Page 1

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

OPM

RELIOBLIOSSAP-3

As an

ENERGY STAR

Burnham Hydronics

has determined that the

MPO84, MPO147, MPO189

and MPO231 meet the

ENERGY STAR

guidelines for Energy

effi ciency established by the

United States Environmental

Protection Agency (EPA).

®

Partner,

®

rebmuNledoMrelioBrebmu

__-___OPM_______6

rotcartnoCgnitaeH rebmuNenohP

gnikeesnehW.reilppusliororotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

gnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliobnonoitamrofni

.reliobehtfopotnodetacollebaL

NlaireSrelioBetaDnoitallatsnI

sserddA

100103-01R3-10/05

Price - $3.00

Page 2

IMPORTANT INFORMATION - READ CAREFULLY

,gnibmulPlacoLdnaetatS,lanoitaNhtiwecnadroccanidellatsniebtsumsreliobllA

sedoCesehT.seitilitugnivresehtfosnoitalugerehtdnasedoClacirtcelEdnagnitaeH

gnivahseitirohtuA.launamnoitcurtsnisihtmorfreffidyamsnoitalugeRdna

.edamerasnoitallatsnierofebdetlusnocebdluohsnoitcidsiruj

:sdradnatSgniwollofehtotedamebdluohsecnerefer,sesacllanI

SRELIOBASU

.A

.secitcarpnoitallatsnidednemmocerrof,”tnempiuqEgninruB

.B

.C

.secivedytefasdnaslortnocfosnoitarepo

.D

.snoitalugeRlacoLro/dnaedoClacirtcelElanoitaN

SRELIOBNAIDANAC

liOfonoitallatsnI“,13APFN/ISNAdradnatSlanoitaNnaciremAfonoitidEtnerruC

,syenmihC“,112APFN/ISNAdradnatSlanoitaNnaciremAfonoitidEtnerruC

.stnemeriuqergnitneVroF,”secnailppAgninruBleuFdiloSdna,stneV,secalperiF

,1-DSCEMSAsreenignElacinahceMfoyteicoSnaciremAfonoitidEtnerruC

dnaylbmessarof,"srelioBderiFyllacitamotuArofseciveDytefaSdnaslortnoC"

ehthtiwecnadroccaniedamebllahsASUehtnidellatsnisreliobnogniriwllA

.A

.secitcarPnoitallatsnIdednemmocerrof,"tnempiuqEgninruBliOrof

.B

.snoitalugeRlacoLro/dnaedoClacirtcelEnaidanaC

The following terms are used throughout this manual to bring attention to the presence of hazards

edoCnoitallatsnI",931BASCnoitaicossAsdradnatSnaidanaCfonoitidEtnerruC

ehthtiwecnadroccaniedamebllahsadanaCnidellatsnisreliobnogniriwllA

of various risk levels, or to important information concerning product life.

REGNAD

suodrazahyltnenimminasetacidnI

tluserlliw,dediovatonfi,hcihwnoitautis

laitnatsbusroyrujnisuoires,htaedni

.egamadytreporp

.egamad

GNINRAW

suodrazahyllaitnetopasetacidnI

dluoc,dediovatonfi,hcihwnoitautis

royrujnisuoires,htaednitluser

reporplaitnatsbus

.egamadyt

NOITUAC

suodrazahyllaitnetopasetacidnI

ytreporproyrujnironimroetaredomni

ECITON

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

.sdrazahyrujnilanosrep

tluseryam,dediovatonfi,hcihwnoitautis

2

ECITON

.launamsihtfokcabehtnodetnirpsihcihwfoypoca,ytnarrawdetimilasahreliobsihT

dnadeniatniam,dellatsnineebsahreliobehtfiylnodilavsireliobsihtrofytnarrawehT

.snoitcurtsniesehthtiwecnadroccanidetarepo

rpgnirutcafunamehtotdetubirttaebyamsnoitcesnoritsacnotsurecafruS

S.egarotsgnirudnoitasnednocsa

reliobafoytivegnolroecnamrofrep

.

ehttceffatonseoddnalamronsitsurecafru

llewsasseco

Page 3

REGNAD

rosihtfoytinicivehtnisdiuqilrosropavelbammalfrehtoroenilosagesuroerotsTONOD

.ecnailpparehtoyna

GNINRAW

ytreporpesuacnacecnanetniamroecivres,noitaretla,tnemtsujda,noitallatsnireporpmI

reporpehtnisnoitcurtsnillawollofoteruliaF.efilfossolroyrujnilanosrep,egamad

anosrepesuacnacredro

.naicinhcetecivresdnarenwoybecnereferrofecnailppa

,snoitcurtsnilladnatsrednudnadaeR.htaedroyrujnil

dedivorperahcihwslaunamsrerutcafunamtnenopmocnideniatnocesohtllagnidulcni

sihtgnicivresrogniniatniam,gnitarepo,pu-gnitrats,gnillatsnierofebecnailppaehthtiw

raendetsopdnanoitidnocelbigelnierutaretildnalaunamsihtpeeK.ecnailppa

efasetarepootecivresdnaecnanetniamralugerseriuqerreliobsihT

.launamsihtnideniatnocsnoitcurtsni

epxenaybylnodemrofrepebtsumecivresdna,ecnanetniam,noitallatsnI

.ycnegaecivresrorellatsnielbaegdelwonkdnadelliks

ordyhfonoitallatsnidnatuoyalehtnielbaegdelwonk

.reliobynafonoitallatsnitpmetta

sievlavfeilererusserpasselnuetelpmoctonsinoitallatsnI

.sliatedroflaunam

noitallatsniehtnehwylreporpgnitarepoeradnadellatsni

tsnirofelbatiussireliobsihT

.gniteprac

.slortnocroreliobehtretlarohtiwrepmattonoD

tsehttaylbareferp-raeyaecnotsaeltasyaweulftcepsnI

.detalumuccasahelacsrotoosfidenaelc

iobsihtgninaelcnehW

.yletaidemmidecalperebtsumnoitalusni

.detelpmocsi

ehtwolloF.yl

,decneir

snosrepylnodnasrotcartnoctnetepmocybdengisedebdluohssmetsysgnitaehllA

dluohssmetsysgnitaehcin

-pat"4/3ehtotnidellatsni

eeS-noitcesraerfopotnossobotnidellatsnisawtahtdlofinamnruternodetacolgnip

sihtfosnoitceSgnipiPrelioBretaWdnaslortnoC&mirT-ylbmessArelioBdegakcaP

yltcerroceraslortnocllatahteesotrotcartnocgnillatsniehtfoytilibisnopserehtsitI

noreliobllatsnitonoD.gniroolfelbitsubmocnonoitalla

.nosaesgnitaehehtfotra

ebdluohssyaweulfreliobdnametsystneveht,rebmahcnoitsubmocehtfoedisniehT

roodgniwsrenrubotegamaddiovaotnoituacerpekat,rel

roodgniwsrenrub,egamadsuoiverpfoecnedivesierehtfiro,degamadfI.noitalusni

.detatissecen

.retaw

ebyamsaroraeyaecnotsaeltadekcehcebtsumslortnoCdnarenruBliO

.sec

ivedytefasroslortnoctnesbaroderepmujhtiwtinuetarepotonoD

tnocynafitinuetarepotonoD

rehtodnastcefedhtrib,recnacesuacotainrofilaCfoetatsehtotnwonkera

.ecnailppaehtybraengnikrowrognicivresnehw

ottcejbusneebsahecivedro,tnenopmoc,hctiws,lor

niatnocleufehtdnanoitsubmocfostcudorp,noitcurtsnocfoslairetamecnailppA

ro/dnasedyhedla,sedixonegortin,edixonomnobrac,slatemyvaeh,acilis,animula

hcihwdnayrujnisuoiresrohtaedesuacnachcihwsecnatsbuslufmrahrocixotrehto

tnempiuqednasrotaripser,gnihtolcytefasreporpesusyawlA.mrahevitcudorper

3

Page 4

GNINRAW

epipynawercsnutonoD.erusserphgihrednuretawtohyrevsniatnocreliobsihT

ylevitisoptuohtiwreliobsihtfostnenopmocynatcennocsidottpmettaronsgnittif

dnagnihtolcevitcetorpraewsyawlA.erusserponsahdnaloocsiretawehtgnirussa

.seirujnidlacstneverpotreliobsihtgnicivresropugnitrats,gnillatsninehwtnempiuqe

dnaerutarepmetehtenimretedotseguagerutarepmetdnaerusserpehtnoylertonoD

nehwtohyrevemocebhcihwstnenopmocsniatnocreliobsihT.reliobehtfoerusserp

.loocerayehtsselnustnenopmocynahcuottonoD.gnitareposireliobeht

btsumyenmihcehT.detnevylreporpebtsumreliobsihT

."gnipiPekatnIriAdnagnitneV",VnoitceSotrefeR

edarofsnoisivorp

ettanutfelebtondluohsmetsys

.evit

areponi

odgniwsrenrubhtiwdeppiuqesreliobllA

.detelpmocsiecivresnehwyletelpmoc

.rianoitalitnevdnanoitsubmocetauq

ibissopasisepipnezorfoteudegamadfI.ecivrestuohtiwtrats-er

gnrubreveN.enilosaggniniatnoclioynaro,sgniniard

ynarofdetcepsnie

detcurtsbonudnanaelcA.nosaesgnitaehhcaeotroirpdenaelcdnasnoitcurtsbo

etaucaveylefasotderiuqertfardmuminimehtecudorpotyrassecensieulfyenmihc

sirbedesoolfoecnedivE.efilfossolroyrujnilanosrepesuacdluoctahtsemufsuoixon

rorotcennoc,eulfyenmihcehtfoesabehttasniatsdecudnietasnednocrodna

sietasnednocsageulF.sesageulfgnisnednocfosngisebyamstniojepipekoms

.yletaidemmidesserddaebtsumdnanoitaredisnoclaicepsseriuqerhcihw,evisorroc

eraerehtosdellatsniebtsumdnanoitarepoefasrofriahserfsdeenreliobsihT

tondnanwodtuhsotreliobehtesuacyamhcihwslortnochtiwdeilppussireliobsihT

gnitaeheht,ytil

dnasdraugefasetairporpparo;rehtaewdlocnidedn

sireliobehtfiegamadtneverpotmetsysgnitaehehtnodellatsniebdluohssmrala

esacknarc,enilosagesutonoD.ylnolioleuf2.oNnrubotdengisedsireliobsihT

.reliobsihtnirepaproegabra

leufsuoesagynaottrevnoctonoD.)laoc,doow.e.i(leufdilosynaottrevnoctonoD

ebdluohs,.cte,sparcsdoow,repap,sgar,sirbedelbammalfllA.)PL,saglarutan.e.i(

.sdrazaheriffoeerfdnanaelcaerareliobehtpeeK.semitllatareliobehtforaelctpek

,derongifi,hcihwdrazahlaitnetopaevahro

gninepoerofeB.efilfossolroyrujnilanosrep,egamadytreporperevesesuacnac

forenrocthgirrewolnidetacolelcatpecermorfdrocrewoprenrubgulpnu,roodgniws

fogniriflatnediccatneverpotreliobothctiwsecivresffonrutdnalenaptnorftekcaj

srenetsafroodgniwsnethgitoteruseB.rebmahcnoitsubmocehtedistuorenrub

4

Page 5

STNETNOCFOELBAT

.I.....................................noitallatsnI-erP8.IIIV.....................................pU-tratSmetsyS53

.II...lortnoC&mirT-.yssArelioBdegakcaP01.XI..........noitcutsnIecivreS&ecnanetniaM34

.III...........

.VI..............

.V.................

.IV...

.IIV..............................

................gnipiPliO33

.........gnipiP&mirTrelioBretaW12.X......................................gninaelCrelioB54

.....gnipiPretaeHretaWtceridnI52.IX...................................gnitoohSelbuorT74

...............................gnitneV62.IIX...........................................straPriapeR84

............................................lacirtcelE13

.IIIX.xidneppA

.................................ffOtuCretaWwoL06

5

Page 6

6

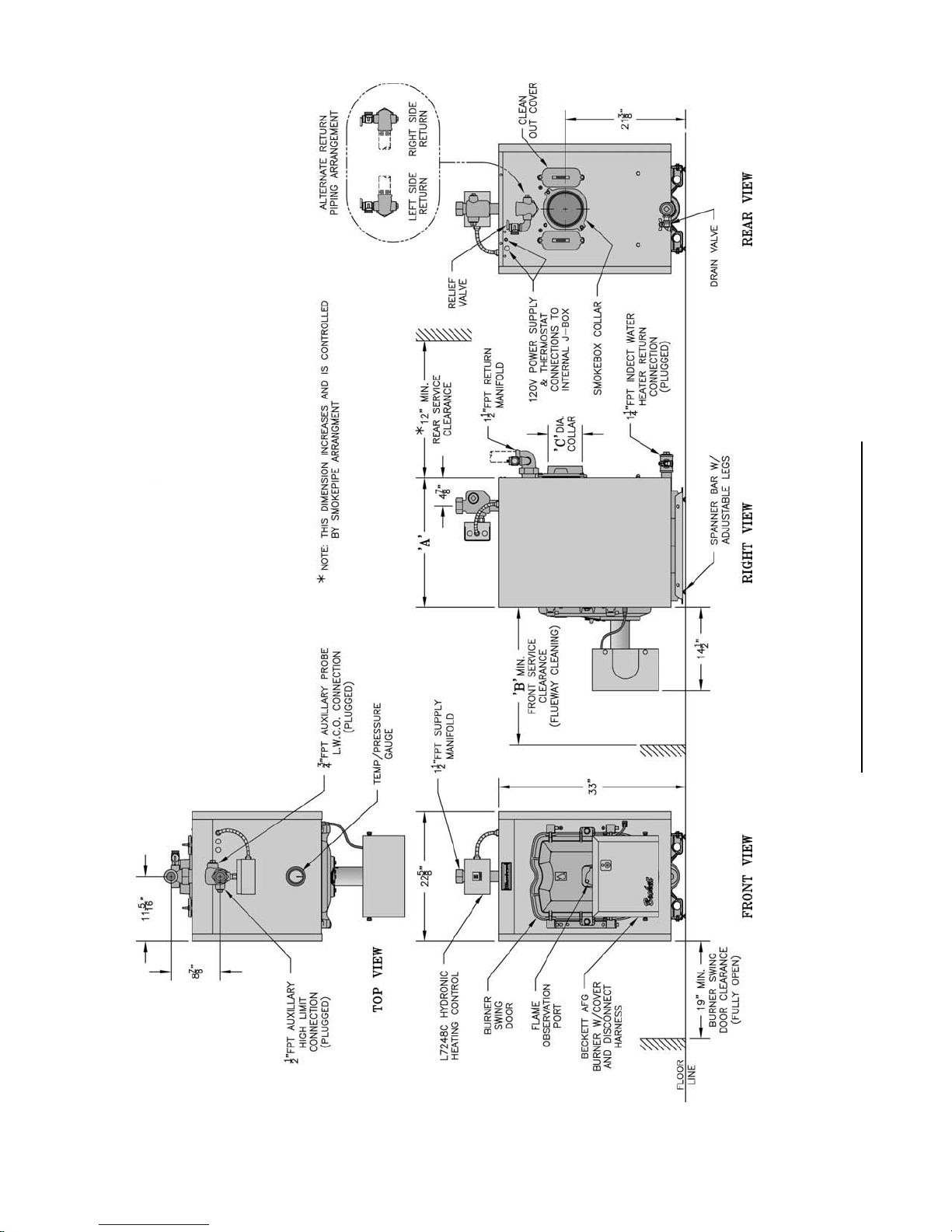

Figure 1: MPO 84 Thru MPO 231 Water Boiler

Page 7

relioB

gnippihSlautcA

).B

retaW

L(thgieW

stnemeriuqeRyenmihCmuminiM%EUFA

thgieH

.tF

-aerAecafruS

refsnarTtaeH

lanoitpOISP05,lanoitpOISP04

elgnatceR

.nIx.nI

.tF.qS

.nIdnuoR

.aiD

-tnetnoC

snollaG

retaW

sgnitaR

R=B=I

TEN

1erugiFeeS

snoisnemiD

yticapaCrenruB

re

taW

gnitaeHEOD

HBM

HBMyticapaC

"A""B""C"

.oNledoM

741OPM"8/5-22"42"680.1192.02545

relioB

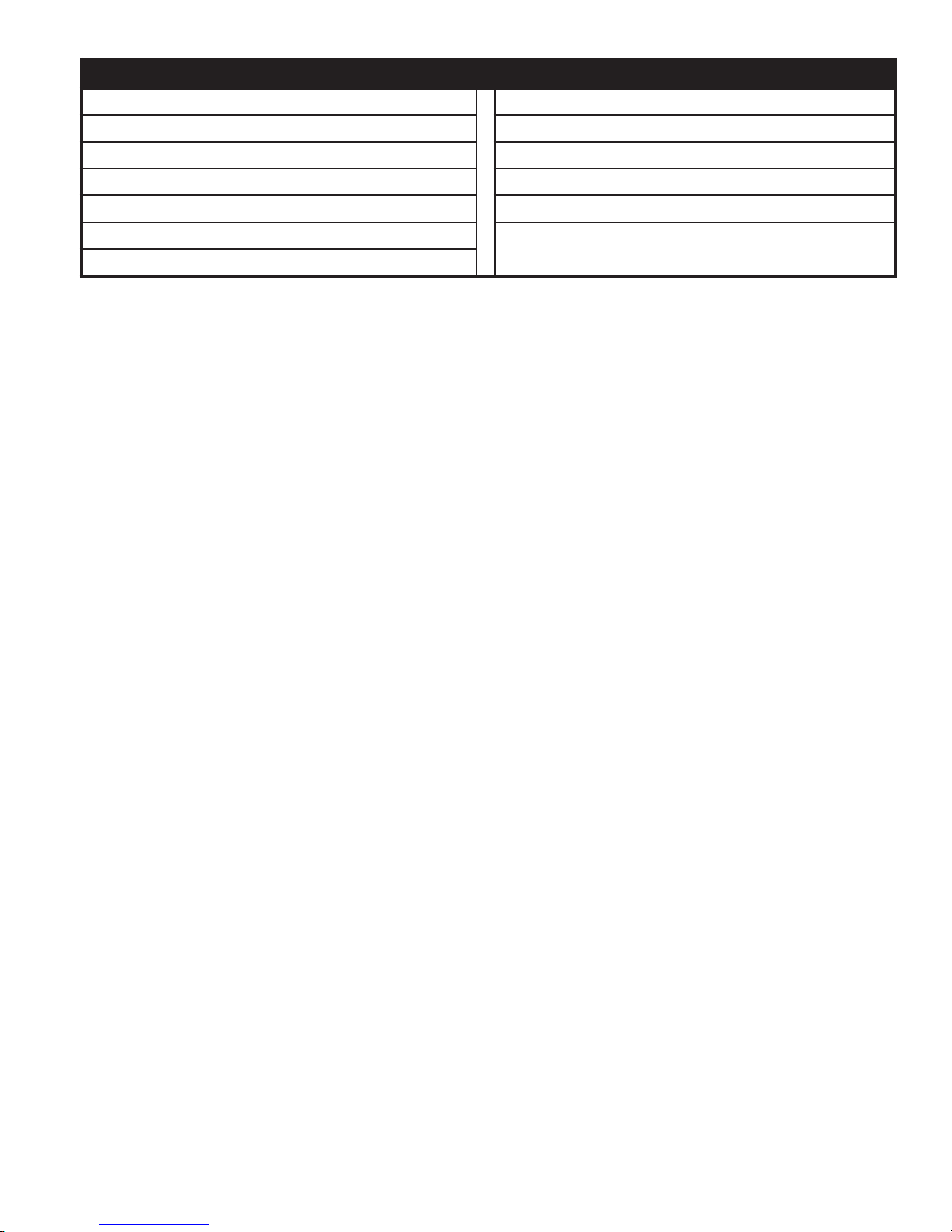

TABLE 1A: DIMENSIONAL DATA (SEE FIGURE 1)

48OPM"8/5-61"42"507.792.31034

HPGHBM

132OPM"8/5-43"63"748.7192.43177

981OPM"8/5-82"03"664.4192.72856

.1:

ETON:retaW:erusserPgnikroWmumixaM ,)dradnatS(yrotcaFmorFdeppihSISP03

TABLE 1B: RATING DATA

.oNledoM

741OPM50.17419212116 8X8510.78

relioB

48OPM06.04847466 8X8510.78

132OPM56.11323027717 8X8510.78

981OPM53.19817615417 8X8510.78

7

Page 8

SECTION I: PRE-INSTALLATION

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. All equipment is carefully manufactured, inspected

and packed. Our responsibility ceases upon delivery

of crated boiler to the carrier in good condition.

2. Any claims for damage or shortage in shipment

must be fi led immediately against the carrier by the

consignee. No claims for variances from, or shortage

in orders, will be allowed by the manufacturer

unless presented within sixty (60) days after receipt

of goods.

B. LOCATE BOILER in front of fi nal position before

removing crate. See Figure 1.

1. LOCATE so that vent pipe connection to chimney

will be short and direct.

2. BOILER IS SUITABLE FOR INSTALLATION

ON COMBUSTIBLE FLOOR. Boiler cannot be

installed on carpeting.

3. FOR BASEMENT INSTALLATION, provide

a solid elevated base, such as concrete, if fl oor is

not level, or if water may be encountered on fl oor

around boiler.

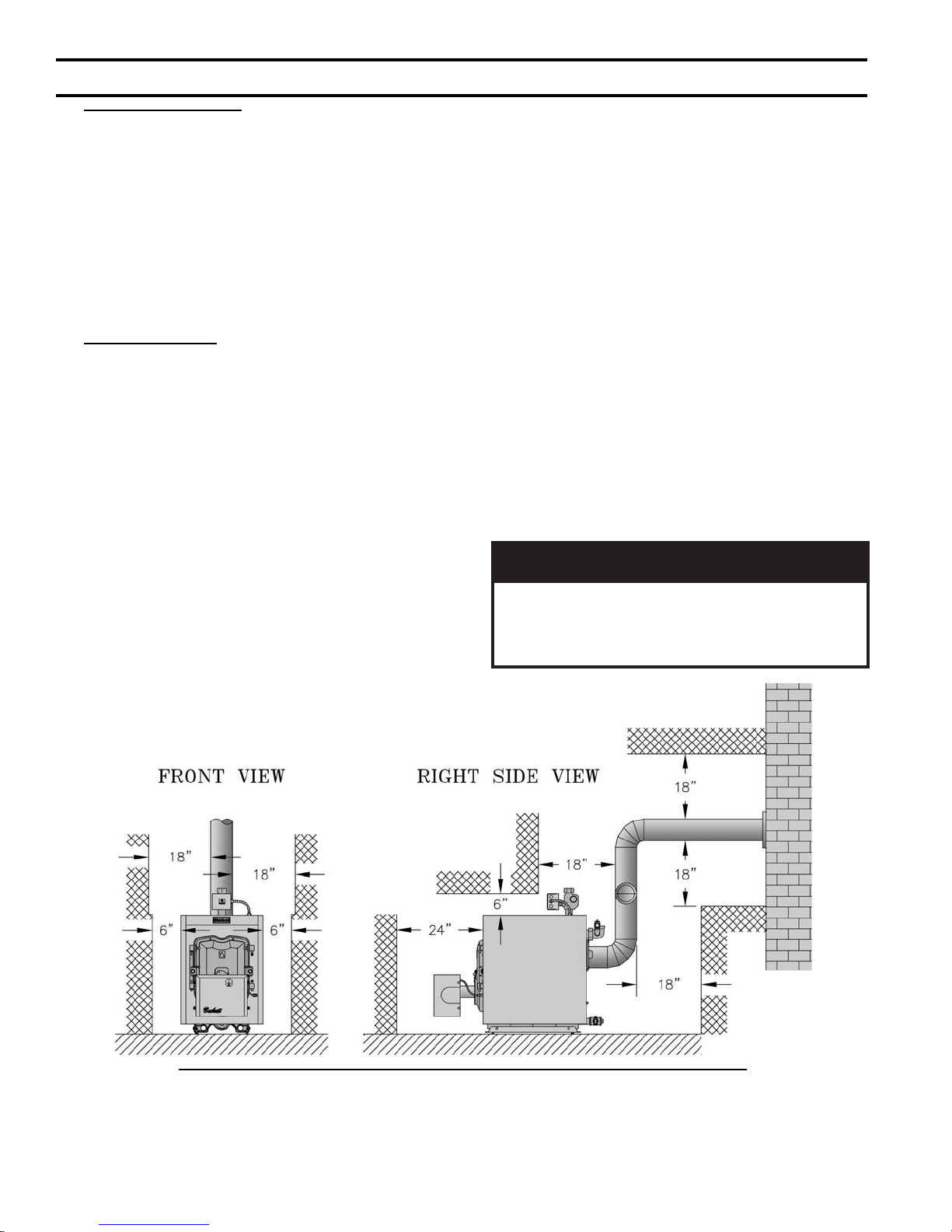

4. PROVIDE RECOMMENDED SERVICE

CLEARANCE, if applicable, as follows:

a. Clearance from Jacket Front Panel -

• 24" for servicing burner

• 24" for fl ueway cleaning (MPO84 & 147)

• 30" for fl ueway cleaning (MPO189)

• 36" for fl ueway cleaning (MPO231)

b. Clearance from Jacket Left Side Panel -

• 19" for burner swing door, if opened fully

with burner mounted, otherwise 1" with

burner removed

• 12" access clearance to service rear of

boiler if right side clearance is less

than 12"

• 1" minimum if right side clearance is 12" or

larger to access and service rear of boiler.

c. Clearance from Jacket Right Side Panel -

• 3" minimum if left side clearance is 12" or

larger to access and service rear of boiler.

d. Clearance from Jacket Rear Panel -

• 12" minimum for rear smokebox cleaning

(Note: This dimension will also be

controlled by horizontal to vertical to

horizontal smokepipe arrangement - See

Figures 2 and 16.)

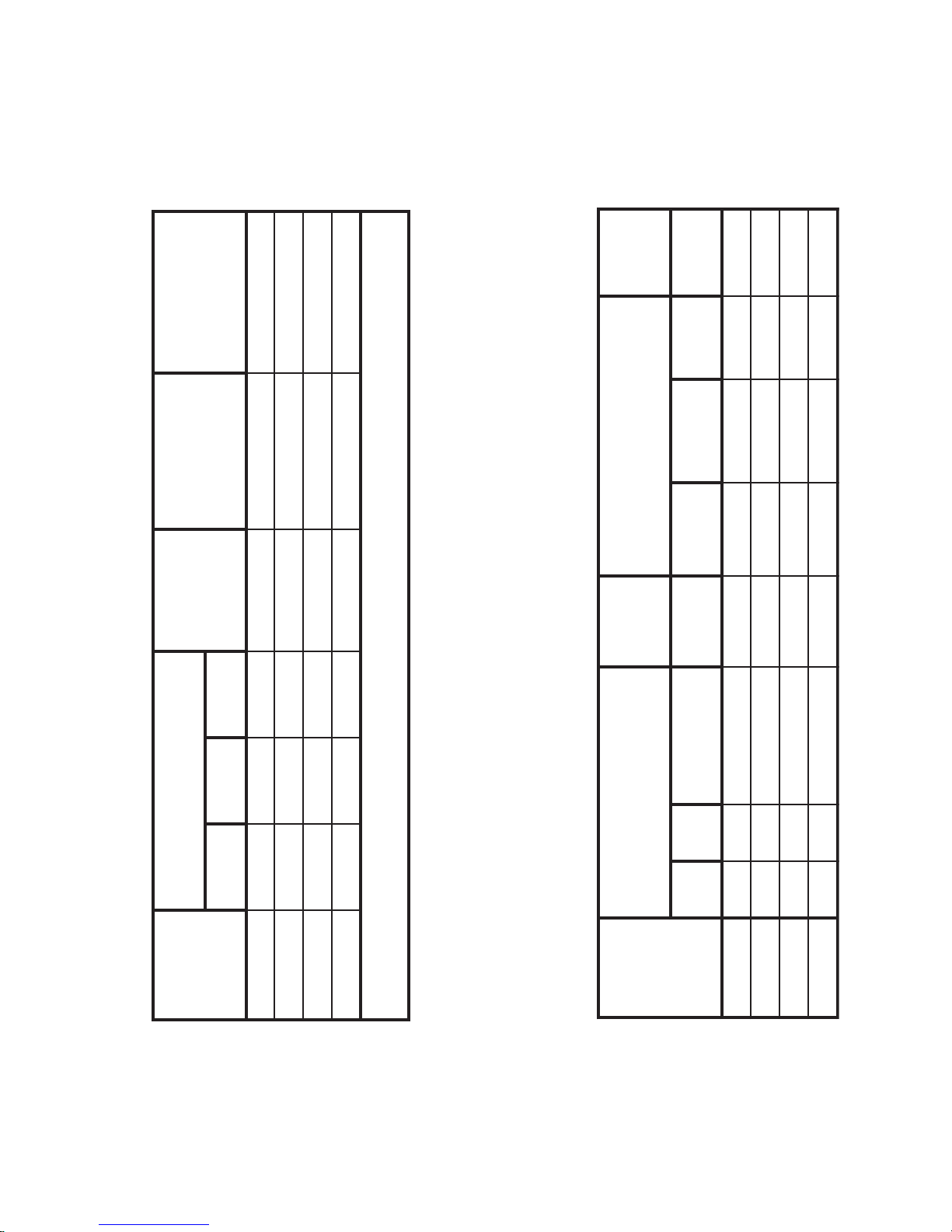

5. For minimum clearances to combustible materials.

See Figure 2.

ECITON

tnevllawelgnisrofsignitnevotecnaraelC

yamecnaraelc,desusitnevLepyTfI.epip

dereb

.rerutcafunamepiptnev

ehtybderiuqermuminimehtotdecu

Figure 2: Minimum Installation Clearances To Combustible Materials (Inches)

NOTES:

1. Listed clearances comply with American National Standard

ANSI/NFPA 31, Installation of Oil Burning Equipment.

2. MPO boilers can be installed in rooms with clearances from

8

combustible material as listed above. Listed clearances cannot

be reduced for alcove or closet installations.

3. For reduced clearances to combustible material, protection

must be provided as described in the above ANSI/NFPA 31

standard.

Page 9

C. PROVIDE COMBUSTION AND VENTILATION

AIR. Local and National Codes may apply and should

be referenced.

GNINRAW

noitalitnevdnanoitsubmocetauqedA

reporperussaotdedivorpebtsumria

efasniatniamotdnanoitsubmoc

.serutarepmetriatneibma

roenilosagerehwreliobllatsnitonoD

ro,sdiuqilrosropavelbammalfrehto

,sehcaelb.e.i(snobracordyhfosecruos

rodesuera).cte,srenetfoscirbaf

.derots

1. Determine volume of space (boiler room). Rooms

communicating directly with the space in which

the appliances are installed, through openings not

furnished with doors, are considered a part of the

space.

Volume(ft3) = Length(ft) x Width(ft) x Height(ft)

2. Determine total input of all appliances in the space.

Add inputs of all appliances in the space and round

the result to the nearest 1000 BTU per hour.

3. Determine type of space. Divide Volume by total

input of all appliances in space. If the result is

greater than or equal to 50 ft3/1000 BTU per hour,

then it is considered an unconfi ned space. If the

result is less than 50 ft3/1000 BTU per hour then the

space is considered a confi ned space.

4. For boiler located in an unconfi ned space of a

conventionally constructed building, the fresh

air infi ltration through cracks around windows

and doors normally provides adequate air for

combustion and ventilation.

5. For boiler located in a confi ned space or an

unconfi ned space in a building of unusually tight

construction, provide outdoor air.

a. Outdoor air for combustion may be provided

with an optional Burnham MPO (V8) Inlet Air

Accessory Kit, Part Number 611280031 (only

available and suitable for use on Beckett AFG

with burner enclosure cover burner). See

Section V for installation details.

or

b. Outdoor air may be provided with the use of two

permanent openings which communicate directly

or by duct with the outdoors or spaces (crawl or

attic) freely communicating with the outdoors.

Locate one opening within 12 inches of top

of space. Locate remaining opening within 12

inches of bottom of space. Minimum dimension

of air opening is 3 inches. Size each opening per

following:

i. Direct communication with outdoors.

Minimum free area of 1 square inch per

4,000 BTU per hour input of all equipment

in space.

ii. Vertical ducts. Minimum free area of 1

square inch per 4,000 BTU per hour input of

all equipment in space. Duct cross-sectional

area shall be same as opening free area.

iii. Horizontal ducts. Minimum free area of 1

square inch per 2,000 BTU per hour input of

all equipment in space. Duct cross-sectional

area shall be same as opening free area.

Alternate method for boiler located within

confi ned space. Use indoor air if two

permanent openings communicate directly

with additional space(s) of suffi cient volume

such that combined volume of all spaces

meet criteria for unconfi ned space. Size each

opening for minimum free area of 1 square

inch per 1,000 BTU per hour input of all

equipment in spaces, but not less than 100

square inches.

6. Louvers and Grilles of Ventilation Ducts

a. All outside openings should be screened and

louvered. Screens used should not be smaller

than 1/4 inch mesh. Louvers will prevent the

entrance of rain and snow.

b. Free area requirements need to consider the

blocking effect of louvers, grilles, or screens

protecting the openings. If the free area of the

louver or grille is not known, assume wood

louvers have 20-25 percent free area and metal

louvers and grilles have 60-75 percent free area.

c. Louvers and grilles must be fi xed in the open

position, or interlocked with the equipment to

open automatically during equipment operation.

9

Page 10

SECTION II: PACKAGED BOILER ASSEMBLY - TRIM & CONTROLS

A. REMOVE CRATE.

1. Remove all fasteners at crate skid.

2. Lift outside container and remove all other inside

protective spacers and bracing. Remove burner and

miscellaneous parts cartons.

B. REMOVE BOILER FROM SKID.

1. To reduce the risk of damage to boiler jacket, use

the following procedure to remove from skid, see

Figure 3:

Step 1. Boiler is secured to base with (4) 5/16" cap

screws, (2) in front and (2) in rear of shipping

skid, see Figure 3. Remove all securing

hardware.

Step 2. Place wooden block(s) 12" from rear of

skid as shown (one piece 4" x 4" x 16" lg. or two

pieces of 2" x 4" x 16" lg.)

Step 3. Insert 1" Sch. 40 pipe handles through leg

hole in front and rear legs. Center end of pipe on

wooden blocks as shown in Figure 3.

NOTE: Pipe handles should extend a minimum

of 48" beyond jacket front panel for best

leverage.

Step 4. Using the pipe handles, lift boiler until

adjustable legs are elevated above the deck

boards.

Step 5. Remove skid from underneath the boiler.

Step 6. Lower pipe handles until front adjustable

legs touch fl oor. If necessary, place wooden

blocks under front legs before lowering to

provide hand clearance.

Step 7. To lower rear of boiler, tilt unit slightly

forward by pushing on smokebox collar or lift

pipes protruding through rear legs until wooden

blocks can be removed (see Figure 3). Slowly

allow the weight of the boiler to tilt backward

until rear legs rest on fl oor.

Step 8. If wood block was placed under front legs,

lift pipe handles, remove wooden block and

lower front legs to fl oor. Remove pipe handles.

NOITUAC

reliobpmubtonoD.reliobpordtonoD

.roolftsniagatekcaj

C. MOVE BOILER TO PERMANENT POSITION

by sliding or walking.

D. PROCEDURE TO OPEN, CLOSE AND

SECURE BURNER SWING DOOR

Throughout this manual you will be instructed to open

and close the burner swing door for various reasons.

There is a proper and improper method to closing and

securing the burner swing door opened for inspection,

cleaning or fi eld service.

1. TO OPEN BURNER SWING DOOR

(see Figures 4A and 4B).

Step 1. Loosen but do not remove left side latching

hardware (3/8" x 1-3/4" lg. tap bolt).

Figure 3: Packaged Boiler Removal from Skid

10

Page 11

Figure 4A: Partial Front View - Burner Swing Door Mounted to Boiler - Fully Closed and Secured

Step 2. Loosen and remove right side latching

hardware (5/16" x 1-3/4" lg. tap bolt and

washer).

Step 3. Remove left side latching hardware (5/16" x

1-3/4" lg. tap bolt and washer).

Step 4. Disconnect burner power cord from

receptacle located in lower right corner of jacket

front panel.

Step 5. Door can be swung to the fully open

position, approximately 90° to 120°, with the

burner mounted providing that there is 19" of

clearance to the adjacent wall, see Figure 1.

NOTE: If reduced clearance prevents the door

from opening fully, one of the following can

provide full access:

a. Burner can be removed to allow full rotation

of door.

b. Door with burner mounted can be lifted

off mounting bracket and set aside during

servicing.

c. The door mounting hardware is reversible

from left side hinge (as shipped) to right side

hinge.

To reverse hinge arrangement (see Figure

4A):

• Lift door off mounting bracket and set

aside.

• Remove mounting bracket and hardware

from left side.

• Remove upper jacket front panel retaining

screw (5/16" x 1/2" lg. Phillip Pan head

machine screw) from right side of door

and re-install in vacated upper mounting

bracket tapping. Do not tighten.

• Move lower jacket panel retaining screw

from right side to left tapping. Do not

tighten.

• Rotate door mounting bracket 180°.

Insert 5/16" cap screw through top hole in

bracket and install in upper vacated jacket

hole on right side of door.

• Install second 5/16" cap through bracket

hole into lower vacated tapping on right

side.

• Tighten both sets of hardware to secure

jacket and mounting bracket.

• Lift door and place integral cast hinge

pins on door into slotted mounting bracket

holes.

2. Perform routine inspection, service or cleaning as

necessary.

3. To close Burner Swing Door (see Figures 4A and

4B):

Step 1. From the fully open position, rotate Burner

Swing Door to the closed position.

Step 2. If necessary, place your right hand under

the burner air tube to lift upward. Lift the

door up unto the built-in cast ramp/door rest

11

Page 12

Figure 4B: Top View - Burner Swing Door Mounted to Cast Iron Block Assembly (Jacket Removed for Clarity)

12

Page 13

(protruding from the bottom of the front section

casting - see Figure 4A).

Step 3. Use one hand to help hold door in position

by lifting up on rear burner housing or applying

pressure directly to the door while re-installing

the securing hardware with your opposite hand.

Always install right side latching hardware

(5/16" x 1-3/4" lg. tap bolt and fl at washer)

fi rst, then install left side hinge hardware (5/16"

x 1-3/4" lg. tap bolt and fl at washer) second.

Apply additional pressure while hand tightening

the hardware as far as possible, then release the

pressure.

E. INSPECT SWING DOOR INSULATION AND

ROPE GASKET.

1. Open burner swing door using procedure previously

outlined in Paragraph D of this section.

2. Inspect fi berglass rope located on the swing door.

The rope must be evenly distributed around the

perimeter of the door groove and cannot bunch or

overhang. There must not be a gap where the two

ends of the rope meet. Repair or replace if the rope

is damaged or if there is a gap between the ends.

3. Inspect burner swing door insulation for damage and

proper type.

ECITON

ekamroodgniwsrenrubgnirucesnehW

.sedishtobnoyllauqeni-nwardsirooderus

Step 4. Use a hand wrench to tighten door hardware

and always start with the right side cap

screw fi rst. Use an alternating tightening

method from right side tap bolt to left side tap

bolt to tighten door equally until sealed without

applying excessive torque. Never tighten left

side fl ange bolt fi rst or tighten either piece of

hardware 100% without using the alternating

tightening method described above.

Failure to follow the prescribed procedure could

cause thread damage to casting or a leak in the

door seal. If left side tap bolt is tightened before

right side tap bolt, right side of door can not be

drawn-in to provide an air tight seal, as shown in

Figure 4C. Applying excessive torque will only

cause thread damage.

a. By design, cast bars on front section between

the combustion chamber and between the left

and right side 2nd and 3rd pass fl ueway should

make an impression in door insulation to seal the

chambers.

b. By design, door insulation on model MPO231

will have two (2) by-pass pockets cast into

the insulation centered on the bar between the

combustion chamber and 3rd pass fl ueways.

On models MPO84 thru MPO189 these pockets

should not be present. If insulation is damaged

or not of proper type regarding pockets, it must

be replaced.

4. Do not close and secure door at this time, proceed to

Field Assembly Details, Paragraph F.

F. FIELD ASSEMBLY OF BOILER TRIM AND

CONTROLS

Open miscellaneous parts carton and remove contents.

Identify the components using the illustrations (Figures

Figure 4C: Top View - Burner Swing Door Fully Closed but Not Properly Secured or Sealed

13

Page 14

5 thru 12) throughout the assembly sequence outlined

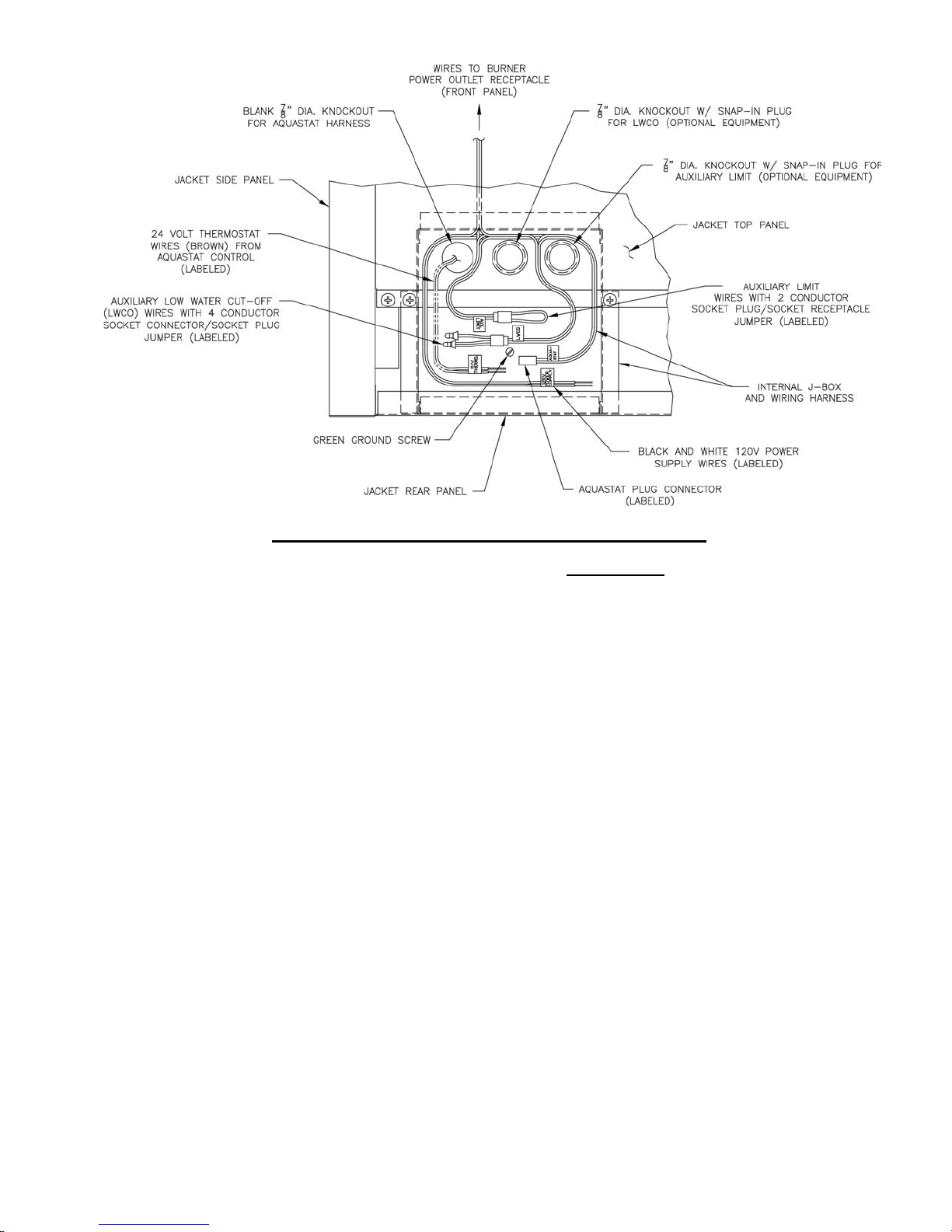

below as it applies to your installation.

1. Install supply manifold and aquastat control, refer to

Figure 5.

Step a. Remove two (2) #8 x 1/2" lg. sheet metal

screws securing jacket top rear panel to jacket

rear panel. Slightly lift and pull jacket top rear

panel away from jacket top panel to gain access

to internal J-box wiring harness.

Step b. Locate the cast iron supply manifold shown

in Figure 5. Apply thread sealant to 1-1/2" NPT

male threads. Thread male end into 1-1/2" NPT

top tapping on rear section. Using hex head on

top, tighten manifold until 1/2" NPT boss for

control well is facing forward and joint is water

tight.

Step c. Locate 1/2" NPT x 1-1/2" immersion well.

Apply thread sealant to 1/2" NPT male threads.

Thread well into 1/2" NPT boss on front of

supply manifold. Using hex head, tighten well

until water tight.

Step d. Locate L7248C Aquastat Control/Harness

Assembly. Loosen mounting screw on bottom of

case. Insert sensor into immersion well. Mount

control on immersion well and tighten screw to

secure control in horizontal position with harness

on right side as shown in Figure 5.

Step e. Insert two (2) brown thermostat wires and

three (3) aquastat wires with Molex socket

connector located on opposite end of aquastat

harness through 7/8" dia. blank knockout in

jacket top panel. Fish these wires to rear of

internal junction box. Insert snap-in conduit

connector in 7/8" blank knockout, squeeze tabs

on side of connector, push into knockout and

release tabs to lock connector in place.

Step f. Inside internal junction box, locate wires

with mating aquastat plug connector labeled

"Aquastat" (refer to Figure 6 for details of

harness located inside internal junction box).

Align mating halves of socket connector from

aquastat control with harness plug connector.

Push connectors together until snap on connector

is locked in place.

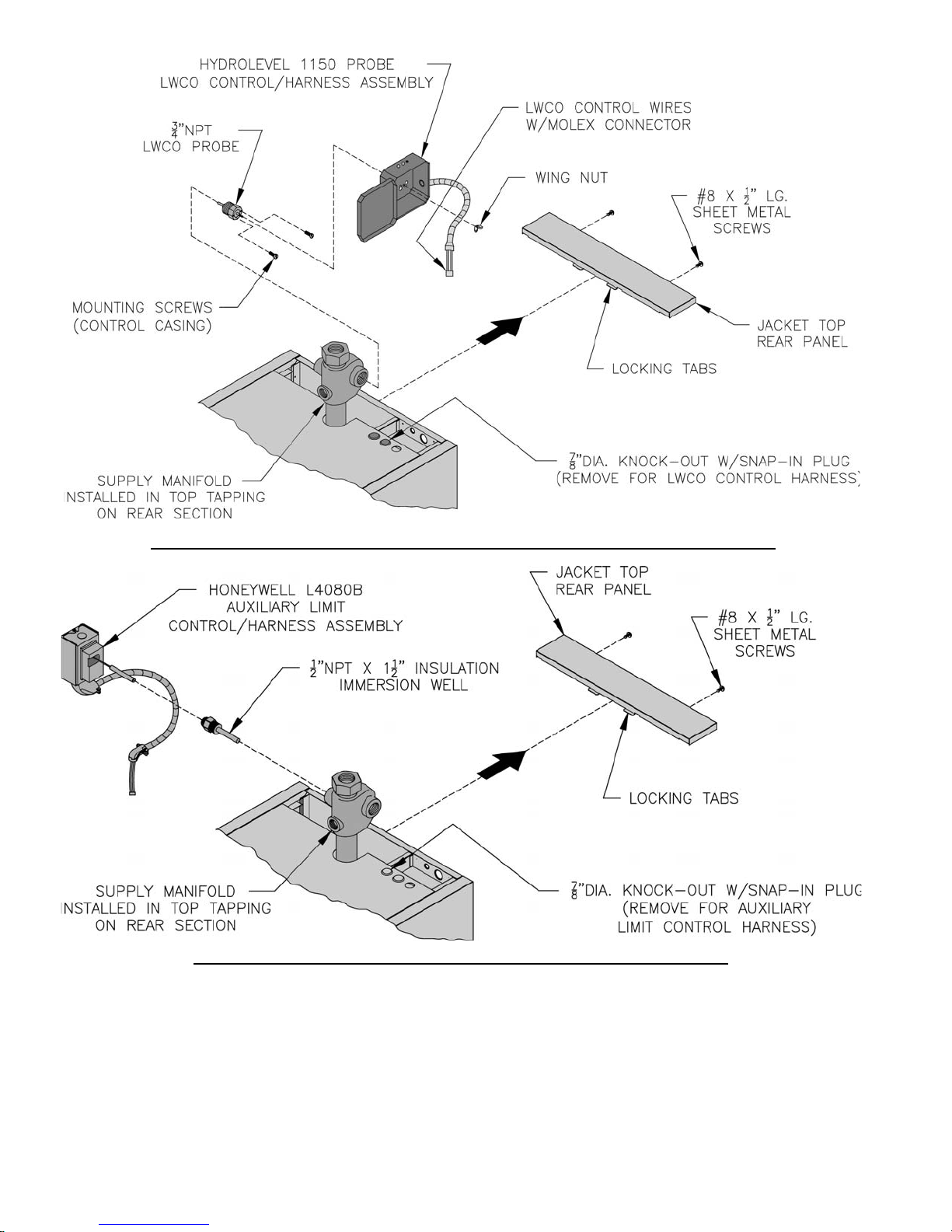

2. If required on this water boiler application, install

low water cut-off (LWCO) Kit, optional equipment

- Burnham P/N 100106-01, refer to Figure 7. Also

refer to instructions provided with LWCO Kit.

If not required, proceed to Paragraph 3.

Step a. Apply sealant to probe threads and install

in 3/4" NPT tapping on right side of manifold as

shown. Tighten so that the mounting screws are

horizontally aligned and joint is water tight.

Step b. Remove wing nut from the probe terminal.

Loosen screw and open cover on control box.

Figure 5: Supply Manifold and Aquastat Control Assembly Details

14

Page 15

Figure 6: Internal Junction Box and Wiring Harness Details

Mount the control box on the probe by aligning

the keyhole slots with the probe mounting

screws. Replace the wing nut. Secure the

control box by tightening wing nut and two (2)

mounting screws.

Step c. Remove snap-in plug from 7/8" dia. center

knockout, adjacent to aquastat control harness.

Step d. Insert three (3) wires with Molex connector

located on opposite end of LWCO harness

through 7/8" dia. knockout. Fish wires with

Molex connector to rear of internal junction box.

Insert snap-in conduit connector into 7/8" dia.

knockout, squeeze tabs on side of connector,

push into knockout and release tabs to lock

connector in place.

Step e. Inside internal junction box, locate wires

with mating LWCO socket connector labeled

"LWCO" (refer to Figure 6 for details of harness

located inside internal junction box). Remove

the factory installed socket plug jumper from

LWCO harness socket connector and discard.

Align mating halves of plug connector from

LWCO control with harness socket connector.

Push connectors together until snap on side of

connector is locked in place.

3. If required on this water boiler application,

install Auxiliary Dual Limit Control Kit, optional

equipment - Burnham P/N 100107-01, refer to

Figure 8. Also refer to instructions provided with

Auxiliary Dual Limit Control Kit.

If not required, proceed to Paragraph 4.

Step a. Locate 1/2" NPT x 1-1/2 immersion well.

Apply thread sealant to 1/2" NPT male threads.

Thread well into 1/2" NPT boss on left side of

supply manifold. Using hex head, tighten well

until water tight.

Step b. Locate L4080B Auxiliary Limit Control/

Harness Assembly. Loosen mounting screw on

side of case. Insert sensing bulb into immersion

well. Mount control on immersion well and

tighten screw to secure control in vertical

position with harness extending toward rear as

shown in Figure 8.

Step c. Remove snap-in plug from 7/8" dia.

knockout closest to supply manifold. Remove

locking ring from 90° conduit connector on end

of control harness.

Step d. Insert two (2) wires with Molex connector

located on end of auxiliary limit control harness

through 7/8" dia. knockout. Fish wires with

Molex connector to rear of internal junction

box. Insert 90° conduit connector into 7/8" dia.

knockout, secure to top panel with locking ring.

Step e. Inside internal junction box, locate wires

with mating auxiliary limit socket connector

labeled "Aux. Limit" (refer to Figure 6 for

details of harness located inside internal junction

box). Remove the factory installed socket plug

jumper from harness socket connector and

discard. Align mating halves of plug connector

15

Page 16

Figure 7: Optional Equipment - Low Water Cut-Off (LWCO) Control Assembly Details

Figure 8: Optional Equipment - Auxiliary Limit Control Assembly Details

from auxiliary limit control with harness socket

connector. Push connectors together until snap,

on side of connector, is locked in place.

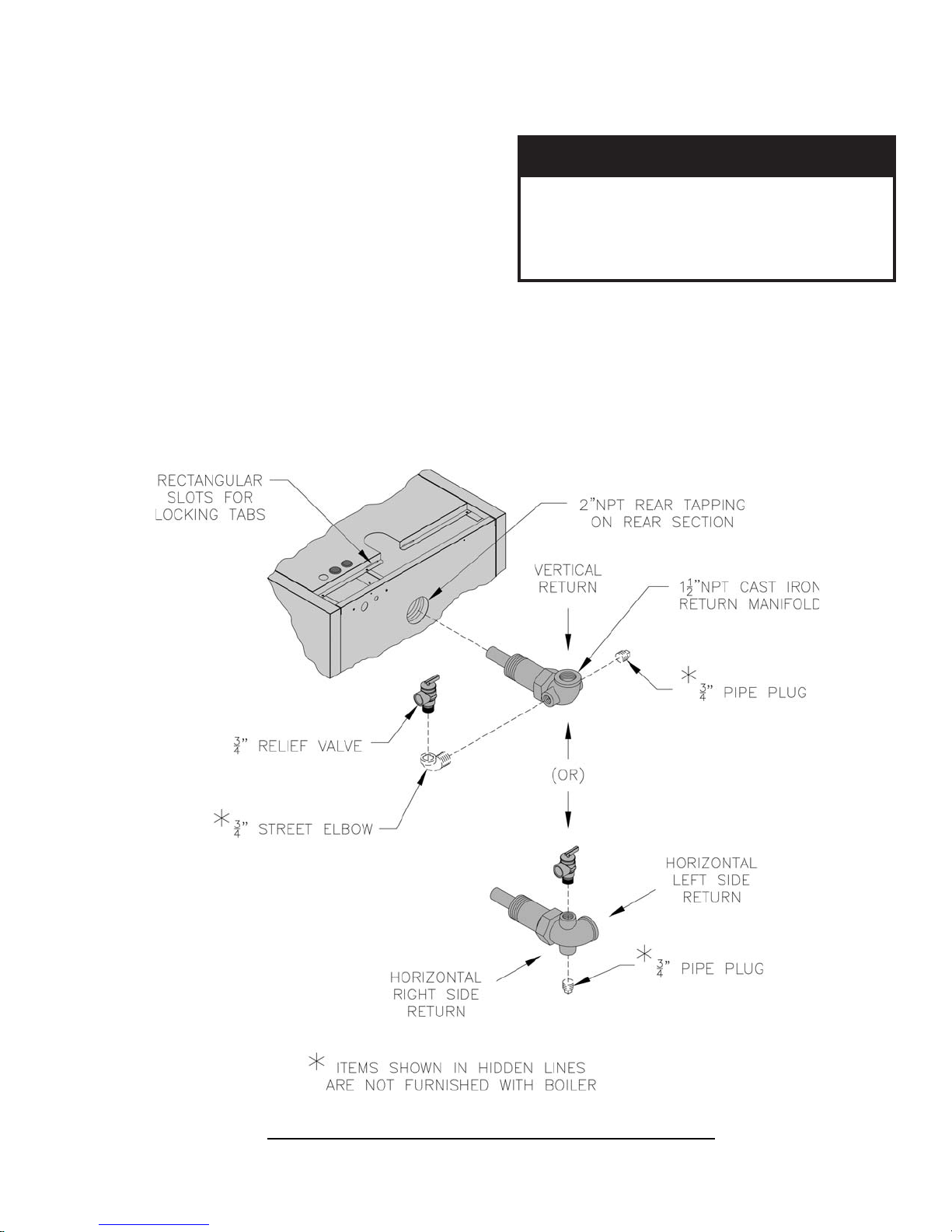

4. Install return manifold and relief valve, refer to

Figure 9.

Step a. Locate the cast iron return manifold with

injector nipple (installed). Apply thread sealant

to 2" NPT male threads. Insert injector nipple

16

into 2" NPT upper rear tapping on rear section,

engage 2" NPT male threads on end of manifold

and hand tighten.

Note: Based on system return piping and access

to service boiler, see Figure 1 and Figures 13A

and 13B, predetermine if manifold orientation

is to be positioned for vertical, horizontal left or

horizontal right side return piping as shown in

Figure 9.

Page 17

Place a wrench on the hex nut portion and

tighten manifold until the return pipe orientation

is correct for your installation and the joint is

water tight.

Step b. Install relief valve using 3/4" NPT tapping

on side of return manifold. Relief valve must

be installed in vertical position. If orientation of

return manifold is for:

• 1-1/2" NPT vertical return piping - Install

3/4" NPT x 90° street ell (not furnished)

into either the left or right side tapping on

return manifold. Install relief valve

vertically into street ell. Install 3/4" pipe

plug (not furnished) in tapping on

opposite side (see Figure 9).

• 1-1/2" NPT horizontal left or right side

return piping - Install relief valve vertically

in 3/4" NPT tapping located on top of

return manifold. Install 3/4" pipe plug (not

furnished) in bottom tapping as shown (see

Figure 9).

Step c. Pipe discharge of relief valve as shown in

Figures 13A and 13B. Installation of the relief

valve must be consistent with ANSI/ASME

Boiler and Pressure Vessel Code, Section IV.

GNINRAW

ub

.spacrosgulp,sevlavffo-tuhs

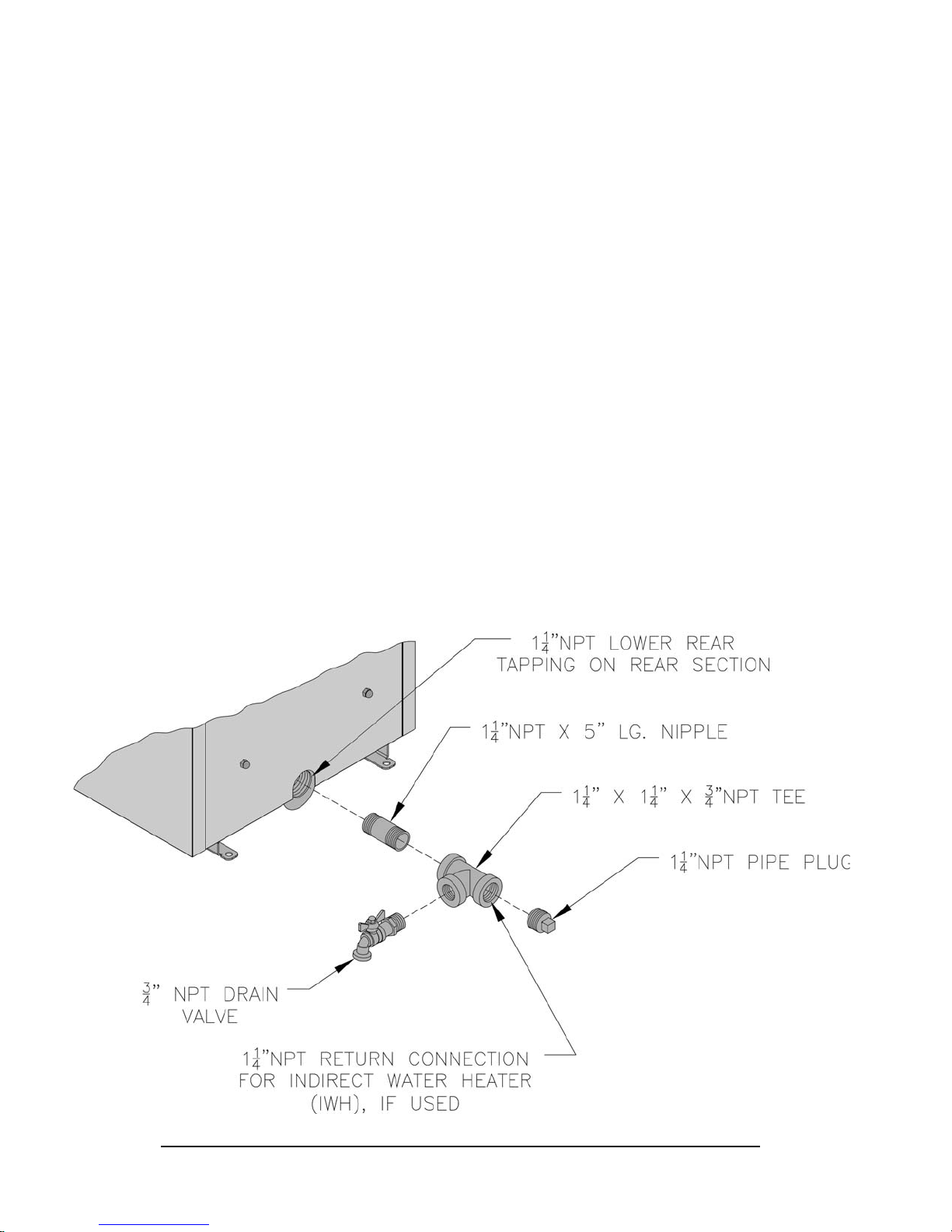

5. Install drain valve and indirect water heater return

piping, see Figure 10.

Step a. Apply pipe sealant to both ends of 1-1/4"

NPT x 5" lg. nipple. Thread nipple into 1-1/4"

NPT lower rear tapping on rear section.

Step b. Thread 1-1/4" x 1-1/4" x 3/4" NPT tee on

opposite end of 5" lg. nipple installed in Step a.

NOTE: Based on access for servicing and

location of sewer or fl oor drain, when tightening

erehwaeraynaniepiptonoD.snr

ynallatsnitonoD.ruccodluocgnizeerf

depipebtsumgnipipegrahcsidevlavfeileR

erevesfolaitnetopetanimileotroolfraen

Figure 9: Return Manifold and Relief Valve Assembly Details

17

Page 18

these fi ttings, determine if drain valve is to be

located on the left or right side.

Tighten nipple and tee into 1-1/4" NPT lower

rear tapping on rear section until joints are water

tight for desired position.

Step c. Apply sealant to 3/4" NPT thread on drain

valve. Thread into 3/4" NPT tapping on side

outlet of tee. Use hex nut portion to tighten

valve until water tight.

Step d. If Alliance ™ Indirect Water Heater is

connected to system, do not install 1-1/4" NPT

pipe plug. Connect piping as shown in Figures

13A, 13B, 15A and 15B, as applicable. Also

refer to Alliance ™ manual for additional

information.

6. Connecting fi eld wiring, refer to Figures 5, 6 and 19.

Step a. 120 volt power supply fi eld wiring will

enter internal junction box through 7/8" dia.

knockout in jacket rear panel, see Figure 5.

Step b. Locate the black and white harness wires

labeled "120V Power Supply" inside internal

junction box, see Figure 6. Using wire nuts,

connect the 120 volt power supply fi eld wires to

the harness wires. Connect the fi eld ground wire

to the green grounding screw located in bottom

of internal junction, refer to Figures 6 and 20.

Step c. 24V thermostat fi eld wiring will enter

internal junction box through 5/16" snap bushing

located on rear panel adjacent to 7/8" dia.

knockout for power supply.

Step d. Locate the two (2) brown wires labeled

"24V Thermostat" inside the internal junction

box, see Figure 6 (these wires originate from

"T-T" terminals in aquastat control and feed

into J-box through harness). Using wire nuts,

connect 24 volt fi eld thermostat wires to brown

wires in J-box.

Step e. Locate jacket top rear panel that was

removed earlier to gain access to internal

junction box. Position panel between side

panels, hold on a slight angle, engage tabs on

front fl ange of top rear panel with rectangle

slots on rear fl ange of top panel, refer to Figures

5 and 9.

NOTE: It may be necessary to lift up slightly

on top panel near slotted opening at supply

manifold to align tabs with rectangular slots on

fl anges.

Lower rear fl ange of jacket top rear panel down

over rear panel. Align holes and secure with

two (2) #8 x 1/2" lg. sheet metal screws.

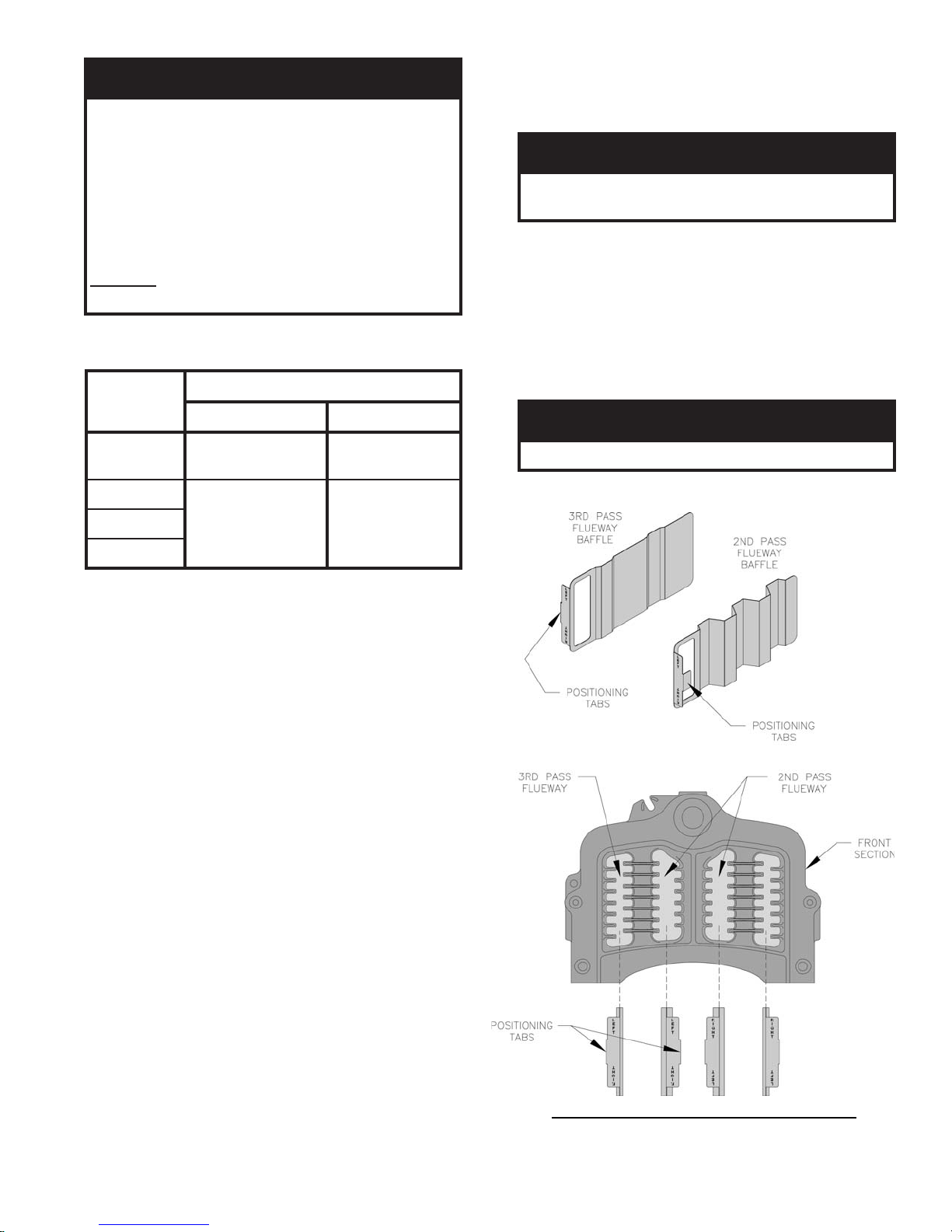

7. Installing stainless steel fl ueway baffl es. Baffl e

requirements differ from model to model, see

Table 2.

NOTE: Read caution statement before proceeding.

Figure 10: Piping Arrangement for Drain Valve and Indirect Water Heating Return

18

Page 19

tsum

TONOD daerevahuoylitnuselffabllatsni

TABLE 2: BAFFLE USAGE

relioB

ledoM

48OPMenoN

741OPM

981OPM

132OPM

dn

2

)2(

NOITUAC

rehgihetareneglliwselffabesehT

.serutarepmetkcatsrewoldnaseicneiciffe

ssorgrewola,snoitidnocniatrecrednU

sahyenmihcehtgniretneerutarepmetkcats

wedehtwolebdeloocebotlaitnetopeht

roiretninoetasnednocetaercdnatniop

,evisorrocsietasnednocsageulF.secafrus

dnanoitaredisnoclaicepsseriuqerhcihw

.yletaidemmidesserddaeb

.yletelpmoc"gnitneV",VnoitceS

egasUelffaB

ssaP3

10-240001N/P

dr

ssaP

)2(

10-180001N/P

enoN

8. Close the burner swing door and securely seal the

door to the boiler front section by reinstalling the

hardware and securing the door using procedure

previously outlined in Paragraph D of this section.

ECITON

ekamroodgniwsrenrubgnirucesnehW

.sedishtobnoyllauqeni-nwardsirooderus

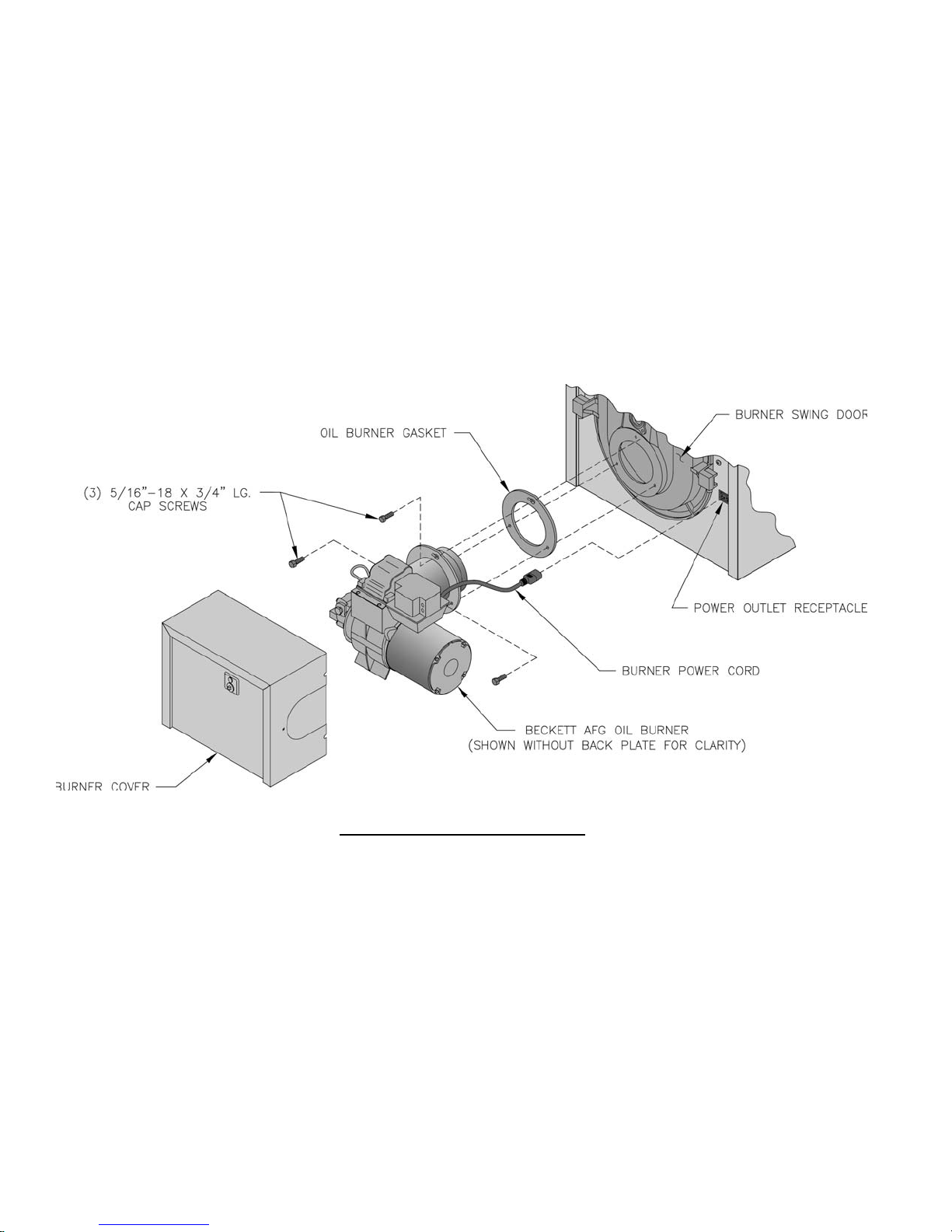

9. Install oil burner, refer to Figure 12.

Step a. Open burner carton and remove contents.

Step b. Check oil nozzle in burner for size, angle

and type, inspect electrode settings, check head

setting, check air band and air shutter settings,

refer to Table 6 at rear of this manual.

Step c. Place oil burner gasket on burner and align

holes.

NOITUAC

.teksagtuohtiwrenrubllatsnitonoD

Step a. Install stainless steel baffl es provided in

miscellaneous parts carton as follows, refer to

Table 2 and Figure 11:

• Model MPO84 - To install fl ueway baffl e

in 3rd pass on left side of boiler, hold baffl e

with word "Left" readable at the top. Slide

baffl e in fl ueway until position tab touches

fi ns on left side of 3rd pass fl ueway. To

install fl ueway baffl e in 3rd pass fl ueway on

right side of boiler, hold baffl e with word

"Right" readable at the top. Slide baffl e in

fl ueway until position tab touches fi ns on

right side of 3rd pass fl ueway.

• Models MPO147, MPO189 and MPO231

- T o install fl ueway baffl e in 2nd pass fl ueway

on left side of boiler, hold baffl e with word

"Left" readable at the top. Slide baffl e in

fl ueway until position tab touches fi ns on

right side of 2nd pass fl ueway. To install

fl ueway baffl e in 2nd pass fl ueway on right

side of boier, hold baffl e with word "Right"

readable at the top. Slide baffl e in fl ueway

until position tab touches fi ns on left side of

2nd pass fl ueway.

NOTE: 2nd and 3rd pass fl ueway baffl e are not

interchangable.

Figure 11: Baffl e Orientation in Flueways

19

Page 20

Step d. Remove three (3) 5/16-18 x 3/4 lg. cap

screw from burner swing door used for mounting

burner.

Step e. Thread (1) 5/16-18 x 3/4 lg. cap screw,

approximately three (3) full turns, into tapping

located at 12:00 o'clock on burner swing door.

Step f. Insert oil burner into the opening of burner

swing door. Align and engage keyhole slot in

burner fl ange over head of protruding cap screw

installed in previous Step. Rotate burner to the

right to lock fl ange behind head of cap screw.

Step g. Align holes and install two (2) remaining

cap screws. Level burner and fully tighten all

three (3) screws.

Step h. Plug burner power cord into power outlet

receptacle located in lower right corner of front

panel.

20

Figure 12: Oil Burner Installation

Page 21

SECTION III: WATER BOILER PIPING

ECITON

.esionmetsysevissecxenitluseryamlaunamsihtnideificepssareliobepipoteruliaF

A. EVALUATE THE EXISTING WATER

SYSTEM.

Design a piping system and install boiler which will

prevent oxygen contamination of boiler water and

frequent water additions.

1. There are many possible causes of oxygen

contamination such as:

a. Addition of excessive make-up water as a result

of system leaks.

b. Absorption through open tanks and fi ttings.

c. Oxygen permeable materials in the distribution

system.

2. In order to insure long product life, oxygen sources

must be eliminated. This can be accomplished by

taking the following measures:

a. Repairing system leaks to eliminate the need for

addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fi ttings which allow

oxygen absorption.

d. Use of non-permeable materials in the

distribution system.

e. Isolating the boiler from the system water by

installing a heat exchanger.

GNINRAW

ebtsumgnipipnruterdnaylppusmetsyS

.sdlofinamreliobtcerrocotdetcennoc

ehtgnizissdnemmocermahnruB

usylppusotrotalucricmetsys

tsomeht,rotalucricmetsyseht

tneiciff

erutarepmetF°02awollaot)MPG(wolf

gnizisnehW.metsysehtnilaitnereffid

desuebdluohsenozelgnisevitcirtser

.porderusserpmumixamenimretedot

NOITUAC

morfecnaraelchcni½muminimniatniaM

B. CONNECT SYSTEM SUPPLY AND RETURN

PIPING TO BOILER. See Figures 13A and 13B.

Also, consult I=B=R Installation and Piping Guides.

1. If this boiler is used in connection with refrigeration

systems, the boiler must be installed so that the

chilled medium is piped in parallel with the heating

boiler using appropriate valves to prevent the chilled

medium from entering the boiler. See Figure 14.

Also, consult I=B=R Installation and Piping Guides.

2. If this boiler is connected to heating coils located

in air handling units where they may be exposed

to refrigerated air, the boiler piping must be

equipped with fl ow control valves to prevent gravity

circulation of boiler water during the operation of

the cooling system.

3. If boiler is used with an Alliance™ Indirect-Fired

Domestic Water Heater, install the Alliance™ as

a separate heating zone. Refer to the Alliance™

Installation, Operating, and Service Instructions for

additional information.

4. Use a boiler bypass if the boiler is to be operated

in a system which has a large volume or excessive

radiation where low boiler water temperatures may

be encountered (i.e. converted gravity circulation

system, etc.) The bypass should be the same size as

the supply and return lines with valves located in

the bypass and return line as illustrated in Figures

13A and 13B in order to regulate water fl ow for

maintenance of higher boiler water temperature.

GNINRAW

elihw,ecivedffo-tucretawwolafoesuehT

wolebsilevelnoitaidarsselnuderiuqerton

.dednemmocerylhgihsi,reliobeht

If a low water cut-off is required, it must be

mounted in the 3/4" supply manifold tapping (see

Figures 7, 13A and 13B) or in the system piping

above the boiler. The minimum safe water level of

a hot water boiler is just above the highest water

containing cavity of the boiler; that is, a hot water

boiler must be full of water to operate safely.

.slairetamelbitsubmocotgnipipretawtoh

5. If it is required to perform a long term pressure

test of the hydronic system, the boiler should fi rst

be isolated to avoid a pressure loss due to the escape

of air trapped must fi rst be removed from the boiler.

21

Page 22

22

Figure 13A: Water Boiler Piping for Circulator Zoned Heating System - Supply Side Circulator

Page 23

Figure 13B: Preferred Water Boiler Piping for Zone Valve Zoned Heating System - Supply Side Circulator

23

Page 24

To perform a long term pressure test including the

boiler, ALL trapped air must fi rst be removed from

the boiler.

A loss of pressure during such a test, with no visible

water leakage, is an indication that the boiler

contained trapped air.

Figure 14: Recommended Piping for Combination Heating and Cooling (Refrigeration) System

24

Page 25

SECTION IV: INDIRECT WATER HEATER PIPING

A. CONNECT ALLIANCE™ INDIRECT WATER

HEATER PIPING as shown in Figures 15A and

15B.

Also refer to Figures 13A and 13B.

1. Refer to Alliance™ manual for additional

information.

Figure 15A: Alliance™ Water Heater Piping w/Supply Side Circulator

on Circulator Zoned Heating System

Figure 15B: Alliance™ Water Heater Piping w/Supply Side Circulator on Zone Valve Zoned Heating System

25

Page 26

SECTION V: VENTING

A. CHIMNEY VENTING

1. Chimney venting is an important part of a safe

and effi cient oil fi red appliance system. Contact

your local fi re and building offi cials on specifi c

requirements for restrictions and the installation

of fuel oil burning equipment. In addition,

consult with a professional knowledgeable on

the requirements of NFPA 31 – Standard for the

Installation of Oil-Burning Equipment and NFPA

211 - Standard for Chimneys, Fireplaces, Vents, and

Solid Fuel-Burning Appliances for installations in

the United States. Installations in Canada must be

reviewed with a professional knowledgeable on the

requirements of CSA B139-04 – Installation Code

for Oil-burning Equipment.

2. The safe venting of oil fi red boilers is dependant on

many factors. Some of these factors include:

a. suffi cient draft during the entire heating season

to allow for the safe discharge of combustion byproducts and;

b. suitable corrosion protection in the event of

condensing fl ue gases. Only a trained and

qualifi ed contractor may install this product.

3. The MPO can be vented into a fi reclay tile-lined

masonry chimney that meets requirements outlined

in Paragraph 4 below. It can also be vented into

a chimney constructed from type L vent or a

factory built chimney that complies with the type

HT requirements of UL 103. The chimney and

vent pipe shall have a suffi cient draft at all times,

to assure safe proper operation of the boiler. See

Figure 16 for recommended installation.

GNINRAW

issecxe

ottfardhguoneetaerctonyamtupni

.noitsubmoc

4. Chimney Inspection – Prior to the installation of

any new or replacement fuel burning equipment the

chimney shall be inspected by a qualifi ed installer.

The chimney shall be inspected for integrity as

well as for proper draft and condensate control.

Some jurisdictions require the use of a liner when

changing fuel types. Some jurisdictions require

the use of a liner even when the same fuel is used.

At a minimum, the chimney shall be examined

by a qualifi ed person in accordance with the

requirements of Chapter 11 of NFPA 211, Standard

for Chimneys, Fireplaces, Vents, and Solid FuelBurning Appliances.

26

a. Loose Mortar – Loose mortar could be an

indication of a prior history of condensing fl ue

gases upon the inside walls of the chimney.

Colder climates are more susceptible to this

condition. Under no circumstances shall a

chimney of this condition be used until it meets

the requirements of NFPA 211 or CSA B139-

04.

b. Unlined Chimney – Under no circumstances

shall a chimney constructed of brick only

be used. Only approved clay liners or listed

chimney lining systems shall be used as specifi ed

in NFPA 31 or CSA B139-04.

c. Abandoned Openings – Openings through the

chimney wall that are no longer used shall

be sealed in accordance to NFPA 211. Often

abandoned openings are improperly sealed and

usually covered by a gypsum wall covering.

d. Clean Chimney – Chimney shall be free of all

loose debris.

5. Draft Regulator – the draft regulator supplied with

the boiler must be used with this appliance. No

other draft regulator shall be used. Refer to Figures

16 and 17.

B. CHIMNEY CONNECTOR

1. A chimney connector (vent pipe) is used to connect

the boiler to the base of the chimney. The chimney

connector should be kept as short as possible. The

horizontal length of the chimney connector shall not

be greater than 10 feet.

NOTE: Secure chimney connector to cast iron

smokebox collar with three (3) #10 x ½" self drilling

hex head TEK screws provided in miscellaneous

parts carton. Locate screws around perimeter of

erifoteruliaF.ecnailppaehtetar-edtonoD

esuacyamtupnidengiseds'titatinueht

roiretniehtnopunoitasnednocev

rewoleht,noitiddanI.yenmihcehtfosllaw

fostcudorp-ybehtetaucaveyletauqeda

connector as shown in Figure 16 and approximately

½" in from edge. Use drill with 5/16" hex bit to

drive screws through connector and smokebox

collar.

REGNAD

ebllahsrotcennocdnayenmihcehT

dnasirbedfosngisrofyllaunnadetcepsni

ehtfoesabehttaratromesooL.noisorroc

etasnednocfongisaebyamyenmihc

yenmihcA.yenmihcehtotegamad

yletaidemmidetcatnocebllahslanoisseforp

adnemmocerdnaegamadehtenimaxeot

sihtnielihwnoitarepomretgnoL.noitulos

dnaeruliafgnitnevaesuacyamnoitidnoc

.ecapsgnivilehtotnisesageulfecrof

ehtesudenil-erebotsiyenmihc

.40-931BASCro

ehtfI

ExidneppA,13APFNnisnoitadnemmocer

Page 27

Figure 16: Recommended Vent Pipe Arrangement and Chimney Requirements

Figure 17: Proper and Improper Locations of Draft Regulator

27

Page 28

2. Type B Chimney Connector - a type B chimney

connector can be used to transmit the fl ue gases

provided fl ue gas temperature entering the chimney

connector is greater than 310°F.

3. Type L Chimney Connector - a type L vent or

other suitable material shall be used for a chimney

connector if the temperature or exiting temperature

is less than 310°F.

2. NFPA 31 and CSA B139-04 have information to

help the installer make an appropriate choice of

venting materials. In some cases a chimney may

have to be lined to create suffi cient draft. In other

cases, the chimney may have to be lined to prevent

the corrosion of a masonry chimney. Consult

with a chimney specialist knowledgeable on the

requirements for chimney requirements in your area.

REGNAD

em

.yletaidemmi

C. DRAFT

1. The natural draft generated through a chimney is

dependent on several factors including, chimney

height, temperature of fl ue gases, cross section area

of chimney, chimney wall insulation value, dilution

air and total volume of fl ue gases, to name a few.

Make sure that the boiler has been running for at

least 5 minutes before measuring the draft.

2. Minimum Draft at Breech (Canopy) – The draft

induced by a chimney must create at least a

pressure of 0 (zero) inches water column (“ w.c.)

at the pressure tapping on the canopy mounted

on rear of boiler (see Figure 18). The pressure

at the canopy cannot be positive since this could

create a condition that allows fl ue gas by-products

to escape from the draft regulator. A negative

pressure reading up to -.03 inches water column

is acceptable for proper operation. (See Table 6,

Burner Specifi cations at the rear of this manual for

more details)

3. Minimum Overfi re Pressure – The overfi re

pressure is another piece of information that is

often measured, however this should be done for

observation purposes only! The breech pressure

must be used to qualify the draft condition. See

Table 6 for more details as a guide. Actual draft and

temperature measurements may be different then

those values in the table.

D. STACK TEMPERATURE

1. The temperature of the fl ue gases has a signifi cant

effect on the amount of draft created in a vertical

chimney as well as the propensity to create

condensate. The higher the stack temperature, the

greater the amount of draft that can be generated. A

lower stack temperature not only reduces the amount

of draft that can be created but it also increases the

possibility that the fl ue gases could condense in the

chimney connector or stack.

28

NOITUAC

ehttaegapeesetasnednocfosngisynA

-midetcepsniebllahsyenmihcehtfoesab

ngisaebyamnoitarolocsidehT.yletaid

deidemerebtsumdnaegamadyenmihcfo

.)adanaC(931BASCro)setatS

royenmihcafonoitidnocehtnotbuodynA

dnanoitarenegehttneverpotytilibas’ti

tsum,etasnednocsageulffonoitalumucca

detinU(13APFNotgnidroccadenilereb

NOITUAC

.ediugasaselbatgnitnevyenmihcehtesU

-redrobynatahtdednemmocerylhgihsitI

gninilerehtnitluserdluohsnoitacilppaenil

tahtrenilelbatiusahtiwyenmihcehtfo

tsniagatcetorpotdnatfardtneiciffussetaerc

.etasnednocsageulfybdesuacnoisorroc

3. Baffl es – The effi ciency of the boiler is based on the

insertion of fl ue baffl es supplied with your product.

Under no circumstances are other baffl es to be

used on this product. The baffl es are installed in

the 2nd pass (two inner fl ueways) on the MPO147,

MPO189 and MPO231. The baffl es on the MPO84

are installed in the 3rd pass only. Refer to Section

II, Item F, Paragraph 7 for baffl e installation. If

there is any doubt on the application of this boiler

on the intended chimney, consult with your local

code offi cials. At a minimum, remove the baffl es

to increase the stack temperature. See Table 6 for

temperature differential (∆T) with baffl es IN and

OUT. In addition, the lower the CO2 level the

higher the stack temperature.

Figure 18: Smokebox Pressure Tapping for

Checking Draft at Breech

Page 29

1. General

GNINRAW

fosngisynaeraerehtfiselffabehtevomeR

yenmihcroyenmihcehtninoitasnednoc

nnoc

.snoitadnemmocerroflanoisseforp

yenmihclacoluoyhtiwtlusnoC.rotce

a. Use 4" dia., single wall galvanized metal pipe

and fi ttings available at most heating distributors

for air intake piping. Maximum allowable air

intake length is 50 equivalent feet. Each elbow

is equal to 6 equivalent feet.

E. MINIMUM CLEARANCES

See Figure 2 for details regarding clearances to

combustibles for the boiler.

F. OPTIONAL AIR INTAKE PIPING

INSTALLATION - All air for combustion can be

supplied directly to the burner from outdoors providing

that the criteria for chimney, vent connector and

minimum stack temperature outlined in this section

can be maintained. (ONLY AVAILABLE WITH

BECKETT BURNER). See Figure 19.

GNINRAW

foelddimehtniriaroodtuognisU

kcatsrewolnitluseryamretniw

sliated

.launamsihtfonoitceS

.noitcessihtnideniltuo

wollofdnadnatsrednu,daeR

tallatsnI-erPehtnideniatnoc

noi

GNINRAW

riaelbawollamumixamdeecxetonoD

.htgnelekatni

b. Start at burner. Work toward air intake terminal.

c. Maintain minimum of 1/4 inch per foot slope in

horizontal run to air intake terminal. Slope down

toward air intake terminal.

d. Seal all joints gas-tight, using silicone caulk or

self-adhesive aluminum tape.

2. After determining location, cut a hole in the wall to

accept 4 inch air intake pipe. See Figure 19.

3. Remove the metal knockout in right side of burner

cover. Install Burnham Inlet Air Accessory Kit, Part

.noitadargedyenmihcdnaserutarepmet

roegapeesetasnednocfosngisynA

yenmihcfoesabehttanoitarolocsid

ehtrepyletaidemmideidemerebtsum

.epipekatniriafoezisecudertonoD

snoitcirtsernoitcurtsnirianoitsubmoc

Number 611280031.

4. Mount the Vacuum Relief Valve Tee Assembly (P/N

8116268 included with Kit) or 90° elbow into the

burner inlet ring. See Figure 18.

a. Secure with at least three (3) sheet metal screws

evenly spaced around the burner inlet ring.

b. Assemble the vacuum relief valve balance

weight onto the gate. Refer to the vacuum relief

valve manufacturer's instructions.

Figure 19: Optional Air Intake Piping Installation - Only Available with Beckett Burner

29

Page 30

c. Mount the vacuum relief valve into the tee and

fasten with a screw and nut in collar tabs. To

ensure proper operation, the gate must be level

across the pivot point and plumb. Refer to

vacuum relief valve manufacturer's instructions.

5. Install remainder of air intake, securing each joint

with at least three (3) sheet metal screws evenly

spaced.

6. Install air intake terminal. See Figure 19.

ECITON

sehcni21tsaeltaebtsumlanimretekatnI

.noitalumuccawonssulpedargevoba

7. Seal all external joints with weatherproof caulk.

GNINRAW

muelorteperehwekatniriaetacoltonoD

elitalov,stnegreted,s'CFC,setallitsid

.tneserperaslacimehcrehtoynarosropav

lliweruliafdnanoisorrocreliobereveS

.tluser

30

Page 31

SECTION VI: ELECTRICAL

REGNAD

ecivresronoitallatsnignitpmettaerofebderewopnuerasnoitcennoclacirtcelellaerussaylevitisoP

sexoblacirtcelellatuokcoL.gnidliubroreliobehtfosnoitcennocrostnenopmoclacirtcelefo

w

.ffodenrutsirewopecnokcoldaphti

GNINRAW

lacisyhpsuoiresnitluseryamreliobehtotsnoitcennoclacirtceleeriwylreporpoteruliaF

.mrah

.krowlacirtceleynagnitpmetta

A. GENERAL

1. Install wiring and electrically ground boiler in

accordance with requirements of the authority

having jurisdiction, or in absence of such

requirements the National Electrical Code, ANSI/

NFPA 70, and/or the CSA C22.1 Electric Code.

2. Refer to National Electric Code or Local Electric

Codes for proper size and type of wire required.

Follow Code.

3. A separate electrical circuit must be run from

the main electrical service with an over-current

device/disconnect in the circuit. A service switch is

recommended and may be required by some local

jurisdictions.

4. Use anti-short bushings on all wiring passing

through boiler jacket, junction boxes and/or control

boxes.

5. Use armored cable (BX) over all exposed line

voltage wiring.

laerusekaM.ecruosenonahterommorfebyamrewoplacirtcelE

ylreporpahtiwdetcetorpebtsumreliobhcaE

6. If an Alliance™ indirect water heater is used, use

priority zoning. Do not use priority zoning for

Hydro-Air Systems.

7. Wiring should conform to Figure 20.

B. INSTALL A ROOM THERMOSTAT on an

inside wall about four feet above fl oor. Never install

thermostat on an outside wall or where it will be

infl uenced by drafts, hot or cold water pipes, lighting

fi xtures, television, rays of the sun or near a fi replace.

Keep large furniture away from thermostat so there will

be free movement of room air around this control.

Heat Anticipator in Thermostat should be set to match

the requirements of the control to which it is connected.

See Figure 20 for desired system and heat anticipator

setting. If system tends to overheat above the

thermostat's temperature setting, reduce heat anticipator

setting by .1 or .2 amps. If system tends to short cycle

without reaching desired room temperature, increase

heat anticipator setting by .1 or .2 amps.

.tcennocsiddesufdezis

.slortnocgnitareporoytefasynaevitareponiekamrotuopmujreveN

erofebffosirewopl

31

Page 32

32

BOILER SEQUENCE OF OPERATION

Figure 20: Schematic Wiring Diagram, Standard Control Set w/Optional LWCO and/or High Limit Accessory Kit

A call for heat by the thermostat energizes the L7248C control which in turn energizes the primary control to turn on the burner. The burner will operate in the following sequence:

operate as long as the thermostat is calling for heat. If the thermostat is not satisfi ed and the operating (high) limit is reached, the circulator will continue to operate, and the burner will stop

until the operating (high) limit is closed by a 15°F drop in boiler water temperature.

On water boiler equipped with Optional L4080B Auxiliary High Limit Control, if boiler water temperature exceeds the operating limit setting and reaches the high limit setting, the circulator

will continue to operate, and the burner will stop until the high limit is closed by an 8°F drop in boiler water temperature.

Prepurge for the fi rst 10 seconds; fi re until the thermostat is satisfi ed or the limit setting on the operating (high) limit is reached; post-purge for the last 10 seconds. The circulator will

On burner start, if the cad cell does not see fl ame within approximately 15 seconds, primary control will shut burner down and enter into a recycle mode, after 60 seconds burner will restart

and repeat trial for ignition. If after three (3) trials for ignition, fl ame is not detected, control will enter into restricted mode and must be reset manually before burner can be restarted.

On water boiler equipped with optional low water cut-off (LWCO) control, if probe senses a low water condition, power to the L7248C control is de-energized. When water level is

replenished, LWCO will automatically re-energize sending power to the L7248C control.

Page 33

SECTION VII: OIL PIPING

A. GENERAL

1. Use fl exible oil line(s) so the burner swing door

can be opened without disconnecting the oil supply

piping.

2. A supply line fuel oil fi lter is recommended as a

minimum for all fi ring rates but a pleated paper fuel

oil fi lter is recommended for the fi ring rates below

1.0 gph to prevent nozzle fouling.

3. Use Flared fi ttings only. Cast iron fi ttings cannot be

used.

ECITON

.sgnittifnoisserpmocesutonoD

.yletelpmoctinuleufdnaenil

lacolruoyotrefeRsnoitcidsiruj-drager

iddanI.stnemeriuqerylppus

.adanaCninoitallatsnI

4. Use of a high effi ciency micron fi lter (Garber or

equivalent) in addition to a conventional fi lter is

highly recommended.

5. Piping used to connect the oil burner to the oil

supply tank shall not be smaller than 3/8" iron pipe

or 3/8" OD copper tubing. Copper tubing shall have

a .032" minimum wall thickness.

GNINRAW

htiwreppocnacsecnatsmucriconrednU

.desuebsrotcennocelytstaews

ECITON

afoesuehteriuqersnoitcidsirujemoS

ehtro/dnaknatehttaevlavffotuhselbisuf

snoitcidsirujemos,noitiddanI.renrub

lacirtceleelbisufafoesuehteriuqer

kcehC.tiucricrenrubehthtiwkcolretni

.stnemeriuqerlaicepsrofsedoClacolruoy

B. SINGLE PIPE OIL LINES

rothgitriayletulosbaebtsumgnipipliO

deelB.tluseryamemirpfossolroskael

leufrofsnoitaredisnoclaicepsynagni

otrefer,noit

fonoitallatsnIehtrofdradnatS,13APFN

nisnoitallatsnIroftnempiuqEgninruB-liO

rof40-931BASCdnasetatSdetinUeht

1. Standard burners are provided with single-stage

3450 rpm fuel units with the bypass plug removed

for single-pipe installations.

2. The single-stage fuel unit may be installed singlepipe with gravity feed or lift. Maximum allowable

lift is 8 feet. See Figure 21.

3. Fuel Oil Line Deaerator – On many occasions a

leaky oil delivery line can introduce air into the

fuel oil supply system. This often creates a rough

starting condition and can create a burner lockout

state. In addition to fi xing the leak, a fuel line

deaerator can be installed to eliminate air. The

single line from the fuel tank is connected to the

deaerator. The burner pump must be connected

to the deaerator as a two pipe system. Follow the

oil pump manufacturer’s recommendations for

conversion to a two pipe system.

Figure 21: Single Pipe Oil Line

33

Page 34

C. TWO PIPE OIL LINES

1. For two piped systems, where more lift is required,

the two-stage fuel unit is recommended. Table

3 (two-stage) and Table 4 (single-stage) show

allowable lift and lengths of 3/8 inch and 1/2 inch

OD tubing for both suction and return lines. Refer

to Figure 22.

2. Follow the oil pump manufacturer’s recommendations on the proper connections for a two pipe

system. Some manufacturers require the insertion

of a bypass plug.

3. Under no circumstances is a manual shutoff valve to

be located on the return line of a two pipe system.

Accidental closure of the return line will rupture the

oil pump seals.

TABLE 4: SINGLE-STAGE UNITS (3450 RPM) -

TWO PIPE SYSTEMS

gnibuTfohtgneLmumixaM

"H"tfiL

)52.giFeeS(

DO"8/3

)52erugiFeeS("R"+"H"

DO"2/1

)HPG3(gnibuT

)HPG3(gnibuT

TABLE 3: TWO-STAGE UNITS (3450 RPM) -

TWO PIPE SYSTEMS

"H"tfiL

)52.giFeeS(

DO"8/3

)HPG3(gnibuT

'0'39'001

'2'58'001

'4'77'001

'6'96'001

'8'06'001

'01'25'001

'21'44'001

'41'63'001

'61'72'001

'81---'67

'0'48'001

'1'87'001

gnibuTfohtgneLmumixaM

)52erugiFeeS("R"+"H"

DO"2/1

)HPG3(gnibuT

'2'37'001

'3'86'001

'4'36'001

'5'75'001

'6'25'001

'7'74'001

'8'24'001

'9'63'001

'01'13'001

'11'62'001

'21'12'38

'31---'26

'41---'14

34

Figure 22: Two Pipe Oil Lines

Page 35

SECTION VIII: SYSTEM START-UP

GNINRAW

erevesesuacnachcihwdrazahlaitnetopaevahroodgniwsrenrubhtiwdeppiuqesreliobllA

ffonrut,roodgniwsgninepoerofeB.derongifiefilfossolroyrujnilanosrep,egamadytreporp

.rebmahcnoitsubmocehtedistuorenrubfogniriflatnediccatneverpotreliobothctiwsecivres

eht,noitiddanI.detelpmocsiecivresnehwyletelpmocrenetsafroodgniwsnethgitoteruseB

.tekcajtnorfehtnielcatpecerehtmorfdetcennocsidebotevahlliwdrocrewoprenrub

A. ALWAYS INSPECT INSTALLATION

BEFORE STARTING BURNER.

1. Verify that the venting, water piping, oil piping, and

electrical system are installed properly. Refer to

Installation Instructions contained in this manual.

2. Confi rm all electrical, water and oil supplies are

turned off at the source and that the vent is clear

from obstructions.

GNINRAW

llawollofdnadnatsrednu,daeryletelpmoC

erofeblaunamsihtnisnoitcurtsni

.putratsgnitpmetta

B. FILL HEATING SYSTEM WITH WATER.

ECITON

lioehtevomerylreporpottnatropmisitI

naelcoteruliaF.metsysehtmorftriddna

yseht

CLEAN HEATING SYSTEM if boiler water is

dirty.

Refer to Maintenance and Service Instructions Section

of this manual for proper cleaning instructions for water

boilers.

1. HOT WATER BOILERS. Fill entire heating

system with water and vent air from system. Use

the following procedure on a series loop or multizoned system installed as per Figures 13A and 13B,

to remove air from system when fi lling:

a. Close full port ball valve in boiler system piping.

b. Isolate all zones by closing zone valves or shut-

off valves in supply and return of each zone(s).

c. Attach a hose to vertical purge valve in boiler

system supply piping up stream from the full

port ball valve.

(Note - Terminate hose in fi ve gallon bucket at a

suitable fl oor drain or outdoor area).

d. Starting with one zone at a time, open zone valve

or shut-off valve in boiler supply and return

piping.

,stnevriadeggolcnitlusernacmets

.sevlavenozdeziesdnaegamadrotalucric

e. Open purge valve.

f. Open shut-off valve in cold water supply piping

located between the air scoop and expansion

tank.

g. Allow water to overfl ow from bucket until

discharge from hose is bubble free for 30

seconds.

h. When zone valve is completely purged of air,

close zone valve or shut-off valve. Open zone

valve to the next zone to be purged. Repeat

this step until all zones have been purged. At

completion, open all zone valves.

i. Close purge valve, continue fi lling the system

until the pressure gauge reads 12 psi. Close shutoff valve in cold water supply piping.

GNINRAW

ergulptonoD.erusserpsihtdeecxe

.evlav

ECITON

htiwdeppiuqesienilretawpu-ekamfI

lliwmetsys,evlavgnicudererusserp

tua

.snoitcurtsnis'rerutcafunam

j. Open full port ball valve in boiler system piping.

k. Remove hose from purge valve.

l. Confi rm that the boiler and system have no water

leaks.

m. It may be necessary to clean the air vent

assembly after a few days of operation.

C. CHECK CONTROLS, WIRING AND

BURNER to be sure that all connections are tight and

burner is rigid, that all electrical connections have been

completed and fuses installed, and that oil tank is fi lled

and oil lines have been tested.

sihtfoerusserpgnitarepomumixamehT

lebaLataDEMSAehtnodetsopsireliob

reveN.reliobehtfopotehtnodetacol

feil

evlavllifwolloF.isp21otllifyllacitamo

35

Page 36

D. ADJUST CONTROL SETTINGS with burner

service switch turned “ON” and room thermostat set

10° below room temperature.

1. Adjustment and display modes of the L7248C Oil

Electronic Aquastat Controller.

a. On the L7248C, the overall range of the High

Limit is from 180°F to 240°F (82°C to 116°C).

b. Set the High Limit (designated HL) on the

L7248C Aquastat Control at 180°F. This

temperature setting may be varied to suit

requirements of installation. Differential is fi xed

at 15°F.

i. Adjusting Settings:

To discourage unauthorized changing of

Aquastat settings, a procedure to enter the

adjustment mode is required. To enter the

adjustment mode, press the UP, DOWN,

and I buttons (see Figure 23) simultaneously

for three (3) seconds. Press the ‘I’ button

until the feature requiring adjustment is

displayed:

· High Limit

· °F -- °C (Toggle)

Then press the UP and/or DOWN buttons

to move the set point to the desired value.

After 60 seconds without any button inputs,

the control will automatically return to the

READ mode.

any key pressed, the display will enter a

dim display mode. To return to the bright

display mode, simply press any key.

Text Description Display

Shows

bt Boiler Temperature

HL High Limit

err Error Code

f Degrees Fahrenheit

c Degrees Celsius

Figure 24: Display Readout Defi nitions

2. Control Operating Characteristics

The L7248C can be in any three (3) operational

states: Normal, High-Limit and Error. The

controller moves back and forth from High-Limit to

Normal state as part of normal operation.

The controller will enter the Error state when there

is an abnormal condition. The operating states are:

a. Normal: Boiler temperature has gone below the

high limit setting (minus the differential) and has

not exceeded the high limit setting.

b. High-Limit: Boiler temperature has gone above

the high limit setting and has not dropped below

the high limit setting (minus the differential).

c. Error: The controller has detected an error

condition (e.g., open sensor) and has shut down

the burner output. The controller continues to

monitor the system and automatically restarts if

the error condition clears. See Table 5.

Figure 23: L7248C Circuit Board Layout -

Horizontal Mount

ii. Display:

In the RUN mode, the Aquastat will fl ash

“bt” (boiler temp.) followed by the temperature (i.e., 220), followed by °F or °C.

To read boiler settings, press the ‘I’ key to

read the parameter of interest. For example,

press I (HL) High Limit is displayed,

followed by a three-digit number, i.e., 220,

followed by °F or °C. See Figure 24 for

Display Readout Defi nitions.

After approximately 60 seconds without

36

TABLE 5: LED ERROR CODES

rorrE

edoC

1rrE.rosneskcehc;tluafrosneS

2rrE.gniriw™MOCarivnEkcehc;tluafMOCE

3rrE.lortnocecalper;tluaferawdraH

d. The operating sequence for L7248C is described

below and shown in Table 6.

The switching action in the L7248C control

has one setting, the high limit, see Figure 25.

The switching relay is controlled by the low

voltage room thermostat. On a call for heat, the

relay contacts make to complete the line voltage

circulator circuit and also the burner circuit if the

boiler water temperature is below the high limit

setting. The high limit switch shuts off the burner

if boiler water temperature exceeds the high limit

setting. The circulator will continue to operate

as long as the thermostat is calling for heat. The

noitcA/esuaC

Page 37

high limit automatically resets after the water

temperature drops past the setpoint and through

the differential.

Figure 25: L7248C Setpoint and Differential

Switching Action

TABLE 6: L7248C CONTROLLER OPERATING

SEQUENCE

noitcAesnopseRmetsyS

3. TURN ‘ON’ BURNER service switch and

allow burner to run until oil fl ows from vent

fi tting in a SOLID stream without air bubbles for

approximately 10 seconds.

NOTE: For Primary Control "Pump Priming

Cycle" details, see Paragraph I, No. 2., Step a., Item

ii .

4. Close vent fi tting and burner fl ame should start

immediately after prepurge is completed. Prepurge

prevents burner fl ame until 15 seconds has elapsed

after initial power is applied to burner. During

prepurge the motor and igniter will operate but the

oil valve will remain closed. Refer to Oil Primary

Control Instructions for more details.

5. Adjust oil pressure.

a. When checking a fuel unit's operating pressure, a

reliable pressure gauge may be installed in either

the bleeder port or the nozzle port. See Figure

26.

tatsomrehT

rofsllac

taeh

relioB

ehtsdeecxe

timilhgih

tatsomrehT

deifsitassi

rorrE

noitidnoc

.stratsrotalucriC

.gnittestimilhgihwoleb

rutarepmetretaweht

.ffonrutrenrubdnarotalucriC

.detcerrocsirorre

.snoitcennocehtninoisorroc

E. ADJUST OIL BURNER BEFORE

STARTING.

1. CHECK BURNER AIR BAND, AIR SHUTTER

AND HEAD SETTING (if applicable), readjust if

necessary, see Table 8 at rear of manual.

2. OPEN ALL OIL LINE VALVES.

3. Attach a plastic hose to fuel pump vent fi tting and

provide a pan to catch the oil.

4. OPEN FLAME OBSERVATION PORT COVER

on burner swing door.

F. START OIL BURNER.

1. Open vent fi tting on fuel pump.

2. PRESS RED RESET BUTTON on front of burner

cover, hold for one (1) second and release to reset

primary control.

renruB.dekcehcsierutarepmetrelioB

sierutarepmetretawehtnehwstratser

nehwstratserrenruB.ffodenrutsirenruB

ehtwolebsporde

.laitnereffidehtsunimgnittestimilhgih

stuptuolla,detcetedsinoitidnocrorrenafI

lortnoC.ffosirenruB.nwodtuhsera

nehwstratserdnanoitcnufotseunitnoc

eht,ecneuqeskcehcrorreehtgniruD

dnarosnesehtnitfirdrofskcehcmetsys

Figure 26: Adjusting Fuel Pump Pressure

b. Locate oil pressure adjusting screw and turn

screw to obtain proper pump pressure, refer to

Table 8 at rear of manual.

c. To check the cut-off pressure, deadhead a reliable

pressure gauge onto the copper connector tube

attached to the nozzle port. Run the burner for

a short period of time. Shut the burner off. The

pressure should drop and hold.

d. Remove the gauge and install bleeder port and/or

reconnect the nozzle port line.

G. ADJUST OIL BURNER WHILE

OPERATING. (fl ame present)