Page 1

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Type ME23

Fieldbus gateway büS to Industrial Ethernet

Feldbusgateway büS zu Industrial Ethernet

Passerelle bus de terrain büS vers Ethernet industriel

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürker t Werke GmbH & Co. KG, 201 - 2017

Operating Instructions 1706/01_EU-EN_008 / Original DE

Page 3

3

Contents

1 THE OPERATING INSTRUCTIONS .............................................................................................................................................5

1.1 Symbols ......................................................................................................................................................................................5

1.2 Definition of the term "device" ........................................................................................................................................5

2 INTENDED USE ....................................................................................................................................................................................6

3 BASIC SAFETY INSTRUCTIONS .................................................................................................................................................7

4 GENERAL INFORMATION ................................................................................................................................................................8

4.1 Contact address .....................................................................................................................................................................8

4.2 Warranty ......................................................................................................................................................................................8

4.3 Information on the Internet ...............................................................................................................................................8

5 DESCRIPTION OF THE DEVICE ..................................................................................................................................................9

5.1 Possible combinations ........................................................................................................................................................9

6 TECHNICAL DATA .............................................................................................................................................................................10

6.1 Conformity ..............................................................................................................................................................................10

6.2 Standards ................................................................................................................................................................................10

6.3 Operating conditions ........................................................................................................................................................10

6.4 Industrial Ethernet ..............................................................................................................................................................10

6.5 Mechanical data ...................................................................................................................................................................11

6.6 Electrical data .......................................................................................................................................................................12

6.6.1 Electrical configuration ....................................................................................................................12

7 INSTALLATION ...................................................................................................................................................................................13

7.1 Safety instructions .............................................................................................................................................................13

7.2 Mount Type ME23 on backplane Type BEF1 ........................................................................................................13

7.3 Establish network connection to the bus ..............................................................................................................14

8 START-UP .............................................................................................................................................................................................15

Fieldbus gateway büS to Industrial Ethernet

Type ME23

English

Page 4

4

Type ME23

8.1 Safety instructions .............................................................................................................................................................15

8.2 Basic settings .......................................................................................................................................................................15

9 OPERATION .........................................................................................................................................................................................16

9.1 Safety instructions .............................................................................................................................................................16

9.2 Configuration and parameterization of the Type ME23..................................................................................16

9.2.1 Configuration .......................................................................................................................................16

9.2.2 Parameterization .................................................................................................................................16

9.3 Display elements .................................................................................................................................................................17

9.3.1 LED for connection to the control status display .......................................................................17

9.3.2 NAMUR mode .....................................................................................................................................18

9.3.3 Flashing of the LED illuminated ring ..............................................................................................18

9.3.4 LED for network connection ............................................................................................................19

9.4 Removable data storage .................................................................................................................................................20

10 FUNCTIONS .........................................................................................................................................................................................21

10.1 Conversion Industrial Ethernet to büS ....................................................................................................................21

10.2 Configuration .........................................................................................................................................................................23

10.2.1 Select process data ...........................................................................................................................25

10.2.2 Fieldbus-specific address mapping ...............................................................................................26

10.2.3 büS network configuration ...............................................................................................................28

10.3 Downloading an existing configuration ..................................................................................................................29

11 MAINTENANCE ..................................................................................................................................................................................30

11.1 Safety instructions .............................................................................................................................................................30

11.2 Replacing the device .........................................................................................................................................................30

11.3 Display of the device status ........................................................................................................................................32

11.4 Troubleshooting ...................................................................................................................................................................34

12 ACCESSORIES ..................................................................................................................................................................................35

13 PACKAGING AND TRANSPORT ...............................................................................................................................................36

14 STORAGE ..............................................................................................................................................................................................36

15 DISPOSAL ............................................................................................................................................................................................36

English

Page 5

5

The operating instructions

Type ME23

1 THE OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user and make these instructions available to every new owner of the device.

Important safety information!

Read the operating instructions carefully and thoroughly. Study in particular the chapters entitled “2 Intended use”

and “3 Basic safety instructions”.

▶ The operating instructions must be read and understood.

1.1 Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property.

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

Refers to information in these operating instructions or in other documentation.

▶ Designates instructions for risk prevention.

→ Designates a procedure which you must carry out.

Indicates a result.

1.2 Definition of the term "device"

→ In these instructions, the term "device" always refers to fieldbus gateway büS to Industrial Ethernet,

Type ME23.

English

Page 6

6

Intended use

Type ME23

2 INTENDED USE

Non-authorized use of the Type ME23 may be dangerous to people, nearby equipment and the

environment.

The fieldbus gateway Type ME23 is used as fieldbus converter between büS and Industrial Ethernet.

▶ Use according to the authorized data, operating conditions and conditions of use specified in the contract

documents and operating instructions.

Observe the following when using the device/product:

▶ Do not use outside.

▶ Use the device only in conjunction with third-party devices and components recommended and authorized

by Bürkert.

▶ Use only when in perfect condition and always ensure proper storage, transportation, installation and operation.

▶ Use only as intended.

English

Page 7

7

Basic safety instructions

Type ME23

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the assembly, operation, and maintenance.

• local safety regulations – the operator is responsible for observing these regulations, also in relation to the installation personnel.

General hazardous situations.

To prevent injuries:

▶ Do not make any internal or external changes on the device and do not subject it to mechanical stress.

▶ Secure the system from unintentional actuation.

▶ Only trained technicians may perform installation and maintenance work.

▶ After an interruption in the power supply, ensure that the process is restarted in a controlled manner.

▶ Observe the general rules of technology.

NOTE!

Electrostatic sensitive components/modules.

The device contains electronic components which react sensitively to electrostatic discharge (ESD). Contact with

electrostatically charged persons or objects are hazardous to these components. In the worst case scenario, they

will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1 to minimize or avoid the possibility of damage

caused by sudden electrostatic discharge.

• Do not touch electronic components while the supply voltage is switched on.

English

Page 8

8

General information

Type ME23

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

4.2 Warranty

The warranty is only valid if the Type ME23 is used as intended in accordance with the specified application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Type ME23 can be found on the Internet at:

www.burkert.com

English

Page 9

9

Description of the device

Type ME23

5 DESCRIPTION OF THE DEVICE

The fieldbus gateway Type ME23 is used as fieldbus converter between büS and Industrial Ethernet.

Application area:

Process values can be exchanged between participants of fieldbus 1 and fieldbus 2.

Device type Fieldbus 1 Fieldbus 2

ME23 büS PROFINET

ME23 büS EtherNet/IP

ME23 büS Modbus TCP

Table 1: Type ME23 application area

The "Bürkert Communicator" software is required for parameterizing Type ME23.

For description see chapter “9.2 Configuration and parameterization of the Type ME23”.

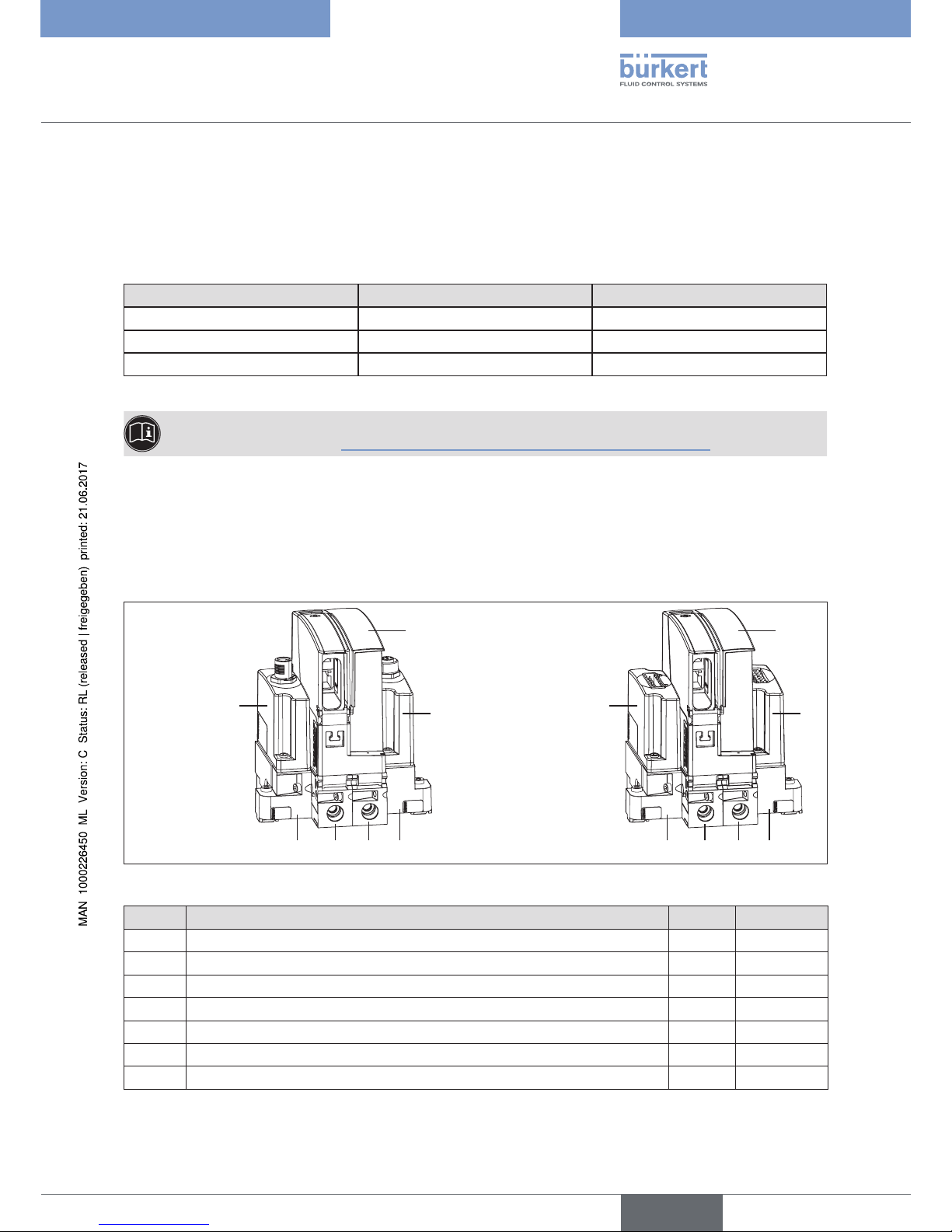

5.1 Possible combinations

The fieldbus gateway Type ME23 can only be operated within a system in combination with additional modules.

For setting up a system comprising several modules, please contact your Bürkert sales office.

In the following, a system in minimum combination is shown as example.

Connection variant:

terminals for cable

gland

Connection variant:

circular plug-in

connector M12

2

4

6 5 5

7

ME23

1

3

6 5 5

7

ME23

Figure 1: Example of a system: Minimum combination of Type ME23 with additional modules

Module Designation Types Order no.

1 Input module (connection variant: circular plug-in connector M12) ME29 00564825

2 Input module (connection variant: terminals for cable gland) ME29 00564826

3 Output module (connection variant: circular plug-in connector M12) ME29 00564827

4 Output module (connection variant: terminals for cable gland) ME29 00564828

5 Backplane for Type ME23 BEF1 00564841

6 Backplane, left BEF1 00564844

7 Backplane, right BEF1 00564846

Table 2: Modules of a possible combination with Type ME23

English

Page 10

10

Technical data

Type ME23

6 TECHNICAL DATA

6.1 Conformity

The fieldbus gateway of Type ME23 conforms to the EC Directives according to the Declaration of Conformity

(if applicable).

6.2 Standards

The applied standards, which are used to demonstrate compliance with the EC Directives, are listed in the EC type

test certificate and/or the EC Declaration of Conformity (if applicable).

6.3 Operating conditions

WARNING!

Risk of injury

Malfunction if used outside.

▶ Do not use Type ME23 outdoors and avoid heat sources which may cause the permissible temperature range

to be exceeded.

Permitted temperatures

Ambient temperature: 0 ... +50 °C

6.4 Industrial Ethernet

Profinet:

Topology recognition LLDP, SNMP V1, MIB2, physical device

Minimum cycle time 1 ms

IRT Support not supported

Media Redundancy MRP client is supported

Additional supported features DCP, VLAN- and priority tagging, Shared Device

Baud rate 100 MBit/s

Data transport layer Ethernet II, IEEE 802.3

Profinet IO specification

V2.3

Multiple Application Relations (AR) The Stack can handle up to 2 IO-ARs, one Supervisor AR and one

Supervisor-DA AR at the same time.

English

Page 11

11

Technical data

Type ME23

Ethernet IP

Predefined standard objects Identity Object (0x01)

Message Router Object (0x02)

Assembly Object (0x04)

Connection Manager (0x06)

DLR Object (0x47)

QoS Object (0x48)

TCP/IP Interface Object (0xF5)

Ethernet Link Object (0xF6)

DHCP supported

BOOTP supported

Baud rates 10 and 100 MBit/s

Duplex modes Half Duplex, Full Duplex, Auto-Negotiation

MDI modes MDI, MDI-X, Auto-MDIX

Data transport layer Ethernet II, IEEE 802.3

Address Conflict Detection (ACD) supported

DLR (ring topology) supported

Integrated switch supported

CIP Reset services Identity Object Reset Service of Type 0 and 1

ModbusTCP

Modbus Function Codes 1, 2, 3, 4, 5, 6, 7, 15, 16, 23

Mode Message Mode: Client, Server

Baud rates 10 and 100 MBit/s

Data transport layer Ethernet II, IEEE 802.3

PROFIBUS

Acyclic communication DP V1 Class 1 Read/Write

DP V1 Class 1 Alarm

DP V1 Class 2 Read/Write/Data Transport

Baud rate Fixed values ranging from 9,6 kBits/s to 12 MBit/s

Auto-detection mode is supported

6.5 Mechanical data

Dimensions: refer to data sheet for Type ME23

Housing material: polycarbonate

English

Page 12

12

Technical data

Type ME23

6.6 Electrical data

Power supply: 18 - 35 V via the backplane BEF1

UL devices: Power supply unit restricted to Class 2

Power consumption < 2 W

Interfaces 2 sockets for RJ45 plug-in connector, for connecting to the fieldbus

1 socket for mini USB connector, for factory service only

Degree of protection: IP 20 according to EN 60529 / IEC 60529

(only if cables, plugs and sockets have been connected correctly)

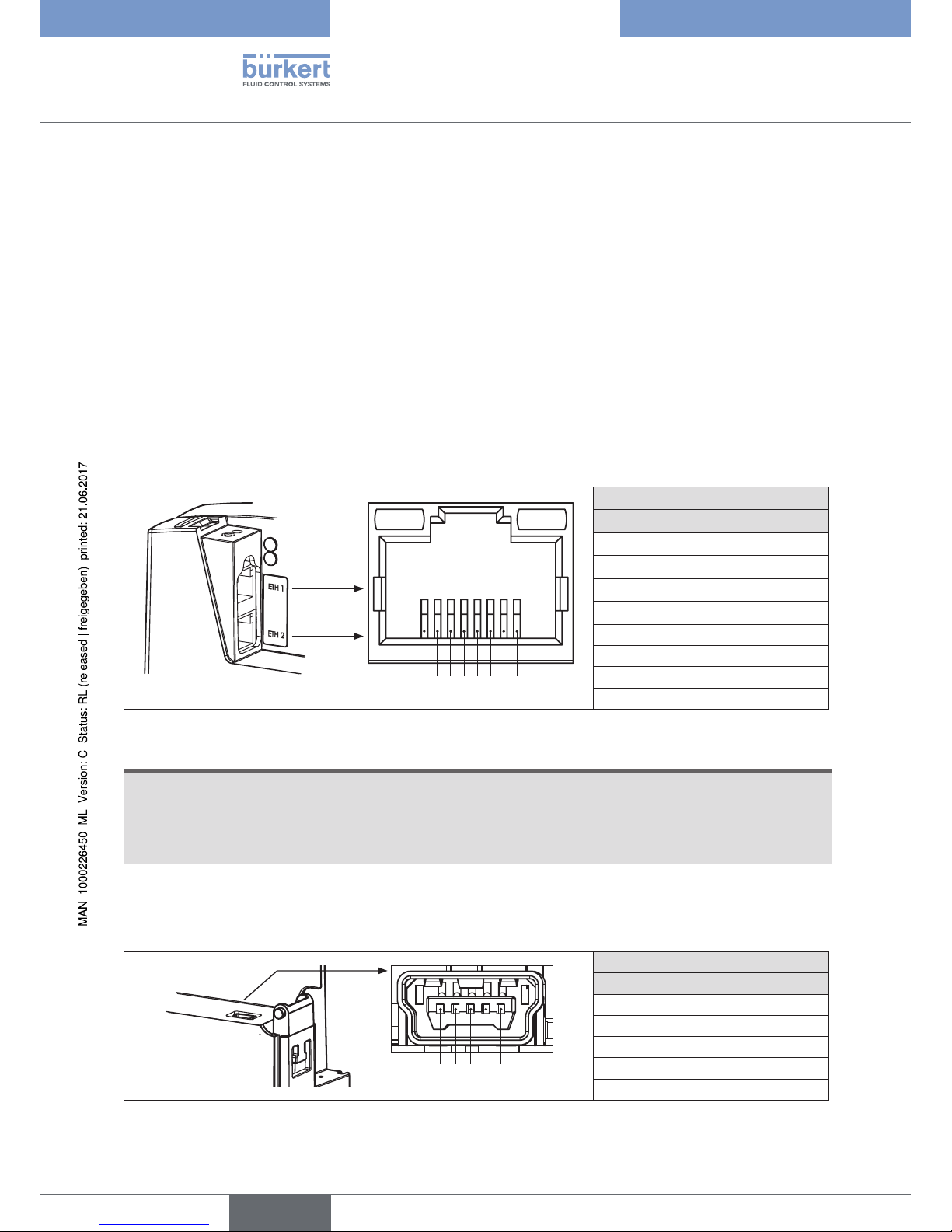

6.6.1 Electrical configuration

Interfaces ETH1 / ETH 2

The two sockets ETH 1 and ETH 2 for RJ45 plug-in connector are equivalent and are used for the connection to

the fieldbus.

1 2 3 4 5 6 7 8

Interface ETH 1 / ETH 2

Pin Plug configuration RJ45

1 TX+

2 TX–

3 RX+

4 Not used

5 Not used

6 RX–

7 Not used

8 Not used

Figure 2: Configuration of interfaces ETH 1 / ETH 2; connection to the fieldbus

NOTE!

To ensure electromagnetic compatibility (EMC)

▶ Only use shielded Ethernet cables.

▶ Connect the Ethernet cables of all participants via the backplane (Type BEF1) to the top hat rail to discharge

the cable shield to ground.

Mini USB interface

The socket for mini USB plugs is intended for factory service only.

1 2 3 4 5

Mini USB interface

Pin Plug configuration

1 5 V

2 D–

3 D+

4 Not used

5 GND

Figure 3: Mini USB interface configuration; for factory service

English

Page 13

13

Installation

Type ME23

7 INSTALLATION

7.1 Safety instructions

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out only by trained technicians and with the appropriate tools.

▶ Secure system against unintentional activation.

▶ Following installation, ensure a controlled restart.

7.2 Mount Type ME23 on backplane Type BEF1

Fieldbus gateway

Type ME23

Fastening screw

Backplane

Type BEF1

Hinge

Figure 4: Mount fieldbus gateway Type ME23 on backplane Type BEF1

→ Insert hinge part of Type ME23 in counter piece of backplane Type BEF1.

→ Press Type ME23 fully on the backplane Type BEF1.

→ Tighten fastening screw. Max. torque 1 Nm.

The fieldbus gateway ME23 is now connected to the power supply of the backplane Type BEF1.

NOTE!

▶ Use power supply unit with adequate power.

English

Page 14

14

Installation

Type ME23

7.3 Establish network connection to the bus

Fastening screw

Cover

opened

Punched-out recess

for securing the

Ethernet cable

Cover

closed

Figure 5: Establish network connection to the fieldbus.

→ Unscrew fastening screw on the cover of the Type ME23.

→ Open cover.

→ Lead the Ethernet cables through the hole at the back of the cover.

→ Insert the Ethernet cables in the sockets ETH 1 / ETH 2 (for plug-in connector RJ45).

→ Close cover and tighten fastening screw. Max. torque 1 Nm.

The network connection to the fieldbus has now been established.

NOTE!

To ensure electromagnetic compatibility (EMC)

▶ Only use shielded Ethernet cables.

▶ Connect the Ethernet cables of all participants via the backplane (Type BEF1) to the top hat rail to discharge

the cable shield to ground.

Securing the Ethernet cable (strain relief):

For strain relief, a cable clip can be used to secure the Ethernet cables in the punched out recess underneath the

cover.

English

Page 15

15

Start-up

Type ME23

8 START-UP

8.1 Safety instructions

WARNING!

Risk of injury from improper operation.

Improper operation may result in injuries as well as damage to the device and the area around it.

▶ Before start-up, ensure that the operating personnel are familiar with and completely understand the contents

of the operating instructions.

▶ Observe the safety instructions and intended use.

▶ Only adequately trained personnel may start up the equipment/the device.

8.2 Basic settings

The fieldbus gateway Type ME23 can be delivered with a customized basic configuration ex factory.

The büS stick and the "Bürkert Communicator" software, which are available as accessories, are required for

changing the basic configuration or for parameterizing additional process values. See chapter “12 Accessories”

The "Bürkert Communicator" software can also be used for further parameterization of the optionally

available software add-on module user-f(x).

For configuration and parameterization refer to the chapter entitled “10 FUNCTIONS”.

English

Page 16

16

Operation

Type ME23

9 OPERATION

9.1 Safety instructions

WARNING!

Danger due to improper operation.

Improper operation may result in injuries as well as damage to the device and the area around it.

▶ The operating personnel must know and have understood the contents of the operating instructions.

▶ Observe the safety instructions and intended use.

▶ Only adequately trained personnel may operate the equipment/the device.

9.2 Configuration and parameterization of the

Type ME23

The "Bürkert Communicator" software is used for configuration and parameterization of the fieldbus gateway.

The basic configuration and how the most important device-specific parameters for the fieldbus gateway ME23

are set using the "Bürkert Communicator" is described in the following sections of these operating instructions.

See chapter “10 FUNCTIONS”.

The "Bürkert Communicator" software and the general description of the software are available on the Bürkert

homepage.

In addition to the "Bürkert Communicator" software, the büS stick, which is available as accessory,

is required for configuration and parameterization of the fieldbus gateway ME23. See chapter

“12 Accessories”.

9.2.1 Configuration

During configuration, the user initially selects the büS participant that the fieldbus gateway ME23 is to use for

communication with the controller (PLC). After that, he defines which process values are to be converted from

Industrial Ethernet to büS. For description see “10.2 Configuration”, page 23.

9.2.2 Parameterization

During parameterization, the input and output values of the büS participants and of the fieldbus gateway ME23

are assigned to the process values to be converted.

English

Page 17

17

Operation

Type ME23

9.3 Display elements

The LED display elements on the fieldbus gateway ME23 provide information on

• the connection to the control

• the device status

• the network connection

Overview:

LED's for status display

for connection to the control, for

description refer to

chapter “9.3.1”

LED for device status

(colors in accordance with

NAMUR NE 107)

For description refer to

chapter “9.3.2”

LED's

for network connection

For description refer to

chapter “9.3.4”

RJ45

RUN LED

(green)

ERROR LED

(red)

Link/Act LED

(green)

Link LED

(yellow)

Figure 6: Overview of display elements; fieldbus gateway ME23

9.3.1 LED for connection to the control status display

Description:

LED status Description and cause of error Procedure

RUN LED

Active Connection to control active. Not active Connection to control not active. Check cable.

Error LED

Active Connection to control not active. Check cable.

Not active Connection to control active. -

Table 3: Description: Displays of the LED's for the connection to the control

English

Page 18

18

Operation

Type ME23

9.3.2 NAMUR mode

In NAMUR mode, the LED illuminated ring lights up according to NAMUR NE 107, in the color specified for the

device status.

If several device statuses exist simultaneously, the device status with the highest priority is displayed. The priority is

determined by the severity of the deviation from standard operation (red = failure = highest priority).

Displays in NAMUR mode:

Display in accordance

with NE 107

Description Meaning

Color

red Failure, error or

fault

Control mode is not possible due to malfunctioning in the device or

at its peripheral equipment.

orange Function check Work is being carried out at the device; control mode is therefore

not currently possible.

yellow Out of

specification

The ambient conditions or process conditions for the device are

outside the specified area.

Device internal diagnostics point to problems in the device or with

the process properties.

blue Maintenance

required

The device is in controlled operation, however function is briefly

restricted.

→ Maintain device.

green Diagnostics

active

Device is operating faultlessly. Status changes are shown in color.

Messages are transmitted via any connected field bus.

Table 4: Display of device status in NAMUR mode

* A detailed fault description can be found in Chapter “11.3 Display of the device status”

9.3.3 Flashing of the LED illuminated ring

Flashing indicates that a connection to the PC software "Bürkert Communicator" has been established.

English

Page 19

19

Operation

Type ME23

9.3.4 LED for network connection

Description:

LED status Description and cause of error Procedure

Link/Act

LED

(green)

Active Rapid flashing: Connection to the higher-level protocol

layer (PROFINET, EtherNet/IP or Modbus TCP) has been

established. Data is being transmitted.

Slow flashing: No connection to the protocol layer has been

established. This normally occurs for approx. 20 seconds

following a restart.

Not active No connection to the network has been established. Check cable.

Link LED

(yellow)

Active Connection to the network has been established. Not active No connection to the network has been established. Check cable.

Table 5: Description: Displays of the LED's for network connection

English

Page 20

20

Operation

Type ME23

9.4 Removable data storage

The fieldbus gateway Type ME23 has a removable data storage in the size of a micro SD card, on which devicespecific data is stored.

Upon delivery, the micro SD card is inserted in the device.

Using the micro SD card, it is possible to exchange the specific data of devices having the same Ident number. For

example for transmitting the data of a defective device to a new device.

The baud rate, the address and / or the configuration of the process values of the device are, for example, stored

on the micro SD card.

If device-specific data is available on the inserted micro SD card during restart, the device will take over this data.

If no device-specific data is available on the micro SD card, the device will store its own data on it.

NOTE!

Do not use a standard micro SD card for the device. Please order the micro SD card for the Type ME23 via

your Bürkert sales department.

See chapter “12 Accessories”.

Replacing the micro SD card

The micro SD card can be found at the bottom side of the device.

Micro SD card

Figure 7: Replacing the micro SD card; fieldbus gateway ME23

Remove the micro SD card:

→ Press on the edge of the engaged micro SD card to unlock it.

→ Pull micro SD card out.

Insert micro SD card in replacement device:

Make sure you insert the card in the correct orientation.

→ Insert the micro SD card in the card holder of the replacement device.

Make sure that the card clicks in place.

English

Page 21

21

FUNCTIONS

Type ME23

10 FUNCTIONS

10.1 Conversion Industrial Ethernet to büS

The function of the fieldbus gateway is to convert the process values between an Industrial Ethernet control and

büS participants. For this, the fieldbus gateway ME23 must be configured and parameterized.

The "Bürkert Communicator" software and the büS stick, which is available as accessory, are required for

configuration and parameterization of the fieldbus gateway ME23, refer to chapter“12 Accessories”.

The "Bürkert Communicator" software and a general description of it are available on the Bürkert

homepage.

Procedure:

Select the büS participants that are to communicate with the controller (PLC) via the fieldbus gateway

ME23:

PLC

büS participant 1

büS participant 2

Fieldbus gateway

Figure 8: Configuration; selection of the büS participants that are to communicate with the PLC

Select which process values are to be converted from "Industrial Ethernet" to "büS":

PLC

büS participant 1

büS participant 2

Fieldbus gateway

Actual value 1

Actual value 2

Set-point value 1

Set-point value 2

Figure 9: Configuration; selection of the process values that are to be converted from "Industrial Ethernet" to "büS".

English

Page 22

22

FUNCTIONS

Type ME23

Define the direction for transmission of the process values (from/to PLC, from/to büS participant):

The direction is assigned from the perspective of the fieldbus gateway ME23 in the fieldbus büS.

Example:

- Set-point values of a büS participant are the output values of the fieldbus gateway ME23.

- Actual values of a büS participant are the input values of the fieldbus gateway ME23.

Process output values of the PLC are received in the fieldbus gateway ME23 as process input values using

Industrial Ethernet. The process input values are converted and provided as process output values using büS.

Vice versa, process output values of the büS participant are received as büS input values. The process input

values are converted and provided as process output values using Industrial Ethernet.

büS

participant

Fieldbus gateway

Output value Input value

Input value Output value

Output value

Input value

Input value

Output value

Conversion of the process values

Industrial Ethernet büS

Figure 10: Configuration; principle of direction allocation for process values

Based on the type of conversion, büS participants can be addressed directly using their process values and the

direction of conversion.

büS participant

Output value Input value

Input value Output value

Figure 11: Configuration; type of conversion for process values from the PLC to the büS participant

English

Page 23

23

FUNCTIONS

Type ME23

10.2 Configuration

The configuration of the fieldbus gateway ME23 is carried out in the following steps:

- Selection of the büS users and process values which are to communicate with the PLC via the fieldbus

gateway ME23 via “Industrial Ethernet”.

See chapter “10.2.1 Select process data”, page 25.

- Fieldbus-specific address mapping of the objects.

See chapter “10.2.2 Fieldbus-specific address mapping”, page 26

- büS network configuration

See chapter “10.2.3 büS network configuration”, page 28

The device can be delivered with a default basic setting in that specific büS participants and process

values for the conversion have already been defined.

The description of the procedure for the configuration refers to the symbols and terms of "Bürkert Communicator" user interface.

→ Use the “Bürkert büS stick” to connect to the “Bürkert Communicator” software.

→ Add interface: Select tool from tool bar.

→ Select Gateway_01 in the navigation area.

→ Open the menu sub-items.

→ Select Industrial communication function.

→ Select Parameter tab.

→ Select Create Gateway configuration.

File

Edit

View Options

Tools

Desktop

Graph

büS

100%

Help

Gateway_01

FLOWave

Industrial Communication

General settings

Device

MFC_02

MFC_01

-

+

+

+

+

+

-

Industrial communication

Gateway_01

Parameter

Diagnostics

Protocol

Advanced settings

Create Gateway configuration

Download Gateway configuration file

>

>

>

Choose protocol..

MFC_03

ProcessValve_01

COMMUNICATOR

Figure 12: Industrial communication

English

Page 24

24

FUNCTIONS

Type ME23

Desktop

Graph

büS

100%

Gateway_01

FLOWave

Industrial Communication

General settings

MFC_02

MFC_01

-

+

+

+

+

+

-

Industrial communication

Gateway_01

MFC_03

ProcessValve_01

COMMUNICATOR

Parameter Diagnostics

Parameter

Create Gateway configuration

Protocol Selection

CANOpen

DeviceNet

EtherCAT

PROFINET

PROFIBUS

EtherNet/IP

ModbusTCP

Edit existing configuration Start new configuration

File

Edit

View Options

Tools

Help

Device

Figure 13: Create Gateway configuration

→ Select target protocol.

Multiple selection is possible. The configuration files are prepared for the selected protocols based on the

following IO value configuration.

→ Edit existing configuration or Start new configuration.

General settings

Create Gateway configuration

General device settings

Product familie

Product code

Product name

Description

1296380467

Gateway

Gateway_Me23_bueS

ME23

Default network settings

Netmask

Gateway IP-Address

Standard gateway

Advanced

192.168.0.100

255.255.255.0

192.168.0.1

NextCancelBack

Figure 14: General settings

→ Adjust general settings for device description file of the target system (PLC) if required.

→ Click Next.

English

Page 25

25

FUNCTIONS

Type ME23

10.2.1 Select process data

Declare inputs and outputs

Create Gateway configuration

+ Input values

NextCancelBack

* Higlighted entries are available in

the current network.

+ Output values

Gateway_01

Cyclic values

Input_1

Flow rate [l/min]

Name

Value type

i

l/min Input_1

Binary value

Density

Floating point number

Flow rate

Generic number %

Mass flow rate

Mass volumen

Temperature

Velocity

Volume

...

Figure 15: Declare inputs and outputs

→ Process values available in the büS network are highlighted.

→ Add process values to the gateway with drag-and-drop or by double-clicking

(right-clicking adds several values to the same unit).

→ Adjust names. These names appear via the device description file in the target control.

→ Add all required values.

→ Click Next.

English

Page 26

26

FUNCTIONS

Type ME23

10.2.2 Fieldbus-specific address mapping

EtherNet/IP settings

Create Gateway configuration

EthernetIP Data

Order number

Major Revision

EtherNet/IP EDS Revision

1

1.1

Addressing

Automatic EtherNet/IP addressing

NextCancleBack

Minor Revision

7

EtherNet/IP Produkt Typ

Generic Device,keyable (43)

^

Start

Reset device

Cyclic Name Index SubIndex Assembly Connection Class

Input_1 0x2540 0x01 0x65 1

device Status NamurNe107 0x2004 0x01 0x66 2

Control Word 0x3C32 0x01 0x67 2

Figure 16: Fieldbus-specific address mapping

→ Click Start to automatically run object addressing, can be manually adjusted.

→ Click Next.

If several protocols were selected (see “Figure 13: Create Gateway configuration”), the corresponding

protocol-specific settings pages follow.

English

Page 27

27

FUNCTIONS

Type ME23

Final settings

Create Gateway configuration

Select output directory

Create new major version

Output directory

C:\User\Max.Mustermann\AppData\Comuni

FinishCancelBack

Browse

Figure 17: Selecting the output directory

→ Save the configuration files and download to the device. This download runs in the background. (The device

description file is in the subfolder “PLC” under the specified path).

→ Click Finish.

→ Click OK, the window is closed and the device automatically restarts.

The gateway configuration is completed. The connection between control and gateway is established. The

device description file is in the subfolder “PLC” under the specified path.

English

Page 28

28

FUNCTIONS

Type ME23

10.2.3 büS network configuration

→ Use the “Bürkert büS stick” to connect to the “Bürkert Communicator” software.

→ Add interface: Select tool from tool bar.

→ Select interface in the navigation area.

→ Select the büS-Map tab.

Desktop

Graph

büS

100%

Gateway_01

FLOWave

Industrial Communication

General settings

MFC_02

MFC_01

-

+

+

+

+

+

-

MFC_03

ProcessValve_01

COMMUNICATOR

büS

+ -

büS-Map

Overview

Gateway_01

Andere

Actual Flow PR...

Actual Flow 02 01

Actual Flow PR...

Actual Flow 02 02

Setpoint PRO 01

Setpoint 02 01

Setpoint PRO 02

Setpoint 02 02

Flow_Gesamt

ActFlowGas 1

ActFlowGas 2

Anteil_Propan

SetpointGas 1

SetpointGas 2

NamurStatus

MFC_02

Sensor

Actual Flow

Medium Temp.

Current Totalizer

Current Setpoint

Setpoint

Manual Setpoint

Current Dutycycle

Dutycycle

NamurStatus

Regler

Stellglied

Andere

File

Edit

View Options

Tools

Help

Device

Figure 18: büS-Map

→ Parametrize the inputs and outputs with drag-and-drop

(dotted lines mean that there is still no active connection between devices.

Compatible connection points are highlighted in blue).

→ Click Apply changes.

All configured devices are restarted.

English

Page 29

29

FUNCTIONS

Type ME23

10.3 Downloading an existing configuration

If a gateway configuration file (*.bgc) is available, it can be installed on a non-configured device.

→ Use the “Bürkert büS stick” to connect to the “Bürkert Communicator” software.

→ Add interface: Select tool from tool bar.

→ Open the menu sub-items.

→ Select Industrial communication function.

→ Select Parameter tab.

→ Select Download Gateway configuration file.

Desktop

Graph

büS

100%

Gateway_01

FLOWave

Industrial Communication

General settings

MFC_02

MFC_01

-

+

+

+

+

+

-

Industrial Communication

Gateway_01

MFC_03

ProcessValve_01

COMMUNICATOR

Parameter Diagnostics

Parameter

Download Gateway configuration file

Gateway configuration

Load configuration to device

General device settings

Restart

Advanced view

File

Edit

View Options

Tools

Help

Device

Figure 19: Downloading an existing configuration

→ Load device configuration into devices with Load configuration to device.

→ Restart device with Restart.

English

Page 30

30

Maintenance

Type ME23

11 MAINTENANCE

11.1 Safety instructions

WARNING!

Risk of injury from improper maintenance.

▶ Maintenance may be carried out only by trained technicians and with the appropriate tools.

▶ Secure system against unintentional activation.

▶ Following maintenance, ensure a controlled restart.

11.2 Replacing the device

To replace the fieldbus gateways ME23, proceed as follows.

1. Switch off supply voltage.

2. Remove Ethernet cable.

→ If Ethernet cables have been secured at the housing for strain relief, remove securing device.

→ Unscrew fastening screw on the cover of the Type ME23.

→ Open cover.

→ Pull out and remove Ethernet cables from the socket.

Fieldbus gateway

Type ME23

Cover

opened

Backplane

Type BEF1

Fastening screw

for backplane

Fastening screw

for cover

Figure 20: Replacing the device; fieldbus gateway ME23

3. Remove fieldbus gateway Type ME23 from backplane Type BEF1.

→ Unscrew fastening screw on the rear of the housing and remove Type ME23.

English

Page 31

31

Maintenance

Type ME23

4. Replacing the micro SD card

The micro SD card can be found at the bottom side of the device.

Micro SD card

Figure 21: Replacing the micro SD card; fieldbus gateway ME23

Remove the micro SD card:

→ Press on the edge of the engaged micro SD card to unlock it.

→ Pull micro SD card out.

Insert micro SD card in replacement device:

Make sure you insert the card in the correct orientation.

→ Insert the micro SD card in the card holder of the replacement device.

Make sure that the card clicks in place.

5. Mount replacement device

→ Insert hinge part of Type ME23 in counter piece of backplane Type BEF1.

→ Press Type ME23 fully on the backplane Type BEF1.

→ Tighten fastening screw for backplane. Max. torque 1 Nm.

→ Unscrew fastening screw on the cover of the Type ME23.

→ Open cover.

→ Lead the Ethernet cables through the hole at the back of the cover.

→ Insert the Ethernet cables in the sockets ETH 1 / ETH 2 (for plug-in connector RJ45).

→ Close cover and tighten fastening screw. Max. torque 1 Nm.

→ Apply supply voltage.

Securing the Ethernet cable (strain relief):

For strain relief, a cable clip can be used to secure the Ethernet cables in the punched out recess underneath the

cover.

Punched-out recess for securing the Ethernet cable

Figure 22: Strain relief for Ethernet cables; fieldbus gateway ME23

English

Page 32

32

Maintenance

Type ME23

11.3 Display of the device status

The fieldbus gateway ME23 is provided with an LED that displays the device status and changes its color and the

status in accordance with NAMUR NE 107.

If several device statuses exist simultaneously, the device status with the highest priority is displayed. The priority is

determined by the severity of the deviation from standard operation (red LED = error = highest priority).

LED display in accordance

with NAMUR NE 107

Description Procedure

No color No power is supplied to the device. Connect device to power supply.

Flashing rapidly

(applies to all colors)

The device was selected using the

"Bürkert Communicator" software.

De-select the device using the

"Bürkert Communicator" software.

White and illuminated Power is supplied to the device.

A büS connection exists and parameterized büS participants have successfully been found.

-

White and flashing

Red and illuminated Mode 1:

Device defective.

Device requires maintenance –

contact the manufacturer.

Mode 2:

Communication with other büS participants not possible.

Link device to a network with other

büS participants.

Red and flashing Mode 1:

Bus fault (e. g. short-circuit).

Check cable connection.

Mode 2:

The device is not connected to the

PLC.

Check cable connection.

Consult device description regarding

connection of the device in PLC.

Mode 3:

The device cannot find the assigned

büS participant.

Make sure the büS participant is

affected to the device.

Orange and illuminated Mode 1:

Device temperature is outside the

specification, destruction of the device

cannot be excluded.

Operate the device inside the

specification.

Mode 2: Device has detected an error

in the fieldbus büS.

Restart the network if the device

status lasts longer than 5 seconds.

Orange and flashing Mode 1:

Search for büS participant active.

Mode exit after a few seconds.

Restart the network if the device

status lasts longer than 4 minutes.

Mode 2: Device has detected an error

in the fieldbus büS.

Restart device.

Yellow and illuminated

Blue and illuminated

Green and illuminated

Table 6: Description: LED display of device status and procedures

English

Page 33

33

Maintenance

Type ME23

LED status Description and cause of error Procedure

RUN LED

Active Connection to control active. Not active Connection to control not active. Check cable.

Error LED

Active Connection to control not active. Check cable.

Not active Connection to control active. -

Table 7: Description: Displays of the LED's for the connection to the control

LED status Description and cause of error Procedure

Link/Act

LED

Active Rapid flashing: Connection to the higher-level pro-

tocol layer (PROFINET, EtherNet/IP or Modbus TCP)

has been established. Data is being transmitted.

Slow flashing: No connection to the protocol layer

has been established. This normally occurs for

approx. 20 seconds following a restart.

Not active No connection to the network has been established. Check cable.

Link LED

Active Connection to the network has been established. Not active No connection to the network has been established. Check cable.

Table 8: Description: Displays of the LED's for network connection

English

Page 34

34

Maintenance

Type ME23

11.4 Troubleshooting

Problem Possible cause Procedure

The NAMUR-LED goes off

periodically.

The power supply collapses periodically – the device implements a reset

each time.

Use power supply with adequate

power.

The drop in power in the connecting

cable is too great.

Increase cable cross-section.

Reduce cable length.

No process values are transmitted between Industrial Ethernet and büS.

No cable connection. Check Ethernet and büS cable

connection.

Reading and writing of the values has

not been allowed by the PLC in the

control object of the participant.

Allow reading and writing of the values

in the control object of the participant.

The process values have been

configured incorrectly.

Check configuration of the process

values.

The process values have been

allocated incorrectly.

Check allocation of the process values

to the büS participants.

The process values cannot

be allocated to the büS

participants.

The process values have not been

configured.

Check configuration of the process

values.

Takeover of the configuration must

be completed by a restart of the

participant.

Restart the participant after

configuration.

The process values have been allocated to different classes.

Check allocation to ensure that büS

participants work with process values

of the same class.

Observe input and output direction

as allocation.

Verify that direction of input and output

is correct.

An incorrect value is transmitted or value is zero.

The process values have not been

allocated or have been allocated to

the wrong participants.

Check allocation of the process values.

Replacement device fails to

take over values from micro SD

card from the defective device.

The device Ident number of the

replacement device and the defective

device differ.

Values can only be transmitted

between devices having the same Ident

number.

The micro SD card is defective. The

device was unable to write any values

on the micro SD card.

Replace the micro SD card (refer to

chapter “12 Accessories”) and retry

transmitting the parameters of the

defective device to the card (refer

to chapter “9.4 Removable data

storage”).

Replacement device fails to take

over all values from micro SD

card from the defective device.

The EDS device description between

the replacement device and the

defective device differs.

Only the existing values of the defective

device can be transferred to the

replacement device. New values of the

replacement device must be parameterized using the "Bürkert Communicator"

software.

Table 9: Troubleshooting

English

Page 35

35

Accessories

Type ME23

12 ACCESSORIES

CAUTION!

Risk of injury and/or damage by the use of incorrect parts.

Incorrect accessories and unsuitable spare parts may cause injuries and damage the device and the surrounding area.

▶ Use original accessories and original spare parts from Bürkert only.

Accessories Order no.

büS Stick set (including power supply unit) and "Bürkert Communicator" software 00772426

Micro SD card on request

English

Page 36

36

Packaging and transport

Type ME23

13 PACKAGING AND TRANSPORT

NOTE!

Transport damage.

Inadequately protected devices may be damaged during transportation.

• Protect the device against moisture and dirt in shock-resistant packaging during transportation.

• Prevent the temperature from exceeding or dropping below the permitted storage temperature.

14 STORAGE

NOTE!

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location.

• Storage temperature: -25...+60 °C.

15 DISPOSAL

NOTE!

Damage to the environment caused by parts contaminated with media.

• Dispose of the device and packaging in an environmentally friendly manner.

• Observe applicable disposal and environmental regulations.

Observe the national waste disposal regulations.

English

Page 37

Page 38

www.burkert.com

Loading...

Loading...