Page 1

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

™GCS

RELIOBDERIF-SAG

As an ENERGY STAR

STAR® guidelines for energy effi ciency established by the United States Environmental Protection Agency (EPA).

sserddA

8140705R3-1/07

®

Partner, Burnham Hydronics has determined that the SCG meets the ENERGY

rebmuNledoMrelioB

___-____GCS

rotcartnoCgnitaeH rebmuNenohP

rebmuNlaireSrelioB

________

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliob

etaDnoitallatsnI

Price - $5.00

nonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

Page 2

IMPORTANT INFORMATION - READ CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations enforced in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or local regulations.

All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or local regulations.

The New York City Department of Buildings has approved the SCG™ Series boiler: Approval No. MEA 5-06-E.

The City of New York requires either a Licensed Master Plumber or a Fire Suppression Piping Contractor supervise the

installation of this product.

The Massachusetts Board of Plumbers and Gas Fitters has approved the SCG™ Series boiler. See the Massachusetts Board of

Plumbers and Gas Fitters website, http://license.reg.state.ma.us/pubLic/pb_pre_form.asp for the latest Approval Code or ask

your local Sales Representative.

The Commonwealth of Massachusetts requires this product to be installed by a Licensed Plumber or Gas Fitter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning product life.

REGNAD

noitautissuodrazahyltnenimminasetacidnI

,htaednitluserlliw,dediovatonfi,hcihw

nisuoires

.egamad

ytreporplaitnatsbusroyruj

.

egamad

GNINRAW

noitautissuodrazahyllaitnetopasetacidnI

,htaednitluserdluoc,dediovatonfi,hcihw

jnisuoires

.egamad

ytreporplaitnatsbusroyru

razahyrujnilanosrep

NOITUAC

noitautissuodrazahyllaitnetopasetacidnI

nitluseryam,dediovatonfi,hcihw

ytreporproyrujnironimroetaredom

ECITON

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

.sd

REGNAD

ynarosihtfoytinicivehtnisdiuqilrosropavelbammalfrehtoroenilosagesuroerotsTONOD

.ecnailpparehto

lacirtceleynahcuotTONOD-ecnailppaynaetarepootyrtTONOD,sropavsagllemsuoyfI

aidemmI.gnidliubehtnienohpynaesurohctiws

.tnemtrapederifeht

yletomeramorfreilppussagehtllac,ylet

tcatnoc,elbaliavanusireilppusehtfirosnoitcurtsnis'reilppussagehtwolloF.enohpdetacol

2

Page 3

GNINRAW

ehtwolloF.ylefasetarepootecivresdnaecnanetniamralugerseriuqerreliobsihT

.launamsihtnideniatnocsnoitcurtsni

ytreporpesuacnacecnanetniamroecivres,noitaretla,tnemtsujda,noitallatsnireporpmI

ehtdnatsrednudnadaeR.efilfossolroyrujnilanosrep,egamad

.detnevylreporpebtsumreliobsihT

.rianoitalitnevdnanoitsubmocetauqedarof

.ycneiciffes'reliobehtgniniatniam

.sliated

erofeblaunameritne

ebtsumecivresdnanoitallatsnI.ecivresro,noitarepopu-trats,noitallatsnignitpmetta

.ycnegaecivresrorellatsnielbaegdelwonkdna,delliks,decneirepxenaybylnodemrofrep

snoisivorperaerehtosdellatsniebtsumdnanoitarepoefasrofriahserfsdeenreliobsihT

ehtfotratsehterofebdenaelcdnadetcepsniebtsummetsysgnitnevehtforoiretniehT

ynarofnosaesgnitaehehttuohguorhtyllacidoirepdetcepsniebdluohsdnanosaesgnitaeh

suoixonwollaotyrassecensimetsysgnitnevdetcurtsbonudnanaelcA.snoitcurtsbo

drawotetubirtnoclliwdnaylefastnevotefilfossolroyrujniesuacdluoctahtsemuf

gnippatehtotnidellatsnisievlavfeilererusserpasselnuetelpmoctonsinoitallatsnI

roflaunamsihtfonoitceSmirTdnagnipiPretaWehteeS-.ecnailppafopotnodetacol

tondnanwodtuhsotreliobehtesuacyamhcihwsecivedytefashtiwdeilppussireliobsihT

metsysgnitaeheht,ytilibissopasisepipnezorfoteudegamadfI.ecivrestuohtiwtrats-er

dluohssmraladnasdraugefasetairporpparo;rehtaewdlocnidednettanutfelebtondluohs

.evitareponisireliobehtfiegamadtneverpotmetsysgnitaehehtnodellatsnieb

sgnittifepipynawercsnutonoD.erusserphgihrednuretawtohyrevsniatnocreliobsihT

ehtgnirussaylevitisoptuohtiwreliobsihtfostnenopmocynatcennocsidottpmettaron

nehwtnempiuqednagnihtolcevitcetorpraewsyawlA.erusserponsahdnaloocsiretaw

ehtnoylertonoD.seirujnidlacstneverpotreliobsihtgnicivresropugnitrats,gnillatsni

.reliobehtfoerusserpdnaerutarepmetehtenimretedotseguagerutarepmetdnaerusserp

oD.gnitareposireliobehtnehwtohyrevemocebhcihwstnenopmocsniatnocreliobsihT

cynahcuotton

.gnicivres

liobpeeK

.sdiuqilrosropav

.loocerayehtsselnustnenopmo

,acilis,animulaniatnocleufehtdnanoitsubmocfostcudorp,noitcurtsnocfoslairetamrelioB

rocixotrehtoro/dnasedyhedla,sedixonegortin,edixonomnobrac,slatemyvaeh

yrujnilanosrepesuacnacredroreporpehtnisnoitcurtsnillawollofoteruliaF

niatnocesohtllagnidulcni,snoitcurtsnilladaeR

.semitllataecalpniebtsumsdraugdnaserusolcne,setalprevocllA

lufmrah

foetatsehtotnwonkerahcihwdnayrujnisuoiresrohtaedesuacnachcihwsecnatsbus

reporpesusyawlA.mrahevitcudorperrehtodnastcefedhtrib,recnacesuacotainrofilaC

.ecnailppaehtybraengnikrowrognicivresnehwtnempiuqednasrotaripser,gnihtolcytefas

.htaedro

slaunamsrerutcafunamtnenopmocnide

rogniniatniam,gnitarepo,pugnitrats,gnillatsnierofebreliobehthtiwdedivorperahcihw

elbammalfrehtodnaenilosag,slairetamelbitsubmocmorfeerfdnaraelcaerare

ECITON

.launamsihtfokcabehtnodetnirpsihcihwfoypoca,ytnarrawdetimilasahreliobsihT

dellatsniyltcerroceraslortnocllatahteesotrotcartnocgnillatsniehtfoytilibisnopserehtsitI

.etelpmocsinoitallatsniehtnehwylreporpgnitarepoeradna

3

Page 4

Table of Contents

I. Pre-Installation ............................... 6

II. Unpack Boiler ................................7

III. Venting/Air Intake Piping .............. 8

IV. Water Piping and Trim .................45

V. Gas Piping .................................... 50

VI. Electrical ....................................... 53

VII. Modular Installation .................... 62

VIII. System Start-up ............................64

IX. Service .......................................... 68

X. Repair Parts .................................. 74

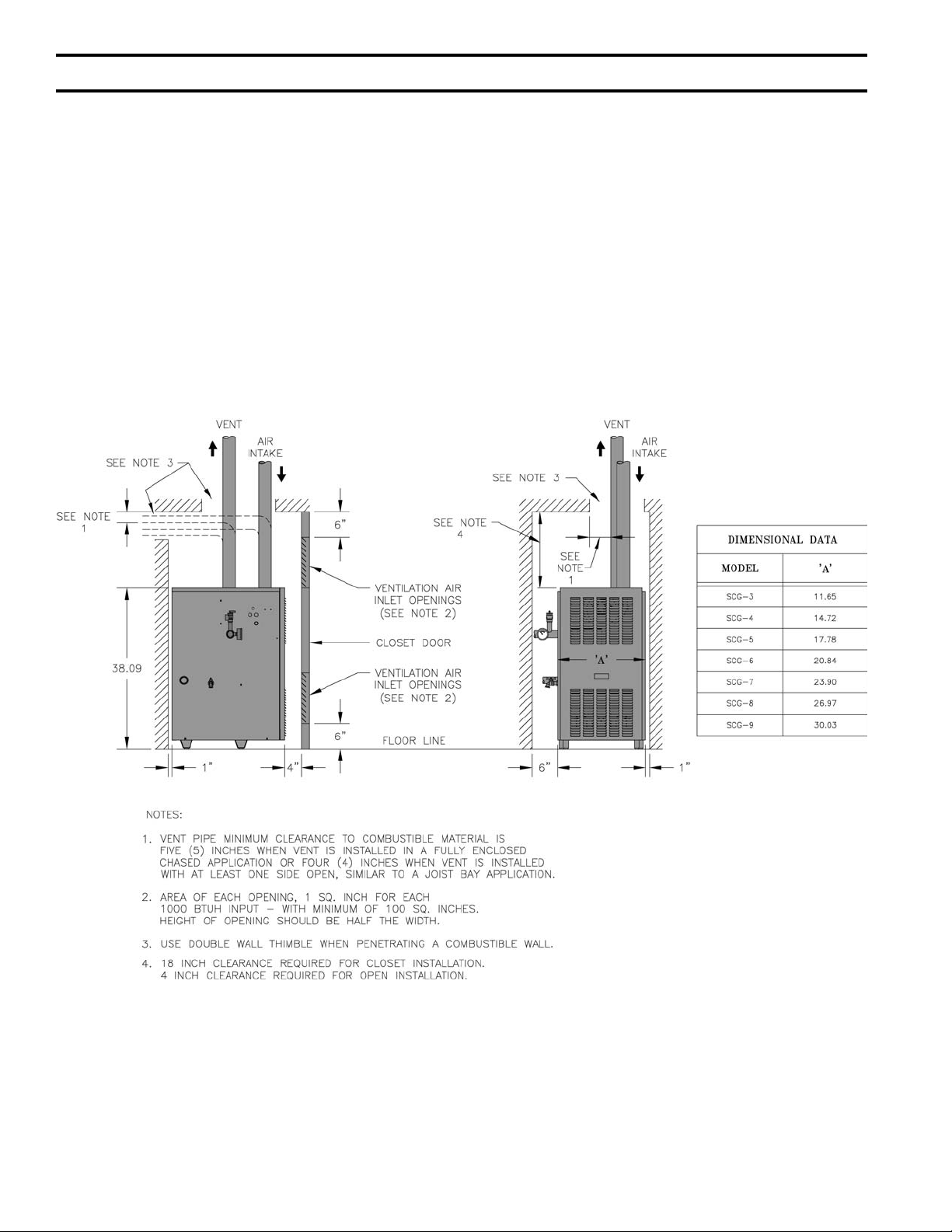

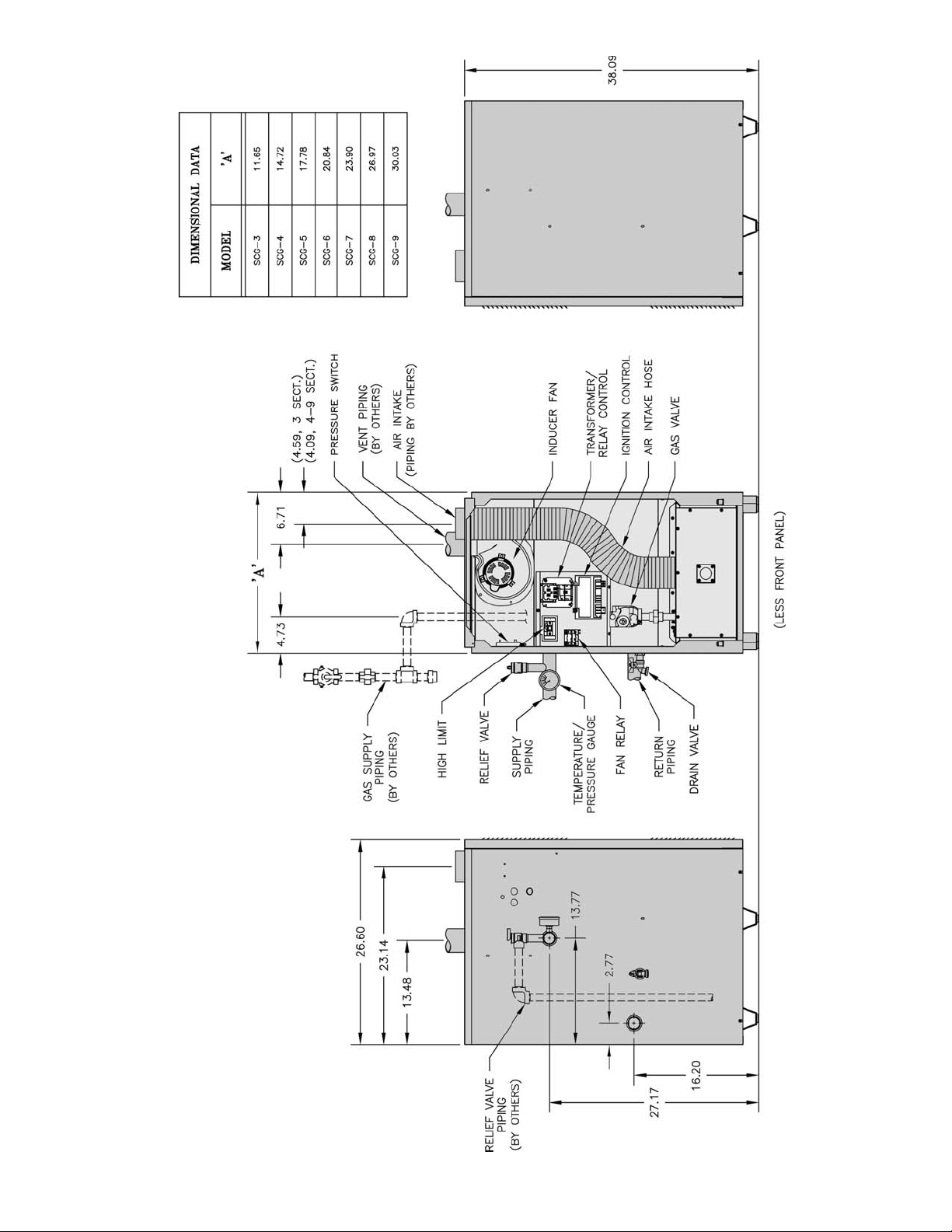

Figure 1: Minimum Clearances to Combustibles

4

Page 5

Figure 2: Dimensions

5

Page 6

I. Pre-Installation

.yru

jni

F. Provide combustion and ventilation air in accordance

GNINRAW

snoitcurtsniesehtwolloftonoduoyfI

tluseryamnoisolpxeroerifa,yltcaxe

lanosreproegamadytreporpgnisuac

with applicable provisions of local building codes,

or: USA - National Fuel Gas Code, NFPA 54/ANSI

Z223.1, Air for Combustion and Ventilation;

Canada - Natural Gas Installation Code, CAN/

CGA-B149.1, or Propane Installation Code, CAN/

CGA-B149.2, Venting Systems and Air Supply for

Appliances.

REGNAD

rehtoroenilosagerehwreliobllatsnitonoD

fosecruosro,sdiuqilrosropavelbammalf

racordyh

,srenaelc,sehcaelb.e.i(snob

cirbaf,srevomertniap,syarps,slacimehc

.derotsrodesuera).cte,srenetfos

ECITON

,reliobehtfotnetnocretawwolehtoteuD

ehtotdragerhtiwreliobehtfognizis-sim

evissecxenitluserlliwdaolmetsysgnitaeh

tnenopmocdetareleccadnagnilcycreliob

tnarrawTONSEODmahnruB.eruliaf

iaf

.gnizisrevo

A. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to the National

Fuel Gas Code, NFPA 54/ANSI Z223.1, and/or CAN/

CGA B149 Installation Codes.

B. Appliance is design certifi ed for installation on

combustible fl ooring. Do not install boiler on

carpeting.

C. Provide clearance between boiler jacket and

combustible material in accordance with local fi re

ordinance. Refer to Figure 1 for minimum listed

clearance from combustible material. Recommended

service clearance is 24 inches from left side, right

side and front. Service clearances may be reduced to

minimum clearances to combustible materials.

D. Install on level fl oor. For basement installation provide

solid base such as concrete, if fl oor is not level or if

water may be encountered on fl oor around boiler. Floor

must be able to support weight of boiler, water and all

additional system components.

reliobdezis-simybdesuacserul

otreliobehtezisrevoTONOD.snoitacilppa

snoitallatsnireliobraludoM.metsyseht

reliobfodoohilekilehtecuderyltaerg

GNINRAW

rianoitalitnevdnanoitsubmocetauqedA

reporperussaotdedivorpebtsum

.noitsubmoc

The following guideline is based on the National Fuel Gas

Code, NFPA 54/ANSI Z223.1.

1. Determine volume of space (boiler room). Rooms

communicating directly with space (through

openings not furnished with doors) are considered

part of space.

Volume [ft³] = Length [ft] x Width [ft] x Height [ft]

2. Determine Total Input of all appliances in space.

Round result to nearest 1,000 Btu per hour (Btuh).

3. Determine type of space. Divide Volume by Total

Input.

a. If result is greater than or equal to 50 ft³ per

1,000 Btuh, space is considered an unconfi ned

space.

b. If result is less than 50 ft³ per 1,000 Btuh, space

is considered a confi ned space.

4. Determine building type. A building of unusually

tight construction has the following characteristics:

a. Walls and ceiling exposed to outside atmosphere

have a continuous water vapor retarder with a

rating of 1 perm or less with openings gasketed

and sealed, and;

b. Weather-stripping has been added on openable

windows and doors, and;

c. Caulking or sealants applied in joints around

window and door frames, between sill plates and

fl oors, between wall-ceiling joints, between wall

panels, at plumbing and electrical penetrations,

and at other openings.

5. For boiler located in an unconfi ned space in a

building of other than unusually tight construction,

adequate combustion and ventilation air is normally

provided by fresh air infi ltration through cracks

around windows and doors.

E. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, condensate trap,

control replacement, etc.).

6

Page 7

ECITON

delaes(tnevtceridhtiwdetareposrelioB

gnideenmorftpmexeera)noitsubmoc

ehtmorfrianoitsubmocrofsnoisivorp

d

ellatsnisignipipekatniriadedivorp,moor

sihtnisnoitcurtsniehtdnaedocrep

.launam

6. For boiler located within unconfi ned space in building

of unusually tight construction or within confi ned

space, provide outdoor air through two permanent

openings which communicate directly or by duct

with the outdoors or spaces (crawl or attic) freely

communicating with the outdoors. Locate one opening

within twelve (12) inches of top of space. Locate

remaining opening within twelve (12) inches of bottom

of space. Minimum dimension of air opening is three

(3) inches. Size each opening per following:

a. Direct communication with outdoors. Minimum

free area of one (1) square inch per 4,000 Btu per

hour input of all equipment in space.

b. Vertical ducts. Minimum free area of one (1)

square inch per 4,000 Btu per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

c. Horizontal ducts. Minimum free area of one (1)

square inch per 2,000 Btu per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

Alternate method for boiler located within

confi ned space. Use indoor air if two permanent

openings communicate directly with additional

space(s) of suffi cient volume such that combined

volume of all spaces meet criteria for unconfi ned

space. Size each opening for minimum free area

of one (1) square inch per 1,000 Btu per hour

input of all equipment in spaces, but not less than

100 square inches.

7. Combustion Air/Ventilation Duct Louvers and

Grilles. Equip outside openings with louvers to

prevent entrance of rain and snow, and screens to

prevent entrance of insects and rodents. Louvers and

grilles must be fi xed in open position or interlocked

with equipment to open automatically before burner

operation. Screens must not be smaller than ¼ inch

mesh.

Consider the blocking effect of louvers, grilles and

screens when calculating the opening size to provide

the required free area. If free area of louver or grille

is not known, assume wood louvers have 20-25

percent free area and metal louvers and grilles have

60-75 percent free area.

.noitareporeporperusniot

II. Unpack Boiler

NOITUAC

reliobpmubtonoD.reliobpordtonoD

.roolftsniagatekcaj

A. Move boiler to approximate installed position.

B. Remove all crate fasteners.

C. Lift and remove outside container. Save two of the

wooden slats from the container sleeve for use in Steps

E and F.

D. Remove all boiler hold-down fasteners.

NOITUAC

nanireliobsihtgnitarepodiova,)riAroodnI-noitceSgnitneVees(noitsubmocrofriaroodnignisufI

sireliobfI.tneserpera.cte,tsudllawyrd,srebifnoitalusniesool,tsudwaserehwtnemnorivne

yliaddetcepsnidnadenaelcebtsumstropdnaroiretnirenrubeht,snoitidnocesehtrednudetarepo

GNINRAW

ebdluohsreliobsihtfonoitallatsnI

delliksdnadeniartybylnonekatrednu

p

E. Tilt the boiler to its front side or back side and slide a

wooden slat under the three raised feet.

F. Tilt the boiler in the opposite direction and slide

another wooden slat under the three raised feet.

G. Slide the boiler left or right off the skid using the two

wooden slats as runners.

.ycnegaecivresdeifilauqamorflennosre

H. Move boiler to its permanent location.

7

Page 8

III. Venting / Air Intake Piping

GNINRAW

®

C4-92LAnonrehtoyna

onoD

perdoogniebdluohssecafrus

.yenmihc

umixamdeecxetonoD

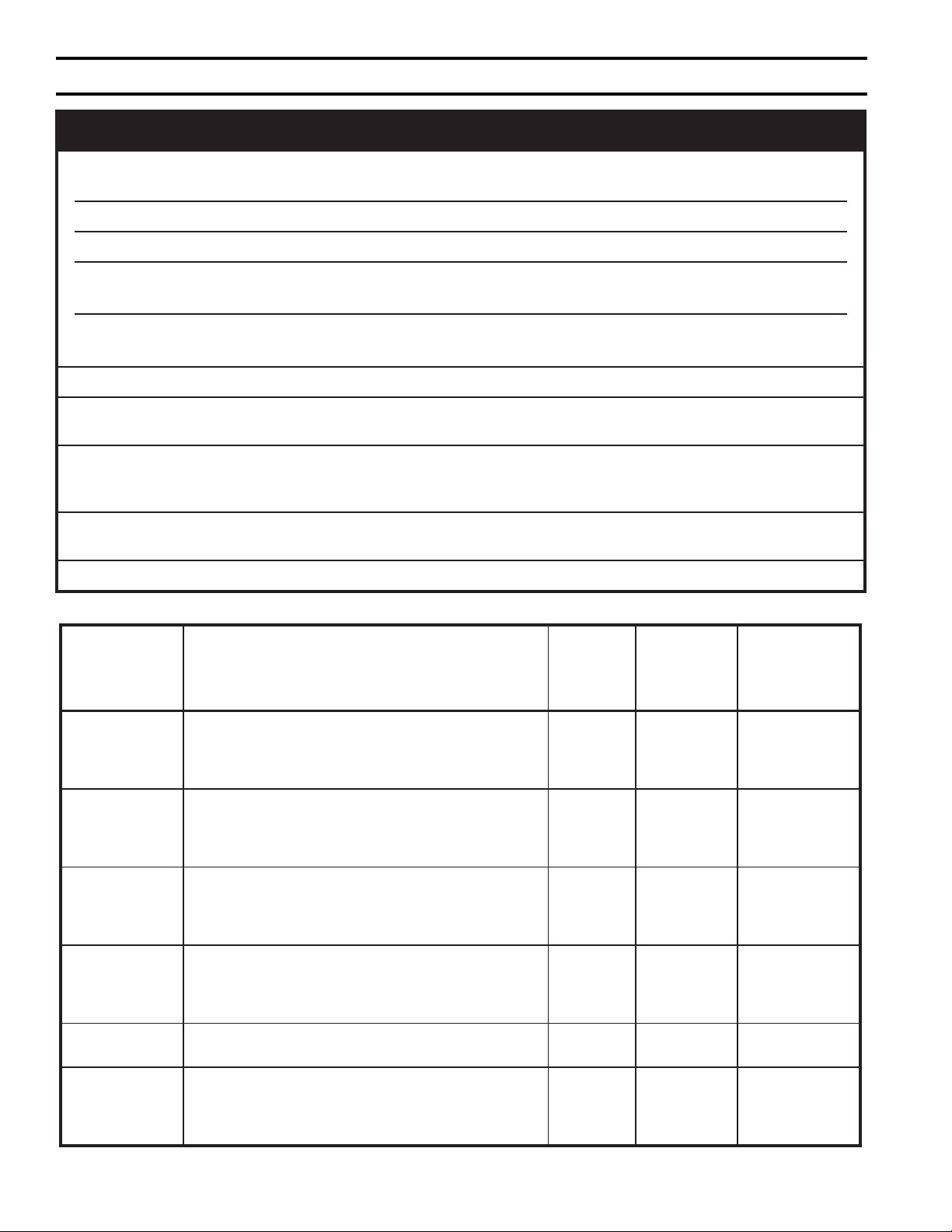

Table 1: Air Intake / Vent System Options

rocillatemnon,leetssselniats613epyTro403epyT,dezinavlaghtiwreliobsihtesutonoD

.smetsystnevdesab

.ecnailppasihthtiwdoohtfardrorepmadcirtemorabaesutonoD

.reliobsihthtiwsrepmadtnevesut

,noitaroiretedtneverpoT.noitanimretdnuorasecafrusnomrofyamecidnaerutsioM

.).cte,detniap,delaes(ria

eraerehtosdellatsniebtsumdnanoitarepoefasrofriahserfsdeenecnailppasihT

italitnevdnanoitsubmocetauqedarofsnoisivorp

.riano

.epipekatniriafoezisecudertonoD

sernoitcurtsnirianoitsubmocwollofdnadnatsrednu,daeR

-erPehtnideniatnocsnoitcirt

.launamsihtfosnoitcurtsninoitallatsnI

diuqilrosropavelbammalfrehtoroenilosagerehwecnailppaetarepotonoD

,slacimehc,srenaelc,sehcaelb.e.i(snobracordyh

fosecruosro,s

,srenetfoscirbaf,srevomertniap,syarps

.riaehtnitneserpro/dnaderots,desuera).cte

nacecnailpparehtoon,yenmihchguorhtepiptnevgnillatsninehW

ehtotnidetneveb

.4elbaTotrefeR.shtgnelekatniria/tnevm

noitpOnoitpircseD

etarapeS.1

latnoziroH

etarapeS.2

lacitreV

lacitreV

riAroodnI.5

lanoitpO.6

etarapeS

latnoziroH

pip

itanibmoC.3

no

latnoziroH

noitanibmoC.4

tniriadna

atniriadnaepip

lanoitiddA

tiKtneV

deriuqeR

tnevehthtobhtiw)noitsubmocdelaes(tneVtceriD

yllatnozirohgnitanimretepipekatniriadnaepip

rofsnoitarteneplaudividnihtiw)llawedisahguorht(

.slanimretdnagnipipekatniriadnatneveht

tnevehthtobhtiw)noitsubmocdelaes(tneVtceriD

yllacitrevgnitanimretepipekatniriadnae

rofsnoitarteneplaudividnihtiw)foorehthguorht(

.slanimretdnagnipipekatniriadnatneveht

epiptnevehthtiw)noitsubmocdelaes(tneVtceriD

lanimretnommocatagniniojepipekatniriadna

pullawedisahguorht(yllatnozirohgnitanimretdna

.noitartenepenoylnohtiw)kciht"51ot

epiptnevehthtiw)noitsubmocdelaes(tneVtceriD

lanimretnommocatagniniojepipeka

htiw)foorehthguorht(yllacitrevgnitanimretdna

.noitartenepenoylno

dedivorpsinoitsubmocrofdesuriA-tneVrewoP

.gnidliubehtnihtiwmorf

tnevehthtobhtiw)noitsubmocdelaes(tneVtceriD

yllatnozirohgnitanimretepipek

rofsnoitarteneplaudividnihtiw)llawedisahguorht(

.slanimretdnagnipipekatniriadnatneveht

oN

oN

seY

seY

oN2elbaTeeS.

oN2

traP

rebmuN

eeS

2elbaT

eeS

2elbaT

116(

eS6-5

elbaTeeS.I

noitceS6-3

)21060

noitceS4-3

)10-222001(

noitc

)10-322001(

noitallatsnI

dnagniwarD

noitacificepS

)noitceSeeS(

.D

.E

.F

.G

H

8

Page 9

Table 2: Vent System Components Included with Boiler

stnenopmoCmetsyStneVrebmuNtraP

"3lanimreTtneVdeteksaG

)7-GCSurht3-GCS(latnoziroH

"4lanimreTtneVdeteksaG

)9GCS&8-GCS(latnoziroH

"3-ekatnIriAcsiD

)4-GCS&3-GCS(

"4-ekatnIriAcsiD

)6-GCS&5-GCS(

"5-ekatnIriA

)9-GCSurht7-GCS(

1070118

70118

20

5406116

9406116

3606116

Table 3: Burnham Vent System and Air Intake System Components

metsyStneV

tnenopmoC

tF1xepiP.aiD"3U6926118

tF1xepiP.aiD"410-671001

tF3xepiP.aiD"3U8926118

tF3xepiP.aiD"410-771001

3U0036118

"410-181001

elbuoD"35116118

tF5xepiP.aiD"

tF5xepiP.aiD"410-871001

elbatsujdAxepiP.aiD"3U9136118

elbats

ujdAxepiP.aiD"410-971001

woblE°09.aiD"3U4926118

woblE°09.aiD"410-081001

woblE°54.aiD"3U2926118

woblE°54.aiD

eeTniarDlatnoziroH.aiD"3U2036618

eeTniarDlatnoziroH.aiD"410-281001

eeTniarDlacitreV.aiD"3U4036

eeTniarDlacitreV.aiD"410-381001

elbmihTllaWelgniS"36116118

elbmihTllaWelgniS"410-481001

elbmihTllaW

elbmihTllaWelbuoD"410-581001

traP

rebmuN

118

tnelaviuqE

epiPfoteeF

1

3

5

otlauqE**

htgneLdellatsnI

)46.1ot60.1(

5

5

½7

½7

---

---

metsySekatnI

stnenopmoC

)srehtOybstraP(

tnelaviuqE

*epiPfoteeF

tF1xepiPDI"5ro,"4,"31

tF2xepiPDI"5ro,"4,"32

tF4xepiPDI"5ro,"4,"34

tF5xepiPDI"5ro,"4,"35

woblE°09"4ro,"35

54"4ro,"35

woblE°

woblE°09"56

woblE°54"56

nodesaBepiPfoteeFtnelaviuqE*

ngiseDepiPekomS"4dradnatS

Table 4: Vent/Air Intake Length

ledoM

.niM.xaM.niM.xaM.niM.xaM.niM.xaM.niM.xaM

4-GCS&3-GCS805----------------805--------

6-GCS&5-GCS--------805--------805--------

7-GCS----------------805805--------

9-GCS&8-GCS-----

epiPekatnIriA"3

).tF.viuqE(

-----------804--------804

epiPekatnIriA"4

).tF.viuqE(

epiPekatnIriA"5

).tF.viuqE(

qE(

epiPtneV"3

).tF.viu

epiPtneV"4

).tF.viuqE(

9

Page 10

A. Vent Guidelines Due to Removal of an Existing

Boiler

For installations not involving the replacement of an

existing boiler, proceed to Step B.

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the remaining

appliances. At the time of removal of an existing

boiler, the following steps shall be followed with each

appliance remaining connected to the common venting

system placed in operation, while the other appliances

remaining connected to the common venting system are

not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion, and other

defi ciencies which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system.

Turn on any exhaust fans, such as range-hoods and

bathroom exhausts, so they will operate at maxi mum

speed. Do not operate a summer exhaust fan. Close

fi replace dampers.

4. Place in operation the appliance being inspected.

Follow the Lighting (or Operating) Instructions.

Adjust thermo stat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after fi ve (5) minutes of main burner operation. Use

the fl ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remain ing connected to the common venting system

properly vents when tested as outlined above, return

doors, win dows, exhaust fans, fi replace dampers and

any other gas burning appliance to their previous

conditions of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, NFPA

54/ANSI Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the minimum

size as determined using the appropriate tables in

Part II in the National Fuel Gas Code, NFPA 54/

ANSI Z223.1.

B. General Guidelines

1. Vent system installation must be in accordance

with National Fuel Gas Code, NFPA 54/ANSI

Z221.3 or applicable provisions of local building

codes. Contact local building or fi re offi cials about

restrictions and installation inspection in your area.

2. The SCG is designed to be installed as either

a Direct Vent boiler or Power Vent boiler. In

the Direct Vent confi guration all of the air for

combustion is supplied directly to the burner

enclosure from outdoors and fl ue gases are vented

directly outdoors (through wall or roof). In the

Power Vent confi guration, room air provides air

for combustion and ventilation. Flue gases are still

vented directly outdoors (through wall or roof).

Note: Venting requirements change if indoor air is

used.

3. Refer to the appropriate drawings in this section of

this manual to determine the proper confi guration of

venting system. See Table 1.

4. This appliance requires a Special Gas Vent. The

product is designed to use Burnham supplied

AL 29-4C® Stainless Steel vent system components.

The following manufacturers offer similar

AL 29-4C® components and are approved for use

with this product. Heat-Fab Inc. - Saf-T-Vent, Flex-L

International Inc. - Star-34, Z-Flex U. S., Inc. -

Z-Vent, and Protech Systems , Inc.- FasNSeal™ or

equivalent. The use of these alternate manufacturer’s

venting systems will require adapters to connect

to the Burnham supplied vent connector and vent

terminal. These adapters are not supplied with this

unit and should be obtained from the supplier of

the alternate manufacturer’s venting system. See

Table 3 for complete list of Burnham Vent System

Components.

5. Horizontal vent pipe must maintain a minimum ¼

inch per foot slope down towards boiler.

6. Use noncombustible ¾ inch pipe strap to support

horizontal runs and maintain vent location and

slope while preventing sags in pipe. Do not restrict

thermal expansion or movement of vent system.

Maximum support spacing is fi ve (5) feet. Do not

penetrate any part of the vent system with fasteners.

7. Vent length restrictions are based on equivalent

length of vent/air pipe (total length of straight

pipe plus equivalent length of fi ttings). Maximum

vent/air lengths are listed in Table 4. Do not exceed

maximum vent/air intake lengths. Table 3 lists

equivalent lengths for fi ttings. Do not include vent/

air terminals in equivalent feet calculations.

8. Provide and maintain vent pipe minimum clearances

to combustible materials. Vent pipe minimum

clearance to combustible material is four (4) inches

when vent is installed in a fully enclosed (chase)

application or three (3) inches when vent is installed

10

Page 11

with at least one side open, similar to a joist bay

application. Use double wall thimble [Burnham

Part No. 8116115 (3”), 100185-01 (4”)] when

penetrating a combustible wall.

9. Do not install venting system components on

the exterior of the building except as specifi cally

required by these instructions. The vent termination

location is restricted as follows:

a. Minimum twelve (12) inches above grade plus

normally expected snow accumulation level, or

seven (7) feet above grade if located adjacent

to public walkway. Do not install over public

walkway where local experience indicates

appliance fl ue gas vapor or condensate creates a

nuisance or hazard.

b. Minimum three (3) feet above any forced air

inlet located within ten (10) feet.

c. Direct Vent - Minimum one (1) foot below, one

(1) foot horizontally from, or one (1) foot above

any door, window, or gravity air inlet.

Power Vent - Minimum four (4) feet below, four

(4) feet horizontally from, or four (4) feet above

any door, window, or gravity air inlet.

d. Minimum four (4) feet horizontally from electric

meters, gas meters, regulators, and relief valves.

This distance may be reduced if equipment is

protected from damage due to condensation or

vapor by enclosure, overhangs, etc.

e. Minimum twelve (12) inches from overhang or

corner of building.

10. Enclose vent passing through occupied or

unoccupied spaces above the boiler with material

having a fi re resistance rating of at least equal to the

rating of the adjoining fl oor or ceiling. Maintain

minimum clearances to combustible materials. See

Figure 1.

Note: For one or two family dwellings, fi re

resistance rating requirement may not need to be

met, but is recommended.

11. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector

on top of boiler and work towards vent terminal.

12. Once a vent pipe manufacturer and system is chosen

never mix and match vent systems.

13. If a non-standard length pipe is required:

Gasketed Vent System: The use of the adjustable

length pipe (P/N 8116319U) is recommended to

complete a non-standard pipe length. This pipe

requires a minimum installed length of 12¾ inch

and can adjust across a 7 inch gap up to a maximum

of 19¾ inch long. (Note for the adjustable pipe

the installed length should be measured from the

centerline of the bead on the male end of the fi rst

pipe to the end of the female pipe excluding the

locking band of the second pipe with a single

gasket.) Only in the event the adjustable length pipe

is not suffi cient a standard length pipe may be cut

using the procedure outlined below for the GasketLess Vent System.

GNINRAW

fohtgneldellatsnimumixamdeecxereveN

.epiphtgnelelbatsujdarofsehcni¾91

.elbissopsiegakaelsageulffoksiR

ECITON

rodelifdnaepiphtiwerauqsebtsumtuC

ylluferaC.gniniojerofebhtoomsdednas

e

.launamsihtnideificeps

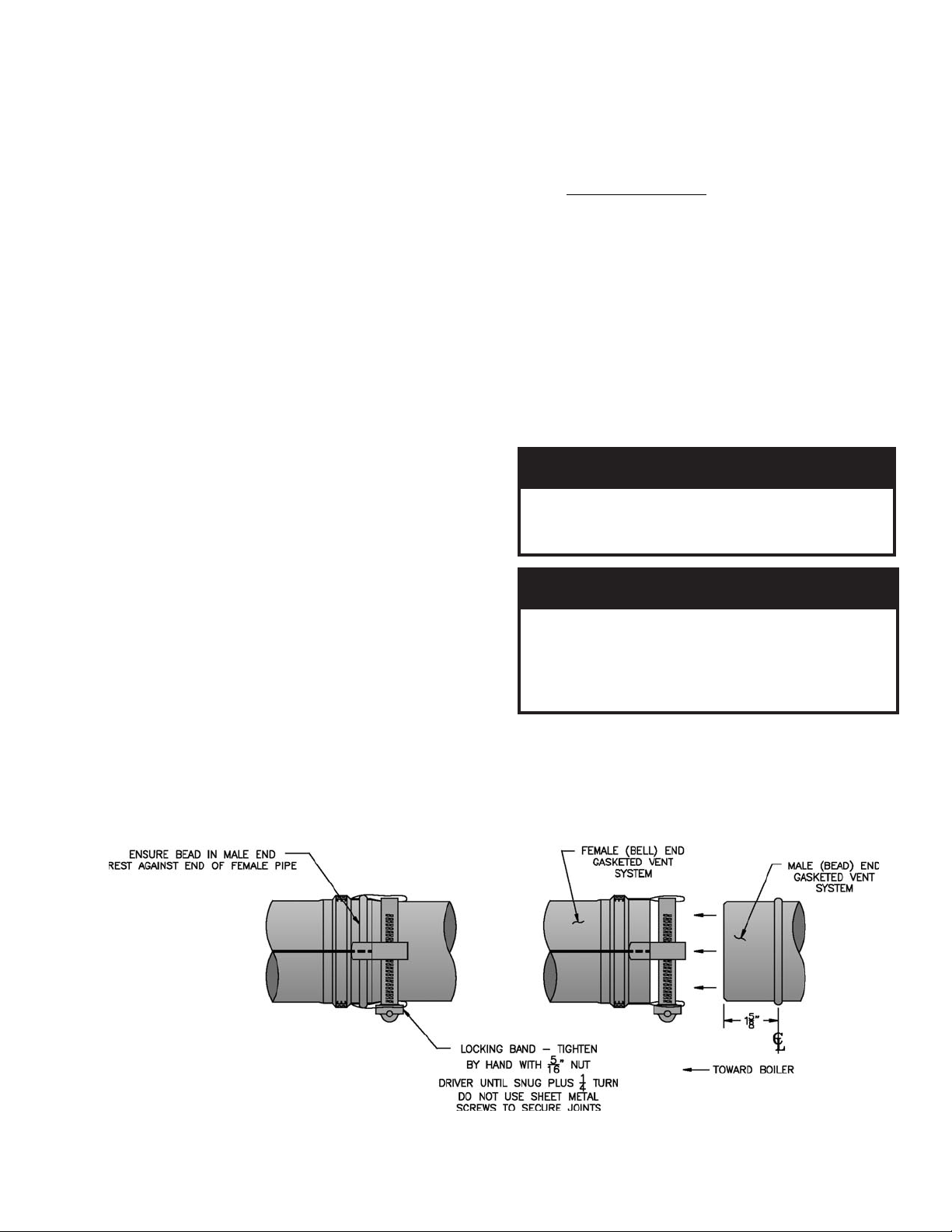

C. Install Vent Pipe, Burnham Gasketed Vent System.

1. Procedure for Joining Burnham Gasketed Vent Pipe

and Fittings. See Figure 3.

htiwdnahybepiptucfossendnuorerusn

VTRhtiwtniojlaeS.gnillatsnierofebsevolg

Figure 3: Burnham Gasketed Vent Joint Detail

11

Page 12

a. Wipe the male end of each joint using an alcohol

pad to remove any dirt and grease.

b. Align weld seams in pipes and use a slight

twisting motion to FULLY insert male end into

female end of joint. Ensure bead in male end

of pipe is below locking band and rest against

the end of the female pipe. Verify the factoryinstalled gasket is not dislodged or cut.

c. Tighten locking band by HAND with a 5/16”

nut driver until snug plus ¼ turn. DO NOT

SECURE JOINTS WITH SHEET METAL

SCREWS OR POP RIVETS. DO NOT

PUNCTURE THE VENT SYSTEM!

d. Once the installation is complete, operate

appliance and inspect all joints to ensure that fl ue

gases and/or liquid condensate will not escape.

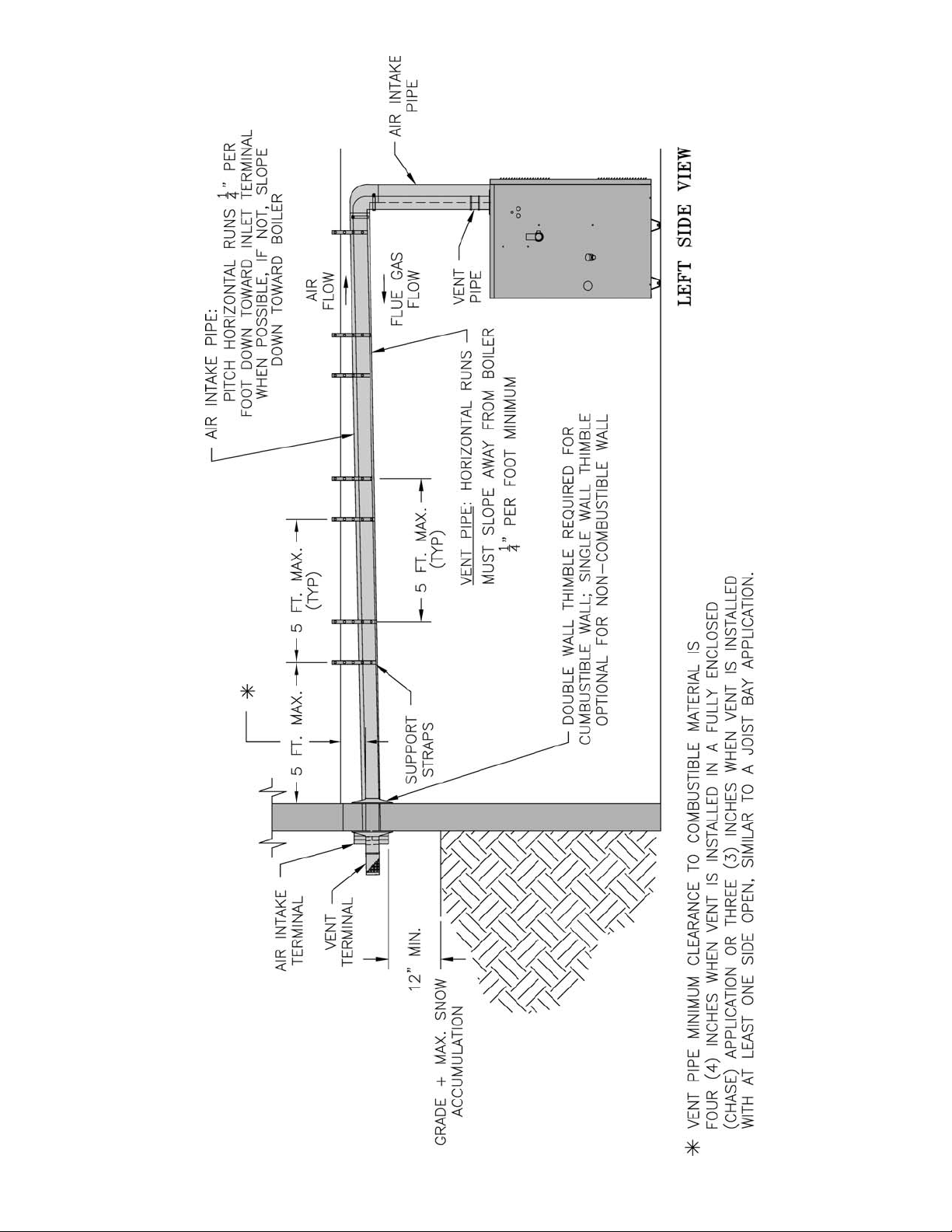

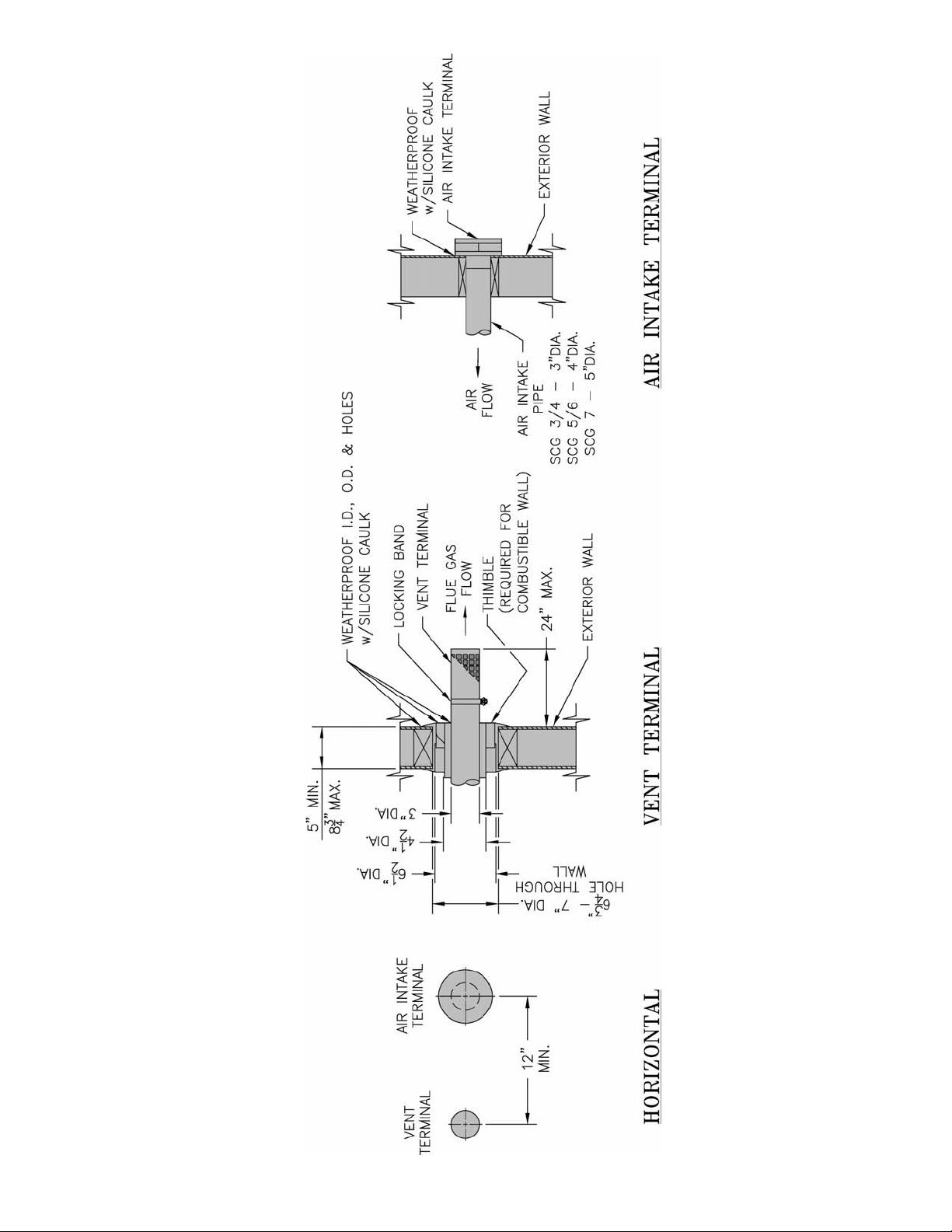

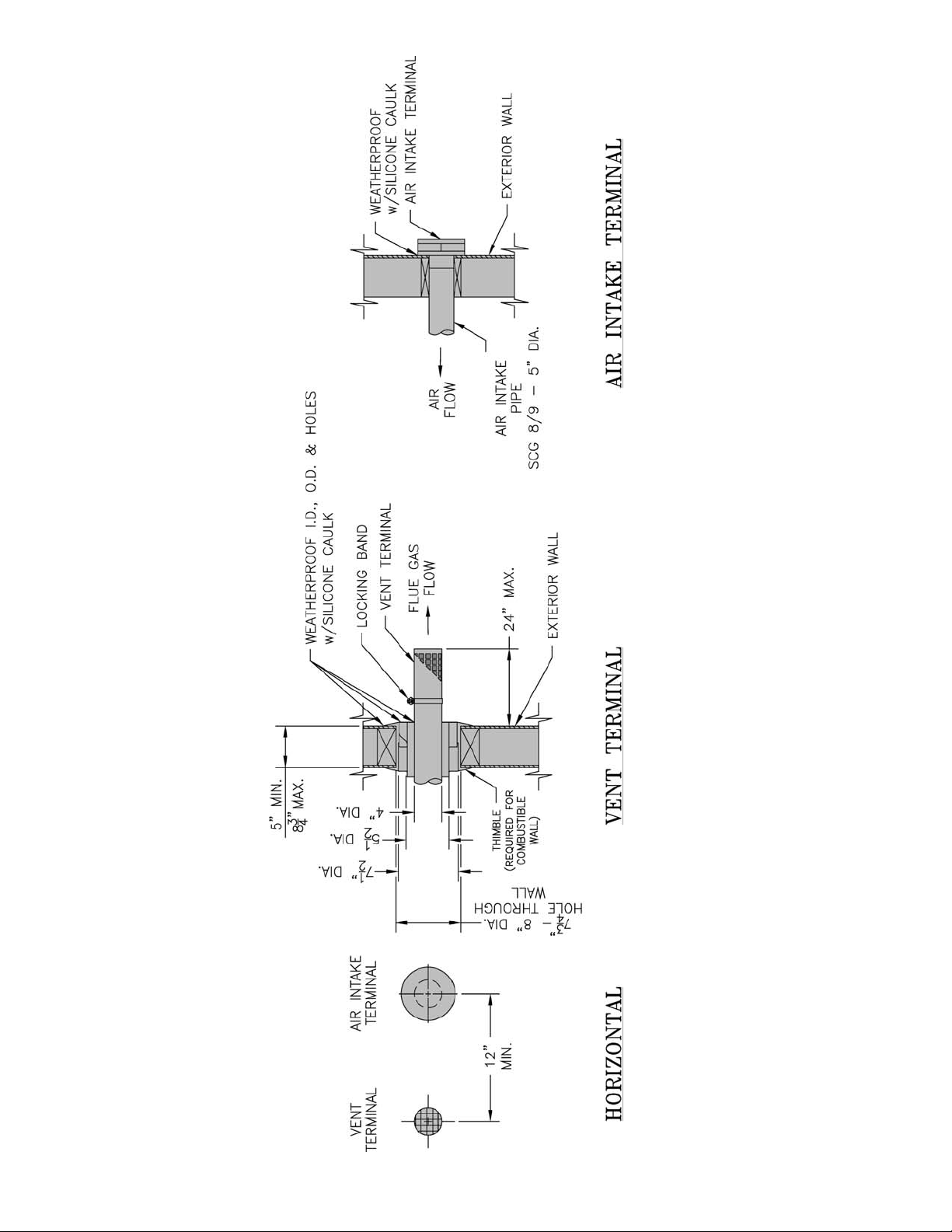

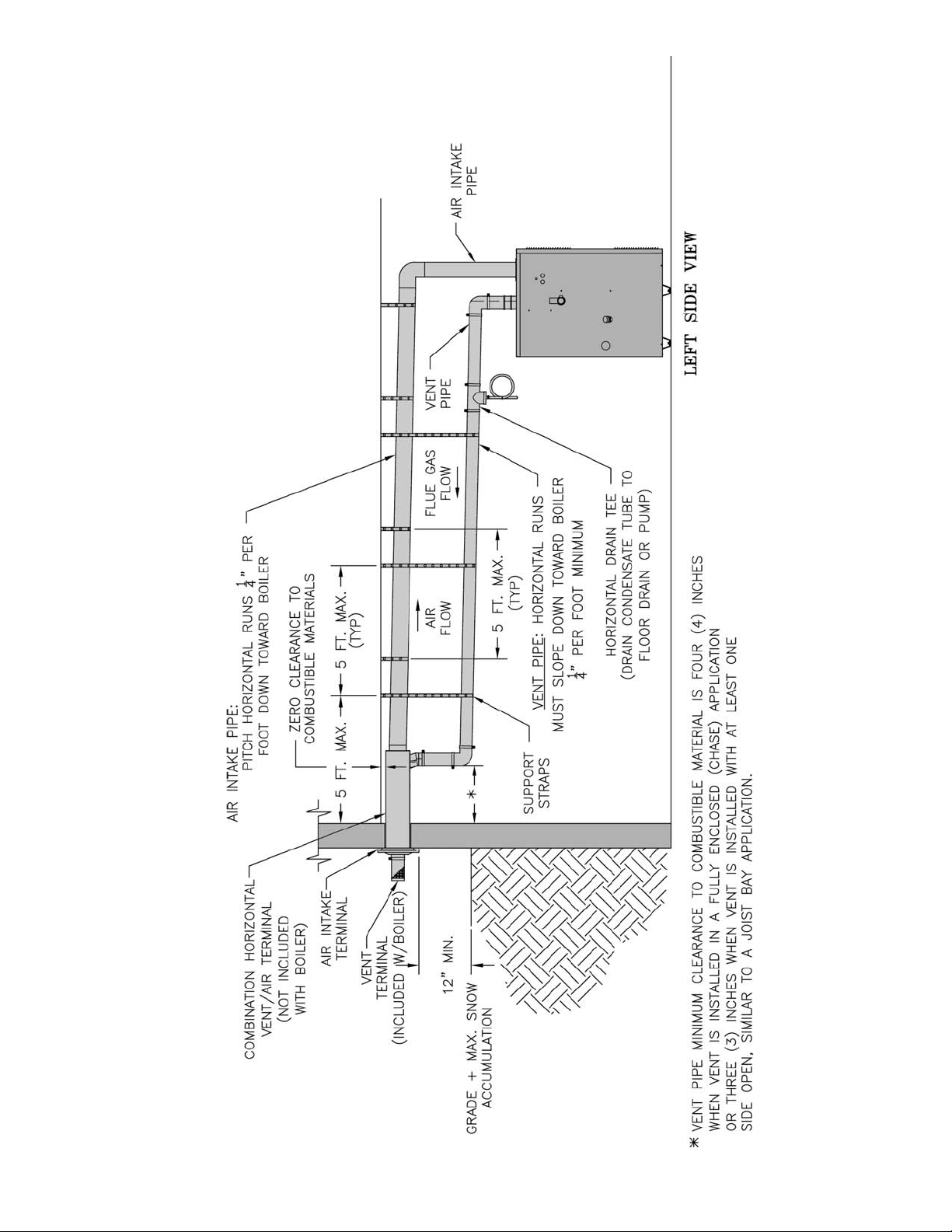

D. Separate Horizontal Venting System. See Figures 4,

5A and 5B.

Vent Piping –

1. This boiler is supplied with components as standard

equipment for installation of the separate horizontal

venting system.

2. Do not exceed maximum vent/air intake lengths.

Refer to Table 4.

3. Recommended horizontal installation consists of

vent being sloped down ¼ inch per foot away from

boiler. See Figure 4.

4. Use appropriate designed thimbles when passing

through combustible walls (thimble use optional for

noncombustible walls). Insert thimble through wall

from outside. Secure outside fl ange to wall with

nails or screws, and seal ID, OD and vent holes with

sealant material. Install inside fl ange to inside wall,

secure with nails or screws, and seal with sealant

material.

5. For noncombustible wall application when thimble

is not used, size opening such that bell with locking

band attached cannot pass through.

6. Join vent terminal to vent pipe. See Figures 5A and

5B.

7. Insert vent pipe through thimble/opening from

outside and join to vent system. Apply sealant

between vent pipe and opening/thimble to provide

weathertight seal.

Air Intake piping - See Figures 4, 5A and 5B.

8. Locate air intake termination on the same wall as

the vent termination if possible, to prevent nuisance

boiler shutdowns. However, boiler may be installed

with vertical venting and sidewall combustion air

inlet or visa versa, if installation conditions do not

allow alternate arrangement.

9. Do not exceed air intake length. See Table 4.

10. Use single wall metal or PVC pipe.

a. Air intake pipe diameter is based on boiler size.

SCG-3 & SCG-4 uses 3 inch diameter piping.

SCG-5 & SCG-6 uses 4 inch diameter piping.

SCG-7 thru SCG-9 uses 5 inch diameter piping.

11. Air intake termination must be located:

Horizontal - At least twelve (12) inches above

grade plus the expected snow accumulation.

12. Start at collar on burner enclosure (inside boiler

jacket) and work towards the air intake terminal.

13. Maintain minimum of ¼ inch per foot slope on

horizontal runs. Slope towards air inlet terminal

when possible. If not, slope towards boiler.

14. The air intake pipe must be adequately supported

with straps or supports no less than fi ve (5) feet

apart on horizontal runs. The complete air intake

piping system must be rigid and able to withstand

minor impacts without collapse.

15. Inlet air pipe penetration:

Horizontal - Size wall penetration to allow easy

insertion of air inlet piping. Seal around pipe with

sealant to form weathertight exterior joint.

16. Seal all joints airtight, using silicone caulk or selfadhesive aluminum tape.

17. Install Air Intake T erminal :

Horizontal - Remove four (4) screws from cover

plate and remove cover plate from terminal. Insert

intake piping into intake terminal collar. Secure

terminal to intake piping and seal joint with silicone

caulk or self-adhesive aluminum tape. Apply

continuous bead of silicone caulk around the back

of the intake terminal, approximately ¼ inch from

its edge. Push inlet terminal inward until terminal’s

back fl ange is against the wall surface. Secure the

terminal with noncorrosive fasteners (stainless steel,

brass or aluminum) to the wall. Reinstall the cover

plate with four (4) screws. Apply a bead of silicone

caulk to perimeter of intake terminal’s back fl ange

to provide a weathertight seal.

12

Page 13

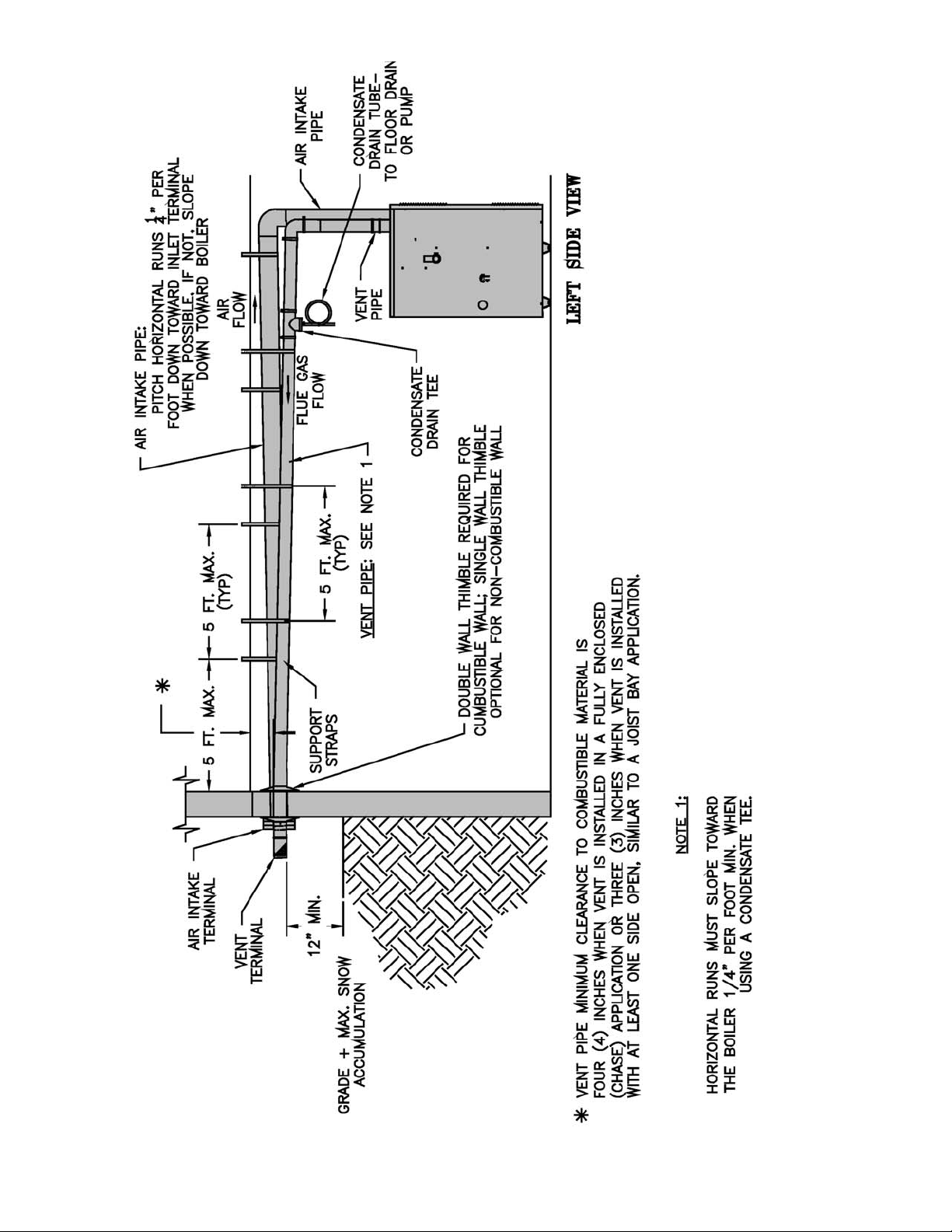

Figure 4: Recommended Separate Horizontal – Vent/Air Intake Installation

13

Page 14

14

Figure 4B: Alternate Separate Horizontal – Vent/Air Intake Installation

Page 15

Figure 5A: Separate Horizontal – Vent/Air Intake Terminal Confi guration (SCG-3 thru 7)

15

Page 16

16

Figure 5B: Separate Horizontal – Vent/Air Intake Terminal Confi guration (SCG-8 and 9)

Page 17

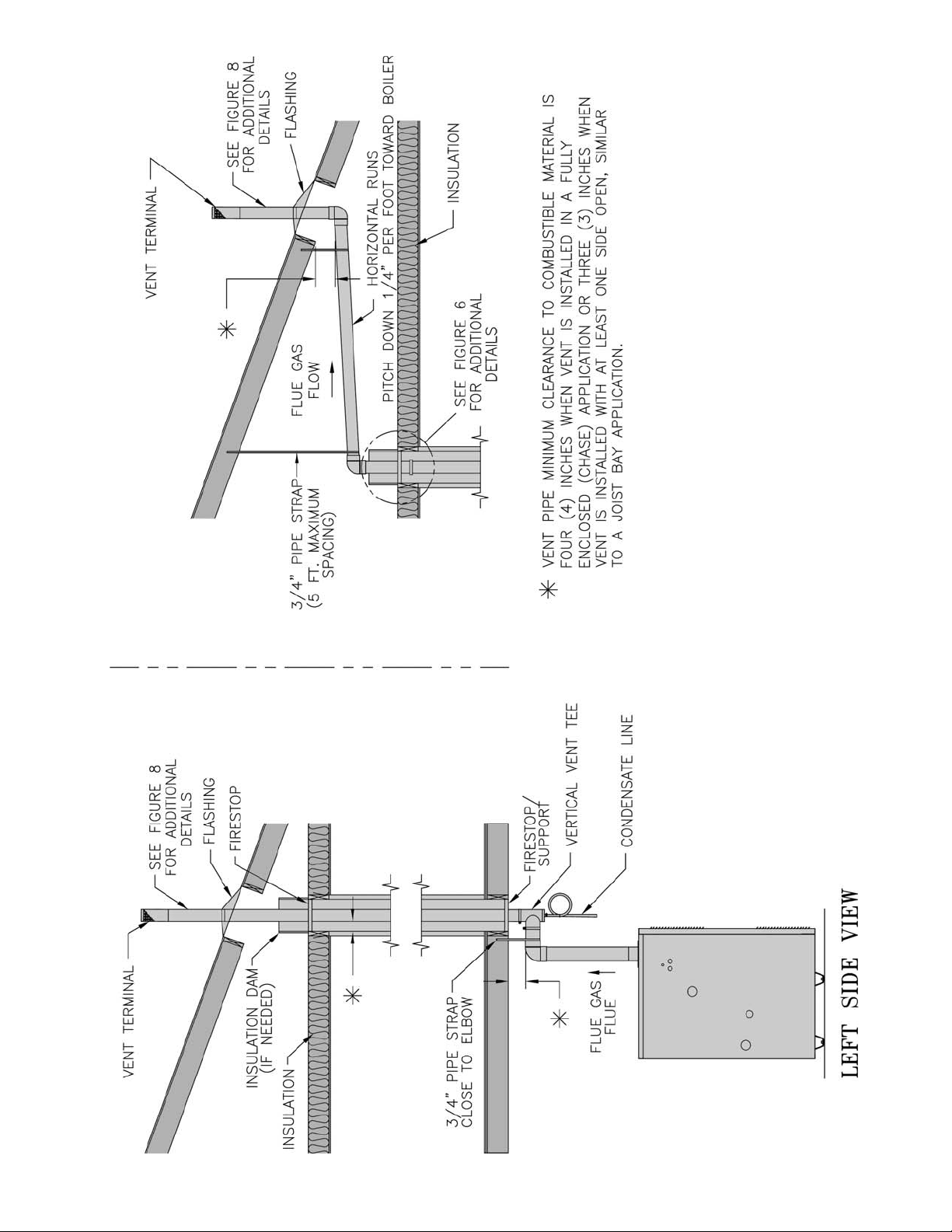

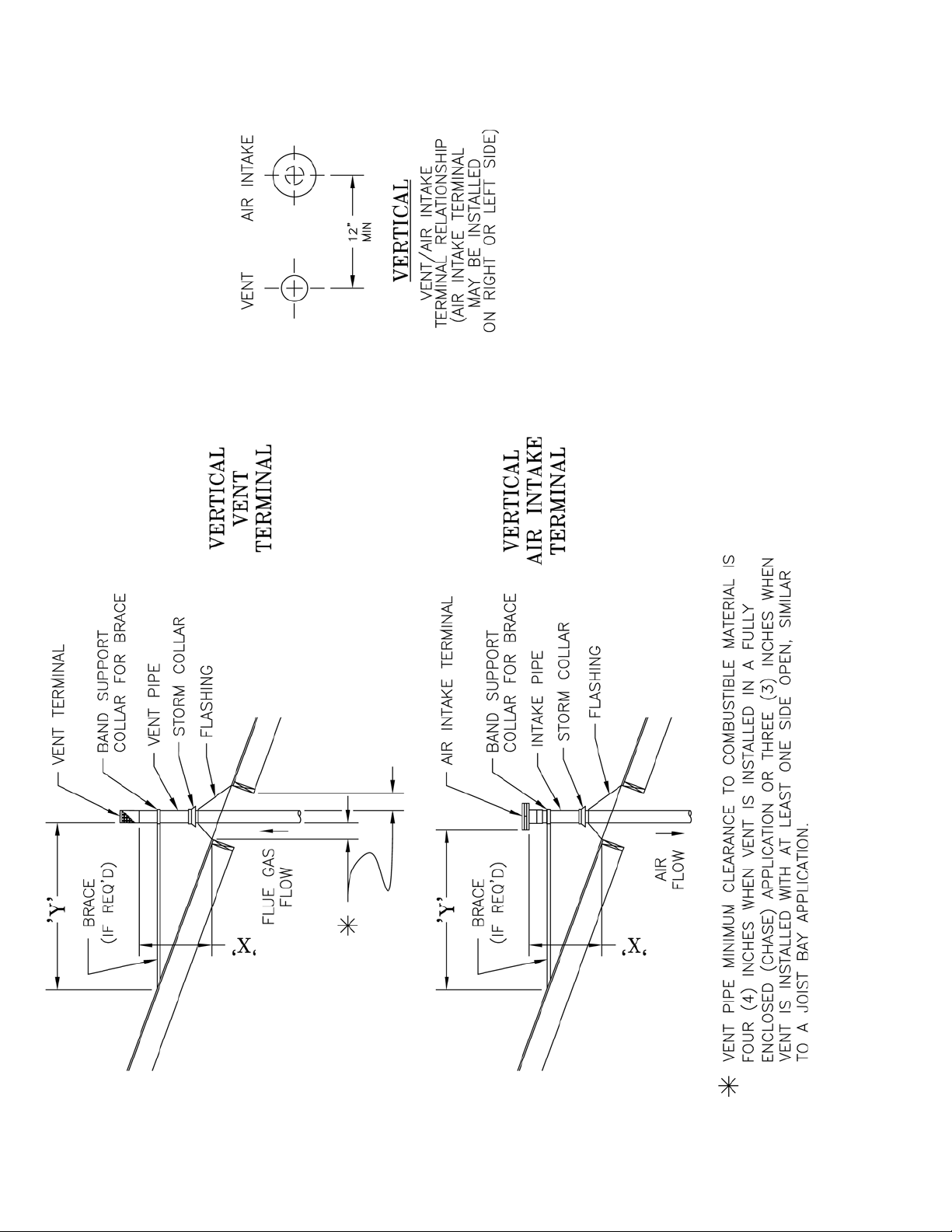

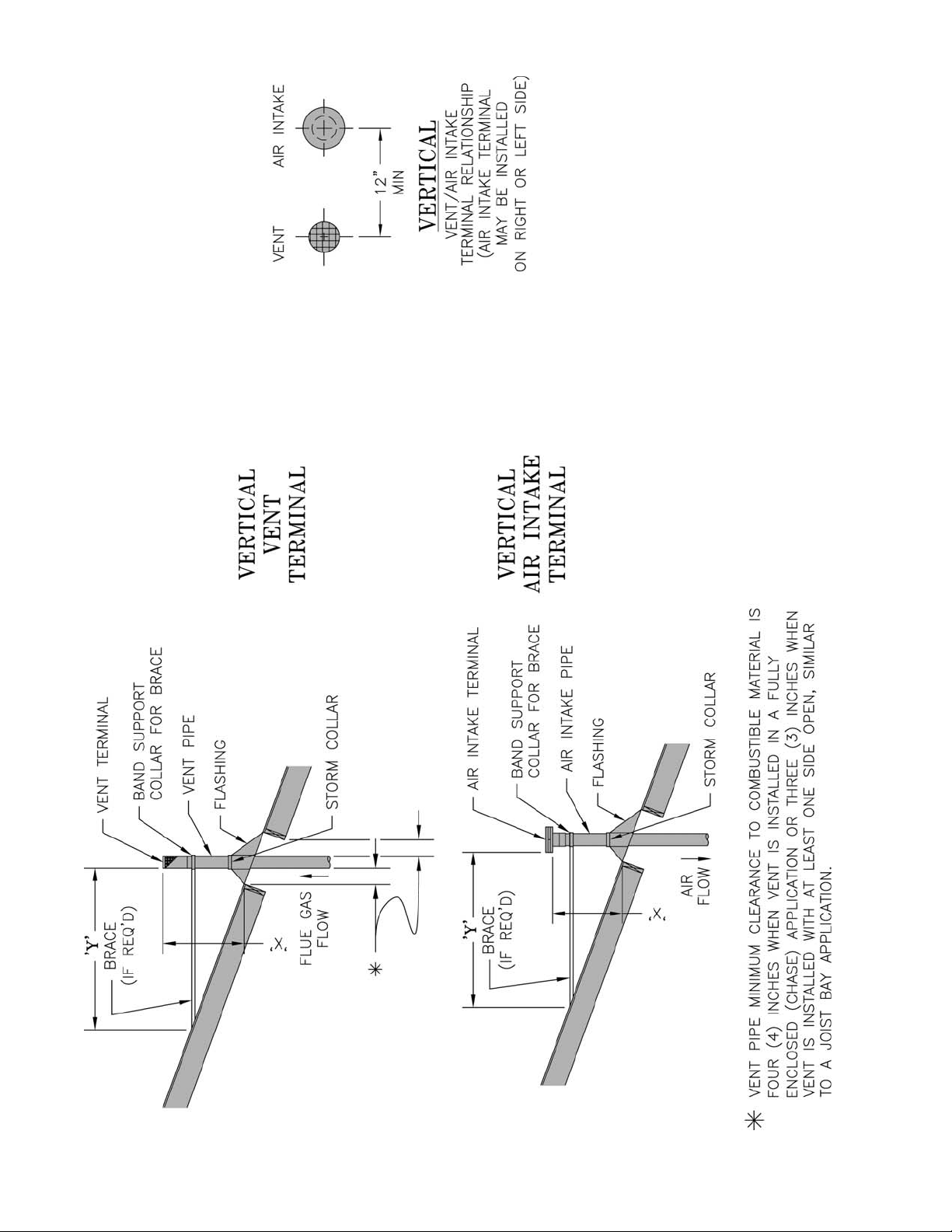

E. Separate Vertical Venting System - See Figures 6, 7, 8A, 8B and 9.

ECITON

.reliob

foorfoesuehteriuqersnoitartenepfooR

htiwdeilppuston-rallocmrotsdnagnihsalf

Vertical Venting

1. Do not exceed maximum vent lengths. Refer to

Table 4.

2. Installation of a vertical vent tee 8116304U is

required on all vertical vent applications. See

Figures 6 and 7. Attach vertical vent drain tee

directly to elbow or horizontal pipe from an elbow

immediately after vent connector.

3. Slope horizontal runs minimum ¼ inch per foot.

Slope towards vertical vent drain tee. Position weld

seams in vent pipes, in all horizontal runs, at the top

to avoid condensate from lying on the seams.

4. Install fi re stops where vent passes through fl oors,

ceilings or framed walls. The fi re stop must close

the opening between the vent pipe and the structure.

5. Whenever possible, install vent straight through

the roof. Refer to Figure 7 if offset is necessary.

Maintain minimum clearance to combustible

materials.

6. Install V ent Terminal.

a. Size roof opening to maintain minimum

clearance from combustible materials.

b. Extend vent pipe to maintain minimum vertical

and horizontal distance of twelve (12) inches

from roof surface. Allow additional vertical

distance for expected snow accumulation.

Provide brace as required. Refer to Figures 8A

and 8B.

–

ECITON

foorfoesuehtseriuqergnitnevlacitreV

tneverpotrallocmrotsadnagnihsalf

.erutcurtsehtgniretnemorferutsiom

c. Install storm collar on vent pipe immediately

above fl ashing. Apply Dow Corning Silastic 732

RTV Sealant between vent pipe and storm collar

to provide weathertight seal.

d. Attach vent terminal.

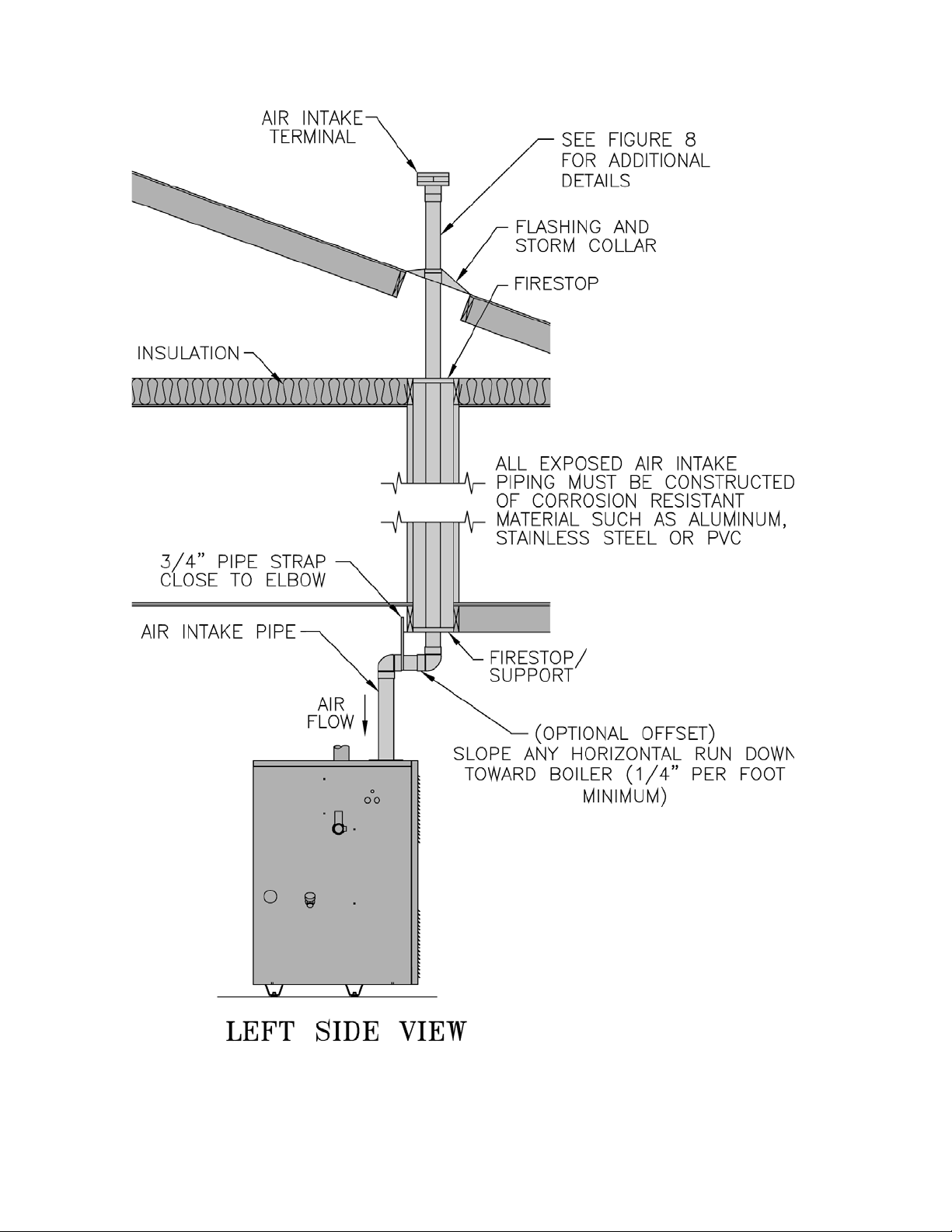

Vertical Air Intake Piping –

7. Do not exceed maximum air intake length. Refer to

Table 4.

8. Locate air intake termination on the same roof

location as the vent termination if possible, to

prevent nuisance boiler shutdowns. However, boiler

may be installed with vertical venting and sidewall

combustion air inlet or visa versa, if installation

conditions do not allow alternate arrangement.

9. Use single wall metal pipe or PVC and fi ttings

available at most heating distributors.

a. Air intake pipe diameter is based on boiler size.

SCG-3 & SCG-4 uses 3 inch diameter piping.

SCG-5 & SCG-6 uses 4 inch diameter piping.

SCG-7 thru SCG-9 uses 5 inch diameter piping.

10. Air intake termination must be located:

Vertical - At least twelve (12) inches above the roof

surface plus the expected snow accumulation.

11. Start at collar on burner enclosure (inside boiler

jacket) and work towards the air intake terminal.

12. Maintain minimum of ¼ inch per foot slope on

horizontal runs. Slope down towards boiler.

13. The air intake pipe must be adequately supported

with straps or supports no less than fi ve (5) feet

apart on horizontal runs. The complete air intake

piping system must be rigid and able to withstand

minor impacts without collapse.

14. Inlet air pipe penetration:

Vertical - Size roof opening to allow easy insertion

of inlet piping and allow proper installation of

fl ashing and storm collar.

a. Use appropriately designed vent fl ashing

when passing through roofs. Follow fl ashing

manufacturers’ instructions for installation

procedures. Flashing manufacturers are AirJet, American Metal Products, Metal Fab, and

Simpson Dura-Vent.

b. Extend air intake pipe to maintain minimum

vertical and horizontal distance of twelve

(12) inches from roof surface. Allow

additional vertical distance for expected snow

accumulation. Provide brace as required. Refer

to Figures 8A and 8B.

c. Vertical air intake requires fl ashing and a storm

collar to prevent moisture from entering the

structure.

17

Page 18

d. Install storm collar on air intake pipe

immediately above fl ashing. Apply Dow

Corning Silastic 732 RTV Sealant between

air intake pipe and storm collar to provide

weathertight seal.

e. All exposed air intake piping must be

constructed of corrosion resistant material such

as aluminum, stainless steel or PVC.

15. Seal all joints airtight, using silicone caulk or selfadhesive aluminum tape.

16. Install Air Intake Terminal:

Vertical - Insert intake piping into intake terminal

collar. Secure terminal to intake piping and seal

joint with silicone caulk.

18

Page 19

Figure 7: Attic OffsetFigure 6: Vertical Vent Installation

19

Page 20

20

Figure 8A: Vertical Vent/Air Termination (3” Vent Terminal)

Extend Vent/Air Intake Piping to maintain minimum vertical (“X”) and minimum horizontal (“Y”) distance of twelve (12) inches from

roof surface. Allow additional vertical (“X”) distance for expected snow accumulation.

Page 21

Figure 8B: Vertical Vent/Air Termination (4” Vent Terminal)

Extend Vent/Air Intake Piping to maintain minimum vertical (“X”) and minimum horizontal (“Y”) distance of twelve (12) inches from roof surface. Allow ad-

21

ditional vertical (“X”) distance for expected snow accumulation.

Page 22

22

Figure 9: Vertical Air Intake Piping

Page 23

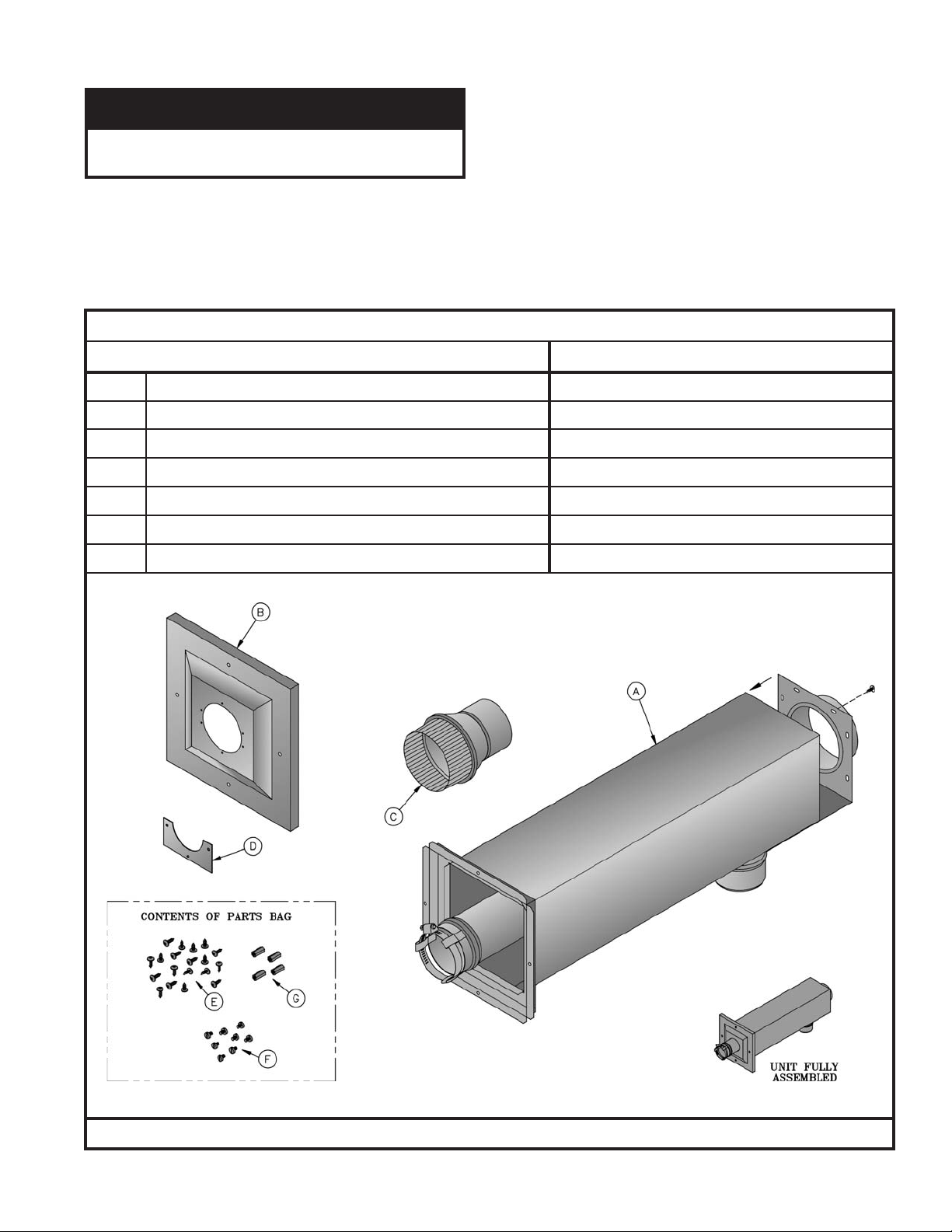

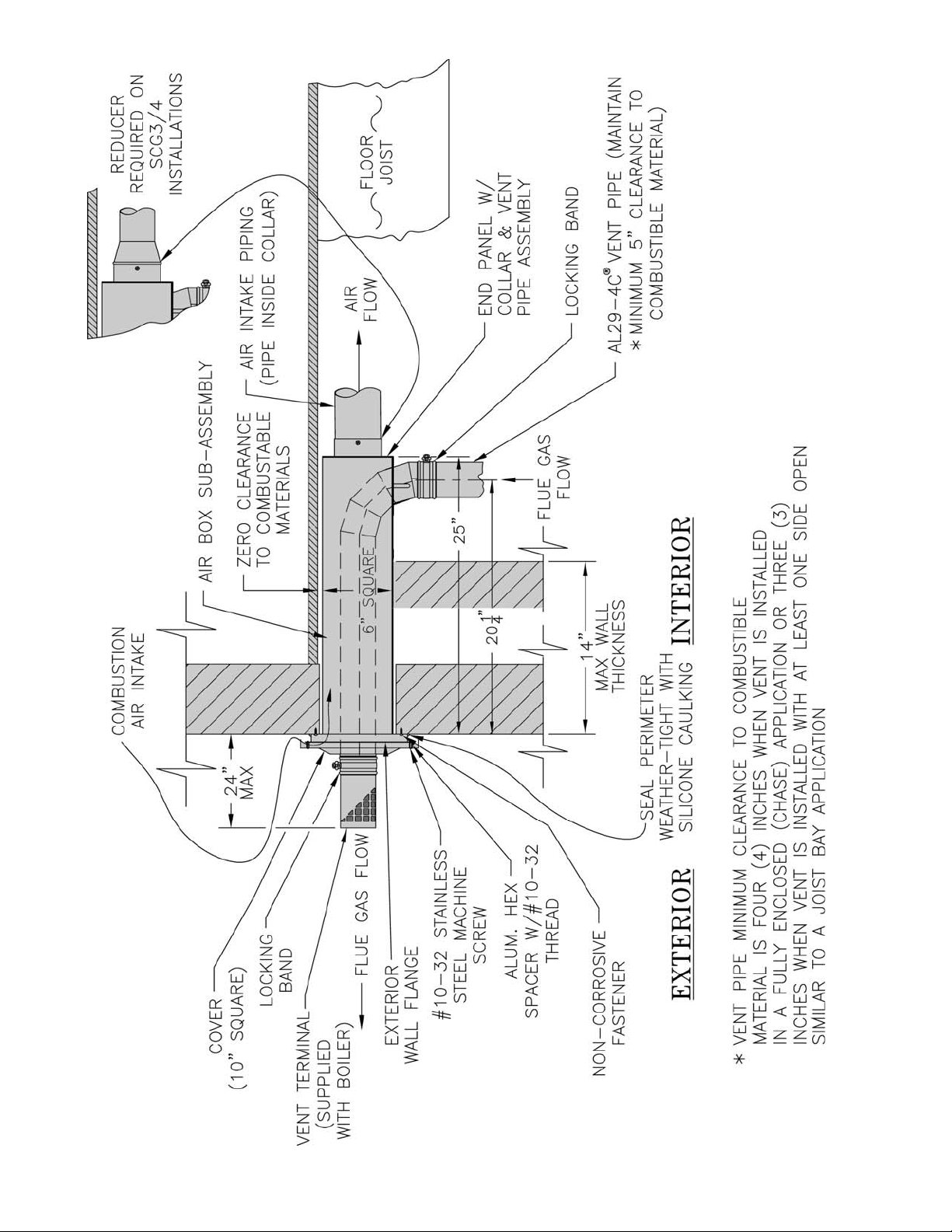

F. Combination Horizontal Venting System –SCG-3 Through SCG-6 ONLY – See Figures 10 and 11.

ECITON

tonstnenopmocseriuqermetsystnevsihT

.reliobehthtiwdeilppus

2.

Install Combination Vent/Air Terminal. See Figure 11.

a. After determining the location with reference to Section B - General Venting Guidelines, cut a 6-1/8 inch square

opening in the wall for the air box sub-assembly which is 6 inch square.

b. Remove and save shipping screw from end panel with collar and vent pipe assembly. This will be reinstalled in a later

step.

1. Do not exceed maximum vent/air intake lengths.

Refer to Table 4.

21060116rebmuNtraPnotraCtneV)wolebsmetisedulcni(

noitpircseDrebmuNtraPtnenopmoC

A)gnol'2xerauqs"6(ylbmessA-buSxoBriA 11060116

B)erauqs"01(revoCllaWroiretxE 61060117

CrecudeRepiPtneV"3x"4 93

D)2(revoCroiretxElaeS-etalP 71060117

E)91(wercSlateMteehSleetSsselniatS"½x8# 74006808

F)8(wercSenihcaMleetSsselniatS"¼x23-01# 24806808

26118

G)4(recapSmunimulA"½x23-01# 71616808

BMOC

STNENOPMOCMETSYSTNEVLATNOZIROHNOITANI

23

Page 24

c. From exterior of building, insert air box sub-

assembly into square opening. Push air box

inward until wall fl ange is against wall, check

for level and mark the location of the four (4)

securing holes on the exterior wall. Remove air

box from wall.

d. Drill four (4) pilot holes, properly sized for the

non-corrosive fasteners (stainless steel, brass, or

aluminum) to be used to secure the wall fl ange to

the exterior wall. (Securing screws not supplied

with kit.)

e. Attach four (4) 1/2 inch long threaded aluminum

spacers to the outer fl anges of the exterior

wall fl ange with four (4) number 10 - 32 x 1/4

inch stainless steel machine screws provided.

(See Figure 11.)

f. Apply a 1/4 inch thick continuous bead of

silicone caulk to perimeter of exterior wall

fl ange’s back surface to provide a weathertight

seal.

g. Reinstall air box sub-assembly into opening in

exterior wall and secure to wall.

GNINRAW

.desuebtsumsrenetsafevisorroc-noN

h. Apply a bead of silicone caulk to perimeter of

wall fl ange, where the wall and fl ange join. Use

a tool or your fi nger and apply pressure while

smoothing caulking to provide a weathertight

seal.

i. From interior of building, insert end panel with

collar and vent pipe assembly into open end of

air box sub-assembly. (See Figure 11.)

j. Secure end panel to air box sub-assembly with

shipping screw and thirteen (13) number 8 sheet

metal screws provided.

k. From exterior of building, position 10 inch

square exterior wall cover over exterior wall

fl ange. Insert 3 inch diameter vent pipe into

center opening in terminal cover. Align four

(4) holes on cover with 1/2 inch long threaded

spacers on wall fl ange. Secure terminal cover

with four (4) number 10 - 32 x 1/4 inch stainless

steel machine screws provided.

l. Apply a bead of silicone caulk to perimeter of

plate-seal and around pipe. Secure plate-seal to

exterior cover with six (6) #8 stainless steel sheet

metal screws provided. Smooth caulk around

plate-seal and pipe to provide weathertight seal.

m. Install Vent Terminal supplied with boiler to vent

pipe penetrating through terminal cover. Join

terminal and pipe with locking band and seal

with RTV (see Figure 3).

3. Install Vent Piping. See Figure 10 and 11.

a. Start at vent connector on boiler and work

towards combination vent/air terminal.

b. Installation of a vertical vent tee 8116304U is

required on all vertical vent applications. See

Figures 12 and 13. Attach vertical vent drain

tee directly to elbow or horizontal pipe from an

elbow immediately after vent connector.

c. Slope horizontal runs minimum ¼ inch per foot.

Slope towards vertical vent drain tee. Position

weld seams in vent pipes, in all horizontal runs,

at the top to avoid condensate from lying on the

seams.

d. Use 3/4 inch pipe strap to support horizontal runs

and maintain vent location and slope. Maximum

support spacing is fi ve (5) feet.

e. Install vent piping to connect vent connector

on boiler and combination vent/air terminal.

Reference Section B - General Venting

Guidelines for proper procedure for joining pipe

and fi ttings.

f. Connect vent piping to combination vent/air

terminal. See Figure 10.

4. Install Air Intake Piping. See Figures 10 and 11.

a. Do not exceed air intake length. See Table 4.

b. Use single wall metal pipe or PVC and fi ttings

available at most heating distributors.

c. Air intake pipe diameter is based on boiler size.

SCG-3 & SCG-4 uses 3 inch diameter piping.

SCG-5 & SCG-6 uses 4 inch diameter piping.

SCG-7 thru SCG-9 uses 5 inch diameter piping.

d. Start at collar on burner enclosure (inside boiler

jacket) and work towards the combination vent/

air terminal.

e. Maintain minimum of 1/4 inch per foot slope on

horizontal runs. Slope down towards boiler.

f. The air intake pipe must be adequately supported

with straps or supports no less than fi ve (5)

feet apart on horizontal runs. The complete air

intake piping system must be rigid and able to

withstand minor impacts without collapse.

g. Connect Air Intake Piping to Combination Vent/

Air Terminal. See Figure 10.

NOTE: When installing 3 inch diameter air intake

piping for a SCG-3 or SCG-4 application, the use of

a 4 inch x 3 inch reducer will be required to connect

air intake piping to combination vent/air terminal.

(Reducer included with combination horizontal

venting kit).

h. Seal all joints airtight, using silicone caulk or

self-adhesive aluminum tape.

24

Page 25

Figure 10: Combination Horizontal – Vent/Air Installation (SCG-3 thru 6)

25

Page 26

26

Figure 11: Combination Horizontal – Vent/Air Terminal Installation (SCG-3 thru 6)

Page 27

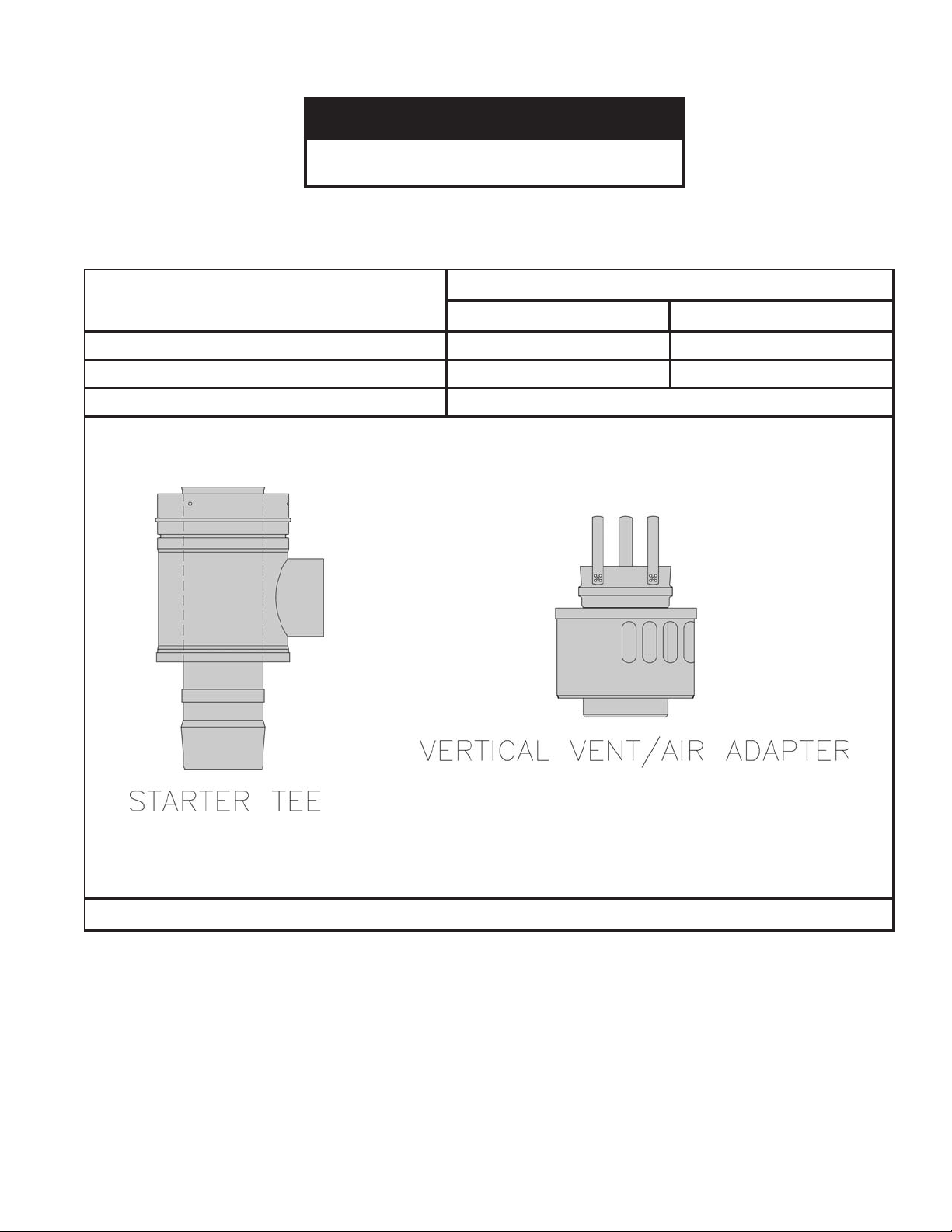

G. Combination Vertical Venting System – SCG-3 Through SCG-6 ONLY – See Figures 12, 13 and 14.

ECITON

tonstnenopmocseriuqermetsystnevsihT

.reliobehthtiwdeilppus

rebmuNtraP

noitpircseD

rebmuNtraPnotraCtneV 10-22200110-322001

eeTretratS 10-42200110-522001

rotpadAriA/tneV 10-622001

4-GCS&3-GCS6-GCS&5-GCS

STNENOPMOCMETSYSTNEVLACITREVNOITANIBMOC

27

Page 28

1. Saf-T Vent SC is an advanced concentric vent

system designed for zero clearance installation

in residential applications. The inner wall is

constructed from superferritic AL29-4C® stainless

steel. The outer wall is also constructed from

stainless steel, providing durability and a lasting

fi nish.

2. As a Special Gas Vent system: Saf-T Vent is

approved for use on ANSI Category I, II, III, and

IV Gas-Burning Appliances and certain Direct Vent

Appliances. Saf-T Vent SC is appropriate for use on

appliances that specify an AL29-4C venting system.

3. As a Sealed Combustion system: The unique

concentric design of Saf-T Vent SC also allows it

to function as a pipe-in-a-pipe vent. Products of

combustion are exhausted out through the inner wall

while combustion air is drawn in through the outer

wall. An appliance can be direct-vented with only

a single penetration through the building structure.

This application must be approved by the

Appliance Manufacturer.

Note: Saf-T Vent SC includes an integral seal and

does not require RTV sealant. However, sealant

may be necessary when connecting Saf-T Vent SC

components directly to certain appliance fl ue collars

and to the gasket-less Saf-T Vent GC and Saf-T Vent

CI vent systems.

For applications up to 550°F/288°C, approved

sealants include GE RTV 106 and Dow Corning

736.

For applications up to 300°F/149°C, approved

sealants include GE RTV 106 and Dow Corning

732.

4. Pre-Installation Considerations:

• Proper planning prior to installation is essential

as to avoid possible contact with concealed

plumbing or electrical wiring inside walls,

fl oors or ceilings as well as maintaining proper

clearances. Be sure to plan a suffi cient number

of supports for the entire system that will

maintain the required straight-line pitch and hold

the system in place. A continuous straight-line

pitch of at least ¼” (2°) to the foot on horizontal

runs must be maintained in order to properly rid

the system of the corrosive condensate.

5. General Installation Requirements:

• Saf-T Vent SC vent sections, or other Saf-T

Vent products, must be used throughout the

entire length of the system. Alternatives such

as galvanized pipe, PVC, nonmetallic pipe,

prefabricated chimney, fi eld-fabricated vents

or Type B vent sections must not be used. Do

not mix pipes, fi ttings, or joining methods from

different manufacturers.

• More than one appliance may not be

interconnected to any part of the venting system.

• Any penetrations of ceilings, fl oors or walls must

be properly fi re-stopped.

• Whenever gas-burning equipment is installed in

the same space where halogenated substances

may exist (refrigerants, solvents, bleaches,

salts, etc.), clean outside air must be utilized for

combustion.

• The vent system shall not be routed into,

through or within any other actively used vent or

chimney.

• Seal weather exposed joints of the outer jacket

with foil tape or an exterior grade silicone

sealant.

• Combustible Material is any material made of

or surfaced with wood, compressed paper, plant

fi bers, or other materials that are capable of

being ignited or burned. Such material shall be

considered combustible even though it is fl ame-

proofed, fi re-retardant, or plastered. (Source:

NPFPA54/ANSI Z223.1-1999.)

• Non-Combustible Material is any material that

is not capable of being ignited and burned, such

material consisting entirely of, or a combination

of, steel, iron, brick, tile, concrete, slate,

asbestos, glass and plaster. (Source: NPFPA54/

ANSI Z223.1-1999.)

28

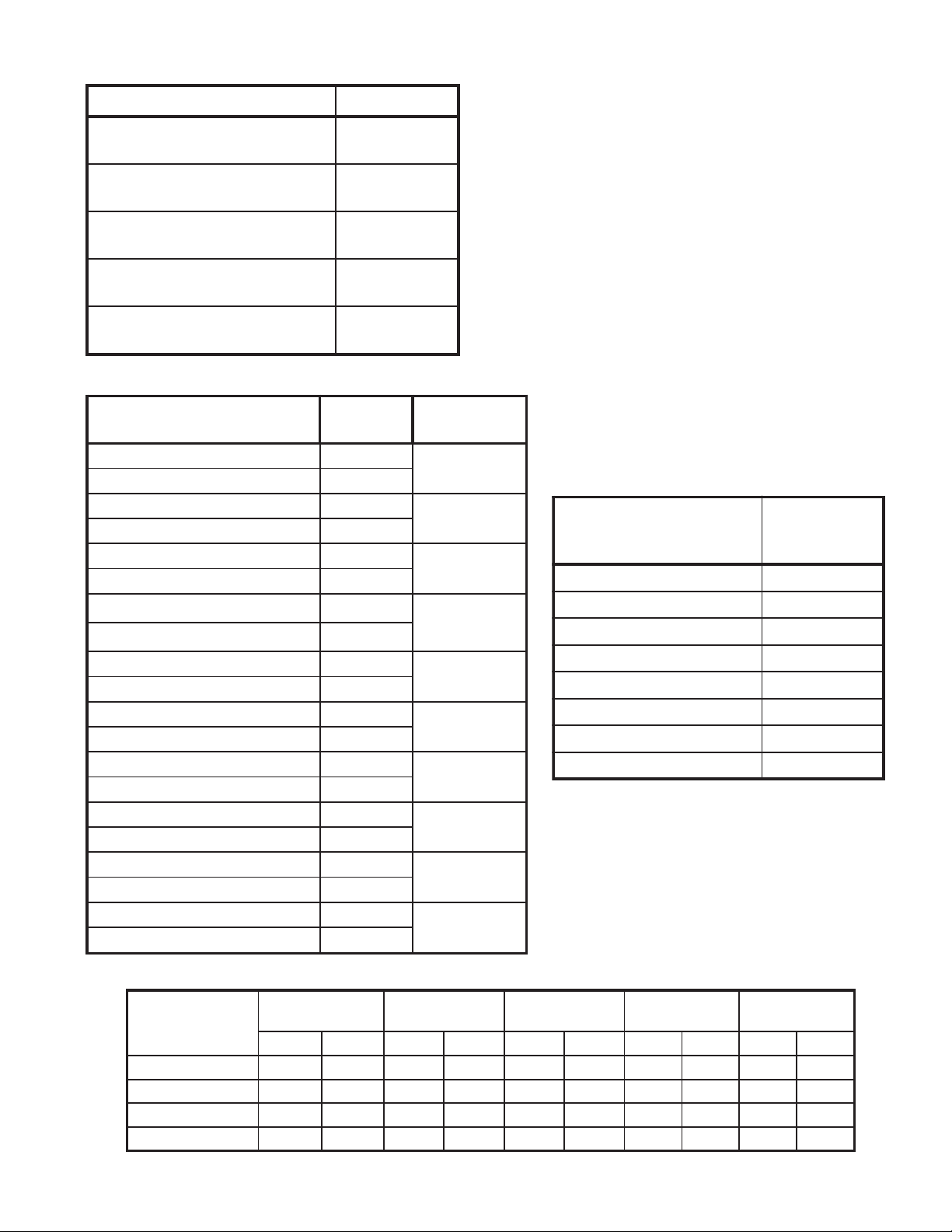

Clearances to Combustibles:

otecnaraelC

retemaiD

elbitsubmoC

lairetaM

"0

"4-"3

"1004

"0

"1055

"0055ynAlairetamelbitsu

eulFmumixaM

)F°(.pmeTsaG

055

033

004,nepoedis1tsaelta,desolcnenU

noitatneirOerusolcnE

,lacitreV

stesffOoN

,latnoziroH

htiwlacitreV

sffO

ste

elbitsubmocybdesolcneylluF

sedisllanolairetam

anolairetamelbitsubmoc

sedis3fomumixam

bmocnoN

Page 29

• For a venting system that extends through

any zone above that on which the connected

appliance is located (except for one and two

family dwellings), the vent system shall be

enclosed with an enclosure having a fi re

resistance rating equal to or greater than that of

the fl oor or roof assemblies through which it

passes.

• Design any enclosure to permit inspection of the

system.

• Do not place any type of insulation in any

required clearance spaces surrounding the vent

system.

6. Vertical Installation Requirements:

a. Seal weather exposed joints of the outer jacket

with foil tape or an exterior grade silicone

sealant.

b. The vent system must terminate at least 3 feet

above the roof line and at least 2 feet higher than

any portion of the building within 10 feet.

c. When terminated at a height of more than 6 feet

the stack must be supported by a support bracing.

The vent should be supported every 10 feet.

d. The total continuous distance of the vent system

from the appliance fl ue collar to the termination

shall not exceed that specifi ed in the appliance

manufacturer’s installation instructions.

e. In cold climates do not install a condensate drain

on the exterior of the building. Doing so may

result in dangerous icy conditions on surfaces

near the drain and may cause damage to the vent

system and/or the building exterior.

f. Install supports every 10 feet vertically along the

vent pipe route. Vertical supports are required

after every transition to vertical and are required

after every offset elbow. When the vent is free

standing and penetrates a roof/ceiling another

means of support must be used at a second

location. Refer to the Vertical Supports section

in this manual.

29

Page 30

7. Joint Assembly Instructions:

a. Before joining the sections or fi ttings together, use an alcohol pad to wipe the joint area of both ends of the inner

pipe. This will remove any foreign matter which may affect the integrity of the seal. Install the system with the

female ends (ends with the red seal) pointing away from the appliance. (Unless specifi ed differently by the appliance

manufacturer.)

b. Insert the male end of the inner pipe into the female end of the previous section. In extremely dry conditions it may be

helpful to moisten the seal with clean water prior to assembly. Push fi rmly until the outer jacket has made contact with

the snap ring located inside the female end of the previous section. When fully assembled the outer female end will

overlap the male end 1”.

30

c. Use the three (3) self-tapping screws provided to connect the outer vents. No pre-drilling is required.

NOITUAC

,llirdeuqrotelbairavagnisufI.nethgitrevotonoD

.desuebnactevirtoptrohsro).xamgnol"½(wercs

swercsllatsniotgnitteseuqrotwolaesu

sa,

retemaidregrala,gninethgitrevooteuddeppirtssemocebelohafI.selohehttuopirtsotton

Page 31

8. Straight Sections Cut To Length:

If a custom length of SC is necessary, a standard vent

section can be cut.

a. Measure the distance of the length needed, taking the

measurement from the end of one of the outer jackets

to the beginning of the other outer jacket on the

section to connect to, (A to B on diagram).

b. Select a section that is longer than the required

length.

c. It will be necessary to disassemble the vent prior to

cutting.

Stand the section on end with the holes up. Find the

end of snap ring and pry it out of its groove, being

careful not to damage the ends of the vent pipes.

Pull up on end of the snap ring and pull it out from

the end of the pipe. It may want to spiral out as it is

removed. After the snap ring is removed, the inner

vent pipe can be separated from the outer jacket.

d. Add 2” to the distance measured previously for the

cut length of the outer jacket. Mark a cut line on the

outer jacket on the male end (the end without holes in

it).

An effective way of marking is to run a length of tape

around the section, assuring a square cut.

e. Add 3” to the distance measured previously for the

cut length of the inner vent pipe. Mark a cut line on

the inner vent on the male end (the end without the

red seal).

The inner pipe is always cut 1” longer than the

outer pipe.

f. WEAR GLOVES, as cut ends are very sharp. Cut

the pipes with an abrasive cutoff saw, plasma cutter,

or compound snips. If using snips, start the cut at

the male end and follow a spiral path around the pipe

until the cutoff mark is reached. File off any burrs

or rough edges that develop in the cutting process

and clean off any dust or grit. If the cutting process

distorts the roundness of the pipes, carefully use your

thumbs to re-round the ends.

g. Reassemble the inner vent into the outer jacket and

reinstall the snap ring into the groove. Push the

inner vent into the outer jacket until the triangle on

the inner vent is seated fi rmly against the bead on

outer jacket. Start one end of the snap ring into the

groove of the outer pipe. Slowly turn and feet the

snap ring into the groove in a spiral motion, and

continue around the pipe until the snap ring is fully

inserted. Ensure that the triangle on the inner vent is

all the way down against the bead of the outer jacket

by pushing in fi rmly. Also ensure that the snap ring

is completely in the groove all the way around outer

jacket.

31

Page 32

9. Air Intake Connections for Direct Vent and Sealed

Combustion Appliances*:

The Air Intake Tee may be used on approved direct vent

and sealed combustion appliances that have separate (nonconcentric) air intake and fl ue exhaust collars. The male end

of the tee connects to EZ Seal appliance adapters and the tee

takeoff/snout connects to the appliance air intake.

• Insert the male end of the Air Intake Tee into the female

end of the EZ Seal vent section or appliance adapter and

complete the ring and tab connection.

• Insert the male end of the next SC section into the female

end of the Air Intake Tee and secure as described elsewhere

in this manual.

• Connect the tee takeoff to the appliance combustion air inlet

using appropriate hose or pipe.

* Direct Vent Appliances are constructed and installed so that

all air for combustion is supplied directly from the outside

atmosphere. The passage for the combustion air is allowed

a small amount of leakage in the building environment. No

special installation considerations are required to use Saf-T

Vent SC on Direct Vent appliances unless specifi ed by the

appliance manufacturer. Sealed Combustion appliances are

similar to Direct Vent except the combustion air passage must

be sealed to prevent leakage within the building envelope.

When Saf-T Vent SC is used on approved Sealed Combustion

appliances the joints of the outer jacket must be sealed with

a foil tape (example: 3M 425), or approved silicone sealant

(example: Dow Corning 732).

10. Condensate Drains:

When An Internal Condensate Drain is NOT Part of the

Appliance:

• A Saf-T Vent SC In-Line Drain Section is strongly

recommended. Install this drain fi tting as close to the

appliance fl ue collar as possible.

• A condensate drain is required for every 30 feet of

horizontal vent and at/near the bottom of a vertical stack.

• Use the In-Line Drain Section for a straight horizontal or

vertical run. When used horizontally, rotate the fi tting so that

the drain tube is as vertical as possible.

• A Condensate Drain Tube Kit is available to direct the

condensate to an appropriate location, i.e. fl oor drain or

vented sanitary sewer connection. A trap loop must be

formed into the drain hose and must be a diameter that is

at least four (4) times the appliance’s rated stack pressure

in inches of water column or 3 inches, whichever is

greater. Secure the loop with a cable tie. Prior to fi nal

assembly the trap loop must be ‘primed’ by pouring a

small quantity of water into the drain hose. Inspect at least

annually to verify the trap is ‘primed’.

• Follow all local and national codes and regulations for the

draining of acidic condensate.

• In cold climates do not install a condensate drain on the

exterior of the building. Doing so may result in dangerous

icy conditions on surfaces near the drain and may cause

damage to the vent system and/or the building exterior.

32

Page 33

11. Horizontal Supports:

Saf-T Vent SC must have supports for every six (6) feet of horizontal run and after every transition from vertical to

horizontal. Support hangers by themselves do not maintain the necessary clearances to combustible materials; be sure to

consider clearances when planning the system.

The supports must be secured to solid material using at least #10 fasteners. Do not fasten supports to drywall sheathing

without using hollow wall anchors. The conduit supports must maintain the ¼” per foot pitch to avoid collection of

condensate in the vent. Position the vent so that the welded seam is on the top.

0” Clearance Support Clamp, (SC_ _SUP): Attach the bracket to the structure but do not tighten in place. Open the

hose clamp and slip it under the support bracket. Position the clamp between the mounting screws and rotate the clamp

so that the screw housing will be accessible after the vent is installed. Restart the threads on the hose clamp and securely

tighten the mounting screws to the structure. This can also be installed vertically.

1” Clearance Support Clamp, (SC_ _SUP1): Supports the vent at 1” clearance to the structure. Line up the support

mounting brackets so that the mounting screws will follow the center line of the vent section. This can also be installed

vertically.

33

Page 34

Support Clamp, (4_ _27SS): Support clamps are sold in pairs and can be clamped around the vent and suspended from a

rod or cable. They can be used singularly as a saddle clamp to rest the vent in and suspended from two (2) rods or cables.

Support Legs Rotated Horizontally: Support legs can be used on horizontal runs by rotating the clamp at the rivet

connection. The legs can be cut to shorter lengths if necessary.

Vertical Supports, (SC_ _VSL): Vertical support legs can be used above or below a structure for support. To install,

slide the support clamp over the end of the vent section, leaving the clamp loose. Position the support legs and install

two (2) screws through each leg into the structure. Tighten the clamp around vent pipe. The legs can be cut to shorter

lengths if necessary and can rotate around the support clamp at the rivet connection. By rotating the clamp to a horizontal

position the support legs can be used on horizontal runs.

34

Page 35

Fire Stop/Wall Thimble/Support, (SC_ _FS):

• The Saf-T Vent SC Fire Stop can be used as a fi restop, a wall thimble, or as a support plate.

• To use as a Wall Thimble prepare an opening according to the chart below. Remove any insulation from the opening,

using additional framing if necessary. Attach the plate over the center of the opening using appropriate fasteners.

• Install the vent section through the thimble plate and secure the section to the thimble by screwing the self-tapping

screws through the holes in the tabs on the plate and into the outer wall of the vent. Apply silicone sealant around the vent

section where it passes through the plate and around the plate where it is attached to the structure.

• To use as a Firestop before passing through ceilings or enclosed chases, prepare a round or square opening ¼” larger than

the outer jacket (5¼” for 3” vent or 7¼” for 4” vent). Remove any insulation from the opening. Secure the fi restop to

the structure at the four (4) corners. Install the vent section through the fi restop and secure to the thimble by screwing the

self-tapping screws through the holes in the tabs on plate and into outer wall of the vent. This method can also be used to

support the vent section either vertically or horizontally.

Tall Cone Flashing:

Directly On Roof or Curb:

Tall Cones are available for fl at (SC_ _TCF), 2/12 pitch (SC_ _TCFA), and 6/12 - 12/12 pitch roofs (SC_ _TCFB).

Prepare a square or round opening at least 1/4” larger than the outer jacket (5¼” for 3” vent or 7¼” for 4” vent). Remove

any insulation from the opening. Apply weather-stripping or outdoor caulk to the bottom of the cone plate and attach the

plate to the roof using common construction methods. Flash over the cone plate and seal the fastener heads using normal

roofi ng requirements. When the vent pipe is in place through the Tall Cone, attach a storm collar (sold separately) around

the pipe. Apply high temperature silicone sealant around the pipe where it passes through the top of the storm collar.

Continue to install vent sections as needed to meet the height requirements by code. Seal weather exposed joints of the

outer jacket with foil tape or an exterior grade silicone sealant.

35

Page 36

Vertical Terminations, (SC_ _VT): Install the vertical termination adapter into the last vent section and secure with the

three (3) self-tapping screws provided. If the exhaust termination needs to be extended, a section of EZ Seal vent can be

connected directly to the vertical termination adapter. Seal weather exposed joints of the outer jacket with foil tape or

an exterior grade silicone sealant. To allow for inspection of the system, do not seal the exhaust termination.

36

Page 37

H. Indoor Air Installation – See Figures 12, 13, 14, 15 and 16.

1. Do not exceed maximum vent length. Refer to

Table 4.

Horizontal –

2. Maintain minimum ¼ inch per foot slope in

horizontal runs.

3 Recommended horizontal installation consists of

vent being sloped down away from boiler. See

Figure 12.

4. Slope horizontal runs minimum ¼ inch per foot.

Slope towards vertical vent drain tee. Position weld

seams in vent pipes, in all horizontal runs, at the top

to avoid condensate from lying on the seams.

5. Use appropriately designed thimbles when passing

through combustible walls (thimble use optional

for noncombustible walls). Insert thimble through

wall from outside. Secure outside fl ange to wall

with nails or screws, and seal with sealant material.

Install inside fl ange to inside wall, secure with nails

or screws, and seal with sealant material.

6. For noncombustible wall application when thimble

is not used, size opening such that female (bell) end

with locking band attached cannot pass through.

7. Join vent terminal to vent pipe. Locate vent

terminal between seventeen (17) inches and twentynine (29) inches from wall when joined to inside

vent piping. See Figure 14.

8. Insert vent pipe through thimble/opening from

outside and join to vent system. Apply sealant

between vent pipe and opening/thimble to provide

weathertight seal.

9. Join vent terminal to 45° elbow included in kit. Join

45° elbow/terminal assembly to vent pipe. Refer

to Section C for proper procedures for joining vent

pipe and fi ttings. See Figure 3 .

Vertical

10. Installation of a vertical vent tee 8116304U is

11. Install fi re stops where vent passes through fl oors,

12. Whenever possible install vent straight through roof.

13.

14. Install supplied air intake terminal onto collar of the

–

required on all vertical vent applications. See

Figure 6. Attach vertical vent drain tee directly to

elbow or horizontal pipe from an elbow immediately

after vent connector.

ceilings or framed walls. The fi re stop must close

the opening between the vent pipe and the structure.

Fire stop manufacturers are Air-Jet, American Metal

Products, Metal-Fab, and Simpson Dura-Vent.

Refer to Figure 13 if offset is necessary. Maintain

minimum clearance to combustible materials.

Install Vent Terminal.

a. Size roof opening to maintain minimum

clearance from combustible materials.

b. Use appropriately designed vent fl ashing

when passing through roofs. Follow fl ashing

manufacturers’ instructions for installation

procedures. Flashing manufacturers are AirJet, American Metal Products, Metal Fab, and

Simpson Dura-Vent.

c. Extend vent pipe to maintain minimum vertical

and horizontal distance of twelve (12) inches

from roof surface. Allow additional vertical

distance for expected snow accumulation.

Provide brace as required. Refer to Figure 15.

d. Vertical venting requires fl ashing and a storm

collar to prevent moisture from entering the

structure.

e. Install storm collar on vent pipe immediately

above fl ashing. Apply Dow Corning Silastic 732

RTV Sealant between vent pipe and storm collar

to provide weathertight seal.

f. Attach vent terminal.

jacket enclosure. See Figure 16.

37

Page 38

38

Figure 12: Recommended Separate Horizontal - Vent Installation

Page 39

Figure 13: Alternate Separate Horizontal - Vent Installation

39

Page 40

Figure 14: Optional Indoor Air - 3” or 4” Vent Terminal Installation

Figure 15: Indoor Air - Horizontal / Vertical Vent Terminal Installation

Extend Vent/Air Intake Piping to maintain minimum vertical (“X”) and minimum horizontal (“Y”) distance of twelve

(12) inches from roof surface. Allow additional vertical (“X”) distance for expected snow accumulation.

40

Figure 16: Indoor Air - Air Intake Terminal Installation

Page 41

I. Optional Exterior Separate Horizontal Vent/Air Intake Terminal Mounting – See Figures 17, 18, 19, 20, 21 and 22.

1. Do not exceed maximum vent/air intake lengths.

Refer to Table 4.

2. This installation will allow a maximum of fi ve (5)

feet vertical exterior run of the vent/air intake piping

to be installed on separate horizontal venting and

indoor air horizontal venting.

ECITON

tnelaviuqenidedulcniebotnurroiretxE

.shtgnelekatniria/tnev

3. Install vent piping.

a. Install vent piping for desired venting system.

Refer to specifi c section for details for vent pipe

installation.

b. After penetrating wall/thimble, install an

AL 29-4C® 90° elbow so that elbow leg is in the

up direction.

c. Install maximum of fi ve (5) feet of AL 29-4C®

vent pipe. Refer to Sections C through E for

proper procedures for joining vent pipe and

fi ttings.

d. At top of vent pipe length install an AL 29-4C

90° elbow so that elbow leg is opposite the

building’s exterior surface.

e. If installation requires indoor air, install

AL 29-4C

to upper AL 29-4C® 90° elbow so that leg of 45°

is in down direction (see Figure 21 or 22). If not

using indoor air, proceed to Step f.

f. Install horizontal vent terminal (provided with

boiler).

g. Brace piping if required.

®

45° elbow (provided in indoor air kit)

4. Air Intake Piping (not required for indoor air).

a. Install air intake piping for desired venting

system. Refer to specifi c section for details for

air intake installation.

b. After penetrating wall, install a corrosion

resistant 90o elbow so that elbow leg is in the up

direction.

c. Install maximum of fi ve (5) feet of corrosion

resistant air intake pipe.

d. At top of air intake pipe install air intake

terminal (provided with boiler).

e. Brace piping if required.

®

Figure17: Optional Separate Horizontal Air 3” or 4” Intake Terminal Installation

41

Page 42

Figure 18: Optional Separate Horizontal Air 5” Intake Terminal Installation

42

Figure 19: Optional Separate Horizontal 3” Vent Terminal Installation

Page 43

Figure 20: Optional Separate Horizontal 4” Vent Terminal Installation

Figure 21: Optional Separate Horizontal 3” Vent Terminal Installation (Indoor Air)

43

Page 44

Figure 22: Optional Separate Horizontal 4” Vent Terminal Installation (Indoor Air)

44

Page 45

IV. Water Piping and Trim

.erutcurts

GNINRAW

roreliobotegamaddnanoitareporeporpminitluseryamreliobepipylreporpoteruliaF

reliobleetsdnanorifonoisorrocesuaclliwretawreliobfonoitanimatnocnegyxO

revoctonseodytnarraWdradnatSs'mahnruB.eruliafreliobotdaelnacdna,stnenopmoc

desuacpu-dliub)emil(elacsroretawreliobfonoitanimatnocnegyxoybdesuacsmelborp

.retawfonoitiddatneuqerfyb

A. Design and install boiler and system piping to

prevent oxygen contamination of boiler water and

frequent water additions.

1. There are many possible causes of oxygen

contamination such as:

a. Addition of excessive make-up water as a result

of system leaks.

b. Absorption through open tanks and fi ttings.

c. Oxygen permeable materials in the distribution

system.

2. In order to insure long product life, oxygen sources

must be eliminated. This can be accomplished by

taking the following measures:

a. Repairing system leaks to eliminate the need for

addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fi ttings which allow

oxygen absorption.

d. Use of non-permeable materials in the

distribution system.

e. Isolating the boiler from the system water by

installing a heat exchanger.

f. Use properly designed and operating air

elimination devices in water piping.

B. Low Water Cut Off (LWCO) on Hot Water Boilers

(Optional)

addition, some jurisdictions require the use of a LWCO

with a hot water boiler.

Where

The universal location for a LWCO on both gas and oil

hot water boilers is above the boiler, in either the supply

or return piping. The minimum safe water level of a

water boiler is at the uppermost top of the boiler; that is,

it must be full of water to operate safely.

What Kind

The SCG boiler is designed to accept the wiring of the

Safgard Model 1100-H4 (P/N 45-1104) LWCO. This is

a probe type LWCO. The factory wiring is designed to

allow simple “Plug-in” installation of the wiring.

How to Pipe

A “tee” is commonly used to connect the probe LWCO

to the supply or return piping, as shown below.

GNINRAW

otseriwyrotcaftucotTPMETTATONOD

ffOtuCretaWwoLtekramretfanallatsni

snoitcennocesuylnO.)OCWL(

tuCretaWwoLrofdeifitnediyllacificeps

.ffO

.snoitcurtsnis'rerutcafunam)OCWL(

When

A low water cutoff is required to protect a hot water

boiler when any connected heat distributor (radiation)

is installed below the top of the hot water boiler (i.e.

baseboard on the same fl oor level as the boiler). In

LWCO Location

Select the appropriate size tee using the LWCO

manufacturer’s instructions. Often, the branch

ffOtuCretaWwoLehtwollof,sesacllanI

connection must have a minimum diameter to prevent

bridging between the probe and the tee. Also, the run

of the tee must have a minimum diameter to prevent

the end of the probe from touching or being located too

close to the inside wall of the run of the tee.

Ideally, manual shutoff valves should be located

above the LWCO and the boiler to allow for servicing.

This will allow probe removal for inspection without

45

Page 46

draining the heating system. Many probe LWCO

manufacturers recommend an annual inspection of the

probe.

How to Wire

Ensure power is turned off to boiler.

Locate the LWCO jumper wire in the factory wiring

harness. Remove the jumper wire and install

the LWCO wiring from LWCO Model 1100-H4

(P/N 45-1100) into the plug of the SCG factory wiring.

How to Test

Shut off fuel supply. Lower water level until water

level is BELOW the LWCO. Generate a boiler demand

by turning up thermostat. Boiler should not attempt to

operate. Increase the water level by fi lling the system.

The boiler should attempt to operate once the water

level is above the LWCO.

ECITON

ehtniOCWLehtfonoitacolehterusnE

ehtfonoitcennocrofwollalliwgnipip

gniriwyrotcafehtotssenrahgniriwOCWL

.G

CSehtfo

C. Connect system supply and return piping to boiler.

See Figures 25 and 26. Maintain minimum ½ inch

clearance from hot water piping to combustible

materials.

GNINRAW

tsumgnipipegrahcsidevlavfeilererusserP

erevesfolaitnetopehttahthcusdepipeb

ynaniepipTONOD.detanimilesisnrub

TONOD.ruccodluocgnizeerferehwaera

.spacrosgulp,sevlavffo-tuhsynallatsni

egrahcsidreporprofsedoClacoLtlusnoC

.tnemegnarragnipip

F. Space heating and domestic water heating with

Alliance™ water heater. Install Alliance water heater as

a separate heating zone. Refer to Alliance Installation,

Operating and Service Instructions for additional

information.

G. If boiler is used in connection with refrigeration

systems, boiler must be installed with chilled medium

piped in parallel with the heating boiler using

appropriate valves to prevent chilled medium from

entering boiler, see Figure 23.

H. If boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

fl ow control valves to prevent gravity circulation of

boiler water during operation of cooling system.

ECITON

metsysehtgnizissdnemmocermahnruB

ot)MPG(wolftneiciffusylppusotrotalucric

02awolla

itcennoclladnagnibuttnaidar

.deredisnoc

D. Install circulator with fl anges, gaskets and bolts

provided. Circulator harness allows circulator to be

mounted on supply or return. Connect harness to

circulator and secure any excess conduit.