Page 1

Electromagnetic Flow Meter

PROFIBUS DP

MODULE

DATA LINK DESCRIPTION

ProfibusDP_ emanual_BUR_04.doc

Page 2

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

2/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

INDEX

1.1 CHARACTERISTICS OF THE MODULES _______________________________________________ 3

1.2. PROFIBUS IDENT NUMBER ________________________________________________________ 4

1.3. SLAVE PARAMETERIZATION _______________________________________________________ 4

1.4. SLAVE CONFIGURATION __________________________________________________________ 5

1.5. SLAVE DIAGNOSTIC AND ALARMS_________________________________________________ 10

1.6. SETTING THE SLAVE ADDRESS ____________________________________________________ 12

1.7. BAUDRATES ____________________________________________________________________ 12

1.8. GSD FILE _______________________________________________________________________ 12

1.9. TERMINALS DESIGNATION AND CABLE CONNECTION _______________________________ 12

2. CYCLIC DATA EXCHANGE___________________________________________________________ 13

2.1. FIRST CONFIGURATION: 8 BYTE INPUT____________________________________________ 13

2.2. DATA TYPE _____________________________________________________________________ 14

2.3. SECOND CONFIGURATION: 16 BYTE INPUT_________________________________________ 14

2.4. DATA TYPE _____________________________________________________________________ 15

2.5. THIRD CONFIGURATION: 24 BYTE INPUT __________________________________________ 16

2.6. DATA TYPE _____________________________________________________________________ 17

2.7. FOURTH CONFIGURATION: 16 BYTE INPUT/OUTPUT ________________________________ 17

2.8. FIFTH CONFIGURATION: 24 BYTE INPUT/OUTPUT __________________________________ 28

3.1 DPV1 ACYCLIC DATA EXCHANGE___________________________________________________ 42

3.2 Acyclic Read Data from the Flow Meter _____________________________________________ 42

4.1 PROGRAMMING ALGORITHMS_____________________________________________________ 50

4.2 NUMERICAL CONVERSION OF THE DATA RECEIVED __________________________________ 50

4.3 DATE CONVERSION FROM TOTAL MINUTES TO DAY/MONTH/YEAR HOURS:MINUTES ____ 51

4.4 DATE CONVERSION FROM DAY/MONTH/YEAR HOURS:MINUTES TO TOTAL MINUTES ____ 52

2

Page 3

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

3/52

File name

ProfibusDP_emanual_Burkert_04.doc

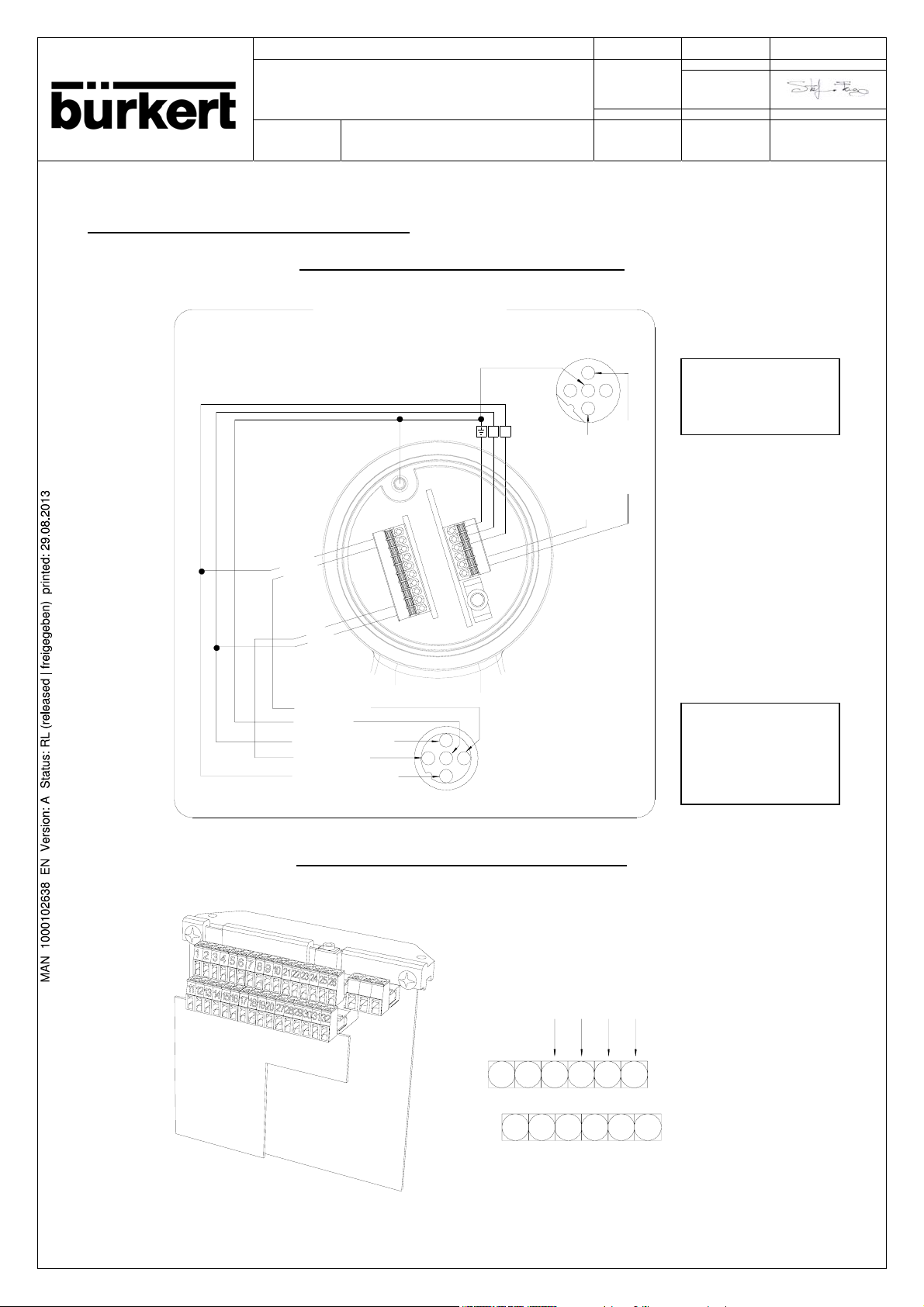

1.1 CHARACTERISTICS OF THE MODULES

ME 35 ( profibus DP for SE 56 converter )

ELECTRICAL CONNECTIONS

1

7

1

8

1

1

T

U

O

+

1

T

U

O

-

1

N

I

+

1

N

I

-

9

2

0

2

1

2

2

2

3

2

4

2

5

Black to 18 ( OUT )

Grey to ground

Cian to power supply " - "

White to 25 ( + IN )

Brown to power supply " + "

ME 100 ( profibus DP for SE 56 converter )

2

6

MAIN POWER

23415

3

52

1

-

+

1

4

1

5

1

6

Green "A" Profibus

TERMINAL "A"

TERMINAL "B"

21 22 23 24 25 26

27 28 29 30 31 32

19/03/08 19/03/08 19/03/08

PROFIBUS

4

Red "B" Profibus

LUMBERG Model

0976 pmc 151

P.S./IN/OUT

Phoenix Model

SACC-ECM12FSB-5CONM16/0,5

TERMINAL "A"

TERMINAL "B"

3

Page 4

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

4/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

The Profibus-DP module mounted in the Electromagnetic Flow Meter is used for to connect the converter of

the Flow meter to the Profibus DP fieldbus in accordance with the DIN 19245 Standard as a passive

instrument (slave).

When this option is installed it is possible to read the process data from the Flow meter.

The process data consists of Dynamic Data and Static Data.

With the keyword Dynamic Data it is indicated measurement values which are continuously changing e.g.

Flow rate, Totalizers, etc..

With the keyword Static Data it is indicated parameters value of the Flow meter which do not change

during operation for example unit Flow rate, unit Totalizers etc. and other parameters that can be

individually written to using the Acyclic Service or an offset to INDEX Output (see Fourth Configuration

with 16 byte Input/Output or Fifth Configuration with 24 byte Input/Output).

The software of the slave module implement the DP standard/DPV1 functionality for the communication of

the slave with a Class 1 (parameterization Master) and a Class 2 Master.

With the data exchange with the Acyclic Service and with the Slot and Acyclic Index it is possible to

send and return configuration parameters of the Flow meter with a Class 1 or Class 2 Master.

For the communication with a Class C1 Master the Slot is ignored.

Only Slot 0 is used for the service of acyclic data exchange for the communication with a Class 2 master.

The module support four type of configurations with is possible sets the better combination of type of

information of the Flow meter.

It is possible select a configuration with only 8 byte or 16 or 24 byte Input and insert or return Static Data

with the Acyclic Service and Class 1 or Class 2 Master.

If the Master doesn't support Acyclic Service it is possible select the fourth configuration with 16 byte

Input/Output or the fifth configuration with 24 byte Input/Output. With these last configuration and

with two bytes, with the function of indexes, and the Output data, it is possible to insert or return Sta t ic

Data in the Flow meter.

With the Acyclic Service and with the Slot and Acyclic Index it is possible to read the data stored in the

Internal Data Logger of the Fow Meter.

The Profibus address of the instrument can be set with the converter keypad in the menu Comunication.

Baudrates range supported are from 9.6 kBaud up to 12 MBaud.

The slave module support the Diagnostic and Process Alarms for monitoring Flow rate with four thresholds.

NOTE: After the power supply of the Flow meter is switch on, there is an interval time of 5 seconds during

that the slave module remain in a Reset Phase necessary for the initialization of the Flow meter.

The reading of the data stored in the Internal Data Logger and the settings for the thresholds of the Flow

rate Control are possible only with the Acyclic Service and with the Slot and

Acyclic Index.

1.2. PROFIBUS IDENT NUMBER

The Profibus Identification Number is 0008hex ( 8dec ).

1.3. SLAVE PARAMETERIZATION

The parameters specified in this respect reach the slave via the parameterization message of the

parameterization Master.

The parameterization data consists of the following:

- DP standard parameters with a length of 7 bytes according to EN 50170

- DPV1 status bytes with a length of 3 bytes according to extensions of EN 50170 which immediately follow

the specified DP standard parameters

4

Page 5

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

5/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

- Optional user parameterization data that immediately follow the DPV1 status bytes ( not implemented for

the this slave module ).

Default Parameterization:

Default parameterization makes it possible for old DP standard masters to exchange data with the DPV1

slave despite missing DPV1 status bytes.

The parameterization message is 7 bytes long and in this case, the slave will use a set of default values for

the missing DPV1 status bytes.

SETTINGS OF THE STATION PARAMETER:

DP Interrupt Mode DPV0

DPV1 Interrupts:

Update Interrupt (OB56) No

Diagnostic Interrupt(OB82) No

Hardware Interrupt(OB40 to OB 47) No

General DP Parameters:

Fail Safe Yes

Startup when expected/actual config diff. No

Device-Specific Parameters:

DPV1 Mode Enabled

Process Alarm Disabled

Diagnostic Alarm Disabled

Update Alarm Disabled

Alarm Type Type mode (Slave is operated alarm type mode: only one alarm of the same type is to be active

at the same time)

Hex Parameter Assignment:

DPV1_Status (0 to 2) E4,00,00

1.4. SLAVE CONFIGURATION

The Configuration possibilities are specified for the Slave module in the device description file (GSD).

Only a single Configuration is available.

The module support four type of configurations with is possible sets the better combination of types of

informations of the Flow meter.

The First type of Configuration consist of 8 byte Input

With this type of configuration is possible exchange with few byte ( only 8 ), the main data of the Flow

meter.

With the setting of a control byte, in the configuration string of the file GSD,it is possible to set the Data

Type of information returned by Input data.

The control byte is the third byte of the Configuration string (see below).

It is also possible to change the Data Type with a Class 1 and Class 2 Master and the relative Slot and

Acyclic Index, during data exchange.

For details Acyclic Service see the relative section in this document.

The reference to the Configuration string in the GSD file is:

-----------------------------------------------------------Module = "8 Byte Input" 0x41,0x07,0x00

1

EndModule-----------------------------------------------------------The settings in the GSD file for to use this configuration is:

5

Page 6

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

6/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

----------------------------------------SlotDefinition

Slot(1) = "Process Data" 1

EndSlotDefinition

-----------------------------------------

The Configuration correspond to 8 bytes Input and the last byte indicate the Data Type selected .

Modifing the last byte in the GSD file it is possible to set the type of the Flow rate:

With the Configuration 0x41,0x0F,0x00 the Flow rate is in % ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

Data Type = 0 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 8 byte )

With the Configuration 0x41,0x0F,0x01 the Flow rate is in tecnical unit ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 8 byte )

With the Configuration 0x41,0x0F,0x02 totalizers positive ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 8 byte )

With the Configuration 0x41,0x0F,0x03 partial totalizers positive ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 8 byte )

With the Configuration 0x41,0x0F,0x04 totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 8 byte )

With the Configuration 0x41,0x0F,0x05 partial totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 8 byte )

6

Page 7

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

7/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

The Second type of Configuration consist of 16 byte Input

With this type of Configuration it is possible exchange with only 16 the same data of the precedent

Configuration and in addition there are the values of the Totalizers positive or negative.

With the setting of a control byte, in the configuration string of the file GSD,it is possible to set the Data

Type of information returned by Input data.

The control byte is the third byte of the Configuration string (see below).

It is also possible to change the Data Type with a Class 1 and Class 2 Master and the relative Acyclic Slot

and Acyclic Index, during data exchange.

For details Acyclic Service see the relative section in this document.

The reference to the Configuration string in the GSD file is:

-----------------------------------------------------------Module = "16 Byte Input" 0x41,0x0F,0x00

2

EndModule

------------------------------------------------------------

The settings in the GSD file for to use this Configuration is:

----------------------------------------SlotDefinition

Slot(1) = "Process Data" 2

EndSlotDefinition

-----------------------------------------

The Configuration correspond to 16 bytes Input and the last byte indicate the Data Type selected .

Modifing the last byte in the GSD file it is possible to set the type of the Flow rate and the type of

Totalizers:

With the Configuration 0x41,0x0F,0x00 the Flow rate is in % ( 4 byte )

totalizers positive ( 4 byte )

partial totalizers positive ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 0 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 16 byte )

With the Configuration 0x41,0x0F,0x01 the Flow rate is in % ( 4 byte )

totalizers negative ( 4 byte )

partial totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 16 byte )

Whit the Configuration 0x41,0x0F,0x02 the Flow rate is in tecnical unit ( 4 byte )

totalizers positive ( 4 byte )

partial totalizers positive ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

7

Page 8

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

8/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

the Data Type = 2 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 16 byte )

Whit the Configuration 0x41,0x0F,0x03 the Flow rate is in tecnical unit ( 4 byte )

totalizers negative ( 4 byte )

partial totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 3 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 16 byte )

Whit the Configuration 0x41,0x0F,0x04 the Flow rate is in % ( 4 byte )

totalizers positive ( 4 byte )

totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 3 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 16 byte )

Whit the Configuration 0x41,0x0F,0x05 the Flow rate is in tecnical unit ( 4 byte )

totalizers positive ( 4 byte )

totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 3 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 16 byte )

The third type of Configuration consist of 24 byte Input

This configuration is used when there is necessary to exchange the information about totalizers positive and

negative at the same time.

The difference with the precedent configurations is the presence of the totalizers positive and negative

contemporary in the block of data exchanged

With the setting of a control byte, in the configuration string of the file GSD,it is possible to set the Data

Type of information returned by Input data.

The control byte is the third byte of the Configuration string (see below).

It is also possible to change the Data Type with a Class 1 and Class 2 Master and the relative Acyclic Slot

and Acyclic Index, during data exchange.

For details Acyclic Service see the relative section in this document.

The reference to the Configuration string in the GSD file is:

-----------------------------------------------------------Module = "24 Byte Input" 0x41,0x17,0x00

3

EndModule

-----------------------------------------------------------The settings in the GSD file for to use this configuration is:

----------------------------------------SlotDefinition

8

Page 9

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

9/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

Slot(1) = "Process Data" 3

EndSlotDefinition

-----------------------------------------

The Configuration correspond to 24 bytes Input and the last byte indicate the Data Type selected .

Changing the last byte in the GSD file it is possible to set the type of the Flow rate:

With the Configuration 0x41,0x0F,0x00 the Flow rate is in % ( 4 byte )

totalizers positive ( 4 byte )

partial totalizers positive ( 4 byte )

totalizers negative ( 4 byte )

partial totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 0 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 24 byte )

With the Configuration 0x41,0x0F,0x01 the Flow rate is in technical unit ( 4 byte )

totalizers positive ( 4 byte )

partial totalizers positive ( 4 byte )

totalizers negative ( 4 byte )

partial totalizers negative ( 4 byte )

process flags ( 2 byte )

dynamic variations ( 1 byte )

the Data Type = 1 ( 1 byte )

-----------------------------------------------------------

Number of Input byte exchanged ( 24 byte )

The fourth type of configuration consist of 16 byte Input/Output

With this type of configuration is possible to insert or return data from the Flow meter with two indexes

exchanged with the 16 byte Output data.

With the 16 byte Output data it is possible to insert other parameters of the Flow meter in the same way

used with the Acyclic Service and Class 1 and Class 2 Master.

The reference to the Configuration string in the GSD file is:

-----------------------------------------------------------------------Module = "16 Byte Input/Output" 0xC0,0x0F,0x0F

4

EndModule

-----------------------------------------------------------------------The settings in the GSD file for to use this configuration is:

-------------------------------------SlotDefinition

Slot(1) = "Process Data" 4

EndSlotDefinition

--------------------------------------

The Configuration correspond to 16 bytes Input/Output.

For details about the type of the data see the Section 2 Cyclic Service below in this document.

The fifth type of configuration consist of 24 byte Input/Output

With this type of configuration is possible to insert or return data from the Flow meter with two indexes

9

Page 10

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

10/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

exchanged with the 24 byte Output data.

With the 24 byte Output data it is possible to insert other parameters of the Flow meter in the same way

used with the Acyclic Service and Class 1 and Class 2 Master.

The reference to the Configuration string in the GSD file is:

-----------------------------------------------------------------------Module = "24 Byte Input/Output" 0xC0,0x17,0x17

5

EndModule

------------------------------------------------------------------------

The settings in the GSD file for to use this configuration is:

-------------------------------------SlotDefinition

Slot(1) = "Process Data" 5

EndSlotDefinition

--------------------------------------

The Configuration correspond to 24 bytes Input/Output.

For details about the type of the data see the Section 2 Cyclic Service below in this document.

NOTE: Any other configuration will not be accepted.

1.5. SLAVE DIAGNOSTIC AND ALARMS

The module support the Diagnostic and Process Alarms for monitoring Flow rate with four thresholds.

With the Acyclic Service and a Class 1 or Class 2 Master and the relative Acyclic Slot and Acyclic Index

it is possible insert four thresholds for monitoring the Flow rate.

The thresholds are:

Flow rate High Alarm

Flow rate High Warning

Flow rate Low Warning

Flow rate Low Alarm

The control is implemented for the Flow rate in technical unit only.

After the insertion of the four thresholds of the Flow rate in technical unit, with the Acyclic Service and

the relative Acyclic Slot and Acyclic Index, it is necessary to enable the control of the Flow rate.

With the Acyclic Service and the relative Acyclic Slot and Acyclic Index it is possible to enable the

control of the Flow rate and if the value of the Flow rate measured by the Flow meter, exceed one of the

thresholds, a diagnostic message in sended to the master.

With the Acyclic Service and the realtive Acyclic Slot and Acyclic Index it is possible to enable the DPV1

Process Alarms for the masters that support this information.

The Process Alarms are set when the value of the Flow rate measured by the Flow meter exceed one of the

two thresholds High Alarm or Low Alarm.

Diagnostic message in details:

The standard diagnostic consists of 6 bytes and in addition, the alarm mechanism with extensions is used.

10

Page 11

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

11/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

Structure of the Standard Diagnostic:

byte 0: station_status_1

byte 1: station_status_2

byte 2: station_status_3

byte 3: master_adress

byte 4: pno_ident_number_high

byte 5: pno_ident_number_low

The implemented diagnostic concept supports the Device-related diagnostic (primarily status messages)

According to the diagnostic message of the DPV1 slave consists of the following:

byte 6: sing_len

byte 7: alarm_type

byte 8: slot_number

byte 9: specifier

byte 10: alarm_data

byte 11: 0x00

Details of the information in the byte alarm_data:

alarm_data = 0x00 --> Flow rate Normal

alarm_data = 0x01 --> Flow rate High Alarm

alarm_data = 0x02 --> Flow rate High Warning

alarm_data = 0x03 --> Flow rate Low Warning

alarm_data = 0x04 --> Flow rate Low Alarm

Max Flow Rate value

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

//////////////// alarm_data = 0x01 ////////////////

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

High Alarm Threshold value

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

//////////////// alarm_data = 0x02 ////////////////

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

High Warning Threshold value

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

//////////////// alarm_data = 0x00 ////////////////

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

Low Warning Threshold value

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

//////////////// alarm_data = 0x03 ////////////////

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

Low Alarm Threshold value

//////////////////////////////////////////////////////////////////////

11

Page 12

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

12/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

//////////////////////////////////////////////////////////////////////

//////////////// alarm_data = 0x04 ////////////////

//////////////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////////////

Min Flow Rate value

1.6. SETTING THE SLAVE ADDRESS

The Profibus address of the slave can be set with the converter keypad and the menu

7 - Communication --> Address

For the changing of address it’s not necessary to switch off the Flow meter by removing the power supply,

because the module detect when the address is changed it set the function Autoreset.

After the time of 5 seconds the slave module return in data exchange with the new address.

NOTE: For reasons of compatibility the menu Address of the Profibus is the same used for inserting the

address of the RS-485 communication channel of the Flow meter that can accept values in the range 000255, but the valid range for the Profibus Address is only 001, 002…126.

NOTE: The menu Communication is visible in the screen of the Flow meter only if the parameter RS 485 is

set ON in the menu 11-Internal Data.

1.7. BAUDRATES

The Baudrates supported are:

9.6 kBaud

19.2 kBaud

31.25 kBaud

45.45 kBaud

93.75 kBaud

187.5 kBaud

500 kBaud

1.5 MBaud

3 MBaud

6 MBaud

12 MBaud

The baudrate is automatically recognized by the slave module.

1.8. GSD FILE

The name of the GSD file is ME10034.GSD is included on the shipment packaging .

1.9. TERMINALS DESIGNATION AND CABLE CONNECTION

For the connection of the Profibus cable to the Flow meter see the section 1.1 Characteristics of the module.

Cable specification:

All cables used must meet the following parameters according to the PROFIBUS specification for copper

signal cable data wires.

12

Page 13

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

13/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

The connectors must allow these connections.

Parameter DP, Cable type A

Surge impedance in Ω 135...165 for a frequency of 3...20 MHz

Effective capacitance (pF/m) ≤ 30

Loop resistance ( Ω/km) ≤ 110

Core design (solid) AWG 22/1

Core design (flexible) > 0,32 mm²

The table shows the cable parameters for PROFIBUS copper signal cables with RS-485 transmission

standard.

2. CYCLIC DATA EXCHANGE

With the Cyclic Service of data exchange the slave return Dynamic Data that include measurement

values which are continuously changing e.g. Flow rate, totalizers, etc..

The module support five type of configurations with is possible sets the better combination of type of

information of the Flow meter.

The type of Configuration is set in the file GSD.

Below there are the description of the possible types of configuration with the realtive structure of data:

2.1. FIRST CONFIGURATION: 8 BYTE INPUT

Below there is a description of the contents of each byte:

bytes 0-3:

(32 bit single precision IEEE floating point, MSB first) Flow rate in % or Flow rate in t.u. or

(32 bit long integer, MSB first) totalizer for TOTAL or PARTIAL volume + or - or batch quantity

(see section 2.2 Data Type)

bytes 4-5: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

byte 6: (8 bits integer) measurement dynamic variation as a %

byte 7: (8 bits integer) Data Type ( see section 2.2 Data Type )

NOTE: The values in the “32 bits single precision IEEE floating point” format are floating point numbers

which can be represented during writing by any decimal digits. To keep the same numerical format visible

13

Page 14

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

14/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

on the instrument display however, it is necessary to calculate the decimal figures with a rather complex

algorithm which takes account of instrument precision, flow rate measurement unit, etc. For this purpose

and to avoid useless calculations, the number of decimals to use to represent the flow rate values is supplied

separately. With the acyclic service it is possible to return the value ( see Acyclic Index Read = 20(dec)

Static Process Data of the Flow Meter byte position 13).

NOTE:The counters are expressed with a 32 bit integer. The «counter decimal figures» parameter, indicates

the point position starting from the right: 0 = no decimal, 1=1 decimal figure, and so on. ( see Acyclic

Index Read = 20(dec) Static Process Data of the Flow Meter byte position 12)

2.2. DATA TYPE

The firsts four byte of the Dynamic Data Block are the information about the Flow rate or Totalizers.

With the Control byte of the Configuration in the GSD file (see the Section Slave Configuration) it is

possible to set the type of the Flow rate returned by the slave or the type of the Totalizers.

The type of the Flow rate may be in % or in technical unit in base of the value of the Control byte inserted

in the Configuration string.

The byte 7 indicate the current type of Flow rate selected or the type of the totalizers:

byte 7 = 0 --> Flow rate in %

byte 7 = 1 --> Flow rate in technical unit

byte 7 = 2 --> totalizers positive or batch quantity ( batch quantity only for ML M3F )

byte 7 = 3 --> partial totalizers positive or batch counter ( batch counter only for ML M3F )

byte 7 = 4 --> totalizers negative or batch quantity ( data valid only for ML 210 )

byte 7 = 5 --> partial totalizers negative or batch counter ( data valid only for ML 210 )

There is a second way to set the type of the Flow rate using the Acyclic Service during data exchange (see

section Acyclic Service).

2.3. SECOND CONFIGURATION: 16 BYTE INPUT

Below there is a description of the contents of each byte:

bytes 0-3: (32 bit single precision IEEE floating point, MSB first) Flow rate in % or Flow rate in t.u. (see

section 2.4 Data Type)

bytes 4-7: (32 bit long integer, MSB first) totalizer for TOTAL volume + or - or batch quantity (see section

2.4 Data Type)

bytes 8-11: (32 bit long integer, MSB first) totalizer for TOTAL or PARTIAL volume + or - or batch counter

(see section 2.4 Data Type)

bytes 12-13: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

14

Page 15

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

15/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

byte 14: (8 bits integer) measurement dynamic variation as a %

byte 15: (8 bits integer) Data Type ( see section 2.4 Data Type )

NOTE: The values in the “32 bits single precision IEEE floating point” format are floating point numbers

which can be represented during writing by any decimal digits. To keep the same numerical format visible

on the instrument display however, it is necessary to calculate the decimal figures with a rather complex

algorithm which takes account of instrument precision, flow rate measurement unit, etc. For this purpose

and to avoid useless calculations, the number of decimals to use to represent the flow rate values is supplied

separately. With the acyclic service it is possible to return the value ( see Acyclic Index Read = 20(dec)

Static Process Data of the Flow Meter byte position 13).

NOTE:The counters are expressed with a 32 bit integer. The «counter decimal figures» parameter, indicates

the point position starting from the right: 0 = no decimal, 1=1 decimal figure, and so on. ( see Acyclic

Index Read = 20(dec) Static Process Data of the Flow Meter byte position 12)

2.4. DATA TYPE

The firsts four byte of the Dynamic Data Block are the information about the Flow rate.

After these bytes there are eight byte for the totalizers.

With the Control byte of the Configuration (see the Section Slave Configuration) it is possible to set the

type of the Flow rate returned by the slave and the type of totalizers.

There are six possible combination of type of data in base of the value inserted in the Control byte of the

Configuration string in the GSD file.

The byte 15 indicate the current type of data selected:

byte 15 = 0 --> Flow rate in %

totalizers positive or batch quantity ( batch quantity only for ML M3F )

partial totalizers positive or batch counter ( batch counter only for ML M3F )

byte 15 = 1 --> Flow rate in %

totalizers negative or batch quantity ( data valid only for ML 210 )

partial totalizers negative or batch counter ( data valid only for ML 210 )

byte 15 = 2 --> Flow rate in technical unit

totalizers positive or batch quantity ( batch quantity only for ML M3F )

partial totalizers positive or batch counter ( batch counter only for ML M3F )

byte 15 = 3 --> Flow rate in technical unit

totalizers negative or batch quantity ( data valid only for ML 210 )

partial totalizers negative or batch counter ( data valid only for ML 210 )

byte 15 = 4 --> Flow rate in %

totalizers positive or batch quantity ( batch quantity only for ML M3F )

totalizers negative or batch quantity ( data valid only for ML 210 )

15

Page 16

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

16/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

byte 15 = 5 --> Flow rate in technical unit

totalizers positive or batch quantity ( batch quantity only for ML M3F )

totalizers negative or batch quantity ( data valid only for ML 210 )

For details see the section Slave Configuration.

There is a second way to set the type of the Flow rate using the Acyclic Service during data exchange (see

section Acyclic Service).

2.5. THIRD CONFIGURATION: 24 BYTE INPUT

Below there is a description of the contents of each byte:

bytes 0-3: (32 bit single precision IEEE floating point, MSB first) Flow rate in % or Flow rate in t.u. (see

section 2.6 Flow Rate Type)

bytes 4-7: (32 bit long integer, MSB first) totalizer for TOTAL volume + or batch quantity ( batch quantity

only for ML M3F )

bytes 8-11: (32 bit long integer, MSB first) totalizer for PARTIAL volume + or batch counter ( batch counter

only for ML M3F )

bytes 12-15: (32 bit long integer, MSB first) totalizer for TOTAL volume - or batch quantity ( data valid only

for ML 210 )

bytes 16-19: (32 bit long integer, MSB first) totalizer for PARTIAL volume - or batch counter ( data valid only

for ML 210 )

bytes 20-21: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

byte 22: (8 bits integer) measurement dynamic variation as a %

byte 23: (8 bits integer) Data Type ( see section 2.6 Data Type )

NOTE: The values in the “32 bits single precision IEEE floating point” format are floating point numbers

which can be represented during writing by any decimal digits. To keep the same numerical format visible

on the instrument display however, it is necessary to calculate the decimal figures with a rather complex

algorithm which takes account of instrument precision, flow rate measurement unit, etc. For this purpose

and to avoid useless calculations, the number of decimals to use to represent the flow rate values is supplied

separately. With the acyclic service it is possible to return the value ( see Acyclic Index Read = 20(dec)

Static Process Data of the Flow Meter byte position 13).

16

Page 17

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

17/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

NOTE:The counters are expressed with a 32 bit integer. The «counter decimal figures» parameter, indicates

the point position starting from the right: 0 = no decimal, 1=1 decimal figure, and so on. ( see Acyclic

Index Read = 20(dec) Static Process Data of the Flow Meter byte position 12)

2.6. DATA TYPE

The firsts four byte of the Dynamic Data Block are the information about the Flow rate.

With the Control byte of the Configuration in the GSD file (see the Section Slave Configuration) it is

possible to set the type of the Flow rate returned by the slave.

The type of the Flow rate may be in % or in technical unit in base of the value of the Control byte inserted

in the Configuration string.

The byte 23 indicate the current type of data selected:

byte 23 = 0 --> Flow rate in %

byte 23 = 1 --> Flow rate in technical unit

For details see the Section Slave Configuration.

There is a second way to set the type of the Flow rate using the Acyclic Service during data exchange (see

section Acyclic Service).

2.7. FOURTH CONFIGURATION: 16 BYTE INPUT/OUTPUT

With the precedent configurations, the type of data as Static Data and other parameters of the Flow meter,

the only possible way for to return the data was with Acyclic Service and Class 1 or Class 2 Master.

In the same way the insertion of data in the slave was with Acyclic Service.

If the Master don't support the Acyclic Service, with this configuration it is possible, with two indexes, read

and write Static Data and insert data to the slave as Output data.

With the Output data it is possible the insertion of the values of the two Indexes used for the selection of

the type of data returned with the Input data, for example the Static Data or others parameters, and insert

other data as the Time of the clock of the Flow meter and other parameters.

The two indexes used for the selection and the insertion of the data are:

INDEX Input

INDEX Output

The two indexes are inserted with the Output data during the cyclic data exchange in the firsts two byte of

the 16 Output data ( see the structure of the 16 bytes below in this section ).

The current value of the two index are returned with the first two byte of the 16 bytes Input data ( see the

structure of the 16 bytes below in this section ).

The byte INDEX Input in the 16 bytes of the Output data, is used for the selection of the type of data

returned with the 16 Input data.

With the value inserted in this byte it is possible to select the type of the Dynamic Data retuned or the

type of the Static Data or other internal parameter of the Flow meter or of the Slave as for example the

Profibus address etc.

The byte INDEX Output in the 16 bytes of the Output data, is used for indicate the type of information that

are inserted with the successive bytes that follow the two indexes ( byte 2 --> 15 ) in the 16 Output data.

For example with the value inserted in this byte it is possible to indicate that the bytes that follow the firsts

17

Page 18

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

18/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

two bytes ( the two indexes ) are the bytes for to update the clock ( to update the clock is possible only for

ML 210 ) of the Flow meter.

The firsts two byte of the Input data indicate always the current value of the INDEX Input and Output

inserted with the 16 Output data.

NOTE: The values in the “32 bits single precision IEEE floating point” format are floating point numbers

which can be represented during writing by any decimal digits. To keep the same numerical format visible

on the instrument display however, it is necessary to calculate the decimal figures with a rather complex

algorithm which takes account of instrument precision, flow rate measurement unit, etc. For this purpose

and to avoid useless calculations, the number of decimals to use to represent the flow rate values is supplied

separately (see INDEX Input = 30(dec) Static Process Data of the Flow Meter

byte position 15).

NOTE: The counters are expressed with a 32 bit integer. The «counter decimal figures» parameter,

indicates the point position starting from the right: 0 = no decimal, 1=1 decimal figure, and so on (see

INDEX Input = 30(dec) Static Process Data of the Flow Meter

byte position 15).

Below there is a description of the contents of each 16 bytes for every type of INDEX Input ( this index is

inserted with the first byte of the Output data):

INDEX Input = 0(dec) Dynamic Process Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) Flow rate in %

bytes 6-9: (32 bit long integer, MSB first) totalizer for TOTAL volume + or batch quantity ( batch quantity

only for ML M3F )

bytes 10-13: (32 bit long integer, MSB first) totalizer for PARTIAL volume + or batch counter ( batch

counter only for ML M3F )

bytes 14-15: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

INDEX Input = 1(dec) Dynamic Process Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) Flow rate in %

bytes 6-9: (32 bit long integer, MSB first) totalizer for TOTAL volume - or batch quantity ( data valid only

for ML 210 )

18

Page 19

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

19/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

bytes 10-13: (32 bit long integer, MSB first) totalizer for PARTIAL volume - or batch counter ( data valid

only for ML 210 )

bytes 14-15: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

INDEX Input = 10(dec) Dynamic Process Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) ) Flow rate in t.u.

bytes 6-9: (32 bit long integer, MSB first) totalizer for TOTAL volume + or batch quantity ( batch quantity

only for ML M3F )

bytes 10-13: (32 bit long integer, MSB first) totalizer for PARTIAL volume + or batch counter ( batch

counter only for ML M3F )

bytes 14-15: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

INDEX Input = 11(dec) Dynamic Process Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) Flow rate in t.u.

bytes 6-9: (32 bit long integer, MSB first) totalizer for TOTAL volume - or batch quantity ( data valid only

19

Page 20

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

20/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

for ML 210 )

bytes 10-13: (32 bit long integer, MSB first) totalizer for PARTIAL volume - or batch counter ( data valid

only for ML 210 )

bytes 14-15: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

INDEX Input = 20(dec) Dynamic Process Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) Flow rate in %

bytes 6-9: (32 bit long integer, MSB first) totalizer for TOTAL volume + or batch quantity ( batch quantity

only for ML M3F )

bytes 10-13: (32 bit long integer, MSB first) totalizer for TOTAL volume - or batch quantity ( data valid

only for ML 210 )

bytes 14-15: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

INDEX Input = 21(dec) Dynamic Process Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) Flow rate in t.u.

20

Page 21

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

21/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

bytes 6-9: (32 bit long integer, MSB first) totalizer for TOTAL volume + or batch quantity ( batch quantity

only for ML M3F )

bytes 10-13: (32 bit long integer, MSB first) totalizer for TOTAL volume - or batch quantity ( data valid

only for ML 210 )

bytes 14-15: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the Flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the Flow rate is lower than the cut-off threshold

bit10=1 if the Flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a Flow rate simulation is in progress

INDEX Input = 30(dec) Static Process Data of the Flow Meter

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5: (32 bit single precision IEEE floating point, MSB first) Flow rate scale range in t.u.

bytes 6-10: (5 bytes ASCII) flow rate measurement unit

byte 12: (8 bits integer) number of decimals after the point for flow rate display

INDEX Input = 31(dec) Static Process Data of the Flow Meter

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-4: (3 bytes ASCII) measurement unit of the counters

byte 6: (8 bits integer) number of decimals after the point for totalizers display

byte 8: (8 bits integer) measurement samples per second (Hz)

byte 20=10(dec) measurement frequency = 10 Hz

byte 20=20(dec) measurement frequency = 20 Hz

byte 20=50(dec) measurement frequency = 50 Hz

byte 20=80(dec) measurement frequency = 80 Hz

byte 20=150(dec) measurement frequency = 150 Hz

byte 20=44(dec) measurement frequency = 300 Hz

byte 20=144(dec) measurement frequency = 400 Hz

INDEX Input = 32(dec) Slave Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

byte 2: (8 bits integer) slave address

byte 3: (8 bits integer) pno identification number high

byte 4: (8 bits integer) pno identification number low

byte 5: (8 bits integer) DPC31 ASIC Step

21

Page 22

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

22/52

File name

ProfibusDP_emanual_Burkert_04.doc

bit 0 =1 if DPC31 B

byte 6: (8 bits integer) MAC State Offline / Passive Idle

bit 0 =1 if the MAC is in Passive Idle

byte 7: (8 bits integer) watchdog state

bit 0-1 = 00 --> Baud Search

01 --> Baud Control

10 --> DP_Control

byte 8: (8 bits integer) baud rate

bit 0-3 = 0000 --> 12 MBd

0001 --> 6 MBd

0010 --> 3 MBd

0011 --> 1.5 MBd

0100 --> 500 kBd

19/03/08 19/03/08 19/03/08

0101 --> 187.5 kBd

0110 --> 93.75 kBd

0111 --> 45.45 kBd

1000 --> 19.2 kBd

1001 --> 9.6 kBd

byte 9: (8 bits integer) DP state machine

bit 0-1 = 11 --> Data_Exchange

INDEX Input = 33(dec) Internal Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

byte 2: (8 bits integer) slave software version (major number)

byte 3: (8 bits integer) slave software version (minor number)

byte 4-9: (8 bits integer) device name («ML 210», «ML M3F»)

byte 10: (8 bits integer) Flow meter software version (major number)

byte 11: (8 bits integer) Flow meter software version (minor number)

byte 12-13: (8 bits integer) (16 bits unsigned integer, byte 13=MSB):hardware / software enabling flags,

bit 0 = LSB, bit 15 = MSB:

Bits Funzioni ML 210/M3F

0-2 current access level (0..7)

3 channel 1 impulses in use

4 channel 2 impulses in use

5 channel 1 frequency in use

6 channel 2 frequency in use

7 scale range 2 in use

22

Page 23

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

23/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

8 specific weight in use

9 additional output 3 present

10 additional output 4 present

11 output 4..20 mA 2 present

12 RS232 present

13 batching functions active

14 output 4..20 mA 2 present

15 RS485 present

byte 14: (8 bits integer) current language set in the Flow meter

Format of the returned data:

0(dec) = English

1(dec) = Italian

2(dec) = French

3(dec) = Spanish

NOTE: For reading the type of language it is first necessary to send to the slave the relative command, see

the INDEX Output = 10

(below in this section) and then read the type of language in the byte 4.

INDEX Input = 34(dec) Data and Time of the Flow meter ( only for ML 210)

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-5 (32 bit long integer, MSB first) clock expressed in minutes starting from 01-01-1992

NOTE: The date and time are expressed with a 32 bit integer containing the number of minutes elapsed

since 01-01-1992. To calculate the date starting from this number, see the programming examples in the

section 4.0 PROGRAMMING ALGORITMS of this manual.

INDEX Input = 40(dec) Batch Data

byte 0: (8 bits integer) current INDEX Input

byte 1: (8 bits integer) current INDEX Output

bytes 2-3: (2 bytes 16 bit unsigned integer, MSB first) number of batch processes done for this batch

memory.

bytes 4-5: (2 bytes 16 bit unsigned integer, MSB first) value of the batch safety timer expressed in tenths of

seconds.

bytes 6-9: (4 bytes 32 bits unsigned long integer, MSB first) batch quantity value expressed in the same

units and with the same decimal digits of the volume counters

byte 10: (8 bits integer) batch status:

Format of the returned data: 1 byte containing the batch process state:

0(dec) = batch process is correctly terminated (pre-set quantity reached).

1(dec) = batch process is running (the valve is opened and the counters are running).

2(dec) = batch process is suspended (the valve is closed before the pre-set quantity is reached).

NOTE: The recipe utilized for this configuration is the 00 in the meter and the name utilized for this recipe is

PROFIBUS.

INDEX Input = 42(dec) Batch Parameters

byte 0: (8 bits integer) current INDEX Input

23

Page 24

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

24/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

byte 1: (8 bits integer) current INDEX Output

byte 2: (8 bits integer) batch status:

Format of the returned data: 1 byte containing the batch process state:

0(dec) = batch process is correctly terminated (pre-set quantity reached).

1(dec) = batch process is running (the valve is opened and the counters are running).

2(dec) = batch process is suspended (the valve is closed before the pre-set quantity is reached).

byte 3: (8 bits integer) menu Measure – Cut-off es. 1(dec) / 10 = 0.1%, 255(dec) / 10 Æ 25.5%

byte 4: (8 bits integer) menu Batch - N.samples

byte 5: (8 bits integer) menu Batch – Diff.thr

bytes 6-7: (2 bytes 16 bit unsigned integer, MSB first) menu Batch – V.com (value expressed in the same

units and with the same decimal digits of the volume counters)

bytes 8-9: (2 bytes 16 bit unsigned integer, MSB first) menu Batch – V.pre (value expressed in the same

units and with the same decimal digits of the volume counters)

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Below there is a description of the contents of each 16 bytes for every type of INDEX Output ( this index

is inserted with the second byte of the Output data):

NOTE: Setting the commands only in the state OPERATE. In the state CLEAR the commands are not

accepted.

INDEX Output = 10(dec) Flow Meter Commands

byte 0: (8 bits integer) INDEX Input: the value set the type of the Input data

byte 1: (8 bits integer) INDEX Output = 10(dec)

byte 2: (8 bits integer) command type

Type of command that is possible to insert in the byte 2:

Byte 2 = 0x06(hex) command for reset the Totalizers of the Flow Meter ( see the Flow Meter Manual and

the relative menu for to enable which totalizers to reset by this command).

Byte 2 = 0x07(hex) command for read the current Language used in the Flow Meter:

The information is returned by the byte 4 of the Input data with Index Input 32.

24

Page 25

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

25/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

Byte 2 = 0x08(hex) command for Reset the slave module. After 5 seconds the module return in the data

exchange.

Byte 2 = 0x32(hex) command for Autozero Calibration

Byte 2 = 0x60(hex) command for set the type of language in the meter ( Note: It is firstly necessary to

read the type of the language of the meter, for to set it with this command )

Byte 3 = type of language:

0x00 = 0(dec) = English

0x01 = 1(dec) = Italian

0x02 = 2(dec) = French

0x03 = 3(dec) = Spanish

es.

Reset Totalizers

byte 0: 0xXX = index input

byte 1: 0x0A = 10(dec) index output

byte 2: 0x06 Æ Command

-----------------------------------------------------------------------------------------------------------------------------

es.

Reading current type language of the Flow Meter

byte 0: 0x21 = 33(dec) index input Æ see INDEX Input = 33(dec)

byte 1: 0x0A = 10(dec) index output

byte 2: 0x07 Æ Command

-----------------------------------------------------------------------------------------------------------------------------

es.

Writing the type language in the Flow Meter after the firsly reading of the current language set in the meter

byte 0: 0x21 = 33(dec) index input Æ see INDEX Input = 33(dec)

byte 1: 0x0A = 10(dec) index output

byte 2: 0x60 = 96(dec) Command for set language

byte 3: 0x01 Æ set italian language in the meter

-----------------------------------------------------------------------------------------------------------------------------

es.

Set Autozero Calibration

byte 0: 0xXX = index input

25

Page 26

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

26/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

byte 1: 0x0A = 10(dec) index output

byte 2: 0x32 Æ Command

-----------------------------------------------------------------------------------------------------------------------------

INDEX Output = 20(dec) Setting Data and Time in the Flow Meter (only for ML 210)

byte 0: (8 bits integer) INDEX Input: the value set the type of the Input data

byte 1: (8 bits integer) INDEX Output = 20(dec)

byte 2-5: 32 bits long integer containing the date and time expressed in minutes starting from 01-01-1992

the most significant byte must be sent first.

INDEX Output = 40(dec) Batch Commands

For to use the batch function it is firstly necessary to set ON the menu Batch in the Flow Meter ( see the

Flow Meter Manual )

byte 0: (8 bits integer) INDEX Input: the value set the type of the Input data

byte 1: (8 bits integer) INDEX Output = 40(dec)

byte 2: (8 bits integer) batch Command

0x10(hex) Read the batch data memory, the data are returned with the INDEX Input = 40(dec)

byte 3: (8 bits integer) batch Code

Type of code that is possible to insert in the byte 3:

0x40(hex) = command for reading the recipe

0x12(hex) Set batch with the code in the byte 3

byte 3: (8 bits integer) batch Code

Type of command that is possible to insert in the byte 3:

0x01(hex) = command for reading the current batch status ( see INDEX Input = 40(dec) or

42(dec) for to read the status)

0x02(hex) = command for starting the current batch process

0x03(hex) = command for suspending the current batch process

0x04(hex) = command for resetting the current batch process

0x13(hex) Read the batch parameters, the data are returned with the INDEX Input = 42(dec)

es. Reading Batch Data:

byte 0: 0x28 = 40(dec) index input Æ see INDEX Input = 40(dec) Batch Data

byte 1: 0x28 = 40(dec) index output

byte 2: 0x10 Æ Command

byte 3: 0x40 Æ Code

-----------------------------------------------------------------------------------------------------------------------------

es. Reading Batch Parameters:

byte 0: 0x2A = 42(dec) index input Æ see INDEX Input = 40(dec) Batch Data

26

Page 27

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

27/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

byte 1: 0x28 = 40(dec) index output

byte 2: 0x13 Æ Command

-----------------------------------------------------------------------------------------------------------------------------

es. Batch Commands:

byte 0: 0x28 = 40(dec) index input Æ see INDEX Input = 40(dec) Batch Data

byte 1: 0x28 = 40(dec) index output

byte 2: 0x12 Æ Command

byte 3:0x01 Æ Code Read Status

0x02 Æ Code Start Batch

0x03 Æ Code Stop Batch

0x04 Æ Code Reset the current Batch process

-----------------------------------------------------------------------------------------------------------------------------

INDEX Output = 41(dec) Setting Batch Data Memory

With this index it is possible to insert the batch data memory

byte 0: (8 bits integer) INDEX Input: the value set the type of the Input data

byte 1: (8 bits integer) INDEX Output = 40(dec)

bytes 2-3: (2 bytes 16 bit unsigned integer, MSB first) number of batch processes done for this batch

memory.

bytes 4-5: (2 bytes 16 bit unsigned integer, MSB first) value of the safety batch timer expressed in tenths of

seconds.

bytes 6-9: (4 bytes 32 bits unsigned long integer, MSB first) batch quantity value expressed in the same units

and with the same decimal digits of the volume counters.

NOTE: The recipe utilized for this configuration (16 bytes I/O) is the 00 in the meter and the name utilized

for this recipe is PROFIBUS.

es.

Insertion of the Batch Data (insertion of the data in the meter is in real time for this type of data):

byte 0: 0x28 = 40(dec) index input Æ see INDEX Input = 40(dec) Batch Data

byte 1: 0x29 = 41(dec) index output

byte 2: 0x00

byte 3: 0x00 Æ 0(dec) value for reset the counter

byte 4: 0x00

byte 5: 0x0F Æ 15 (dec) safety batch timer

byte 6: 0x00

byte 7: 0x00

byte 8: 0x00

byte 9: 0x01 Æ 1(dec) batch quantity

---------------------------------------------------------------------------------------------------------------------------

INDEX Output = 42(dec) Setting Batch Parameters

With this index it is possible to insert the batch parameters

27

Page 28

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

28/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

byte 0: (8 bits integer) INDEX Input: the value set the type of the Input data

byte 1: (8 bits integer) INDEX Output = 42(dec)

byte 2: (8 bits integer) menu Measure – cut-off es. 1(dec) / 10 = 0.1%, 255(dec) / 10 Æ 25.5%

byte 3: (8 bits integer) menu Batch - N.samples

byte 4: (8 bits integer) menu Batch – Diff.thr

bytes 6-7: (2 bytes 16 bit unsigned integer, MSB first) menu Batch – V.com (value expressed in the same

units and with the same decimal digits of the volume counters)

bytes 8-9: (2 bytes 16 bit unsigned integer, MSB first) menu Batch – V.pre (value expressed in the same

units and with the same decimal digits of the volume counters)

es.

Insertion of the parameters value:

byte 0: 0xXX index input

byte 1: 0x2A = 42(dec) index output

byte 2: 0x01 Æ cut-off ( menu Measure ) = 0.1%

byte 3: 0x02 Æ N.samples ( menu Batch ) = 2

byte 4: 0x03 Æ Diff.thr ( menu Batch ) = 3%

byte 5: 0x00 Æ byte alignment

byte 6: 0x00

byte 7: 0x04 Æ V.com ( menu Batch ) = 00.004

byte 8: 0x00

byte 9: 0x05 Æ V.pre ( menu Batch ) = 00.005

-----------------------------------------------------------------------------------------------------------------------------

2.8. FIFTH CONFIGURATION: 24 BYTE INPUT/OUTPUT

With the precedent configurations, the type of data as Static Data and other parameters of the Flow meter,

the only possible way for to return the data was with Acyclic Service and Class 1 or Class 2 Master.

In the same way the insertion of data in the slave was with Acyclic Service.

If the Master don't support the Acyclic Service, with this configuration it is possible, with two indexes, read

and write Static Data and insert data to the slave as Output data.

With the Output data it is possible the insertion of the values of the two Indexes used for the selection of

the type of data returned with the Input data, for example the Static Data or others parameters, and insert

other data as the Time of the clock of the Flow meter and other parameters.

The two indexes used for the selection and the insertion of the data are:

INDEX Input

INDEX Output

The two indexes are inserted with the Output data during the cyclic data exchange in the firsts two byte of

the 24 Output data ( see the structure of the 24 bytes below in this section ).

The current value of the two index are returned with the first two byte of the 24 bytes Input data ( see the

structure of the 24 bytes below in this section ).

28

Page 29

TECHNICAL MANUAL

PROFIBUS DP MODULE- DATA LINK

DESCRIPTION

Rev. Pagine

Filling By Checked By

03

Document Data Date Date

29/52

File name

ProfibusDP_emanual_Burkert_04.doc

19/03/08 19/03/08 19/03/08

The byte INDEX Input in the 24 bytes of the Output data, is used for the selection of the type of data

returned with the 24 Input data.

With the value inserted in this byte it is possible to select the type of the Dynamic Data retuned or the

type of the Static Data or other internal parameter of the Flow meter or of the Slave as for example the

Profibus address etc.