Page 1

Condensing

High Efficiency

Defining the Best in Home Heating

Gas Water Boiler

Natural or LP Gas

Water Only Boiler

94+% AFUE

ENERGY STAR® Certified

Cast Aluminum Heat Engine

Direct Vent Sealed Combustion

150 - 225 MBH (2 sizes)

Fully Modulating Firing Rates

Low NOx and CO Ratings

Page 2

Defining the Best in Home Heating

Here at Burnham we are passionate about our products and want to help insure your family’s comfort with the

security of the Burnham Hydronics name. When you select Burnham, you’re buying more than just an appliance.

Every product is crafted with the highest quality materials and components – by experts committed to delivering

the absolute best performance. With Burnham products, you can count on the best craftsmanship, ingenuity, and

customer service and support that the industry has to offer.

CHG “Condensing, High Efficiency, Gas” Boilers

Today’s lifestyles have created ever increasing demands for abundant supplies of comfortable space heating including radiant

heat, domestic hot water, and snow melting to keep walks and driveways clear – all with the best possible efficiencies available.

A condensing boiler can help ensure that all of these needs are met.

Burnham now offers the best solution for these demanding needs with a ruggedly designed, cast aluminum, condensing boiler

that has efficiency ratings exceeding 94+%. The CHG boiler will meet your family’s heating needs and save you money in energy

operating costs.

94+% Efficiency

Burnham CHG condensing boilers

achieve 94+% efficiency through

our uniquely designed heat engines.

These sectional, cast aluminum

designs use the heat in the exhaust

gases from the boiler’s combustion

process to preheat the water as it

enters the boiler, thus capturing

energy that otherwise would be lost.

Full Modulating Operation

Our CHG boilers are designed to automatically adjust the

firing rate to match your home’s heating needs. With up

to a 5-to-1 turn down ratio, a CHG boiler will continuously

adjust its output to more efficiently and effectively provide

the right amount of heat which further helps conserve fuel

and reduce heating costs.

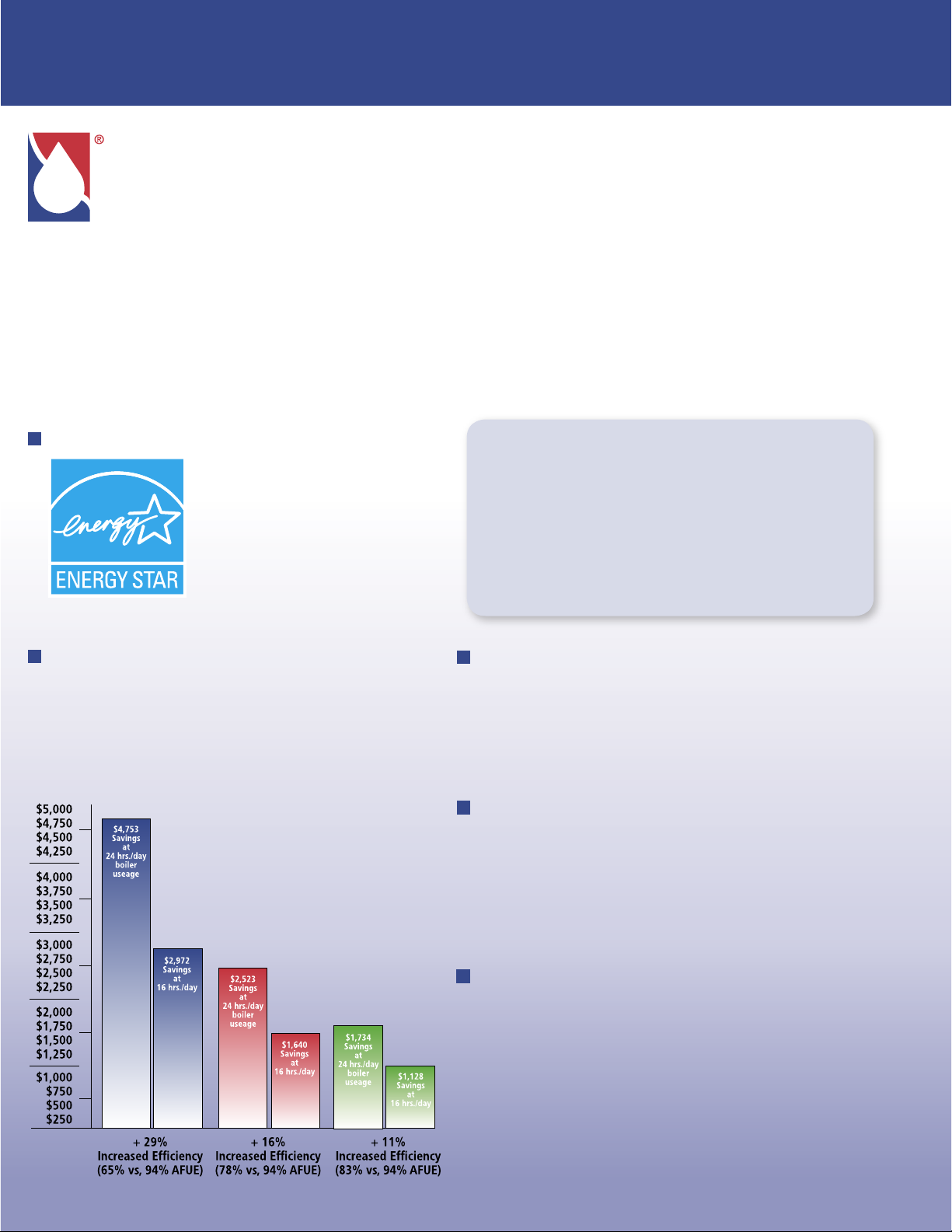

Potential Annual Fuel Savings

by Increasing Efficiency

Example Savings for:

150,000 Btu Boiler

Gas price at $12.00/Mcf

NOTE - When determining potential savings, all of

these factors must be considered: (1) increased efficiency

rating over previous equipment , (2) new boiler BTU rating,

(3) cost of fuel, and (4) hours per day of full operation.

What is a “condensing” boiler?

When a condensing boiler is working at its peak efficiency,

the water vapor produced in the gas combustion process

condenses back into water – hence the name “condensing” boiler. This condensation of exhaust gases releases

the latent heat that is given off when water is vaporized.

Together these two processes, condensation and vaporization, create the high efficiencies associated with Burnham’s

CHG condensing boilers.

The “Quiet” Boiler

Through its state-of-the-art design, packaging, and unique

combustion process, a CHG boiler operates so quietly

that you may not even “hear” it firing, but you can see its

operating sequence with a digital display mounted on the

top of the boiler.

15-Year Limited Warranty

The aluminum heat engine in our CHG boilers is covered

by a 15-year limited factory warranty. The purchase of an

optional Burnham’s Winter Warmth Assurance program

for your CHG boiler can extend our True Blue Warranty

protection to include parts and labor for the entire boiler

for either 5 or 10 years.

Safety with Increased Efficiency

CHG boilers use a sealed combustion system that isolates

the combustion process in the boiler from the air inside

your home. This design helps save energy dollars by using

outside air, rather than room air you’ve already paid to

heat, and assures that exhaust gases go directly outside.

In addition, the CHG boilers are designed to keep your

heating system running efficiently with Annual Fuel Utilization Efficiencies (AFUE) of 94+% which can save you

hundreds of dollars on your annual heating bill.

Page 3

CHG Site Glass & Burner

The flame can be continuously

modulated from an orange

glow to a full blue flame.

The burner is located on the

top of the heat engine forcing

the heat down while the water

flows upward. This allows the

condensation to drain down

and away from the boiler.

Cutaway view showing

actual water flow path.

Supply

Manifold

Return

Manifold

Negative regulated gas valve

with factory set outlet pressure.

Venturi

Variable

Speed

Blower

Boiler Operations

The CHG castings incorporate a multi-pass water

flow with the return water entering the lower

manifold and progressing upward to the supply manifold. This counterflow from bottom to

top provides for maximum heat transfer while

the serpentine pattern offers low pressure drop.

Each section’s water flow is independent with no

port connections between sections. The supply

and return manifolds are designed to balance

the flow across all sections.

Premix Technology

CHG boilers utilize a pre-mix combustion assembly that includes a modulating gas valve, variable speed blower and a venturi to provide an

optimal fuel/air mixture to a stainless steel mesh

burner. Together these components accurately

and efficiently help control the fully modulating

combustion process which automatically adjusts

the boiler’s firing rate to match your heating

needs.

Domestic Hot Water

Abundant domestic hot water

is available with a matching

Alliance indirect-fired hot

water heater. Select from

several sizes to meet your

specific needs. In addition, the

CHG boiler control module

is preset for domestic hot

water priority and set point

temperature.

Boiler

Horizontal

Model

Vent Max.

CHG150 55 ft. 49.5 ft. 3 in.

CHG225 55 ft. 47 ft. 4 in.

Vertical

Vent Max.

Vent

Diameter

Boiler Control Module & Outdoor Reset

The MCBA microprocessor control manages all

boiler functions including supervising the combustion process and monitoring key operating

functions. Included is a digital display that can

provide detailed boiler information as well as be

an invaluable service and troubleshooting tool.

The MCBA module stores set points for boiler

and domestic hot water supply temperatures,

and monitors supply and return water temperatures, flue gas temperature, the flame sensor,

and the included outdoor reset. The boiler control module allows for continuous modulation

(firing rates) by varying the combustion fan

speed.

CHG Venting

The CHG incorporates a sealed combustion

system that uses outside air for combustion and

the safe and proven AL29-4C stainless steel material for venting the exhaust. Both horizontal

(“sidewall”) and vertical (“through-the-roof”)

venting options are available.

Page 4

Back View

1-1/4 Return

Ga

s

Connection

Condensate Drain

Connection

Front View

F

Vent

Adapter

4" Air

Inlet Collar

LWCO

43-3/4

Top View

22-1/4

C

B

E

D

A

HG

Right View

Temperature/

Pressure

Gauge

Relief

Valv

e

1-1/4 Supply

Alternate

1-1/4 Return

Line Voltage

Connections

Low Voltage

Connections

Alternate

Condensate Drain

Connection

Alternate Ga

s

Connection

RATINGS

DOE

Boiler

Model

Maximum Input

(MBH)

Minimum Input

(MBH)

Heating Capacity

(MBH)

CHG150 150,000 30,000 135,000 117,000 93.10

CHG225 225,000 56,250 202,000 176,000 94.20

I=B=R

Net Rating

(MBH) AFUE %

SPECIFICATIONS

Horizontal Venting Vertical Venting

Boiler

Model

Vent

Diameter

(inches)

Air Inlet

Diameter

(inches)

Maximum

Vent

Length

(Equiv. Ft.)

Maximum

Air Inlet

Length

(Equiv. Ft.)

Maximum

Vent

Length

(Equiv. Ft.)

Maximum

Air Inlet

Length

(Equiv. Ft.)

Water

Volume

(gal.)

CHG150 3 4 55 60 49.5 52 1.3 258

CHG225 4 4 55 60 47 52 1.1 323

DIMENSIONS

Boiler

Model ‘A’ ‘B’ ‘C’ ‘D’ ‘E’

CHG150 23-3/8 18-3/4 8-1/8 13 3-1/2

CHG225 27 22-3/8 8-1/4 7-1/8 3

* All dimensions in inches

Approx.

Shipping

Weight

(lbs.)

STANDARD EQUIPMENT

Deluxe Insulated Jacket

Circulator - Shipped Loose

Pressure Temperature Gauge

Drain Valve

MCBA Microprocessor Control

w/ Outdoor Reset (standard)

Digital Touchpad Display Panel

Variable Speed Combustion Blower

Negative Regulation Gas Valve

Venturi

Stainless Steel Mesh Burner

Supply Water Temperature Sensor

Return Water Temperature Sensor

© 2006 U.S. Boiler Company, Inc. - Lancaster, PA

Phone: 1-888-432-8887

www.burnham.comForm No. PL81401311000-6/06-10MS Printed in the U.S.A.

Flue Gas Temperature Sensor

Flame Sensor

Differential Pressure Switch

High Limit

LWCO and Transformer

Condensate Trap

Air Inlet Screen

Safety Relief Valve

Loading...

Loading...