Page 1

Sage Boiler Control

(SBC)

Instruction Manual

Contents

Introduction

Quick Reference 2

Overview 4

Product Features

Boiler Sequence 6

Single Boiler Control Mode 9

Multiple Boiler Control Mode 10

EMS Boiler Control Mode 11

Manual Boiler Control Mode 14

Auiliary Device 15

Front Panel

Features 16

Display Mode 17

Menu Navigation 18

Setpoints Menu 19

Installation

Mounting & Wiring Sensors 20

Terminal Layout 25

External Connections 26

Communication 28

Peer-To-Peer Network 30

RS485 Modbus Network 31

Application

The Sage Boiler Control (SBC) has been designed

for commercial hot water boiler applications.

Intent

This instruction manual includes detailed functional,

installation and setup information.

www.burnhamcommercialcastiron.com

Setup & Tuning

Boiler Configuration Menu 33

System Configuration Menu 34

Setup Menu 35

Manual Mode 40

Trouble Shooting

Alarm Messages 41

Diagnostics Menu 43

Sensor Resistance Chart 46

Security Menu 47

Specifications

General 48

Component Description & Repair Part Numbers 49

Appendix

A. Parameter Summary 50

B. Customer Parameter Worksheet 52

Warranty Rear Cover

Sage Boiler Control Front Panel

(Showing Power & Alarm LEDs,

2 Line 16 Character Message Display

and 4 Pushbuttons)

Sage Boiler Control Instruction Manual Page 1 of 56 102121-01R2 - 4/11

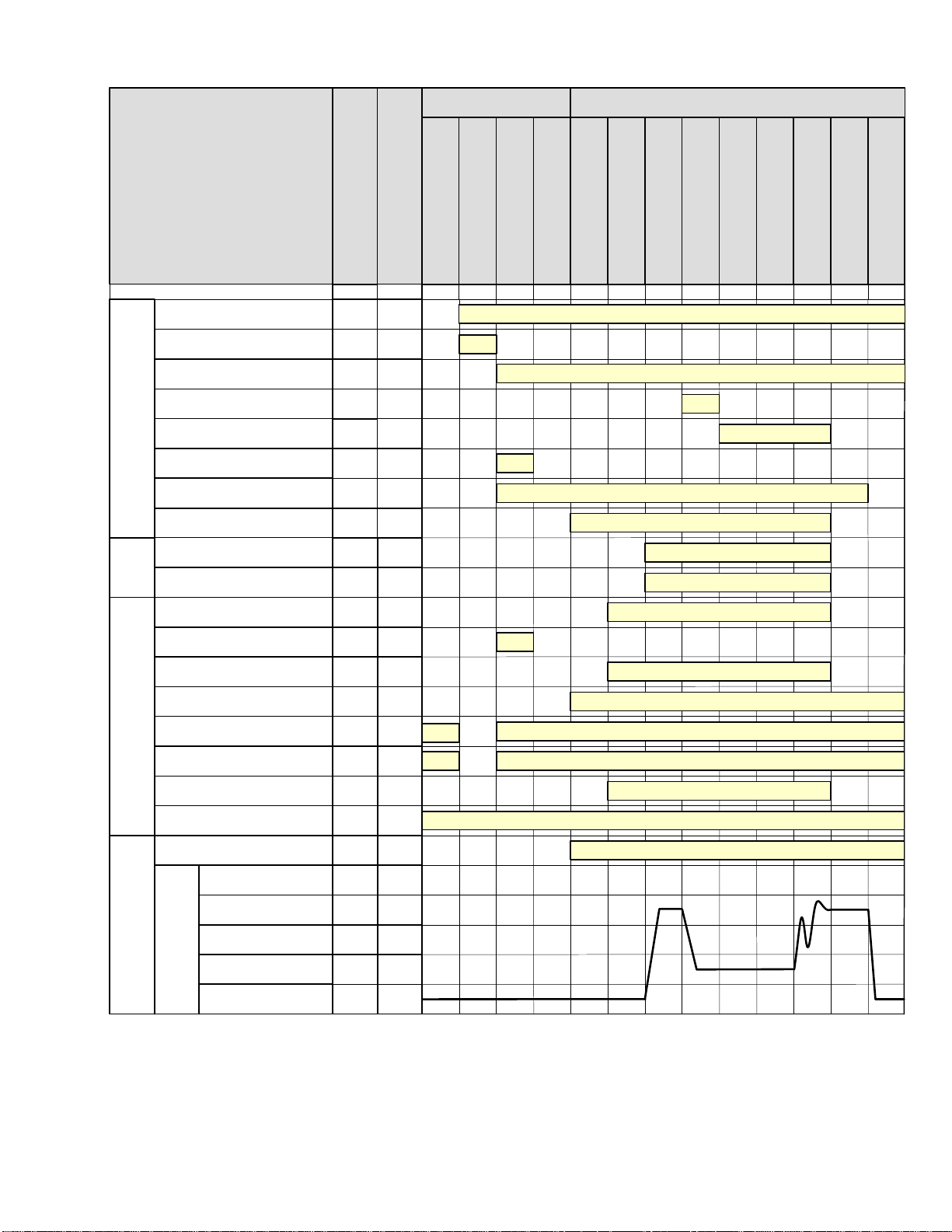

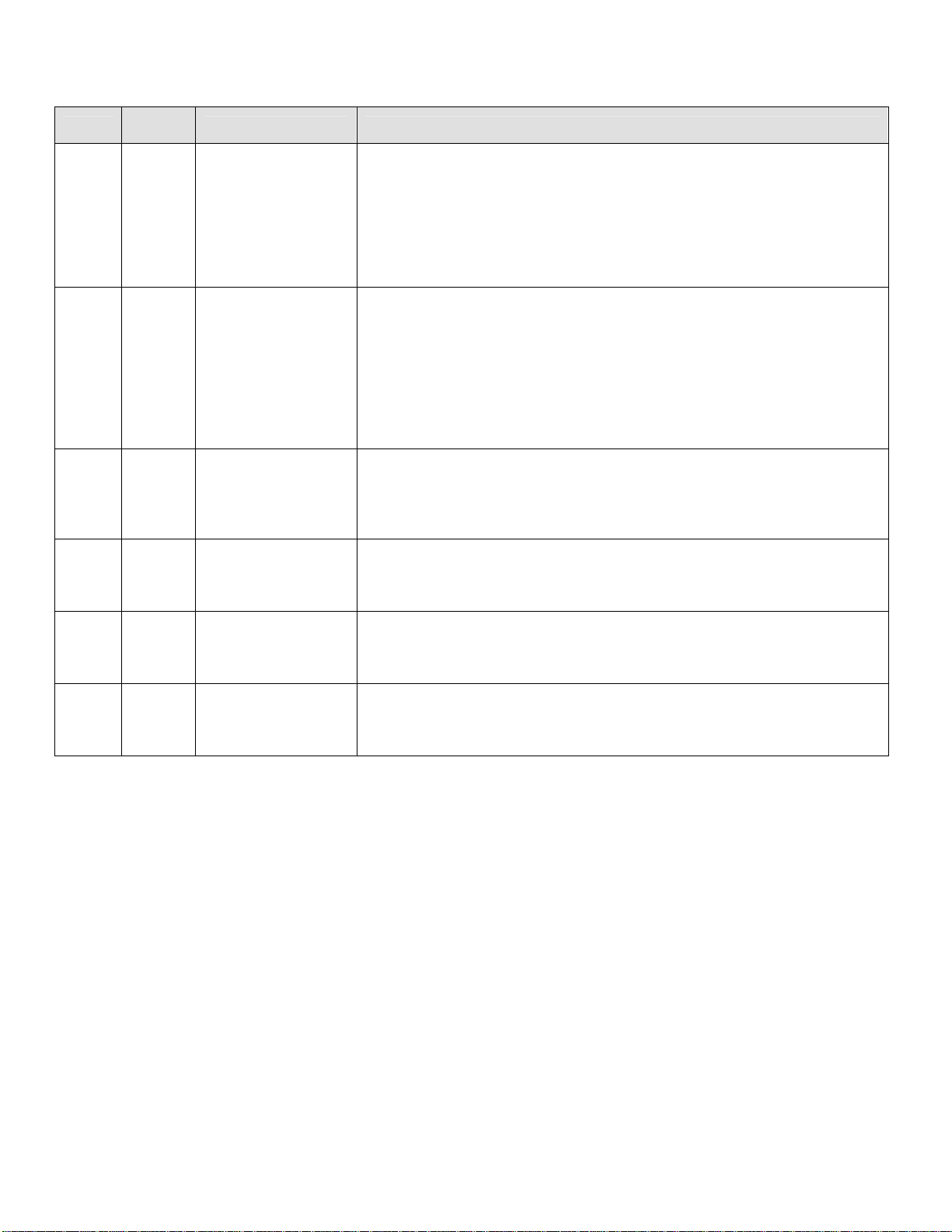

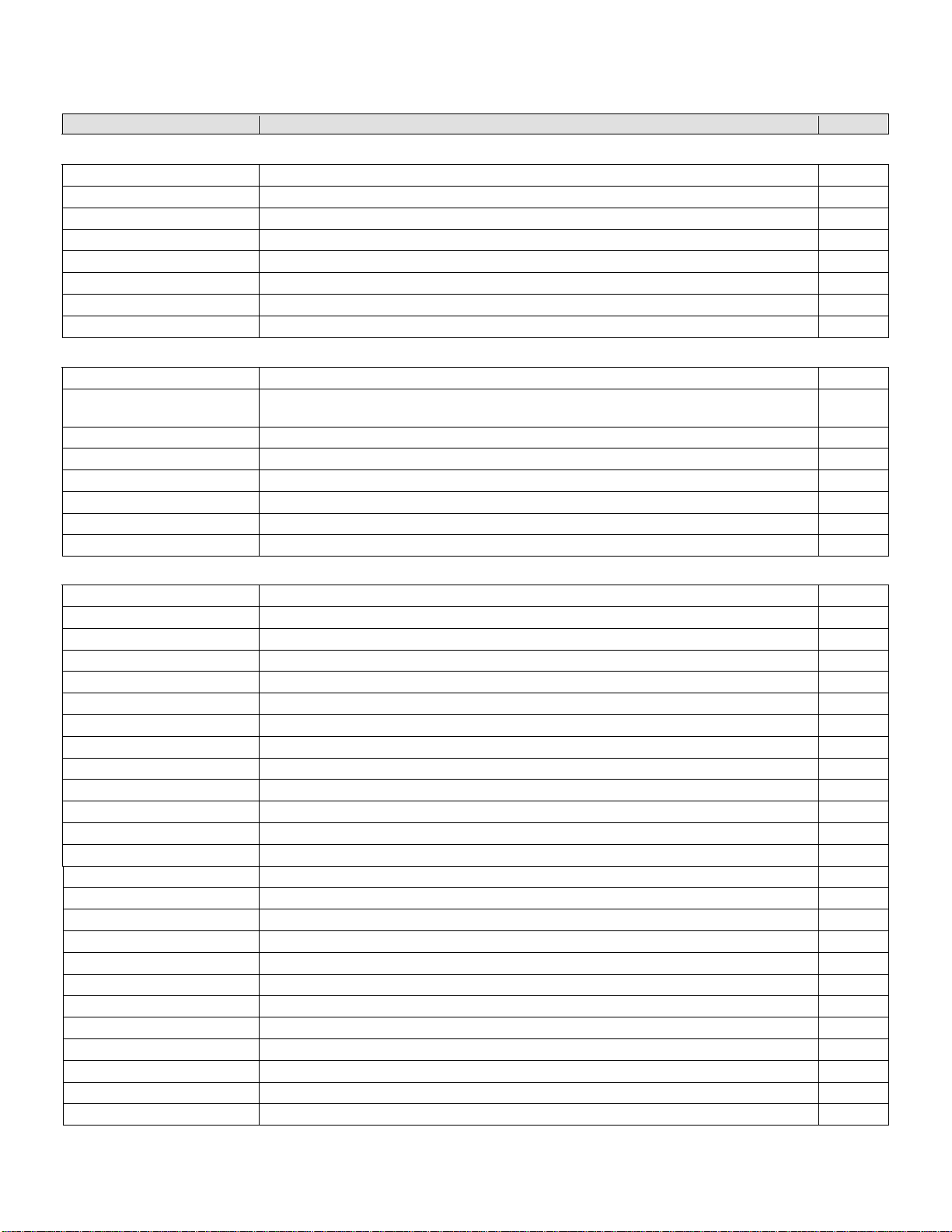

Page 2

Introduction

Quick Reference

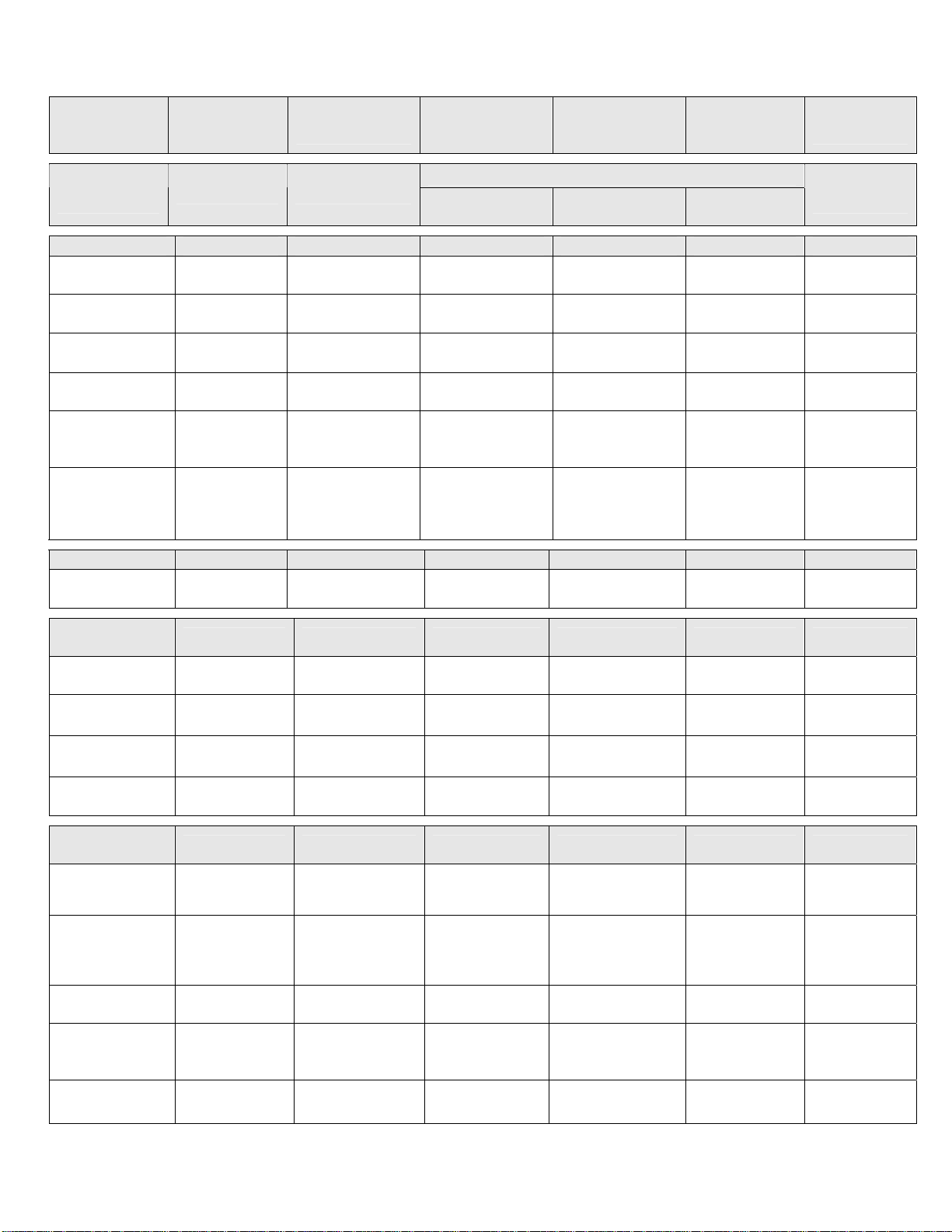

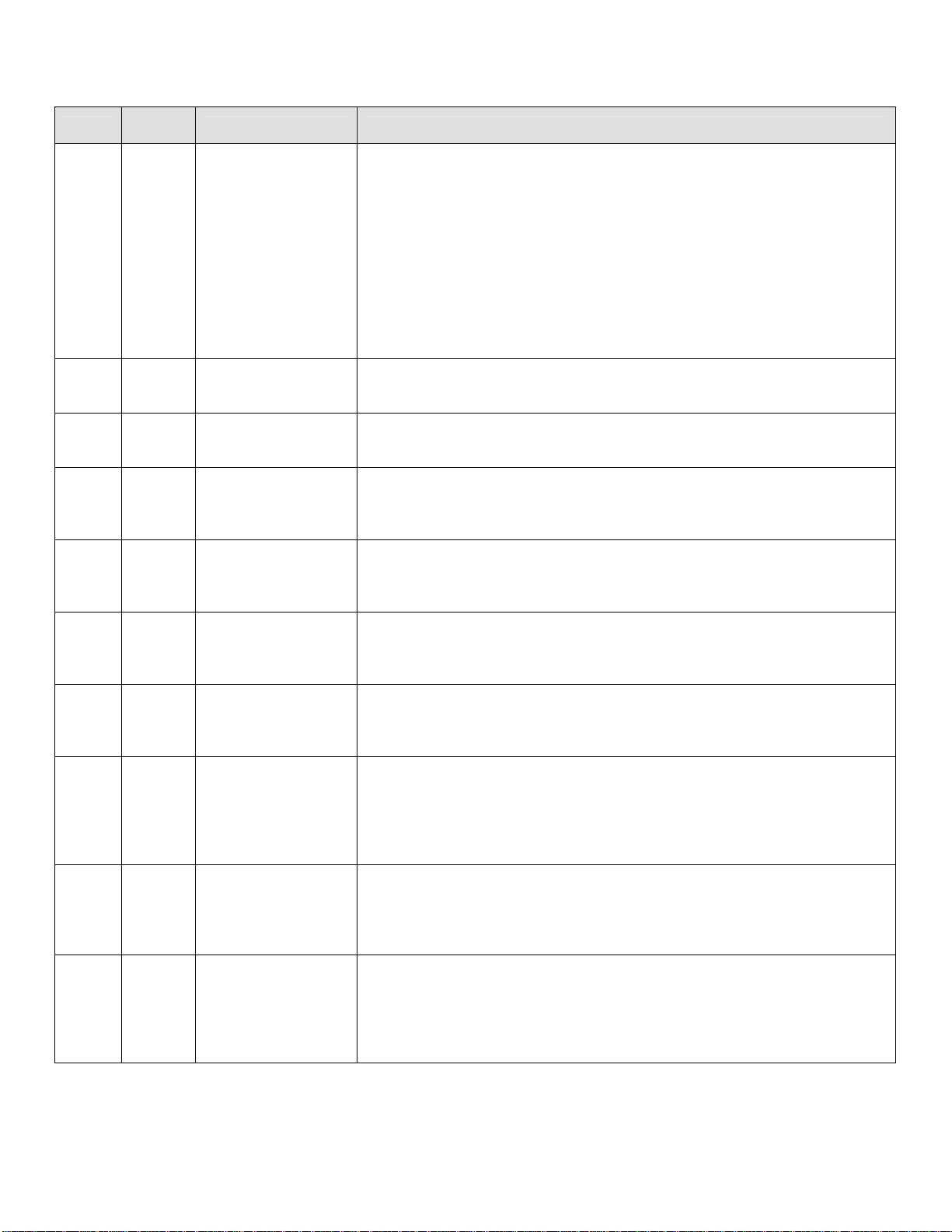

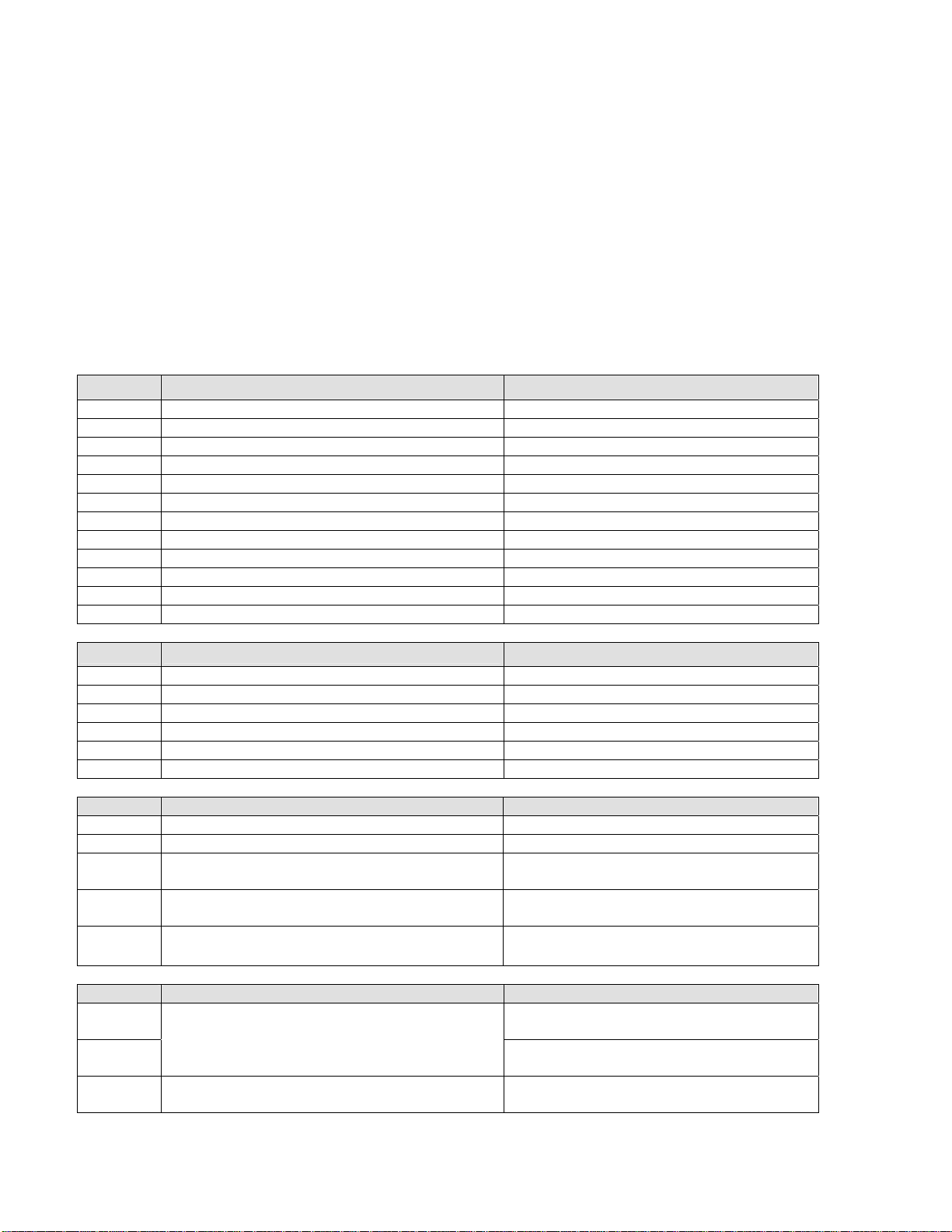

CONTROL

MODE

LCD Display

Typical

Application

Water Setpoint

Temperature

Sensor

Setpoint Operator Operator

“On” and “Off”

Point

Outdoor Air

Reset

Domestic Hot

Water Priority

(DHWP)

Warm Weather

Shutdown

(WWSD)

Call For Heat

Call For Heat

Modulation

Rate

Internal Boiler

Control

Lead Boiler

Control

Remote EMS

Control

Manual

Control

Remote

Connections

Local / Remote

Input (LR)

Outlet Sensor

& Local SP

Mode

Remote Sensor

& Local SP Mode

Single Boiler Multiple Boilers

Outlet Sensor &

Remote SP

Mode

Remote Sensor

& Remote SP

Mode

Remote

Control

Mode

Energy Management System (EMS) Boiler Control

Single Boiler

Setpoint Input

Multiple Boilers

Setpoint Input

Modulation

Rate Input

Manual

Mode

Manual

Operation

Boiler Outlet Remote System Boiler Outlet Remote System Ignored Ignored

Input (C+C-) or

Modbus*

Input (C+C-) or

Modbus*

Ignored Ignored

Operator Operator Operator Operator Ignored Ignored

Option Option Ignored Ignored Ignored Ignored

Option Option Ignored Ignored Ignored Ignored

Option Option Option Option Option Ignored

Based on

Setpoints

Based on

Setpoints

Based on

Setpoints

Based on

Setpoints

Input (RO) or

Modbus

Manually Set

Based on

Setpoint

Peer-to-Peer

Connected

Ignored Ignored Ignored Ignored

Based on

Setpoint

With Peer-to-

Peer Connected

Based on

Setpoint

With Peer-to-

Peer Connected

Based on

Setpoint

With Peer-to-

Peer Connected

Ignored Ignored

Ignored Ignored

Input (C+C-)

or Modbus

Ignored

Ignored Ignored Ignored Ignored Ignored By Operator

Ignored Ignored Closed Closed Closed Ignored

Remote On/Off

(Enable)

Input (RO)

Remote Control

Input (C+C-)

Communication

Network

Additional

Information

Enable/

Disable

No No

Peer-To-Peer

or

Modbus*

Enable/

Disable

Peer-To-Peer

or

Modbus*

Enable/

Disable

Remote

Setpoint

Peer-To-Peer

or

Modbus*

Enable/

Disable

Remote

Setpoint

Peer-To-Peer

or

Modbus*

On/Off Ignored

Remote

Modulation

Modbus

Only

Ignored

Modbus Only

Page 9 Page 10 Page 11 Page 12 Page 13 Page 14

* If Modbus is selected the Peer-To-Peer Network can not be used. Modulating Lead/Lag features require the Peer-ToPeer Network.

Sage Boiler Control Instruction Manual Page 2 of 56

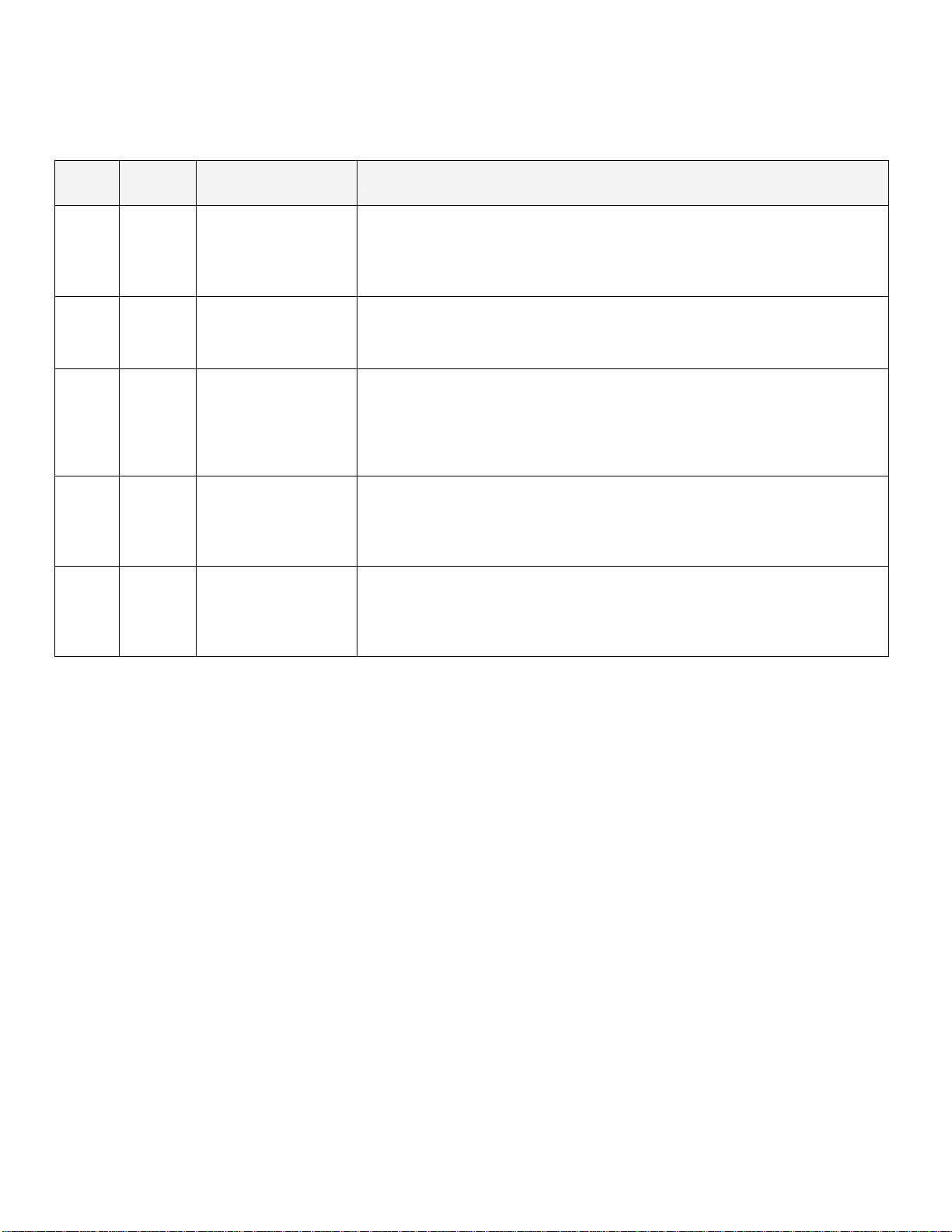

Page 3

Introduction

Quick Reference

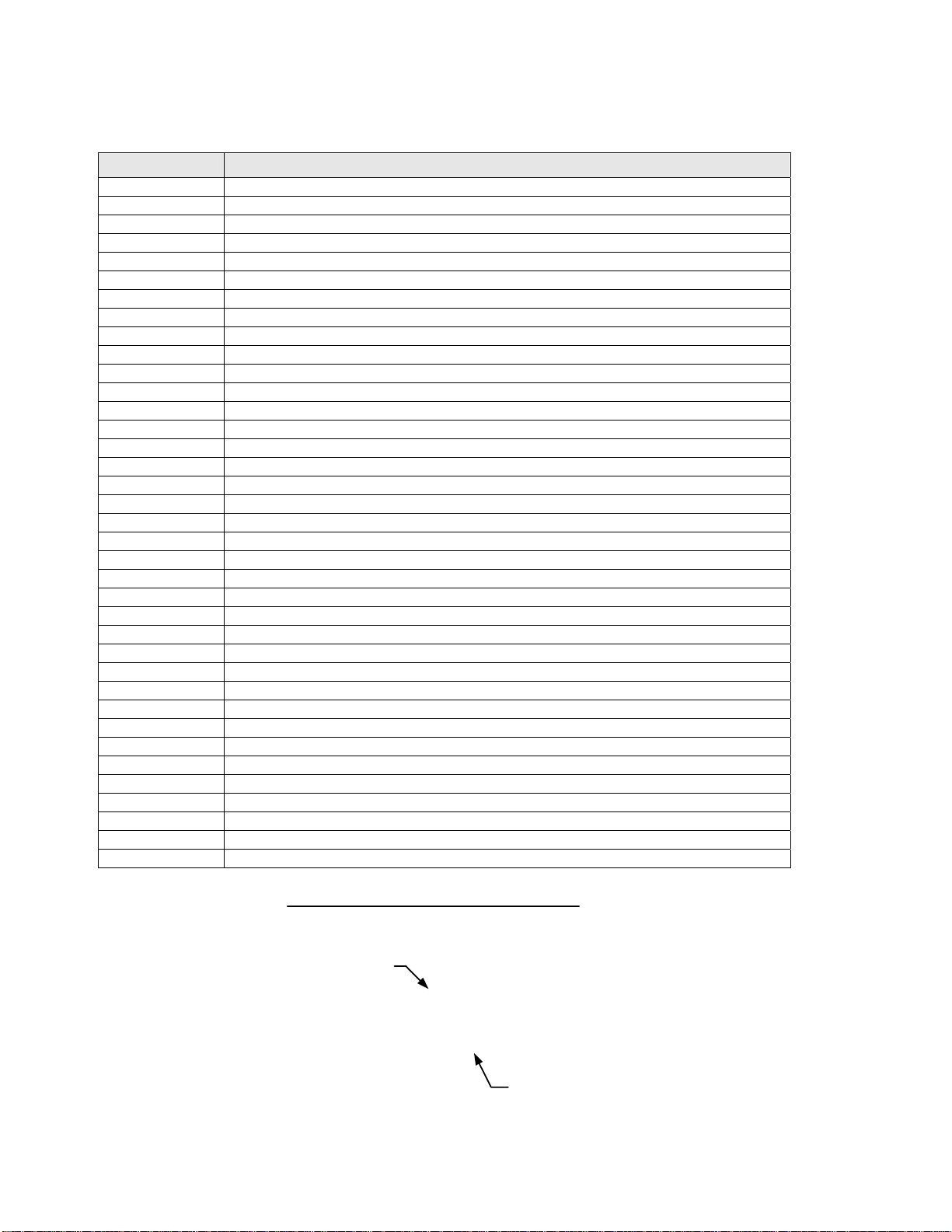

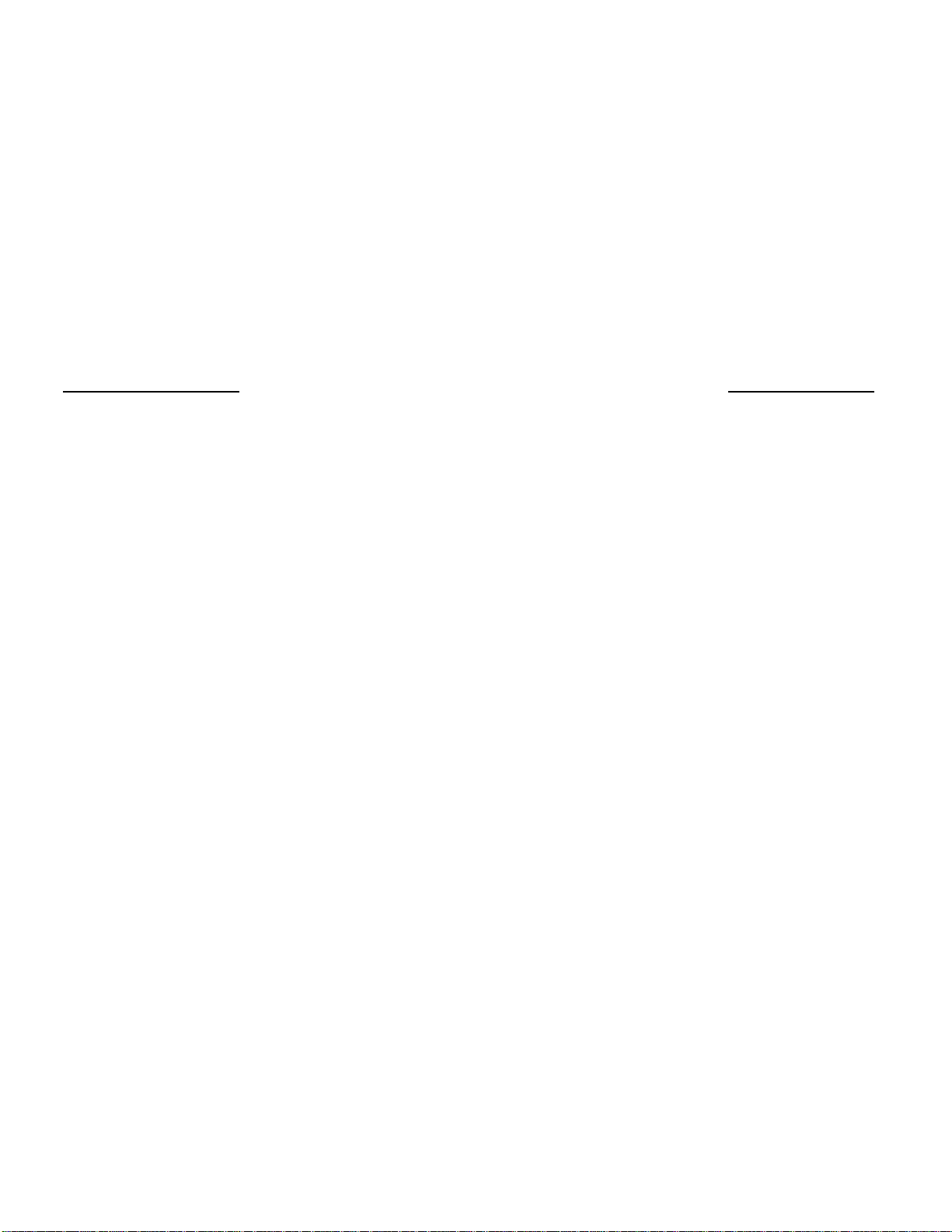

Abbreviation List

Abbreviation Description

AL Flame Safeguard Alarm

BIT Boiler Inlet Temperature

BOT Boiler Outlet Temperature

BP Boiler Pump

BV Blocked Vent Switch

C Common Termination Point

CA Low Combustion Air Flow

CH Call For Heat (CFH)

CS Fuel Valve Energized

DH Domestic Hot Water Heating Demand

DP Domestic Hot Water Priority (DHWP)

SBC Sage Boiler Control

EMS Energy Management System

GP High and Low Gas Pressure Switches

HL High Limit Aquastat

HP High Pressure Gas Switch

IN Boiler Inlet Water Temperature

LC Low Water Cutoff Switch

LL Lead Lag

LO Lockout Indicator

LR Local / Remote

M Electric Motor

Mix 3 Way Mixing Valve

OA Outside Air Temperature

OL Operating Limit Aquastat

OO Burner On / Off Switch

OUT Boiler Outlet Water Temperature

RO Remote On / Off

RST Remote System Temperature

SH Space Heating Demand

SI Spare Input (Programmable)

SO Spare Output (Programmable)

SP Setpoint (As found in “Ope rational SP” and “Remote SP”

SP System Pump

VI Vent Inducer

WF Low Water Flow

WWSD Warm Weather Shutdown

Termination Number Identification (Typical):

Description

Mixing Valve

Control, (MR, MS)

Termination

Numbers

Sage Boiler Control Instruction Manual Page 3 of 56

Page 4

Introduction

Overview

Sage Boiler Control Overview

The Sage Boiler Control (SBC) is a complete boiler monitoring and automation system. The SBC provides advanced

boiler modulation, operating control, diagnostics, multiple boiler lead-lag and auxiliary device control. The SBC provid es

advanced control features in an easy to use package.

Flexible, Field Selectable Control

Control modes, water system, boiler auxiliary and

modulating lead/lag control features are menu selectable

without the need for external programmers, laptops or

down loads. Every boiler is shipped with factory defaults

that make field menu selections unnecessary unless you

are applying additional control features.

Boiler Monitoring and Diagnostic Displays

The SBC’s two line by sixteen character LCD display

may be used for monitoring boiler inlet and outlet,

remote system and outside air temperatures, modulation

rate setpoint and modulating percent and mixing valve

demand percent. Additionally, the display automatically

presents boiler sequence messages, alarms, hold and

lockout messages. A diagnostic menu is included that

provides the last 10 alarm messages and boiler inlet

temperature alarm history. Boiler inlet temperature

alarm history includes time and date, the lowest inlet

temperature reached and the amount of time the water

temperature dropped below the alarm setpoint.

Modulation Rate and On/Off Modes

The SBC may simply control boiler modulation and

on/off output based on the boiler water outlet

temperature and an operator adjusted setpoint.

However, using parameter selections, the SBC allows

the boiler modulation and on/off output to respond to

remote system water and outside air temperatures,

Domestic Hot Water Priority (DHWP) input or Energy

Management System (EMS) modulation rate demand,

remote setpoint or remote start/stop commands.

Parameter selections of remote system water

temperature and remote mode determine the choice of

one of six different control modes.

Advanced Availability

The above control modes are menu selectable options.

However, if a selected sensor fails, the SBC

automatically changes to a control mode that will allow

continued automatic operation of the boiler. For

example, in the event of a remote system temperature

sensor failure, the SBC will automatically switch to boiler

outlet temperature sensor based control.

Outdoor Air Reset

When selected the modulation rate setpoint is

automatically adjusted based on outside air temperature.

Outdoor air “reset” setpoint saves fuel by adjusting the

water temperature of a heating boiler lower as the

outside air temperature increases.

Warm Weather Shutdown (WWSD)

Some boilers are used primarily for heating buildings,

and the boilers can be automatically shutdown when the

outdoor air temperature is warm. When outside air

temperature is above the WWSD setpoint, this function

will prevent the boiler, boiler pump and/or the system

pump from starting.

Domestic Hot Water Priority (DHWP)

Some boilers are used primarily for building space

heating, but also provide heat for the domestic hot water

users. When the outdoor temperature is warm, the

outdoor reset setpoint may drop lower than a desirable

domestic hot water temperature. When enabled and a

DHWP contact input is detected, the hot water setpoint

is adjusted to be greater than a field adjustable DHWP

Setpoint.

Water Side Control Outputs

In order to maximize the life and availability of hot water

systems it may be desirable to automate mixing valves,

boiler pumps, system pumps, and standby system

pumps. The SBC makes this type of automation totally

integrated and cost effective. The control of these

devices is field selectable through simple yes/no menu

selections.

Combustion Air Side Control Outputs

Boiler room Combustion air dampers (fresh air dampers)

and Vent Inducer control outputs are field selectable

options.

Peer-To-Peer Network

The SBC includes state-of-the-art modulating lead-lag

sequencer for up to eight (8) boilers capable of auto

rotation, outdoor reset and peer-to-peer communication.

The peer-peer network is truly “plug and play”.

Communication is activated by simply connecting a

RJ11 telephone line between boilers. The SBC provides

precise boiler coordination by sequencing boilers based

on both remote system water temperature and boiler

modulation rate. For example, the lead boiler can be

configured to start a lag boiler after operating above 90%

modulation rate for longer than an adjustable time. The

boilers are modulated in “unison” (parallel) modulation

rate to ensure even heat distribution

Modbus Communication Interface

A factory configured RS485 Modbus interface is

available

for Energy Management System (EMS) or SCADA

system monitoring and control.

Sage Boiler Control Instruction Manual Page 4 of 56

Page 5

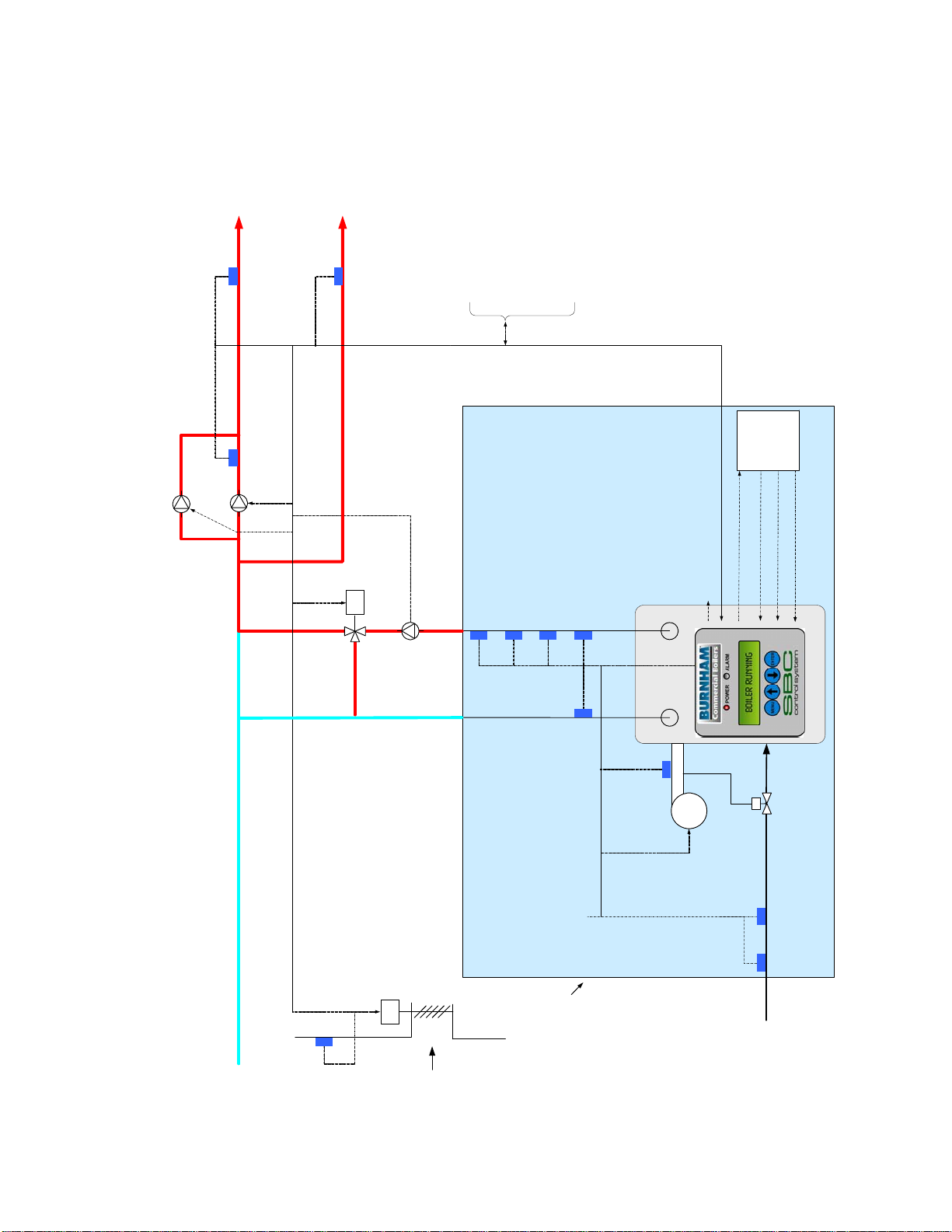

Introduction

Overview

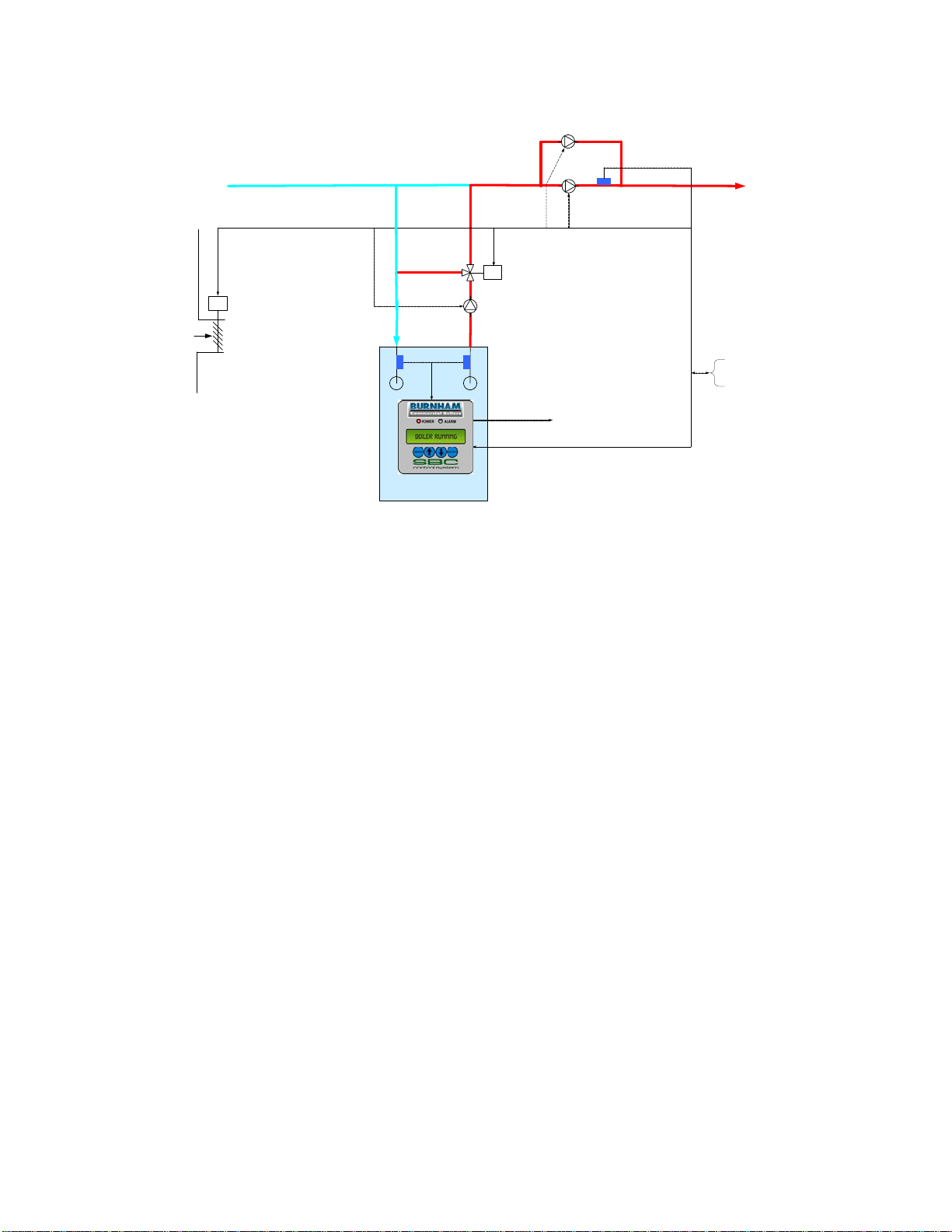

Standby System Pump

Remote System

System Pump

System

Supply Water

Switch

Domestic Hot

Temperature

Feedback

Water Override

System Pump

Supply

Domestic

Hot Water

System

Modbus RS-485, RJ-11

Local / Remote Switch

High Temperature Limit

Connection

Boiler Outlet TemperatureBoiler Inlet Temperature

Primary

Spare Output

Call For Heat Relay

Fuel Valve Energized

Control

Alarm (Lockout)

Low Fire

Remote On / Off (Enable)

Lockout Indicator

Building Automation

Control

M

Mixing Valve

Boiler Pump

Low Water Flow Switch

Low Water Cutoff Switch

Return Water

Outside Air

Temperature

Sage Boiler Control

FAN

Switch

Air Flow

Combustion

Control

Modutrol Motor

Switch

Damper

Combustion Air

M

Supply

Fresh Air

Boiler On/Off

Boiler

Jacket

Fuel

Fuel Switches

Supply

Sage Boiler Control Instruction Manual Page 5 of 56

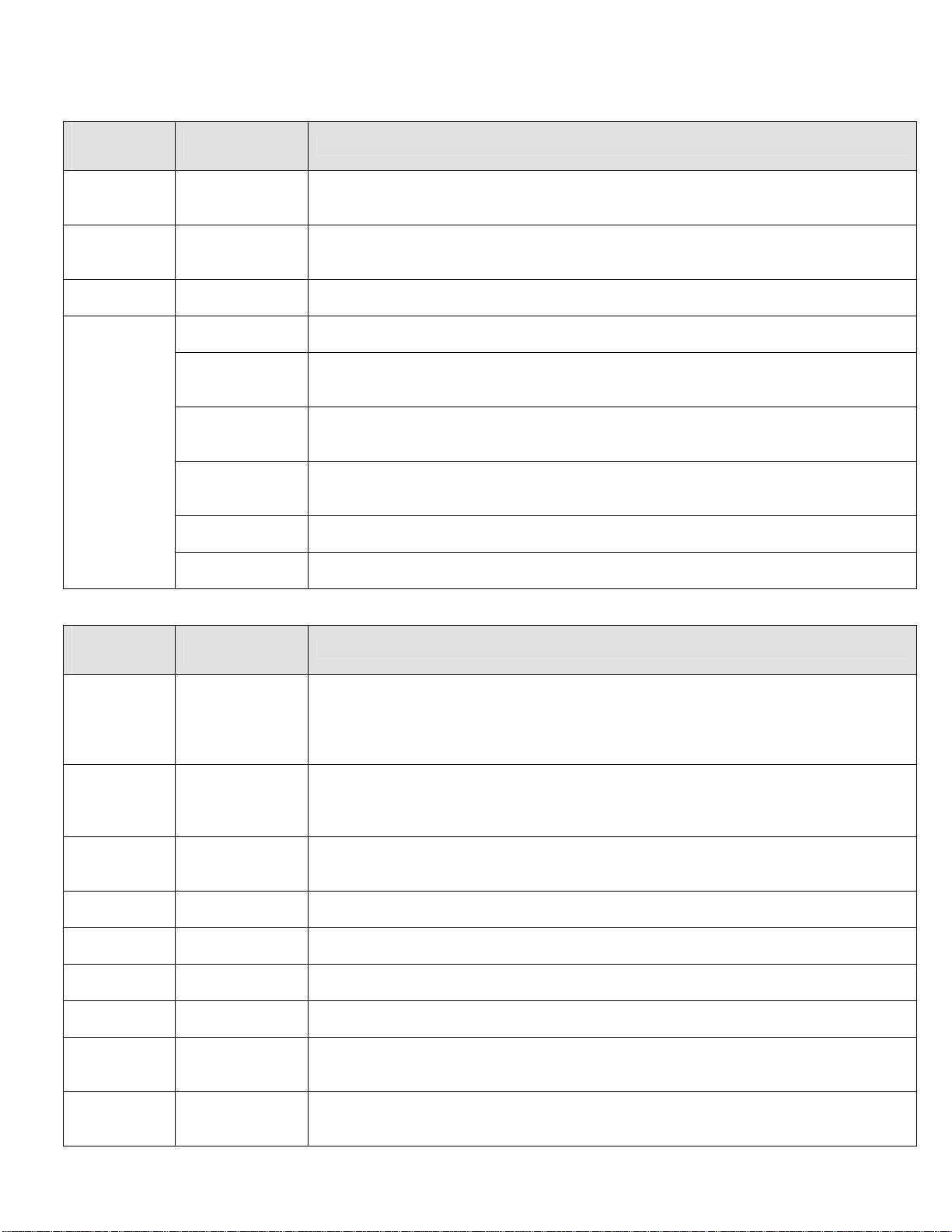

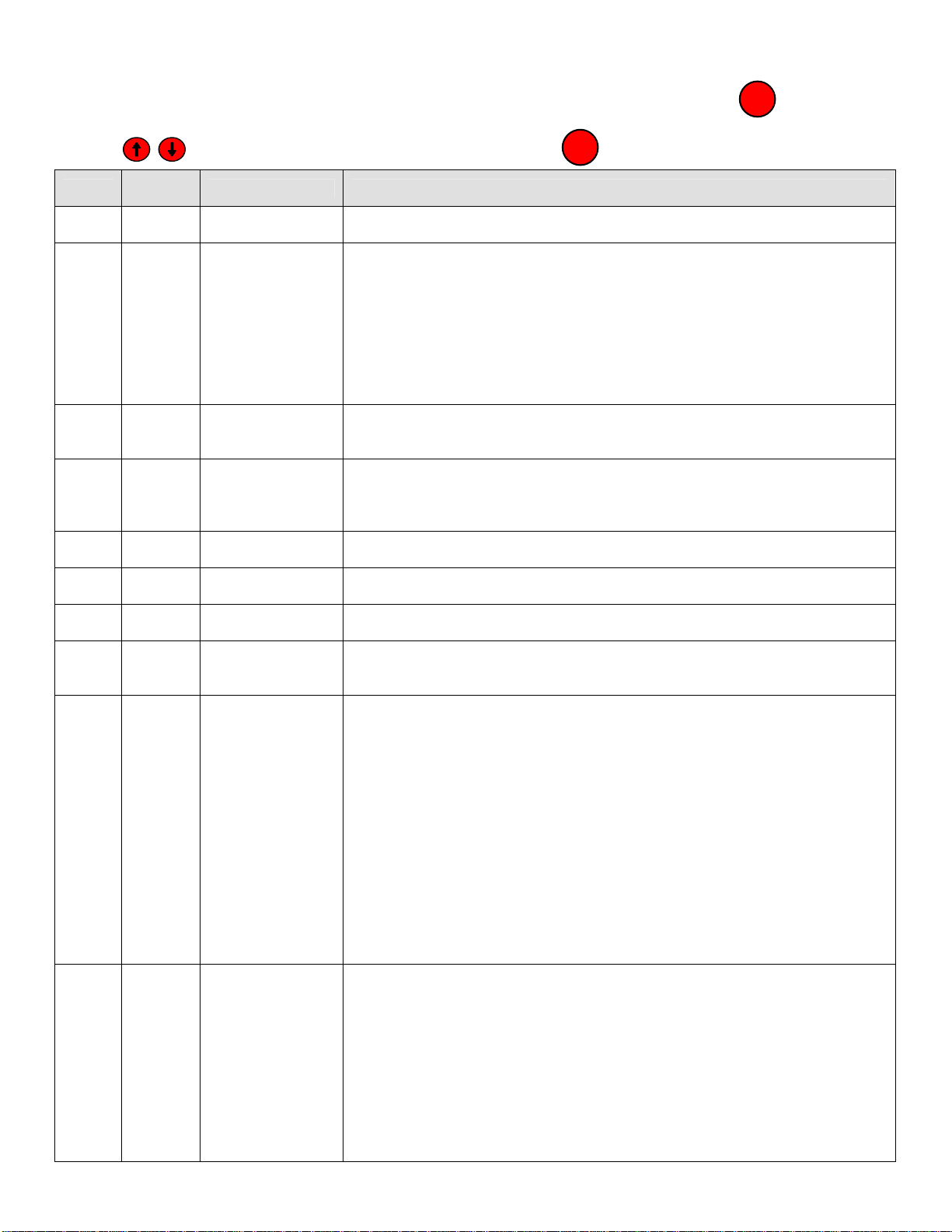

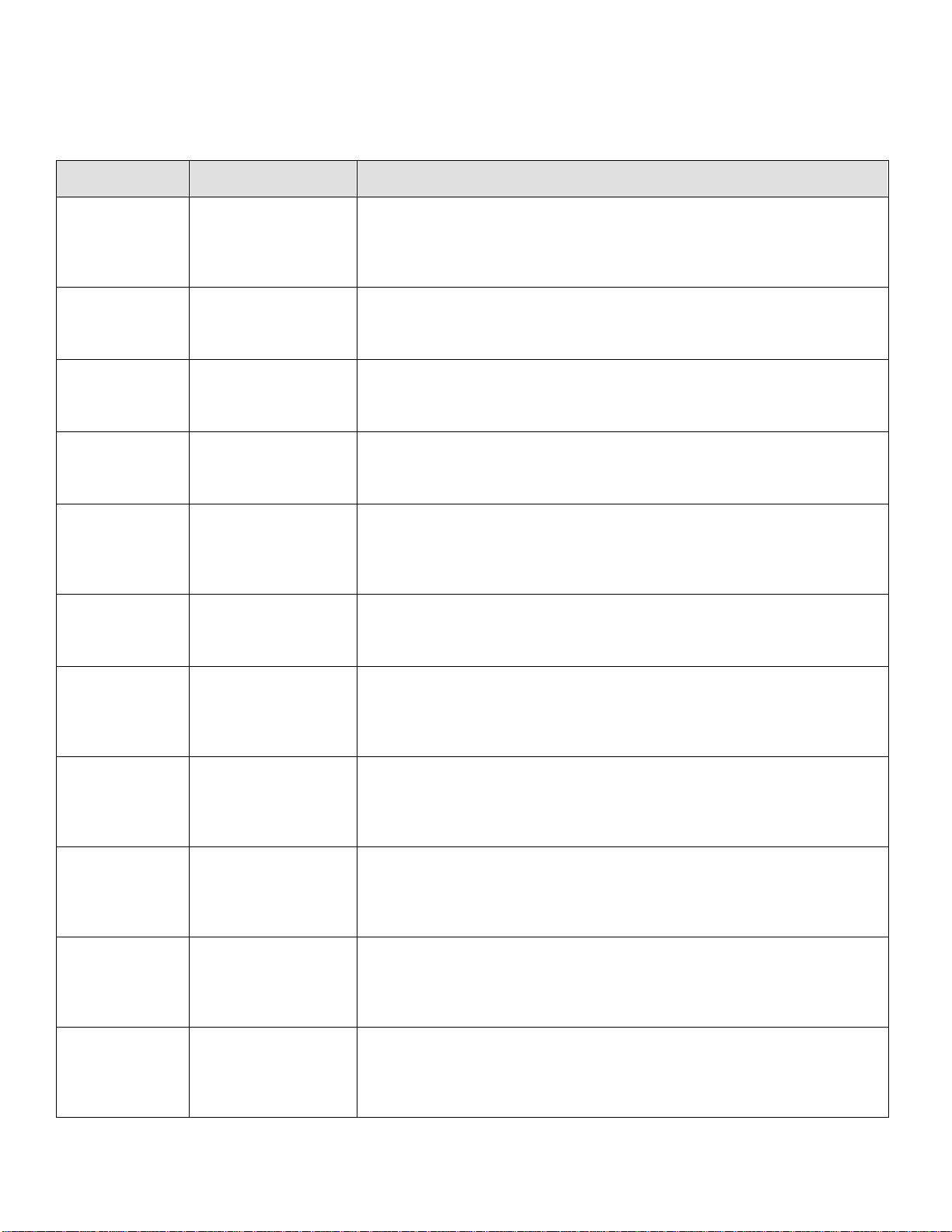

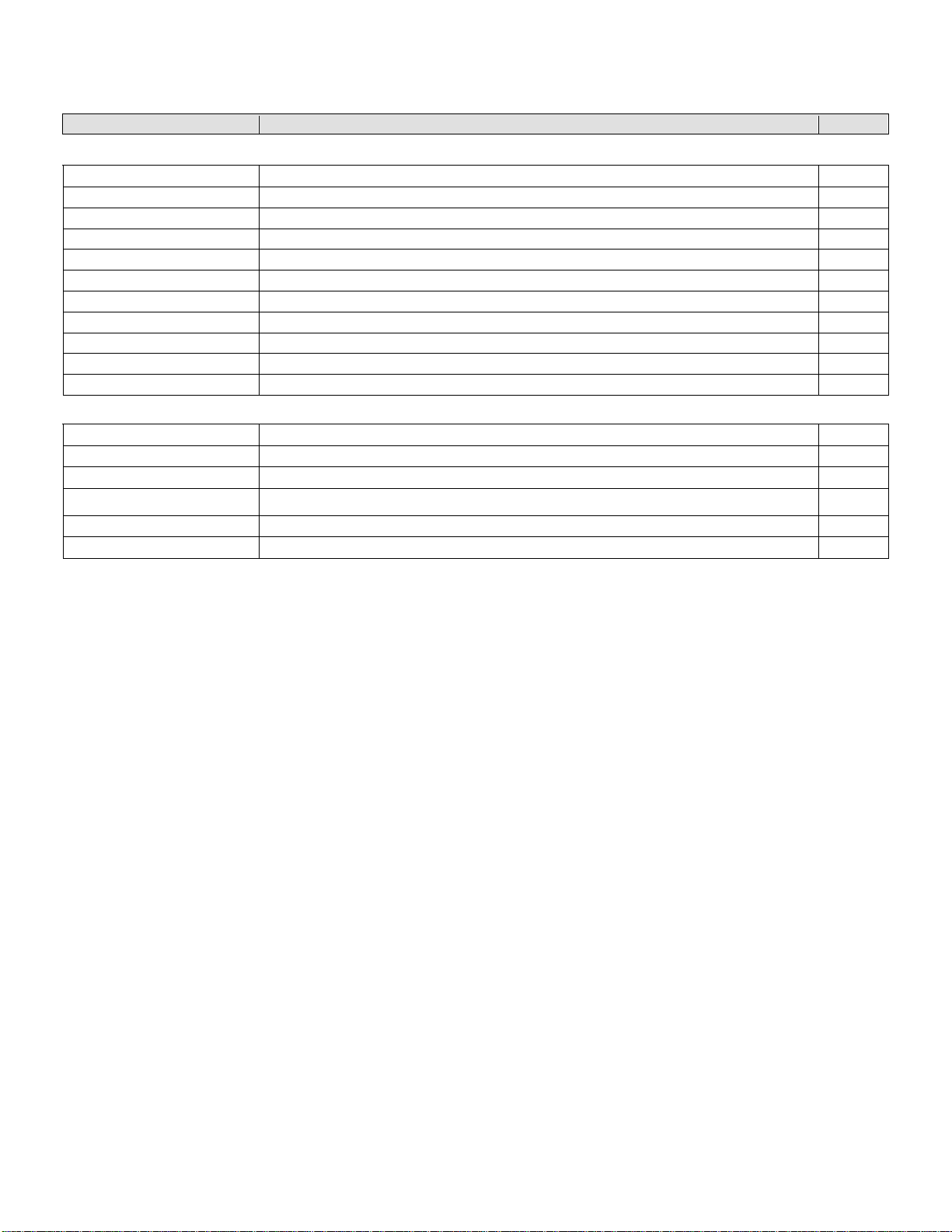

Page 6

Product Features

Boiler Sequence

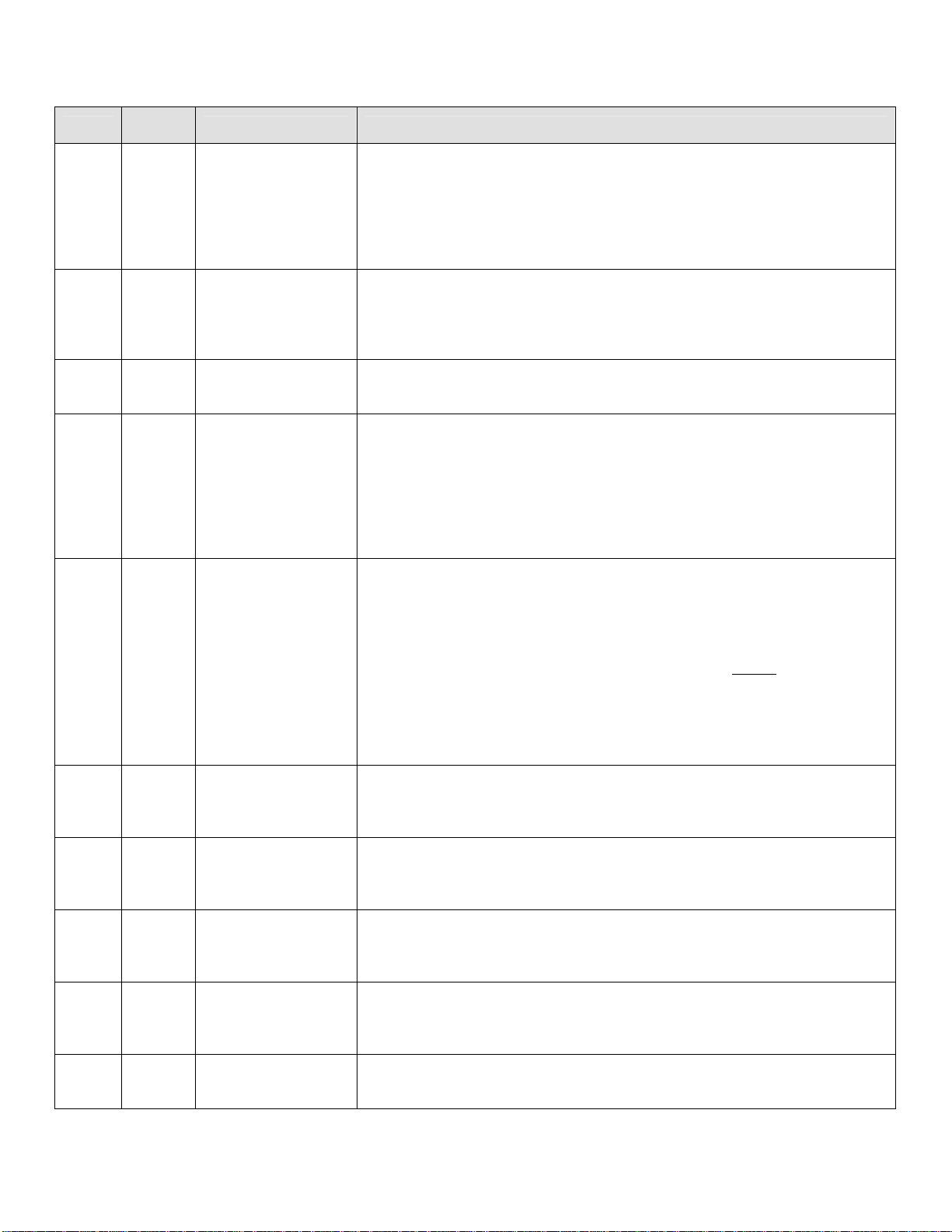

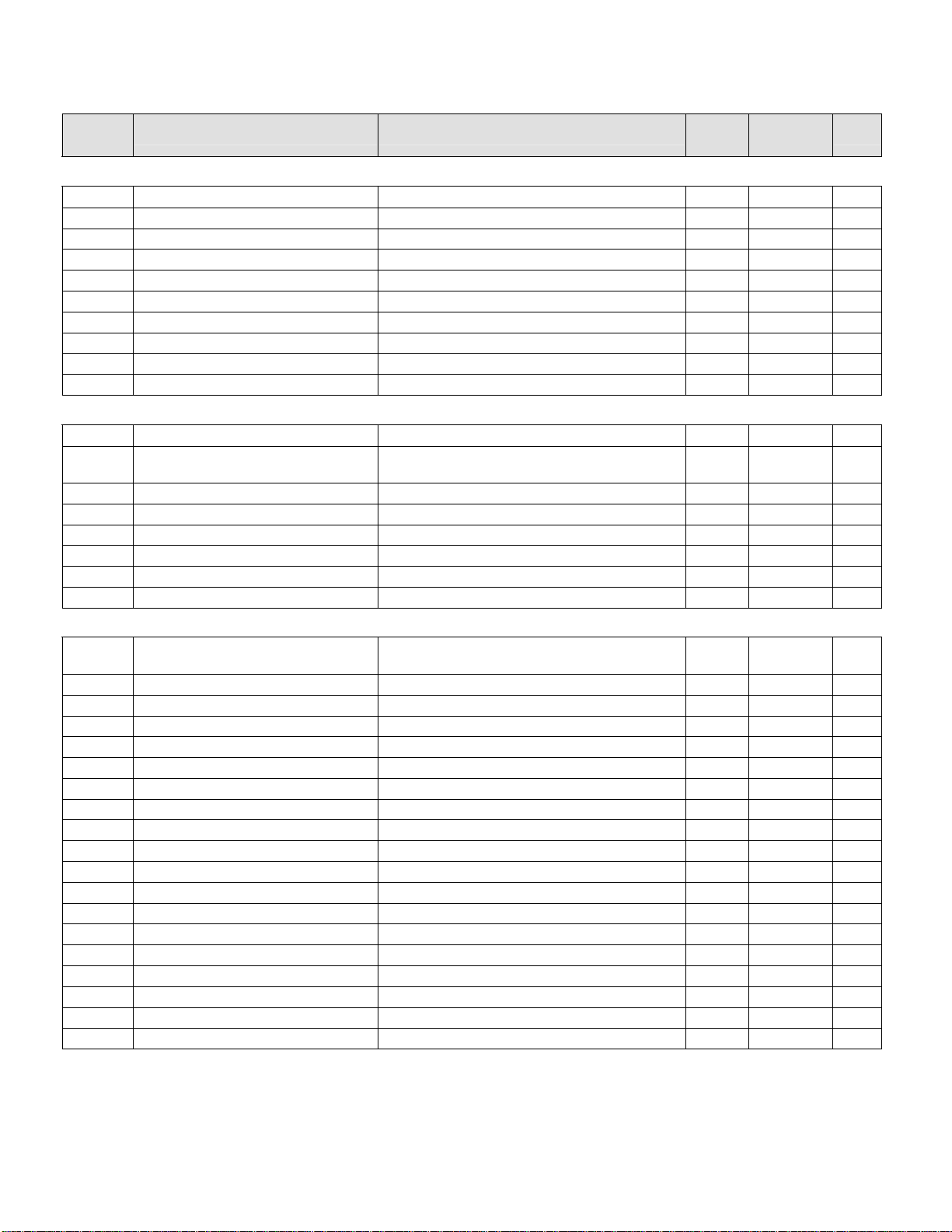

BOI LER STATE

LCD Display

Pa r a me ter / Notes

Boiler Disable or R em ot e On/Off

Outdoor Air T em p >

Warm Weat her Shut down Set point

Domestic Hot Water Priority

RO

O+,O-

DP

Terminal Number

-

44,30,

75

20,74

Start/ Sto p Seq u en ce St atesPre-Seq u en ce States

Parameter/Note

Boiler Disable

Warm Weather

Shutdown

Locko ut

b &ca aa

Pump Purge

Standby

Purge / Pilot Ignition

Limit Hold

-3/d - - -53 4/d

-

Low Fire / Ignition

Main I gnition

Low Fire Hold

Boiler Running

Pump Cooldown

Fan Post Purge

54/d

Boil e r Enabl e/Disable On

Domestic Hot Water Demand Monitored

Low Fire Hold

Fuel Valv e Energiz ed

Flame Saf eguard Alarm

Sys t em Pum p F eedback

Call For Heat

Recycling Limits

(LC, OO, WF, GP and HL inputs)

Limits

Inputs

Non-Recycling Limits

(Combustion Air Flow (CA Input))

Call For Heat Relay

Lockout Indicator

( M anual R es et R equire d)

Spare Output

Boiler Pump

System Pump

Relay Outputs Inter lo ck Inpu ts

Syst em Pum p Bac k up Pump

Combustion Air Damper

System Alarm

Mix ing Valve Out put

Blower High Speed

Purge %

Modulation

Firing Rat e

Modulation Outputs

Low F ire %

Blower 0 Volts

SI

CS

AL

SI

R+,R-

OR

BO,BC

LC , O O ,WF,

GP,HL

CA

CH

LO

VI

BP

SP

SO

SO

SO

MS,MR

V+,V-,

P+,P-

V+,V-,

P+,P-

V+,V-,

P+,P-

V+,V-,

P+,P-

V+,V-,

P+,P-

9

-

-

9

70,71,

72

8,27,

28

-

-

-

-

2,30

25,30

10

10,27/

e

10

6,79,

80

49

52

-

9,51/f

50

System Pump Feedback Monitored

Call For Heat

Recycling Limits Made

Non-Recycling Limits Made

Call For Heat Relay On

Spare Output On

Boiler Pump On

System Pump On

Starts in response to System Pump Feedback In put SI

Combustion Air Damper Open

Alarm Status is Monitored

Modulate

Notes

a. Boiler Pump is “On” when the Boiler Pump is set to “On Always” or the boiler is lead boiler and Boiler Pump is set to “On Lead”

b. Boiler Pump is "On" when the Boiler Pump is set to "On Always" and WWSD is set to "WWSD of System Pump" or “Off”

c. System Pump is "On" when the System Pump is set to “yes” and WWSD is set to either "WWSD of Boiler" or "Off"

d. Boiler pump is "On" during Prepurge and Post Purge when Boiler Pump is set to "Purge" or boiler is lead & Boiler Pump is set to “On Lead”

e. Combustion Air Damper Spare Output is maintained “On” for 2 minutes after the Call For Heat is removed.

f. Modulation rate is held at purge % when low fire input is not provided.

Sage Boiler Control Instruction Manual Page 6 of 56

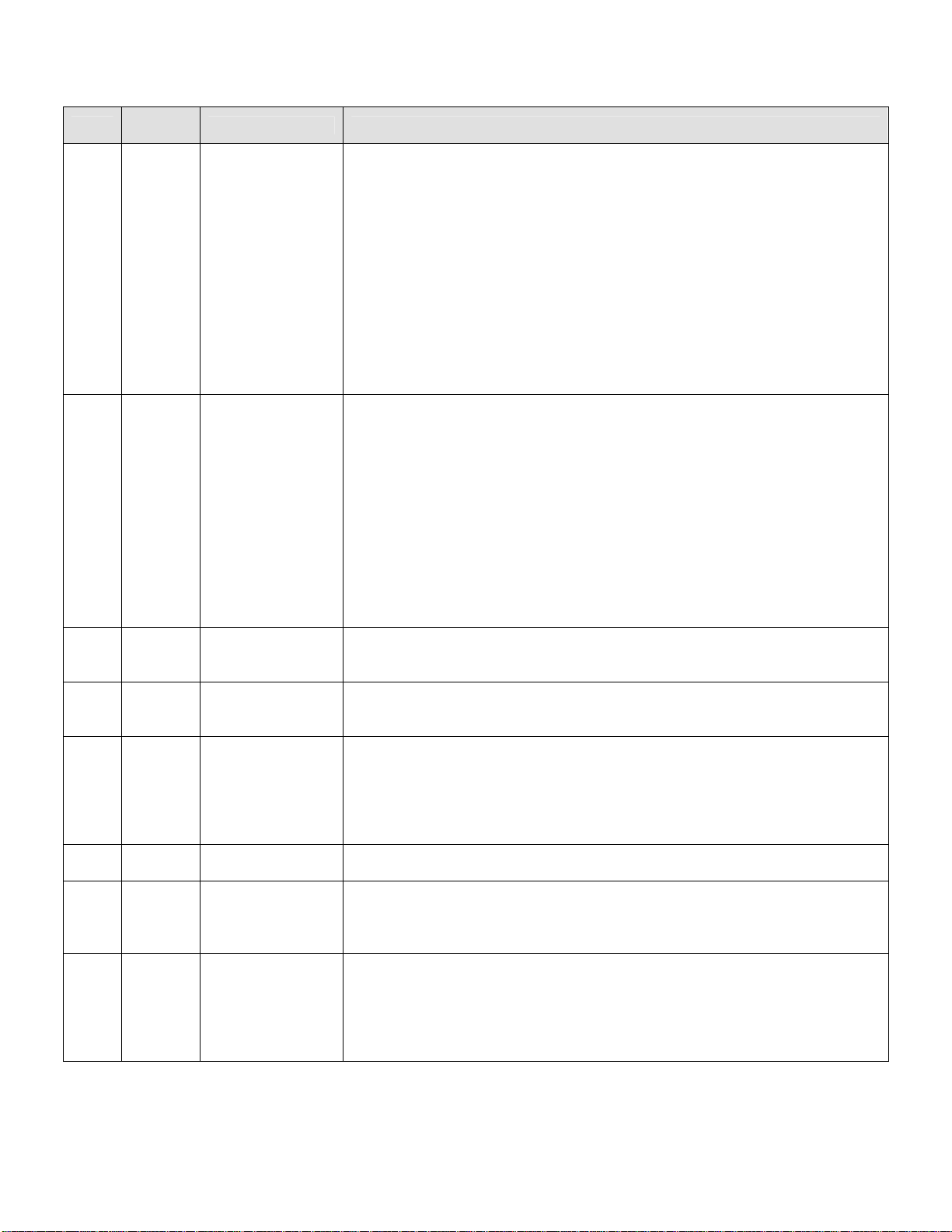

Page 7

Product Features

Boiler Sequence (Continued)

Pre-Sequence States

BOILER

STATE

LCD Display

Boiler

Disabled

Warm

Weather

Shutdown

Lockout Any Mode

Standby

Start/Stop Sequence States

BOILER

STATE

LCD Display

Pump Purge

Limit Hold Any Mode

Purge / Pilot

Ignition

Low Fire /

Ignition

Main Ignition Any Mode

Low Fire

Hold

Boiler

Running

Fan Post

Purge

Pump

Cooldown

CONTROL MODE

LCD Display

Any Mode

(Except for

Remote Control)

Any Mode

(Except for

Manual Mode)

Outlet Sensor &

Local SP Mode

Remote Sensor

& Local SP

Mode

Outlet Sensor &

Remote SP

Mode

Remote Sensor

& Remote SP

Mode

Remote Control

Mode

Manual

Operation Mode

CONTROL MODE

LCD Display

Any Mode

(Except

Manual Mode)

Any Mode

Any Mode

Any Mode The modulation output is held at the Low Fire for the Low Fire Hold time.

Any Mode

Any Mode

Any Mode

Description

Boiler is prevented from starting; Remote On/Off (Enable) (Terminal RO) Input is not

energized.

Boiler is prevented from starting, Warm Weather Shutdown (WWSD) is enabled and

outside air temperature is above the WWSD Setpoint

Boiler is prevented from starting, Flame Safeguard lockout is present. A Flame

Safeguard manual reset is required

Control monitors boiler outlet temperature, a Call For Heat is initiated when boiler

outlet temperature is below the Operational Setpoint

Control monitors Remote System Temperature, a Call For Heat is initiated when

Remote System Temperature is below the Operational Setpoint

Control monitors boiler outlet temperature, a Call For Heat is initiated when boiler

outlet temperature is below the Remote Setpoint Input (Terminal C+,C- or Modbus

Interface)

Control monitors Remote System Temperature, a Call For Heat is initiated when

Remote System Temperature is below the Remote Setpoint Input (terminal C+,C- or

Modbus Interface)

Control monitors Remote On/Off (Enable) input (Terminal RO or Modbus Interface), a

Call For Heat is initiated when input is energized

A Call For Heat is initiated when Manual Mode Menu item Boiler On/Off is set to On

Description

Once a Call For Heat is initiated and Boiler Pump Purge is selected, the pump output

is energized until the Pump Prepurge Time is complete. If the Call For Heat condition

still exists at the end of the Prepurge Time (the temperature of the water at the sensor

may rise with boiler water flowing passed it) the pump will continue to operate and the

Call For Heat Relay is energized

Power is applied to the safety limit string. If any limits does not pass power (is not

energized), the alarm LED and LCD display shows the reason the start sequence is

on Hold. Refer to Trouble shooting section for explanation of individual lockout and

alarm messages

After the limit string passes power, the fan is started, the modulation output is set to

Purge Rate. When the purge period is complete, the flame safeguard sequences on

the ignition transformer and pilot

When the Spare Input Low Fire is selected, modulation output is set to the Low Fire

Speed when the Spare Input is energized.

The main gas valve input is energized and the modulation output is held constant for

an ignition stabilization period

When this Low Fire Hold time is complete, the modulation output is released to

modulate

When water temperature is above setpoint, there is a Flame Safeguard or Limit fault,

the Call For Heat is ended and the modulating output is set to Purge Rate for the Post

Purge Time

When Boiler Pump Purge is selected, the boiler pump remains “on” until the boiler

outlet temperature is less than the Post Purge Delta (default is 5 F) above the Boiler

Inlet Temperature.

Sage Boiler Control Instruction Manual Page 7 of 56

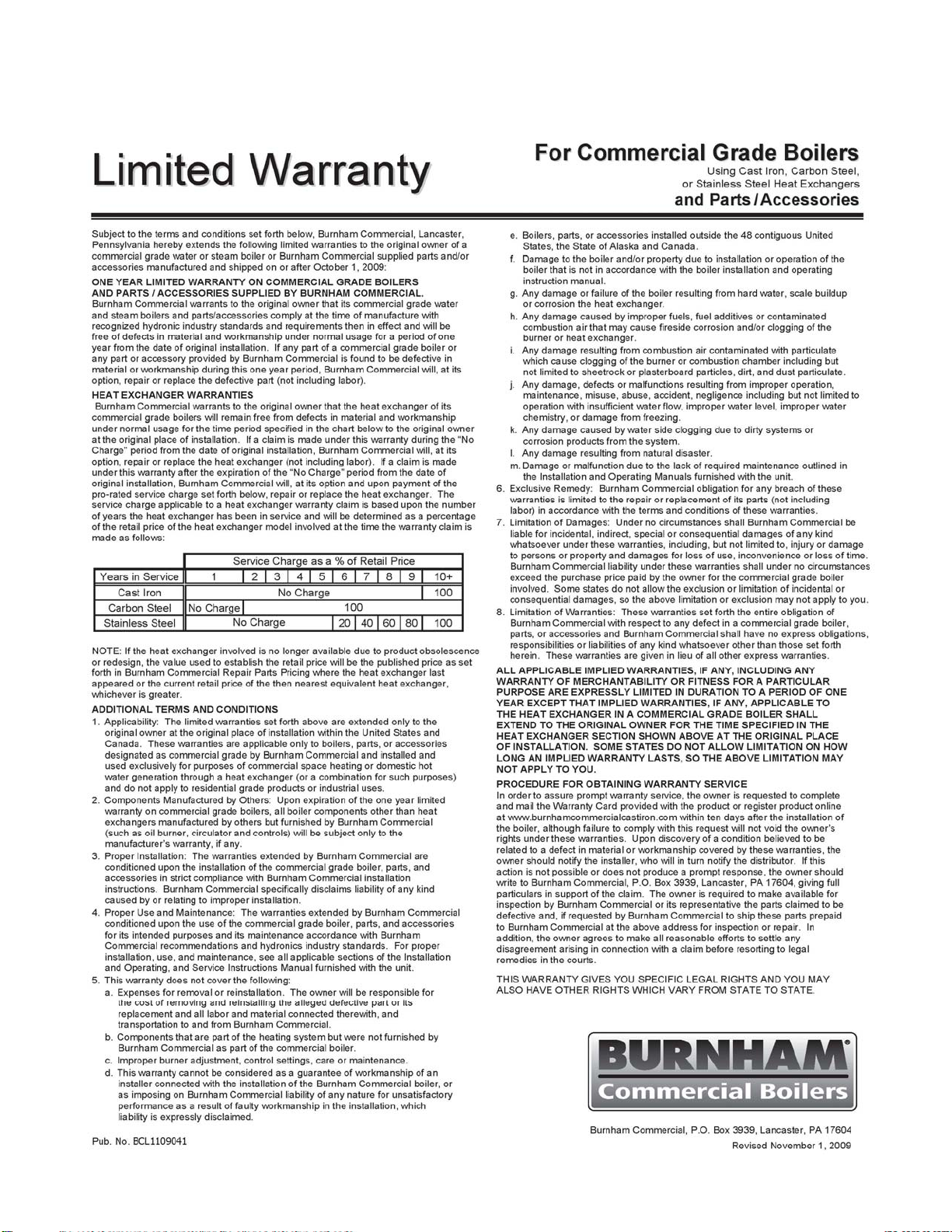

Page 8

Product Features

Boiler Sequence (Continued)

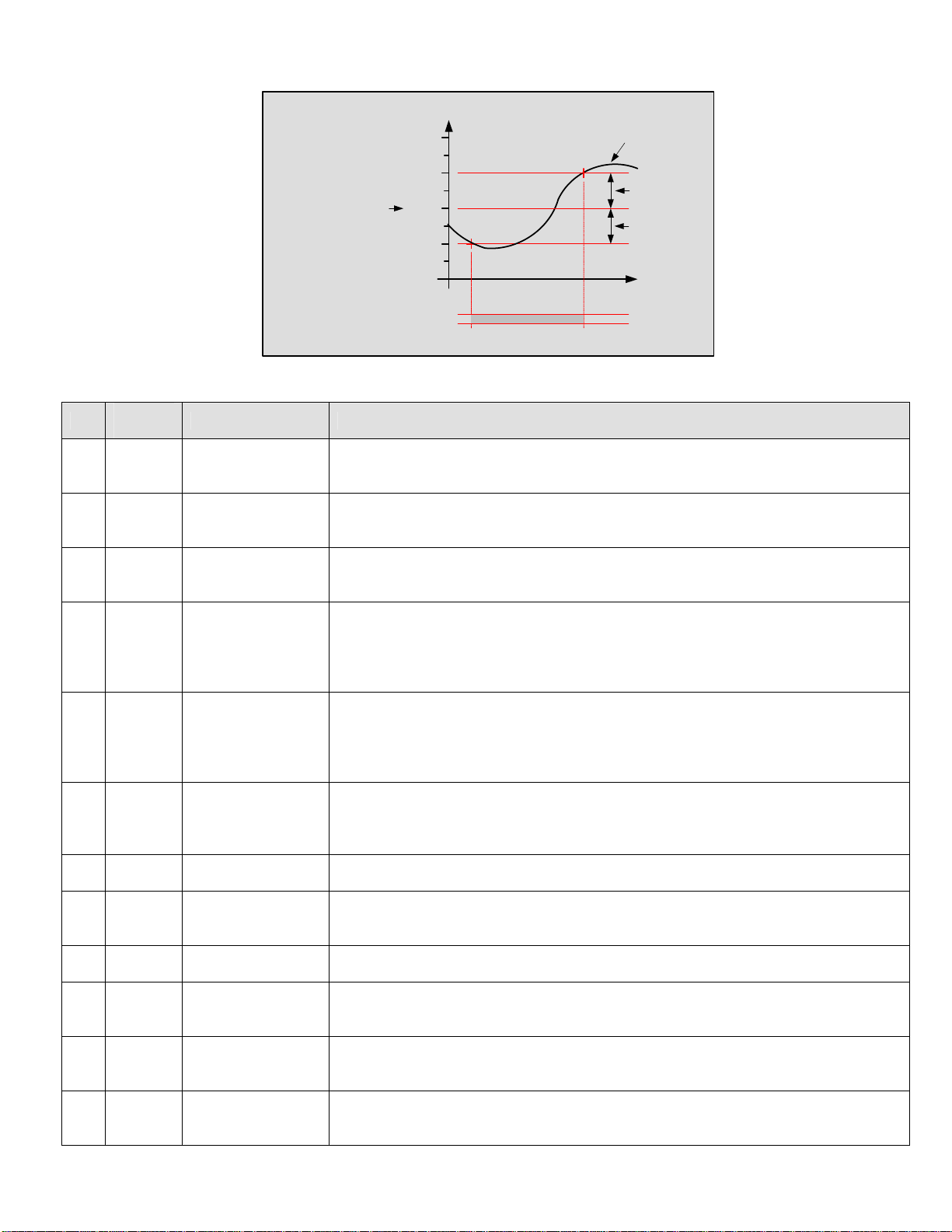

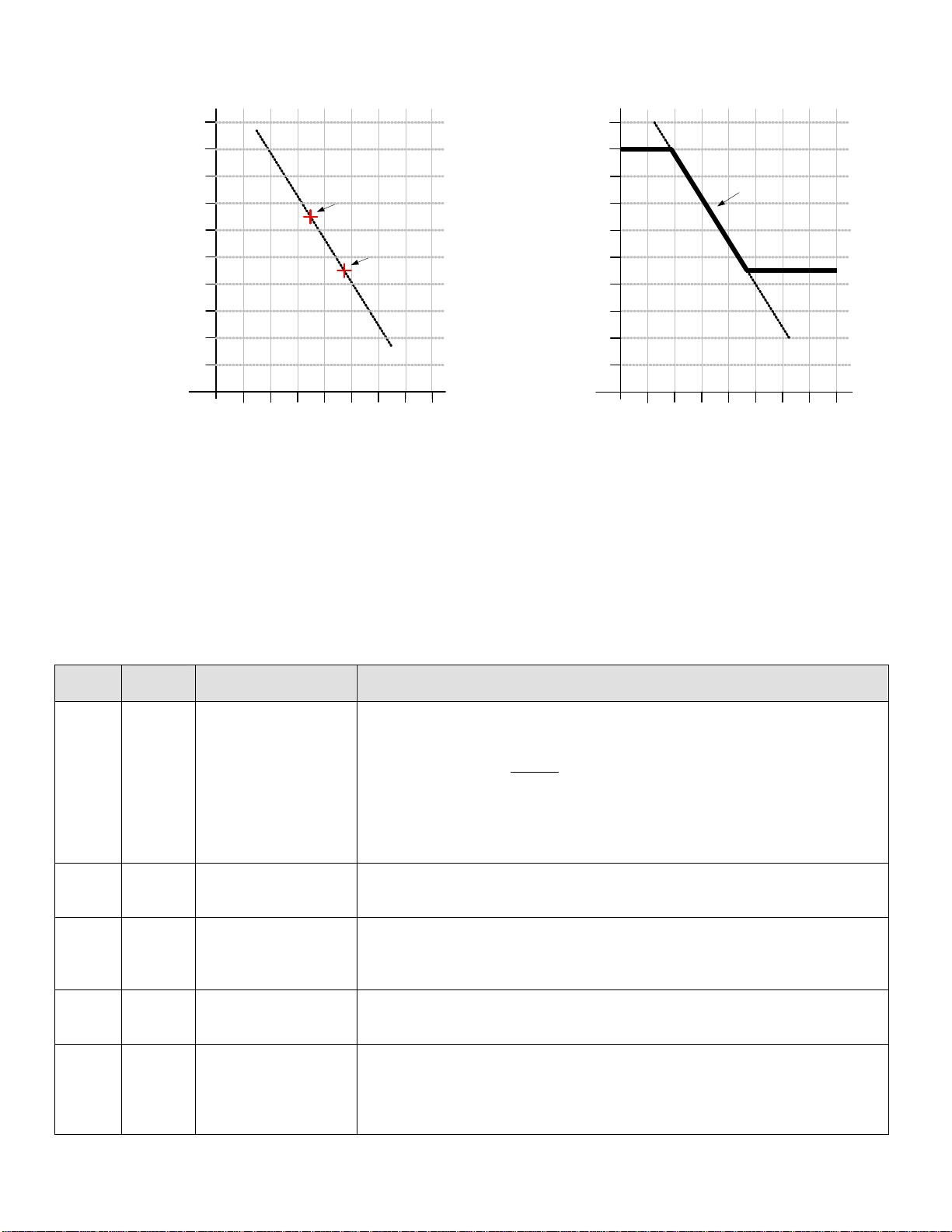

Multiple Boilers

185

Setpoint

High Fire Limit

(Parameter 37)

1

- Lead Boiler Start

2

- Temperature Based Lag Boiler Start

3

- Modulation % Based Lag Boiler Start

4

- Lag Boiler Stop

5

- Lead Boiler Stop

Notes

- The “Boiler Address” parameter assignment determines the boiler sequencing order.

- The Lead Boiler automatically rotates (when “Rotate” parameter is enabled) based on field adjusted time

- Lead Boiler is the first boiler to turn on and the last boiler to turn off, (First On, Last Off, FOLO).

- Lag Boilers are turned on in order and turned off in reverse order, (First On, Last Off, FOLO).

- Tripped boilers are replaced without waiting for the Boiler On Delay timer. If a tripped boiler becomes available

180

SYSTEM

BOILER

PLANT LOAD

175

TEMPERATURE

100

50

FIRING RATE

0

3

2

1

0

(# BOILERS REQURED)

Lead Boiler

Start

1

Start

st

1

Fast

Load

Change

Lag

2

2

Slow

Load

Change

3

2

Start

nd

Lag

Stop

nd

2

Lag

4 54

Stop

1st Lag

Lead Boiler

Boiler Start and Stop Peer-To-Peer Network Sequence Diagram

(3 boiler system shown, typical for up to 8 boilers)

Water temperature is below the setpoint by more than the “On Point” differential

Water temperature is below the setpoint by more than the “On Point” differential for longer than the adjustable

time delay (“Boiler On Delay” parameter).

The boiler modulation rate has been above the adjustable limit (“LL Start Trigger” parameter) for longer than the

time delay.

The boiler modulation rate has been below the adjustable limit (“LL Stop Trigger” parameter) for long er than the

time delay. Additionally, lag boilers are stopped when water temperature is above the setpoint by more than the

“Off Point” differential for longer than the “Boiler Off Delay” parameter)

The last boiler remains on line until the water temperature is above the “Off Point” setpoint for longer than the

time delay.

(“Rotate After” parameter, default is 168 hours). When rotating, the lead boiler will move to the end of the lag

order and the 1

st

lag boiler will become the lead. The rest of the boilers will then move up in the lag order

accordingly.

it is returned to service.

5

Stop

Sage Boiler Control Instruction Manual Page 8 of 56

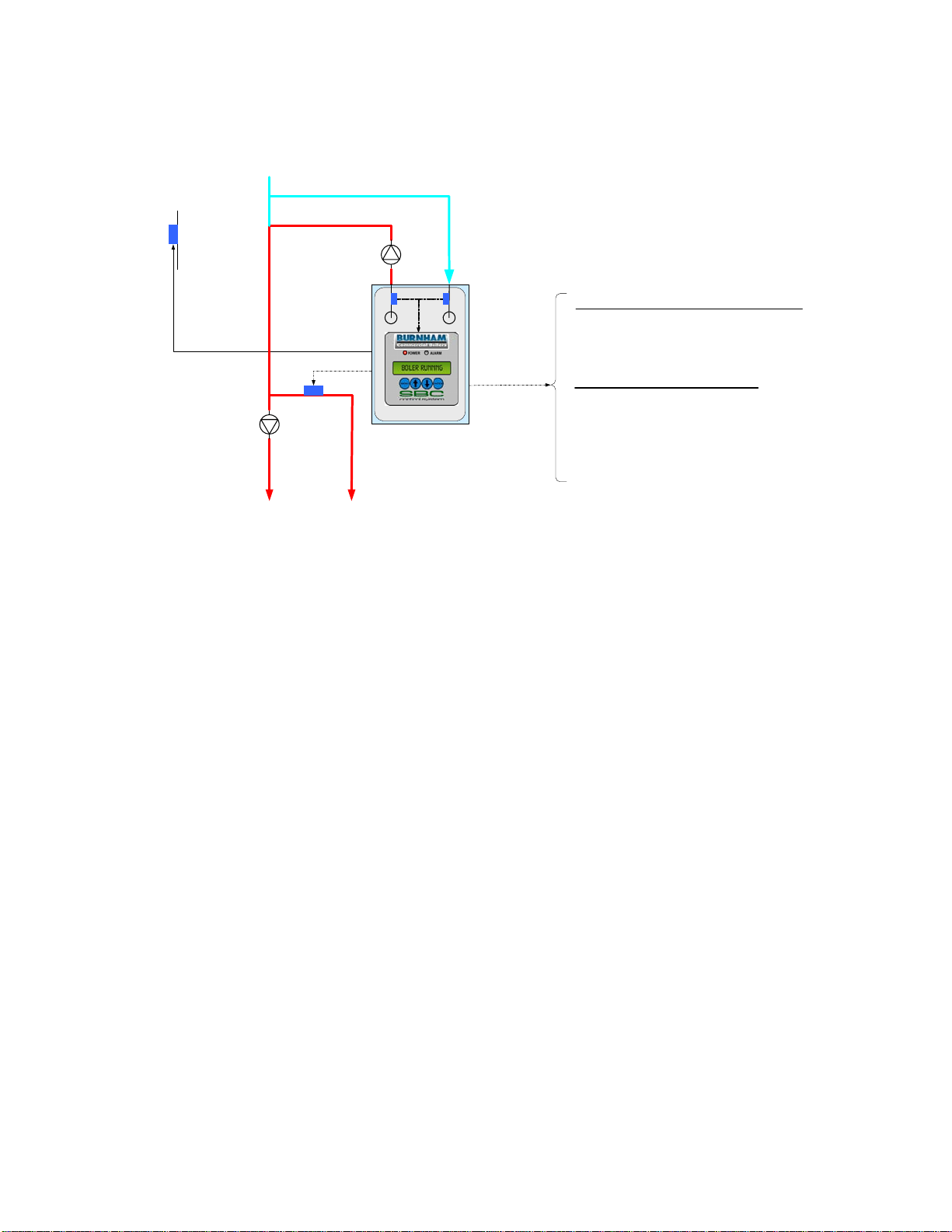

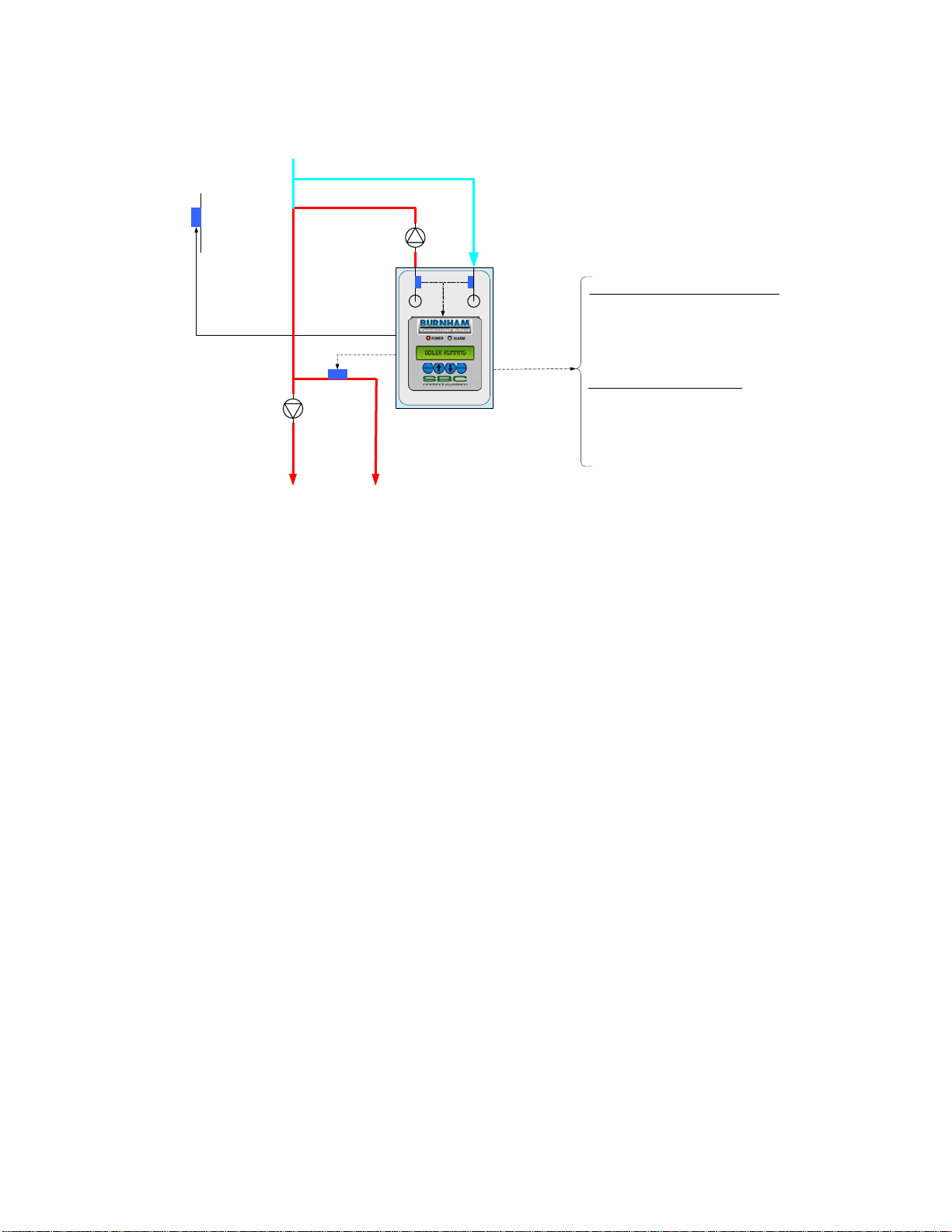

Page 9

Product Features

Single Boiler Control

Display Shows: Outlet Sensor & Local SP Mode

Return

Water

Outside Air

Temperature

(O+, O-)

Boiler

Circulator

Boiler Outlet

Temperature

(BO, BC)

System

Circulator

System

Supply Water

DHW

Override

Switch (DP)

Domestic Hot

Water (DHW)

Supply

Outlet Sensor & Local SP Mode Application Diagram

(Showing Relevant Connections)

Features

Setpoints

The operator selects the setpoint and on and off points

from the LCD display.

Modulation Rate Control

Boiler automatically modulates to maintain the boiler

outlet temperature at setpoint.

Call for Heat

The Call For Heat is determined by the setpoint, on

and off points and boiler outlet temperature.

Options

Outside Air Reset

If enabled, the Outside Air Sensor will automatically

adjusted the setpoint.

Warm Weather Shutdown (WWSD)

If enabled, the WWSD will disable a boiler start when

outside air temperature is above a Warm Weather

Shutdown (WWSD) setpoint.

Domestic Hot Water Priority (DHWP)

If enabled, the DHWP will adjust the setpoint to satisfy

the DHWP setpoint when a DHWP input (DP) is

energized.

Boiler Inlet

Temperature

(BI, BC)

EMS System Hardwired Connections

Lockout Indicator (LO)

Soft Alarm (SO)

Remote On / Off (Enable) (RO)

RJ11, RS-485 Communication

Peer-To-Peer Network

for Modulating Lead/Lag

Or

Modbus Network

for Touch Screen or EMS Monitoring

Selecting This Control Mode

To select Outlet Sensor & Local SP Mode set the following

parameters:

System Configuration Menu:

Remote Control = “No”

Remote System Temperature Sensor = “No”

Remote On / Off (Enable) Input (RO) = Closed

[Jumper (RO) to (C)]

If the Remote On / Off (Enable) (RO) input is opened, the Call

For Heat Relay (CH) is de-energized.

Modbus Network

To establish a Modbus network set the following parameters:

Communication Menu:

Protocol = Modbus

Modbus Address = Give each boiler a unique address.

Baud Rate = Set identical to remote system

Parity = Set identical to remote system

Connect all boilers using a RJ11 ended telephone cable

If the Modbus network is activated the remote system may

monitor and/or control boiler operation. Refer to page 29 for

additional information.

Sage Boiler Control Instruction Manual Page 9 of 56

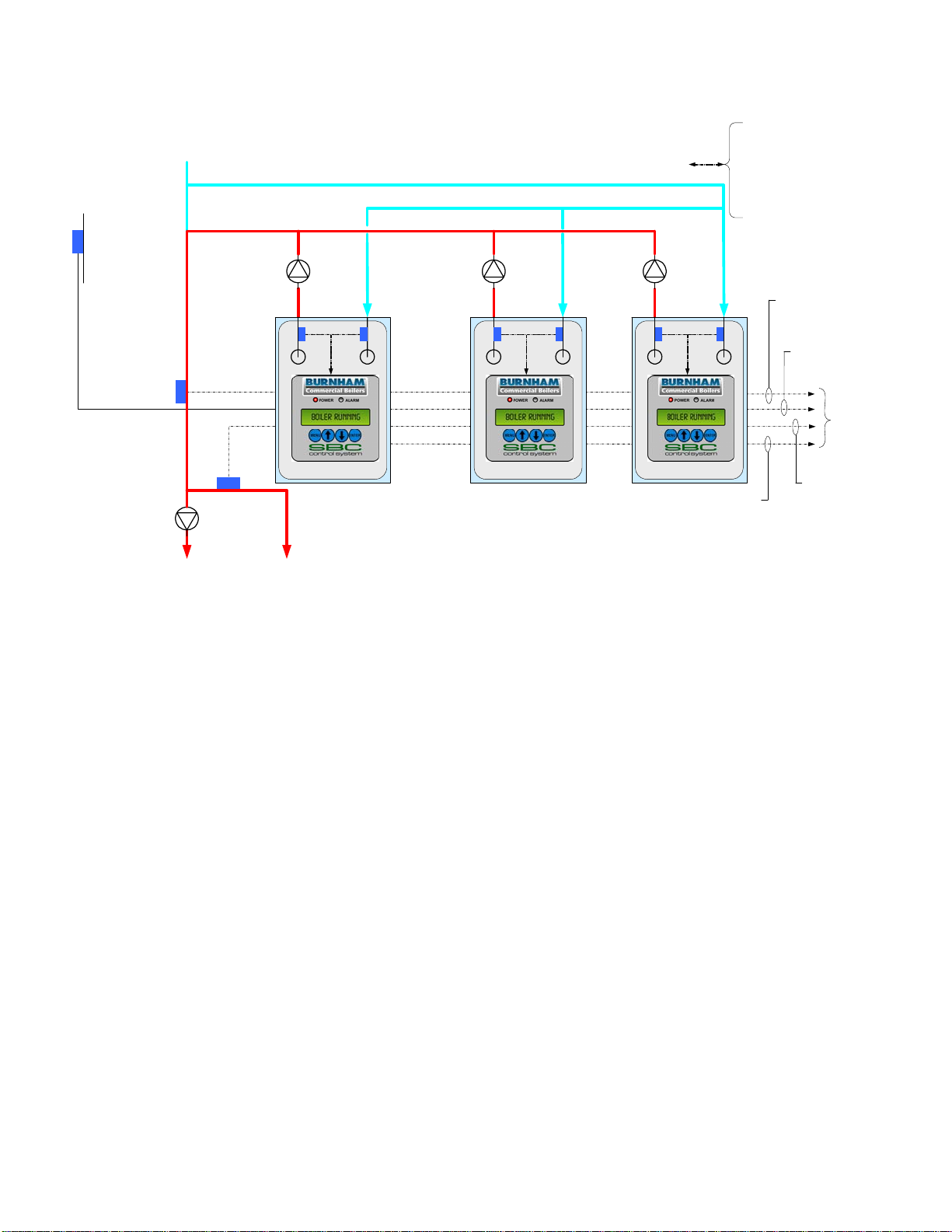

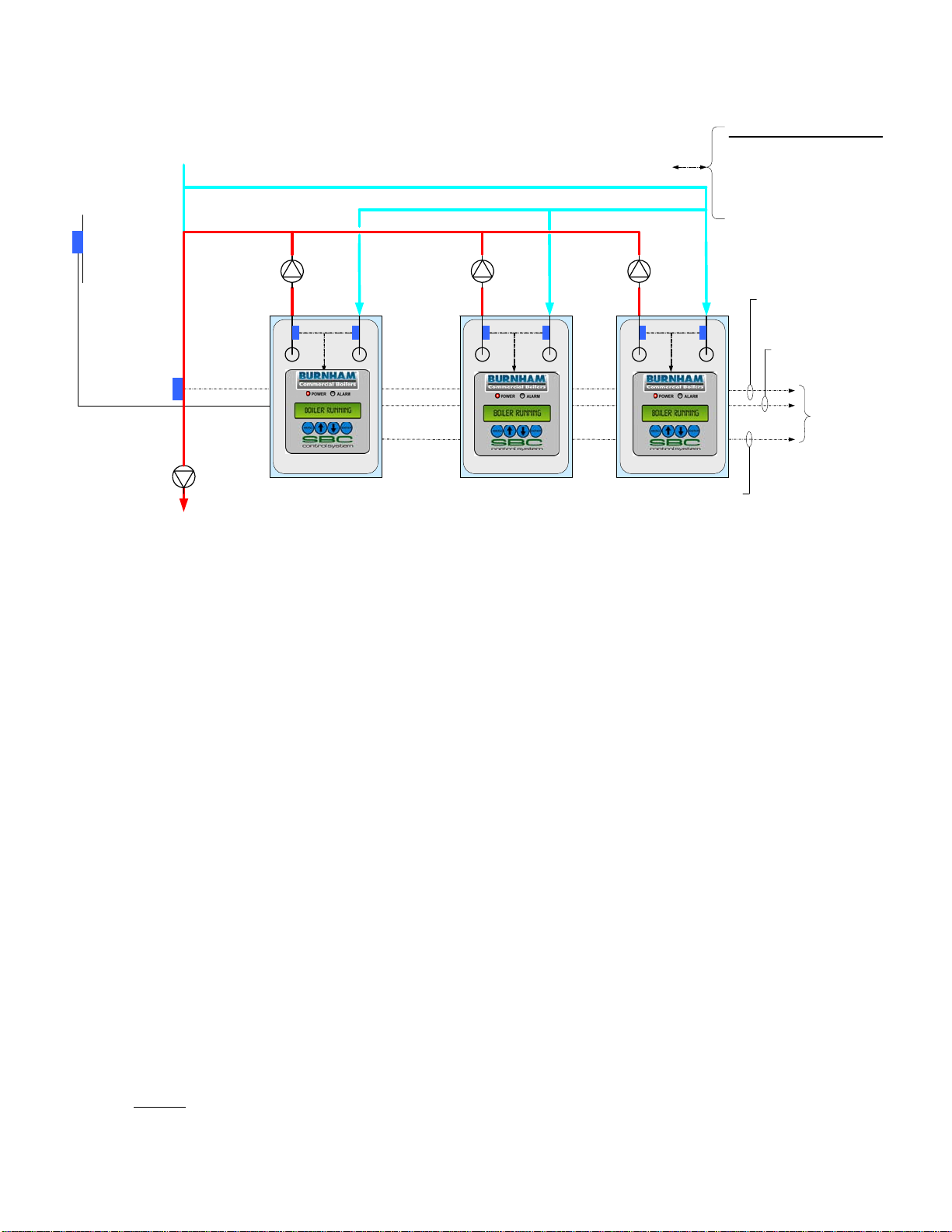

Page 10

Product Features

Multiple Boiler Control

Display Shows: Remote Sensor & Local SP Mode

Outside Air

Temperature

(O+, O-)

Remote System

Temperature

(R+,R-)

System

Circulator

Boiler

Circulator

Boiler Outlet

Temperature

(BO, BC)

Boiler

Circulator

Boiler Inlet

Temperature

(BI, BC)

DHW Override

Switch (DP)

Wired to Each

ECM Controller

Boiler

Circulator

RJ11, RS 485

Peer to Peer

Network

Remote System

Temperature

(R+,R-)

Outside Air

Temperature

(O+, O-)

Connects to

Up to Eight

Boilers

Domestic Hot

Water Priority

(DP)

Remote Sensor & Local SP Mode Application Diagram

(Showing relevant connections for 3 boilers, typical for up to 8)

Features

Setpoints

The ope

rator selects the setpoint and on and off points

from the LCD display.

Modulation Rate Control

Boiler automatically modulates to maintain the Remote

System Temperature (RST) at setpoint.

Call for Heat

The Call for Heat is determined by setpoint, on and off

points and RST. If a Peer-To-Peer network is activated, a

Call for Heat is also initiated when the Lead boiler

modulation rate % is above an adjustable High Fire Rate

Limit (parameter 37) for too long a time.

Options

Outside Air Reset

If enabled, the Outside Air Sensor will automatically

adjusted the setpoint.

Warm Weather Shutdown (WWSD)

If enabled, the WWSD will disable a boiler start when

temperature is above a Warm Weather Shutdown (WWSD)

setpoint.

Domestic Hot Water Priority (DHWP)

If enabled, the DHWP will adjust the setpoint to satisfy the

DHWP setpoint when a DHWP contact input (DP) is

closed. When multiple boilers monitor the DHWP input, an

isolated contact is required for each boiler.

Selecting This Control Mode

To select Remote Sensor & Local SP Mode set the

following parameters:

System Configuration Menu:

Remote Control = “No”

Remote System Temperature Sensor = “Control”

Remote On / Off (Enable) Input (RO) = Closed

[Jumper (RO) to (C)]

If the Remote On / Off (Enable) (RO) input is opened, the

Call For Heat Relay (CH) is de-energized.

If the Remote System Temperature Sensor (RST) fails, the

control mode is automatically switched to Outlet Sensor &

Local SP Mode.

Peer-To-Peer Network

To establish a Peer-To-Peer network follow the procedure

provided on page 28.

If the Peer-To-Peer network is activated the Lead boiler

controls modulation rate and Call for Heat for all

networked boilers. Up to 8 networked boilers are fired in

“Unison” (all at the same modulation rate).

Sage Boiler Control Instruction Manual Page 10 of 56

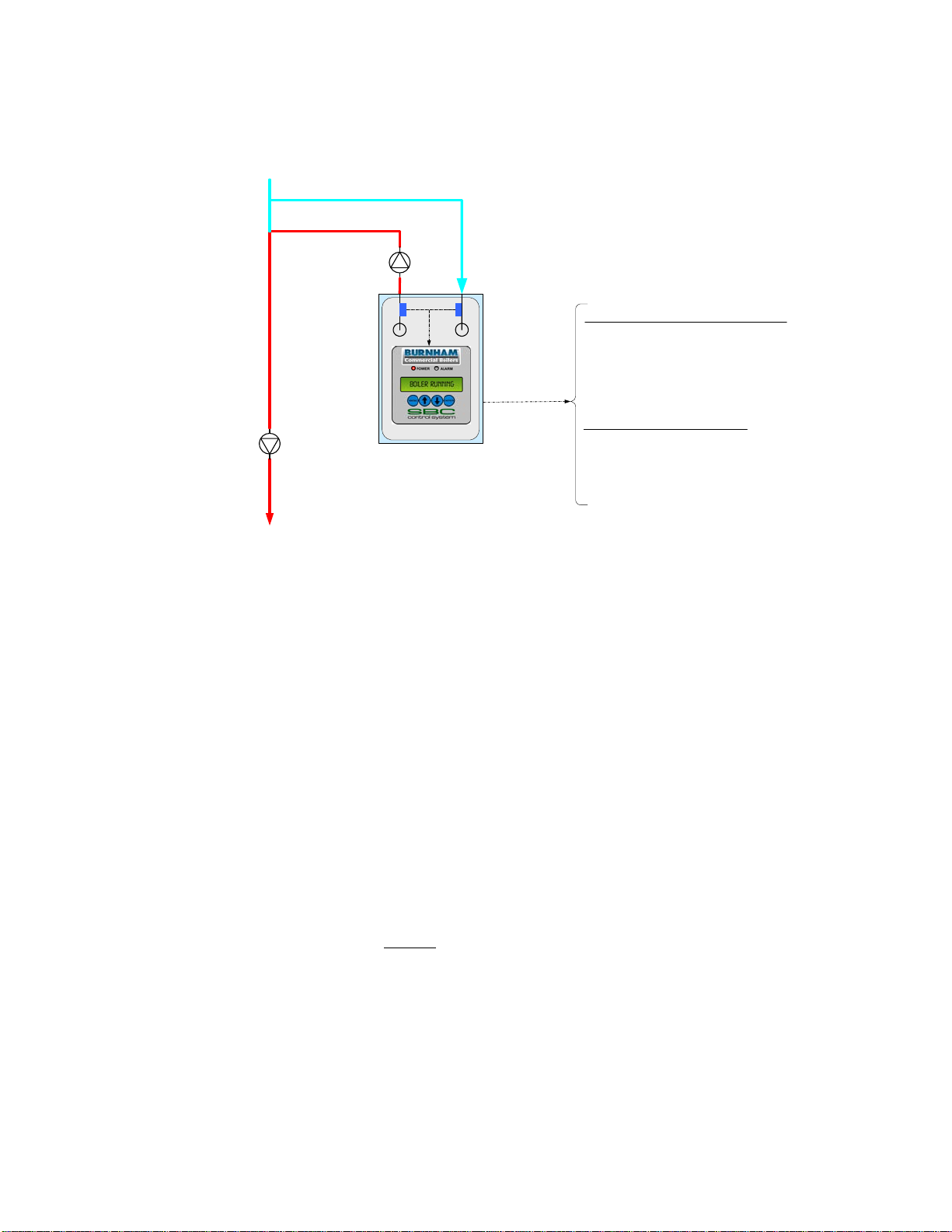

Page 11

Product Features

Energy Management System (EMS) Boiler Control

Display Shows: Outlet Sensor & Remote SP Mode

Return

Water

Outside Air

Temperature

(O+, O-)

Boiler

Circulator

Boiler Outlet

Temperature

(BO, BC)

System

Circulator

System

Supply Water

DHW

Override

Switch (DP)

Domestic Hot

Water (DHW)

Supply

Outlet Sensor & Remote SP Mode Application Diagram

(Showing relevant connections)

Features

Setpoints

The setpoint is determined by the Remote Input (C+,C-)

or Modbus Input and operator sets the on and off points

from the LCD display.

Modulation Rate Control

Boiler automatically modulates to maintain the boiler

outlet temperature at setpoint.

Call for Heat

The Call For Heat is determined by setpoint, on and off

points and boiler outlet temperature.

Options

Warm Weather Shutdown (WWSD)

If enabled, the WWSD will disable a boiler start when

temperature is above a Warm Weather Shutdown

(WWSD) setpoint.

Outside Air Temperature may be displayed only.

Outside Air Reset and Domestic Hot Water Priority input

(DP) are ignored.

Boiler Inlet

Temperature

(BI, BC)

EMS System Hardwired Connections

Lockout Indicator (LO)

Soft Alarm (SO)

Remote On / Off (Enable) (RO)

Remote Setpoint (C+,C-)

RJ11, RS-485 Communication

Peer-To-Peer Network

for Modulating Lead/La g

Or

Modbus Network

for Touch Screen or EMS Monitoring

Selecting This Control Mode

To select Outlet Sensor & Remote SP Mode set the following

parameters:

System Configuration Menu:

Remote Control = “Remote SP”

Remote System Temperature Sensor = “No”

Local / Remote Input (LR) = Closed

Remote On / Off (Enable) Input (RO) = Closed

[Jumper (RO) to (C)]

When the Local / Remote Input (LR) is open, Remote Input

(C+,C-) is ignored and Outlet Sensor & Local SP Mode is

active.

If the Remote On / Off (Enable) (RO) input is opened, the

Call For Heat Relay (CH) is de-energized.

Modbus Network

To establish a Modbus network set the following parameters:

Communication Menu:

Protocol = Modbus

Modbus Address = Give each boiler a unique address.

Baud Rate = Set identical to remote system

Parity = Set identical to remote system

Connect all boilers using a RJ11 ended telephone cable

If the Modbus network is activated the remote system may

monitor and/or control boiler operation. Refer to page 29 for

additional information.

Sage Boiler Control Instruction Manual Page 11 of 56

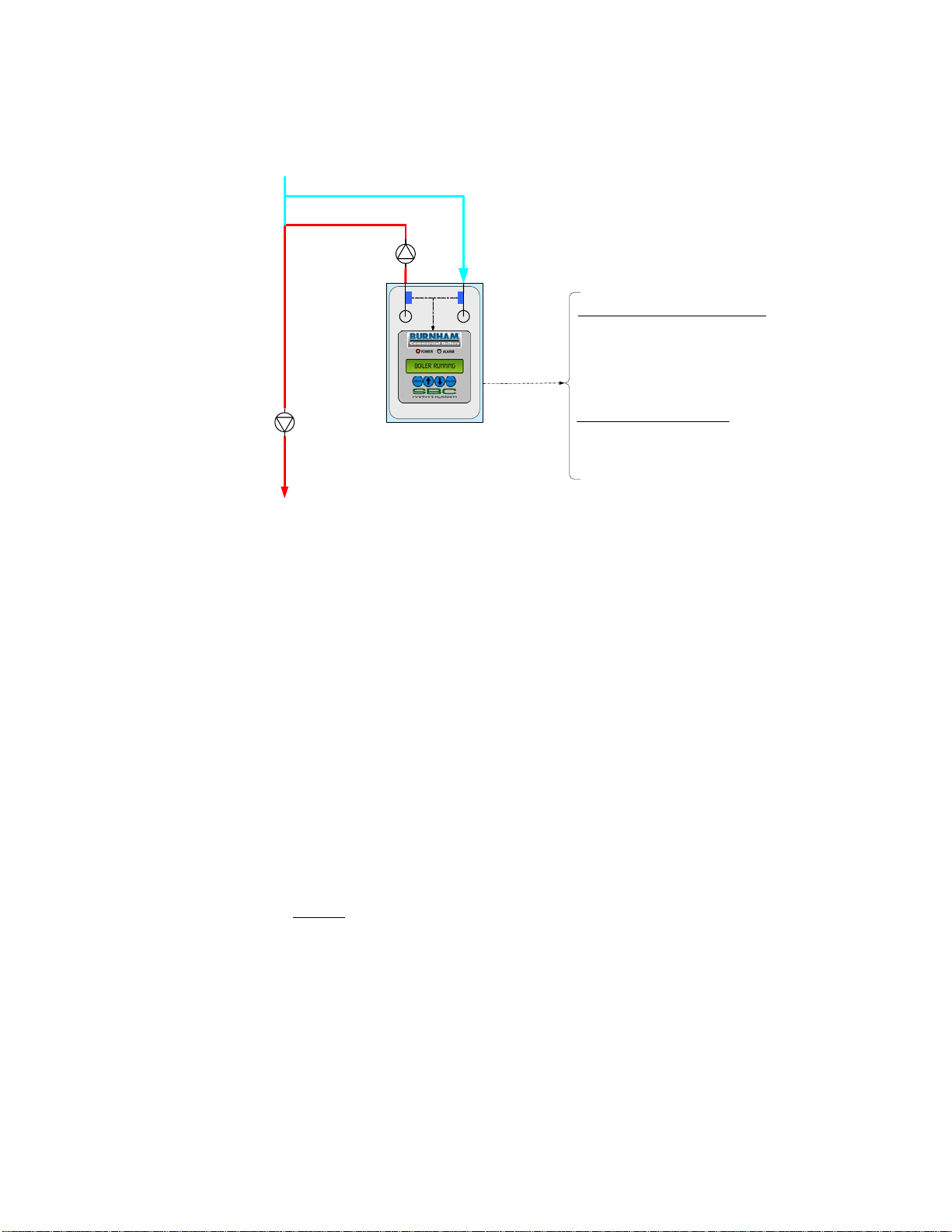

Page 12

Product Features

Energy Management System (EMS) Boiler Control (continued)

Display Shows: Remote Sensor & Remote SP Mode

Return

Water

Outside Air

Temperature

(O+, O-)

Remote System

Temperature

(R+,R-)

System

Circulator

System

Supply Water

Features

Setpoints

The setpoint is determined by the Remote Input (C+,C-)

and operator sets the on and off points from the LCD

display.

Modulation Rate Control

Boiler automatically modulates to maintain the Remote

System Temperature (RST) at setpoint.

Call for Heat

The Call For Heat is determined by setpoint, on and off

points and Remote System Temperature. If a Peer-ToPeer network is activated, a Call for Heat is also initiated

when the Lead boiler modulation rate % is above an

adjustable High Fire Rate Limit (Parameter 37) for too

long a time.

Options

Warm Weather Shutdown (WWSD)

If enabled, the WWSD will disable a boiler start when

temperature is above a Warm Weather Shutdown

(WWSD) setpoint.

Outside Air Reset and Domestic Hot Water Priority input

(DP) are ignored

.

Boiler

Circulator

Boiler Outlet

Temperature

(BO, BC)

Boiler

Circulator

Boiler Inlet

Temperature

(BI, BC)

Remote Sensor & Remote SP Mode Application Diagram

(Showing relevant connections for 3 boilers, typical for up to 8)

Selecting This Control Mode

To select Remote Sensor & Remote SP Mode set the

following parameters:

System Configuration Menu:

Remote Control = “Remote SP”

Remote System Temperature Sensor = “Control”

Local / Remote Input (LR) = Closed [Jumper (LR) to (C)]

Remote On / Off (Enable) Input (RO) = Closed

[Jumper (LR) to (C)]

When the Local / Remote Input (LR) is open, Remote Input

(C+,C-) is ignored and Remote Sensor & Local SP Mode is

active.

If the Remote On / Off (Enable) (RO) input is opened, the

Call For Heat Relay (CH) is de-energized.

Peer-To-Peer Network

To establish a Peer-To-Peer network follow the procedure

provided on page 28.

If the Peer-To-Peer network is activated the Lead boiler

controls modulation rate and Call for Heat for all networked

boilers. Up to 8 networked boilers are fired in “Unison” (all

at the same modulation rate).

Wired to Each

ECM Controller

Boiler

Circulator

EMS System Connections

Lockout Indicator (LO)

Soft Alarm (SO)

Remote On / Off (Enable) (RO)

Remote Setpoint (C+,C-)

Remote System

Temperature

(R+,R-)

Outside Air

Temperature

(O+, O-)

Connects to

Up to Eight

Boilers

RJ11, RS 485

Peer to Peer

Network

Sage Boiler Control Instruction Manual Page 12 of 56

Page 13

Product Features

Energy Management System (EMS) Boiler Control (continued)

Display Shows: Remote Control Mode

Return

Water

Boiler

Circulator

Boiler Outlet

Temperature

(BO, BC)

System

Circulator

System

Supply Water

Remote Control Mode Application Diagram

(Showing relevant connections)

Features

Modulation Rate Control

The Remote Input (C+,C-) or Modbus input sets

modulation rate. The setpoint is ignored.

Call for Heat

The Call For Heat is determined by Remote On/Off

input (RO) or Modbus input. The on and off points are

ignored. The boiler will turn off if the water

temperature increases past the temperature set on the

Operational Temperature Limit.

Options

Outside Air Reset and Domestic Hot Water Priority

input (DP) and Warm Weather Shutdown are ignored

.

Boiler Inlet

Temperature

(BI, BC)

EMS System Hardwired Connections

Lockout Indicator (LO)

Soft Alarm (SO)

Remote On / Off (Enable) (RO)

Remote Setpoint (C+,C-)

RJ11, RS-485 Communication

Modbus Network

EMS Monitoring and Control

Remote Firing Rate via Modbus

Remote on/off via Modbus

Selecting This Control Mode

To select Remote Control Mode set the following parameters:

System Configuration Menu:

Remote Control = “Remote Mod”

Remote System Temperature Sensor = “Display Only”

Local / Remote Input (LR) = Closed [Jumper (LR) to (C)].

When the Local / Remote Input (LR) is open, Remote Input

(C+,C-) is ignored and Remote Sensor & Local SP Mode is

active.

Modbus Network

To establish a Modbus network set the following parameters:

Communication Menu:

Protocol = Modbus

Modbus Address = Give each boiler a unique address.

Baud Rate = Set identical to remote system

Parity = Set identical to remote system

Connect all boilers using a RJ11 ended telephone cable

If the Modbus network is activated the remote system may

monitor and/or control boiler operation. Refer to page 29 for

additional information.

Sage Boiler Control Instruction Manual Page 13 of 56

Page 14

Product Features

Manual Boiler Control Mode

Display Shows: Manual Operation Mode and Lost Sensor Blind Mode

Return

Water

Boiler

Circulator

Boiler Outlet

Temperature

(BO, BC)

System

Circulator

System

Supply Water

Boiler Inlet

Temperature

(BI, BC)

EMS System Hardwired Connections

Lockout Indicator (LO)

Soft Alarm (SO)

Remote On / Off (Enable) (RO)

RJ11, RS-485 Communication

Modbus Network

EMS Monitoring

Manual Operation Mode and Lost Sensor Blind Mode Application Diagram

(Showing relevant connections)

MANUAL OPERATION MODE

Features

Modulation Rate Control

The operator sets the modulation rate. The setpoint is

ignored.

Call for Heat

The Call For Heat Relay (CH) is directly controlled by

the operator. The on and off points are ignored. The

boiler will turn off if the water temperature increases

past the temperature set on the High Temperature

LOST SENSOR BLIND MODE

If both Remote System Temperature (RST) and boiler outlet

temperature and the Remote Control input signal (C,-C+) have

failed, the boiler is started and run continuously at the lowest

modulation rate.

If the controller has entered Lost Sensor Blind Mode, the user

may switch the boiler into manual mode or repair, replace or

reconnect required temperature sensors.

Stop parameter.

Options

Outside Air Reset, Warm Weather Shutdown and

Domestic Hot Water Priority are ignored

.

The Spare Output (VI) and Combustion Air Damper

(SO) outputs are energized when the operator starts

the boiler in manual mode.

Selecting This Control Mode

Manual Mode is activated from the Manual Mode

menu when Supervisor password is entered. Simply

set the Boiler Man/Auto parameter to “Man” and adjust

the Modulation Rate and Boiler On/Off menu items as

required. Once activated the green LED flashes. To

leave manual mode set the Boiler Man/Auto parameter

to “Auto”.

Sage Boiler Control Instruction Manual Page 14 of 56

Page 15

Product Features

Auxiliary Device Control

Return

Water

M

Fresh Air

Supply

Combustion Air

Open/Close (SO)

Damper

Boiler Inlet

Temperature

(BI, BC)

Standby System Pump

Mixing Valve

M

Control (MR, MS)

Boiler Pump

Start/Stop (BP)

Boiler Outlet

Temperature

(BO, BC)

Start/Stop (SO)

System Pump

Start/Stop (SP)

Spare Output (VI)

System Pump

Feedback (SI)

System

Supply Water

Energy Management

System (EMS)

Interface

Modbus RS-485, RJ-11

Connection

Auxiliary Control Application Diagram

(Showing All Options)

Features

Mixing Valve

The primary function of the mixing valve is to protect the

boiler from thermal shock and sustained flue gas

condensation. When configured, the mixing valve output

compares both minimum return water temperature setpoint

to measured return water temperature and boiler

differential temperature setpoint to measured differential

temperature (boiler outlet minus inlet temperature).

If the boiler return water temperature drops below the

minimum inlet water temperature setpoint (“Min In H2O

Temp” parameter) or the differential temperature increases

above the maximum water differential temperature setpoint

(“Max H2O Delta T” parameter) the mixing valve opens to

allow hot boiler outlet water to blend with cold return water.

The valve repositions toward 0% recirculation after return

water increases above setpoint and the differential

temperature reduces below setpoint.

The mixing valve may be controlled manually from the

Manual Mode menu when Supervisor password is entered.

Simply set the Mixing Valve M/A parameter to “Man” and

adjust the Mixing Valve % as required. Once activated the

green LED flashes. To leave manual mode set the Mixing

Valve M/A parameter to “Auto”

Combustion Air Damper and Vent Inducer

When the Relay (CH) is closed, the Combustion Air

Damper (CAD) and Vent Inducer outputs are energized. If

the CAD open position is needed to be proven, a limit

switch may be wired in series with the Low Water Cut-off

Switch input (LC). The alarm Message may be modified to

reflect this change.

Boiler Pump

The Boiler Pump output (BP) may be configured as None,

Always On, Purge or Lead On by setting the Boiler Pump

(parameter 2) (refer to page 31):

Always On Boiler pump runs continuously.

Purge Boiler pump runs during a pump Prepurge

(Pump Prepurge (parameter 3) time before

boiler starts) while the boiler is running and

during a pump cooldown period (pump

cooldown maintains the boiler pump running

until the boiler outlet temperature is within

the Postpurge Delta (parameter 4) degrees

above the boiler inlet temperature).

Lead On: Boiler Pump runs continuously when the

boiler is the lead and during the fan prepurge, while the boiler is running and during

fan post purge when a lag boiler.

The boiler pump sequences are detailed on the boiler

sequence diagram on page 6.

System and Standby System Pump

When configured, the System Pump output (SP) is always

energized except when turned off by the Warm Weather

Shutdown feature. A Standby System Pump output (SO)

may be configured as a backup to the system pump. The

Standby System Pump is started based on the System

Pump Feedback input (SI).

Selecting This Control Mode

These control modes may be selected using the Boiler and

System Configuration menus.

Sage Boiler Control Instruction Manual Page 15 of 56

Page 16

Front Panel

Features

POWER LED [Steady On Green LED] indicates power is available down

stream of the Sage Boiler Control’s on board fuse.

[Flashing On Green LED] indicates manual mode operation

for boiler modulation

ALARM LED [Steady On Red LED] indicates an alarm is active.

[Flashing On Red LED] indicates a lockout alarm is a c tive

and a manual reset may be required

SCREEN 2 line by 16 character display provides operational, alarm,

sequence status, configuration and diagnostic user in terface

ENTER The ENTER key has no function in display mode. The

ENTER key is used to select menus, menu items and save

edited parameters as follows:

Select Mode (steady text):

Mode or select a menu or menu item

Edit Mode (blinking text):

value. Press MENU to cancel the current editing operation

UP, DOWN Select Mode (steady text):

selected display and move up and down menu items.

Edit Mode (blinking text):

decreases the value of the number being edited, or scrolls

through a list of choices.

MENU Press and hold MENU to change to the Main Menu screen.

When in a sub menu screen, press MENU to move to the

next higher menu. When in Edit Mode (blinking text) Press

MENU to cancel the current editing operation

Press ENTER to change into Edit

Press ENTER to save the current

Press UP, DOWN to change the

Press UP, DOWN to increases or

Sage Boiler Control Instruction Manual Page 16 of 56

Page 17

Front Panel

Display Mode

All values shown in Display Mode are for display only and can not be adjusted by the operator. The

keys scroll through the Display Mode screens:

Standby

Low Inlet Temp

OUT 189F IN 180F

RST 189F OA 180F

OUT 189F SP 180F

MOD RATE SH 100%

Boiler State

Alarm Message Low Inlet Temp alarm shown, refer to page 41 for

OUT Boiler Outlet Temperature

IN Boiler Inlet Temperature

RST Remote System Temperature

OA Outside Air Temperature

OUT or RST Boiler Outlet or Remote System Temperature

SP Active Setpoint

MOD RATE Modulation Rate

SH Space Heating (active when DH is not)

DH Domestic Hot Water Priority

Standby boiler state shown, refer to the top of page 6 &

7 for explanation of each boiler state

explanation of all possible alarm messages, the

alarm line is left blank when no alarm is active

(visible when ‘Remote Sensor’ = Display Only or

Control)

(visible when ‘Outdoor Sensor’ = Display Only or

Outdoor Reset)

(Remote System when ‘Remote Sensor’ = Control)

(visible when ‘DHWP’ = Yes and DP input is true)

In 180F SP 130F

MIX VALVE 100%

Outlet Sensor &

Local SP Mode

LEAD BOILER 8

Cycles #,###,###

Hours #,###,###

Home Screen

The Boiler State and Alarm Message screen is the ‘Home Screen’ and is reverted to when no key has been selected for

longer than 30 minutes.

Alarm LED

New alarms illuminate the alarm LED and energize an alarm output (SO) (if enabled). If a lockout condition is detected,

the alarm LED will blink and the lockout indication output (LI) is energized. The display Message is cleared and relays

de-energize when the alarm condition is cleared.

In Boiler Inlet Temperature

SP Min In H2O Temp

MIX VALVE Modulation Rate

Control Mode

LEAD BOILER (0 – 8) Lead Boiler, when zero is displayed modulating

CYCLES Number of boiler cycles

HOURS Number of boilers operating hours

Outlet Sensor & Local SP Mode message shown, refer

to page 2 for an overview of each control mode

lead-lag functions are not available

Sage Boiler Control Instruction Manual Page 17 of 56

Page 18

Front Panel

Display Navigation

Press and hold the key to leave the Display Mode and access the Main Menu:

Main Menu

DISPLAY MODE

BOILER CONFIG

SYSTEM CONFIG

SETUP

SETPOINTS

COMMUNICATION

DIAGNOSTICS

SECURITY

MANUAL MODE

Arrow Keys :

Up / Down

thr oug h Lis t s

MENU

ENTER

MENU

Sub Menus

DISPLAY MODE

BOILER CONFIG

SYSTEM CONFIG

SETUP

SETPOINTS

COMMUNICATION

DIAGNOSTICS

SYSTEM

SECURITY

MANUAL MODE

Display Mode Displays: Boiler operating status, Display

Only, Values Are Not Editable from this display

Configuration and Setup Menus: Sensor, boiler and

system options selections

(refer to page 31)

Setpoints Menu: Operational, On, Off, Min & Max

Setpoints, Editable Values

(refer to page 19)

Communication Menu

Modbus and Peer-To-Peer Network Selections

(refer to page 27)

Diagnostic Menu: Fault and Low Inlet Temp history,

Input & Output Status

(refer to page 41)

System Menu: Software revision, parameter code and

sensor calibration

(refer to page 43)

Security Menu: Supervisor and Factory access

(refer to page 45)

Manual Mode: User set Call For Heat and modulation

rate. Menu is visible when supervisor password is

entered (Refer to page 38)

Sage Boiler Control Instruction Manual Page 18 of 56

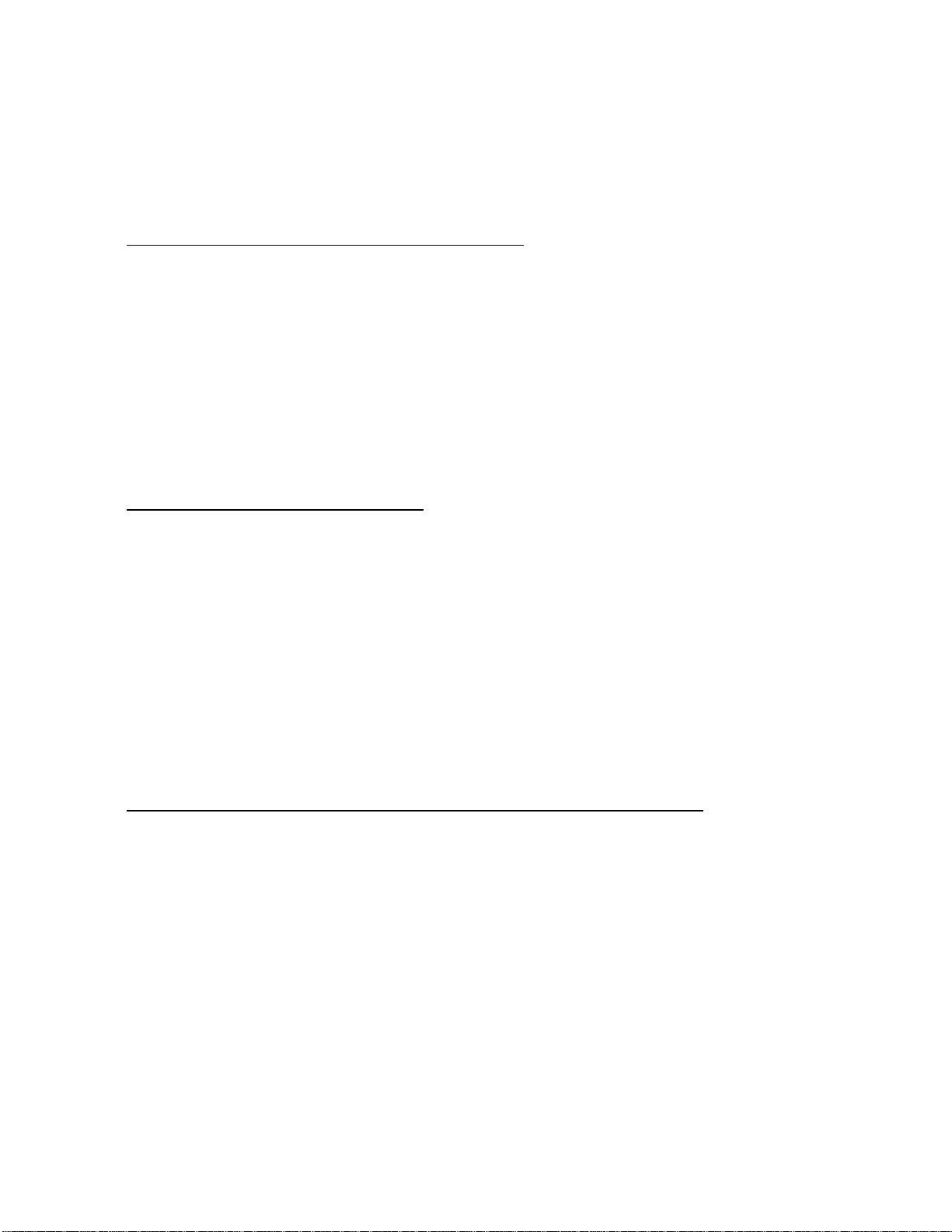

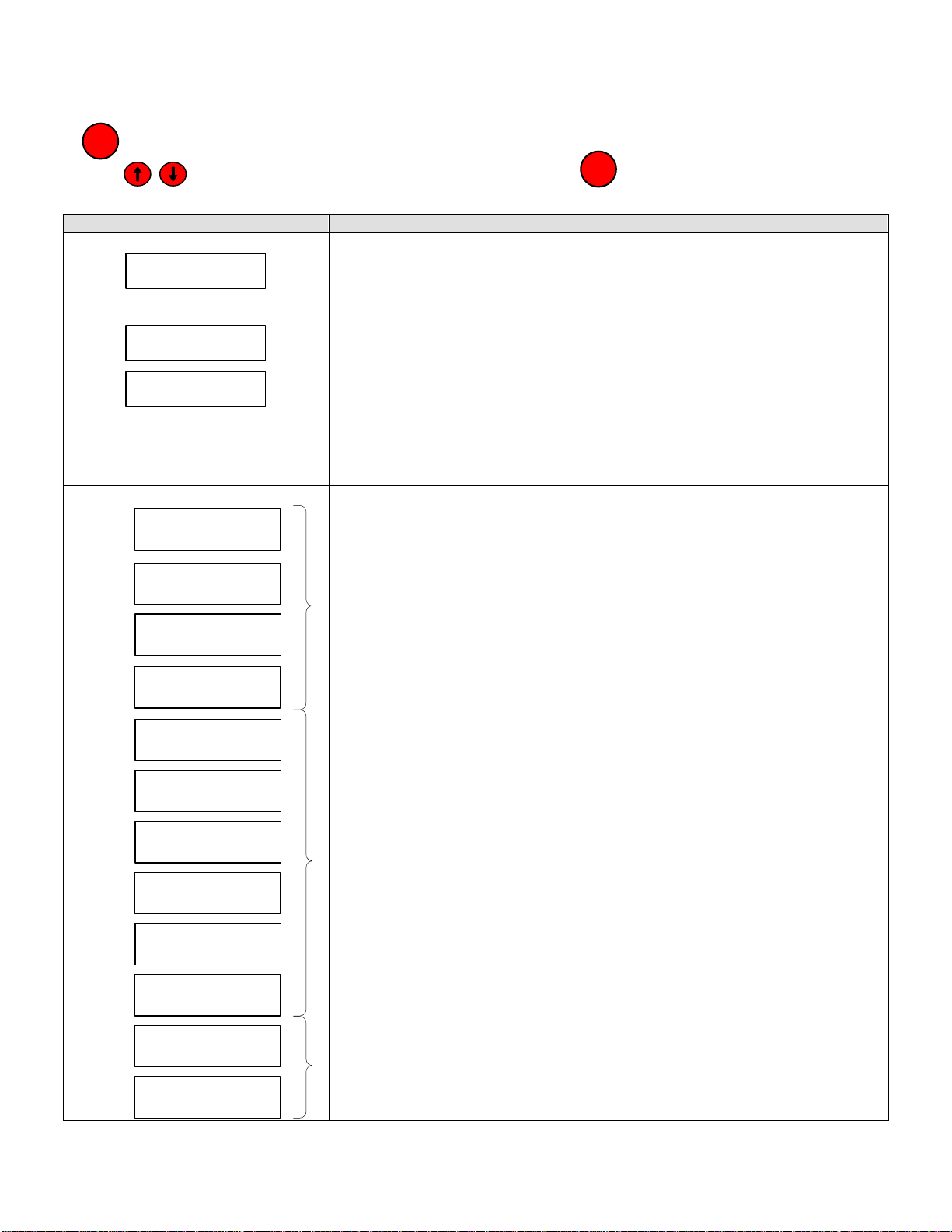

Page 19

Front Panel

Setpoints Menu

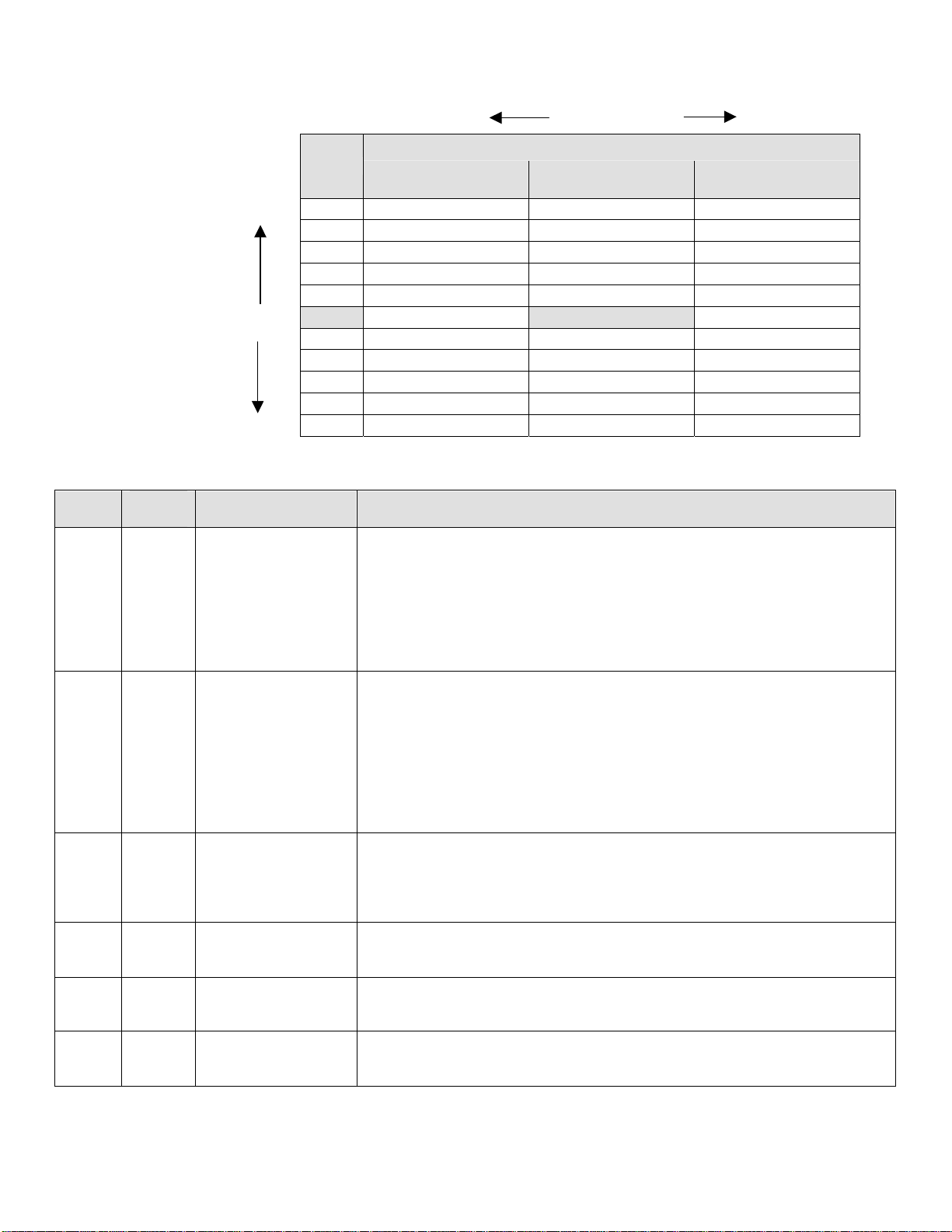

Water

Temperature

Operational SP

Call For Heat

Relay (CH)

Deg F

185

180

175

Call For Heat Settings

Factory

No.

Setting

Range / Choices Parameter and Description

Operational Setpoint

70 180 60 F to 230 F

Setpoint used in Local Setpoint Mode when not servicing a Domestic Hot Water

Priority (DHWP) request

On Point

71 -5 0 F to –99 F

The boiler starts when the water temperature drops ‘On Point’ degrees below the

setpoint.

Off Point

72 15 0 F to 99 F

The boiler stops when the water temperature rises ‘Off Point’ degrees above the

setpoint.

High Temp Stop

The boiler stops when the boiler outlet water temperature is above the High

73 210 60 F to 230 F

Temperature Stop setpoint. This setpoint is active in every control mode. If the

lead boiler’s boiler outlet temperature is above the high temperature stop all

boilers are stopped.

*DHWP Setpoint

The Domestic Hot Water Priority (DHWP) Setpoint is active when DHWP Input

74 180 140 F to 230 F

(DP) closes and “DHWP” parameter is set to “yes” and Local SP Mode is

selected. When the contact is closed, the boiler outlet is maintained at, or above,

the DHW Setpoint.

*WWSD Setpoint

75 60 40 to 90 F

The Warm Weather Shutdown (WWSD) Setpoint used to disable boiler and or

system pump operation when enabled by setting the “WWSD” parameter to

“WWSD of Boiler”, “WWSD of Sys Pump” or “Both”

76 230 140 F to 230 F

Max SP

The Maximum Operational Setpoint for all possible Local and Remote modes

Min SP

77 140 60 F to 230 F

The Minimum Operational Setpoint is the lower limit for all Local and Remote

modes

78 120 110 F to 235 F

Min BIT

Low Boiler Inlet Temperature alarm and event setpoint.

*Min In H2O Temp.

79 130 110 F to 180 F

Minimum Inlet Water Temperature setpoint used as the Mixing Valve inlet

temperature setpoint.

*Max H2O Delta T

80 50 20 F to 50 F

Maximum Water Differential (Boiler Outlet minus Boiler Inlet) Temperature

setpoint used as the Mixing Valve differential temperature setpoint.

Max Delta T Hold

81 40 20 F to 50 F

Maximum Water Differential (Boiler Outlet minus Boiler Inlet) Temperature used

to hold modulation rate at low fire.

* Only visible when parameter enabled on the configuration and setup menus

Off Point

On Point

Time

Sage Boiler Control Instruction Manual Page 19 of 56

Page 20

Installation

Mounting & Wiring Sensors

The Sage Boiler Control (SBC) is mounted in the burner control panel and wired to the burner circuitry at the factory.

These installation instructions will explain how the boiler inlet and outlet water temperature sensors are mounted in the

boilers supply and return connections and wired to the SBC. Keep a copy of the boiler installation manual on hand to

supplement these instructions.

MPC Boiler

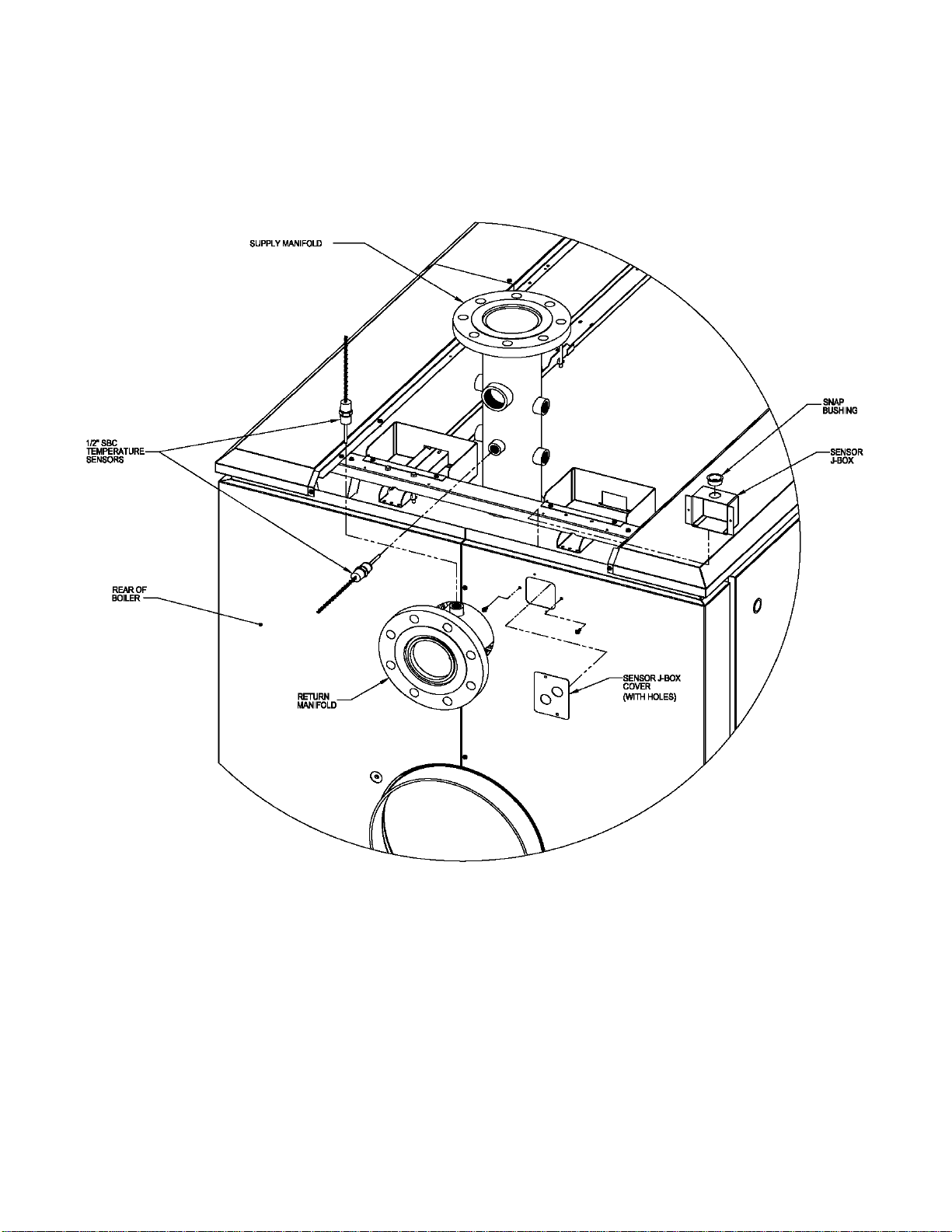

1. Mount Boiler Inlet and Outlet Water Temperature Sensors

a. Remove one of the ½” immersion temperature sensors from the Sage Boiler Control Parts Carton and

apply thread sealant to the threads between the probe and hex shoulder.

b. Install the sensor in the ½” tapping faci ng upward on the MPC return manifold. Refer to Figure 1. (If

an RWMT positioning plug has already been installed in this tapping, remove it and replace it with the

sensor.) Make sure that the hole in the top of the return water mixing tube is aligned with the tapping

in the manifold and that the sensor probe slides through this hole without interference. Wrench the

sensor until watertight.

c. Remove the other ½” temperature sensor from the Sage Boiler Control Parts Ca rton and apply thread

sealant to the threads between the probe and hex shoulder.

d. Install the sensor in the ½” supply manif old tapping that faces the rear of the boiler. Refer to Figure 1.

Wrench the sensor until watertight.

2. Install Sensor Junction Box in Boiler Jacket

a. The temperature sensor wiring can be run to the burner control panel under the boiler jacket, using the

internal wiring chaseway, or it can be run externally, in rigid or flexible conduit. If the sensor wiring will

be run externally, proceed immediately to Part 4 of these instructions. If the sensor wiring will be run

within the boiler’s internal chaseway, continue to step b. below.

b. If the jacket front, intermediate, and rear top panels have already been installed, remove them (using

the MPC manual’s installation instructions and working in reverse).

c. If the boiler control wiring has already been installed in the rear top panel, remove the two (2) screws

from the rear flange of the panel, slide the panel back, and tilt it upward in order to gain access to the

primary internal junction box.

d. Remove the senso r J-box and black snap bushing from the Sage Boiler Control Parts Carton and

install the bushing in the 7/8” hole in the J-box. Mount the sensor J-box (with the snap bushing facing

upward) to the inside surface of the right split rear panel using two (2) of the #8 x ½” lg. hex head SMS

provided. See Figure 1.

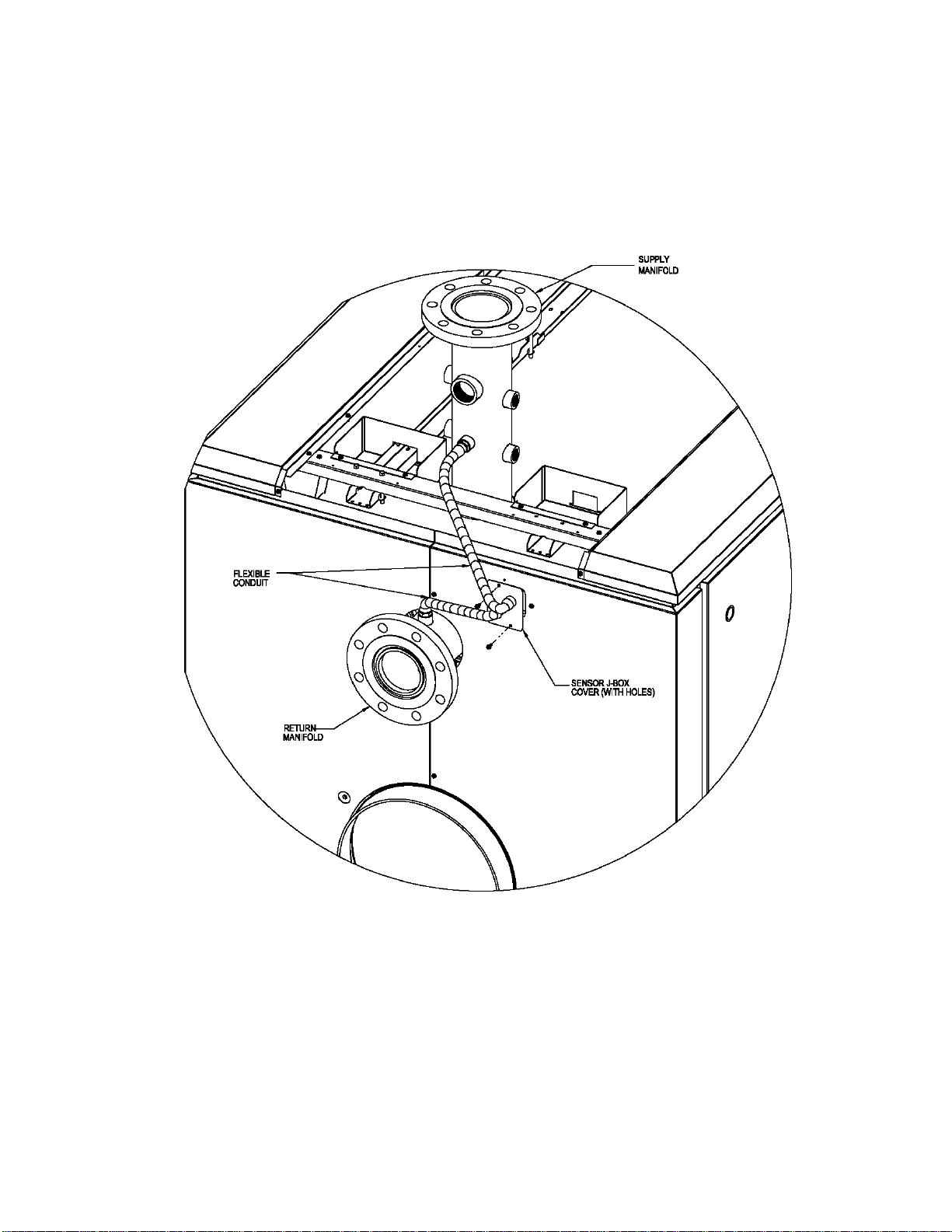

3. Install and Connect Temperature Sensor Wiring (If Using Internal Wiring Chaseway)

a. Remove the painted sensor J-box cover (with holes) from the carton. If the blank cover plate is

already mounted on the right rear split panel, remove it. Using flexible conduit and the appropriate

conduit connectors (supplied by others), connect the inlet and outlet temperature sensor wiri ng to the

two (2) holes in the sensor J-box cover plate. Refer to Figures 1 and 2. The conduit length should be

sufficient to allow the cover plate to be installed over the sensor J-box opening in the right rear panel.

b. Install one length of shielded electronic wire cable (supplied by others). To prevent electrical

interference from the internal control/safety circuit wiring harness already installed in the chaseway,

use foil-shielded, 3-conductor (22 AWG), UL-listed cable, as a minimum. The cable length should be

sufficient to reach from the sensor J-box to the SBC terminals in the burner control panel, following the

same path as the internal wiring harness.

c. Pull one end of the shielded cable through the snap bushing on top of the sensor J-box. Trim any

excess length from the sensor wires and connect them to the shielded cable leads in the following

manner:

i. Connect one wire from each sensor to the black wire in the shielded cable.

ii. Trim the shielded cable’s silver drain wire, so that it will not come in contact with any metal

surfaces within the J-box. The drain wire is not used at this end of the cable.

Sage Boiler Control Instruction Manual Page 20 of 56

Page 21

iii. Connect the second wire from the inlet temperature sensor to one of the remaining wires in

the cable. Be sure to note the color of the cable wire to ensure that it is connected to the

correct terminal on the SBC in later steps.

iv. Connect the second wire from the outlet temperature sensor to the remaining wire in the

cable. Be sure to note the color of the cable wire to ensure that it is connected to the correct

terminal on the SBC in later steps.

d. Mount the sensor J-box cover to the right rear panel using two (2) of the #8 x ½” lg. hex head SMS

provided. See Figure 2. Make sure that all of the exposed wires fit inside of the sensor J-box and that

none of them are pinched once the cover plate is installed.

e. Using wire ties, secure the shielded cable to the primary junction box and chaseway channel in the

same manner as the internal wiring harness, as shown in the MPC installation manual.

f. When the cable reaches the end of the chaseway at the front of the boiler, secure it to the vertical

frame rail using the same cable clamps that were installed with the internal wiring harness. Refer to

the MPC installation manual for details. It may be necessary to temporarily loosen the screws holding

the cable clamps in place, in order to fit the shielded cable through each loop along with the internal

wiring harness. If it is necessary to loosen these screws, the jacket front panel will have to be

removed (if already installed).

g. The shielded cable should exit the boiler jacket through the unused hole in the side of the front panel.

Using flexible conduit and the appropriate conduit connectors (supplied by others), connect the

shielded cable to the burner control panel through one of the panel knockouts n ear the SBC.

h. Connect the wire leads to the appropriate SBC terminals, as shown on the “External Connections”

label on the back of the control. (These terminals are also shown on the “Installation: Terminal Layout”

page of this manual). For easier access to the SBC terminals in Power Flame burner control panels,

remove the screws at the left and right edges of the top panel and rotate the top panel upward, around

the hinge at the top rear of the panel box. (See the Power Flame burner manual for details and

illustration.)

i. Connect the black wire and silver drain wire from the cable to the SBC’s “BC” terminal.

j. Reinstall any jacket panels that may have been removed.

4. Install and Connect Temperature Sensor Wiring (If Using Electrical Conduit Outside of the Boiler Jacket)

a. Using flexible conduit and the appropriate conduit connectors (supplied by others), run the inlet and

outlet temperature sensor wiring to a suitable metal junction box. To prevent electrical interference

from other wiring in the burner control panel, connect the sensor wires to foil-shielded, 3-conductor (22

AWG), UL-listed cable, as a minimum. Do not make any other wiring connections inside of this

junction box. Trim any excess length from the sensor wires and connect them to the shielded cable

leads in the following manner:

i. Connect one wire from each sensor to the black wire in the shielded cable.

ii. Trim the shielded cable’s silver drain wire, so that it will not come in contact with any metal

surfaces within the junction box. The drain wire is not used at this end of the cable.

iii. Connect the second wire from the inlet temperature sensor to one of the remaining wires in

the cable. Be sure to note the color of the cable wire to ensure that it is connected to the

correct terminal on the SBC in later steps.

iv. Connect the second wire from the outlet temperature sensor to the remaining wire in the

cable. Be sure to note the color of the cable wire to ensure that it is connected to the correct

terminal on the SBC in later steps.

b. Using properly supported conduit and the appropriate connectors (supplied by others), connect the

shielded cable to the burner control panel through one of the panel knockouts n ear the SBC.

c. Connect the wire leads to the appropriate SBC terminals, as shown on the “External Connections”

label on the back of the control. (These terminals are also shown on the “Installation: Terminal Layout”

page of this manual). For easier access to the SBC terminals in Power Flame burner control panels,

remove the screws at the left and right edges of the top panel and rotate the top panel upward, around

the hinge at the top rear of the panel box. (See the Power Flame burner manual for details and

illustration.)

Connect the black wire and silver drain wire from the cable to the SBC’s “BC” terminal.

Sage Boiler Control Instruction Manual Page 21 of 56

Page 22

Installation

Mounting & Wiring Sensors (Cont.)

Figure 1: Installation of SBC Components (Part 1)

Sage Boiler Control Instruction Manual Page 22 of 56

Page 23

Installation

Mounting & Wiring Sensors (Cont.)

Figure 2: Installation of SBC Components (Part 2)

Sage Boiler Control Instruction Manual Page 23 of 56

Page 24

Installation

Mounting & Wiring Sensors (Cont.)

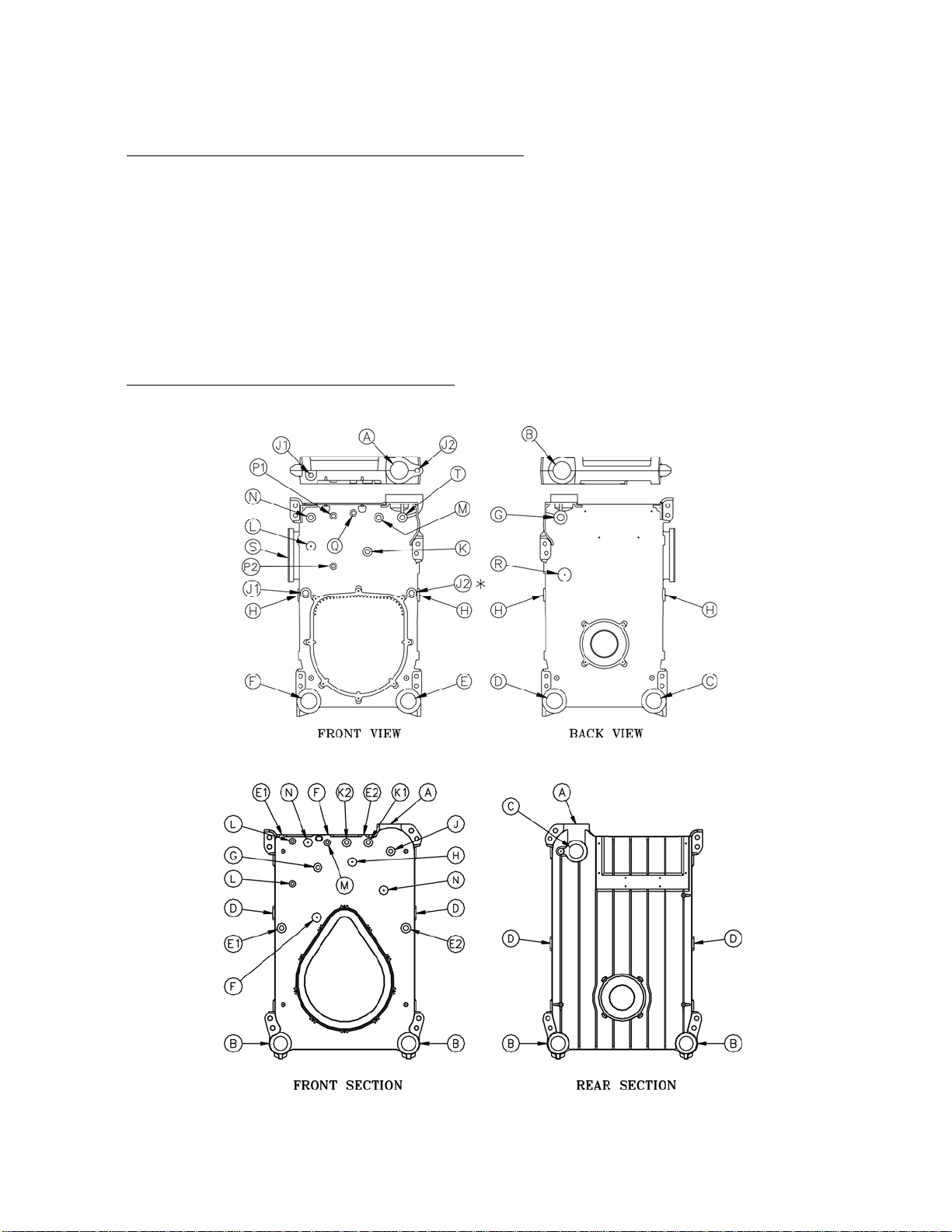

V9/V11 Boilers

1. Mount Boiler Inlet and Outlet Water Temperature Sensors

a. Remove one of the ½” immersion temperature sensors from the Sage Boiler Control Parts Carton and

apply thread sealant to the threads between the probe and hex shoulder.

b. Install the supply sensor in the 3/4” tapping T or J (V9, V11 respectfully) using a ¾” x ½” bushing.

Refer to Figure 3. Wrench the sensor until watertight.

c. Remove the other ½” temperature sensor from the Sage Boiler Control Parts Ca rton and apply thread

sealant to the threads between the probe and hex shoulder.

d. Install the return sensor at the lower rear return tapping, using a short 3” nipple and a 3” x 3” x 3” tee

with the branch of the tee bushed down to ½” (or, use a 3” x 3” x ½” tee, if available). For V9, use

tapping C and for V11, use tapping B. Refer to Figure 3. Wrench the sensor until watertight.

2. Install and Connect Temperature Sensor Wiring

Follow the instructions above for the MPC sensor wiring, Step 4 “If Using Electrical Conduit Outside of the

Boiler Jacket”.

V9

V11

Figure 3

Sage Boiler Control Instruction Manual Page 24 of 56

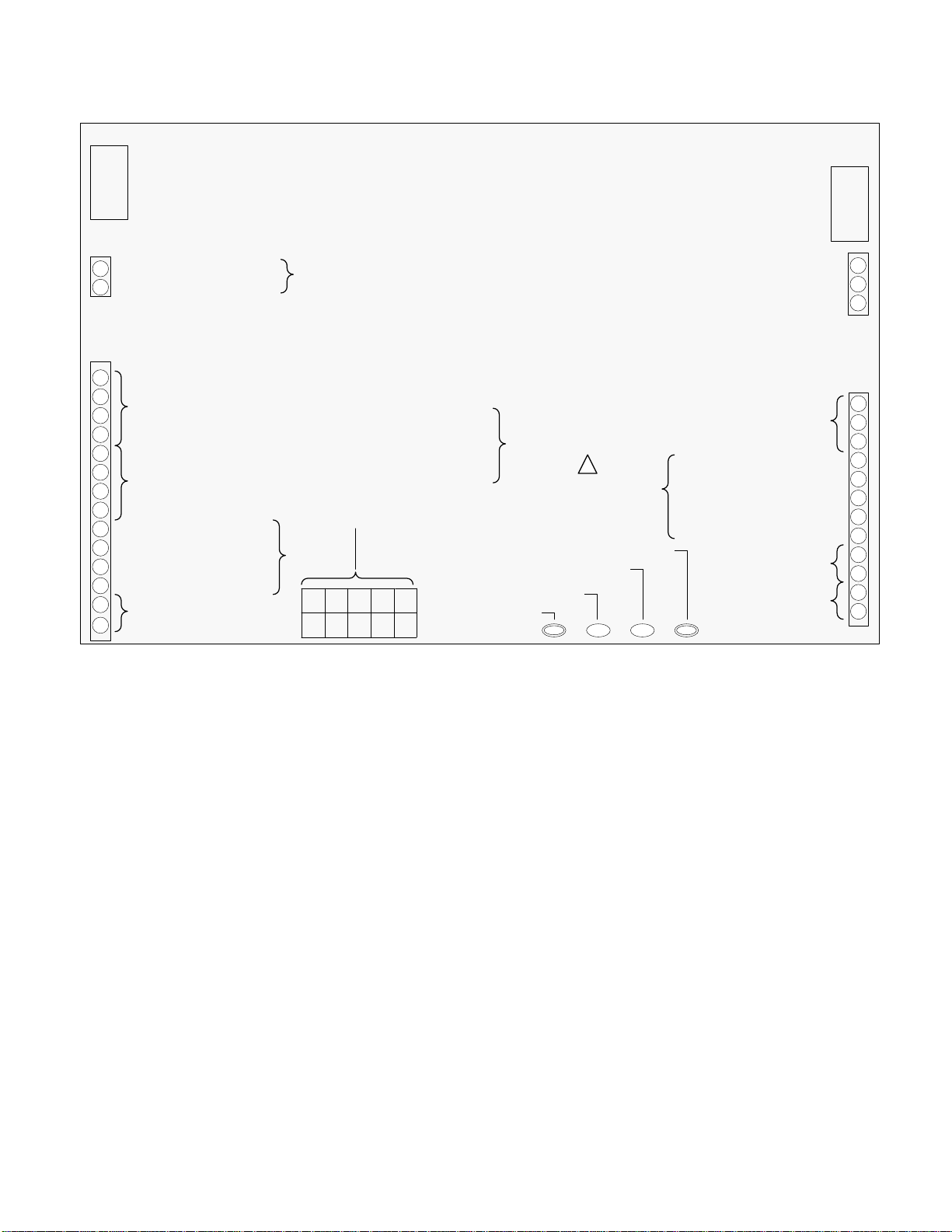

Page 25

Installation

Terminal Layout

Alternate Connection For

Outside Air Temperature and

RJ-45

(8 pin)

Remote System Temperature

(10k ohm Thermister, 5Vdc)

Label 901 a

Boiler Peer-To-Peer

Communication

Network

RJ-11

(6 pin)

LC

Low Water Cutoff Switch Input

CH

Call For Heat Output

O+

O+

Outside Air Temperature

(10k ohm Thermister, 5Vdc)

O-

OR+

R+

Remote System Temperature

(10k ohm Thermister, 5Vdc)

R-

RDP

Domestic Hot Water Priority

LR

Local / Remote

RO

Remote On / Off (Enable)

SI

Spare Input (Programmable)

C

12 Vdc Common

C

24

(10k ohm Thermister, 5Vdc) Common

Vac

CA - Low Combustion Air Flow

HL - Operating or High Limit

GP - Gas Pressure Switch

WF - Low Water Flow Switch

OO - Burner On/Off Switch

V-, V+ - Firing Rate Demand (0-10Vdc)

P-, P+ - Firing Rate Demand (0-10 Vdc, PWM)

12

Vdc

CA

OO

V- V+ P- P+

GP WFHL

Flame Safeguard Alarm

Fuel Valve Energized

24

Vac

Power Common (-24 Vac)

Power Supply (+24 Vac)

(24 Vac)

(24 V ac)

!

12 Vdc,

0.5 A max total

for LO, VI, BP,

SP and SO

Sage Boiler Control Terminal Arrangement (rear view)

Boil er Outlet Temperature

Boiler Inlet Temperature

12Vdc Common

Spare Output (Programmable)

System Pump Start/Stop

Boiler Pump Start/Stop

Vent Inducer Start/Stop

Alarm Indicator

Mixing Valve Output

(4-20 mAdc)

Remote Firing Rate or

Setpoint Input (0-10 Vdc)

CPRALCS

BC

BO

BI

C

C

C

SO

SP

BP

VI

LO

MR

MS

CC+

Sage Boiler Control Instruction Manual Page 25 of 56

Page 26

Installation

External Connections

System Water Temperature Sensor

Mount the sensor in the common header downstream of all boiler connections. Locate the sensor a minimum distance

of 10 straight pipe diameters from the from flow disturbing fittings.

Outdoor Air Temperature Sensor

Mount the temperature sensor on an outside wall out of direct sunlight, preferably on a north facing wall. Do not mount

sensor near exhaust of any kind, as this may affect readings.

Sage Boiler Control Instruction Manual Page 26 of 56

Page 27

Installation

External Connections (Continued)

Outside Air and Remote System Temperature Sensor RJ45 Connection

All boilers may be connected to the remote system temperature (RST) and the outdoor air temperature (OAT) sensors.

Only one of each type sensor is needed for connections with up to eight boilers. The lead boiler is automatically

enabled to monitor the sensors. As the boiler lead rotates the sensor monitoring is automatically transferred to the new

lead boiler.

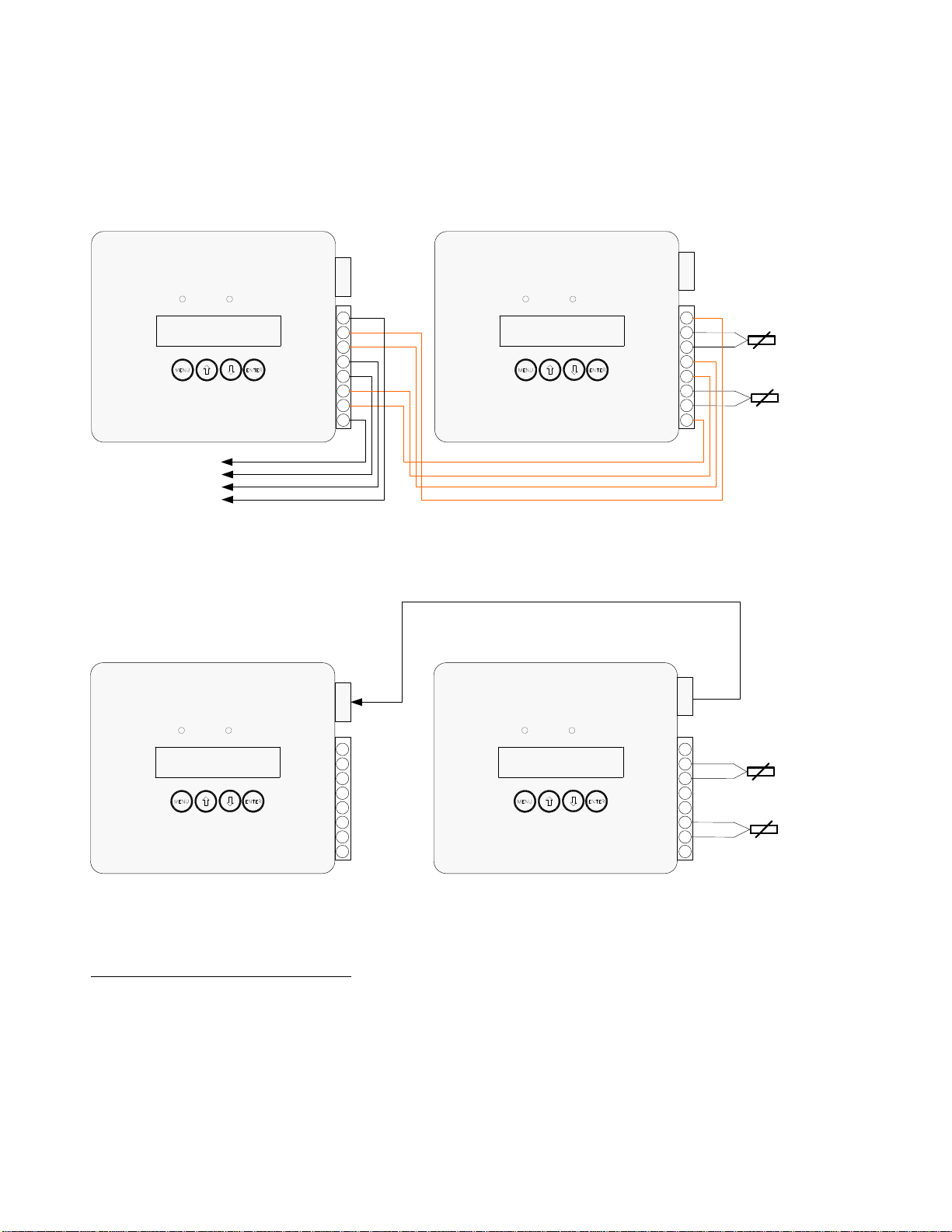

Boiler 2

Boiler 1

BO I L E R RUNNING

Connect s t o

Up to 8 Boil ers

Power

BOILER RUNNING

Power

Boiler 2

Alarm

Alarm

RJ-45

Power

O+

O+

O-

OR+

R+

R-

R-

BO ILER RUNNING

Alarm

Mult i pl e Boil er Connec tion Diag ram

(Us i ng the ex tra O+, O-, R+ & R- term inal s t o dai sy chain

the boi l ers t ogether )

Boiler 1

RJ-45

Power

O+

O+

OO-

R+

R+

RR-

BOILER RUNNING

Alarm

RJ-45

O+

O+

O-

OR+

R+

R-

R-

RJ-45

O+

O+

OO-

R+

R+

RR-

Outsi de Ai r

Temperature

Remote

System

Temperature

Outsi de Ai r

Temperature

Remote

System

Temperature

Two Boiler

RJ45 C onnec tion Di agram

(Refer to Note 2)

Notes

1. Used Only For Peer-To-Peer Network

. When using Modbus Network wire Outside Air and Remote System sensor

to only one boiler.

2. Wiring from the Outside Air and Remote System Temperature sensors should use low impedance, shielded, twisted

pair wire and go directly to the terminals on any one boiler. Signal wiring should not be run in the same conduit with

power wiring. Wire shields may be connected to the common terminal (C) located on the same terminal block with

the outside air and remote system temperature connections.

3. The RJ45 sensor cables need to be a straight through type cable that connects each pin of the connector on one

end to it’s identical pin on the opposite end. Up to a total of three boilers may be connected using a RJ45 splitter.

When connecting more than three boilers, it is recommended, and may be more convenient, to use the extra O+, O, R+ & R- terminals to daisy chain the boilers together (eliminating the need for RJ45 cables and splitters and

reducing the loop impedance).

Sage Boiler Control Instruction Manual Page 27 of 56

Page 28

Installation

Communication

The Peer-To-Peer or Modbus networks allow boiler information, including modulation rate and on/off commands, to be

sent via a standard phone cable thus avoiding the cost, time and complexity of wiring multiple signals.

RJ11

Sage Control

Boiler 1 Boiler 2

RJ11

RJ11 Splitter

(Not Inc l uded)

RJ11

Sage ControlSage Control

Boiler 3

RJ11 S plitt er

(Not Inc luded)

Connect s to

Up to 8 Boilers

Or Building

Aut om at i on S ys t em

(BAS) Modbus

Connection

Mu ltiple Boile r

RJ11 Connection Diagram

Sage Control

RJ11

Sage Control

RJ11

Boiler 1 Boiler 2

Two Bo ile r

RJ11 Connection Diagram

When Wiring Modbus Communication to a Building Automation System (BAS)

The Modbus communication connects to the same RJ11 port that is used by the peer-to-pee r communication. Connect

one end of the RJ11 cable to the SBC and cut off the other end of the cable to access the individual conductors. The

SBC is a 2-wire Modbus communication. Connect the "A" and "B " terminals of a four wire or six wire phone cable (as

shown below) to the BAS terminals. The SBC includes two sets of A and B connections, where the A represents the

active transmission state of the RS485 transmitter (as opposed to the line idle stat e). You need only to wire to one of the

"A" terminals and one of the "B" terminals.

Phone cable signals (4 wire) - connect to pin black or yellow and red or green:

Wire

Color

Black 1 A

Red 2 B

Green 3 B

Yellow 4 A

Notes

1.

2. Please note that all connections between boilers must be kept as short as possible. The maximum cable length

3. In all cases, the wires should be routed away from any obvious sources of electrical noise or magnetic fields

4. SBC power supply common must be grounded at each boiler to enable network communication.

Slot

Connection

Number

Use standard phone cables (although ones that have all six wires terminated at each end) and splitters to

connect each boiler.

between boilers must be kept under 25 feet (average distance between all boilers).

(motors, fluorescent lights, contactors, spark generators, etc.). Use a separate conduit and junction box from

the power wiring.

Sage Boiler Control Instruction Manual Page 28 of 56

Page 29

Installation

Communication (Continued)

The Sage Boiler Control communication selections are found on the Communication Menu. Press and hold the

key to leave the Display Mode and access the Main Menu:

Use the keys scroll down to the Communication Menu and push the key:

Communication Menu

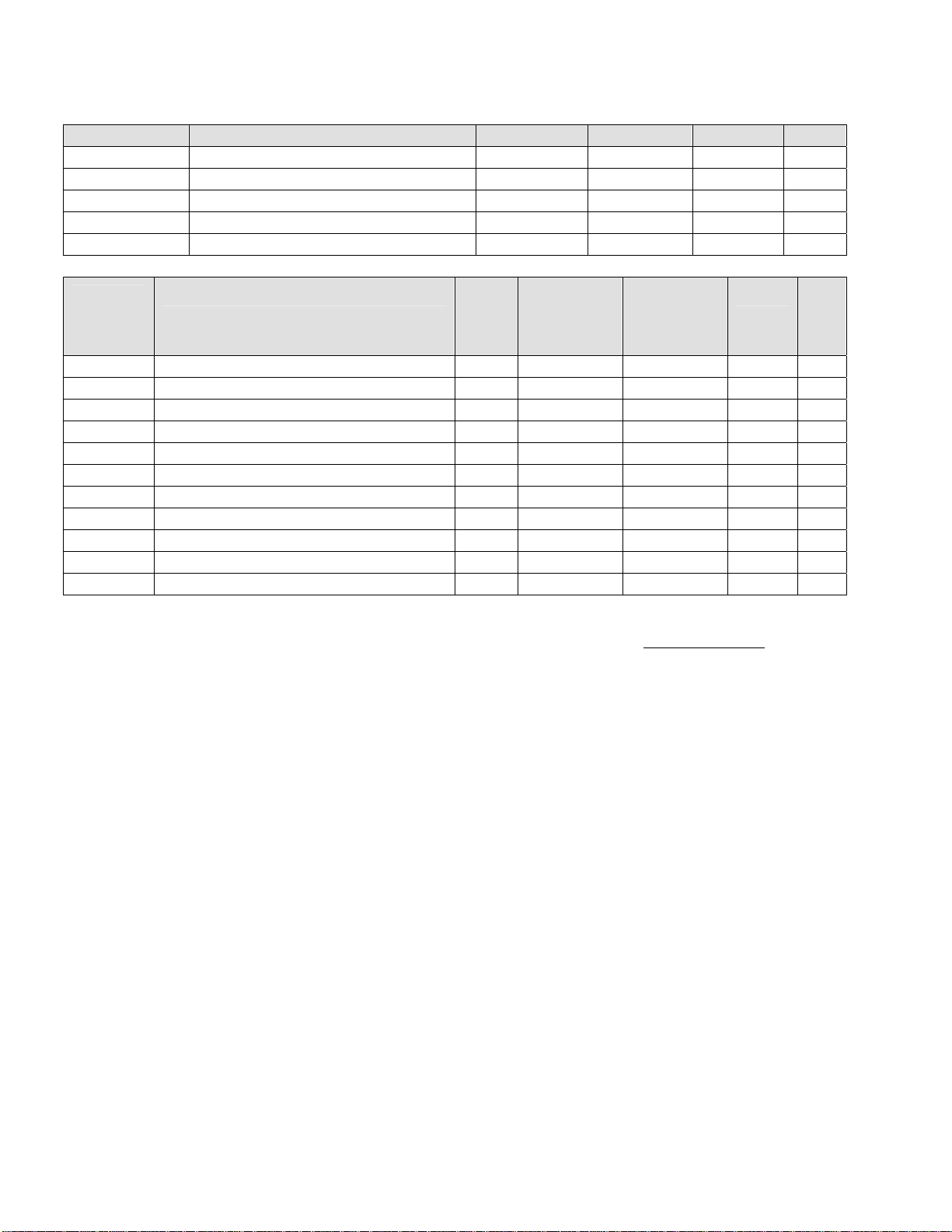

No.

90

91 1 1-247

92 19.2

93 None

94 30

95

96

97 1 1 to 8

98 - - 6 - - - 321

Factory

Setting

Peer to

Peer

Range / Choices Parameter and Description

Peer to Peer

Modbus

Protocol

Selects between Peer-To-Peer (multiple boiler Lead/Lag control network) and

a Modbus slave communication.

Modbus Address

Each boiler must be given a unique address. Only visible when Protocol

equals Modbus.

9.6

19.2

38.4

Odd

Even

None

1-120

Seconds

Baud Rate

Units are 1000 Bits Per Second (KBPS). Only visible when Protocol equals

Modbus.

Parity

Only visible when Protocol equals Modbus.

Timeout

Only visible when Protocol equals Modbus.

Messages Rcvd

Diagnostic tool used to confirm wiring and Modbus master configuration.

Only visible when Protocol equals Modbus.

Messages Sent

Diagnostic tool used to confirm wiring and Modbus master configuration.

Only visible when Protocol equals Modbus.

Boiler Address

Each boiler must be given a unique address. The boiler address assignment

determines the boiler sequencing order. A value of 0 disables the network

communications. Only visible when Protocol equals Peer to Peer.

Online Status

Each space can be either the boiler address or a ‘ - ‘ depending on whether

there is a boiler of that address on-line. Only visible when Protocol equals

Peer to Peer.

Example: - - 6 - - - 321 indicates that boilers 6,3,2 and 1 are online

ENTER

MENU

Sage Boiler Control Instruction Manual Page 29 of 56

Page 30

Installation

Peer-To-Peer Network

The Sage Boiler Control includes a dependable Peer-To-Peer communication network. This network allows multiple

boiler modulating lead/lag control and status signals to be transferred between boilers. In order to succe ssful use this

network certain requirements must be followed.

Network Relevant & Updated Parameters

When using the Peer-To-Peer network certain “Network Relevant” parameters must be configured the same in all

boilers (refer to Appendix B for parameter identification). To facilitate the configuration of these “Network Relevant”

parameters, a network update feature has been included. Once communications is established between all boilers in a

system, changing to a “Network Relevant” parameter at the keypad of any boiler will update that parameter in all boilers.

In addition to the “Network Relevant” parameters, other common parameters are also “Updated” over the network

(although it is not necessary for them to be set identically among boilers on the network). If you wish to configure them

differently among boilers, you will have to disconnect the boiler from the network while you change them to prevent the

other boiler from being changed as well. “Network Relevant” and additional “Updated” parameters are identified in

Appendix B, Parameter Summary.

Initially Establishing Peer-to-Peer Communication

A Peer-to-Peer network is established as follows:

1. Assign all boilers a unique Boiler Address between 1 and 8 and set the Protocol to Peer-to-Peer

2. Connect all boilers using a RJ11 ended telephone cable

3. Configured all “Network Relevant” parameters identically on all boilers. Unexpected boiler behavior may result if

these parameter values differ among boilers on the network. When “Network Relevant” parameters are iden tical

the ‘Param Code’ parameter will be identical on each boiler (refer to page 43 for parameter location).

4. When two or more boilers are properly configured for communication, the controllers “auto detect” each other and

shares information.

Re-Establishing Peer-to-Peer Communication After an individual boiler Communication Failure

A Peer-to-Peer network is re-established as follows:

1. Ensure Boiler address is between 1 and 8 and is unique

2. Ensure the Protocol parameter is set to Peer-to-Peer

3. Use the ‘Param Code’ parameter to check that “Network Relevant” parameters are configured identically (refer to

page 43 for parameter location).

4. Remove control power from the boiler

5. Connect the boiler to the network using a RJ11 ended telephone cable

6. Apply control power to the boiler

7. The network will “auto detect” the new boiler and assign it a position in the sequence based on the boiler address.

When a boiler is operated as a stand alone boiler, away from the network, it establishes itself as a lead boiler. If this

stand alone boiler is simply re-connecting to a network of operating boilers there is a potential that boiler operation will

be disrupted as the new boiler becomes lead. This potential is avoided by following the above Re-Establishing

procedure.

Sage Boiler Control Instruction Manual Page 30 of 56

Page 31

Installation

RS485 Modbus Network

The Sage Boiler Control includes a dependable Modbus communication network. This network allows boilers to be

controlled and/or monitored by a remote system via a RS485 Modbus communication network. Each Sage Boiler

Control is a Modbus slave with the following available boiler information:

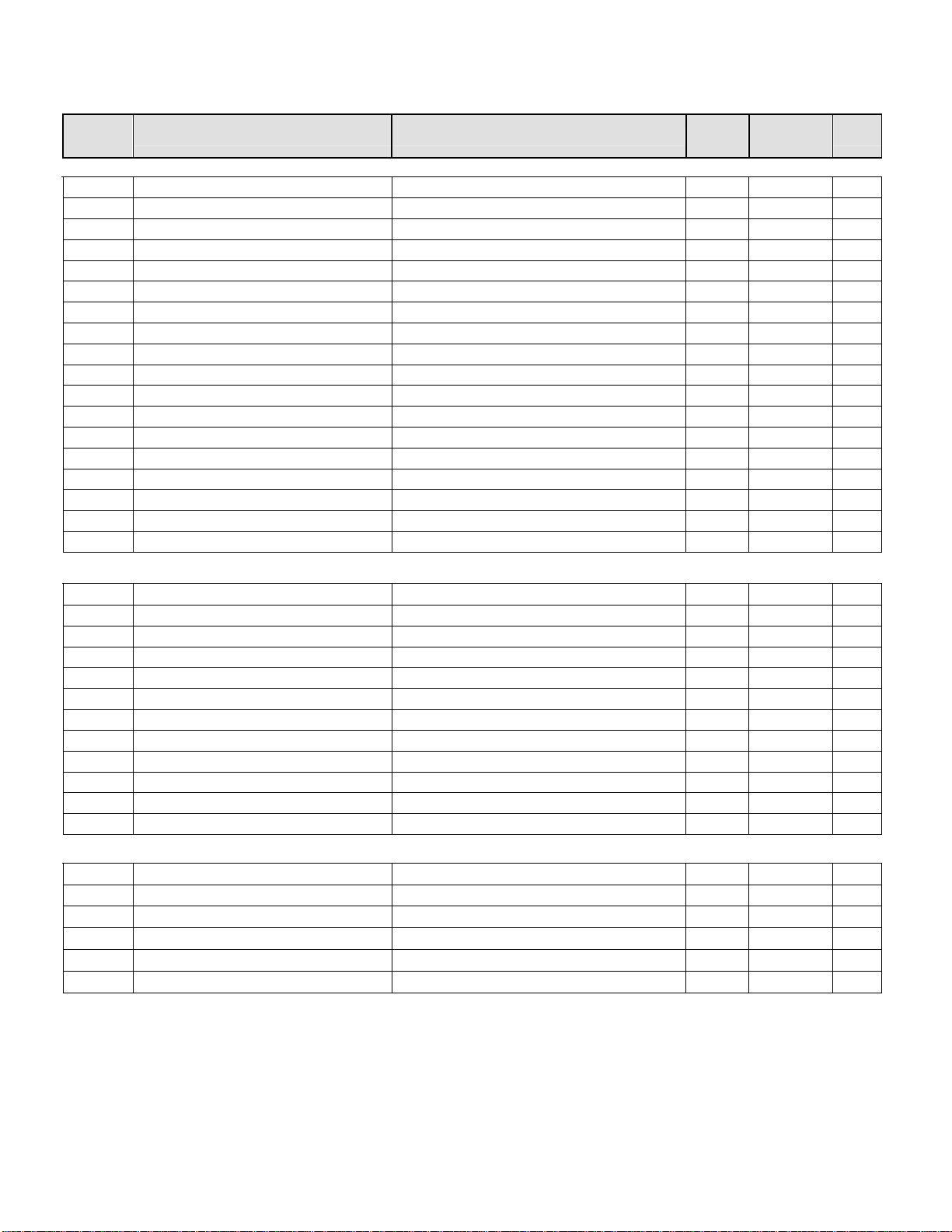

Modbus Addresses

Coil Address Description Read/Write coil = 0 coil = 1 Notes

00001

00002

00003

00004

00005

00006

00007

00008

00009

00010

00011

00012

00013

00014

00015

00016

00017

00018

00019

00020

00021

00022

00023

00024

00025

00026

00027

00028

00029

00030

00031

00032

00033

00034

00035

00036

00037

00038

00039

00040

00041

00042

Outdoor Air Reset Enable/Disable

Domestic Hot Water Priority (DHWP)

Local / Remote

Remote On / Off Modbus Command

Spare Input (Programmable)

Low Water Cutoff Switch

Burner On / Off Switch

Low Water Flow

High and Low Gas Pressure Switches

Operating or High Limit

Low Combustion Air Flow

Fuel Valve Energized

Flame Safeguard Alarm

Call For Heat (CFH)

General Alarm

Vent Inducer

Boiler Pump

System Pump

Spare Output (Programmable)

State Boiler Disabled

State Weather Shutdown

State Lockout

State Pump Purge

State Limit Hold

State Purge/Pilot Ign

State Low Fire/Ignition

State Main Ignition

State Low Fire Hold

State Boiler Running

State Fan Post Purge

State Pump Cool Down

State Standby

Annunciator Low Water Level

Annunciator Off Switch

Annunciator Low Water Flow

Annunciator Fuel Limit

Annunciator High Temp Limit

Annunciator Low Air Flow

Annunciator FSG Lockout

Annunciator Outlet Temp Fail

Annunciator Inlet Temp Fail

Annunciator OA Temp Fail

Disable Enable Disable Enable Local Remote

Y

Off On

Off On 2

Off On 2

Off On 2

Off On 2

Off On 2

Off On 2

Off On

Off On

Off On

Off On 4

Off On

Off On

Off On

Off On

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off On 3

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off On 1

Off On 3

On

On

On

On

On

On

On

On

On

On

On

3

4

4

4

4

4

4

4

4

4

4

Sage Boiler Control Instruction Manual Page 31 of 56

Page 32

Installation

RS485 Modbus Network

Modbus Addresses (continued)

Coil Address Description Read/Write coil = 0 coil = 1 Notes

00043