Page 1

Operating Instructions

Type 2000/2002

2/2-Way Angle-Seat Valve

3/2-Way Globe Valve

Page 2

We reserve the right to make technical changes without notice.

© 2003 Bürkert Werke GmbH & Co. KG

Operating Instructions No. 893086 - ind 01 - oct 03

Page 3

2/2 OR 3/2-WAY ANGLE-SEAT VALVE TYPE 2000/2002

3/2-WAY GLOBE VALVE TYPE 2002

CONTENTS

GENERAL INFORMATION ................................................................................................................................ 2

Symbols ................................................................................................................................................................. 2

Safety instructions ........................................................................................................................................... 2

Scope of delivery .............................................................................................................................................. 3

Guarantee provisions ..................................................................................................................................... 3

GENERAL DESCRIPTION ................................................................................................................................. 3

TECHNICAL DATA ................................................................................................................................................. 4

Design..................................................................................................................................................................... 4

Actuator size ....................................................................................................................................................... 5

Material ................................................................................................................................................................... 5

Fluids ....................................................................................................................................................................... 5

Temperature range .......................................................................................................................................... 6

Maximum pilot pressure 2/2-way and 3/2-way valve ................................................................... 7

Operating pressure 3/2-way valve ......................................................................................................... 7

Minimum pilot pressures ............................................................................................................................... 8

Port connections ............................................................................................................................................. 10

Pressure surge test to DIN 1988, Part 2 ........................................................................................... 10

english

COMMISSIONING .................................................................................................................................................11

Installation of valve ........................................................................................................................................ 11

Connections for 3/2-way valve ...............................................................................................................11

Electrical connection of pilot valve ........................................................................................................12

MAINTENANCE AND SERVICING.............................................................................................................. 13

Repair.................................................................................................................................................................... 13

Spare parts ........................................................................................................................................................ 13

Spare parts drawings ...................................................................................................................................15

2000/2002 - 1

Page 4

GENERAL INFORMATION

Symbols

The following symbols are used in these instructions:

➔ Marks a work step that you need to perform

CAUTION!

Indicates instructions which, if ignored, puts your health or the

ability of the device or devices to function at risk.

english

NOTE

Indicates important additional information, tips and

recommendations.

Safety instructions

Please observe the instructions contained in this operating manual as well as

the application conditions and permissible parameters as specified in the data

sheet for device Type 2000/2002 so that the device functions flawlessly over a

long service life.

• Observe generally recognised technical regulations during application

planning and operation of the device!

• Installation and maintenance tasks are only to be carried out by trained

personnel equipped with the appropriate tools!

• Observe accident prevention and safety guidelines applicable for electrical

equipment during the operation and maintenance of the device!

• Always disconnect from power before working on the system!

• Please note that systems must first be depressurized before lines and

valves are disconnected!

• Take necessary precautions to prevent unintentional activation or

unauthorized interventions!

• If electrical power supply or pneumatic pressure sources have been

interrupted, make sure that system processes are restarted according to

defined specifications. Monitor the restart of system processes!

• We refuse all liability resulting from a failure to adhere to these instructions as

well as unauthorized operations on the device. Such actions likewise

invalidate the warranty on the devices and accessories.

2 - 2000/2002

Page 5

Scope of delivery

After delivery of goods, please immediately check the contents for damage and

compare the goods actually delivered with those items specified in the delivery

note. Please contact our Customer Service department regarding any

discovered inconsistencies:

Bürkert Steuer- und Regelungstechnik

Service-Abteilung

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen, Germany

Tel.: +49 (0)7940 10-111

Fax: +49 (0)7940 10-448

E-mail: service@buerkert.com

or your local Bürkert sales representative, listed at the end of this document.

Guarantee provisions

This document contains no warranty statements. Please refer to our general

terms of sales and business. The prerequisite for the guarantee is the use of the

device in accordance with the prescribed operating conditions.

english

CAUTION!

The guarantee only warrants that the valve, Type 2000/2002, is

free of defects. No liability is accepted for loss or damage of

any type resulting from failure or malfunction of the device.

GENERAL DESCRIPTION

The externally piloted angle-seat valve (Type 2000/2002) / globe valve (Type

2002) consists of a pneumatically operated piston actuator and a 2/2-way

valve body (angle-seat valve Type 2000/2002) / 3/2-way valve body (globe

valve Type 2002). The actuator casing is manufactured of polyamide (PA) or,

alternatively, polyphenylene sulfide (PPS) for special applications. The timeproven, self-adjusting packing gland ensures high seal integrity. The flow

optimizing valve body made of gunmetal (bronze) or stainless steel enables high

flow-rates.

2000/2002 - 3

Page 6

TECHNICAL DATA

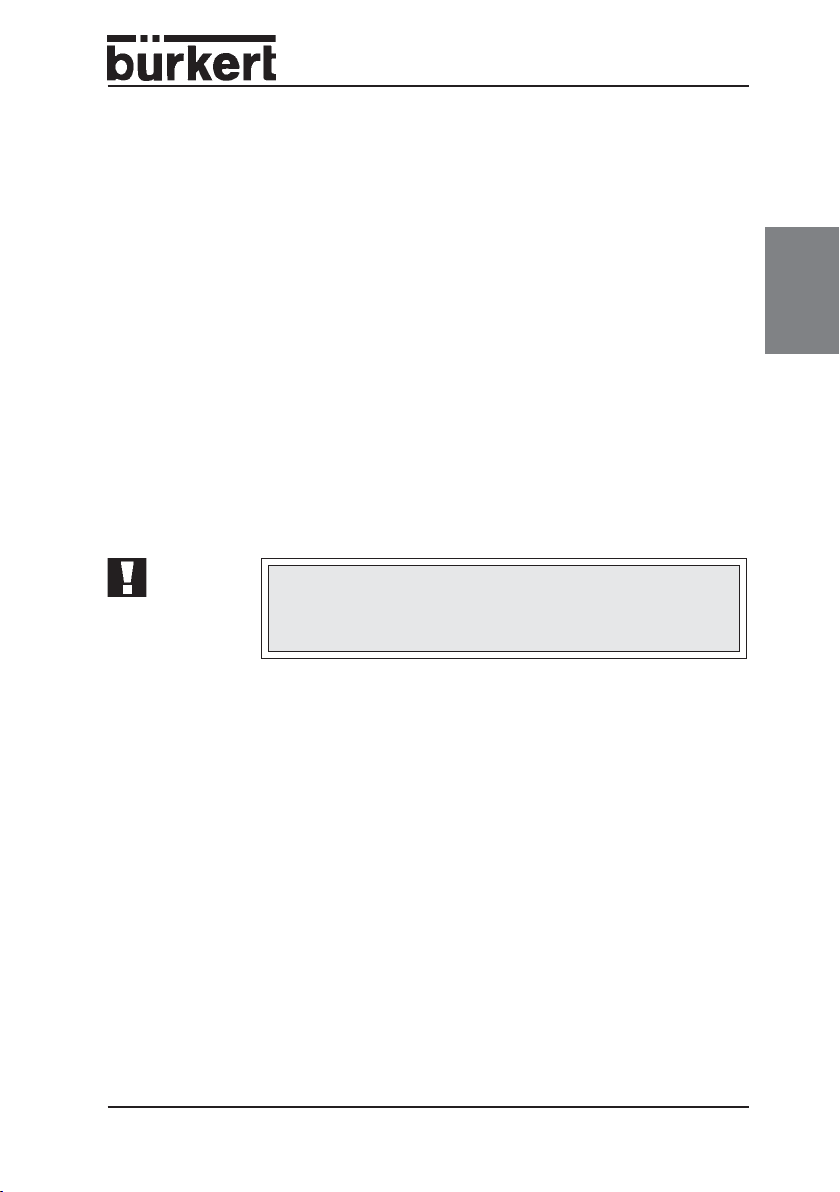

Design

2/2-way globe valve Type 2000/2002)

english

Control function A

Normally closed with spring force

(when de-energised).

3/2-way globe valve Type 2002

Control function A

Port connection 1

normally closed with

spring force (when

de-energised).

3

1

Control function C

Pressure inlet 1 normally closed

(when de-energised); service port 2

is without load.

Control function B

Normally open with spring force

(when de-energised).

Control

function

CPAR

DRAP

EPAP1

FAPB

2

A, B: Service ports

P, P1: Pressure inlets

R: Pressure relief

Ports

123

Control function D

Pressure inlet 3 connected to

service port 2 when de-energised;

relief port 1 closed.

Control function E (mixer valve)

Pressure inlet 3 connected to service

port 2 when de-energised; Pressure

inlet 1 closed.

4 - 2000/2002

Control function F (distributor

valve)

Pressure inlet 2 connected to service

port 3 when de-energised; service

port 1 closed.

Page 7

NOTE

Accidental switching of the pressure inlet lines for the service

port lines during connection of globe valve Type 2002 can

actuate valve operations other than those intended for the

selected control function.

Actuator size

Actuat or s i z e C D E F G H

Ø [mm] 40 50 63 80 100 125

Materials

Valve Type 2000

Threaded body:

Gunmetal,

Body material

Actuator

casing

Seal material PTFE (NBR; FPM, EPDM on request) PTFE

Packing gland

(with silicone

grease)

Stainless steel

1.4408

Body w/weld ends:

St. steel 1.4581

Polyamide or PPS

PTFE V-ring with spring compensation

Angle-seat valve Globe valve

Gunmetal,

St. steel 316L

(316L also

includes 1.4404

and 1.4408)

Type 2002

Gunmetal

PA

(PPS on request)

Fluids

CAUTION!

Observe permissible pressure range as specified on the rating

plate.

english

Water, alcohols, oils, fuels, hydraulic fluid, salt solutions, lyes, organic solvents,

steam.

Pilot fluids: Neutral gases, air

CAUTION!

Valves directing the flow over the seat should not be used for

liquid media; there is a danger of waterhammer!

2000/2002 - 5

Page 8

Operating temperature range

english

Actuator

type

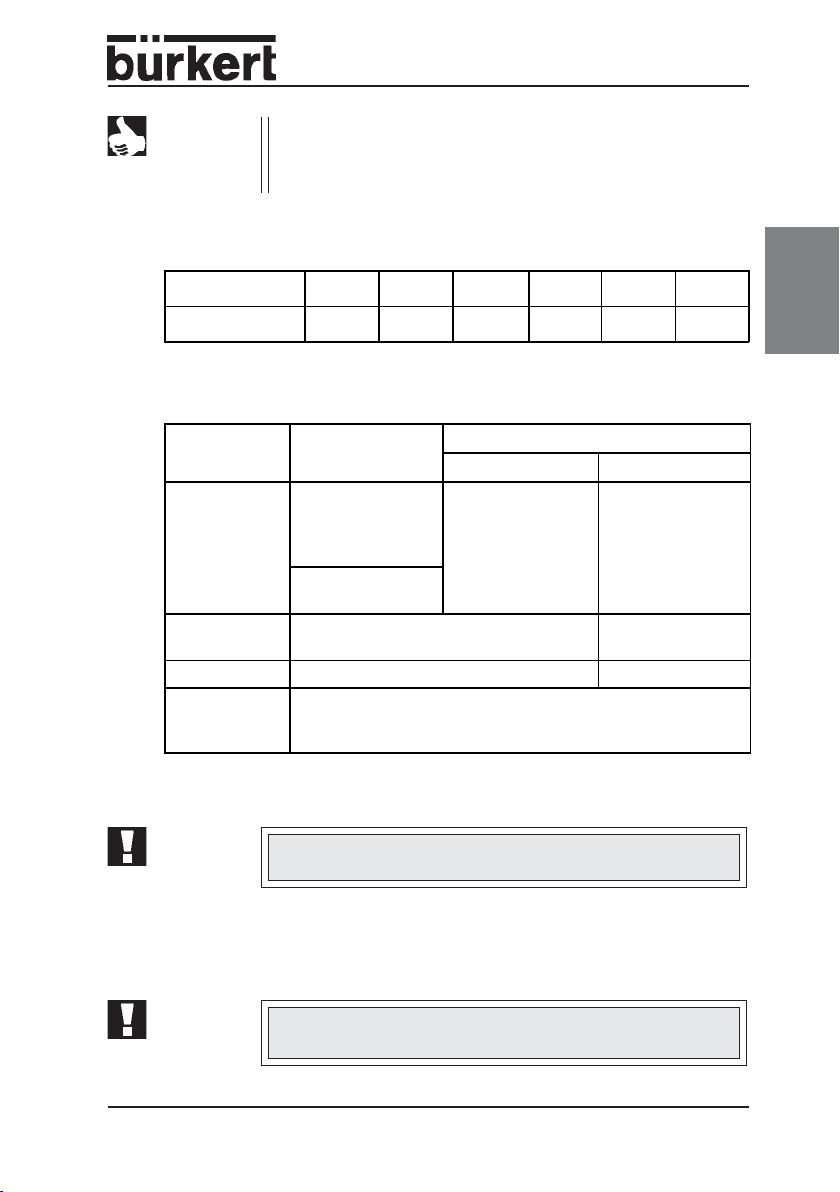

B/C Ø 40 to 63 PA

B/C Ø 80 to 125 PA -10 to +180 °C -10 to +60 °C

* short-term up to max. 140 °C

CAUTION!

Ambient

temperature °C

Actuator size

[mm]

D Ø 40 to 80 PPS -10 to +180 °C +5 to +140 °C

D Ø 100 to 125 PPS -10 to +180 °C +5 to +90 °C *

The maximum ambient temperature for a pilot valve is

+55 °C (131 °F)

Actuator

casing

Media temperature

(with PTFE seal)

-10 to

(see Diagram 1)

Ambient

temperature

(see Diagram 1)

-10 to

Diagram 1: Temperature range of the maximum media and ambient

NOTE

6 - 2000/2002

temperature for PA actuators

Temperature °F = (9/5) · (Temperature °C) + 32

Media

temperature °C

Page 9

Maximum pilot pressure 2/2-way and 3/2-way valve

Actuator type Actuator size [mm]

B/C (PA actuator)

D (PPS actuator)

Ø 40 to 100 10 bar

Ø 125 7 bar

Ø 40 to 80 10 bar

Ø 100 to 125 7 bar

Max. permissible

pilot pressure

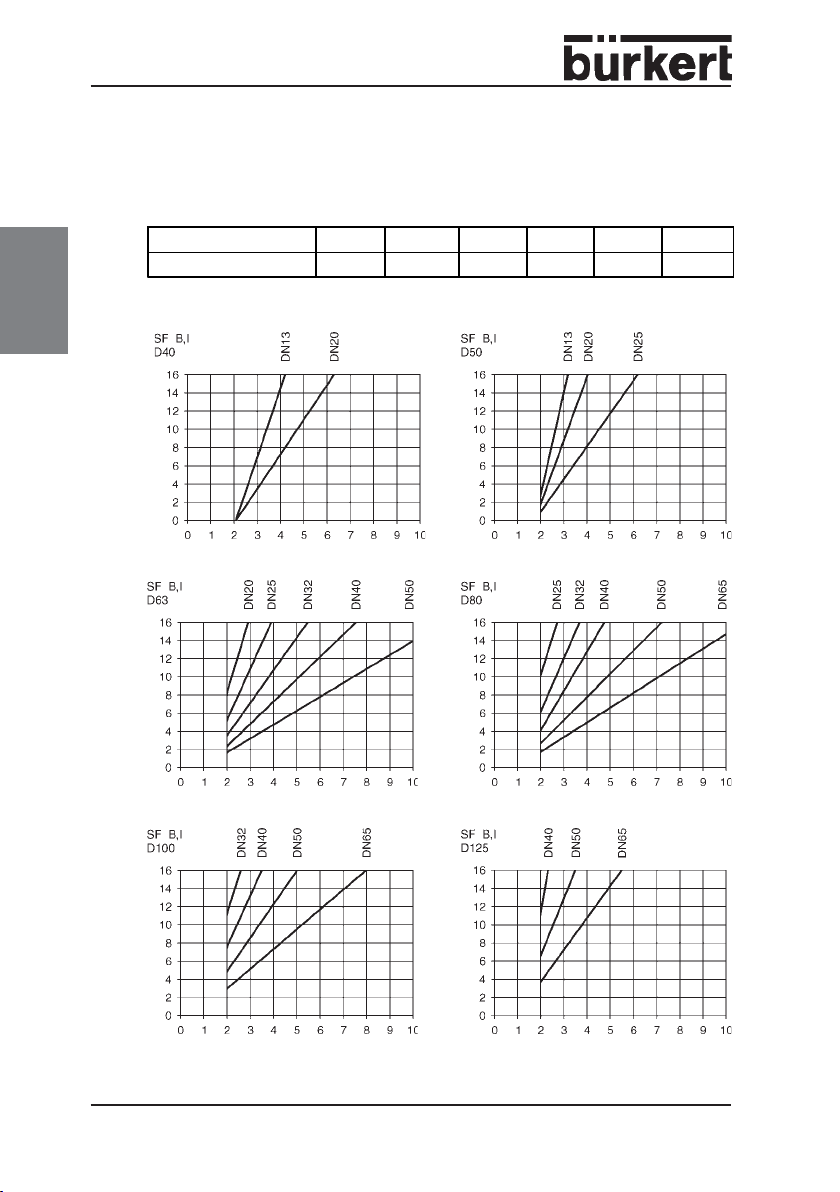

Operating pressure 3/2-way valve

The permissible operating pressure for control function A is:

Actuator

size

Ø [mm]

50 11 4.4

63 16 4.7

63 10 4.9

80 9 6.0

125 14 3.4

125 10 4.3

The maximum permissible operating pressure for control function F equals 16

bar.

Max. permissible operating pressure ∆p

[bar] at DN (flow direction 1 → 2)

13/20 25 32/40 50

Min. pilot

pressure [bar]

english

NOTE

1 bar = 14.5 psi

2000/2002 - 7

Page 10

english

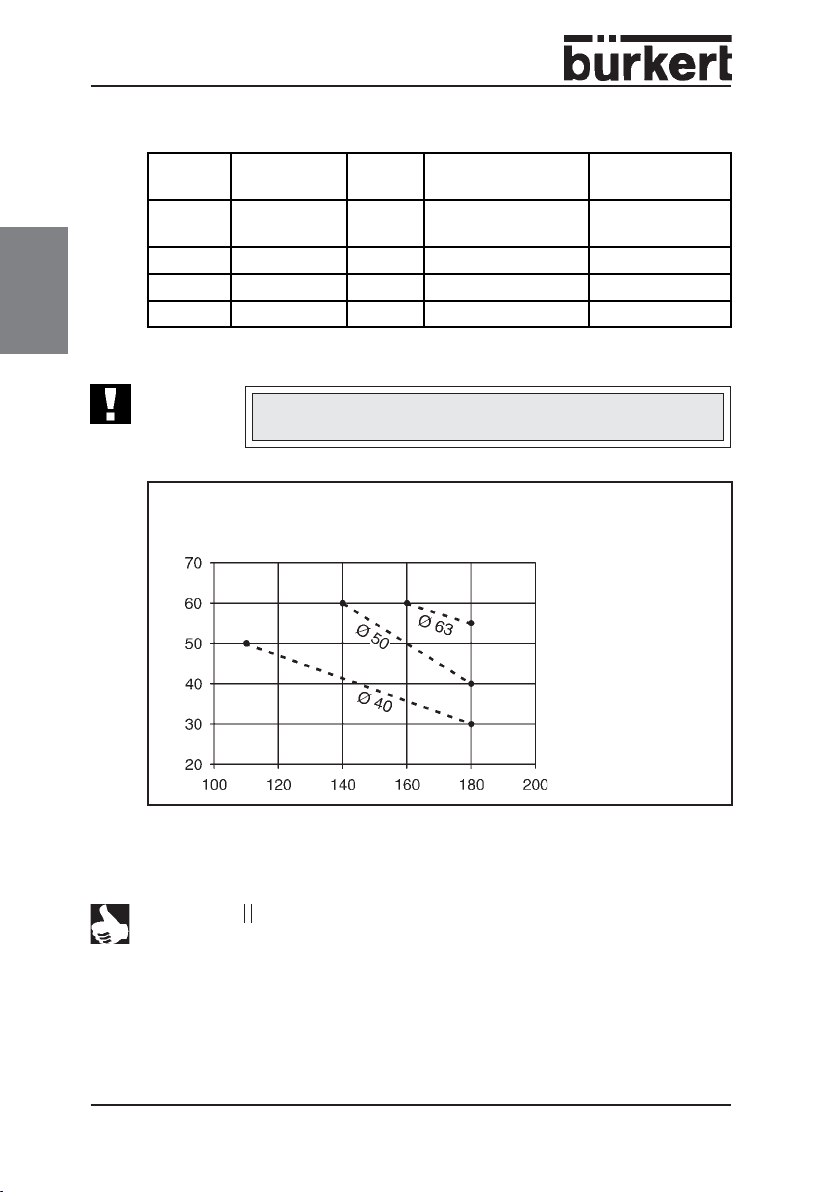

Minimum pilot pressures

Flow direction below seat

closing direction)

The necessary minimum pilot pressure P

Actuator size [mm] Ø 40 Ø 50 Ø 63 Ø 80 Ø 100 Ø 125

P

min

The pilot pressure P

min

(media flows in the opposite direction to valve

for control function A equals:

min

4.0 bar 3.9 bar 4.2 bar 5.0 bar 4.4 bar 3.2 bar

for control function B and I can be found in Diagram 2.

Fluid pressure [bar]

Pilot pressure [bar] Pilot pressure [bar]

Fluid pressure [bar]

Pilot pressure [bar]

Fluid pressure [bar]

Pilot pressure [bar]

Diagram 2: Pilot pressure P

for control function B and I (SFB, I).

min

Fluid pressure [bar]

Fluid pressure [bar]

Pilot pressure [bar]

Fluid pressure [bar]

Pilot pressure [bar]

8 - 2000/2002

Page 11

Flow direction above seat

closing direction)

(media flows in the opposite direction to valve

The pilot pressure P

Fluid pressure [bar]

Pilot pressure [bar]

Fluid pressure [bar]

Pilot pressure [bar] Pilot pressure [bar]

for control function A: see Diagram 3.

min

Fluid pressure [bar]

Fluid pressure [bar]

english

Pilot pressure [bar]

Fluid pressure [bar]

Pilot pressure [bar] Pilot pressure [bar]

Diagram 3: Pilot pressure P

for control function A.

min

Fluid pressure [bar]

2000/2002 - 9

Page 12

english

Port connections

Type 2000 Typ 2002

Angle-seat valve Globe valve

Threaded port:

NPT 3/8 to NPT 2 1/2

(G upon request)

Weld end connection:

-to ISO 4200

-to DIN 11850 R2

-OD tube (U. S.) 1/2" - 2" not available

NPT 3/8 to NPT 2 1/2

(G upon request))

G 1/2 to G 2

(NPT is not available)

Requirements placed on the closing behaviour of angle-seat

valves by DIN 1988 Part 2

To satisfy the requirements of the push-through test to DIN 1988 Part 2, the

exhaust air must be throttled with a throttle having a maximum diameter of 1

mm.

The flow restriction options are as follows:

• Integrated construction of a restrictor or a one-way flow restrictor directly

in the pneumatic actuator.

• Restrictor in the exhaust air port of a 4-way pilot valve.

• Restrictor or one-way flow restrictor directly at the outlet of a

3-way pilot valve.

Bürkert offers the appropriate valves for this purpose.

10 - 2000/2002

Page 13

COMMISSIONING

Installation of valve

Mounting position: any; preferentially with the actuator oriented upward.

➔ Install in accordance with the flow direction.

CAUTION!

In all cases, remove all contamination from the piping (excess

sealing material, metal debris, etc.).

Procedure for installing the valve:

➔ Connect the valve. Make sure the pipe run is correctly oriented.

➔ VA/VS body w/ weld ends: Disassemble and remove actuator before welding.

➔ Threaded body: Only disassemble the actuator if required by customer.

Instructions for actuator disassembly and assembly

Disassembly:

➔ Depressurize the valve seat before the removing and reassembly.

➔ Control function A: Turn on the actuator or release the tension of the return

spring by removing the actuator cover.

➔ Control function B or I: Switch off the pilot pressure.

➔ Screw the threaded nipple out from the body.

Assembly:

➔ Only for the stainless steel body: Grease the nipple threads with a suitable

lubricant.

➔ Screw the threaded nipple and the actuator into the body.

english

2000/2002 - 11

Page 14

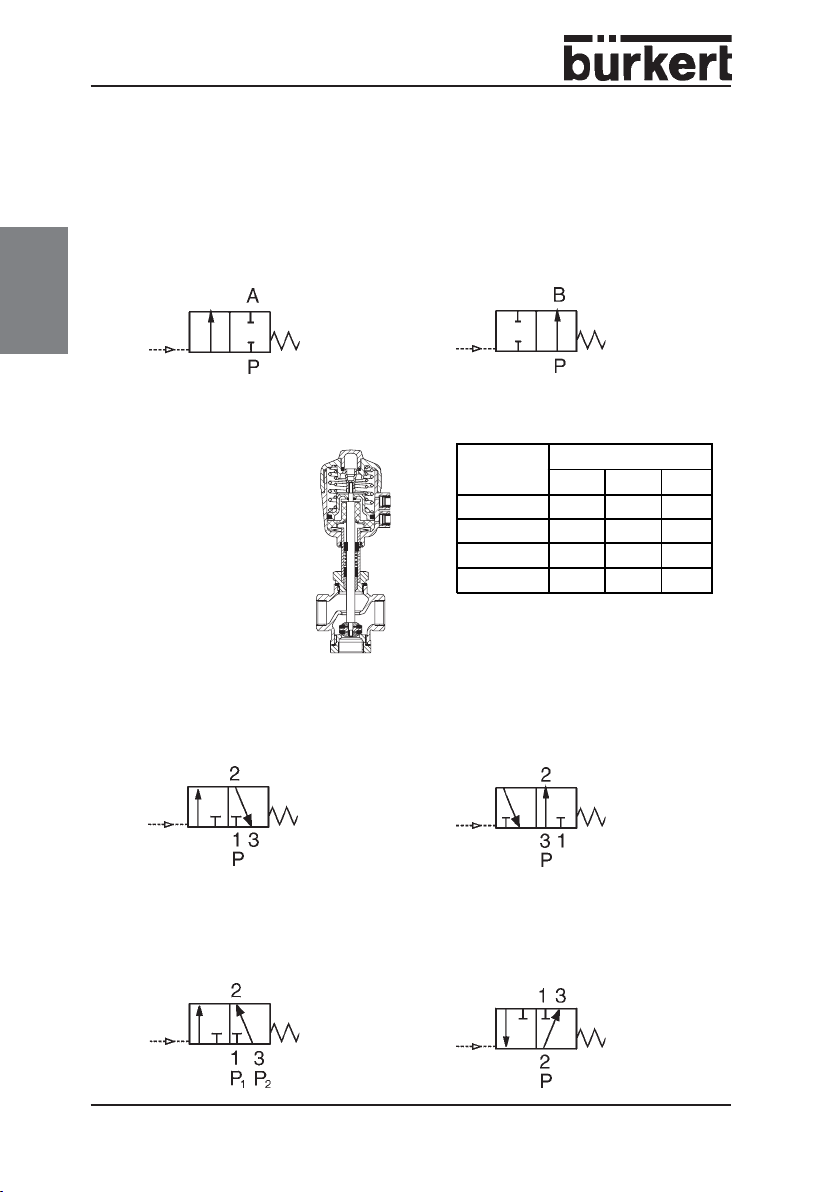

Connections for 3/2-way valve

english

Control

function

CPAR

DRAP

EPAP1

FAPB

A, B: Service ports

P, P1: Pressure inlets

R: Pressure relief

Connection of the pilot fluid:

Control function A, to lower connection port

Control function B, to upper connection port

Control function I,at the upper and lower actuator ports using a threaded

G 1/8" (Ø 40) or G 1/4" (Ø 50-125) connection.

The pilot port can rotate 360 degrees.

➔ Use banjo bolts (Type 6012 P, 6014 P) to attach the pilot valves to each respec-

tive pilot air connection on the actuator

➔ Switch on the pilot air at connection port P of the pilot valve

Ports

123

Electrical connection of pilot valve

CAUTION!

Please observe the voltage and current data specified on the

rating plate (voltage tolerance ±10%) as well as information

contained in the data sheet and the pilot valve instructions.

12 - 2000/2002

Page 15

MAINTENANCE AND SERVICING

Repair

CAUTION!

Before dismounting or opening the device, depressurize the

media supply and pilot air supply piping system.

Spare part sets (kits)

Includes as consumable parts a valve seat or sealing seat set (see drawing).

SET 6 Valve seat (2/2-way valve, gunmetal body)

DN

13

20

25*

25**

32

40

50

65

SET 6 Valve seat (2/2-way valve, stainless steel body)

DN

13

20

25*

25**

32

40

50

65

* Actuator size 50, Letter code D.

** Actuator size 63, Letter code E.

Item No.

PTFE seal

010 984 011 065

010 986 011 070

010 988 011 085

159 635 011 044 011 088

011 046 011 107

011 390 011 109

011 064 011 120

Item No.

PTFE seal

011 134 011 234

011 171 011 253

011 202 011 259

160 737 -

011 208 0 11 262

011 209 011 267

011 214 011 26 9

011 216 011 307

Item No.

FPM seal

Item No.

FPM seal

english

2000/2002 - 13

Page 16

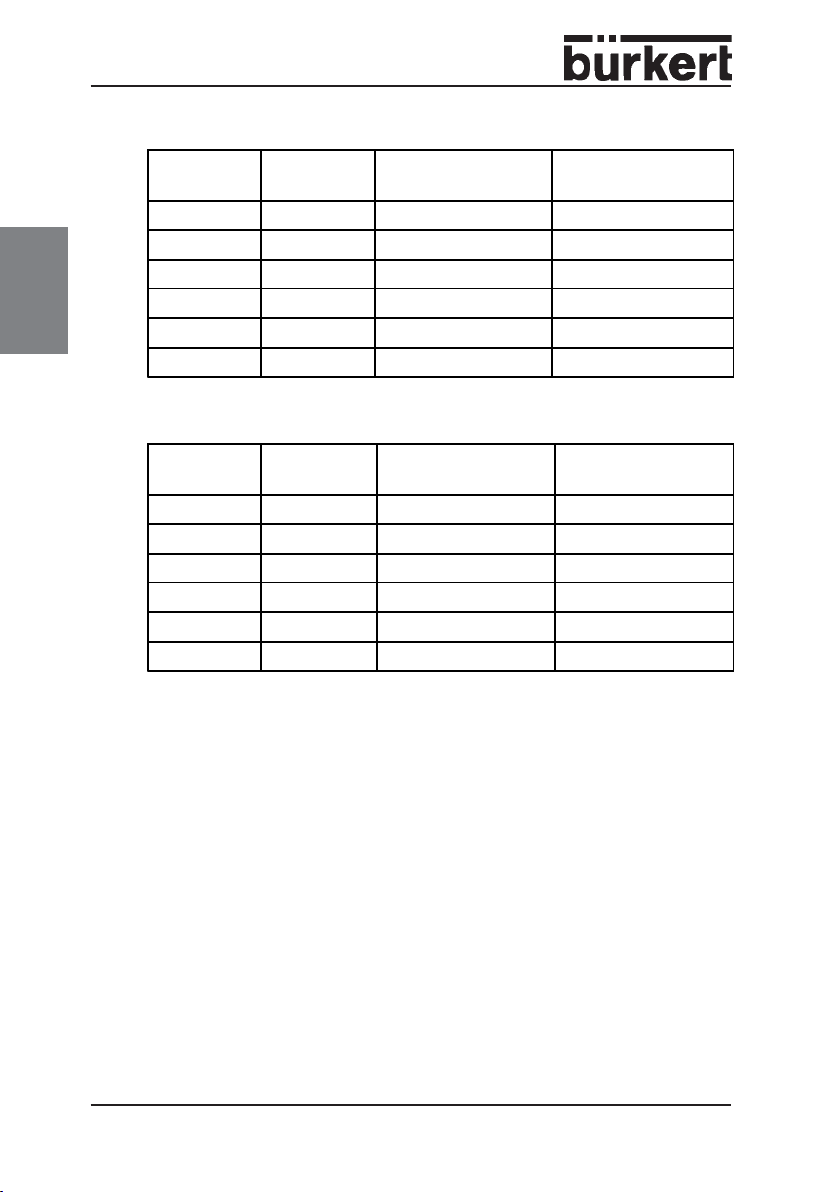

SET 5 Sealing set for PA actuator

english

Actuator

size

C (Ø 40) DN 13/20/25

D (Ø 50) DN 13/20/25

E (Ø 63) DN 25-50

F (Ø 80) DN 25-65

G (Ø 100) DN 32-65

H (Ø 125) DN 40-65 011 368 011 387

Fitting

valve sizes

Item No.

Gunmetal body

011 420 011 420

011 308 011 369

011 334 011 372

011 366 001 902

007 763 011 386

St.Steel body

SET 5 Sealing set for PPS actuator

Actuator

size

C (Ø 40) DN 13/20/25

D (Ø 50) DN 13/20/25

E (Ø 63) DN 25-50

F (Ø 80) DN 25-65

G (Ø 100) DN 32-65

H (Ø 125) DN 40-65

Fitting

valve sizes

Item No.

Gunmetal body

011 465 011 465

011 373 011 388

007 765 007 766

011 375 007 767

011 374 011 389

007 764 007 768

St.Steel bod y

Item No.

Item No.

14 - 2000/2002

Page 17

Spare parts drawings

Drawing showing spare part sets for angle-seat valves

Sealing set

SET 5

FPM

english

FPM only used with

gunmetal body

Valve seat

set

SET 6

2000/2002 - 15

Page 18

english

Drawing showing spare part sets for 3/2-way globe valve

Sealing sets

SET 5

(same as 2/2-way

angle-seat valve)

Valve seat

set

(upon

request)

16 - 2000/2002

Page 19

Page 20

Addresses of BC offices/Adressliste BC Länder Europe/Europa

BC-A Austria, Österreich

Burkert-Contromatic Ges.m.b.H.

Diefenbachgasse 1-3

A-1150 Wien

Phone: Int.(+43 1)894 13 33, Nat.(01)894 13 33

Fax: Int.(+43 1)894 13 00, Nat.(01)894 13 00

E-mail: info@buerkert.at

BC-B Belgium, Belgien

Burkert-Contromatic SA

Bijkhoevelaan 3

B-2110 Wijnegem

Phone: Int.(+32 3)325 89 00, Nat.(03)325 89 00

Fax: Int.(+32 3)325 61 61, Nat.(03)325 61 61

E-mail: sales.be@burkert.com

BC-CH Switzerland, Schweiz

Burkert-Contromatic AG Schweiz

Bösch 71

CH-6331 Hünenberg ZG

Phone: Int.(+41 41)785 66 66, Nat.(041)785 66 66

Fax: Int.(+41 41)785 66 33, Nat.(041)785 66 33

E-mail: info.ch@buerkert.ch

BC-CZ Czech Rep., Tschech. Rep.

Burkert-Contromatic Ges.m.b.H.

Branch-Office Austria

Krenova 35

CZ-602 00 Brno

Phone: Int.(+420 543)25 25 05,Nat.(543)25 25 05

Fax: Int.(+420 543)25 25 06,Nat.(543)25 25 06

E-mail: obchod@buerkert.cz

BC-DK Denmark, Dänemark

Burkert-Contromatic A/S

Hørkær 24

DK-2730 Herlev

Phone: Int.(+45 44)50 75 00, Nat.44-50 75 00

Fax: Int.(+45 44)50 75 75, Nat.44-50 75 75

E-mail: info.dk@burkert.com

BC-E Spain, Spanien

Burkert Contromatic, S.A.

Avda. Barcelona, 40

E-08970 Sant Joan Despi, Barcelona

Phone: Int.(+34 93)477 79 80, Nat.(93)477 79 80

Fax: Int.(+34 93)477 79 81, Nat.(93)477 79 81

E-mail: bc-e@burkert.com

BC-F France, Frankreich

Burkert Contromatic France

Rue du Giessen

F-67220 Triembach au Val

Phone: Int.(+33 388)58 91 11,Nat.(0388)58 91 11

Fax: Int.(+33 388)57 20 08,Nat.(0388)57 20 08

E-mail: burkert.france@buerkert.com

BC-GB Great Britain, Großbritannien

Burkert Fluid Control Systems

Brimscombe Port Business Park

Brimscombe, Stroud

Glos, GL5 2QF /Great Britain

Phone: Int.(+44 1453)73 13 53,Nat.(01453)73 13 53

Fax: Int.(+44 1453)73 13 43,Nat.(01453)73 13 43

E-mail: sales.uk@burkert.com

BC-I Italy, Italien

Burkert Contromatic Italiana S.p.A.

Centro Direzionale „Colombirolo“

Via Roma, 74

I-20060 Cassina De’ Pecchi (Mi)

Phone: Int.(+39 02)959 071,Nat.(02)959 071

Fax: Int.(+39 02)959 07251,Nat.(02)959 07 251

E-mail: info@buerkert.it

BC-N Norway, Norwegen

Burkert-Contromatic A/S

Hvamstubben 17

N-2013 Skjetten

Phone: Int.(+47 63)84 44 10,Nat.(63)84 44 10

Fax: Int.(+47 63)84 44 55,Nat.(63)84 44 55

E-mail: buerkert@online.no

BC-NL Netherlands, Niederlande

Burkert-Contromatic BV

Computerweg 9

NL-3542 DP Utrecht

Phone: Int.(+31 346)58 10 10,Nat.(0346)58 10 10

Fax: Int.(+31 346)56 37 17,Nat.(0346)56 37 17

E-mail: sales.nl@burkert.com

BC-P Portugal, Portugal

Burkert Contromatic

Phone: Int.(+35121)21 28 490, Nat.(21)21 28 490

Fax: Int.(+35121)21 28 491, Nat.(21)21 28 491

E-mail: portugal@burkert.com

BC-PL Poland, Polen

Burkert-Contromatic Ges.m.b.H

Branch-Office Austria

Bernardynska street 14 a

PL-02-904 Warszawa

Phone: Int.(+48 22)840 60 10,Nat.(022)840 60 10

Fax: Int.(+48 22)840 60 11,Nat.(022)840 60 11

E-mail: buerkert@buerkert.pl

BC-S Sweden, Schweden

Burkert-Contromatic AB

Skeppsbron 13 B

S-211 20 Malmö

Phone: Int.(+46 40)664 51 00,Nat.(040)664 51 00

Fax: Int.(+46 40)664 51 01,Nat. (040)664 51 01

E-mail: info.se@burkert.com

BC-SA South Africa, Südafrika

Burkert Contromatic Pty. Ltd.

233 Albert Amon Road

Millenium Business Park

Meadowale / Edenvale

Republic of South Africa

Phone: Int.(+27 11)397 29 00, Nat.(011)397 29 00

Fax: Int.(+27 11)397 44 28, Nat.(011)397 44 28

E-mail: sales.za@burkert.com

BC-SF Finland, Finnland

Burkert Oy

Atomitie 5

SF-00370 Helsinki

Phone: Int.(+358 9)549 706 00,Nat.(09)549 70600

Fax: Int.(+358 9)503 12 75,Nat.(09)503 1275

E-mail: sales.fi@burkert.com

BC-TR Turkey, Türkei

Burkert Contromatic Akiskan

Kontrol Sistemleri Ticaret A.S.

1203/8 Sok. No2-E

TR-Yenisehir, Izmir

Phone: Int.(+90 232)459 5395,Nat.(0232)459 5395

Fax: Int.(+90 232)459 7694,Nat.(0232)459 7694

E-mail: burkert@superonline.com

Page 21

Addresses of BC offices/Adressliste BC Länder APAC

BC-HKG (China) Hong Kong, Hongkong

Burkert-Contromatic (China/HK) Ltd.

Unit 708 Prosperity Centre,

77 - 81, Container Port Road

Kwai Chung, N.T.

Phone: Int.(+852)248 012 02,Nat. 248 012 02

Fax: Int.(+852)241 819 45,Nat. 241 819 45

E-mail: info.hkg@burkert.com

BC-CN China, China

Burkert-Contromatic (Suzhou) Co.Ltd.

9-2, Zhu Yuan Road

Suzhou, New District

Jiangsu, 215011

Peoples Republic of China

Phone: Int.(+86 512)6808 19 16,Nat (512)6808 19 16

Fax: Int.(+86 512)6824 51 06,Nat (512)6824 51 06

E-mail: info.chn@burkert.com

BC-KOR Korea, Korea

Burkert Contromatic Korea Co., Ltd.

287-2, Doksan 4 Dong

Kumcheon-ku

Seoul 153-811

Korea

Phone: Int.(+82 2)33462 55 92, Nat.(02)33462 55 92

Fax: Int.(+82 2)33462 55 94, Nat.(02)33462 55 94

E-mail: info.kor@burkert.com

BC-RC Taiwan, Taiwan

Burkert Contromatic Taiwan Ltd.

3 F, No. 475, Kuang-Fu South Road

Taipei 110

Taiwan, R.O.C.

Phone: Int.(+886 2)275 831 99,Nat.(02)275 831 99

Fax: Int.(+886 2)275 824 99,Nat.(02)275 824 99

E-mail: info.rc@burkert.com

BC-RP Philippines, Philippinen

Burkert Contromatic Philippines, Inc.

8467, West Service Road

South Superhighway, Sunvalley

Paranaque City, Metro Manila

Philippines

Phone: Int.(+63 2)776 43 84, Nat.(02)776 43 84

Fax: Int.(+63 2)776 43 82, Nat.(02)776 43 82

E-mail: info.rp@burkert.com

BC-SIN Singapore, Singapur

Burkert Contromatic Singapore Pte. Ltd.

51 Ubi Avenue 1, #03-14

Paya Ubi Industrial Park

Singapore 408933

Singapore

Phone: Int.(+65)6844 2233,Nat.6844 2233

Fax: Int.(+65)6844 3532,Nat.6844 3532

E-mail: info.sin@burkert.com

BC-AUS Australia, Australien

Burkert Fluid Control Systems

No. 2 Welder Road

Seven Hills, NSW 2147

Australia

Phone: Int.(+61 2)1300 888 868,Nat.(02)1300 888 868

Fax: Int.(+61 2)1300 888 076,Nat.(02)1300 888 076

E-mail: sales.au@burkert.com

BC-NZ New Zealand, Neuseeland

Burkert Contromatic Ltd.

2A, Unit L, Edinburgh Street

Penrose, Auckland

New Zealand

Phone: Int.(+64 9)622 28 40,Nat.(09)622 28 40

Fax: Int.(+64 9)622 28 47,Nat.(09)622 28 47

E-mail: sales.nz@burkert.com

BC-J Japan, Japan

Burkert-Contromatic Ltd.

1-8-5 Asagaya Minami

Suginami-ku

Tokyo 166-0004

Japan

Phone: Int.(+81 3)5305 3610,Nat.(03)5305 3610

Fax: Int.(+81 3)5305 3611,Nat.(03)5305 3611

E-mail: info.jpn@burkert.com

Page 22

Addresses of BC offices/Adressliste BC Länder NAFTA

BC-BRA Brazil, Brasilien

Burkert-Contromatic Brasil Ltda.

Rua Américo Brasiliense, 2171 cj.1007

04715-005 São Paulo - SP

Brazil

Phone: Int.(+55 11)5182 0011, Nat.(011)5182 0011

Fax: Int.(+55 11)5182 8899, Nat.(011)5182 8899

E-mail: burkert@burkert.com.br

BC-CDN Canada, Kanada

Burkert Contromatic Inc.

760 Pacific Road, Unit 3

Oakville, Ontario L6L 6M5

Canada

Phone: Int.(+1 905)847 55 66,Nat.(905)847 55 66

Fax: Int.(+1 905)847 90 06,Nat.(905)847 90 06

E-mail: sales.ca@burkert.com

BC-USA (Main Office) USA, USA

Burkert Contromatic USA

2602 McGaw Avenue

Irvine, CA 92614

USA

Phone: Int.(+1 949)223 31 00,Nat.(949)223 31 00

Fax: Int.(+1949)223 31 98,Nat.(949)223 31 98

E-mail: marketing-usa@burkert.com

Page 23

Adressliste Bürkert Fluid Control Systems Deutschland

Vertriebs-Center

Berlin

Bruno-Taut-Straße 4

12524 Berlin

Telefon:Int. (+4930)6797170, Nat. (030)6797170

Fax: Int. (+4930)67971766, Nat. (030)67971766

Hannover

Rendsburger Straße 12

30659 Hannover

Telefon:Int. (+49511)902760, Nat. (0511)902760

Fax: Int. (+49511)9027666, Nat. (0511)9027666

Dortmund

Holzener Straße 70

58708 Menden

Telefon:Int. (+492373)96810, Nat. (02373)96810

Fax: Int. (+492373)968166, Nat. (02373)968166

Frankfurt

Am Flugplatz 27

63329 Egelsbach

Telefon:Int. (+496103)94140, Nat. (06103)94140

Fax: Int. (+496103)941466, Nat. (06103)941466

Stuttgart

Karl-Benz-Straße 19

70794 Filderstadt-Bernhausen

Telefon:Int. (+49711)451100, Nat. (0711)451100

Fax: Int. (+49711)4511066, Nat. (0711)4511066

München

Paul-Gerhardt-Allee 24

81245 München

Telefon:Int. (+4989)8292280, Nat. (089)8292280

Fax: Int. (+4989)82922850, Nat. (089)82922850

Dienstleistungs-Center

Dortmund

Holzener Straße 70

58708 Menden

Telefon: Int. (+492373)968134, Nat. (02373)968134

Fax: Int. (+492373)968132, Nat. (02373)968132

Dresden

Christian-Bürkert-Straße 2

01900 Großröhrsdorf

Telefon: Int. (+4935952)36-300, Nat. (035952)36-300

Fax: Int. (+4935952)36-551, Nat. (035952)36-551

Service-Center

Ingelfingen

Christian-Bürkert-Straße 13-17

74653 Ingelfingen

Telefon: In t. (+ 497940)10-111, Nat. (07940)10-111

Fax: Int. (+497940)10-448, Nat. (07940)10-448

E-mail: info@de.buerkert.com

Page 24

The smart choice

of Fluid Control Systems

www.burkert-usa.com

Loading...

Loading...