Page 1

I-IYDRON

IC

CAST

I

RON

H EAT

OIL CASORCOI4BINATION

PF-5

5ER|E5

@o

UBurnharri

AMERICAS

Heating

6ZOto

Gpacities:

545O

BOILER

COMPANY

t-4BH

Page 2

PF5 sERIEs

HOTWATER

ORSTEA[.4

BOILER

Maximum Water Working Pressur€: rc PSFWater;

The finest

in farge

cast iron

boiler design.

Utilizing a completely

forced draft wet base

Burnhamo

separate base or

The sealed,

optimum draft

tion, eliminating

neys or mechanical equipment

to artificial$

PF-5 Series

installations where the

not

limitations.

shipped

boiler is available

bled sections

aged unit.

fastened to a steel skid

ingwith a

can serve as

replacing the

factory

aged

ing at Gross Outputs

PF-5

bination

either steam

with a combustion

82o/o.

requirements of

Quality

Each

hydrostatically

half times

make sure

Factory-assembled

at one and

working

PF-5 Series

combustion chamber.

forced draftdesign

for controlled combus-

need for high chim-

the

proper

induce

The sectional

makes it ideal

accessible due

easily

In

as individual

The

fork truck or crane.

fire-test is available on

units.

Available

frres

Series

and can be

product

The

All sizes exceed the

breeds

construction of

addition

with

or as a comptetely

packaged

the boiler

for

need

in eighteen sizes

gas,

equipped with

or water

is energy

efflciency of up

ASHRAE 90.1.

SecuritY

PF-5 boiler section

tested

ratedworking

thatthe

section

sections

half times

one

pressure.

The sections

sealed,

design, the

requires

draft.

for

use

room is

boiler

to structural

to being

sections the

factorv-assem-

unit

to facilitate

foundation,

a concrete

MBH, the

of 620

gas/oil

oil or

trim and controls.

efficient

efficiency

is

two and

at

pressure

flawless.

is

are tested

rated

the

no

provides

the

in

pack-

is

lift-

The skid

pad.

pack-

all

start-

com-

to

one

to

are

surface

ground

surface mating,

with an elastic

sealant

is

used

guarantee

tight assembly

operation.

and takes

less time than

conventional

many

times

Each section is then

quality

which can deteriorate the

in

proven

the boiler. They expand and contract

along with

ensuring the integrity of the entire section assembly.

A

cast

some competitor's boilers.

cast iron nipples last the

Thermal

Making

Incorporated

is a

desrgn

greatly improves

that

water

both

PF-S Series.

the

insures

good

maximum

The thermal

by caming

on one

the

occurs

side

other.

on the

greatest,

is

results on

flow

transfer

is lowest.

circulation

insure

to

smooth

and sealed

sealing compound.

all section

on

a completely

required

The sealant

sealed and

for forced draft

is easily applied

applying

gasket

materials

longer.

joined

iron nipples which will

gaskets

sections

the

they

Pump-

Waves

"thermal

into the

pump"

circulation

versions

steam

and

This thermal

qualify

steam

tankless

heater capacity.

pumping action

greater heat transfer

than on

boiler

of the

An upward

side

and

flow of

heat

where

a downward

the side

where

Continuous

is assured.

15 P5l-Steam

gas-tight

This

joints

to

gas-

lasts

and

with

increase

the

longevity

of the

boiler by

resisting

petroleum

based

chemicals,

including

antifreeze

used

Time-

life

of

join

wet base

action

in

of

pumP

well as

as

is

created

water

transfer

water

heat

water

water

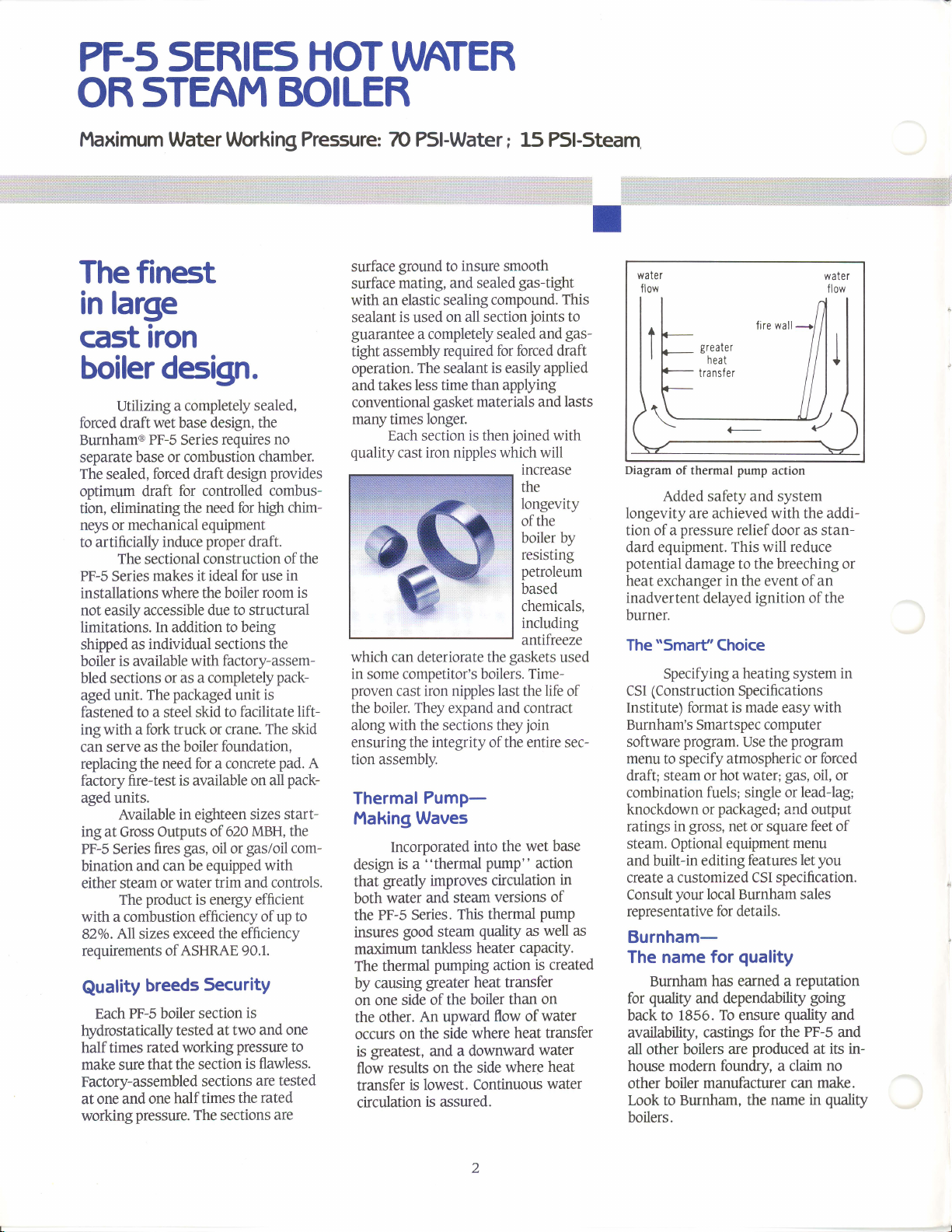

Diagram

longevity

tion of a

dard equipment.

potential

heat

inadvertent

burner.

The

CSI

Institute) format is made easy with

Burnham's Smartspec computer

software

menu to specify atmospheric or

draft; steam or

combination

knockdown

ratings in

steam. Optional equipment

and

create a customized

Consult

representative

Burnham-

The name for

for

back to 1856.

availability,

all other boilers

house modern foundry, a claim

other boiler

Look to Burnham, the

boilers.

flow flow

wall

fire

greate

r

heat

tra nsfe r

of thermal

Added

are achieved

pressure

damage to the

exchanger

"Smarf'Choice

Specifying a

(Construction

program.

gross,

built-in editing

your

pump

action

safety and system

with

relief

door as stan-

This

will

breeching or

in the event ofan

delayed

fuels;

or

local Burnham sales

ignition of the

heating

Specifrcations

Use the

hotwater;

single

packaged;

net

or square

features

CSI specification.

for

details.

water

addi-

the

reduce

system

program

forced

gas,

oil, or

or leadJag;

and output

feet of

menu

letyou

quality

Burnham

quality

has earned a

and dependabiliry

castings

manufacturer can

To ensure

are

reputation

going

quality

PF-5

for the

produced

in

name

and

its in-

at

no

make.

quality

in

and

Page 3

PF-5

FEATURES

AN D

F,q*b,1$$€u1.*e,+r1

sTAN DARD EQU|

ffii€ffitrfffffE$ffEi$il*fitti$ffFigi#fffi

+-l-

P[,4ENT

$f+ififff

I i

1"/,

,

--t-1,*1-.rP-

1,

'-1

jff$i1

I

i

I

r

l

ti

i

trffi ff

iff

Eil$#iEi+trffi

I

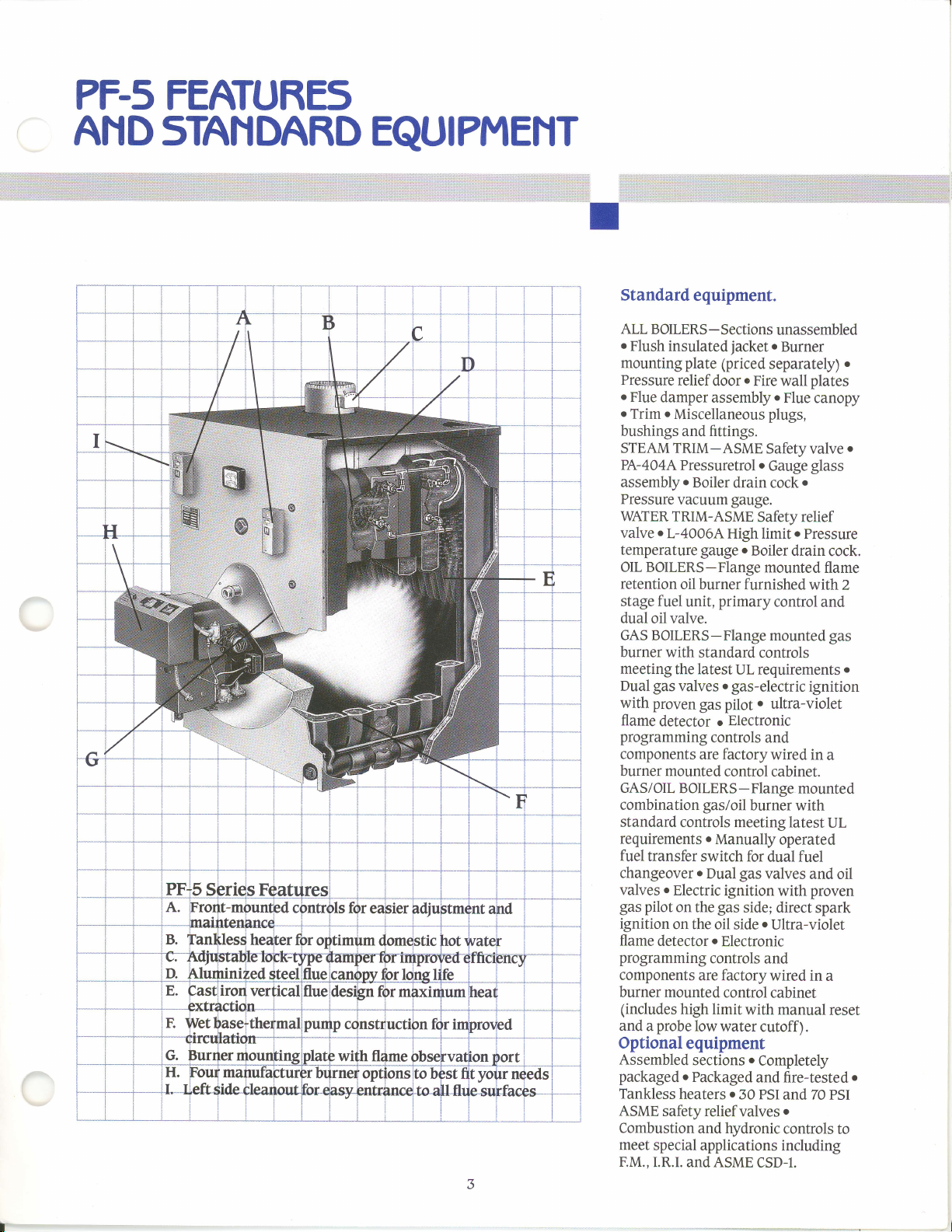

Standard

ALL

o

Flush

mounting

Pressure

o

Flue

o

Trim

bushings

STEAM

P{-4}4LPressuretrol

assembly

Pressure

WATER

valve

temperature gauge

OIL

BOILERS-Flange

retention

stage fuel

dual

GAS BOILERS-Flange

burner

meeting

Dual

with

flame

programming

components

burner mounted

GAS/OL BOILERS

combination

standard

requirements

fuel

changeover

valves

gas

pilot

ignition

flame

programming

components

burner

(includes

and a

Optional

Assembled

packaged

Tankless

ASME

Combustion

meet

F.M..

equipment.

BOILERS

insulated

plate

relief

damper

o

Miscellaneous

and

TRIM-ASME

o

Boiler

vacuum

TRIM-ASME

oL-4O06AHigh

oil

unit,

oil valve.

with standard

the latest

gas

valves.

proven

detector

controls

transfer

o

Electric

on the

on the

detector

mounted

high limitwith

probe

low

equipment

sections

o

Packaged

heaters

safety relief

special

I.R.I.

and ASME

ffi

ffi

EE$€$$$fl$$E$gssff$$,F,FF

-

Sections

(priced

door r Fire

assembly

fittings.

burner furnished

primary

gas pilot

Electronic

o

controls

are factory

control

gas/oil

o

Manually

switch for

o

Dual

ignition

gas

oil side

o

Electronic

controls

are factory

control

water

o

and hydronic

applications

unassembled

jacketo

drain

gauge.

gas-electric

Burner

separately)

wall

o

Flue

plugs,

Safety valve

o

Gauge

cock.

Safety relief

o

limit

o

Boiler

drain cock.

mounted

control

mounted gas

controls

UL requirements

o

ultra-violet

and

wired in

cabinet.

-Flange

burner with

meeting latest

operated

dual fuel

gas

valves

with

side; direct

o

Ultra-violet

and

wired

cabinet

manual

cutoffl.

.

Completely

and fire-tested

PSI

30

and

o

valves

controls

including

CSD-I.

o

plates

canopy

glass

Pressure

flame

with2

and

o

ignition

a

mounted

UL

and oil

proven

spark

in a

reset

PSI

70

to

.

r

Page 4

DfMENSIONS

(in

inches)

I

I

,qr:soc

Pr-51t5_

",

pF-50s:

ptlols".i

'Flfli

,ilffi

10

11

,12

13

14

15

17

18

19

20

21

:::i,i l,

10

10

10

10

10

14

14

14

14

18

1B

18

gi

19Vz

12

1n

251/z

12

311/z

12

37Vz

1'

431/z

IL

49Vz

tt

551/z

12

611/z

27

33

39

45

51

57

63

69

75

B1

67Vz

731/z

79Vz

BSVz

911/z

971/z

1031/z

1091/z

1151/z

1211/z

A

A

A

B

B

B

A

5

6

7

B

I

to

ro*e{iame:

29

29

29

34

34

34

34

34

34

34

34

34

39

39

39

39

39

39

29

29

29

34

34

34

34

34

34

34

34

34

39

39

39

39

39

39

0

34

34

34

34

34

34

34

34

34

34

34

34

39

39

39

39

39

39

,

1n

23

23

23

24

24

24

24

24

25

25

25

25

26

26

26 30

17

22

22

22

22

22

22

22

22

22

29

29

29

30

30

30

30

ff

:",R:;i

26

26

26

26

26

26

26

29

29

29

2S

2S

29

29

29

29

29

29

253/q

25

25

313/q

25

373/4

43s/a

25

49s/q

25

25

55Tc

25

613/q

25

673/t

733/+

25

793/q

25

29

853/a

913/q

29

973/4

29

29

1033/q

1093/4

29

29

115s/q

1213/q

29

1273/q

29

1 650

2000

2300

26s0

2950

3300

3650

3950

4300

4600

4950

5300

5600

5950

6300

6600

6950

7300

1

975

2330

2705

3050

3430

3775

4175

461

4985

5330

5720

6055

6405

6745

7110

7420

7880

8235

0

RECOMMENDED

NOTES:

1. This boiler can

lifting from rear, forks must extend beyond center of

2. When

3. When lifting

4.

from

Cable spreader

lift

lengths to

at approx.

SLING

be li{ted by fork truck. Do not truck

{orks must extend to opposite skid

side,

jacket

prevent

is to

center of

gravity per

ARRANGEMENT

from front.

gravity

damage. Spreader should

rail and straddle center of

chart.

and second skid

(width

be B

of skid)

gross

bar.

gravity.

+

12". Adjust cable

DIMENSIONS

,

3

slightly

4

5

7 BB

B

I

10

11

ta 24

IJ 30

14

tc 42

to

17 54

18 60

19 66

20

21 7B

with burner and

PF-5$4

PF 50s

PF:506 :6

PF:5{l?.

PF-508

Pf-509

PF51O

PF-511:

pF-sre.

PF-51

PF.514 r

PF-515

Pf-s16'

pr-sI?

PF.F1$

PF-51S

PF:5?{l

Pf-521

-Varies

70 44 65Vc

44 651/q

76

82

94

gas

44 651/q

44 651/q

44

44 651/t

00

44

2

1B 44 651/q

44 65Va

44 651/q

44 65Vc 521/z

44 651/n

441/z 67Vq

48

44Vz 671/c

441/z 671/q 651/z

441/z

441/z 671/t

441/z 671/q

train configuratton

211/z

241/z

271/z 3087

311/z

651/q

65Va

671/q 681/z

341/z

371/z

401/z

431/z 51

46Vz

491/z 5982

551/z

58Vz

o t'/2

711/z 8785

7 41/z

2322

2694

3450

3879

4242

4709

71

5586

6392

6748

7178

7539

797

8305

91 61

4

Page 5

TANKLESS

i

i!!l:!!

lit li!

lli!! !l ill !i:l

:1{111 1:::: t:: u

..FflW:;:-r

]9@ffi::

iegiffil{iill:

*,f;fgffi;::t;:

i#F".ffiff;

3r:ri#f,.+ffie.:i

:Jii;iRF.;ffiii:.1

88",l$1fl,-ry;E;

eilf"r-

B?i.hi:i

;E::rFF;g;l, i:t;;r

I'li.FiF.F.i.€fif.ec

sBt#l

iE;:€

i$,f.##

ieiP;.€rF#

iF;##iHiF-:

ii'i.ii:?.F;$*$.i:

iii?"f#ilil+

ii:i:3f;"F3$;

3:iffi$As.:

',iiirf,,f;FB-lli

'Ratings

boiler water.

HEATER

;15:l

8.0

8.0 16.0

8.0 16.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0 16.0 24.0

8.0 16.0 24.0

8.0 16.0

8.0 16.0 24.0

8.0 16.0 24.0

8.0 16.0 24.0

8.0 16.0

8.0

8.0

gjven

gallons per

are

in

RATINGS.

;Hu"rnbei

:s*

16.0 24.0

16.0

24.0

16.0

24.0

16.0 24.0

16.0 24.0

16,0 24.0

24,0

24.0

.16.0

24.0

16.0

24.0

minute

conlinuous

(Water

d"

tantd;is

6as

32.0

32.0

32.0

32.0 40,0

32.0 40.0

32.0 40.0

32.0 40.0

32.0

32.0 40.0 48.0

32.0 40.0 48.0

32.0 40.0

32.0

32.0

draw of water heated from 40oF

'4r

ttq4q9

i

$..

40.0 48.0

40.0 48.0

40.0 48.0

and Steam)

tnsdred:

tt 8.:

.6.l

48.0

56.0

48.0 56.0

56.0 64.0

56.0 64.0

to 140oF with 200.F

front

of

boiler

s/a"

/

/

copper

elbow

7a"

copper tube

+ouT

3/c"

x1"

copper tee

x3/c"

CONTROL

::;;;R:;]

irii:-!li:#ri

;c

E;ir:;

i,Fii,,:

h:

:l:l+

NOTE-3"

blow-off

on

BURNER

MOUNTING

TAPPINGS

ia$R$,##ir

lil#fS3.l

:E;

3

3/t

3h

Vz

3h

3h

Yz

1

3A

back section

safely or relief valve

(8V2"

diameter mounting

except

Low water cut-ofl

Pressure

limit

Operating cont.

Tankless heater

gauge

Pressure

Not

used

Not

used

glass

Gauge

Water Feeder,

Water

Column

Probe

Type Low

Water

Cutoff

piped

PLATES

as

shown

GORDON & PIATT

;.lffidil,i

Not

0perating

Tankless

Pressure

Gauge

Not used

Reverse

acting

Not used

Not

Not Used

used

limit

Temperature

used

control Temperature

LWC0.

in connection

plate

with

is

standard

blow-olf

below.)

control

cont.

heater

control

CARLIN

F----, t---l

lilumberlDl

f---------

PF-514-516 1 a7h"

I

PF-517-s21

I

|

-------l

101/8',

I

I

POWER FLAME

r.*-T---l

t

lHumter I

Fr--rr-u'u f---t-l

PF-516-52r

I

WEBSTER

fr'* [

lr{umber ]

T____

PF-504-513

I

PF514-s21

I

|

|

|

o

103/8"

'-_]

0

______t

lvi'

e%"

I

I

l

I

I

5

Page 6

MI

N II4UM

?I?ING

RECOMMEN

DATIONs

I

WATER

BOILER

Steam Boiler

:"detum

(1)

4

(1)

4

(2)

4

(2)

4

(2)

4

(2)

4

(3)

4

(3)

4

(3)4

(3)

4

(4)

4

(4)

4

(4)

4

(4)4

(5)

4

(5)

4

(5)

4

(5)4

ZVz

5

Pinc

z

z

2Vz

zf2

21/z

21/z

2Vz

3

$iii

PF-504

iinc*mt

4

4

6

6

6

o

8

8

8

8

8

8

I

8

I

8

I

10

supply

thru PF-5O7 PF-508 thru PF-513

21/z

21/z

zv2

ZVz

21/z

ZVz

21/z

A

4

+

4

4

A

+

4

I

suppry

I--

-+

"

return

3

header

j

24"

turn

18't

mtn

min

supply

3"

neaoer

'/

t\

::

:] !:

:]]i

::::

-5OO

thru

PF-509

oplronal

supply

pply

su

water

2" to

back

ltne

4"

PF-514 thru

PF-517

Page 7

BURNERSCHEDULES

lr t:r !:1 !

laat:a:

tt

i:

!t :t:l

OIL BURNERS

Seckotl :

,;Bltr,ng-ri

lllumEtf

gil.:,

CFBOO

:iBr.*

cF1400

ilE€a;'

,#,F:;ffi*ir

cF1400

cF1400

cF2300

cF2300

cF2300

cF2300

cF2300

cF2500

rP.'f;:r.Et:l'Sl

cF2500

.Ff!5ii4:

cF2500

iEI;919;

cF2500

:f F,51€

?fr.t17.

cF3500

cF3500

im,*$.f$i

Fof.l.{tl*,

cF3500

PF-520

cF3500

PF-521

cF3500

20t60t1

20160t1

20t60/1

120/60t1

120160t1

120t60t1

120t60t1

120/60t1

120/60t1

230t60t1

230t60t1

23016011

230t6011

230/60t1

230t60t1

230t60/

230/60/

230/60t

GAS BURNERS*

Gordon:Ptatt:

R6.2-G

R6.2-G

R6.2-G

;*Fi3.fi;

iS:F.S{#

'x,Fg99'9j

19f:'5t8

:PF:,Sif.Ii

?F.5,1t*

Ffir:.f.

:Pf.,'558;i

ffiE

iptF;rs-.t6:

.flFr*f?:.:

,F#5|fi:

,F,f'$?{.

::B'1[.i$l$.'

:FF';' li

*For

R8-G

R8.G

R8-G

RB..1.G

R8.2-G

RB.3.G

R10.9-G

R10.9-G

R10.9-G

R1O-G

R1O-G

R10.1-G

R10 1-G

R10..1-G

R10.1-G

gas

connection sLe

6.7

5.9

6.3

,6.4

o. I

6.4

6.7

6.6

4.9

5.9

55

5.3

7.5

6.8

o.4

71

7.0

7.7

see Gas/Oil

:;:B,iiiiiei:

:i

Llutfibst:

301

CRD

701

CRD

701

CRD

701

CRD

701

CRD

BO1 CRD

BO1 CRD

BO1 CRD

BOl CRD

BO1

CRD

l05OFFD

lOSOFFD

lO5OFFD

115OFFD

1150FFD

50FFD

5OFFD

5OFFD

20/60/1

20/6011

20160t1

120t60t2

120160t2

120t60t2

240/60t1

240t60t1

240t60t3

240t60t3

240/6013

240160t3

240160t3

240t60t3

240t60t3

24016013

240t6013

240t60t3

Carttn

i i iElandairfi.r:

{tlBl6t xr$R*d$

20t60t

20t60t

20t60t

120t60t

120t60t

230160t

230t60t

230t60/

230t601

230/6011

230160t3

230/60t3

230t60/3

230t6013

230/60t3

230160t3

230t60/3

230t6013

Burner

chart.

Bt$it]t:t:"

:;

,:m#:b-gr:

R6.2-0

R6.2-0

R6

RB-O

RB.O

RB-O

RB.1-0

RB.2-0

RB.3-0

R10

R 10.9R 10.9-

R 10-0

R 10-0

R10.1-0

R10

R10 1-0

R10.1-0

::Brtirlci:

illlur*tsl

Ul-tr-lZ

u t-u- tz

u t-u- tz

c2-G-15

c2-G-1s

c2-G-15

c2-c-20A

c2-G-20A

c2-G-20A

c2-G-208

c2-G-208

c2-G-208

c3-G-20

c3-G-20

c3-G-20

c3-G-25

c3-G-25

c3-G-25

Gordon-PlaJt

ii:i$lmdaiC:-:

:!tr6t*B$,sllara:

120t60t1

120t60t1

2-0

120t60t1

120t6011

120t6011

120t60t1

24016011

240t6011

240t60/3

9-0

240t6013

0

240/60t3

0

24016013

240t60t3

240t60/3

240t60t3

1-0

240/60t3

240160t3

240t60t3

,,

FlafiP:

F,*r't

1::'$i6;$P3.:.

:FilSs:R:c4d;

't

:1{;0::

::lllr

50

5.9

6B

8.1

7.3

7.6

q5

65

6.6

4.9

51

5.8

6.5

72

5.9

64

7.0

Bllti:rufi:

.

:N3iliESt:

Cl.OS

c1-0s

C1-OS

C2-OAS

C2-OAS

c2-0AS

c2-0BS

c2-0BS

C2.OBS

C2-OBS

C2.OBS

c2-0BS

c3-0

c3-0

c3-0

c3-0

c3-0

c3-0

,i.:$lgn#r.d

: :

:,lff*lor'Vol{5gB:

120160t1

120160t1

120160/1

120t6011

120t60t1

120t60t1

240t60t1

240t60t1

240t60t1

240t6011

240t6011

240t60t1

240t60t3

240t60t3

24016013

240t6013

24016013

240160t3

PbwerlFlamq

$tandafS

voftage

Motrr

120t60/1

120t60t1

120t60t1

240160t1

240t60/1

240t6011

240t6011

240t60t1

240t60t1

240160t1

240t60t3

240t60t3

240t6013

240t6013

240/60t3

240160t3

24016013

240t60t3

,

:,gUl-n€r,;

: :

.lhfuiitdr:=

JB

G-03

JB

G-03

JB

G-03

JB1 G.03

JB] G.03

JBl G-07

JBl G.Oi

JBl

G-07

JBl G-07

JB1 G-07

J B2G-10

J B2G-10

J B2G-10

JB2G-10

JB2G-10

JB2G-10

JB2G-10

JB2G-20

Webster

i$iiiet;'

::lIwEbafi.

l

JB10-03

JB10-03

JB10-03

J 810-03

J 810-03

JB10-07

J 810-07

J 810-07

J 810-07

JB10-07

JB20-10

J B20-10

JB20-10

JB20-10

J820-10

820-10

J

lB20-20

JB20-20

::llllGbster

::,MltliG-a$::i;

F1lt$*,;Fb"qrd":

:,

ln;:lff e;:: i:

4.0

o.l

5.0

6.8

69

66

4.1

4.7

5.7

66

4. Cl

5.5

63

59

56

59

6.4

6B

,

120t60t

120t60t

120t60t

120t60t1

120t60t1

120/60t1

120160/1

120t6011

120t6011

120t6011

240160t3

240t60t3

240t6013

240t60t3

240/60t3

240t60/3

240t6013

240t6013

120t60t

120t60t

120/60t

120t60t

120t60/

120t60t

120t60t

120t60t

120t60t

120160/1

24016013

240160t3

240t60t3

240t60t3

24016013

240t60t3

240t60t3

240t60t3

.;a;:::;::t,:!a;:.1

ir

!:

:: :r!:':

::

: :j :

a,:::la.!a'a'.,::

GAS/LIGHT

.. Qoilrit. r i

:HEnbei l

P.F'5ffi:t

Fp:$d6,i

Ft';5tF,

PF6oti

,?F,::fBF'

iPJjfiti*

:;F

i,f-#6fa

:rf,.f;.+5;19

PF-520

Pf-521'

-For

PF:606, l

5t-+:

minimum

R6.2-G0

R6.2-G0

R6.2-G0

RB.1-GO

RB.2.GO

RB.3.G0

R10.9-G0

R10 9-G0

R10.9-G0

R10-G0

R10-G0

R10.1-G

R10

R10

R10

R8-GO

RB-GO

RB-GO

10

-G0

-G0

-G0

gas pressure

OIL

BURNERS*

120t60t

120t60t

120t60t

24016011

240t60t1

240t60t1

240t60t1

240t60t1

240t60t3

240t60t3

240t60t3

240t60t3

240t60t3

240t60t3

240t60t3

240160t3

240t60t3

24016013

requirements

1l/q

11/z

11/z

1t/z

1t/z

2

2

2

2

2

2

21/z

21/z

21/z

21/z

)/c

1/q

:B,i!*nrEr

,llnfabefi:

-G0-12

c1

c1-G0-12

c1-G0-12

c2-G0-15

c2-G0-15

c2-G0-15

c2-G0-20A

c2-G0-20A

c2-G0-20A

c2-G0-208

c2-G0-208

c2-G0-208

c3-G0-20

c3-G0-20

c3-G0-20

c3-G0-25

c3-G0-25

c3-G0-25

see

Gas Burner chart.

iF.b,$raliFlsfie

;:t|!RffSd,$':

:€ohntcliolt

it

:.:tnbfi

2

2

2

2

2

1

11/q

11/q

1'/q

11/t

11/z

2

2

2

2

.$;:

!;

120t60t

120t60t

120160t

240t60t

240t60t

240t601

240t60t

240t60t

240t60t

240t60t1

240t60t1

240t6011

240t60t3

240160t3

240t6013

240160t3

240t60t3

240t60t3

JBl C-03

JBl C-03

JB1 C.O3

JB1 C-03

JB1 C-03

JB1 C.O7

JBl C-07

JBl C-07

JB1 C.07

JB1

C-07

JB2C-10

JB2C-10

JB2C-10

B2C-]O

J

J B2C-1 O

J B2C-1

O

JBZC-20

JBZC-20

'$/,*bslcti

:

,l0lE!:Gaii:,

0ongsrli0r*:'

::lfitfild$j;;.

1Yq

11/t

11/a

11/c

1fz

1fz

2

2

2

2

2

2

2

21/z

21/z

21/z

21/z

2'/z

::ita::,::r:,!::

;5,165d.6id:

hgG

::tf

:

120t60t

120t60t

120t60t

20t60t

201601

20t60t

20t60t

20t60t

20t60t

120160t1

240t60t3

240t60t3

24016013

240t60t3

24016013

240t60t3

240160t3

240160t3

Page 8

SPECIFICATION5

UBurnhard

AMERICAS BOILER COMPANY

PF5

Boiler

Number

(1)

PF-504

PF-505

PF-506

PF-507

PF-508

PF-509

PF-510

PF-511

PF-512

PF-513

PF-514

PF-515

PF-516

PF-517

PF-518

PF-519

PF-520

PF-521

Boiler

H.P.

18,5

23.4

28.4

JJ.J

J6.Z

43.2

482

JJ. I

*

cd. I

630

679

729

77.8

82.7

87,7

qzA

974

102

RATINGs

Netl = B = R

(2)

l=B=R

0utpul

5

Gross

MBH

620

785

oq1

1116

1281

1446

1612

1777

1942

21

08

2273

2438

2604

2769

2934

3099

3265

3430

Steam

Sq. Ft.

1

938

2454

2971

3488

401

3

4583

51 58

5725

6283

6821

7354

7888

8425

8958

9492

1

0025

I USOJ

11096

Rating

Steam

MBH

4bc

589

ttJ

837

963

1 100

1238

1374

1

508

1

637

tioJ

1

893

2022

2150

2278

2406

2535

2663

Waler

s@

LighlOil

MBH

111 A

| | tT

I lcl

1402

1

1

1

1977

2120

2264

2408

2551

2695

2839

2983

(3)

539

683

827

970

545

689

833

GPH

112

ILO

14.0

15

| /.u

18 4

19.8

21 5

22.5

240

25.5

zt.u

285

30.0

l=B=R

Burner

Capacity

Net

Firebox

Volume

Gas

MBH Steam Water

{4)

55

69

1204

8.3

't

t+tL

98

1619

1826

2033

2240

6

2448

2655

2862

3069

3276

3484

3691

3898

41 05

+Jtt

790

997

Al a

Ft.3

85

11 1

15.I

to.J

18.9

o1 A

Ll,a

z+. I

26.8

29.4

32.0

346

372

398

42.4

450

476

502

528

Plessure

In Firebox

(lnches

Water

Column)

(5)

244

244

245

245

246

246

247

aA1

L+t

248

248

249

249

250

250

lJl

251

252

252

57.45

73.44

89

105 42

121 41

137 40

ICJ.JY

169 38

185

201

217

ZJJ.J+

249.33

265.32

281

297

313 29

329.28

Heating

Surlace

Ft.,

43

37

36

35

31

30

66 12

85.00

103

88

12276

141

64

160

52

179 40

198 28

217.16

236.04

254

92

273.80

292

68

J I t.JO

44

330

349.32

20

368

387.08

Water Content

Gal.

Steam

Water

58

69

81

92

104

|3

126

138

149

tot

172

184

195

207

218

230

itl

zt+ |

253

IU

84

98

112

127

1i4

l.+ |

tco

170

184

198

212

226

244

255

270

280

298

otz

"S"

1 . Su'llix

gas

2. t= B = B

varytrom 1.333to 1.288 for

Net

3.

rem

For hish€r wat€r r€mp.rarurss' s.rect boirsr on basis

MBH.

4. Th6 |

'140,000

NOTE: WalerWor<iig

ndical6s sisam boil€r,

"O"

fir6d,

perarure

oil tircd and

n6t ralings shown ar€ bas6d on

ratings for water, squaro l6€t, ar€ bassd on 170.F average water

In

system.

= B =

R bu rnor capaclty in G PH i5 bas€d on oit hsving a heal value

p€r gallon.

BTu

Pr€ssurs

"W"

''GO"

ndicat€s wal€r boiler.

for comblnalion

steam and 1.15iorwat€r.

15 PSIWI-.

Sl€awal6r

PslwP

50

Water loolional)

{Oolional) 30

piping

70 PSIWP

gas-oil

and

PslwP

pick

Sutf

fted.

up a owancss wh tch

r=B=R Net Rarrnss'

ot

UBurnhard

AMERICA'S

BURNHAM CORPORATION

BOILER

COMPANY

'G"

x

ind

cates

-

ol

5.

Boilgr ratings ara basad

boilsr llu€ outl6t.

l=B=Av6ntdlam€leftor Boller

PF-515is14"andlorPF_516-PF-521ls18".

con

manulactuf€r tor Installalions

'sult

rsquirsm€nls, such as Inl€rmlltent

illiil":iii"

gas.

For

'ale

ol 4% lor each 1OO0 t€€t sbove

**"

altitudos abov€lhoss indicatsd, ihe ralings

12y.,k

on

*rry

Form No. 4256-C-10

Printed in

O 1990 Burnham

COz,

PF-504thru

No.

having unusual

sFtem operation, €xl€nsivs

at arritud€s up to 1oo0 r€st on ol and 2000 reer

t€vet.

sea

U.S.A.

piping

pre$ur€

pick

snd

+.10"

weter colu mn

PF-508is10",for PF-509-

shoutd be reduced at th€

I 94-2AMa

Corporation, Lancaster,

up

piping

PA

at

on

Loading...

Loading...