Page 1

Chemical Feed System

Continuous Run & On-O Boiler

Feedwater Pump Applications

• Equipment to dose chemicals to treat boiler feedwater.

• Introduces chemicals to the boiler or boiler

feedwater piping.

• Vertical 50 gallon polyethylene tank on stand with lid

(other size tanks and tank materials available).

• 5/8" piston pump, adjustable from 0 to 6.2 gallons

per hour (GPH) (other size and capacity of piston and

diaphragm pumps available).

• Piston pump to 1000 psig (various stainless steel heads

available as an option).

• Modular conguration to meet customer requirements

includes: tank with lid on stand, piston pump, factor

suction piping and agitator. Continuous Run Only:

control panel and make-up water meter.

• Can be custom congured to meet customer requirements.

• More than one pump may be mounted under a 50

gallon tank.

• 1/4 HP, totally enclosed non-ventilated (TENV), 115/1/60

volt motor standard (50 hertz and many other motor

options available).

• Factory suction piping includes: strainer and safety relief

valve.

• Agitator: angle or clamp mounted, 1/4 HP TENV, 115/1/60

volt motor standard (50 hertz and many other motor

options available).

• Pump control via make-up water meter signal to

panel-mounted timer.

• Continuous Run—NEMA 12 control panel includes:

mixer and pump switches, motor relays, fuses, terminal

strip and timer.

• On-O—Control panel and water meter available

as options.

Page 2

Chemical Feed System

CONTINUOUS RUN & ONOFF BOILER

FEEDWATER PUMP APPLICATIONS

Specications

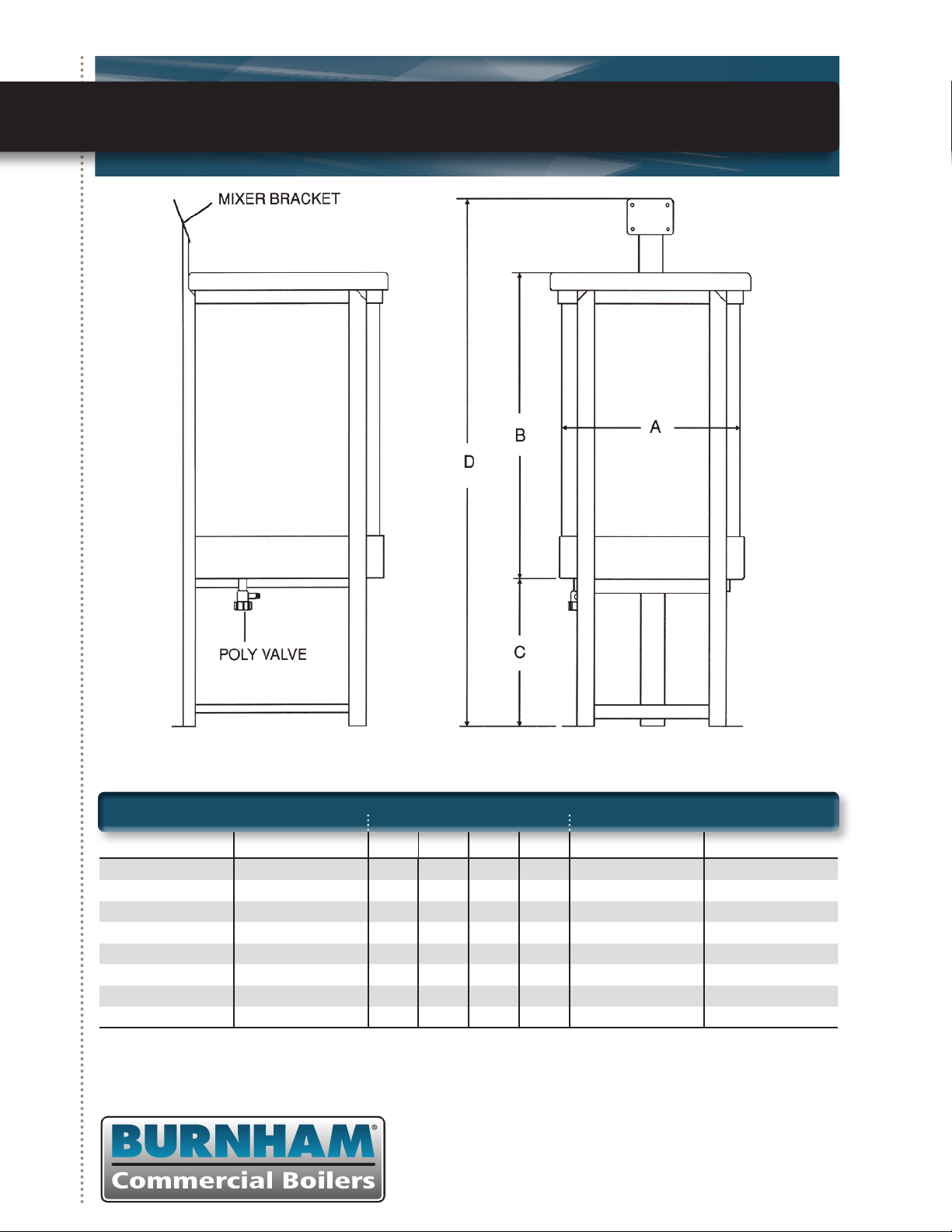

DIMENSIONS

Capacity in Gallons Wall in Inches A B C D Part Number Tank and Lid Only

30 1/8 18 30 12 49 103 030

55 1/8 22 34 17 60 305 050

100 1/4 28 42 18 70 310 0100

150 1/4 31 47 18 75 315 0150

200 1/4 36 48 20 77 320 0200

275 1/4 42 48 20 77 327 0275

360 1/4 48 48 20 77 336 0360

500 5/16 54 60 20 89 350 0500

©2012 Burnham Commercial

P.O. Box 3939 • Lancaster, PA 17604

Phone: 888.791.3790 • Fax: 717.293.5803

www.burnhamcommercial.com

Form No. PL81465601003-12/12-1Mc

Printed in the U.S.A.

Loading...

Loading...