Page 1

INSTALLATION MANUAL

ELECTROMAGNETIC FLOWMETER

“FULL BORE” SENSORS

Page 2

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

INDEX

INTRODUCTION .................................................................................... 3

START UP AND MAINTENANCE OF THE INSTRUMENTS ........................... 3

SAFETY ................................................................................................. 4

GENERAL INFORMATION ON THE SENSORS INSTALLATION .................... 4

OPERATING TEMPERATURES ................................................................. 5

ELECTRICAL CONNECTIONS OF SENSOR TO TRANSMITTER .................... 6

GROUNDING INSTRUCTIONS ................................................................. 7

TORQUES (Nm) FOR SENSOR BOLTS (FLANGED & WAFER) ..................... 8

NOTE FOR 3A APPROVED SENSORS ....................................................... 8

2

ESENS_FULLBORE_05.doc

Page 3

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

INTRODUCTION

- This manual is integral part of the product. Read carefully the instructions

contained since it contains important indications for the safety of use and

of maintenance.

- The technical information and the relative products of this manual could be

modified without any previous notice.

- The flowmeter must be used for the use it has been built for. The improper

use, possible tampering of the instrument or parts of it and substitutions of

any components not original, makes the warranty to decay automatically.

- The manufacturer is considered responsible only if the instrument is used in

its original configuration and setting.

- The flowmeter makes measures of liquids with conductivity greater than

5µS/cm; it consists of a sensor (described in this manual) and a converter,

for it see the manual provided.

- If the sensor is supplied in compact version to the converter, consider the

operating temperatures more restrictive, otherwise refer to the respective

manuals.

- When transporting, unpacking and handling the flowmeter, be careful and

care.

- In the case of prolonged storage and of transport, use and store in the

original container in a dry place, do not place more than 3 packs one above

the other. It is possible pallets storage and transport (in case of wooden

crates do not place one above the other).

- For the cleaning of the device use only a damp cloth, and for the

maintenance/repairs, contact the customer service.

- For the disposal of the device and of the packaging make strict reference to

the regulations.

- It is forbidden the reproduction of the present manual and of possible

software supplied with the instrument.

START UP AND MAINTENANCE OF THE INSTRUMENTS

- Before starting up the instrument, always make a secure connection to

ground as suitable to page 6.

- Verify periodically: the cables integrity, the tightening of the sealing

elements (cable glands, covers, etc.), the mechanical fixing of the

instrument on the pipe or on the wall.

3

ESENS_FULLBORE_05.doc

Page 4

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

T

SAFETY

GENERAL INFORMATION ON THE SENSORS INSTALLATION

o

Flow direction

Before installing the sensor checkthe

direction of the liquid in the piping.

The sign of the flow rate is positive,

when the flow direction is from – to +

as printed on the tag plate.

If the device is mounted in the reverse

normal flow direction, the sign of the

flow rate can be corrected by changing

the sign of the coefficient KA.

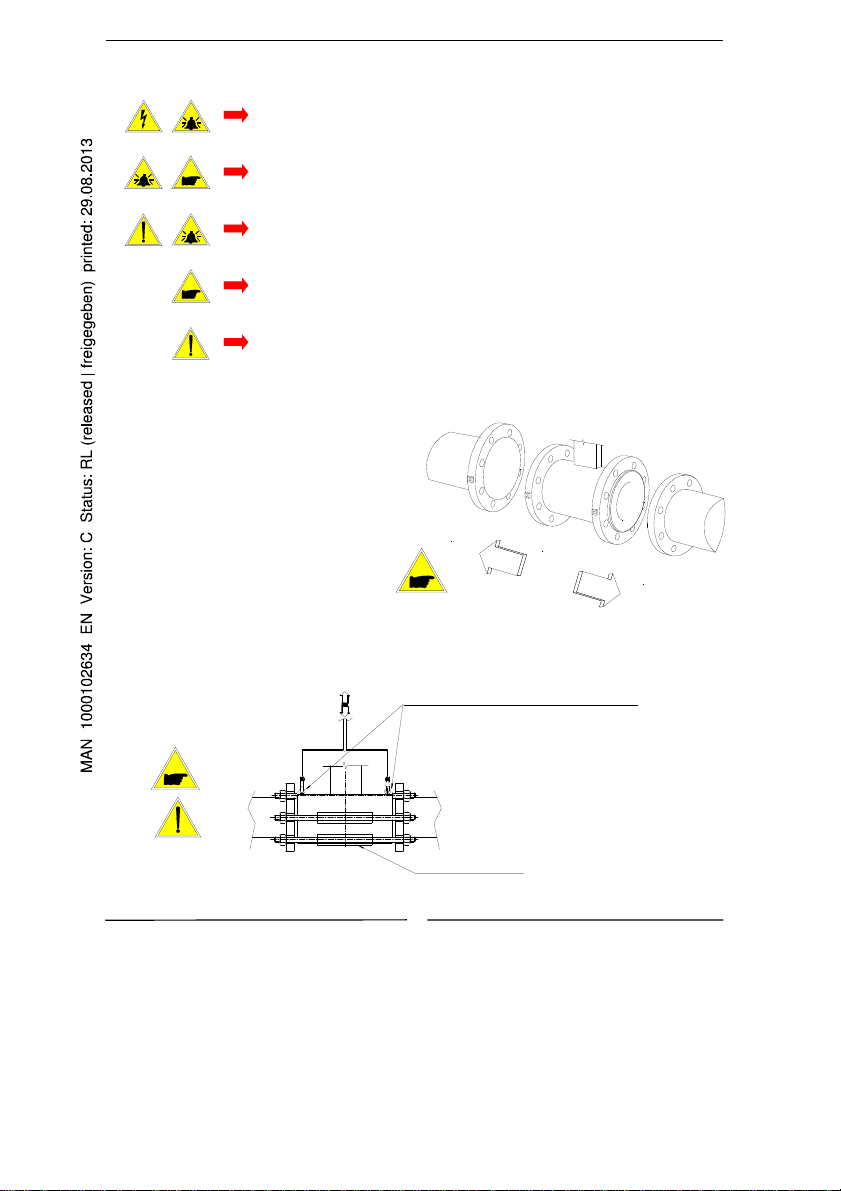

o Installation (Method recommended for ALL THE SENSOR WITH EYEBOLT)

Before using the instrument, always make a secure

connection to the ground

Avoid any attempt to repair the instrument. If the instrument

is not functioning properly, please call the nearest assistance

service

Pay maximum attention during the operations

ATTENTION !!!

DANGER !!!

?

he eye-bolt are measured to sustain

exclusively the weight of the meter

Centring cylinders

N.B.: For sensor S054 we recommend the use of centring cylinders

4

+

ESENS_FULLBORE_05.doc

Page 5

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

A

g

g

g

g

g

g

A

A

g

g

f

A

g

y

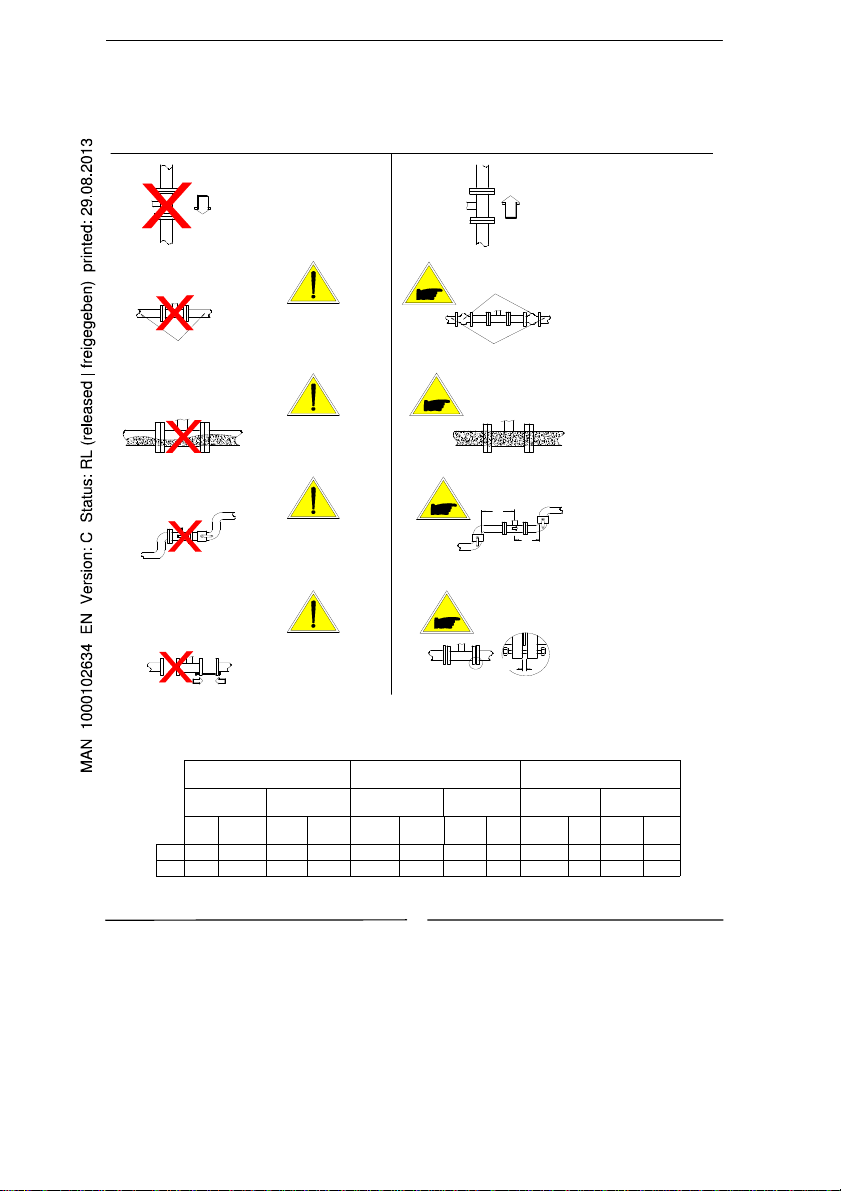

o Shrewdness and precautions

NO YES

For vertical installations with

descending flow direction

contact the manufacturer

LONG PIPE

void the installation of the

sensor in a lon

without an

same

pipe,

support of the

NTI VIBRATION JOINTS

LONG PIPE

void operatingwhen the

pipe is partially empty

void the installation next to

bows in pipes and respect

min. inlet and outlet sections

3 X DN

2 X DN

Avoid the approach of the

e and counter flange

flan

the closing force o

usin

the nuts

GASKET THICKNESS + 4mm

OPERATING TEMPERATURES

EBONITE LINING PP LINING PTFE LINING

Liquid Temp.

Min. Max Min. Max Min. Max Min. Max Min. Max Min. Max

° C 0 80 -5 60 0 60 0 60 -20 130 -10 60

° F 30 176 23 140 32 140 32 140 -4 266 14 140

Ambient

Temp.

Liquid Temp.

Ambient

Temp.

Liquid Temp.

For vertical installations is

preferable an ascendin

For installations on lon

pipes, please use the

anti vibration joints

Durin

operation, the pipe

must be either completely full

of liquid, or completely empty

Install the sensor at a min.

distance to bows in pipes and

hydraulic accessories

htening the nuts,

Before ti

place both the flan

and device as near to

as possible.

Ambient

Temp.

flow

es of pipe

ether

5

ESENS_FULLBORE_05.doc

Page 6

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

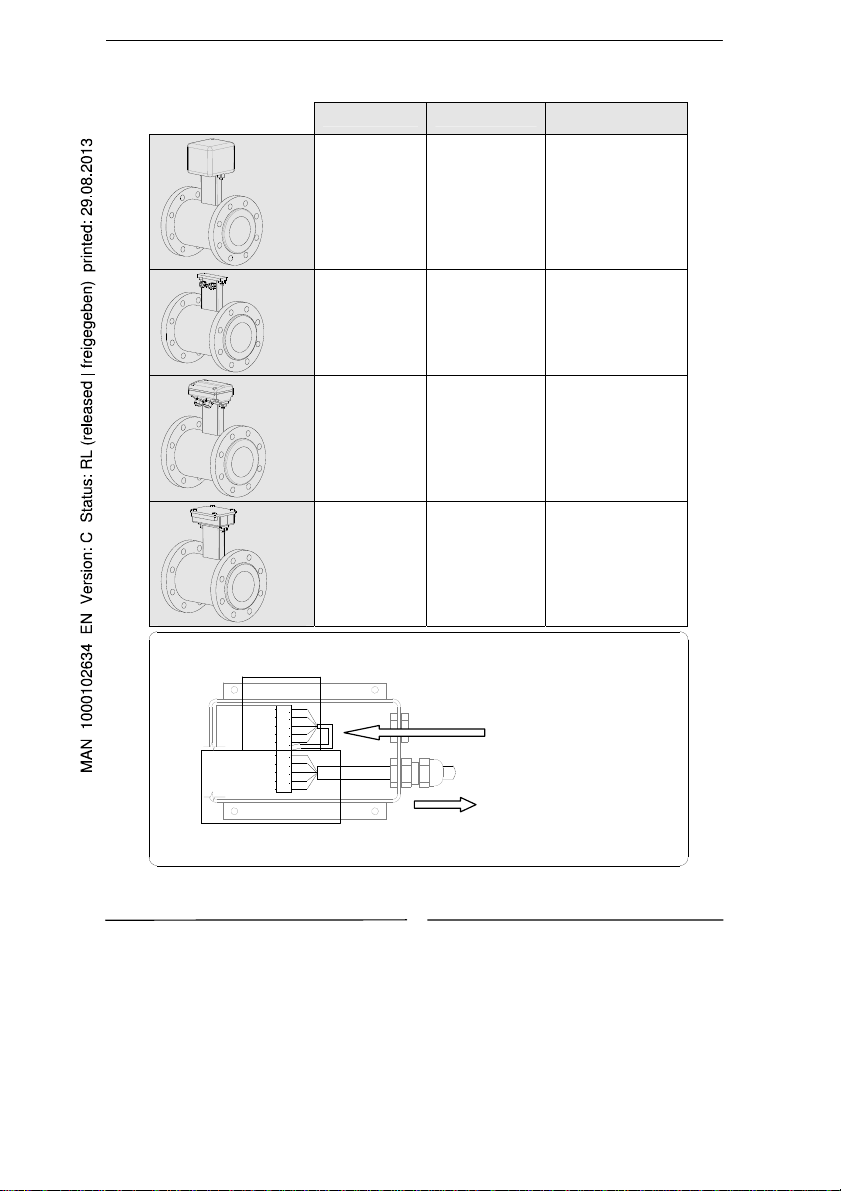

ELECTRICAL CONNECTIONS OF SENSOR TO TRANSMITTER

(CONNECTIONS TO TRANSMITTER: SEE RELATED MANUAL)

VERSION SUITABLE FOR

SENSOR’S

CONNECTION

COMPACT

ALL SENSORS

MODEL

NO CONNECTIONS

SEPARATE

WITHOUT

JUNCTIONS-

BOX

STAINLESS

STEEL MODEL

NO CONNECTIONS

REQUIRED

(CABLE ALREADY

CONNECTED AND

POTTED)

SEPARATE

WITH

JUNCTIONS-

BOX

ALL CARBON

STEEL MODELS

NO CONNECTIONS

REQUIRED

(CABLE ALREADY

CONNECTED AND

POTTED)

SEPARATE

WITH

PREAMPLIFIER

ALL SENSORS

MODEL

SEE BELOW

Cavo 1

Cavo 2

Cavo 3

Cavo 12

Cavo 13

Cavo 6

Cavo 7

Cavo 8

Cavo 9

Cavo 10

123456789

10

CABLE FROM INSIDE THE

SENSOR (PINS 1 – 5 ) ALREADY

CONNECTED

CABLE C014 TO THE

CONVERTER (PINS 6 – 10)

6

ESENS_FULLBORE_05.doc

Page 7

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

GROUNDING INSTRUCTIONS

For correct operation of the meter, it is NECESSARY that the sensor and the

liquid are equipotential, so ALWAYS connect the sensor and converter to

ground:

o

Grounding with metallic pipe

Sensors with ground socket

on the connection box

Wafer sensors Flanged sensors

METALLIC

RING

o Grounding with insulating pipe

INSULATING GASKET

If the sensor is mounted on a pipe made of an insulating material,

If the sensor has to be mounted on a

do one of the following:

pipe made of an insulating material

- Install a metallic ring between the sensor flange and the

is necessary:

pipe counter flange,

- or use a sensor with the additional grounding electrode.

- Install two metallic ring between

the sensor flanges and the counter

flanges of the pipe lin e or:

- Use a sensor with the additional

grounding electrode

Grounding when there is a cathodic protection over the pipe

oo

METALLIC RING

INSULATING GASKET

ISOIL

If the sensor is mounted on a pipe with a cathode protection, do the

If the sensor must be install

following:

in the piping with a chatode

- use insulating bushes to isolate the bolts,

protection, is necessary:

- insert insulating gaskets on both sides of the rings to

ground the metallic rings and hence the liquid.

INSULATING

BUSH

- using insulating bushes to isolate

the bolts

- Grounding metallic rings should be

provided to ground the liquid using

insulating gasket between the rings

- IMPORTANT :

- IMPORTANT :

The ripple of DC power source used

The ripple of DC power

for cathodic protection

source used for

shall be = 0

cathodic protection

must be 0.

7

ESENS_FULLBORE_05.doc

Page 8

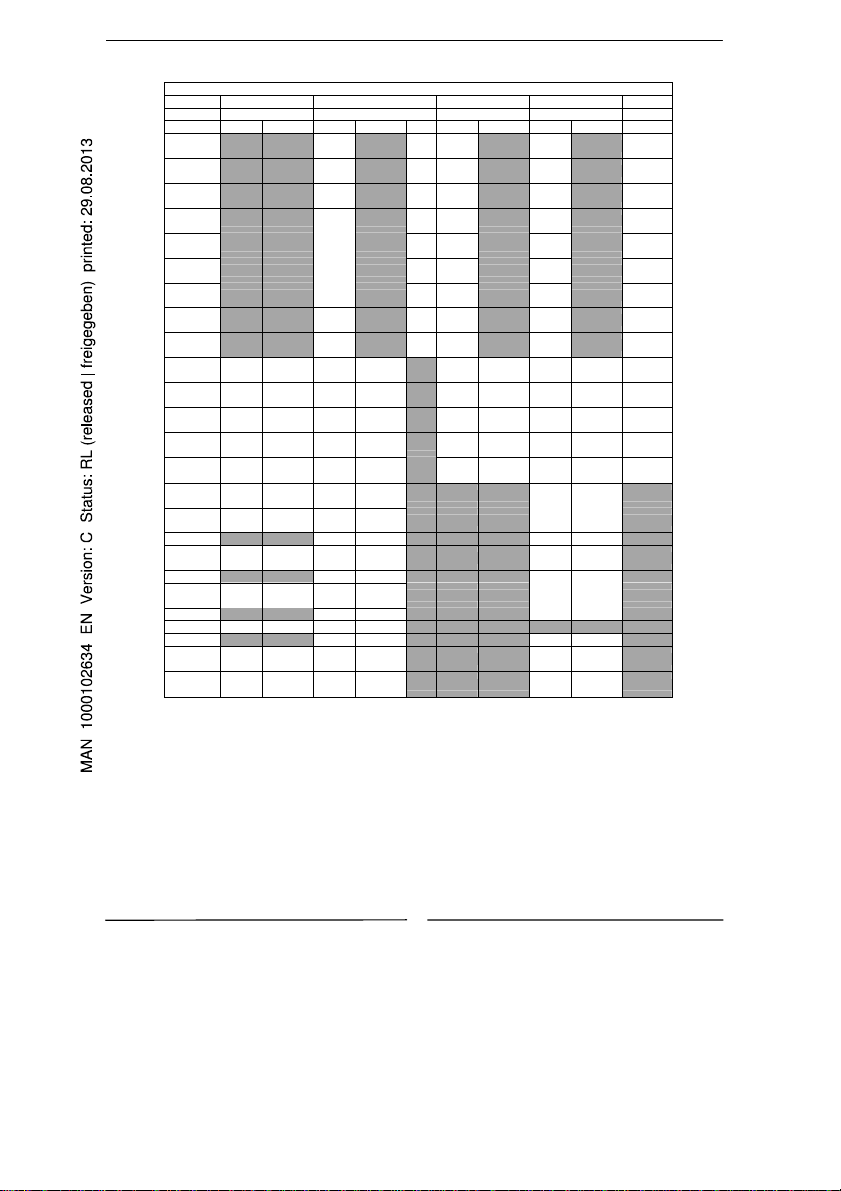

TORQUES (Nm) FOR SENSOR BOLTS (FLANGED & WAFER)

Kpa 1000 1600 2500 4000 6400

psi 140 260 350 600 1000

DN PTFE EBON. PTFE EBON. PP PTFE EBON. PTFE EBON. EBON.

25

32

40

50

65

80

100

125

150

200 148 432

250 123 359

300 142 415

350 172 502

400 217 632

450 194 564

500 224 652

550 (379) (1105) [608] [1772]

600 323 942

650 (429) (1251) [753] [2195]

700 356 1040

750 (451) (1315) [1105] [3223]

800 476 1388 549 1603

850 (563) (1642) [1373] [4006]

900 450 1312

1000 582 1699

OPERATIVE PRESSURE

25

(21)

43

(26)

53

(32)

68

(60)

90

(78)

53

(89)

59

(70)

77

(94)

108

(106)

99

288

(148)

(433)

140

408

(156)

(455)

175

510

(234)

(683)

205

598

(325)

(946)

282

821

(312)

(911)

281

981

(336)

(926)

382

1113

(317)

(924)

568

1658

(463)

(1350)

421

1230

(503)

(1468)

519

1515

(618)

(1803)

721

2105

(736)

(2146)

o Tighten uniformly in an alternating pattern

o The torque listed in tab are applicable to flanges:

EN1092-1, DIN 2501, BS 4504, ANSI B16.5 , JIS

o Use gaskets acc. to DIN 2690

o For DN > 1000 contact the manufacturer

o (***)= ANSI 150

o [***]= ANSI 300

NOTE FOR 3A APPROVED SENSORS

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

19 25

28 43

36 53

52 68

75 45

41 53

56 83

71 112

106 135

134 391

204 595

201 588

324 945

426 1243

[398] [1161]

[465] [1356]

[774] [2258]

[947] [2761]

[1408] [4106]

[1598] [4662]

8

25

[32]

43

[40]

53

[63]

68

[35]

45

[53]

53

[68]

83

[94]

112

[130]

135

[113]

178

520

[178]

[519]

267

780

[185]

[540]

278

812

[275]

[803]

422

1231

[318]

[927]

619

1805

[411]

[1198]

ESENS_FULLBORE_05.doc

39

[32]

53

[40]

72

[63]

81

[35]

58

[53]

62

[68]

87

[94]

148

[130]

217

[113]

816

[519]

1124

[540]

1108

[803]

1684

[927]

2180

[1198]

Page 9

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

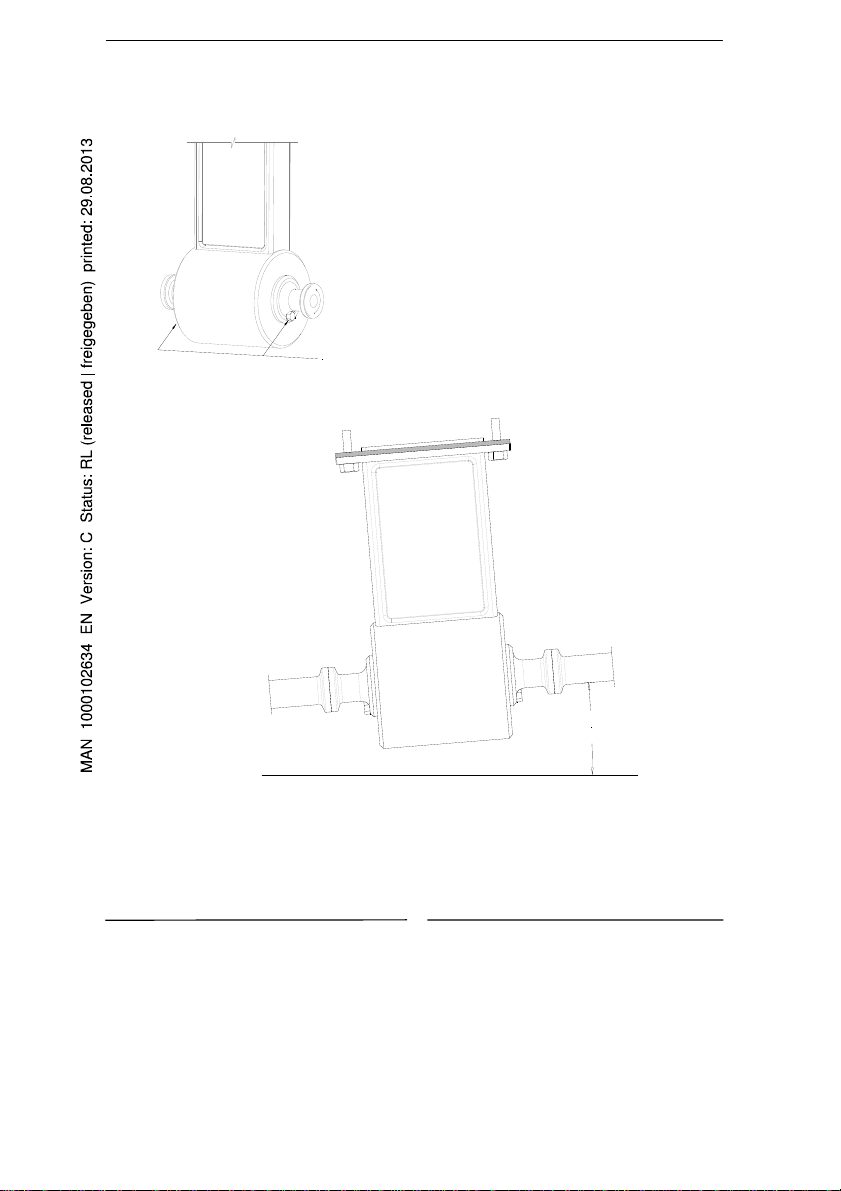

V

erify periodically the sensor’s seals integrity: with

piping full of liquid, unscrew the Inspection

screws (see drawing aside) and verify the total

absence of liquid from inspection hole!

After the above operation, REMEMBER to close

again the holes.

In case of leakage contact immediately our

Customer Service.

Inspection

screw

3°

When flowmeter is installed horizontally, ensure minimum angle of 3° for self draining purposes

9

ESENS_FULLBORE_05.doc

Page 10

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

10

ESENS_FULLBORE_05.doc

Page 11

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

11

ESENS_FULLBORE_05.doc

Page 12

SENSOR FOR ELECTROMAGNETIC FLOW METER – MANUAL

12

ESENS_FULLBORE_05.doc

Page 13

ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT

„FULL BORE“-SENSOREN

INSTALLATIONSANLEITUNG

Page 14

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

INHALTSVERZEICHNIS

EINLEITUNG ......................................................................................... 3

INBETRIEBNAHME UND WARTUNG DER GERÄTE .................................... 3

SICHERHEIT ......................................................................................... 4

ALLGEMEINE INFORMATIONEN ZUR INSTALLATION DER SENSOREN ....... 4

BETRIEBSTEMPERATUREN ..................................................................... 5

ELEKTRISCHE VERBINDUNGEN ZWISCHEN SENSOR UND TRANSMITTER . 6

ERDUNGSANWEISUNGEN ...................................................................... 7

DREHMOMENTE (Nm) FÜR DIE SENSORBOLZEN (FLANSCH /

ZWISCHENFLANSCH) ............................................................................. 8

HINWEIS FÜR SENSOREN MIT 3A-ZULASSUNG ....................................... 9

2

DE_ESENS_FULLBORE_05.doc

Page 15

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

EINLEITUNG

- Dieses Handbuch ist integraler Bestandteil des Gerätes. Lesen Sie die hierin

enthaltenen Anweisungen sorgfältig durch, da sie wichtige Hinweise zur

sicheren Verwendung und zur Wartung enthalten.

- Änderungen der technischen Daten der in diesem Handbuch genannten

Produkte sind ohne Vorankündigung vorbehalten.

- Das Durchflussmessgerät muss für den Zweck verwendet werden, für den

es entwickelt wurde. Bei unsachgemäßer Verwendung, Manipulationen des

Gerätes oder seiner Komponenten oder Einsatz von Ersatzteilen anderer

Hersteller verfällt sofort jeglicher Garantieanspruch.

- Der Hersteller ist nur haftbar, wenn das Gerät in seiner

Originalkonfiguration und -einstellung verwendet wird.

- Das Durchflussmessgerät nimmt Messungen an Flüssigkeiten mit einer

Leitfähigkeit von über 5µS/cm vor; es besteht aus einem Sensor (in dieser

Anleitung beschrieben) und einem Transmitter, für letzteren siehe das

entsprechende Handbuch.

- Wenn der Sensor in der Kompaktversion mit Transmitter geliefert wird,

bitte beachten, dass die Betriebstemperaturgrenzwerte restrictiver sind.

Für details siehe die jeweiligen Handbücher.

- Bei Transport, Auspacken und Handhabung des Durchflussmessers

vorsichtig und sorgfältig vorgehen.

- Bei längerfristiger Lagerung und beim Transport den Originalbehälter an

einem trockenen Ort lagern, dabei nicht mehr als 3 Packungen

übereinander stapeln. Für Lagerung und Transport können Paletten

verwendet werden (im Fall von Holzkisten: nicht stapeln).

- Zur Reinigung des Gerätes nur ein feuchtes Tuch verwenden, und für die

Wartung/Reparaturen den Kundendienst kontaktieren.

- Bei der Entsorgung des Gerätes und der Verpackung die gesetzlichen

Bestimmungen strikt einhalten.

- Die Vervielfältigung dieses Handbuchs und jeglicher mit diesem Gerät

gelieferten Software ist verboten.

INBETRIEBNAHME UND WARTUNG DER GERÄTE

- Vor Inbetriebnahme des Gerätes immer eine geeignete sichere

Erdungsverbindung sicherstellen, wie auf Seite 6 angegeben.

- Überprüfen Sie in regelmäßigen Abständen: die Unversehrtheit der Kabel,

den festen Sitz der Dichtelemente (Kabelmuffen, Abdeckungen usw.), die

mechanische Befestigung des Gerätes an der Rohrleitung oder der

Wandhalterung.

3

DE_ESENS_FULLBORE_05.doc

Page 16

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

V

A

SICHERHEIT

LLGEMEINE INFORMATIONEN ZUR INSTALLATION DER SENSOREN

or Installation des Sensors die

Strömungsrichtung in der Rohrleitung

beachten.

Das Vorzeichen des Durchflusses ist

positiv, wenn die Strömungsrichtung

von – nach + verläuft, wie auf dem

Typenschild angegeben.

Wenn das Vorzeichen des

Durchflusses nach der Installation

gewechselt werden muss, reicht es,

das Vorzeichen des Koeffizienten KA

zu wechseln

Vor Einsatz des Gerätes immer eine sichere

Erdungsverbindung herstellen

o

Strömungsrichtung

Nicht versuchen, das Gerät zu reparieren. Wenn das Gerät

nicht korrekt arbeitet, wenden Sie sich bitte an den

nächstgelegenen Kundendienst

Während des Betriebs maximale Aufmerksamkeit aufwenden

ACHTUNG!!!

GEFAHR!!!

?

o Installation (Empfohlene Methode für ALLE SENSOREN MIT RINGBOLZEN)

Die Ringbolzen sind so bemessen, dass sie

nur das Gewicht des Messgerätes tragen

Hinweis: Für Sensor S054 empfehlen wir die Verwendung von Zentrierzylindern

Zentrierzylinder

4

DE_ESENS_FULLBORE_05.doc

+

Page 17

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

o Korrekter Einbau und Vorsichtsmaßnahmen

NEIN JA

Für senkrechte Installationen

mit Strömungsrichtung nach

unten wenden Sie sich bitte

an den Hersteller

LANGE

ROHRLEITUNG

Eine Installation des Sensors

in einer langen Rohrleitung

ohne Unterstützung

vermeiden

SCHWINGUNGSDÄMPFENDE DICHTUNGEN

LANGE ROHRLEITUNG

Betrieb mit teilweise leerer

Rohrleitung vermeiden

Installation in der Nähe von

Krümmungen und

Hydraulikzubehör vermeiden

3 X DN

2 X DN

BETRIEBSTEMPERATUREN

Die Flansche von Rohrleitung

und Sensor nicht durch das

Festziehen der Muttern

annähern

DICKE DER DICHTUNG + 4 mm

HARTGUMMI-AUSKLEIDUNG PP-AUSKLEIDUNG PTFE-AUSKLEIDUNG

Flüssigkeits-

Temp.

Min. Max. Min. Max. Min. Max. Min.

°C 0 80 -5 60 0 60 0 60 -20 130 -10 60

°F 30 176 23 140 32 140 32 140 -4 266 14 140

Umgebungs-

Temp.

Flüssigkeits-

Temp.

Umgebungs-

Temp.

Max

.

Flüssigkeits-

Temp.

Min.

Für senkrechte Installationen

ist die Strömungsrichtung

nach oben vorzuziehen

Für Installationen an langen

Rohrleitungen bitte

schwingungsdämpfende

Dichtungen verwenden

Im Betrieb muss die

Rohrleitung ganz mit

Flüssigkeit gefüllt oder völlig

leer sein

Den Sensor nicht in der Nähe

von Krümmungen und

Hydraulikzubehör installieren

Vor dem Festziehen der

Muttern den Flansch der

Rohrleitung so weit wie

möglich dem Flansch des

Sensors nähern

Umgebungs-

Temp.

Max

Min. Max.

.

5

DE_ESENS_FULLBORE_05.doc

Page 18

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

R

ELEKTRISCHE VERBINDUNGEN ZWISCHEN SENSOR UND TRANSMITTER

(ANSCHLUSS DES TRANSMITTERS: SIEHE EIGENES HANDBUCH)

VERSION GEEIGNET FÜR SENSOR-ANSCHLUSS

KOMPAKT

SEPARAT OHNE

ANSCHLUSSBOX

SEPARAT MIT

ANSCHLUSSBOX

SEPARAT MIT

VORVERSTÄRKER

ALLE

SENSOR-MODELLE

EDELSTAHL-MODELL

ALLE

KARBONSTAHL-

MODELLE

ALLE

SENSOR-MODELLE

KEINE ANSCHLÜSSE

KEINE ANSCHLÜSSE

ERFORDERLICH

(KABEL SCHON

ANGESCHLOSSEN UND

ABGEDICHTET)

KEINE ANSCHLÜSSE

ERFORDERLICH

(KABEL SCHON

ANGESCHLOSSEN UND

ABGEDICHTET)

SIEHE UNTEN

Cavo 1

Cavo 2

Cavo 3

Cavo 12

Cavo 13

Cavo 6

Cavo 7

Cavo 8

Cavo 9

Cavo 10

123456789

10

KABEL VOM SENSORINNEREN

(PINS 1–5 ) SCHON

ANGESCHLOSSEN

KABEL C014 ZUM TRANSMITTE

(PINS 6–10)

6

DE_ESENS_FULLBORE_05.doc

Page 19

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

A

ERDUNGSANWEISUNGEN

Für den korrekten Betrieb des Durchflussmessgerätes ist es NOTWENDIG, dass

der Sensor und die Flüssigkeit dasselbe Potential haben, schließen Sie daher

IMMER den Sensor und den Transmitter an Erdpotential an:

o

Erdung mit Metallrohr

Sensors with ground socket

Sensoren mit

on the connection box

Erdungsanschluss an der

nschlussbox

Wafer sensors Flanged sensors

ZwischenflanschVersion

Flansch-Version

ISOLIERDICHTUNG

METALLIC

METALL-

RING

RING

o Erdung mit Isolierrohr

INSULATING GASKET

Wenn der Sensor in einer Rohrleitung

If the sensor has to be mounted on a

pipe made of an insulating material

aus isolierendem Material installiert

is necessary:

werden muss, ist eine der folgenden

Maßnahmen notwendig:

- Zwei Metallringe zwischen den

- Install two metallic ring between

Sensorflanschen und den

the sensor flanges and the counter

flanges of the pipe lin e or:

Gegenflanschen der Rohrleitung

installieren oder:

- Use a sensor with the additional

grounding electrode

- Einen Sensor mit zusätzlicher

Erdungselektrode verwenden

oo

INSULATING GASKET

ISOLIERDICHTUNG

METALLIC RING

METALLRING

Erdung bei kathodischem Schutz über die Rohrleitung

- using insulating bushes to isolate

- Isolierhülsen zur Isolierung der

the bolts

Bolzen verwenden

- Grounding metallic rings should be

- Zur Erdung der Flüssigkeit sollten

provided to ground the liquid using

geerdete Metallringe installiert

insulating gasket between the rings

werden, dabei zwischen den

- IMPORTANT :

Ringen Isolierdichtungen

The ripple of DC power source used

- WICHTIG:

for cathodic protection

Die Welligkeit der für den

shall be = 0

kathodischen Schutz

ISOIL

If the sensor must be install

Wenn der Sensor in einer

in the piping with a chatode

Rohrleitung mit kathodischem

protection, is necessary:

Schutz installiert werden muss,

sind die folgenden Maßnahmen

notwendig:

INSULATING

ISOLIERHÜLSE

BUSH

verwendeten DC-Stromquelle

sollte 0 sein

7

DE_ESENS_FULLBORE_05.doc

Page 20

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

DREHMOMENTE (Nm) FÜR DIE SENSORBOLZEN (FLANSCH /

ZWISCHENFLANSCH)

25

(21)

43

(26)

53

(32)

68

(60)

90

(78)

53

(89)

59

(70)

77

(94)

108

(106)

99

(148)

140

(156)

175

(234)

205

(325)

282

(312)

281

(336)

382

(317)

568

(463)

421

(503)

519

(618)

721

(736)

(433)

(455)

(683)

(946)

(911)

(926)

1113

(924)

1658

(1350)

1230

(1468)

1515

(1803)

2105

(2146)

BETRIEBSDRUCK

19 25

28 43

36 53

52 68

75 45

41 53

56 83

71 112

106 135

288

134 391

408

204 595

510

201 588

598

324 945

821

426 1243

981

[398] [1161]

[465] [1356]

[774] [2258]

[947] [2761]

[1408] [4106]

[1598] [4662]

25

[32]

43

[40]

53

[63]

68

[35]

45

[53]

53

[68]

83

[94]

112

[130]

135

[113]

178

[178]

267

[185]

278

[275]

422

[318]

619

[411]

520

[519]

780

[540]

812

[803]

1231

[927]

1805

[1198]

39

[32]

53

[40]

72

[63]

81

[35]

58

[53]

62

[68]

87

[94]

148

[130]

217

[113]

816

[519]

1124

[540]

1108

[803]

1684

[927]

2180

[1198]

kPa 1000 1600 2500 4000 6400

psi 140 260 350 600 1000

DN PTFE HARTG. PTFE HARTG. PP PTFE HARTG. PTFE HARTG. HARTG.

25

32

40

50

65

80

100

125

150

200 148 432

250 123 359

300 142 415

350 172 502

400 217 632

450 194 564

500 224 652

550 (379) (1105) [608] [1772]

600 323 942

650 (429) (1251) [753] [2195]

700 356 1040

750 (451) (1315) [1105] [3223]

800 476 1388 549 1603

850 (563) (1642) [1373] [4006]

900 450 1312

1000 582 1699

o Gleichmäßig abwechselnd über Kreuz festziehen

o Anzuwendende Drehmomente für die folgenden Flanschtypen:

EN1092-1, DIN 2501, BS 4504, ANSI B16.5, JIS

o Die Verwendung von Dichtungen nach DIN 2690 wird empfohlen

o Für DN > 1000 wenden Sie sich bitte an den Hersteller

o (***) = ANSI 150

o [***] = ANSI 300

8

DE_ESENS_FULLBORE_05.doc

Page 21

A

g

HINWEIS FÜR SENSOREN MIT 3

Inspektions-

Inspection

schraube

screw

Bei horizontaler Installation des Durchflussmess

um eine Selbstentleerung zu ermöglichen.

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

-ZULASSUNG

Regelmäßig die Unversehrtheit der

Sensordichtungen überprüfen: Bei ganz mit

Flüssigkeit gefüllter Rohrleitung die

Inspektionsschrauben (siehe nebenstehende

Zeichnung) lösen, dabei muss die Kontrolle

ergeben, dass keinerlei Flüssigkeit aus dem

Inspektionsloch austritt!

Nach dem o.g. Vorgang DARAN DENKEN, die

Löcher wieder zu verschließen.

Im Fall von Flüssigkeitsaustritt wenden Sie sich

sofort an unseren Kundendienst.

3°

erätes einen Neigungswinkel von mindestens 3°,

9

DE_ESENS_FULLBORE_05.doc

Page 22

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

10

DE_ESENS_FULLBORE_05.doc

Page 23

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

11

DE_ESENS_FULLBORE_05.doc

Page 24

SENSOR FÜR ELEKTROMAGNETISCHES DURCHFLUSSMESSGERÄT – HANDBUCH

12

DE_ESENS_FULLBORE_05.doc

Page 25

MANUEL D’INSTALLATION

CAPTEURS À PASSAGE

DÉBITMÈTRE ÉLECTROMAGNÉTIQUE

INTÉGRAL

Page 26

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

TABLE DES MATIÈRES

INTRODUCTION .................................................................................... 3

DÉMARRAGE ET ENTRETIEN DES INSTRUMENTS .................................... 3

SÉCURITÉ : ........................................................................................... 4

INFORMATIONS GÉNÉRALES SUR L'INSTALLATION DU CAPTEUR ............ 4

TEMPÉRATURES DE FONCTIONNEMENT ................................................. 5

BRANCHEMENTS ÉLECTRIQUES ENTRE LE CAPTEUR ET

LE

TRANSMETTEUR ............................................................................... 6

INSTRUCTIONS DE MISE A LA TERRE ..................................................... 7

COUPLES DE SERRAGE (Nm) POUR LES BOULONS DU

CAPTEUR (BRIDES ET ENTRE-BRIDES) ................................................... 8

REMARQUE CONCERNANT LES CAPTEURS HOMOLOGUÉS 3A .................. 9

2

FR_ESENS_FULLBORE_05.doc

Page 27

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

INTRODUCTION

- Le présent manuel fait partie intégrante du produit. Lisez attentivement les

instructions qu’il contient car elles donnent des indications importantes

pour une utilisation et un entretien en toute sécurité.

- Les informations techniques et produits correspondants du manuel peuvent

être modifiés sans avertissement préalable.

- Le débitmètre doit être utilisé dans le but pour lequel il a été conçu. Toute

utilisation inadéquate, modification non autorisée de l’appareil ou de ses

pièces, ainsi que tout remplacement d’un ou plusieurs des composants

d’origine invalident automatiquement la garantie.

- La responsabilité du fabricant est engagée uniquement si l’appareil est

utilisé dans sa configuration et avec ses réglages d’origine.

- Le débitmètre effectue des mesures de liquides dont la conductivité est

supérieure à 5µS/cm ; il se compose d’un capteur (décrit dans ce manuel)

et d’un transmetteur (pour ce dernier, voir le manuel fourni).

- Si le capteur est ajouté au transmetteur en version compacte, il est

recommandé d’envisager une plage de températures d’exploitation plus

restreinte, ou de consulter les manuels correspondants.

- Transportez, déballez et manipulez le débitmètre avec précauti on.

- En cas de stockage prolongé et lors du transport, placez l’appareil dans son

emballage d’origine, à l’abri de l’humidité, et n’empilez pas plus de 3

paquets les uns au-dessus des autres. Le stockage et le transport sur

palettes est possible (si l’emballage est une caisse en bois, ne pas empiler

les caisses).

- L’appareil doit être nettoyé exclusivement avec un linge humide. Pour les

opérations de maintenance et les réparations, contactez le service clientèle.

- Pour la mise au rebut de l’appareil et de l’emballage, respectez la

réglementation en vigueur.

- La reproduction du présent manuel et de tout logiciel fourni avec

l'instrument est interdite.

DÉMARRAGE ET ENTRETIEN DES INSTRUMENTS

- Avant de démarrer l’instrument, établissez systématiquement une

connexion de mise à la terre sécurisée comme indiqué page 7.

- Vérifiez périodiquement : l’intégrité des câbles, le serrage des éléments

d'étanchéité (passe-câbles, couvercles, etc.) et la fixation mécanique de

l’instrument sur la conduite ou le support mural.

3

FR_ESENS_FULLBORE_05.doc

Page 28

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

V

SÉCURITÉ :

Avant d’utiliser l’instrument, établissez systématiquement une

connexion de mise à la terre sécurisée.

N’essayez jamais de réparer vous-même l’instrument. Si

l’instrument ne fonctionne pas correctement, contactez le

service d’assistance le plus proche.

Soyez extrêmement attentifs durant les opérations.

ATTENTION !!!

DANGER !!!

INFORMATIONS GÉNÉRALES SUR L'INSTALLATION DU CAPTEUR

o

Sens du débit

Avant d’installer le capteur,

déterminez le sens d’écoulement du

liquide dans la conduite.

Le signe du débit est positif lorsque

le sens du débit va de – vers +,

comme indiqué sur la plaque

signalétique.

Si l’appareil est monté à l’envers, le

signe du débit peut être corrigé en

modifiant le signe du coefficient KA.

?

o Installation (méthode recommandée pour TOUS LES CAPTEURS AVEC BOULON À

ŒIL)

Les boulons à œil sont dimensionnés pour

supporter uniquement le poids du débitmètre.

N.B. : Pour les capteurs S054, nous recommandons l’utilisation de vérins de

centrage.

érins de centrage

4

FR_ESENS_FULLBORE_05.doc

+

Page 29

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

j

o Conseils et précautions

NON OUI

Pour les installations

verticales avec sens de débit

descendant, contactez le

fabricant.

Pour les installations

verticales, il est préférable

d’avoir un débit ascendant.

CONDUITE LONGUE

Évitez d’installer le capteur

dans une longue conduite

sans support.

JOINTS ANTI-VIBRATIONS

CONDUITE LONGUE

Évitez un fonctionnement

avec une conduite en partie

vide.

Évitez une installation à

proximité de coudes ou de

composants hydrauliques.

3 X DN

2 X DN

TEMPÉRATURES DE FONCTIONNEMENT

°C 0 80 -5 60 0 60 0 60 -20 130 -10 60

°F 30 176 23 140 32 140 32 140 -4 266 14 140

Évitez de rapprocher la bride

et la contre-bride sous l’effet

de la force de serrage des

écrous.

LINING ÉBONITE LINING PP LINING PTFE

Temp. du

liquide

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

Temp.

ambiante

ÉPAISSEUR DE JOINT + 4 mm

Temp. du

liquide

Temp.

ambiante

Temp. du

liquide

Pour les installations sur une

longue conduite, utilisez des

oints anti-vibrations.

Durant le fonctionnement, la

conduite doit être entièrement

remplie de liquide ou

complètement vide.

Installez le capteur à l'écart

des coudes et des

composants hydrauliques.

Avant de serrer les écrous,

rapprochez autant que

possible la bride de la

conduite de la bride du

capteur.

Temp.

ambiante

5

FR_ESENS_FULLBORE_05.doc

Page 30

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

(

)

R

BRANCHEMENTS ÉLECTRIQUES ENTRE LE CAPTEUR ET LE TRANSMETTEUR

(BRANCHEMENTS VERS LE TRANSMETTEUR : VOIR LE MANUEL CORRESPONDANT)

VERSION

COMPACTE

SÉPARÉE SANS

BOÎTE DE

JONCTION

SÉPARÉE AVEC

BOÎTE DE

JONCTION

SÉPARÉE AVEC

PRÉAMPLIFICATEUR

COMPATIBLE

AVEC

TOUS LES

MODÈLES DE

CAPTEURS

MODÈLE INOX

MODÈLES EN

ACIER CARBONE

MODÈLES DE

CAPTEURS

TOUS LES

TOUS LES

BRANCHEMENT DU

CAPTEUR

AUCUN

BRANCHEMENT

AUCUN

BRANCHEMENT

REQUIS

(CÂBLE DÉJÀ

CONNECTÉ ET

MOULÉ)

AUCUN

BRANCHEMENT

REQUIS

(CÂBLE DÉJÀ

CONNECTÉ ET

MOULÉ)

VOIR CI-DESSOUS

Cavo 1

Cavo 2

Cavo 3

Cavo 12

Cavo 13

Cavo 6

Cavo 7

Cavo 8

Cavo 9

Cavo 10

123456789

10

CÂBLE À PARTIR DE L'INTÉRIEU

DU CAPTEUR (BROCHES 1 – 5 )

DÉJÀ CONNECTÉ

CÂBLE C014 VERS LE

TRANSMETTEUR

BROCHES 6 –10

6

FR_ESENS_FULLBORE_05.doc

Page 31

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

T

É

INSTRUCTIONS DE MISE A LA TERRE

Pour un fonctionnement correct du débitmètre, il est IMPÉRATIF que

le capteur et le liquide aient le même potentiel : par conséquent, vous

devez TOUJOURS mettre à la terre le capteur et le transmetteur.

o

Mise à la terre avec conduite métallique

Sensors with ground socket

Capteurs avec prise de terre

on the connection box

sur le boîtier de connexion

Wafer sensors Flanged sensors

Capteurs avec entrebrides

Capteurs à brides

o Mise à la terre avec conduite isolée

METALLIC

ANNEAU

M

TALLIQUE

INSULATING GASKET

JOINT ISOLAN

RING

Si le capteur doit être monté sur une

If the sensor has to be mounted on a

pipe made of an insulating material

conduite en matériau isolant, il est

is necessary:

nécessaire :

- Install two metallic ring between

- d’installer deux anneaux

the sensor flanges and the counter

métalliques entre les brides du

flanges of the pipe lin e or:

capteur et les contre-brides de la

conduite, ou

- Use a sensor with the additional

grounding electrode

- d'utiliser un capteur avec une

électrode de mise à la terre

supplémentaire.

Mise à la terre avec une protection cathodique sur la conduite

oo

INSULATING GASKET

JOINT ISOLANT

ISOIL

METALLIC RING

ANNEAU MÉTALLIQUE

If the sensor must be install

Si le capteur doit être installé

in the piping with a chatode

sur une conduite avec

protection, is necessary:

protection cathodique, il est

nécessaire :

INSULATING

MANCHON

BUSH

ISOLANT

- using insulating bushes to isolate

- d’utiliser des manchons isolants

the bolts

pour isoler les boulons,

- Grounding metallic rings should be

- d’insérer un joint isolant de part et

provided to ground the liquid using

d’autre des anneaux métalliques

insulating gasket between the rings

pour mettre à la terre les anneaux

- IMPORTANT :

et donc le liquide.

The ripple of DC power source used

- IMPORTANT :

for cathodic protection

L’ondulation de la source

shall be = 0

d’alimentation DC utilisée pour

la protection cathodique doit

être = 0

7

FR_ESENS_FULLBORE_05.doc

Page 32

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

COUPLES DE SERRAGE (Nm) POUR LES BOULONS DU CAPTEUR

(BRIDES ET ENTRE-BRIDES)

Kpa 1000 1600 2500 4000 6400

psi 140 260 350 600 1000

DN PTFE ÉBON. PTFE ÉBON. PP PTFE ÉBON. PTFE ÉBON. ÉBON.

25

32

40

50

65

80

100

125

150

200 148 432

250 123 359

300 142 415

350 172 502

400 217 632

450 194 564

500 224 652

550 (379) (1105) [608] [1772]

600 323 942

650 (429) (1251) [753] [2195]

700 356 1040

750 (451) (1315) [1105] [3223]

800 476 1388 549 1603

850 (563) (1642) [1373] [4006]

900 450 1312

1000 582 1699

PRESSION DE SERVICE

25

19 25

(21)

43

28 43

(26)

53

36 53

(32)

68

52 68

(60)

90

75 45

(78)

53

41 53

(89)

59

56 83

(70)

77

71 112

(94)

108

106 135

(106)

99

288

(148)

(433)

140

408

(156)

(455)

175

510

(234)

(683)

205

598

(325)

(946)

282

821

(312)

(911)

281

981

(336)

(926)

382

1113

(317)

(924)

568

1658

(463)

(1350)

421

1230

(503)

(1468)

519

1515

(618)

(1803)

721

2105

(736)

(2146)

134 391

204 595

201 588

324 945

426 1243

[398] [1161]

[465] [1356]

[774] [2258]

[947] [2761]

[1408] [4106]

[1598] [4662]

25

[32]

43

[40]

53

[63]

68

[35]

45

[53]

53

[68]

83

[94]

112

[130]

135

[113]

178

[178]

267

[185]

278

[275]

422

[318]

619

[411]

o Serrer de manière homogène et en croix.

o Les couples de serrage indiqués entre parenthèses s’appliquent aux brides :

EN 1092-1, DIN 2501, BS 4504, ANSI B16.5, JIS

o Utiliser des joints selon DIN 2690.

o Pour DN > 1000, consulter le fabricant.

o (***)= ANSI 150

o [***]= ANSI 300

8

39

[32]

53

[40]

72

[63]

81

[35]

58

[53]

62

[68]

87

[94]

148

[130]

217

[113]

520

816

[519]

[519]

780

1124

[540]

[540]

812

1108

[803]

[803]

1231

1684

[927]

[927]

1805

2180

[1198]

[1198]

FR_ESENS_FULLBORE_05.doc

Page 33

Q

A

V

g

REMAR

UE CONCERNANT LES CAPTEURS HOMOLOGUÉS3

Vis

Inspection

d'inspection

screw

Si le débitmètre est installé à l’horizontale, prévoyez un an

vidange.

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

érifiez régulièrement l’intégrité des joints du

capteur : avec une conduite remplie de liquide,

dévissez les vis d’inspection (voir schéma cicontre) et assurez-vous de l’absence totale de

liquide dans le trou d’inspection.

Une fois cette opération terminée, N’OUBLIEZ PAS

de refermer les trous.

En cas de fuite, contactez immédiatement notre

service clientèle.

3°

le minimum de 3° pour l’auto-

9

FR_ESENS_FULLBORE_05.doc

Page 34

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

10

FR_ESENS_FULLBORE_05.doc

Page 35

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

11

FR_ESENS_FULLBORE_05.doc

Page 36

CAPTEUR POUR DÉBITMÈTRE ÉLECTROMAGNÉTIQUE – MANUEL

12

FR_ESENS_FULLBORE_05.doc

Loading...

Loading...