Page 1

Type 2651, 2654, 2660, TKU 001

Stainless-steel and brass ball valves in 2-way and 3-way design

Kugelhähne aus Edelstahl und Messing in 2-Wege und 3-Wege Ausführung

Robinets à boisseau sphérique en acier inoxydable et en laiton, modèles à 2 ou 3 voies

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2008 - 2010 Bürkert Werke GmbH

Operating Instructions 1011/03_EU-ML_00805911 / Original DE

Page 3

Types 2651, 2654, 2660,

TKU 001

Contents

1. OPERATING INSTRUCTIONS ...................................................................4

1.1. Symbols ..............................................................................................4

2. INTENDED USE ................................................................................................5

2.1. Restrictions ........................................................................................5

2.2. Predictable Misuse ..........................................................................5

3. BASIC SAFETY INSTRUCTIONS .............................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Contact address ............................................................................... 7

4.2. Warranty ............................................................................................. 7

4.3. Information on the Internet ............................................................. 7

5. SYSTEM DESCRIPTION ...............................................................................7

5.1. Intended Application Area .............................................................. 7

5.2. Functions ............................................................................................ 7

6. TECHNICAL DATA ...........................................................................................8

6.1. Operating conditions ....................................................................... 8

6.2. General technical data .................................................................... 8

7. INSTALLATION ..................................................................................................9

7.1. Safety instructions ...........................................................................9

7.2. Installation in the Pipeline .............................................................10

8. OPERATION AND FUNCTION ................................................................10

8.1. Safety instructions .........................................................................10

8.2. Operation of the ball valve ...........................................................10

8.3. Functions ..........................................................................................11

9. SPARE PARTS ................................................................................................11

10. MAINTENANCE, TROUBLESHOOTING .......................................... 12

10.1. Maintenance Work .......................................................................12

11. PACKAGING, TRANSPORT, STORAGE, DISPOSAL ................ 12

english

3

Page 4

Types 2651, 2654, 2660,

TKU 001

Operating Instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous

situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a medium or minor

injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Page 5

Types 2651, 2654, 2660,

TKU 001

Intended Use

2. INTENDED USE

The ball valves types 2651, 2654 and 2660 (in general below as "Ball

valves") are intended for the installation to pneumatic or electric rotary

actuators. They can be used indoors as well as outdoors, in compliance

with the permissible operating conditions.

Non-intended use of the ball valves can be dangerous to

people, nearby equipment and the environment.

• The ball valves are used for shutting off media flows in a wide

range of industrial applications.

• The ball valves may be used only in conjunction with third-party

devices and components recommended and authorized by Bürkert.

• During use observe the authorised data and operating conditions

specified in the contract documents and operating instructions

as well as the range of applications described in „5.1. Intended

Application Area“.

• Correct transportation, correct storage and installation and careful use

and maintenance are essential for reliable and faultless operation.

• Use the ball valves only as intended.

2.1. Restrictions

If exporting the System/Device, observe any existing restrictions.

2.2. Predictable Misuse

• Operate the ball valves only with media which do not corrode the

housing or seal material.

• Do not physically stress the housing (e.g. by placing objects on it

or standing on it).

• Do not make any external modifications to the housing.

english

5

Page 6

Types 2651, 2654, 2660,

TKU 001

Basic Safety Instructions

3. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• Local safety regulations; the operator is responsible for observing

these regulations, also with reference to the installation personnel.

WARNING!

Unintentional activation or non-permitted impairment may

cause general hazardous situations through to physical injury.

To prevent injury, ensure that:

• The system cannot be activated unintentionally.

• Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

• After an interruption in the power supply or fluid supply, ensure

that the process is restarted in a defined or controlled manner.

• The device may be operated only when in perfect condition and

in consideration of the operating instructions.

• The general rules of technology apply to application planning

and operation of the device.

DANGER!

Danger – high pressure!

• There is a serious risk of injury when reaching into the equipment.

• Turn off the pressure and release the pressure in the pipes

before loosening pipes and valves!

CAUTION!

The general rules of technology apply to application planning

and operation of the device!

• Failure to observe these rules may result in injuries and/or damage to the device and possibly the area around it as well.

• Observe the general rules of technology!

NOTE!

The ball valves were developed with due consideration given to

the accepted safety rules and are state-of-the-art. Nevertheless,

dangerous situations may occur.

• Operate the ball valves only when they are in perfect condition

and in accordance with the operating instructions.

Failure to observe this operating manual and its operating instructions as well as unauthorized tampering with the device release us

from any liability and also invalidate the warranty covering the device

and accessories!

6

english

Page 7

Types 2651, 2654, 2660,

TKU 001

General Information

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: +49 (0)7940 - 10 91 111

Fax: +49 (0)7940 - 10 91 448

E-mail: info@de.burkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type 2651, 2654, 2660

and TKU 001 can be found on the Internet at: www.burkert.com

5. SYSTEM DESCRIPTION

5.1. Intended Application Area

The ball valves are used for shutting off media flows in a wide range

of industrial applications.

They are particularly suitable for application conditions which make

high demands in the areas of thermal loads and are also suitable for

applications which use aggressive media.

5.2. Functions

The ball valves for shutting off media flows are available in different

sizes. They are equipped with a mechanical interface as per ISO 5211.

This interface is used to install a pneumatic or electric rotary actuator

to the ball valves.

On request the ball valves can be supplied complete with a

pneumatic actuator (Types 2652, 2655, 8805) or an electric

actuator (Type 8804).

english

7

Page 8

Types 2651, 2654, 2660,

TKU 001

Technical Data

6. TECHNICAL DATA

6.1. Operating conditions

Allowable temperatures

Ambient temperature: Stainless-steel housing -10 – +80 °C

Brass housing -20 – +80 °C

Medium temperature: Stainless-steel housing -10 – +100 °C

Brass housing -20 – +100 °C

Media: Aggressive, neutral, gaseous and liquid

media and vapours

Pressure ranges: 0 – 100 bar (depending on the design)

6.2. General technical data

6.2.1. Mechanical data

Housing material: Stainless steel 1.4401; Nickel-plated brass

Sealing material: PTFE

6.2.2. Pressure-temperature graphs,

2/2-way and 3/2-way ball valves

50

40

30

20

Pressure [bar]

10

0

-20 1201008060400 20 140160

Fig. 1: Pressure-temperature Graph / Brass housing

40 bar

30 bar

25 bar

16 bar

10 bar

Temperature [°C]

8

english

Page 9

Types 2651, 2654, 2660,

100 bar

63 bar

40 bar

Pressure [bar]

TKU 001

Installation

7. INSTALLATION

7.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

There is a serious risk of injury when reaching into the equipment.

• Turn off the pressure and release the pressure in the pipes before

loosening pipes and valves!

WARNING!

16 bar

0 bar

Temperature [°C]

100400

200 230

Fig. 2: Pressure-temperature Graph / Stainless-steel housing

Risk of injury due to improper installation!

Improper installation may result in injuries as well as damage to

the device and the area around it.

• This work may be carried out by authorised technicians only and

with the appropriate tools!

Risk of injury due to unintentional activation!

Hazardous situations may arise due to unintentional activation of

the system.

• Take appropriate measures to prevent the equipment from being

unintentionally activated.

english

9

Page 10

Types 2651, 2654, 2660,

TKU 001

Operation and function

7.2. Installation in the Pipeline

Procedure:

→ Check that the pipes which are to be connected to the ball valve are

on one level. This will prevent mechanical tension on the screw joint.

→ Screw the ball valve to the pipe.

→ Check that the ball valve is firmly attached to the pipe to ensure

appropriate tightness.

8. OPERATION AND FUNCTION

8.1. Safety instructions

WARNING!

Danger due to improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

• The operating personnel must know and have understood the

contents of the operating instructions.

• Observe the safety instructions and intended use.

• Only adequately trained personnel may operate the equipment/

the device.

8.2. Operation of the ball valve

Via the mechanical interface as per ISO 5211, the ball valves can be

connected to a pneumatic rotary actuator (e.g. Types 2050 or 2051)

or an electric rotary actuator (e.g. Types 3003, 3004 or 3005).

10

english

Page 11

Types 2651, 2654, 2660,

TKU 001

Spare parts

8.3. Functions

The ball valves are available in 2-way or 3-way design. The 3-way

designs are available with the following functions:

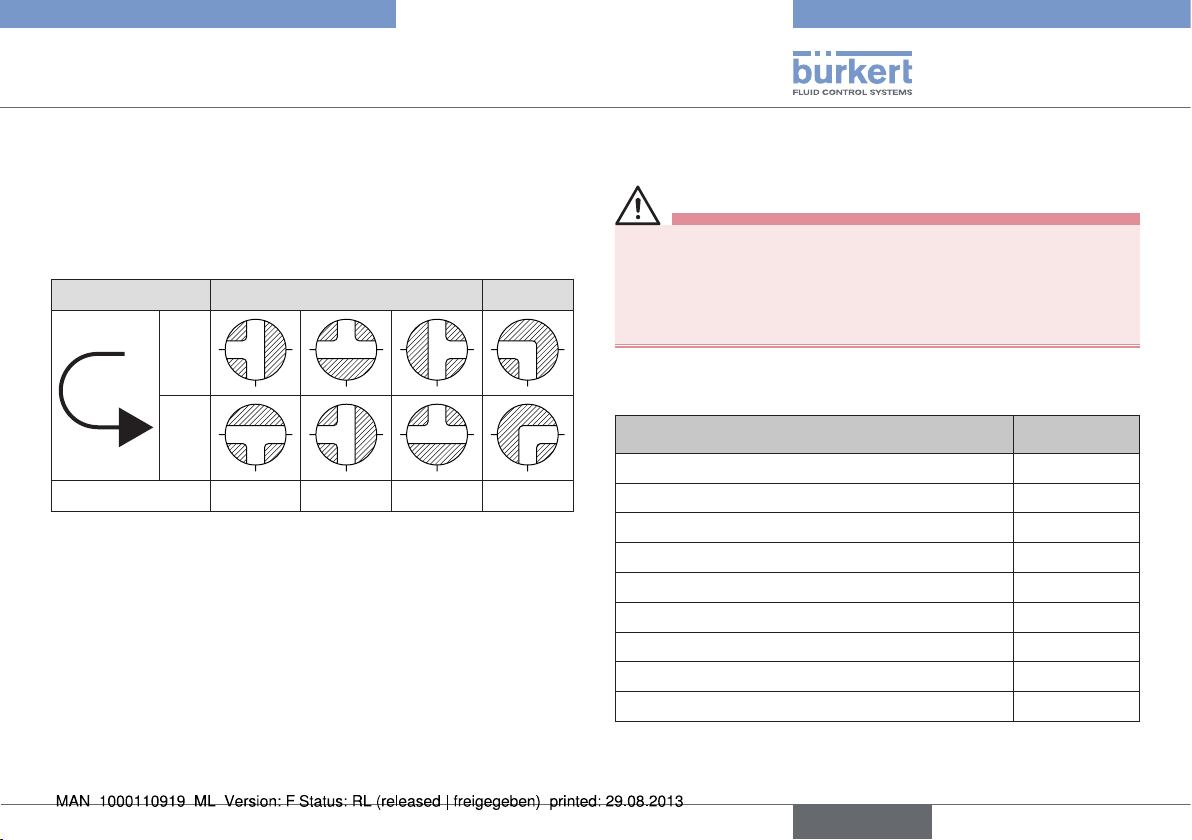

8.3.1. Switching positions

Ball bore T L

Position

0°

90°

Switching position

T1 T2 T3 L4

9. SPARE PARTS

CAUTION!

Risk of injury and / or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the device and the surrounding area.

• Use original accessories and original spare parts from Bürkert

only.

Wearing part-sets for the three-part ball valve of type 2654:

Wearing part-set Order No.

Wearing part-set DN 15, VL-521 1/2" 789821

Wearing part-set DN 20, VL-501, VL-521 3/4" 789822

Wearing part-set DN 25, VL-501, VL-521 1" 789823

Wearing part-set DN 32, VL-501, VL-521 1 1/4" 789824

Wearing part-set DN 40, VL-501, VL-521 1 1/2" 789825

Wearing part-set DN 50, VL-501, VL-521 2" 789826

Wearing part-set DN 65, VL-501, VL-521 2 1/2" 789827

Wearing part-set DN 80, VL-501, VL-521 3" 789828

Wearing part-set DN 100, VL-501, VL-521 4" 789829

english

11

Page 12

Types 2651, 2654, 2660,

TKU 001

Maintenance, Troubleshooting

10. MAINTENANCE,

TROUBLESHOOTING

10.1. Maintenance Work

The ball valves are maintenance-free when operated according to the

instructions indicated in this manual.

11. PACKAGING, TRANSPORT,

STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

• Protect the pneumatic connections from damage by placing caps

on them.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -40 ... +55 °C.

Damage to the environment caused by device components

contaminated with media.

• Dispose of the device and packaging in an environmentally

friendly manner.

• Observe applicable regulations on disposal and the environment.

• Observe national waste disposal regulations.

12

english

Page 13

Typ 2651, 2654, 2660, TKU 001

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ............................................................14

1.1. Darstellungsmittel ...........................................................................14

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ...................................15

2.1. Beschränkungen ............................................................................15

2.2. Vorhersehbarer Fehlgebrauch .....................................................15

3. GRUNDLEGENDE SICHERHEITSHINWEISE ................................. 16

4. ALLGEMEINE HINWEISE .......................................................................... 17

4.1. Kontaktadresse ...............................................................................17

4.2. Gewährleistung...............................................................................17

4.3. Informationen im Internet ..............................................................17

5. SYSTEMBESCHREIBUNG ....................................................................... 17

5.1. Vorgesehener Einsatzbereich ......................................................17

5.2. Funktionen........................................................................................17

6. TECHNISCHE DATEN ................................................................................ 18

6.1. Betriebsbedingungen ....................................................................18

6.2. Allgemeine Technische Daten .....................................................18

7. INSTALLATION ............................................................................................... 19

7.1. Sicherheitshinweise .......................................................................19

7.2. Einbau in die Rohrleitung .............................................................20

8. BEDIENUNG UND FUNKTION .............................................................. 20

8.1. Sicherheitshinweise .......................................................................20

8.2. Bedienung des Kugelhahns .........................................................20

8.3. Funktionen........................................................................................21

9. ERSATZTEILE ................................................................................................. 21

10. WARTUNG, FEHLERBEHEBUNG....................................................... 22

10.1. Wartungsarbeiten ........................................................................22

11. VERPACKUNG, TRANSPORT, LAGERUNG,

ENTSORGUNG .................................................................................................... 22

deutsch

13

Page 14

Typ 2651, 2654, 2660, TKU 001

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

Bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

Verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den sie ausführen müssen.

14

deutsch

Page 15

Typ 2651, 2654, 2660, TKU 001

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Die Kugelhähne Typ 2651, 2654 und 2660 (im Folgenden allgemein

„Kugelhähne“) sind für den Anbau an pneumatische oder elektrische

Drehantrieben bestimmt. Sie können sowohl im Innenbereich als auch

im Außenbereich unter Einhaltung der zulässigen Einsatzbedingungen

eingesetzt werden.

Bei nicht bestimmungsgemäßem Einsatz der Kugelhähne

können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Die Kugelhähne sind zum Absperren von Medienströmen in

Industrieanwendungen vielfältig einsetzbar.

• Die Kugelhähne dürfen nur in Verbindung mit von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten und -komponenten

eingesetzt werden.

• Für den Einsatz sind die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten und Betriebsbedingungen sowie die im Kapitel „5.1. Vorgesehener Einsatzbereich“

beschriebenen Einsatzbereiche zu beachten.

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie die Kugelhähne nur bestimmungsgemäß ein.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Gerätes gegebenenfalls

bestehende Beschränkungen.

2.2. Vorhersehbarer Fehlgebrauch

• Betreiben Sie die Kugelhähne nur mit Medien, die Gehäuse- oder

Dichtwerkstoff nicht angreifen.

• Belasten Sie das Gehäuse nicht mechanisch (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen Veränderungen an dem Gehäuse vor.

deutsch

15

Page 16

Typ 2651, 2654, 2660, TKU 001

Grundlegende Sicherheitshinweise

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

WARNUNG!

Unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung können zu allgemeinen Gefahrensituationen bis hin

zur Körperverletzung führen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

• Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf

des Prozesses zu gewährleisten.

• Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung der Bedienungsanleitung betrieben werden.

• Für die Einsatzplanung und den Betrieb des Gerätes müssen

die allgemeinen Regeln der Technik eingehalten werden.

GEFAHR!

Gefahr durch hohen Druck!

• Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Schalten Sie den Druck ab und entlüften Sie die Leitungen,

bevor Sie Leitungen und Ventile lösen!

VORSICHT!

Für die Einsatzplanung und den Betrieb des Gerätes gelten

die allgemeinen Regeln der Technik!

• Beachten Sie die Regeln nicht, können Verletzungen entstehen

und/oder das Gerät, ggf. auch dessen Umgebung, können

beschädigt werden.

• Halten Sie die allgemeinen Regeln der Technik ein!

HINWEIS!

Die Kugelhähne wurden unter Einbeziehung der anerkannten

sicherheitstechnischen Regeln entwickelt und entsprechen dem

Stand der Technik. Trotzdem können Gefahren entstehen.

• Betreiben Sie die Kugelhähne nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung.

Bei Nichtbeachtung dieser Bedienungsanleitung und ihrer Hinweise

sowie bei unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die Gewährleistung auf Geräte

und Zubehörteile!

16

deutsch

Page 17

Typ 2651, 2654, 2660, TKU 001

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. : +49 (0) 7940 - 10 91 111

Fax: +49 (0) 7940 - 10 91 448

E-mail: info@de.burkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten

Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 2651, 2654, 2660

und TKU 001 finden Sie im Internet unter: www.buerkert.de

5. SYSTEMBESCHREIBUNG

5.1. Vorgesehener Einsatzbereich

Die Kugelhähne sind zum Absperren von Medienströmen in Industrieanwendungen vielfältig einsetzbar.

Sie sind besonders geeignet für Einsatzbedingungen, die hohe Anforderungen in den Bereichen der thermischen Belastung stellen, sowie

für Anwendungen mit aggressiven Medien.

5.2. Funktionen

Die Kugelhähne zum Absperren von Medienströmen stehen in verschiedenen Baugrößen zur Verfügung. Sie sind mit einer mechanischen

Schnittstelle nach ISO 5211 versehen. Diese Schnittstelle dient zur

Montage eines pneumatischen oder elektrischen Drehantriebs auf die

Kugelhähne.

Auf Anfrage können die Kugelhähne komplett mit pneumatischem Antrieb (Typen 2652, 2655, 8805) oder elektrischem

Antrieb (Typ 8804) geliefert werden.

deutsch

17

Page 18

Typ 2651, 2654, 2660, TKU 001

Technische Daten

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Zulässigen Temperaturen

Umgebungstemperatur: Edelstahlgehäuse -10 … +80 °C

Messinggehäuse -20 … +80 °C

Mediumstemperatur: Edelstahlgehäuse -10 … +100 °C

Messinggehäuse -20 … +100 °C

Medien: Aggressive, neutrale gasförmige und

flüssige Medien und Dämpfe

Druckbereiche: 0 … 100 bar (je nach Ausführung)

6.2. Allgemeine Technische Daten

6.2.1. Mechanische Daten

Gehäusematerial: Edelstahl 1.4401; Messing vernickelt

Dichtungsmaterial: PTFE

6.2.2. Druck-Temperatur Diagramme,

2/2-Wege und 3/2-Wege Kugelhähne

50

40

30

20

Druck [bar]

10

0

-20 1201008060400 20 140160

Bild 1: Druck-Temperatur Diagramm / Messinggehäuse

40 bar

30 bar

25 bar

16 bar

10 bar

Temperatur [°C]

18

deutsch

Page 19

Typ 2651, 2654, 2660, TKU 001

Installation

100 bar

63 bar

7. INSTALLATION

7.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Schalten Sie den Druck ab und entlüften Sie die Leitungen,

bevor Sie Leitungen und Ventile lösen!

40 bar

Druck [bar]

16 bar

0 bar

Temperatur [°C]

100400

200 230

Bild 2: Druck-Temperatur Diagramm / Edelstahlgehäuse

WARNUNG!

Verletzungsgefahr durch unsachgemäße Installation!

Nicht sachgemäße Installationen können zu Verletzungen, sowie

Schäden am Gerät und seiner Umgebung führen.

• Diese Arbeiten dürfen nur durch autorisiertes Fachpersonal und

mit geeignetem Werkzeug durchgeführt werden!

Verletzungsgefahr durch unbeabsichtigte Betätigung!

Durch unbeabsichtigtes Betätigen der Anlage können Gefahrensituationen entstehen.

• Verhindern Sie durch geeignete Maßnahmen, dass die Anlage

unbeabsichtigt betätigt werden kann.

deutsch

19

Page 20

Typ 2651, 2654, 2660, TKU 001

Bedienung und Funktion

7.2. Einbau in die Rohrleitung

Vorgehensweise:

→ Prüfen Sie, ob sich die mit dem Kugelhahn zu verbindenden Rohre

auf einem Niveau befinden. Damit vermeiden Sie mechanische

Spannungen auf die Verschraubung.

→ Verschrauben Sie den Kugelhahn mit der Rohrleitung.

→ Achten Sie auf festen Sitz des Kugelhahns in der Rohrleitung, um

die entsprechende Dichtheit zu gewährleisten.

8. BEDIENUNG UND FUNKTION

8.1. Sicherheitshinweise

WARNUNG!

Gefahr durch unsachgemäßen Bedienung!

Nicht sachgemäße Bedienung kann zu Verletzungen, sowie

Schäden am Gerät und seiner Umgebung führen.

• Das Bedienungspersonal muss den Inhalt der Bedienungsanleitung kennen und verstanden haben.

• Die Sicherheitshinweise und die Bestimmungsgemäße Verwendung müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Gerät

bedienen.

8.2. Bedienung des Kugelhahns

Die Kugelhähne können über die mechanische Schnittstelle nach

ISO 5211 mit einem pneumatischen (z. B. Typ 2050 oder 2051)

oder elektrischen Drehantrieb (z. B. Typen 3003, 3004 oder 3005)

verbunden werden.

20

deutsch

Page 21

Typ 2651, 2654, 2660, TKU 001

Ersatzteile

8.3. Funktionen

Die Kugelhähne werden in 2-Wege oder 3-Wege Ausführung angeboten. Die 3-Wege Ausführungen stehen mit folgenden Funktionen

zur Verfügung.

8.3.1. Schaltstellungen

Kugelbohrung T L

Position

0°

90°

Schaltstellung

T1 T2 T3 L4

9. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen

und Schäden am Gerät und dessen Umgebung verursachen.

• Nur Originalzubehör sowie Originalersatzteile der Firma Bürkert

verwenden.

Verschleißteilsätze für 3-teiligen Kugelhahn Typ 2654:

Verschleißteilsätze Bestell-Nr.

Verschleißteilsatz DN15, VL-521 1/2" 789821

Verschleißteilsatz DN20, VL-501, VL-521 3/4" 789822

Verschleißteilsatz DN25, VL-501, VL-521 1" 789823

Verschleißteilsatz DN32, VL-501, VL-521 1 1/4" 789824

Verschleißteilsatz DN40, VL-501, VL-521 1 1/2" 789825

Verschleißteilsatz DN50, VL-501, VL-521 2" 789826

Verschleißteilsatz DN65, VL-501, VL-521 2 1/2" 789827

Verschleißteilsatz DN80, VL-501, VL-521 3" 789828

Verschleißteilsatz DN100, VL-501, VL-521 4" 789829

deutsch

21

Page 22

Typ 2651, 2654, 2660, TKU 001

Wartung, Fehlerbehebung

10. WARTUNG,

FEHLERBEHEBUNG

10.1. Wartungsarbeiten

Die Kugelhähne sind bei Betrieb entsprechend den in dieser Anleitung

angegebenen Anweisungen wartungsfrei.

11. VERPACKUNG, TRANSPORT,

LAGERUNG, ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

• Pneumatische Anschlüsse mit Schutzkappen vor Beschädigungen

schützen.

Falsche Lagerung kann Schäden am Gerät verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -40 … +55 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Entsorgen Sie das Gerät und die Verpackung umweltgerecht.

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

• Die nationalen Abfallbeseitigungsvorschriften beachten.

22

deutsch

Page 23

Types 2651, 2654, 2660,

TKU 001

Sommaire

1. LES INSTRUCTIONS DE SERVICE ..................................................... 24

1.1. Moyens de représentation ............................................................24

2. UTILISATION CONFORME.......................................................................25

2.1. Limitations ........................................................................................25

2.2. Mauvaise utilisation prévisible .....................................................25

3. CONSIGNES DE SÉCURITÉ FONDAMENTALES ......................... 26

4. INDICATIONS GÉNÉRALES .................................................................... 27

4.1. Adresse ............................................................................................27

4.2. Garantie légale ................................................................................27

4.3. Informations sur Internet ...............................................................27

5. DESCRIPTION DU SYSTÈME ................................................................27

5.1. Utilisation prévue ............................................................................27

5.2. Fonctions ..........................................................................................27

6. CARACTÉRISTIQUES TECHNIQUES ................................................28

6.1. Conditions d'exploitation ..............................................................28

6.2. Caractéristiques techniques générales ....................................28

7. INSTALLATION ............................................................................................... 29

7.1. Consignes de sécurité ..................................................................29

7.2. Montage dans la tuyauterie ..........................................................30

8. UTILISATION ET FONCTIONNEMENT...............................................30

8.1. Consignes de sécurité ..................................................................30

8.2. Utilisation du robinet à boisseau sphérique .............................30

8.3. Fonctions ..........................................................................................31

9. PIÈCES DE RECHANGE ........................................................................... 31

10. MAINTENANCE, DÉPANNAGE ............................................................32

10.1. Travaux de maintenance .............................................................32

11. EMBALLAGE, TRANSPORT, STOCKAGE, ELIMINATION ...... 32

français

23

Page 24

Types 2651, 2654, 2660,

TKU 001

Les instructions de service

1. LES INSTRUCTIONS DE

SERVICE

Les instructions de service décrivent le cycle de vie complet de l’appareil. Conservez ces instructions de sorte qu’elles soient accessibles

à tout utilisateur et à disposition de tout nouveau propriétaire.

Les instructions de service contiennent des informations

importantes sur la sécurité !

Le non-respect de ces consignes peut entraîner des situations

dangereuses.

• Les instructions de service doivent être lues et comprises.

1.1. Moyens de représentation

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement dangereuse !

• Risque de blessures graves, voire la mort en cas de non-respect.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou de

moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

• L’appareil ou l’installation peut être endommagé(e) en cas de

non-respect.

Désigne des informations supplémentaires importantes, des

conseils et des recommandations d’importance.

Renvoie à des informations dans ces instructions de service

ou dans d’autres documentations.

→ identifie une opération que vous devez effectuer.

24

français

Page 25

Types 2651, 2654, 2660,

TKU 001

Utilisation conforme

2. UTILISATION CONFORME

Les robinets à boisseau sphérique du type 2651, 2654 ou 2660

(ci-après « Robinets à boisseau sphérique ») sont conçus pour un

branchement sur les servomoteurs pneumatiques ou électriques. Ils

peuvent être utilisés à l’intérieur comme à l’extérieur en respectant les

conditions d’utilisation autorisées.

L’utilisation non conforme des robinets à boisseau sphérique

peut présenter des dangers pour les personnes, les installations proches et l’environnement.

• Les robinets à boisseau sphérique ont été conçus pour arrêter

les flux de fluides comme on les rencontrent lors de la réalisation

d’applications industrielles.

• Les robinets à boisseau sphérique doivent uniquement être utilisés

en liaison avec les appareils et composants étrangers recommandés ou agréés par Bürkert.

• L’utilisation doit se faire dans le respect des données admissibles

spécifiées dans les documents contractuels et les instructions de

service ainsi que des conditions d’exploitation et des utilisations

prévues décrites au chapitre „5.1. Utilisation prévue“.

• Les conditions pour l’utilisation sûre et parfaite sont un transport, un

stockage et une installation dans les règles ainsi qu’une parfaite

utilisation et maintenance.

• N’utilisez jamais les robinets à boisseau sphérique pour un

usage autre que l’usage prévu.

2.1. Limitations

Lors de l’exportation du système/de l’appareil, veuillez respecter les

limitations éventuelles existantes.

2.2. Mauvaise utilisation prévisible

• Utilisez uniquement les robinets à boisseau sphérique avec les fluides

qui n’attaquent pas les matériaux du corps et du joint.

• Ne soumettez pas le corps à des contraintes mécaniques (par ex. en

y déposant des objets ou en l’utilisant comme marche).

• N’apportez pas de modifications à l’extérieur du corps.

français

25

Page 26

Types 2651, 2654, 2660,

TKU 001

Consignes de sécurité fondamentales

3. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte :

• Des hasards et des événements pouvant survenir lors du montage,

de l'exploitation et de la maintenance des appareils.

• Des prescriptions de sécurité locales que l’exploitant est tenu de

faire respecter par le personnel chargé du montage.

AVERTISSEMENT !

L’actionnement involontaire ou l’intervention non autorisée

peut entraîner des situations dangereuses, voire des blessures

corporelles.

Pour prévenir les blessures, respectez ce qui suit :

• L’installation ne peut pas être actionnée par inadvertance.

• Les travaux d’installation et de maintenance doivent être

effectués uniquement par des techniciens qualifiés et habilités

disposant de l’outillage approprié.

• Après une interruption de l’alimentation électrique ou du fluide,

un redémarrage défini ou contrôlé du process doit être garanti.

• L’appareil doit être utilisé uniquement en parfait état et en respectant les instructions de service.

• Les règles générales de la technique sont à appliquer pour

l’opérationnel et l’utilisation de l’appareil.

DANGER !

Danger dû à la haute pression !

• Il y a risque important de blessures lors d’interventions sur

l'installation.

• Avant de desserrer les conduites et les vannes, dépressurisez

l’installation et purgez l’air des conduites !

ATTENTION !

Les règles générales de la technique sont d'application pour

planifier l’utilisation et utiliser l’appareil !

• Si ces règles ne sont pas respectées, il peut s’ensuivre des blessures et/ou des dommages sur l’appareil ou son environnement.

• Respectez les règles générales de la technique !

REMARQUE !

Les robinets à boisseau sphérique ont été développés en tenant

compte des règles de technique de sécurité reconnues et correspondent à l’état actuel de la technique. Néanmoins, des risques

peuvent se présenter.

• Utilisez l’appareil uniquement en parfait état et en respectant les

instructions de service.

Le non-respect de ces instructions de service avec ses consignes

ainsi que les interventions non autorisées sur l’appareil excluent

toute responsabilité de notre part et entraînent la nullité de la

garantie légale concernant les appareils et les accessoires !

26

français

Page 27

Types 2651, 2654, 2660,

TKU 001

Indications générales

4. INDICATIONS GÉNÉRALES

4.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. : +49 (0)7940 - 10 91 111

Fax : +49 (0)7940 - 10 91 448

E-mail : info@de.burkert.com

International

Les adresses se trouvent aux dernières pages des instructions de

service imprimées. Egalement sur internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie légale est l’utilisation

conforme de l’appareil dans le respect des conditions d’utilisation

spécifiées.

4.3. Informations sur Internet

Vous trouverez les instructions de service et les fiches techniques

concernant le type 2651, 2654, 2660 et TKU 001 sur Internet

sous : www.buerkert.fr

5. DESCRIPTION DU SYSTÈME

5.1. Utilisation prévue

Les robinets à boisseau sphérique ont été conçus pour arrêter les flux

de fluides comme on les rencontrent lors de la réalisation d’applications industrielles.

Il sont particulièrement adaptés aux conditions d’utilisation très exigeantes dans les domaines des charges thermiques ou vibratoires

ainsi qu’aux applications faisant usage de fluides agressifs.

5.2. Fonctions

Différents modèles de robinets à boisseau sphérique sont disponibles

pour l’arrêt des flux de fluides. Ils sont munis d’une interface mécanique

selon ISO 5211. Cette interface sert au montage d’un entraînement

rotatif pneumatique ou électrique sur les robinets à boisseau sphérique.

Sur demande, les robinets à boisseau sphérique peuvent être

livrés avec un entraînement pneumatique (Types 2652, 2655,

8805) ou avec un entraînement électrique (Type 8804).

français

27

Page 28

Types 2651, 2654, 2660,

TKU 001

Caractéristiques techniques

6. CARACTÉRISTIQUES

TECHNIQUES

6.1. Conditions d'exploitation

Températures admissibles

Température ambiante : Corps en acier inoxydable -10 – +80 °C

Corps en laiton : -20 – +80 °C

Température du fluide : Corps en acier inoxydable -10 – +100 °C

Corps en laiton : -20 – +100 °C

Fluides : fluides et vapeurs gazeux et liquides,

agressifs et neutres

Plage de pression : 0 – 100 bars (selon le modèle)

6.2. Caractéristiques techniques

générales

6.2.1. Caractéristiques mécaniques

Matériau du boîtier : Acier inoxydable 1.4401 ; laiton nickelé

Matériau d'étanchéité : PTFE

6.2.2. Diagrammes pression-température,

robinets à boisseau sphérique

2/2 voies et 3/2 voies

50

40

30

20

Pression [bars]

10

0

-20 1201008060400 20 140160

Fig. 1 : Diagrammes pression-température / corps en laiton

40 bar

30 bar

25 bar

16 bar

10 bar

Température [°C]

28

français

Page 29

Types 2651, 2654, 2660,

TKU 001

Installation

7. INSTALLATION

7.1. Consignes de sécurité

100 bar

63 bar

40 bar

Pression [bars]

16 bar

0 bar

Température [°C]

100400

200 230

Fig. 2 : Diagrammes pression-température / corps en acier

inoxydable

français

DANGER !

Risque de blessures dû à la présence de haute pression dans

l'installation !

Il y a risque important de blessures lors d’interventions sur l'installation.

• Avant de desserrer les conduites et les vannes, dépressurisez

l’installation et purgez l’air des conduites !

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme !

Les installations non conformes peuvent occasionner des blessures

et endommager l’appareil et son environnement.

• Ces travaux doivent être effectués uniquement par des techniciens

qualifiés et habilités disposant de l’outillage approprié !

Danger dû à l’actionnement involontaire !

Des situations dangereuses peuvent se présenter en cas de

manoeuvres accidentelles.

• Evitez l’actionnement involontaire de l’installation par des

mesures appropriées.

29

Page 30

Types 2651, 2654, 2660,

TKU 001

Utilisation et fonctionnement

7.2. Montage dans la tuyauterie

Procédure à suivre :

→ Assurez-vous que les tuyaux à raccorder se trouvent au même

niveau que le robinet à boisseau sphérique. Vous évitez ainsi des

tensions mécaniques sur le raccord fileté.

→ Vissez le robinet à boisseau sphérique sur la conduite.

→ Veillez à positionner correctement le robinet à boisseau sphérique

sur la conduite afin de garantir l’étanchéité de l’installation.

8. UTILISATION ET

FONCTIONNEMENT

8.1. Consignes de sécurité

AVERTISSEMENT !

Danger dû à une utilisation non conforme !

Une utilisation non conforme peut entraîner des blessures et

endommager l'appareil et son environnement.

• Les opérateurs doivent connaître le contenu des instructions de

service et les avoir comprises.

• Respectez les consignes de sécurité et l'utilisation conforme.

• L’appareil/l'installation doit uniquement être utilisé par un personnel

suffisamment formé.

8.2. Utilisation du robinet à boisseau

sphérique

L’interface mécanique selon ISO 5211 permet de relier les robinets

à boisseau sphérique avec un servomoteur pneumatique (par ex. du

type 2050 ou 2051) ou avec un servomoteur électrique (par ex. du

type 3003, 3004 ou 3005).

30

français

Page 31

Types 2651, 2654, 2660,

TKU 001

Pièces de rechange

8.3. Fonctions

Les robinets à boisseau sphérique sont disponibles en version à 2 ou

3 voies. Les modèles 3 voies offrent les fonctions suivantes :

8.3.1. Positions de commutation

Perçage de

boisseau

sphérique

Position

Position de

commutation

0°

90°

T1 T2 T3 L4

T L

9. PIÈCES DE RECHANGE

ATTENTION !

Risque de blessures, de dommages matériels dus à de mauvaises pièces !

De mauvais accessoires ou des pièces de rechange inadaptées

peuvent provoquer des blessures et endommager l‘appareil ou

son environnement.

• Utiliser uniquement des accessoires et des pièces de rechange

d‘origine de la société Bürkert.

Jeux de pièces d’usure pour robinet à boisseau sphérique 3

pièces types 2654 :

Jeux de pièces d‘usure N° Réf.

Jeu de pièces d‘usure DN 15, VL-521 1/2" 789821

Jeu de pièces d‘usure DN 20, VL-501, VL-521 3/4" 789822

Jeu de pièces d‘usure DN 25, VL-501, VL-521 1" 789823

Jeu de pièces d‘usure DN 32, VL-501, VL-521 1 1/4" 789824

Jeu de pièces d‘usure DN 40, VL-501, VL-521 1 1/2" 789825

Jeu de pièces d‘usure DN 50, VL-501, VL-521 2" 789826

Jeu de pièces d‘usure DN 65, VL-501, VL-521 2 1/2" 789827

Jeu de pièces d‘usure DN 80, VL-501, VL-521 3" 789828

Jeu de pièces d‘usure DN 100, VL-501, VL-521 4" 789829

français

31

Page 32

Types 2651, 2654, 2660,

TKU 001

Maintenance, dépannage

10. MAINTENANCE, DÉPANNAGE

10.1. Travaux de maintenance

Les robinets à boisseau sphérique ne nécessitent pas d’entretien dans

la mesure où les présentes instructions sont respectées.

11. EMBALLAGE, TRANSPORT,

STOCKAGE, ELIMINATION

REMARQUE !

Dommages dus au transport !

Les appareils insuffisamment protégés peuvent être endommagés

pendant le transport.

• Transportez l'appareil à l'abri de l'humidité et des impuretés et

dans un emballage résistant aux chocs.

• Évitez le dépassement vers le haut ou le bas de la température

de stockage admissible.

• Protégez les raccords pneumatiques des dommages en utilisant

des capuchons de protection.

Un mauvais stockage peut endommager l’appareil.

• Stockez l’appareil au sec et à l’abri des poussières !

• Température de stockage : -40 ... +55 °C.

Dommages à l’environnement causés par des pièces d’appareil

contaminées par des fluides.

• Eliminez l’appareil et l’emballage dans le respect de

l’environnement.

• Respectez les prescriptions en matière d’élimination des déchets

et de protection de l’environnement en vigueur.

• Respectez les prescriptions nationales en matière d’élimination des

déchets.

32

français

Page 33

Page 34

www.burkert.com

Loading...

Loading...