Page 1

Type 8098

FLOWave

Flowmeter

QUICKSTART - English

From software version A01.05.00

Page 2

We reserve the right to make technical changes without notice.

© Bürker t SAS, 2015 - 2017

QUICKSTART 1712/02_EU-EN 00567159 / Original EN

Page 3

Type 8098

Table of Contents

1 ABOUT THE QUICKSTART ............................................................................................................................................................6

1.1 Symbols used .........................................................................................................................................................................6

1.2 Definition of the word device ..........................................................................................................................................7

1.3 Definition of the word büS ................................................................................................................................................7

1.4 Validity of the Quickstart ...................................................................................................................................................7

2 INTENDED USE ....................................................................................................................................................................................7

3 BASIC SAFETY INFORMATION ....................................................................................................................................................8

4 GENERAL INFORMATION .............................................................................................................................................................10

4.1 Manufacturer's address and international contacts .........................................................................................10

4.2 Warranty conditions ........................................................................................................................................................... 10

4.3 Information on the Internet ............................................................................................................................................10

5 DESCRIPTION ....................................................................................................................................................................................11

5.1 Knowing the device ...........................................................................................................................................................11

5.2 Understanding the rating plates .................................................................................................................................12

5.3 Description of the device status LED .....................................................................................................................14

6 TECHNICAL DATA .............................................................................................................................................................................15

6.1 Operating conditions ........................................................................................................................................................15

6.2 Conformity to standards and directives .................................................................................................................15

6.3 Conformity to the Pressure Equipment Directive ..............................................................................................15

6.4 UL certification .....................................................................................................................................................................16

6.5 EHEDG certification ...........................................................................................................................................................16

6.6 Fluid data .................................................................................................................................................................................17

6.7 Measurement data .............................................................................................................................................................18

6.8 Electrical data .......................................................................................................................................................................19

6.9 Mechanical data ...................................................................................................................................................................20

7 INSTALLATION AND WIRING ......................................................................................................................................................22

7.1 Safety instructions .............................................................................................................................................................22

7.2 Preparing the device before installation into the pipe ...................................................................................23

7.2.1 Changing the position of the transmitter on the sensor ............................................................ 24

English

3

Page 4

Type 8098

7.2.2 Switching positions of the blind cover and the display module ..............................................28

7.3 Recommendations for the installation into the pipe .......................................................................................30

7.4 Installing the device into the pipe ..............................................................................................................................32

7.4.1 Before installing the device into the pipe ......................................................................................32

7.4.2 Installing a device with clamp connections ..................................................................................32

7.4.3 Installing a device with flange connections .................................................................................. 32

7.5 Wiring the device .................................................................................................................................................................33

7.5.1 Specifications of the cable for the male M12 fixed connector ................................................33

7.5.2 Assembling and wiring the female M12 connector ....................................................................34

7.5.3 Connecting the device to a power supply ....................................................................................34

7.5.4 Connecting the device to büS ........................................................................................................35

7.5.5 Activating the device internal termination resistor ......................................................................36

7.5.6 Specifications of the cables for the two M20x1,5 cable glands .............................................36

7.5.7 Specifications of the wires for the terminal strip .........................................................................36

7.5.8 Terminal assignment of the terminal strip .....................................................................................37

7.5.9 Opening the front to have access to the terminal strip ............................................................. 38

7.5.10 Wiring the device through the M20x1,5 cable glands ..............................................................39

7.5.11 Connecting the device to a 12...35 V DC power supply, through the cable glands ..........41

7.5.12 Wiring the output 1 (analogue) and the output 3 configured as an analogue output ........42

7.5.13 Wiring the output 2 (digital) and the output 3 configured as a digital output ......................43

8 HOW TO DO THE SETTINGS .....................................................................................................................................................44

8.1 Safety instructions .............................................................................................................................................................44

8.2 Available software to do the settings ......................................................................................................................44

8.3 Preparing the Bürkert Communicator software .................................................................................................44

8.4 Display module: description of the user interface ............................................................................................46

8.4.1 Description of the display .................................................................................................................47

8.4.2 How to use the touch sensitive keys .............................................................................................48

8.4.3 Minimum and maximum values when entering a numerical value ...........................................48

8.5 Available login user levels .............................................................................................................................................48

8.6 Default settings ....................................................................................................................................................................49

8.7 Menu structure .....................................................................................................................................................................50

8.7.1 Opening or closing the context menu in any view (display module only) ..............................51

8.7.2 Adding your own context menu items (shortcuts, display module only) ................................52

4

8.7.3 Reading out the messages generated by the device.................................................................53

English

Page 5

Type 8098

8.7.4 Changing the login user level if the adjustment is not protected through passwords .......53

8.7.5 Changing the login user level if the adjustment is protected through passwords .............. 54

8.7.6 Logging out from the Advanced user, Installer or Bürkert user level ...............................54

8.7.7 Reading out the access path to a menu item (display module only) ......................................55

8.8 How to navigate in the menus and to adjust values .......................................................................................55

8.8.1 Adjusting a percentage or selecting a value in a list ..................................................................55

8.8.2 Navigating in a wizard and adjusting numbers ............................................................................56

8.8.3 Setting negative or positive numbers ............................................................................................57

8.8.4 Entering a name ..................................................................................................................................58

8.8.5 Activating or deactivating a feature ................................................................................................59

8.9 Doing the Quick start adjustments when energizing the device for the first time (display

module only) ..........................................................................................................................................................................59

8.10 Changing the type of the output 3 ............................................................................................................................60

9 MAINTENANCE AND TROUBLESHOOTING .......................................................................................................................61

9.1 Safety instructions .............................................................................................................................................................61

9.2 Information to return the device to the manufacturer or to the reseller .............................................. 61

9.3 Cleaning the outer surface of the device .............................................................................................................. 62

9.4 Cleaning In Place (CIP) of the device ......................................................................................................................62

9.5 Sterilisation In Place (SIP) of the device ...............................................................................................................63

9.6 Troubleshooting, when no message is displayed .............................................................................................63

9.7 Troubleshooting if a message is displayed ..........................................................................................................63

10 SPARE PARTS AND ACCESSORIES ......................................................................................................................................65

11 PACKAGING, TRANSPORT ..........................................................................................................................................................66

12 STORAGE ..............................................................................................................................................................................................66

13 DISPOSAL OF THE DEVICE ........................................................................................................................................................66

English

5

Page 6

Type 8098

About the Quickstart

1 ABOUT THE QUICKSTART

The Quickstart includes main information and instructions for using the device.

The complete description of the product is in the Operating Instructions of the device.

Please keep this Quickstart in a safe place, accessible to all users and any new owners.

Important safety information.

Fully read the Quickstart. In particular, observe the safety recommendations and intended use.

▶ The Quickstart must be read and understood.

The full Operating Instructions are available on the internet at www.burkert.com

1.1 Symbols used

DANGER

Warns against an imminent danger.

▶ Failure to observe this warning results in death or in serious injury.

WARNING

Warns against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or even death.

CAUTION

Warns against a possible risk.

▶ Failure to observe this warning can result in substantial or minor injuries.

NOTICE

Warns against material damage.

Indicates additional information, advice or important recommendations.

Refers to information contained in the Quickstart or in other documents.

▶ Indicates an instruction to be carried out to avoid a danger, a warning or a possible risk.

→ Indicates a procedure to be carried out.

An highlighted term is related to a menu or a menu item.

Indicates the result of a specific instruction.

6

English

Page 7

Type 8098

About the Quickstart

1.2 Definition of the word device

The word "device" used in the Quickstart always refers to the flowmeter type 8098.

1.3 Definition of the word büS

The word "büS" used in the Quickstart refers to the communication bus, developped by Bürkert, based on the

CANopen protocol.

→ To get more information regarding büS, read the cabling guide available in English and German (Cabling_

guide_for_büS_networks.pdf) at www.burkert.com.

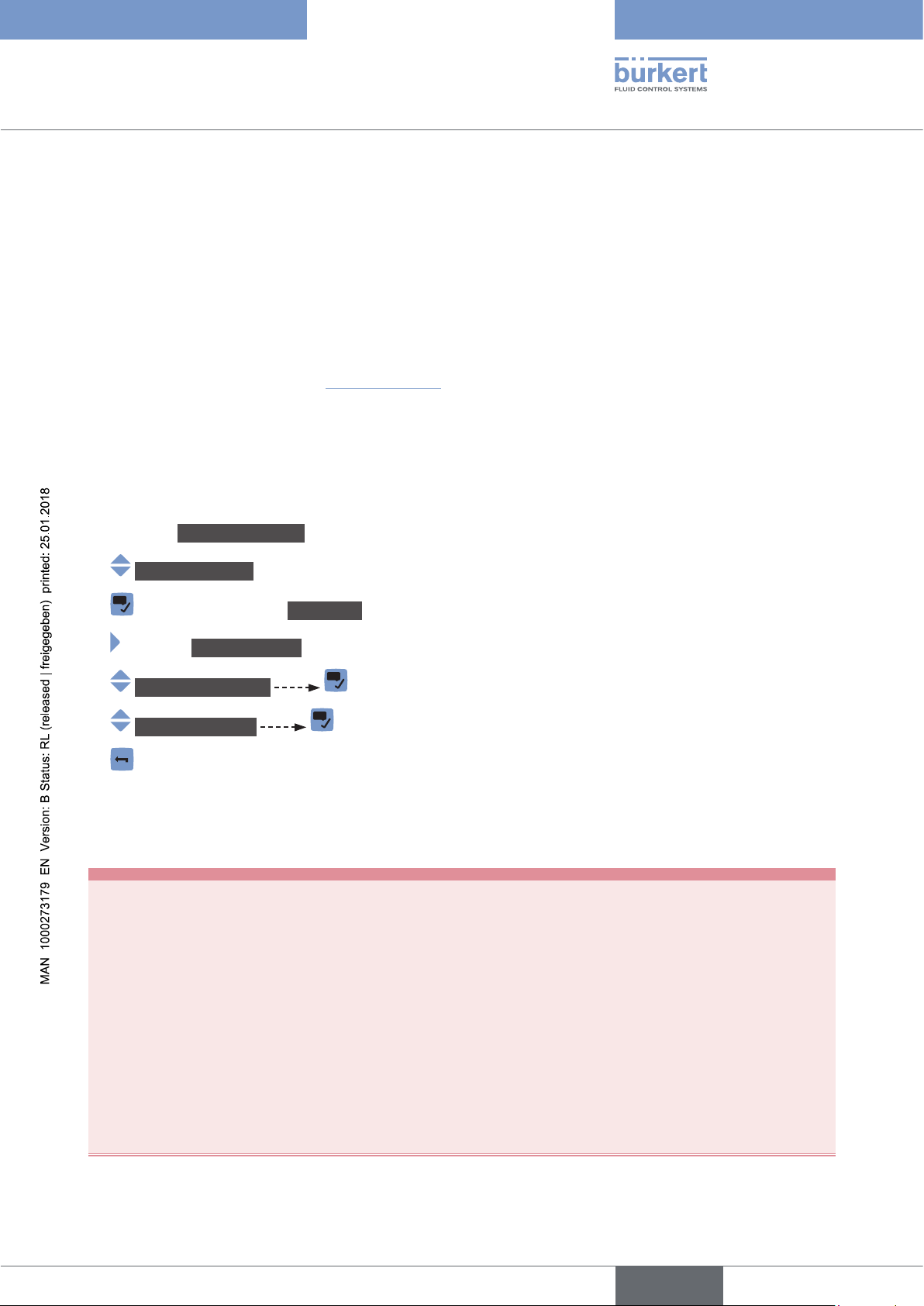

1.4 Validity of the Quickstart

The Quickstart is valid for the devices from software version A01.05.00.

To read out the version number of the device software, do the following:

→ Go to the CONFIGURATION view.

→ General settings

→ Confirm to access the Parameter view.

→ Go to the MAINTENANCE view.

→ Device information

→ Software version

→ Go back to the parent menu.

2 INTENDED USE

Use of the device that does not comply with the instructions could present risks to people, nearby

installations and the environment.

The flowmeter type 8098 is intended to measure the flow rate of clean liquids, non emulsified (homogeneous liquids) and free of air bubbles and free of gas bubbles and free of solids, using the Surface

Acoustic Wave (SAW) measurement principle.

▶ Use the device in compliance with the characteristics and the conditions of commissioning and use specified

in the contractual documents and in the Operating Instructions.

▶ Protect the device against electromagnetic interference, ultraviolet rays and, when installed outdoors, against

the effects of climatic conditions.

▶ Only operate a device in perfect working order.

▶ Properly transport, store, install and operate the device.

▶ Only use the device as intended.

7

English

Page 8

Type 8098

Basic safety information

3 BASIC SAFETY INFORMATION

This safety information does not take into account any contingencies or occurrences that may arise during installation, use and maintenance of the product.

The operating company is responsible for the respect of the local safety regulations including for the staff safety.

Risk of injury due to electrical voltage.

▶ Before carrying out work on the system, disconnect the electrical power for all the conductors and isolate it.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to high pressure in the installation.

▶ Before any intervention on the installation, stop the circulation of fluid, cut off the pressure and drain the pipe.

▶ Before any intervention on the installation, make sure there is no pressure in the pipe.

▶ Observe the fluid temperature-pressure dependency depending on the fitting used.

If switched on for a prolonged time, risk of burn injury or fire due to hot device surface

▶ Do not touch with bare hands.

▶ Keep the device away from highly flammable substances and fluids.

Risk of burn injury due to high fluid temperatures.

▶ Do not touch with bare hands the parts of the device that are in contact with the fluid.

▶ Use safety gloves to handle the device.

▶ Before opening the pipe, stop the circulation of fluid and drain the pipe.

▶ Before opening the pipe, make sure the pipe is completely empty.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and safety relating to the use of dangerous fluids.

General dangerous situations

To avoid injury:

▶ Do not use the device in explosive atmospheres.

▶ Do not use the device in an environment incompatible with the materials it is made of.

▶ Do not use fluid that is incompatible with the materials the device is made of.

▶ Do not subject the device to mechanical loads.

▶ Do not make any modifications to the device.

▶ Prevent any unintentional power supply switch-on.

▶ Only qualified and skilled staff can carry out the installation and maintenance work.

▶ Guarantee a defined or controlled restarting of the process, after a power supply interruption.

▶ Observe the general technical rules.

8

English

Page 9

Type 8098

Basic safety information

CAUTION

Risk of injury due to a heavy device.

A heavy device can fall down during transport or during installation and cause injuries.

▶ Transport, install and dismantle a heavy device with the help of another person.

▶ Use appropriate tools.

NOTICE

The device may be damaged by the fluid in contact with.

▶ Systematically check the chemical compatibility of the component materials of the device and the fluids likely

to come into contact with the materials (for example: alcohols, strong or concentrated acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons, oxidants and

chlorinated agents).

NOTICE

Elements/components sensitive to electrostatic discharges

▶ This device contains electronic components sensitive to electrostatic discharges. They may be damaged if

they are touched by an electrostatically charged person or object. In the worst case scenario, these components are instantly destroyed or go out of order as soon as they are activated.

▶ To minimise or even avoid all damage due to an electrostatic discharge, take all the precautions described in

the standard EN 61340-5-1.

▶ Also make sure that you do not touch any of the live electrical components.

English

9

Page 10

Type 8098

General information

4 GENERAL INFORMATION

4.1 Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the internet at:

www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of the device in observance of the operating

conditions specified in this manual.

4.3 Information on the Internet

You can find the Operating Instructions and the technical data sheets regarding the type 8098 at:

www.burkert.com

10

English

Page 11

Type 8098

Description

5 DESCRIPTION

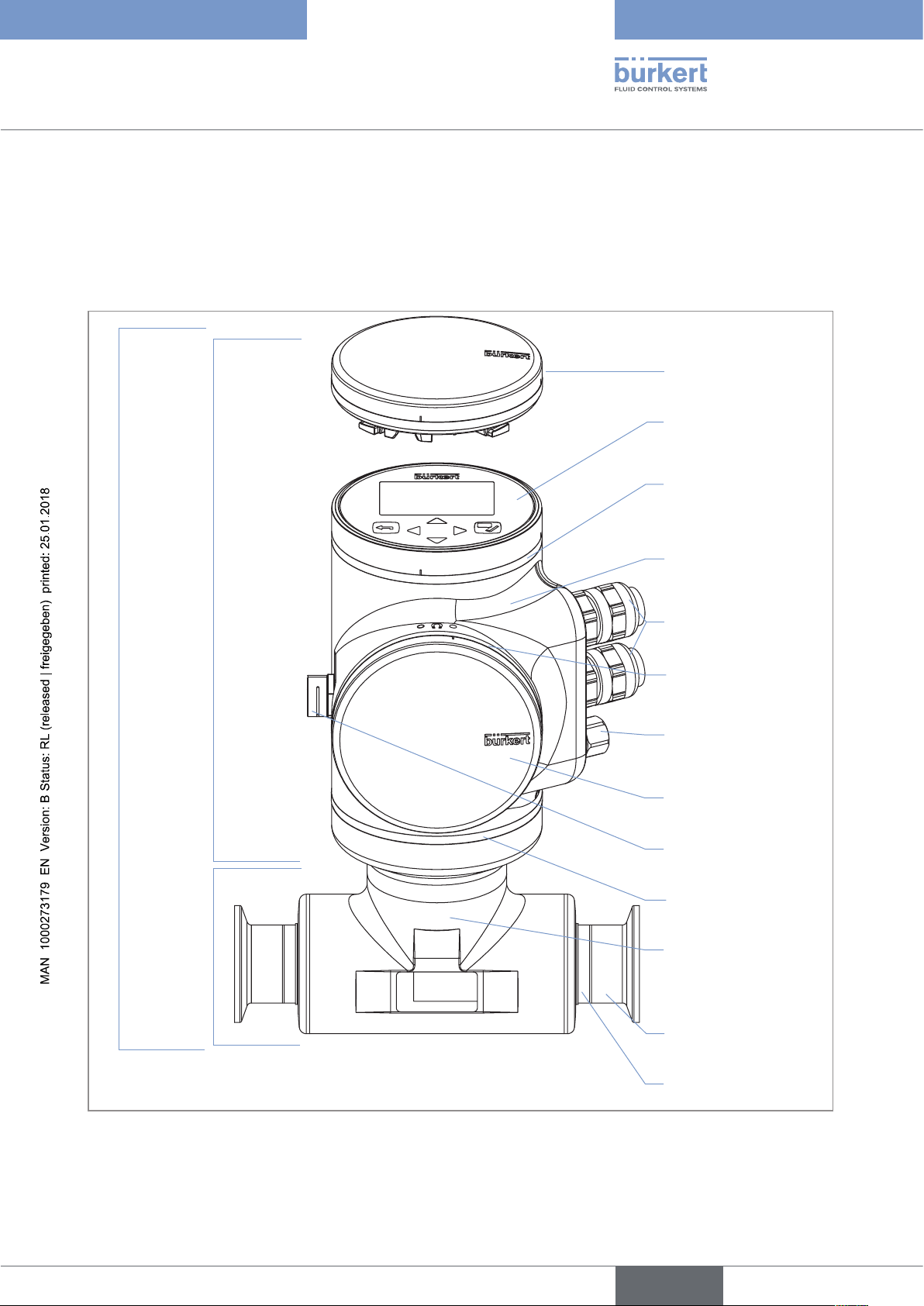

5.1 Knowing the device

The flowmeter type 8098 is made up of a transmitter type SE98 and a flow sensor type S097.

Blind cover, or

Display module (type ME31)

Device status LED indicating the

status of the device, and seal

Transmitter type

Flowmeter type 8098

Flow sensor type

SE98

S097

Transmitter housing, including

the electronic board(s)

Cable glands, with plugs

Seal

M12 male fixed connector, with

screwed plug

Blind cover

Pressure compensating element

Seal

Sensor housing

Fig. 1 : Description of the device

Process connection

Sensor measurement tube

11

English

Page 12

Type 8098

1

68

9

7

Description

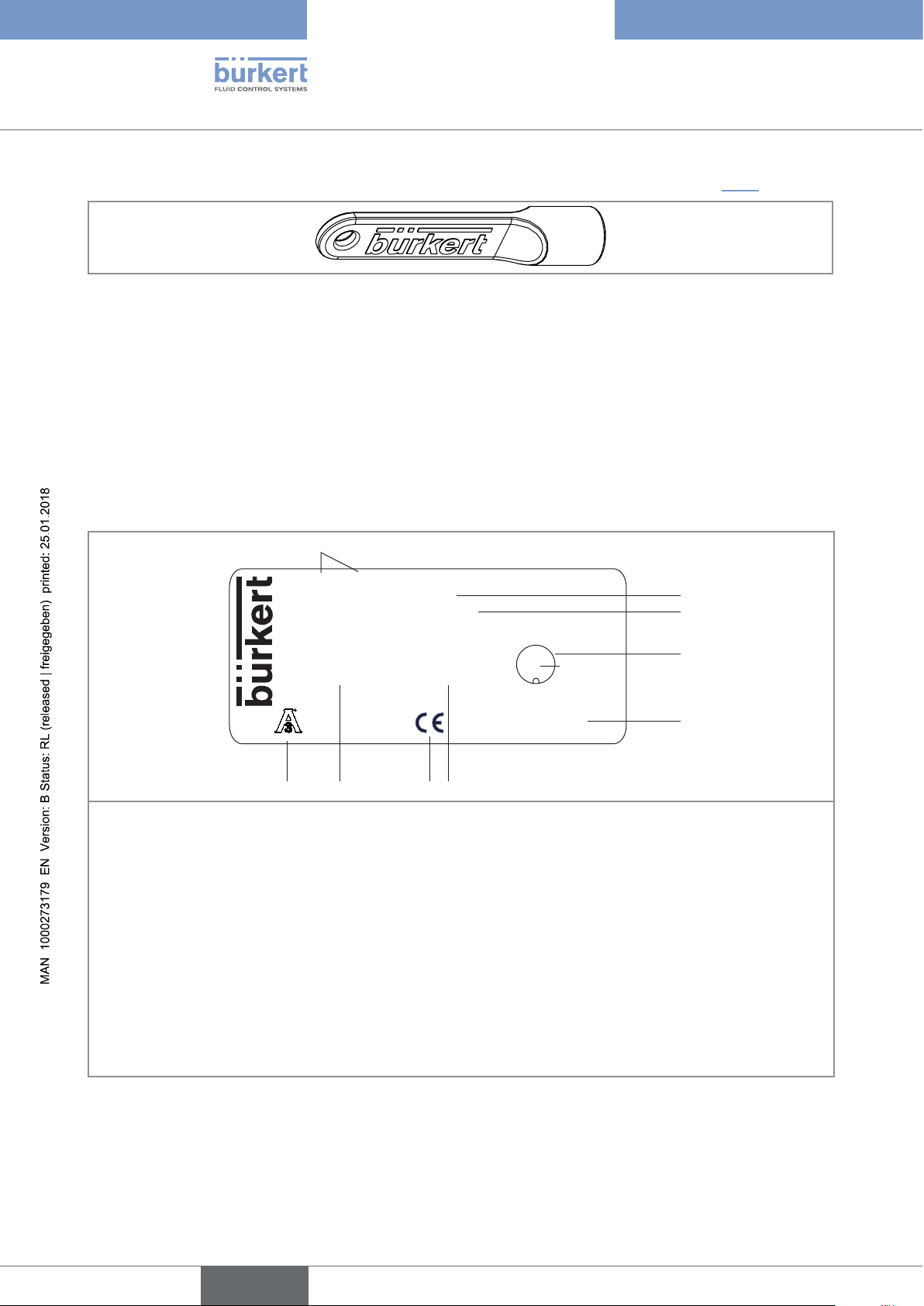

The device is delivered with a magnetic key to unlock the display module or the blind cover. See Fig. 2.

Fig. 2 : Unlocking magnetic key

The device operates on a 4 wire system and needs a 12...35 V DC power supply.

The device has three outputs:

• 1 analogue output,

• 1 digital output,

• 1 output, which can be configured as an analogue output or as a digital output.

5.2 Understanding the rating plates

8098 FLOWave Flowmeter

IP65 / IP67 / NEMA 4X

Temp. ambient: -10 to 70°C

00566187 SN:1001

F-67220 Triembach

W49MN

28-04

1. Type of the device

2. Protection classes of the device

3. Ambient temperature range

4. Pin assignment of the M12 fixed connector

5. Construction code

6. Serial number

7. Conformity marking

CAN_H GND

34

5 CAN_L

21

CAN shield

Made in France

V+

2

3

4

5

12

8. Ordering code

9. Certification

Fig. 3 : Rating plate of the flowmeter 8098 (example)

English

Page 13

Type 8098

1

6

1

7

Description

SE98 FLOWave Transmitter

Supply: 12-35V 5W max.

Housing: 304/1.4301

Slot 5: 1AO-1DO-1AO/DO

F-67220 Triembach

W49MN

1. Type of the transmitter

2. Power supply and max. power consumption

3. Material the housing is made of

2

3

4

5

Made in France

4. Available outputs

5. Construction code

6. Conformity marking

Fig. 4 : Rating plate of the transmitter SE98 (example)

S097 FLOWave Flow sensor

Pipe: 316L/1.4435 Housing: 304/1.4301

DIN 11866 C / Clamp D50.5 DIN 32676 B DN15

PN25bar Max. flow:10 m3/h

Temp. medium : -20 to 110°C

F-67220 Triembach

W4ZMN

Made in France

2

3

4

5

6

1. Type of the fitting

2. Material of the pipe and material of the housing

3. Standard the pipe conforms to; Type of process connection, external diameter of the clamp and standard the

process connection conforms to; DN of the measurement tube

4. Pressure class of the device and maximal flow rate

5. Fluid temperature range

6. Construction code

7. Conformity marking

Fig. 5 : Rating plate of the flow sensor S097 (example)

13

English

Page 14

Type 8098

Description

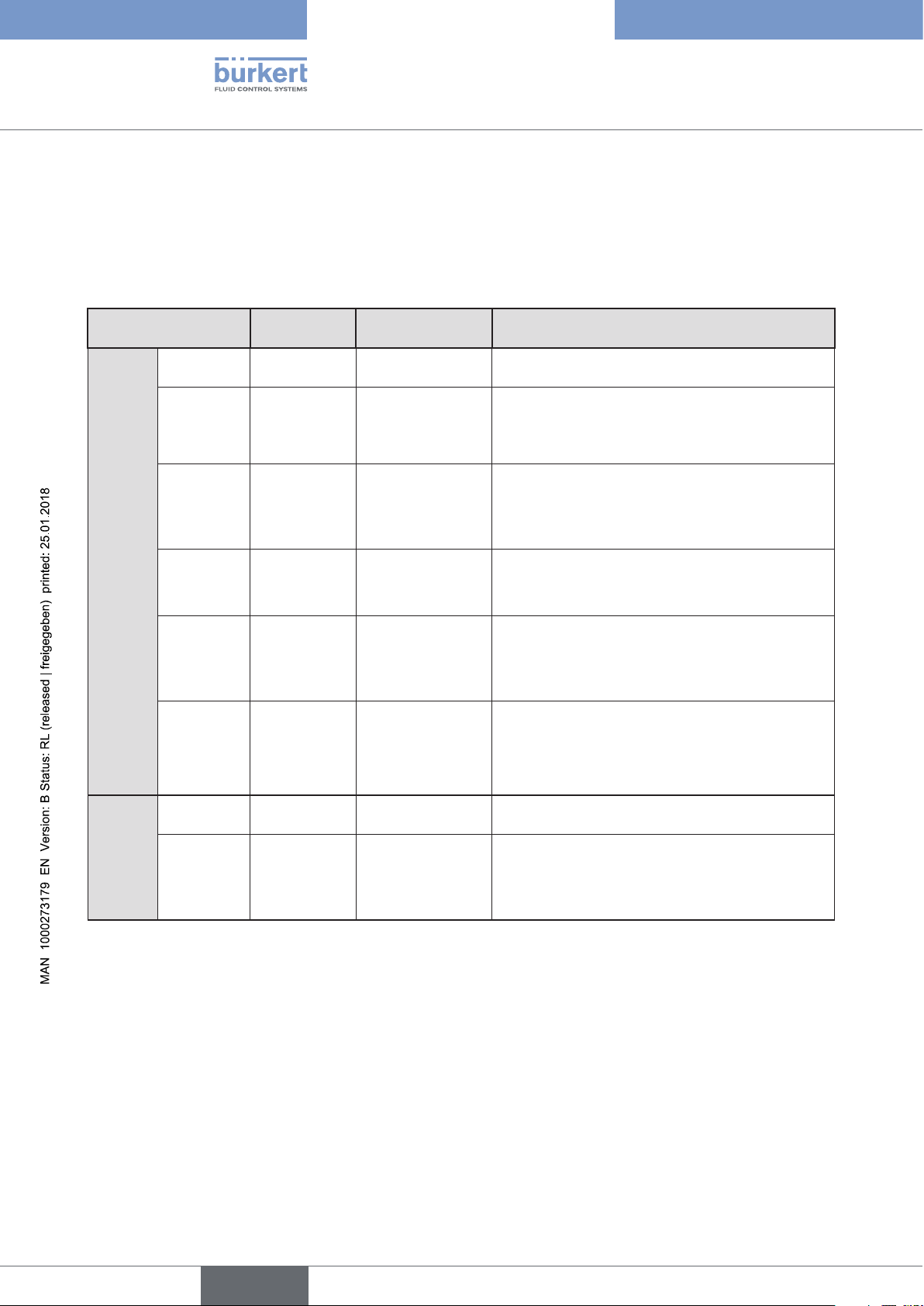

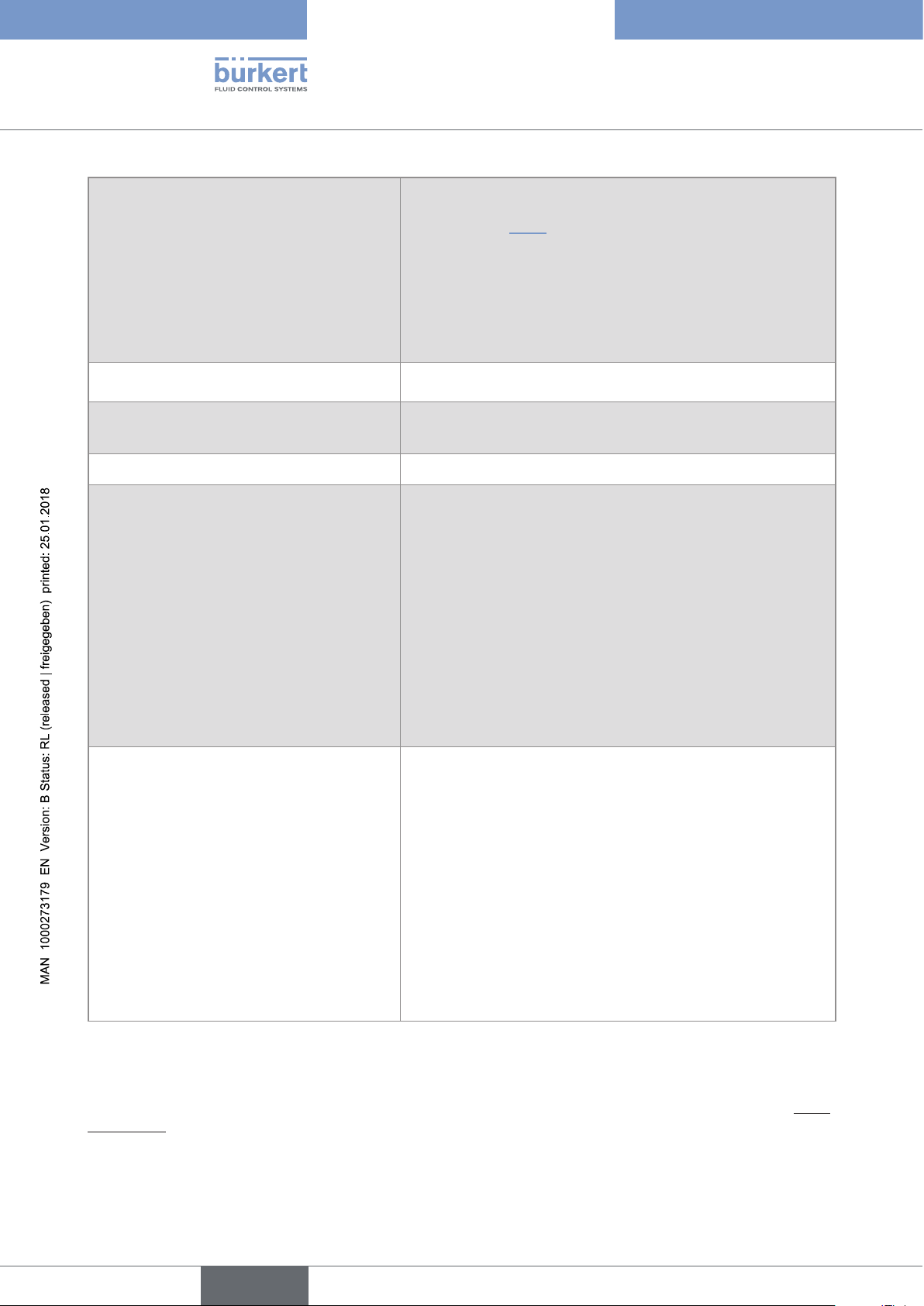

5.3 Description of the device status LED

Ex works, the LED that indicates the state of the device changes its colour and state based on the NAMUR

NE 107 recommendation.

If several states exist simultaneously, the state with the highest priority is displayed. The priority is determined by

the severity of the deviation from standard operation (red LED = failure, error or malfunction = highest priority).

Device status LED Colour code

(for a PLC)

Colour

State

Red 5 Failure, error,

Orange 4 Function check Ongoing work on the device (for example,

Yellow 3 Out of

Blue 2 Maintenance

Green 1 Diagnostic active No event has been generated. Status changes are

White 0 Diagnostic inactive Device is switched on.

ON - Device is in oper-

Flashing

rapidly

- Identification Serves for identification of a device in the

Description Signification

Due to a malfunction of the device or its periphery,

malfunction

specification

required

the measured values can be incorrect.

checking the correct behaviour of the outputs by

simulating measurement values); the output signal

is temporarily invalid (e.g. frozen).

The ambient conditions or process conditions for

the device are outside the permitted ranges.

Device internal diagnostics point to problems in

the device or with the process properties.

The device continues to measure but a function is

temporarily restricted.

→ Do the required maintenance operation.

shown in color.

Messages are listed and possibly transmitted via

any connected fieldbus.

Status changes are not shown.

Messages are not listed nor transmitted via any

connected fieldbus.

Device is in standard operation.

ating state.

büS network.

14

The device was selected using the Bürkert Communicator software.

Table 1: Device status LED - Colours and states in accordance with NAMUR NE 107, edition 2006-06-12

English

Page 15

Type 8098

Technical data

6 TECHNICAL DATA

6.1 Operating conditions

Ambient temperature –10...+70 °C

Air humidity < 85%, non condensated

Height above see level max. 2000 m

Installation category Category I according to UL 61010-1

Pollution degree Degree 2 according to EN 61010-1

Protection class according to

EN 60529

Protection class according to

NEMA250

(not evaluated by UL)

IP65, IP67, if the device is wired and if the cable glands are tightened and

the covers are screwed tight. Unused cable glands must be sealed with the

stopper gaskets provided (mounted at the delivery of the device). Unused

M12 male fixed connector must be protected with the screwed plug.

4X, if the device is wired and if the cable glands are tightened and the

covers are screwed tight. Unused cable glands must be sealed with the

stopper gaskets provided (mounted at the delivery of the device). Unused

M12 male fixed connector must be protected with the screwed plug.

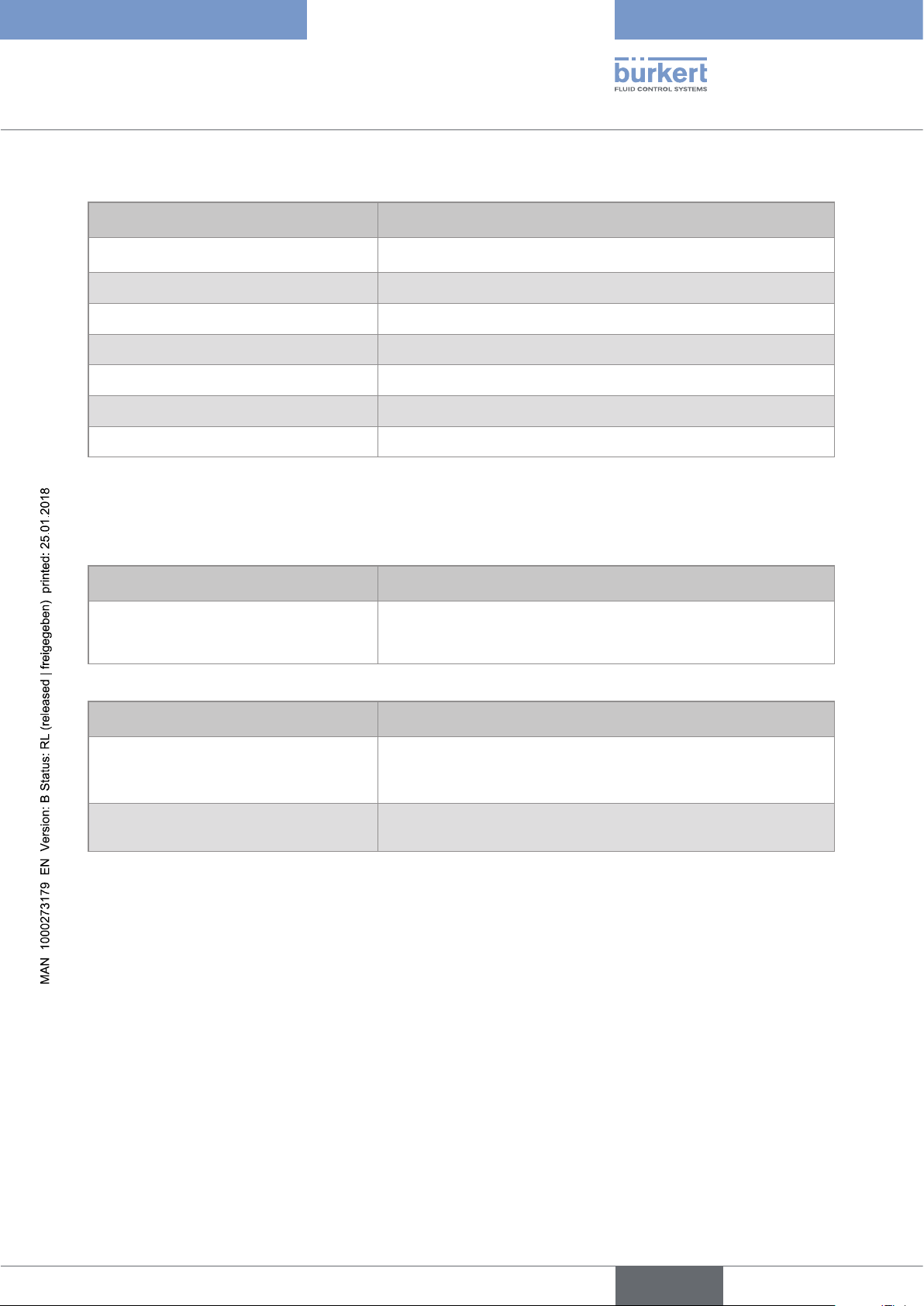

6.2 Conformity to standards and directives

The applied standards, which verify conformity with the EU Directives, can be found on the EU Type Examination

Certificate and/or the EU Declaration of Conformity (if applicable).

6.3 Conformity to the Pressure Equipment Directive

The device conforms to article 4§1 of the Pressure Equipment Directive 2014/68/EU under following conditions.

The device can only be used in the following cases (depending on the maximum pressure, the DN of the pipe and

the fluid):

Type of fluid Conditions

Fluid group 1, art. 4 §1.c.i Forbidden

Fluid group 2, art. 4 §1.c.i

Fluid group 1, art. 4 §1.c.ii

Fluid group 2, art. 4 §1.c.ii

DN ≤ 32

or PNxDN ≤ 1000

DN ≤ 25

or PNxDN ≤ 2000

DN ≤ 200

or PN ≤ 10

or PNxDN ≤ 5000

English

15

Page 16

Type 8098

Measuring

Equipment

EXXXXXX

®

Technical data

6.4 UL certification

The devices with variable key PU01 or PU02 are UL-certified devices and comply also with the following standards:

• UL 61010-1

• CAN/CSA-C22.2 n°61010-1

Identification on the device Certification Variable key

UL-recognized PU01

UL-listed PU02

6.5 EHEDG certification

• EL class I

• The following versions are EHEDG certified:

Process connections Diameters

• Clamp 1) connections according to ASME BPE

(DIN 32676 series C)

• Clamp connections according to DIN 11864-3

series C

• Flange connections according to DIN 11864-2

series C

• Clamp 1) connections according to

DIN 32676 series B

1)

• Clamp

connections according to

DIN 32676 series A

• Clamp connections according to DIN 11864-3

series A, DIN 11864-3 series B

• Clamp 1) connections according to SMS 3017 /

ISO 2852 for pipes according to SMS 3008

• Flange connections according to DIN 11864-2

series A, DIN 11864-2 series B

1)

The EHEDG compliance is only valid if used in combination with EHEDG-compliant gaskets from Combifit

International B.V.

• 3/4'', 1'', 1 1/2'', 2''

• 3/4'', 1'', 1 1/2'', 2''

• 3/4'', 1'', 1 1/2'', 2''

• DN15 (except variants with a clamp diameter of

34.0 mm) DN25, DN40, DN50

• DN15, DN25, DN40, DN50

• DN15, DN25, DN40, DN50

• DN25, DN40, DN50

• DN15, DN25, DN40, DN50

→ To make sure you use EHEDG-compliant gaskets, refer to the "EHEDG Position Paper" available on the

EHEDG web site.

The manufacturer of the device does not deliver any gasket for the process connections.

16

English

Page 17

Type 8098

80 140

°C

°C

0204060 100 120-20

-1

Technical data

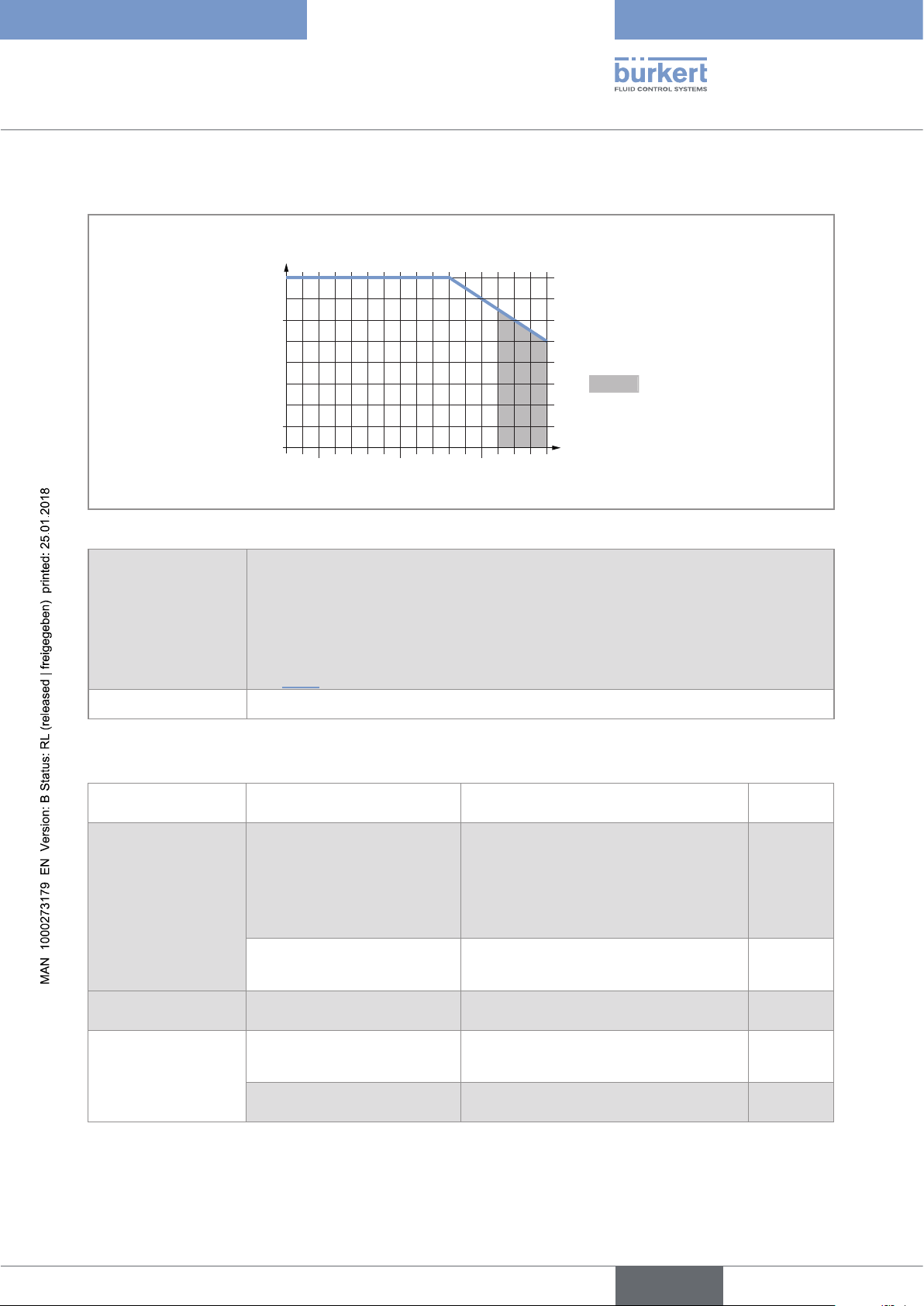

6.6 Fluid data

Ambient temperature

70

60

40

20

Temperatures authorized

for a limited duration

0

0

Fluid temperature

Fig. 6 : Dependency between the fluid temperature and the ambient temperature

Fluid temperature –20...+110 °C, with clamp process connections. Up to 140 °C for max. 60 minutes for

a sterilisation process.

Maximum temperature gradient: 10°C/s [measured by the sensor integrated in the

device]

The maximum fluid temperature can be restricted by the ambient operating temperature.

See Fig. 6

Type of fluids Non dangerous liquids complying with article 4 §1 from directive 2014/68/EU

Size of the process

connection

Kind of process connection

Standards the process connections

conform to

PN

• DIN 11864-3 series A

DN15, DN25

DN25 clamp

3/4'', 1'', 1 1/2''

• DIN 11864-3 series B

clamp

PN25

• DIN 32676 series A

• DIN 32676 series B

• DIN 11864-2 series A

flange

PN25

• DIN 11864-2 series B

clamp

SMS 3017 / ISO 2852 for pipes

according to SMS 3008

• ASME BPE (DIN 32676 series C)

PN25

PN25

• DIN 11864-3 series C

flange DIN 11864-2 series C PN25

English

17

Page 18

Type 8098

Technical data

Size of the process

connection

DN40

DN50

2''

Kind of process connection

Standards the process connections

conform to

PN

• DIN 11864-3 series B

PN16

• DIN 32676 series B

• DIN 11864-3 series A

clamp

• DIN 32676 series A

PN25

• SMS 3017 / ISO 2852 for pipes

according to SMS 3008

DIN 11864-2 series B PN16

flange

DIN 11864-2 series A PN25

• DIN 11864-3 series A

• DIN 11864-3 series B

clamp

• DIN 32676 series A

PN16

• DIN 32676 series B

• SMS 3017 / ISO 2852 for pipes

according to SMS 3008

• DIN 11864-2 series A

flange

PN16

• DIN 11864-2 series B

• ASME BPE (DIN 32676 series C)

clamp

PN16

• DIN 11864-3 series C

flange DIN 11864-2 series C PN16

18

Table 2: Fluid pressure, depending on the pipe diameter, the type of process connections and the process connection

standard

6.7 Measurement data

Flow rate measurement

• Measurement range • 0...7 m

• Measurement deviation

for a flow rate

• ±0.4% of the measured value

1) 2)

between 10% of the full scale and the full

scale

• Measurement deviation

for a flow rate

• < ±0.08% of the full scale

1) 2)

between 1% of the full scale and 10% of the

full scale

• Repeatability

for a flow rate between 10% of

• ±0.2% of the measured value

2)

the full scale and the full scale

• Repeatability

for a flow rate between 1% of

• ±0.04% of the full scale

2)

the full scale and 10% of the full scale

• Refresh time • Adjustable

3

/h to 0...90 m3/h, depending on the DN of the sensor

English

Page 19

Type 8098

°C

-1

V

Technical data

Temperature measurement

• Measurement range • –20...+140 °C

• Measurement deviation

1)

for temperatures up

• ±1 °C

to 100 °C

• Measurement deviation

for temperatures

• ±1.5%

1)

between 100 °C and 140 °C

• Refresh time • 1 s

Density factor measurement

• Measurement range • 0,8...1,3

• Resolution • 0,00001

• Repeatability • ±0.5% of the measured value

• Refresh time • Adjustable

Acoustic transmission factor measurement

• Measurement range • 10...120%

• Resolution • 0,01%

• Repeatability • ±2% of the measured value

• Refresh time • Adjustable

1) "Measurement bias" as defined in the standard JCGM 200:2012.

2) Determined in the following reference conditions: fluid = water, free of gas bubbles and solids; water and ambient

temperatures = 23 °C, refresh time of 190 ms, applying the minimum inlet (40xDN) and minimum outlet (1xDN) straight pipe

lengths, appropriate pipe dimensions.

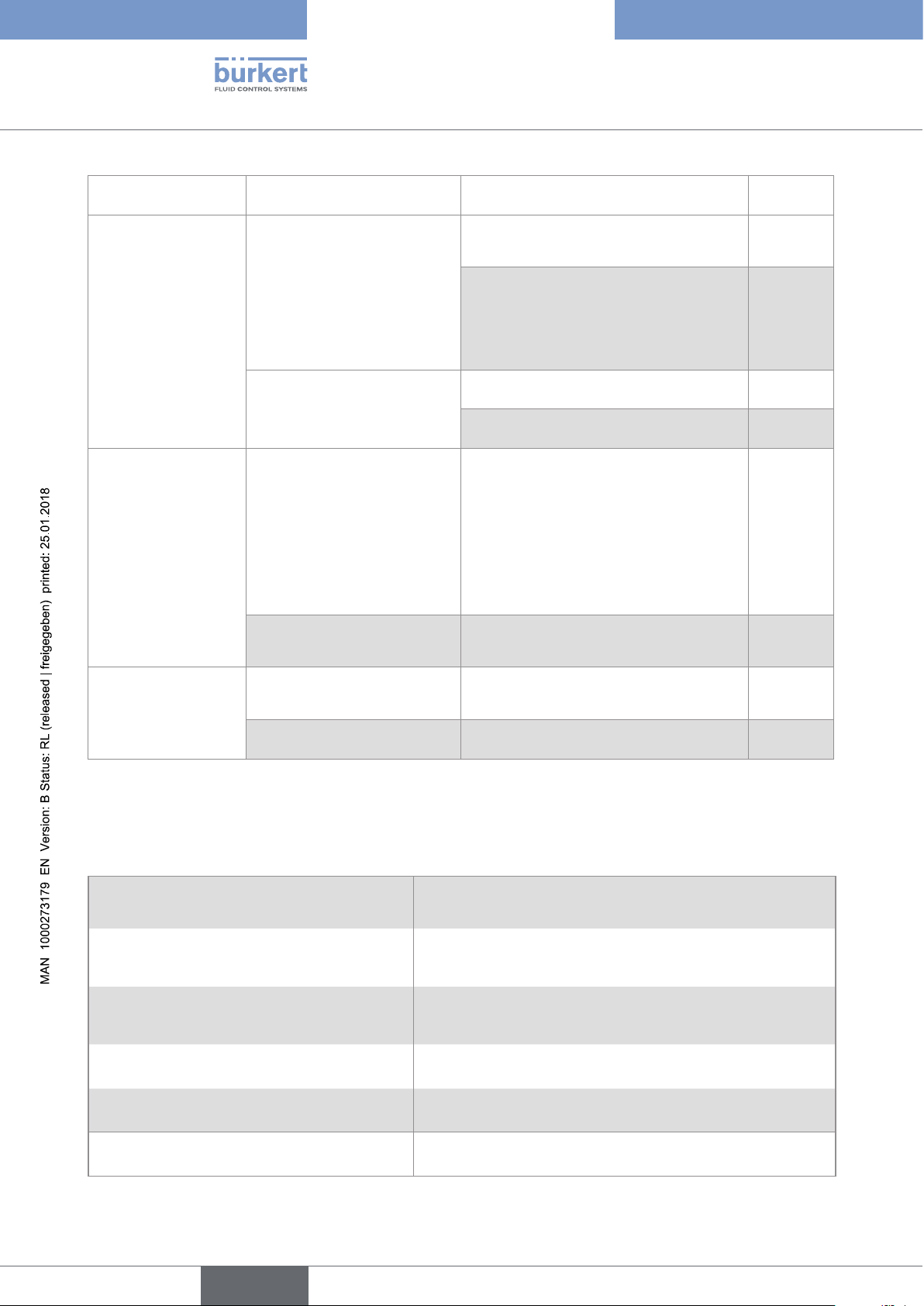

6.8 Electrical data

Ambient temperature

60

20

0

0

-20

0204060 100 120

Fluid temperature

80 14040°C

Supply voltage

35

30

25

20

15

10

minimum supply voltage

Fig. 7 : Minimum supply voltage depending on the ambient temperature and on the fluid temperature

19

English

Page 20

Type 8098

Technical data

Operating voltage • 12...35 V DC; The minimum voltage to be supplied depends

on the fluid temperature and on the ambient operating temperature: see Fig. 7

• current consumption: max. 2 A

• filtered and regulated

• tolerance: ±10%

• SELV circuit, at a non-dangerous energy level

Energy source (not supplied) Limited energy source according to paragraph 9.4 of

EN 61010-1 standard

Power consumption (without the consumption

of the outputs)

Polarity reversal Protected

≤ 5 W

Analogue output 1, also output 3 if configured

as an analogue output

Digital output 2, also output 3 if configured as

a digital output

• 4...20 mA current; 3.6 mA or 22 mA to indicate an error

• Uncertainty: ±0.04 mA

• Resolution: 0.8 µA

• Open loop detection through diagnostic software function

• Any connection mode, in sink or source mode

• Galvanically isolated, passive

• Protected against polarity reversal

• Maximum loop impedance 1300 W at 35 V DC, 1000 W at

30 V DC, 700 W at 24 V DC, 450 W at 18 V DC

• Transistor

• Any connection mode, in NPN or PNP mode

• Pulse (by default), can be changed by the user

• 0...2000 Hz

• 5...35 V DC, max. 700 mA

• Galvanically isolated, passive

20

• Overload information through diagnostic software function

• Protected against overloads

• Protected against polarity reversals

6.9 Mechanical data

Dimensions and weight of the device: refer to the technical data sheet regarding the type 8098 available at www.

burkert.com

English

Page 21

Type 8098

Technical data

Table 3: Materials in contact with the ambient air

Component Material

Transmitter housing

1)

, sensor housing Stainless steel 304 / 1.4301, outer surface finish Ra < 1.6 µm

Cable glands / Blind plugs Nickel plated brass / Black polyoxymethylene (POM)

M12 male connector and blind plug Nickel plated brass

Pressure compensating element Stainless steel

Display Float glass, stainless steel 304 / 1.4301

Seals VMQ silicone

Name plate Metallized polyester

1)

The housing may have light machining marks due to the manufacturing process. These marks do not affect the

operation of the device and are not a manufacturing defect.

Table 4: Materials in contact with the fluid

Component Material

• Sensor measurement tube

Stainless steel 316L / DIN 1.4435 BN2

• Clamp connections

Table 5: Available surface finish

Component Surface finish according to ISO 4288

Ra < 0.8 µm

Measurement tube (inner surface)

or Ra < 0.4 µm

• Measurement tube (outer surface)

Ra < 1,6 µm (excluding welding seams)

• housing

English

21

Page 22

Type 8098

Installation and wiring

7 INSTALLATION AND WIRING

7.1 Safety instructions

DANGER

Risk of injury due to electrical voltage.

▶ Before carrying out work on the system, disconnect the electrical power for all the conductors and isolate it.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to high pressure in the installation.

▶ Before any intervention on the installation, stop the circulation of fluid, cut off the pressure and drain the pipe.

▶ Before any intervention on the installation, make sure there is no pressure in the pipe.

▶ Observe the fluid temperature-pressure dependency depending on the fitting used.

If switched on for a prolonged time, risk of burn injury or fire due to hot device surface

▶ Do not touch with bare hands.

▶ Keep the device away from highly flammable substances and fluids.

Risk of burn injury due to high fluid temperatures.

▶ Do not touch with bare hands the parts of the device that are in contact with the fluid.

▶ Use safety gloves to handle the device.

▶ Before opening the pipe, stop the circulation of fluid and drain the pipe.

▶ Before opening the pipe, make sure the pipe is completely empty.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and safety relating to the use of dangerous fluids.

WARNING

Risk of injury due to non-conforming installation.

▶ The electrical and fluid installations can only be carried out by qualified and authorized personnel with the

appropriate tools.

▶ Fit a circuit breaker or a switch to the electrical installation of the building in which the device is installed.

▶ Install the circuit breaker or the switch in an easily accessible place.

22

▶ Identify the circuit breaker or the switch as the disconnecting component for the electrical power supply to

the device.

▶ Install overload devices that are appropriate to the electrical installation.

▶ Respect standard NF C 15-100 / IEC 60364.

English

Page 23

Type 8098

Installation and wiring

WARNING

Risk of injury due to unintentional switch on of power supply or uncontrolled restarting of the

installation.

▶ Take appropriate measures to avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subsequent to any intervention on the device.

WARNING

Risk of injury if the fluid pressure/temperature dependency is not respected.

▶ Observe the fluid temperature-pressure dependency. Refer to Fig. 6 chap. 6.6 Fluid data.

▶ Observe the Pressure Equipment Directive 2014/68/EU.

CAUTION

Risk of injury due to a heavy device.

A heavy device can fall down during transport or during installation and cause injuries.

▶ Transport, install and dismantle a heavy device with the help of another person.

▶ Use appropriate tools.

NOTICE

The device will be damaged if you use a tool to turn the blind cover or the display module.

▶ Do not use a tool to turn the blind cover or the display module.

7.2 Preparing the device before installation into the pipe

The device is delivered as described in Fig. 1, chap. 5.1.

Before installing the device into the pipe, you may:

• change the position of the transmitter on the sensor. Refer to chap. 7.2.1.

• switch positions of the display module and the blind cover. Refer to chap. 7.2.2.

English

23

Page 24

Type 8098

Installation and wiring

7.2.1 Changing the position of the transmitter on the sensor

The transmitter type SE98 can have four positions on the flow sensor type S097. See 7.2.1.

Fig. 8 : Possible positions of the transmitter SE98

→ To change the position of the transmitter as it is described in Fig. 1, chap. 5.1., do the following:

For safety reasons and to comply with the UL 61010-1

standard, the blind cover and the display module are

locked.

→ Prepare the unlocking magnetic key, that is

delivered with the device, to change the position of

the transmitter.

1. Put the magnetic key on the

to the display module. You should hear a soft click

indicating that the display module is unlocked. Do

not use a tool to turn the display module.

2. While the magnetic key is on the mark, turn

the display module by hand only from the locked

position to the unlocked position. If you cannot turn

the display module by hand, contact Bürkert.

mark related

The blind cover or the display module is

locked

The blind cover or the display module is

unlocked

24

English

Page 25

Type 8098

Installation and wiring

3. Carefully lift the display module because

a cable connects the display module to the

transmitter.

4. Push the tab of the cable connector to disconnect

the display module from the transmitter.

5. Remove the display module and put it on a clean

surface to protect the seal from dirt.

Push the tab to

unlock the cable

connector

6. With an hexagonal key size 3, loosen the screw that

is marked with the arrow and that locks the transmitter to the flow sensor.

7. Hold the flow sensor with one hand and, with the

other hand, turn the transmitter by about 20 deg

counterclockwise.

English

25

Page 26

8. Lift the transmitter carefully because a

cable connects the transmitter to the flow sensor.

9. If the seal is damaged, replace it. Apply a layer of

lithium soap grease to the new seal before you put

it in place.

Type 8098

Installation and wiring

10. If the seal is out of the groove, put it back in the

groove.

11. Turn the transmitter in the wanted position.

12.

Make sure the cable stays inside the

transmitter.

13. Turn the transmitter by about 20 deg

counterclockwise.

Seal in the groove:

correct

Seal out of the groove:

NOT correct

26

English

Page 27

Type 8098

Installation and wiring

14. Screw the transmitter clockwise on the flow sensor

until the blind cover is perfectly parallel or perpendicular to the axis of the pipe.

15. Fasten the screw with an hexagonal key size 3 at a

tightening torque of 1.3 N·m ±0.05 N·m (0.96 ft·lbf

±0.04 ft·lbf)

16. Connect the display module to the transmitter.

17. Put the mark of the cover on the unlocked marking

of the housing and screw the cover clockwise

on the transmitter until the mark is on the locked

position. You should hear a click

English

27

Page 28

Type 8098

Installation and wiring

7.2.2 Switching positions of the blind cover and the display module

CAUTION

Risk of injury due to a heavy device.

A heavy device can fall down during transport or during installation and cause injuries.

▶ Transport, install and dismantle a heavy device with the help of another person.

▶ Use appropriate tools.

The device is delivered with the display module screwed on the top and the blind cover screwed on the housing

side.

→ To switch positions of the display module and the blind cover, do the following:

For safety reasons and to comply with the UL 61010-1

standard, the blind cover and the display module are

locked.

→ Prepare the unlocking magnetic key, that is

delivered with the device.

1. Put the magnetic key on the

to the display module. You should hear a soft click

indicating that the display module is unlocked. Do

not use a tool to turn the display module.

2. While the magnetic key is on the mark, turn

the display module by hand only from the locked

position to the unlocked position. If you cannot turn

the display module by hand, contact Bürkert.

3. Carefully lift the display module because a cable

connects the display module to the transmitter.

4. Push the tab of the cable connector to disconnect

the display module from the transmitter.

5. Remove the display module and put it on a clean

surface to protect the seal from dirt.

mark related

The blind cover or the display module is locked

The display module is unlocked

28

Push the tab to

unlock the cable

connector

English

Page 29

Type 8098

Installation and wiring

6. Put the magnetic key on the mark related to

the blind cover. You should hear a click indicating

that the blind cover is unlocked. Do not use a tool

to turn the blind cover.

7. Turn the blind cover by hand only to the unlocked

position and remove it. If you cannot turn the blind

cover by hand, contact Bürkert.

8. Engage the cable of the display module through the

front opening.

9. Connect the cable to the connector, as shown in

the picture.

10. Put the mark of the display module on the unlocked

marking of the housing and screw the cover

clockwise on the transmitter until the mark is on the

locked position.

11. Put the mark of the blind cover on the unlocked

marking of the top of the transmitter housing.

Connect the cable here

12. Screw the blind cover clockwise on the transmitter

until the mark is on the locked position. You should

hear a click.

The blind cover is locked.

29

English

Page 30

Type 8098

1 x DN

Installation and wiring

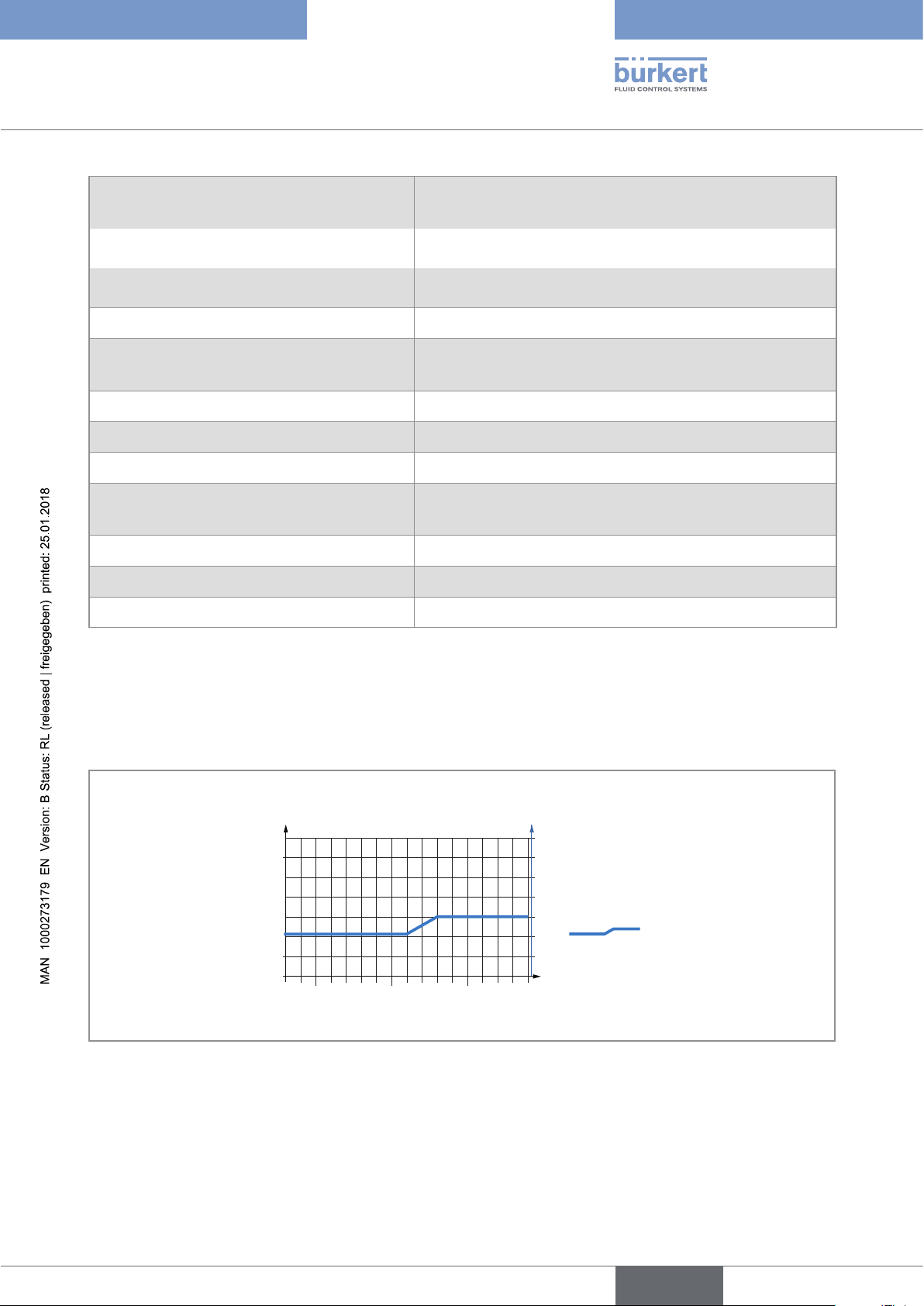

7.3 Recommendations for the installation into the pipe

→ Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors, the

effects of the climatic conditions.

→ Make sure the DN of the measurement tube is suited to the flow velocity: refer to the data sheet of the device,

available at www.burkert.com

→ Choose a location with enough free space to put the magnetic key on the symbol at the rear side of the

device.

→ Install the device upstream a valve or any equipment that changes the pipe diameter or the pipe direction. If

the recommendation cannot be respected, install the device in the pipe in such a way that the straight downstream distances are respected depending on the design of the pipes, refer to standard ISO 9104:1991 and

Fig. 9. If these recommendations cannot be respected, contact Bürkert.

flow direction

2 x 90° elbow

Control valve

40 x DN

2 x 90°

elbow joint, 3

60 x DN

1 x DN

1 x DN

joint

50 x DN

40 x DN

90° elbow joint or

T-piece

1 x DN

dimensional

Fig. 9 : Upstream and downstream straight distances for special pipe designs

→ To allow proper self-draining and to respect the 3A and EHEDG requirements, install the device into a pipe

with a minimum angle against the horizontal. See Table 6.

Kind of process connection Standards the process connections conform to Angle against the horizontal

• DIN 32676 series A

30

clamp

• DIN 11864-3 series A

minimum 5°

• SMS 3017 / ISO 2852 for pipes according to

SMS 3008

flange DIN 11864-2 series A minimum 5°

English

Page 31

Type 8098

Installation and wiring

Kind of process connection Standards the process connections conform to Angle against the horizontal

• ASME BPE (DIN 32676 series C)

• DIN 32676 series A

clamp

minimum 3°

• DIN 11864-3 series B

• DIN 11864-3 series C

• DIN 11864-2 series B

flange

minimum 3°

• DIN 11864-2 series C

Table 6: Minimum angle against the horizontal for proper self-draining

→ If the pipe is fitted with a thermal insulation, do not thermally insulate the measurement tube of the device to

make sure that the temperature in the device is less than 70°. Refer to Fig. 10 and, for the minimum supply

voltage, to chap. 7.5.3.

Pipe insulation

Fig. 10 : Thermal insulation of the pipe

No pipe insulation

English

31

Page 32

Type 8098

Installation and wiring

7.4 Installing the device into the pipe

CAUTION

Risk of injury due to a heavy device.

A heavy device can fall down during transport or during installation and cause injuries.

▶ Transport, install and dismantle a heavy device with the help of another person.

▶ Use appropriate tools.

7.4.1 Before installing the device into the pipe

• Prepare the device as described in chap. 7.2.

• Follow the recommendations given in chap. 7.3.

7.4.2 Installing a device with clamp connections

The manufacturer of the device does not deliver any gasket for the process connections.

→ If the installation must be EHEDG-compliant and the device is fitted with clamp connections according to

ASME BPE (DIN 32676 series C), DIN 32676 series A, DIN 32676 series B or SMS 3017 / ISO 2852 for

pipes according to SMS 3008, use EHEDG-compliant gaskets from Combifit International B.V.

→ To make sure you use EHEDG-compliant gaskets, refer to the "EHEDG Position Paper" available on the

EHEDG web site.

→ The clamp connections according to DIN 11864-3 series A, B and C are hygienic connections. You can use

any gaskets that are adapted to the process.

→ Make sure the gaskets on the clamp connections are in good condition.

→ Place gaskets adapted to the process (temperature, fluid type) in the grooves of the clamp connections.

→ Attach the clamp connections to the pipe by means of clamp collars.

7.4.3 Installing a device with flange connections

The flange connections according to DIN 11864-2 series A, B and C are hygienic connections. You can use

→

any gaskets that are adapted to the process.

→ Make sure the gaskets on the flange connections are in good condition.

→ Place gaskets adapted to the process (temperature, fluid type) in the grooves of the flange connections.

32

→ Use bolts with dimensions as given in the relevant flange standard and adapted to the process.

→ Tighten the bolts at a torque as given in the relevant flange standard, to fix the fitting to the pipe.

English

Page 33

Type 8098

Installation and wiring

7.5 Wiring the device

DANGER

Risk of injury due to electrical voltage.

▶ Before carrying out work on the system, disconnect the electrical power for all the conductors and isolate it.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

WARNING

Risk of injury due to non-conforming installation.

▶ Fit a circuit breaker or a switch to the electrical installation of the building in which the device is installed.

▶ Install the circuit breaker or the switch in an easily accessible place.

▶ Identify the circuit breaker or the switch as the disconnecting component for the electrical power supply to

the device.

▶ Install overload devices that are appropriate to the electrical installation.

▶ Respect standard NF C 15-100 / IEC 60364.

Risk of injury due to unintentional switch on of power supply or uncontrolled restarting of the

installation.

▶ Take appropriate measures to avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subsequent to any intervention on the device.

NOTICE

The device is not tight if at least one cable gland is not used

▶ Make sure the unused cable glands are sealed with the supplied plugs.

• Use a high quality electrical power supply, filtered and regulated.

• Engage only one cable in each cable gland.

• Do not install the cables near high voltage or high frequency cables; If this cannot be avoided, observe a

min. distance of 30 cm.

7.5.1 Specifications of the cable for the male M12 fixed connector

Use a 5-pin M12 female connector (not supplied) to connect the male M12 fixed connector, for example the

female M12 connector with order code 917116.

If you use the female M12 connector with order code 917116, observe the specifications for the cable and wires,

given in Table 7.

English

33

Page 34

Type 8098

11,5

°C

-1

V

Installation and wiring

Table 7: Specifications of the cable and wires for the M12 female connector with order code 917116

Specification Recommended value

• Electromagnetic protection (EMC)

• shielded

• Cross section of the wires

• Diameter of the cable

• Maximum operating temperature

• max. 0.75 mm

• 3 to 6.5 mm

• min. 80 °C

2

7.5.2 Assembling and wiring the female M12 connector

To assemble and wire the female M12 connector with order code 917116, do the following:

1 2

→ Completely loosen the nut [1].

→ Remove the rear part of the connector [2].

20

5,5

→ Engage the cable through the nut and the rear part

of the connector.

→ Strip 20 mm of the cable.

→ Cut the central wire so that its length is equal to

11.5 mm.

→ Expose 5.5 mm of the other wires.

→ Insert each wire into the appropriate pin. Refer to

chap. 7.5.4.

34

→ Pull the cable and tighten the connector nut.

Fig. 11 : M12 multipin connector with order code 917116 (not provided)

→ Plug and tighten the female M12 connector with your hand to the M12 male connector of the device.

7.5.3 Connecting the device to a power supply

The minimum voltage to be supplied depends on the fluid temperature and on the ambient operating temperature:

see Fig. 12.

Ambient temperature

60

20

0

0

-20

0204060 100 120

80 14040°C

Fluid temperature

Fig. 12 : Minimum supply voltage depending on the ambient temperature and on the fluid temperature

Supply voltage

35

30

25

20

15

10

minimum supply voltage

English

Page 35

Type 8098

4

Installation and wiring

The device is wired in the factory to be easily energized through the M12 male fixed connector.

→ Connect the device to a 12...35 V DC power supply:

• either through the M12 male fixed connector, refer to chap. 7.5.4.

• or through the cable glands and the terminal strip located in the transmitter housing. Refer to chap. 7.5.11 for

the wiring procedure.

7.5.4 Connecting the device to büS

The M12 male fixed connector (A-coding) is used to connect the device to büS.

Malfunction of the internal and external communication if the M12 male fixed connector is not used.

• Put a protection cap on an unused M12 fixed connector.

• Make sure pins 4 and 5 are not in contact with each other and not in contact with the other pins.

→ If the device is connected to büS and at one end of büS, either install a 120 W termination resistor in the line

or activate the device internal termination resistor: see chap. 7.5.5.

The M12 male fixed connector can be used to connect the device to a 12...35 V DC power supply.

• Pin 1: CAN shield

2

3

Fig. 13 : Pin assignment of the M12 male fixed connector

5

1

• Pin 2: 12...35 V DC

• Pin 3: GND

• Pin 4: CAN_H

• Pin 5: CAN_L

Fig. 14 : Wiring of the device ex works

Cable and conductors connected inside

the device to the M12 fixed connector

35

English

Page 36

Type 8098

Installation and wiring

7.5.5 Activating the device internal termination resistor

The device has an internal termination resistor that can be activated if the device is installed at one end of büS.

If you activate the device internal termination resistor, do not install a termination resistor at the same end of büS.

To activate the device internal termination resistor, do the following:

→ Go to the CONFIGURATION view.

→ General settings

→ Confirm to access the Parameter view.

→ büS

→ Advanced

→ Termination resistor

→ On

→ Save.

The internal termination resistor is activated.

7.5.6 Specifications of the cables for the two M20x1,5 cable glands

Table 8: Specifications of the cables for the M20x1.5 cable glands

Specification of the cables Recommended value

Electromagnetic protection (EMC) shielded

Diameter 5...14 mm

Maximum operating temperature min. 90 °C

7.5.7 Specifications of the wires for the terminal strip

Table 9: Specifications of the wires for the terminal strip

Specification of the lead wires Recommended value range

Cross section of a solid wire H05(07) V-U 0,25...1,5 mm

Cross section of a stranded wire H05(07) V-K, with a

wire ferrule but without collar

Cross section of a stranded wire H05(07) V-K, with a

wire ferrule with a plastic collar

Cross section of other kinds of wires 0,2...1,5 mm2 (AWG24... AWG16)

0,25...1,5 mm

0,25...0,75 mm

2

2

2

36

English

Page 37

Type 8098

123456789111210

Installation and wiring

7.5.8 Terminal assignment of the terminal strip

The terminal strip located in the transmitter housing, has 12 push-in terminals.

Green LED Orange LED

• Green LED:

- flashes slowly if the operation of the device is correct.

- flashes quickly if there is a communication problem with the measurement board.

• Orange LED lit if the related digital output is switched to ON.

• Terminal 1: GND (blue wire, factory wired, internally connected to the M12 male fixed connector)

• Terminal 2: CAN_L (grey wire, factory wired, internally connected to the M12 male fixed connector)

• Terminal 3: Shield (brown wire, factory wired, internally connected to the M12 male fixed connector)

• Terminal 4: CAN_H (black wire, factory wired, internally connected to the M12 male fixed connector)

• Terminal 5: 12...35 V DC (white wire, factory wired, internally connected to the M12 male fixed connector)

• Terminal 6: GND (for the connection of the power supply through the cable glands)

• Terminal 7: negative output 3 (analogue output or digital output)

• Terminal 8: positive output 3 (analogue output or digital output)

• Terminal 9: negative output 2 (digital output)

• Terminal 10: positive output 2 (digital output)

• Terminal 11: negative output 1 (analogue output)

• Terminal 12: positive output 1 (analogue output)

Fig. 15 : Terminal assignment of the terminal strip located in the transmitter housing

Fig. 16 : Wiring ex works of the 12 push-in terminal strip

→ To disconnect a wire, first push the terminal with a slot screwdriver 3.0 mm (any length) and a force of

max. 40 N.

37

English

Page 38

Type 8098

Installation and wiring

7.5.9 Opening the front to have access to the terminal strip

The terminal strip can be accessed by opening the front of the transmitter housing, i.e. by removing either the

blind cover or the display module.

Procedure to access the terminal strip if the blind cover is on the front of the device

1. Put the magnetic key on the mark related to

the blind cover. You should hear a click indicating

that the blind cover is unlocked. Do not use a tool

to turn the blind cover.

2. Turn the blind cover by hand to the unlocked

position and remove it.

Fig. 17 : Procedure to access the terminal strip if the blind cover is on the front of the device

Procedure to access the terminal strip if the display module is on the front of the device

1. Remove the blind cover from the top of the

transmitter.

2. Put the magnetic key on the

mark related

to the display module. You should hear a click indicating that the display module is unlocked. Do not

use a tool to turn the display module.

3. Turn the display module by hand to the unlocked

position.

4. Carefully pull the display module

because a cable connects the display module to

Push the tab to unlock

the cable connector

the transmitter.

38

5. Push the tab of the cable connector to disconnect

the display module from the transmitter.

6. Remove the display module and put it on a clean

surface to protect the seal from dirt.

Fig. 18 : Procedure to access the terminal strip if the display module is on the front of the device

English

Page 39

Type 8098

100 mm ±5

8 mm

Installation and wiring

7.5.10 Wiring the device through the M20x1,5 cable glands

Engage only one cable in each cable gland.

→ Prepare cables that obey the specifications given

in chap. 7.5.6 and chap. 7.5.7.

→ To open the front of the transmitter, follow the

instructions given in chap. 7.5.9.

1. With an hexagonal key size 10 loosen the 2 screws

of the functional earth plate.

2. Strip 100 mm of the cable.

3. Reduce the shield to 20 mm.

4. Expose 8 mm of the wires.

5. Remove the plug of the cable gland.

6. If the cable diameter is between 5 and 9 mm,

engage the cable through the cable gland as

shown in the figure.

2 screws

20 mm

7. If the cable diameter is between 9 and 14 mm,

→ vertically engage a screwdriver between the two

seals,

→ lift the inner seal and remove it.

→ Engage the cable through the cable gland.

39

English

Page 40

8. Attach each cable to the functional earth plate. The

shield must be in contact with the functional earth

plate.

9. Put the functional earth plate in its original place.

Type 8098

Installation and wiring

10. With an hexagonal key size 10, tighten the 2

Functional earth

screws of the functional earth plate at a tightening

torque of 0.2 N·m.

IT IS NOT MANDATORY TO

CONNECT THE DEVICE TO A

PROTECTIVE EARTH - MEANT FOR

FUTURE USE

11. Engage each wire in the correct terminal of the terminal strip.

12. To connect the 12...35 V DC power supply through the cable glands, refer to chap. 7.5.11.

13. To connect the outputs, refer to chap. 7.5.12 and chap. 7.5.13.

14. Connect the functional earth to the functional earth plate as shown in Fig. 20, chap. 7.5.11.

2 screws

40

15. If the display module is removed, connect it back.

16. Close the front and the top of the transmitter housing

Fig. 19 : Wiring the device through the M20x1,5 cable glands

English

Page 41

Type 8098

Installation and wiring

7.5.11 Connecting the device to a 12...35 V DC power supply, through the cable glands

1. With a slot screwdriver 3.0 mm (any length) and a force of max. 40 N, push the terminal 5 and disconnect the

white wire. Do not cut the white wire.

2. Insulate the white wire.

3. Connect the power supply as shown in Fig. 20.

To connect to the positive 12...35 V DC power supply for

the device, through a cable gland

To connect to the negative power supply for the device,

Green LED flashes slowly if

the operation of the device

is correct

through a cable gland

11234567891 1210

Internally connec-

ted to the M12

fixed connector

Insulated

white wire

To connect to the functional

earth, through a cable gland

Fig. 20 : Connecting the 12...35 V DC power supply, through the cable glands

English

41

Page 42

Type 8098

11234567891 1210

Installation and wiring

Fig. 21 : Device connected to a 12...35 V DC power supply, through the cable glands

7.5.12 Wiring the output 1 (analogue) and the output 3 configured as an analogue output

NOTICE

Risk of short-circuit if the configuration of output 3 is wrong.

▶ Before wiring the output 3 as an analogue output, make sure the output 3 is configured as an analogue out-

put in the Parameters menu of the Outputs. See chap. 8.10 Changing the type of the output 3.

An analogue output can be wired either in sourcing mode or in sinking mode.

+-

output 1

4...20 mA input, at

external instrument,

connected to output 1

+-+-

4...20 mA input, at

external instrument,

connected to output 3

+-

12-35 V DC

Power supply for

output 3

12-35 V DC

Power supply for

42

Fig. 22 : Wiring the analogue outputs

English

Page 43

Type 8098

11234567891 1210

Installation and wiring

7.5.13 Wiring the output 2 (digital) and the output 3 configured as

a digital output

NOTICE

Risk of short-circuit if the configuration of output 3 is wrong.

▶ Before wiring the output 3 as a digital output, make sure the output 3 is configured as a digital output in the

Parameters menu of the Outputs. See chap. 8.10 Changing the type of the output 3.

A digital output can be wired either in NPN mode or in PNP mode.

Orange LED is lit if the

related digital output is

switched to ON

12-35 V DC

Power supply for

output 3

Fig. 23 : Wiring the digital outputs

+-

Load connected to

output 3

+-

+-

12-35 V DC

Power supply for

output 2

+-

Load connected to

output 2

43

English

Page 44

Type 8098

How to do the settings

8 HOW TO DO THE SETTINGS

8.1 Safety instructions

WARNING

Risk of injury due to nonconforming adjustment.

Nonconforming adjustment could lead to injuries and damage the device and its surroundings.

▶ The operators in charge of adjustment must have read and understood the contents of the Operating

Instructions.

▶ In particular, observe the safety recommendations and intended use.

▶ The device/installation must only be adjusted by suitably trained staff.

8.2 Available software to do the settings

The settings of the device can be done with:

• the display module type ME31. The device can be equipped with a display module or not.

• the Bürkert Communicator software type 8920, which must be installed on a PC.

The menu structure is the same in the display module and in the Bürkert Communicator software.

→ To do the settings of the device with the display module type ME31, refer to the next chapters of the Quickstart

and to the Operating Instructions type 8098.

→ To use the Bürkert Communicator software, first prepare the necessary hardware and the software itself. Refer

to chap. 8.3. Then do the settings as described in the Operating Instructions type 8098.

→ To use some specific functions that are only available with the Bürkert Communicator software, refer to the

Operating Instructions type 8920, available on the internet at www.burkert.com

→ To get detailed information on the software of the display module type ME31, refer to the related Operating

Instructions, available on the internet at www.burkert.com

8.3 Preparing the Bürkert Communicator software

To do the settings with the Bürkert Communicator software type 8920, do the following steps:

4. Buy the USB-büS-interface set with order code 772426.

5. Download the latest version of the Bürkert Communicator software type 8920 from www.burkert.com

44

6. Install the Bürkert Communicator software on a PC. Obey the installation recommendations given in the USB-

büS-Interface set. During installation, the büS stick must not be plugged in the PC.

7. Screw the termination resistance into the Y plug or activate the device internal termination resistor (see

chap. 7.5.5)

8. Screw the female M12 connector at the end of the delivered cable into the Y plug.

9. Insert the micro-USB of the cable into the delivered büS stick.

10. Insert the appropriate power adapter into the AC/DC adapter.

English

Page 45

Type 8098

How to do the settings

11. Connect the cable of the AC/DC adapter to the related connector of the female M12 connector.

micro-USB

büS stick

Termination

resistance

Cable of the AC/DC adapter

Y plug

Female M12

connector

Power adapter

AC/DC adapter

Fig. 24 : Assembled connection cables, plugs and büS stick

12. Screw the Y plug on the male M12 connector of the device.

13. Insert the büS stick into a USB port of the PC.

14. Wait for the Windows pilot of the büS stick to be completely installed on the PC.

15. Connect the AC/DC adapter to the power supply.

16. Start the Bürkert Communicator software.

17. Click on

in the Bürkert Communicator software to establish the communication between the Bürkert Com-

municator software and the device. A window opens.

18. Select büS-Stick.

19. Choose the port Bürkert büS Stick, click on Finish and wait until the device symbol appears in the list of

devices.

20. In the list of devices, click on the symbol related to the device: the menu structure for the device is displayed.

English

45

Page 46

Type 8098

How to do the settings

8.4 Display module: description of the user interface

To get detailed information on the display software, refer to the Operating Instructions of the display

software type ME31, available on the internet at www.burkert.com

The user interface is made up of a display and touch sensitive keys.

View 1 of 4

Display

Volume flow

View 2

30.1

CONFIGURATION

Navigation keys OK keyBACK key

Fig. 25 : Overview of the user interface

l/min

46

English

Page 47

Type 8098

How to do the settings

8.4.1 Description of the display

Symbol of the active user level. See chap. 8.5 Available login user levels.

Symbol of the device status

To the DIAG-

NOSTICS menu, by

pressing

Display

Parameter

Brightness 56%

Contrast 64%

Screen saver [+]

DIAGNOSTICS

Information bar

MAINTENANCE

Name of the customized view or of the menu

SAW sensor

Parameter

Stand. meas. values [+]

Add. meas. values [+]

Diag. events [+]

DIAGNOSTICS

Refresh time Long

More menu items are available

The symbol [+] at the end of a menu item means that sub-menu items are available.

Title of the menu or of

the menu item

MAINTENANCE

To the MAINTENANCE

menu, by pressing

Fig. 26 : Description of the display (examples)

47

English

Page 48

8.4.2 How to use the touch sensitive keys

The highlighted terms are related to menus or menu items.

Table 10: How to use the keys

Key Description

Short press: to go back to the parent menu or to the parent view. This key is called BACK in the

display messages.

If the user makes changes but does not save these, then a message is displayed asking if the

changes should be saved.

Long press: to go back to View 1

If one or both keys are displayed:

• To switch between views, from the left to the right and vice versa. Only possible

between the views that can be customized and the CONFIGURATION view, and

between the Diagnostics, Parameter and Maintenance views.

Type 8098

How to do the settings

• When being asked to enter a value, to select the digit to the left or the digit to the right.

• To select a Menu item.

• To select an option or to change a value.

This key is called OK in the display messages.

Short press:

• to confirm a selection.

• to save a choice.

• to go to the next screen of the wizard.

Long press: to open the context menu

8.4.3 Minimum and maximum values when entering a numerical value

When you are requested to enter or to change a numerical value, the minimum and maximum authorized values

are always displayed.

8.5 Available login user levels

The following 4 login user levels are available to operate or adjust the device:

48

• the basic user level, which is the level with the less functions,

• the Advanced User user level,

• the Installer user level (default),

• the Bürkert user level.

By default the device adjustment is not protected by passwords.

Table 11 shows the symbol displayed in the information bar, depending on the user level that is active on the

device, and what can be done with each kind of user level.

English

Page 49

Type 8098

How to do the settings

Symbol1) User level Description

• No password is required.

Basic user

• The menu items with the symbol

are in read-only access.

• Not all the menu items that are available with a higher user level are displayed.

• Password required, if the password protection is active. Default password is

005678.

Advanced

user

• The menu items with the symbol

are in read-only access.

• Not all the menu items that are available with a higher user level are displayed.

• Password required, if the password protection is active. Default password is

001946.

Installer

• This level is active by default (and by default, password protection is switched

off).

• All the available menu items can be adjusted.

• Password required, if the password protection is active.

Bürkert

Table 11: Possible login user levels

1)

displayed in the information bar, only if the adjustment is protected through passwords.

• Only for Bürkert service.

→ If you have forgotten your passwords, you can restore the default passwords with the Communicator software

type 8920. Refer to the related Operating Instructions.

8.6 Default settings

You can find the default settings of the device in the CANopen supplement for the type 8098 at www.burkert.com

→ Before making any change in the settings, use the Bürkert Communicator software to print a pdf file with all

the default settings of the device.

49

English

Page 50