Page 1

Types 8202 / 8222

ELEMENT

pH / Redox or conductivity meter

pH- / Redox- oder Leitfähigkeits-Messgerät

pH / Redox-mètre ou conductivimètre

Quickstart

English / Deutsch / Français

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modification technique.

© Bürkert SAS, 2012 - 2018

Quickstart 1809/05_EU-ML 00567367 / ORIGINAL_FR

Page 3

Type 8202/8222

Contents

1 ABOUT THIS QUICKSTART ....................................................................4

1.1 Definition of the word “device” ............................................... 4

1.2 Validity of the quickstart ........................................................... 4

1.3 Symbols used ............................................................................. 4

2 INTENDED USE .............................................................................................5

3 BASIC SAFETY INFORMATION ............................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Contact ........................................................................................ 7

4.2 Warranty conditions .................................................................. 7

4.3 Information on the internet ...................................................... 7

5 DESCRIPTION OF THE RATING PLATE ............................................8

6 TECHNICAL DATA ........................................................................................9

6.1 Conditions of use ...................................................................... 9

6.2 Conformity to standards and directives ............................... 9

6.3 Dimensions of devices ...........................................................10

6.4 Mechanical data.......................................................................10

6.5 Fluid data ...................................................................................11

6.6 Electrical data ...........................................................................14

6.7 Data of connectors and cables ............................................15

6.8 pH/Redox probe of the 8202 ...............................................16

6.9 Sensor specifications of the 8222 ......................................16

7 ASSEMBLY ....................................................................................................16

7.1 Safety instructions ...................................................................16

7.2 Install the display module ......................................................16

7.3 Install the pH or redox probe in the sensor holder of the

8202 (without fluid) .............................................................................17

7.4 Mounting the electronic module to the sensor holder of

the 8202 (without fluid) ......................................................................18

8 INSTALLATION ............................................................................................ 19

8.1 Safety instructions ...................................................................19

8.2 Installation of the 8202 onto the pipe ................................19

8.3 Installation of the 8222 onto the pipe ................................22

8.4 Wiring.........................................................................................24

9 ADJUSTMENT AND COMMISSIONING .........................................28

9.1 Safety instructions ...................................................................28

9.2 Using the navigation button ..................................................29

9.3 Using the dynamic functions.................................................31

9.4 Knowing the display ................................................................31

9.5 Knowing the operating levels ...............................................33

9.6 Knowing the Process level ....................................................34

9.7 Choosing the output wiring mode .......................................35

9.8 Setting the probe parameters of the 8202 .......................35

9.9 Activating/deactivating the Hold function ..........................35

9.10 Calibrate the pH or redox probe (8202) ............................35

9.11 Calibrating the sensor of the 8222 .....................................37

10 PACKAGING, TRANSPORT .................................................................. 38

11 STORAGE ......................................................................................................38

12 DISPOSAL OF THE DEVICE ................................................................ 38

English

3

Page 4

Type 8202/8222

About this quickstart

1 ABOUT THIS QUICKSTART

This quickstart describes the entire life cycle of the device. Please

keep this quickstart in a safe place, accessible to all users and any

new owners.

This quickstart contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations. Pay attention in particular to the chapters „Basic safety

information“ and „Intended use“.

▶ Irrespective of the version of the device, this quickstart must be read

and understood.

The quickstart explains how to install, adjust, and start-up the device.

A detailed description of the device can be found in the related

operating instructions.

The operating instructions for the device can be found on the

Internet at: www.burkert.com

1.1 Definition of the word “device”

The word “device” used within this quickstart refers to:

• the Type 8202 ELEMENT pH-meter and redox-meter or

• the Type 8222 ELEMENT conductivity meter.

1.2 Validity of the quickstart

This quickstart is valid for the following devices:

• Type 8202 ELEMENT pH-meter and redox-meter, version V2,

• Type 8222 ELEMENT conductivity meter, version V2.

These informations are available on the rating plate, see chap. 5.

1.3 Symbols used

Danger

Warns against an imminent danger.

▶ Failure to observe this warning results in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or

even death.

CaUTiOn

Warns against a possible risk.

▶ Failure to observe this warning can result in substantial or minor

injuries.

nOTiCe

Warns against material damage.

4

English

Page 5

Type 8202/8222

Intended use

Advice or important recommendations.

Refers to information contained in this quickstart or in other

documents.

▶ Indicates an instruction to be carried out to avoid a danger, a

warning or a possible risk.

→ Indicates a procedure to be carried out.

2 INTENDED USE

Use of this device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

The Type 8202 ELEMENT pH-meter and redox-meter is intended

solely for the measurement of:

- the pH in clean liquids or liquids containing solids, sulphides

or proteins.

- or the oxidation reduction potential (ORP) in clean liquids or

liquids containing solids, sulphides or proteins which may

present low conductivity.

The Type 8222 ELEMENT conductivity meter is intended for the

measurement of the conductivity.

▶ Use this device in compliance with the characteristics and

commissioning and use conditions specified in the contractual

documents and in the Operating Instructions.

▶ Never use this device for security applications.

▶ Protect this device against electromagnetic interference, ultra-

violet rays and, when installed outdoors, the effects of climatic

conditions.

▶ Use this device only if in perfect working order.

▶ Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

▶ Only use the device as intended.

English

5

Page 6

3 BASIC SAFETY INFORMATION

This safety information does not take into account any contingencies

or occurrences that may arise during installation, use and maintenance of the device.

The operating company is responsible for the respect of the local

safety regulations including staff safety.

Risk of injury due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ If a 12...36 V DC or a 14...36 V DC powered version is installed

either in a wet environment or outdoors, all the electrical voltages must be of max. 35 V DC.

▶ All equipment connected to the device must be double insu-

lated with respect to the mains according to the standard IEC

61010-1:2010.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Risk of injury due to high pressure in the installation.

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of burns due to high fluid temperatures.

▶ Use safety gloves to handle the device.

▶ Stop the circulation of fluid and drain the pipes before loosening

the process connections.

Type 8202/8222

Basic safety information

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and

safety relating to the use of dangerous fluids.

Various dangerous situations.

To avoid injury take care:

▶ not to use the device in explosive atmospheres.

▶ not to use the device in an environment incompatible with the

materials it is made of.

▶ not to use fluid that is incompatible with the materials the device

is made of.

▶ not to subject the device to mechanical loads.

▶ not to make any modifications to the device.

▶ to prevent any unintentional power supply switch-on.

▶ to carry out the installation and maintenance work by qualified

and skilled staff with the appropriate tools.

▶ to guarantee a defined or controlled restarting of the process,

after a power supply interruption.

▶ to observe the general technical rules when installing and using

the device.

6

English

Page 7

Type 8202/8222

General information

nOTiCe

The device may be damaged by the fluid in contact with.

▶ Systematically check the chemical compatibility of the com-

ponent materials of the device and the fluids likely to come

into contact with the materials (for example: alcohols, strong

or concentrated acids, aldehydes, alkaline compounds, esters,

aliphatic compounds, ketones, halogenated aromatics or hydrocarbons, oxidants and chlorinated agents).

nOTiCe

Elements / Components sensitive to electrostatic discharges

▶ This device contains electronic components that are sensitive

to electrostatic discharges. They may be damaged if they are

touched by an electrostatically charged person or object. In the

worst case scenario, these components are instantly destroyed

or disabled as soon as they are activated.

▶ To minimise or even avoid any damage caused by an elec-

trostatic discharge, take all the precautions described in the

EN 61340-5-1 norm.

▶ Also make sure that you do not touch any of the live electrical

components.

4 GENERAL INFORMATION

4.1 Contact

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at: www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of

the device in observance of the operating conditions specified in the

Operating Instructions.

4.3 Information on the internet

You can find the Operating Instructions and technical data sheets

for Type 8202 and for Type 8222 at: www.burkert.com

English

7

Page 8

Type 8202/8222

1

8

10

12

11

Description of the rating plate

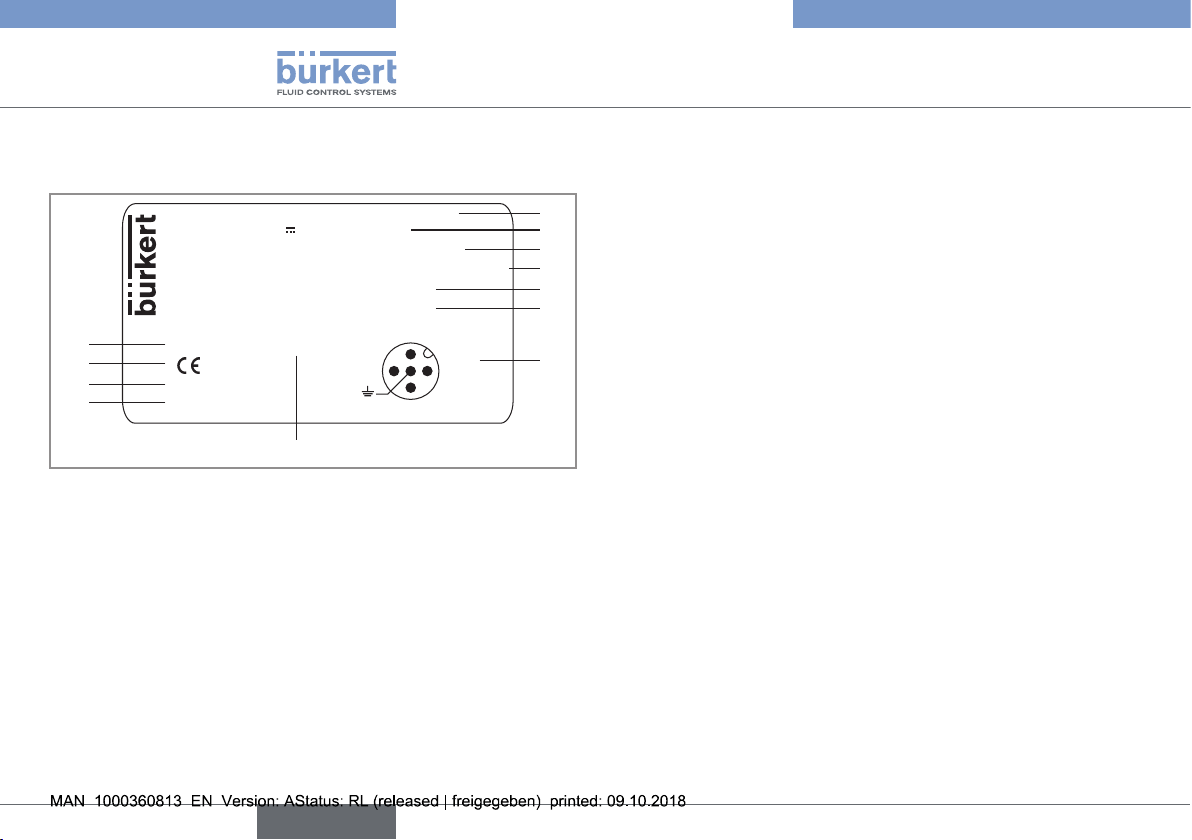

5 DESCRIPTION OF THE RATING

PLATE

8202 pH/ORP Transmitter V2

Supply: 14-36V 40W Max

Output: 1x 4-20mA 2x Trans 1A Max

Cell: pH -2/16 ORP +-2V 120mm PG13.5

Process: Temp 0/50°C limited by cell

PN 16 Bar limited by cell

Made in France

IP65 -IP67 W41MT

9

Fig. 1: Rating plate of the device Type 8202 (example)

S-N:3054

00559630

2:NPN/PNP1

3:0V

4:NPN/PNP2

1:V+

2

3

4

5

6

7

1. Type of the device, measured variable and version

2. Electrical power supply and power consumption

3. Output specifications

4. Sensor specifications

5. Temperature range of the fluid, without sensor

6. Nominal pressure of the fluid, without sensor

7. Allocation of the pins on the M12 fixed connectors

8. Construction code

9. Article number

10. Serial number

11. Conformity marking

12. Protection rating

8

English

Page 9

Type 8202/8222

Technical data

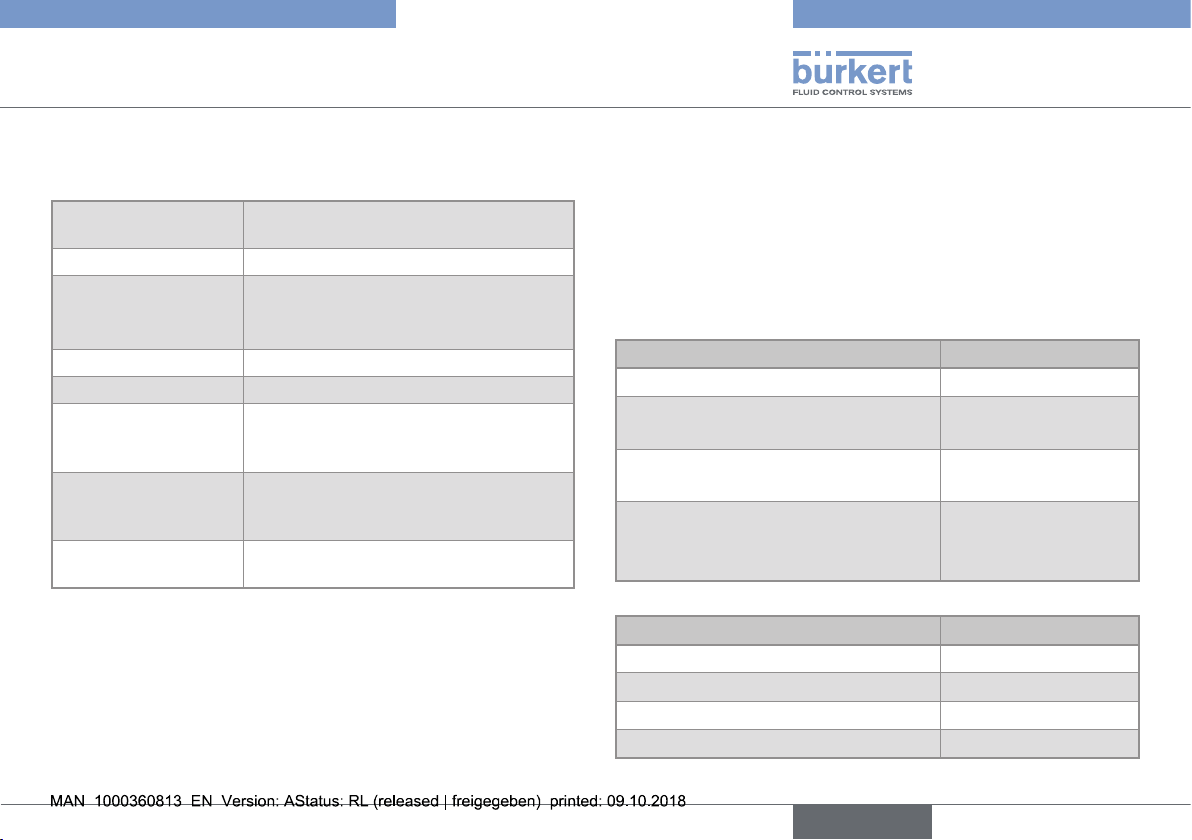

6 TECHNICAL DATA

6.1 Conditions of use

Ambient temperature

Air humidity

Protection rating

according to

EN 60529

Operating conditions

Equipment mobility

Degree of pollution

(UL and CSA recognized version)

Installation category

(UL and CSA recognized version)

Max. height above

sea level

–10...+60 °C (without pH or redox probe

for the 8202)

< 85%, non condensing

IP65 and IP67 with connectors plugged

in and tightened and electronic module

cover fully sealed

Continuous

Fixed

Degree 2 according to EN 61010 -1

Category I according to UL 61010-1 Indoor use

2000 m

6.2 Conformity to standards and directives

The applied standards, which verify conformity with the EU directives, can be found on the EU-type examination certificate and/or the

EU declaration of conformity (if applicable).

6.2.1 Conformity to the Pressure Equipment

Directive

→ Make sure the device materials are compatible with the fluid.

→ Make sure the pipe DN and the PN are adapted for the device.

The device conforms to Article 4, Paragraph 1 of the Pressure

Equipment Directive 2014/68/EU under the following conditions:

• Device used on a piping (PS = maximum admissible pressure;

DN = nominal diameter of the pipe)

Type of fluid Conditions

Fluid group 1, Article 4, Paragraph 1.c.i DN≤25

Fluid group 2, Article 4, Paragraph 1.c.i

Fluid group 1, Article 4, Paragraph 1.c.ii

Fluid group 2, Article 4, Paragraph 1.c.ii

• Device used on a vessel (PS = maximum admissible pressure)

Type of fluid Conditions

Fluid group 1, Article 4, Paragraph 1.a.i PS ≤ 200 bar

Fluid group 2, Article 4, Paragraph 1.a.i PS ≤ 1000 bar

Fluid group 1, Article 4, Paragraph 1.a.ii PS ≤ 500 bar

Fluid group 2, Article 4, Paragraph 1.a.ii PS ≤ 1000 bar

DN≤32

or PSxDN≤1000

DN≤25

or PSxDN≤2000

DN≤200

or PS≤10

or PSxDN≤5000

English

9

Page 10

Type 8202/8222

Measuring

Equipment

EXXXXXX

®

Technical data

6.2.2 UL certification

The devices with variable key PU01 or PU02 are UL certified

devices and comply also with the following standards:

• UL 61010-1

• CAN/CSA-C22.2 n°61010-1

Identification on the device Certification Variable key

UL recognized PU01

UL listed PU02

6.3 Dimensions of devices

→ Please refer to the technical data sheets related to the device at:

www.burkert.com

6.4 Mechanical data

Table 1: Materials used in the device Type 8202 (without the

probe) or the device Type 8222

Part Material

Box / seals stainless steel, PPS / EPDM

Cover / seal PC / silicone

Display module PC / PBT

M12 fixed connector nickel-plated brass (stainless

steel on request)

Fixed connector holder stainless steel 1.4404 (316L)

Screws stainless steel

Nut PVC or PVDF

Sensor holder / seal of the 8202 (*) PVDF, stainless steel 1.4571

(316Ti) / EPDM

pH or Redox probe of the 8202 refer to the related Operating

Instructions

Conductivity sensor of the 8222 (*) PVDF

Pt1000 of the 8222 (*) stainless steel 1.4571 (316Ti)

Electrodes of the 8222

• sensor C=1 • graphite

• sensor C=0.1 or C=0.01 • stainless steel 1.4571

(316Ti)

(*) in contact with the fluid

10

English

Page 11

Type 8202/8222

Technical data

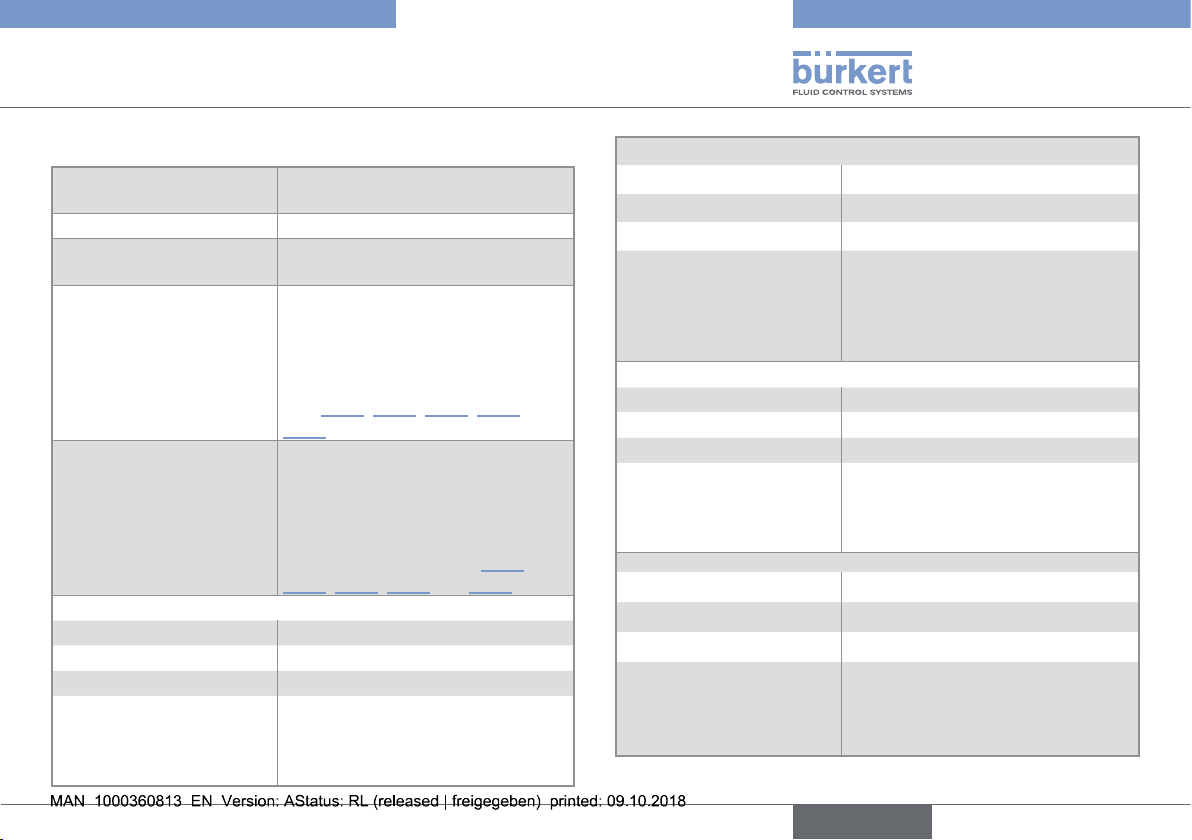

6.5 Fluid data

Pipe diameter

Type of fitting

Nut between the device

and the fitting

Max. fluid temperature

Max. fluid pressure

pH measurement (8202)

• Measurement range • 2...16 pH or –580...+580 mV

• Resolution • 0.001 pH or 0.1 mV

• Measurement deviation • ±0.02 pH or 0.5 mV

• Recommended min.

divergence of the pH

range associated to the

4...20 mA signal

DN25 to DN110 (DN15 to DN20

under specific conditions)

Adapter S022

G 1 1/2'' internal thread

The fluid temperature may be

restricted by the probe used (see

the related Operating Instructions),

by the pressure of the fluid and

the material of the S022 adapter

(see Fig. 2, Fig. 3, Fig. 4, Fig. 5 and

Fig. 6)

PN16

The fluid pressure may be restricted

by the probe used (see the related

Operating Instructions), by the temperature of the fluid and the material

of the adapter S022 (see Fig. 2,

Fig. 3, Fig. 4, Fig. 5 and Fig. 6)

• 0.5 pH unit or 30 mV (e.g.: range

6,7...7,2 pH or –20...+10 mV

associated to the 4...20 mA output

current)

Redox potential measurement (8202)

• Measurement range • –2000...+2000 mV

• Resolution • 1 mV

• Measurement deviation • ±3 mV

• Recommended min.

divergence of the redox

potential range associated to the 4...20 mA

signal

Conductivity measurement (8222)

• Measurement range • 0,05 µS/cm...10 mS/cm

• Resolution • 1 nS/cm

• Measurement deviation • ±3 % of the measured value

• Recommended min. divergence of the conductivity

range associated to the

4...20 mA signal

Temperature measurement

• Measurement range • –40...+130 °C

• Resolution • 0.1 °C

• Measurement deviation • ±1 °C

• Recommended min. divergence of the temperature

range associated to the

4...20 mA signal

• 50 mV (e.g.: range

1550...1600 mV associated to the

4...20 mA output current)

• 2 % of the full scale (e.g. for the

sensor with C=0.1: range from

100...104 µS corresponds to the

4...20 mA output current)

• 10 °C (e.g. range +10...+20 °C

corresponds to the 4...20 mA

output current)

English

11

Page 12

Type 8202/8222

Technical data

Temperature probe

Temperature compensation (8202)

Temperature compensation (8222)

• Pt1000 integrated in the sensor

holder (8202)

• Pt1000 integrated in the conductivity sensor (8222)

Automatic (integrated Pt1000),

Reference temperature = 25°C

• none or

• according to a predefined graph

(NaCl or ultra pure water) or

• according to a graph defined

especially for your process

A

PVDF

+140

T ( ° C)

P (bar)

16

15

14

13

12

11

10

B

PVDF

PVC

9

8

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +120

A: application range of a 8202 with a PVDF nut

B: application range of a 8202 with a PVC nut

The measures have been made at an ambient temperature of 60 °C

Fig. 2: Fluid temperature / fluid pressure dependency of the 8202

(without the probe) with a PVC or PVDF nut

P (psi)

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

12

English

Page 13

Type 8202/8222

Technical data

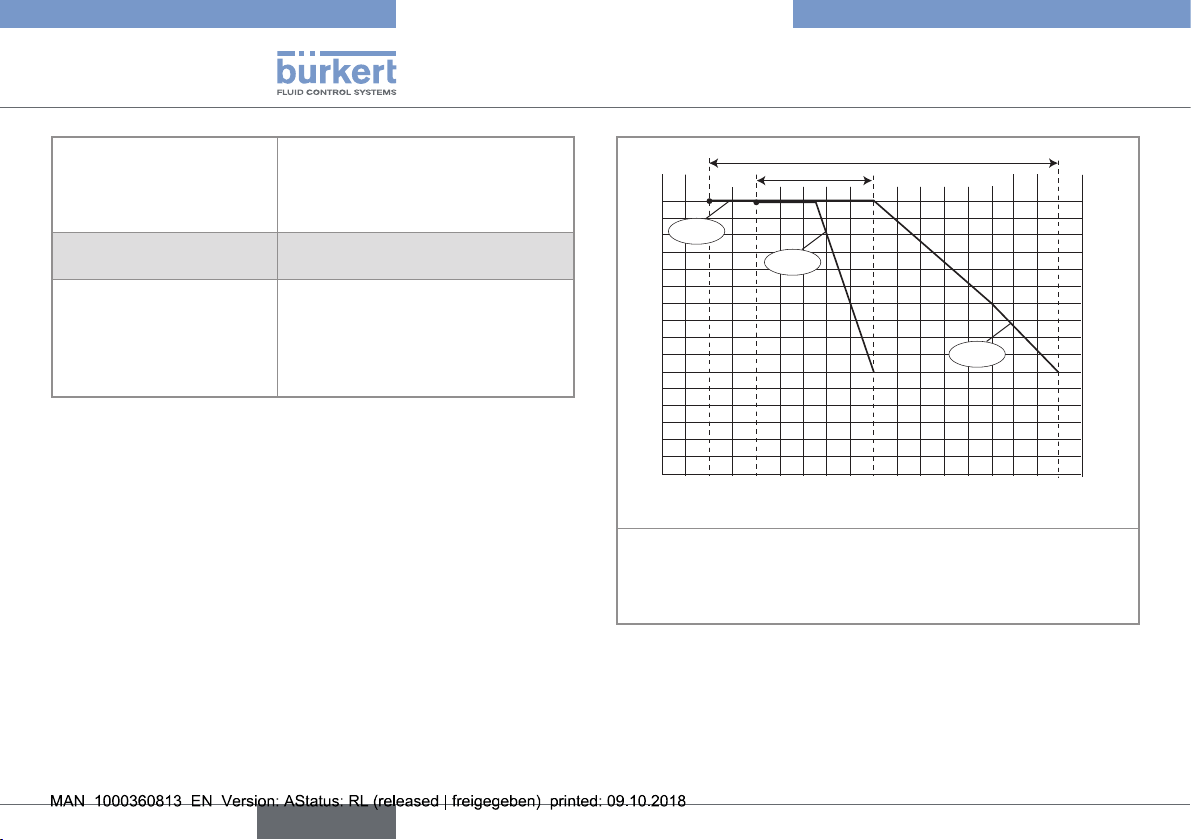

A

P (bar)

16

15

14

13

12

11

10

PVDF

9

8

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +120

B

PVC

PVDF

A: application range of a 8222 with a PVDF nut

B: application range of a 8222 with a PVC nut

The measures have been made at an ambient temperature of 60 °C

Fig. 3: Fluid temperature / fluid pressure dependency of the 8222 with a

PVC or PVDF nut

P (psi)

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

T ( ° C)

16

P (bar)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

-20

PVC + PP

Metal

0 +20 +40 +60

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

T (°C)

P (psi)

Fig. 4: Fluid temperature / fluid pressure dependency of the 8202

(without the probe) or the 8222, with a PVC nut and a metal, PVC

or PP S022 adapter

P (bar)

16

15

14

13

12

11

10

9

8

PVC + PP

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +140

PVC

PP

Metal

+120

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

P (psi)

T (°C)

Fig. 5: Fluid temperature / fluid pressure dependency of the 8202

(without the probe) with a PVDF nut and a metal, PVC or PP S022

adapter

English

13

Page 14

Type 8202/8222

Technical data

P (bar)

16

15

14

13

12

11

10

9

8

PVC + PP

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +140

PVC

PP

Metal

+120

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

P (psi)

T (°C)

Fig. 6: Fluid temperature / fluid pressure dependency of the 8222, with a

PVDF nut and a metal, PVC or PP S022 adapter

6.6 Electrical data

Power supply

• Version with 3 outputs • 14...36 V DC, filtered and regulated

• Version with 4 outputs • 12...36 V DC, filtered and regulated

Characteristics of the

power source (not supplied) of the UL versions

Current consumption

• Version with 3 outputs • 25 mA max. (at 14 V DC)

• Version with 4 outputs • 5 mA max. (at 12 V DC)

Current consumption,

with loads on the

transistors

Power consumption

Protection against polarity

reversal

Protection against voltage

spikes

Protection against short

circuits

• limited power source according to

§9.4 of EN 61010-1 standard

• or class 2 source according to

UL 1310/1585 and EN 60950-1

standards

1 A max.

40 W max.

yes

yes

yes, transistor outputs

14

English

Page 15

Type 8202/8222

Technical data

Transistor output

Current output

• Response time (10 %

- 90 %)

• Version with 1 current

output

• Version with 2 current

outputs

NPN (/sink) or PNP (/source)

(depending on software setting),

open collector, 700 mA max., 0.5 A

max. per transistor if both transistor

outputs are wired.

NPN output: 0.2...36 V DC

PNP output: supply voltage

4...20 mA, sink ("NPN sink") or

source ("PNP source") (depending

on software setting)

• 150 ms (default value)

• max. loop impedance: 1100W

at 36 V DC, 610W at 24 V DC,

180W at 14 V DC

• max. loop impedance: 1100W

at 36 V DC, 610W at 24 V DC,

100W at 12 V DC

6.7 Data of connectors and cables

Number of fixed

connectors

1 male M12 fixed

connector

1 male M12 fixed

connector and 1

female M12 fixed

connector

Type of connector

5-pin female M12 connector (not supplied).

For the M12 connector with article number

917116, use a shielded cable:

• diameter: 3...6.5 mm

• wire cross section: max. 0.75 mm

5-pin female M12 connector (not sup-

plied) and 5-pin male M12 connector (not

supplied).

For the M12 connector with article number

917116, use a shielded cable:

• diameter: 3...6.5 mm

• wire cross section: max. 0.75 mm

2

2

English

15

Page 16

Type 8202/8222

Assembly

6.8 pH/Redox probe of the 8202

The pH or redox probe must satisfies the following specifications:

• combined probe;

• length: 120 mm;

• with PG 13.5 head;

• with an S7/S8 fixed connector;

• without temperature probe.

The specifications of the probe can be found in the Operating Instructions of the probe used.

6.9 Sensor specifications of the 8222

Conductivity sensor C=0.01

• Measurement range • 0.05...20 µS/cm

• Type of fluid • ultra-pure water, pure water

Conductivity sensor C=0.1

• Measurement range • 0.5...200 µS/cm

• Type of fluid • pure water, industrial wastewater

Conductivity sensor C=1

• Measurement range • 5 µS/cm...10 mS/cm

• Type of fluid • industrial wastewater, wastewater

7 ASSEMBLY

7.1 Safety instructions

Warning

Risk of injury due to non-conforming assembly.

▶ The device must only be assembled by qualified and skilled staff

with the appropriate tools.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶ Avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subse-

quent to any intervention on the device.

7.2 Install the display module

nOTiCe

The tightness of the device is not guaranteed when the cover

is removed.

▶ Prevent the projection of liquid inside the housing.

The device may be damaged if a metal component comes

into contact with the electronics.

▶ Prevent contact of the electronics with a metallic item.

16

English

Page 17

Type 8202/8222

1

Assembly

a)

b)

20°

→ Remove the cover.

→ Set the display module

at an angle of ca. 20° in

relation to the desired

position.

The module can be fitted in

4 different positions, at 90°

intervals.

c)

d)

→ Fully push in the module

and turn clockwise to

lock it.

→ Check that there is a

seal on the housing and

2

that it is not damaged.

Replace it if necessary.

→ Grease the seal if nec-

essary, using a component compatible with

the seal material.

→ [1] Set the cover to

ensure that the 4

grooves of the cover

match with the 4 pins of

the housing.

→ [2] Turn the cover

clockwise with an angle

of about 15° to lock it.

Fig. 7: Mounting the display module

7.3 Install the pH or redox probe in the sensor holder of the 8202 (without fluid)

Following instructions are valid for a Bürkert probe.

If you use a probe from another supplier, respect the related

Operating Instructions.

English

17

Page 18

Type 8202/8222

Assembly

probe head

H

compression washer

→ Remove the protective

plugs.

→ Check that dimension H on

seal

A

the probe is between

34 and 46mm. If necessary,

adjust the height of the

compression washer.

→ At first use, apply water

or soapy water on the "A"

seal.

→ Insert the seal into the

groove on the holder.

→ Insert the probe with its

seal into the holder from

above.

7.4 Mounting the electronic module to the sensor holder of the 8202 (without fluid)

→ Check that the pH or redox probe is mounted into the sensor

holder.

→ Check that seal "A" on the

holder is in good condition.

Replace it if necessary.

→ Clean connectors "B" and

"C" for connection of the pH/

redox probe with alcohol to

avoid measurement errors.

→ Insert the electronic module

into the holder, making sure

the polarising slots are correctly positioned.

→ Apply slight vertical pressure

C

to engage the seal.

→ Tighten the probe head

using a suitable wrench.

A

B

Fig. 8: Mounting the probe into the holder of the 8202 (without fluid)

18

English

Page 19

Type 8202/8222

Installation

→ Fasten the electronic module

and the holder together by

tightening the G2'' nut.

→ Tighten the G2'' nut by hand

only, until it stops turning,

to ensure good electrical

contact.

Fig. 9: Mounting the electronic module to the holder, without fluid (8202)

→ Mounting the display module.

→ Calibrate the device.

8 INSTALLATION

8.1 Safety instructions

Warning

Risk of injury due to non-conforming installation.

▶ The electrical and fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

▶ Install appropriate safety devices (correctly rated fuse and/or

circuit-breaker).

▶ Respect the assembly instructions for the fitting used.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶ Avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subse-

quent to any intervention on the device.

8.2 Installation of the 8202 onto the pipe

Danger

Risk of injury due to high pressure in the installation.

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and

safety relating to the use of dangerous fluids.

English

19

Page 20

Type 8202/8222

Installation

If a pH/redox probe (with PG 13.5 head, 120 mm long

and without temperature probe) from a supplier other than

Bürkert is used, follow the relevant instructions on installation in the pipe.

Flow direction

Fig. 10: Mounting positions of the 8202 in the pipe

→ Choose an appropriate position in the pipe to install the fitting.

→ Fit the pipe with a fitting with G 1” ½ external threaded sensor

connection with respect to the instructions delivered with the

fitting.

75°

75°

Fig. 11: Angle to the vertical (8202)

→ Fit the fitting at an angle of ±75° max. to the vertical in order to

ensure the good operation of the pH/redox probe.

The pH or redox probe must always be immersed in the fluid

to prevent it drying out.

→ Once the device has been calibrated, remove the electronic

module from the sensor holder as shown Fig. 12.

→ Unscrew the nut between the electronic

module and the sensor holder.

20

English

Page 21

Type 8202/8222

Installation

→ Remove the electronic module by pulling it

straight out. There may be a resistance due

to the seal.

Fig. 12: Remove the electronic module from the sensor holder (8202)

→ Install the holder with its probe on the fitting as shown Fig. 13.

→ Check the presence and the condition of

seal B on the fitting. Replace the seal if

necessary.

→ Insert the holder with its probe carefully

into the fitting.

B

→ Tighten the nut on the fitting by hand.

→ Charge the pipe to check the tightness of

the assembly.

Fig. 13: Installing the sensor holder with its probe on a fitting (8202)

→ If the sensor holder is tight, insert the electronic module back

onto the sensor holder as shown Fig. 14.

English

21

Page 22

Type 8202/8222

Installation

electrical contacts

polarising slots

A

→ Check that the electrical

contacts are in good

condition and clean them

with a brush if necessary.

→ Check that seal "A" on

the holder is in good

condition. Replace it if

necessary.

→ Insert the electronic

module into the holder,

making sure the

polarising slots are

correctly positioned.

→ Apply slight vertical

pressure to engage the

seal.

→ Fasten the electronic

module and the holder

together by tightening

the G2'' nut.

→ Tighten the G2'' nut, until

it stops turning, to ensure

good electrical contact

with the temperature

probe.

Fig. 14: Mounting the electronic module to the sensor holder, after instal-

lation of the holder on a fitting (8202)

8.3 Installation of the 8222 onto the pipe

Danger

Risk of injury due to high pressure in the installation.

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and

safety relating to the use of dangerous fluids.

22

English

Page 23

Type 8202/8222

Installation

→ Select an appropriate position on the pipe (prefer “A” mounting

to install a 8222 with sensor C=0.1 or C=0.01).

A

B

Flow direction

Fig. 15: Mounting positions of the 8222 in the pipe

→ Mount the display module to calibrate and configure the device.

→ Calibrate the device.

→ Mount the device into the fitting, as shown Fig. 16.

→ Check that seal

"A" is set on the

cover and that it

is not damaged.

Replace the seal

if necessary.

→ Carefully insert

the device into

the fitting.

A

→ Position the

device in such

a way that the

markings located

on either side of

the electronics

box are parallel to

the pipe.

→ Tighten the nut

on the fitting.

Fig. 16: Installation of the device Type 8222 in a fitting

English

23

Page 24

Type 8202/8222

Installation

8.4 Wiring

Danger

Risk of injury due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ If a 12...36 V DC or a 14...36 V DC powered version is installed

either in a wet environment or outdoors, all the electrical voltages must be of max. 35 V DC.

▶ All equipment connected to the device must be double insu-

lated with respect to the mains according to the standard

IEC 61010-1:2010.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

• Use a high-quality electrical power supply (filtered

and regulated).

• Make sure the installation is equipotential (see

chap. 8.4.1).

8.4.1 Making the installation equipotential

To ensure the equipotentiality of the installation (power supply device - medium):

→ Connect together the various earth spots in the installation to

eliminate the potential differences that may occur between different earthes.

→ Observe faultless grounding of the shield of the power supply

cable.

→ Special attention has to be paid if the device is installed on

plastic pipes because there is no direct earthing possible.

Proper earthing is performed by earthing together the metallic

devices such as pumps or valves, that are as close as possible

to the device.

Power supply

+

12-36 V DC

Fig. 17: Equipotentiality skeleton diagram with pipes in metal

24

English

Page 25

Power supply

12-36 V DC

Pipes in plastic

Type 8202/8222

Installation

8.4.2 Wiring a version with a single M12

fixed connector

Transistor output 1

+

Devices such

as valves,

pumps,...

0V

2

V+ (14...36 V DC)

3

1

4

Transistor output 2

Fig. 19: Pin assignment of the fixed connector on a version with a single

M12 fixed connector

Fig. 18: Equipotentiality skeleton diagram with pipes in plastic

Pin of the M12 female cable available as

an accessory (article number 438680)

1 brown

2 white

3 blue

4 black

5 grey

English

Colour of the wire

25

Page 26

Type 8202/8222

Installation

+ -

+ -

4...20 mA input

at external

device

Load 1

Load 2

black

white

2

3

1

4

blue

Power supply

brown

grey

14-36 V DC

Fig. 20: NPN wiring of both transistor outputs and wiring the current output in

sinking mode (software setting "NPN/sink")

Load 1

white

black

Load 2

2

3

1

4

Power supply

blue

brown

grey

+ -

+ -

4...20 mA input

at external

device

14-36 V DC

Fig. 21: PNP wiring of both transistor outputs and wiring the current output in

sourcing mode (software setting "PNP/source")

8.4.3 Wiring a version with 2 M12 fixed

connectors

Male fixed connector Female fixed connector

Transistor output 1

2

0V

3

1

V+

(12...36 V DC)

(12...36 V DC)

4

Current output 1

Fig. 22: Pin assignment of the male and female M12 fixed connectors

V+

Transistor output 2

2

1

3

4

Current output 2

Connect the power supply for the device to the male

fixed connector; the supply is then transferred internally

to pins 1 and 3 of the female fixed connector in order to

ease wiring of the load to the female fixed connector.

0V

26

English

Page 27

Type 8202/8222

Installation

Pin of the M12 female cable available as

an accessory (article number 438680)

1 brown

2 white

3 blue

4 black

5 grey

Pin of the M12 male cable available as

an accessory (article number 559177)

1 brown

2 white

3 blue

4 black

5 grey

Colour of the wire

Colour of the wire

Load 1

white

2

blue

3

black

brown

1

4

grey

+ - + -

brown

1

+ -

4

Load 2

white

2

3

black

12-36 V DC

st

1

4...20 mA input

at external device

Power supply

Fig. 23: NPN wiring of both transistor outputs and wiring of both current

outputs in sinking mode, on a version with 2 fixed connectors

(software setting “NPN/sink”)

nd

2

4...20 mA input at

external device

English

27

Page 28

Type 8202/8222

Adjustment and commissioning

Load 1

white

2

blue

black

+ - + -

brown

3

1

4

grey

+ -

white

1

4

2

black

Load 2

blue

3

12-36 V DC

st

1

4...20 mA input at

external device

Fig. 24: PNP wiring of both transistor outputs and wiring of both current

outputs in sourcing mode, on a version with 2 fixed connectors

(software setting “PNP/source”)

Power supply 2nd 4...20 mA input

at external device

9 ADJUSTMENT AND

COMMISSIONING

• The settings can only be done on a device with a display

module.

• Do not remove the display module while making the settings on the device.

9.1 Safety instructions

Warning

Risk of injury due to nonconforming adjustment.

Nonconforming adjustment could lead to injuries and damage the

device and its surroundings.

▶ The operators in charge of adjustment must have read and

understood the contents of this quickstart.

▶ In particular, observe the safety recommendations and intended

use.

▶ The device/installation must only be adjusted by suitably trained

staff.

28

English

Page 29

Type 8202/8222

Adjustment and commissioning

Warning

Danger due to nonconforming commissioning.

Nonconforming commissioning could lead to injuries and damage

the device and its surroundings.

▶ Before commissioning, carry out the settings described in

chap. 9.7 to 9.11.

▶ Before commissioning, make sure that the staff in charge have

read and fully understood the contents of this quickstart.

▶ In particular, observe the safety recommendations and intended

use.

▶ The device/installation must only be commissioned by suitably

trained staff.

Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors,

the effects of the climatic conditions.

9.2 Using the navigation button

Symbolised by

Symbolised by in

this quickstart

Symbolised by in

this quickstart

Fig. 25: Using the navigation button

this quickstart

by

Symbolised by

in this quickstart

in

Symbolised

in this

quickstart

English

29

Page 30

Type 8202/8222

Adjustment and commissioning

You want to... Press...

...browse in Process level

• next screen:

• previous screen:

• ...access the Settings

level

• ...display the Param menu

...browse in the menus of

the Settings level

...access the menu

displayed

...browse in the menu

functions

...select the highlighted

function

for at least 2 sec., from any

screen of the Process level

• next menu:

• previous menu:

• next function:

• previous function:

You want to... Press...

...browse in the dynamic

functions bar (MEAS,

BACK, ABORT, OK, YES,

NO)

...confirm the highlighted

dynamic function

...modify a numerical value

- increment the figure

selected

- decrement the figure

selected

- select the previous

figure

- select the next figure

- allocate the "+" or "-"

sign to the numerical

value

- move the decimal

point

• next function:

• previous function:

-

-

-

-

-

numerical value then

the desired sign is displayed

-

the numerical value then

until the decimal point is in the

desired place

to the extreme left of the

until

to the extreme right of

30

English

Page 31

Type 8202/8222

Adjustment and commissioning

9.3 Using the dynamic functions

You want to... Choose...

...go back to the Process level,

without validating the modifications made

...validate the input dynamic function "OK"

...go back to the parent menu dynamic function "BACK"

... abort the current operation

and go back to the parent menu

...answer the question asked dynamic function "YES" or "NO"

dynamic function "MEAS"

dynamic function "ABORT"

9.4 Knowing the display

9.4.1 Knowing the icons and LEDs

Red LED:

shows an error

Yellow LED:

shows that transistor 1 is

ERR

switched

N

E

P

O

mV_pH

TempC

L

O

C

K

1423 mV

23.8 °C

Yellow LED:

shows that transistor 2 is switched

not used

English

31

Page 32

Type 8202/8222

T

Adjustment and commissioning

Yellow LED: shows that

transistor 1 is switched

Yellow LED:

shows that transistor 2 is

switched

Fig. 26: Position of the icons and description of the LEDs

Green LED: shows that

the device is energized

Red LED:

shows an error

The LEDs of the display module are duplicated on the electronic board that is located under the display module: these

LEDs can only be seen if the device has no display module.

Icon Meaning and alternatives

8202: pH or redox probe in good condition and fluid

temperature within the set range.

8222: Sensor in good condition, fluid conductivity and

fluid temperature within the set ranges.

If the monitoring of the impedance on the electrodes

(8202) or the monitoring of the fluid conductivity (8222)

or the monitoring of the polarizing slope (8222) or the

monitoring of the fluid temperature has been activated,

the alternative icons in this position are:

, associated with

•

• , associated with

ERR

The device is measuring.

The alternative icons in this position are:

!

HOLD

flashing: HOLD mode activated

•

•

: running check that the outputs are working and

behaving correctly

"maintenance" message

"warning" message

ERR

"error" message

32

English

Page 33

Type 8202/8222

Adjustment and commissioning

9.4.2 Knowing the display at the power-up of

the device

When the device is switched on or the display module mounted on

the electronic module, the display indicates the software version of

the display.

9.5 Knowing the operating levels

The device has 2 operating levels:

Process level

This level is used:

• to read the measured values of 2 process values selected in the

Parameters menu,

• to read both the lowest and highest values of the chosen process

value, that have been measured by the device since the latest

reset (this feature is not active by default),

• to reset both the lowest and highest values of the chosen process

value, if the feature has been activated,

• to read the current values emitted on the 4...20 mA outputs.

• to get the state of the device and of the conductivity sensor with

the icons.

Configuration level

This level comprises 5 menus:

Menu title Related icon

"Param"

default code (0000)

This is

when the

device is being parame-

tered............

....................

"Calib"

default code (0000)

"Diagnostic"

default code (0000)

"Test"

default code (0000)

"Info"

default code (0000)

English

33

Page 34

Type 8202/8222

Adjustment and commissioning

9.6 Knowing the Process level

A

First view of the Process

level.

Zoom on the value in the

first line.

Zoom on the value in the

second line.

Display of the highest and

lowest values of the process

value chosen

mV_pH

TempC

mV_pH

1423

TempC

Max

Min

B

1423 mV

55 °C

55

1450mV

1200mV

1)

1)

mV

1)

°C

2)

Reset: Yes/No

B

Display of the current

outputs.

Zoom on the value of the

first current output.

AC1

AC2

AC1

18.3 mA

7.5 mA

18.3 mA

Zoom on the value of the

second current output.

AC2

7.5 mA

A

1)

To choose the process values to be displayed, refer to the complete Operating Instructions available on the internet at:

www.burkert.com.

2)

The display of the lowest and highest values in the Process level

is deactivated by default. To activate the feature and choose the

process values refer to the complete Operating Instructions.

34

English

Page 35

Type 8202/8222

Adjustment and commissioning

9.7 Choosing the output wiring mode

The setting has no effect on a version with one fixed connector, if the sole current output is wired.

Param

This is

when the

device is being parame-

tered............

....................

Outputs

This is

when the

device is being parame-

tered............

....................

HWMode

source/PNP

sink/NPN

9.8 Setting the probe parameters of the 8202

The monitoring of the redox (ORP) sensor is impossible if

the measurement mode is set to “asymmetrical”.

Param

This is

when the

device is being parame-

tered............

....................

Sensor Type: pH

This is

when the

device is being parame-

tered............

....................

Mode:

ORP

Symmetric

Asymmetric

Mains Fcy:

50Hz

60Hz

9.9 Activating/deactivating the Hold function

If the mode “Hold” is activated and if there is a power interruption, then, when the device restarts, the mode “Hold” is

automatically deactivated.

Calib System Hold

Hold:Disable

Hold:Enable

9.10 Calibrate the pH or redox probe (8202)

Danger

Risk of injury due to electrical voltage

▶ Observe all applicable accident protection and safety guidelines

for electrical equipment.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and

safety relating to the use of dangerous fluids.

English

35

Page 36

Type 8202/8222

Adjustment and commissioning

Choose the type of probe the device type 8202 is fitted with before calibrating the sensor.

• In order not to interrupt the process, activate the HOLD function (see chap. 9.9).

• Before each calibration, correctly clean the electrode with a suitable product.

• In a 2-point calibration, the buffer solutions used must be at the same temperature.

• Set the periodicity of calibrations in the “Interval” function in the sub-menu CALIB INTERVAL: each time a calibration is due, the device

generates a “maintenance” event and a “warning” event.

36

Calib

Sensor

English

Probe

CalibTemperat.

Calibration

Probe constant

Calib. interval

NO

Auto

Constant

1st point

2nd point?

YES

Rinse

2nd point

Cal. Result

Offset:

Span:

Last cal. date

Interval

if pH probe

INPUT

INPUT

VALUE

INPUT

Page 37

Type 8202/8222

Adjustment and commissioning

9.11 Calibrating the sensor of the 8222

Danger

Risk of injury due to electrical voltage.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and safety relating to the use of dangerous fluids.

• In order not to interrupt the process, activate the HOLD function (see chap. 9.9).

• Before each calibration, correctly clean the electrodes with a suitable product.

• Set the periodicity of calibrations in the “Interval” function in the sub-menu “Calib interval”: each time a calibration is due, the device

generates a “maintenance” event and a “warning” message.

Calib Sensor Probe

Calibration INPUT

Cell constant

Cell cst. TDS

Calib interval

Teach special

INPUT

INPUT

Last cal. date

Interval

Start temp

INPUT

Stop temp

INPUT

Processing

RESULT

READ

INPUT

English

37

Page 38

Type 8202/8222

Packaging, Transport

10 PACKAGING, TRANSPORT

nOTiCe

Damage due to transport

Transport may damage an insufficiently protected device.

▶ Transport the device in shock-resistant packaging and away

from humidity and dirt.

▶ Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

▶ Protect the electrical interfaces using protective plugs.

11 STORAGE

nOTiCe

Poor storage can damage the device.

▶ Store the device in a dry place away from dust.

▶ Storage temperature of the device Type 8202 without probe:

–10...+60 °C.

▶ Storage temperature of the device Type 8202 with probe: refer

to the Operating Instructions delivered with the probe used.

▶ Storage temperature of the device Type 8222: –10...+60 °C.

12 DISPOSAL OF THE DEVICE

→ Dispose of the device and its packaging in an environmentally-

friendly way.

nOTiCe

Damage to the environment caused by parts contaminated by

fluids.

▶ Comply with the national and/or local regulations which concern

the area of waste disposal.

38

English

Page 39

www.burkert.com

Loading...

Loading...