Page 1

TABLE OF CONTENTS

1 INTRODUCTION ......................................................................................................................... E-2

1.1 Unpacking and Control ................................................................................................................ E-2

1.2 About this Manual ........................................................................................................................ E-2

1.3 User's Responsibility for Safety .................................................................................................. E-2

1.4 Electromagnetic Compatibility ..................................................................................................... E-2

2 SPECIFICATION .........................................................................................................................E-3

2.1 Type Specification ....................................................................................................................... E-3

2.2 Design and Measuring Principle ................................................................................................. E-4

2.3 Dimensions Electronic housing SE35 Batch controller .............................................................. E-5

2.4 Technical Data ............................................................................................................................. E-6

3 INSTALLATION .......................................................................................................................... E-7

3.1 Installation Guidelines ................................................................................................................. E-7

3.2 Process Mounting ........................................................................................................................ E-8

3.3 General electrical connection ...................................................................................................... E-9

3.4 Electrical Wiring ........................................................................................................................... E-9

3.5 Electrical Wiring with Power Supply 230/115 VAC...................................................................E-10

4. OPERATION AND CONFIGURATION.....................................................................................E-11

4.1 Controller operating and Control elements ............................................................................... E-11

4.2 Description of the Dosing Options ............................................................................................ E-12

4.2.1. «LOC.MANU» Option......................................................................................................E-12

4.2.2. «LOC.MEM» Option ....................................................................................................... E-12

4.2.3. «MEM+MANU» Option....................................................................................................E-12

4.2.4. «EXT.MEM» Option ........................................................................................................ E-13

4.2.5. «EXT.[T]» Option ............................................................................................................ E-14

4.3 Main menu .................................................................................................................................E-15

4.3.1. Dosage in manual mode .................................................................................................E-15

4.3.2. Dosage in automatic mode ............................................................................................. E-16

4.3.3. Dosage proportional to a pulse duration ........................................................................ E-17

4.3.4. Display of flow rate and the initial preset volume during the dosage ............................ E-17

4.3.5. Pause / reset function ..................................................................................................... E-18

4.4. Calibration Menu ....................................................................................................................... E-19

4.4.1. Language.........................................................................................................................E-19

4.4.2. Measurement units ..........................................................................................................E-20

4.4.3. K-Factor ........................................................................................................................... E-20

4.4.4. Dosing options.................................................................................................................E-21

4.4.5. Overfill correction ............................................................................................................ E-23

4.4.6. Alarm ............................................................................................................................... E-23

4.4.7. Relays ..............................................................................................................................E-24

4.4.8. Totalizer ........................................................................................................................... E-26

4.5. Test Menu .................................................................................................................................. E-26

4.5.1. EXT.ACT. ........................................................................................................................ E-26

4.5.2. Check on operation of relays ..........................................................................................E-27

4.5.3. Transducer frequency readout........................................................................................E-27

5. MAINTENANCE ........................................................................................................................ E-28

5.1 Fault prompts ............................................................................................................................. E-28

5.2. Transducer maintenance...........................................................................................................E-30

5.3. Default configuration of 8035 INLINE Batch controller on delivery ..........................................E-31

5.4 Spare Parts List .........................................................................................................................E-31

BATCH CONTROLLER SE35

APPENDIX ................................................................................................................................. A-1

Flow Chart (l/min, DN in mm and m/s)........................................................................................A-1

Flow Chart (US-gallon/min, DN in inch and Ft/s) ....................................................................... A-2

8035

E-1- Ref. 419744

Page 2

1 INTRODUCTION

Dear Customer,

BATCH CONTROLLER SE35

Congratulations on your purchase of our

batch controller SE35 INLINE.

Before installing or mounting this device,

please take our advice and read the entire

manual thoroughly.

This will enable you to fully profit from all of

the advantages offered by this product.

1.1 Unpacking and Control

Please verify that the product is complete

and free from any damage. The standard

delivery must include:

-1 Batch Controller electronic SE35

-1 Instruction manual SE35

-1 Instruction manual S030 Inline

Compare the type specification on the

label to the following list to ensure that

you have received the proper unit.

If there is any loss or damage, please contact

your local Bürkert subsidiary.

1.2 About this Manual

1.3 User's Responsibility for Safety

Bürkert manufactures a broad range of flow

sensors. While each of these products is

designed to operate in a wide variety of

applications, it is the user's responsibility to

select a controller model that is appropriate

for the application, install it properly, and

maintain all components. Special attention

must be paid to the chemical resistance of

the sensor against the fluids which are

directly contacting the product.

This symbol appears in the

manual to call special attention

to instructions that affect the safe

!

installation, function and use of

the product.

1.4 Electromagnetic compatibility

This device conforms to the EMC-Directive

of the European Community 89/336/EEC.

In order to comply with this directive, the

wiring instructions must be followed.

This manual does not contain any warranty

statement. Please refer to our general terms

of sale and delivery.

Only properly-trained staff should install and/

or repair this product. If difficulties

should occur at the time of installation,

please contact your nearest Bürkert sales

office for assistance.

E-2-

8035

Page 3

2 SPECIFICATION

BATCH CONTROLLER SE35

2.1 Batch controller electronic SE35 Batch INLINE,

The batch controller 8035 is consisting of a S030 fitting which houses the paddle-wheel

and an electronic controller SE35, specially designed to be installed on the fitting.

Use a separate order N° for the S030 Fitting. For more informations about the fittings see

the corresponding instruction manual.

International Standard Version Cable Input Order Nr

Batch Controller SE35, Power Supply 12-30 VCC

2 totalizers, 2 relays 2 x PG 13,5 423920

Batch Controller SE35, Power Supply 115-230 VAC

2 totalizers, 2 relays 2 x PG 13,5 423926

North-America Standard Version Cable Input Order Nr

Batch Controller SE35, Power Supply 12-30 VCC

2 totalizers, 2 relays 2 x PG 13,5 423932

Batch Controller SE35, Power Supply 115-230 VAC

2 totalizers, 2 relays 2 x PG 13,5 423937

8035

E-3-

Page 4

2 SPECIFICATION

2.2 Design and Measuring Principle

Design

BATCH CONTROLLER SE35

The Batch Controller SE35 Inline consists

of an electronic IP65 housing SE35 set by

quarter turn on the fitting S030. The

electronic housing integrates the electronic

board with display, programmation keys and

also a the transducer. The paddle-wheel is

mounted in the fitting.

The transducer component converts the

measured signal and displays the actual

value.The output signals are provided via

two PG 13.5.

Measuring and Dosing Principle

When liquid flows through the pipe, 4

magnets inserted in the paddle-wheel set in

rotation produce a measuring signal in the

transducer.

The frequency modulated induced voltage

is proportional to the flow velocity of the fluid.

A conversion coefficient, specific to each

pipe (size and material) enables the

conversion of this frequency into flowrate.

This coefficient (Factor-K in pulse/liter) is

available in the instruction manual of the

inline fitting (S030).

The controller electronic module SE35

Batch requires a power supply of 12...30

VDC (230/115 VAC as option).

Dosing options

Following dosing modes are available

I) Local dosing command:

a) The user enters the volume to be

measured and initiates the dosing from the

keypad. ("LOC.MANU") (§ 4.3.1)

b) Local dosing with preset volumes.

Selection of a pre-set volume and activation

of the process from the keypad.("LOC.MEM").

(§ 4.3.2)

c) Combination from "LOC.MANU" and

"LOC.MEM" options. activated from the

keyboard ("MEM+MANU") (§ 4.3.1 + § 4.3.1).

II) Remote dosing command:

a) Dosing controlled by binary inputs issued

from a PLC. Each pulse controls the dosing

of a preselected volume.("EXT.MEM") (§ 4.3.4)

b) Automatic dosing controlled by the pulse

duration. The ditributed volume is directly

proportionnal to the pulse duration ("EXT .

[T]") (§ 4.3.3)

The controller SE35 Batch is mounted on a

pipe in series with the valve. The SE35 unit

measures the flow, calculates the volumes,

and operates the valve(s) according to the

selected program (see § 4).

E-4-

8035

Page 5

2 DESCRIPTION

BATCH CONTROLLER SE35

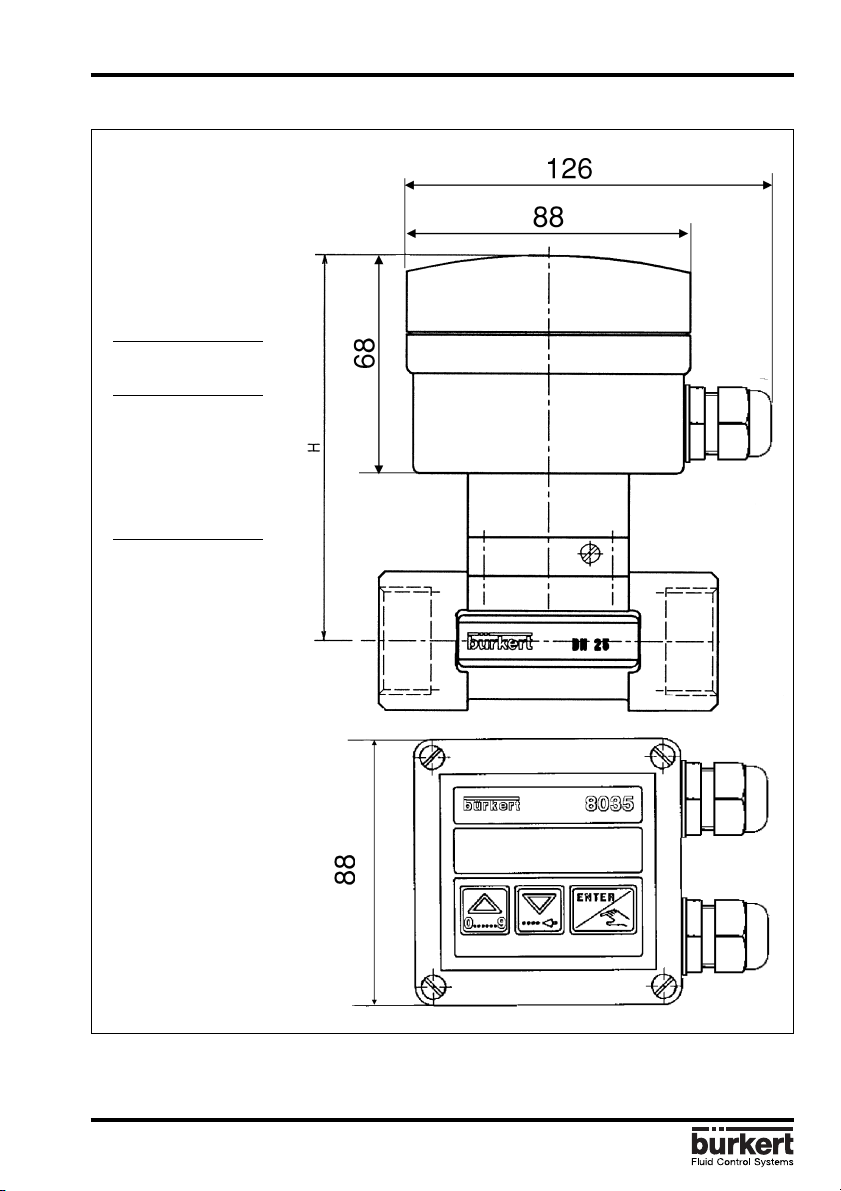

2.4 Batch Controler 8035 INLINE external dimensions (mm)

DN H

mm "

15 122 4.81

20 119 4.69

25 120 4.73

32 123 4.85

40 127 5.00

50 134 5.28

The height H is

independant from the

connection type and

material of the fitting.

Fig. 1 Batch Controler 8035 INLINE external dimensions

8035

E-5-

Page 6

2 SPECIFICATION

BATCH CONTROLLER SE35

2.4 Technical Data

Pipe diameter from DN 15 to DN 50 (1/2" to 2")

Measuring range 0,3 to 10 m/s (1.0 to 32.8 ft/s)

flow range as from 3 l/min (DN15 pipe, 0.3 m/s flow velocity)

flow range as from 0.8 gpm (1/2" pipe, 1.0 ft/s flow velocity)

Plastic fitting PN10

Fluid temperature max PVC: 50 °C (132°F); PP: 80 °C (176°F); PVDF: 100 °C (212°F)

Metal fitting PN16

Fluid temperature max: 100 °C (212°F)

Ambiant temperature 0 to 60 °C (32 to 140 °F)

Storage temperature 0 to 60 °C (32 to 140 °F)

Relative humidity 80 %

Enclosure IP65

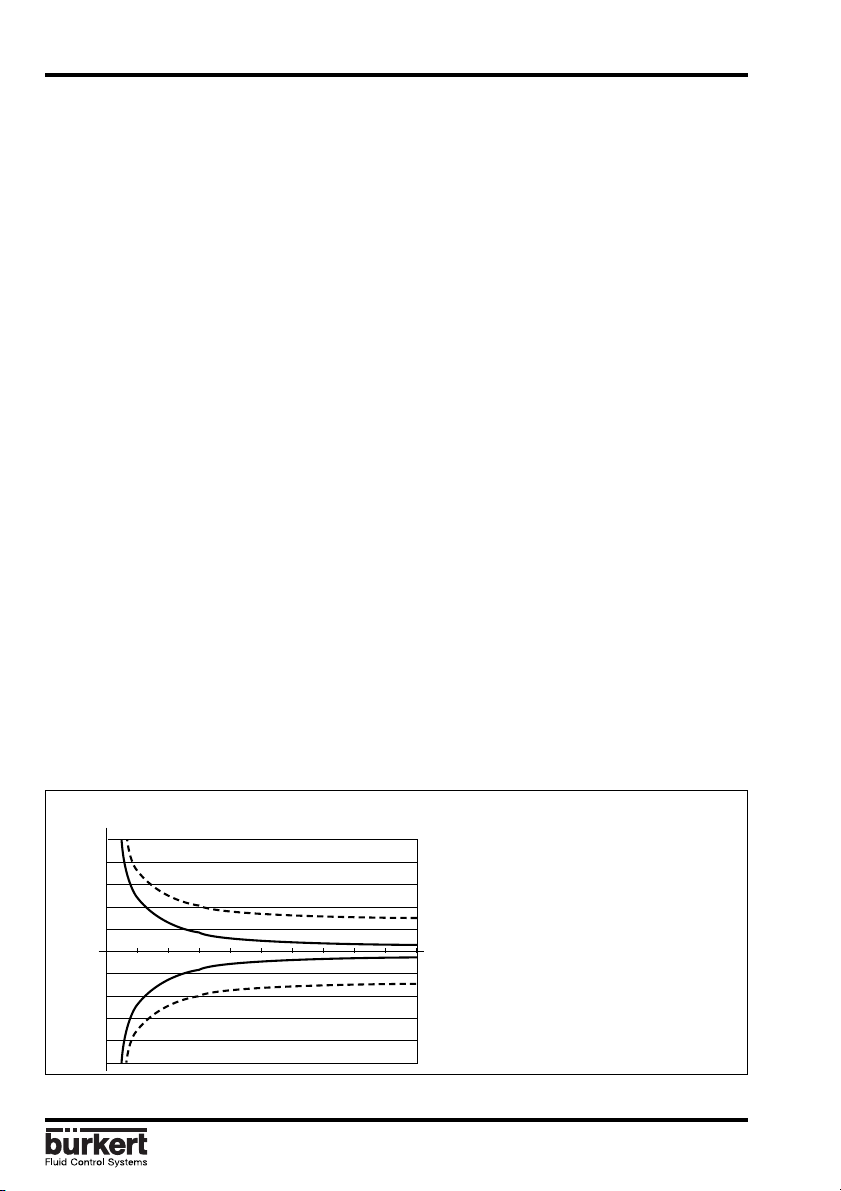

Measuring error 1.With In-line calibration (Teach-In):

≤± 0.5% o.F.S. (at 10 m/s) *

2.With standard mean K-Factor:

≤ ± (0.5% o.F.S. +2.5% o.R.) *

Linearity ≤ ± 0.5% o.F.S. (at 10 m/s) *

Repeatability 0.4% o.R. *

Display 15 x 60 mm LCD 8 digits, alphanumeric,

Sensor holder PVDF, PP, PVC, SS 316L (1.4404), Brass

Paddle-wheel PVDF

Axis and bearing ceramic

O-rings FPM

Electronics housing PC; Front plate foil polyester

Voltage supply 12...30 VDC (230 VAC power supply as option )

Binary inputs 4 inputs, 5...30 VDC

15 segments, 9 mm high

Relay output 2 relays, 3 A, 220 V, freely adjustable

(*) Under reference conditions i.e. measuring fluid water, ambient and water temperature 20°C,

applying the minimum inlet and outlet pipe straights, matched pipe dimensions.

o.F.S. = of standard Full Scale (10 m/s) - o.R. = of Reading

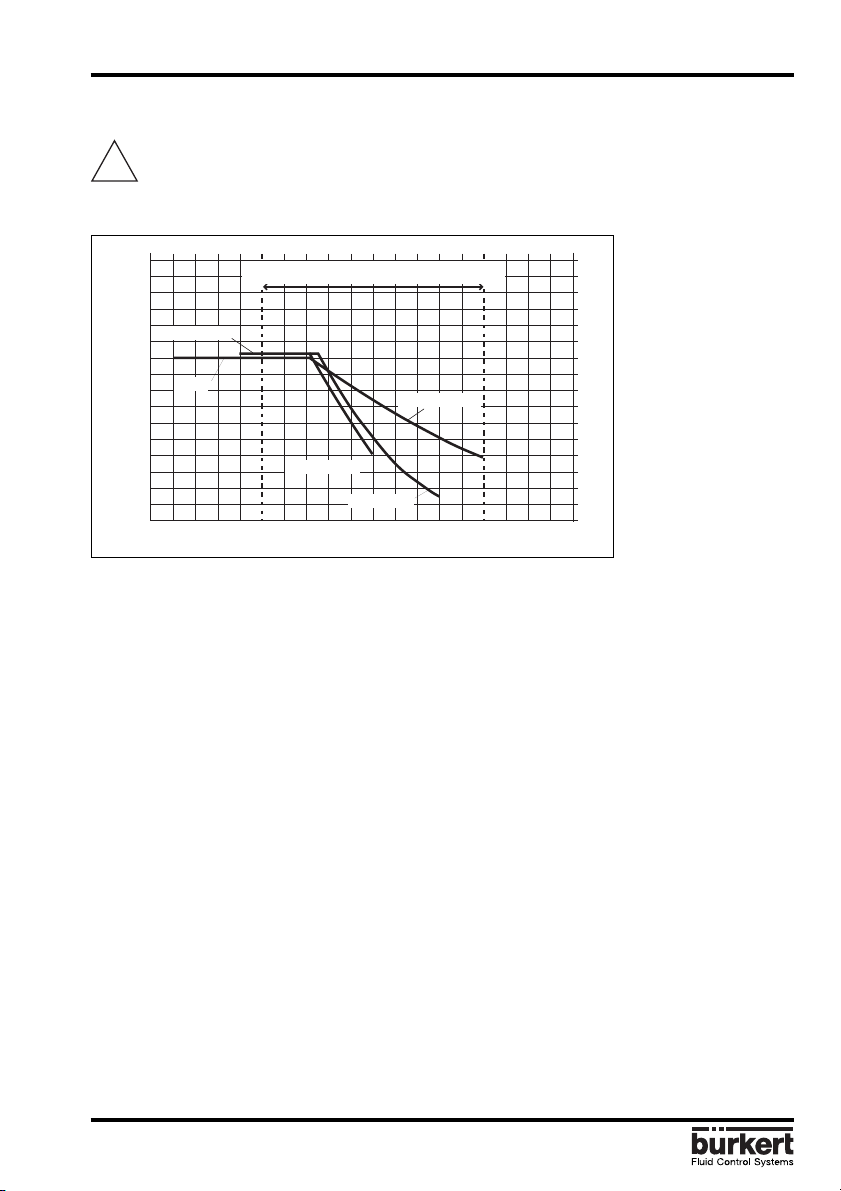

% max.

error

10

8

6

4

2

-2

-4

-6

-8

Measuring error % of measured value (*)

-10

0

.

5

%

o

.

F

.

S

.

+

2

.

5

%

0

.

5

%

o

.

F

.

S

.

19

2345 6 78 10

Flow velocity m/s

o

.

R

.

with standard K-factor

with Teach-In

m/s

Measuring error with/without Teach-In

E-6-

8035

Page 7

3 INSTALLATION

BATCH CONTROLLER SE35

3.1 Installation Guidelines

The controller SE35 Batch INLINE can only be used to measure pure, liquid and

!

water-like fluids (solids content ≤ 1%, viscosity max. 300 cSt with on-line calibration).

Observe pressure-temperature dependence according to the respective fitting materials.

P

16

bar

15

14

13

12

PVC + PP

11

10

9

PVDF

8

7

6

5

4

3

2

1

0

-30

-50

Fig. 2 Pressure-Temperature-Diagram

Application range for SE35 INLINE

PVDF (PN 10)

PVC (PN 10)

PP (PN 10)

-10 +10

+30

+50 +70

+90

+110 +130

T° C

Fitting S030 installation guidelines

The pipe must be completely filled with the

liquid, i.e. air bubbles must not be present.

The flow sensor is not designed for gas flow

measurement.

The device must be protected from constant

heat radiation and other environmental

influences, such as direct exposure to

sunlight.

The recommended upstream and

downstream straight pipe length should

respect 10xD in and 3xD out.

According to pipe's design, necessary

distances can be bigger or use a flow

straightener to obtain the best accuracy.

For more information please refer to EN ISO

5167-1.

8035

The flow sensor can be installed in either

horizontal or vertical pipe.

The suitable pipe size is selected using the

diagram on the end pages. Pressure and

temperature ratings must be respected

according to to the selected fitting material.

(see fig. 2)

E-7-

Page 8

3 INSTALLATION

BATCH CONTROLLER SE35

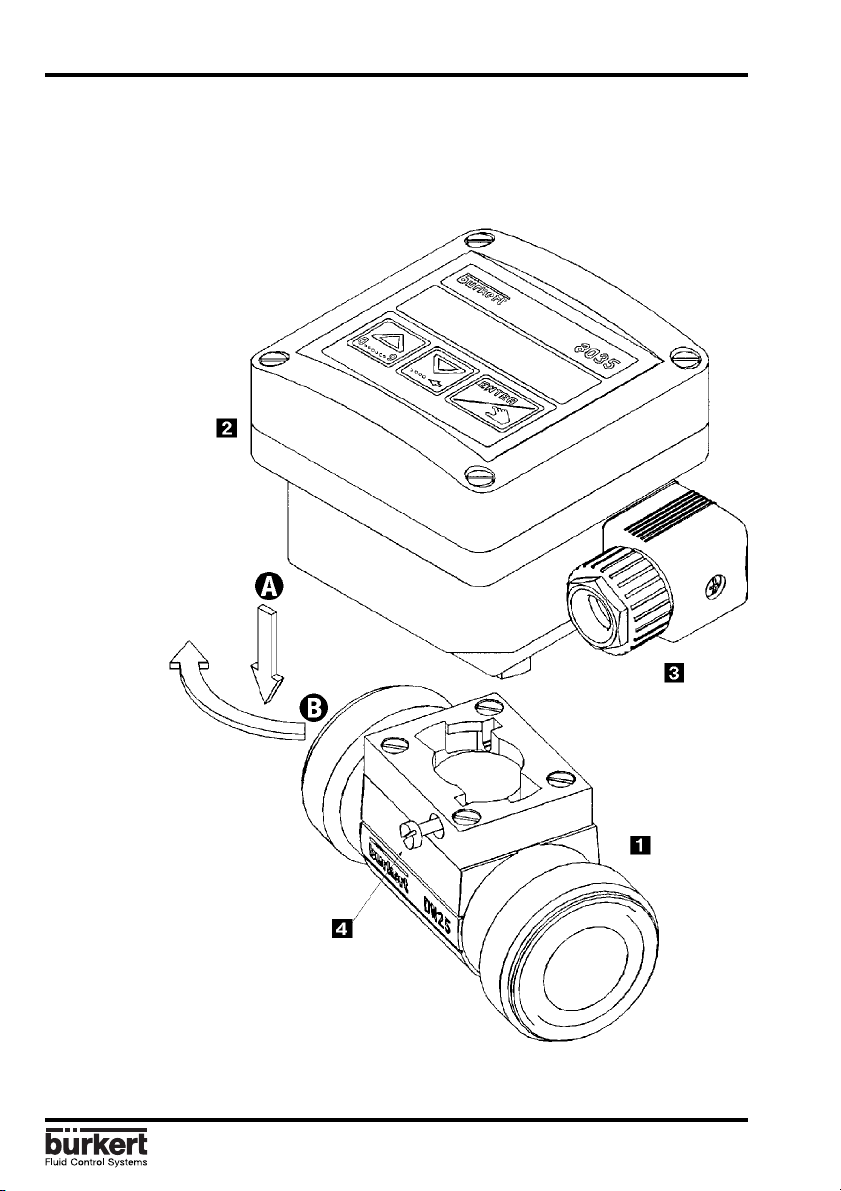

3.2 Process mounting

The flow controller electronic module SE35 Batch INLINE can be easily installed in pipes

using the specially designed fitting system S030 INLINE.

1.The fitting must be installed into the

pipe according to the installation

specifications (see § 3.1).

2.Fasten the electronic

housing to the

fitting using the

bayonet connection,

and turn by 30°.

Wiring instructions § 3.4

3.Tighten the electronic

housing with the screw

.

Fig. 3 Batch controller 8035 INLINE Batch mounting diagram

E-8-

8035

Page 9

3 INSTALLATION

BATCH CONTROLLER SE35

3.3 General Electrical Connection

The connecting cable conducts the input/output signals and must not be installed in

combination with high voltage or high frequency carrying lines. If a combined installation

cannot be avoided, either keep a min. space of 30 cm (approx. 1 ft) or use coax cables.

When using coax cables observe faultless grounding of the shield. For normal operating

conditions, the input/output signal can be transmitted by a simple cable of 0.75 mm2 cross

section.

The power supply must be of good quality (filtered and regulated).

Note: For EMC purposes,the earth must be connected via the earth lug on the side

of the enclosure. This point must be connected locally to a good earth.

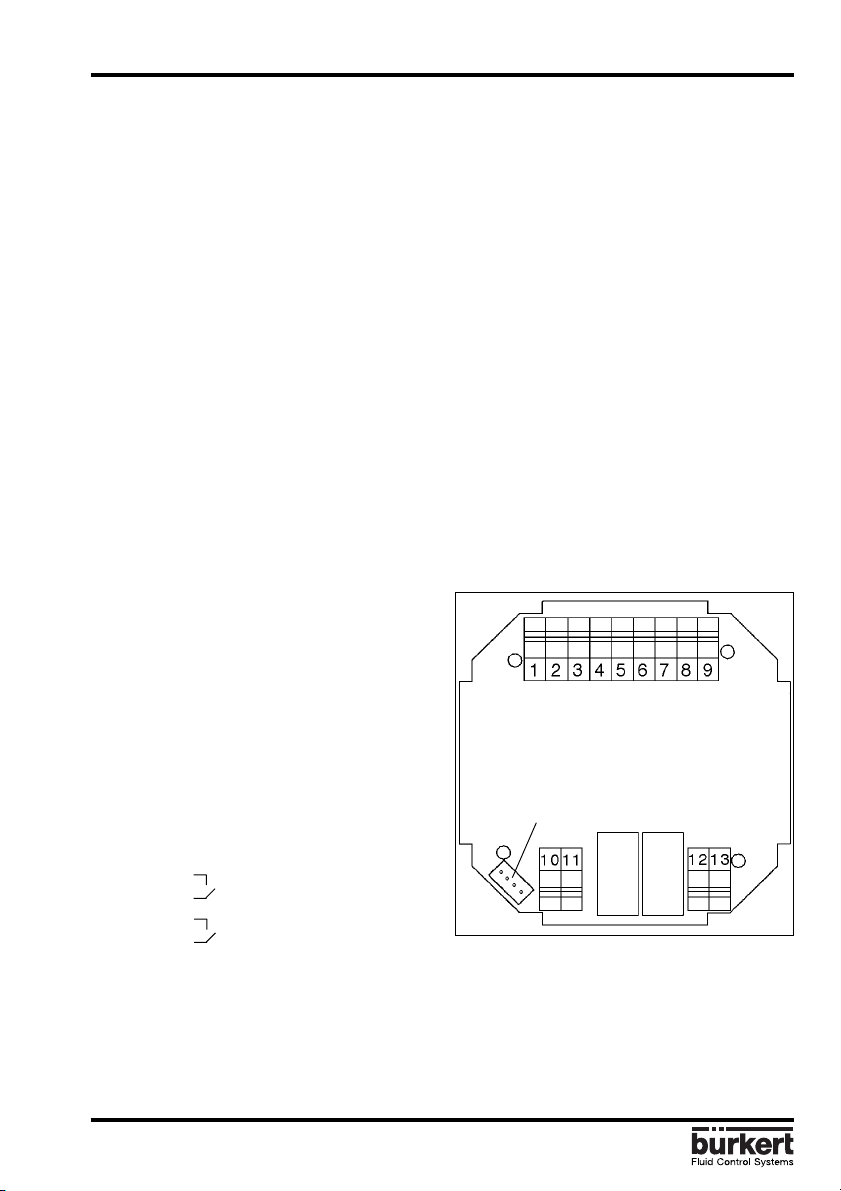

3.4 Electrical connection SE35 Batch

The connections are made via the two 13,5 cable glands.

Remove cover, pull the cable through a PG

13.5 and wire according to following pin

assignment and fig. 4:

1: Binary input 1

2: Binary input 2

3: Binary input 3

4: Binary input 4

5: Indicator lamp output (Transistor Open

Collector)

6: Common (binary inputs and outputs)

7: L+ (12...30 VDC)

8: L9: Earth

10: Relay 2

11: Relay 2

12: Relay 1 Main valve

13: Relay 1 see § 4.4.7

Note: The driver unit supply voltage can be used for the binary inputs and the indicator

lamp output (open collector). In this case the common terminal (6) and the L- terminal (8)

should be connected together.

8035

Fig. 4 Pin assignment SE35 Batch

E-9-

Sensor connection

Page 10

3 INSTALLATION

BATCH CONTROLLER SE35

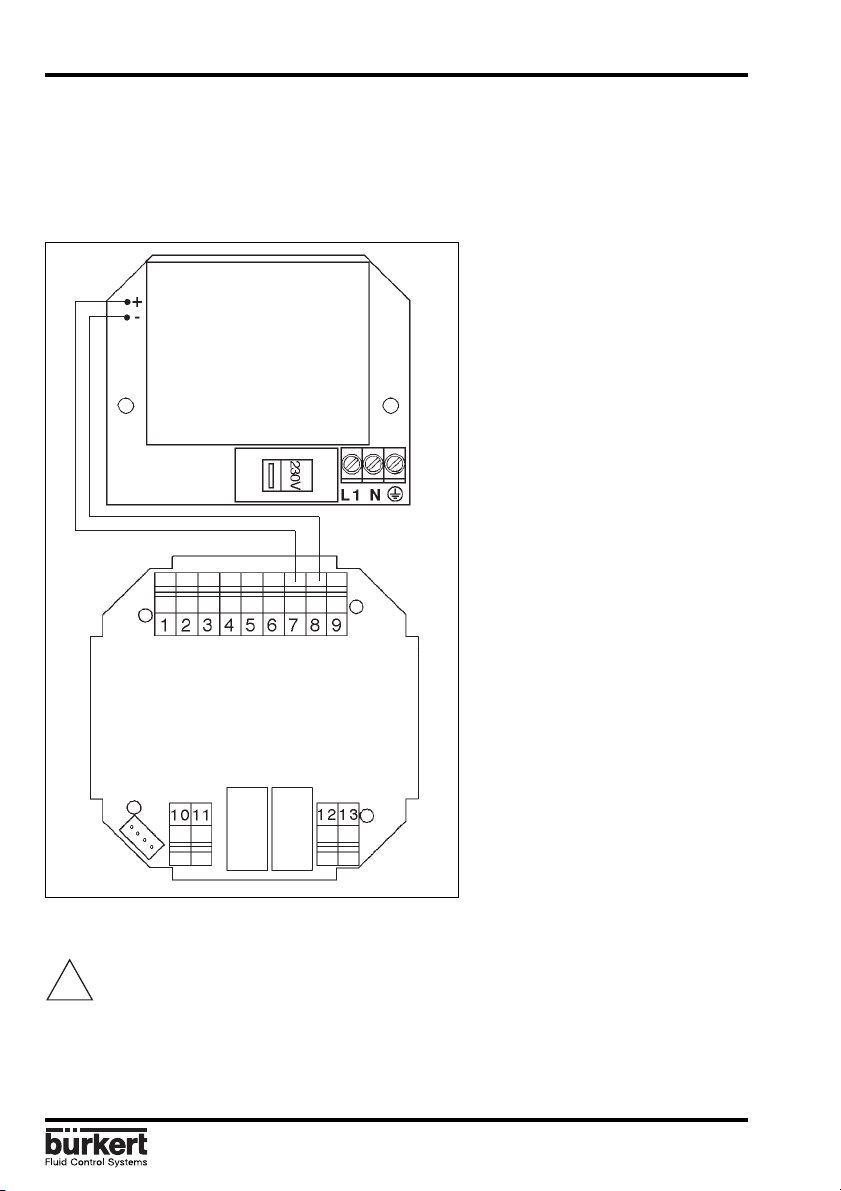

3.5. Electrical Connections for a Supply Voltage of 230/115 VAC (option)

Remove the cover from the unit, the power supply board is on the bottom of the housing.

Pull the cable through a PG 13.5 cable gland and wire according to fig. 5. The other

connections will be the same as on the standard version § 3.4.

Sensor connection

Fig. 5 Connection diagram for controller 8035Batch 230V /115 V AC option

Important: The 230/115 VAC version doesn't allow the driver unit power supply to

!

be used for the binary data inputs and the indicator lamp output (open collector).

E-10-

8035

Page 11

4 OPERATION

BATCH CONTROLLER SE35

The operation is classified according to three levels.

A) Display

This menu allows the user to control the dosing by the keypad (start, pause, reset, stop);

using the LCD display, he can monitor the flow rate and the initial preset volume throughout

the dosing operation. The readings of the main counter and the daily counter are displayed

within this menu. The daily counter can be set to zero.

B) Parameter Definition

This menu enables the setting of dosing parameters (languages, measurement units,

equipment, K factor, dosing option, overfill correction, alarm and relay thresholds).

Simultaneous resetting of the two counters is carried out within this menu.

C) Testing

This menu enables the user to check the binary inputs (remote control) and to simulate the

operation of the relays.

It also caters for measuring the rotation frequency of the paddle wheel.

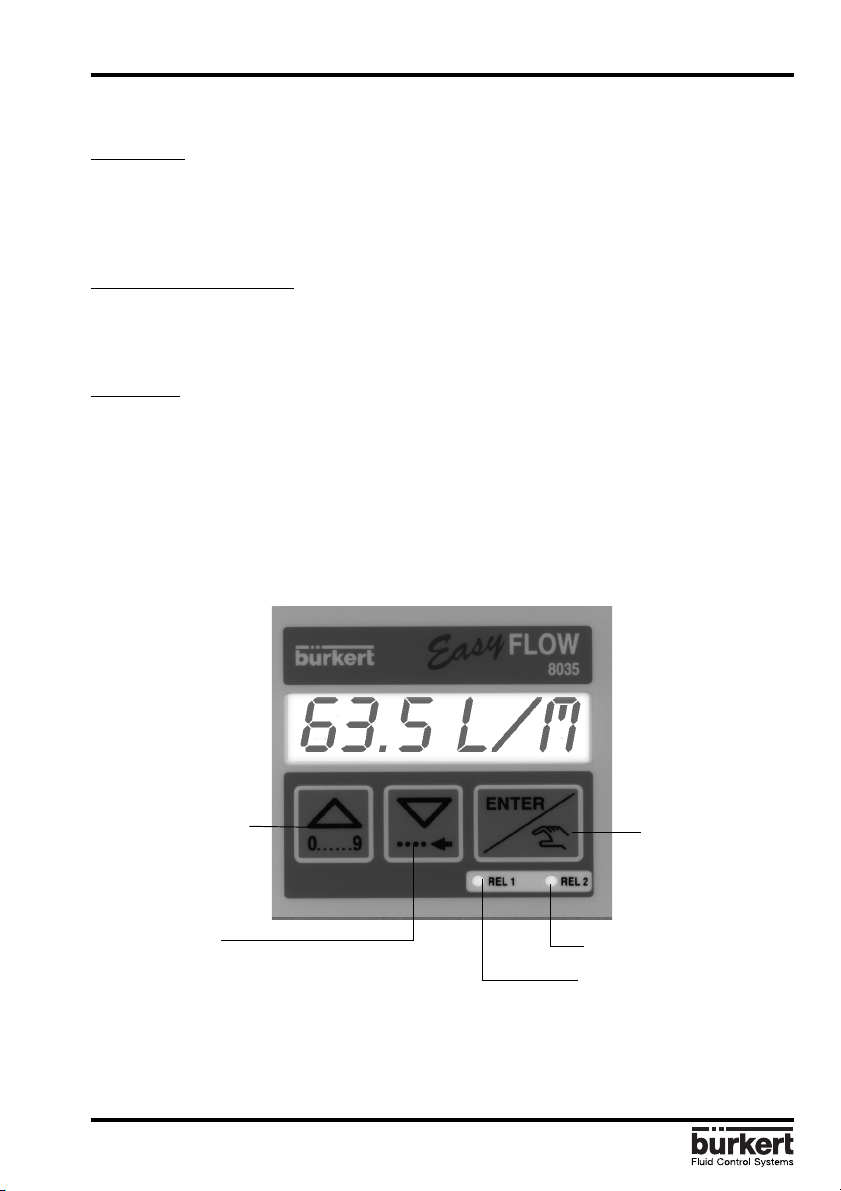

4.1 Controller Operating and Control Elements

Choice of digit value

Steps from 0 to 9

Menu selection

Direction

downwards in

menu or

sideways for digit

selection

8035

Accept of

choosen

parameter or

adjusted value

Relay 2 (contact closed)

Relay 1(contact closed)

E-11-

Page 12

4 CONFIGURATION

BATCH CONTROLLER SE35

4.2 Description of Dosing Options

Dosing options are selected within the «OPTION» sub-menu of the Calibration Menu. ( §

4.4.4.)

4.2.1. «LOC.MANU» Option»

When this option is selected, the prompt «BATCH M» is displayed within the main menu. It

enables the generation of a volume which can be defined using the keypad. (see § 4.3.1.)

4.2.2. «LOC.MEM» Option

When this option is selected, the prompt «BATCH A» is displayed within the main menu.

Generation of a volume previously entered into the memory (7 in total) from the keypad

(see § 4.3.2.).

4.2.3.»MEM+MANU» Option

When this option is selected, the prompts «BATCH M» and «BATCH A» are displayed within

the main menu.

Generation of a volume either manually or automatically. (see § 4.3.1 and § 4.3.2).

E-12-

8035

Page 13

4 CONFIGURATION

BATCH CONTROLLER SE35

4.2.4 »EXT.MEM» Option

Generation of a volume previously entered into the memory (7 in total) from a remote

position by using the binary data inputs (See § 4.2.2.). The following example describes

the various methods of connection.

L+(12...30VDC)

GND

123456789

S/S

LED

쏏

쏏

쿘

+ - 쵰

COM

PLC, switch, push button,

etc.

Batch controller

8035 INLINE

PE

GND

L+(12...30VDC)

Fig. 6 Connection to a PLC

The selection of a volume from the memory (1 to 7) is carried out by encoding the binary

data at inputs 1,2 and 3. The following table shows the logic value at each input to provide

each of the desired seven quantities:

Volume V1 V2 V3 V4 V5 V6 V7

Input 1 1 010101

Input 2 0 110011

Input 3 0 001111

1: Input enabled (switch closed)

0: Input disabled (switch open)

Input 4: Start / Pause function (from a push button, for example).

Output 5: Transistor output (open collector)

Provides Batch controller status information. For example, it can be used to feed an

indicator lamp.

The following status can be indicated:

Lamp off No dosing in progress

Lamp on Dosing in progress

Slow flashing (1 Hz) Pause in dosing operation

Rapid flashing (3.5 Hz) Alarm (problem during dosing operation)

8035

E-13-

Page 14

4 CONFIGURATION

BATCH CONTROLLER SE35

4.2.5. «EXT. [T]» Option

Delvery of a volume proportional to the duration of the high level on the input 1

(see § 4.3.3.). The proportional relationship is as follows:

X = Volume = (A x t) +B A Coefficient of proportionality (/s;...)

B Offset (l;...)

t Duration of input 1 activation (ms, s;...)

X Dosing volume (l;...)

Coefficients A and B entered by the user.

Pulse specification

T

: 100 ms

min

T

: 300 s

max

Definition: 5 ms

Delay between 2 pulses: min 100 ms

Practical examples:

- Filling cans of 5, 10 and 50 litres respectively. The following values can be entered:

A = 5 l/s

B = 0 l

The activation times for binary data input 1 for the three volumes are as follows:

Volume (l) 5 10 50

Duration (s) 1 2 10

- Doses of chemical products as a function of required concentration. Volumes of 110,

120, 130, and 150 litres. The following values can be entered:

A = 5 l/s

B = 100 l

The activation times for binary data input 1 for the three volumes are as follows:

Volume (l) 110 120 130 150

Duration (s) 2 4 6 10

Notes:

- The activation time for the binary data input must always be lower than the actual filling

time. A margin of safety should be allowed when choosing the coefficients A and B.

- The coefficients A and B should be chosen such that the activation times for the binary

data input should be efficient. In the example , one could have choosen A = 100 l/s and

B = 0 l. The resulting activation times would be 1.1, 1.2, 1.3 and 1.5 seconds. In this case

the distributed doses would be less accurate.

E-14-

8035

Page 15

4 CONFIGURATION

BATCH CONTROLLER SE35

4.3 Main menu

Within the main menu, following readouts are available:

BATCH M

Dosing in manual mode (see § 4.3.1.).

Only available if the «LOC.MEM» or the «MEM+MANU» Options

have been selected within the Calibration menu (see § 4.4)

0......9

BATCH A

Dosing in automatic mode (see § 4.3.2.).

Only available if the «LOC.MEM» or the «MEM+MANU» have been

selected within the Calibration menu (see § 4.4)

24563 L

456 L.

Main counter using the selected measurement unit (see

Calibration menu). Zero setting within the Calibration menu.

Daily counter using the same measurement unit as the main

counter. A decimal point after the unit differentiates it from the

main counter. Zero setting by simultaneously pressing the two

keys for 3 seconds.

0......9

The following sub-routines describe the various dosing options together with the prompts

displayed within the main menu. The GREY CHARACTERS are flashing when displayed.

4.3.1.Dosing in manual mode»LOC.MEM» or «MEM+MANU» Options

Generation of a volume previously entered from the keypad.

BATCH M

ENTER

00000 L

Entering of

volume

0......9

00100 L OK Y/N

ENTER

Countdown of

*

ENTER

volume to 0

00100 L

* You can also start the dosage using

the “Start/Pause” binary data input

(see 4.2.4).

OK Y/N

ENTER

The volume must be greater than 6 pulses generated by the paddle-wheel. The entry of

a zero volume forces a return to the «BATCH M» option.

The «ALARM» prompt during a dosing operation signifies a dosing problem (see § 5.1).

During the measure of the selected volume, displaying the flow rate, pause, reset or stop

the dosing operation. (see § 4.3.4.; § 4.3.5.) are still possible.

8035

E-15-

Page 16

4 CONFIGURATION

BATCH CONTROLLER SE35

4.3.2. Dosing in automatic mode («LOC.MEM», «MEM+MANU», or «EXT.MEM» Options)

Generation of the volume from one of the 7 values previously entered into the memory.

The selected volume can be initiated either from the keypad or by the binary inputs.

Initiating the dosing from the keypad («LOC.MEM», «MEM+MANU» Options)

1 sec.

*

BATCH A

ENTER

V1 250 L

V2 50 L

V7 1250 L

ENTER

END

ENTER

OK Y/N

OK Y/N

* You can also start the

dosage using the “Start/

Pause” binary data input

(see 4.2.4).

ENTER

ENTER

Zero quantities (from V1 to V7) will not be displayed.

Initiating the dosing from the binary data inputs («EXT.MEM» Option)

1

2885 L

Choice of volume from

memory by encoding the

binary data inputs 1, 2 and 3.

2

3

1 sec.

V2 50 L

Enabling of input 4

(push button for example)

to initiate dosing

4

Countdown of the

volume to 0

38 L

«ALARM» prompt during dosing operation: dosing problem (see § 5.1.)

Countdown of the

volume to 0

250 L

During the dosing of the selected volume, it is possible to display the flow rate, to pause,

to reset or to stop the operation (see § 4.3.4. and § 4.3.5)

E-16-

8035

Page 17

4 CONFIGURATION

BATCH CONTROLLER SE35

4.3.3. Dosing proportional to a pulse duration («EXT.[T]» Option)

This option enables the initiation of a dosing volume proportional to the time during which

binary data input 1 is enabled. The following prompts are displayed within the principal

menu during the dosing operation.

Countup of the

Totalizer

display

2885 L

1

Activation time

proportional to

dosing volume

volume to dose

38 L

Fig. 9 Exemple of electrical connection

L+(12...30VDC)

GND

123456789

S/S

LED

쏏

쏏

쿘

+ - 쵰

COM

PLC, switch, push

button, etc.

Batch controller

8035 INLINE

PE

GND

L+(12...30VDC)

«ALARM» prompt during the dosing operation: dosing problem (see § 5.1.).

During the dosing of the selected volume, it is possible to display the flow rate, to pause,

to reset or to stop the operation. These facilities are only selected on the keypad. (see §

4.3.4. and § 4.3.5)

4.3.4. Display of flow rate and the initial preset volume during the dosing.

To display the flow rate and of the initial preset volume values during the dosing operation,

press the key briefly. This is a useful facility irrespective of the dosing option chosen.

Countdown of the

dosing operation

in progress

221 L

Initial preset volume Flow rate

250 L

2 s.

2.34 L/S

2 s.

Automatic refresh after 2 s

8035

E-17-

Page 18

4 CONFIGURATION

BATCH CONTROLLER SE35

4.3.5. Pause / reset function

A current dosage can be momentarily or definitively stopped (except mode EXT [T]).

a) Modes MEM+MANU, LOC.MEM, LOC.MANU :

Countdown of the

dosage operation in

progress

221 L

ENTER

CONTINUE

*

RESET

ENTER

221 L

*

ENTER

Device ready for a

new batch (see 4.3.1)

Current batch

continues

*

* When in mode MEM+MANU, LOC.MEM or LOC.MANU, you can also start the

dosage using the 'Start/Pause' Binary Data Input.

b) Mode EXT.MEM :

Countdown of the dosage

operation in progress

4

Pause

**

4

**

CONTINUE221 L

1

2

3

"zero" position: no

input is enabled

221 L

RESET

Current batch

continues

Device ready

**

4

(see 4.3.2)

for a new

batch

c) Mode EXT [T] :

221 L

4

Pause

**

CONTINUE

Choice "Reset" can only be

made on keypad.

RESET

**

4

4

221 L

Device ready

**

for a new batch

Current batch

continues

(see 4.3.3)

(**) When in mode EXT.MEM or EXT [T], you can also press the Enter key on the keypad.

E-18-

8035

Page 19

4 CONFIGURATION

BATCH CONTROLLER SE35

4.4. Calibration Menu: pressing simultaneously for 5 seconds

Within this menu, the following parameters may be set:

LANGUAGE

K-FACTOR

OPTION

OVERFILL

ALARM

RELAY

TOTAL

Choice of language used for prompts (German, English, French,

Italian, etc.)

Choice of measurement unit used for volume, flow rate and

UNIT

counters.

Entry of K factor or automatic evaluation using the «Teach in»

function.

Choice of the dosing mode

Overfill correction taken into account or not

Choice of options and programming of the time delay before the

alarm is triggered off.

Allocation of relay parameters: function, delay, inversion, etc.

Simultaneous resetting of both totalizers.

Return to main menu and entering the new Calibration parameters.

END

ENTER

4.4.1 Language

LANGUAGE

UNIT

8035

ENTER

ENTER

ENGLISH

DEUTSCH

FRANCAIS

ITALIANO

The required language becomes

operational when the ENTER key is

pressed.

E-19-

Page 20

4 CONFIGURATION

4.4.2 Unit

ENTER

UNIT BATCH

ENTER

BATCH CONTROLLER SE35

LITER

LITER

M3

ENTER

LIT/SEC

LIT/MIN

LIT/H

M3/MIN

M3/H

UGAL/SEC

UGAL/MIN

UGAL/H

IGAL/SEC

IGAL/MIN

IGAL/H

m

0......9

US GAL

IMP GAL

TOTAL

ENTER

ENTER

LITER

M3

US GAL

IMP GAL

K-FACTOR

ENTER

Note: Return to the main menu is only available from the «TOTAL» Sub-Menu.

4.4.3 K-factor

The K-factor of the fitting is entered within this menu (see instruction manual fitting S030).

The "TEACH IN" function allows the practical determination of the specific K-factor. The

user only needs to run a known volume through his system.

Example: In order to determine a volume as accurately as possible, the user shall fill a tank

of 100 l. When the message "TEACH YES" appears, he presses the ENTER key to start the

measuring procedure. The message "FILL END" (end of filling) will appear. He then switches

on a pump or opens a valve. As soon as the tank is empty, he switches off the pump or

closes the valve. Pressing Enter stops the measurement. The user will then be asked to

enter the volume (100 l). The calculated K-factor is displayed after confimation.

E-20-

8035

Page 21

4 CONFIGURATION

BATCH CONTROLLER SE35

Note: The device uses the last K-factor entered or determined .

K-FACTOR

ENTER

TEACH N

OPTION

TEACH O END DOSE

OPTION

Note: A decimal point can be entered by simultaneously pressing keys . It will

ENTER

ENTER

ENTER

Start of measurement.

Indication of calculated

K-factor.

K=000.00

0......9

K=046.60

K=044.12

Entering of K-factor as

specified in the charts.

ENTER

Stop of

measurement.

Entering the measured

volume. Same unit as for flow.

ENTERENTER

0000.0 L

0......9

0200.0 L

0......9

always be positioned to the right of the flashing digit. Three positions are possible, «00000»,

«0000.0» or «000.00».

Adjustment range for the K factor : 0,01 to 99999.

4.4.4. Dosing Options

Selection the dosing option from: LOC.MEM, LOC.MANU, MEM+MANU, EXT.MEM, and

EXT.[T].

For more information on these options, see § 4.2

8035

E-21-

Page 22

4 CONFIGURATION

BATCH CONTROLLER SE35

OPTION

OVERFILL

OVERFILL

OVERFILL

OVERFILL

ENTER ENTER

LOC.MEM

LOC.MANU

+

MANU

MEM

EXT.MEM

ENTER

ENTER

ENTER

V1

=

00000

0......9

V1

=

00100

V1

=

00000

0......9

V1=00100

V1

=

00000

0......9

V1

=

00100

ENTER

ENTER

ENTER

V7

V7

V7

V7

V7

V7

=

00000

=

00700

=

00000

=

00700

=

00000

=

00700

0......9

ENTER

0......9

ENTER

0......9

ENTER

EXT. [T] A

OVERFILL

When entering volumes (quantities) V1 to V7, the measurement unit which applies is that

which was selected for the the dosing volume (see Calibration Menu).

Note: A decimal point can be entered by simultaneously pressing keys . It will

always be positioned to the right of the flashing digit.

ENTER

E-22-

=

0000/S

=

0005/S

A

0......9

ENTER

ENTER

=

B

B

=

0050 L

0......9

0000 L

0......9

8035

Page 23

4 CONFIGURATION

BATCH CONTROLLER SE35

4.4.5. Overfill correction

The 8035 Batch controller has an overfill correction facility. It memorises the fluid volume

which flows after the closure of the valve so that this volume can be deducted from the next

batch. In this sub-menu the user enables or disables the overfill correction facility.

OVERFILL

ALARM

ENTER

ENTER

OVERF. NO

OVERF. Y

4.4.6 Alarm

The menu makes it possible to enable or disable the trigger-off of the alarm during a

dosage (DURING option) and/or after a dosage (AFTER option). It also makes it

possible to program the time delay before the alarm is triggered off, for either option.

The alarm display prompt is «

ALARM

». This alarm data prompt is also available on tag

strip terminal N°. 5 (transistor output, open collector) and on Relay N° 2 if this relay

has been configured as an alarm relay (see next paragraph).

For the conditions required to trigger off the alarm, see Section 5.

ALARM

ENTER

DURING

ENTER

ON

OFF

ENTER

ENTER

DEL1= 000

0......9

DEL1

=

015

ENTER

AFTER

ENTER

ON

ENTER

DEL2

DEL2

=

=

000

0......9

015

OFF

ENTER

ENTER

RELAY

Range of adjustment: between 0 and 999 seconds.

Remark: The time delay before the alarm is triggered off must take into account the

overfill correction if enabled.

8035

E-23-

Page 24

4 CONFIGURATION

4.4.7. Relays

The 8035 Batch controller provides 2 relays:

- Relay 1 controls the opening of the main valve (high flow rate). A delay before activation

may be selected and the operating polarity may be inverted; the user also has the facility

of setting the percentage of the selected volume to be delivered through the main valve

(high flow rate). This implies that the Relay 2 controls an auxiliary valve (low flow rate) in

order to provide the remainder of the entire selected volume.

- Relay 2 can be configured for three different functions: Alarm, End of the dosing and

Control of an auxiliary valve. In each configuration the operating polarity can be inverted.

BATCH CONTROLLER SE35

E-24-

8035

Page 25

4 CONFIGURATION

BATCH CONTROLLER SE35

RELAY

TOTAL

ENTER ENTER

RELAY 1

RELAY 2

ENTER

=

000

DEL

0......9

=

020

DEL

INV NO

INV YES

ALARM

END DOSE

ENTER

ENTER

ENTER

ENTER

ENTER

100 %

0......9

85 %

INV NO

INV YES

ENTER

INV NO

INV YES

TOTAL

VALVE

ENTER

ENTER

INV NO

INV YES

TOTAL

Notes:

- If Relay 1 is configured for a percentage flow rate different from 100, then Relay 2 will

automatically be configured for valve control. The other options will no longer be available.

- Relay 1 will not open the valve until the entered delay period has elapsed.

8035

E-25-

ENTER

Page 26

4 CONFIGURATION

4.4.8 Totalizer

Simultaneous setting of both counters to zero. This facility becomes operational when the

user presses the ENTER key while in the «END» option within the Calibration menu.

BATCH CONTROLLER SE35

TOTAL

ENTER

RES NO

RES YES

END

4.5 Test Menu: Press simultaneously for 5 s.

The following adjustments and checks are carried out in the Test Menu:

ENTER

0......9

EXT.ACT.

RELAY 1

RELAY 2

FREQUENC

END

ENTER

Verification of the binary data inputs in mode «EXT.MEM».

Readout of Pulse duration in «EXT.[T] mode.

Check on relay 1 operation.

Check on relay 2 operation.

Transducer frequency readout

Return to the Main Menu and the setting of new parameters.

4.5.1 EXT.ACT.

This sub-menu provides for checking the allocation of binary logic levels to the binary data

inputs under the «EXT.MEM» dosing option and also provides a readout of the pulse duration

under option «EXT [T]».

«EXT.MEM» Option

EXT.ACT.

RELAY 1

ENTER

V 1 V4

Readout of quantities corresponding to the coding of the binary

ENTER

inputs (by using the rotary knob, for example). If the readout

shows «--» the coding of the inputs corresponds to a zero volume.

E-26-

8035

Page 27

4 CONFIGURATION

«EXT. [T] Option

In this option, the user can check the pulse duration being sent to the 8035 Batch controller.

EXT.ACT.

RELAY 1

4.5.2. Check on operation of relays

This option allows the operator to check for correct operation of the relays by using the

keypad to energise the relays.

ENTER

0.00 SEC

Start of pulse End of pulse

ENTER

BATCH CONTROLLER SE35

. . . . SEC

5.35 SEC

RELAY 1 REL OFF

ENTER

ENTER

REL ON

RELAY 2 REL OFF

ENTER

REL ON

ENTER

FREQUENC

4.5.3. Frequency readout

Readout of paddlewheel rotation frequency. To clear the display and proceed to the next

option, press the ENTER key.

END

ENTER

ENTER

FREQUENC 15.25 HZ

Note: After the display of the «FREQUENC» prompt, pressing the ENTER key will energise

Relay 1 (to open the valve).

8035

E-27-

Page 28

5 MAINTENANCE

BATCH CONTROLLER SE35

5.1 Fault prompts

5.1.1. «

ALARM

"ALARM" PROMPT DURING A DOSAGE

The «

ALARM

dosage option) if one or both valves are open but the controller does not detect any flow.

The time delay before triggering the alarm is set in the Calibration menu. (see § 4.4.6).

A dosage that has been stopped by the alarm can either be continued or cancelled:

a) Manual or automatic dosage activated by LOC.MANU, LOC.MEM or MEM+MANU:

» prompt

« prompt will be displayed during a dosage operation (irrespective of the

ALARM

ENTER

CONTINUE

ENTER

Current batch

continues

*

ENTER

RESET

Device ready for a new batch

(see 4.3.1 or 4.3.2)

*

* When in mode MEM+MANU, LOC.MEM or LOC.MANU, you can also start the

dosage using the 'Start/Pause' Binary Data Input.

b) Dosage through Binary Inputs and activated by EXT.MEM :

Device ready for a

new batch (see 4.3.2)

**

3

CONTINUE

4

Current batch

continues

ALARM

1

2

then

3

Place the Binary

Inputs to 0

OR

4

1

2

**

4

RESET

Place the Binary

Inputs to the position

of the current dosage

**

(**) When in mode EXT.MEM or EXT [T], you can also press the Enter key on the keypad.

E-28-

8035

Page 29

5 MAINTENANCE

BATCH CONTROLLER SE35

c) Dosage through Binary Inputs and activated by EXT.MEM :

Device ready for a

ALARM

**

4

RESET

Choice "Continue" can only

be made on keypad.

CONTINUE

**

4

4

new batch (see 4.3.3)

**

221 L

Current batch

continues

(**) When in mode EXT.MEM or EXT [T], you can also press the Enter key on the keypad.

"ALARM" PROMPT AT THE END OF A DOSAGE

The «

ALARM

» prompt will be displayed at the end of a dosage operation (irrespective of

the dosage option) if one or both valves are closed and if the controller detects that there

is still a flow condition after the time delay period before alarm triggering has elapsed.

Note: The alarm time delay must take account of any jet correction that may have been

entered (the fluid quantity which continues to flow after the closure of the valve).

a) Manual or automatic dosage activated by LOC.MANU, LOC.MEM or MEM+MANU:

ALARM

ENTER

Device ready for a

new batch (see 4.3.1)

b) Dosage through Binary Inputs and activated by EXT.MEM or EXT [T]:

ALARM

4

new batch (see 4.3.2)

Device ready for a

**

(**) When in mode EXT.MEM or EXT [T], you can also press the Enter key on the keypad.

8035

E-29-

Page 30

BATCH CONTROLLER SE35

5.1.2.«[T] ERROR» prompt

This error prompt only occurs in the «EXT.[T]» option. It is displayed during a dosing

operation if the duration of the pulse is greater than 300 seconds, or if it is greater than the

duration necessary to deliver the relevant volume.

It will also appear if the volume to deliver is greater than 100000 (l, m3, etc.) or if the volume

delivered has reached 100000 (l, m3, etc.) and when the pulse has not been switched off.

T [ERROR]

(**) When in mode EXT.MEM or EXT [T], you can also press the Enter key on the keypad.

5.1.3. «ERROR» prompt

The «ERROR» prompt flashes then the calibration parameter values have been lost. Press

the ENTER key, the Main Menu is displayed, but the unit is set in the basic default

configuration (see § 5.3). It is necessary to re-program the driver unit. If the display of this

prompt recurs, return the unit to your supplier.

4

Device ready for a new batch

(see 4.3.3)

**

5.2. Transducer maintenance

In correct installation conditions, the 8035 Batch controller is maintenance free. If clogging

occurs, the immersed parts of the sensor can be cleaned with water or any other cleaning

agent suitable for use with PVDF.

E-30-

8035

Page 31

5 MAINTENANCE

BATCH CONTROLLER SE35

5.3 Factory setting of Batch controller SE35 INLINE on delivery

Language: English

Unit flow: L/s

Unit totalizers: L

Unit batch: L

K-Factor: 001.00

Batch option: MEM+MANU

Quantities V1 to V7: 00000

Language:

Unit flow:

Unit totalizers:

Overfill correction: yes

Alarm DURING: On, DEL1 = 100

Alarm AFTER: On, DEL2 = 100

Relay 1: DEL = 000

100 %

inversion: NO

Relay 2: VALVE

inversion: NO

Overfill correction:

Alarm DURING: DEL1 =

Alarm AFTER: DEL2 =

Unit batch:

K-Factor:

Relay 1: inversion:

Batch option:

Quantities V1 to V7:

Relay 2: inversion:

5.4. Spare Parts List

Controller electronic module SE35 BATCH, 2 totalizers

Position Specification Order N°.

1 Sensor housing with 2 flat seals 425248

2 PG 13.5 444778

3 PG 13.5 USA-version (G 1/2 ") 444779

4 Cover with screws, sheeting and printed circuit board

Controller software version Batch 425432

5 Power supply board 115/230 VAC 419581

Instruction manual Fitting S030 426107

Instruction manual controller 419744

8035

E-31-

Page 32

BATCH CONTROLLER SE35

E-32-

8035

Page 33

ANHANG - ANNEX - ANNEXE

Durchfluss-Diagramm (l/s, l/min, m3/h, DN in mm und m/s)

Flow chart (l/s, l/min, m3/h, DN in mm und m/s)

Abaque débit/vitesse/diamètre (l/s, l/min, m3/h, DN en mm et m/s)

m3/h

l/s

l/s l/min

Durchfluss

Flow

Débit

500

100

100

50

10

10

5

1

0.5

0.1

0.05

0.01

0.005

5000

l/min

50000

2000

1000

10000

m3/h

500

500

5000

5000

200

1000

1000

100

10

2

1

0.5

0.3

0.2

200

100

100

50

50

500

500

20

20

10

10

100

5

5

50

50

2

2

20

20

1

1

10

0.5

0.5

5

5

0.2

3

3

0.2

2

0.1

0.1

1

0.05

0.05

0.02

0.01

0.3 0.5 1 2 3 5 10

0.1 0.2

0.2

0.1

0.3 0.5

DN 200

DN 150

DN 100

DN 80

DN 65

DN 50

DN 40

DN 32

DN 25

DN 20

DN 15

1235

50

5

1

0.5

0.1

10

DN 400

DN 350

DN 300

DN 250

DN 200

DN 150

DN 125

DN 100

DN 80

DN 65

DN 50

DN 40

DN 32

DN 25

DN 20

DN 15

DN 10

m/s

m/s

SE35

Durchflussgeschwindigkeit - Flow velocity - Vitesse du fluide

Auswahlbeispiel/Example/Exemple

Vorgabe/Specifications/Données

Nominaler Durchfluss/Flow/Débit 10 m3/h

Ermittlung mit idealer Durchflussgeschwindigkeit: 2...3 m/s

Determination with ideal flow velocity: 2...3 m/s

Vitesse optimale du fluide 2...3 m/s

Aus dem Diagramm resultiert die erforderliche Nennweite von DN 40

With these specifications, the required orifice as defined by the flow chart is DN 40

Selon l'abaque un raccord de DN 40 est le mieux approprié.

8035

A-1-

Page 34

ANHANG - ANNEX - ANNEXE

Durchfluss-Diagramm (gpm, DN in inch und fps)

Flow chart (gpm, DN in inch and fps)

Abaque débit/vitesse/diamètre (US-gallon/min, DN en inch et ft/s)

SE35

gpm

20000

10000

5000

2000

1000

Durchfluss

Flow

Débit

500

200

100

0.5

0.2

0.1

0.05

16''

14''

12''

10''

8''

6''

5''

4''

3''

2 1/2''

2''

1 1/2''

1 1/4''

1''

50

20

10

5

2

1

3/4''

1/2''

3/8''

0.02

0.01

fps

30200.3 0.5 1 2 3 5 10

Durchflussgeschwindigkeit - Flow velocity - Vitesse du fluide

Auswahlbeispiel/Example/Exemple

Vorgabe/Specifications/Données

Nominaler Durchfluss/Flow/Débit50 gpm

Ermittlung mit idealer Durchflussgeschwindigkeit: 8 fps

Determination with ideal flow velocity: 8 fps

Vitesse optimale du fluide 8 fps

Aus dem Diagramm resultiert die erforderliche Nennweite von DN 40

With these specifications, the required orifice as defined by the flow chart is DN 40

Selon l'abaque un raccord de DN 40 est le mieux approprié.

A-2-

8035

Page 35

SERVICE

Australia

Burkert Fluid Control Systems

Unit 1 No.2, Welder Road

Seven Hills NSW 2147

Tel +61 (0) 2 967 461 66

Fax +61 (0) 2 967 461 67

Austria

Bürkert Contromatic GmbH

Central and Eastern Europe

Diefenbachgasse 1-3

A-1150 Wien

Tel +43 (0) 1 894 13 33

Fax +43 (0) 1 894 13 00

Belgium

Bürkert Contromatic N.V/S.A

Middelmolenlaan 100

B-2100 Deurne

Tel +32 (0) 3 325 89 00,

Fax +32 (0) 3 325 61 61

Canada

Bürkert Contromatic Inc.

760 Pacific Road, Unit 3

Oakville, Ontario, L6L 6M5

Tel +1 905 847 55 66,

Fax +1 905 847 90 06

China

Bürkert Contromatic

(Suzhou) Co. Ltd.

9-2, Zhu Yuan Road

New District, Suzhou

Jiangsu, 215011 P.R.C

Tel +86 512 808 19 16

Fax +86 512 824 51 06

Bürkert Contromatic

China/HK Ltd.

Rm. 1313

No. 103, Cao Bao Road

200233 Shanghai P.R.C

Tel +86 21 6427 1946

Fax +86 21 6427 1945

Bürkert Contromatic

China/HK Ltd.

Beijing Office

Rm. 808, Jing Tai Building

No. 24, Jianguomen

Waidajie

100022 Beijing P.R.C

Tel +86 10 65 15 65 08

Fax +86 10 65 15 65 07

Bürkert Contromatic

China/HK Ltd.

Cheng Du Representative Office

Rm. 502, Fuji Building

No. 26 Shududadao

Dongfeng Street

Chengdu P.R.C

Tel +86 28 443 1895

Fax +86 28 445 1341

Bürkert Contromatic

China/HK Ltd.

Guangzhou Representative Office

Rm. 1305, Tower 2

Dong-Jun Plaza

Dongfeng, Road East

Guangzhou P.R.C

Tel +86 28 443 1895

Fax +86 28 445 1341

Denmark

Bürkert-Contromatic A/S

Hørkær 24

DK-2730 Herlev

Tel +45 44 50 75 00

Fax +45 44 50 75 75

Finland

Bürkert Oy

Atomitie 5

SF-00370 Helsinki

Tel +358 (0) 9 549 706 00

Fax +358 (0) 9 503 12 75

France

Bürkert Contromatic

B.P. 21

Triembach au Val

F-67220 Villé

Tel +33 (0) 388 58 91 11

Fax +33 (0) 388 57 09 61

Germany / Deutschland

Bürkert Steuer- und Regeltechnik

Christian-Bürkert-Straße 13-17

D-74653 Ingelfingen

Tel +49 7940 10-0

Fax +49 7940 10 361

Niederlassung NRW

Holzener Straβe 70

D-58708 Menden

Tel +49 2373 96 81-0

Fax +49 2373 96 81-52

Niederlassung Frankfurt

Am Flugplatz 27

D-63329 Egelsbach

Tel +49 6103 94 14-0

Fax +49 6103 94 14-66

Niederlassung München

Paul-Gerhardt-Allee 24

D-81245 München

Tel +49 89 82 92 28-0

Fax +49 89 82 92 28-50

Niederlassung Berlin

Bruno-Taut-Straβe 4

D-12524 Berlin

Tel +49 30 67 97 17-0

Fax +49 30 67 97 17-66

Niederlassung Dresden

Christian Bürkert Straße 2

D-01900 Großröhrsdorf

Tel +49 35952 3 63 00

Fax +49 35952 3 65 51

Niederlassung Hannover

Rendsburger Straße 12

D-30569 Hannover

Tel +49 511 9 02 76-0

Fax +49 511 9 02 76-66

Niederlassung Stuttgart

Karl-Benz-Straße 19

D-70794 Filderstadt (Bernh.)

Tel +49 711 4 51 10-0

Fax +49 711 4 51 10-66

Great Britain

Bürkert Contromatic Ltd.

Brimscombe Port Business Park

Brimscombe, Stroud, Glos.

GL5 2QF

Tel. +44 (0) 1453 73 13 53

Fax +44 (0) 1453 73 13 43

Hong Kong

Burkert Contromatic

(China/HK) Ltd.

Unit 708, Prosperity Centre

77-81 Container Port Road

Kwai Chung N.T.

Hong Kong

Tel +852 248 012 02

Fax +852 241 819 45

Italy

Bürkert Contromatic Italiana S.p.A.

Centro Direzionale 'Colombirolo'

Via Roma 74

I-20060 Cassina De' Pecchi (MI)

Tel +39 02 959 071

Fax +39 02 959 07 251

Japan

Bürkert Contromatic Ltd.

3-39-8 Shoan

Suginami-ku

Tokyo 167-0054

Tel +81 (0) 3 3247 3411

Fax +81 (0) 3 3247 3472

Korea

Bürkert Contromatic Korea Co. Ltd.

4-10 Yangjae-Dong

Seocho-Ku

Seoul 137-130

Tel. +82 (0) 2 346 255 92

Fax +82 (0) 2 346 255 94

Page 36

SERVICE

Malaysia

Bürkert Malaysia Sdn. Bhd.

N° 22 Lorong Helang 2

11700, Sungai Dua

Penang

Tel. +60 (0) 4 657 64 49

Fax +60 (0) 4 657 21 06

Netherlands

Bürkert Contromatic BV

Computerweg 9

NL-3606 AV Maarssen

Tel. +31 (0) 346 58 10 10

Fax +31 (0) 346 56 37 17

New Zealand

Burkert Contromatic Ltd.

Unit 5, 23 Hannigan drive

Mt Welligton

Auckland

Tel +64 (0) 9 570 25 39

Fax +64 (0) 9 570 25 73

Norway

Bürkert Contromatic A/S

Hvamstubben 17

Box 243

N-2026 Skjetten

Tel +47 63 84 44 10

Fax +47 63 84 44 55

Philippines

Bürkert Contromatic Inc.

8467, West Service Rd Km 14

South Superhighway, Sunvalley

Paranaque City, Metro Manila

Tel +63 (0) 2 776 43 84

Fax +63 (0) 2 776 43 82

Poland

Bürkert Contromatic Sp.z.o.o.

Bernardynska street

PL-02-904

Warszawa

Tel +48 (0) 22 840 60 10

Fax +48 (0) 22 840 60 11

Singapore

Burkert Contromatic Singapore Pte.Ltd.

No.11 Playfair Road

Singapore 367986

Tel +65 383 26 12

Fax +65 383 26 11

Spain

Bürkert Contromatic Española S.A.

Avda. Barcelona, 40

E-08970 Sant Joan Despi,

Barcelona

Tel +34 93 477 79 80

Fax +34 93 477 79 81

South Africa

Burkert Contromatic Pty.Ltd.

P.O.Box 26260, East Rand 1462

Republic of South Africa

Tel +27 (0) 11 397 2900

Fax +27 (0) 11 397 4428

Sweden

Bürkert Contromatic AB

Skeppsbron 13 B

S-21120 Malmö

Tel +46 (0) 40 664 51 00

Fax +46 (0) 40 664 51 01

Bürkert Contromatic AB

Havsörnstorget 21

Box 1002

S-12349 Farsta

Tel +46 (0) 40 664 51 00

Fax +46 (0) 8 724 60 22

Switzerland

Bürkert-Contromatic AG Schweiz

Bösch 71

CH-6331 Hünenberg / ZG

Tel +41 (0) 41 785 66 66

Fax +41 (0) 41 785 66 33

Taiwan

Bürkert Contromatic Taiwan Ltd.

3F No. 475 Kuang-Fu South Road

R.O.C - Taipei City

Tel +886 (0) 2 275 831 99

Fax +886 (0) 2 275 824 99

Turkey

Bürkert Contromatik

Akiskan Kontrol Sistemleri Ticaret

A.S

1203/8 Sok. No. 2-E

Yenisehir

Izmir

Tel +90 (0) 232 459 53 95

Fax +90 (0) 232 459 76 94

Tzechia

Bürkert Contromatic Spol.s.r.o

Prosenice c. 180

CZ - 751 21 Prosenice

Tel +42 0641 226 180

Fax +42 0641 226 181

USA/West/Main office

Burkert Contromatic Corp.

2602 McGaw Avenue

Irvine, CA 92614, USA

Tel. +1 949 223 31 00

Fax +1 949 223 31 98

USA/South

Burkert Contromatic Corp.

6724 Alexander Road

Charlotte, North Carolina, 28270

Tel. +1 704 367 11 73

Fax +1 704 367 11 74

USA/North-East

Burkert Contromatic Corp.

7173 Thermal Road

Charlotte, North Carolina, 28211

Tel. +1 704 386 21 41

Fax +1 704 366 24 28

USA/West

Burkert Contromatic Corp.

4449 East Bradford

Orange, CA 92867

Tel. +1 714 637 26 39

Fax +1 714 637 21 62

USA/Mid-West

Burkert Contromatic Corp.

726 Evergreen Street North

Royalton, MN 56373

Tel. +1 320 584 58 47

Fax +1 320 584 58 71

Loading...

Loading...