Page 1

Operating Instructions

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

Bedienungsanleitung

Instructions de Service

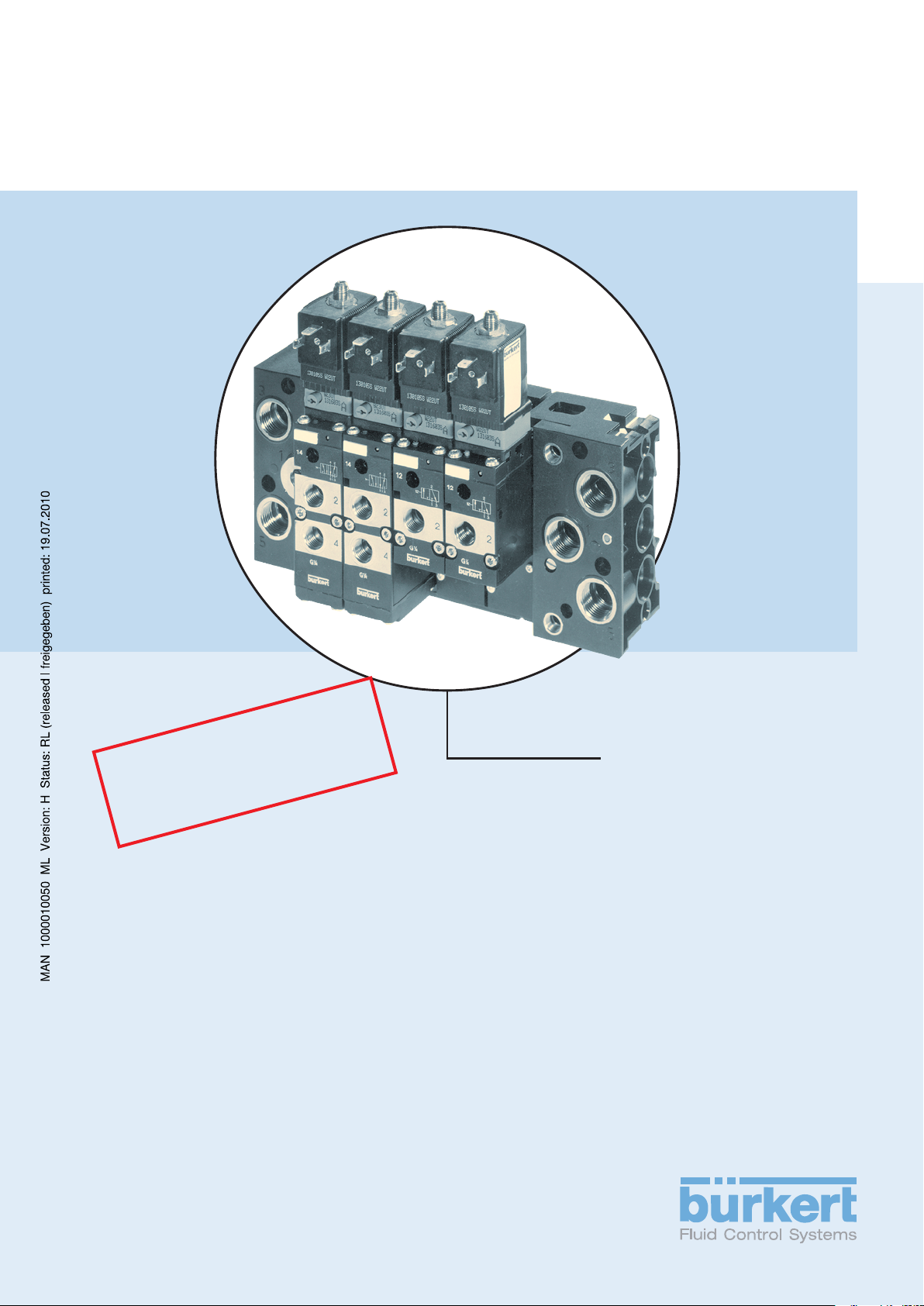

Block Assemblies and Modular Pneumatic

pneumatische Grundschiene Type MP07

Type 6518 / 6519

Basic Rail Type MP07

Mehrfachblöcke und modulare,

Blocs multiples et Profil pneumatique

modulaire Type MP07

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2000 Bürkert Werke GmbH & Co. KG

Operating Instructions 0507/12_EU-ML_00803150

Page 3

Contents of the

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

Operating Instructions for the

Block Assemblies

Type 6518 / 6519

and Modular Pneumatic

Basic Rail Type

C

ONTENTS

Type MP07

GENERAL NOTES............................................................................................................................................................................................................................. 3

Symbols................................................................................................................................................................................................................................................. 4

Safety notes

Warranty conditions

TECHNICAL DESCRIPTION ............................................................................................................................................................................................ 7

Valve Constructions ............................................................................................................................................................................................................... 8

Valve operations of the Type 6518 / 6519

Media

Electrical connections

Example of a block assembly

..................................................................................................................................................................................................................................... 4

......................................................................................................................................................................................................................................................... 9

................................................................................................................................................................................................................ 5

................................................................................................................................................... 8

......................................................................................................................................................................................................... 9

................................................................................................................................................................................ 10

english

INSTALLATION, INITIALISATION AND SERVICE..................................................................................................................... 11

General notes ............................................................................................................................................................................................................................. 12

Setting up block assemblies using the modular pneumatic rail

type MP07

Dismantling the module

Other possible uses of the connecting module, - right-hand -

Mounting the valve block

Mounting single valves

Measures to be taken before putting into service

Pulse operation

Faults

........................................................................................................................................................................................................................................ 12

................................................................................................................................................................................................... 13

........................................................................................ 13

................................................................................................................................................................................................ 13

.................................................................................................................................................................................................... 15

......................................................................................................................... 16

......................................................................................................................................................................................................................... 16

........................................................................................................................................................................................................................................................ 17

6518 / 6519 - 1

Page 4

C

ONTENTS

english

2 - 6518 / 6519

Page 5

G

ENERAL NOTES

GENERAL NOTES

Symbols................................................................................................................................................................................................................................................. 4

Safety notes

Warranty conditions

..................................................................................................................................................................................................................................... 4

................................................................................................................................................................................................................ 5

english

6518 / 6519 - 3

Page 6

G

ENERAL NOTES

Symbols

In these Operating Instructions, the following symbols are used:

indicates a working step that you will have to carry out

ATTENTION!

NOTE

english

Safety notes

To ensure that the device will function correctly, and have a long service life, please comply with the

information in these Operating Instructions, as well as with the application conditions and additional data

given in the Type 6518 and 6519 data sheet:

• When planning the application of the device, and during its operation, observe the general technical

rules!

• Observe the relevant accident prevention and safety regulations applicable for electrical equipment

throughout the operation, maintenance and repair of the device!

• Always switch off the voltage supply before working on the system!

indicates information which must be followed. Failure to do this could endanger your

health or the functionality of the device

indicates important additional information, tips and recommendations

• Note that lines and valves must not be unscrewed from systems that are under pressure!

• Take suitable measures to prevent unintentional operation or impermissible impairment!

• If these instructions are ignored, no liability will be accepted from our side, and the guarantee on the

device and on accessories will become invalid!

NOTE

If there are discrepancies, please contact immediatley your Bürkert subsidiary or our customer service.

Approvals such as Ex, UL, UR, CSA, DVGW etc., will be indicated on the rating plate, or

by a special label.

With devices with approval according to Service Requirement Category AK 5, either

purified control air must be used or a sieve with a maximum mesh width of 1 mm must be

installed upstream.

Bürkert Steuer- und Regelungstechnik, Service-Abteilung

Chr.-Bürkert-Str. 13-17, D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

eMail: info@de.buerkert.com

4 - 6518 / 6519

Page 7

Warranty conditions

This document contains no warranty statements. In this connection we refer to our general sales and

business conditions. A prerequisite for validity of the warranty is unse of the device as intended with

observance of the specified conditions of use.

ATTENTION!

The warranty covers only faultless condition of the Block Assemblies Type 6518,6519

and Modular Pneumatic Basic Rails Type MP07. No liability will be accepted for

consequent damage of any kind that max arise form failure or malfunctioning of the

device.

G

ENERAL NOTES

english

6518 / 6519 - 5

Page 8

G

ENERAL NOTES

english

6 - 6518 / 6519

Page 9

T

ECHNICAL DESCRIPTION

TECHNICAL

DESCRIPTION

Valve Constructions ............................................................................................................................................................................................................... 8

Valve operations of the Type 6518 / 6519

Media

Electrical connections

Example of a block assembly

......................................................................................................................................................................................................................................................... 9

........................................................................................................................................................................................................... 9

................................................................................................................................................................................ 10

................................................................................................................................................... 8

english

6518 / 6519 - 7

Page 10

T

ECHNICAL DESCRIPTION

Valve Constructions

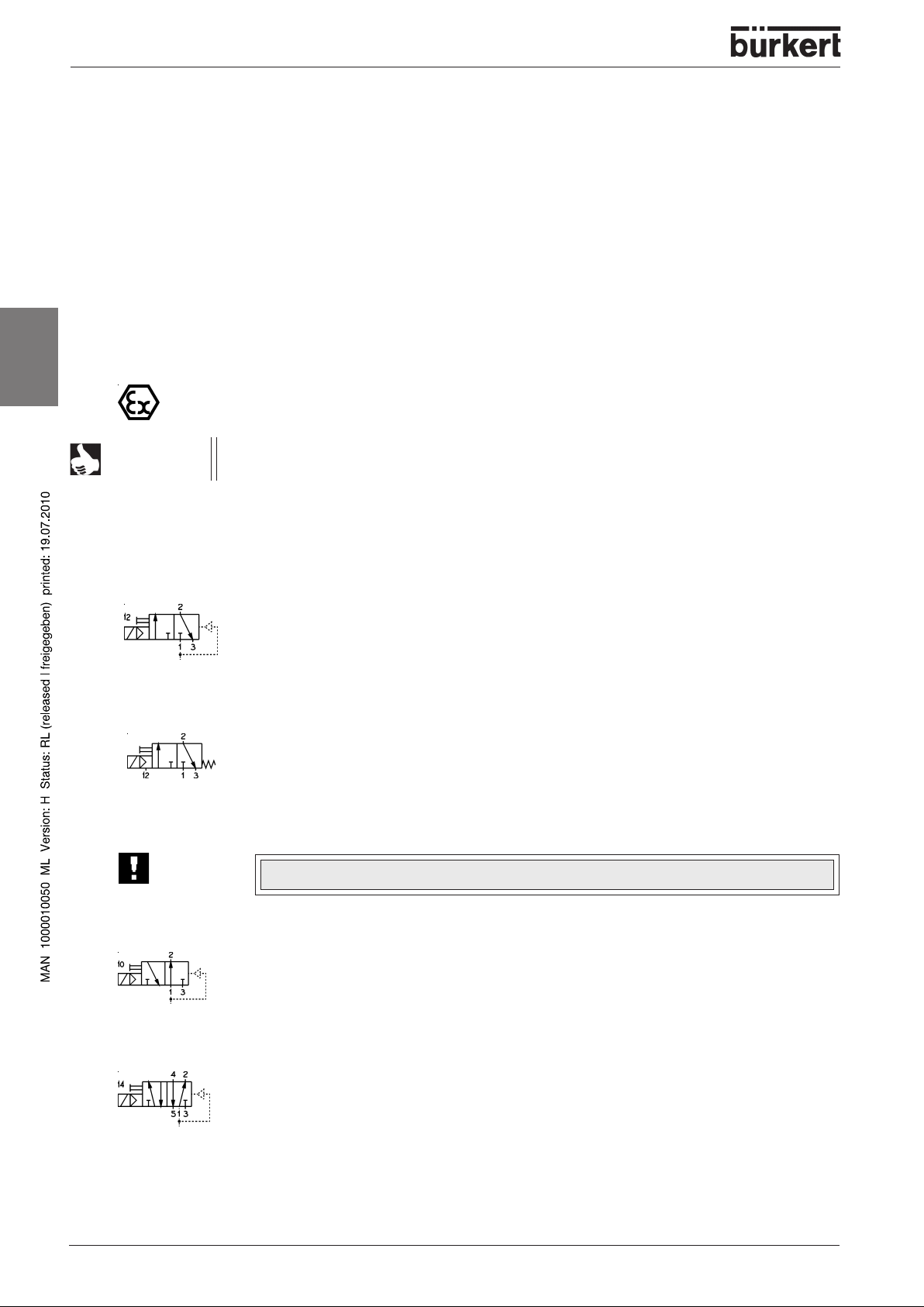

• 3/2 way pilot valve with various electrical connection possibilities

• the top-mounted coil can be locked in 4 x 90° steps, for optional positioning in between around the core

guide tube

• valve body with diaphragm and seat seals (3/2 and 5/2), or with gate valve (5/3)

• working connections 2 (B) / 4 (A) and supply and ventilation connections 1 (P) / 3 (S) / 5 (R) with G 1/4

internal thread or plug connection for 8 mm hose external diameter

• the valves can be mounted on the modular pneumatic basic rail Type MP07

• can be mounted in any position, preferably with the magnetic system at the top

english

NOTE

the valves are also available in explosion-proof versions

Plug-in connections only for the service ports 2 (B) and 4 (A).

The valves require no maintenance.

Valve operations of the Type 6518 / 6519

3/2 way valve:

In de-energised position, Pressure Inlet 1 closed, Outlet Port 2 exhausted

3/2 way valve for vacuum, with auxiliary pilot air:

In de-energised position, Pressure Inlet 1 closed, Outlet Port 2 exhausted

ATTENTION!

3/2 way valve:

In de-energised position, Pressure Inlet 1 connected to Outlet Port 2

5/2 way valve:

In de-energised position, Pressure Inlet 1 connected, to Outlet Port 2, Outlet Port 4 exhausted.

8 - 6518 / 6519

The vacuum generator must be connected to port 1!

Page 11

5/3 way valve:

in middle position, all outlet ports closed

5/3 way valve:

in middle position, Outlet Ports 2 and 4 vented, Pressure Inlet 1 closed

T

ECHNICAL DESCRIPTION

Media

• filtered compressed air (max. particle size 10 µm), preferably non-oiled, operation is possible with oiled

• seal materials: NBR or PUR for 3/2 and 5/2 valves

• permissible medium temperature: -10 to +50° C

• permissible ambient temperature: -10 to +55° C

• operational pressure range: 2 - 8 bar

NOTE

ATTENTION!

air; neutral gas

NBR for 5/2 pulse valves and 5/3 valves

The pilot pressure of the pneumatic controller is dependent on the pressure of the flow of

medium: it must not exceed a maximum of 8 bar!

Observe the permissible pressure range given on the rating plate!

Pressure difference between Ports 1 and 3/5

≥ ≥

≥ 2 bar

≥ ≥

english

Electrical connections

• read the voltage, electrical power, type of protection and current from the rating plate!

• voltage tolerance ±10%

• electrical connection: Instrument socket type 2508 to the tag connection on the coil (tightening torque: 1

Nm)

• protection level IP 65 (only in combination with appliance socket type 2508)

• to match the cable run, the instrument socket can be mounted rotated by 4 x 90°

• refer to types 6014 or 8640 for other connection possibilities

ATTENTION!

When screwing down the instrument socket onto the coil, ensure that the flat seal is

well seated!

6518 / 6519 - 9

Page 12

T

ECHNICAL DESCRIPTION

english

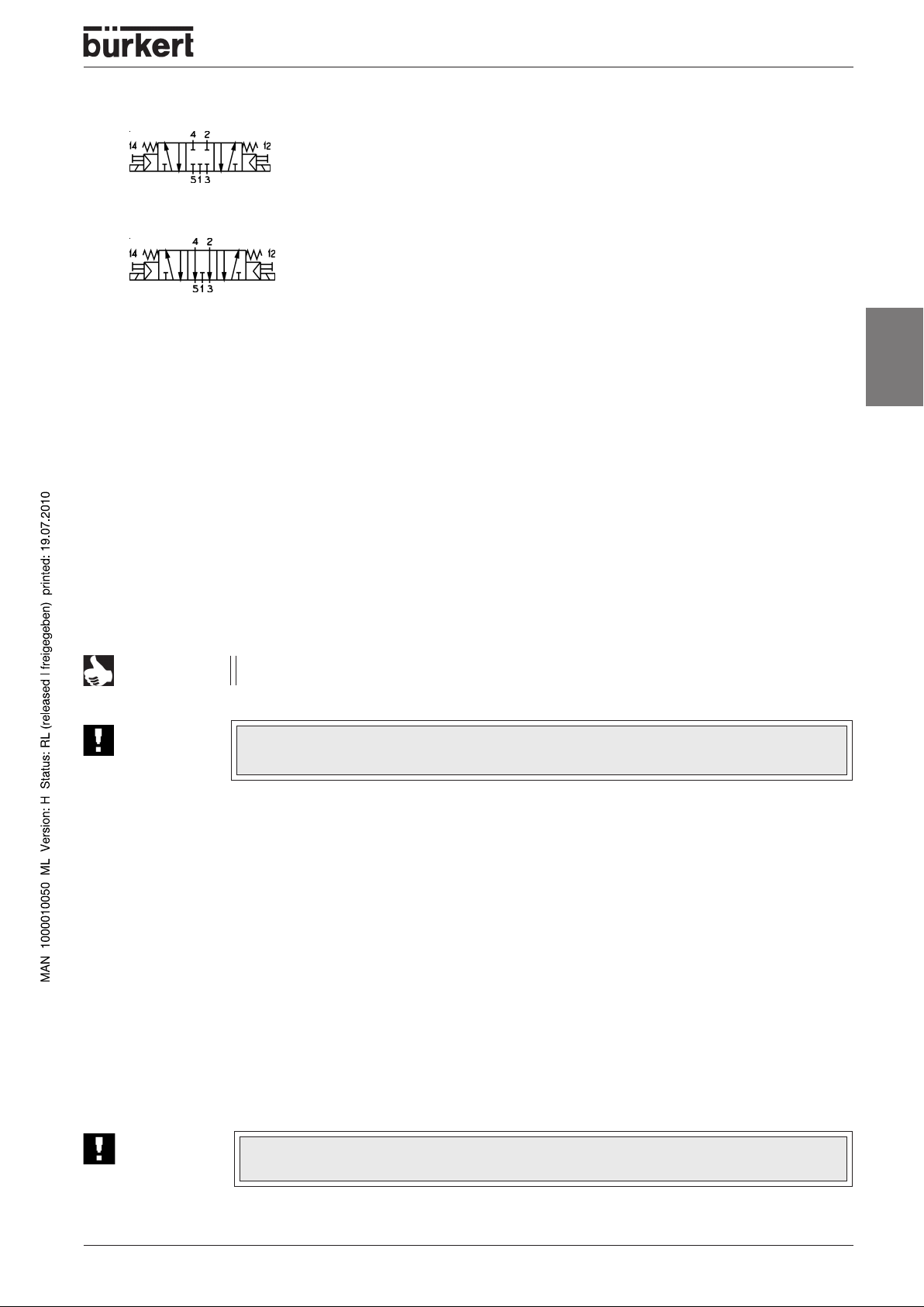

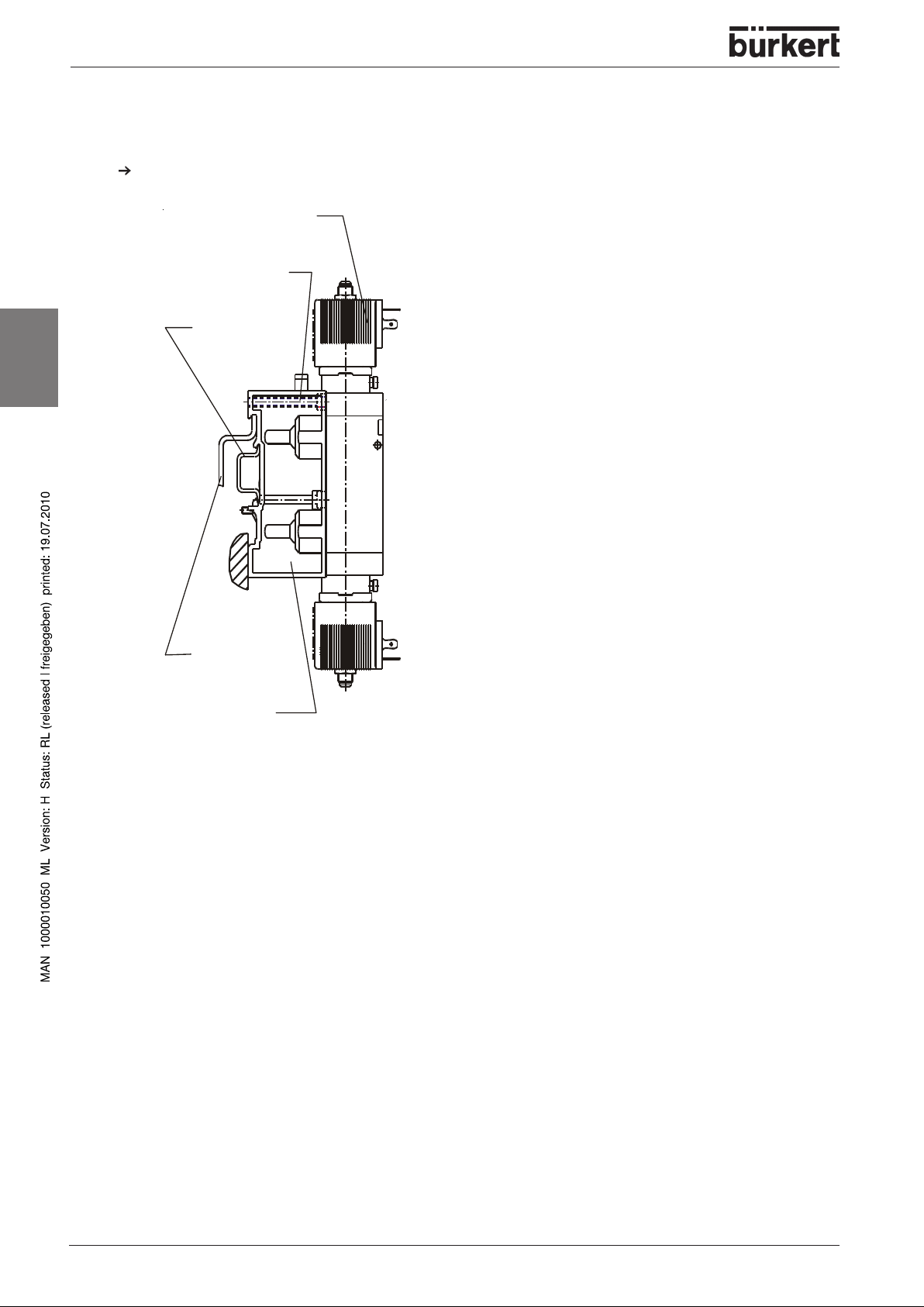

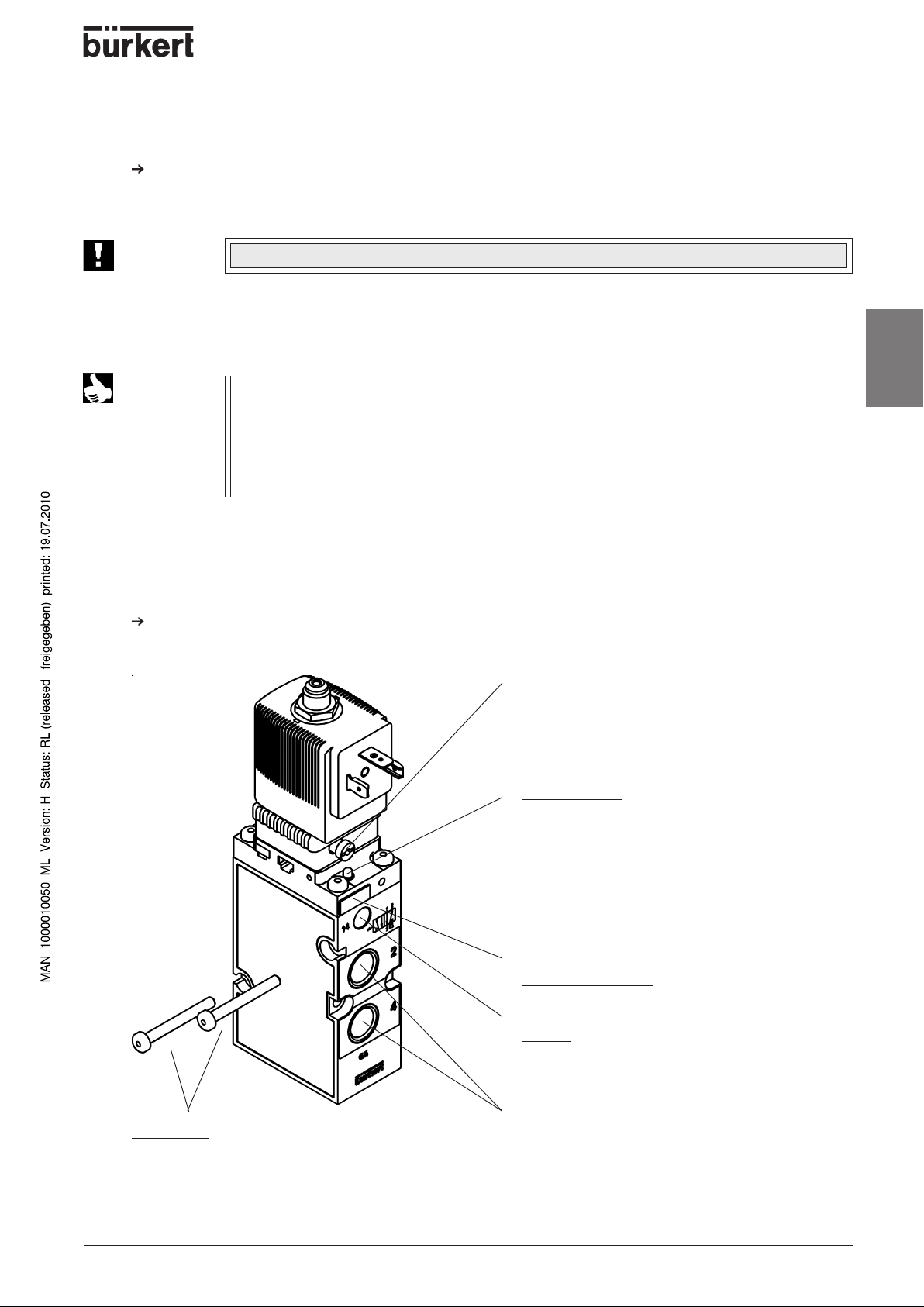

Example of a block assembly

10 - 6518 / 6519

Bild: Beispiel eines Mehrfachblocks

Page 13

I

NSTALLATION

, I

NITIALISATION AND SERVICE

INSTALLATION,

INITIALISATION AND

SERVICE

General notes ............................................................................................................................................................................................................................. 12

Setting up block assemblies using the modular pneumatic rail

type MP07

Dismantling the module

Other possible uses of the connecting module, - right-hand -

Mounting the valve block

Mounting single valves

Measures to be taken before putting into service

...................................................................................................................................................................................................................................... 12

................................................................................................................................................................................................... 13

...................................................................................... 13

.............................................................................................................................................................................................. 13

.................................................................................................................................................................................................... 15

........................................................................................................................... 16

english

Pulse operation

Faults

...................................................................................................................................................................................................................................................... 17

......................................................................................................................................................................................................................... 16

6518 / 6519 - 11

Page 14

I

NSTALLATION

, I

NITIALISATION AND SERVICE

General notes

Work on the valve should only be carried out by specialist staff and with the correct tools!

Before working on the system, always turn off the supply voltage!

Clean the piping system before installing the valve!

Where necessary, connect a strainer upstream to protect against faults.

When tightening the connections, never use the coil as a lever!

Ensure that the operational conditions agree with the performance data of the unit!

Avoid back-pressures in the exhaust channels by the use of large-volume silencers!

english

ATTENTION!

Pressure indicator with indicating pin on the connecting module - right -

(Figure:

- Indicating pin can be pressed in: pressure in valve block < 1 bar

- Indicating pin cannot be pressed in: there is pressure in the valve block

- Indicating pin springs back: there is pressure in the valve block

Technical Description - Example of a block assembly

Lines or valves must never be loosened while the system is under pressure!

Observe the pressure indicator on the right-hand connecting module.

)

(vent the system before dismantling

lines or devices)

Setting up block assemblies using the modular pneumatic

rail MP07

With combination of two-way and three-way base modules, you can assemble valve blocks of any size.

NOTE

Check that each module is completely pre-fitted with O-rings!

Before locking together, lightly grease or oil the fitted O-rings.

Insert the hooks of the module being added into the slot on the previous module, ensuring that the O-

rings are correctly seated!

Press the modules together until both hooks latch.

Ensure that the profile gaskets are correctly seated on the base module!

ATTENTION!

12 - 6518 / 6519

It is advisable to start the assembly with the left-hand connector module. (Figure:

Technical Descriptions - Example of a block assembly

Squashed O-rings and profile gaskets sause leackages in the block!

)

Page 15

I

NSTALLATION

Secure the valves to the base module using 2 M4 screws each.

(Tightening torque max. 1.5 Nm).

Mount the complete valve block onto the wall or the standard rail.

Connect the supply and working lines.

Make the electrical connections to the pilot valves: in doing this, observe the values given on the rating

plate!

, I

NITIALISATION AND SERVICE

Dismantling the module

Unlatch both locking hooks by using a screwdriver on the end dismantling-grooves.

Remove the block part / module sideways.

Other possible uses of the connecting module, - right-hand -

• As a separation module for special applications when building up several pressure levels in a single

block

english

• Additional supply lines for larger valve blocks

NOTE

Where necessary, break out the rated break-points of Ports 1, 3 and 5 and

the upper pilot venting.

Mounting the valve block

Standard rails

• Standard rail 35 x 15 DIN 50022 (Standard)

• Standard rail 75 x 25 DIN 50023

NOTE

Installation

When using the 75 x 25 DIN 50023 standard rail, change over the pre-assembled screws

with clamps and springs as necessary.

Hang the valve block onto the upper groove of the standard rail.

Latch the lower clamp into the standard rail.

Firmly tighten the screws on the clamp.

Dismounting

Loosen the clamping screws (by about 4 revolutions).

Remove the block upwards from the standard rail.

6518 / 6519 - 13

Page 16

I

NSTALLATION

english

, I

NITIALISATION AND SERVICE

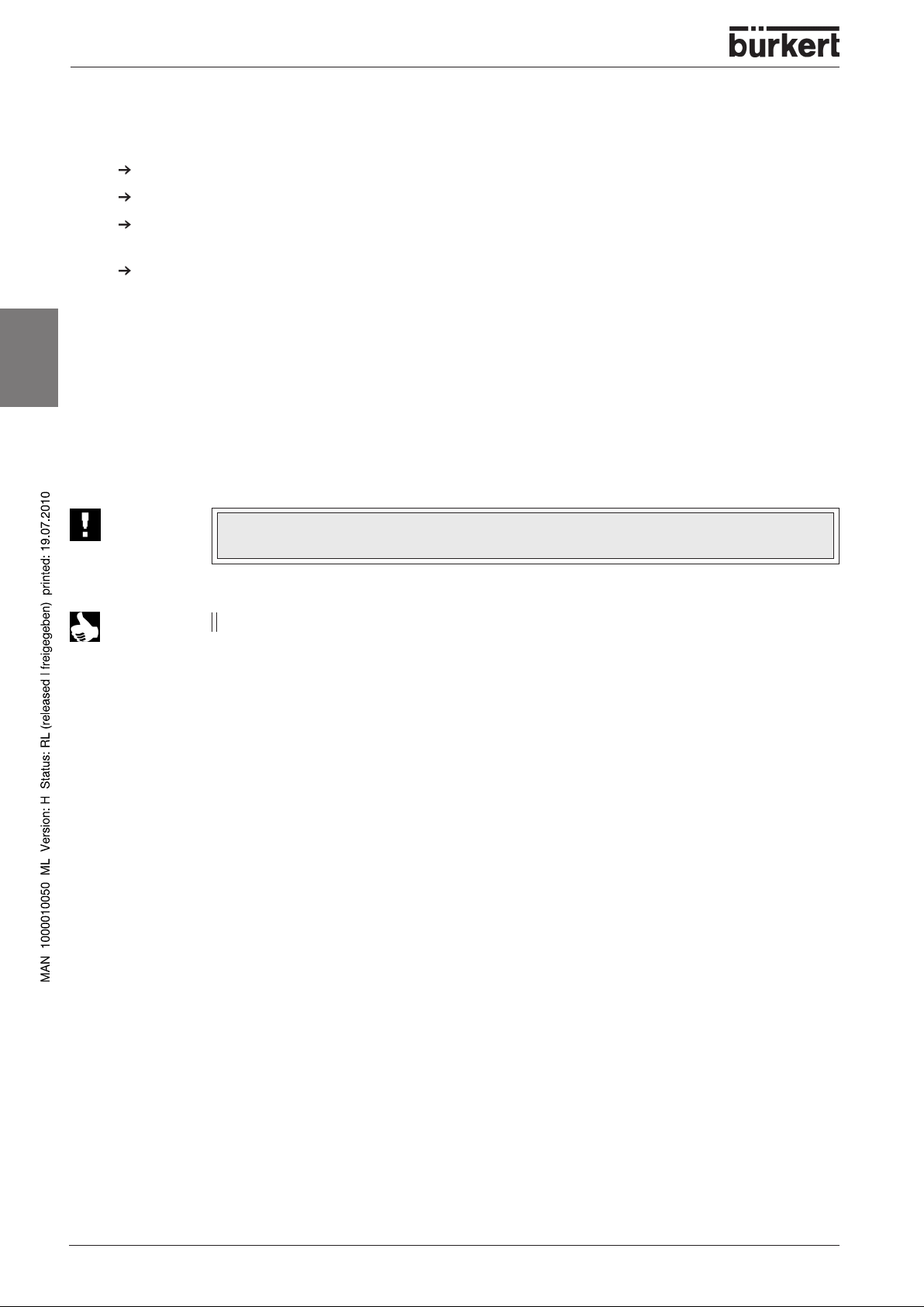

Wall mounting

Fix the module system directly to the wall using M5 screws.

Electrical connection

can be turned trough 180°

Wall-fixing

Standard rail

35 x 15

DIN 50022

Standard rail

75 x 25

DIN 50023

Connecting module

Figure: Mounting the valve block

14 - 6518 / 6519

Page 17

Mounting single valves

I

NSTALLATION

, I

NITIALISATION AND SERVICE

Fix the single valve directly to the wall using M4 screws. (Figure:

- Mounting single valves

ATTENTION!

When mounting, do not distort the valve body!

,

Plug-in connections

NOTE

For plug-in connections, the hose lines must meet the following requirements:

• Minimum rigidity of 40 Shore D (to DIN 53505 or ISO 868);

• External diameter corresponding to DIN 73378 (max. permissible deviation ± 0.1 mm

from nominal dimension);

• Without burr, cut at right-angles and with undamaged circumference;

• The hose lines must be pushed into the plug-in connectors up to the stop.

Dismantling the plug-in connections

Insstallation, Initialisation and Service

english

To release the line, press in the pressure ring and pull out the hose line.

Manual override

For manual operation of the valve depress the

manual actuator to the stop. The manual

actuator is then locked by turning 90° to the

right.

Indicating pin for indicating the pneumatic

position

With the valve not switched, the red indicating

pin can be pressed in. If the valve has been

switched, the indicating pin moves outwards,

and remains in this position. The indicating pin

must be pushed in again for every functional

test.

Designation plate (can be removed for marking

/ engraving)

Port 14

• not used in the standard model

• used as an auxiliary pilot air connection

and as the connection for pneumatic

controls

M4 screws

for wall mounting

the single valve

Service ports

2 (B) and 4 (A)

Figure: Mounting single valve / Fix the single valve directly to the wall using M4 screws.

6518 / 6519 - 15

Page 18

I

NSTALLATION

, I

NITIALISATION AND SERVICE

Measures to be taken before putting into service

Check all connections, voltages and the operational pressure!

Ensure that the max. operational conditions (see rating plate) will not be exceeded!

Check that Ports 1, 3 and 5 are correctly connected according to the regulations. These connections

must not be interchanged for any reason!

When operating electrically, unlock the manual override!

Pulse operation

english

Function:

The pulse-controlled solenoid valves operate with two coils connected alternately.

ATTENTION!

NOTE

Observe the “Pulse” data on the rating plate!

Avoid simultaneous pulse input to both coils!

The valves can be reversed with the manual actuator.

16 - 6518 / 6519

Page 19

Faults

Fault Possible cause Correction

I

NSTALLATION

, I

NITIALISATION AND SERVICE

Valve does not

switch

Valves switch

with a delay, or

exhaust

through the

venting ports:

Operational voltage too low or

not present;

Manual override not in neutral

position;

Compressed air supply not

available or insufficient.

Compressed air supply not

available or insufficient;

Valves are not in the starting

position (whitout current)

during pressure build-up.)

Insufficient venting of the

exhaust channels due to

silencers that are too small or

are soiled (back-pressure);

Check the electrical supply connections.

Ensure that the electrical power supply is the same as

that spe-cified on the rating plate.

Set the manual override to the zero position.

Carry out the dimensioning of the compressed air

connection with volumes as large as possi-ble (including

that of upstream pressure regulators, service units, cutoff valves etc.)

Minimum operational pressure 2 bar

Führen Sie die Druckversorgung möglichst großvolumig

aus (auch bei vorgeschalteten Geräten wie

Druckreglern, Wartungseinheiten, Absperrventilen usw.).

Mindestbetriebsdruck 2 bar

Appley pressure to the valve block before you switch the

valves

Use silencers or expansion channels with sufficient

dimensions.

Clean soiled silencers.

english

Leaking valve

block:

Impurities or foreign matter in

the pilot valve or main valve.

O-rings between the modules missing or damaged;

Missing or incorrectly positioned profile gaskets between the valve and the

baseplate.

Blast through the exhaust cahnnels with pulsed

compressed air, to blow out impurities. Install a new pilot

or main valve if these measures bring no improvement.

Check for leaks and for missing seals.

Install the missing seals and replace damaged seals.

6518 / 6519 - 17

Page 20

I

NSTALLATION

Notes

english

, I

NITIALISATION AND SERVICE

18 - 6518 / 6519

Page 21

I

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

NHALT

Inhaltsverzeichnis

der Betriebsanleitung

Mehrfachblöcke Typ 6518 / 6519

Modulare, pneumatische Grundschiene

Typ MP07

ALLGEMEINE HINWEISE.................................................................................................................................................................................................. 21

Darstellungsmittel..................................................................................................................................................................................................................... 22

Sicherheitshinweise

Garantiebestimmungen

............................................................................................................................................................................................................ 22

................................................................................................................................................................................................... 23

TECHNISCHE BESCHREIBUNG ......................................................................................................................................................................... 25

Ventilaufbau .................................................................................................................................................................................................................................... 26

Wirkungsweise der Ventile Typ 6518 / 6519

Medien

Elektrischer Anschluss

Beispiel eines Mehrfachblocks

.................................................................................................................................................................................................................................................. 27

................................................................................................................................................................................................... 27

............................................................................................................................................................................. 28

MONTAGE, INBETRIEBNAHME UND WARTUNG ...................................................................................................................... 29

Allgemeine Hinweise .......................................................................................................................................................................................................... 30

Aufbau von Mehrfachblöcken mit der modularen, pneumatischen

Grundschiene Typ MP07

Demontage der Module

............................................................................................................................................................................................... 30

................................................................................................................................................................................................... 31

......................................................................................................................................... 26

deutsch

Weitere Einsatzmöglichkeiten der Anschlussmodule, rechts

Befestigung des Ventilblocks

Befestigung von Einzelventilen

Maßnahmen vor Inbetriebnahme

Impulsbetrieb

Störungen

................................................................................................................................................................................................................................ 34

........................................................................................................................................................................................................................................... 35

................................................................................................................................................................................... 31

............................................................................................................................................................................. 33

........................................................................................................................................................................ 34

....................................................................................... 31

6518 / 6519 - 19

Page 22

I

NHALT

deutsch

20 - 6518 / 6519

Page 23

A

LLGEMEINE HINWEISE

ALLGEMEINE HINWEISE

Darstellungsmittel..................................................................................................................................................................................................................... 22

deutsch

Sicherheitshinweise

Garantiebestimmungen

.............................................................................................................................................................................................................. 22

................................................................................................................................................................................................... 23

6518 / 6519 - 21

Page 24

A

LLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes gefährdet ist.

kennzeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen.

Sicherheitshinweise

deutsch

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen

Daten gemäß den Datenblättern Typ 6518 und Typ 6519, damit das Gerät einwandfrei funktioniert und

lange einsatzfähig bleibt.

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der

Technik!

• Beachten Sie, dass in Systemen, die unter Druck stehen, Leitungen und Ventile nicht gelöst werden

dürfen.

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte

während des Betriebes, der Wartung und der Reparatur des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung auszuschließen!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung

unsererseits, ebenso erlischt die Garantie auf Geräte und Zubehörteile!

HINWEIS

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an Ihre Bürkert-Niederlassung oder an unseren

Kundenservice:

Zulassungen wie Ex, UL, UR, CSA, DVGW usw. werden auf dem Typenschild oder

durch einen besonderen Aufkleber gekennzeichnet.

Bei Geräten mit der Zulassung nach der Anforderungsklasse AK5 muss entweder gereinigte Steuerluft verwendet werden oder es muss ein Sieb mit einer maximalen Maschenweite von 1 mm vorgeschaltet werden.

Bürkert Steuer- und Regelungstechnik, Service-Abteilung

Chr.-Bürkert-Str. 13-17, D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

eMail: info@de.buerkert.com

22 - 6518 / 6519

Page 25

Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf unsere allgemeinen Verkaufs- und Geschäftsbedingungen. Voraussetzung für die Garantie ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten Einsatzbedingungen.

ACHTUNG!

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit der Mehrfachblöcke Typ

6518 und Typ 6519 sowie die modulare pneumatische Grundschiene Typ MP07. Es

wird keine Haftung übernommen für Folgeschäden jeglicher Art, die durch Ausfall oder

Fehlfunktion des Gerätes entstehen könnten.

A

LLGEMEINE HINWEISE

deutsch

6518 / 6519 - 23

Page 26

A

LLGEMEINE HINWEISE

deutsch

24 - 6518 / 6519

Page 27

T

ECHNISCHE BESCHREIBUNG

TECHNISCHE

BESCHREIBUNG

deutsch

Ventilaufbau .................................................................................................................................................................................................................................... 26

Wirkungsweise der Ventile Typ 6518 / 6519

Medien

Elektrischer Anschluss

Beispiel eines Mehrfachblocks

.................................................................................................................................................................................................................................................. 27

................................................................................................................................................................................................... 27

............................................................................................................................................................................. 28

......................................................................................................................................... 26

6518 / 6519 - 25

Page 28

T

ECHNISCHE BESCHREIBUNG

Ventilaufbau

• 3/2-Wege-Vorsteuerventil mit unterschiedlichen elektrischen Anschlussvarianten.

• Die übergesteckte Spule ist in 4 x 90° - Schritten arretierbar, dazwischen um das Kernführungsrohr

beleibig positionierbar.

• Ventilgehäuse mit Membran und Sitzdichtungen (3/2 und 5/2) bzw. Schieber (5/3).

• Arbeitsanschlüsse 2 (B) / 4 (A) sowie Versorgungs- und Entlüftungsanschluss 1 (P) / 3 (R) / 5 (S)

mit G1/4-Innengewinde oder Steckanschluss für Schlauchaußendurchmesser 8 mm.

• Die Ventile können auf den modularen, pneumatischen Grundschienen Typ MP07 zu Ventilblöcken

montiert werden.

• Beliebige Einbaulage, vorzugsweise mit Magnetsystem oben.

Die Ventile sind auch in explosionsgeschützter Ausführung verfügbar.

HINWEIS

Steckanschlüsse gelten nur für die Arbeitsanschlüsse 2 (B) und 4 (A).

Die Ventile arbeiten wartungsfrei.

deutsch

Wirkungsweise der Ventile Typ 6518 / 6519

3/2-Wege-Ventil

In Ruhestellung Druckanschluss 1 gesperrt, Ausgang 2 entlüftet.

3/2-Wege-Ventil für Vakuum, mit Steuerhilfsluft

In Ruhestellung Druckanschluss 1 gesperrt, Ausgang 2 entlüftet.

ACHTUNG!

Der Vakuumerzeuger muss an Anschluss 1 angeschlossen werden.

3/2-Wege-Ventil

In Ruhestellung Druckanschluss 1 mit Ausgang 2 verbunden.

5/2-Wege-Ventil

In Ruhestellung Druckanschluss 1 mit Ausgang 2 verbunden, Ausgang 4 entlüftet.

26 - 6518 / 6519

Page 29

5/3-Wege-Ventil

In Mittelstellung alle Anschlüsse gesperrt.

5/3-Wege-Ventil

In Mittelstellung Ausgänge 2 und 4 entlüftet, Druckanschluss 1 gesperrt.

Medien

• gefilterte Druckluft (Partikelgröße max. 10 µm), vorzugsweise ungeölt

• Betrieb mit geölter Luft ist möglich; neutrale Gase

• Dichtwerkstoff NBR oder PUR für 3/2- und 5/2-Ventile

T

ECHNISCHE BESCHREIBUNG

deutsch

NBR für 5/2-Impuls- und 5/3-Ventile

• zulässige Temperatur Medium - 10 ... + 50 °C

Umgebung - 10 ... + 55 °C

• Betriebsdruckbereich 2 - 8 bar

HINWEIS

ACHTUNG!

Der Steuerdruck bei pneumatischer Ansteuerung ist abhängig vom Druck des

Durchflussmediums; er darf maximal 8 bar betragen!

Beachten Sie den zulässigen Druckbereich auf dem Typenschild!

Druckdifferenz zwischen Anschluss 1 und 3/5

Elektrischer Anschluss

• Entnehmen Sie Spannung, elektrische Leistung und Stromart dem Typenschild!

• Spannungstoleranz: ±10 %

≥≥

≥ 2 bar

≥≥

• Elektrischer Anschluss: Gerätesteckdose Typ 2508 an den Anschlusssteckerfahnen der Spule

(Drehmoment zur Befestigung: 1 Nm).

• Schutzart IP65 (nur in Verbindung mit der Gerätesteckdose Typ 2508)

• Die Gerätesteckdose ist zur Wahl des Kabelganges um 4 x 90° versetzt montierbar.

• Weitere elektrische Anschlussmöglichkeiten siehe Typ 6114 bzw. 8640

ACHTUNG!

Achten Sie beim Verschrauben der Gerätesteckdose mit der Spule auf einwandfreien

Sitz der Flachdichtung!

6518 / 6519 - 27

Page 30

T

ECHNISCHE BESCHREIBUNG

deutsch

Beispiel eines Mehrfachblocks

28 - 6518 / 6519

Bild: Beispiel eines Mehrfachblocks

Page 31

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

MONTAGE

INBETRIEBNAHME

UND WARTUNG

deutsch

Allgemeine Hinweise .......................................................................................................................................................................................................... 30

Aufbau von Mehrfachblöcken mit der modularen, pneumatischen

Grundschiene Typ MP07

Demontage der Module

Weitere Einsatzmöglichkeiten der Anschlussmodule, rechts

Befestigung des Ventilblocks

Befestigung von Einzelventilen

Maßnahmen vor Inbetriebnahme

Impulsbetrieb

Störungen

................................................................................................................................................................................................................................ 34

........................................................................................................................................................................................................................................... 35

............................................................................................................................................................................................... 30

................................................................................................................................................................................................... 31

....................................................................................... 31

................................................................................................................................................................................... 31

............................................................................................................................................................................... 33

........................................................................................................................................................................ 34

6518 / 6519 - 29

Page 32

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Allgemeine Hinweise

Eingriffe dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen.

Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab.

Säubern Sie vor Montage des Ventils die Rohrleitungen.

Schalten Sie gegebenenfalls zum Schutz vor Störungen einen Schmutzfänger vor.

Verwenden Sie die Spule in keinem Fall als Hebel, wenn Sie die Anschlüsse einschrauben.

Achten Sie auf Übereinstimmung der Betriebsbedingungen mit den Leistungsdaten des Gerätes.

Vermeiden Sie Staudrücke in den Abluftkanälen durch großvolumige Schalldämpfer.

ACHTUNG!

deutsch

Druckanzeige mit Anzeigestift am Anschlussmodul - rechts

(Bild:

- Anzeigestift lässt sich eindrücken: Druck im Ventilblock < 1 bar

- Anzeigestift lässt sich nicht eindrücken: Ventilblock ist druckbeaufschlagt

- Anzeigestift federt zurück: Ventilblock ist druckbeaufschlagt

Technische Beschreibung - Beispiel eines Mehrfachblocks

In Systemen, die unter Druck stehen, dürfen Leitungen oder Ventile nicht gelöst werden! Beachten Sie die Druckanzeige am rechten Anschlussmodul.

)

(entlüften Sie das System, bevor Sie Leitungen oder

Geräte demontieren)

Aufbau von Mehrfachblöcken mit der modularen, pneuma-tischen

Grundschiene Typ MP07

Sie erhalten durch die Kombination von 2fach- und 3fach-Grundmodulen beliebig große Ventilblöcke.

HINWEIS

Kontrollieren Sie die Module auf vollständige Bestückung mit O-Ringen!

Ölen oder fetten Sie die aufgezogenen O-Ringe vor dem Rasten leicht ein.

Rasten Sie die Haken des anzubauenden Moduls in die Rastnuten des vorgehenden Moduls ein, achten

Sie dabei auf exakten Sitz der O-Ringe!

Drücken Sie die Module bis zum Einrasten beider Haken zusammen.

Achten Sie auf exakten Sitz der Profildichtungen auf dem Grundmodul!

ACHTUNG!

30 - 6518 / 6519

Beginnen Sie die Montage zweckmäßig mit dem Anschlussmodul - links (Bild:

sche Beschreibung - Beispiel eines Mehrfachblocks

Gequetschte O-Ringe und Flachdichtungen haben Undichtheit des Blocks zur Folge.

).

Techni-

Page 33

M

ONTAGE

Befestigen Sie die Ventile mit je 2 M4-Schrauben auf dem Grundmodul

(Anzugsmoment max.1,5 Nm).

Montieren Sie den kompletten Ventilblock auf der Wand oder auf der Normschiene.

Schließen Sie Versorgungs- und Arbeitsleitungen an.

Stellen Sie die elektrischen Anschlüsse zu den Vorsteuerventilen her; beachten Sie dabei die Werte

auf dem Typenschild!

, I

NBETRIEBNAHME UND WARTUNG

Demontage der Module

Rasten Sie den oberen Rasthaken mittels Schraubendreher an der stirnseitigen Demontagenut aus.

Nehmen Sie den Teilblock / das Modul seitlich ab.

Weitere Einsatzmöglichkeiten der Anschlussmodule, rechts

• Als Teilermodule bei besonderen Anwendungsfällen zum Aufbau von mehreren Betriebs-Druckstufen

in einem Block.

• Zusätzliche Einspeisung bei größeren Ventilblöcken.

HINWEIS

Durchstoßen Sie bei Bedarf die seitlichen Sollbruchstellen der Anschlüsse 1, 3, 5 und

die der oberen Vorsteuerentlüftung.

Befestigung des Ventilblocks

Normschiene

• Normschiene 35 x 15 DIN 50022 (Standard)

• Normschiene 75 x 25 DIN 50023

HINWEIS

Setzen Sie bei Verwendung der Normschiene 75 x 25 DIN 50023 die vormontierten

Schrauben mit Klemmstücken und Federn entsprechend um.

deutsch

Montage

Hängen Sie den Ventilblock mit der oberen Nut in die Normschiene ein.

Rasten Sie die unteren Klemmstücke in die Normschiene ein.

Ziehen Sie die Schrauben an den Klemmstücken fest.

Demontage

Lösen Sie die Klemmschrauben (ca. 4 Umdrehungen).

Entnehmen Sie den Block nach oben von der Normschiene.

6518 / 6519 - 31

Page 34

M

ONTAGE

Wandmontage

deutsch

, I

NBETRIEBNAHME UND WARTUNG

Befestigen Sie den Ventilblock mit M5-Schrauben direkt an der Wand.

Bild: Befestigung des Ventilblocks

32 - 6518 / 6519

Page 35

Befestigung von Einzelventilen

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Befestigen Sie das Einzelventil mit M4-Schrauben direkt an der Wand (Bild:

und Wartung - Befestigung des Einzelventils, Handbetätigung, Pneumatische Stellungsanzeige

ACHTUNG!

Verspannen Sie das Ventilgehäuse beim Einbau nicht!

Montage, Inbetriebnahme

Steckanschlüsse

HINWEIS

Für die Steckanschlüsse müssen die Schlauchleitungen folgende Anforderungen

erfüllen:

• Mindesthärte von 40 Shore D (nach DIN 53505 bzw. ISO 868).

• Außendurchmesser entsprechend DIN 73378 (max. zul. Abweichung ± 0,1 mm vom

Nennmaß).

• Gratfrei, rechtwinklig abgeschnitten und am Außendurchmesser unbeschädigt.

• die Schlauchleitungen sind bis zum Anschlag in die Steckanschlüsse einzudrücken.

Demontage der Steckanschlüsse

).

deutsch

Drücken Sie zum Lösen der Leitungen den Druckring ein und ziehen Sie die Schlauchleitung heraus.

Handbetätigung

Drehen Sie zur manuellen Betätigung des Ventils die Handbetätigung bis zum Anschlag ein.

Durch anschließendes Dehen um 90° nach

rechts ist die Handbetätigung verriegelt.

Anzeigestift zur pneumatischen Stellungsanzeige.

Bei ungeschaltetem Ventil lässt sich der rote

Anzeigestift eindrücken. Wird das Ventil geschaltet, fährt der Anzeigestift aus und bleibt

in dieser Stellung. Bei jeder Funktionsüberprüfung muss der Anzeigestift erneut eingedrückt werden.

Kennzeichnungsschild (abnehmbar für Markierungen/Beschriftungen)

Anschluss 14

• in Standardausführung nicht belegt

• dient als Steuerhilfsluftanschluss und als

Anschluss für pneumatische Ansteuerungen

Arbeitsanschlüsse 2 (B) und 4 (A)

M4-Schrauben

zur Wandmontage des Einzelventils

Bild: Befestigung des Einzelventils, Handbetätigung, Pneumatische Stellungsanzeige

6518 / 6519 - 33

Page 36

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Maßnahmen vor der Inbetriebnahme

Überprüfen Sie Anschlüsse, Spannung und Betriebsdruck!

Beachten Sie, dass max. Betriebsdaten (siehe Typenschild) nicht überschritten werden!

Überprüfen Sie die vorschriftsmäßige Belegung der Anschlüsse 1 und 3 bzw. 5, diese dürfen auf keinen

Fall vertauscht werden!

Entriegeln Sie bei elektrischem Betrieb die Handbetätigung!

Impulsbetrieb

Funktion

Die impulsgesteuerten Magnetventile arbeiten mit zwei Spulen, die im Wechsel geschaltet werden.

deutsch

ACHTUNG!

Beachten Sie die Angabe

Impulsgabe auf beide Spulen!

Impuls

auf dem Typenschild! Vermeiden Sie gleichzeitige

HINWEIS

Mit der Handbetätigung sind die Ventile umsteuerbar.

34 - 6518 / 6519

Page 37

Störungen

Störung mögliche Ursache Behebung

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Ventile

schalten nicht

Ventile

schalten

verzögert oder

blasen an den

Entlüftungsan-

schlüssen ab

Keine oder nicht

ausreichende

Betriebsspannung

Handbetätigung nicht in

neutraler Stellung

Druckversorgung nicht

ausreichend oder nicht

vorhanden

Druckversorgung nicht

ausreichend oder nicht

vorhanden

Ventile sind während des

Druckaufbaus nicht in

Grundstellung (stromlos)

keine ausreichende

Entlüftung der Abluftkanäle

durch zu kleine oder

verschmutzte

Geräuschdämpfer

(Rückdrücke);

Überprüfen Sie den elektrischen Anschluss.

Stellen Sie die Betriebsspannung laut Typenschild

sicher.

Bringen Sie die Handbetätigung in Null-Stellung.

Führen Sie die Druckversorgung möglichst großvolumig

aus (auch bei vorgeschalteten Geräten wie

Druckreglern, Wartungseinheiten, Absperrventilen usw.).

Mindestbetriebsdruck 2 bar

Führen Sie die Druckversorgung möglichst großvolumig

aus (auch bei vorgeschalteten Geräten wie

Druckreglern, Wartungseinheiten, Absperrventilen usw.).

Mindestbetriebsdruck 2 bar

Beaufschlagen Sie den Ventilblock mit Druck, bevor Sie

die Ventile schalten!

Verwenden Sie entsprechend groß dimensionierte

Geräuschdämpfer bzw. Expansionsgefäße.

Reinigen Sie verschmutzte Geräuschdämpfer.

deutsch

Undichte

Ventilblöcke

Verunreinigungen bzw.

Fremdkörper im Vorsteueroder Hauptventil.

Fehlende oder gequetschte

O-Ringe zwischen den

Modulen

Fehlende oder falsch

positionierte Flachdichtungen

zwischen Ventil und

Grundplatte

Beaufschlagen Sie die Abluftkanäle mit impulsartigem

Druck, um die Verunreinigungen auszublasen

Bauen Sie ein neues Vorsteuer- bzw. Hauptventil ein,

wenn diese Maßnahme keinen Erfolg bringt.

Ermitteln Sie die Leckstelle oder fehlende Dichtungen

Setzen Sie fehlende Dichtungen ein oder erneuern Sie

beschädigte Dichtungen.

6518 / 6519 - 35

Page 38

M

ONTAGE

Notizen

deutsch

, I

NBETRIEBNAHME UND WARTUNG

36 - 6518 / 6519

Page 39

S

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

OMMAIRE

Table de matieres

Instructions de service

Blocs multiples et profils pneumatiques

modulaires Type 6518/6519 et

Type MP07

REMARQUES GENERALES........................................................................................................................................................................................ 39

Représentation .......................................................................................................................................................................................................................... 40

Consignes générales de sécurité

Clauses de garantie

.............................................................................................................................................................................................................. 41

...................................................................................................................................................................... 40

DESCRIPTION TECHNIQUES ...................................................................................................................................................................................... 43

Construction de la vanne................................................................................................................................................................................................ 44

Fonctionnement des vannes du type 6518 / 6519

Fluides

Raccordement électrique

Exemple d’un bloc multiple

.................................................................................................................................................................................................................................................... 45

............................................................................................................................................................................................. 45

......................................................................................................................................................................................... 46

....................................................................................................................... 44

MONTAGE, MISE EN SERVICE ET ENTRETIEN ........................................................................................................................... 47

Remarques générales ...................................................................................................................................................................................................... 48

Montage de blocs multiples avec les modules de base

pneumatiques type MP07

Démontage des modules

Autres possibilités d’application du module de raccordement - à droite -

Fixation du bloc de vannes

.............................................................................................................................................................................................. 48

................................................................................................................................................................................................ 49

...................................................... 49

........................................................................................................................................................................................ 49

français

Fixation des vannes seules

Précautions à prendre avant la mise en service

Fonctionnement par impulsion

Dérangements

............................................................................................................................................................................................................................ 53

...................................................................................................................................................................................... 51

............................................................................................................................................................................... 52

............................................................................................................................... 52

6518 / 6519 - 37

Page 40

S

OMMAIRE

français

38 - 6518 / 6519

Page 41

R

EMARQUES GENERALES

REMARQUES GENERALES

Représentation ............................................................................................................................................................................................................................ 40

Consignes générales de sécurité

Clauses de garantie

.............................................................................................................................................................................................................. 41

...................................................................................................................................................................... 40

français

6518 / 6519 - 39

Page 42

R

EMARQUES GENERALES

Représentation

On utilise dans ces instructions de service les modes de représentation suivants:

marque une phase de travail que vous devez exécuter

ATTENTION!

REMARQUE

caractérise des indications dont l’observation peut mettre en danger votre santé ou la

fonctionnalité de l’appareil

caractérise des indications supplémentaires, des conseils et des

recommandations

Consignes générales de sécurité

Observez les indications de ces instructions de service ainsi que les conditions d’utilisation et les

caractéristiques admissibles selon la fiche technique du type 6518 / 6519, afin que l’appareil fonctionne

parfaitement et reste longtemps en état de fonctionnement:

français

• respectez lors du projet d’utilisation et de l’exploitation de l’appareil les règles générales reconnues de la

technique;

• observez les dispositions en vigueur sur la prévention des accidents et la sécurité pour les appareils

électriques, pendant l’exploitation, l’entretien et la réparation de l’appareil; déclenchez dans tous es cas

la tension électrique avant toute intervention dans le système!

• prenez les mesures appropriées afin d’exclure un actionnement involontaire ou un préjudice

inadmissible;

• observer que les conduites et les vannes des systèmes se trouvant sous pression ne doivent pas être

démontées;

• en cas d’inobservation de cette indication, toute responsabilité de notre part sera exclue, de même la

garantie sur l’appareil et les accessoires sera supprimée.

REMARQUE

En cas de non concordance, s’adresser immédiatement à votre succursuale Bürkert ou à notre service

aprés ventre:

Des homologations telles que Ex, UL, UR, CSA, DVGW, etc. sont indiquées sur la

plaquette signalétique ou sur une étiquette collante spéciale.

Dans le cas des appareils homologués en classe AK 5, soit de l’air de commande purifié

doit être utilisé, soit un tamis comportant une largeur de maille de 1 mm doit être branché

en amont.

Bürkert Steuer- und Regelungstechnik, Service-Abteilung

Chr.-Bürkert-Str. 13-17, D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

eMail: info@de.buerkert.com

40 - 6518 / 6519

Page 43

Clauses de garantie

Ce dokument ne constitue aucun assentiment de garantie. Nous vous renvoyons à cet effet à nos

conditions générales de vente et commerciales.La condition préalable au consentement de la garantie est

l’utilisation conforme de l’appareil à l’usage auquel il est destiné, compte tenu de l’observation des

conditions d’emploi spécifiées.

R

EMARQUES GENERALES

ATTENTION!

Les prestations de garantie ne s’étendent qu’à l’absence de défaut de la bloc multiples

6518/6519 et Profils pneumatiques modulaires Type MP07. Nous déclions, par contre,

toute responsabilité pour des dégâts consécutifs de toute nature susceptibles de

survenir par suite de défaillance ou défaut de fonctionnement de l’appareil.

français

6518 / 6519 - 41

Page 44

R

EMARQUES GENERALES

français

42 - 6518 / 6519

Page 45

DESCRIPTION

TECHNIQUES

D

ESCRIPTION TECHNIQUES

Construction de la vanne................................................................................................................................................................................................ 44

Fonctionnement des vannes du type 6518/6519

Fluides

Raccordement électrique

Exemple d’un bloc multiple

.................................................................................................................................................................................................................................................. 45

............................................................................................................................................................................................. 45

......................................................................................................................................................................................... 46

........................................................................................................................... 44

français

6518 / 6519 - 43

Page 46

D

ESCRIPTION TECHNIQUES

Construction de la vanne

• Vanne pilote à 3/2 voies, avec différentes variantes de raccordement électrique

• La bobine insérée au-dessus peut être bloquée par pas sur 4 x 90°, et peut être positionnée entre ces

points à volonté autour du tube de guidage du noyau

• Corps de vanne avec membrane et joints du siège (3/2; 5/2), resp. avec tiroir (5/3)

• Raccords de travail 2 (B) / 4 (A) ainsi que raccords d’alimentation et de purge d’air

1 (P) / 3 (S) / 5 (R) au choix avec taraudage intérieur G 1/4 ou raccord à fiche pour diamètre de tuyau

souple de 8 mm

• Les vannes peuvent être montées sur les profils pneumatiques modulaires MP07

• Position de montage quelconque, de préférence avec système magnétique en haut

Les vannes sont aussi disponibles en exécution antidéflagrante

REMARQUE

Les raccords à fiche ne s’appliquent qu’aux raccords de travail

2 (B) et 4 (A). Les vannes travaillent sans entretien.

Fonctionnement des vannes du type 6518 / 6519

français

Vanne à 3/2 voies:

en position de repos, raccord de pression 1 bloqué, sortie 2 à l’air libre

Vanne à 3/2 voies pour vide, avec air auxiliaire de commande

en position de repos, raccord de pression 1 bloqué,

sortie 2 à l’air libre

ATTENTION!

La source de vide doit être reliée au raccordement 1!

Vanne à 3/2 voies:

en position de repos, raccord de pression 1 relié à la sortie 2

Vanne à 5/2 voies:

en position de repos, raccord de pression 1 relié à la sortie 2, sortie 4 à l’air libre

44 - 6518 / 6519

Page 47

Vanne à 5/3 voies:

tous les raccordements bloqués en position médiane

Vanne à 5/3 voies:

en position médiane, sorties 2 et 4 à l’air libre; raccord de pression 1 bloqué

Fluides

• Air comprimé filtré (grandeur max. des particules 10 µm), de préférence sans huile, le fonctionnement

avec de l’air huilé est possible; gaz neutres

• Matière du joint: NBR ou PUR pour vannes 3/2 et 5/2

D

NBR pour vannes 5/2 à impulsion et vannes 5/3

ESCRIPTION TECHNIQUES

• Température admissible du fluide: -10 à +50° C

• Température ambiante admissible: -10 à +55° C

• Domaine de pression de service: 2 - 8 bars

REMARQUE

ATTENTION!

La pression de commande en pilotage pneumatique dépend de la pression du fluide

traversant; elle doit se monter au maximum à 8 bars!

Observez le domaine de pression admissible sur la plaquette signalétique!

Différence de pression entre raccords 1 et 3/5 ≥ 2 bars

Raccordement électrique

• Lisez sur la plaquette signalétique la tension, la puissance électrique, le genre de protection et de

courant!

• Tolérance de tension ±10%

français

• Raccordement électrique: prise d’appareil type 2508 sur les fiches de raccordement de la bobine (couple

de serrage de la fixation: 1 Nm)

• Mode de protection IP 65 (seulement en relation avec la prise d’appareil type 2508)

• La prise d’appareil peut être montée inversée de 4 x 90° pour le choix du passage du câble

• Autres possibilités de raccordement électrique, voir type 6014, resp. 8640

ATTENTION!

Veiller en vissant la prise d’appareil avec la bobine à une application parfaite du joint

plat!

6518 / 6519 - 45

Page 48

D

ESCRIPTION TECHNIQUES

français

Exemple d’un bloc multiple

46 - 6518 / 6519

Bild: Beispiel eines Mehrfachblocks

Page 49

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

MONTAGE,

MISE EN SERVICE

ET ENTRETIEN

Remarques générales ...................................................................................................................................................................................................... 48

Montage de blocs multiples avec les modules de base

pneumatiques type MP07

Démontage des modules

Autres possibilités d’application du module de raccordement - à droite -

Fixation du bloc de vannes

Fixation des vannes seules

Précautions à prendre avant la mise en service

Fonctionnement par impulsion

Dérangements

.............................................................................................................................................................................................................................. 53

............................................................................................................................................................................................ 48

.............................................................................................................................................................................................. 49

...................................................... 49

........................................................................................................................................................................................ 49

...................................................................................................................................................................................... 51

............................................................................................................................ 52

............................................................................................................................................................................... 52

français

6518 / 6519 - 47

Page 50

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Remarques générales

Des interventions ne doivent être effectuées que par un personnel qualifié équipé de l’outillage

approprié!

Déclencher dans tous les cas la tension avant toute intervention sur le système!

Nettoyer les conduites avant le montage de la vanne!

Monter éventuellement un filtre en amont pour prévenir des dérangements.

N’utiliser en aucun cas la bobine comme levier lors du vissage des raccordements!

Veiller à la concordance des conditions d’exploitation avec les caractéristiques de débit de l’appareil!

Eviter les accumulations de pression dans les canaux d’échappement d’air en employant des silencieux

de grand volume!

ATTENTION!

Indication de pression avec tige indicatrice sur le module de raccordement - à droite -

(figure:

- La tige indicatrice se laisse enfoncer: pression dans le bloc de vanne < 1 bar

français

- La tige indicatrice ne se laisse pas enfoncer: le bloc de vanne est sous pression

- La tige indicatrice fait ressort: le bloc de vanne est sous pression

Description Techniques - Exemple d’un bloc multiple

Ne pas démonter des conduites ou des vannes dans des systèmes se trouvant sous

pression! Observer l’indication de pression sur le module de raccordement de droite!

)

(purger le système avant de démonter les conduites

ou appareils)

Montage de blocs multiples avec le profil modulaire pneumatique type MP07

On obtient en combinant des modules de base doubles ou triples des blocs de vannes de dimensions

illimitées.

REMARQUE

Contrôler si les modules sont équipés complètement avec les joints toriques!

Huiler ou graisser légèrement les joints toriques posés avant d’emboîter.

Introduire les crochets du module à ajouter dans les rainures du module précédent, en veillant alors à la

tenue exacte des joints toriques!

Presser le module jusqu’à l’emboîtement des deux crochets.

Veiller à la tenue exacte des joints du profil sur le module de base!

ATTENTION!

48 - 6518 / 6519

Commencer de préférence le montage par le module de raccordement - à gauche - (figure:

Description Techniques - Exemple d’un bloc multiple).

Les joint toriques et les joints du profil écrasés ont pour conséquence des fuites dans le

bloc!

Page 51

M

ONTAGE

Fixer les vannes sur le module de base avec 2 vis M4 pour chacune (couple de serrage max. 1,5 Nm).

Monter le bloc de vannes complet sur la paroi ou le profil normalisé.

Raccorder les conduites d’alimentation et de travail.

Etablir les raccordements électriques aux vannes pilotes, en observant les valeurs sur la plaquette

signalétique!

, M

ISE EN SERVICE ET ENTRETIEN

Démontage des modules

Décrocher avec un tournevis les deux crochets d’emboîtement sur la rainure frontale de démontage.

Extraire latéralement le bloc partiel / le module.

Autres possibilités d’application du module de raccordement - à

droite -

• En tant que module diviseur pour des cas particuliers d’application, pour la réalisation de plusieurs

étages de pression de service en un seul bloc:

• Alimentation supplémentaire en cas de grands blocs de vannes

REMARQUE

Briser si nécessaire les points de passage des raccordements

1 / 3 / 5 et de l’échappement d’air du pilotage en haut.

Fixation du bloc de vannes

Profil normalisé

• Profil normalisé 35 x 15 DIN 50022 (standard)

• Profil normalisé 75 x 25 DIN 50023

REMARQUE

Montage

Pour l’utilisation du profil normalisé 75 x 25 DIN 50023, inverser les vis préalablement

montée avec les pièces de serrage et les ressorts.

français

Accrocher le bloc de vannes avec la rainure supérieure dans le profil normalisé.

Emboîter la pièce de serrage inférieure dans le profil normalisé.

Serrer les vis sur les pièce de serrage.

Démontage

Dévisser les vis de serrage (env. 4 tours).

Enlever le bloc du profil normalisé, vers le haut.

6518 / 6519 - 49

Page 52

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Montage mural

Fixer le bloc de vannes avec 4 vis M4 directement contre la paroi.

Raccordement électrique

tounant de 180°

Fixation murale

Profil normalisé

35 x 15

DIN 50022

français

Figure: Fixation du bloc de vannes

Profil normalisé

75 x 25

DIN 50023

Module de

raccordement

50 - 6518 / 6519

Page 53

Fixation des vannes seules

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Fixer la vanne seule avec les vis M4 directement contre la paroi. (figure:

Entretien - Fixation de vanne seule / Actionnement manuel / indication pneumatique de position)

ATTENTION!

Ne pas déformer le boîter de vanne au montage!

Montage, Mise en Service et

Raccords à fiches

REMARQUE

Pour les raccords à fiches, les conduites souples doivent remplir les exigences

suivantes:

• Dureté minimale de 40 Shore D (selon DIN 53505, resp. ISO 868)

• Diamètre extérieur selon DIN 73378 (écart max. adm. ± 0,1 mm de la cote nominale)

• Exempt de bavures, coupé d’équerre et sans dommages sur le diamètre extérieur

• Les conduites souples doivent être enfoncées jusqu’à la butée dans les raccords à

fiche

Démontage des raccords à fiches

français

Presser la bague de pression pour détacher les conduites et retirer les conduites souples.

Actionnement manuel

Presser pour l’actionnement manuel de la vanne

le bouton jusqu’en butée. En tournant ensuite de

90° vers la droite, l’actionnement manuel sera

verrouillé.

Tige indicatrice pour l’indication pneumatique

de position.

Si la vanne n’est pas activée, la tige indicatrice

rouge peut être enfoncée. Si la vanne est

activée, la tige indicatrice sort et reste dans

cette position. A chaque vérification de fonction,

il faut de nouveau enfoncer la tige indicatrice.

Etiquette d’identification (amovible pour

marquages/inscriptions)

Raccordement 14

• pas raccordé dans l’exécution standard

• sert de raccord d’air auxiliaire de

commande et de raccord pour les

pilotages pneumatiques

Vis M4 pour la fixation murale de la

vanne seule

Figure: Fixation de vanne seule / Actionnement manuel / indication pneumatique de position

Raccords de travail 2 (B) et 4 (A)

6518 / 6519 - 51

Page 54

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Précautions à prendre avant la mise en service

Vérifier les raccordements, la tension et la pression de service!

Veiller à ce que les données de service maximales (voir plaquette signalétique) ne soient pas

dépassées!

Vérifier le raccordement conforme aux prescriptions des raccords 1 et 3 resp. 5, qui ne doivent en aucun

cas être permutés!

En cas de fonctionnement électrique, déverrouiller l’actionnement manuel!

Fonctionnement par impulsion

Fonction

Les vannes magnétiques commandées par impulsion travaillent avec deux bobines couplées en

alternance.

ATTENTION!

français

REMARQUE

Observer l’indication

Eviter de donner simultanément une impulsion sur les deux bobines!

Les vannes peuvent être commutées avec l’actionnement manuel.

«Impulsion»

sur la plaquette signalétique!

52 - 6518 / 6519

Page 55

Dérangements

Dérangement Cause possible Remède

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Les vannes ne

commutent

pas:

Les vannes

commutent à

retardement

ou sifflent aux

rac-cords

d’échapement

d’air:

Tension de service absente

ou insuffisante;

Actionnement manuel pas

en position neutre;

Pression d'alimentation

absente ou insuffisante.

Pression d'alimentation

absente ou insuffisante.

Les souppes ne doivent pas

être en position initiale (sans

courant) pendant

l'établissement de la

pression

Aération des canaux

d’échappement d’air

insuffisantes à cause de

silencieux trop petits ou

sales (contre-pressions).

Vérifier le raccordement électrique.

Assurer la tension de service selon la plaquette

signalétique.

Placer l'actionnement manuel en position neutre

Exécuter l'alimentation en pression avec le plus gand

volume possible (aussi avec les appareils en amont

tels que régulateurs de pression, unités de

conditionnement, vannes d'arrêt, etc.)

pression de service ≥ 2 bar

Exécuter l'alimentation en pression avec le plus gand

volume possible (aussi avec les appareils en amont

tels que régulateurs de pression, unités de

conditionnement, vannes d'arrêt, etc.)

pression de service ≥ 2 bar

Mettre les appareils de distribution groupés sous

pression avant de mettre les soupapes en circuit.

Utiliser des silencieux resp. des vases d’expansion

dimensionnés assez grands.Nettoyer les silencieux

sales.

français

Blocs de

vannes pas

étanches:

Saletés ou corps étrangers

dans la vanne de pilotage ou

principale.

Joints toriques absents ou

écrasés entre les modules;

Joints du profil absents ou

mal positionnés entre vanne

et plaque de base.

Appliquer des impulsions de pression sur les canaux

d’échappement d’air pour expulser les saletés. Monter

une nouvelle vanne de pilotage ou principale si cette

mesure n’a pas de succès..

Localiser la fuite ou les joints manquants.

Poser les joints manquants ou remplacer les joints

endommagés.

6518 / 6519 - 53

Page 56

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Bürkert Company Locations

Page 57

The smart choice

of Fluid Control Systems

www.buerkert.com

Loading...

Loading...