Page 1

Type 8025

UNIVERSAL

Flow transmitter

Operating Instructions

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2012 - 2013

Operating Instructions 1311/2_EU-ML 00555851 ORIGINAL_FR

Page 3

Type 8025 UNIVERSAL

Type 8025 UNIVERSAL

1 ABOUT THIS MANUAL .....................................................................................................................................................................4

1.1 Symbols used ..........................................................................................................................................................................4

1.2 Definition of the word "device" .......................................................................................................................................4

2 INTENDED USE ....................................................................................................................................................................................5

3 BASIC SAFETY INFORMATION ....................................................................................................................................................6

4 GENERAL INFORMATION ................................................................................................................................................................7

4.1 Manufacturer's address and international contacts ............................................................................................7

4.2 Warranty conditions ..............................................................................................................................................................7

4.3 Information on the Internet ...............................................................................................................................................7

5 DESCRIPTION .......................................................................................................................................................................................8

5.1 Area of application ................................................................................................................................................................8

5.2 General description ..............................................................................................................................................................8

5.3 Available versions ..................................................................................................................................................................8

5.4 Description of the name plate ........................................................................................................................................9

6 TECHNICAL DATA .............................................................................................................................................................................10

6.1 Conditions of use ................................................................................................................................................................10

6.2 Conformity to standards and directives .................................................................................................................10

6.3 General technical data .....................................................................................................................................................10

6.3.1 Mechanical data ..................................................................................................................................10

6.3.2 Electrical data ......................................................................................................................................11

6.3.3 Specifications of the connected flow sensor...............................................................................13

6.3.4 Electrical connection .........................................................................................................................13

7 INSTALLATION AND WIRING ......................................................................................................................................................14

7.1 Safety instructions .............................................................................................................................................................14

7.2 Installation of a panel version ......................................................................................................................................14

7.3 Installation of a wall-mounted version ....................................................................................................................16

7.4 Wiring .........................................................................................................................................................................................17

7.4.1 Equipotentiality of the installation ...................................................................................................17

7.4.2 Terminal assignment and use of the selectors ............................................................................19

7.4.3 Wiring a panel version .......................................................................................................................21

English

1

Page 4

Type 8025 UNIVERSAL

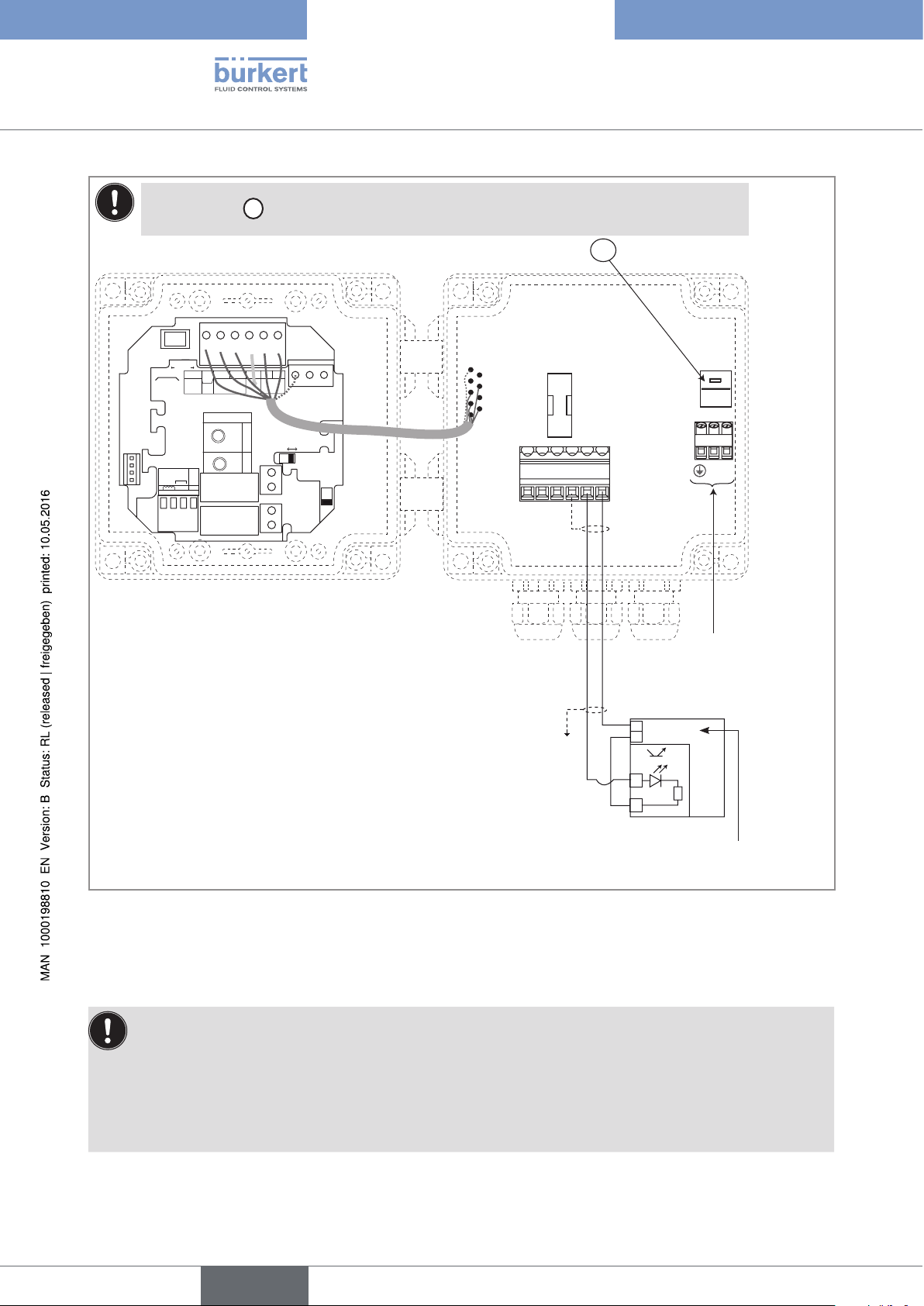

7.4.4 Wiring a wall-mounted version ........................................................................................................21

7.4.5 Wiring the AO1 current output of a panel version or a wall-mounted version,

12-36 V DC ......................................................................................................................................... 23

7.4.6 Wiring the DO1 transistor output of a panel version or a wall-mounted version,

12-36 V DC ......................................................................................................................................... 24

7.4.7 Wiring the AO1 current output of a wall-mounted version, 115/230 V AC ........................24

7.4.8 Wiring the DO1 transistor output of a wall-mounted version, 115/230 V AC ....................26

7.4.9 Wiring the relay outputs DO2 and DO3 of the panel or a wall-mounted version ...............28

7.4.10 Connecting the flow sensor to the transmitter ............................................................................29

8 OPERATING AND COMMISSIONING .....................................................................................................................................33

8.1 Safety instructions .............................................................................................................................................................33

8.2 Operating levels of the device .....................................................................................................................................33

8.3 Description of the navigation keys and the status LEDs ..............................................................................35

8.4 Using the navigation keys ..............................................................................................................................................36

8.5 Details of the Process level ..........................................................................................................................................37

8.6 Details of the Parameters menu .................................................................................................................................37

8.6.1 Choosing the display language .......................................................................................................38

8.6.2 Choosing the flow rate units, the number of decimals and the units of the totalizers ........39

8.6.3 Entering the K factor of the fitting used ........................................................................................41

8.6.4 Determining the fitting K factor using a Teach-In procedure ...................................................41

8.6.5 Configuring the outputs (general diagram) ..................................................................................44

8.6.6 Associating a flow rate range to the current output AO1 .........................................................44

8.6.7 Activating / Deactivating the emission of a 22 mA current on the current output ..............45

8.6.8 Configuring the transistor output DO1 as a pulse output proportional to a volume ..........46

8.6.9 Configuring the transistor output DO1 to transmit the rotational frequency of

the paddle wheel ................................................................................................................................46

8.6.10 Configuring the transistor output DO1 to switch a load depending on two

threshold values ..................................................................................................................................47

8.6.11 Configuring the transistor output DO1 to switch a load when a warning mes-

sage is generated by the device .....................................................................................................49

8.6.12 Configuring the relay outputs DO2 and DO3 to switch a load depending on

two thresholds .....................................................................................................................................50

8.6.13 Configuring the relay outputs DO2 and DO3 to switch a load when a warning

message is generated by the device .............................................................................................51

8.6.14 Configuring the filter of the measured flow rate .......................................................................... 51

8.6.15 Resetting both totalizers ...................................................................................................................52

8.6.16 Parameterizing the cut-off flow rate ...............................................................................................53

2

English

Page 5

Type 8025 UNIVERSAL

8.6.17 Setting the brightness of the display and how long it stays ON, or deactivating

the backlight ........................................................................................................................................53

8.7 Details of the Test menu .................................................................................................................................................54

8.7.1 Adjusting the current output ............................................................................................................55

8.7.2 Reading the rotational frequency of the paddle wheel ..............................................................56

8.7.3 Checking the outputs behaviour .....................................................................................................56

8.7.4 Monitoring the flow rate in the pipe ...............................................................................................56

8.7.5 Monitoring the value of the daily totalizer ......................................................................................58

8.8 Details of the Information menu .................................................................................................................................58

9 MAINTENANCE AND TROUBLESHOOTING .......................................................................................................................59

9.1 Safety instructions .............................................................................................................................................................59

9.2 Cleaning the device ...........................................................................................................................................................59

9.3 If you encounter problems ............................................................................................................................................59

9.3.1 Resolution of problems when the device status LED is OFF ..................................................59

9.3.2 Resolution of problems without message generation and device status LED red ............. 60

9.3.3 Resolution of problems without message generation and with device status

LED orange ..........................................................................................................................................61

9.3.4 Resolution of problems without message generation but device status LED ON ..............62

9.3.5 Resolution of problems without message generation and with device status LED green 63

9.3.6 Resolution of problems linked to warning messages not registered in the Infor-

mation menu ........................................................................................................................................64

10 SPARE PARTS AND ACCESSORIES ......................................................................................................................................65

11 PACKAGING, TRANSPORT ..........................................................................................................................................................65

12 STORAGE ..............................................................................................................................................................................................65

13 DISPOSAL OF THE PRODUCT ..................................................................................................................................................65

English

3

Page 6

Type 8025 UNIVERSAL

About this manual

1 ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep this manual in a safe place, accessible to all

users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous situations.

▶ This manual must be read and understood.

1.1 Symbols used

danger

Warns against an imminent danger.

▶ Failure to observe this warning can result in death or in serious injury.

Warning

Warns against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or even death.

attention

Warns against a possible risk.

▶ Failure to observe this warning can result in substantial or minor injuries.

note

Warns against material damage.

▶ Failure to observe this warning may result in damage to the device or system.

Indicates additional information, advice or important recommendations.

Refers to information contained in this manual or in other documents.

→ Indicates a procedure to be carried out.

1.2 Definition of the word "device"

The word "device" used within this manual refers to the transmitter type 8025 Universal with serial numbers higher

or equal to 20 000.

4

English

Page 7

Type 8025 UNIVERSAL

Intended use

2 INTENDED USE

Use of the device that does not comply with the instructions could present risks to people, nearby

installations and the environment.

▶ The transmitter 8025 Universal has been designed to process a frequency signal, received from a flow sensor

connected to the transmitter.

▶ This device must be protected against electromagnetic interference, ultraviolet rays and, when installed out-

doors, the effects of climatic conditions.

▶ This device must be used in compliance with the characteristics and commissioning and use conditions

specified in the contractual documents and in the operating instructions.

▶ Requirements for the safe and proper operation of the device are proper transport, storage and installation, as

well as careful operation and maintenance.

▶ Only use the device as intended.

→ Observe any existing restraints when the device is exported.

English

5

Page 8

Type 8025 UNIVERSAL

Basic safety information

3 BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during installation, use and maintenance of the devices.

• the local safety regulations for which the operating company is responsible including the staff in charge of

installation and maintenance.

Danger due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Various dangerous situations

To avoid injury take care:

▶ not to use the device in explosive atmospheres.

▶ not to use the device in an environment incompatible with the materials it is made of.

▶ not to subject the device to mechanical loads (e.g. by placing objects on top of it or by using it as a step).

▶ not to make any external or internal modifications to the device.

▶ to prevent any unintentional power supply switch-on.

▶ to ensure that installation and maintenance work are carried out by qualified, authorised personnel in posses-

sion of the appropriate tools.

▶ to guarantee a defined or controlled restarting of the process, after a power supply interruption.

▶ to use the device only if in perfect working order and in compliance with the instructions provided in the oper-

ating instructions.

▶ to observe the general technical rules when installing and using the device.

note

Elements / Components sensitive to electrostatic discharges

▶ This device contains electronic components sensitive to electrostatic discharges. They may be damaged if

they are touched by an electrostatically charged person or object. In the worst case scenario, these components are instantly destroyed or go out of order as soon as they are activated.

▶ To minimise or even avoid all damage due to an electrostatic discharge, take all the precautions described in

the EN 61340-5-1 and 5-2 norms.

▶ Also ensure that you do not touch any of the live electrical components.

6

English

Page 9

Type 8025 UNIVERSAL

General information

4 GENERAL INFORMATION

4.1 Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the internet at: www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of the device in observance of the operating

conditions specified in this manual.

4.3 Information on the Internet

You can find the user manuals and technical data sheets regarding the type 8025 at: www.burkert.com

English

7

Page 10

Type 8025 UNIVERSAL

Description

5 DESCRIPTION

5.1 Area of application

The transmitter 8025 Universal can be connected to a remote flow sensor which emits a frequency signal. The

specifications of the flow sensor which can be connected to the transmitter are described in chapter “6 Technical

data”.

When connected to a flow sensor, the device makes it possible to switch a solenoid valve, activate an alarm or

generate a flow rate proportional frequency, thanks to a transistor output and, for some versions, by means of two

relay outputs, fully configurable, and to establish a control loop thanks to a 4-20 mA current output.

5.2 General description

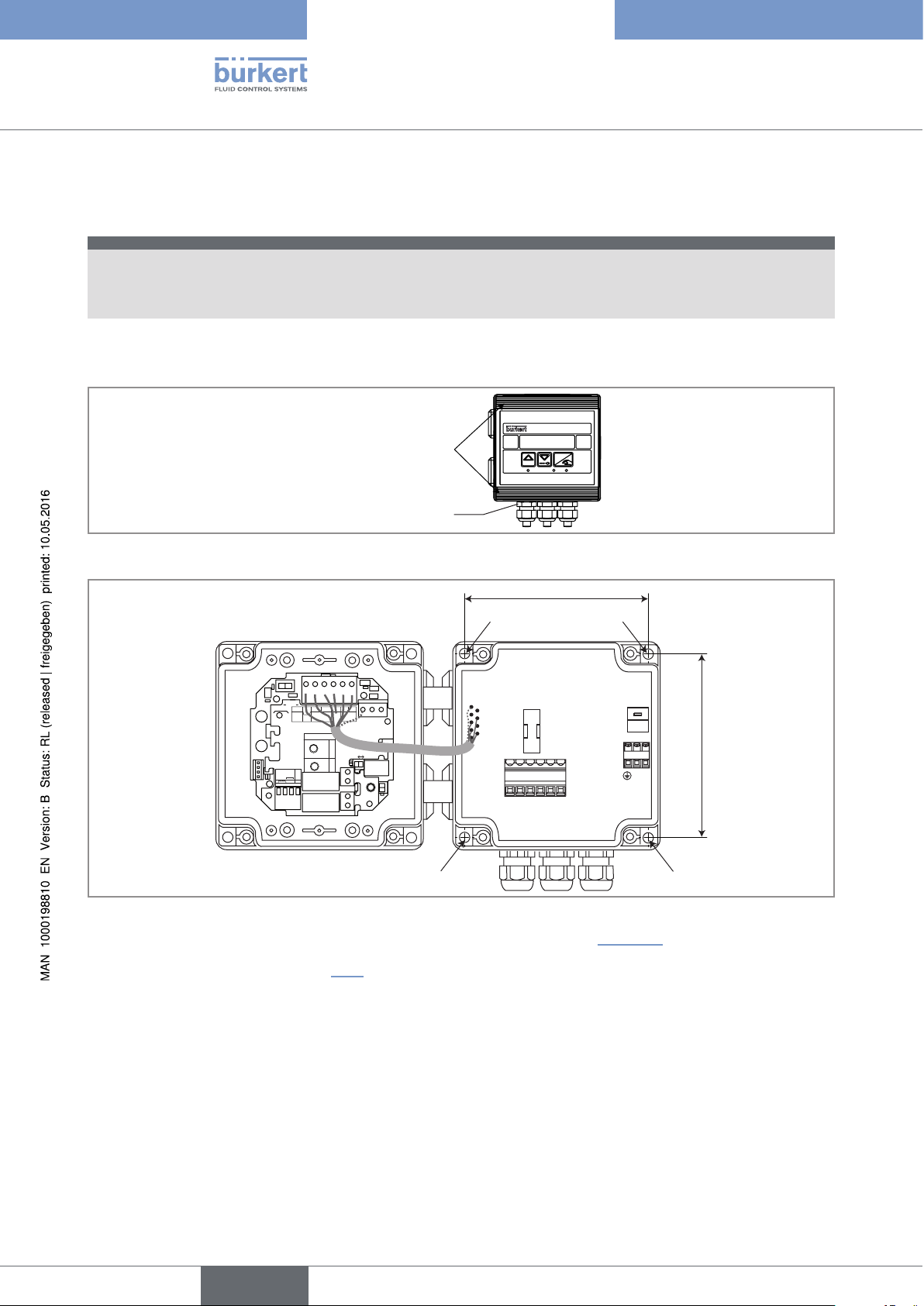

The 8025 Universal is a flow transmitter with display, available in wall-mounted and panel versions:

• The panel version is made up of an electronics integrated in an open housing with display.

• The wall-mounted version is made up of an electronics integrated in a housing with cover, display and 3 cable

glands.

The device is equipped with a 4-20 mA current output (analogue output, called AO1), a transistor output (configured as a pulse output by default, called DO1) and two totalizers.

Some versions are also fitted with two relay outputs (called DO2 and DO3).

The device operates on a 3 wire system and needs a 12-36 V DC or a 115/230 V AC power supply.

The electrical connection is carried out on the terminal blocks of the electronic board.

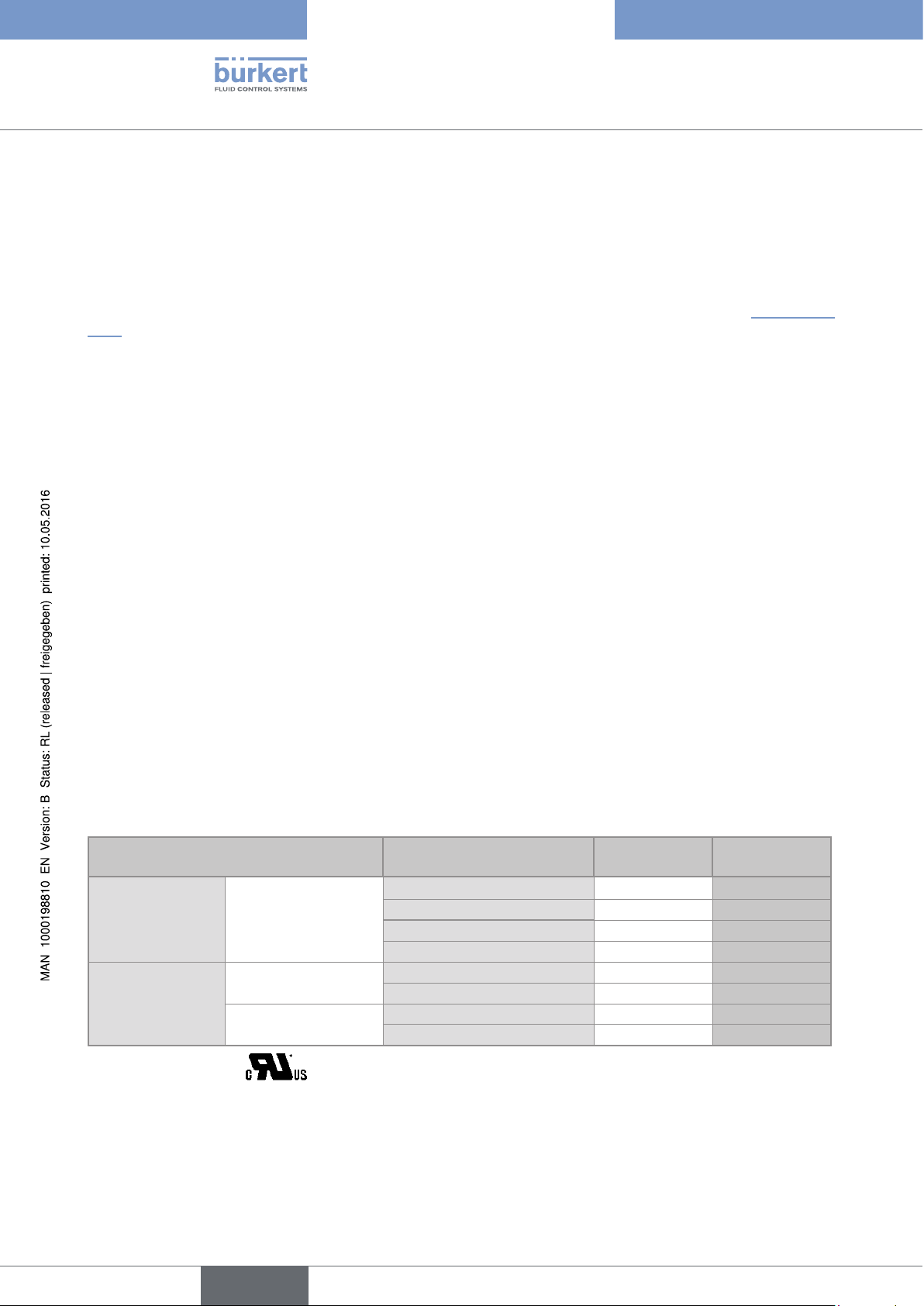

5.3 Available versions

The following versions of transmitter 8025 Universal are available.

All these versions have a 4-20mA current output (AO1), a transistor output (DO1) and two totalizers.

Version 8025

Universal

Panel 12-36 V DC - no

Wall-mounted 12-36 V DC - no

Supply voltage Relay outputs (DO2, DO3) UL

2 no

- yes

2 yes

2 no

115/230 V AC - no

2 no

1)

Order code

419538

419537

564416

564417

419541

419540

419544

419543

1)

identified by the logo on the name plate of the device.

8

English

Page 11

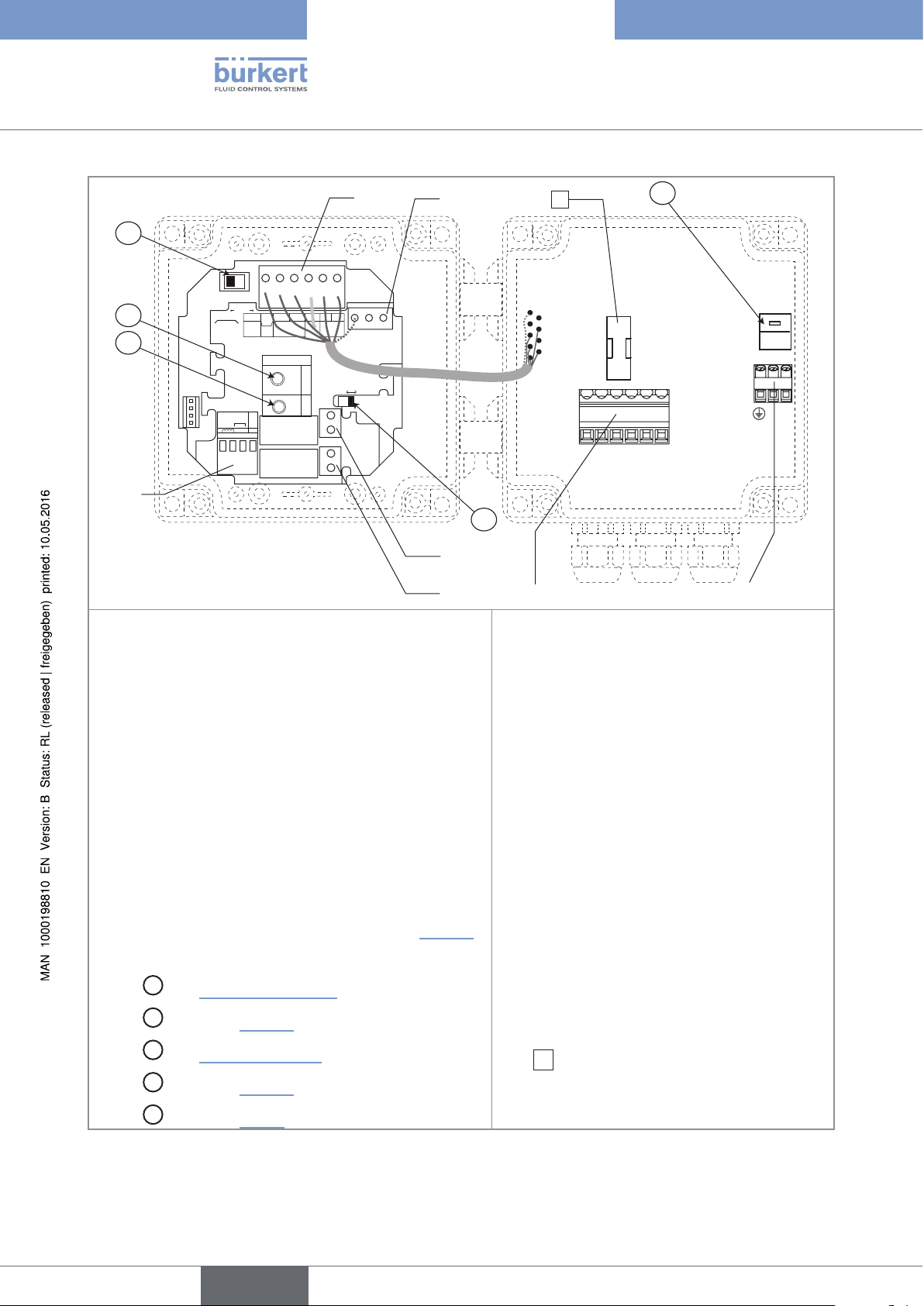

1

35

4

2

Type 8025 UNIVERSAL

Description

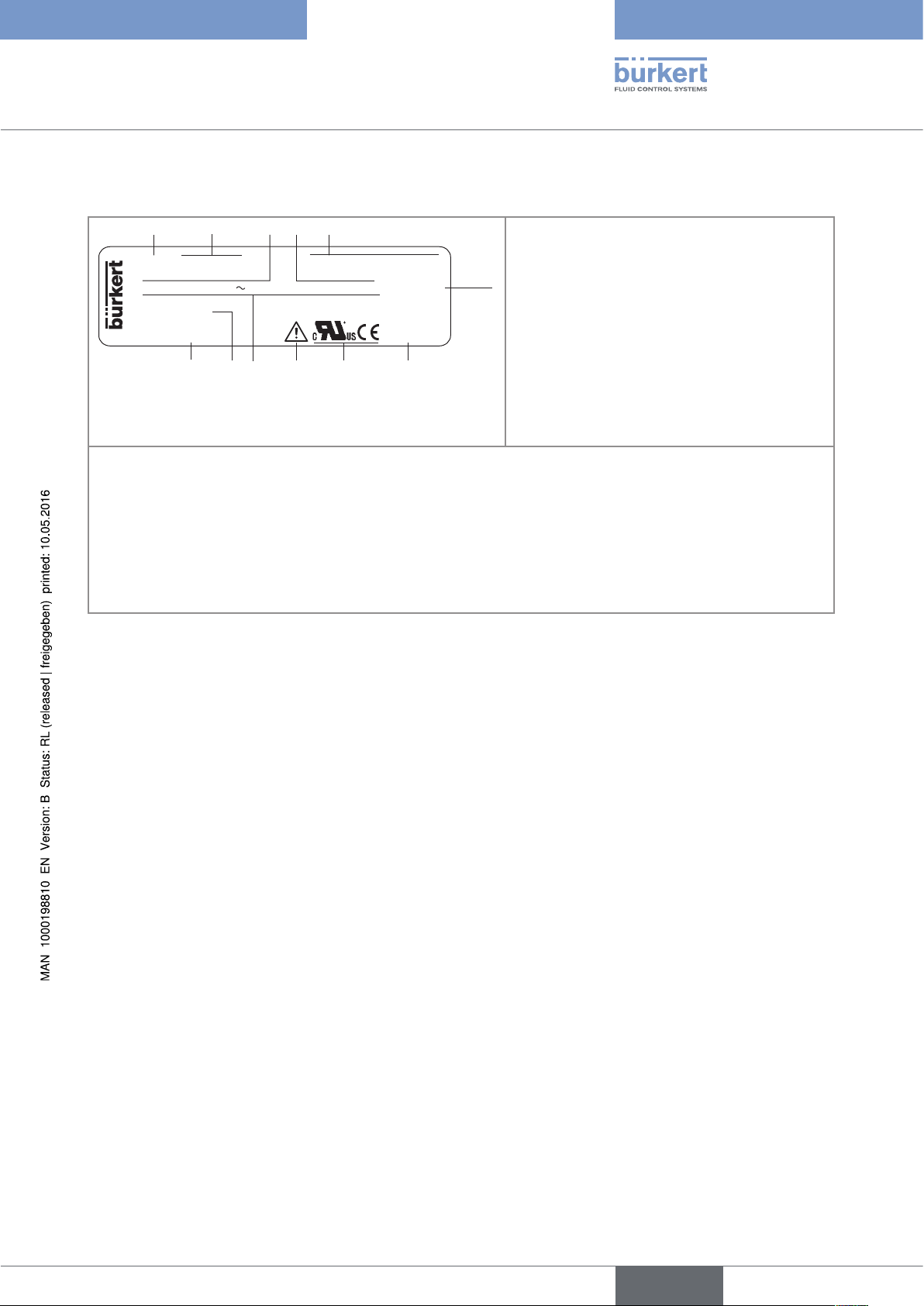

5.4 Description of the name plate

1. Measured value

LFLOW 8025 PANEL SUPPLY: 12-36V= 210 mA

DO1: 5-36V= 100mA AO1:4-20mA

DO2&3: 2xRelay 30 and 42V peak or 60V... max. IP20

S/N 20 000

Made in France

00564417 W46MA

10

9

781112

2. Type of the device, housing

6

3. Specifications of the transistor output DO1

4. Specifications of the analogue output AO1

5. Supply voltage and max. current

consumption

6. Protection class of the device

7. Manufacturing code

8. Conformity logos

9. Warning: Before using the device, take into account the technical specifications described in these operating instructions.

10. Specifications of the relay outputs DO2 and DO3

11. Serial number

12. Order code

Figure 1: Name plate of transmitter 8025 Universal (example)

9

English

Page 12

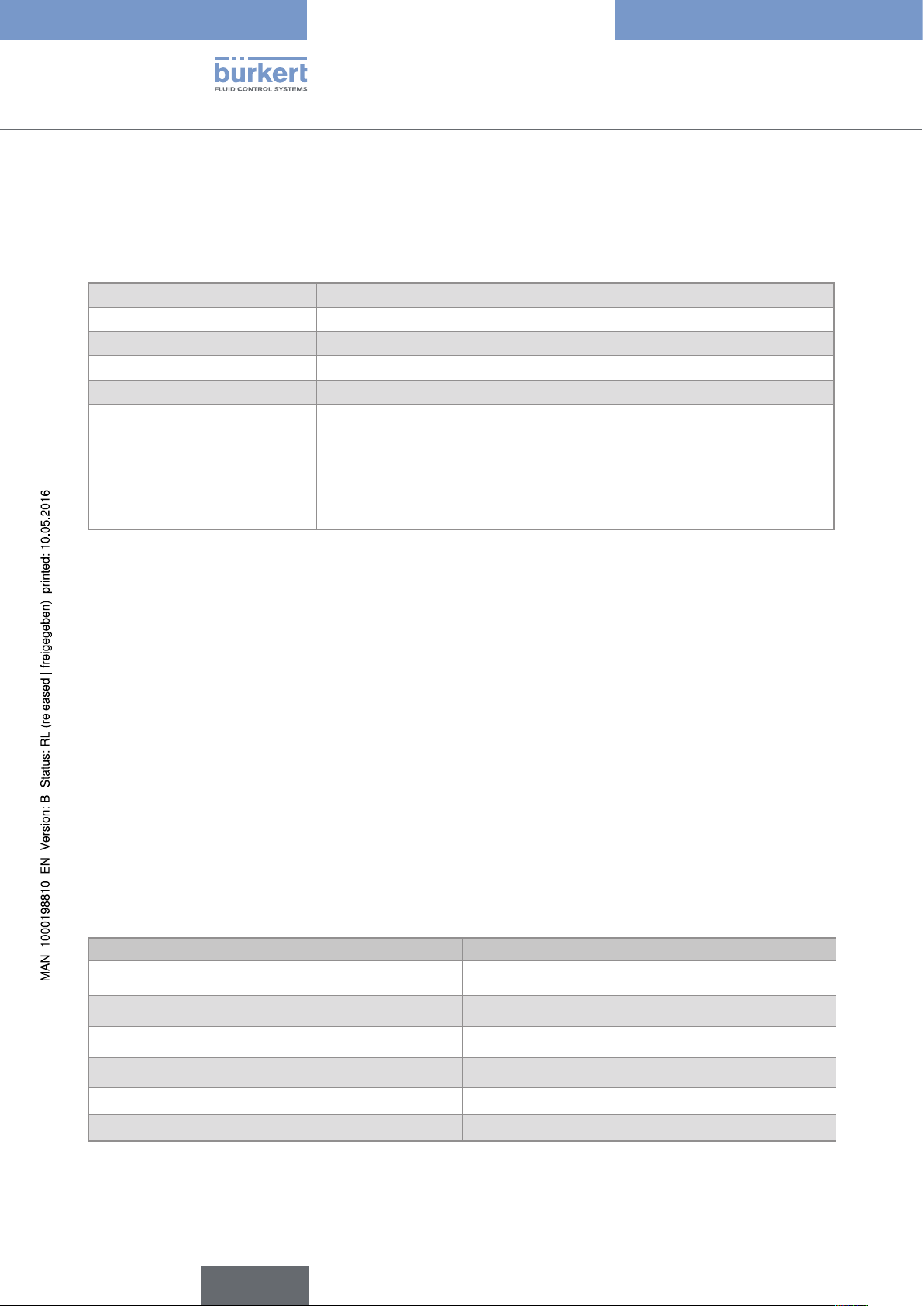

6 TECHNICAL DATA

6.1 Conditions of use

Ambient temperature -10 to +60 °C

Air humidity < 80 %, non condensated

Height above see level max. 2000 m

Installation class Class I acc. to UL 61010-1

Degree of pollution Degree 2 acc. to EN 61010-1

Protection rating

acc. to EN 60529

Type 8025 UNIVERSAL

Technical data

• wall-mounted version

• panel version

• IP65, device wired, cable glands tightened, cover lid screwed tight and

entry item nuts of the cable glands tightened at a screwing torque of

1.5 Nm.

• front side IP65, rear side IP20

6.2 Conformity to standards and directives

The device conforms to the EC directives through the following standards:

• EMC: EN 61000-6-2, EN 61000-6-3

• LVD: EN 61010-1

• Environnemental testing: Vibration: EN 60068-2-6, Shock: EN 60068-2-27.

The UL devices with PU01 variable key comply with the following standards:

• UL 61010-1

• CAN/CSA-C22.2 n° 61010-1

6.3 General technical data

10

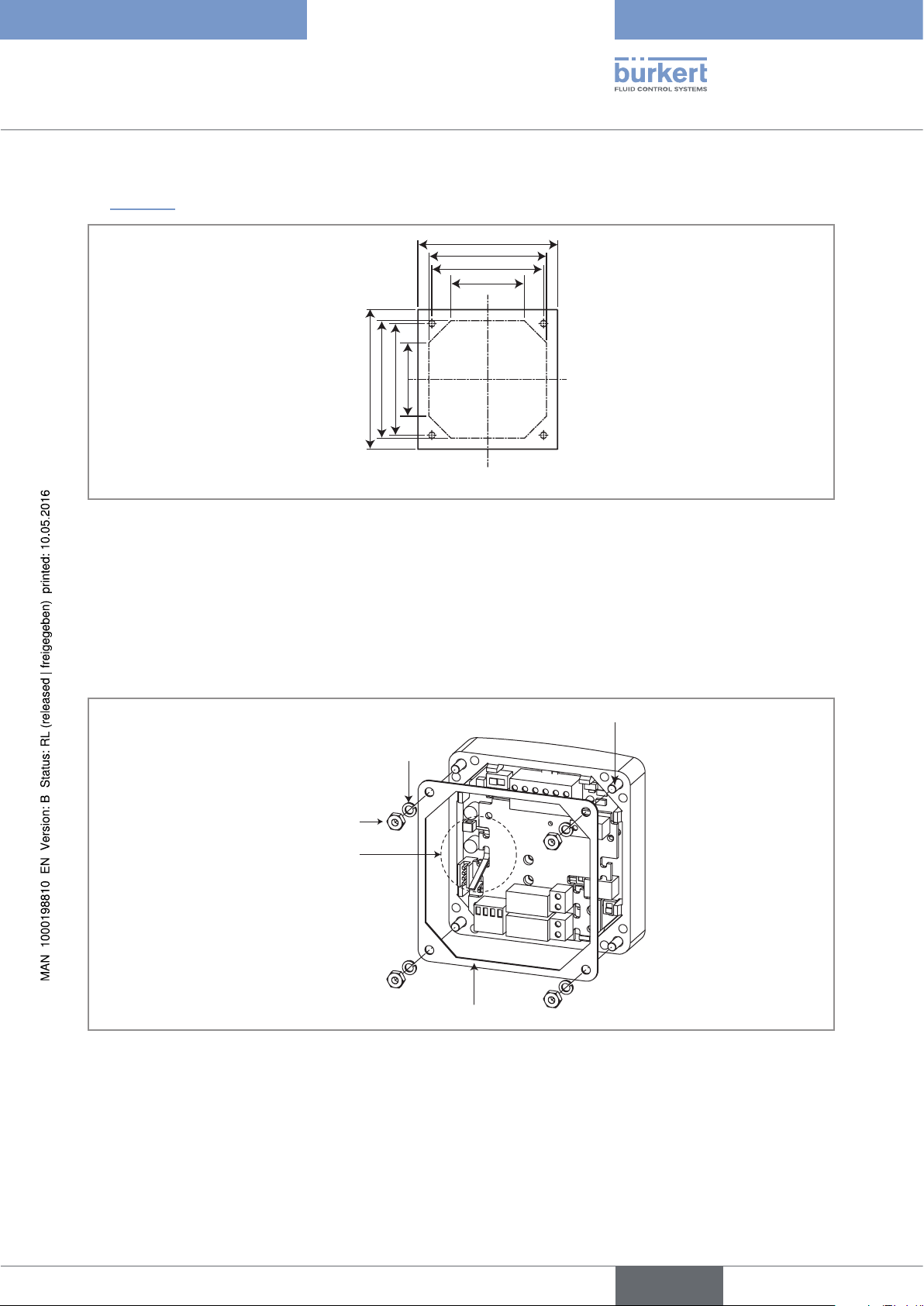

6.3.1 Mechanical data

Part Material

Housing with cover, wall-mounted version ABS

Cable glands, wall-mounted version PA

Open housing, panel version PC

Foil polyester

4 screws Stainless steel

Cable clips PA

English

Page 13

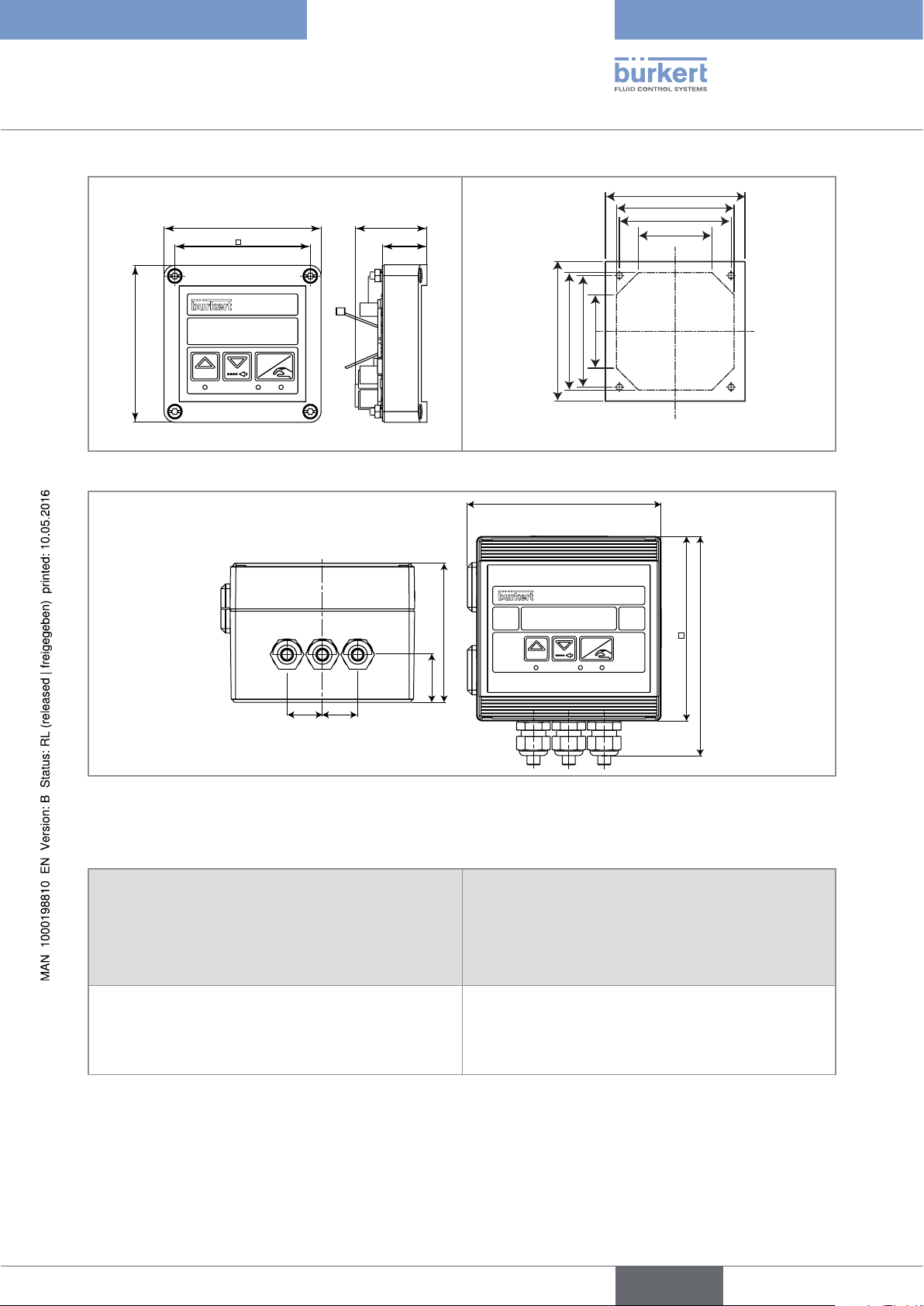

88

95

95

126

Type 8025 UNIVERSAL

Technical data

88

76

FLOW

ENTER

0....9

40

25

80

76

50

Drilling jig

Figure 2: Dimensions of transmitter 8025 Universal, panel version, and of the drilling jig [mm]

80

76

50

FLOW

120

143

23

23

90

31.50

0....9

ENTER

Figure 3: Dimensions of transmitter 8025 Universal, wall-mounted version [mm]

6.3.2 Electrical data

Power supply 12-36 V DC • filtered and regulated

• SELV circuit, with a safe energy level

• max. tolerance 12 V DC: -5 % or +10%

• max. tolerance 36 V DC: ±10 %

Power source (not provided) • Source with limited power in accordance with § 9.3

of the EN 61010-1 standard

• or class 2 source in accordance with the

UL 1310/1585 and EN 60950-1 standards

11

English

Page 14

Power supply 115/230 V AC

Type 8025 UNIVERSAL

Technical data

• frequency

• supplied voltage

• current

• integrated protection

• power

Current consumption (without the consumption of the

4-20 mA output)

• version without relays, energized with 12-36 V DC

• version with relays, energized with 12-36 V DC

• version without relays, energized with 115/230 V AC

• version with relays, energized with 115/230 V AC

Transistor output DO1

• type

• function

• frequency (f)

• Electrical data

• 50/60 Hz

• 27 V DC, regulated

• max. 250 mA

• 250 mA time delay fuse

• 6 VA

• 60 mA (at 12 V DC) and 30 mA (at 36 V DC)

• 90 mA (at 12 V DC) and 45 mA (at 36 V DC)

• 40 mA

• 55 mA

polarized, potential-free

• NPN / PNP (wiring dependent), open collector

• pulse output (by default), user configurable

• 0,6-2200 Hz

• 5-36 V DC, 100 mA max., voltage drop 2,7 V DC at

100 mA

• duty cycle if 0,6 < f < 300 Hz

• duty cycle if 300 < f < 1500 Hz

• duty cycle if 1500 < f < 2200 Hz

• protection

Relay outputs (DO2 and DO3)

• operating

• electrical data of the load (non UL devices)

• electrical data of the load (UL devices)

• max. breaking capacity

• life span

Current output AO1

• specification

• max. loop impedance

• > 0.45

• > 0.4

• < 0.4

• galvanically isolated, and protected against overvoltages, polarity reversals and short-circuits

• hysteresis (by default), user configurable, normally

open

• 230 V AC / 3 A or 40 V DC / 3 A

• max. 30 V AC and 42 V peak or max. 60 V DC, 3 A

• 750 VA (resistive load)

• min. 100000 cycles

• 4-20 mA, sink or source (wiring dependent), 22 mA

to indicate a fault (can be activated)

• 1300W at 36 V DC, 1000W at 30 V DC, 750W at

24 V DC, 300W at 15 V DC, 200W at 12 V DC

12

• 900W if the device is energized with 115/230 V AC

English

Page 15

Type 8025 UNIVERSAL

Technical data

6.3.3 Specifications of the connected flow sensor

Signal originating from the remote sensor

• type

• pulse, sine-wave (typical sensitivity 50 mV peakto-peak at 250 Hz), "on/off", or standard voltage

0-5 V DC

• frequency

• max. voltage

Input impedance

• 0,6 Hz to 2,2 kHz, can be adjusted

• 36 V DC

depends on the position of selector "LOAD" on the

electronic board of the 8025. See chap. “7.4.10”

Power supply supplied by the transmitter depending on the position

of selector "SENSOR SUPPLY" of the 8025, either:

• 5 V DC, 30 mA max.

• (L+)-12V: supply voltage (L+) of the transmitter

minus 12 V DC (minus 12,5 V DC max.), 80 mA max.

• L+: supply voltage (L+) of the transmitter (minus

1,5 V DC max.), 140 mA max. (if the device is energized with 12-36 V DC), 80 mA max. (if the device is

energized with 115/230 V AC)

6.3.4 Electrical connection

Type of connection on the terminal blocks of the electronics (and through

cable glands M16x1,5, for the wall-mounted versions)

Cable specifications

• cable type

• Cross section of wires

• Diameter of each cable (for the cable glands

M16x1,5 of the wall-mounted version)

• shielded

• 0.2 to 1.5 mm

• 4 to 8 mm

2

13

English

Page 16

Type 8025 UNIVERSAL

Installation and wiring

7 INSTALLATION AND WIRING

7.1 Safety instructions

danger

Risk of injury due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Warning

Risk of injury due to non-conforming installation.

▶ The electrical installation can only be carried out by qualified and skilled staff with the appropriate tools.

▶ Install appropriate safety devices (correctly rated fuse and/or circuit-breaker); For the versions with a

115/230 V AC supply voltage, insert a safety device between the phase and the neutral conductor.

▶ Respect standard NF C 15-100 / IEC 60364.

Risk of injury due to unintentional switch on of power supply or uncontrolled restarting of the

installation.

▶ Take appropriate measures to avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subsequent to any intervention on the device.

Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects of the climatic conditions.

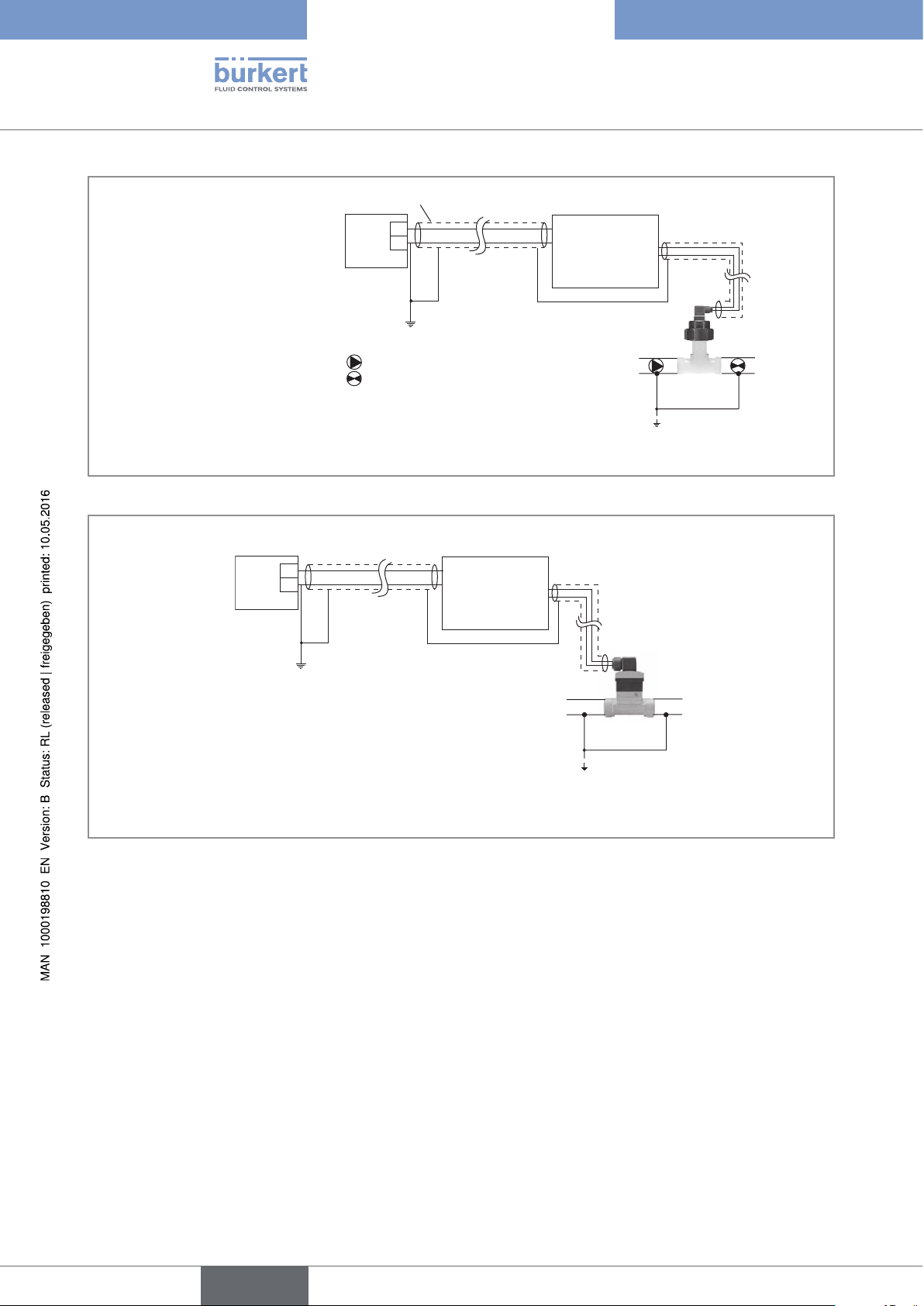

7.2 Installation of a panel version

Install the panel version of the device in a cabinet with a protection class at least IP54 to ensure a

degree of pollution 2 inside the cabinet.

14

English

Page 17

95

95

Type 8025 UNIVERSAL

Installation and wiring

→ To cut the opening in the cabinet door, use the supplied drilling jig, respecting the dimensions indicated in

“Figure 4”.

80

76

50

80

76

50

Drilling jig

Figure 4: Dimensions of the drilling jig [mm]

→ Insert the 4 screws in the housing (from the front).

→ Insert the seal on the external threads of the 4 screws (rear of the housing).

→ Put the assembly on the cutout, electronics turned to the inside of the cabinet.

→ Put the 4 washers on the 4 screws.

→ Put a nut on each of the 4 screws and tighten the nuts to secure the device to the cabinet.

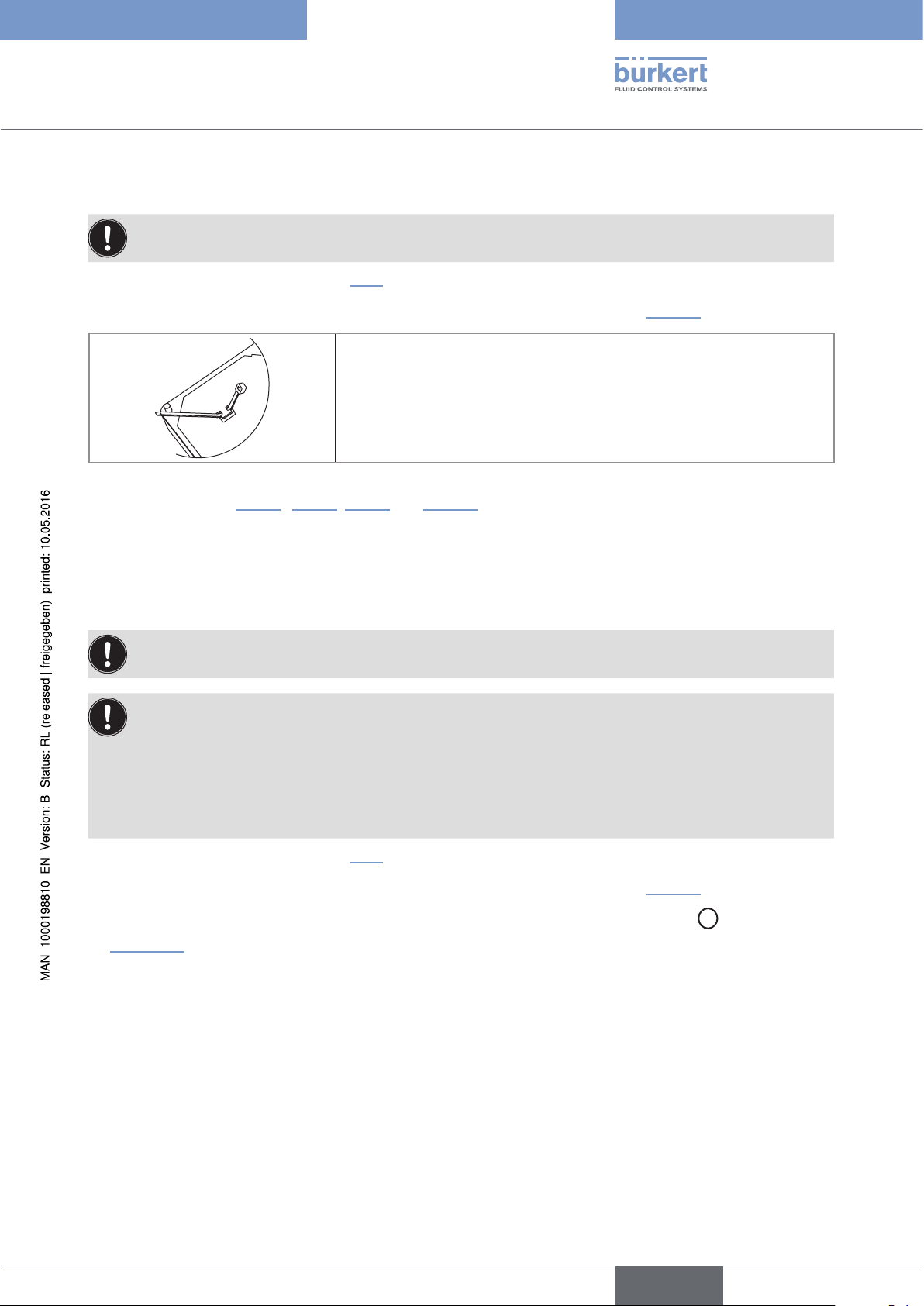

Screws

Washer

Nut

Cable clip

Seal

Figure 5: Installation of a 8025, panel version

15

English

Page 18

11

106 mm

Type 8025 UNIVERSAL

Installation and wiring

7.3 Installation of a wall-mounted version

note

Risk of material damage if the cable glands are not tightly screwed on the housing

▶ Before installing the wall-mounted housing on its support, tighten the nuts of the entry item of the cables

glands at a torque of 1.5 Nm.

The flow transmitter in a wall-mounted version has 4 holes in the bottom of the housing.

→ Remove blanking strips covering the screws.

FLOW

Blanking strips

ENTER

0....9

Nut of the entry item

→ Loosen the 4 screws and open the cover to get access to the holes [1].

SOURCE SINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

PULSE

Supply

FLOW

SENSOR

Batch

PE

ISOG

DO4

DI4

DI3

DI2

DI1

SUPPLY

INPUT

+-

PULSE

NC

COIL

213PE

NPN/PNP

NC

L+

2.2K

(L+)-12V

12..36Vdc

SENSOR

+5V

470

39K

COIL/PNP

SUPPLY

LOAD

DO1

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

PE PEPE

T 250 mA

OFFON

56789 10

1 1

Figure 6: Installation of a wall-mounted version

→ Secure the housing to the support respecting the dimensions indicated in “Figure 6”.

LN

LN

230V

230V

230V

106 mm

16

→ Wire acc. to instructions in chap. “7.4”.

→ Close the housing and tighten the 4 screws of the cover.

English

Page 19

Type 8025 UNIVERSAL

Installation and wiring

7.4 Wiring

danger

Risk of injury due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Insert the supplied stopper gaskets into the unused cable glands of a wall-mounted version to ensure the

tightness of the device.

Only move the selectors when the power supply is off.

• Use a filtered and regulated 12-36 V DC power supply.

• Make sure the installation is equipotential. See chap. “7.4.1”.

• Use shielded cables with a temperature limit of 80 °C minimum.

• Do not install the cables near high voltage or high frequency cables; If this cannot be avoided, observe a

min. distance of 30 cm.

• Protect the device power supply by means of a 300 mA fuse and a switch.

• Protect the power supply of each transistor output by means of a 125 mA fuse.

• Protect the relays by means of a max. 3 A fuse and a circuit breaker (depending on the process).

• Do not apply both a dangerous voltage and a safety extra-low voltage to the relays.

7.4.1 Equipotentiality of the installation

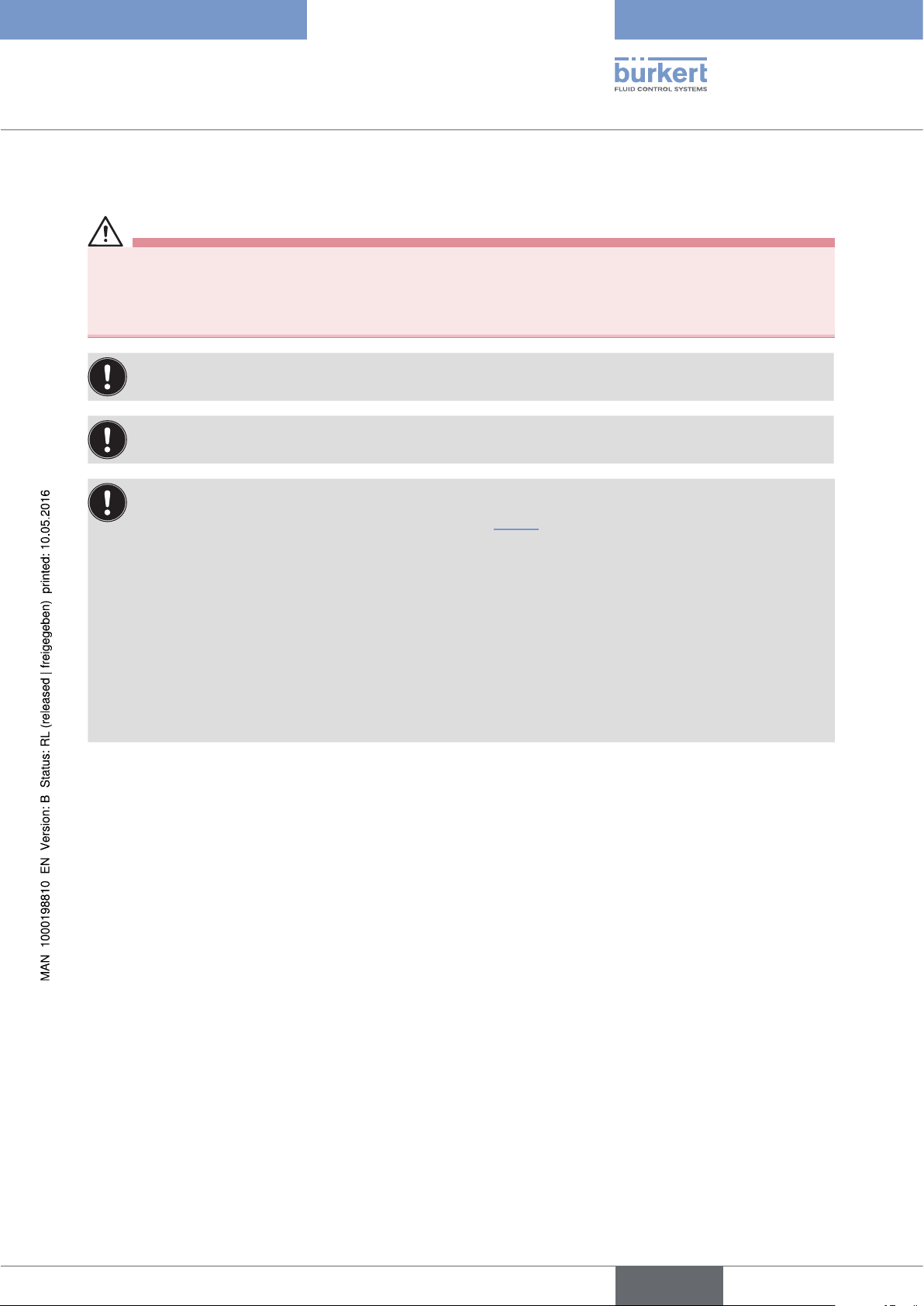

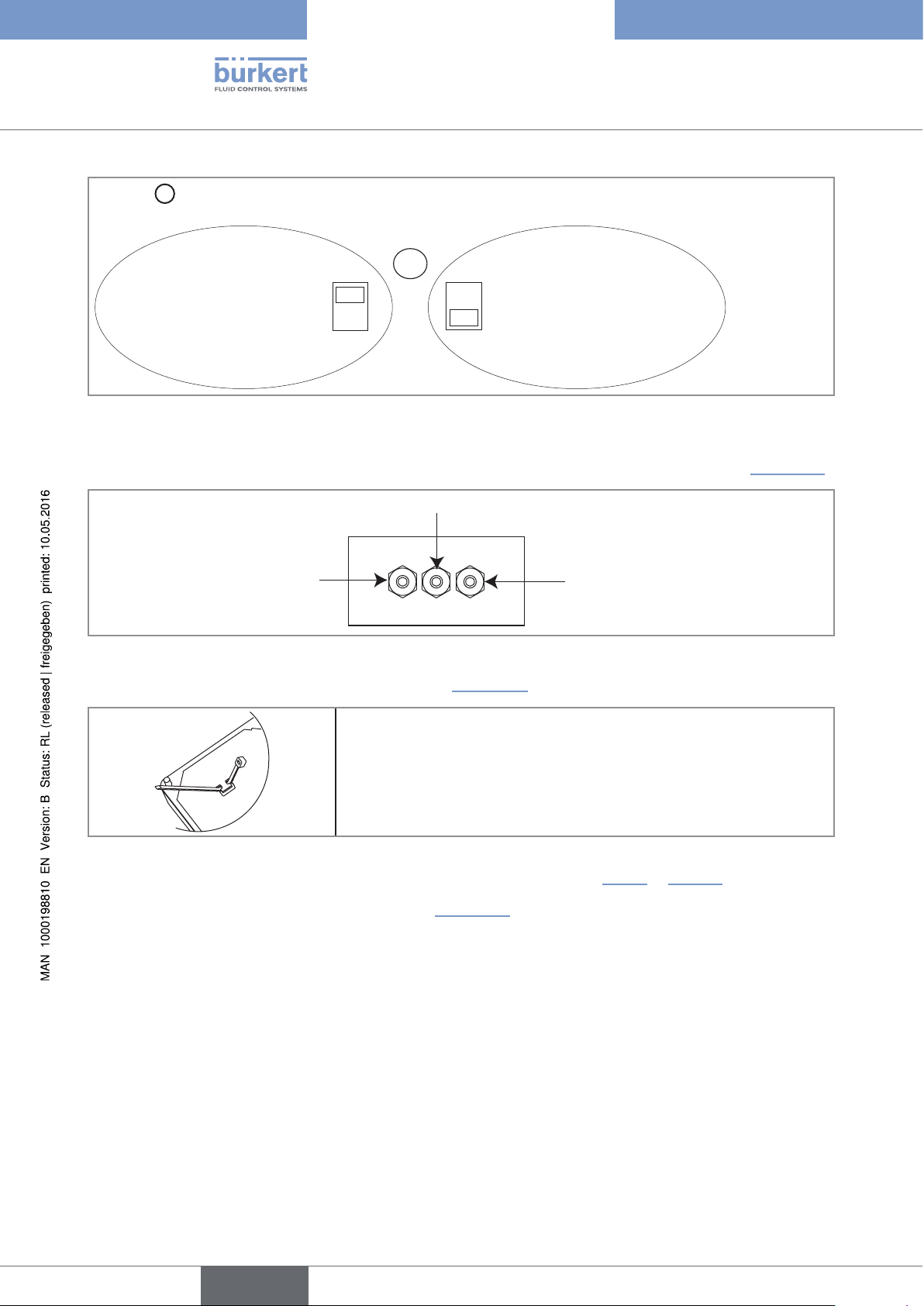

To ensure the equipotentiality of the installation (power supply - device - fluid):

→ Connect together the various earth spots in the installation to eliminate the potential differences that may

occur between different earthes.

→ Observe faultless earthing of the shield of the power supply cable, at both ends.

→ Connect the negative power supply terminal to the earth to suppress the effects of common mode currents. If

this connection cannot be made directly, a 100 nF/50 V capacitor can be fitted between the negative power

supply terminal and the earth.

→ Special attention has to be paid if the device is installed on plastic pipes because there is no direct earthing

possible. Proper earthing is performed by earthing together the metallic instruments such as pumps or valves,

that are as close as possible to the device. If no such instrument is near the device, insert metallic earthing

rings inside the plastic pipes upstream and downstream the device and connect these parts to the same

earth. The earth rings must be in contact with the fluid.

English

17

Page 20

Type 8025 UNIVERSAL

Installation and wiring

Power cable shield

+

-

Power supply

Valve, pump,... (or earth rings, not

provided, inserted into the pipe)

*)

If a direct earth connection is not possible, fit a 100 nF / 50 V capacitor between the negative power supply terminal and

(*)

8025 Universal

Flow sensor

Plastic pipe

the earth.

Figure 7: Equipotentiality skeleton diagram with pipes in plastic

8025 Universal

+

-

Power supply

(*)

Flow sensor

Metal pipe

*)

If a direct earth connection is not possible, fit a 100 nF / 50 V capacitor between the negative power supply terminal and

the earth.

Figure 8: Equipotentiality skeleton diagram with pipes in metal

18

English

Page 21

Type 8025 UNIVERSAL

Installation and wiring

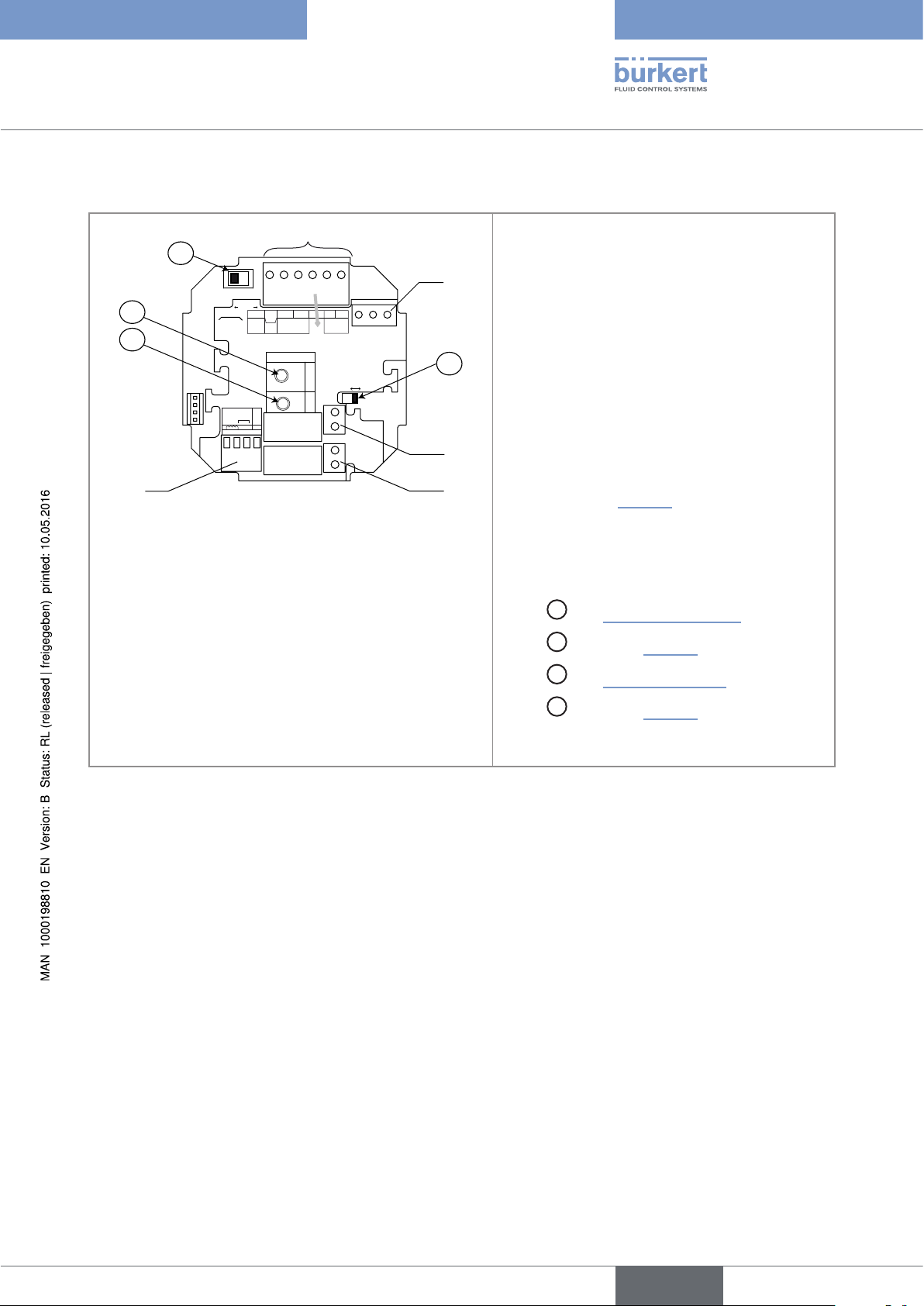

7.4.2 Terminal assignment and use of the selectors

1

A

SOURCESINK

CURRENT

B

BINARY

C

FLOW

SENSOR

PE

ISOG

DO4

DI4

DI3

DI2

DI1

PULSE

INPUT

SUPPLY

+-

NC

213PE

Univ

Batch

COIL

Iout

(AO1)

NC

L+

2.2K

NPN/PNP

L+ L- PE P- P+

Supply

12..36Vdc

SENSOR

+5V

SUPPLY

(L+)-12V

COIL/PNP

470

39K

LOAD

5

Terminal block 1

• Iout: 4-20 mA output (AO1)

• L+: V+ (positive voltage)

• L-: 0V (power supply ground)

• PE: protective earth, factory wired

• P-: Negative transistor output DO1

PULSE

DO1

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

PE PEPE

Terminal block 2

PE: Shieldings of both the power supply cable

2

and the AO1 and DO1 output cables

Terminal block 3 Wiring of the relay output DO2

(if the device has relays).

D

Terminal block 4 Wiring of the relay output DO3

(if the device has relays).

OFF ON

3

4

Terminal block 5 "FLOW SENSOR": Wiring the

remote flow sensor. The wiring depends on the

type of output signal originating from the flow

sensor: see chap. “7.4.10”.

A

Switch

Switch

Switch

Switch

: see “Figure 15”, page 23

B

: see chap. “7.4.10”

C

: see “Table 1”, page 30

D

: see chap. “7.4.10”

• P+: Positive transistor output DO1

Figure 9: Terminal assignment of a panel version or a wall-mounted version, 12-36 V DC

19

English

Page 22

Type 8025 UNIVERSAL

Installation and wiring

2

A

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

FLOW

PULSE

PE

ISOG

DO4

DI4

DI3

DI2

DI1

INPUT

Univ

Batch

SUPPLY

+-

NC

213PE

COIL

(AO1)

NC

L+

2.2K

NPN/PNP

Supply

12..36Vdc

SENSOR

+5V

(L+)-12V

470

39K

SUPPLY

COIL/PNP

LOAD

PULSE

DO1

PE PEPE

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

OFF ON

B

C

SENSOR

3

Terminal block 1

PE: factory wired shield.

Terminal block 2

• Iout: 4-20 mA output (green wire, factory wired)

• L+: V+ (red wire, factory wired)

1

8

E

230V

230V

230V

T 250 mA

LN

LN

56789 10

D

4

5

6 7

Terminal block 4 Wiring of the relay output DO2

(if the device has relays).

Terminal block 5 Wiring of the relay output DO3

(if the device has relays).

Terminal block 6

• terminal 5: 4-20 mA output (AO1)

20

• L-: 0V (black wire, factory wired)

• PE: protective earth, factory wired

• P-: negative transistor output (brown wire, factory wired)

• P+: positive transistor output (white wire, factory wired)

Terminal block 3 "FLOW SENSOR": Wiring the remote

flow sensor. The wiring depends on the type of output

signal originating from the flow sensor: see chap. “7.4.10”.

• terminal 6: positive 27 V DC power supply,

available to energize an external instrument

• terminal 7: 0V (earth of the power supply

available to energize an external instrument)

• terminal 8: protective earth: shields of the AO1

and DO1 output cables

• terminal 9: Negative transistor output (DO1)

• terminal 10: Positive transistor output (DO1)

Switch

A

: see “Figure 15”, page 23

Terminal block 7 Wiring of the 115/230 V AC

power supply

Switch

Switch

Switch

Switch

Figure 10: Terminal assignment of a wall-mounted version, 115/230 V AC

B

: see chap. “7.4.10”

C

: see “Table 1”, page 30

D

: see chap. “7.4.10”

E

: see chap. “7.4.4”

8

Mark

115/230 V AC power supply

: time-delay fuse to protect the

English

Page 23

Type 8025 UNIVERSAL

Installation and wiring

7.4.3 Wiring a panel version

Only move the selectors when the power supply is off.

→ Install the device as described in chap. “7.2”.

→ Set the selectors "SENSOR TYPE", "SENSOR SUPPLY" and "LOAD": see chap. “7.4.10”.

→ Before wiring the device insert the supplied cable clips into the slots of

the electronic board.

Figure 11: Inserting the cable clips

→ Wire acc. to chap. “7.4.5” , “7.4.6”, “7.4.9” and “7.4.10”.

→ Secure the power supply cable, the flow sensor connection cable and, depending on the version, the relay

connection cables, with the cable clips.

7.4.4 Wiring a wall-mounted version

Only move the selectors when the power supply is off.

Insert the supplied stopper gaskets into the unused cable glands to ensure the tightness of the device.

• Unscrew the unused cable gland.

• Remove the transparent disk.

• Insert the supplied stopper gasket.

• Screw the nut of the cable gland.

→ Install the device as described in chap. “7.3”.

→ Set the selectors "SENSOR TYPE", "SENSOR SUPPLY" and "LOAD": see chap. “7.4.10”.

→ If the wall-mounted version is energized with a 115/230 V AC power supply, set selector

“Figure 12”.

E

as shown in

English

21

Page 24

Type 8025 UNIVERSAL

Installation and wiring

E

Selector

makes it possible to configure the supply voltage of the device in a 115/230 V AC version.

E

→ Energize the device with a

230 V AC voltage.

Figure 12: Selector of the supply voltage on a 115/230 V AC version

230V

→ Loosen the nuts of the cable glands.

→ Insert each cable through a nut than through the cable gland, using the cable glands as shown in “Figure 13”.

Cables of the outputs

115V

→ Energize the device with a

115 V AC voltage.

Flow sensor cable

Figure 13: Using the cable glands

Power supply cable

12-36 V DC or 115/230 V AC

→ Remove the two terminal blocks (marked 6 and 7 in “Figure 10”) from the housing.

→ Before wiring the device insert the supplied cable clips into the slots of

the electronic board and of the 115/230 V AC power supply board if

the device has such a board.

Figure 14: Inserting the cable clips

→ Depending on the operating voltage of the device, wire according to chap. “7.4.5” to “7.4.10”.

→ Insert the two terminal blocks (marked 6 and 7 in “Figure 10”) into their original position.

→ Letting the housing stay completely open, secure the power supply cable, the flow sensor connection cable

and, depending on the version, the relay connection cables, with the cable clips.

→ Tighten the cable glands making sure the cable in the housing is long enough to allow complete opening of

the housing.

22

→ Close the cover.

→ Fully screw the 4 screws.

→ Put the blanking strips on the housing.

English

Page 25

12-36 V DC

Type 8025 UNIVERSAL

Installation and wiring

7.4.5 Wiring the AO1 current output of a panel version or a wallmounted version, 12-36 V DC

Only move the selectors when the power supply is off.

Insert the supplied stopper gaskets into the unused cable glands to ensure the tightness of the device.

• Unscrew the unused cable gland.

• Remove the transparent disk.

• Insert the supplied stopper gasket.

• Screw the nut of the cable gland.

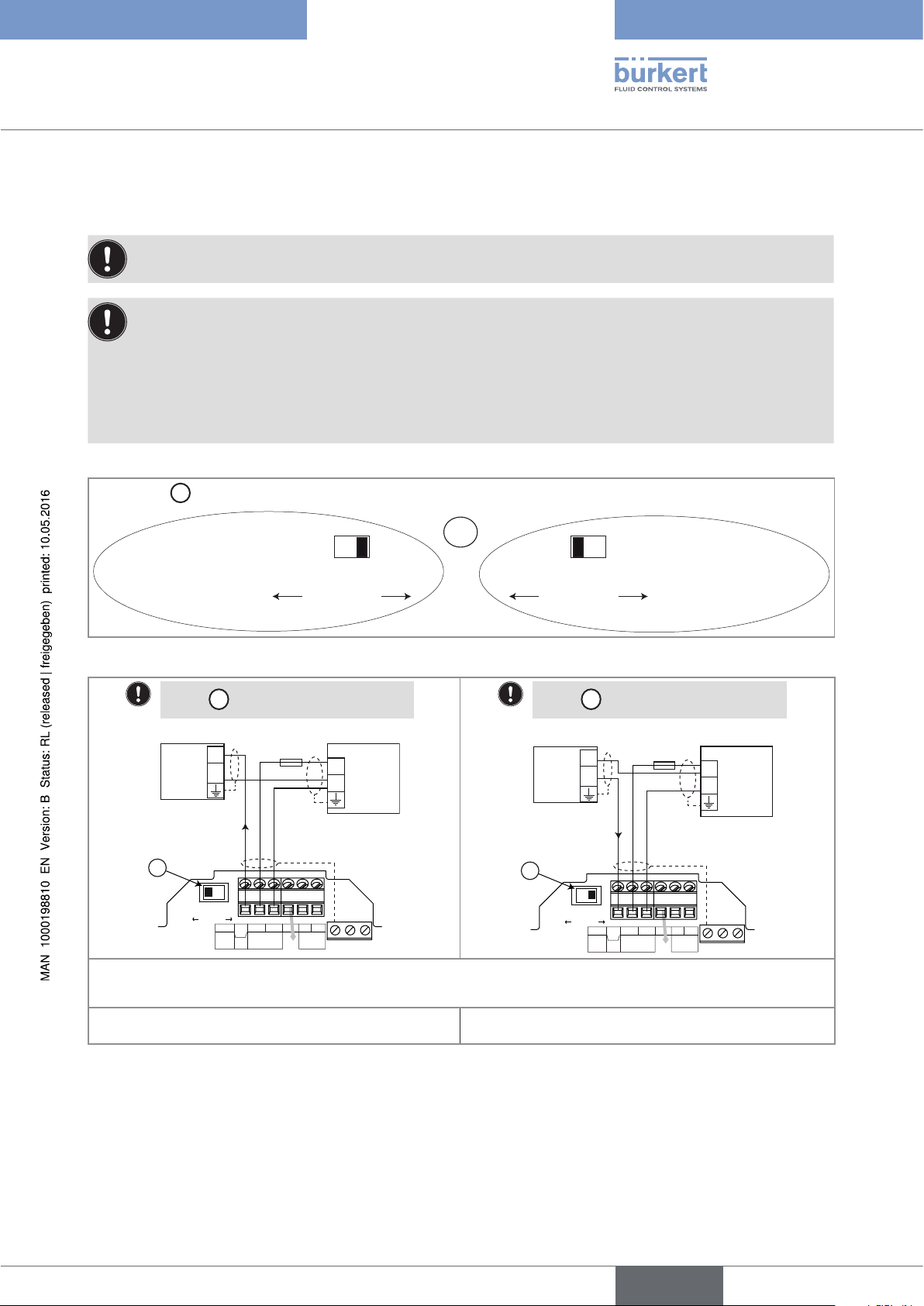

The 4-20 mA output can be wired in either sourcing or sinking mode.

A

Use switch

to configure the wiring of the 4-20 mA current output in sinking or sourcing mode.

A

→ Wire the current

output in sinking

mode.

Figure 15: Using the sink/source switch

Set the A switch on the left.

+

-

4-20mA input at external

*) If a direct earth connection is not possible, fit a 100 nF/50 V capacitor between the negative power supply terminal and

the earth

A

instrument

SOURCESINK

CURRENT

Univ

Batch

SOURCE SINK

CURRENT

12-36 V DC

+

-

(*)

Power supply

PULSE

DO1

PE PEPE

I

Iout

L+ L- PE P- P+

(AO1)

Supply

12..36Vdc

NC

300 mA

SOURCE SINK

CURRENT

Set the A switch on the right.

+

-

4-20mA input at external

A

instrument

SOURCESINK

CURRENT

Univ

Batch

I

Iout

L+ L- PE P- P+

(AO1)

Supply

12..36Vdc

NC

→ Wire the current

output in sourcing

mode.

300 mA

(*)

PULSE

DO1

+

-

Power supply

PE PEPE

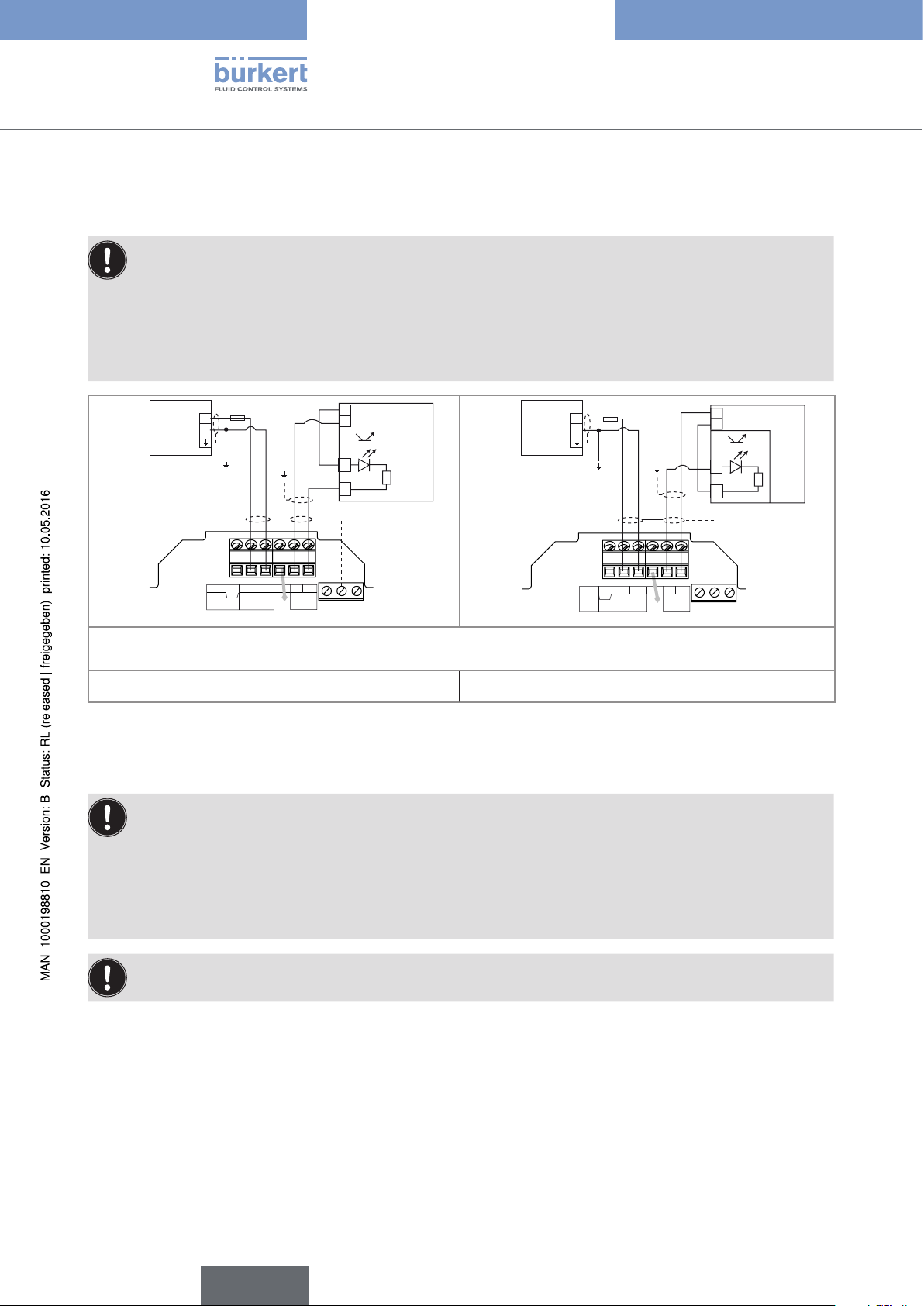

Figure 16: Wiring of the 4-20 mA output (AO1) in

sourcing mode

Figure 17: Wiring of the 4-20 mA output (AO1) in sinking

mode

23

English

Page 26

Type 8025 UNIVERSAL

Installation and wiring

7.4.6 Wiring the DO1 transistor output of a panel version or a wall-mounted version, 12-36 V DC

Insert the supplied stopper gaskets into the unused cable glands to ensure the tightness of the device.

• Unscrew the unused cable gland.

• Remove the transparent disk.

• Insert the supplied stopper gasket.

• Screw the nut of the cable gland.

12-36 V DC

Power supply of

the device

+

-

(*)

Univ

Batch

300 mA

Iout

L+ L- PE P- P+

(AO1)

Supply

12..36Vdc

NC

PULSE

DO1

PE PEPE

+

5-36 VDC

-

+

-

PLC

12-36 V DC

Power supply of

the device

+

-

(*)

Univ

Batch

300 mA

Iout

L+ L- PE P- P+

(AO1)

Supply

12..36Vdc

NC

PULSE

DO1

PE PEPE

+

5-36 VDC

-

+

-

PLC

*) If a direct earth connection is not possible, fit a 100 nF/50 V capacitor between the negative power supply terminal and

the earth

Figure 18: NPN wiring of the DO1 transistor output Figure 19: PNP wiring of the DO1 transistor output

7.4.7 Wiring the AO1 current output of a wall-mounted version, 115/230 V AC

Insert the supplied stopper gaskets into the unused cable glands to ensure the tightness of the device.

• Unscrew the unused cable gland.

24

• Remove the transparent disk.

• Insert the supplied stopper gasket.

• Screw the nut of the cable gland.

Only move the selectors when the power supply is off.

The 4-20 mA output can be wired in either sourcing or sinking mode.

English

Page 27

Type 8025 UNIVERSAL

Installation and wiring

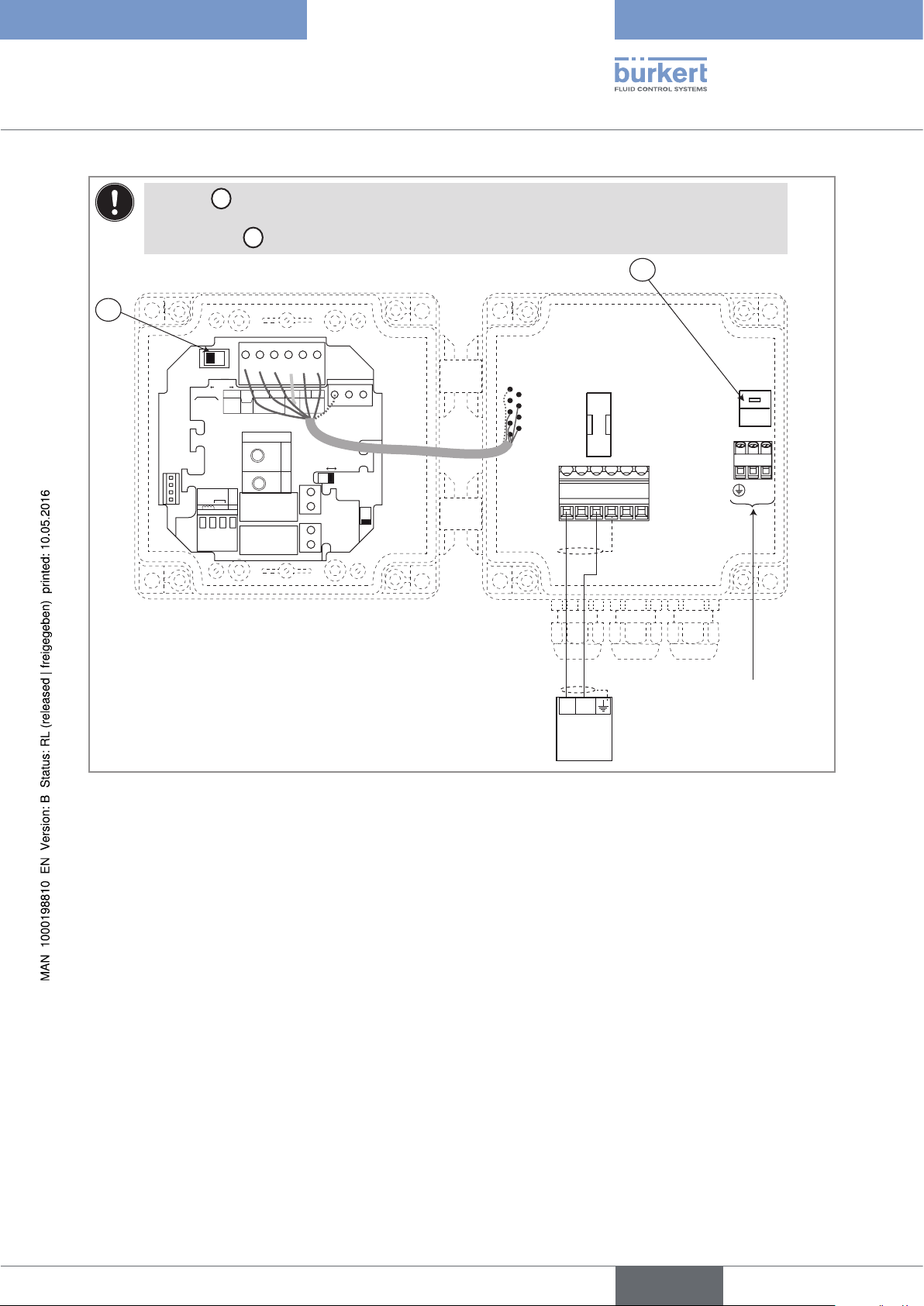

A

• Set the

A

• Set selector

SOURCESINK

CURRENT

BINARY

Univ

Batch

PE

ISOG

DO4

DI4

DI3

DI2

DI1

SUPPLY

INPUT

+-

PULSE

NC

COIL

213PE

FLOW

SENSOR

switch on the left.

E

depending on the value of the power supply.

Iout

L+ L- PE P- P+

(AO1)

NC

L+

2.2K

NPN/PNP

SENSOR

(L+)-12V

Supply

12..36Vdc

+5V

COIL/PNP

470

39K

PULSE

SUPPLY

LOAD

DO1

PE PEPE

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

OFFON

T 250 mA

56789 10

E

230V

230V

230V

LN

LN

Connection of the power

+

-

supply for the 8025

4-20mA input at external instrument

Figure 20: Wiring of the 4-20 mA output (AO1) of a wall-mounted version, 115/230 V AC, in sourcing mode

English

25

Page 28

Type 8025 UNIVERSAL

Installation and wiring

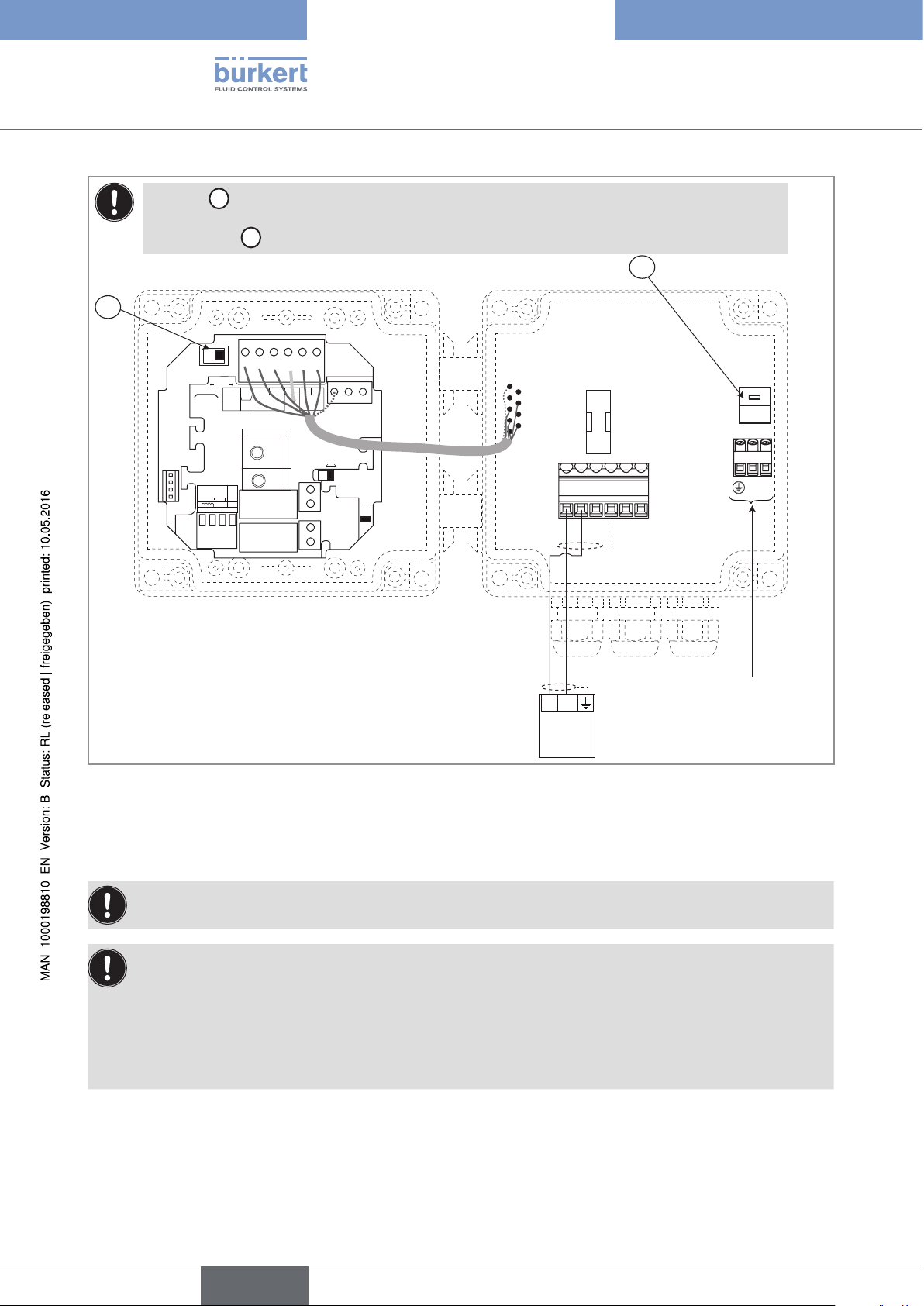

• Set the

• Set selector

A

FLOW

SENSOR

A

switch on the right.

E

depending on the value of the power supply.

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

Supply

Batch

12..36Vdc

NC

PE

ISOG

DO4

SENSOR

SUPPLY

+-

NC

213PE

+5V

L+

(L+)-12V

COIL/PNP

470

2.2K

39K

NPN/PNP

COIL

PULSE

DI4

DI3

DI2

DI1

INPUT

PULSE

SUPPLY

LOAD

DO1

PE PEPE

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

E

230V

230V

230V

T 250 mA

LN

OFFON

56789 10

LN

Connection of the power

+

-

supply for the 8025

4-20mA input at external instrument

Figure 21: Wiring of the 4-20 mA output (AO1) of a wall-mounted version, 115/230 V AC, in sinking mode

7.4.8 Wiring the DO1 transistor output of a wall-mounted version, 115/230 V AC

Only move the selectors when the power supply is off.

Insert the supplied stopper gaskets into the unused cable glands to ensure the tightness of the device.

• Unscrew the unused cable gland.

• Remove the transparent disk.

• Insert the supplied stopper gasket.

• Screw the nut of the cable gland.

26

English

Page 29

Type 8025 UNIVERSAL

Installation and wiring

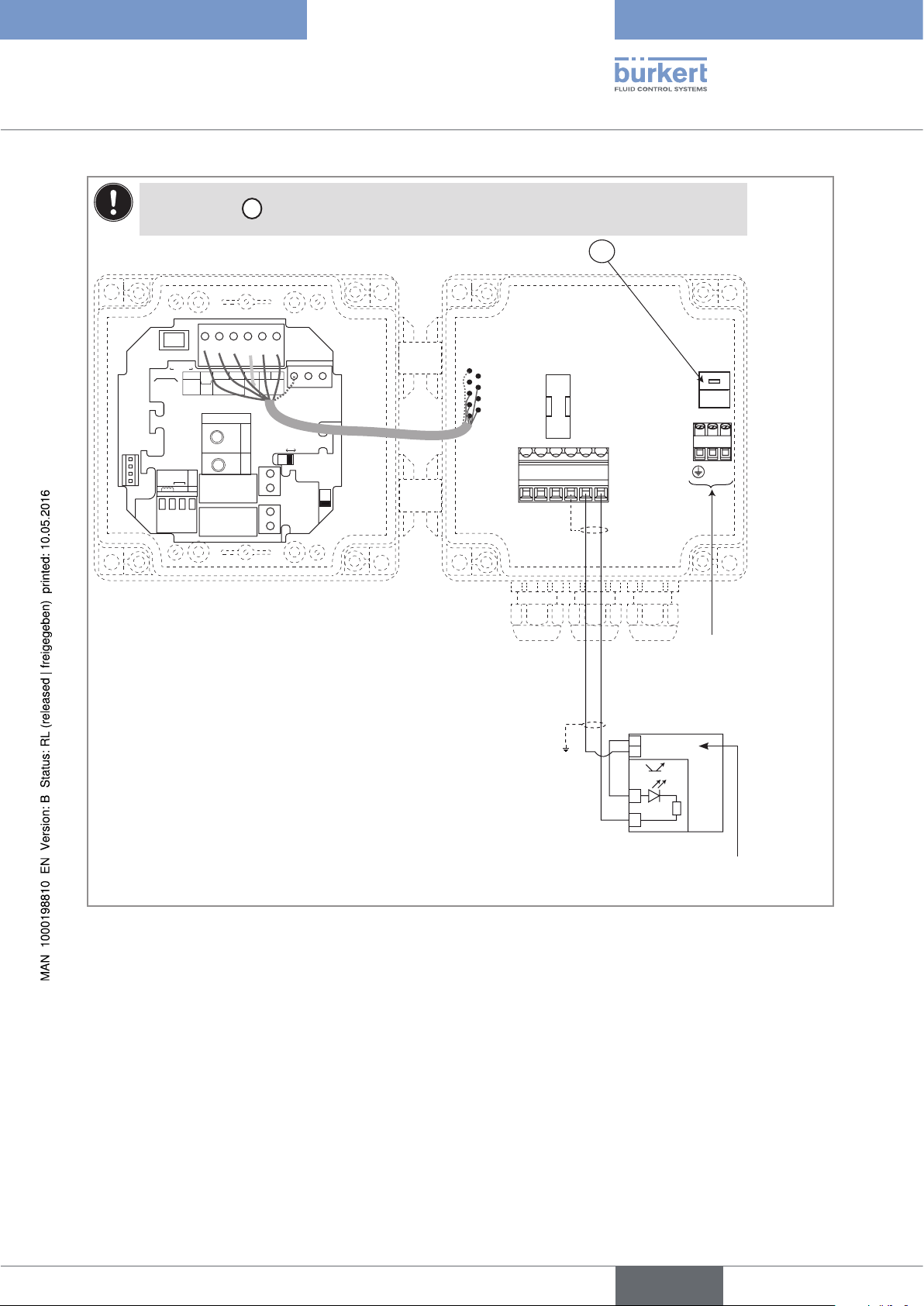

Set of selector

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

Supply

Batch

12..36Vdc

NC

PE

ISOG

DO4

SENSOR

SUPPLY

+-

NC

213PE

+5V

L+

(L+)-12V

470

2.2K

NPN/PNP

COIL

FLOW

SENSOR

PULSE

DI4

DI3

DI2

DI1

INPUT

E

depending on the value of the power supply.

PULSE

DO1

PE PEPE

SENSOR TYPE

SUPPLY

COIL NPN/PNP

COIL/PNP

39K

LOAD

DO2

DO3

OFFON

T 250 mA

56789 10

E

230V

230V

230V

LN

LN

Connection of the power

supply for the 8025

+

5-36 VDC

-

+

-

Figure 22: NPN wiring of the DO1 transistor output of a wall-mounted version, 115/230 V AC

PLC

Power supply for the PLC

English

27

Page 30

Type 8025 UNIVERSAL

Installation and wiring

Set of selector

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

Supply

Batch

12..36Vdc

NC

PE

ISOG

DO4

SENSOR

SUPPLY

+-

NC

213PE

+5V

L+

(L+)-12V

470

2.2K

NPN/PNP

COIL

FLOW

SENSOR

PULSE

DI4

DI3

DI2

DI1

INPUT

E

depending on the value of the power supply.

PULSE

DO1

PE PEPE

SENSOR TYPE

SUPPLY

COIL NPN/PNP

COIL/PNP

39K

LOAD

DO2

DO3

OFF ON

T 250 mA

56789 10

E

230V

230V

230V

LN

LN

Connection of the power supply

for the 8025

PLC

+

5-36 VDC

-

+

-

Power supply for the PLC

Figure 23: PNP wiring of the DO1 transistor output of a wall-mounted version, 115/230 V AC

7.4.9 Wiring the relay outputs DO2 and DO3 of the panel or a

wall-mounted version

Insert the supplied stopper gaskets into the unused cable glands to ensure the tightness of the device.

• Unscrew the unused cable gland.

• Remove the transparent disk.

• Insert the supplied stopper gasket.

• Screw the nut of the cable gland.

28

English

Page 31

m

SENSOR

Type 8025 UNIVERSAL

Installation and wiring

FLOW

SENSOR

PULSE

INPUT

SUPPLY

+-

NC

213PE

NPN/PNP

COIL

DO2

DO3

OFFON

3 A

3 A

230 V AC

230 V AC

Figure 24: Wiring of the DO2 and DO3 relay outputs

7.4.10 Connecting the flow sensor to the transmitter

Before connecting the flow sensor to the transmitter 8025 UNIVERSAL:

• set selector "SENSOR TYPE" depending on the output signal providing from the flow sensor. See

“Figure 25” and “Table 1”, page 30.

• if the selector "SENSOR TYPE" is set on "NPN/PNP", set the selector "SENSOR SUPPLY" depending

on the transmitter supply voltage. See “Figure 26”.

• set selector "LOAD" depending on the type of signal sent out by the flow sensor and on the load

wanted on terminal 1 "PULSE INPUT" of terminal block "FLOW SENSOR". See “Table 1”, page 30.

D

Selector

makes it possible to configure the type of signal the 8025 Universal receives from the flow sensor.

D

SENSOR TYPE

COIL NPN/PNP

SENSOR TYPE

COIL NPN/PNP

→ Set the selector on the right (default position) when

the signal from the flow sensor which is connected to

the 8025 Universal is either:

• a pulse signal, NPN or PNP

• an "on/off" signal (Reed relay for example)

• a 0-5 V DC standard voltage signal (TTL, for example)

Figure 25: Using selector "SENSOR TYPE"

When selector "SENSOR TYPE"

above is set on "NPN/PNP",

B

selector

makes it possible to

configure the supply voltage for the

flow sensor.

→ If the 8025 Universal is energized with a 115/230 V AC power supply,

set selector "SENSOR SUPPLY" on "L+" (default position).

→ If the 8025 Universal is energized with a 12-36 V DC power supply,

set the voltage selector "SENSOR SUPPLY" depending on the voltage

+5V

B

Figure 26: Using selector "SENSOR SUPPLY"

L+

(L+)-12V

SUPPLY

needed by the remote flow sensor: "+5V", "L+" (default position) or

"(L+)-12V".

→ Set the selector on the left when the

signal from the flow sensor which is

connected to the 8025 Universal is a

sine-wave signal (coil).

29

English

Page 32

13

Type 8025 UNIVERSAL

Installation and wiring

Table 1: Position of selectors "SENSOR TYPE" and "LOAD" and terminal assignment of terminal block "FLOW

SENSOR" depending on the signal emitted by the flow sensor

Terminal assignment of

Type of signal

emitted by the

flow sensor

Selector

"SENSOR

TYPE"

D

)

(

Selector

"SENSOR

SUPPLY"

(B)

Selector "LOAD"

C

2.2K

470

COIL/PNP

39K

terminal block "FLOW

SENSOR"

LOAD

FLOW

SENSOR

8025

PULSE

INPUT

SUPPLY

2

+-

NPN/PNP

NC

COIL

PE

sinusoid (coil)

pulse, PNP

→ Set the

selector

on "COIL"

(“Figure

25”)

→ Set the

selector on

"NPN/PNP"

(“Figure

25”)

→ Any

position.

→ Set the

selector as

shown in

“Figure 26”.

→ Set selector "LOAD" on

"39K": the input impedance

on terminals 1 and 2 of

terminal block "FLOW

SENSOR" will then be

39 kW

→ Set selector "LOAD" on

"39K": the input impedance

on terminals 1 and 2 of

terminal block "FLOW

SENSOR" will then be

39 kW

39 kΩ

NC

213PE

Flow sensor

8025

39 kΩ

213PE

30

Flow sensor

English

Page 33

13

Type 8025 UNIVERSAL

Installation and wiring

Type of signal

emitted by the

flow sensor

Selector

"SENSOR

TYPE"

(

Terminal assignment of

Selector

"SENSOR

SUPPLY"

D

)

(B)

C

470

2.2K

COIL/PNP

39K

Selector "LOAD"

terminal block "FLOW

SENSOR"

LOAD

FLOW

SENSOR

39 kΩ

SUPPLY

INPUT

PULSE

2

8025

213PE

+-

NPN/PNP

NC

COIL

PE

0-5 V DC

standard

voltage signal

(TTL, for

example)

pulse, NPN

→ Set the

selector on

"NPN/PNP"

(“Figure

25”)

→ Set the

selector on

"NPN/PNP"

(“Figure

25”)

→ Set the

selector as

shown in

“Figure 26”.

→ Set the

selector as

shown in

“Figure 26”.

→ Set selector "LOAD" on

"39K": the input impedance

on terminals 1 and 2 of

terminal block "FLOW

SENSOR" will then be

39 kW

Flow sensor

8025

+3 V

R

213PE

→ Set selector "LOAD":

• either on "2.2k": the load

resistance R is then 2,2 kW

• either on "470": the load

resistance R is then 470 W

Flow sensor

31

English

Page 34

Type of signal

13

emitted by the

flow sensor

"on/off" signal

(Reed relay for

example)

Selector

"SENSOR

TYPE"

D

)

(

→ Set the

selector on

"NPN/PNP"

(“Figure

25”)

Selector

"SENSOR

SUPPLY"

(B)

→ Set the

selector as

shown in

“Figure 26”.

Selector "LOAD"

COIL/PNP

470

C

2.2K

39K

→ Set selector "LOAD":

• either on "2.2k": the load

resistance R is then 2,2 kW

• either on "470": the load

resistance R is then 470 W

Type 8025 UNIVERSAL

Installation and wiring

Terminal assignment of

terminal block "FLOW

SENSOR"

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

2

LOAD

FLOW

SENSOR

8025

R

PE

+3 V

213PE

Table 2: Default positions of selectors "SENSOR SUPPLY", "LOAD" and "SENSOR TYPE"

Selector Default position

SENSOR SUPPLY (

LOAD (

SENSOR TYPE (

C

)

D

B

)

)

L+

2.2KOhms

NPN/PNP

...

Flow sensor

32

English

Page 35

Type 8025 UNIVERSAL

Operating and commissioning

8 OPERATING AND COMMISSIONING

8.1 Safety instructions

Warning

Risk of injury due to nonconforming operating.

Nonconforming operating could lead to injuries and damage the device and its surroundings.

▶ The operators in charge of operating must have read and understood the contents of this manual.

▶ In particular, observe the safety recommendations and intended use.

▶ The device/installation must only be operated by suitably trained staff.

Warning

Danger due to nonconforming commissioning.

Nonconforming commissioning could lead to injuries and damage the device and its surroundings.

▶ Before commissioning, make sure that the staff in charge have read and fully understood the contents of the

operating instructions.

▶ In particular, observe the safety recommendations and intended use.

▶ The device / the installation must only be commissioned by suitably trained staff.

▶ Before commissioning the device, enter the K factor of the fitting used. See chap. “8.6.3”.

8.2 Operating levels of the device

The device has two operating levels: the Process level and the Configuration level.

The Process level makes it possible:

• to read the flow rate measured by the device, the value of the current transmitted on the 4-20 mA analogue

output, the values of both the daily and main totalizers.

• to reset the daily totalizer.

• to access the Configuration level.

The Configuration level comprises three menus (Parameters, Test and Information) and makes it possible:

• to set the device parameters.

• to test some device parameters.

• to read, when the status LED of the device is orange or red, the warning and fault messages generated by the

device.

Table 3: Default settings of the device

Function Default value

LANGUAGE English

UNIT of the flow rate l/min

UNIT of the totalizers litre

English

33

Page 36

Function Default value

OUTPUT AO1 4mA= 0.000

20mA= 0.000

ERR. 22mA disabled

OUTPUT DO1 pulse

PU= 0.00 litre

OUTPUTS DO2 and DO3 Hysteresis, not inverted

2- = 3- = 0.000

2+ = 3+ = 0.000

time delays 2 and 3 = 0

K FACTOR

FILTER

CUT-OFF

1

2, fast

0.000

BACKLIT level 9, activated for 30s

FLOW-WARNING W- = W+ = 0.000

VOLUME-WARNING 000000

Type 8025 UNIVERSAL

Operating and commissioning

Process level

12.6 L/MiN

16.45 MA

0......9

87654 L

231 L.

+

0......9

> 2 s

To reset the daily totalizer

(identified by a dot after the

volume units).

> 5 s

Parameters menu

ENTER

0......9

> 5 s

0......9

LANGUAGE

UNit

K-FACtOR

OUtPUt

FiLtER

tOtAL

CUt-OFF

Configuration level

ENTER

0......9

> 2 s

Test Menu

CAL AO1

FREQUENC.

FLOw

wARNiNG

END

Information menu

MEAS. OVF

DiSP. OVF

AO1 LOSt

0......9

END

ENTER

1)

34

BACKLit

END

1)

Accessible when the device status LED is orange or red (see chap. “8.3”).

English

SAVE N/Y

Process

level

Page 37

Type 8025 UNIVERSAL

Operating and commissioning

8.3 Description of the navigation keys and the status

LEDs

• Scrolling up the

parameters

• Incrementing the figure

selected

Device status LED: see

following table.

Device status

LED

Green The device operates correctly.

Orange

Status of the device

A warning message is generated.

• Selecting the displayed

parameter

• Confirming the settings

Status LED of relay DO3 (LED ON

= contact closed)

Status LED of relay DO2 (LED ON

= contact closed)

• Reading the messages

• Scrolling through the parameters

• Selecting the figure on the left

Red

Blinking,

whatever the

colour

→ Press the key for 2 seconds in the Process level to access the message. See

chap. “9.3” for the meaning of the message.

Furthermore, a relay output (DO2 or DO3) or the transistor output DO1 switches if it is

configured in the "WARNING" mode (see Figure 41 or Figure 43)

An error message has been generated and the current output sends out a 22 mA current (if

parameter "ERR. 22mA" is set to "ENABLED". See chap. “8.6.7”. ) .

→ Press the key for 2 seconds in the Process level to access the message. See

chap. “9.3” for the meaning of the message.

A check for the correct behaviour of the outputs is running (see chap. “8.7.3”)

35

English

Page 38

8.4 Using the navigation keys

You want to... Press...

move between parameters within a level or a menu.

access the Parameters menu.

•

to go to the next parameter.

•

to go to the previous parameter.

0......9

ENTER

+ simultaneously for 5 s, in the Process level

Type 8025 UNIVERSAL

Operating and commissioning

access the Test menu.

access the Information menu.

reset the daily totalizer, from the Process level.

select the displayed parameter.

confirm the displayed value.

modify a numerical value.

0......9

+ +

ENTER

simultaneously for 5 s, in the Process

level

for 2 s, in the Process level, when the device status

LED is orange or red.

0......9

+ simultaneously for 2 s, when the daily totalizer

is displayed in the Process level

ENTER

ENTER

•

to increase the blinking digit.

0......9

to select the digit at the left of the blinking digit.

•

0......9

+ to move the decimal point.

•

36

English

Page 39

Type 8025 UNIVERSAL

Operating and commissioning

8.5 Details of the Process level

This level is active by default when the device is energized.

The displayed flow rate is set to 0 (a dot is displayed after the

flow rate units when the funntion CUT-OFF is active) because

0......9

12.6 L/MiN

16.45 MA

or

0 L/MiN.

Value of the measured flow rate, displayed in the unit chosen in the "UNIT" parameter

of the Parameters menu.

Value of the current output, proportional to the measured flow rate.

the measured flow rate is below the threshold value defined in

the "CUT-OFF" parameter of the Parameters menu. See chap.

“8.6.16”.

87654 L

Value of the main totalizer, volume of fluid counted by the device since the last reset.

Value of the daily totalizer (identified by a dot after the volume units), volume of fluid

231 L.

counted by the device since the last reset.

0......9

+

> 2 s

Resetting the daily totalizer.

8.6 Details of the Parameters menu

ENTER

To access the Parameters menu, simultaneously press keys

This menu comprises the following configurable parameters:

for at least 5 s.

English

37

Page 40

Type 8025 UNIVERSAL

Operating and commissioning

0......9

LANGUAGE

UNit

K-FACtOR

OUtPUt

FiLtER

tOtAL

CUt-OFF

BACKLit

END

Choosing the display language

Choosing the flow rate unit, the number of decimals and the unit the totalizers are

displayed in.

Entering the K factor of the fitting used or have it defined through a Teach-In

procedure.

Parameterizing the 4-20 mA current output (AO1) and configuring the transistor

output (DO1) and, if the device is equipped with, the 2 relay outputs (DO2 and DO3).

Choosing the filter level of the measured flow rate, on the displayed flow rate and the

AO1 current output.

Resetting both totalizers.

Entering the measured flow rate value below which the device sets the measured flow

rate to 0 with effect on the display, the outputs and the totalizers.

Setting the brightness of the display and how long it stays ON, or deactivating the

backlight.

SAVE N/Y

Saving the changes made within the Parameters

menu or not. If the changes are saved, the device

operates with the new settings.

12.6 L/MiN

Process level

Figure 27: Diagram of the Parameters menu

8.6.1 Choosing the display language

When the device is energized for the first time, the display language is English.

LANGUAGE ENGLiSh

DEUtSCh

0......9

FRANçAiS

→ Confirm the displayed language: the

selected language is immediately active.

itALiANO

ESPANOL

UNit

Figure 28: Diagram of the "LANGUAGE" parameter of the Parameters menu

→ If you do not want to adjust another parameter, go to the "END" parameter of the Parameters menu and press

ENTER

to save the settings or not and go back to the Process level.

38

English

Page 41

Type 8025 UNIVERSAL

Operating and commissioning

8.6.2 Choosing the flow rate units, the number of decimals and the units of the totalizers

When the flow rate unit has been changed:

• Manually reset both totalizers.

• Manually convert the flow rate values in the different settings.

• If, furthermore, the unit changes from "metric" to "gallon" and vice versa, convert the K factor using following formulae:

- K factor in pulse/US Gallon = K factor in pulse/l x 3,785

- K factor in pulse/IMP Gallon = K factor in pulse/l x 4,546

The max. flow rate that can be displayed depends on the number of decimals chosen:

• 9999 if the number of decimals = 0 or AUTO,

• 999,9 if the number of decimals = 1,

• 99,99 if the number of decimals = 2,

• 9,999 if the number of decimals = 3.

• If the units chosen for the totalizers is "millilitre", the totalizer values are displayed in litres followed by

three decimals.

• If the units chosen for the totalizers is "litre", the totalizer values are displayed in litres without decimals.

The "UNIT" parameter makes it possible to choose:

• the flow rate units.

• a fixed number of decimals (choose 0, 1, 2 or 3) to display the flow rate in the Process level, or a floating

decimal point (choose "AUTO"): the device automatically adjusts the position of the decimal point depending

on the chosen unit and the measured flow rate.

• the volume units of the totalizers if the unit previously chosen is in litres, in millilitres or in m

3

. The totalizer values

are automatically displayed in gallons if the flow rate unit chosen is in gallons.

English

39

Page 42

Type 8025 UNIVERSAL

Operating and commissioning

UNit MLit/SEC

FLOw

MLit/MiN

MLit/h

Lit/SEC

Lit/MiN

Lit/h

M3/MiN

0......9

M3/h

US GAL/S

0......9

US GAL/M

US GAL/h

iMP GA/S

→ Choose the flow rate

unit.

→ Confirm

AUtO

DEC Pt 3

0......9

DEC Pt 2

DEC Pt 1

DEC Pt 0

→ Choose the

number of decimal

positions.

→ Confirm

iMP GA/M

GA/h

If the chosen unit is in litres, millilitres or m3.

tOtAL

0......9

MLitRE

LitRE

→ Choose the totalizer unit.

→ Confirm

If the chosen

unit is in

gallons.

M3

K-FACtOR

Figure 29: Diagram of the "UNIT" parameter of the Parameters menu

→ If you do not want to adjust another parameter, go to the "END" parameter of the Parameters menu and press

ENTER

to save the settings or not and go back to the Process level.

REtURN

40

English

Page 43

Type 8025 UNIVERSAL

Operating and commissioning

8.6.3 Entering the K factor of the fitting used

The device determines the flow rate in the pipe using the fitting K factor.

The K factor of the fitting used can be entered here. The device may also determine the K factor using a Teach-In

procedure: see chap. “8.6.4”.

The device will use the new K factor as soon as "SAVE YES" is confirmed when leaving the Parameters

menu.

The K factor of the fitting used is in the operating instructions of the fitting.

The operating instructions of the Bürkert fittings can be found on the CD delivered with the device or on

the internet at www.burkert.com.

K-FACtOR K=10.000

The display shows the K factor of

the fitting, last entered or determined

using a Teach-In procedure.

K=2.8500

→ Enter the K factor (value between 0.01 and

99999.9) of the fitting used.

→ Confirm the displayed value.

→ Edit the parameter.

OUtPUt VALiD N/Y

REtURN

Is only displayed if the K factor has been changed.

→ Confirm the entered K factor or not.

Figure 30: Entering the K factor of the fitting used

→ If you do not want to adjust another parameter, go to the "END" parameter of the Parameters menu and press

ENTER

to save the settings or not and go back to the Process level.

8.6.4 Determining the fitting K factor using a Teach-In procedure

The device determines the flow rate in the pipe using the fitting K factor.

The "TEACH V." or "TEACH F." parameter allows the device to determine the fitting K factor using a Teach-In

procedure. The K factor may also be directly entered: see chap. “8.6.3”.

The Teach-In can be done either depending on a known volume ("TEACH V.") or depending on the flow rate

("TEACH F.") in the pipe, measured by a reference instrument.

English

41

Page 44

Type 8025 UNIVERSAL

Operating and commissioning

Determining the fitting K factor using a Teach-In procedure depending on a volume ("TEACH V.")

The device will use the new K factor as soon as "SAVE YES" is confirmed when leaving the Parameters

menu.

→ Prepare a tank with a known volume.

→ Stop the fluid circulation.

→ Confirm "TEACH V.": "FILL END" is displayed.

K-FACtOR K=2.8500

tEACh V.

0......9

tEACh F.

The display shows the K factor of the fitting, may it have been entered

or determined by a Teach-In procedure.

FiLL END

→ Charge the pipe to fill the tank.

→ When the tank is full, confirm "FILL END":

0000.0 L

→ Enter the volume (value between 0.1 and 9999.9 in the units

chosen for the totalizers at the "UNIT" parameter) of fluid

that passed in the circuit.

→ Confirm.

K=2.9000

The device calculates the K factor of the fitting

and displays it.

→ Confirm the displayed value.

42

OUtPUt

REtURN

VALiD N/Y

→ Confirm the K factor determined through Teach-In or not.

Figure 31: Teach-In procedure depending on a volume

→ If you do not want to adjust another parameter, go to the "END" parameter of the Parameters menu and press

ENTER

to save the settings or not and go back to the Process level.

English

Page 45

Type 8025 UNIVERSAL

Operating and commissioning

Determine the fitting K factor using a Teach-In procedure depending on a volume ("TEACH F.")

The device will use the new K factor as soon as "SAVE YES" is confirmed when leaving the Parameters

menu.

→ Charge the pipe.

→ Wait for the flow rate to be stable.

→ confirm "TEACH F.": "MEASURE \" is displayed.

K-FACtOR K=10.000

tEACh V.

tEACh F.

0......9

The display shows the K factor of the fitting, may it have been entered

or determined by a Teach-In procedure.

MEASURE \

The device calculates the mean flow rate in the pipe, during

approximately 50 s.

0.000 L/MiN

→ Enter the actual flow rate (value between 0.001 and

9999, in the units chosen for the flow rate at the "UNIT"

parameter) in the pipe, which has been measured by a

reference instrument.

→ Confirm.

The device calculates the K factor of the fitting and displays

it.

K=2.8500

→ Confirm the displayed value.

OUtPUt

REtURN

VALiD N/Y

→ Confirm the K factor determined through Teach-In or

not.

Figure 32: Teach-In procedure depending on the flow rate

→ If you do not want to adjust another parameter, go to the "END" parameter of the Parameters menu and press

ENTER

to save the settings or not and go back to the Process level.

English

43

Page 46

Type 8025 UNIVERSAL

Operating and commissioning

8.6.5 Configuring the outputs (general diagram)

OUtPUt AO1

DO1 PULSE

0......9

0......9

0......9

4MA-20MA

ERR. 22MA.

REtURN

hYStERES.

wiNDOw

wARNiNG

Parameterizing the 4-20 mA analogue output, AO1. See chap.

“8.6.6”.

Activate / deactivate the generation of a 22 mA current on the

AO1 current output, when the device generates a fault. See

chap. “8.6.7”.

Configuring the transistor output DO1 as a pulse output. See

“Figure 36”, chap. “8.6.8”.

Configuring the transistor output DO1 to switch a load

depending on two threshold values. See “Figure 39” and

“Figure 38”, chap. “8.6.8”.

Configuring the transistor output DO1 to switch a load when a

warning message is generated by the device. See “Figure 41”

chap. “8.6.8”.

If the device is equipped with relays, configuring the relay

DO2

hYStERES.

output DO2 or DO3 to switch a load depending on two

threshold values. See “Figure 39”, chap. “8.6.8” and “Figure

DO3

wiNDOw

0......9

42” chap. “8.6.12”.

If the device is equipped with relays, configuring the relay

wARNiNG

output DO2 or DO3 to switch a load when a warning message

is emitted by the device. See “Figure 43” chap. “8.6.12”.

FiLtER

Figure 33: Diagram of the "OUTPUT" parameter of the Parameters menu

REtURN

8.6.6 Associating a flow rate range to the current output AO1

The 4-20 mA output provides an electrical current, the value of which reflects the flow rate measured by the

device.

Example of relation between the measuring range and the current output:

mA

20

44

English

4

20 180

l/min

Page 47

Type 8025 UNIVERSAL

Operating and commissioning

OUtPUt 4 = 20.00AO1

4MA-20MA

→ Enter the flow rate associated to a 4 mA current

value, in the unit chosen in the "UNIT" parameter.

→ Confirm.

ERR. 22MA.

See chap. 8.6.7.