Page 1

- Installation & Maintenance Manual

Input

Heat

Demand

Signal

Output

Boiler

Circulator

Input

Well Sensor

Included

Input

Universal Sensor

Optional

Input

Outdoor

Sensor

Optional

Output

Boiler

Input

120 V (ac)

Power

Supply

Do not apply power

Signal wiring must be

rated at least 300 V.

Made in Canada 912-06

L N Pmp N Ret

Boil

BoilCom Mix

R R N

Com Out

1 3 5 9 10 112

4

6

7 8 12

13 141516

Heat

Power

Demand

Boiler

Enable

Item

Test

Monitor

Demand

Power: 120 V ±10% 50/60 Hz 1300 VA

Floating Output: 24 V (ac) 0.34 A 8 VA

Relays: 240 V (ac) 10 A 1/3 hp, pilot duty 240 VA

Demand: 20 to 260 V (ac) 2 VA

H6026A

RTC/Return Temperature Control

Open

Delay

Close

24 Volt Output

Use supply wires

suitable for 120˚F

(50˚C) above ambient

158033

Output

Mixing Valve &

Actuating Motor

RTC/Return Temperature Control

The Burnham Return Temperature Control (RTC) is designed to operate a 3-way or a 4-way valve to protect the boiler against flue

gas condensation and thermal shock. The RTC can also optionally control the supply water temperature to the system based on a

setpoint temperature or an outdoor reset strategy. A boiler post purge is provided by keeping the boiler recirculating pump running

after the call for heat is removed.

Additional functions include:

• Counts boiler run time

• Counts the number of boiler cycles

• Counts boiler cold shocks

• Warns of cold boiler return temperatures

• Test sequence to ensure proper operation

• CSA C US certified

P/N 81460382 1 of 60

Page 2

How To Use This Manual

Item

Item

This manual is organized into four main sections. They are: 1) Sequence of Operation, 2) Installation, 3) Control Settings, and

4) Testing and Troubleshooting. The Sequence of Operation section has four sub-sections. We recommend reading Section A:

General Operation of the Sequence of Operation section, as this contains important information on the overall operation of the

control. Then read the sub sections that apply to your installation.

The Control Settings section of this manual describes the various items that are adjusted and displayed by the control. The control

functions of each adjustable item are described in the Sequence of Operation.

Table of Contents

User Interface ..................................................Pg 2

Display .............................................................Pg 3

Sequence of Operation ..................................Pg 3

Section A: General Operation .............. Pg 3

Section B: Control Operation ...............Pg 4

Section C: Control Settings .................. Pg 5

Section D: Temperature Monitoring ....Pg 6

Installation .......................................................Pg 7

Control Settings ..............................................Pg 20

View Menu ..............................................Pg 20

Adjust Menu ...........................................Pg 21

Testing the Control .........................................Pg 22

Troubleshooting ............................................. Pg 22

Error Messages ...............................................Pg 23

Repair Parts ....................................................Pg 24

Appendix A: Mechanical And Electrical

Application Drawings ............... Pg 25

Appendix B: Boiler Circulator And Diverting

Valve Selection Charts ............. Pg 46

Appendix C: Valve And Actuator

Mounting Instructions .............. Pg 58

Technical Data................................................. Pg 60

Limited Warranty ............................................Pg 60

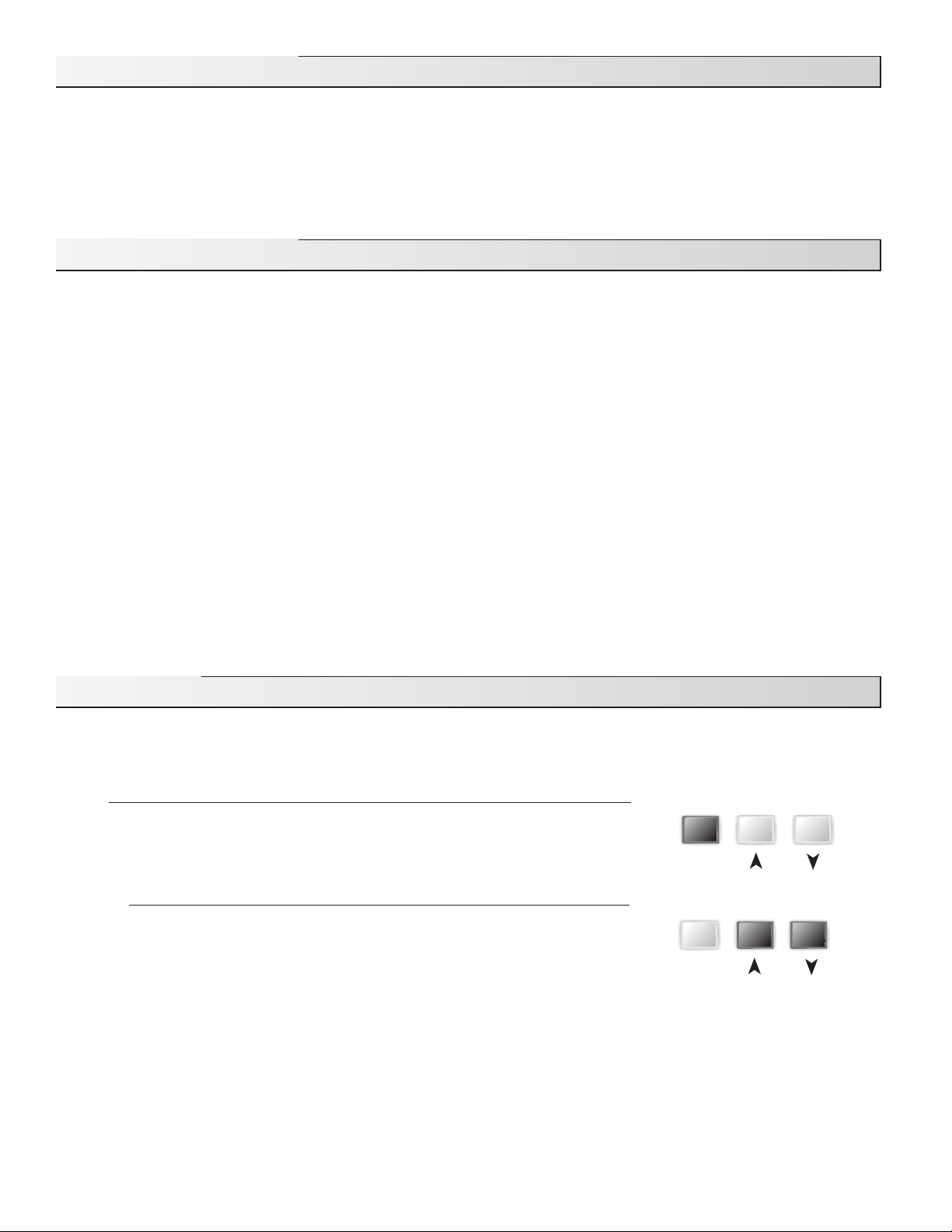

User Interface

The control uses a Liquid Crystal Display (LCD) as the method of supplying information. The LCD is used in order to setup and monitor

the operation of the system. The control has three push buttons (Item, , ) for selecting and adjusting settings. As the control is

programmed, record the settings in the Adjust menu table, which is found in the second half of this manual.

Item

The abbreviated name of the selected item will be displayed in the item field of the

display. To view the next available item, press and release the Item button. Once the last

available item in a menu has been reached, pressing and releasing the Item button will

return the display to the first item in the selected menu.

Adjust

To make an adjustment to a setting in the control, press all 3 buttons for 1 second (the

Item, and buttons). The display will then show the word ADJUST in the top right

corner. Then select the desired item using the Item button. Finally, use the and/or

button to make the adjustment.

To exit the ADJUST menu, leave the adjustment buttons alone for 20 seconds.

When the Item button is pressed and held in the VIEW menu, the display scrolls through all the adjust items.

Additional information can be gained by observing the status field and pointers of the LCD. The status field will indicate which of

the control’s outputs are currently active. Most symbols in the status field are only visible when the VIEW menu is selected.

2 of 60

Page 3

Display

Displa

y

s the

cur

r

ent

menu

Displa

y

s an abbre

viat

e

d

name of the sele

cted item

Displa

y

s the

cur

r

ent v

alue

of the sele

cted item

Displa

y

s the

cur

r

ent s

t

atus of

the

contr

ol's i

nputs, ou

tputs a

nd oper

ation

Selects Menu

s, Items

and adjusts setti

ngs

Item

Monitor Delay Open Close

Demand

Symbol Description

Sequence of Operation

Section A

General

Operation

Page 3 - 4

Section A: General Operation

POWERING UP THE CONTROL

When the control is powered up with 120 V (ac), the control displays “rtc” for 2 seconds followed by the software version for 2

seconds. The control then enters the normal operating mode

OPERATION

The control operates a floating action actuator motor connected to a 3-way or 4-way valve to control the boiler return water

temperature to prevent flue gas condensation and thermal shock. The control can also be used to provide outdoor reset or a fixed

setpoint temperature to the supply water temperature.

Pump

Displays when the boiler recirculating pump is

in operation.

Burner

Displays when the boiler relay is turned on.

Section B

Control

Operation

Page 4 - 5

Section C

Control

Settings

Page 5 - 6

°F, °C

Displays the unit of measure that all of the

temperatures are to be displayed in the

control.

Pointer

Displays the control is operating as indicated

by the text.

Section D

Temperature

Monitoring

Page 6

3 of 60

Page 4

Fixed PointFixed Point

By Changing

the Mix Design

and the Outdoor

Design settings

the Reset Ratio

changes.

By Changing

the Mix Design

and the Outdoor

Design settings

the Reset Ratio

changes.

70˚F

70˚F

Outdoor Reset

When the outdoor design (OUTDR DSGN) setting is set to a temperature, the control calculates a mix supply temperature based

on the outdoor air temperature and the programmed reset ratio. An outdoor sensor and a mix supply sensor must be installed.

Setpoint Control

When the outdoor design (OUTDR DSGN) setting is set to OFF, and there is a mix supply sensor installed, the control supplies a

fixed mix supply temperature equal to the MIX TARGET setting. An outdoor sensor is not required during this mode of operation.

No Diverting Valve

If a diverting valve is not installed, the outdoor design (OUTDR DSGN) is set to OFF. The boiler return sensor must be installed

to provide monitoring of the boiler conditions.

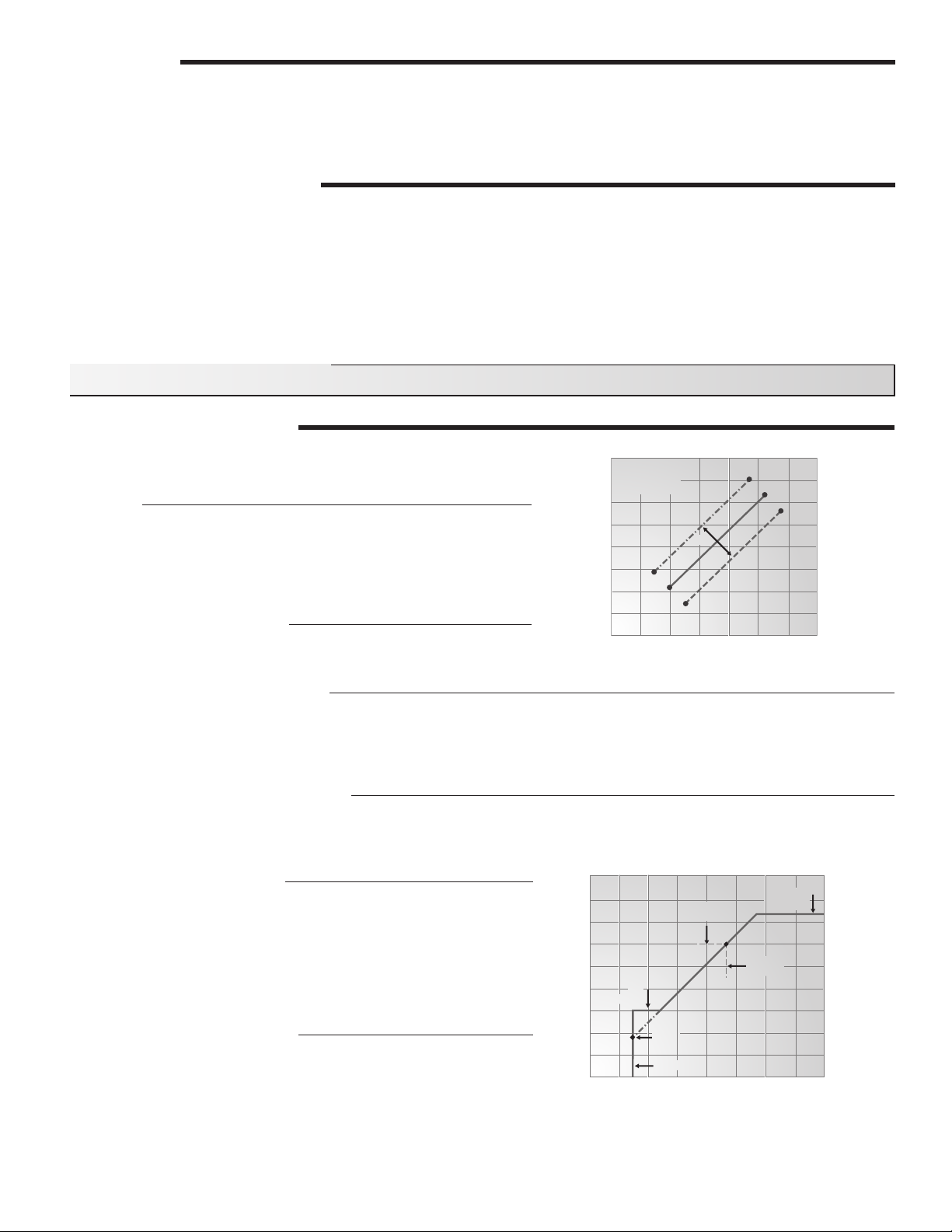

Floating Action

A 24 V (ac) floating action actuator motor is connected directly to the control on the R, R and N terminals (9, 10 and 11). The

R on terminal 9 is used to open the 3-way diverting valve to the system. The valve can open either in the clockwise or the

counterclockwise direction depending on the orientation of the valve. The R on terminal 10 is used to close the valve. The control

pulses the actuating motor to open or close to maintain the correct mixed supply water temperature at the mix sensor when

there is a heat demand. A visual indication as to whether the control is currently opening or closing the 3-way diverting valve is

displayed in the LCD.

Boiler Protection

The control is capable of providing boiler protection from cold return water temperatures. If the boiler sensor temperature is

cooler than the BOIL MIN setting while the boiler is firing, the control reduces the output to the 3-way diverting valve. This limits

the amount of cool return water to the boiler and allows the boiler temperature to recover. This feature can only be used if a 3-way

diverting valve is installed.

Exercising

The control has a built-in exercising function. If the boiler recirculating pump or valve has not been operated at least once every

3 days, the control turns on the output for a minimum of 10 seconds. This minimizes the possibility of a pump or valve seizing

during a long period of inactivity. The control ensures that the diverting valve operates over its entire range at least once each

exercising period. While the control is exercising, the Test LED flashes.

Note: The exercising function does not work if power to the control, pump, or valve is disconnected.

Section B: Control Operation

HEAT DEMAND

A heat demand is required in order for the control to provide heat by firing the boiler and opening the 3-way diverting valve. To

generate a heat demand, apply between 24 and 240 V (ac) across the Heat Demand terminals (1 and 2). Once voltage is applied,

the Demand pointer is displayed in the LCD.

When the heat demand is removed, the 3-way diverting valve is fully closed before the control is allowed to register a new heat

demand. The Demand pointer will be displayed whenever voltage is present on the Heat Demand terminals, even if the heat

demand is not registered. The 3-way diverting valve is closed to ensure the boiler is protected in the next boiler cycle.

Optionally, the control can be set up to target a setpoint mix supply temperature or outdoor reset temperature through the diverting

valve.

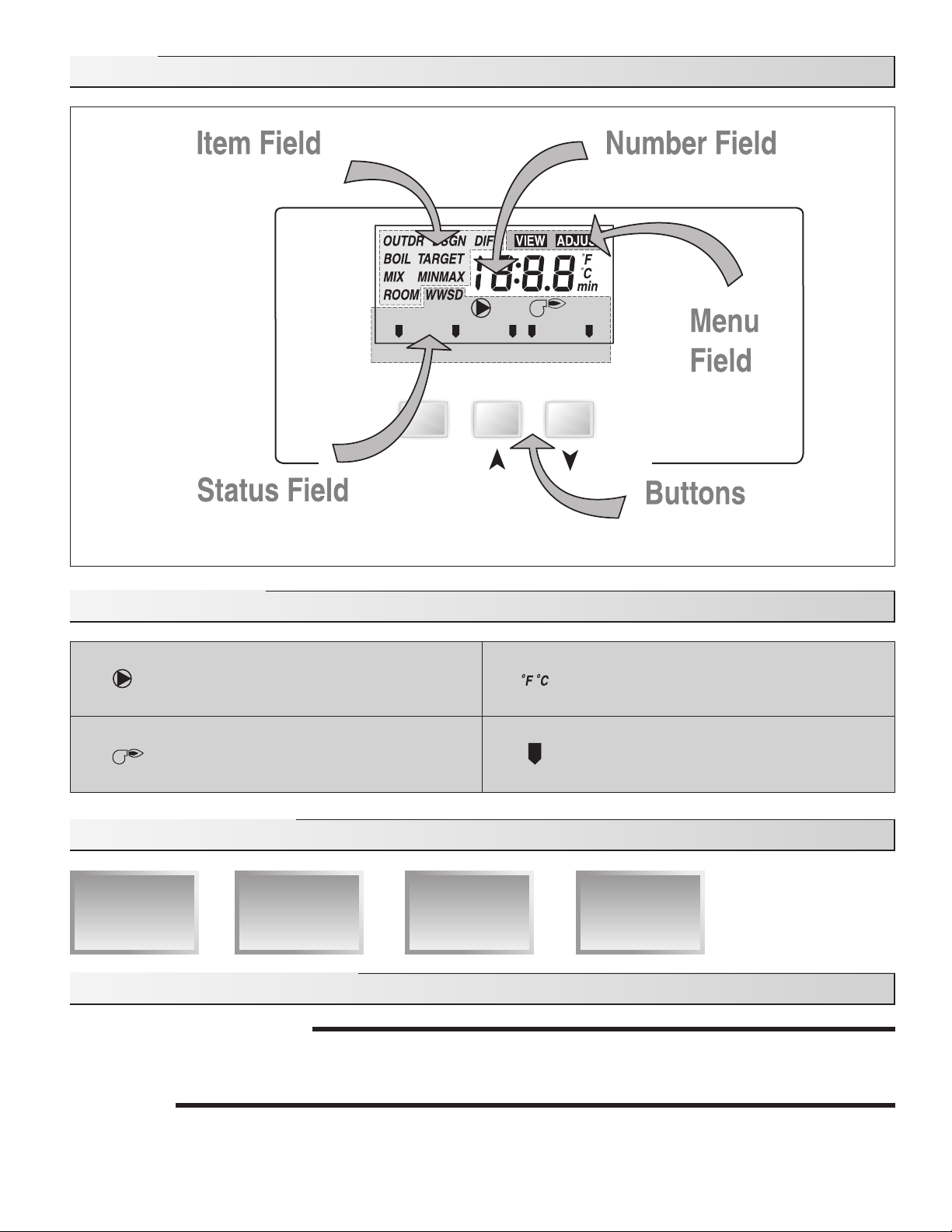

OUTDOOR RESET RATIO

When the control is used as a mixing reset control, the control uses

an outdoor sensor to measure the outdoor temperature. The reset

ratio increases the mix water temperature for every degree the outdoor

temperature falls. The slope of the reset ratio determines the rate at

which the temperature increases with falling outdoor temperatures.

The reset ratio is adjustable using the mix design (MIX DSGN) and the

outdoor design (OUTDR DSGN) settings.

4 of 60

Page 5

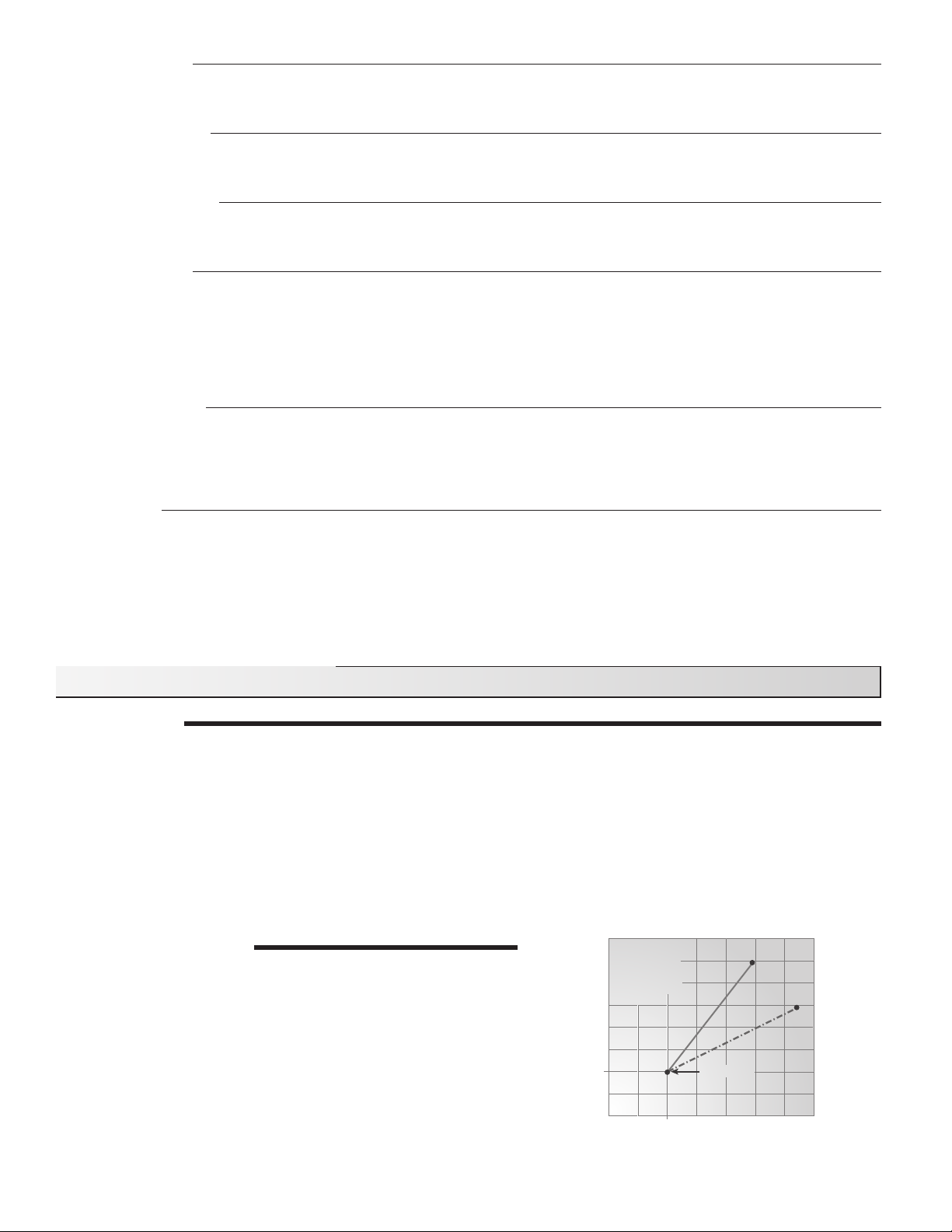

MIX TARGET

Parallel Shift

Using the

ROOM Setting

Parallel Shift

Using the

ROOM Setting

upup

downdown

6060

-40-40-20-20002020404060608080

8080

100100

120120

140140

160160

180180

200200

Mix

Design

Mix

Design

Mix

Maximum

Mix

Maximum

Mix

Minimum

Mix

Minimum

Outdoor

Design

Outdoor

Design

FixedFixed

Outdoor TemperatureOutdoor Temperature

Supply Water TemperatureSupply Water Temperature

WWSDWWSD

When used as a mixing reset control, the MIX TARGET temperature is calculated from the reset ratio and outdoor air temperature.

When used as a setpoint control, the installer sets the MIX TARGET temperature. The control displays the temperature that it is

currently trying to maintain as the mix supply temperature. If the control does not have a heat demand,”– – –” is displayed as the

MIX TARGET.

BOILER RECIRCULATING PUMP

The boiler recirculating pump contact (Boil Pmp, terminal 5) closes whenever there is a registered heat demand and the control is

not in warm weather shut down (WWSD). The boiler recirculating pump segment is displayed in the LCD. When the heat demand

is satisfied, the control continues to operate the boiler recirculating pump for the purge time. The diverting valve remains open

at the current setting during the purge time and will modulate to protect the boiler. Once the purge time has expired, the boiler

recirculating pump shuts off and the valve closes. If at any time the boiler return temperature falls below 135°F (57°C), the purge is

canceled. During the WWSD, the control exercises the pump for 10 seconds every 3 days of no activity.

Section C: Control Settings

OUTDOOR RESET SETTINGS

Note: For single boiler installations only. When multiple boilers are installed, use an appropriate staging control for outdoor reset

functions.

Room

The ROOM setting is the desired room temperature in the heating zone.

The ROOM setting provides a method to parallel shift the reset ratio

so that higher (or lower) mix water target temperatures are available

over the entire reset range. Adjusting the ROOM setting increases or

decreases the heat delivery to the building.

Mixing Design (MIX DSGN)

The MIX DSGN temperature is the supply water temperature required

to heat the mixing zones when the outdoor air temperature is as cold as the OUTDR DSGN Setting.

Outdoor Design (OUTDR DSGN)

The OUTDR DSGN is the outdoor air temperature that is the typical coldest temperature of the year where the building is located.

This temperature is used when doing the heat loss calculations for the building. If a cold outdoor design temperature is selected,

the mix supply temperature rises gradually as the outdoor temperature drops. If a warm outdoor design temperature is selected,

the mix supply temperature rises rapidly as the outdoor temperature drops.

Warm Weather Shut Down (WWSD)

When the outdoor air temperature rises above the WWSD setting, the control turns on the WWSD segment in the display. When

the control is in WWSD, the Demand pointer is displayed, if there is a demand. However, the control does not operate the heating

system to satisfy this demand. If the control is in setpoint mode, the WWSD feature is not functional.

Mixing Minimum (MIX MIN)

The MIX MIN is the lowest temperature that the control is allowed

to use as a mix target temperature. During mild conditions, if the

control calculates a mix target temperature that is below the MIX MIN

setting, the mix target temperature is adjusted to match the MIX MIN

setting. During this condition, the MIN segment will be displayed in

the LCD when either the MIX TARGET or MIX temperature is being

viewed.

Mixing Maximum (MIX MAX)

The MIX MAX sets the highest water temperature that the control

is allowed to calculate as the mix target temperature. If the control

does target the MIX MAX setting, and the MIX temperature is near

the MIX MAX, the MAX segment will be displayed in the LCD while

either the MIX TARGET temperature or the MIX temperature is

being viewed.

5 of 60

Page 6

SETPOINT OPERATION

Monitor

Monitor

Monitor

Mix Target

For setpoint control, set the OUTDR DSGN to OFF. The mix target becomes the setpoint supply temperature that the control is

to maintain. The mix target temperature is set by the installer in the ADJUST menu. An outdoor sensor is not required during this

mode of operation.

COMMON SETTINGS

The following settings are common to both the outdoor reset and setpoint operations.

Open Delay

The open delay is the amount of time that the actuating motor requires to operate the valve from fully closed to fully open.

Boiler Minimum (BOIL MIN)

Most boilers require a minimum water temperature in order to prevent flue gas condensation. The BOIL MIN adjustment is set to

the boiler’s minimum recommended operating temperature. The lowest boiler minimum temperature is 135°F (57°C).

Boiler Minimum Delay (BOIL MIN Delay)

The boiler minimum delay allows a time for the boiler temperature to rise to the boiler minimum temperature while there is a heat

demand. After the time delay, the control begins to count the boiler minimum run time (Monitor BOIL MIN run).

Pump Delay

The pump delay allows the boiler recirculating pump to purge heat from the boiler into the system after the heat demand is

removed. The amount of purge time is determined by the Pump Delay setting.

Section D: Temperature Monitoring

Boiler Temperature (BOIL)

The actual boiler return temperature as measured by the boiler return sensor.

Mix Target

The current mix target temperature if outdoor reset or setpoint operation is selected.

Mix

The actual mix temperature as measured by the mix supply sensor if a mix supply sensor is installed.

Outdoor

The current outdoor temperature as measured by the outdoor sensor, if the outdoor sensor is installed and Outdoor Design is

set to a temperature.

Monitor Items

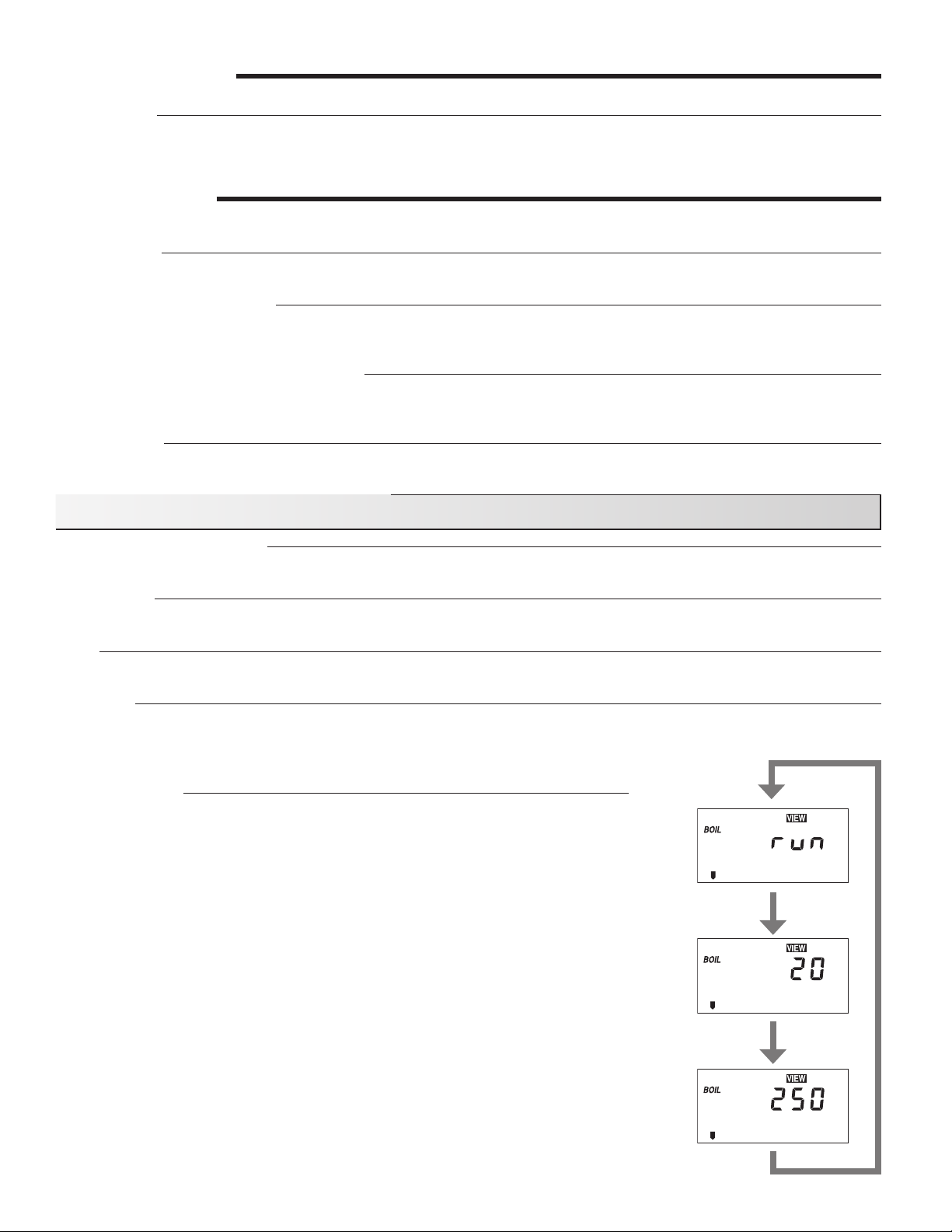

Monitor Items are displayed using a five digit number. The display cycles between the

monitor name, the first two digits, and the last three digits.

Boiler Run Time (Monitor BOIL run)

The control records the number of hours the boiler enable contact has been closed.

Number of Boiler Cycles (Monitor BOIL CYC)

The control records the number of cycles of the boiler enable contact.

Boiler Run Time Below Return Water Minimum (Monitor BOIL MIN run)

The control records the number of hours the boiler return temperature is below the

boiler minimum temperature and the boiler enable contact is closed. The control does

not record any time while the control is within the boiler minimum delay period.

Number of Boiler Cold Shock Conditions (Monitor BOIL CS)

The control records the number of large and quick temperature swings, which could

be an indication of erratic system behavior.

Boiler Sensor Error Time (Monitor BOIL MIN Err)

The control records the number of hours the boiler return sensor is not functioning.

6 of 60

Page 7

Installation

Caution

Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury. It is the

installer’s responsibility to ensure that this control is safely installed according to all applicable codes and standards. This electronic

control is not intended for uses as a primary limit control. Other controls that are intended and certified as safety limits must be placed

into the control circuit. Do not open the control. Refer to qualified personnel for servicing. Opening voids warranty and could result in

damage to the equipment and possibly even personal injury.

STEP ONE

Check the contents of this package. If any of the contents listed are missing or damaged, please contact your wholesaler or

Burnham representative for assistance.

Burnham RTC includes: Burnham Return Temperature Control, Return Temperature Control manual, 1 boiler return

sensor, 4 #8-32 x ½” Phillips screws.

STEP TWO

A. Return Temperature Control (RTC) – Mount the control to the boiler front jacket panel at the top right. See Figures 1 and 2

for general component placement. The RTC mounting bracket must be attached to the jacket first, using four (4) #8 x ¾” drill point

sheet metal screws. Before attaching the RTC to the mounting bracket, remove the controller from the control base/wiring chamber

by pressing the tab on the base and pulling the controller up and off. (This is to prevent accidental damage to the controller during

the mounting process.) One may find it easier to install some of the conduit connectors, along with their corresponding conduit

runs, onto the RTC control base/wiring chamber before mounting it to the bracket. Before choosing which wiring knockouts to

use, read Step Four. Mount the control base/wiring chamber to the bracket using the four (4) #8-32 x ½” Phillips pan head screws

supplied with the RTC. Then reattach the RTC controller to the control base.

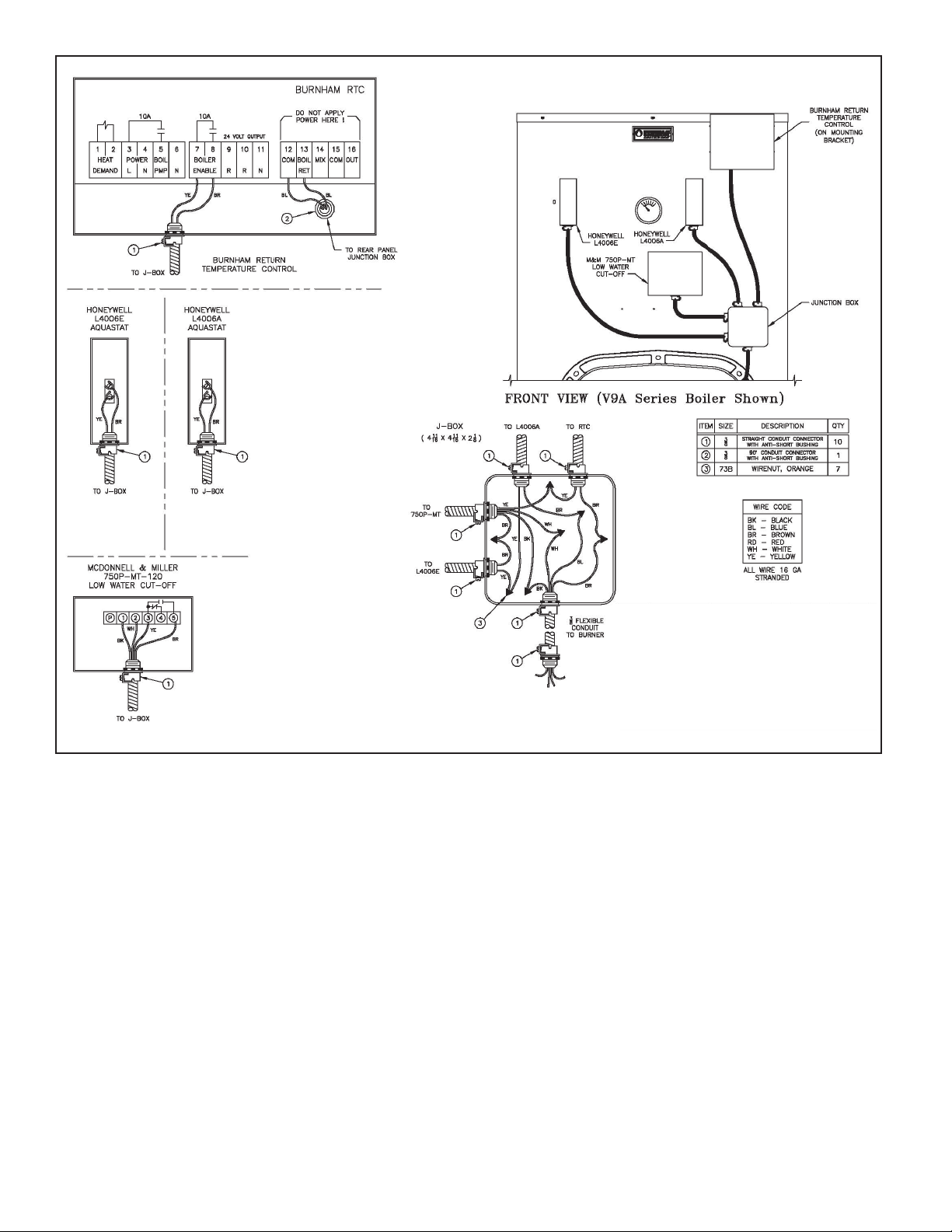

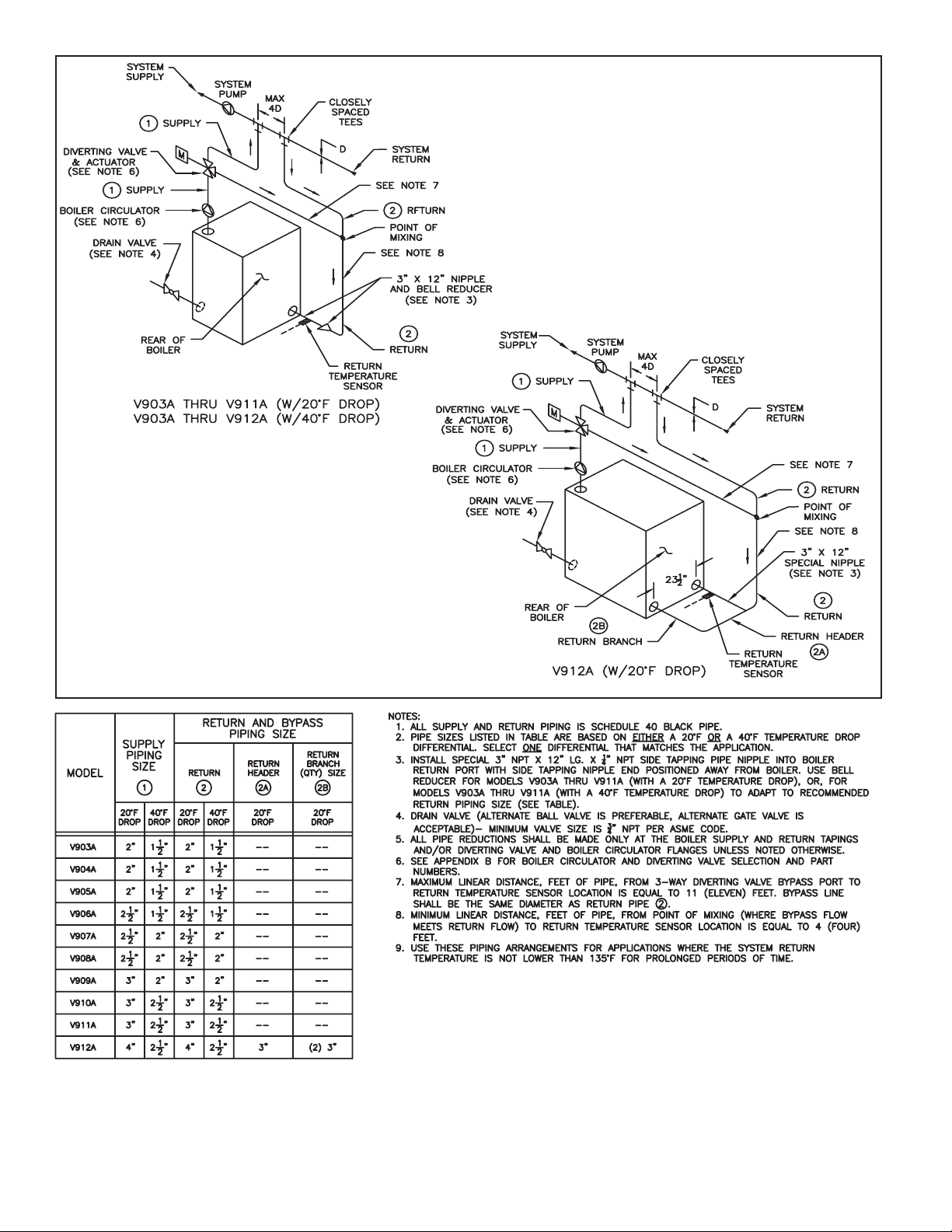

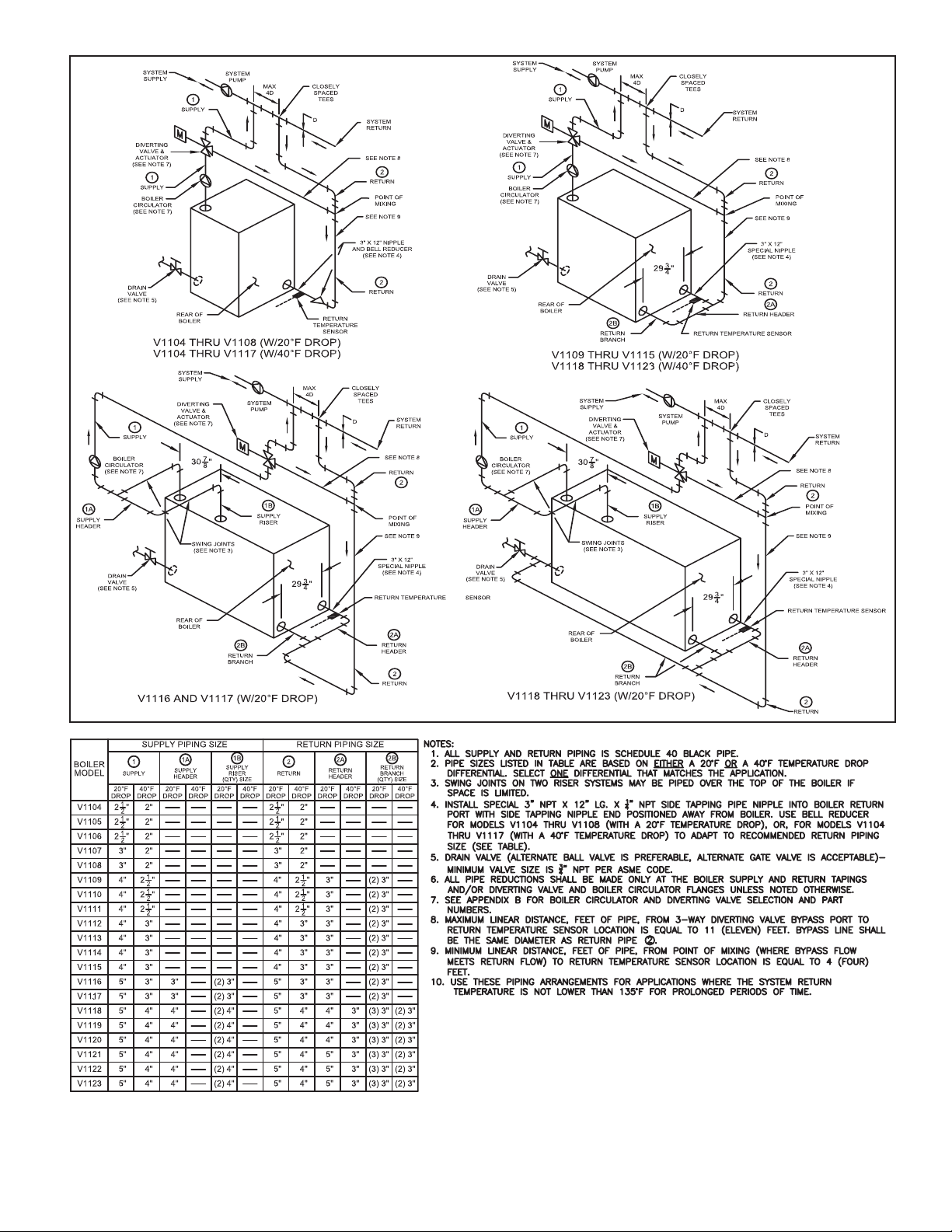

B. Return Sensor – The return water temperature sensor must be mounted in a special 3”NPT x 12” long nipple with ¼” NPT side

tapping supplied by Burnham. Apply pipe dope to special nipple both threaded ends and mount the nipple into the boiler’s right

rear return port (as viewed from the rear of the boiler), so that nipple side tapping end is positioned away from the boiler. Apply pipe

dope to the sensor threads and install the sensor into the nipple ¼” NPT side tapping making sure the connection is watertight. Use

bell reducer (refer to Figure 3 or Figure 4) to adapt to recommended return piping size. See Figure 3 or 4 (depending on the boiler

being installed) for the proper location of the return nipple. See Figure 2 for return sensor wiring details. Run the sensor wiring to a

suitable junction box, using a grommet to protect the leads as they enter the box. Mount the junction box to the boiler’s rear jacket

panel, as shown in Figure 2. Connect the sensor wiring from the junction box to the RTC control at the front of the boiler, using the

appropriate conduit and connectors.

INSTALLING THE CONTROL AND RELATED COMPONENTS

GETTING READY

C. Diverting Valve and Actuator – A diverting 3-way or 4-way valve must be installed in the boiler loop piping in order for the RTC

to provide boiler protection. Only a Burnham-approved valve and actuator may be used with the RTC. The diverting valve sizing

depends upon the designed boiler delta T. See Appendix B for proper valve selection. The valve actuator is mounted to the top of

the diverting valve. Position the valve so that the actuator is not on the underside of the valve. Mount and connect the actuator as

illustrated in Appendix C. The electrical connections depend on the valve orientation.

D. Boiler Circulator – A properly selected boiler circulator will maintain a constant and minimum flow through the boiler during

each heat demand. The appropriate circulator must be selected, based upon the designed boiler delta T. See Appendix B for

appropriate boiler circulator selections for 20°F and 40°F delta T applications.

WARNING: IF THE SELECTED BOILER CIRCULATOR IS GREATER THAN 1/3 HP, AN ISOLATION RELAY MUST BE ADDED

WHEN USING THE RTC. IF A 3-PHASE BOILER CIRCULATOR OR A CIRCULATOR WITH AN AMP DRAW GREATER THAN 10

AMP IS SELECTED, AN APPROPRIATE MOTOR STARTER MUST BE USED.

STEP THREE

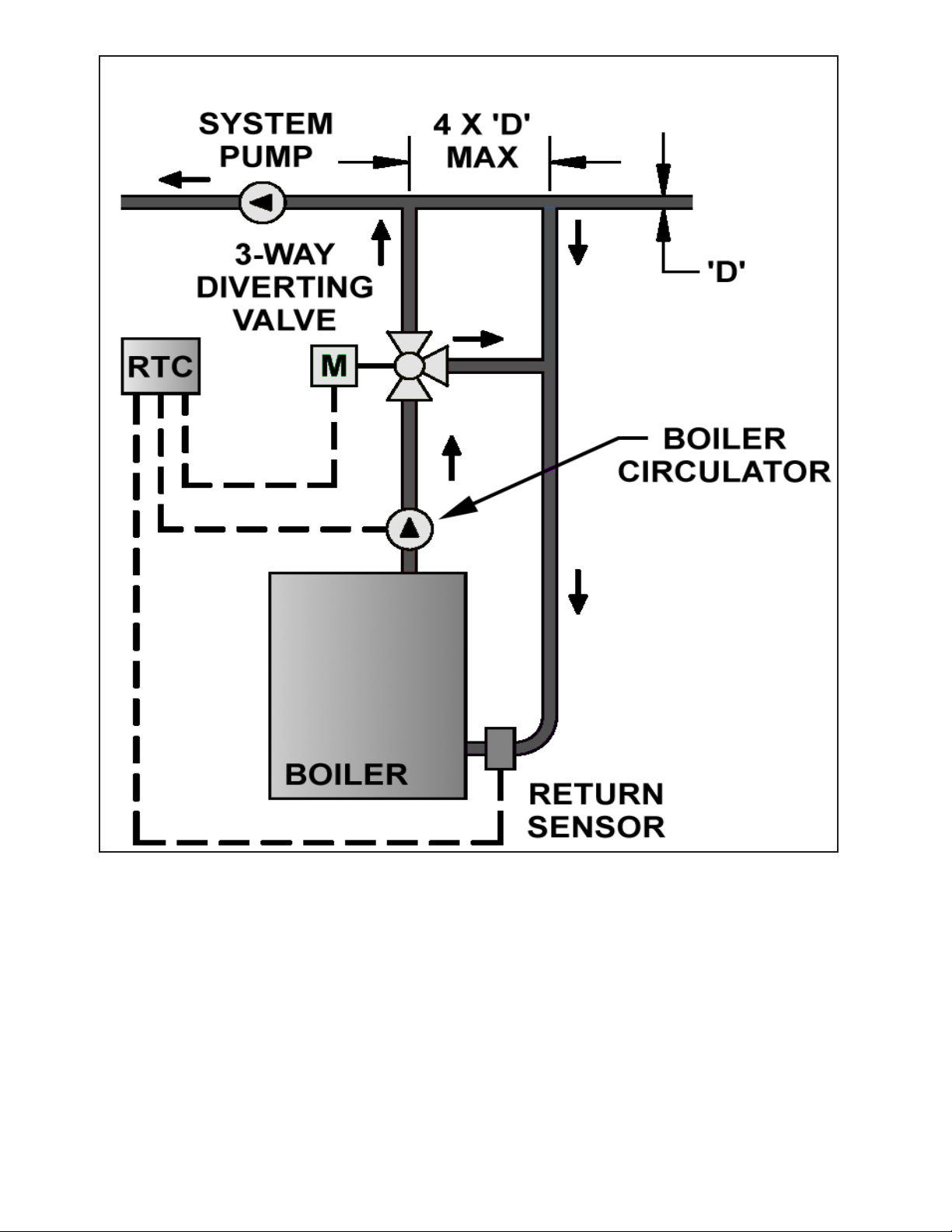

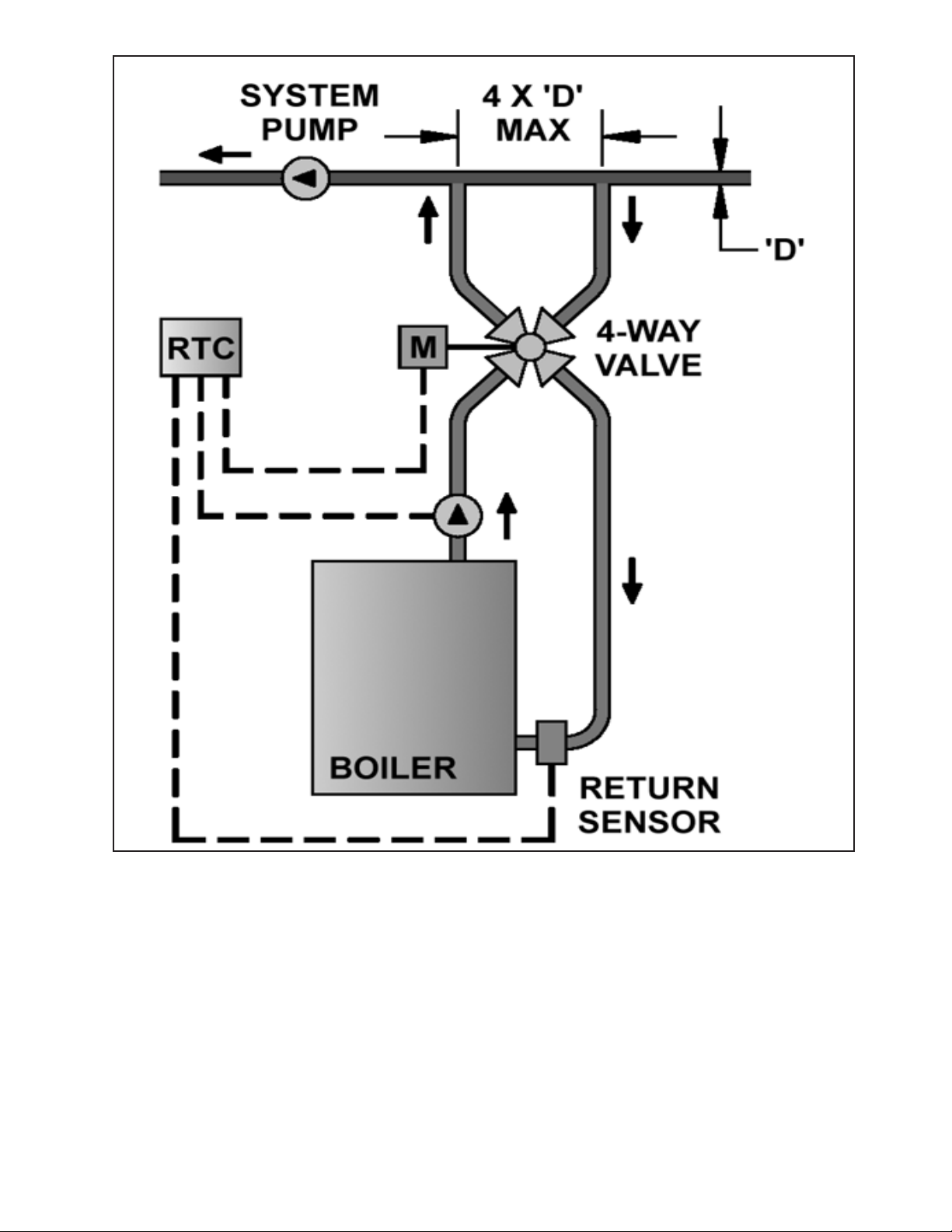

When using the RTC control, the boiler loop piping must contain the boiler, the boiler circulator, a 3-way or 4-way diverting valve,

and the return sensor. The boiler loop injects hot water into the primary loop, provided that the boiler return water temperature

(measured by the return sensor) is at least 135°F. If the return temperature is below 135°F, the diverting valve closes, recirculating

boiler supply water through the boiler loop until the return water has been heated to at least 135°F. The RTC controls the diverting

value actuator based upon the absolute return water temperature, as well as the rate of temperature change.

Several typical RTC applications are shown in Appendix A. Select the appropriate application before proceeding.

See Figures 5 and 6 for general component and piping arrangements when using 3-way and 4-way diverting valves. See Figure

3 for V9A piping recommendations for 3-way valve applications. See Figure 4 for V11 piping recommendations for 3-way valve

applications. As shown in these diagrams, the boiler loop’s supply and return are connected to the primary loop through two closely

spaced tees, at a maximum branch centerline distance of four times the primary loop diameter (4 x D Max).

NEAR BOILER PIPING

7 of 60

Page 8

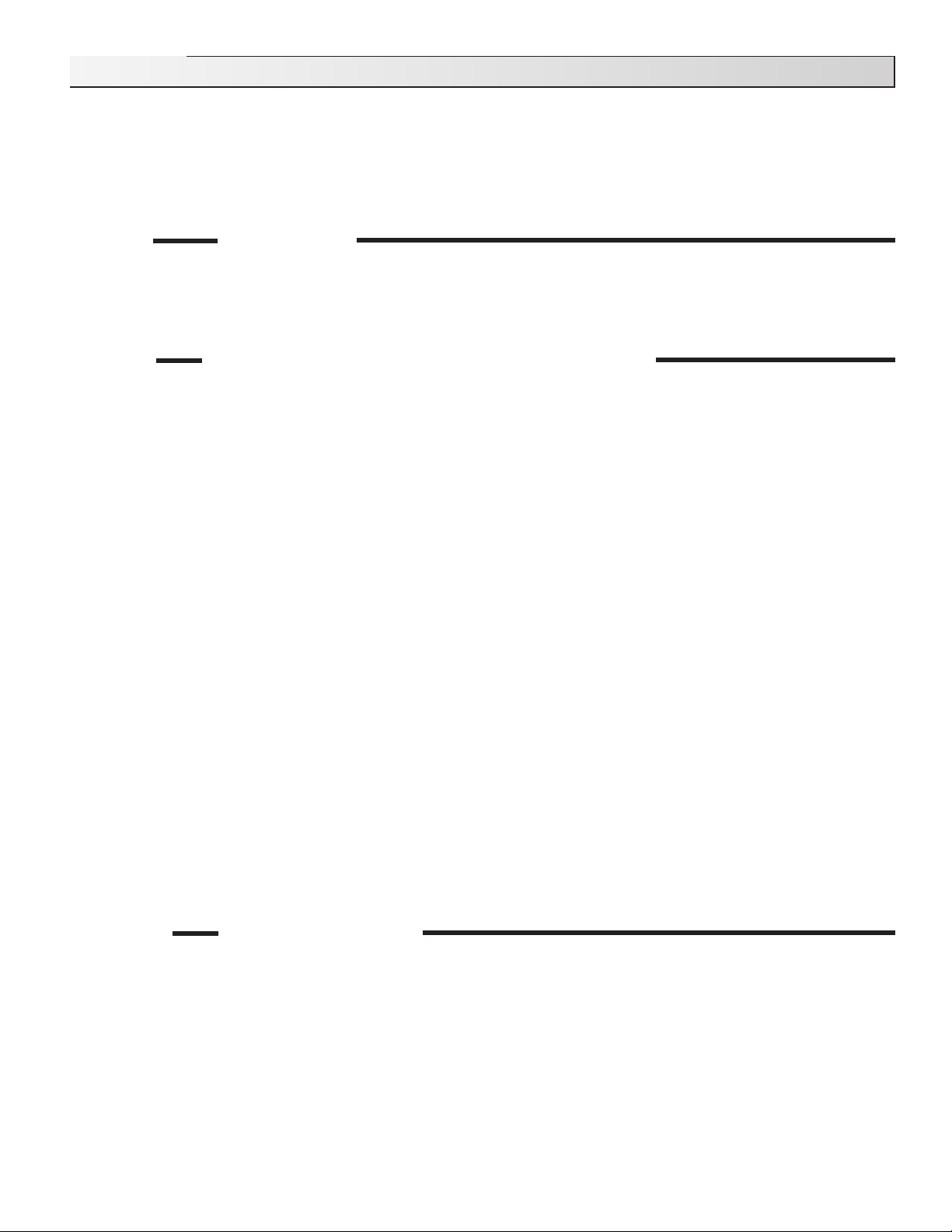

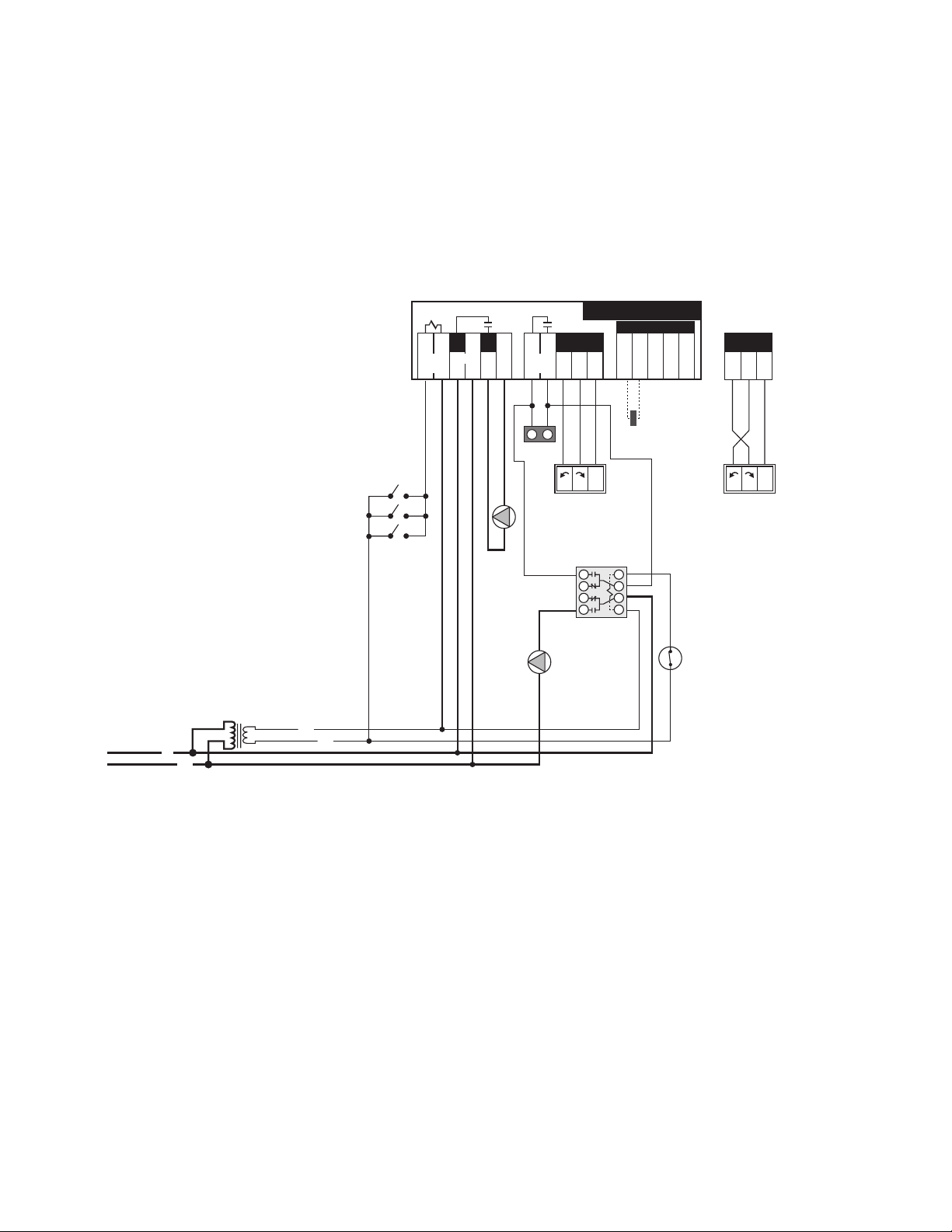

Figure 1: Typical Boiler Wiring With RTC (Front)

8 of 60

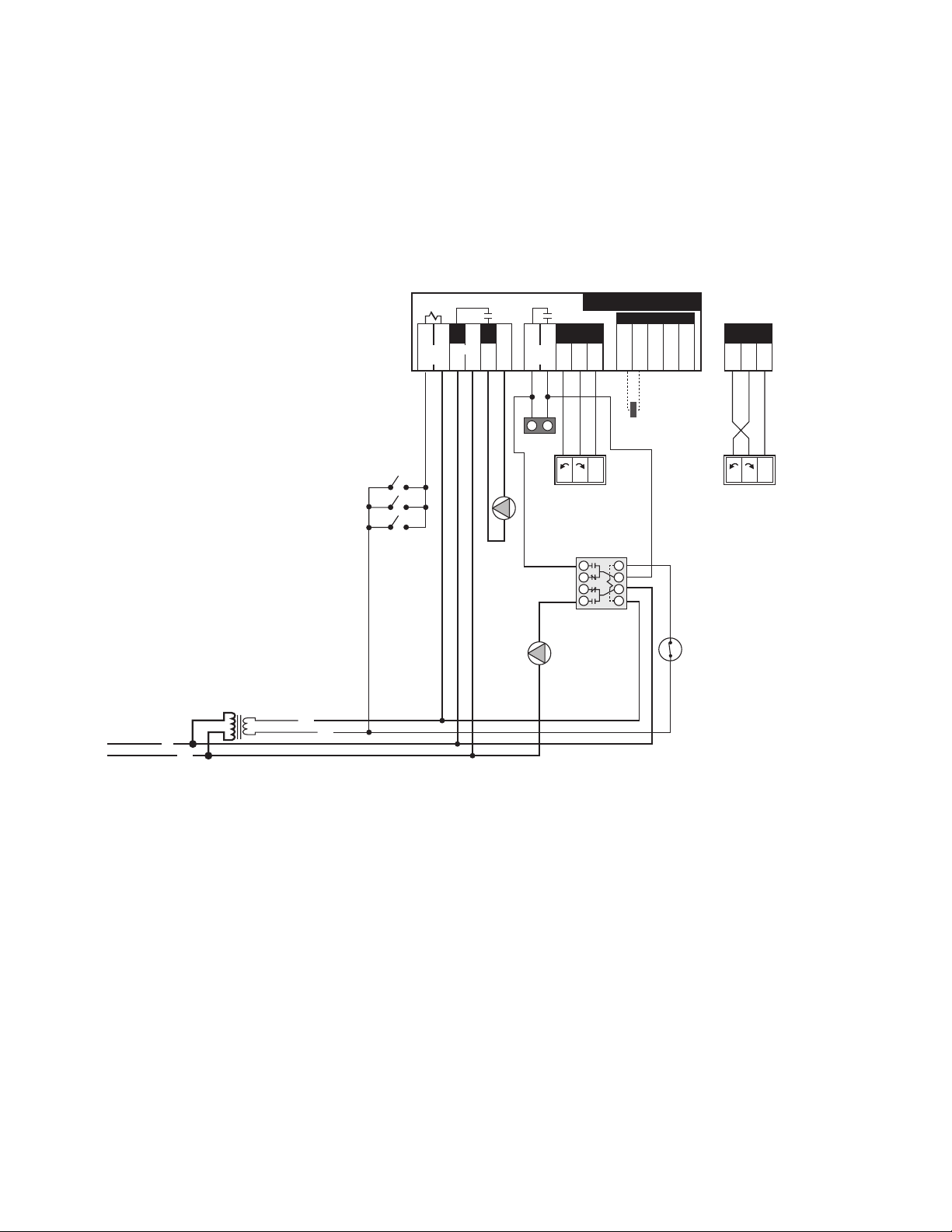

Page 9

Figure 2: Typical Boiler Wiring With RTC Return Sensor (Rear)

9 of 60

Page 10

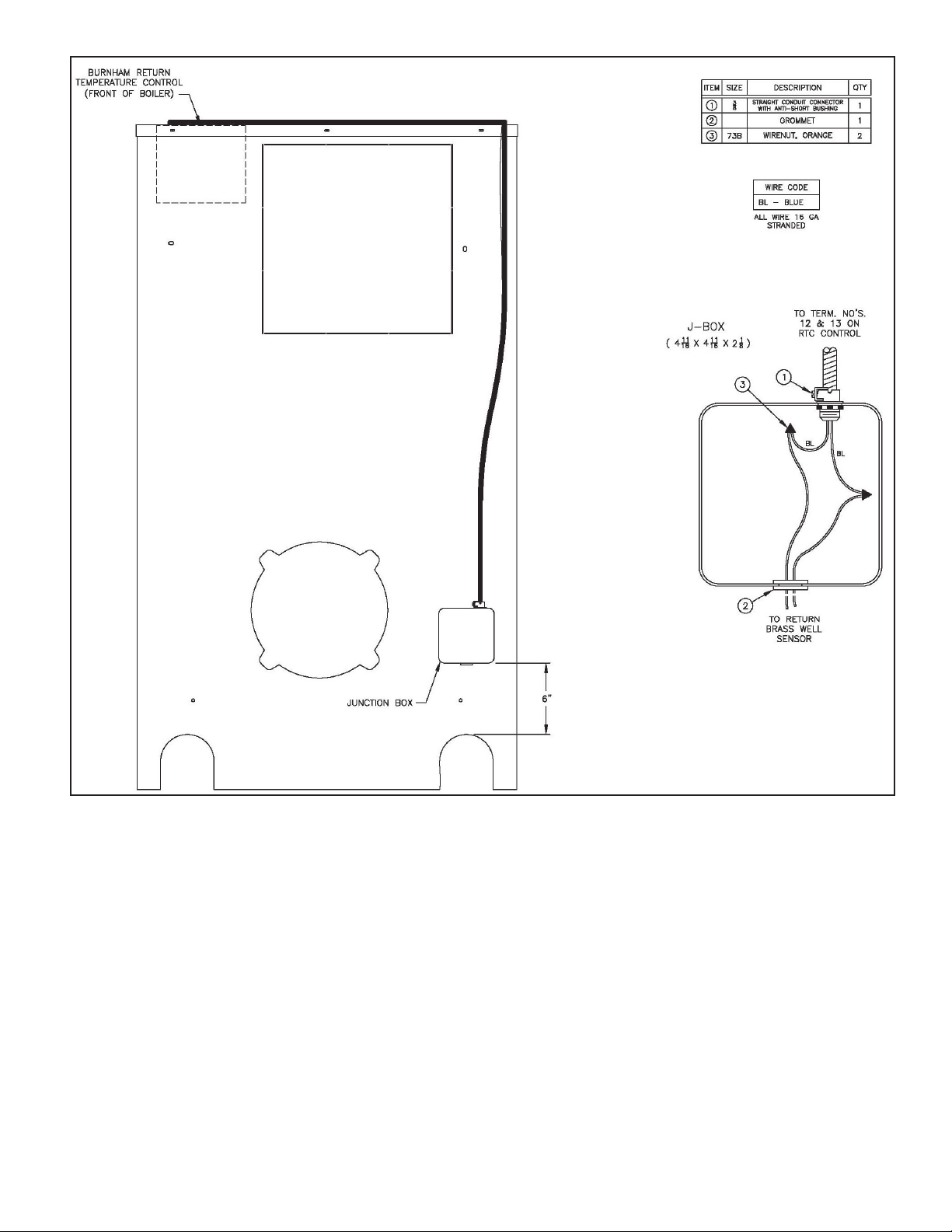

Figure 3: V9A Series Boiler Recommended Minimum Piping

- RTC With 3-Way Diverting Valve

10 of 60

Page 11

Figure 4: V11 Series Boiler Recommended Minimum Piping

- RTC With 3-Way Diverting Valve

11 of 60

Page 12

Figure 5: Typical Burnham Boiler Loop w/3-Way Diverting

Valve

12 of 60

Page 13

Figure 6: Typical Burnham Boiler Loop w/4-Way Diverting

Valve

13 of 60

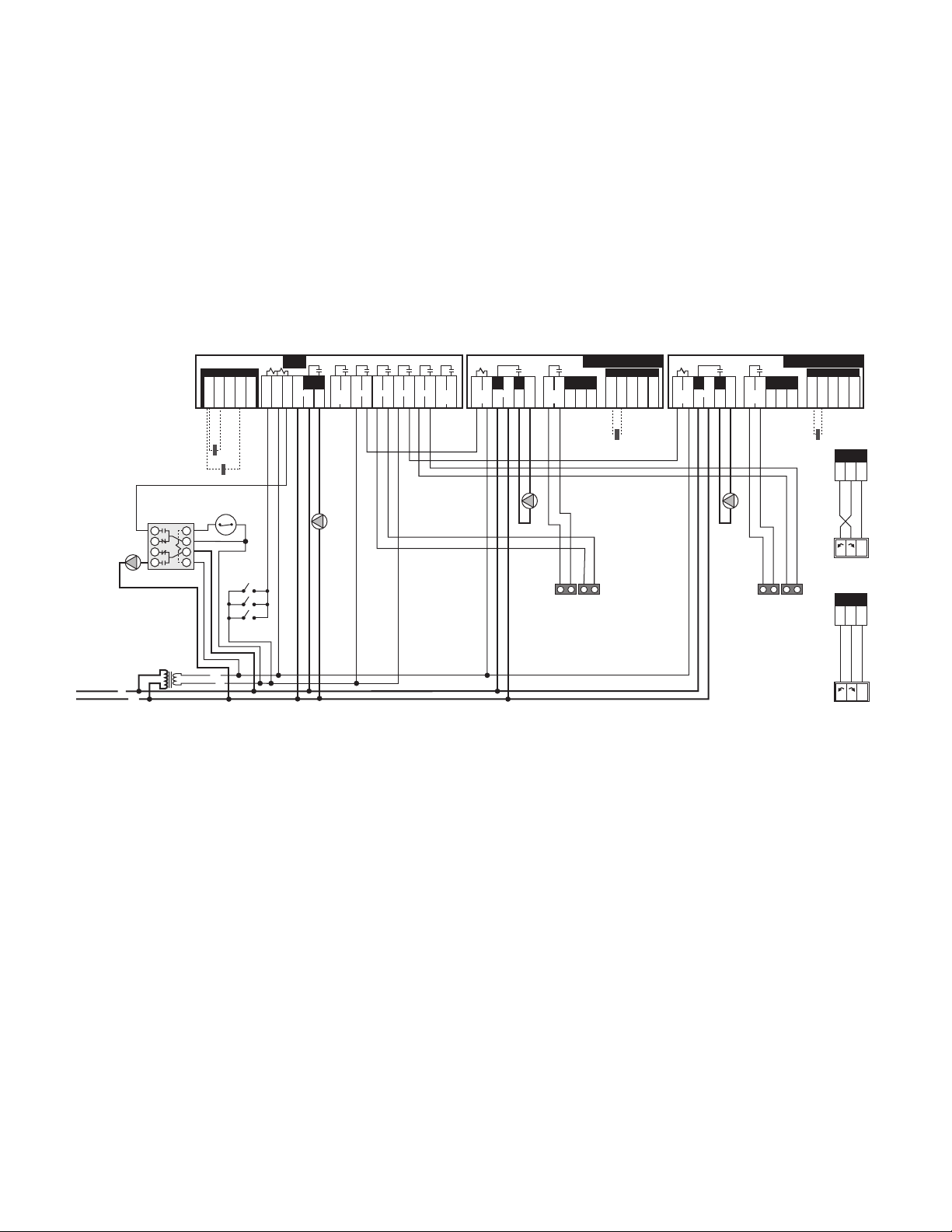

Page 14

On multiple boiler applications, each boiler is installed in the same arrangement as a single boiler application. Each boiler loop contains

5

Boil

Pm

p

Po

we

r

6

N

3

L

120 V (ac)

N

L

4

N

1

Heat

Demand

2

24 to 240 V (ac)

N

L

Po

we

r

4

120 V (ac)

L

N

3

its own boiler circulator, diverting valve and actuator, RTC control, and return sensor. A number of different boiler sequencers can be

used in conjunction with the RTC by energizing the control’s heat demand circuit. The RTC control’s outdoor reset feature cannot be

used on multiple boiler installations. The sequencer’s outdoor reset feature (if available) would have to be utilized instead.

STEP FOUR

ROUGH-IN WIRING

All electrical wiring terminates in the control base wiring chamber. The base has standard 7/8” (22 mm) knockouts, which accept

common wiring hardware and conduit fittings. Before removing the knockouts, check the wiring diagram and select those sections

of the chamber with common voltages. Do not allow the wiring to cross between sections, as the wires will interfere with safety

dividers, which should be installed at a later time.

Power must not be applied to any of the wires during the rough-in wiring stage.

- All wires are to be stripped to a length of 3/8 in (9 mm) to ensure proper connection to the control.

- If a Mix Sensor 071 or an Outdoor Sensor 070 is used, install the sensor according to the installation instructions in the Data

Brochure D 070 and run the wiring back to the control.

- Make sure the Boiler Return Sensor is installed and run the wiring back to the control.

- Run wire from other system components (pumps, boilers, etc.) to the control.

- Run wires from the 120 V (ac) power to the control. Ideally, a separate dedicated circuit should power the control.

- Use a clean power source with a 15 A circuit to ensure proper operation. Multi-strand 16 AWG wire is recommended for all

120 V (ac) wiring due to its superior flexibility and ease of installation into the terminals.

STEP FIVE

ELECTRICAL CONNECTIONS TO THE CONTROL

The installer should test to confirm that no voltage is present at any of the wires. Push the control into the base and slide it down

until it snaps firmly into place.

Powered Input Connections

120 V (ac) Power

Connect the 120 V (ac) power supply to the Power L and Power N terminals (3 and 4).

This connection provides power to the microprocessor and display of the control. As

well, this connection provides power to the Boil Pmp terminal (5). The control should

be powered from a dedicated circuit. This avoids power disruption to the control in

the event of failure on another electrical device on the same circuit. DO NOT power

the control from the boiler or burner circuit, since there may be times where the

boiler or burner circuit may be switched off in the summer. This would prevent the

exercising of the boiler recirculating pump and the diverting valve. Boiler protection

for dormant boilers, in a multiple boiler application, will not be possible if the control

is not powered.

Heat Demand

To generate a heat demand, a voltage between 24 V (ac) and 240 V (ac) must be

applied across the Heat Demand terminals (1 and 2).

Output Connections

Boiler Recirculating Pump Contact (Boil Pmp)

The Boil Pmp output terminal (5) on the control is a powered output. When the relay in

the control closes, 120 V (ac) is provided to the Boil Pmp terminal (5) from the Power L

terminal (3). To operate the boiler recirculating pump, connect one side of the boiler

recirculating pump circuit to terminal (5), and the second side of the pump circuit to

the neutral (N) terminal (6).

14 of 60

Page 15

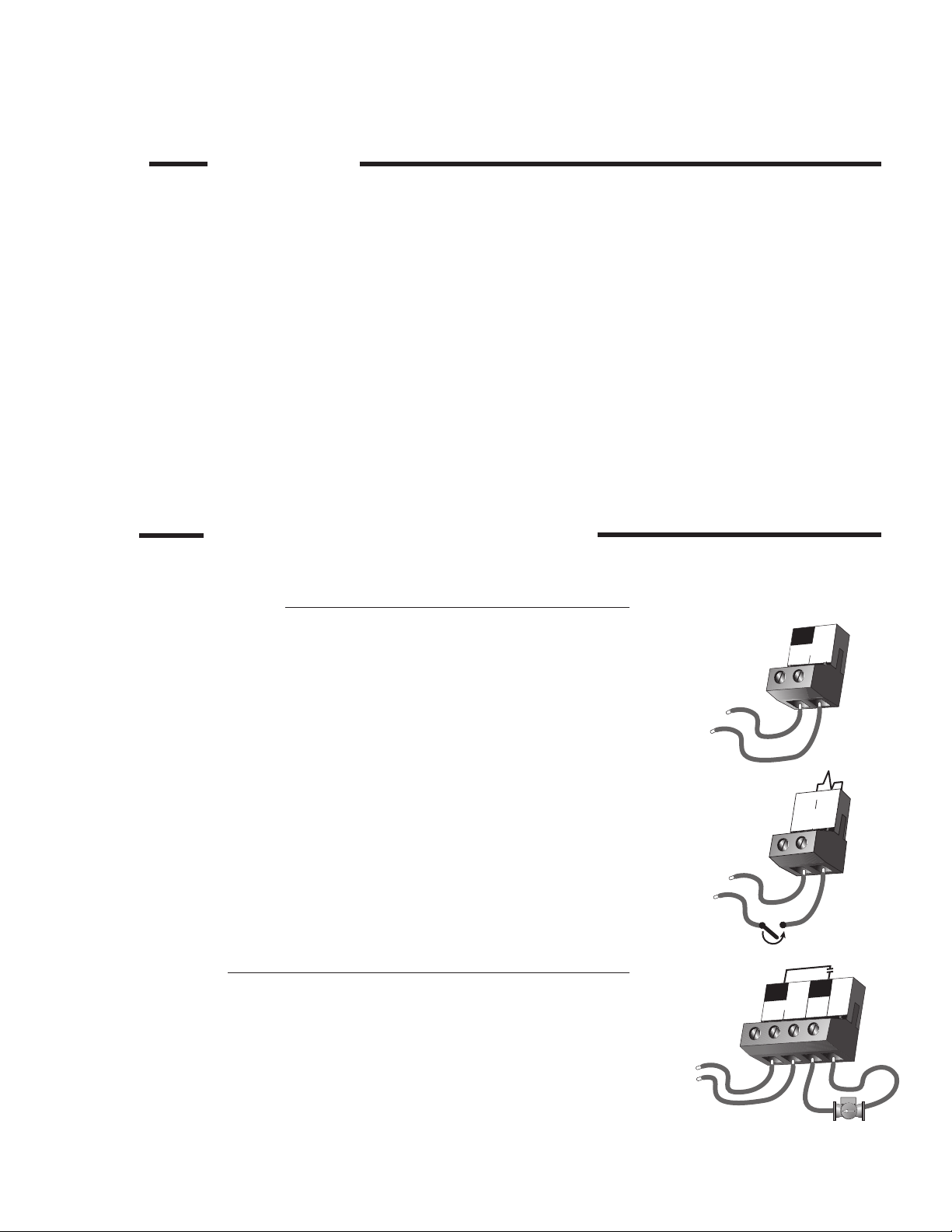

Diverting Valve Actuator

Supply

from

Boiler

No Flow

to

System

Full

Flow

thru

Bypass

No

Flow

thru

Bypass

COUNTER CLOCKWISE (CCW) = OPEN TO SYSTEM

CLOCKWISE (CW) = CLOSED TO SYSTEM

Supply

from

Boiler

Full Flow

to

System

RTC Terminals

Actuator Terminals

9

R

10

R

11

N

L1

N

L1

0

0

9

R

10

R

11

N

Open

N

Close

24 Volt Output

Supply

from

Boiler

0

5

10

No Flow

to

System

RTC Terminals

Actuator Terminals

Full

Flow

thru

Bypass

CLOCKWISE (CW) = OPEN TO SYSTEM

COUNTER CLOCKWISE (CCW) = CLOSED TO SYSTEM

Supply

from

Boiler

Full Flow

to

System

No

Flow

thru

Bypass

0

5

10

9

R

10

R

11

N

L

1

N

L1

Terminals 9, 10 and 11 are powered with 24 V (ac) from the control.

There is no need to provide a separate 24 V (ac) power source for

the diverting valve actuator. R (9) is connected to the open terminal

of the actuating motor and R (10) is connected to the close terminal

of the actuating motor. N (11) is then connected to the common

terminal of the actuating motor.

The control’s Test Sequence can be used to check the motor circuit. Once the Test button is pressed, the valve should move to

the fully open position. If the motor closes instead of opening, the wiring of the actuating motor must be reversed. Next, the valve

should move to the fully closed position. If it does not, check the wiring between the terminals and the actuating motor. Refer to

any installation or troubleshooting information supplied with the motor.

15 of 60

Page 16

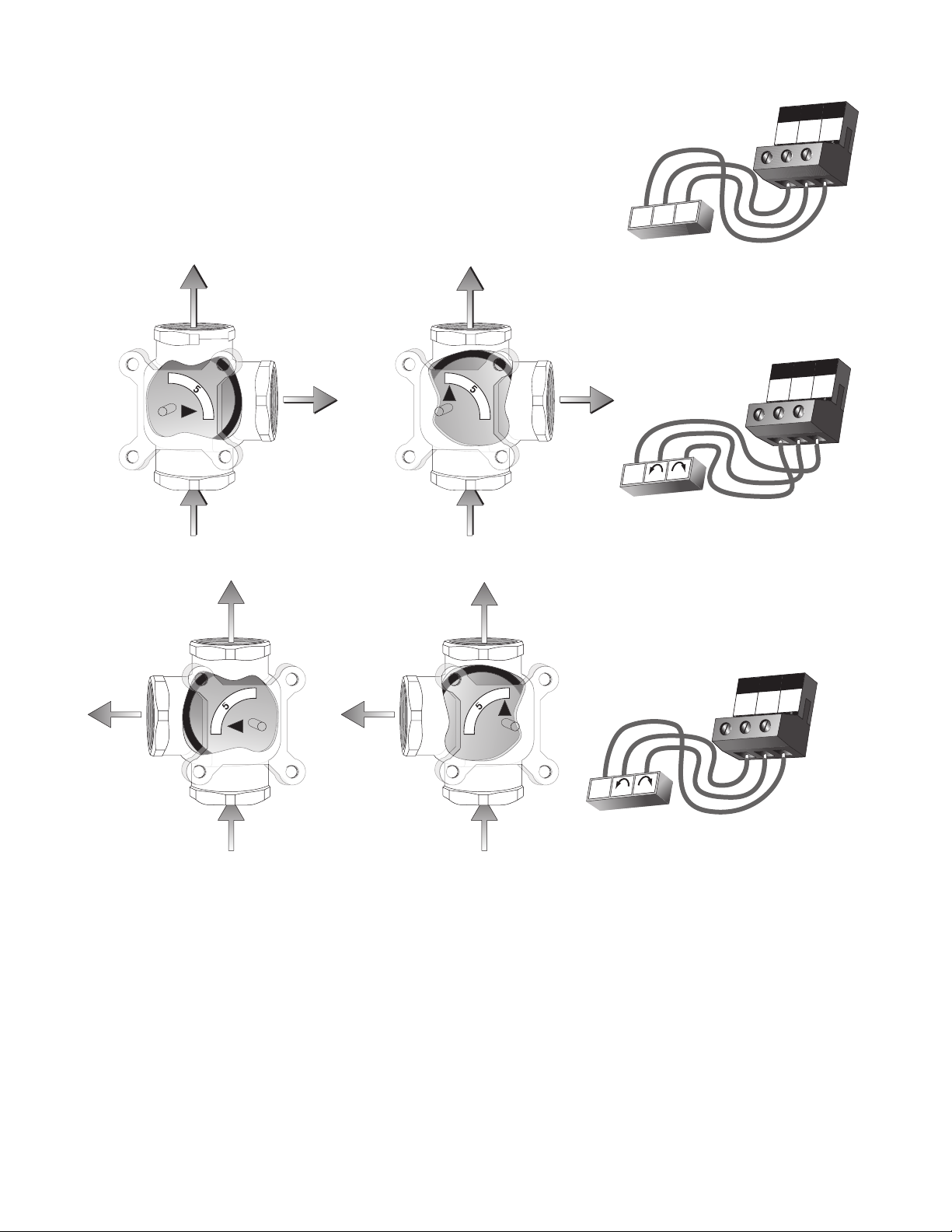

Boiler Enable Contact

7

Boiler

Enable

8

12

Com

13

Boil

Re

t

Boiler

Sensor

12

Com

13

Boil

Re

t

14

Mi

x

Mix Supply

Sensor

System

Pump

15

Com

16

Out

The Boiler Enable terminals (7 and 8) are an isolated output in the

control. There is no power available on these terminals from the

control. These terminals are to be used as a switch to either make

or break the boiler limit circuit. When the control requires the boiler

to fire, it closes the contact between terminals 7 and 8.

Sensor and Unpowered Input Connections

Do not apply power to these terminals, as this will damage the control.

Boiler Return Sensor

Connect the two wires from the Boiler Return Sensor to the Com

and Boil Ret terminals (12 and 13). The boiler return sensor is used

by the control to measure the boiler return temperature.

Mix Sensor (Outdoor Reset and Setpoint Modes)

Connect the two wires from the Mix Sensor 071 to the Com and Mix

terminals (12 and 14). The mix sensor is used by the control to measure the mixed supply water temperature in the primary loop. Typically the sensor is attached to the pipe downstream of the system

pump.

Outdoor Sensor (Outdoor Reset Mode)

Connect the two wires from the Outdoor Sensor 070 to the Com and

Out terminals (15 and 16). The outdoor sensor is used by the control

to measure the outdoor air temperature.

STEP SIX

Each terminal block must be unplugged from its header on the control before power is applied for testing. To remove the terminal

block, pull straight down from the control.

The following tests are to be performed using standard testing practices and procedures and should only be carried out by properly

trained and experienced persons.

A good quality electrical test meter, capable of reading from at least 0 – 300 V (ac) and at least 0 – 2,000,000 Ohms, is essential to

properly test the wiring and sensors.

TESTING THE WIRING

16 of 60

Page 17

13

14

15

Boi

l

Re

t

Mi

x

Co

m

12

Co

m

2

Heat

Demand

1

V

20 to 260 V (ac)

4

N

Po

w

er

3

L

V

108 to 132 V (ac)

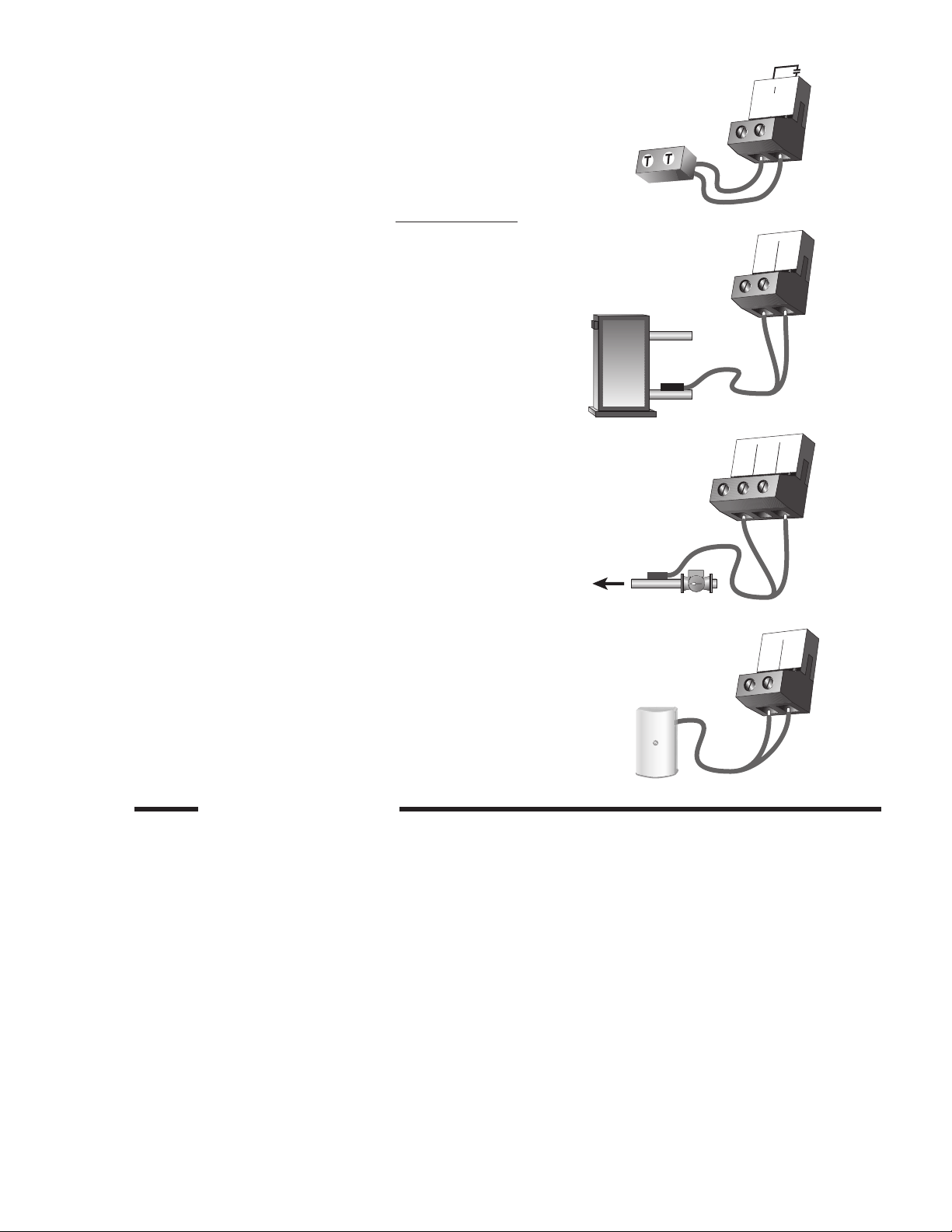

Test the Sensors

A good quality test meter capable of measuring up to 2,000,000 Ω (1kΩ = 1000 Ω) is required to measure the sensor resistance.

In addition to this, the actual temperature should be measured with a good quality digital thermometer.

First measure the temperature using the thermometer.

Then measure the resistance of the sensor at the control.

The wires from the sensor must not be connected to the

control while the test is performed. Using the chart below,

estimate the temperature measured by the sensor. The

sensor and thermometer readings should be close. If the

test meter reads a very high resistance, there may be

a broken wire, a poor wiring connection or a defective

sensor. If the resistance is very low, the wiring may be

shorted, there may be moisture in the sensor or the

sensor may be defective. To test for a defective sensor,

measure the resistance directly at the sensor location.

Do not apply voltage to a sensor at any time as damage

to the sensor may result.

Temperature

°F

-50

-45

-40

-35

-30

-25

-20

-15

-10

-5

0

5

10

15

°C

-46

-43

-40

-37

-34

-32

-29

-26

-23

-21

-18

-15

-12

-9

Resistance

Ω

490,813

405,710

336,606

280,279

234,196

196,358

165,180

139,402

118,018

100,221

85,362

72,918

62,465

53,658

Temperature

°F

°C

20

25

30

35

40

45

50

55

60

65

70

75

80

85

Resistance

-7

-4

-1

2

4

7

10

13

16

18

21

24

27

29

Test the Power Supply

Make sure exposed wires and bare terminals are not in

contact with other wires or grounded surfaces. Turn on

the power and measure the voltage between the Power

L and Power N terminals (3 and 4) using an AC voltmeter,

the reading should be between 108 and 132 V (ac).

Ω

46,218

39,913

34,558

29,996

26,099

22,763

19,900

17,436

15,311

13,474

11,883

10,501

9,299

8,250

Temperature

°F

90

95

100

105

110

115

120

125

130

135

140

145

150

155

°C

32

35

38

41

43

46

49

52

54

57

60

63

66

68

Resistance

Ω

7,334

6,532

5,828

5,210

4,665

4,184

3,760

3,383

3,050

2,754

2,490

2,255

2,045

1,857

Temperature

°F

160

165

170

175

180

185

190

195

200

205

210

215

220

225

°C

71

74

77

79

82

85

88

91

93

96

99

102

104

107

Resistance

Ω

1,689

1,538

1,403

1,281

1,172

1,073

983

903

829

763

703

648

598

553

Test the Powered Inputs

Heat Demand

Measure the voltage between the Heat Demand

terminals (1 and 2). When the heat demand device

calls for heat, between 20 and 260 V (ac) should be

measured at the terminals. When the heat demand

device is off, less than 5 V (ac) should be measured.

17 of 60

Page 18

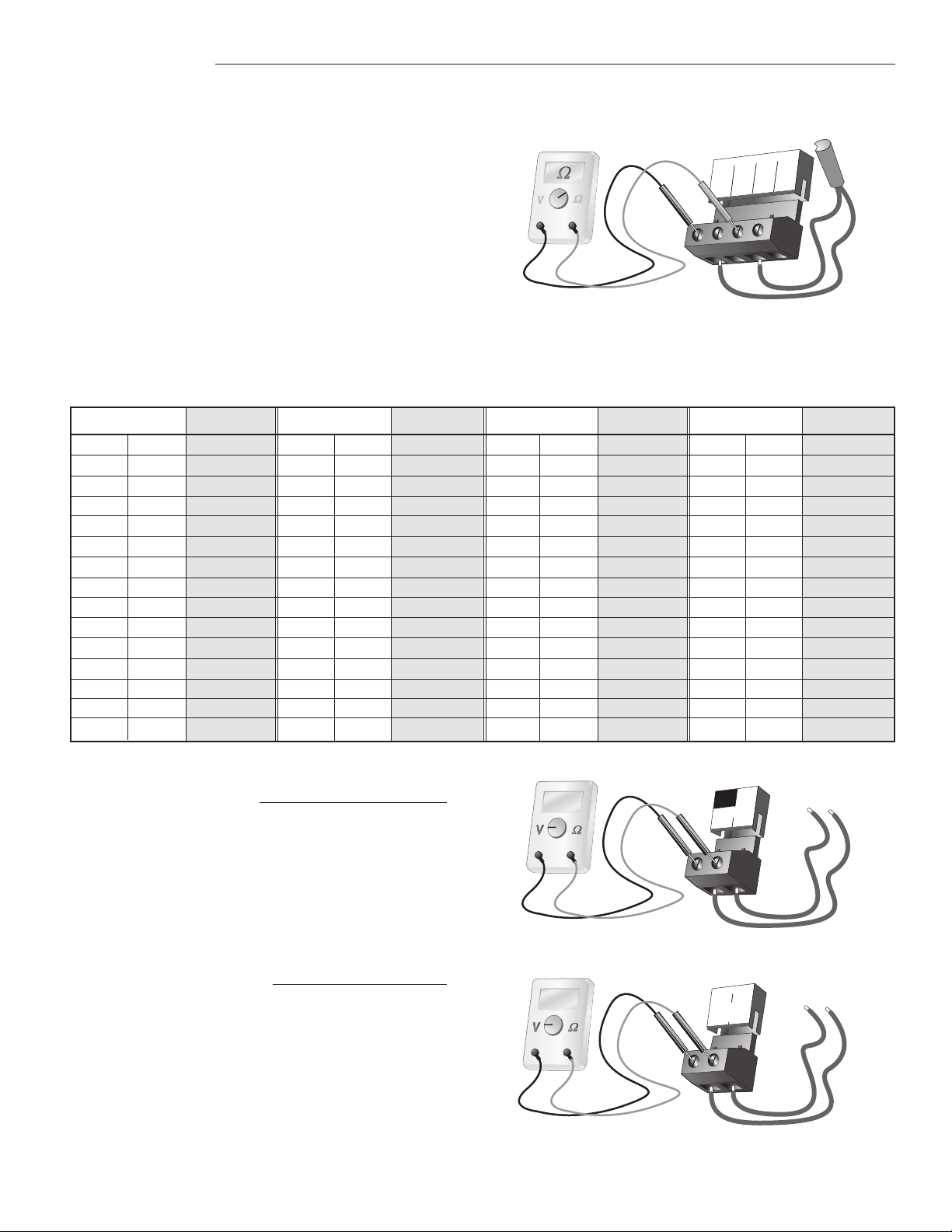

Test the Outputs

4

5

6

Boi

l

Pm

p

Po

we

r

N

3

L

120 V (ac)

Boiler Recirculating

Pump

N

L

N

14

13

15

12

16

Com

Com

Out

Boil

Re

t

Mix

Boiler Recirculating Pump (Boil Pmp)

The boiler recirculating pump is connected to the Boil Pmp

terminal (5). Make sure that power to the terminal block is off,

and install a jumper between the Power L and the Boil Pmp

terminals (3 and 5). Install a second jumper between Power N

and N terminals (4 and 6). When power is applied to the Power

L and Power N terminals (3 and 4), the boiler recirculating

pump should start. If the pump does not turn on, check the

wiring between the terminal block and pump, and refer to any

installation or troubleshooting information supplied with the

pump. If the pump operates properly, disconnect the power

and remove the jumpers.

Boiler Enable Contact

If the boiler limit circuit is connected to the Boiler Enable terminals (7 and 8), make sure power to the boiler circuit is off, and

install a jumper between the terminals. When the boiler limit circuit is powered up, the boiler should fire. If the boiler does not

turn on, refer to the installation or troubleshooting information supplied with the boiler. Check for proper operation of each

device in the boiler limit circuit. If the boiler operates properly, disconnect the power and remove the jumper.

Connecting the Control

Make sure all power to the devices and terminal blocks is off, and remove any remaining jumpers from the terminals.

Reconnect the terminal blocks to the control by carefully aligning

them with their respective headers on the control, and then pushing

the terminal blocks into the headers. The terminal blocks should

snap firmly into place.

Install the supplied safety dividers between the unpowered sensor

inputs and the powered or 120 V (ac) wiring chambers.

Apply power to the control. The operation of the control on power up

is described in the Sequence of Operation section of this manual.

STEP SEVEN

ADJUSTING THE CONTROL SETPOINTS

In order for the RTC to function properly, several control settings must be adjusted. Review the “User Interface” and “Sequence

of Operation” sections of this manual for descriptions of each setting and instructions on how to adjust them. Adjust the following settings as specified:

A. ROOM (Room Temperature) – Set the desired room temperature.

B. MIX TARGET – This setting can only be used on applications where the mix sensor is installed. When the outdoor reset

feature is not selected, this setting represents the fixed target supply water temperature. On this type of application, the MIX

TARGET setting should be adjusted to match the boiler operating aquastat’s setpoint temperature.

C. MIX DSGN (Mixing Design) – When the outdoor reset feature is selected, this setting represents the design system supply

water temperature. If unsure about the original design temperature, set the MIX DSGN to match the boiler operating aquastat’s

setpoint temperature.

D. OUTDR DSGN (Outdoor Design) – When the outdoor reset feature is selected, this setting represents the typical coldest

temperature of the year in the area where the installation is located. If this value is unknown, use the temperature value found

in ASHRAE Fundamentals for the area closest to the installation.

18 of 60

Page 19

E. WWSD (Warm Weather Shut Down) – This feature is only used when the outdoor reset feature is selected. Set the WWSD

as desired, keeping in mind that, when the outdoor air temperature rises above the WWSD setting, the control will not operate the

boiler to satisfy any demands for heat.

F. MIX MIN (Mixing Minimum) – When the outdoor reset feature is selected, this setting represents the minimum mix target

supply water temperature. Set as desired.

G. MIX MAX (Mixing Maximum) – When the outdoor reset feature is selected, this setting represents the maximum allowable

mix target supply water temperature. Typically, this is set between 200°F and 220°F. However, the MIX MAX setting must below the

highest permissible temperature for any system component affected by the boiler supply water.

H. OPEN DELAY – This setting represents the number of seconds required for the actuator to move the valve from a fully

closed to a fully open position. Keep this setting at the default value of 50 seconds.

I. BOIL MIN (Boiler Minimum) – This setting represents the minimum allowable boiler return water temperature. Keep this

setting at 135°F, unless a higher minimum return water temperature is required.

J. BOIL MIN DELAY (Boiler Minimum Delay) – This setting represents the number of seconds required for warm-up during

an initial cold start. Use the appropriate value from Table I or II, depending on the specific application. (These values include 90

seconds of pre-purge time.)

K. PUMP DELAY – This setting represents the time (in seconds) for boiler circulator (pump) purge after a heat demand cycle.

This minimizes the amount of boiler temperature overshoot at the end of a cycle. During the pump purge, the diverting valve will continue to operate and prevent low temperature return water from entering the boiler. At the end of the pump purge period, the diverting

valve will close immediately. Set the pump delay as desired. (The default setting is 30 seconds.)

STEP EIGHT

The control’s exterior can be cleaned using a damp cloth. Moisten the cloth with water and wring out prior to wiping control. Do not

use solvents or cleaning solutions.

CLEANING THE CONTROL

19 of 60

Page 20

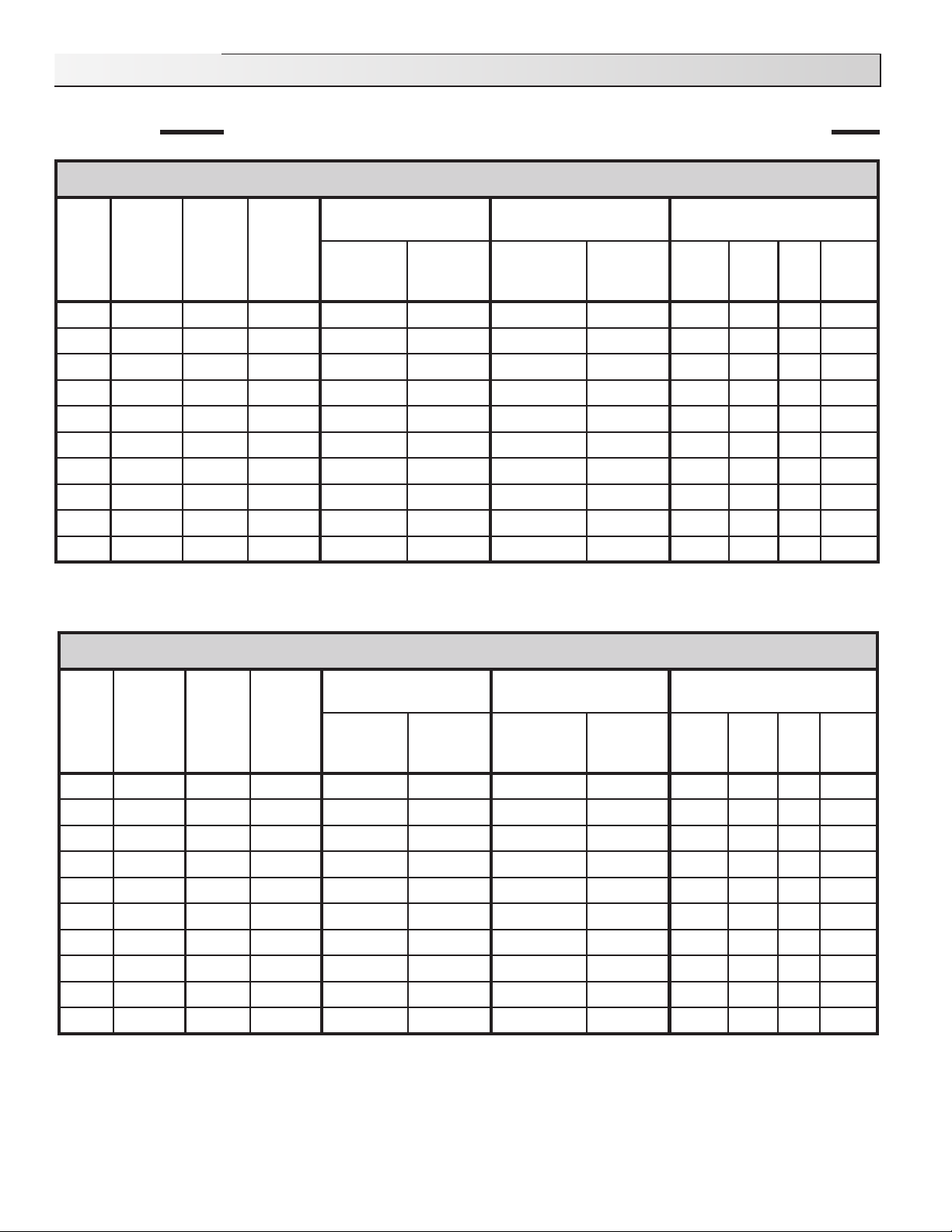

View Menu (1 of 1)

Monitor

Monitor

Monitor

Monitor

Monitor

Display Description

Section

BOIL

D

Current boiler return temperature as measured by the boiler sensor.

MIX TARGET

Target mixed supply is the temperature the control is currently trying to maintain

D

at the mixing sensor.

(Mix sensor is present or OUTDR DSGN = OFF)

MIX

Current mixed supply water temperature as measured by the mixing sensor.

D

(Mix sensor is present or OUTDR DSGN = OFF)

OUTDR

Current outdoor air temperature as measured by the outdoor sensor.

D

(Outdoor sensor is present and OUTDR DSGN ≠ OFF)

Monitor BOIL run

The control records the number of hours the boiler enable contact has been

D

closed.

Range

14 to 266°F

(-10 to 130°C)

– – –, 14 to 266°F

(– – –,-10 to 130°C)

14 to 266°F

(-10 to 130°C)

-67 to 149°F

(-55 to 65°C)

run <> 0 to 99 999

Monitor BOIL CYC

D

The control records the number of boiler enable relay cycles.

Monitor BOIL MIN run

D

Below return water minimum. The control records the number of hours the boiler

operates below the boiler minimum setting.

Monitor BOIL CS

D

The number of times the boiler has experienced cold shock conditions.

Monitor BOIL MIN Err

D

The number of hours the boiler return sensor is not functioning.

CYC <> 0 to 99 999

run <> 0 to 99 999

CS <> 0 to 99 999

Err <> 0 to 99 999

20 of 60

Page 21

Adjust Menu (1 of 1)

Delay Open

Delay

Delay

Display Description

Section

Range

Actual

Setting

ROOM

C

The desired room air temperature.

(OUTDR DSGN ≠ OFF)

MIX TARGET

C

Mixing setpoint temperature.

(OUTDR DSGN = OFF)

MIX DSGN

The design supply water temperature used in the heat loss

C

calculation for the heating system.

(OUTDR DSGN ≠ OFF)

OUTDR DSGN

The design outdoor air temperature used in the heat loss calculation

C

for the heating system. For setpoint operation, set the OUTDR

DSGN to OFF

WWSD

The system’s warm weather shut down during the occupied (Day)

C

period.

MIX MIN

C

The minimum supply temperature for the mixing system.

(OUTDR DSGN ≠ OFF)

35 to 100°F

(2 to 38°C)

Default = 70°F (21°C)

60 to 200°F

(16 to 93°C)

Default = 180°F (82°C)

70 to 210°F

(21 to 99°C)

Default = 180°F (82°C)

-60 to 32°F, OFF

(-51 to 0°C, OFF)

Default = OFF

35 to 100°F, OFF

(2 to 38°C, OFF)

Default = 70°F (21°C)

OFF, 35 to 150°F

(OFF, 2 to 66°C)

Default = OFF

MIX MAX

C

The maximum supply water temperature for the mixing system.

(OUTDR DSGN ≠ OFF)

Open Delay

C

The time the actuating motor requires to operate from fully closed

to fully open.

BOIL MIN

C

The minimum boiler return water temperature.

BOIL MIN Delay

C

The amount of time the boiler requires to heat up to the boiler

minimum temperature from a cold start.

Pump Delay

C

The amount of time the boiler recirculating pump purges the boiler.

Temperature Units

The units of measure that all of the temperatures are to be displayed

C

in the control.

80 to 220°F

(27 to 104°C)

Default = 200°F (93°C)

30 to 230 seconds

Default = 50 seconds

135 to 230°F

(57 to 110°C)

Default = 135°F (57°C)

210 to 540 seconds

(10 second increments)

Default = 540 seconds

0 to 240 seconds

Default = 30 seconds

°F, °C

Default = °F

21 of 60

Page 22

Testing the Control

Test

The control has a built-in test routine, which is used to test the main control functions. The

control continually monitors the sensors, and displays an error message whenever a fault is

found. See the following pages for a list of the control’s error messages and possible causes.

When the Test button is pressed, the test light is turned on. The individual outputs and relays

are tested in the following test sequence.

TEST SEQUENCE

Each step in the test sequence lasts at least 10 seconds.

During the test routine, the test sequence may be paused by pressing the Test button. Only if there is a heat demand can the control

be paused in a step. If the Test button is not pressed again for 5 minutes while the test sequence is paused, the control exits the

entire test routine. If the test sequence is paused, the Test button can be pressed again to advance to the next step. This can also

be used to rapidly advance through the test sequence. To reach the desired step, repeatedly press and release the Test button

until the appropriate device and segment in the display turn on.

Step 1 -The diverting valve is run fully open.

Step 2 -The diverting valve is run fully closed.

Step 3 -The boiler recirculating pump (Boil Pmp) is turned on and waits 10 seconds.

Step 4 -The Boiler Enable contact is turned on for 10 seconds. After 10 seconds, the Boiler Enable and Boil Pmp contacts are shut off.

Step 5 -The test sequence is completed and the control resumes its normal operation.

Troubleshooting

When troubleshooting any heating system, it is always a good idea to establish a set routine to follow. By following a consistent

routine, many hours of potential headaches can be avoided. Below is an example of a sequence that can be used when diagnosing

or troubleshooting problems in a hydronic heating system.

Establish the problem. Get as much information from the customer as possible about the problem. Is there

Establish the

Problem

Understanding

the Sequence of

Operation

Use the Test

Routine

Sketch the

Piping in the

System

too much heat, not enough heat, or no heat? Is the problem only in one particular zone or area of the

building, or does the problem affect the entire system? Is this a consistent problem or only intermittent?

How long has the problem existed for? This information is critical in correctly diagnosing the problem.

Understand the sequence of operation of the system. If a particular zone is not receiving enough heat,

which pumps or valves in the system must operate in order to deliver heat to the affected zone? If the

zone is receiving too much heat, which pumps, valves, or check valves must operate in order to stop the

delivery of heat?

Press the Test button on the control and follow the control through the test sequence as described

in the Testing section. Pause the control as necessary to ensure that the correct device is operating

as it should.

Sketch the piping of the system. This is a relatively simple step that tends to be overlooked, however, it

can often save hours of time in troubleshooting a system. Note flow directions in the system paying close

attention to the location of pumps, check valves, pressure bypass valves, and diverting valves. Ensure

correct flow direction on all pumps. This is also a very useful step if additional assistance is required.

Document the control for future reference. Before making any adjustments to the control, write down

Document the

Control

22 of 60

all of the items that the control is currently displaying. This includes items such as error messages,

current temperatures and settings, and which devices should be operating as indicated by the LCD. This

information is an essential step if additional assistance is required to diagnose the problem.

Page 23

Isolate the

Problem

Test the Contacts,

Voltages and

Sensors

Error Messages

Isolate the problem between the control and the system. Now that the sequence of operation is known and

the system is sketched, is the control operating the proper pumps and valves at the correct times? Is the

control receiving the correct signals from the system as to when it should be operating? Are the proper

items selected in the menus of the control for the device that is to be operated?

Test the contacts, voltages and sensors. Using a multimeter, ensure that the control is receiving adequate

voltage to the power terminals and the demand terminals as noted in the technical data. Use the

multimeter to determine if the internal contacts on the control are opening and closing correctly. Follow

the instructions in the Testing the Wiring section to simulate closed contacts on the terminal blocks as

required. Test the sensors and their wiring as described in the Test the Sensors section.

The control was unable to read a piece of information from its EEPROM. This error can be caused by

a noisy power source. The control will load the factory defaults and continue operation if possible. All

settings in the Adjust menu must be reviewed before the error will clear.

The control is no longer able to read the boiler sensor due to a short circuit. The control will continue

to enable the boiler and will operate the diverting valve at 30% output while there is a heat demand

and until the sensor problem is repaired. The control will also record the time without the boiler return

sensor. Locate and repair the problem as described in the Test the Sensors section. To clear the error

message from the control after the sensor has been repaired, press the Item button.

The control is no longer able to read the boiler sensor due to an open circuit. The control will continue

to enable the boiler and will operate the diverting valve at 30% output while there is a heat demand

and until the sensor problem is repaired. The control will also record the time without the boiler return

sensor. Locate and repair the problem as described in the Test the Sensors section. To clear the error

message from the control after the sensor has been repaired, press the Item button.

The control is no longer able to read the mix supply sensor due to a short circuit. In this case the control

will operate the diverting valve at 30% output as long as there is a heat demand and until the sensor

problem is repaired. Locate and repair the problem as described in the Test the Sensors section. To

clear the error message from the control after the sensor has been repaired, press the Item button.

The control is no longer able to read the mix supply sensor due to an open circuit. In this case the

control will operate the diverting valve at 30% output as long as there is a heat demand and until

the sensor problem is repaired. Locate and repair the problem as described in the Test the Sensors

section. To clear the error message from the control after the sensor has been repaired, press the Item

button. Note: If a diverting valve is not installed, set the outdoor design (OUTDR DSGN) setting to

OFF, power off the control and then re-power.

The control is no longer able to read the outdoor sensor due to a short circuit. In this case the control

targets the design mix supply temperature and continues operation. Locate and repair the problem as

described in the Test the Sensors section. To clear the error message from the control after the sensor

has been repaired, press the Item button.

The control is no longer able to read the outdoor sensor due to an open circuit. In this case the control

targets the design mix supply temperature and continues operation. Locate and repair the problem as

described in the Test the Sensors section. To clear the error message from the control after the sensor

has been repaired, press the Item button. Note: If a diverting valve is operated as a setpoint control,

set the outdoor design (OUTDR DSGN) setting to OFF.

23 of 60

Page 24

STRAPCTR relioB/ytQ

traP

rebmuN

swercsgnitnuomdnarosnesreliobhtiw)CTR(lortnoCerutarepmeTnruteR 1 61906108

.3598F560#ssofnaD,rotomdnoceS05,V42,M29EBSE,rotoMlortnoC 1 55306108

21-52GMledoM;TPN"1-8698B560#ssofnaD,evlaVgnitreviDyaW-3 1 31094108

8-23GMledoM;TPN"4/1-1-9698B560#ssofnaD,evlaVgnitreviDyaW-3 1 65306108

831GledoM;TPN"2/1-1-3598B560#ssofnaD,evlaVgnitreviDyaW-3 1 75306108

151GledoM;TPN"2-4598B560#ssofnaD,evlaVgnitreviDyaW-3 1 85306108

05-561FledoM;degnalf"2/1-2-0698B560#ssofnaD,evlaVgnitreviDyaW-3 1 95306108

561FledoM;degnalf"2/1-2-1698B560#ssofnaD,evlaVgnitreviDyaW-3 1 06306108

081FledoM;degnalf"3-2698B560#ssofnaD,evlaVgnitreviDyaW-3 1 16306108

0011FledoM;degnalf"4-3698B560#ssofnaD,evlaVgnitreviDyaW-3 1 26306108

5211FledoM;degnalf"5-4698B560#ssofnaD,evlaVgnitreviDyaW-3 1 36306108

21-52GM4ledoM;TPN"1-5898B560#ssofnaD,evlaVgnitreviDyaW-4 1 61094108

8-23GMledoM;TPN"4/1-1-6898B560#ssofnaD,evlaVgnitreviDyaW-4 1 71094108

834GledoM;TPN"2/1-1-9798B560#ssofnaD,evlaVgnitreviDyaW-4 1 42094108

154GledoM;TPN"2-0898B560#ssofnaD,evlaVgnitreviDyaW-4 1 52094108

054FledoM;degnalf"2/1-2-0516B560#ssofnaD,evlaVgnitreviDyaW-4 1 66306108

564FledoM;degnalf"2/1-2-5616B560#ssofnaD,evlaVgnitreviDyaW-4 1 62094108

084FledoM;degnalf"3-0816B560#ssofnaD,evlaVgnitreviDyaW-4 1 84306108

0014FledoM;degnalf"4-0026B560#ssofnaD,evlaVgnitreviDyaW-4 1 46306108

5214FledoM;degnalf"5-5226B560#ssofnaD,evlaVgnitreviDyaW-4 1 56306108

elppinlaicepsnidetnuomebot;daeL"23htiwssarB,TPN"4/1,rosneSrelioB 1 51906108

04HCS,dnEmorF"3TPN"4/1,laicepS,"21X"3,elppiN 1 624006608

seireS11V&9V,)CTR(lortnoCerutarepmeTnruteRroftekcarBgnitnuoM 1 4306107

relioB11V&9V,srosneSxiMdnateseRroodtuOsseL,tiKtiforteRmetsySCTR 1 5806106

relioB11V&9V,srosneSxiMdnateseRroodtuOhtiW,tiKtiforteRmetsySCTR 1 6806106

gnitnuomepipecafrusrofdael"01,rosneSerutarepmeTdiulFlasrevinU170#ramket,rosneSxiM 1 37106108

070#ramket,rosneSriAroodtuO 1 27106108

P300#ramket,lioCtloV42,yaleR 1 69106108

P400#ramket,lioCtloV021,yaleR 1 56106108

TPN"Ω2xegnalf"Ω2;tiKegnalFyaW-3 1 07806106

TPN"3xegnalf"3;tiKegnalFyaW-3 1 17806106

TPN"4xegnalf"4;tiKegnalFyaW-3 1 27806106

TPN"5xegnalf"5;tiKegnalFyaW-3 1 37806106

egnalfdlewnopils"4xegnalf"4;tiKegnalFyaW-3 1 47806106

egnalfdlewnopils"5xegnalf"5;tiKegnalFyaW-3 1 57806106

Repair Parts

24 of 60

Page 25

This page has intentionally been left blank.

25 of 60

Page 26

Appendix A: Application Drawings

120 V (ac)

24 V (ac)

Class II

Transformer

RTC

Outdoor Sensor

(S3) 070

M

Z3

V2

Boiler Return

Sensor

(S1) 071

P1

M

Z1

P2

M

Z2

S2

4D Max

V1

C1

M1

A1. 3-way RTC in Primary/Secondary - Heating Only/No DHW; with/without Outdoor Reset (Mechanical)

C1 = Diverting Valve Actuator

M1 = By-Pass Mix Point

P1 = Boiler Circulator

P2 = System Pump (runs on call for heat)

S1 = Boiler Return Sensor

S2 = Mix Supply Sensor 071 (Required for Reset

or Set-point Control)

S3 = Outdoor Sensor 070 (Required for Reset

Control)

V1 = 3-Way Diverting Valve

V2 = Ball Valve, Balancing Valve

Z1...Z3 = Zones

NOTES:

1) Install the boiler as indicated above for systems where return temperatures may be less than 135F and heating

application only.

2) The Outdoor Sensor (S3) and the Mix Supply Sensor (S2) are required when the Outdoor Reset feature is selected. The

mix sensor must be installed 10 pipe diameters downstream of the system pump, in the primary loop. The mix sensor must be

secured to the surface of the pipe using a wire tie or similar device.

3) The by-pass piping, diverting valve and boiler circulator must be sized using the sizing charts found in Appendix B.

4) Closely spaced tees must connect the branch to the larger header. The Tee centerlines must be no greater than 4 times the

larger header pipe diameter.

5) The diverting valve, V1, must be no greater than 11 linear feet of pipe from the Return Sensor, S1.

6) There shall be a MINIMUM of 4 linear feet of pipe between the By-pass Mix Point, M1, and the Return Sensor, S1.

7) The balancing valve in the boiler return line, V2, may be necessary in low head by-pass loop applications.

8) Expansion tanks, air scoops and other components left out for clarity.

9) Observe all applicable plumbing and electrical codes.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design of the

system.

26 of 60

Page 27

A1. 3-way RTC in Primary/Secondary - Heating Only/No DHW; with/without Outdoor Reset (Electrical)

C

24 V (ac)

R

N

120 V (ac)

Class II

Transformer

L

S1

S2 S3

Do not apply power

10A

Boil

Ret

Com Mix OutCom

L

12 13 14 15 16

Boil

Pmp N

6

Burnham RTC

3 5

R

9

R

10

N

11

N

4

Power

10A

24 Volt Output

7 8

Boiler

Enable

1 2

Heat

Demand

P1

Boiler

C1

CW - Closed to System

C1

CW - Open to System

NL1 L1

Z1...Z3

R

9

R

10

N

11

24 Volt Output

NL1 L1

C1 = Mixing Valve Actuating Motor

P1 = Boiler Circulator

S1 = Boiler Return Sensor

S2 = Mix Supply Sensor 071

S3 = Outdoor Sensor 070

Z1...Z3 = Zone Valves, Zone Relays,

Thermostats or BMS Signal

NOTES:

1) Refer to the I&O to determine correct valve orientation and actuator wiring.

2) 120 VAC supplying the RTC should be separate from the burner/boiler circuit.

3) Heat demand can be any electrical signal consisting of 24 - 240 VAC.

4) Use isolation relays for circulators greater than 1/3 HP. Use motor starters for 3 phase circulators.

5) The Outdoor Sensor (S3) and the Mix Supply Sensor (S2) are required if the Outdoor Reset feature is selected.

6) System Pump (P2) to be operated by zone relay or other installer supplied device.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design of the

system.

27 of 60

Page 28

A2. 3-way RTC in Primary/Secondary - Heating and DHW using Tankless Coil; with/without Outdoor Reset

120 V (ac)

24 V (ac)

Class II

Transformer

RTC

Outdoor Sensor

(S3) 070

V2

Boiler Return

Sensor

(S1) 071

A1

P2

A1

COLD

Water

IN

HOT

Water

OUT

P1

M

Z3

M

Z1

P3

M

Z2

S2

4D Max

V1

C1

M1

R2

R1

ST1

(Mechanical)

A1 = Tankless Coil or Storage Tank Aquastat

C1 = Mixing Valve Actuating Motor

M1 = By-Pass Mix Point

P1 = Boiler Circulator

P2 = Tankless System Circulator

P3 = System Pump (runs on call for heat)

R1 = Relay (Required with and without priority)

R2 = Relay (Required for Priority)

S1 = Boiler Return Sensor

S2 = System Mix Sensor 071

S3 = Outdoor Sensor 070

ST1= Storage Tank

TK1= Tankless Coil

V1 = 3-Way Diverting Valve

V2 = Ball Valve, Balancing Valve

Z1...Z3 = Zones

NOTES:

1) Install the boiler as indicated above for systems where return temperatures may be less than 135F and heating/DHW

with tankless coils..

2) The Outdoor Sensor (S3) and the Mix Supply Sensor (S2) are required when the Outdoor Reset feature is selected.

The mix sensor must be installed 10 pipe diameters downstream of the system pump, in the primary loop. The mix sensor

must be secured to the surface of the pipe using a wire tie or similar device.

3) The by-pass piping, diverting valve and boiler circulator must be sized using the sizing charts found in Appendix B.

4) Closely spaced tees must connect the branch to the larger header. The Tee centerlines must be no greater than 4

times the larger header pipe diameter.

5) The diverting valve, V1, must be no greater than 11 linear feet of pipe from the Return Sensor, S1.

6) There shall be a MINIMUM of 4 linear feet of pipe between the By-pass Mix Point, M1, and the Return Sensor, S1.

7) The balancing valve in the boiler return line, V2, may be necessary in low head by-pass loop applications.

8) Domestic Hot Water must be tempered for safe usage. The tankless aquastat and/or storage tank aquastat (A1) are

normally closed switches. Circuit breaks on temperature rise.

9) Expansion tanks, air scoops and other components left out for clarity.

10) Observe all applicable plumbing and electrical codes.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design

of the system.

28 of 60

Page 29

C

24 V (ac)

R

N

120 V (ac)

Class II

Transformer

L

S1

S2 S3

Do not apply power

10A

Boil

Ret

Com Mix OutCom

L

12 13 14 15 16

Boil

Pmp N

6

Burnham RTC

3 5

R

9

R

10

N

11

N

4

Power

10A

24 Volt Output

7 8

Boiler

Enable

1 2

Heat

Demand

P1

Boiler

C1

CW - Closed to System

C1

CW - Open to System

NL1 L1

Z1...Z3

R

9

R

10

N

11

24 Volt Output

NL1 L1

2

1

8

7

3

4

5

6

S1

S2 S3

Do not apply power

10A

Boil

Ret

Com Mix OutCom

L

12 13 14 15 16

Boil

Pmp N

6

Burnham RTC

3 5

R

9

R

10

N

11

N

4

Power

10A

24 Volt Output

7 8

Boiler

Enable

1 2

Heat

Demand

P1

Boiler

C1

CW - Open to System

NL1 L1

Z1...Z3

R

9

R

10

N

11

24 Volt Output

NL1 L1

P2

A1

2

1

8

7

3

4

5

6

2

1

8

7

3

4

5

6

Breaks on

Temp. Rise

A1

Breaks on

Temp. Rise

P2

C1

CW - Close

to System

R1

R1

R2

A2. 3-way RTC in Primary/Secondary - Heating and DHW using Tankless Coil; with/without Outdoor Reset

(Electrical)

A1 = Tankless Coil or Storage Tank

Aquastat

C1 = Mixing Valve Actuating Motor

P1 = Boiler Circulator

P2 = Tankless Coil System Circulator

R1 = Relay (Required with and

without priority)

R2 = Relay (Required for priority)

S1 = Boiler Return Sensor

S2 = Mix Supply Sensor 071

S3 = Outdoor Sensor 070

Z1...Z3 = Zone Valves, Zone Relays,

Thermostats or BMS Signal

NOTES:

1) Refer to the I&O to determine correct valve orientation and actuator wiring.

2) 120 VAC supplying the RTC should be separate from the burner/boiler circuit.

3) Heat demand can be any electrical signal consisting of 24 - 240 VAC.

4) Use isolation relays for circulators greater than 1/3 HP. Use motor starters for 3 phase circulators.

5) The Outdoor Sensor (S3) and the Mix Supply Sensor (S2) are required if the Outdoor Reset feature is selected.

6) Connect the tankless aquastat (A1) if you are not using a storage tank. If you are using a storage tank with the tankless

heater, use the storage tank aquastat.

7) System Pump (P3) to be operated by zone relay or other installer supplied device.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design

of the system.

29 of 60

Page 30

A3. 3-way RTC in Primary/Secondary - Heating and DHW using Indirect Water Heater; with/without

120 V (ac)

24 V (ac)

Class II

Transformer

RTC

Outdoor Sensor

(S3) 070

M

Z3

V2

Boiler Return

Sensor

(S1) 071

P1

M

Z1

P3

M

Z2

S2

4D Max

V1

C1

M1

A1

P2

R1

R2

Indirect

DHW

Tank

Outdoor Reset (Mechanical)

A1 = Indirect Hot Water Aquastat

C1 = Diverting Valve Actuating Motor

M1 = By-Pass Mix Point

P1 = Boiler Circulator

P2 = Indirect Circulator

P3 = System Pump (runs on call for heat)

S1 = Boiler Return Sensor

S2 = Mix Supply Sensor 071 (Required for Reset

or Set-point Control)

S3 = Outdoor Sensor 070 (Required for Reset

Control)

V1 = 3-Way Diverting Valve

V2 = Ball Valve, Balancing Valve

Z1...Z3 = Zones

NOTES:

1) Install the boiler as indicated above for systems where return temperatures may be less than 135F and heating/DHW

with an indirect water heater.

2) The Outdoor Sensor (S3) and the Mix Supply Sensor (S2) are required when the Outdoor Reset feature is selected.

The mix sensor must be installed 10 pipe diameters downstream of the system pump, in the primary loop. The mix sensor

must be secured to the surface of the pipe using a wire tie or similar device.

3) The by-pass piping, diverting valve and boiler circulator must be sized using the sizing charts found in Appendix B.

4) Closely spaced tees must connect the branch to the larger header. The Tee centerlines must be no greater than 4

times the larger header pipe diameter.

5) The diverting valve, V1, must be no greater than 11 linear feet of pipe from the Return Sensor, S1.

6) There shall be a MINIMUM of 4 linear feet of pipe between the By-pass Mix Point, M1, and the Return Sensor, S1.

7) The balancing valve in the boiler return line, V2, may be necessary in low head by-pass loop applications.

8) The indirect heater aquastat (A1) is a normally closed switch. Circuit breaks on temperature rise.

9) Expansion tanks, air scoops and other components left out for clarity.

10) Observe all applicable plumbing and electrical codes.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design

of the system.

30 of 60

Page 31

A3. 3-way RTC in Primary/Secondary - Heating and DHW using Indirect Water Heater; with/without

C

24 V (ac)

R

N

120 V (ac)

Class II

Transformer

L

S1

S2 S3

Do not apply power

10A

Boil

Ret

Com Mix OutCom

L

12 13 14 15 16

Boil

Pmp N

6

Burnham RTC

3 5

R

9

R

10

N

11

N

4

Power

10A

24 Volt Output

7 8

Boiler

Enable

1 2

Heat

Demand

P1

Boiler

C1

CW - Closed to System

C1

CW - Open to System

NL1 L1

Z1...Z3

R

9

R

10

N

11

24 Volt Output

NL1 L1

2

1

8

7

3

4

5

6

S1

S2 S3

Do not apply power

10A

Boil

Ret

Com Mix OutCom

L

12 13 14 15 16

Boil

Pmp N

6

Burnham RTC

3 5

R

9

R

10

N

11

N

4

Power

10A

24 Volt Output

7 8

Boiler

Enable

1 2

Heat

Demand

P1

Boiler

C1

CW - Open to System

NL1 L1

Z1...Z3

R

9

R

10

N

11

24 Volt Output

NL1 L1

P2

A1

2

1

8

7

3

4

5

6

2

1

8

7

3

4

5

6

Breaks on

Temp. Rise

A1

Breaks on

Temp. Rise

P2

C1

CW - Close

to System

R1

R1

R2

Outdoor Reset (Mechanical)

A1 = Indirect Hot Water Aquastat

C1 = Mixing Valve Actuating Motor

P1 = Boiler Circulator

P2 = Indirect Circulator

R1 = Relay (Required with and

without priority)

R2 = Relay (Required for priority)

S1 = Boiler Return Sensor

S2 = Mix Supply Sensor 071

S3 = Outdoor Sensor 070

Z1...Z3 = Zone Valves, Zone Relays,

Thermostats or BMS Signal

NOTES:

1) Refer to the I&O to determine correct valve orientation and actuator wiring.

2) 120 VAC supplying the RTC should be separate from the burner/boiler circuit.

3) Heat demand can be any electrical signal consisting of 24 - 240 VAC.

4) Use isolation relays for circulators greater than 1/3 HP. Use motor starters for 3 phase circulators.

5) The Outdoor Sensor (S3) and the Mix Supply Sensor (S2) are required if the Outdoor Reset feature is selected.

6) System Pump (P3) to be operated by zone relay or other installer supplied device.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design

of the system.

31 of 60

Page 32

A4. 3-way RTC in Primary/Secondary - Heating and DHW using Indirect Water Heater on Primary Loop;

120 V (ac)

24 V (ac)

Class II

Transformer

RTC

V2

Boiler Return

Sensor

(S1) 071

P1

M

Z1

P3

M

Z2

4D Max

V1

C1

M1

A1

P2

R1

Indirect

DHW

Tank

V3

without Outdoor Reset (Mechanical)

A1 = Indirect Hot Water Aquastat

C1 = Diverting Valve Actuating Motor

M1 = By-Pass Mix Point

P1 = Boiler Circulator

P2 = Indirect Circulator

P3 = System Pump (runs on call for heat)

R1 = Relay

S1 = Boiler Return Sensor

V1 = 3-Way Diverting Valve

V2 = Ball Valve, Balancing Valve

V3 = Ball Valve, System Balancing

Z1...Z3 = Zones

NOTES:

1) Install the boiler as indicated above for systems where return temperatures may be less than 135F and heating/DHW

with an indirect water heater.

2) This arrangement is NOT recommended for outdoor reset applications. The reset temperature will constantly change

DHW water performance.

3) The by-pass piping, diverting valve and boiler circulator must be sized using the sizing charts found in Appendix B.

4) A domestic hot water priority could be used provided the diversion from the heating system loop does not impact the

system heater’s performance.

5) Closely spaced tees must connect the branch to the larger header. The Tee centerlines must be no greater than 4

times the larger header pipe diameter.

6) The diverting valve, V1, must be no greater than 11 linear feet of pipe from the Return Sensor, S1.

7) There shall be a MINIMUM of 4 linear feet of pipe between the By-pass Mix Point, M1, and the Return Sensor, S1.

8) The balancing valve in the boiler return line, V2, may be necessary in low head by-pass loop applications.

9) The indirect heater aquastat (A1) is a normally closed switch. Circuit breaks on temperature rise.

10) Expansion tanks, air scoops and other components left out for clarity.

11) Observe all applicable plumbing and electrical codes.

This diagram is for reference only. The installer or designer is responsible for the proper selection and design

of the system.

32 of 60

Page 33

A4. 3-way RTC in Primary/Secondary - Heating and DHW using Indirect Water Heater on Primary Loop;

C

24 V (ac)

R

N

120 V (ac)

Class II

Transformer

L

S1

Do not apply power

10A

Boil

Ret

Com Mix OutCom

L

12 13 14 15 16

Boil

Pmp N

6

Burnham RTC

3 5

R

9

R

10

N

11

N

4

Power

10A

24 Volt Output

7 8

Boiler

Enable

1 2

Heat

Demand

P1

Boiler

C1

CW - Closed to System

C1

CW - Open to System

NL1 L1

Z1...Z3

R

9

R

10

N

11

24 Volt Output

NL1 L1

2

1

8

7

3

4

5

6

P2

A1

Breaks on

Temp. Rise

R1

without Outdoor Reset (Electrical)

A1 = Indirect Hot Water Aquastat

C1 = Mixing Valve Actuating Motor

P1 = Boiler Circulator

P2 = Indirect Circulator

R1 = Relay

S1 = Boiler Return Sensor

Z1...Z3 = Zone Valves, Zone Relays,

Thermostats or BMS Signal

NOTES:

1) Refer to the I&O to determine correct valve orientation and actuator wiring.

2) 120 VAC supplying the RTC should be separate from the burner/boiler circuit.

3) Heat demand can be any electrical signal consisting of 24 - 240 VAC.

4) Use isolation relays for circulators greater than 1/3 HP. Use motor starters for 3 phase circulators.

5) System Pump (P3) to be operated by zone relay or other installer supplied device.