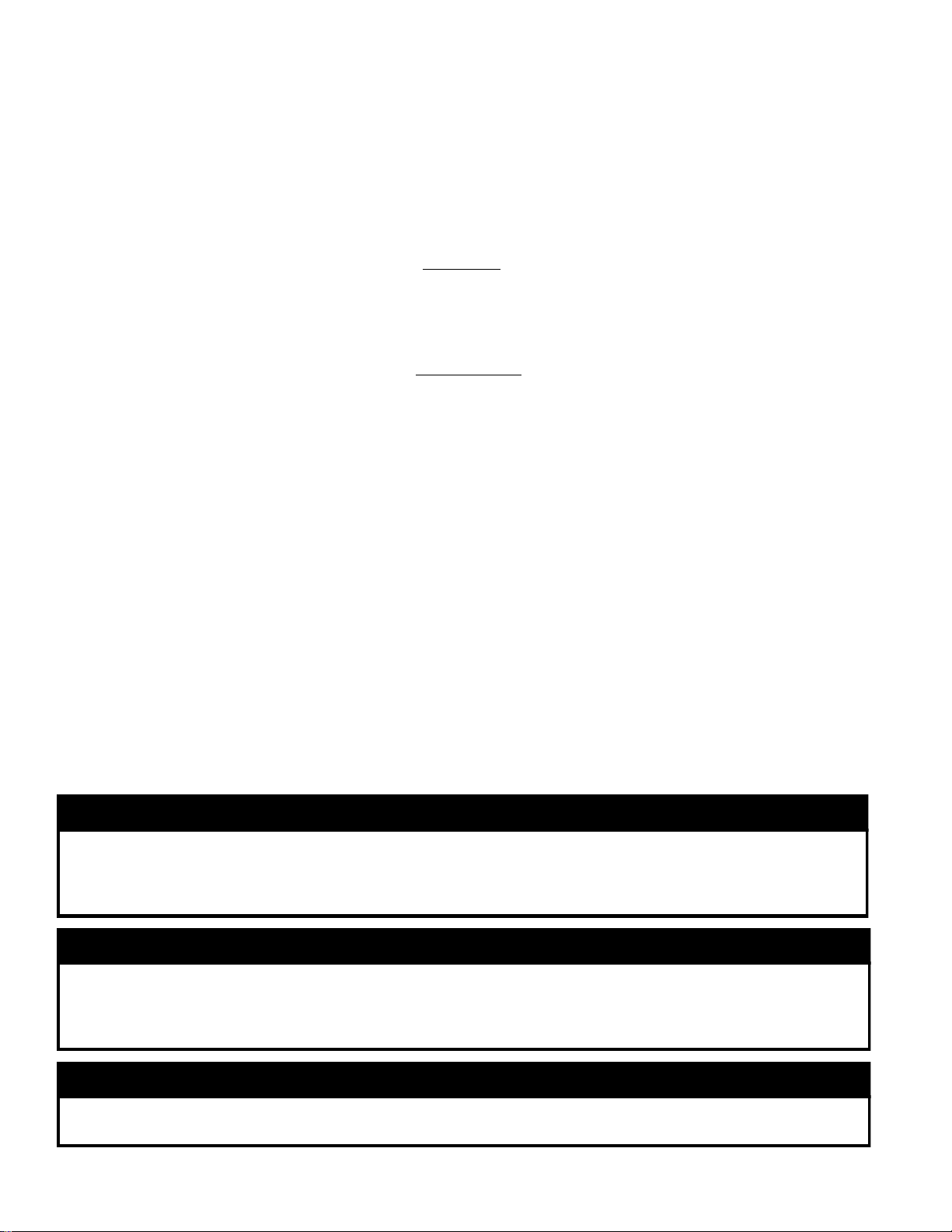

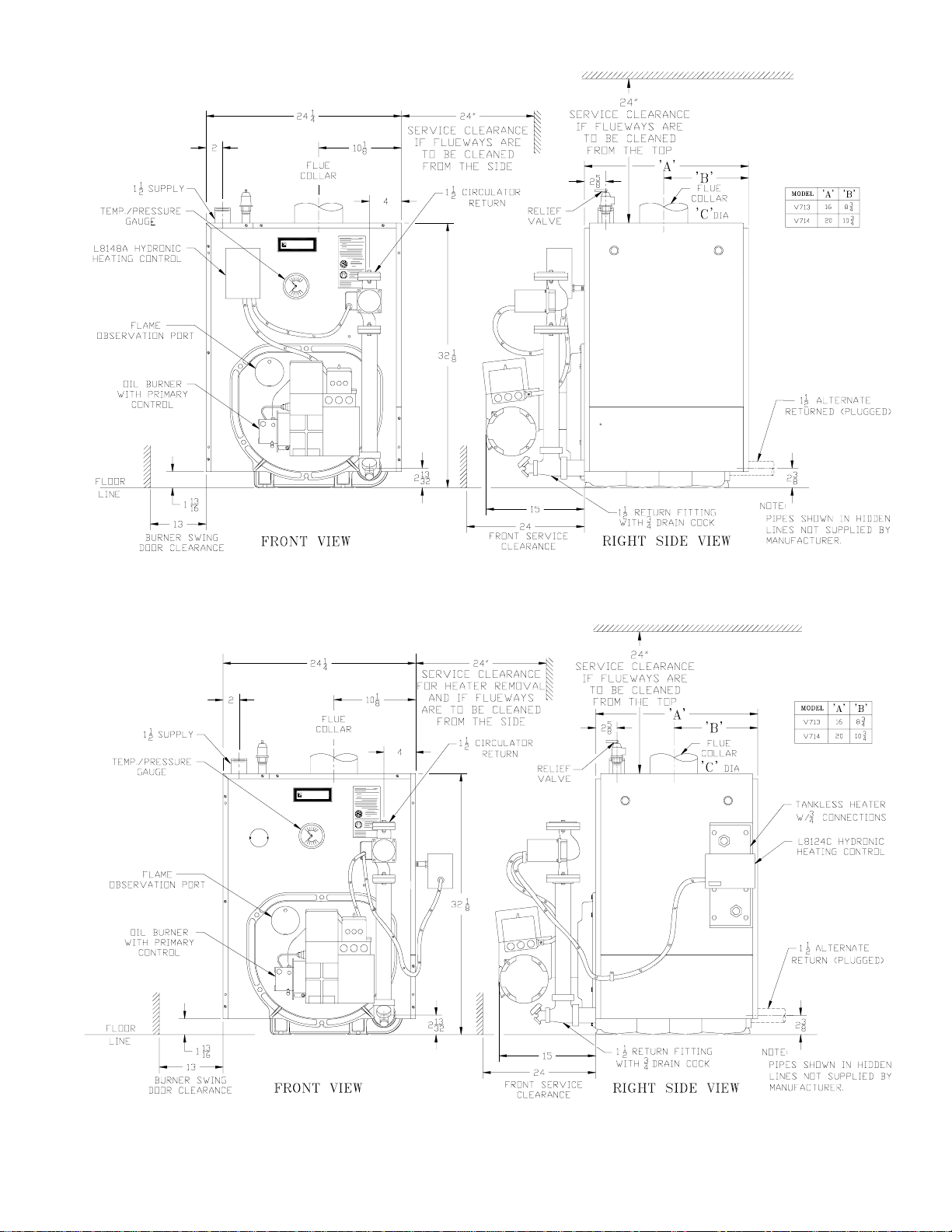

Figure 1A: V72 thru V79 Water Boiler Without Tankless Heater (WB)

TABLE 1: DIMENSIONAL DATA (SEE FIGURES 1A THRU 1E)

Boiler

Model

No.

V72 11-3/8" 6-3/ 8" 5" 8" x 8 " x 15' --- - 10.6 --- - 381

V71 3 16" 8-3/ 4" 6" 8" x 8" x 15' --- - 1 3.5 ---- 524

V73 15-3/8" 8-3/8" 6" 8" x 8" x 15' 10. 8 13.2 13. 8 47 8

V71 4 20" 10-3/ 4" 6" 8" x 8 " x 15' --- - 15.9 --- - 580

V74 19-3/8" 10-3/ 8" 6" 8" x 8 " x 15' 1 3. 5 15.9 1 9.7 575

V75 23-3/8" 12-3/ 8" 7" 8" x 8 " x 15' 1 6. 1 18.5 2 5.6 674

V76 27-3/8" 14-3/ 8" 7" 8" x 8 " x 15' 1 8. 6 21 31. 4 77 3

V77 31 -3/8" 16 -3/8" 8" 8 " x 12" x 15' 21.2 2 3. 6 37. 3 872

V78 35 -3/8" 18 -3/8" 8" 8 " x 12" x 15' 23.8 2 6. 2 43. 1 971

V79 39 -3/8" 20 -3/8" 8" 8 " x 12" x 15' 26.4 2 8. 8 49. 0 1070

Dimensions

Minimum

Chimney S ize

"A" "B" "C"

NO TE: 1. M aximum Working Pressure 15 PS I (S team) and 30 PSI (Water )

2. The V72 , V713 an d V71 4 Boilers are avail abl e as pack aged wa ter boi lers only

3. The V713 and V714 are no t ULC li sted Models

Water Content -

Ga llons

Steam

Boiler

Water

Boiler

3

Heat Transfer

Surface Area -

Sq. Ft .

Steam Boiler

Approximate

Shippin

(LB.)

Weight

Page 4

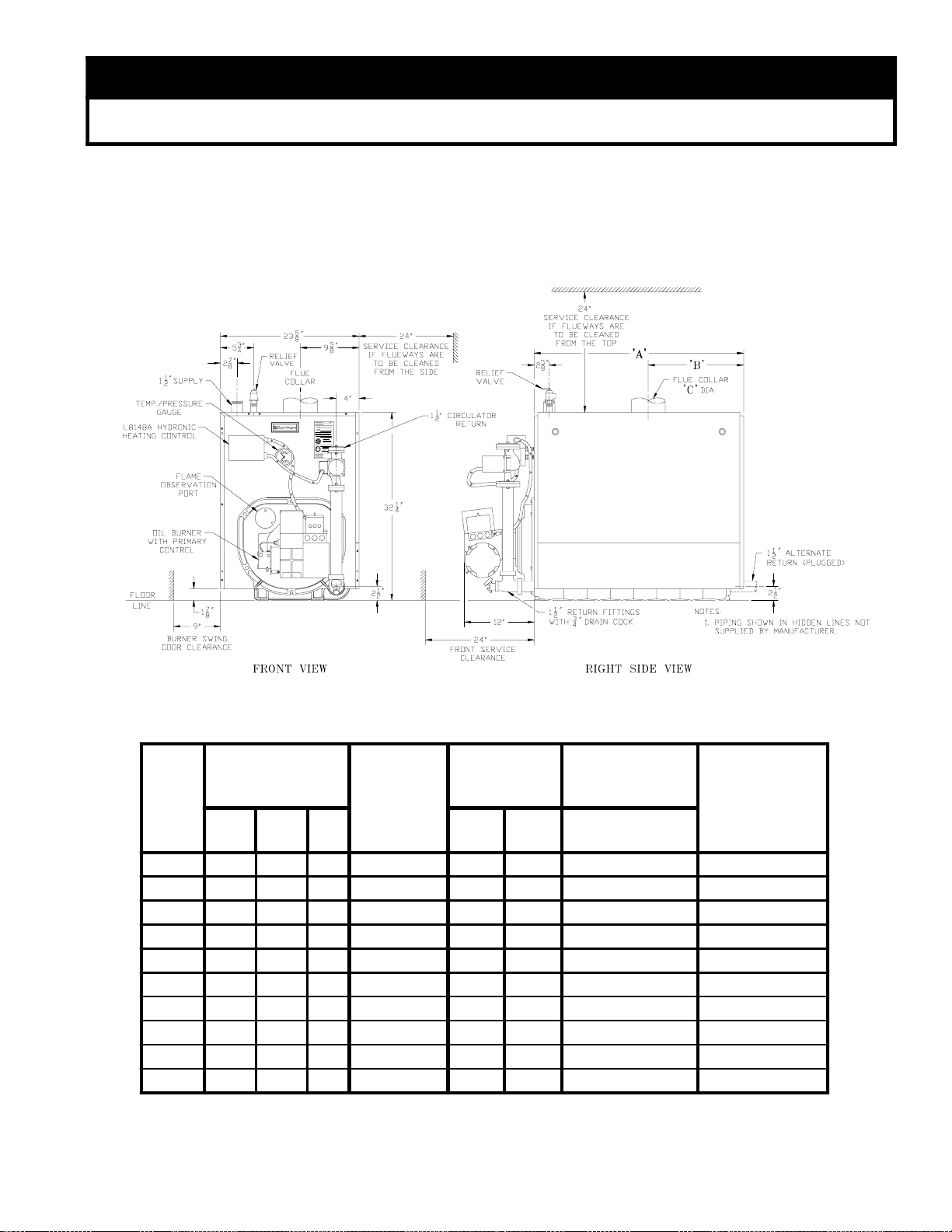

Figure 1B: V73 thru V79 Water Boiler with Tankless Heater (WBT)

Figure 1C: V73 thru V79 Steam Boiler with or without Tankless Heater ("SBT" or "SB")

4

Page 5

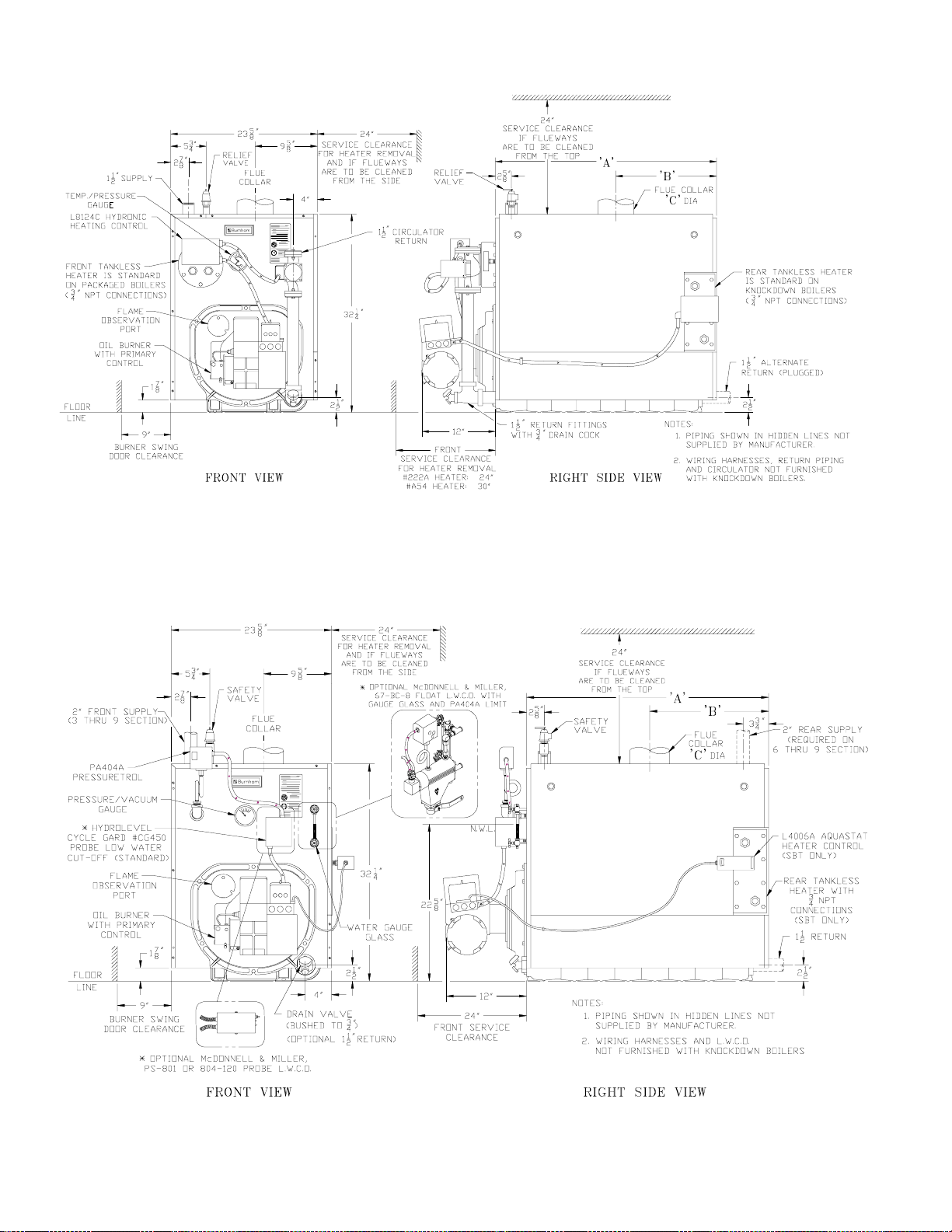

Βυρνηαµ

Figure 1D: V713 and V714 Packaged Water Boiler Less Tankless Heater (WB)

Burnham

Figure 1E: V713 and V714 Packaged Water Boiler with Tankless Heater (WBT)

5

Page 6

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be filed immediately against the carrier by the

consignee. No claims for variances from, or

shortage in orders, will be allowed by the

manufacturer unless presented within sixty (60)

days after receipt of goods.

B. LOCATE BOILER in front of final position before

removing crate. See Figures 1A thru 1E.

1. LOCATE so that smoke pipe connection to

chimney will be short and direct. BOILER IS

SUITABLE FOR INSTALLATION ON

COMBUSTIBLE FLOOR. Boiler cannot be

installed on carpeting.

2. FOR BASEMENT INSTALLATION, provide a

solid base, such as concrete, if floor is not level, or

if water may be encountered on floor around boiler.

3. PROVIDE SERVICE CLEARANCE of at least 24”

on right side of boiler for removal of rear tankless

heater. Provide at least 24” clearance from front

jacket panel for servicing and removal of front

tankless heater (increase to 30" for #A54 heater).

Provide at least 24" clearance from right side of

boiler or top of boiler for cleaning flueways. Boiler

flueways may be cleaned either from the top or

from the side.

4. For minimum clearances to combustible materials.

See Table 2.

C. PROVIDE AIR SUPPLY AND VENTILATION to

accommodate proper combustion. If natural ventilation

is inadequate, provide a screened opening or duct from

the boiler room to the outside. The opening or duct

must be sized so the boiler input will not exceed 4,000

BTUH/Sq. In. of free area. If other air consuming

appliances are near the boiler, the air inlet should be

larger. Consult respective manufacturers.

TABLE 2: Minimum Installation Clearances To

Combustible Materials (Inches)

C

Chimney

BoilerAAboveBFront

V7 6 24 18 6 6

ConnectorDRearESides

NO TE 1: Listed c l ear anc es c om ply with A m er ica n

National Standard ANSI/NFPA 31, Installation of Oil

Burning Equipment.

NOT E 2: V7 Serie s boilers can be ins ta lled in room s

with clea rance s from combus tible ma te rial as listed

a bove. List ed c lea ranc es can not b e red uced for

alcove or clos et installations.

N OTE 3: F or redu ced cle ara nc es to co mbus tib le

mater ial, prot ection mu st be pro vided as desc ribed in

the abo ve ANSI/NF PA 31 standa rd.

6

Page 7

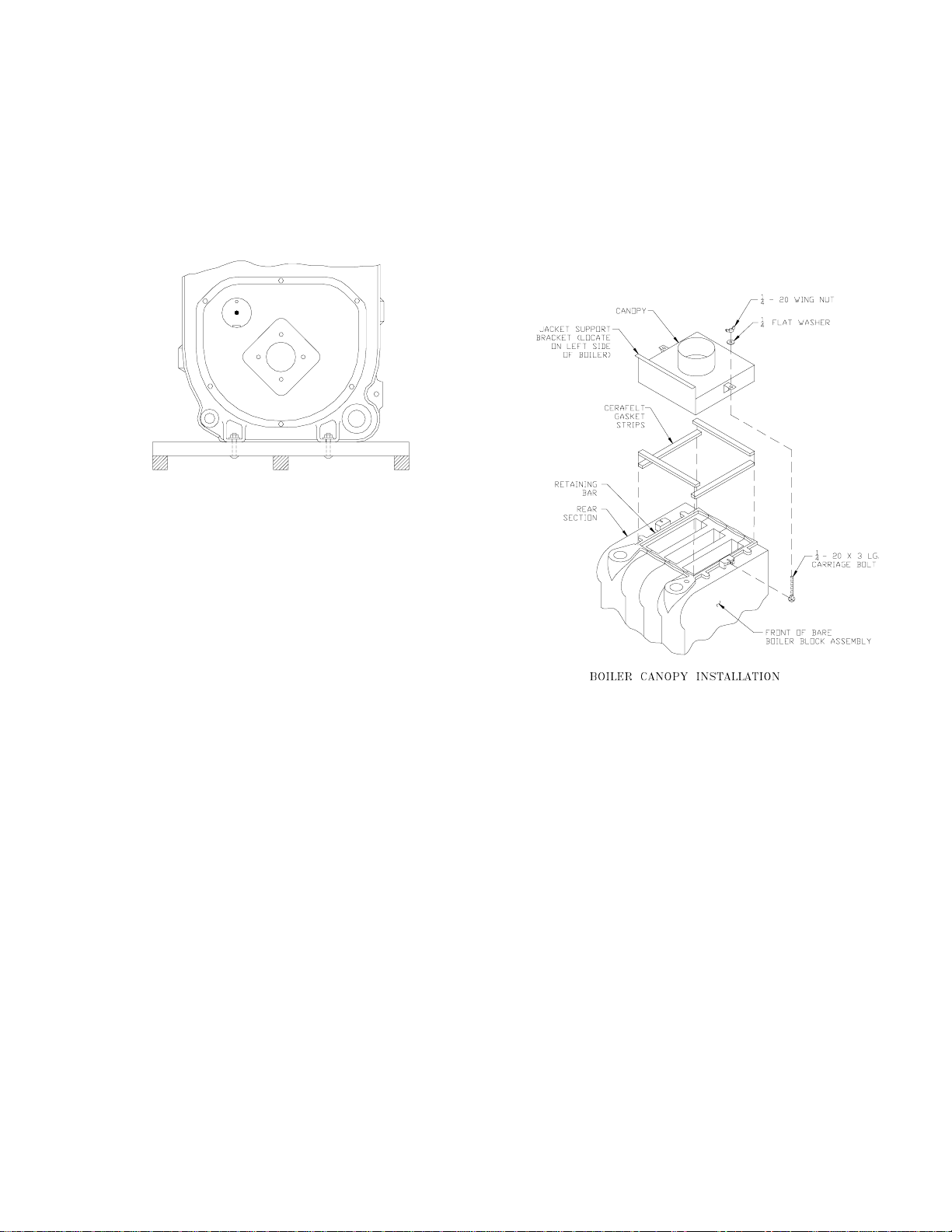

SECTION II: KNOCKDOWN BOILER ASSEMBLY

Note: If Boiler is Packaged Go To Section III

A. REMOVAL OF BARE BOILER FROM SKID

1. Boiler is secured to base with 4 bolts, 2 on front and

2 on rear, see Figure 2. Remove all bolts.

2. Tilt boiler to right and to rear. Using right rear leg

as pivot, rotate boiler 90° in a clockwise direction,

and lower left side of boiler to floor. Tilt boiler and

remove crate skid.

Figure 2

B. MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

C. TEST BOILER FOR LEAKS before installing

controls, trim, and jacket, and before connecting to

heating system.

1. Loosen nuts on tie rods until only finger tight.

2. Install pressure gauge (at least 30 P.S.I. capacity), a

hose to the city water and a valve in the supply

tapping. Plug remainder of tappings.

3. Fill boiler with water and apply a pressure of at

least 10 pounds but no more than 30 pounds gauge

pressure.

4. Examine Boiler carefully inside and outside for

leaks or damage due to shipment or handling.

D. DRAIN WATER FROM BOILER. Remove gauge,

valve and plugs from those tappings to be used. Leave

other tappings plugged or bushed according to Figure

4.

E. INSPECT JOINTS BETWEEN SECTIONS. All joints

are factory sealed. If there are any spaces due to

shipment or handling, seal them with boiler putty.

F. INSPECT FLUE COVER PLATES for tightness. If

loose, retighten mounting hardware. If flue plate or

sealing insulation is damaged repair or replace as

needed.

G. INSTALL AND SECURE CANOPY with cerafelt

gasket and hardware provided to ensure gas tight seal

— see Figure 3.

1. Cut two (2) strips 13 ¾” lg. from the roll of cerafelt

gasket insulation. Place one (1) strip across the top

of the front section and the other across the rear

section as shown in Fig. 3. Place gaskets so as not

to allow any flueway blockage.

2. Cut the remainder of the roll into two (2) equal

pieces. Place each piece along the sides, allowing

the ends to overlap the front and rear pieces.

Do not allow any flueway blockage.

3. Position canopy body within the retaining bar

which borders the flueway openings on top of the

bare boiler block assembly.

Figure 3

IMPORTANT: Jacket support bracket must be

facing left side of boiler — see Figure 3.

4. Secure canopy to boiler with two (2) 1/4" - 20 x 3"

lg. carriage bolts, 1/4" flat washers and 1/4" - 20

wing nuts provided.

H. INSTALL the following steam or water trim that

would be concealed or inaccessible after flush jacket is

installed, see Figure 4 for boiler tapping locations and

usage.

1. STEAM BOILER — Top tappings:

a. Tapping "L" — Install 2" plug in rear section

top supply tapping on boiler sizes V73 thru

V75.

b. Tapping “M” — Install ¾” coupling and ¾” x

8” long nipple into ¾” tapping located next to

front section top supply tapping — all boiler

sizes.

2. WATER BOILER — Top tappings:

a. Tapping “L” — Install 2” plug in rear section

top supply tapping on boiler sizes V73 thru

V79.

7

Page 8

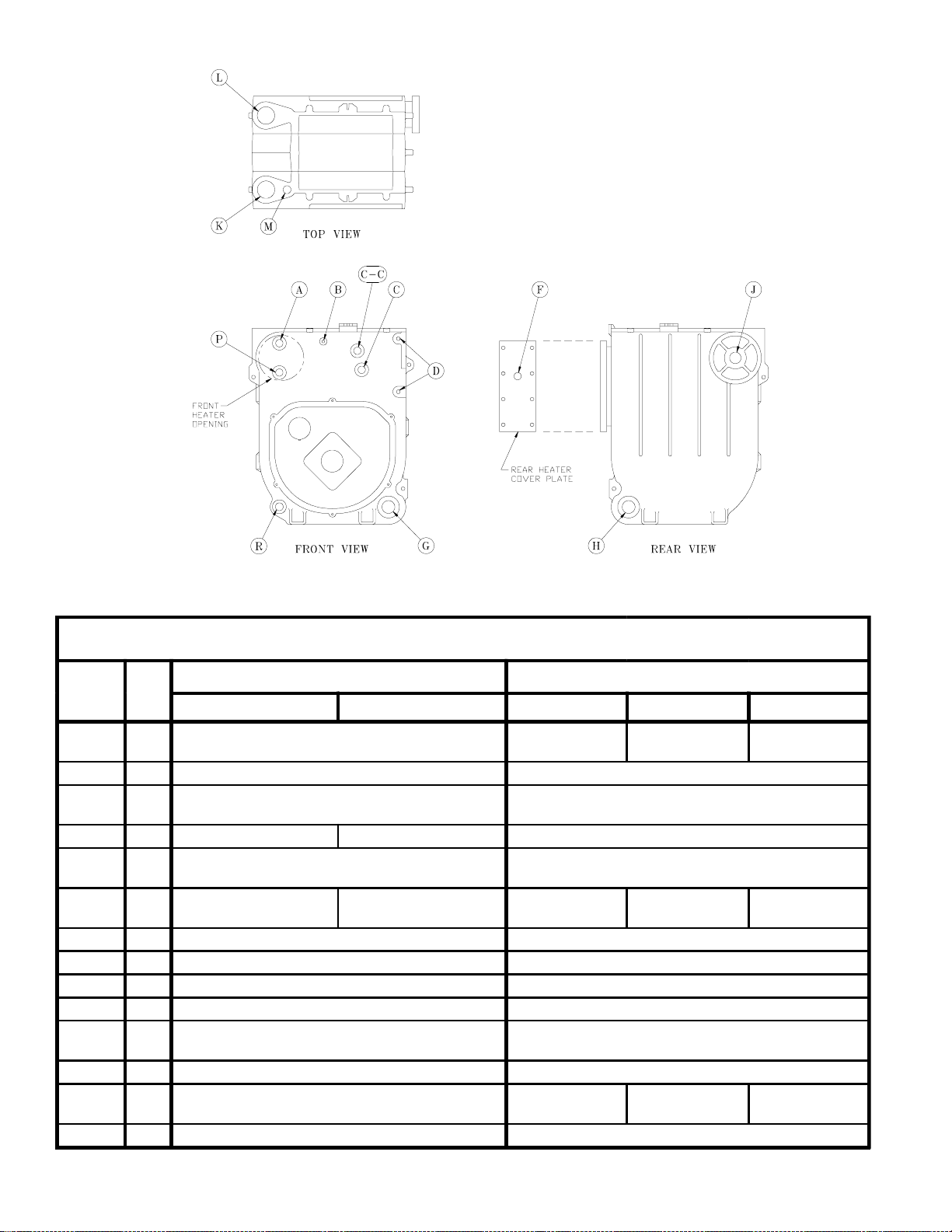

Figure 4: Boiler Tapping Locations and Usage (Knockdown Boilers Only)

g

PURPOSE OF TA PPINGS

Tappin

Location

Size

Steam Boiler Water Boiler

Non-Heater w/Heater Non-Heater Front Heater R ear Heater

A¾"

B ¼" P ressure /Vacuum G au g e Temp era ture/Press ure Gaug e

C¾"

C-C ¾ " Flus h Plug Flus h Plug Flus h Plug

D½"

F ¾" -----

G 1½" B us he d to ¾" for Drainc ock (O ptiona l Re turn ) R eturn

H 1½" R eturn Bus he d to ¾" for Drainc ock (O ptiona l Re turn )

J 1½ " Su rface Blow off - Plugged Flush Plu g

K 2" Front Su pply (3 thru 9 Section) Front Su pply (3 thru 9 Section)

L2"

M ¾" Safety Valve Re lief Valve

P ¾" Au xilia ry Tapping - Plugge d

R ¾" Au xiliary Tapping - Plu gge d Auxiliary Tapping - Plu gge d

Water Gaug e Glass, P ress uretrol, and LWC O (Flo at)

Plug ged, Optional Se co nd Supply (3 thru 5 Section)

PA4 04A Pr es suretrol (Probe LW CO)

Plugg ed (Float LW CO)

Pro be LWC O Std.

Plugg ed (Flo at LW CO)

Water Gauge Glass (Probe LWCO )

L40 06A O p eratin g

Control

R equired Se cond Su pply (6 thru 9 Section )

L8148A

Op era tin g C on trol

-- --- Di sreg ard

Plugge d (3 thru 9 Section)

Aux . Ta pping -

Plugge d

L81 24 C

Op era tin g C on trol

Flush Plug

Flush Plug

Disre gard

Op era tin g C on trol

Aux . Ta pping -

Flush Plug

L81 24 C

Plugge d

8

Page 9

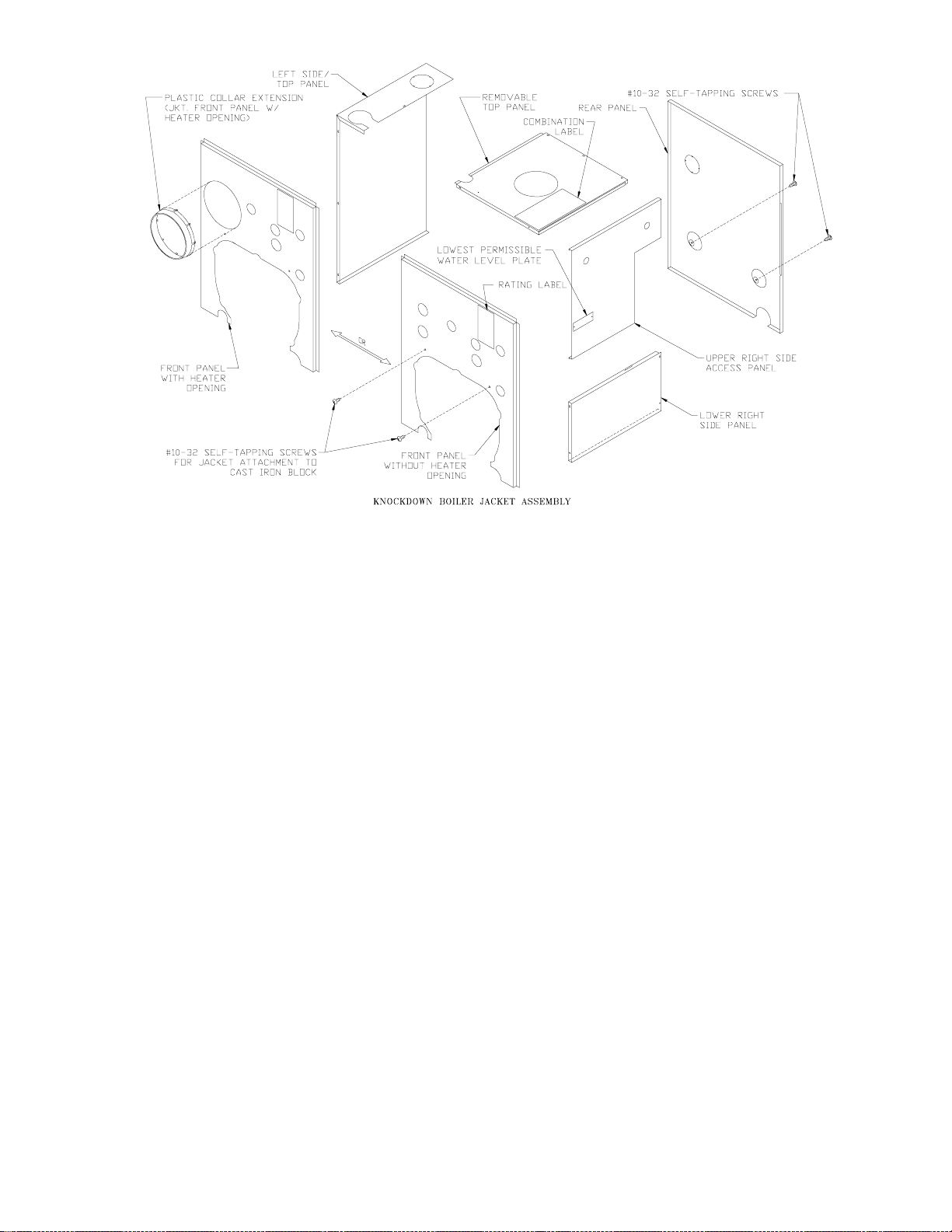

Figure 5: Knockdown Boiler Jacket Assembly

b. Tapping “M” —Install ¾” x 8” long nipple into

¾” tapping located next to front section top

supply tapping — all boiler sizes.

I. INSTALL FLUSH JACKET (See Figure 5).

1. Remove burner swing door mounting plate. Loosen

the bottom bolt three full turns. Remove (5)

remaining 5/16” bolts securing mounting plate to

boiler sections.

Lift up and remove plate.

2. Install rear jacket panel. Align two dimpled holes

on jacket panel with the cast iron lugs. Secure with

two #10 x 3/8” long self tapping screws.

3. JACKET FRONT PANEL

a. Install black plastic collar extension to jacket

front panels with 7-13/16" dia. heater opening.

Engage two (2) retaining tabs over raw edge of

opening. Provide support behind the panel with

one hand while applying pressure on collar to

snap each tab over edge of opening until all

eight (8) tabs are securing collar.

b. Install front jacket panel. Locate two 3/16”

diameter holes on front panel approximately 16”

up from the bottom of the panel and 4½” in

from each side. Align these holes with the

similarly located cast iron lugs on the front

section. Secure with two #10 x 3/8” long selftapping screws.

4. Install jacket left side panel. Fold panel at

perforation keeping insulation inward. Align left

side panel mounting holes with the front and rear

panel holes. Secure with #8 x ½” long sheet metal

screws.

5. Install jacket top panel. Place jacket top panel on

boiler and secure to front, rear and left side panels

with #8 x ½” long sheet metal screws.

6. Install jacket lower right side panel. Align right

side panel mounting holes with front and rear panel

holes. Secure with #8 x ½” long sheet metal screws.

7. Install jacket upper right side access panel. Using

the thumb holes, hold access panel 1” above lower

right side panel. Engage flanges on access panel

with surrounding panels and lower into position

until access panel is resting flush with top panel

and bottom flange is properly locked into position

with lower right side panel.

8. Attach the data labels shipped in the instruction

envelope as follows: (see Figure 5).

a. Place the Rating Label (serialized)

approximately 1/4" below the top edge and

3-1/2" from the right edge of the jacket front

panel as shown. Mark outline of label on jacket

with a pencil. Remove paper backing from

label, realign label with pencil marks and apply

label to jacket by using backing paper to rub

across face of label.

b. Locate the Combination Label (P/N 8142756)

on the front right corner of top panel,

approximately 3/8" from each edge as shown.

Mark the location and apply label in the same

9

Page 10

Figure 6

manner as rating label.

c. On steam boilers, install the Lowest Permissible

Water Level Plate, Form No. 1204 (shipped in

Steam Trim Carton), on the jacket right side

panel. Align the two holes in the plate with the

two 1/8” dia. holes located near the front edge,

in line with the lower sight glass tapping, and

secure with #8 x ½” lg. sheet metal screws.

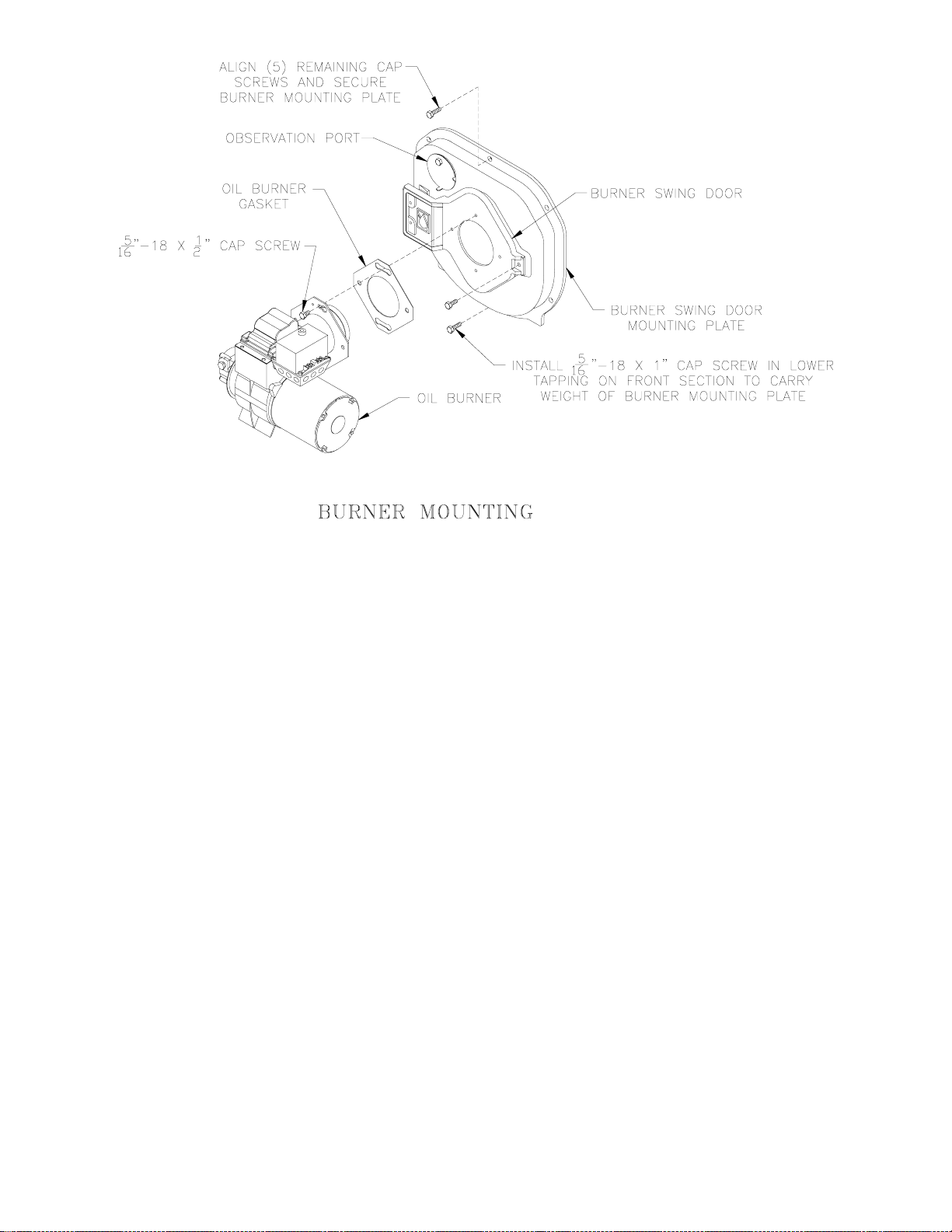

J. INSTALL OIL BURNER (See Figure 6).

1. Check target wall and cerafelt blanket in

combustion chamber. If any damage or movement

occurred during shipment, repair or replace as

needed.

2. Check the burner mounting plate and swing door

insulation pieces for damage and adhesion. If

damaged, replace insulation. If loose, re-attach with

RTV 732 or 736 silicone caulk.

3. Engage bottom slot on burner mounting plate with

matching bolt in bottom tapping of front section.

Align mounting holes and fasten the mounting

plate to the boiler sections with (5) five 5/16” bolts

and washers removed in step 8a. Fully tighten all

bolts.

4. Place burner flange gasket on burner swing door

and thread two 5/16” x ½” long bolts into vertical

set of holes approximately three full turns.

5. Insert oil burner air tube into the opening of the

burner swing door. Align keyhole slot with vertical

set of bolts, engage hex head of bolts and rotate

burner to the left. Install two remaining 5/16” x ½”

long bolts in horizontal sets of holes. Level burner

and fully tighten all bolts.

K. INSTALL STEAM BOILER TRIM AND CONTROLS

(See Figures 1C & 4).

1. Thread the combination pressure/vacuum gauge

into the ¼” tapping. Tighten with wrench applied

to the square shank of the gauge. Do not apply

pressure to the gauge case — this might destroy the

calibration of the gauge.

2. Thread 1½” x ¾” bushing and a ¾” drain cock into

the 1½” tapping located in the lower right corner of

the front casting. Tighten with wrench.

NOTE: Lower rear section tapping “H” is used for

standard condensate return on steam boilers.

3. Thread safety relief valve, as shown in Figure 1C,

into 3/4" coupling and 3/4” x 8” nipple previously

installed in step H. Tighten with wrench.

NOTE: Pipe discharge as shown in Figure 8.

4. Install probe type LWCO if so equipped. Thread

probe into ¾” tapping located on the front section

directly above the protectorelay on the oil burner.

Read the manufacturer’s instructions packed with

the probe LWCO for proper pipe dope application.

DO NOT use Teflon tape on probe threads. Use of

teflon can render the probe LWCO inoperational.

Slip the LWCO control over the probe and clamp in

place. Connect the wire(s) between the probe and

control per the manufacturer’s instructions. Install

10

Page 11

the sight glass using the two ½” tappings to the

right of the probe LWCO.

5. Install float-type Low Water Cutoff, if so equipped.

See Figure below.

a. Install nipples and unions in Tappings D.

b. Mount hardware to low water cutoff body. Install

assembly.

c. Install water gage glass on low water cutoff

assembly's tee fittings.

6. Install Limit Control.

a. Probe LWCO: Install Limit in Tapping A using

¾ NPT x 2" nipple, ¾ NPT elbow, ¾ NPT x ¼

NPT bushing, and syphon. See Figure below

right.

b. Float LWCO: Remove ¼ NPT plug from top of

Low Water Cutoff. Install Syphon and Limit into

this tapping. See Figure below.

7. On units equipped with a tankless heater, install the

aquastat controller well in the ¾” tapping in tankless

heater plate. Slip the bulb of the aquastat into the well

and secure the control in place with the set screw.

8. Connect the field wiring to the pressure limit, the

LWCO, the burner J-box, and from the aquastat

control (if equipped with tankless heater) to the oil

burner primary control's "T-T" terminals. Make the

wiring connections as shown in Figures 17 thru 20.

L. INSTALL WATER TRIM AND CONTROLS

(See Figures 1B and 4).

1. Thread ½” pipe plugs into gauge glass tappings in

the upper right side of front section.

2. Thread ¾” pipe plug in probe low water cut off

tapping (just left of gauge glass tappings).

3. Thread combination pressure/temperature gauge into

¼” tapping. Tighten with wrench applied to the

square shank of the gauge. Do not apply pressure to

the gauge case - this might destroy the calibration of

the gauge.

4. Screw drain valve into 1½” tapping in lower rear

section using 1½” x ¾” bushing (note - lower front

section tapping “G” (see Figure 4) is used for

standard return on water boilers).

5. If CIRCULATOR (not supplied with boiler) is to be

mounted directly to 1½" boiler return tapping "G",

use the piping arrangements outlined in steps a. thru

e. as follows:

a. Thread 1½” x 3” long nipple and 1½” x 90°

elbow into the return tapping and tighten with a

pipe wrench.

b. Thread 1½” NPT x 15” long pipe nipple into the

90° elbow and tighten with a pipe wrench.

c. Thread one of the circulator flange onto the pipe

nipple and tighten with a pipe wrench. Position

flange so that the bolt slots are perpendicular to

the boiler front.

d. Place a flange gasket in the flange groove on the

circulator and mount the circulator on the flange

installed in step 3. Note that this is the return

piping and the flow arrow on the circulator should

point down ê. Fasten circulator with 7/16” nuts

and bolts.

e. Bolt second circulator flange and gasket to the

circulator with 7/16” nuts and bolts.

6. Install pressure relief valve, as shown in Figure 1B,

onto ¾” x 8” nipple previously installed in Step H.

Tighten with wrench.

NOTE: Pipe discharge as shown in Figure 9.

7. On units without a tankless heater, install the control

well into the ¾” tapping located on the front of the

boiler in the upper left corner. Tighten the well and

insert the control’s bulb into the well. Secure the

control with set screw on the control.

8. On units with a tankless heater, install the control

well in the ¾” tapping on the tankless heater plate.

Tighten the well and insert the control’s bulb into the

well. Secure the control with set screw on the control.

9. Connect the field wiring from the circulator to the

control and from the control to the burner J-Box.

Make the wiring connections as shown on Figures 21

and 22.

NOTE: Proceed to Installation Instructions Section

III, step E, to continue.

Float-type Low Water Cutoff Installation

11

Limit Installation for Probe LWCO Equipped

Boilers

Page 12

SECTION III: INSTALLATION INSTRUCTIONS

A. REMOVE CRATE — (Packaged Boilers)

1. Remove all fasteners at crate skid.

2. Lift outside container and remove all other inside

protective spacers and bracing. Remove draft

regulator box and miscellaneous trim bag

containing safety/relief valve, and pipe fittings.

B. REMOVAL OF BOILER FROM SKID

TS-39-26-A

Fig. 7

1. Boiler is secured to base with 4 bolts, 2 on left side

and 2 on right side, see Figure 7. Remove all bolts.

2. Tilt boiler to right and to rear. Using right rear leg

as pivot, rotate boiler 90° in a clockwise direction,

and lower left side of boiler to floor. Tilt boiler and

remove crate skid. Care should be exercised to

prevent damage to jacket or burner.

C. MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

D. INSPECT COMBUSTION TARGET WALL AND

COMBUSTION CHAMBER LINER

1. OPEN FLAME OBSERVATION DOOR AND/OR

BURNER SWING DOOR on front of boiler. Use

flashlight to inspect target wall secured to rear

section with silastic sealant. Inspect ceramic fiber

blanket secured to floor of boiler with water glass

adhesive. If either is damaged they must be

replaced.

E. CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM.

CLEARANCES — Steam and hot water pipes shall

have clearances of at least ½” from all combustible

construction.

1. With STEAM HEATING, see Figure 8. Consult I =

B = R Installation and Piping Guide No. 200.

2. With Forced Circulation HOT WATER HEATING,

see Figure 9. Consult I = B = R Installation and

Piping Guide No. 200.

3. Packaged boilers. Install Safety Valve in Tapping

M. Use ¾ NPT x 8" nipple and ¾ NPT coupling

included in trim bag. Safety Valve must be

installed with spindle in vertical position.

4. Packaged boilers with Probe style LWCO. Install

Limit in Tapping A using ¾ NPT x 2" nipple, ¾

NPT elbow, ¾ NPT x ¼ NPT bushing, and syphon

included in trim bag. See Figure on previous page.

Connect wiring harness from Low Water Cutoff.

See Figure below.

TS-39-126-A

5. If this boiler is used in connection with

refrigeration systems, the boiler must be installed so

that the chilled medium is piped in parallel with the

heating boiler using appropriate valves to prevent

the chilled medium from entering the boiler, see

Figure 10. Also consult I = B = R Installation and

Piping Guides.

6. If this boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air, the boiler piping must be equipped

with flow control valves to prevent gravity

circulation of boiler water during the operation of

the cooling system.

7. Use a boiler bypass if the boiler is to be operated in

a system which has a large volume or excessive

radiation where low boiler water temperatures may

be encountered (i.e. converted gravity circulation

system, etc.).

Remove the circulator and install a pipe tee

between the circulator and boiler return along with

a second tee in the supply piping as shown in

Figure 11. The bypass should be the same size as

the supply and return lines with valves located in

the bypass and supply outlet as illustrated in Figure

11 in order to regulate water flow for maintenance

of higher boiler water temperature.

Set the by-pass and boiler supply valves to a half

throttle position to start. Operate boiler until the

system water temperature reaches its normal

operating range.

Adjust the valves to maintain 180°F boiler water

temperature. Adjust both valves simultaneously.

Closing the boiler supply valve and opening the bypass valve will raise the boiler water temperature

and lower the supply temperature. Opening the

boiler supply valve while closing the by-pass valve

will lower the boiler water temperature and raise

the supply temperature.

8. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of the installation.

12

Page 13

TS-39-17-D

Fig 8: V73 Thru V79 Recommended Boiler Piping For Gravity Return Steam Boiler

TS-39-4-C

Fig. 9: V72 thru V79, V713 and V714 Recommended Boiler Piping for Series Loop Forced Hot Water System

13

Page 14

TS-O-62-B

Fig. 10: Recommended Piping for Combination

Heating & Cooling (Refrigeration) Systems

Water Boilers

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by taking

the following measures:

1. Repairing system leaks to eliminate the need for

addition of make-up water.

2. Eliminating open tanks from the system.

3. Eliminating and/or repairing fittings which allow

oxygen absorption.

4. Use of non-permeable materials in the distribution

system.

5. Isolating the boiler from the system water by installing

a heat exchanger.

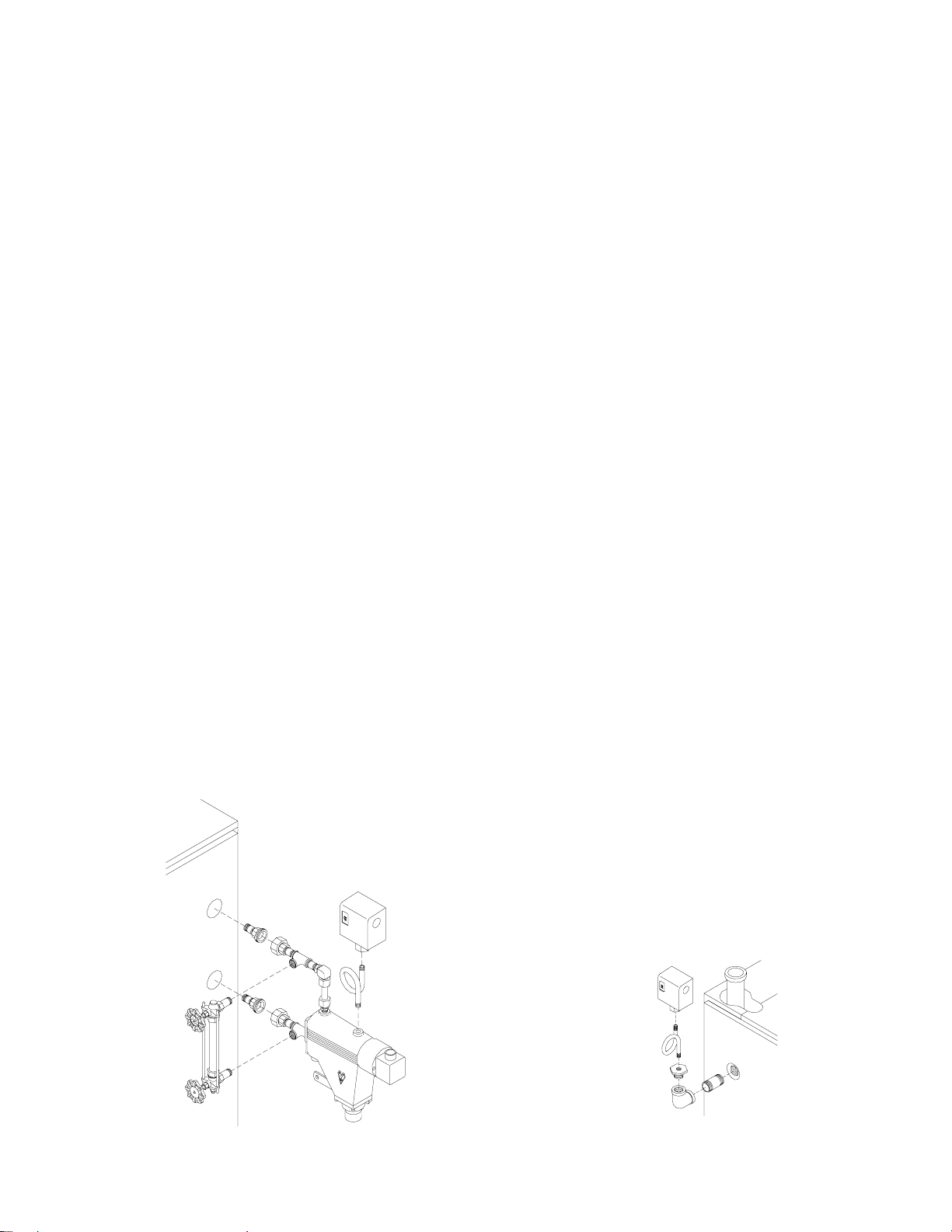

F. CONNECT TANKLESS HEATER PIPING AS

SHOWN IN Figure 12. See Tables 3 and 3A for

Tankless Heater Ratings.

TS-39-7-A

Fig. 11: Recommended Bypass Piping

Water Boilers

CAUTION

Oxygen contamination of boiler water will cause

corrosion of iron and steel boiler components,

and can lead to boiler failure. Burnham's

standard warranty does not cover problems

caused by oxygen contamination of boiler water.

There are many possible causes of oxygen contamina-

tion such as:

1. Addition of excessive make-up water as a result of

system leaks.

2. Absorption through open tanks and fittings.

3. Oxygen permeable materials in the distribution

system.

TS-0-63-B

Fig. 12: Schematic Tankless Heater Piping

THE FOLLOWING GUIDELINES SHOULD BE FOLLOWED WHEN PIPING THE TANKLESS HEATER:

1. FLOW REGULATION — If flow through the

heater is greater than its rating, the supply of

adequate hot water may not be able to keep up with

the demand. For this reason a flow regulator

matching the heater rating should be installed in

the cold water line to the heater. The flow regulator

should preferably be located below the inlet to the

heater and a minimum of 3’ away from the inlet so

that the regulator is not subjected to excess

temperatures that may occur during “off” periods

when it is possible for heat to be conducted back

through the supply line. The flow regulator also

limits the flow of supply water regardless of inlet

pressure variations in the range of 20 to 125 psi.

2. TEMPERING OF HOT WATER — Installation of

an automatic mixing valve will lengthen the

delivery of the available hot water by mixing some

14

Page 15

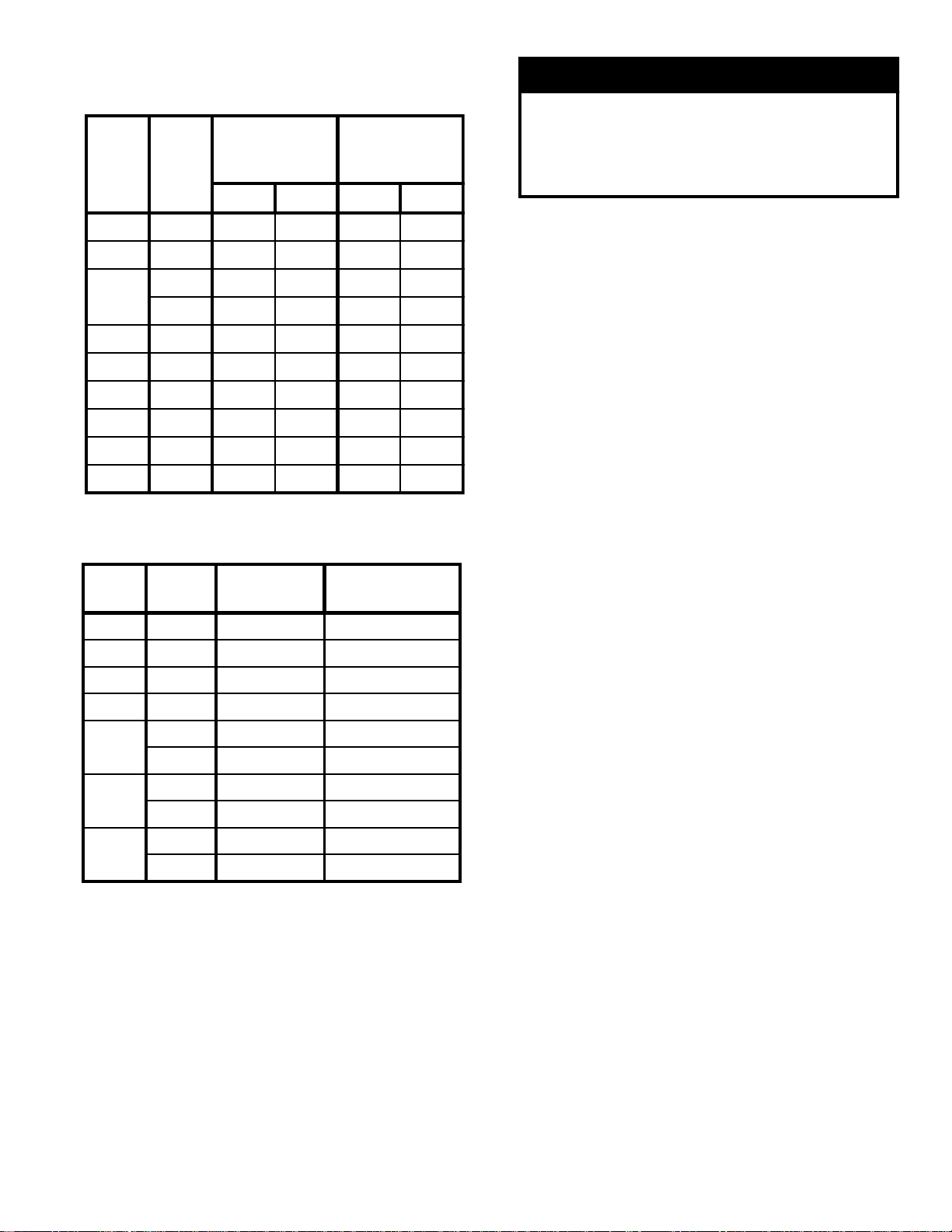

TABLE 3: TANKLESS HEATER DATA: Rear

Mounted Heater on Steam and Water

Boilers

Pressure Drop

thru Heater

(PSI)

Boiler

Model

Heater

No.

Heater Rating

(GPM)

Steam Water Steam Water

WARNING

Install an automatic mixing valve at the tankless

heater outlet to avoid risk of burns or scalding

due to excessively hot water at the fixtures.

Adjust and maintain the mixing valve in

accordance with the manufacturer's instructions.

V713 V1-2 --- 3.25 --- 5.6

V73 V1-2 2.75 3 3.9 4.7

V714

V74 V1-2 3 3.25 4.7 5.6

V75 V1-2 3.25 3.5 5.6 6.4

V76 V1-2 3.75 3.75 7.2 7.2

V77 V1-2 3.75 4 7.2 8

V78 V1-2 4 4.5 8 9.8

V79 V1-2 4 4.5 8 9.8

V1-1 --- 3.5 --- 4.4

V1-2 --- 4 --- 8

TABLE 3A: TANKLESS HEATER DATA: Front

Mounted Heater on Water Boilers

Boiler

Model

V73 222 3 22

V74 222 3.5 22

V75 222 4 30.5

V76 222 4.5 33

V77

V78

V79

Heater

No.

222 4.6 33

A54 5.5 36

222 4.75 40

A54 6 39.5

222 4.75 40

A54 6 39.5

Heater Rating

(GPM)

Pressure Drop

Thru Heater (PSI)

cold water with the hot. This prevents excessive

and possibly scalding hot water at the fixtures. In

addition, savings of hot water will be achieved

since the user will not waste as much hot water

while seeking water temperature to his liking.

Higher temperature hot water required by

dishwashers and automatic washers is possible by

piping the hot water from the heater prior to

entering the mixing valve. The mixing valve should

be “trapped” by installing it below the cold water

inlet to heater to prevent lime formation in the

valve.

3. FLUSHING OF HEATER — All water contains

some sediment which settles on the inside of the

coil. Consequently, the heater should be

periodically backwashed. This is accomplished by

installing hose bibs as illustrated and allowing

water at city pressure to run into hose bib A,

through the heater, and out hose bib B until the

discharge is clear. The tees in which the hose bibs

are located should be the same size as heater

connections to minimize pressure drop.

4. HARD WATER — A water analysis is necessary

to determine the hardness of your potable water.

This is applicable to some city water and

particularly to well water. An appropriate water

softener should be installed based on the analysis

and dealer’s recommendation. This is not only

beneficial to the tankless heater but to piping and

fixtures plus the many other benefits derived from

soft water.

NOTE: STEAM BOILERS

a. During summertime operation, the normal water

line should be raised 1”, from 22-5/8” to

23-5/8” (see Figure 1C) for improved tankless

heater performance.

G. INSTALL SMOKEPIPE — The V7 should be vented

into a fireclay tile-lined masonry chimney or chimney

constructed from type L vent or a factory built chimney

that complies with the type HT requirements of

UL103. The chimney and vent pipe shall have a

sufficient draft at all times, to assure safe proper

operation of the boiler. See Figure 13 for recommended

installation.

1. Install a draft regulator (supplied with boiler)

following the instructions furnished with the

regulator. See Figure 14 for alternate draft regulator

locations.

2. Consider the chimney overall. Chimneys that have

a high heat loss may become less suitable as the

heat loss of the home goes down and the efficiency

of the boiler installed goes up. Most homes have a

chimney appropriate for the fuel and the era in

which the home was built. That may have been a

coal fired or an inefficient oil fired boiler built into

a home without insulation or storm windows. With

increasing fuel prices that home probably has been

insulated and fitted with storm windows so that the

heat loss of the home has been reduced. This

15

Page 16

Fig. 13: Recommended Smokepipe Arrangement

and Chimney Requirements

requires less fuel to be burned and sends less heat

up the chimney.

A new boiler probably has a higher efficiency than

the boiler being replaced. That probably means that

the stack temperature from the new boiler will be

lower than that from the old boiler and with less

room air being drawn up the chimney to dilute the

stack gases. The combination of a large uninsulated

chimney, reduced firing rate, reduced firing time,

lower stack temperature and less dilution air can, in

some cases, contribute to the condensing of small

amounts of water vapor in the chimney. Such

condensation, when it occurs, can cause chimney

deterioration. In extreme cases, condensed water

may be visible on the outside of the breeching or

chimney. In those extreme cases, the chimney may

have to be lined to insulate the chimney and thus

prevent the condensation. The addition of dilution

air into the chimney may assist in drying the

chimney interior surfaces.

A massive chimney on a cold, or exposed outside

wall may have produced adequate draft when it was

fired with a higher input and greater volumes of

heated gases. With reduced input and volume, the

draft may be severely affected. In one instance our

research showed a new chimney of adequate sizing

produced only -.035" W.C. after 30 minutes of

continuous firing at 13.0% CO2. Outside wall

chimneys take longer to heat up and can have .00"

W.C. draft at burner startup. You may have to

consider a special alloy chimney flue liner with

insulation around it and a stabilizing draft cap or

even a draft inducing fan in severe cases.

Fig. 14: Proper and Improper Locations

of Draft Regulator

3. For the same reasons as in (2.) above, heat

extractors mounted into the breeching are not

recommended.

H. INSTALL ELECTRIC WIRING in accordance with

National Electrical Code and local regulations. A

separate ELECTRICAL CIRCUIT should be run from

meter with a Fused Disconnect Switch in the Circuit.

Wiring should conform to Figures 17 thru 23.

CANADA- Refer to CSA standard C22.2 Part 1, 1990,

Electrical Features of Fuel Burning Equipment (Gas

and Oil).

I. FUEL UNITS AND OIL LINES

SINGLE-PIPE OIL LINES - Standard burners are

provided with single-stage 3450 rpm fuel units with

the by-pass plug removed for single-pipe installations.

The single-stage fuel unit may be installed single-pipe

with gravity feed or lift. Maximum allowable lift is 8

feet. See Figure 15.

TWO-PIPE OIL LINES - For two-pipe systems where

more lift is required, the two-stage fuel unit is

recommended. Table 4 (single-stage) and Table 5

(two-stage) show allowable lift and lengths of 3/8-inch

and 1/2-inch OD tubing for both suction and return

lines. Refer to Figure 16.

Be sure that all oil line connections are absolutely

airtight. Check all connections and joints. Flared

fittings are recommended. Do not use compression

fittings or PTFE ("Teflon®") tape.

Open the air-bleed valve and start the burner. For

clean bleed, slip a 3/16" ID hose over the end of the

bleed valve and bleed into a container. Continue to

bleed for 15 seconds after oil is free of air bubbles.

Stop burner and close valve.

16

Page 17

TABLE 4: SINGLE-STAGE UNITS (3450 RPM) -

TWO-PIPE SYSTEMS

Manimum Length of Tubing

Lift "H"

(See Fig. 16)

"H" + "R" (See Figure 16)

3/8" OD

Tubing (3 GPH)

Tubing (3 GPH)

1/2" OD

0' 84' 100'

1' 78' 100'

2' 73' 100'

3' 68' 100'

4' 63' 100'

5' 57' 100'

6' 52' 100'

Figure 15

IMPORTANT

Single-pipe installations must be absolutely

airtight or leaks or loss of prime may result.

Bleed line and fuel unit completely.

7' 47' 100'

8' 42' 100'

9' 36' 100'

10' 31' 100'

11' 26' 100'

12' 21' 83'

13' --- 62'

14' --- 41'

TABLE 5: TWO-STAGE UNITS (3450 RPM) -

TWO-PIPE SYSTEMS

Maximum L e ng th o f Tu bi n g

Lift "H"

(See Fig. 16)

0'

"H" + "R" (See Figure 16)

3/8" OD

Tubing (3 GPH)

Tubing (3 GPH)

93' 100'

1/2" OD

Figure 16

2' 85' 100'

4' 77' 100'

6' 69' 100'

8' 60' 100'

10' 52' 100'

12' 44' 100'

14' 36' 100'

16' 27' 100'

18' --- 76'

17

Page 18

Fig. 17: Wiring Diagram for Steam Boilers with Standard Hydrolevel CG-450 Probe LWCO,

Beckett AFG Burner and Controls, with or without Tankless Heater

Fig. 18: Wiring Diagram for Steam Boilers with Optional McDonnell & Miller PS-801 Probe LWCO,

Beckett AFG Burner and Controls, with or without Tankless Heater

BOILER SEQUENCE OF OPERATION WITH PROBE LWCO

When the thermostat calls for heat, it energizes the cad cell primary control, bringing on the burner. The burner will operate until the

thermostat is satisfied or the limit setting on the high limit is reached. When the high limit control restores the circuit on a drop in

pressure, the burner will start if the thermostat is still calling for heat.

Any of the probe low water cutoffs will shut down the burner after a 10-15 second delay, if the water level in the boiler drops too low.

The Hydrolevel CG-450 and the McDonnell & Miller PS-804-120 low water cutoffs will shut down the burner for 90 seconds every 10

minutes of firing time to allow water level to stabilize. If the water level is too low the burner will not be allowed to restart.

Any of the probe low water cutoffs reset and restart the burner with a call for heat a few seconds after the water is returned to its

normal level.

On burner start, if the cad cell does not see flame within approximately 45 seconds, primary control will lock out on safety and must be

reset before burner can be restarted.

When there is no demand for heat, the operating control will maintain the boiler water temperature at the selected setting for proper

operation of the domestic water heater, if equipped with optional tankless heater.

18

Page 19

TS-39- -C Rev. O

Fig. 19: Wiring Diagram for Steam Boilers with Optional McDonnell & Miller PS-804-120 Probe LWCO,

Beckett AFG Burner and Controls, with or without Tankless Heater

NOTE: The McDonnell Miller low water cut off incorporates a 10 second delay to prevent nuisance burner cut-off due to rapid

water level fluctuations. The LWCO also has a time delay of 15 seconds which allows additional fill time after water touches the

probe. Red LED indicates a low water condition.

Fig. 20: Wiring Diagram for Steam Boilers with McDonnell & Miller #67 LWCO,

Beckett AFG Burner and Controls, with or without Tankless Heater

BOILER SEQUENCE OF OPERATION WITH FLOAT LWCO

When the thermostat calls for heat, it energizes the cad cell primary control, bringing on the burner. The burner will operate until

the thermostat is satisfied or the limit setting on the high limit is reached. When the high limit control restores the circuit on a

drop in pressure, the burner will start if the thermostat is still calling for heat. The low water cut off will shut down the burner if the

water level in the boiler drops too low. The control resets and restarts the burner with a call for heat a few seconds after the water

is returned to its normal level.

On burner start, if the cad cell does not see flame within approximately 45 seconds, primary control will lock out on safety and

must be reset before burner can be restarted.

When there is no demand for heat, the operating control will maintain the boiler water temperature at the selected setting for

proper operation of the domestic water heater, if equipped with optional tankless heater.

19

Page 20

Fig. 21: Wiring Diagram for Water Boilers with Beckett AFG Burner and Controls, without Tankless Heater

SEQUENCE OF OPERATION

A call for heat by the thermostat energizes the L8148A control which in turn energizes the R4184D primary control to turn on the

burner. If burner ignites within approximately 45 seconds and the cad cell sees flame, the burner will continue to operate until the call

for heat is satisfied or the setting of the high limit is reached. The circulator will operate as long as the thermostat is calling for heat. If

the thermostat is not satisfied and the high limit is reached, the circulator will continue to operate, and the burner will stop until the high

limit is closed by a drop in boiler water temperature.

Fig. 22: Wiring Diagram for Water Boilers with Beckett AFG Burner and Controls, with Tankless Heater

SEQUENCE OF OPERATION

A call for heat by the thermostat energizes the L8124C control which in turn energizes the R4184D primary control to turn on the

burner. If burner ignites within approximately 45 seconds and the cad cell sees flame the burner will continue to operate until the call

for heat is satisfied. The circulator will also operate when the thermostat calls for heat if the boiler water temperature is up to the setting

of the low limit in the L8124C control. If boiler water temperature is below the low limit setting the burner will operate but the circulator

will not, giving preference to the domestic hot water demand.

On call for heat by the thermostat the burner will continue to operate until the thermostat is satisfied or the setting of the high limit is

reached. If the thermostat is not satisfied when the high limit is reached the burner will stop but the circulator will continue to operate

until the thermostat is satisfied. Any time the boiler water temperature drops below the setting of the low limit the burner will be

energized in order to maintain domestic water temperature.

20

Page 21

SECTION IV: OPERATING AND SERVICE INSTRUCTIONS

WARNING

All boilers equipped with burner swing door have a potential hazard which can cause severe property

damage, personal injury or loss of life if ignored. Before opening swing door, turn off service switch to

boiler to prevent accidental firing of burner outside the combustion chamber. Be sure to tighten swing door

fastener completely when service is completed.

A. ALWAYS INSPECT INSTALLATION BEFORE

STARTING BURNER.

. FILL HEATING SYSTEM WITH WATER.

B

NOTE: It is important, especially in a steam system,

to properly remove the oil and dirt from the system.

Failure to clean the system can result in erratic water

lines and surging.

CLEAN HEATING SYSTEM IF boiler water or

condensate return water is dirty or if erratic water lines

or surging exist after a few days of boiler operation.

Refer to step "N" for proper cleaning instructions for

steam and water boilers.

1. STEAM BOILERS — Fill boiler to normal water

line. Refer to Figure No. 1C.

2. HOT WATER BOILERS. Fill entire heating system

with water and vent air from system. Use the

following procedure on a series loop or multi-zoned

system installed as per Figure 9, to remove air from

system when filling:

a. Close isolation valve in boiler supply piping.

b. Isolate all circuits by closing zone valves or

balancing valves.

c. Attach a hose to bib cock located just below

isolation valve in boiler supply piping.

(Note - Terminate hose in five gallon bucket at a

suitable floor drain or outdoor area).

d. Starting with one circuit, open zone valve.

e. Open bib cock.

f. Open fill valve (make-up water line should be

located directly above isolation valve in boiler

supply piping).

g. Allow water to overflow from bucket until

discharge from hose is bubble free for 30

seconds.

h. Open zone valve to the second zone to be

purged, then close the first. Repeat this step

until all zones have been purged, but always

have one zone open. At completion, open all

zone valves.

i. Close bib cock, continue filling the system until

the pressure gauge reads 12 psi. Close fill valve.

(Note - If make-up water line is equipped with

pressure reducing valve, system will

automatically fill to 12 psi. Leave globe valve

open).

j. Open isolation valve in boiler supply piping.

k. Remove hose from bib cock.

C. CHECK CONTROLS, WIRING AND BURNER to be

sure that all connections are tight and burner is rigid,

that all electrical connections have been completed and

fuses installed, and that oil tank is filled and oil lines

have been tested.

D. LUBRICATION — Follow instruction on burner and

circulator label to lubricate, if oil lubricated. Most

motors currently used on residential type burners

employ permanently lubricated bearings and thus do

not require any field lubrication. Water lubricated

circulators do not need field lubrication.

Do not over-lubricate. This can cause as much trouble

as no lubrication at all.

E. SET CONTROLS with burner service switch turned

“OFF”.

1. SET ROOM THERMOSTAT about 10° above

room temperature.

2. PRESS RED RESET BUTTON on primary control

(R4184D/R8184G) and release.

3. On STEAM BOILERS, set cut-in pressure on

PA404 pressuretrol for three (3) pounds and

differential pressure for two (2) pounds. These

pressures may be varied to suit individual

requirements of installation.

4. On STEAM BOILERS WITH TANKLESS

DOMESTIC WATER HEATERS, set boiler water

temperature dial on L4006 operating control at

190°F (max.). Set differential at 10°.

5. On WATER BOILERS WITHOUT TANKLESS

HEATERS, set high limit dial on L8148 at 210°F.

This temperature may be varied to suit

requirements of installation.

6. On WATER BOILERS WITH TANKLESS

HEATERS, set operating control dial (low limit) on

L8124 at 190°F and high limit dial at 210°F.

Operating control (low limit) must be a minimum

of 20° below high limit setting. Set differential at

25°.

21

Page 22

NOTICE

Burner-specific references in the following instructions pertain to the Beckett AFG, supplied as

standard equipment. For optional burners, Riello R40 and Carlin EZ-1HP and 102CRD -3, consult

Table 6 at the rear of this m anual for specifications, th e instruction booklet shipped with the

burner, and the appropriate Supplemental Instructions shipped w ith the boiler:

Burnh am P art Num ber

Supplem ent al Inst ructio ns for: Riello R40

Carlin EZ-1HP

Carlin 102CRD-3

8142761

8142759

8142760

F. REMOVE GUN ASSEMBLY

1. Items to be checked are nozzle size, type, and

angle; head size (and setting on MD(V1)head); gun

setting; and positioning of electrodes. This

informations is shown in Figures 23 and 24 and

Table 6 (at rear of manual).

2. Reinstall gun assembly.

G. ADJUST OIL BURNER BEFORE STARTING.

1. SET BURNER AIR BAND AND AIR SHUTTER,

see Table 6 at rear of manual..

2. OPEN ALL OIL LINE VALVES.

3. Attach a plastic hose to fuel pump vent fitting and

provide a pan to catch the oil.

4. REMOVE GAUGE PORT PLUG from fuel pump

and install pressure gauge capable of reading at

least 150 PSI.

5. OPEN FLAME OBSERVATION DOOR on front

of boiler.

H. START OIL BURNER.

1. Open vent fitting on fuel pump.

2. TURN ‘ON’ BURNER service switch and allow

burner to run until oil flows from vent fitting in a

SOLID stream without air bubbles for

approximately 10 seconds.

3. Close vent fitting and burner flame should start

immediately.

I. ADJUST OIL PRESSURE.

1. Locate oil pressure adjusting screw and turn screw

to obtain 140 PSI pressure (100 PSI for V74R

only).

2. DO NOT REMOVE PRESSURE GAUGE until

later.

J. OTHER ADJUSTMENTS

1. ADJUST THE AIR BAND AND/OR AIR

SHUTTER.

Adjust air supply by loosening lock screws and

moving the air shutter and if necessary the air band.

Refer to Table 6 for preliminary settings.

2. ADJUST THE COMBUSTION HEAD.

V72 thru V77; V713 and V714:

"L1" and "F" head burners have a fixed head which

is non-adjustable. To check combustion head

location refer to Figure 24.

V78 & V79:

“V1” (variable) head burners have the ability to

control air by moving the head either forward or

back.

Loosen the adjusting plate assembly hold down

screw. Slide the head and plate to the required

firing rate setting as shown in Figure 24. Tighten

the screw and knurled nut.

It might be necessary to move the head forward or

back one position at a time to optimize the smoke

and CO2 readings. See Figure 24.

3. ADJUST DRAFT REGULATOR for a draft

of — .02” (water gauge) over the fire after chimney

has reached operating temperature and while

burner is running.

4. READJUST AIR BANDS on burner for a light

orange colored flame while the draft over the fire is

—.02”. Use a smoke tester and adjust air for

minimum smoke (not to exceed #1) with a

minimum of excess air. Make final check using

suitable instrumentation to obtain a CO2 of 11.5 to

12.5% with draft of —.02” (water gauge) in fire

box. These settings will assure a safe and efficient

operating condition. If the flame appears stringy

instead of a solid fire, try another nozzle of the

same type. Flame should be solid and compact.

After all adjustments are made recheck for a draft

of —.02” over the fire.

(Non-Burnham Drawing

Copy from other Manual)

Fig. 23: "F" Head Electrode Positioning and Gun

Setting (Beckett AFG)

22

Page 23

(Non-Burnham Drawing,

Copy from LE Manual, 81433010R4, Page 13, without

"Figure 12A, 12B, 12C and 12D"; sample enclosed)

Fig. 24: "L1" and "V1" Head Electrode Positioning and Gun Setting (Beckett AFG)

5. TURN “OFF” BURNER and remove pressure

gauge. Install gauge port plug and tighten. Start

burner again.

6. CAD CELL LOCATION AND SERVICE

The burner is supplied with a cadmium sulfide

flame detector mounted at the factory, mounted on

the bottom of the ignitor. See Figure 25. To service

cad cell or to replace the plug in portion, swing

open the ignitor. After service is complete, be sure

to fasten down the ignitor.

7. FLAME FAILURE

The V7 boiler controls operate the burner

automatically. If for unknown reasons the burner

ceases to fire and the reset button on the primary

control has tripped, the burner has experienced

ignition failure. Before pressing the reset button

call your serviceman immediately.

Figure 25: Cad Cell Location

23

Page 24

K. CHECK FOR CLEAN CUT OFF OF BURNER.

1. AIR IN THE OIL LINE between fuel unit and

nozzle will compress when burner is on and will

expand when burner stops, causing oil to squirt

from nozzle at low pressure as burner slows down

and causing nozzle to drip after burner stops.

Usually cycling the burner operation about 5 to 10

times will rid oil line of this air.

2. IF NOZZLE CONTINUES TO DRIP, repeat step

K.1.. If this does not stop the dripping, remove

cutoff valve and seat, and wipe both with a clean

cloth until clean, then replace and readjust oil

pressure. If dripping or after burn persist replace

fuel pump.

L. TEST CONTROLS.

WARNING

Before installation of the boiler is considered

complete, the operation of the boiler controls

should be checked, particularly the primary

control and high limit control.

1. Check thermostat operation. Raise and lower

thermostat setting as required to start and stop

burner.

2. VERIFY PRIMARY CONTROL SAFETY

FEATURES using procedures outlined in

Instructions furnished with control (See back of

control cover) or instructions as follows:

CHECKOUT PROCEDURE

FOR SERVICEMAN ONLY

a. Check wiring connections. Close line switch.

Check power at control.

PRIMARY RELAY TEST

b. Disconnect cad cell leads (f-f). Reset safety

switch.

c. Set controller to call for heat. Burner should

start.

d. Jumper F-F terminal within 15 to 30 seconds.

Burner should run.

e. Remove F-F Jumper. Burner shuts down in

approximately 15 to 60 seconds.

f. If burner operates as described, relay is good. If

not, install new relay.

CAD CELL TEST

g. Open line switch. Clean cell face and see that

cell is securely in socket. Reconnect leads. Reset

safety switch.

h. Close line switch. If burner starts and runs

beyond safety switch cut-out time, cell is good.

If not, install new cell.

3. WARNING — Check High Limit Control —

Jumper Thermostat Terminals. Allow burner to

operate until shut-down by limit. Installation is not

considered complete until this check has been

made.

REMOVE JUMPER.

4. Check low water cut off control with water level at

normal water line (see Figure 1C). Raise thermostat

setting to allow burner to operate. Open boiler drain

to allow water level to drop to bottom of sight glass

until burner operation is shut-down by low water

cutoff.

Close boiler drain and refill to normal water line.

Burner should automatically restart during fill.

Lower thermostat setting.

5. Check operating control on boiler equipped with

tankless heaters. With burner off, draw hot water

until burner starts, then turn off hot water and

check burner shut-down.

IF CONTROLS DO NOT MEET REQUIREMENTS

OUTLINED IN PARAGRAPH L., REPLACE

CONTROL AND REPEAT CHECK-OUT

PROCEDURES.

M. MAINTENANCE OF LOW WATER CUTOFF

DEVICES

IMPORTANT

Probe and float type low water cut-off devices

require annual inspection and maintenance.

1. PROBE TYPE LOW WATER CUT-OFF

Although these devices are solid state in their

operation, the probe is exposed to possible

contamination in the boiler water and subject to

fouling.

It is important to physically remove the probe from

the boiler tapping annually and inspect that probe

for accumulation of scale or sediment.

Follow these steps to inspect, clean and/or replace

the probe:

a. Turn off electric service to the boiler.

b. Drain boiler water to a level below the tapping

for the probe.

c. Disconnect wiring connections between the low

water cutoff control and the probe.

24

Page 25

d. Dismount the low water cutoff control from the

probe.

e. Unscrew the probe from the boiler tapping.

f. Inspect that portion of the probe that is exposed

to the boiler water for a scale or sediment

buildup.

g. Light deposits may be removed by wiping the

probe with a damp cloth. Wiping the probe with

a cloth soaked in vinegar will remove more

tenacious lime deposits. The most stubborn

deposits may be removed from the probe by

using a diluted amount, 3 parts of water to 1

part of phosphoric acid (H

2PO4

).

CAUTION

Exercise caution when handling phosphoric acid

and follow the instruction label on its container.

h. Clean the pipe threads of the probe to remove

old, hardened pipe dope and other foreign

matter.

i. Apply a moderate amount of good quality pipe

dope to the pipe threads on the probe, leaving

the two end threads bare. Do not use PTFE

(Teflon) tape.

j. Screw the probe into the boiler tapping.

k. Mount the low water cutoff control on the probe.

l. Reconnect the control to probe wiring.

m. Fill the boiler to its normal waterline.

n. Add boiler water treatment compound as needed

(refer to paragraph N.).

o. Restore electric service to the boiler.

p. Fire burner to bring the water in the boiler to a

boil to drive off free oxygen.

q. WARNING — BEFORE RETURNING

BOILER TO SERVICE: Follow the low water

cutoff check out procedure in step L.4..

2. FLOAT TYPE LOW WATER CUT-OFF

During the heating season, if an external low water

cutoff is on the boiler, the blow off valve should be

opened once a month (use greater frequency where

conditions warrant), to flush out the sediment

chamber so the device will be free to function

properly.

Low-water cutoffs and water feeders should be

dismantled annually by qualified personnel, to the

extent necessary to insure freedom from

obstructions and proper functioning of the working

parts. Inspect connecting lines to boiler for

accumulation of mud, scale, etc., and clean as

required. Examine all visible wiring for brittle or

worn insulation and make sure electrical contacts

are clean and that they function properly. Give

special attention to solder joints on bellows and

float when this type of control is used. Check float

for evidence of collapse and check mercury bulb

(where applicable) for mercury separation or

discoloration. Do not attempt to repair mechanisms

in the field. Complete replacement mechanisms,

including necessary gaskets and installation

instructions are available from the manufacturer.

N. BOILER AND SYSTEM CLEANING

INSTRUCTIONS FOR TROUBLE FREE

OPERATION.

1. STEAM BOILERS

a. Oil, greases & sediments which accumulate in a

new boiler and piping must be removed from the

system in order to prevent an unsteady water

line and carry over of the water into the supply

main above boiler.

Operate the boiler with steam in the entire

system for a few days allowing the condensate to

return to the boiler. If the condensate can

temporarily be wasted, operate boiler only for

the length of time it takes for condensate to run

clear. If the latter cannot be achieved or if the

condensate is returned to the boiler, boil out the

boiler using the SURFACE BLOWOFF

connection, see Figure 4.

i. Drain boiler until 1” of water is visible in

gauge glass. Run temporary 1½” pipe line

from the surface blowoff connection to an

open drain or some other location where hot

water may be discharged safely. Do not

install valve in this line.

ii. Drain about 5 gallons of hot water from

boiler into a container and dissolve into it

an appropriate amount of recommended

boil out compound. Remove safety valve &

add solution to boiler water thru exposed

tapping using a funnel.

NOTICE

Check with local authorities or consult local

water treatment services for acceptable chemical

cleaning compounds.

iii. Start burner and operate sufficiently to boil

the water without producing steam pressure.

Boil for about 5 hours. Open boiler feed

pipe sufficiently to permit a steady trickle of

water from the surface blowoff pipe.

25

Page 26

Continue this slow boiling and trickle of

overflow for several hours until the water

coming from the overflow is clear.

iv. Stop burner and drain boiler in a manner

and to a location that hot water can be

discharged with safety.

v. Refill boiler to normal water line. If water

in gauge glass does not appear to be clear,

repeat steps (i. thru iii.) and boil out the

boiler for a longer time.

b. Low pressure steam boilers such as the V7

Series should be maintained with appropriate

water treatment compounds. Add suitable water

treatment compounds as recommended by your

qualified water treatment company.

c. Remove temporary surface blowoff piping, plug

tapping and reinstall safety valve. Boil or bring

water temperature to 180°F promptly in order to

drive off the dissolved gases in the fresh water.

d. If unsteady water line, foaming or priming

persist, install gate valve in Hartford Loop and

drain valves in return main and at boiler as

shown in Figure 8 and proceed as follows:

i Connect hoses from drain cocks to floor

drain. Close gate valve in Hartford Loop

and open drain cock in return main. Fill

boiler to normal water level, turn on oil

burner and operate boiler at this water level

for at least 30 minutes after the condensate

begins to run hot, then turn off burner.

Close all radiator valves. Remove all supply

main air valves and plug the openings in

supply main.

ii. Draw about 5 gallons of hot water from

boiler into a container and dissolve into it

the appropriate amount of a recommended

boilout compound. Remove safety valve

from boiler and pour this solution into

boiler, then reinstall safety valve.

iii. Turn on oil burner and keep operating

while feeding water to boiler slowly. This

will raise water level in boiler slowly so that

water will be boiling hot and will rise

slowly into supply main and back through

return main, flowing from drain hose at

about 180°F. Continue until water runs

clear from drain hose for at least 30

minutes.

iv. Stop feeding water to boiler but continue

operating oil burner until excess water in

boiler flows out through supply main and

water lowers (by steaming) until it reaches

normal level in boiler. Turn off oil burner.

Drain boiler. Open all radiator valves.

Reinstall all supply main air valves. Open

gate valve in Hartford Loop.

v. When boiler has cooled down sufficiently

(crown sheet of sections are not too hot to

touch), close the drain cocks at boiler and in

return main and feed water slowly up to

normal level in boiler. Turn on oil burner

and allow boiler to steam for 10 minutes,

then turn off burner. Draw off one quart of

water from bottom gauge glass fitting and

discard. Draw off another quart sample and

if this sample is not clear, repeat the cycle

of draining the boiler and return main and

refilling the boiler until sample is clear.

vi. If the boiler water becomes dirty again at a

later date due to additional sediment

loosened up in the piping, close gate valve

in Hartford Loop, open drain cock in return

main, turn on oil burner and allow

Condensate to flow to drain until it has run

clear for at least 30 minutes while feeding

water to boiler so as to maintain normal

water level. Turn off oil burner, drain

boiler, open gate valve in Hartford Loop,

then repeat step 1 above.

e. Make pH or Alkalinity Test.

After boiler and system have been cleaned and

refilled as previously described, test the pH of

the water in the system. This can easily be done

by drawing a small sample of boiler water and

testing with hydrion paper which is used in the

same manner as litmus paper, except it gives

specific readings. A color chart on the side of

the small hydrion dispenser gives the reading in

pH. Hydrion paper is inexpensive and

obtainable from any chemical supply house or

through your local druggist. The pH should be

higher than 7, but lower than 11. Add some of

the washout chemical (caustic soda), if

necessary, to bring the pH within the specified

range.

f. Boiler is now ready to be put into service.

2. WATER BOILERS

a. Filling of Boiler and System — General —-In a

hot water heating system, the boiler and entire

system (other than the expansion tank) must be

full of water for satisfactory operation. Water

should be added to the system until the boiler

pressure gauge registers 12 psi. To insure that

the system is full, water should come out of all

air vents when opened.

b. Boiling Out of Boiler and System. The oil and

grease which accumulate in a new hot water

boiler can be washed out in the following

manner.

i. Remove safety relief valve using extreme

care to avoid damaging it.

ii. Add an appropriate amount of

26

Page 27

recommended boil out compound.

iii. Replace safety relief valve.

iv. Fill the entire system with water.

v. Start firing the boiler.

vi. Circulate the water through the entire

system.

vii. Vent the system, including the radiation.

viii. Allow boiler water to reach operating

temperature, if possible.

ix. Continue to circulate the water for a few

hours.

x. Stop firing the boiler.

xi. Drain the system in a manner and to a

location that hot water can be discharged

with safety.

xii. Remove plugs from all available returns and

wash the water side of the boiler as

thoroughly as possible, using a highpressure water stream.

xiii. Refill the system with fresh water.

c. Add appropriate boiler water treatment

compounds as recommended by your qualified

water treatment company.

d. Make pH or Alkalinity Test.

After boiler and system have been cleaned and

refilled as previously described, test the pH of

the water in the system. This can easily be done

by drawing a small sample of boiler water and

testing with hydrion paper which is used in the

same manner as litmus paper, except it gives

specific readings. A color chart on the side of

the small hydrion dispenser gives the reading

pH. Hydrion paper is inexpensive and

obtainable from any chemical supply house or

thru your local druggist. The pH should be

higher than 7 but lower than 11. Add

appropriate water treatment chemicals, if

necessary, to bring the pH within the specified

range. With this lower level of protection, care

must be exercised to eliminate all of the free

oxygen in the system.

e. Boiler is now ready to be put into service.

O. HINTS ON COMBUSTION

1. NOZZLES — Although the nozzle is a relatively

inexpensive device, its function is critical to the

successful operation of the oil burner. The selection

of the nozzle supplied with the V7 boiler is the

result of extensive testing to obtain the best flame

shape and efficient combustion. Other brands of the

same spray angle and spray pattern may be used but

may not perform at the expected level of CO

smoke. Nozzles are delicate and should be protected

from dirt and abuse. Nozzles are mass-produced

and

2

and can vary from sample to sample. For all of

those reasons a spare nozzle is a desirable item for

a serviceman to have.

2. FLAME SHAPE — Looking into the combustion

chamber through the observation door, the flame

should appear straight with no sparklers rolling up

toward the crown of the chamber. If the flame drags

to the right or left, sends sparklers upward or makes

wet spots on the target wall, the nozzle should be

replaced. If the condition persists look for fuel

leaks, air leaks, water or dirt in the fuel as

described above.

3. FUEL LEAKS — Any fuel leak between the pump

and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the air

tube, under the ignitor, and around the air inlet.

Any such leaks should be repaired as they may

cause erratic burning of the fuel and in the extreme

case may become a fire hazard.

4. AIR LEAKS — Any such leaks should be repaired,

as they may cause erratic burning of the fuel and in

extreme cases may become a fire hazard.

5. GASKET LEAKS — If 11.5 to 12.5% CO2 with a

#1 smoke cannot be obtained in the breeching, look

for air leaks around the burner mounting gasket,

observation door, and canopy gasket. Such air leaks

will cause a lower CO2 reading in the breeching.

The smaller the firing rate the greater effect an air

leak can have on CO2 readings.

6. DIRT — A fuel filter is a good investment.

Accidental accumulation of dirt in the fuel system

can clog the nozzle or nozzle strainer and produce a

poor spray pattern from the nozzle. The smaller the

firing rate, the smaller the slots become in the

nozzle and the more prone to plugging it becomes

with the same amount of dirt.

7. WATER — Water in the fuel in large amounts will

stall the fuel pump. Water in the fuel in smaller

amounts will cause excessive wear on the pump, but

more importantly water doesn’t burn. It chills the

flame and causes smoke and unburned fuel to pass

out of the combustion chamber and clog the

flueways of the boiler.

8. COLD OIL — If the oil temperature approaching

the fuel pump is 40°F or lower poor combustion or

delayed ignition may result. Cold oil is harder to

atomize at the nozzle. Thus, the spray droplets get

larger and the flame shape gets longer. An outside

fuel tank that is above grade or has fuel lines in a

shallow bury is a good candidate for cold oil. The

best solution is to bury the tank and lines deep

enough to keep the oil above 40°F.

9. HIGH ALTITUDE INSTALLATIONS

Air openings must be increased at higher altitudes.

Use instruments and set for 11.5 to 12.5% CO2.

27

Page 28

IMPORTANT

SUCTION LINE LEAKS - THE OIL MUST BE

FREE OF AIR. Try bleeding the pump

through a clear tube. There must be no froth

visible. There are various test kits available

to enable you to look at the oil through clear

tubing adapted to the supply line at the

pump fitting. Air eliminators are on the

market that have potential. Also, electronic

sight glasses are being used with good

success. At times, new tubing must be run

to the tan k or new fitting s put on . Just make

sure you get the air out.

Any air leaks in the fuel line will cause an

unstable flame and may cause delayed

ignition noises. Use only flare fittings in the

fuel lines.

10. START-UP NOISE — Late ignition is the cause of

start-up noises. If it occurs recheck for electrode

settings, flame shape, air or water in the fuel lines.

11. SHUT DOWN NOISE — If the flame runs out of

air before it runs out of fuel, an after burn with

noise may occur. That may be the result of a faulty

cut-off valve in the fuel pump, or it may be air

trapped in the nozzle line. It may take several firing

cycles for that air to be fully vented through the

nozzle. Water in the fuel or poor flame shape can

also cause shut down noises.

clean water to prescribed water level.

4. Always keep the manual fuel supply valve shut off

if the burner is shut down for an extended period of

time.

5. To recondition the heating system in the fall season

after a prolonged shut down, follow the instructions

outlined in Section IV, Items A through M.

CAUTION

This boiler contains controls which may

cause the boiler to shut down and not

restart without service. If damage due to

fro ze n pi pes is a po ssibil ity, the heat ing

system should not be left unattended in

cold weather; or appropriate safeguards

and alarms should be installed on the

heating system to prevent d amage if the

bo ile r is in ope rativ e.

Q. FREQUENT WATER ADDITION

IMPORTANT

CHECK TEST PROCEDURE. A very good test for

isolating fuel side problems is to disconnect the

fuel system and with a 24" length of tubing, fire

out of an auxiliary five gallon pail of clean, fresh,

warm #2 oil from another source. If the burner

runs successfully when drawing out of the

auxiliary pail then the problem is isolated to the

fuel or fuel lines being used on the jobsite.

P. ATTENTION TO BOILER WHILE NOT IN

OPERATION.

1. IMPORTANT

IF BOILER IS NOT USED DURING WINTER

TIME, IT MUST BE FULLY DRAINED TO