Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

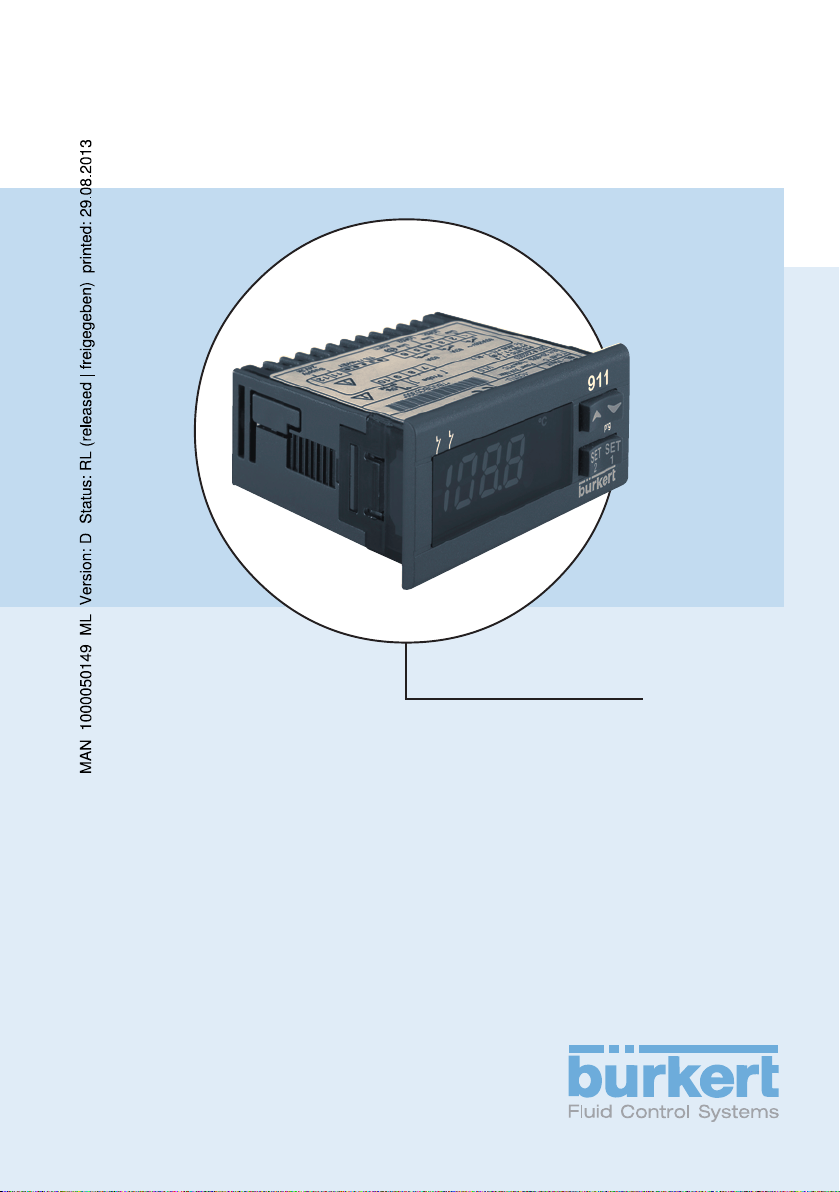

Type 0911

3 stage controller

3-Punkt-Regler

3 Régulateur Ponctuel

Id. No. 788 267

788 268

788 269

788 270

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2004 Bürkert Werke GmbH & Co.

Operating Instructions 0509/03_EU-ml_00804610

Page 3

3-STAGE CONTROLLER

TYPE 0911

1 GENERAL INFORMATION ........................................................................................................................ 2

1.1 Symbols ......................................................................................................................................................... 2

1.2 Safety notes ................................................................................................................................................ 2

1.3 Scope of delivery ...................................................................................................................................... 3

1.4 Warranty provisions ............................................................................................................................... 3

2 SYSTEM DESCRIPTION ............................................................................................................................ 4

2.1 General description ................................................................................................................................. 4

2.2 Operation ...................................................................................................................................................... 4

2.3 Before the installation ............................................................................................................................. 7

2.4 Control ............................................................................................................................................................ 8

2.5 Parameters ................................................................................................................................................ 10

2.6 Controlling the loads 13

3 TECHNICAL DATA .....................................................................................................................................14

4 ASSEMBLY, INSTALLATION AND COMMISSIONING .......................................................... 15

4.1 General information regarding the installation and operation ......................................... 15

4.2 Assembly .................................................................................................................................................... 15

4.3 Electrical connections .......................................................................................................................... 16

english

5 HOT-KEY FUNCTION ................................................................................................................................. 18

6 FACTORY SETTING .................................................................................................................................. 19

7 MAINTENANCE ............................................................................................................................................21

8 REPAIR WORK .............................................................................................................................................. 21

8.1 Faults.............................................................................................................................................................21

8.2 Ordering table for basic unit/accessories ................................................................................ 22

0911 - 1

Page 4

1 GENERAL INFORMATION

1.1 Symbols

The following symbols are used in these operating instructions:

marks a work step that must be carried out.

ATTENTION!

english

NOTE indicates important additional information,

1.2 Safety notes

Please observe the notes in these operating instructions together with the

conditions of use and permitted data that are specified in the data sheets of the

0911 controller, so that the device will function perfectly and will have a long

service life.

• Keep to the standard engineering rules when planning and operating the

device!

• Installation and maintenance work may only be carried out by specialist

personnel using the correct tools!

• Observe the current regulations on accident prevention and the safety

regulations for electrical devices during the operation and maintenance of

the device!

• Comply with the intended usage of the device.

• Only operate the device with its housing fitted.

• Before connecting the device, check that the power supply corresponds to

the values printed on the device.

• Check that the connections are correct before switching on the device.

• Observe the maximum load of the relay contacts (see technical data).

• Ensure that all sensors are installed with sufficient separation from voltageconducting lines. This will avoid incorrect temperature readings and will

protect the device from voltage interference at the sensor inputs.

• For applications in the industrial sector with critical environments, switch an

RC element in parallel (FT1).

• Always switch off the mains supply before carrying out manipulations on

the system.

• Take suitable measures to exclude unintended operation and damage by

unauthorised operation!

indicates information which, if ignored, could lead to a risk to

your health or to the functionality of the device.

tips and recommendations.

2 - 0911

Page 5

• Please observe the prescribed environmental conditions with regard to

dampness and temperature limits. Malfunctions cannot be excluded if these

conditions are not complied with.

• Call in your authorised Bürket sales centre in case of doubt or faulty

functioning.

In the case of the non-observance of these notes or of unauthorised

manipulation of the device, we will accept no liability, and the guarantee on the

device and its accessories will become void!

1.3 Scope of delivery

Immediately after receiving the delivery, ensure that the contents agree with

the scope of the delivery. This includes:

• 1 Type 0911 controller

• 1 set of operating instructions (where required, on a data carrier)

• 1 front seal

• 2 Mounting clamps

In case of discrepancy, please contact our Customer centre immediately.

Bürkert Steuer- und Regelungstechnik

or your Bürkert Sales Centre.

Service-Abteilung

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

1.4 Warranty provisions

Bürkert provideds a guarantee of one year on the correct functioning of the

controller, under the precondition that the device is employed for its intended

use and under compliance with the specified conditions for use.

If the functions of the device are not in order, the respective device will be

repaired free of charge or will be replaced.

ATTENTION!

The warranty only covers the the controller and its

components, but does not cover consequential damage of

any kind that could arise from the failure or malfunctioning of

the device.

english

0911 - 3

Page 6

2 SYSTEM DESCRIPTION

2.1 General description

3-point or neutral zone controller, 74 x 32 mm, with predefinable control

function (e.g., heating/cooling or moisten/dehumidify)

The following models are available:

TYPE Configurable Input Parameter UDM

english

TU

Temperature

controller

AU

Control device with

current/voltage input

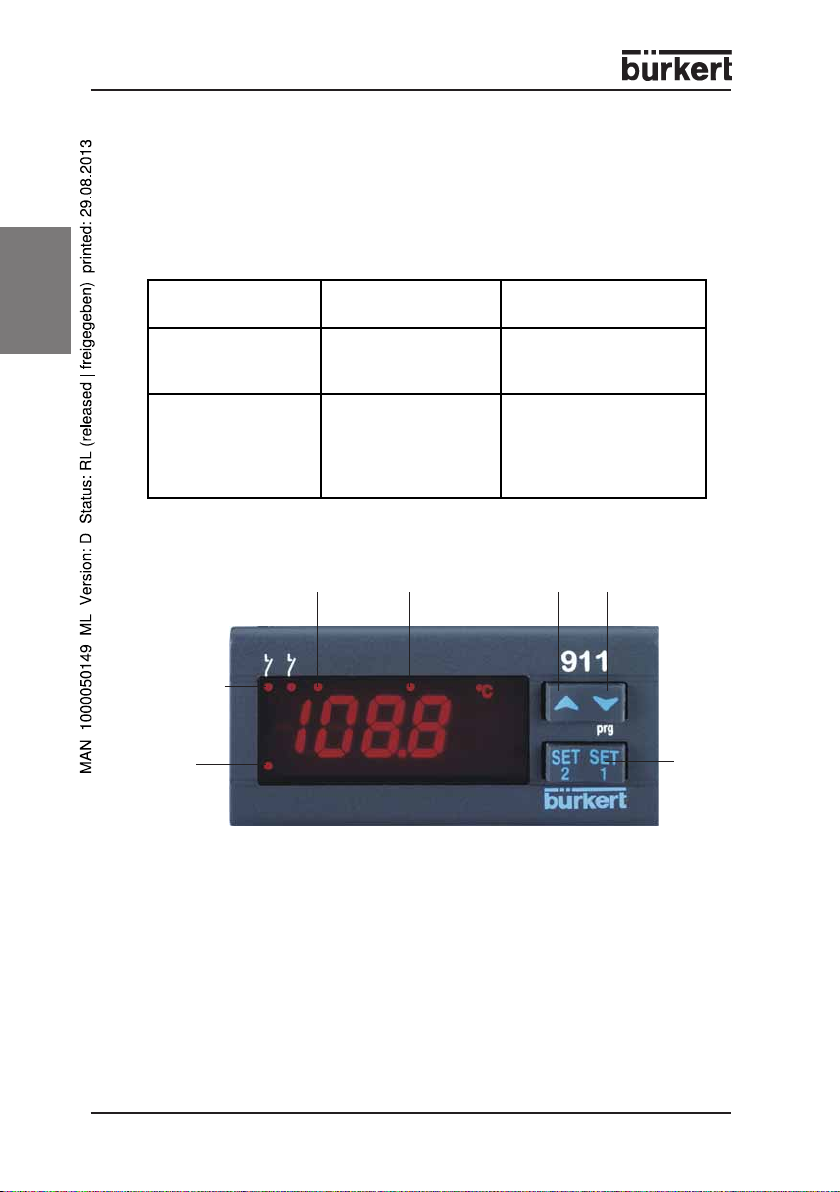

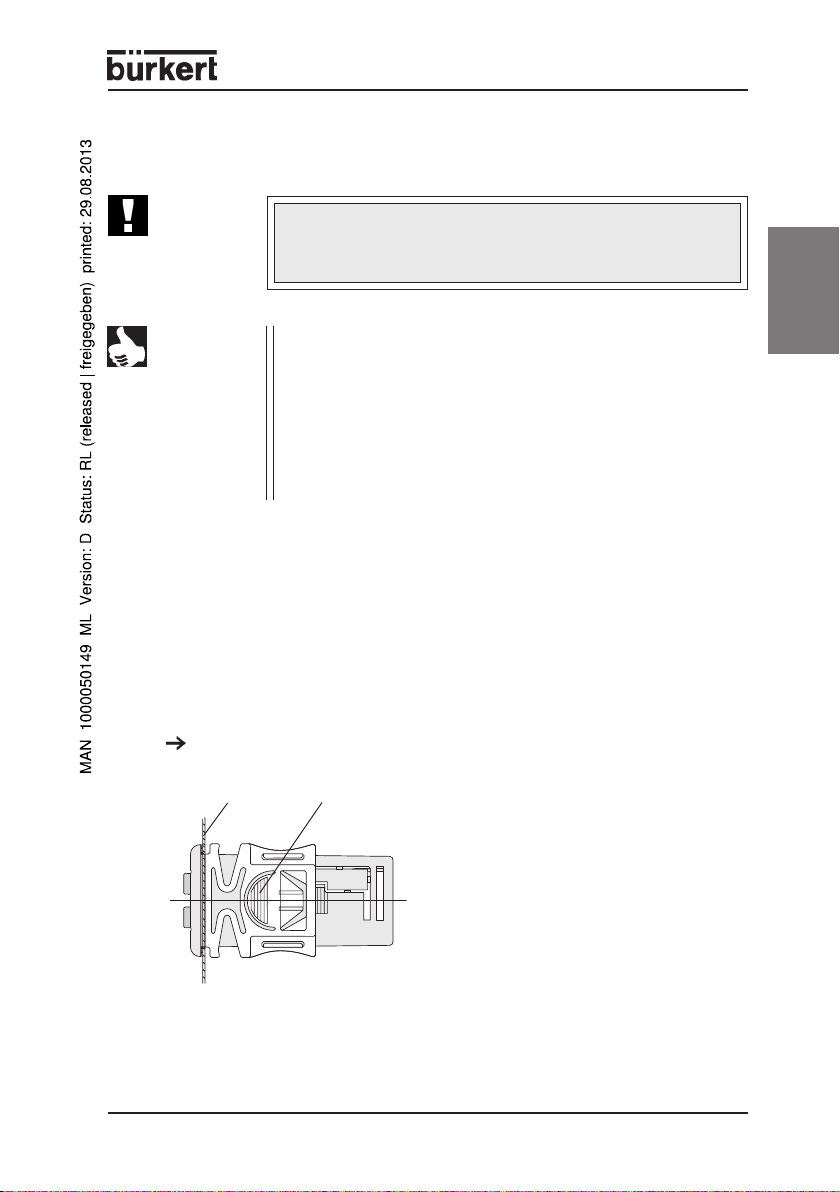

2.2 Operation

Output

LEDs

Alarm

LED

PTC, NTC, Pt100

Thermoelements J, K,

S

4 ... 20 mA

0 ... 1 V

0 ... 10 V

LED1

LED 2

(Defined by display unit)

UDM = °C

UDM = °F

0 = °C; 1 = °F

2 = % RH

3 = bar

4 = PSI

5 = without units

upwards

downwards

SET

button

BUTTONS

SET1 Display of Set-value 1

SET2 Display of Set-value 2

4 - 0911

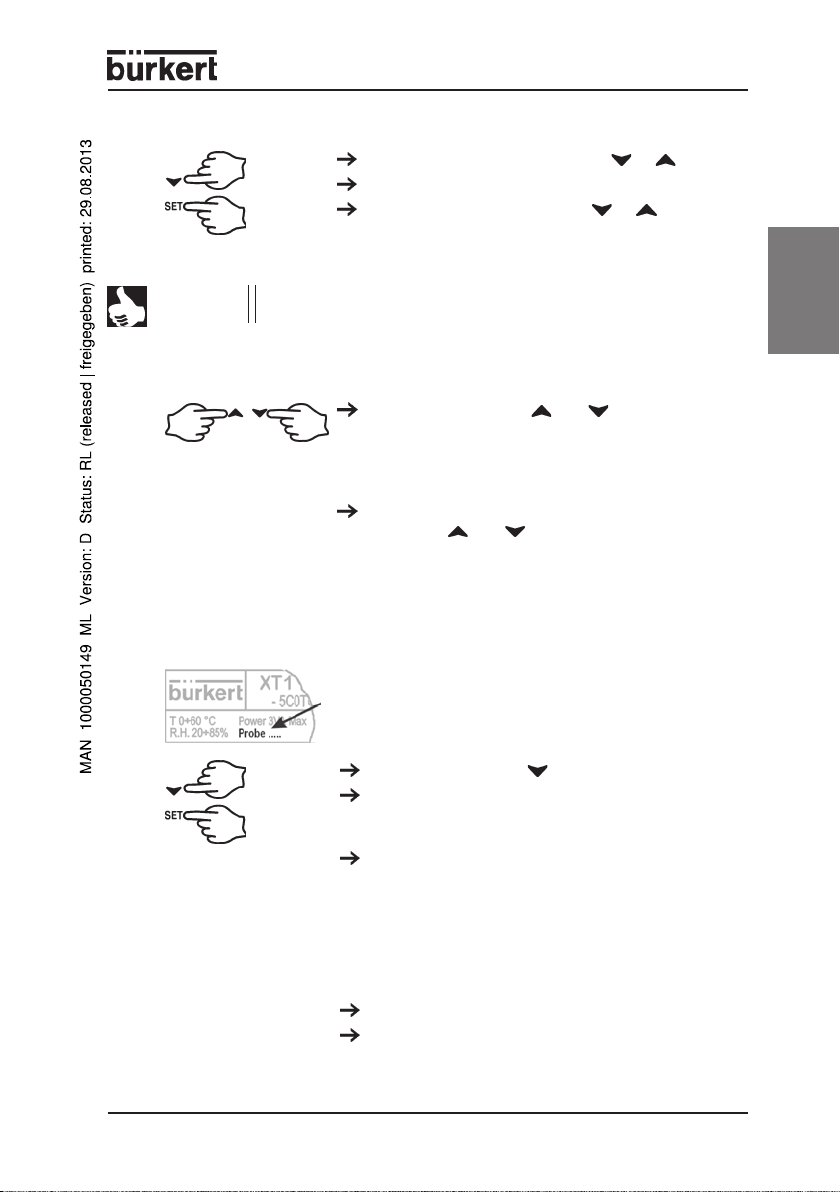

Changing and confirming a default during the programming phase

Page 7

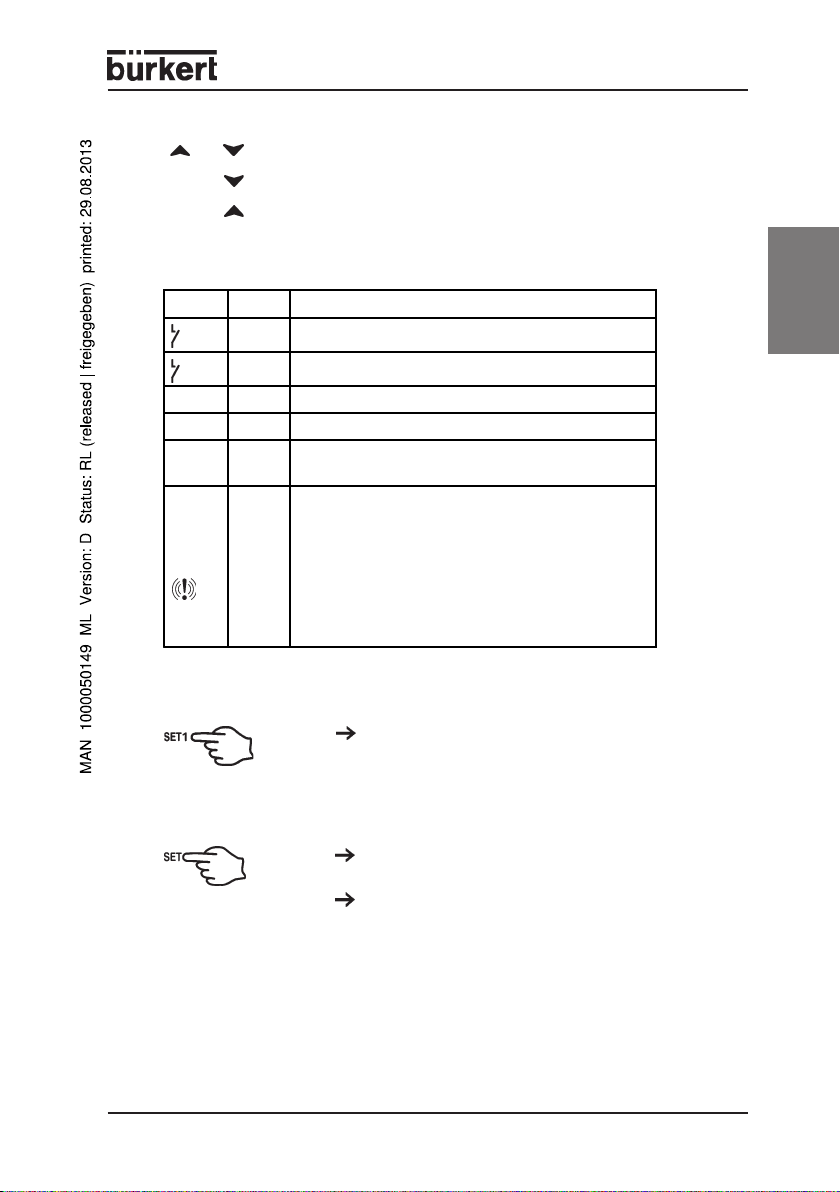

BUTTON COMBINATIONS

+

Locking and unlocking the keypad

SET1+ Selecting the programming level

SET1+ Return to the room temperature display

LED MESSAGES

LED Mode Meaning

on Output 1 active

on Output 2 active

LED1 blinks Programming level (blinks together with LED2)

LED2 blinks Programming level (blinks together with LED1)

E.S. on

Alarm

LED on

SWITCH DEVICE ON/OFF

Energy-saving mode (second set-value) has

been activated by the digital input

- Signals an Alarm state

- If you are in the lower programming level

"Pr2", which can only be accessed using a

password, the lighting up of the Alarm LED

signals that the displayed parameters can

also be accessed in the first level "Pr1"

(without password).

english

SET-VALUE DISPLAYS

Hold the SET1 button down for at least 4 sec (only

for parameter OnF = yes).

Briefly press the SET button once. The set-value

display appears in the display.

Briefly press the SET button again, or wait 5

seconds in order to display the room temperature.

0911 - 5

Page 8

english

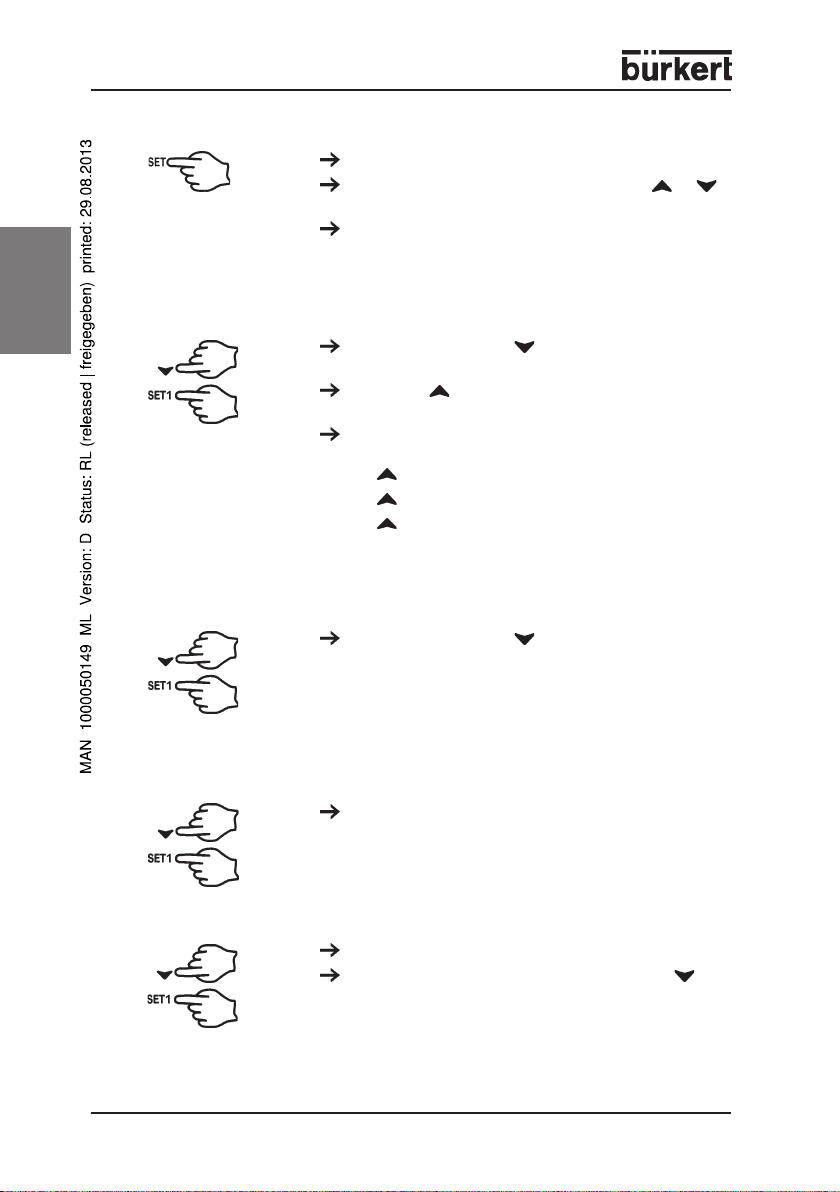

CHANGING SET-VALUE 1 / SET-VALUE 2

Hold down the SET button for 2 seconds.

Change the set-value within 10 s with the or

buttons.

You can save the new set-value by briefly pressing

the SET button or by waiting 10 seconds.

ENTER PROGRAMMING LEVEL

Hold down the SET1 + button for at least 3

seconds.

Select with Pr2 and then confirm with the SET1

button.

Enter the password 321 and then confirm with the

SET1 button.

Enter the „3“ and then 1x SET1 button

Enter the „2“, and then 1x the SET1 button

Enter the „2“, and then 1x the SET1 button

You are now in the Parameter List.

USER LEVEL PR1

Hold down the SET1 + button for at least 3

seconds. PR1 contains all the parameters that can

be accessed by the user. The device shows the first

parameter that is available in the user level.

SERVICE LEVEL PR2 (PASSWORD 321)

See:

Accessing the programming level

ADDING/REMOVING PARAMETERS IN THE USER LEVEL PR1

Accessing the programming level

The status can be changed with the SET1 +

buttons.

If a parameter is not visible in the PR1 level, this will

be indicated by an LED point.

6 - 0911

.

Page 9

CHANGING THE DEFAULT PARAMETERS

Enter a desired value with SET + or .

Then confirm with the SET button.

Enter a desired parameter with or .

NOTE All the parameter values can only be seen by repeatedly

pressing the SET1 buttons.

LOCKING AND UNLOCKING THE KEYPAD

Hold down the buttons and for at least 3

seconds. The POF message appears on the

display. The keyboard is locked. The POF

message also appears if you hold down a button for

longer than 3 s.

The keyboard will be unlocked if you hold down

the buttons and for 3 s. POn appears in the

display for a few seconds.

2.3 Before the installation

PREDEFINE THE SENSOR TYPE

The configurable input type is noted on the controller

label. Please enter this input type if it does not

corresponds to the connected sensor type.

Hold down the SET + buttons for 3 seconds.

Select the parameter Pbc (sensor type) and then

confirm with the SET button to see the current

default.

Type TU (temperature controller):

J = Thermoelement J; Pt = Pt100;

C = Thermoelement K; Ptc = PTC;

S = Thermoelement S; ntc = NTC

Type AU

(control devices with voltage/current input):

cur = 4...20 mA; 0-1 = 0...1 V; 10 = 0...10 V

Confirm the default with the SET button.

Briefly switch off the power to the device.

english

0911 - 7

Page 10

english

2.4 Control

MEASUREMENT LIMITS FOR THE SENSOR TYPES

Sensor Lower limit Upper limit

NTC -40°C 110°C

PTC -50°C 150°C

Pt100 -200°C 600°C

TcK 0°C 1300°C

TcJ 0°C 600°C

TcS 0°C 1400°C

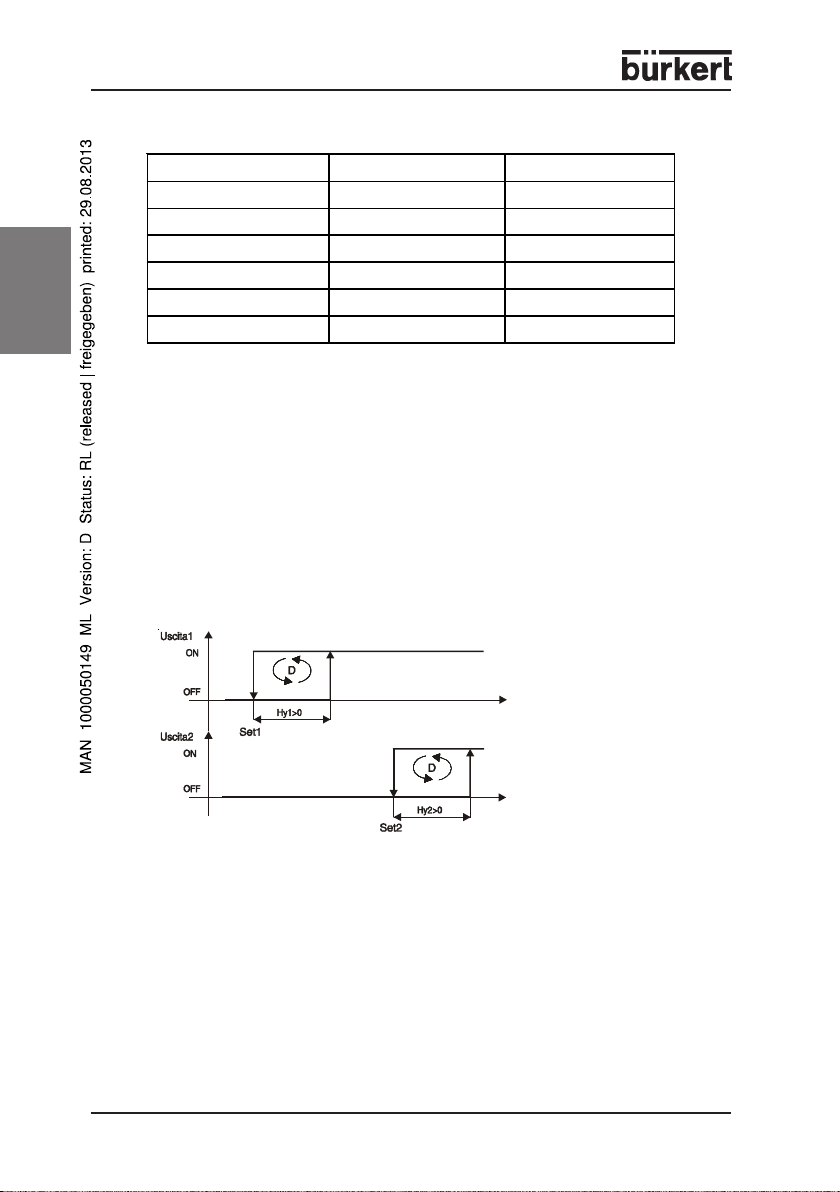

TWO OUTPUTS INDEPENDENT OF ONE ANOTHER (OUC = IND)

Example:

Default for the set-values SET1 = 50°C und SET2 = 20°C. With parameter

default OUC = ind, both set-values are completely independent of each other.

The control function must also be predefined. For the control circuit No. 1 Par.

S1C = in (heating, humidifying, etc.,) or S1C = dir (cooling, dehumidification,

etc.). Also predefined for the control relay No. 2 (S2C = in or S2C = dir).

Example: ouC = ind, S1c = dir, S2c = dir

TWO OUTPUTS INDEPENDENT OF ONE ANOTHER (OUC = DIP)

3-STAGE CONTROLLER

Example:

Default for set-value SET1 = 50°C (for control circuit No. 1). Then predefine a

number for SET2 = 5 Kelvin (Delta value). The resulting set-value is then SET2

= 55 °C (SET2 = SET1 + Delta-SET2). If SET1 is then increased, for example

by 2 Kelvin to 52°C, SET2 increases to the same extent, i.e., also by 2 Kelvin

to 57°C. Also define the control direction of the outputs via the parameters S1C

and S2C. In the same way, the set-value default limits for SET2 result from

LS2 = SET1 -Delta-LS2 and HS2 = +Delta-HS2.

8 - 0911

Page 11

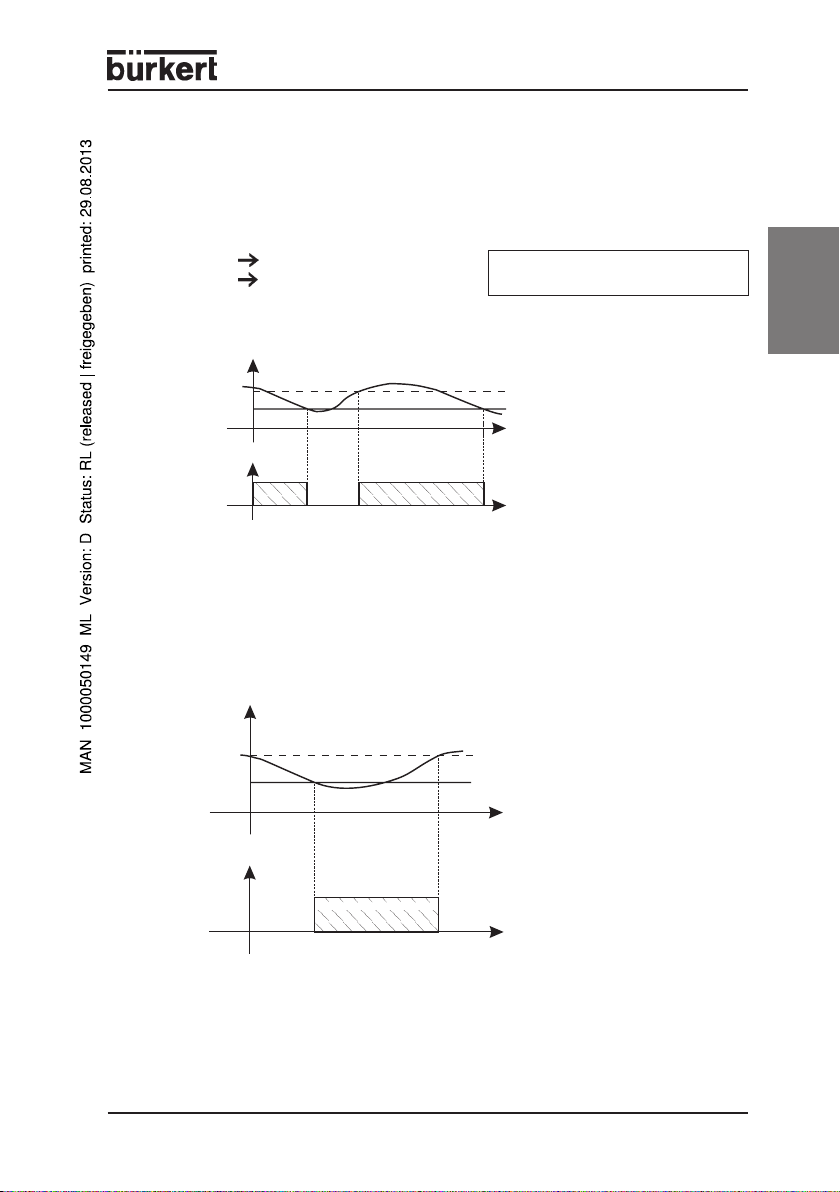

NEUTRAL ZONE CONTROLLER

Example:

Default for set-value SET1 = 50°C (for control circuit No. 1). In order to

configure a neutral zone control behaviour, always predefine:

SET2 = 0 Kelvin; LS2 = 0 and US2 = 0.

Configure the function of Relay 1 („uscita1“ in the following diagram):

S1C = in (heating) and Hy1= -2 Kelvin).

Configure the function of Relay 2 („uscita2“ in the following diagram):

S2C = dir (heating) and Hy2= +2 Kelvin).

Result (see following diagram):

SET1 = Set Point; db = Hy1 = Hy2

If the neutral zone SET1 - Hy1 is undershot, heating will take place (Relay 1

activated) until the set-value SET1 is reached. If the room temperature

exceeds the neutral zone SET1 + Hy1, Relay 2 is activated (cooling) and will

be switched off again at exactly SET1.

ON

english

OFF

NOTE

db db

Set point

Var iabl e

Different values can also be predefined in Hy1 and Hy2. In this

way, the switch-off point can be changed within the neutral

zone!

0911 - 9

Page 12

2.5 Parameters

Control

Hy1

Hy2

english

LS1

LS2

US1

US2

S1C

S2C

AC

ouc

on

ono

Hysteresis 1

Hysteresis 2

Lowest set-value setting

Lowest set-value setting

Highest set-value setting

Highest set-value setting

Control function 1

Control function 2

Minimum switch-off period

Dependency of the

set-values

Minimum switch-on period

Minimum delay

Switch hysteresis of Set-value 1 with

positive or negative values. The default

range is dependent on the input type.

The parameter may not be entered as

zero. The control function is predefined

with S1C.

Switch hysteresis of Set-value 2 with

positive or negative values(as Hy1).

The control function is predefined with

S2C.

Set-value limits 1 for operator

Set-value limits 2 for operator

Set-value limits 1 for operator

Set-value limits 2 for operator

in = inverted (Heating, humidifying)

dir = direct (cooling, dehumidifying)

in = inverted (heating, humidifying)

dir = direct (cooling, dehumidifying)

0 ... 250 sec relay switch-off period

diP = dependent

ind = independent

0...250 sec relay switch-on period

0...120 min; minimum delay between two

activations of the control relay.

Alarms

ALC

ALL

ALU

ALd

10 - 0911

Configuration

Temperature alarm

Low temperature alarm

Over-temperature alarm

Alarm delay

at temperature

Overshoot/Undershoot

rE = relative to the set-value (in Kelvin)

Ab = absolute values (in °C)

If SET - ALL is undershot, a low

temperature alarm will be triggered after

the delay time ALd.

If SET + ALU exceeded, a high

temperature alarm will be triggered after

delay time ALd.

0...999 min; Minimum time in which the

conditions for an alarm situation

must be present.

Page 13

Alarms

ALH

Hysteresis for the

Limit value alarms

ALL and ALU

dAO

Alarm delay at

with Mains ON

So1

Status of Control Relay 1

with sensor fault

So2

Status of Control Relay 2

with sensor fault

tbA

Status of the control relay

after acknowledgement by

of an alarm situation

AS

Configuration of the alarm

relay at an alarm

Measured value display

LCI

Lower analog

Display value

(-1999...1999)

UCI

Upper analog

display value

(-1999...1999)

OPb

calibration of the sensor

rES

Resolution

UdM

Units

PbC

Type of sensor

Temperature sensor U):

current/voltage input

(AU)

P3F

Third terminal of a

Pt100 sensor

Automatic alarm acknowledgement:

With high alarm undershot by

ALU - ALH and with low alarm with

under shooting of ALL + ALH

0...23.5 hours; suppression of

Alarms after commissioning.

oFF = opened

on = closed

oFF = opened

on = closed

oFF = Relay deactivated

on = Relay activated

cL = Terminal 5-6 closed

oP = Terminal 5-6 closed

scaling of the lower display value at

Current input 4 mA or at

Voltage input 0 V (only for the

inputs 0-20 mA, 0-1V, 0-10 V)

Scaling of the upper display value at

current input 20 mA or with voltage

input 1 V and 10 V (only for the

inpits 0-20 mA, 0-1V, 0-10 V)

regardless of the measurement range

in = only whole numbers

dE = also tenths

ce = hundreths

Display of the units directly in the

illuminated display. Regardless of which

controller type is being used:

see

General description

Type of inout

J = Thermoelement „J“; Pt = Pt100;

C = Thermoelement „K“; Ptc = PTC;

S = Thermoelement „S“; ntc = NTC

cur = 4...20 mA; 0-1 = 0...1 V;

10 = 0...10 V

(if present)

no = Pt100 2-wire wired

yES = Pt100 3-wire wired

english

0911 - 11

Page 14

english

Digital inputs

HES

Temperature increase/

Reduction

i1F

Function of the digital

Input

i1P

Polarity of the digital

input

did

Alarm delay time

of the digital input

(0...120 min)

Miscellaneous

Adr

Serial address RS485

(1...247)

OnF

Set device to STAND-BY

Ptb

Number of the parametertable

rEL

Version

Pr2

Display of the parameters

in Level Pr2

Set-value is increased/lowered by HES

during an energy-saving phase

Activation via digital input

(i1F = Es).

EAL = external alarm; OFF = unused;

bAL = serious external alarm;

Es = Energy saving mode Start/Stop;

onF = switch the device ON/OFF

externally;

C-H = reverse the control effect

CL: active with closed contact

OP: active with opened contact

For i1F = EAL or i1F = bAL.

The corresponding alarm then takes

place display or message.

Address for XJ500 recording

system. Identifies the device if it

is linked into a ModBUS-compatible

system.

no = not possible via keyboard

yes = STAND-BY can be activated by

holding down the SET button for

at least 4 sec. If you want to change the

set-value, hold down the SET button for

approx. 2 sec.

only read-out value

only read-out value

display only

NOTE

12 - 0911

You can access hidden parameters by holding down the

keys SET + for 3 sec in the programming level HY. The

message Pr2 appears.

Page 15

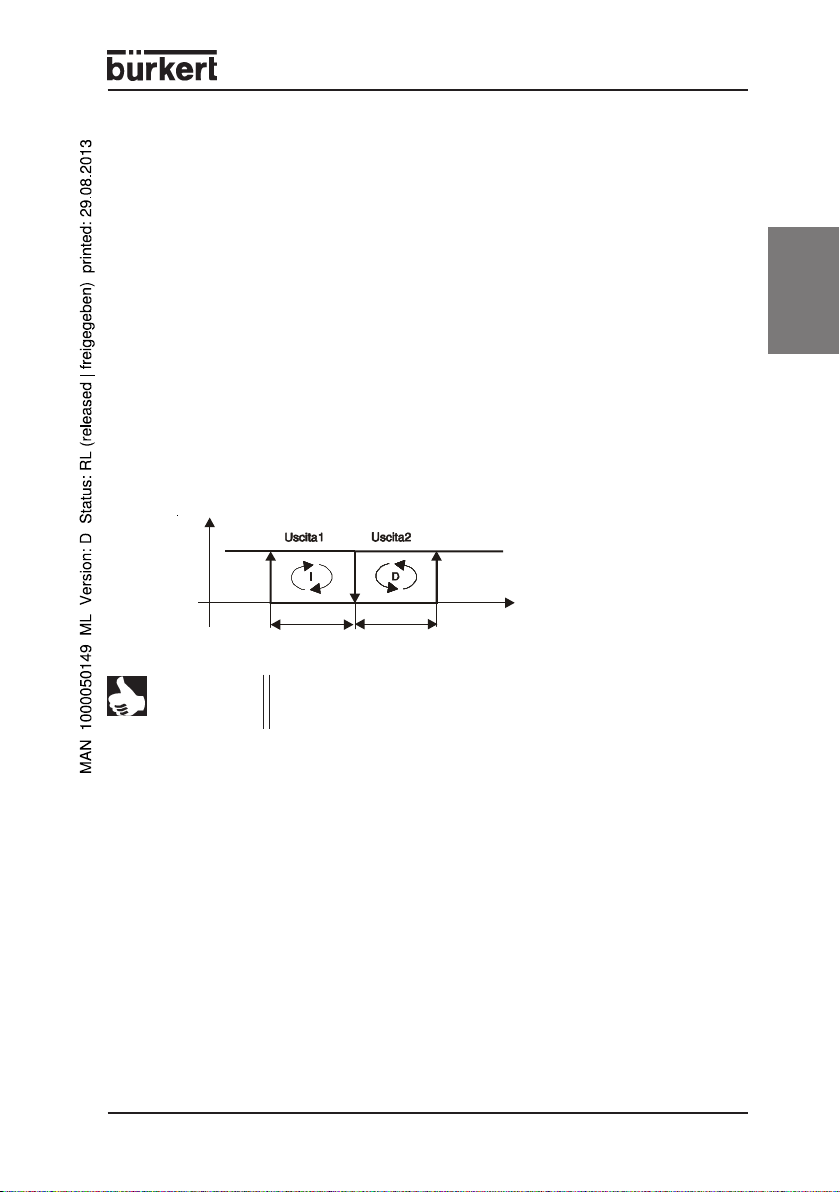

2.6 Controlling the loads

CONTROLLER OUTPUT

The control is dependent on the measurement temperature (= sensor

temperature). Program the control direction (heating or cooling) with the parameters

S1C and S2C.

S1C = dir Cooling Set = Set-value

S1C = in Heating Hy = Switch hysterisis

COOLING

temperature

SET+HY

SET

t

compessor

ON

t

Parameter S1C = dir; The value HY has been preset to 2K in the factory.

If the temperature exceeds the value SET + HY, the compressor is switched on

and will be switched off again when the temperature falls below SET.

HEATING

temperature

SET

SET-HY

t

heat

ON

english

t

Parameter S1C = in; The value HY has been preset to 2 K in the factory.

If the temperature falls below the value SET-HY, the controller output will be

switched on and will be switched off again when SET is exceeded.

0911 - 13

Page 16

3 TECHNICAL DATA

• Housing ABS, self-extinguishing

• Dimensions Front 74 x 32 mm, Depth 60 mm

• Assembly Panel-mounting unit for 29 x 71 mm cutout

• Protection class IP65 from front, only with front seal RG-C

• Connections Screw terminals

• Pipe cross-section ≤2.5 mm

english

• Auxiliary energy depending on model

• Power consumption max. 3 VA

• Display 3½ digits, red LED, height 12 mm

• Inputs configurable NTC / PTC or

• Relay outputs 2 x NO 8(3) A, 250 V AC + 1 x NC

• Data memory EEPROM

• Ambient temperature 0...+60°C / +32...+140°F

• Storage temperature -30...+85°C / -22...+185°F

• Air humidity 20...85% (non-condensing)

• Measurement range according to sensor

• Resolution 0.1°C or 1°F

• Accuracy at +25 °C better than 0.5% of the limit value of the

IP20

2

12...24 V AC/DC; ±10%

230 V AC; ±10%; 50/60 Hz

optional 110 V AC; ±10%; 50/60 Hz

NTC / PTC / Pt100 / Thermoelement J, K, S

or 4... 20 mA / 0...1 V / 0...10 V

measurement range

14 - 0911

Page 17

4 ASSEMBLY, INSTALLATION AND COMMISSIONING

4.1 General information regarding the installation and operation

ATTENTION!

NOTE

• Do not lay cables for inputs next to lines carrying voltage.

• Avoid heavy vibrations, aggressive gases, heavy soiling

and damp.

• Before connecting the device, check that the power supply

corresponds to the values shown on the rating plate.

• Observe the maximum loading of the relay contacts (see

Technical data

• Ensure that you install all sensors with sufficient separation

from lines carrying voltage, in order to avoid incorrect

temperature measurements and to protect the device from

voltage interference over the sensor inputs.

).

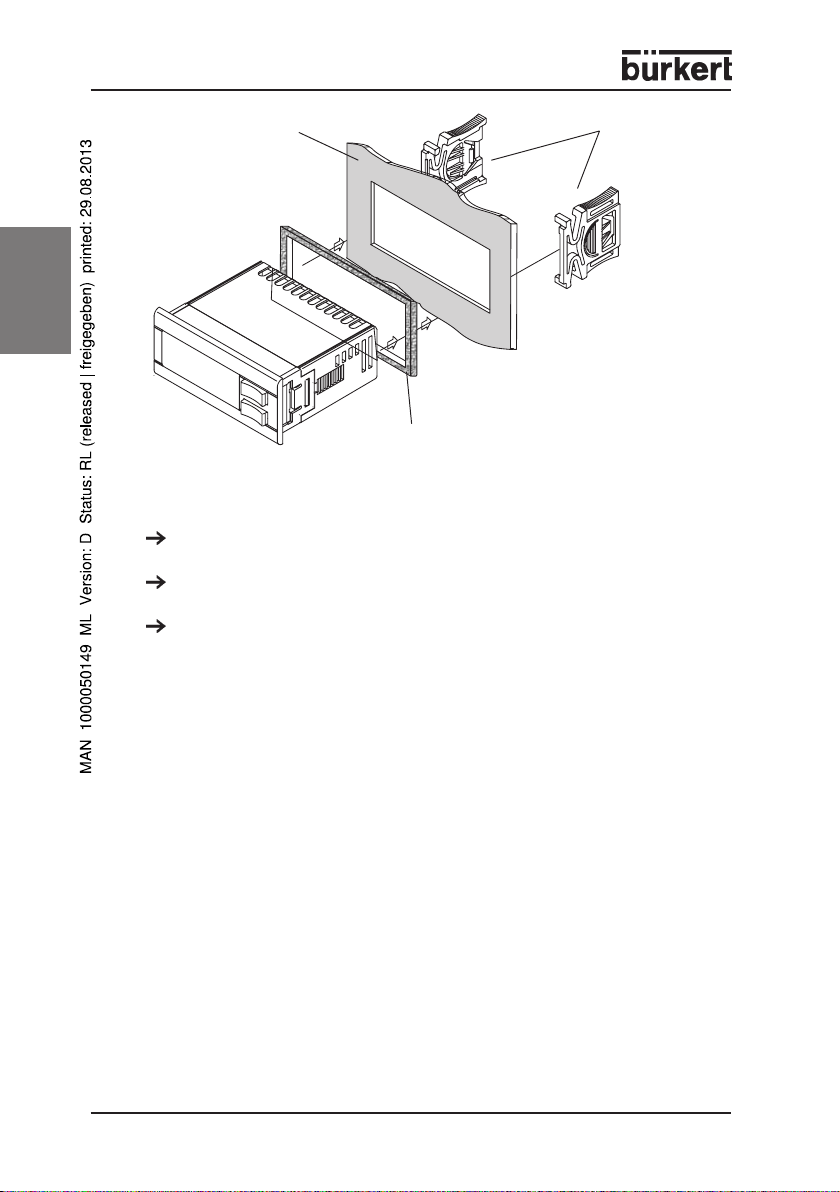

4.2 Assembly

The device is designed for panel mounting in a cutout of 71 x 29 mm, and is

secured with mounting brackets.

In order to ensure the IP65 front protection, a rubber seal must be fitted begind

the front frame (optional with RG-C).

The ambient temperature for trouble-free operetion is in the range from

0 ... +60°C.

Ensure sufficient ventilation through the cooling slots.

english

Panel

Mounting bracket

0911 - 15

Page 18

english

4.3 Electrical connections

Use cable with a cross-section of max. 2.5 mm2. The device is provided

with the corresponding screw terminals.

Check the auxiliary energy before you connect the power supply

(see

Technical data

Do not load the relay contacts higher than permitted. Where necessary,

make use of a contactor.

Panel Mounting clamp

Front seal

).

16 - 0911

Page 19

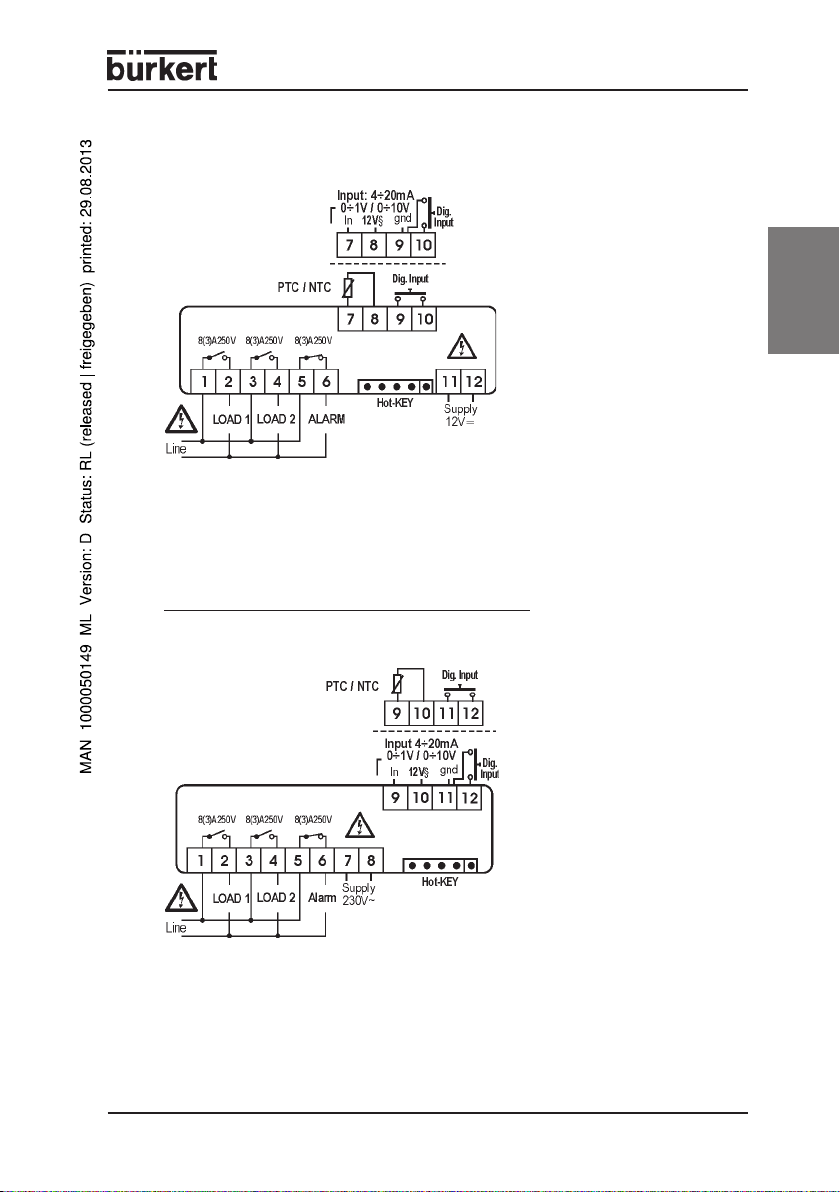

PIN ASSIGNMENT

12 V AC/DC or 24 V AC/DC

english

Standard signal input: 0...1 V; 0...10 V = 7(+), 9(-)

Thermoelement J, K, S = 7(+) - 9(-)

sensor: Pt100 = 7 - 9(8)

voltage supply: 24 V AC/DC = 11 - 12

230 V AC

Standard signal input: 0...1 V; 0...10 V = 9(+), 11(-)

Thermoelement J, K, S = 9(+) - 11(-)

sensor: Pt100 = 9 - 11(10)

voltage supply: 230 V AC = 7 - 8

4...20 mA = 7(+), 9(-)

4...20 mA = 9(+), 11(-)

0911 - 17

Page 20

5 HOT-KEY function

DOWNLOAD (HOT-KEY CONTROL DEVICE)

Writing the stored parameter set of the HOT-KEY into the control device:

Switch off the POWER SUPPLY to the controller, or set it to STAND-BY.

Insert the HOT-KEY up to the stop in the marked position on the controller.

Re-activate the controller.

english

The default parameters of the HOT-KEY will be automatically written into the

controller. During this time, the DoL message blinks in the display. The

programming prpcedure is finished after 10 sec, and normal operation

starts automatically with the new parameter set.

The HOT-KEY can be removed.

The following messages are possible at the end of the data transfer:

end for a correct data transfer

err for a failed data transfer

In this case, switch off the power to the device in order to repeat the

procedure. If you want to cancel the procedure, simply remove the HOTKEY.

UPLOAD (CONTROL DEVICE HOT-KEY)

Writing the current default parameters of the control device into the HOT-KEY:

Insert the HOT-KEY into the provided position when the controller is

switched on again.

Operate 1x with . The message uPL is displayed.

Press the SET1 button in order to start the data transfer. uPL starts to

blink.

You can remove the HOT-KEY again after about 10 seconds.

The following messages are possible at the end of the data transfer:

end for a correct data transfer

err for a failed data transfer

In this case, press the SET button again to repeat the procedure. If you

want to cancel the procedure, remove the HOT-KEY.

18 - 0911

Page 21

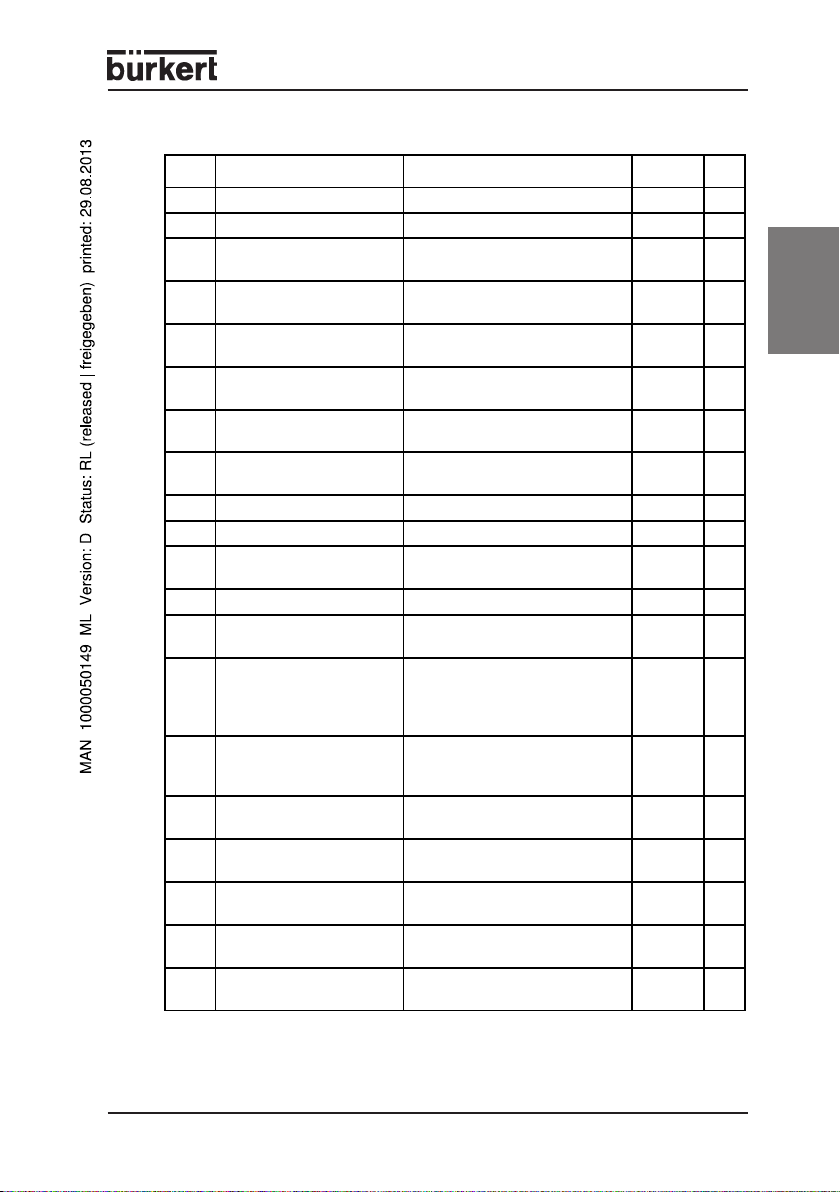

6 FACTORY SETTING

1

PA

Description Range Default PE

SET1 Set-value 1 LS1 + US1 0 Pr1

SET2 Set-value 2 LS2 + US2 1 Pr1

HY1 Switch hysterisis 1

HY2 Switch hysterisis 2

LS1 Lowest set-value 1

LS2 Lowest set-value 2

US1 Largest set-value 1

US2 Largest set-value 2

dependent on measurement

range

dependent on measurement

range

Lower measurement range +

SET1

Lower measurement range +

SET2

Upper measurement range +

SET1

Upper measurement range +

SET2

-1 Pr1

-1 Pr1

min Pr2

min Pr2

max Pr2

max Pr2

S1C Control effect Output 1 in = inverse; dir = direct in Pr2

S2C Control effect Output 2 in = inverse; dir = direct in Pr2

Dependency of the set-

ouc

values

ind = independent;

diP = dependent

ind

Ac Delay time for the relay 0...250 sec 0 Pr2

Minimum switch-on time

on

for a relay

0...250 sec 0 Pr2

Minimum waiting time

between two consecutive

ono

activations of the same

0...120 min 0 Pr2

load

Alarm limits are absolute

ALC

values or related to the

rE = relative; Ab = absolute rE Pr2

set-value

ALL

ALU

ALH

ALd

dAO

1

Parameter

2

Programming level

Lower Alarm Limit

(ALC = rE; ALC = Ab)

Upper Alarm Limit

(ALC = rE; ALC = Ab)

Switch hysterisis for

temperature alarms

Alarm delay time during

Alarm delay time after

the operation

commissioning

dependent on measurement

range

dependent on measurement

range

dependent on measurement

range

0...999 min 15 Pr2

0...23.5 h 1.3 Pr2

10 Pr2

10 Pr2

2Pr2

2

english

0911 - 19

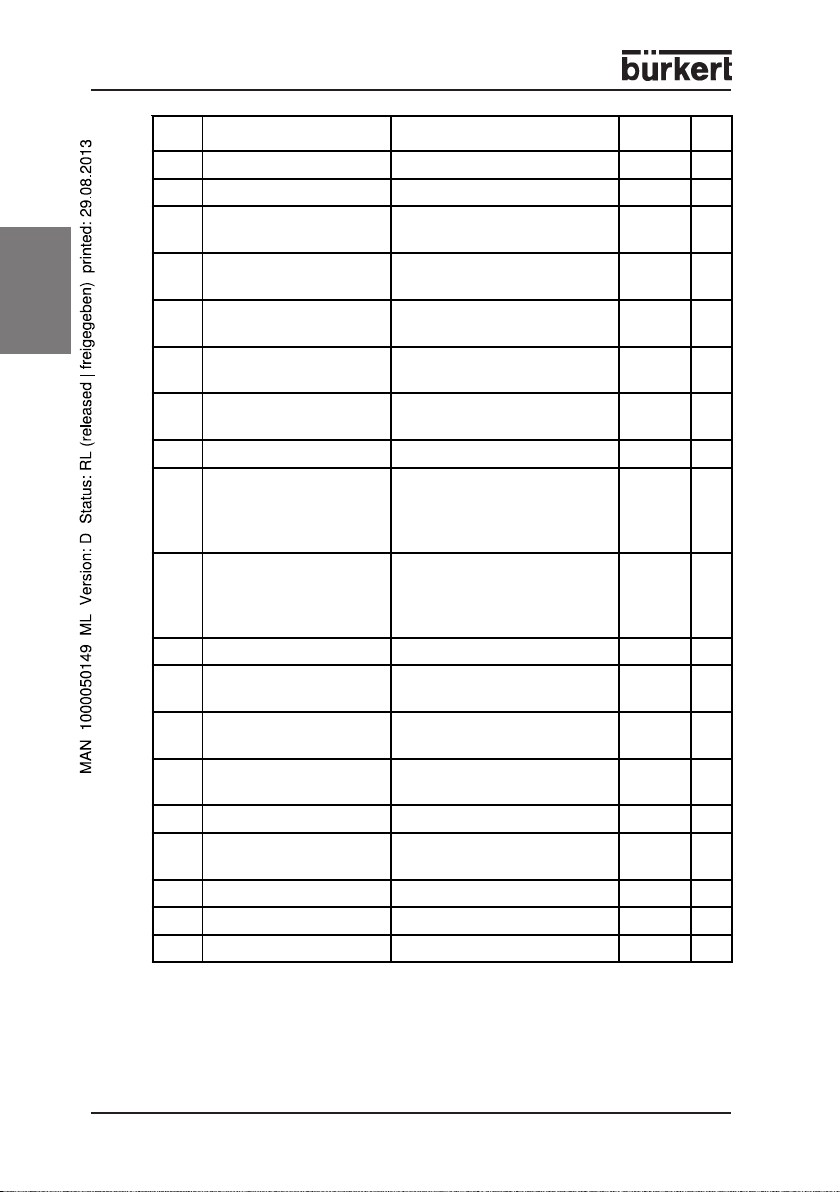

Page 22

english

1

PA

Description Range Default PE

So1 Output 1 for sensor error oFF = open; on = closed oFF Pr2

So2 Output 2 for sensor error oFF = open; on = closed oFF Pr2

tbA

AS

LCI

UCI

Alarm relay can be

acknowledged

Polarity of the Alarm

relay

Lower analog display

3

3

value

Upper analog display

value

Opb Sensor calibration

depending on measurement

no; yES yES Pr2

CL...oP oP Pr2

depending on sensor var. Pr1

depending on sensor var. Pr1

range

0Pr1

rES Resolution in = NO; dE = 0,1; cE = 0,01 in Pr2

Type TU: °C = °C, °F = °F;

UdM Units

Type AU: 0 = °C, 1 = °F;

2 = RH, 3 = bar, 4 = PS,

var. Pr1

5 = without display

Pt = Pt100; J = tcJ; c = tck;

PbC Type of sensor

S = tcS; Ptc = PTC;

ntc = NTC; 0.1 = 0...1 V;

var. Pr1

10 = 0...10 V; cur = 0...20 mA

P3F PT100; 3-wire no = no; yES =yes no Pr2

Configuration of the

i1F

i1P

did

digital input

Polarity of the digital

input

Alarm delay of the digital

input

c-H / oFF / off / HES /

EAL / bAL

cL = closed;

oP = open

EAL Pr2

cL Pr2

0...120 min 0Pr2

Adr Serial address for XJ500 RS485 adress 1 Pr2

OnF

Activate Standby

function

no = no; oFF = active no Pr2

Ptb Parameter table Read value - Pr2

rEL Software version Read value - Pr2

Pr2 Parameter access to Pr2 Read value 321 Pr1

2

1

Parameter

2

Programming level

3

Only for devices with voltage and current input

20 - 0911

Page 23

7 MAINTENANCE

When operated in accordance with the instruction in this handbook, the 0911

controller is maintenance-free.

8 REPAIR WORK

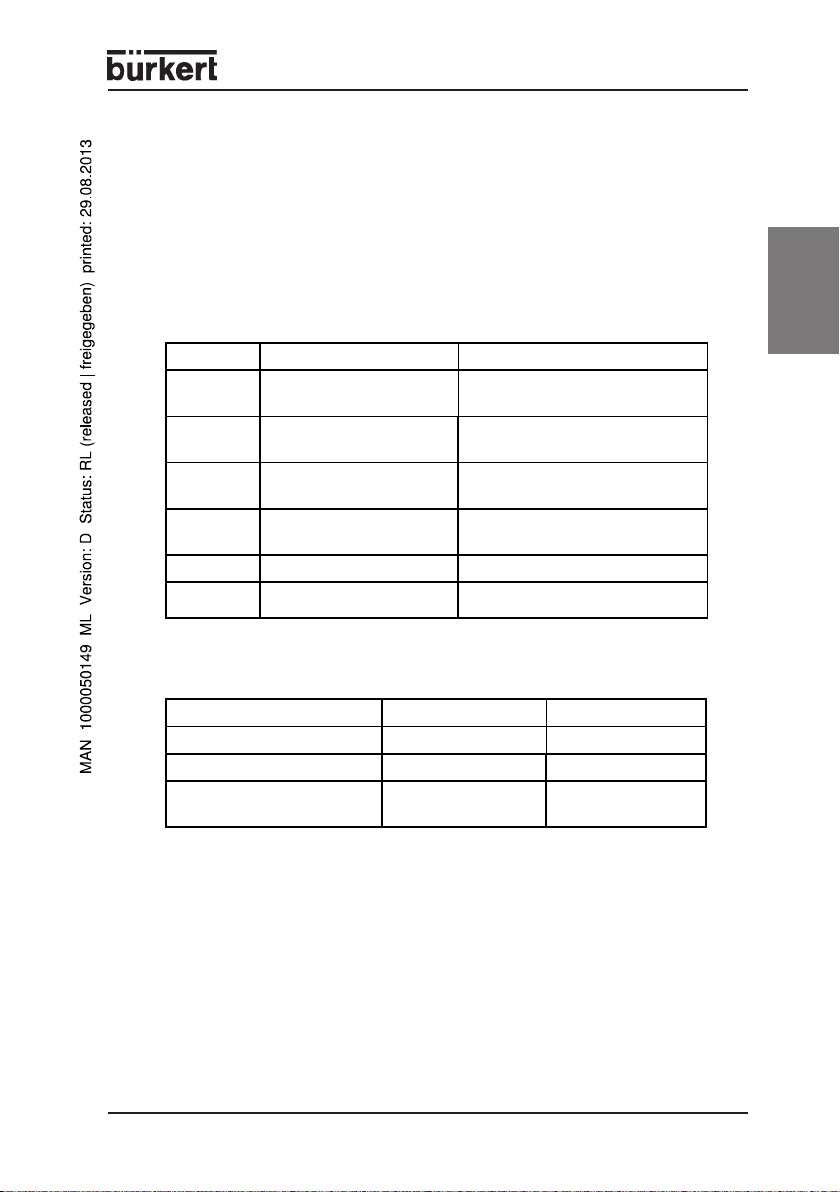

8.1 Faults

ERROR MESSAGES

Message Cause Effect

PFo

PFc Sensor short-circuit

HA High temperature alarm

LA Low temperature alarm

EAL Digital input alarm Outputs remain unchanged

BAL Serious digital alarm All control outputs deactivated

STATUS OF THE ALARM RELAY

Sensor defective or not

connected

Alarm relay ON; control circuit

according to So1

Alarm relay ON; control circuit

according to So1

Alarm relay ON; outputs remain

unchanged

Alarm relay ON; Outputs remain

unchanged

english

Device status AS = CL AS = OP

Device without power 5 - 6 closed 5 - 6 closed

Normal operation 5 - 6 closed 5 - 6 open

Alarm situation during

operation

5 - 6 open 5 - 6 closed

0911 - 21

Page 24

ACKNOWEDGING ERRORS VIA THE KEYBOARD

Press any button.

The Alarm message remains on the display as long as the alarm conditions

are present. The device then switches to normal operation.

AUTOMATIC ACKNOWLEDGEMENT OF THE ERROR

english

• Message

After approx. 30 seconds or once the error has been cleared, the

message will be acknowledged automatically. Check the connections

before any replacement of the sensor.

• Messages

The messages disappear automatically as soon as the normal temperature

range is reached again or if defrosting starts.

• External alarms EAL and BAL are acknowledged after deactivation of the

digital input.

PFo and PFc -

HA/LA -

High/Low temperature alarm

Room sensor error

8.2 Ordering table for basic unit/accessories

Article Inputs Order No.

3-stage controller 0911

12-24 V AC/DC

3-stage controller 0911

12-24 V AC/DC

3-stage controller 0911 230 V AC PTC/NTC; Pt100, Typ J, K, S 788 269

3-stage controller 0911 230 V AC 4-20 mA; 0-10 V; 0-1 V 788 270

PTC sensor

with 1.5 m cable, installation sleeve

L = 62 mm D = 6 mm

Protective cover 787 937

Transformer 230 V / 24 V 3 VA 787 938

PTC/NTC; Pt100,

Type J, K, S

4-20 mA; 0-10 V; 0-1 V 788 268

788 267

781 969

22 - 0911

Page 25

3-PUNKT-REGLER

TYP 0911

1 ALLGEMEINE HINWEISE

1.1 Darstellungsmittel ................................................................................................................................... 24

1.2 Sicherheitshinweise .............................................................................................................................. 24

1.3 Lieferumfang .............................................................................................................................................25

1.4 Garantiebestimmungen ...................................................................................................................... 25

2 SYSTEMBESCHREIBUNG

2.1 Allgemeine Beschreibung .................................................................................................................. 26

2.2 Bedienung ................................................................................................................................................... 26

2.3 Vor der Installation .................................................................................................................................29

2.4 Regelung .....................................................................................................................................................30

2.5 Parameter................................................................................................................................................... 32

2.6 Regelung der Lasten ............................................................................................................................35

3 TECHNISCHE DATEN

4 MONTAGE, INSTALLATION UND INBETRIEBNAHME

4.1 Allgemeine Hinweise zu Installation und Betrieb ................................................................... 37

4.2 Montage ....................................................................................................................................................... 37

4.3 Elektrische Anschlüsse ...................................................................................................................... 38

5 HOT-KEY FUNKTION

.....................................................................................................................

..................................................................................................................

............................................................................................................................

....................................................

.............................................................................................................................

24

26

36

37

40

deutsch

6 WERKSEINSTELLUNG

7 WARTUNG

.....................................................................................................................................................

8 INSTANDHALTUNG

8.1 Störungen ...................................................................................................................................................43

8.2 Bestelltabelle Grundgerät/Zubehör .............................................................................................. 44

.........................................................................................................................

................................................................................................................................

0911 - 23

41

43

43

Page 26

1 ALLGEMEINE HINWEISE

1.1 Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

1.2 Sicherheitshinweise

deutsch

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten, die in dem Datenblatt des Reglers 0911

spezifiziert sind, damit das Gerät einwandfrei funktioniert und lange einsatzfähig bleibt.

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die

allgemeinen Regeln der Technik!

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit

geeignetem Werkzeug erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte während des Betriebs und der Wartung des

Gerätes!

• Achten Sie auf die bestimmungsgemäße Verwendung des Gerätes.

• Betreiben Sie das Gerät immer mit Gehäuse.

• Prüfen Sie vor dem Anschluß des Gerätes ob die Spannungsversorgung

dem auf dem Gerät aufgedruckten Zahlenwert entspricht.

• Überprüfen Sie vor Einschalten des Gerätes den korrekten Anschluss.

• Beachten Sie die maximale Belastung der Relais-Kontakte (siehe technische Daten).

• Beachten Sie, dass alle Fühler mit genügend großem Abstand zu

spannungsführenden Leitungen installiert werden. Damit werden verfälschte Temperatur-Messungen vermieden und das Gerät vor

spannungseinstreuungen über die Fühlereingänge geschützt.

• Schalten Sie bei Anwendungen im industriellen Bereich mit kritischer

Umgebung die RC-Gliedern parallel(FT1).

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder

unzulässige Beeinträchtigung auszuschließen!

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes gefährdet ist.

kennzeichnet wichtige Zusatzinformationen,

Tipps und Empfehlungen.

24 - 0911

Page 27

• Beachten Sie die vorgeschriebenen Umgebungsbedingungen bzgl. deren

Feuchte- und Temperatur-Grenzen. Werden diese Bediengungen nicht

eingehalten sind Fehlfunktionen nicht auszuschliessen.

• Bei Auftreten einer Fehlfunktion oder Zweifeln wenden Sie sich an das

zuständige Bürkert-Vertriebs-Center.

Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät

entfällt jegliche Haftung unsererseits, ebenso erlischt die Garantie auf Geräte

und Zubehörteile!

1.3 Lieferumfang

Überzeugen Sie sich unmittelbar nach Erhalt der Lieferung, ob der Inhalt mit

dem angegebenen Lieferumfang übereinstimmt. Zu diesem gehören:

• 1 Regler Typ 0911

• 1 Betriebsanleitung (ggf. auf Datenträger)

• 1 Frontdichtung

• 2 Befestigungsbügel

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an unser Kundencenter:

Bürkert Steuer- und Regelungstechnik

Service-Abteilung

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

oder an Ihr Bürkert-Vertriebs-Center.

deutsch

1.4 Garantiebestimmungen

Bürkert gewährt auf die ordnungsgemäße Funktion des Regler eine Garantie

von einem Jahr unter der Voraussetzung, dass das Gerät bestimmungsgemäß

und unter Beachtung der spezifizierten Einsatzbedingungen verwendet wird.

Bei nicht einwandfreier Funktion wird das betreffende Gerät innerhalb der

Garantiefrist kostenlos repariert bzw. ausgetauscht.

ACHTUNG!

Die Gewährleistung erstreckt sich nur auf den Regler und

seine Bauteile, jedoch nicht auf Folgeschäden irgendwelcher

Art, die durch Ausfall oder Fehlfunktion des Gerätes entstehen

könnten.

0911 - 25

Page 28

2 SYSTEMBESCHREIBUNG

2.1 Allgemeine Beschreibung

3-Punkt- bzw. Neutralzonenregler, 74 x 32 mm, mit vorgebbarer Regelwirkung

(z.B. Heizen/Kühlen oder Befeuchten/Entfeuchten)

Folgende Ausführungen sind verfügbar:

Typ Konfigurierbarer

TU

Temperaturregler

AU

Regelgerät mit

Strom-/Spannung-

deutsch

seingang

2.2 Bedienung

Ausgangs

LED´s

Alarm

LED

Eingang

PTC, NTC, Pt100

Thermoelemente J, K, S

4 ... 20 mA

0 ... 1 V

0 ... 10 V

LED1

LED 2

Parameter UDM

(Anzeigeeinheit

vorgeben)

UDM = °C

UDM = °F

0 = °C; 1 = °F

2 = % RH

3 = bar

4 = PSI

5 = ohne Maßeinheit

nach

nach

oben

unten

SETTasten

TASTEN

SET1 Anzeige des Sollwertes 1

SET2 Anzeige des Sollwertes 2

26 - 0911

Ändern und Bestätigen einer Vorgabe während der Programmierphase

Page 29

TASTENKOMBINATIONEN

+

Tastatur verriegeln und entriegeln

SET1+ Programmierebene auswählen

SET1+ Zurück zur Raumtemperatur-Anzeige

LED-MELDUNGEN

LED Mode Bedeutung

ein Ausgang 1 aktiv

ein Ausgang 2 aktiv

LED1 blinkt Programmierebene (blinkt zusammen mit LED2)

LED2 blinkt Programmierebene (blinkt zusammen mit LED1)

E.S. ein

Alarm

LED ein

GERÄT EIN/AUS-SCHALTEN

Energiesparmodus (zweiter Sollwert) wurde über

digitalen Eingang aktiviert.

- Signalisierung eines Alarm-Zustandes

- Befindet man sich in der tieferen

Programmierebene "Pr2", die nur mit

Passwort erreichbar ist, wird durch das

Leuchten der Alarm-LED signalisiert, daß

der angezeigte Parameter auch in der

ersten Ebene "Pr1" (ohne Passwort)

erreichbar ist.

deutsch

SOLLWERT ANZEIGEN

Halten Sie die SET1-Taste mindestens 4 sec

gedrückt (Nur bei Parameter OnF = yes).

Betätigen Sie einmal kurz die SET-Taste. Die

Sollwertanzeige erscheint am Display.

Betätigen Sie nochmals kurz die SET-Taste oder

warten Sie 5 sec, um die Raumtemperatur anzeigen

zu lassen.

0911 - 27

Page 30

deutsch

SOLLWERT 1 / SOLLWERT 2 ÄNDERN

Halten Sie eine SET-Taste 2 sec gedrückt.

Ändern Sie den Sollwert innerhalb von 10 sec mit

den Tasten bzw. .

Sie speichern den neuen Sollwert durch kurzes

Betätigen der SET-Taste oder warten Sie 10 sec.

PROGRAMMIEREBENE BETRETEN

Halten Sie die Tasten SET1 + mindestens 3 sec

gedrückt.

Wählen Sie mit Pr2 an und bestätigen danach mit

der SET1 Taste.

Geben Sie das Passwort 321 vor und bestätigen

danach mit der SET1-Taste.

die "3" vorgeben, danach 1 x SET1-Taste

die "2" vorgeben, danach 1 x SET1-Taste

die "1" vorgeben, danach 1 x SET1-Taste

Sie befinden sich in der Parameterliste.

ANWENDEREBENE PR1

Drücken Sie dieTasten SET1 + für 3 sec. PR1

beinhaltet alle für den Anwender erreichbaren

Parameter. Das Gerät zeigt den ersten Parameter

an, der in der Anwenderebene verfügbar ist.

SERVICE-EBENE PR2 (PASSWORT 321)

Siehe:

Programmierebene betreten

PARAMETER IN ANWENDEREBENE PR1 HINZUFÜGEN / ENTFERNEN

Programmierebene betreten

Der Status ist mit den Tasten SET1 + veränder-

bar.

Wenn ein Parameter in der PR1-Ebene sichtbar ist,

wird dies durch ein LED-Punkt angezeigt.

28 - 0911

.

Page 31

PARAMETER-VORGABEN ÄNDERN

Geben Sie mit SET + oder einen gewünsch-

ten Wert vor.

Bestätigen Sie danach mit der SET-Taste.

Wählen Sie mit oder einen gewünschten

Parameter an.

HINWEIS

TASTATUR VER- BZW. ENTRIEGELN

Allein durch mehrmaliges Betätigen der SET1-Tasten können alle

Parameterwerte eingesehen werden.

2.3 Vor der Installation

FÜHLERTYP VORGEBEN

Halten Sie die Tasten und für 3 sec gedrückt.

Am Display erscheint die Meldung POF

Tastatur ist verriegelt

auch, wenn Sie eine Taste länger als 3 sec ge-

drückt halten.

Die Tastatur ist entriegelt

und für 3ec s gedrückt halten. Für einige

Sekunden erscheint POn in der Anzeige.

Auf dem Etikett des Reglers ist der konfigurierbare

Eingangstyp vermerkt. Geben Sie den Eingangstyp

bitte vor, wenn dieser nicht dem angeschlossenen

Fühlertyp entspricht.

Halten Sie die Tasten SET + 3 Sekunden

gedrückt.

Wählen Sie den Parameter Pbc (Fühlertyp) an, und

bestätigen Sie danach mit der SET-Taste, um die

aktuelle Vorgabe zu sehen.

Typ TU (Themperaturregler)

J = Thermoelement J; Pt = Pt100;

C = Thermoelement K; Ptc = PTC;

S = Thermoelement S; ntc = NTC

Typ AU

(Regelgeräte mit Strom-/Spannungseingang)

cur = 4...20 mA; 0-1 = 0...1 V; 10 = 0...10 V

Bestätigen Sie die Vorgabe mit der SET-Taste.

Schalten Sie das Gerät kurz stromlos.

. Die POF-Meldung erscheint

, wenn Sie die Tasten

:

.

Die

deutsch

:

0911 - 29

Page 32

MESSWERTGRENZEN DER FÜHLERTYPEN

Fühler Untere Grenze Obere Grenze

NTC -40°C 110°C

PTC -50°C 150°C

Pt100 -200°C 600°C

TcK 0°C 1300°C

TcJ 0°C 600°C

TcS 0°C 1400°C

2.4 Regelung

ZWEI VONEINANDER UNABHÄNGIGE AUSGÄNGE (OUC = IND)

deutsch

Beispiel:

Vorgabe der Sollwerte SET1 = 50°C und SET2 = 20°C. Bei Parametervorgabe

OUC = ind sind beide Sollwerte völlig unabhängig voneinander. Außerdem muß

die Regelwirkung vorgegeben werden. Für das Regelrelais Nr. 1 Par. S1C = in

(Heizen, Befeuchten, etc.) oder S1C = dir (Kühlen, Entfeuchten, etc.). Für das

Regelrelais Nr. 2 ebenfalls vorgeben (S2C = in oder S2C = dir).

Beispiel: ouC = ind, S1c = dir, S2c = dir

ZWEI VONEINANDER ABHÄNGIGE AUSGÄNGE (OUC = DIP)

3 PUNKT-REGLER

Beispiel:

Vorgabe des Sollwertes SET1 = 50 °C (für Regelrelais Nr. 1). Danach Vorgabe

einer Zahl bei SET2 = 5 Kelvin (Delta-Wert). Als Sollwert ergibt sich dann SET2

= 55 °C (SET2 = SET1 + Delta-SET2). Wird danach der SET1 z.B. um 2 Kelvin

erhöht auf 52°C, erhöht sich im selben Maß der SET2, also ebenfalls um 2

Kelvin auf 57°C. Den Wirksinn der Ausgänge ebenfalls über die Parameter S1C

und S2C festlegen. Analog ergeben die Sollwertvorgabegrenzen für SET2 aus

LS2 = SET1 -Delta-LS2 und HS2 = +Delta-HS2.

30 - 0911

Page 33

NEUTRALZONEN-REGLER

Beispiel:

Vorgabe des Sollwert SET1 = 50°C (für Regelrelais Nr. 1). Um eine Neutralzonen-Regelverhalten zu konfigurieren immer vorgeben:

SET2 = 0 Kelvin; LS2 = 0 und US2 = 0.

Funktion des Relais 1 (im nachstehenden Bild "uscita1") konfigurieren:

S1C = in (Heizen) und Hy1= -2 Kelvin).

Funktion des Relais 2 (im nachstehenden Bild "uscita2") konfigurieren:

S2C = dir (Kühlen) und Hy2 = +2 Kelvin).

Ergebnis (siehe nachstehendes Bild):

SET1 = Set Point; db = Hy1 = Hy2

Bei unterschreiten der Neutralzone SET1 - Hy1 wird geheizt (Relais 1 aktiviert) bis wieder der Sollwert SET1 erreicht wird. Übersteigt die Raumtemperatur die Neutralzone SET1 + Hy2 wird Relais 2 aktiviert (Kühlen) und

genau bei SET1 wieder abgeschaltet.

ON

deutsch

OFF

HINWEIS

db db

Set point

Var iabl e

In Hy1 und Hy2 können auch unterschiedliche Werte vorgeben

werden. Damit lässt sich der Abschaltpunkt innerhalb der

Neutralzone verändern!

0911 - 31

Page 34

2.5 Parameter

Regelung

Hy1

Hy2

LS1

LS2

deutsch

US1

US2

S1C

S2C

AC

ouc

on

ono

Hysterese 1

Hysterese 2

Niedrigste Sollwerteinstellung

Niedrigste Sollwerteinstellung

Höchste Sollwerteinstellung

Höchste Sollwerteinstellung

Regelwirkung 1

Regelwirkung 2

Mindestausschaltdauer

Abhängigkeit der Sollwerte

Mindesteinschaltdauer

Mindestverzögerung

Schalthysterese des Sollwerts 1 mit

positiven oder negativen Werten. Der

Vorgabebereich ist abhängig vom Eingangstyp. Der Parameter darf nicht mit

Null vorgegeben werden. Die Regelwirkung wird mit S1C vorgegeben.

Schalthysterese des Sollwerts 2 mit

positiven oder negativen Werten

(wie Hy1). Die Regelwirkung wird mit

S2C vorgegeben.

Sollwertgrenzen 1 für Bediener

Sollwertgrenzen 2 für Bediener

Sollwertgrenzen 1 für Bediener

Sollwertgrenzen 2 für Bediener

in = invers (Heizen, Befeuchten)

dir = direkt (Kühlen, Entfeuchten)

in = invers (Heizen, Befeuchten)

dir = direkt (Kühlen, Entfeuchten)

0...250 sec Relais-Ausschaltdauer

diP = abhängig

ind = unabhängig

0...250 sec Relais-Einschaltdauer

0...120 min; Mindestverzögerung

zwischen zwei Aktivierungen des

Regelrelais.

Alarme

ALC

ALL

ALU

ALd

32 - 0911

Konfiguration

Temperatur-Alarm

Alarm-Tieftemperatur

Alarm-Übertemperatur

Alarm-Verzögerung

bei Temperatur

Über-/Unterschreitung

rE = relativ zum Sollwert (in Kelvin)

Ab = absolute Werte (in °C)

Bei unterschreiten von SET - ALL

wird ein Tieftemperatur-Alarm nach

Verzögerungszeit ALd ausgelöst.

Bei überschreiten von SET + ALU wird

ein Hochtemperatur-Alarm nach

Verzögerungszeit ALd ausgelöst.

0...999 min; Mindestzeit, in der die Bedingungen für eine Alarm-Situation gegeben sein müssen.

Page 35

Alarme

ALH

Hysterese für die

Grenzwertalarme

ALL und ALU

dAO

Alarm-Verzögerung bei

Netz EIN

So1

Status des Regelrelais 1

bei Fühlerfehler

So2

Status des Regelrelais 2

bei Fühlerfehler

tbA

Status des Alarmrelais

nach dem Quittieren bei

einer Alarmsituation

AS

Konfiguration des AlarmRelais bei einem Alarm

Messwert-Anzeige

LCI

Unterer analoger

Anzeigewert

(-1999...1999)

UCI

Oberer analoger

Anzeigewert

(-1999...1999)

OPb

Kalibrierung des Fühlers

rES

Auflösung

UdM

Maßeinheit

PbC

Fühlerart

Temperaturfühler (TU):

Strom/Spannungseingang

(AU)

P3F

Dritte Klemme eines

Pt100-Fühlers

Automatische Alarmquittierung:

Bei Hochalarm unterschreiten von

ALU - ALH und bei Tiefalarm bei überschreiten von ALL + ALH

0...23,5 Stunden; Unterdrückung von

Alarmen nach Inbetriebnahme.

oFF = geöffnet

on = geschlossen

oFF = geöffnet

on = geschlossen

oFF = Relais deaktiviert

on = Relais aktiviert

cL = Klemme 5-6 geschlossen

oP = Klemme 5-6 geschlossen

Scalierung des unteren Anzeigewert bei

Stromeingang 4 mA oder bei

Spannungseingang 0 V (nur bei den

Eingängen 0-20 mA, 0-1V, 0-10 V)

Scalierung des oberen Anzeigewert bei

Stromeingang 20 mA oder bei Spannungseingang 1 V und 10 V (nur bei den

Eingängen 0-20 mA, 0-1V, 0-10 V)

abhängig vom Messbereich

in = nur Ganze Zahlen

dE = auch Zehntelwerte

ce = Hundertstelwerte

Anzeige der Maßeinheit direkt im

Leuchtdisplay. Abhängig davon, welcher

Reglertyp verwendet wird:

siehe

Allgemeine Beschreibung

Eingangasart

J = Thermoelement "J"; Pt = Pt100;

C = Thermoelement "K"; Ptc = PTC;

S = Thermoelement "S"; ntc = NTC

cur = 4...20 mA; 0-1 = 0...1 V;

10 = 0...10 V

(falls vorhanden)

no = Pt100 2-Leiter verdrahtet

yES = Pt100 3-Leiter verdrahtet

deutsch

0911 - 33

Page 36

deutsch

Digitale Eingänge

HES

Temperatur-Erhöhung/

Senkung

i1F

Funktion des digitalen

Eingangs

i1P

Polarität des digitalen

Eingangs

did

Alarmverzögerungszeit

des digitalen EIngangs

(0...120 min)

Sonstiges

Adr

Serielle Adresse RS485

(1...247)

OnF

Gerät in STAND-BY setzen

Ptb

Nummer der Parametertabelle

rEL

Version

Pr2

Anzeige der Parameter in

Ebene Pr2

Sollwert wird um HES erhöht/gesenkt

während der Energiesparphase

Aktivierung über digitalen Eingang

(i1F = Es).

EAL = externer Alarm; AUS = ungenutzt;

bAL = ernsthafter externer Alarm;

Es = Energiesparmodus starten/stopen;

onF = von extern das Gerät EIN/AUS

schalten; C-H = Regelwirkung umdrehen

CL: aktiv bei geschlossenem Kontakt

OP: aktiv bei geöffnetem Kontakt

Bei i1F = EAL oder i1F = bAL.

Danach erfolgt die entsprechende Alarmanzeige bzw. Meldung.

Adresse für XJ500 Aufzeichnungssystem. Identifiziert das Gerät, wenn es

in einem ModBUS kompatiblen System

eingebunden ist.

no = nicht über Tastatur möglich

yes = STAND-BY aktivierbar durch

Gedrückthalten der SET-Tastevon

mindestens 4 sec. Möchte man

den Sollwert ändern, die SET-Taste ca.

2 sec gedrückt halten.

nur Auslesewert

nur Auslesewert

nur Anzeige

HINWEIS

34 - 0911

Versteckte Parameter

mierebene HY die Tasten SET + für 3 sec gedrückt halten. Es

erscheint die Meldung Pr2.

erreichen Sie, wenn Sie in der Program-

Page 37

2.6 Regelung der Lasten

REGLER-OUTPUT

Die Regelung ist abhängig von der Mess-Temperatur (= Fühler-Temperatur).

Den Wirksinn (Heizen oder Kühlen) programmieren Sie mit den Parmetern

S1C und S2C.

S1C = dir Kühlen Set = Sollwert

S1C = in Heizen Hy = Schalthysterese

KÜHLEN

Parameter S1C = dir; Der Wert HY ist im Werk auf 2 K voreingestellt.

Überschreitet die Temperatur den Wert SET + HY, wird der Kompressor eingeschaltet und bei Unterschreitung von SET wieder abgeschaltet.

HEIZEN

deutsch

Parameter S1C = in; Der Wert HY ist im Werk auf 2 K voreingestellt.

Unterschreitet die Temperatur den Wert SET - HY, wird der Regler-Output

eingeschaltet und bei Überschreitung von SET wieder abgeschaltet.

0911 - 35

Page 38

3 TECHNISCHE DATEN

• Gehäuse ABS, selbstverlöschend

• Abmessungen Front 74 x 32 mm, Tiefe 60 mm

• Montage Tafeleinbaugerät für Ausschnitt 29 x 71 mm

• Schutzart IP65 von vorn, nur mit Frontdichtung RG-C

• Anschlüsse Schraubklemmen

• Leitungsquerschnitt 2,5 mm

• Hilfsenergie je nach Ausführung

• Leistungsaufnahme max. 3 VA

deutsch

• Anzeige 3½ Ziffern, LED rot, Höhe 12 mm

• Eingänge konfigurierbar NTC / PTC oder

• Relais-Ausgänge 2 x SCHLIESSER 8(3) A, 250 V AC + 1 x NC

• Daten-Speicher EEPROM

• Umgebungstemperatur 0...+60°C / +32...+140°F

• Lagertemperatur -30...+85°C / -22...+185°F

• Luftfeuchtigkeit 20...85% (nicht kondensierend)

• Messbereich gemäß Fühler

• Auflösung 0,1°C oder 1°F

• Genauigkeit bei + 25 °C besser als 0,5% des Messbereichsendwertes

IP20

2

12...24 V AC/DC; ± 10%

230 V AC; ± 10%; 50/60 Hz

optional 110 V AC; ± 10%; 50/60 Hz

NTC / PTC / Pt100 / Thermoelement J, K, S

oder 4... 20 mA / 0...1 V / 0...10 V

36 - 0911

Page 39

4 MONTAGE, INSTALLATION UND INBETRIEBNAHME

4.1 Allgemeine Hinweise zu Installation und Betrieb

ACHTUNG!

HINWEIS

• Verlegen Sie die Kabel von Eingängen getrennt von

spannungsführenden Leitungen.

• Vermeiden Sie starke Vibration, aggressive Gase, starke

Verschmutzung und Feuchtigkeit.

• Prüfen Sie vor Anschluss des Gerätes, ob die Spannungsversorgung den auf dem Typenschild angegebenen Werten

entspricht.

• Beachten Sie die maximale Belastung der Relaiskontakte

(siehe Technische Daten).

• Beachten Sie, dass Sie alle Fühler mit genügend großem

Abstand zu spannungsführenden Leitungen installieren,

damit fehlerhafte Temperaturmessungen vermieden werden

und das Gerät vor Spannungseinstreuung über die FühlerEingänge geschützt wird.

4.2 Montage

Das Gerät ist für Tafeleinbau auf einen Ausschnitt von 71 x 29 mm konzipiert

und wird mit Befestigungsbügeln fixiert.

Um die Frontschutzart IP65 zu gewährleisten, muss eine Gummidichtung

hinter dem Frontrahmen gelegt werden (RG-C optional).

Die Umgebungstemperatur für den einwandfreien Betrieb liegt im Bereich von

0...+60°C.

Sichern Sie eine ausreichende Belüftung durch die Kühlschlitze.

deutsch

Panel

Befestigungsbügel

0911 - 37

Page 40

Panel Befestigungsbügel

deutsch

4.3 Elektrische Anschlüsse

Verwenden Sie Kabel mit einem Querschnitt von maximal 2,5 mm2. Das

Gerät ist mit entsprechenden Schraubklemmen versehen.

Prüfen Sie die Hilfsenergie, bevor Sie die Spannungsversorgung

anschließen (siehe Technische Daten).

Belasten Sie die Relais-Kontakte nicht mit höheren Leistungen, als zulässig.

Schalten Sie gegebenenfalls Schütze nach.

Frontdichtung

38 - 0911

Page 41

ANSCHLUSSBELEGUNG

12 V AC/DC oder 24 V AC/DC

Normsignaleingang: 0...1 V; 0...10 V = 7(+), 9(-)

4...20 mA = 7(+), 9(-)

Thermoelement J, K, S = 7(+) - 9(-)

Fühler: Pt100 = 7 - 9(8)

Spannungsversorgung: 24 V AC/DC = 11 - 12

230 V AC

deutsch

Normsignaleingang: 0...1 V; 0...10 V = 9(+), 11(-)

4...20 mA = 9(+), 11(-)

Thermoelement J, K, S = 9(+) - 11(-)

Fühler: Pt100 = 9 - 11(10)

Spannungsversorgung: 230 V AC = 7 - 8

0911 - 39

Page 42

5 HOT-KEY Funktion

DOWNLOAD (HOT-KEY REGELGERÄT)

Schreiben des gespeicherten Parametersatzes des HOT-KEY in das Regelgerätes:

Schalten Sie den Regler STROMLOS oder setzen Sie ihn in STAND-BY.

Stecken Sie den HOT-KEY in die markierte Position am Regler bis zum

Anschlag.

Aktivieren Sie den Regler wieder.

Die Parametervorgaben des HOT-KEY werden automatisch in den Regler

geschrieben. Während dieser Zeit blinkt die Meldung DoL in der Anzeige.

Nach 10 sec ist der Programmiervorgang beendet und der Normalbetrieb

startet automatisch mit dem neuen Parametersatz.

Der HOT-KEY kann entfernt werden.

deutsch

Am Ende der Datenübertragung sind folgende Meldungen möglich:

end für eine korrekte Datenübertragung

err für eine gescheiterte Datenübertragung

Schalten Sie in diesem Fall das Gerät kurz stromlos, um den Vorgang zu

wiederholen. Wenn Sie den Vorgang abbrechen möchten, entfernen Sie

einfach den HOT-KEY.

UPLOAD (REGELGERÄT HOT-KEY)

Schreiben der aktuellen Parametervorgaben des Regelgeräts in den HOTKEY:

Stecken Sie den HOT-KEY in die vorgesehene Position, wenn der Regler

wieder eingeschaltet ist.

Betätigen Sie 1x mit . In der Anzeige steht die Meldung uPL.

Betätigen Sie die SET1-Taste, um die Datenübertragung zu starten. uPL

beginnt zu blinken.

Sie können den HOT-KEY nach etwa 10 sec wieder entfernen.

Am Ende der Datenübertragung sind folgende Meldungen möglich:

end für eine korrekte Datenübertragung

err für eine gescheiterte Datenübertragung

In diesem Fall nochmals die SET-Taste betätigen, um den Vorgang zu

wiederholen. Wenn Sie den Vorgang abbrechen möchten, entfernen Sie den

HOT-KEY.

40 - 0911

Page 43

6 WERKSEINSTELLUNG

1

PA

Beschreibung Bereich Vorgabe PE

SET1 Sollwert 1 LS1 + US1 0 Pr1

SET2 Sollwert 2 LS2 + US2 1 Pr1

HY1 Schalthysterese 1 Abhängig vom Messbereich -1 Pr1

HY2 Schalthysterese 2 Abhängig vom Messbereich -1 Pr1

LS1 Kleinster Sollwert 1 Unterer Messbereich + SET1 min Pr2

LS2 Kleinster Sollwert 2 Unterer Messbereich + SET2 min Pr2

US1 Größter Sollwert 1 Oberer Messbereich + SET1 max Pr2

US2 Größter Sollwert 2 Oberer Messbereich + SET2 max Pr2

S1C Regelwirkung Ausgang 1 in = invers; dir = direkt in Pr2

S2C Regelwirkung Ausgang 2 in = invers; dir = direkt in Pr2

ouc

Ac

on

Abhängigkeit der

Verzögerungszeit der

Mindesteinschaltdauer

eines Relais

Sollwerte

Relais

ind = unabhängig;

diP = abhängig

ind

0...250 sec 0 Pr2

0...250 sec 0 Pr2

Mindestwartezeit

zwischen zwei aufein-

ono

ander folgenden Akti-

0...120 min 0 Pr2

vierungen der selben

Last

Alarmgrenzen sind

ALC

absolute Werte oder

rE = relativ; Ab = absolut rE Pr2

Sollwertbezogen

ALL

ALU

ALH

ALd

dAO

1

Parameter

2

Programmierebene

Untere Alarmgrenze

(ALC = rE; ALC = Ab)

Obere Alarmgrenze

(ALC = rE; ALC = Ab)

Schalthysterese für

Temperaturalarme

Alarmverzögerungszeit

während des Betriebes

Alarmverzögerungszeit

nach Inbetriebnahme

Abhängig vom Messbereich 10 Pr2

Abhängig vom Messbereich 10 Pr2

Abhängig vom Messbereich 2 Pr2

0...999 min 15 Pr2

0...23,5 h 1,3 Pr2

2

deutsch

0911 - 41

Page 44

deutsch

1

PA

So1

So2

Beschreibung Bereich Vorgabe PE

Ausgang 1 bei

Fühlerfehler

Ausgang 2 bei

Fühlerfehler

oFF = offen; on = geschlossen oFF Pr2

oFF = offen; on = geschlossen oFF Pr2

tbA Alarm-Relais quittierbar no; yES yES Pr2

AS

LCI

UCI

Polarität des Alarm-

Unterer analoger

3

3

Anzeigewert

Oberer analoger

Anzeigewert

Relais

CL...oP oP Pr2

Abhängig von Fühler var. Pr1

Abhängig von Fühler var. Pr1

Opb Fühlerkalibrierung Abhängig vom Messbereich 0 Pr1

rES Auflösung in = NO; dE = 0,1; cE = 0,01 in Pr2

Typ TU: °C = °C, °F = °F;

UdM Maßeinheit

Typ AU: 0 = °C, 1 = °F;

2 = RH, 3 = bar, 4 = PS,

var. Pr1

5 = ohne Anzeige

Pt = Pt100; J = tcJ; c = tck;

PbC Fühlerart

S = tcS; Ptc = PTC;

ntc = NTC; 0.1 = 0...1 V;

var. Pr1

10 = 0...10 V; cur = 0...20 mA

P3F PT100; 3 Leiter no = nein; yES = ja no Pr2

i1F

i1P

did

Adr

OnF

Konfiguration des

digitalen Eingangs

Polarität des digitalen

Alarmverzögerung des

digitalen Eingangs

Serielle Adresse für

Standby-Funktion

Eingangs

XJ500

aktivieren

c-H / oFF / Aus / HES /

EAL / bAL

cL = geschlossen;

oP = geöffnet

EAL Pr2

cL Pr2

0...120 min 0Pr2

RS485 Adresse 1 Pr2

no = nein; oFF = Aktiv no Pr2

Ptb Parametertabelle Lesewert - Pr2

rEL Software-Version Lesewert - Pr2

Pr2 Parameterzugang zu Pr2 Lesewert 321 Pr1

1

Parameter

2

Programmierebene

3

Nur bei Geräten mit Strom- oder Spannungseingang

2

42 - 0911

Page 45

7 WARTUNG

Der Regler 0911 ist bei Betrieb entsprechend den in dieser Anleitung gegebenen Hinweisen wartungsfrei.

8 INSTANDHALTUNG

8.1 Störungen

FEHLERMELDUNGEN

Meldung Ursache Wirkung

PFo

PFc Fühlerkurzschluss

HA Hochtemperatur-Alarm

LA Tieftemperatur-Alarm

EAL Digitaler Eingangsalarm Ausgänge bleiben unberührt

BAL

STATUS DES ALARM-RELAIS

Fühler defekt oder nicht

angeschlossen

Ernsthafter digitaler

Alarm

Alarm-Relais EIN; Regelrelais

gemäß So1

Alarm-Relais EIN; Regelrelais

gemäß So1

Alarm-Relais EIN; Ausgänge

bleiben unberührt

Alarm-Relais EIN; Ausgänge

bleiben unberüht

Alle Regel-Ausgänge deaktiviert

deutsch

Gerätestatus AS = CL AS = OP

Gerät stromlos 5 - 6 geschlossen 5 - 6 geschlossen

Normalbetrieb 5 - 6 geschlossen 5 - 6 geöffnet

Alarmsituation während des

Betriebes

5 - 6 geöffnet 5 - 6 geschlossen

0911 - 43

Page 46

FEHLER QUITTIEREN ÜBER DIE TASTATUR

Betätigen Sie eine beliebige Taste.

Die Alarm-Meldung bleibt in der Anzeige, solange die Alarmbedingungen

bestehen. Danach geht das Gerät in den Normalbetrieb über.

AUTOMATISCHES QUITTIEREN DES FEHLERS

deutsch

• Meldung

Nach ca. 30 sec bzw. nach Beseitigung der Fehler-Ursache wird die

Meldung automatisch quittiert. Vor eventuellem Fühleraustausch die

Anschlüsse überprüfen.

• Meldungen HA/LA

Die Meldungen erlöschen automatisch, sobald wieder der Normal-

temperaturbereich erreicht wurde oder wenn eine Abtauung startet.

• Externe Alarme EAL und BAL sind nach Deaktivierung des digitalen

Eingangs quittiert.

PFo und PFc -

-

Hoch-/Tieftemperatur-Alarm

Fehler Raum-Fühler

8.2 Bestelltabelle Grundgerät/Zubehör

Artikel Eingänge Best.-Nr

3-Punkt-Regler 0911 12-24 V AC/DC PTC/NTC; Pt100, Typ J, K, S 788 267

3-Punkt-Regler 0911 12-24 V AC/DC 4-20 mA; 0-10 V; 0-1 V 788 268

3-Punkt-Regler 0911 230 V AC PTC/NTC; Pt100, Typ J, K, S 788 269

3-Punkt-Regler 0911 230 V AC 4-20 mA; 0-10 V; 0-1 V 788 270

PTC-Fühler

mit 1,5 m Kabel, Einbauhülse

L = 62 mm D = 6 mm

Schutzabdeckung 787 937

Trafo 230 V / 24 V 3 VA 787 938

781 969

44 - 0911

Page 47

3 RÉGULATEUR PONCTUEL

TYPE 0911

1 REMARQUES GÉNÉRALES

1.1 Symboles de reprèsentation ............................................................................................................46

1.2 Consignes de sécurité ........................................................................................................................ 46

1.3 Fourniture ...................................................................................................................................................47

1.4 Clauses de garantie .............................................................................................................................. 47

2 DESCRIPTION DU SYSTÈME

2.1 Description générale ............................................................................................................................ 48

2.2 Commande ................................................................................................................................................ 48

2.3 Avant l’installation ................................................................................................................................... 51

2.4 Régulation ................................................................................................................................................... 52

2.5 Paramètres ................................................................................................................................................ 54

2.6 Régulation des charges .....................................................................................................................57

3 CARACTÉRISTIQUES TECHNIQUES

4 MONTAGE, INSTALLATION ET MISE EN SERVICE

4.1 Remarques générales sur l’installation et le service .......................................................... 59

4.2 Montage ....................................................................................................................................................... 59

4.3 Branchements électriques ................................................................................................................60

5 FONCTION HOT-KEY

..............................................................................................................

............................................................................................................

..........................................................................................

...........................................................

............................................................................................................................

46

48

58

59

62

français

6 RÉGLAGE USINE

7 ENTRETIEN

8 MAINTENANCE

8.1 Pannes .........................................................................................................................................................65

8.2 Table de commande appareil de base/accessoires ........................................................... 66

......................................................................................................................................

...................................................................................................................................................

..........................................................................................................................................

0911 - 45

63

65

65

Page 48

1 REMARQUES GÉNÉRALES

1.1 Symboles de représentation

Les symboles de représentation suivants sont utilisés dans ces instructions

de service:

marque une étape de travail à exécuter.

ATTENTION!

marque des instructions dont l’inobservation risque de porter

atteinte à votre santé et à la fonctionnalité de l’appareil.

REMARQUE

1.2 Consignes de sécurité

Veuillez tenir compte des remarques de ces instructions de service de même

que des conditions d’emploi et des données tolérées spécifiées dans la fiche

technique du régulateur 0911 afin que l’appareil fonctionne parfaitement et

reste longtemps en service.

français

• Tenez vous-en lors de la planification de l’emploi et du service de l’appareil

aux règles générales de la technique!

• Les travaux d’installation et d’entretien ne doivent être exécutés que par un

personnel qualifié muni de l’outillage approprié.

• Tenir compte des prescriptions de prévention des accidents et de sécurité

concernant les appareils électriques pendant le service et l’entretien de

l’appareil!

• Veiller à ce que l’appareil soit utilisé de manière conforme à sa destination.

• Toujours utiliser l’appareil avec son boîtier.

• Vérifier avant de brancher l’appareil si la tension d’alimentation correspond

à celle figurant sur la plaque signalétique

• Vérifier que le branchement est correct avant d’enclencher l’appareil.

• Tenir compte de la charge maximale des contacts du relais (voir

Caractéristiques techniques).

• Veiller à ce que tous les capteurs soient installés à une distance suffisante

des lignes conductrices de tension. Ainsi seront évitées des mesures

erronées de température et l’appareil sera protégé de perturbations de

tension provenant des entrées de capteur.

• Brancher les circuits RC en parallèle (FT1) lors d’applications en milieu

industriel dans un environnement critique.

• Toujours couper la tension avant d’intervenir dans le système!

• Prendre les mesures appropriées pour exclure toute commande

involontaire ou préjudice inadmissible!

marque des informations importantes additionnelles,

des conseils et des recommandations.

46 - 0911

Page 49

• Tenir compte des conditions ambiantes prescrites concernant les limites

d’humidité et de température Si ces conditions ne sont pas observées, des

dysfonctionnements ne sont pas exclus.

• En cas de dysfonctionnement ou de doute, s’adresser au centre de

distribution Bürkert compétent.

Nous déclinons toute responsabilité en cas d’inobservation de ces instructions

et d’interventions non autorisées dans l’appareil. Tout droit à la garantie est

également annulé sur les appareils et les accessoires!

1.3 Fourniture

S’assurer immédiatement après réception de la fourniture si le contenu est

conforme à ce qui a été indiqué. Font partie de celle-ci:

• le régulateur type 0911

• des instructions de service (évent. sur support de données)

• un joint frontal

• 2 Etrier de fixation

En cas de litiges, veuillez vous adresser sans délai à notre centre client:

Bürkert Steuer- und Regelungstechnik

Service-Abteilung

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tél. : 07940-10111

ou à votre centre de distribution Bürkert.

français

1.4 Clauses de garantie

Bürkert accorde sur le fonctionnement correct du régulateur une garantie d’un

an à condition que l’appareil soit utilisé conformément à sa destination et en

tenant compte des conditions spécifiques d’emploi.

En cas de défaut de fonctionnement de l’appareil pendant la période de

garantie, il sera réparé ou échangé gratuitement.

ATTENTION!

La prestation de garantie ne couvre que le régulateur et ses

composants, mais pas les dégâts consécutifs de nature

quelconque susceptibles de survenir à la suite d’un dysfonctionnement ou d’une panne.

0911 - 47

Page 50

2 DESCRIPTION DU SYSTÈME

2.1 Description générale

Régulateur par plus ou moins ou de zone neutre, 74 x 32 mm, avec action de

régulation définissable (p.ex. chauffer/refroidir ou humidifier/déshumidifier)

Les versions suivantes sont disponibles:

Type Entrée configurable Paramètre UDM (définir

TU

Thermorégulateur

AU

Dispositif de

régulation avec

entrée

courant/tension

2.2 Maniement

français

LED

de sortie

LED

d’alarme

PTC, NTC, Pt100

Thermoéléments J, K, S

4 ... 20 mA

0 ... 1 V

0 ... 10 V

LED1

LED 2

unité d'affichage)

UDM = °C

UDM = °F

0 = °C; 1 = °F

2 = % RH

3 = bars

4 = PSI

5 = sans unité de mesure

vers le

haut

vers le

bas

Touche

SET

TOUCHES

SET1 Affichage de la valeur de consigne 1

SET2 Affichage de la valeur de consigne 2

48 - 0911

Changer et valider une donnée allouée pendant la phase de

programmation

Page 51

COMBINAISON DE TOUCHES

+

Verrouiller et déverrouiller le clavier

SET1+ Sélectionner le niveau de programmation

SET1+ Retour à l’affichage de la température ambiante

MESSAGES LED

LED Mode Signification

allumée Sortie 1 active

allumée Sortie 2 active

LED1 clignote Niveau de programmation (clignote avec LED2)

LED2 clignote Niveau de programmation (clignote avec LED1)

E.S. allumée

Alarme

LED

COMMUTER L’APPAREIL MARCHE/ARRÊT

allumée

Mode énergie (deuxième valeur de consigne) a

été activé par entrée numérique.

- Signalisation d'un état d'alarme

- Si l'on se trouve au niveau de programmation

plus pas "Pr2", seulement accessible par

mot de passe. La LED d'alarme en s'allumant

signale que le paramètre affiché est également

accessible au premir niveau "Pr1" (sans mot de

passe).

français

Maintenir la touche SET1 pendant au moins 4 sec

enfonçée (seulement avec paramètre OnF = yes).

AFFICHER VALEUR DE CONSIGNE

Presser une fois brièvement la touche SET. La

valeur de consigne apparaît sur l’afficheur.

Presser encore une fois brièvement la touche SET

ou attendre 5 sec. pour faire afficher la température.

0911 - 49

Page 52

MODIFIER VALEUR DE CONSIGNE 1 / VALEUR DE CONSIGNE 2

Maintenir une touche SET 2 s. enfoncée.

Modifier la valeur de consigne dans les 10 s avec

les touches ou .

Vous mémorisez la nouvelle valeur de consigne en

pressant brièvement la touche SET ou attendre

10 s.

ACCÉDER AU NIVEAU DE PROGRAMMATION

Maintenir les touches SET + au moins 3 s

enfoncées

Sélectionner avec Pr2 et valider ensuite avec la

touche SET1.

Définiri le mot de passe 321 et valider ensuite avec

la touche SET1.

Définir la „3“, puis 1 x la touche SET1

définir la „2“ , puis 1 x la touche SET1

définir la „1“ , puis 1 x la touche SET1

Vous vous trouvez dans la liste des paramètres.

français

NIVEAU UTILISATEUR PR1

NIVEAU DE SERVICE PR2 (MOT DE PASSE 321)

AJOUTER / ENLEVER DES PARAMÈTRES AU NIVEAU UTILISATEUR PR1

50 - 0911

Presser les touches SET1 + pendant 3 sec.

PR1 contient tous les paramètres accessibles à

l’utilisateur. L’appareil indique le premier paramètre

disponible au niveau de l’utilisateur.

Voir:

accéder au niveau de programmation.

Accéder au niveau de programmation

L’état peut être changé avec les touches SET1 + .