Page 1

INSTALLATION, OPERATING

AND

SERVICE INSTRUCTIONS

PRICE

-

$3.00

PF-5

SERIES

CAST IRON

HYDRONIC

HEATING UNIT

FORCED DRAFT

FOR

LIGHT OIL,

GASILIGHT OIL,

OR GAS

HOT

WATER

OR

STEAM

18

SIZES:

GROSS

3,430,000

For service & repairs to the heating plant, call your heating contractor. When seeking information on the boiler, provide

series and size designation shown on the rating plate.

Type

Boiler Number

Heating Contractor

Address

Form

8142501

.

No. 52009N-8194-1725f

AMERICA'S BOILER COMPANY

Firing Type System

Phone No.

Burnham Corporation

Lancaster,

PA

1

7604-3079

OUTPUT-

620,000

to

BTU/HR

Page 2

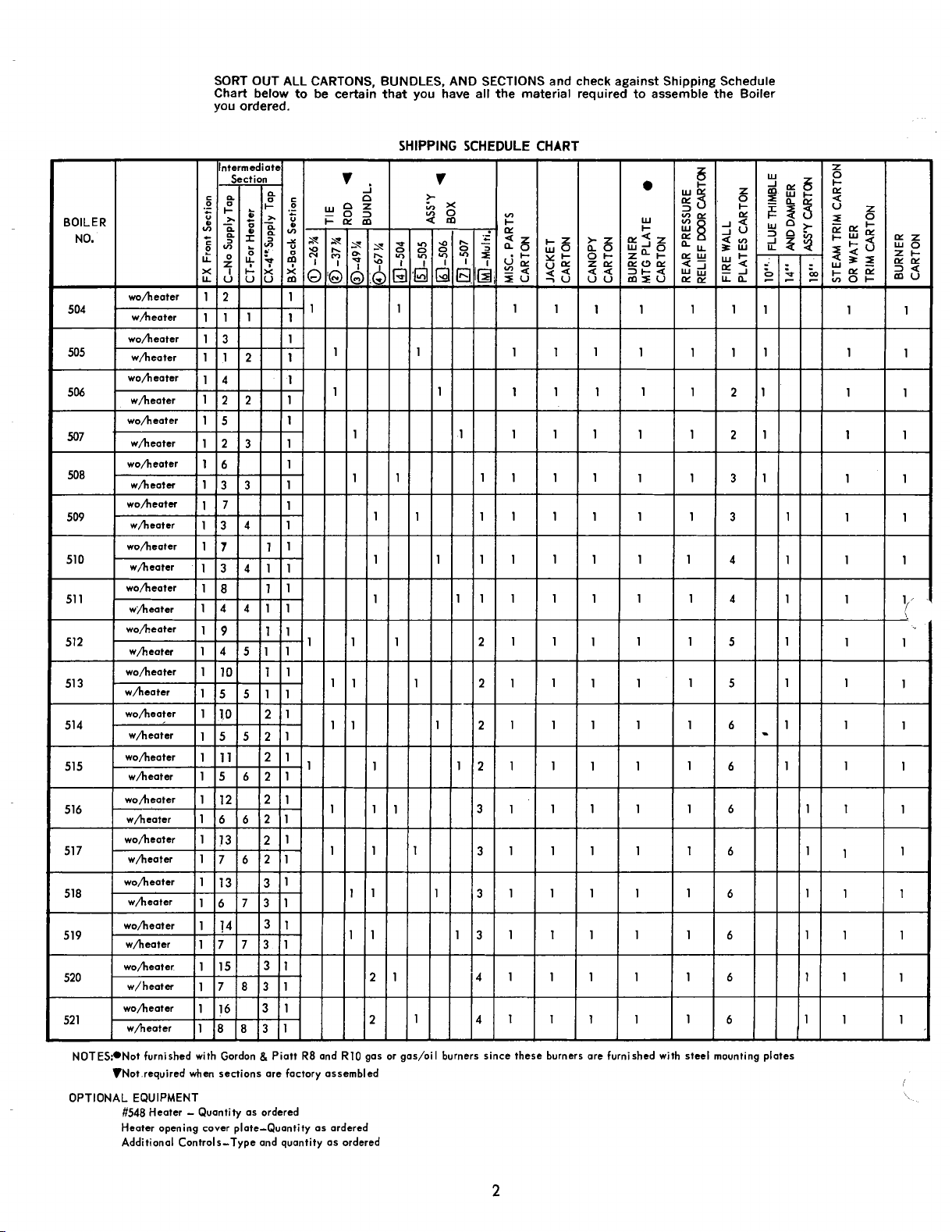

SORT OUT ALL CARTONS, BUNDLES, AND SECTIONS and check against Shipping Schedule

Chart below

you ordered.

to

be certain that you have all the material required to assemble the Boiler

SHIPPING SCHEDULE CHART

NOTES:*Not furnished with Gordon & Piatt

VNot.required when sections are factory assembled

OPTIONAL EQUIPMENT

#548

Heater - Quantity as ordered

Heater opening cover plate-Quantity as ardered

Additional Controls-Type and quantity as ordered

R8

and

R10

gas or gas/oiI burners since these burners are furnished with steel mounting plates

Page 3

IMPORTANT INFORMATION

PLEASE READ THIS PAGE CAREFULLY

1.

READ THIS MANUAL AND BURNER INSTALLATION MANUAL CAREFULLY BEFORE INSTALL

ING, OPERATING, OR SEBVICING THIS UNIT.

TO BURNHAM AND ASK FOR FORM NO.

2.

ALL BOILERS MUST BE INSTALLED IN ACCORDANCE WITH NATIONAL, STATE AND LOCAL

PLUMBING, HEATING AND ELECTRICAL C0DE.S AND THE REGULATIONS OF THE SERVING

UTILITIES.

ALL HEATING SYSTEMS SHOULD BE DESIGNED BY COMPETENT CONTRACTORS AND ONLY

3.

PERSONS KNOWLEDGEABLE IN THE LAYOUT AND INSTALLATION

SYSTEMS SHOULD ATTEMPT INSTALLATION OF ANY BOILER.

4.

THE BOILER MUST BE PROPERLY VENTED IN ACCORDANCE WITH NATIONAL FUEL GAS

CODE AND LOCAL CODES. SERIOUS PROPERTY DAMAGE

NOT PROPERLY VENTED.

5.

READ THE LITERATURE ENCLOSED BY THE MANUFACTURER WITH THE VARIOUS ACCESS-,

ORY DEVICES. THESE ACCESSORY DEVICES MUST BE INSTALLED AND USED ACCORDING TO

/

\

THE RECOMMENDATIONS OF THE MANUFACTURER.

6.

IT IS THE RESPONSIBILITY OF THE INSTALLING CONTRACTOR TO SEE THAT ALL CONTROLS

ARE CORRECTLY INSTALLED AND ARE OPERATING PROPERLY WHEN THE INSTALLATION

COMPLETED.

52003

IF

YOU DO NOT HAVE A BURNER MANUAL, WRITE

(Part

#814502).

0 F HYDRONIC HEATING

COULD RESULT IF THE BOILER

IS

IS

7.

FOR OPTIMUM PERFORMANCE FROM THIS UNIT SEIRVECE AS SPE(C1FIED IN SECTION V OF

THIS MANUAL.

8.

IN ALL CASES, CLEARANCES BETWEEN BOILER AND/OR SMOKE PIPE SURFACES AND COMBUSTIBLE MATERIALS MUST COMPLY WITH NATIONAL FUEL GAS CODE ANSI

DATED

ALL FLAMMABLE DEBRIS, RAGS, PAPER, WOOD SCRAPS, ETC., SHOULD BE KEPT CLEAR OF

9.

THE BOILER AT ALL TIMES. KEEP THE BOILER AREA CLEAN AND FREE OF FIRE HAZARDS.

10.

PROBE AND FLOAT TYPE LOW WATER CUTOFF DEVICES REQUIRE ANNUAL INSPBCTION AND

MAINTENANCE. REFER TO SECTION V ITEM

ING INSTRUCTIONS.

HIGH WATER TEMPERATURES INCREASE THE RISK OF BURNS OR SCALDING INJURY. INSTALL

AUTOM-4TIC MIXING VALVE AT THE TANKLESS HEATER OUTLET TO AVOID EXCESSIVELY HOT

WATER AT THE FIXWRES AS SHOWN IN FIGURE

1988

OR CURRENT EDITION AND, FOR OIL, NFPA

@

26.

211.

FOR STEP BY STEP INSPECTION AND CLEAN-

2223.1

(NFPA

54)

AN

Page 4

TABLE OF CONTENTS

.

SECTION I

Ratings . Data

Setting the Unit

Air Supply/Venting

.SECTION TI . CAST IRON BLOCK ASSEMBLY

GENERAL INFORMATION

................................................................................................................................................

.............................................................................................................................................

....................................................................................................................................

6

7

7

..

Assembly of Sections, Manual Draw-up

Assembly of Sections. Hydraulic Draw-up

Hydrostatic Test

SECTION I11 . INSTALLATION INSTRIJCTIONS

Flue Cover Plates

Pressure Relief Door

Firewall Plates

Burner Mounting Plate

Canopy

Boiler Piping

Jacket Assembly

Tankless Heater Piping

Steam Trim

Water Trim

Burner Installation

SECTION IV . OPERATING INSTRUCTIONS

Filling System

Adjusting Controls

Adjusting Burner

Testing Controls

Initial Cleaning, Steam Boilers

Initial Cleaning, Water Boilers

Boiler Water Treatment

pH or Alkalinity Test

Warnings about Frequent Water Addition

............................................................................................................................................................

............................................................................................................................................

.........................................................................................................................................

.....................................................................................................................................

...............................................................................................................................................

.................................................................................................................................

...............................................................................................................................................

............................................................................................................................................

.................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

......................................................................................................................................

................................................................................................................................................

........................................................................................................................................

..........................................................................................................................................

............................................................................................................................................

................................................................................................................

.....................................................................................................................

... ; ...........................................................................................................................

....................................................................................................................................

.....................................................................................................

.................................................................................................

................................................................................................

9

13

14

15

15

15

15

16

18

22

24

24

28

28

29

29

29

29

29-31

31

31

32

32

SECTION V . SERVICE INSTRUCTIONS

Cleaning Boiler Heating Surfaces

Maintenance of Low Water Cutoff Devices

Checking Burner & Controls

Lubrication

General Maintenance Considerations

Attention to Boiler while not in Operation

.SECTION VI . REPAIR PARTS

Regional Office Directory

Bare Boiler Assembly

Steam/Water Trim

Jacket Assembly

....................................................................................................................................................

.............................................................................................................................

..............................................................................................................................

......................................................................................................................................

......................................................................................................................................

................................................................................................................

.........................................................................................................................

33

.............................................................................................

.........................................................................................................

..................................................................................................

33

34

35

35

35

35

36-38

3.

40-41

9

.

Page 5

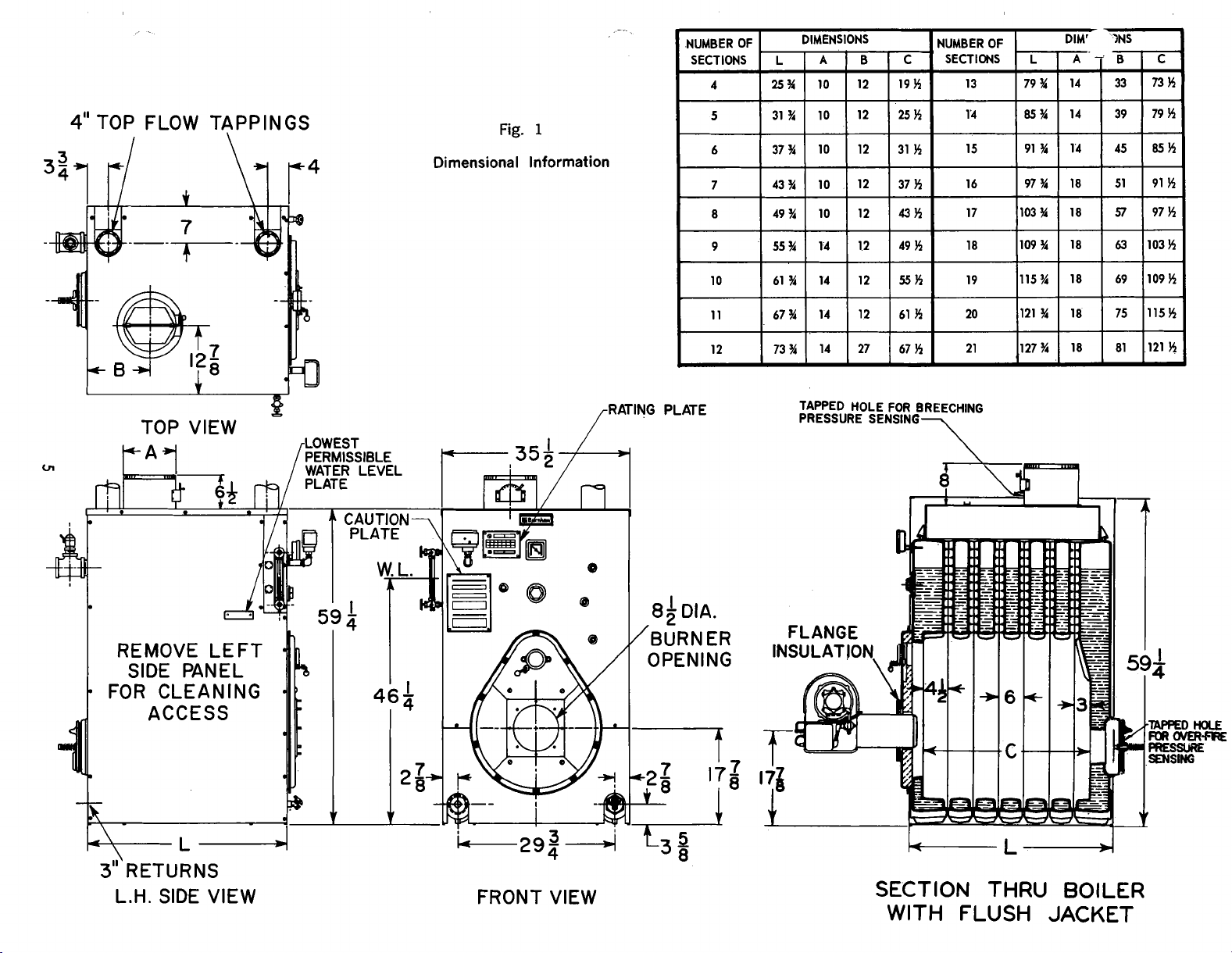

4"

TOP FLOW TAPPINGS

Fig.

1

Dimensional Information

TOP VlEW

REMOVE LEFT

SlDE PANEL

FOR CLEANING

ACCESS

4

YL

3

RETURNS

L.H.

SlDE VlEW

$2

WATER LEVEL

I

L29:

FRONT VlEW

4

8h

DIA.

'BURNER

OPENING

TAPPED HOLE FOR BREECHING

PRESSURE SENSING

SECTION THRU BOILER

WITH FLUSH

JACKET

Page 6

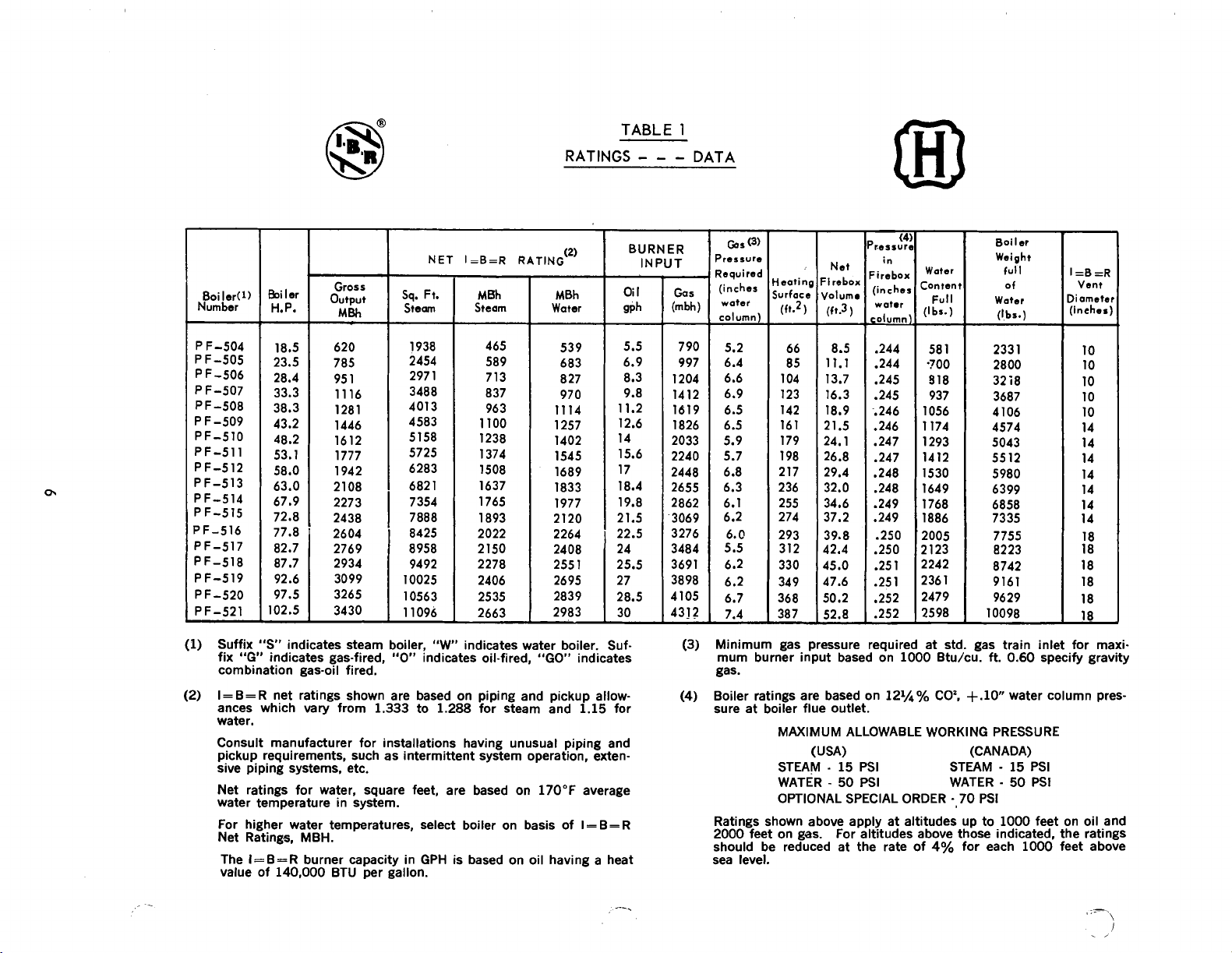

TABLE

RATINGS

-

- -

1

DATA

NET I=B=R RATING

Boiler(1)

Number

5iler

H.P.

Gross

output

-

MBh

sq.

Steam

Ft.

Bh

M

Steam

Water

620

785

1

95

16

11

1281

1446

1612

1777

1942

2108

2273

2438

2604

2769

2934

3099

3265

3430

Suffix "S" indicates steam boiler,

(1)

(2)

"G"

fix

combination gas-oil fired.

I=B=R net ratings shown are based on piping and pickup allowances which vary from

water.

Consult manufacturer for installations having unusual piping and

pickup requirements, such as intermittent system operation, extensive piping systems, etc.

Net ratings for water, square feet, are based on

water temperature in system.

For higher water temperatures, select boiler on basis of

Net Ratings, MBH.

The I=B=R burner capacity in GPH is based on oil having a heat

value of

indicates gas-fired,

1.333

140,000

BTU per gallon.

"W

"0"

to

indicates water boiler. Suf-

indicates oil-fired, "GO" indicates

1.288

for steam and

170°F

(2)

MBh

1.15

for

average

I

=

B= R

BURNER

INPUT

-

Gas

(mbh)

-

1204

1412

1619

I826

2033

2240

2448

2655

2862

3069

3276

3484

3691

3898

4105

4312

-

-

Boil

Gas

(3)

'ressure

?equired

(inches

watet

column)

790

5.2

6.4

997

6.6

6.9

6.5

6.5

5.9

5.7

6.8

6.3

6.1

6.2

6.0

5.5

6.2

6.2

6.7

7.4

-

Minimum gas pressure required at std. gas train inlet for maxi-

(3)

mum burner input based on

gas.

Boiler ratings are based on

(4)

sure at boiler flue outlet.

MAXIMUM ALLOWABLE WORKING PRESSURE

STEAM

WATER

OPTIONAL SPECIAL ORDER

Ratings shown above apply at altitudes up to

2000

feet on gas. For altitudes above those indicated, the ratings

should be reduced at the rate of

sea level.

Net

:irebo:

4olum1

(ft.3

8.5

11.1

13.7

16.3

18.9

21.5

24.1

26.8

29.4

32.0

34.6

37.2

39.8

42.4

45.0

47.6

50.2

52.8

-

(USA)

-

-

Water

Eonten

)

(I

-

Full

br.)

58

-700

918

937

1056

1174

1293

1412

1530

1649

I768

1886

2005

2

123

2242

236

2479

2598

1000

Btu/cu. ft.

121/q%

15

PSI STEAM

50

PSI

COZ,

4%

1

1

+.lo

(CANADA)

WATER

-

70

for each

er

Weight

full

of

Water

(1,bs.)

233

1

2800

32i8

3687

4106

4574

5043

5512

5980

6399

6858

7335

7755

8223

8742

9161

9629

10098

0.60

specify gravity

water column pres-

-

15

PSI

-

50

PSI

PSI

1000

feet on oil and

1000

=B

=R

Vent

liarnetel

inehes]

feet above

Page 7

SECTION

I

-

GENERAL INFORMATION

(

CONTINUED

)

@

INSPECT SHIPMENT carefully for any signs

.

damage.

4.

ALL EQUIPMENT is carefully manufactured, inspect-

ed and packed. Our responsibility ceases upon delivery

of crated Boiler to the carrier in good condition.

B. ANY CLAIM'S for damage or shortage in shipment

must be filed immediately against the carrier by the

consignee. No claims for variances from, or shortage

in orders, will be allowed by the manufacturer unless

presented within sixty (60) days after receipt of

goods.

@

BOILER INSTALLATION - Must conform to the

authority having jurisdiction, or in the absence of such

-

:

-

1967 (Re-

Above or Top

-

6 Inches

requirements to

USA

-

Installation of oil burning equipment, AN'SIINFPA 31.

CANADA

Oil Fired Steam and Hot Water Boilers for 'Commercial

and Industrial use, ,CSA Standard B140.7.2

affirmed 1991)

MINIMUM INSTALLATION CLEARANCES TO COMBUSTIBLE MATERIAL:

-

Front

Sides

Rear

24 Inches

-

6 Inches Vent Connector Pipe - 18 Inches

-

6 Inches

of

IF BOILER

A

WATXR COWDIIIOR mIST8. A BOILER WUHDATIOR

ROW

PICOR IS WEAK

OR

UHEVEW

Fig.

OR

IF

2

VOTE:

Listed clearances comply with American National Standard ANSIINFPA 31, Installation of oil ,burning

equipment.

Listed clearances can not be reduced for alcove or

closet installations.

For reduced clearances to combustible material, protection must be provided as described in the above

31

ANSIINFPA

A. SERVICE 'CLEARANCE

er room so as to provide ease of venting and adequate

clearance for maintenance, serviceability, and installation of piping. Allow a minimum clearance of

at front and back of boiler for burner service and access to pressure relief

on each side of the unit for cleaning of flues and for

tankless water heater installation. 'Refer

for boiler dimensional data.

B. PROVIDE ADEQUATE FOUNDATION for the unit.

ON CARPETING. 'Boiler is suitable for installation

on combustible floors.

2. Floor construction should have adequate load bearing characteristics to bear the weight of the boiler

filled with water (see Table 1). A boiler foundation

similar to the one shown in Figure 2 is recommended if the boiler room floor is weak or uneven or if

a water condition exists.

standard.

-

Locate the unit in the boil-

door/flame observation port and

to

Figure

3

feet

1

TYPICAL ARRANGEMENT

FOR STUB VENT

Fig.

3

Page 8

@

PROVIDE AIR SUPPLY AND VENTILATION to

accomodate proper combustion.

A permanent opening or duct should be provided so that

4,000

the boiler input will not exceed

area.

@

CHIMNEY OR VENT

The PF-5 is designed for forced draft firing and may be

a

used with

conventional natural draft stack or a stub

Btuhlin of free

vent (see Figure

Draft controls are not normally required, although they

may be used on installations where a natural draft stack

is used or on multiple boiler installations with a common

stack. The boiler is provided with a breeching

which should be adjusted to maintain a slightly positidt

pressure in the vent connector box (up to

ing burner operation.

3).

See Table I for the proper vent size.

0.1"

W.C.) dur-

dampey-

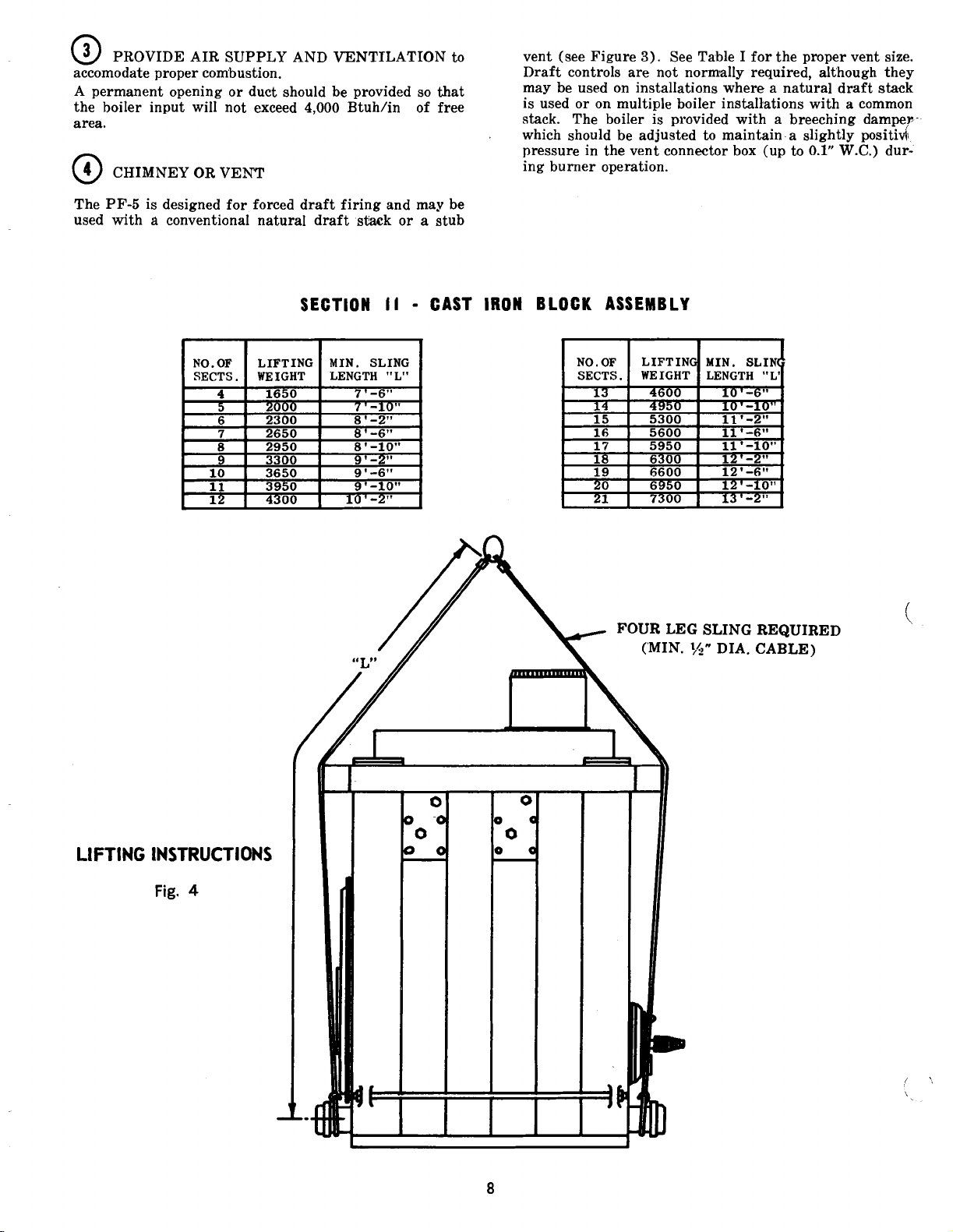

SECTION

II

-

CAST IRON BLOCK ASSEMBLY

FOUR LEG SLING

('MIN.

34"

DIA.

REQUIRED

CABLE)

LIFTING INSTRUCTIONS

Fig.

4

Page 9

@

FACTORY ASSEMBLED SECTIONS - The assemblage should be set in the proper location as outlined in

9ection

Figure

The tie-rod nuts should then be loosened until finger

tight. Now proceed to part

STATIC TEST".

@

sembly procedure outlined on the following pages.

A. Assembly of Sections (Manual Draw-Up)

DRAULIC DRAW-UP EQUIPMENT, NEVER

B'LE MORE THAN ONE SECTION AT A TIME.

(

I.

Lifting arrangement and weights are given in

4.

@

of this section "HYDRO-

FIELD ASSEMBLED SECTIONS - Follow the as-

WHEN ASSEMBLING 'SECTION'S WITHOUT HY-

ASSEM-

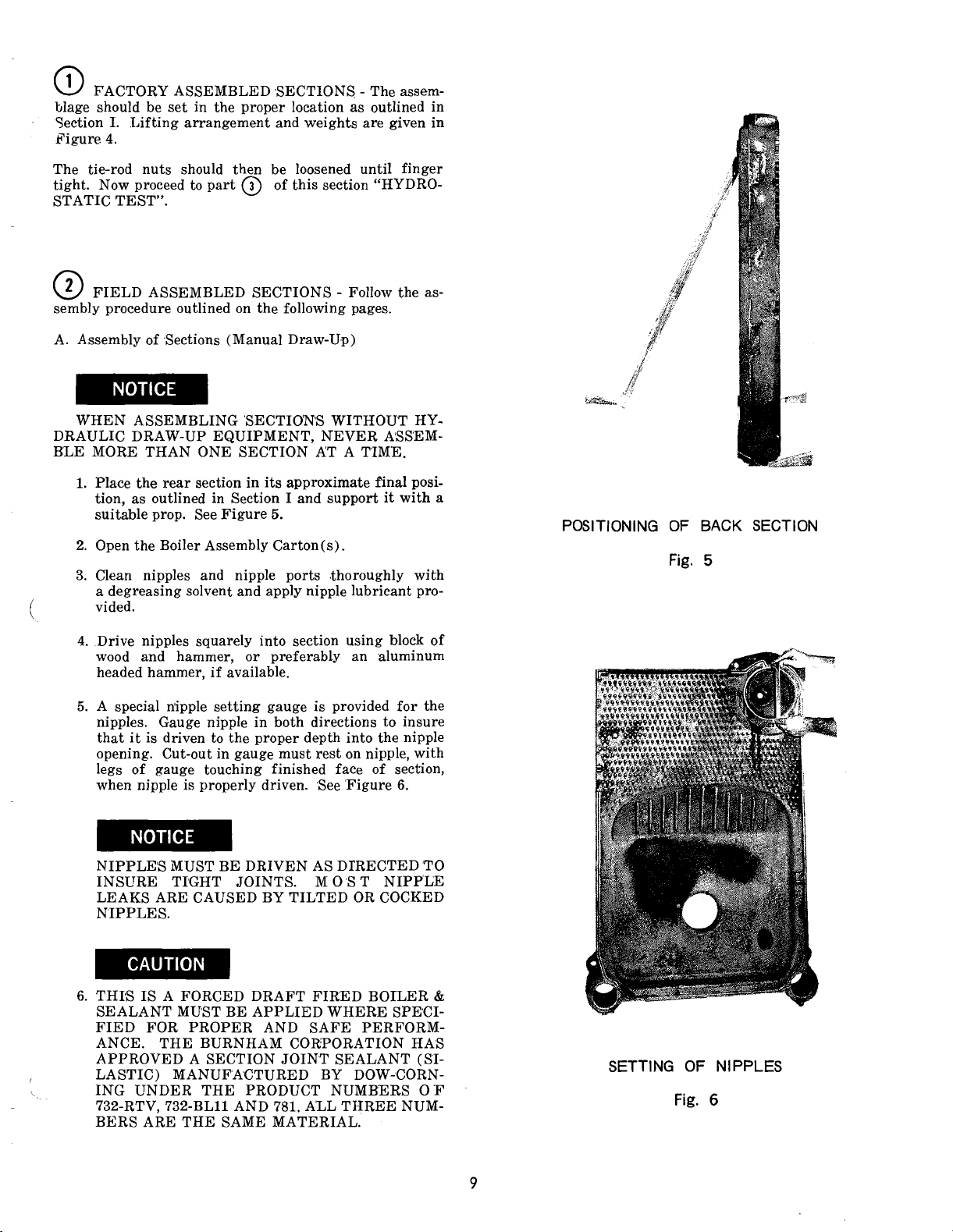

1.

Place the rear section in its approximate final position, as outlined in Section I and support it with a

suitable prop. See Figure

2.

Open the Boiler Assembly Carton(s)

3. Clean nipples and nipple ports ,thoroughly with

a degreasing solvent and apply nipple lubricant provided.

5.

.

POSITIONING OF BACK SECTION

Fig.

5

4.

Drive nipples squarely into section using block of

wood and hammer, or preferably an aluminum

headed hammer, if available.

5.

A special n'ipple setting gauge is provided for the

nipples. Gauge nipple in both directions to insure

that it is driven to the proper depth into the nipple

opening. Cut-out in gauge must rest on nipple, with

legs of gauge touching finished face of section,

when nipple is properly driven. See 'Figure

NIPPLE'S MUST BE DRIVEN AS DTRECTED'TO

INSURE TXHT JOINTS. M

LEAKS ARE CAUSED BY TILTED OR COCKED

NIPPLES.

6.

THIS IS A FORCED DRAFT FIRED BOILER

SEALANT MUST BE APPLIED WHERE SPECIFIED FOR PROPER AND SAFE PERFORMANCE. THE BURNHAM CORPORATION HAS

APPROVED A SECTION JOINT SEALANT

LASTIC) MANUFACTURED BY DOW-CORN-

\

ING UNDER THE PRODUCT NUMBERS OF

732-RTV, 732-BLll AND 781. ALL THREE NUMBERS ARE THE SAME MATERIAL.

0

B T NIPP'LE

6.

&

(SI-

SETTING OF NIPPLES

Fig.

6

Page 10

The grooves in the ground joint along the edge of

the section should be cleaned with a wire brush.

a

Then using

apply

'/a"

cartridge of sealant in a caulking gun,

bead of Silastic to one side of each joint.

to be mated. Touch up any missed spots before

draw-up. Touch-up after draw-up has no value. See

Figure

7.

SECTIONS MUST BE DRAWN-UP TIGHT

WTTHIN FOUR HOURS OF TWE TIME WHEN

STLASTIC I'S FIRST APPLIED. 'SILASTIC

CURES IN FOUR HOURS AND WILL NOT

FLOW INTO SEAL GROOVES AFTER FOUR

HOURS FROM APPLICATION, REGARDLESS

OF THE PRESSURE APPLI'ED.

7.

From arrangement of sections chart (see Figure

8)

select next section according to code letters on

section.

SECTIONS MUST BE ASSEMBLED IN PROPER

ORDER.

Clean .nipple ports and place section on nipples in

rear section. 'To facilitate assembly, it is advisable

to enter the upper nipple first in its port, then enter

the lower nipples in their respective ports.

Drive section in place with a heavy block of wood,

striking blows as squarely as

%"

Insert the three

draw-up rods through the nipple

possible over nipples.

ports in the intermediate section extending them

through the tapped holes in the rear section.

Place a 12" lg. steel channel on each end of the

upper draw-up rod and an

8%" lg. steel channel on

each end of the lower draw-up rods along with nuts

and washers. These items are all located in the

9

Draw-Up Kit. See Figures

and 10.

Be sure to apply the sealant to the groove in the

ground joints between adjacent sections as the boiler operates with a positive pressure ,in the fireboxf

and products of combustion will escape between

sections unless the sections are properly sealed. The

sealant should be applied before each section is phced on the assemblage.

I

AVOID DAMAGE TO THE DRAW ROD

THREADS WHILE DRAWING UP SECTIONS.

APPLY OIL OR GREASE FREELY 'TO TIE ROD

THREADS WHILE ASSEMBLING SECTIONS

TO PREVENT STRIPPING OF THREADS ON

ROD.

DRAW UP SECTION SLOWLY AND EVENLY,

tightening each draw-up rod a little at a time so

that sections are equally spaced, starting with

lower draw-up rods.

KEEP NIPPLES ALIGNED WITH NIPPLE

PORTS. If necessary, tap nipples lightly with a

blunt tool or rod to keep nipples from cocking while

sections are being drawn up. DO NOT DRAW UP

SECTION WHEN

NIPP-LES ARE COCKED. Continue tightening draw-up rods equally, periodically

bumping the section with the heavy block of wood

to relieve tensi'on on the draw-up rods, until sections meet iron-to-iron on the ground surfaces.

CONTINUE ASSEMBLING SECTIONS IN

THEIR RESPECTIVE ORDER. Be certain that

all sections are drawn up iron-to-iron at all three

nipple ports.

APPLICATION

Fig.

OF

7

SEALANT

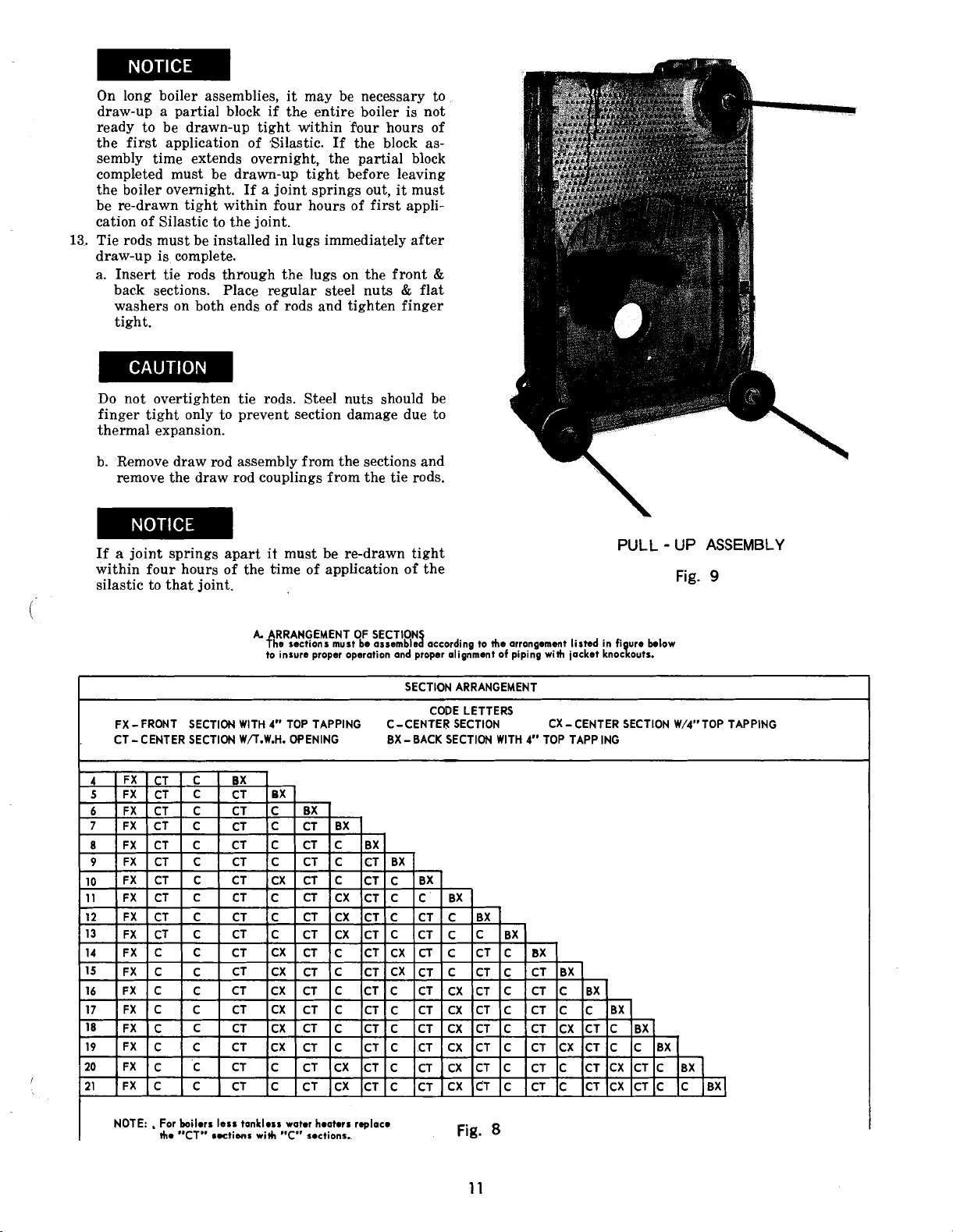

Page 11

On long boiler assemblies, it may be necessary to

draw-up a partial block if the entire boiler is not

ready to be drawn-up tight within four hours of

the first application of Silastic. If the block assembly time extends overnight, the partial block

completed must be drawn-up tight before leaving

the boiler overnight. If a joint springs out, it must

be re-drawn tight within four hours of first application of Silastic to the joint.

13.

Tie rods must be installed in lugs immediately after

draw-up is complete.

a. Insert tie rods through the lugs on the front

back sections. Place regular steel nuts & flat

washers on both ends of rods and tighten finger

tight.

Do not overtighten tie rods. Steel nuts should be

finger tight only to prevent section damage due to

thermal expansion.

b. Remove draw rod assembly from the sections and

remove the draw rod couplings from the tie rods.

&

i.

If

a

joint springs apart it must be re-drawn tight

within four hours of the time of application of the

silastic to that joint.

A

RRANGEMENT OF SECTION3

?he sections must be assemble according to the arronpemont listed in figure blow

to insure proper operation and proper alignment of pipiG with jacket knockouts.

--

FX-FRONT SECTION WITH 4'* TOP TAPPING C-CENTER SECTION CX

CT

-

r

CENTER SECTION W/T.W.H. OPENING

--

SECTION ARRANGEMENT

CODE LETTERS

BX - BACK SECTION WITH

-

CENTER SECTION W/4"TOP TAPPING

4"

TOP TAPP ING

PULL - UP ASSEMBLY

Fig.

9

NOTE: . For boilers less tmklns water hooters replace

I

the

"CT"

~utions with p'~s* sections..

Fig.

8

Page 12

CHANNEL BLOCK IN POSITION

Fig.

10

SECTION ASSEMBLEDGE

Fig.

11

Page 13

14.

Excess length of tie rods must be sawed off so they

will not extend beyond end sections. Rods should

project equally

the jacket.

See Figure

blage. Illustration shows boiler equipped with sections for built-in water heater.

B. Assembly of Sections (Hydraulic Draw-Up)

The entire assemblage may be drawn up at one time

using hydraulic draw-up equipment providing the

eration is completed within four hours after application of the sealant.

"Hydraulic Draw-Up Equipment" is available through

Burnham by ordering part number

1.

Repeat steps 1 through 9 under "Assembly of Sec-

tions (Manual Draw-Up)

2.

Continue driving sections in place (in their respective order) until all sections are in the assemblage.

Ground surfaces between adjoining sections should

be spaced

%"

will limit number of sections that can be drawn

up in one unit and could indicate cocked nipples.

Be sure to apply the sealant to the groove in the

ground joints between adjacent sections as the boiler operates with a positive pressure

and products of combustion will escape between

sections unless the secti'ons are properly sealed. The

sealant should be applied before each section is

placed on the assemblage.

On long boiler assemblies, it may be necessary to

draw-up a partial block if the entire boiler is not

ready to be drawn-up tight within four hours of

the first application of Silastic.

sembly time extends overnight, the partial block

completed must be drawn-up tight before leaving

the boiler overnight. If a joint springs out, it must

be re-drawn tight within four hours of first application of Silastic to the joint.

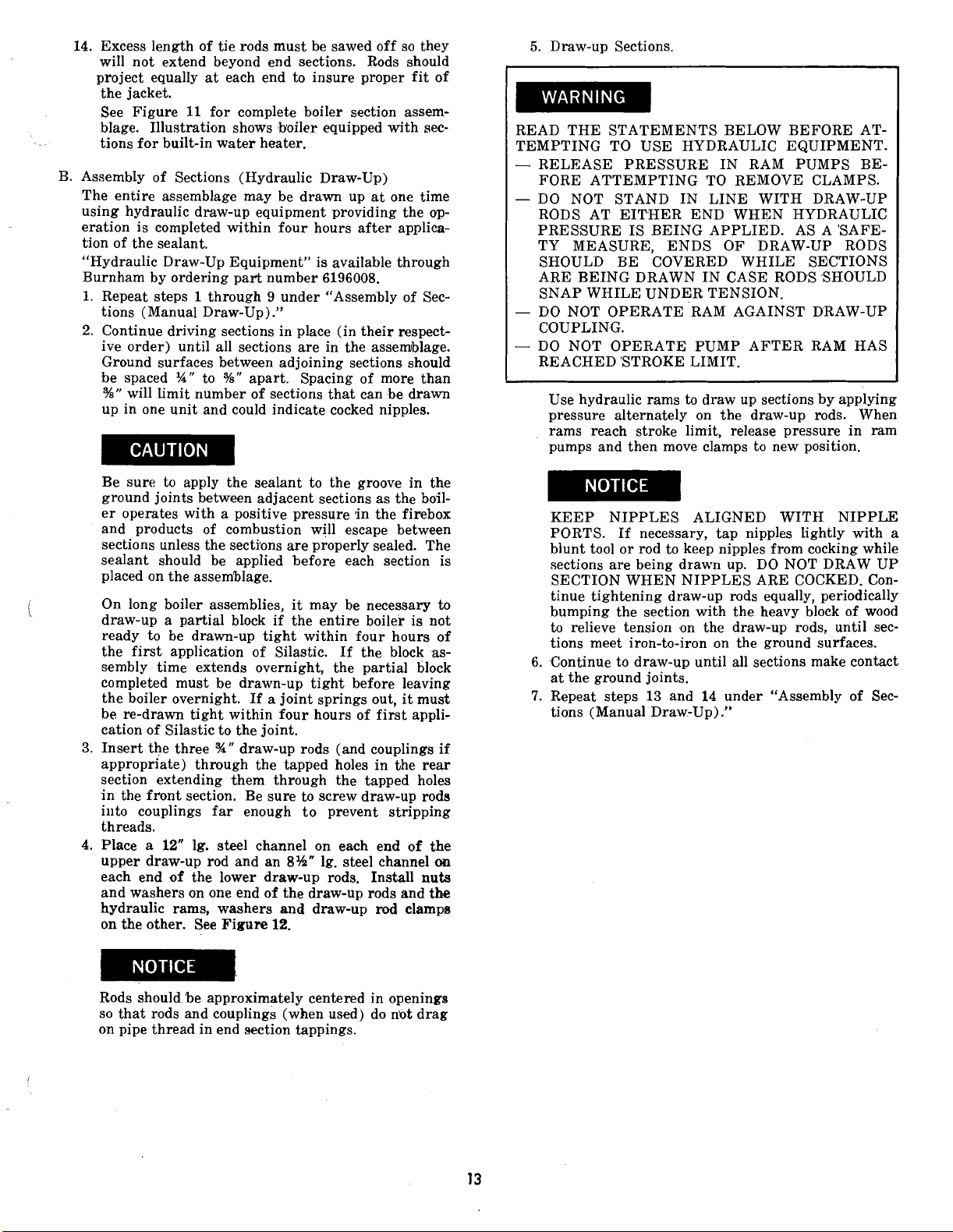

3.

Insert the three

appropriate) through the tapped holes in the rear

section extending them through the tapped holes

in the front section. Be sure to screw draw-up rods

illto couplings far enough to prevent stripping

threads.

4.

Place a

upper draw-up rod and an

each end of the lower draw-up rods.

and washers on one end of the draw-up rods and

hydraulic rams, washers

on the other. See Figure

at

each end to insure proper fit of

11

for complete boiler section assem-

6196008.

."

%"

to

%"

apart.

%"

draw-up rods (and couplings if

12"

lg. steel channel on each end of the

Spacing of more than

'in the firebox

If the block as-

8%"

lg. steel channel

Install

and

draw-up

rod

12.

op-

on

nuts

the

elampe

5.

Draw-up Sections.

READ THE STATEMENTS BELOW BEFORE ATTEMPTING TO USE HYDRAULIC EQUIPMENT.

-

RELEASE PRESSURE IN RAM PUMPS BEFORE ATTEMPTING TO REMOVE CLAMPS.

-

DO NOT STAND IN LINE WITH DRAW-UP

RODS AT EITHER END WHEN HYDRAULIC

PRESSURE IS BEING APPLIED.

TY MEASURE, ENDS OF DRAW-UP RODS

SHOULD BE COVERED WHILE SECTIONS

ARE BEING DRAWN IN CASE RODS SHOULD

SNAP WHILE UNDER TENSION.

-

DO NOT OPERATE RAM AGAINST DRAW-UP

COUPLING.

-

DO NOT OPERATE PUMP AFTER RAM HAS

REACHED 'STROKE LIMIT.

Use hydraulic rams to draw up sections by applying

pressure alternately on the draw-up rods. When

rams reach stroke limit, release pressure in ram

pumps and then move clamps to new position.

KEEP NIPPLES ALIGNED WITH NIPPLE

PORTS. If necessary, tap nipples tightly with a

blunt tool or rod to keep nipples from cocking while

sections are being

SECTION WHEN NIPPLES ARE COCKED. Continue tightening draw-up rods equally, periodically

bumping the section with the heavy block of wood

to relieve tension .on the draw-up rods, until sections meet iron-to-iron on the ground surfaces.

6.

.Continue to draw-up until all sections make contact

at the ground joints.

7.

Repeat steps

tions (Manual Draw-Up)

drawn up. DO NOT DRAW UP

13

and

14

under "Assembly of Sec-

."

AS A 'SAFE-

Rods should be approximately centered in openings

so that rods and couplings (when used) do njot drag

on pipe thread in end section tappings.

Page 14

:L

CHANNEL BLOCK

7

BLOCK

HYDRAULIC DRAW-UP

Fig.

@

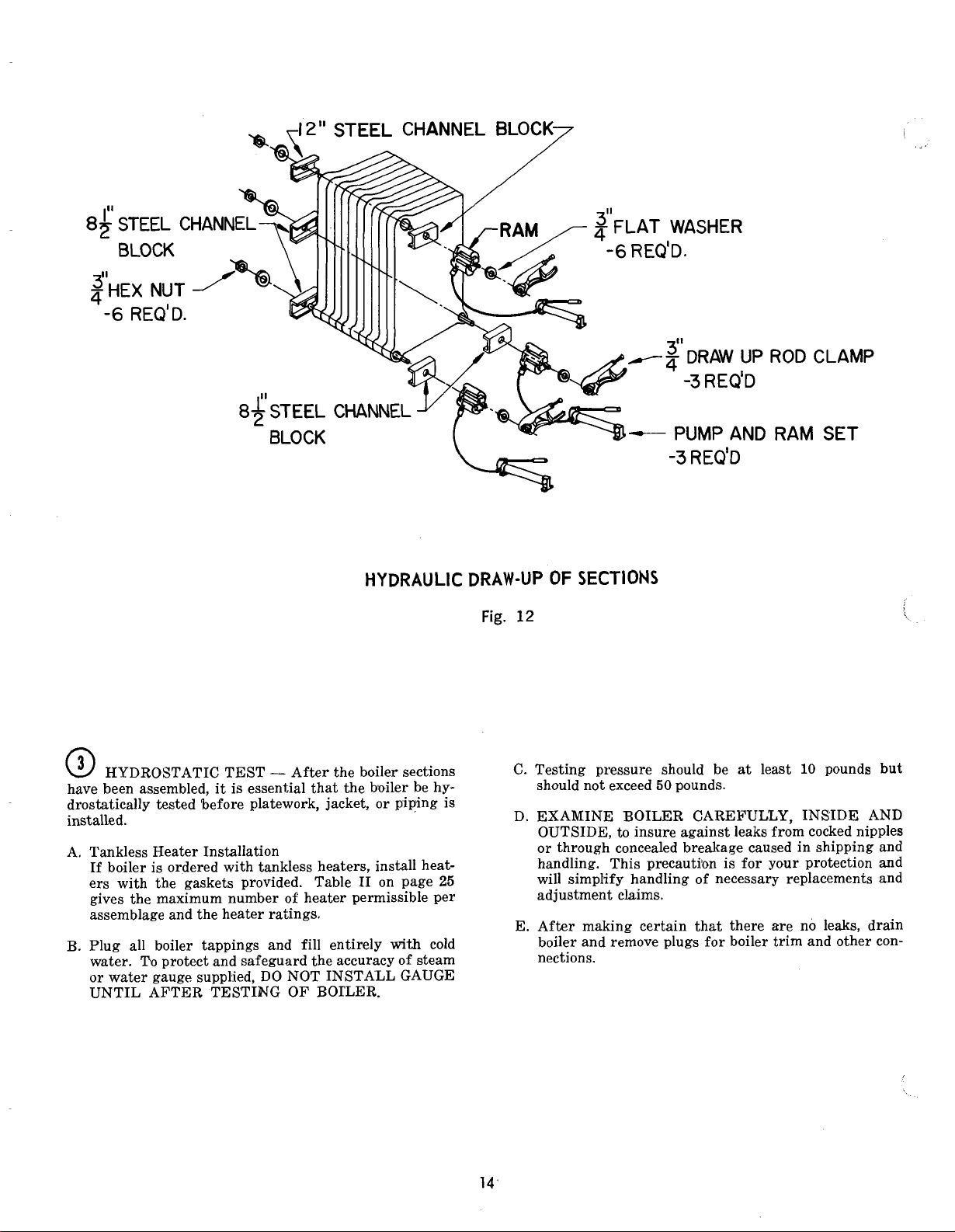

HYDROSTATIC TEST - After the boiler sections

have been assembled, it is essential that the boiler be hydrostatically tested before platework, jacket, or piping is

installed. D.

Tankless Heater Installation

If boiler is ordered with tankless heaters, install heaters with the gaskets provided. Table

gives the maximum number of heater permissible per

assemblage and the heater ratings.

Plug all boiler tappings and fill entirely

water. To protect and safeguard the accuracy of steam

or water gauge supplied, DO NOT INSTALL GAUGE

UNTIL AFTER TESTING OF BOILER.

I1

on page

with

25

cold

C. Testing pressure should be

E.

3''

--q

-

-

OF

SECTIONS

12

should not exceed

EXAMINE BOILER CAREFULLY, INSIDE AND

OUTSIDE, to insure against leaks from cocked nipples

or through concealed breakage caused in shipping and

handling. This precauti'on is for your protection and

will simplify handling of necessary replacements and

adjustment claims.

After making certain that there

boiler and remove plugs for boiler trim and other con-

nections.

DRAW UP

-3

REQ'D

PUMP AND

PUMP AND

50

pounds.

ROD CLAMP

RAM

at

least

are no leaks, drain

SET

10

pounds but

Page 15

SECTION

a

INSTALL FLUE COVER PLATES over cleanout

openings 'on left side of boiler as shown in Figure 13.

A. Locate the cover plates, carriage bolts, nuts and wash-

ers in the miscellaneous parts carton.

11

I

-

INSTALLATION INSTRUCTIONS

CLEANOUT COVER

7

r

COVER GASKET

B. Attach the carriage bolts to the top and bottom of the

flue openings with washers and hex nuts to provide a

fixed stud.

C.

Install flue cover plates & gaskets over studs and secure

with washers and nuts.

@

MOUNT PRESSURE RELIEF DOOR

A. Apply a

inside face of the pressure relief door.

B. Mount the pressure relief door onto the rear section

(with the word "Top" in the upright position) using

the (4) -&"-18 x

aneous parts carton.

side of the center sections. The plates should be 'installed

toward the front of the boiler.

IMPORTANT

BUSTION CHAMB.ER.

%"

bead of Silastic along the groove on the

1"

cap screws located in the miscell-

Install the refractory firewall plates on the right

See Figure 14.

-

THIS BOILER REQUIRE'S NO COM-

INSULATION

CLEANOUT NU

AND WASHER

TOP VIEW

CLEANOUT COVER ASSEMBLY

Fig.

13

@

MOUNT BURNER MOUNTING PLATE

A. Cast iron burner mounting plate. Install (10)

long studs with the short length of threads into the

boiler front section. Apply a bead of sealant around

the periphery of the cast iron burner plate and secure

to front section with

B. Cast iron burner mounting plate with adapter plate

(R-6 Burner Only). The adapter plate is furnished by

Gordon-Piatt and

the cast iron burner mounting plate as stated in (A)

above. Mount the adapter plate to the mounting plate

(8)

%"

with

and gasket provided. The R6 burner can now be secured to (4) studs on adapter plate using

nuts and washers.

x

h''

nuts and washers.

'is shipped with the burner. Mount

1%" cap screws, %-I6 hex nuts, washers

(4)

15"

x

2

%-I6 hex

FIREWALL PLATES

Fig.

14

Page 16

Steel burner mounting plate (see item D below for R-8

&

R-10 mounting plate instructions). With the use of

silastic, secure the rope gasket to the front section just

inside the rib to which the burner plate seats. Using

the (10) &"-I8 x

mount burner plate to front section. With bolts provided mount burner to steel ,burner plate, see Figure

15

for view showing steel burner plate installed.

D. Steel burner mounting plate with mounting lugs (R-8

and R-10 Burner Only). Mount .the burner mounting

plate as stated in (c) above. Locate the (6)

ing lugs in the mounting plate carton. Attach the lugs

to the weld studs on the burner mounting plate with

the

%"

stalled, orient the lugs towards the center of the opening such that they hold the burner flange in place.

@

Attach the canopy brackets to the ends of the canopy

wit& sheet metal screws. Two piece canopies should

be joined together using the #10 x

screws provided.

hex nuts & washers.

Canopy Assembly

1"

long hex head machine screws,

%"

When the burner is in-

%"

sheet metal

mount-

Along the groove provided on top of the sections and

across the top of the end sections, apply 2" wide strips

of cerafelt and lap joint at corners. 'See Fig. 16.

Place the canopy on the sections with the word

"FRONT" positioned over the front section.

Secure the canopy to the end sections by extending the

&"

x 11%" carri.age bolts from the end sections to the

canopy brackets. Attach the canopy channels to the

canopy and intermediate sections with the appropriate

J-bolts.

Check the seal between the canopy and the sections.

Assemble the flue thimble to the top of the canopy

with the bracket toward the front of the boiler using

#10 x

%"

screws.

Figure 17 shows the canopy assembled to the sections

with the flue

Place canopy insulation over canopy foil side up, fold

down sides and secure with wire.

@

Inspect Seal

A. After the platework is in place, a visual inspection

should be made of all sealed joints and repairs made

if necessary. A darkened boiler room with a light

source in the combustion space and canopy will aid

this inspection.

thim'ble in place.

Fig.

15

@

BOILER PI'PING

CONNECT SUPPLY AND RETURN PIPING

HEATING SYSTEM.

MUM PIPING REQUIREMENTS AND ARRANGEMENTS BE COMPLIED WITH IN ORDER TO INSURE

MAXIMUM RELIABILITY PERFORMANCE.

A. CLEARANCES

have clearances of at least

construction.

B. W5th STEAM HEATING, see Figure 20, consult I=B

=R Installation and Piping Guide No. 200.

BE GIVEN TO THE CONSTRUCTION OF THE

HARTFORD LOOP ON STEAM BOILERS. FIGURE

22 ILLUSTRATES THE RIGHT AND WRONG WAY

TO CONSTRUCT THE STEAM HEADER.

With forced circulation HOT WATER HEATING,

see Figure 21, consult

Guide No. 200.

1.

If this boiler is used in connection with refrigeration systems, the boiler must be installed so that

the chilled medium is piped in parallel with the(

heating boiler using appropriate valves to prevent\

the chilled medium from entering the boiler, see

Figure 18. Also, consult

Piping Guides.

IT IS IMPORTANT THAT THE MINI-

-

All steam and hot water pipes shall

%"

from all combustible

PARTICULAR ATTENTION SHOULD

I=B=R Installation and Piping

I=B=R Installation and

TO\

Page 17

GROOVES AT TOP OF SECTION

FOR CANOPY SEALANT

Fig.

16

THIMBLE & CANOPY ASSEMBLY SECURED & SEALED TO SECTIONS

Page 18

If this boiler ,is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air, the boiler piping must be equipped

with flow control valves to prevent gravity circulation of boiler water during the operation of the

cooling system.

If the boiler will be operated where low boiler water

temperatures may be encountered (i.e. converted

gravity circulation systems, etc.) the use of a boiler

water bypass is recommended to maintain optimum

operation.

Remove the circulator and install a pipe tee between 'the circulator and boiler return along with a

second tee in the supply piping as shown in Figure

19.

The bypass should be the same size as the supply and return lines with valves located in the bypass and supply outlet as illustrated in Figure

order to regulate water flow for main-tenance of

higher boiler water temperature.

Set the by-pass and boiler supply valves to a half

throttle position to start.

system water temperature is at a normal operating

range.

Adjust the salves to provide 180" to 200°F supply

water temperature. Opening the boiler supply valve

will raise the system temperature, while opening

the by-pass valve will lower the system supply temperature.

Operate boiler until the

19

OXYGEN CORROSION

Oxygen contamination of the boiler water will cause

corrosion of the iron and steel boiler components, which

can lead to failure. As such, any system must be designed

to prevent oxygen absorption in the first place or prevent

it from reaching the boiler. Problems caused by oxygen

contamination of boiler water are not covered by Buw-

ham's standard warranty.

There are many possible causes of oxygen contamination such as

1.

Addition of excessive make-up water as a result of

system leaks.

2.

Absorption through open tanks and fittings.

3.

Oxygen permeable materials in the distribution system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by taking

the following measures

Repairing system leaks to eliminate the need for

addition of make-up water.

Eliminating open tanks from the system.

Eliminating and/or repairing fittings which allow

oxygen absorption.

Use of non-permeable materials in the .distribution

system.

Isolating the boiler from the system water by installing a heat exchanger.

:

:

:

'

A hot water boiler installed above radiation level

must be provided with a low water cutoff device

as part of the installation.

WUT - OFF

VALVE

HEATING

BOILER

[AIR CUSHION TANK

CIRCULATOR

I

I

RECOMMENDED PIPING FOR COMBINATION

&

HEATING

COOLING (REFRIGERATION) SYSTEMS

WATER BOILERS

Fig.

18

RETUN MAIN

FROM

COYDINED

nEAT1NG

COOLING

SYSTEM

a

BYPASS

RECWENDED

VALVE

BY

TO SYSTEM

THERMOMETER

-

PASS PI PING - WATER BOILERS

Fig.

19

COCK

..

Page 19

I

BOILER

1

PIPE SIZE ( INCHES)

IR'si~~z'NGI

PF-

504

PF-

AND

514

THRU PF-

PF

-

505

517

PF

-

506

THRU PF

-

509

FRONT EQUALIZER

HARTFORD

LOOP

PF

PF

RETURN

-

518

-

510

THRU PF - 513

THRU PF

-

521

OPTIONAL

SECONDARY

TO

4"

2"

PF-504(1)4

PF-505

PF

-

PFPF-510

508

509

(1)

4

(21

4

(2)

4

(314

2

2

'I2

2

2

b2

2Il2

4

4

6

6

8

21/2

29,

2

2

2

b2

----

----

- - -

42;

4eh

24$+

-

-

-

-

-

*

Secondary Supply Connections illustrated ,in dotted lines are to be used

only in addition to supply~connections shown in solid lines, not in lieu of.

MINIMUM PIPING REQUIREMENTS STEAM BOILERS

Fig.

20

Page 20

SUPPLY

SUPPLY

FRONT

SUPPLY

I

PF - 504 THRU PF - 507 PF - 508 THRU PF - 513

3"

RETURN

HEADER

(INCHES)

I

RETURN

PF

-

514

THRU PF

MINIMUM PIPING REQUIREMENTS WATER BOILERS

-

521

HEADER

Page 21

HORIZONTAL

ON RISERS

'.*

SECONDARY

SUPPLY

-USE REDUCING ELBOW

OR ATTACH EQUALIZER

TO

BOTTOM OF HEADER

'YQUALIZER

GATE VALVE

CORRECT PHYSICAL ARRANGEMENT FOR STEAM HEADERS

INCLUDING RECOMMENDED VALVING FOR EFFECTIVE CLEANING

BOILER MAKE-UP

GLOBE VALVE

SUPPLY

WATE

BUSHED DOWN

NO HORIZONTAL RUNS HORIZONTALLY

INCORRECT PHYSICAL ARRANGEMENT FOR STEAM HEADERS

*Secondary Supply connections illustrated in dotted lines are to be used only in addition to supply connections shown in

solid lines not in lieu of.

Fig.

22

21

Page 22

@

ASSEMBLY OF JACKET

Open jacket carton and jacket hardware package. Unless otherwise stated, all jacket components are fastened with

sheet metal screws tight until jacket assembly is com-

plete.

Install threaded plastic leg spacers (2 per panel) into

bottom of each jacket panel. See Figure

Place the lower front jacket panel in place below the

burner plate. Install upper front panel by sliding it

down behind the flanges of the front burner plate. At-

tach the lower panel to the upper panel with two sheet

metal screws. Figure 23 shows the front panels assembled to the boiler.

Assemble jacket side panels.

If the boiler

side panels will consist of two pieces which should be

assembled before application (in addition a small

filler piece attaches to the left side panel). If the boil-

er has more than. sixteen sections, the jacket s'ide

panels will consist of three pieces which should be assembled before application. See Figure 24 for proper

arrangement of right side panels.

#8 x %"

sheet metal screws.

Do not drive

1.

has more than eight sections, the jacket

Install jacket side panels.

In case of steam boilers, remove knockouts from the

left side panel filler piece for gauge glass fittings.

When tankless heaters are used, remove the appropriate knockouts from the right hand side panel.

Install the back panel and then the top panel(s). If

11

the boiler has more than

panels will consist of two pieces which should be assembled before application.

Knockouts in the top panel are provided for supply

piping clearance. Filler pieces are to be assembled

panel where knockouts are removed.

G.

Tighten all jacket screws uniformly tight.

sections, the jacket top

to

FRONT JACKET PANEL IN POSITION

Fig.

23

H.

Locate the Rating Plate, Water Treatment Caution

Plate, and Burnham Logo Plate 'in the Miscellaneous

Parts Carton. Install the Rating Plate and Water

Treatment Caution Plate on the jacket front panel

using sheet metal screws. Attach

Plate to the front panel by peeling off the paper backing and lining up the tabs with the jacket slots. Fig-

1

shows correct placement of the plates.

ure

I.

Install the Lowest Permissible Water Level Plate

(located in the steam/water trim carton) on the jacket

left panel using sheet metal screws. See Figuri

the Burnham Logo

'\.

1.

Page 23

-.

-

FNT REAR

BOILER

-

TANKLESS HEATER KNOCKOUT

0000 0 :lo00 0 0

0

PF-5 JACKET RIGHT SIDE PANEL ARRANGEMENT

6

0

0

IlOOO

00::

00

[l

KNOCKOUT NOT USED

OF

BO I LER

Fig.

24

COMPLETELY ASSEMBLED JACKET

Fig.

25

Page 24

For boilers with no tankless heaters, proceed to Step

@

-

Steam Trim or Step

@

Install the tankless heater manifolds according to

Figure

@

SHOWN IN Fig.

Ratings.

THE FOLLOWING GUIDELINES SHOULD BE FOG

LOWED WHEN PIPING THE TANKLESS HEATER:

A. Flow Regulation

R.

27.

CONNECT TANKLESS HEATER PIPINC AS

If flow through the heater is greater than its rating,

the supply of adequate hot water may not be able

keep up with the demand. For this reason a FLOW

REGULATOR matching the heater rating should be

installed in the cold waterline to the heater. Refer to

Figure

ulator should preferably be located below the inlet to

the heater and a minimum of

so that the regulator is not subjected to excess temperatures that may occur during "off" periods when

it is possible for heat to be conducted back through

the supply line. The flow regulator also limits the

flow of supply water regardless of inlet pressure variations in the range of

'Tempering of Hot Water

26

26.

See Table I1 for Tankless Heater

for piping recommendations. The flow reg-

20

to

@

125

-

Water Trim.

12"

away from the inlet

psi.

to

cautions are necessary. A water analysis is necessary

and an appropriate water softener installed. This is

not only beneficial to the heater but

tures plus the many other benefits derived from soft

water.

@

STEAM BOILERS - INSTALL STEAM TRIM

Items for steam trim are located in the steam trim carton

(except for the separately ordered low cutoff and tankless

heater control). Figure

each item. Figure

steam boiler.

A. Install the gauge glass set into the extension fittings

that were installed before the jacket was assembled.

B.

Install the low water cutoff.

C.

Install the Pressuretrol to the boiler using the

90" (2%")

'bushing.

D. Install the

hex bushing.

E. Install the steam gauge using the

hex bushing.

F.

Install the safety valve to the 'back section as shown

in Figure

provided for blow-off piping.

syphon and the

%"

29.

30

28

drain cock using bhe

The safety valve 'is installed in the tee

shows the proper tappings for

shows front view of an assembled

%"

to

piping and fix-

NPT

x

3"

NPT x

%"

NPT

%"

x

%"

FPT hex

%"

FPT

Y4"

FPT

x

a

Install

avoid risk of burns or scalding due to excessively hot

water at the fixture. Refer to Figure

recommendations. Adjust and maintain the mixing

valve in accordance with manufacturers instructions.

Installation of a tempering or mixing valve will

also lengthen the delivery of the8available hot water by

mixing some cold water with the hot. In addition, savings of hot water will be achieved since the user will

not waste as much hot water while seeking water tem-

peratures to his liking. Higher temperature hot water

required by dishwashers and automatic washers is possible by piping the hot water from the heater prior to

entering the mixing valve. 'The mixing valve should

be "trapped" by installing it below the cold water inlet

to heater to prevent lime formation in the valve.

C. Flushing of Heater

All water contains some sediment which settles on the

inside of the coil. Consequently, the heater should be

periodically backwashed. This is accomplished by installing hose bibs as illustrated in Figure

lowing water at city pressure to run into hose bib A,

through the heater, and out hose bib B until the discharge is clear. The tees in which the hose bibs are

located should be the same size as heater connections

to minimize pressure drop.

D.

Hard Water

'This fs applicable to some city water and particularly

to well water. This should not be a deterent but pre-

mixing valve at the tankless heater outlet to

26

for piping

26

and al-

G. For boilers with tankless heaters, install the operating

control in an unused tapping through one of the heater

plates.

H. Plug extra tappings.

TANKLESS

7

HEATER

SCHEMATIC TANKLESS HEATER PIPING

TEMPERED

HOT WATER AUTOMATIC

COLD

WATER

SUPPg

RELIEF LINE AT LEAST

VALVE HAD OF TANKLESS

HIGH TEMP.

WATER FOR

FL&

IN

COLD WATER

HEATER

Fig.

REGULATOR

26

3

OUTLET

INLET

i

@-

FEET

i

Page 25

NOTE:

IN

IT IS IMPORTANT THAT WATER HEATERS

BE CENTRALLY LOCATED IN BOILER.

OUT

TWO HEATER MANIFOLD THREE HEATER MANIFOLD FOUR HEATER MANIFOLD

CUl

FITTINGS

a

COPPER ELBOW

I

2

IXZXQ

L

...

.

..

-

-

COPPER

.. -

.

-

TEE

1

SEVEN HEATER MANIFOLD

EIGHT HEATER MANIFOLD

MINIMUM PIPING RECOMMENDATION FOR PF-5

TANKLES WATER HEATER MANIFOLDS

Fig.

27

Page 26

TANKLESS 'ATER HEATER RATINGS

(Steam and Water)

*

BOILER MODEL

NUMBER

NUMBER OF #548 HEATERS INSTALLED

Ratings are given in gallons per minute continuous flow

heated from 409 to 1404 with 2004 boilor water.

of

water

TABLE II

SURFACE BLOW-OFF

CONNECTION

SAFETY VALVE,

7

/

STEAM BOILER - FRONT VIEW

Fig.

28

STEAM BOILER - SAFETY VALVE

Fig.

29

HOOK-UP

Page 27

Fig.

30

DRAIN

VALVE

I

L°CAT'oN

I

I

G

H

J

K

L

M

N

CONTROL APPLICATIONS

SIZE OF

I

TAPPINGS

3/4

1

NOTE: -3" TAPPING ON BACK SECTION. SAFETY VALVE PIPED IN

CONNECTION WITH BLOW OFF ON STEAM BOILERS

29. TAPPING USED FOR CONNECTING SAFETY RELIEF VALVE

ON WATER BOILERS - SEE FIG. 32.

3

3/4

3!4

1

/2

3/4

3/4

1

/2

1

I

LOW WATER CUT-OFF

1LowwATERcuT-OFF

TANKLESS HEATER

STEAM

PROBE TYPE

-PRESSURE

LIMIT CONTROL

OPERATING CONT.

PRESSURE

GAGE

NOT USED

NOT USED

GAGE GLASS

LOW WATER

CUT-OFF

I

GAUGE6 THERMOMETER

WATER

NOT USED

NOT USED

TEMPERATURE

LIMIT CONTROL

OPERATING CONT.

TANKLESS HEATER

COMB. ALTITUDE

NOT USED

REVERSE ACTING

CONTROL

NOT USED

NOT USED

-

SEE FIG.

I

Page 28

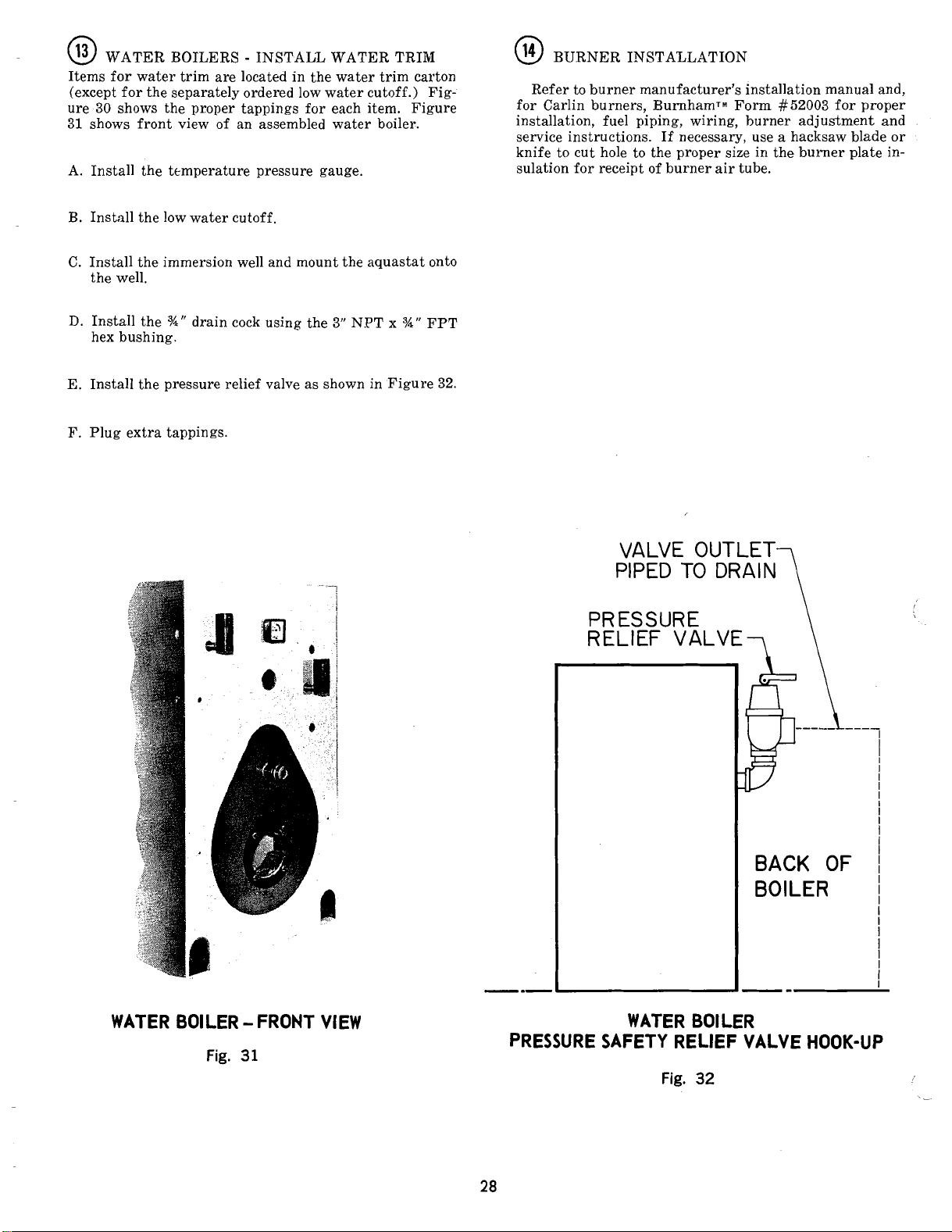

@

WATER BOILERS - INSTALL WATER TRIM

Items for water trim are located in the water trim carton

(except for the separately ordered low water cutoff.) Fig-

30

ure

31

A. Install the temperature pressure gauge.

B.

C.

D.

E.

F.

shows the proper tappings for each item. Figure

shows front view of an assembled water boiler.

Install the low water cutoff.

Install the immersion well and mount the aquastat onto

the well.

Install the

hex bushing.

Install the pressure relief valve as shown in Figure

Plug extra tappings.

%"

drain cock using the

3"

NPT x

%"

FPT

32.

@

BURNER INSTALLATION

Refer to burner manufacturer's installation manual and,

for Carlin burners,

installation, fuel piping, wiring, burner adjustment and

service instructions. If necessary, use a hacksaw blade or

knife to cut hole to the proper size in the burner plate

sulation for receipt of burner air tube.

burn ham^^

Form

#52003

for proper

in-

VALVE OUTLET

PIPED

TO

DRAIN?

PRESSURE

RELIEF VALVE-\

BACK OF

BOILER

WATER BOILER - FRONT VIEW

Fig.

31

WATER BOILER

PRESSURE SAFETY RELIEF VALVE HOOK-UP

Page 29

SECTION

1V

-

OPERATING INSTRUCTIONS

@

ALWAYS INSPECT INSTALLATION BEFORE

STARTING BURNER.

@

FILL HEATING SYSTEM WITH WATER.

STEAM BOILERS

As shown in Figure 1, the normal water line is

from the floor. At the start of each heating season and

once or twice during the season try SAFETY VALVE

to be sure it is in working condition. To do this, fasten wire or cord to lever of valve and pull lever

standing safe distance away from valve.

HOT WATER BOILERS.

In a hot water heating system, the boiler and entire

system (other than the expansion tank) must be full

of water for satisfactory operation. Water should be

added to the system until the boiler pressure gauge

registers normal system design operating pressure. To

insure that the system is full, water should come out

of all air vents when opened.

ON A

MUST NOT EXCEED

BOILER IS EQUIPPED ESPECIALLY FOR

MAXTfiIUM WORKING PRESSURE.

SURE EXCEED'S PRESSURE SETTING OF SAFETY

RELIEF VALVE, IT MUST BE RELIEVED IMMEDIATELY AND THE CAUSE OF RELIEF VALVE FAILURE INVESTIGATED AND CORRECTED. EXCESS

PRESSURE IS DANGEROUS, IN ADDITION, COULD

CALJSE DAMAGE TO HEATING SYSTEM.

DO NOT draw water from boiler while in use. When

adding water while boiler is in operation, do not open

supply valve fully but add water slowly.

HOT WATER SYSTEM THE PRESSURE

-

Fill boiler to normal water line.

46%"

50

POUNDS UNLESS THE

7Q

LBS.

IF

BOrLER PRES-

--

C. CHECK LOW WATER CUTOFF control with water

level at normal water line (see Figure 1). Raise operating control setting to allow burner to operate. Open

boiler drain to allow water level to drop to bottom of

sight glass until burner operation is shut down by

water cutoff.

Close boiler drain and refill to normal water line.

Burner should automatically restart during fill. Reset

operating control.

PROBE

OFF DEVICES REQUIRE ANNUAL INSPECTION

AND MAINTENANCE. Refer to step

Instructions for proper cleaning instructions.

D.

'CHECK OPERATING CONTROL on boiler equipped

with tankless heaters. With burner off, draw hot

water until burner starts,

and check burner shutdown.

@

CLEANWG A NEW STEAM BOILER

Oil, greases

boiler and piping must be removed from the system in

order to prevent an unsteady water line and carry over

of the water into the supply main above

the boiler with steam in the entire system for a few days

allowing the condensate to return to the boiler. If the

condensate can temporarily be wasted, operate boiler only

for the length of time it takes for condensate to run clear.

If the latter cannot be achieved or if the condensate is. returned to the boiler, boil out the boiler using the SURFACE

AN.D FLOAT TYPE LOW WATER CUT-

@

then turn off hot water

&

sediments which accumulate in a new

.boiler. Operate

BLOWOFF connection. See Figure

29.

low

of Service

0

SET

"OFF".

@

facturer's specifications and, for Carlin Burners, according to

@

Before Installation of the boiler is considered complete

the operation of the boiler controls should be checked,

particularly the low water cutoff and the high limit control.

CHECK OPERATING CONTROL OPERATION.

Raise and lower operating control setting as required

to start and stop burner.

WARNING

'Jumper Operating 'Control Terminals: Allow burner

to operate until shutdown by limit. Installation is not

considered complete until this check has been made.

REMOVE JUMPER.

CONTROIlS with burner service switch turned

ADJUST BURNER according to the burner manu-

BurnhamTM Form

TEST CONTROLS

-

#52003.

CHECK HIGH LIMIT CONTROL

-

Drain boiler until water is just visible in gauge glass.

Run temporarily 1%" pipe line from the surface blowoff connection to an open drain or some other location

where hot water may be discharged safely. Do not install valve in this line.

Certain state and local codes may restrict the use of

some of the chemicals listed for cleaning and main-

taining the boiler. Check with local authorities before

proceeding to use these chemicals.

Drain about

container and dissolve into it

and

1

lons of boiler water. See Table

valve 2nd 2dd solution to boiler water thru exposed

tapping.

Use extreme care in handling these chemicals. Caustic

Soda is harmful to skin, clothing, and eyes. Do not

permit the dry material or

to come into contact with skin or clothing.

5

gallons of hot water from boiler into a

1

pound of caustic soda

pound of trisodium phosphate for each

3.

Remove safety

.the concentrated solution

50

gal-

Page 30

QUANTITY CLEANING SOLUTION

BOILER

NO.

PF-504

P F-505

WATER CAPACITY

TO WATER LINE

GALS.

58

69

CAUSTIC

SODA

LBS.

1.2

1.4

TRlSODlUM

PHOSPHATE

LBS.

1.2

1.4

Maintain

the following concentration after boiler ,is cleaned:

NOTE - THE USE OF THESE CHEMICALS MAY BE RESTRICTED IN SOME AREAS.

95%

Sodium Chromate and

Steam Boilers

Hotwater Boilers

-

5%

Sodium Borate water treatment compound at

2

Ib. per 100 gallons of boiler water

-

1

Ib. per 1400 gallons of heating system water

TABLE Ill

Page 31

C. Start burner and operate sufficiently to boil the water

without producing steam pressure. 'Boil for about 5

hours. Open boiler feed pipe sufficiently to permit a

steady trickle of water from the surface blowoff pipe.

Continue this slow boiling and trickle of overflow for

several hours until the water coming from the overflow is clear.

D. Stop burner and drain boiler in a manner and to a

location that hot water can be discharged with safety.

E. Refill (boiler to normal water line. If water in gauge

glass does not appear to be clear, repeat steps A thru

C,

and boil out the boiler for a longer time.

F.

Remove temporary surface blowoff piping, plug tap-

ping and reinstall safety valve. Boil or bring water

temperature to 180°F promptly in order to drive off

the dissolved gases in the fresh water.

G.

If unsteady water line, foaming or priming persist,

install gate valve in Hartford Loop and drain valves

in return main and at boiler and proceed as follows:

1. Connect hoses from drain cocks to floor drain. Close

gate valve in Hartford 'Loop and open drain cock in

return main. Fill boiler to normal water level, turn

on oil burner and operate boiler at this water level

for at least 30 minutes after the condensate begins

to run hot, then turn off burner.

Close all radiator valves. Remove all supply main

air valves and plug the openings in supply

2. Draw about 5 gallons of hot water from boiler into

a. container and dissolve into it the quantities of

caustic soda and trisodium phosphate shown in

Table 3. Remove safety valve from boiler and pour

this solution into

3. Turn on burner and keep operating while feeding

water to boiler slowly. This will raise water level

in boiler slowly so that water will be boiling hot and

will rise slowly into supply main and back through

return main, flowing from drain hose at about

180°F. Continue until water runs clear from drain

hose for at least 30 minutes.

4.

Stop feeding water to boiler but continue operating

burner until excess water in boiler flows out

through supply main and water lowers (by steam-

ing) until it reaches normal level in boiler. Turn

off burner. Drain

Reinstall all supply main air valves. Open gate valve

in Hartford Loop.

5. When boiler has cooled down sufficiently

sheet of sections are not too hot to touch), close

the drain cocks

feed water slowly up to normal level in boiler. Turn

on burner and allow boiler to steam for 10 minutes

then turn off burner. Draw off one quart of water

from bottom gauge glass fitting and discard. Draw

off another quart sample and if this sample is not

clear, repeat the cycle of draining the boiler and

and return main and refilling the boiler until sample is clear.

6.

If the boiler water becomes dirty again at a later

date due to additional sediment loosened up in the

piping, close gate valve in Hartford Loop, open

drain cock in return main, turn on burner and

allow condensate to flow to drain until it has run

clear for at least 30 minutes while feeding water to

boiler so as to maintain normal water level. Turn

off burner, drain boiler, open gate valve in Hart-

ford Loop, then repeat step

.boiler, then reinstall safety valve.

lboiler. Open all radiator valves.

at

boiler and in return main and

1

above.

inain.

(crown-

@

CLEAEilNG A WATER BOILER

in

a

The oil and grease which accumulate

boiler can be washed out in the following manner.

A. Remove safety relief valve using extreme care to avoid

damaging it.

Centain state and local codes may restrict the use of

some of 'the chemicals listed for cleaning and maintaining the boiler. Check with local authori'ties before

proceeding to use these chemicals.

Partially fill boiler and add caustic soda or trisodium

phosphate to the boiler water at the rate of

either chemical per 50 gallons of total water in the

system. See Table 3.

C. Reinstall safety relief valve.

D. Fill the entire system with water.

E. Start firing the boiler.

F.

Circulate the water through the entire system.

G.

Vent the system, including the radiation.

H. Allow boiler water to reach operating temperature, if

possible.

I.

Continue to circulate the water for a few hours.

J.

Stop firing the boiler.

K.

Drain the system in a manner and to a location that

hot water can be discharged with safety.

L. Remove plugs from all available returns and wash the

water side of the boiler as thoroughly as possible, using a high-pressure water stream.

M.

Refill the system with fresh water.

BOILER WATER TREATMENT

Certain state and local codes may restrict the use of some

of the chemicals lis'ted for cleaning and maintaining the

boiler. Check with local authorities before proceeding to

use these chemicals.

Add boiler water treatment compound as

chromate boiler water treatment compound consisting of

95% sodium chromate and 5% sodium borate has been

tested and found reliable. These tests have shown that

the material, when used and maintained at the concentrations listed below, is effective in controlling and arresting corrosion. These chemicals may be purchased from

any reliable chemical company.

A. Low pressur. steam boilers, such as the PF-5 Series

should be miintained with a chromate concentration

of 2 ljb./100 gal. (see Table 3) of boiler water (2200

ppm). This concentration will be effective where all

or practically all of the condensate is returned to the

boilers.

new- hot water

1

lb. of

nezded. A

Page 32

B. Hot Water Boilers.

The use of chromxte boiler water treatment compound

in a water boiler involves considerations. Too high a

concentration must be avoided as it may damage pump

seals. Therefore, with a lower level of protection, it

is necessary to take even greater

free oxygen out of the system. Free oxygen can enter

from system leaks, faulty vents, or vents improperly

located with regard to pumps and from makeup water.

Hot water heating boilers should be maintained with a

chromate concentration of

water. See Table

@

Make pH or Alkalinity Test.

After boiler and system have been cleaned and refilled

as previously described, test the pH of the water in the

system. This can easily be done 'by drawing a small

sample .of boiler water and testing with hydrion paper

which is used in the same manner as litmus paper, except

it gives specific readings.

of the small hydrion dispenser gives the reading in pH.

Hydrion paper is inexpensive and obtainable from any

chemical supply house or through your local druggist. The

pH should be higher than

of the washout chemical (caustic soda), if necessary, to

bring the pH within the specified range.

3.

A

small color chart on the side

7,

but lower than

precaultions to keep

1

lb.11400 gal. of boiler

11.

Add some

If, during normal operation, it is necessary to add water

to this boiler more frequently than once a month consult

a qualified service technician to check your system for

leaks. A leaky system will increase the volume of make-up

water supplied to the boiler which can significantly shorten the life of the boiler. Entrained in make-up water are

dissolved minerals and oxygen. When the fresh, cool

make-up water is heated in the boiler the minerals fall

out as sediment and the oxygen escapes as a gas. Both

can result in reduced boiler life. The accumulation of

sediment can eventually isolate the water from contacting

the cast iron. When this happens the cast iron in that

area gets extremely hot and eventually cracks. The presence of free oxygen in the boiler creates a corrosive atmosphere which; if the concentration becomes high

enough, can corrode the cast iron through from the inside.

Since neither of these failure types are the result of a

casting defect the warranty does not apply. Clearly it is

in everyone's best interest to prevent this type of failure.

The maintenance of system integrity is the best method

to achieve this.

Page 33

SECTION V - SERVICE INSTRUCTIONS

0

IMPORTANT - See Item

Instructions if it be comes necessary to add water to the

boiler more frequently than once a month.

I

@

GENERAL - Inspection should be conducted annual-

ly. Service as frequently .as specified in paragraphs below. While service or maintenance is being done, electrical power to the boiler must be "off".

@

CLEAN THE 'BOILER HEATING SURFACES

at

AND FLUE

end

of

the heating season.

A. CLEAN THE VENT SYSTEM

be checked annually for:

1.

Obstructions.

2.

Accumulations of soot.

3. Deterioration of vent pipe or vent accessories due

to condensati.on or other reasons.

4.

Proper support - no sags, particularly in horizontal

runs.

5.

Tightness of joints.

Remove all accumulations of soot with wire brush and

vacuum. Remove all obstructions. Replace all deteriorated parts and support properly. Seal all joints.

B. CLEAN THE BOILER FLUEWAYS

1.

Remove the smokepipe.

2.

Remove the jacket top and left side panels.

3.

Remove the canopy being careful n,ot to damage the

cerafelt gasket.

4.

Loosen nuts securing the flue cleanout plates and

remove the plates. The insu1,ation should be removed with the plates taking care not to damage the

insulation.

5.

Using a

(36"

top and side using horizontal and diagonal strokes

for best results.

least once each year, preferably at the

1%''

diameter wire or fibre bristle brush

handle) clean the flueways. Brush from the

@

under Operating

-

Vent system should

5.

Reinstall jacket top and left side panels.

6.

Reinstall smokepipe.

MAINTENANCE OF LOW WATER,CUTOFF DE-

VICE'S

PROBE AND FLOAT TYPE LOW WATER CUTOFF

DEVICES REQUIRE ANNUAL INSPECTION AND

MAINTENANCE.

A. PROBE TYPE LOW WATER CUTOFF

Athough these devices are solid state in the operation,

the probe

boiler water and subject to fouling.

It is

the boiler tapping annually and inspect that probe for

accumulation of scale or sediment.

Follow these steps to inspect, clean and/or replace the

probe

Turn off electric service to the boiler.

Drain boiler water t,o a level below the tapping for

the probe.

Disconnect wiring connections between the low

water cutoff control and the probe.

Dismount the low water cutoff control from the

probe.

Unscrew the probe from the boiler tapping.

Inspect that portion of the probe that is exposed to

the boiler water for a scale or sediment buildup.

Light deposits may be removed by wiping the probe

with a damp cloth. Wiping the probe with a cloth

soaked in vinegar will remove more tenacious lime

deposits. The most stubborn deposits may be re-

moved from the probe by using a diluted amount (3

part of water to

po4).

is exposed to possible contamination in the

impoptant to physically remove the probe from

:

1

part) of phosphoric acid (H,

C. CLEAN TOP OF BOI'LER SECTIONS.

Brush and vacuum the tops of the boiler sections.

D. CLEAN THE FIREBOX

1.

Disconnect fuel line(s) and remove burner and

burner mounting plate.

2.

Using wire or fibre bristle brush clean crown of

boiler and inside of water legs.

.E. REASSEMBLE BOILER

1.

Install the canopy taking care to align the cerafelt

strips. If strips are damaged replace as needed.

2.

Reinstall burner mounting plate to front section

making sure Flextex rope gasket is in place and

forms gas tight seal. If gasket is damaged, replace.

3.

Bolt burner to burner mounting plate. Inspect gas-

ket to assure adequate seal. Replace if damaged.

Connect oil line(s) and/or gas line (s).

4.

Reinstall flue plates making sure gasket on each

plate is in place and forms gas tight seal. If damaged, all edges of the cleanout plates should be sealed with Silastic sealant when reinstalled until insulation can be replaced.

Exercise cautioii when handling phosphoric acid and follow the instruction label on its container.

Wire brushing of the probe is not recommended as

the soft platinum guard ring sandwiched between

the ceramic insulators may be damaged. 'Care must

be taken not to damage this ring in any way or the

useful life of the probe may be shortened.

Clean the pipe threads of the probe to remove old,

hardened pipe dope and other foreign matter.

Apply a moderate amount of good quality pipe dope

to the pipe threads on the probe, leaving the two

end threads bare. Do not use PT'FE (Teflon) tape.

Screw the probe into the boiler tapping.

Mount the low water cutoff control on the probe.

Reconnect the control to probe wiring.

Fill the boiler to its normal waterline.

Add boiler water treatment compound as needed

(see Table

Restore electric service to .the boiler.

Fire burner to bring the water in the boiler to a

boil tadrive off free oxygen.

3).

Page 34

18.

WARNING - BEFORE RETURNING BOILER TO

:

SERVICE

procedure on page 29.

Follow the low water cutoff check out

a

GENERAL MAINTENANCE CONSIDERATIONS

A. Keep radiators and convectors clean.

B. FLOAT TYPE LOW WATER CUTOFF

During the heating season, if an external low water

cutoff is on the boiler, the blow of! valve sh,ould be

opened once a month (use greater frequency where

conditions warrant), to flush out the sediment chamber

so the device will be free to function properly.

Low water cutoffs and water feeders should be dismantled annually by qualified personnel, to the extent

necessary to insure freedom from obstructions and proper

functioning of the working parts. Inspect connecting

lines to boiler for accumulation of mud, scale, etc., and

clean as required. Examine all visible wiring for brittle

or worn insulation and make sure electrical contacts are

clean and that they function properly. Give special attention to solder joints on bellows and float when this type

of control is used. Check float for evidence of collapse and

check mercury bulb (where applicable) for mercury separation

PAIR MECHANISMS IN THE FIELD. Complete re-

placement mechanisms, including necessary gaskets and

installation instructions, are available from the manufacturer.

@

Item

See Burner Manual for burner tests and adjustments.

orr discoloration. DO NOT ATTEMPT TO RE-

Check burner and controls at least once a year. See

@

under Operating Instructions for control checks.

B.

If a hot water radiator is hot at the bottom but not at

the top, it indicates that air has accumulated inside

and should be vented. To vent radiator, hold small cup

under air vent (located near top of radiator), open

vent until water escapes and then close.

C. If much water is added to system, it is advisable to

heat system to a high temperature and vent again.

This will make less venting necessary during the

winter.

D. Where an expansion tank is used, make sure that neith-

er the tank nor its drain pipe is exposed to freezing

temperatures. Never place valves in piping leading to

or from expansion tank.

E. Boiler and system cleaning will help assure trouble

free operation. See Item

structions for procedure.

@

ATTENTION TO BOILER WHILE NOT IN OP-

ERATION

A. IMPORTANT

IF BOILER IS NOT USED DURING WINTER

TIME, IT MUST BE FULLY DRAINED TO

VENT FREEZE DAMAGE.

B. Spray inside surfaces with light lubricating or crank-

case oil using gun with extended stem so as to reach

all comers.

under Operating In-

@

PRE-

,

@

LUBRICATE BOILER COMPONENTS according

to manufacturer's instructions. Generally, this involves

the oil burner and circulator. This includes the type of

lubricant to use, frequency of lubrication, and points to

lubricate.

C. With steam boilers, at end of season add sufficient