Page 1

Type 8025

UNIVERSAL

Quickstart

English - Deutsch - Français

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2012 - 2013

Quickstart 1311/2_EU-ML 00564360 ORIGINAL_FR

1 ABOUT THE QUICKSTART .....................................................................3

2 INTENDED USE .............................................................................................4

3 BASIC SAFETY INFORMATION ............................................................4

4 GENERAL INFORMATION ........................................................................5

5 DESCRIPTION ................................................................................................6

6 TECHNICAL DATA ........................................................................................7

7 INSTALLATION AND WIRING ..............................................................11

8 ADJUSTMENT AND COMMISSIONING ....................................................35

9 PACKAGING, TRANSPORT .................................................................. 44

1. STORAGE ......................................................................................................44

10 DISPOSAL OF THE PRODUCT ..........................................................44

Page 3

Type 8025 UNIVERSAL

Warns against material damage.

Failure▶to▶observe▶this▶warning▶may▶result▶in▶damage▶to▶the▶device▶

About the Quickstart

1 ABOUT THE QUICKSTART

The▶quickstart▶describes▶the▶life▶cycle▶of▶the▶device.▶Please▶keep▶this▶

manual▶in▶a▶safe▶place,▶accessible▶to▶all▶users▶and▶any▶new▶owners.

Important safety information.

Respect▶the▶safety▶instructions.▶Study▶in▶particular▶the▶chapters▶

entitled▶Intended Use▶and▶Basic Safety Information.

▶▶ The▶quickstart▶must▶be▶read▶and▶understood.

The▶quickstart▶explains▶how▶to▶install,▶set,▶and▶start-up▶the▶device.

A▶detailed▶description▶of▶the▶device▶can▶be▶found▶in▶the▶related▶

operating▶instructions▶on▶the▶delivered▶CD.

1.1 Symbols used

danger

Warns against an imminent danger.

▶▶ Failure▶to▶observe▶this▶warning▶can▶result▶in▶death▶or▶in▶serious▶

injury.

Warning

Warns against a potentially dangerous situation.

▶▶ Failure▶to▶observe▶this▶warning▶can▶result▶in▶serious▶injury▶or▶even▶

death.

attention

Warns against a possible risk.

▶▶ Failure▶to▶observe▶this▶warning▶can▶result▶in▶substantial▶or▶minor▶

injuries.

note

▶▶

or▶system.

Indicates▶additional▶information,▶advice▶or▶important▶

recommendations.

Refers▶to▶information▶contained▶in▶this▶manual▶or▶in▶other▶

documents.

▶→ Indicates▶a▶procedure▶to▶be▶carried▶out.

1.2 Definition of the word "device"

The▶word▶"device"▶used▶within▶this▶manual▶refers▶to▶the▶transmitter▶

type▶8025▶Universal▶with▶serial▶numbers▶higher▶or▶equal▶to▶20▶000.

English

3

Page 4

Type 8025 UNIVERSAL

Intended use

2 INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

▶▶ The▶transmitter▶8025▶Universal▶has▶been▶designed▶to▶process▶a▶

frequency▶signal,▶received▶from▶a▶flow▶sensor▶connected▶to▶the▶

transmitter.

▶▶ This▶device▶must▶be▶protected▶against▶electromagnetic▶interfer-

ence,▶ultraviolet▶rays▶and,▶when▶installed▶outdoors,▶the▶effects▶of▶

climatic▶conditions.

▶▶ This▶device▶must▶be▶used▶in▶compliance▶with▶the▶characteristics▶

and▶commissioning▶and▶use▶conditions▶specified▶in▶the▶contractual▶documents▶and▶in▶the▶operating▶instructions.

▶▶ Requirements▶for▶the▶safe▶and▶proper▶operation▶of▶the▶device▶

are▶proper▶transport,▶storage▶and▶installation,▶as▶well▶as▶careful▶

operation▶and▶maintenance.

▶▶ Only▶use▶the▶device▶as▶intended.

•▶ Observe▶any▶existing▶restraints▶when▶the▶device▶is▶exported.

3 BASIC SAFETY INFORMATION

This▶safety▶information▶does▶not▶take▶into▶account:▶

•▶ any▶contingencies▶or▶occurrences▶that▶may▶arise▶during▶assembly,▶

use▶and▶maintenance▶of▶the▶device.

•▶ the▶local▶safety▶regulations▶for▶which▶the▶operating▶company▶

is▶responsible▶including▶the▶staff▶in▶charge▶of▶installation▶and▶

maintenance.

Danger due to electrical voltage.

▶▶ Shut▶down▶the▶electrical▶power▶source▶of▶all▶the▶conductors▶and▶

isolate▶it▶before▶carrying▶out▶work▶on▶the▶system.

▶▶ Observe▶all▶applicable▶accident▶protection▶and▶safety▶regulations▶

for▶electrical▶equipment.

Various dangerous situations

To▶avoid▶injury▶take▶care:

▶▶ not▶to▶use▶the▶device▶in▶explosive▶atmospheres.

▶▶ not▶to▶use▶the▶device▶in▶an▶environment▶incompatible▶with▶the▶

materials▶it▶is▶made▶of.

▶▶ not▶to▶subject▶the▶device▶to▶mechanical▶loads▶(e.g.▶by▶placing▶

objects▶on▶top▶of▶it▶or▶by▶using▶it▶as▶a▶step).

▶▶ not▶to▶make▶any▶external▶or▶internal▶modifications▶to▶the▶device.

4

English

Page 5

Type 8025 UNIVERSAL

General information

4 GENERAL INFORMATION

Various dangerous situations

To▶avoid▶injury▶take▶care:

▶▶ to▶prevent▶any▶unintentional▶power▶supply▶switch-on.

▶▶ to▶ensure▶that▶installation▶and▶maintenance▶work▶are▶carried▶out▶

by▶qualified,▶authorised▶personnel▶in▶possession▶of▶the▶appropriate▶tools.

▶▶ to▶guarantee▶a▶defined▶or▶controlled▶restarting▶of▶the▶process,▶

after▶a▶power▶supply▶interruption.

▶▶ to▶use▶the▶device▶only▶if▶in▶perfect▶working▶order▶and▶in▶compli-

ance▶with▶the▶instructions▶provided▶in▶the▶operating▶instructions.

▶▶ to▶observe▶the▶general▶technical▶rules▶when▶installing▶and▶using▶

the▶device.

note▶

Elements / Components sensitive to electrostatic discharges

▶▶ This▶device▶contains▶electronic▶components▶sensitive▶to▶electro-

static▶discharges.▶They▶may▶be▶damaged▶if▶they▶are▶touched▶by▶

an▶electrostatically▶charged▶person▶or▶object.▶In▶the▶worst▶case▶

scenario,▶these▶components▶are▶instantly▶destroyed▶or▶go▶out▶of▶

order▶as▶soon▶as▶they▶are▶activated.

▶▶ To▶minimise▶or▶even▶avoid▶all▶damage▶due▶to▶an▶electrostatic▶

discharge,▶take▶all▶the▶precautions▶described▶in▶the▶EN▶613405-1▶and▶5-2▶norms.

▶▶ Also▶ensure▶that▶you▶do▶not▶touch▶any▶of▶the▶live▶electrical▶

components.▶

4.1 Manufacturer's address and

international contacts

To▶contact▶the▶manufacturer▶of▶the▶device,▶use▶following▶address:

Bürkert▶SAS

Rue▶du▶Giessen

BP▶21

F-67220▶TRIEMBACH-AU-VAL

You▶may▶also▶contact▶your▶local▶Bürkert▶sales▶office.

The▶addresses▶of▶our▶international▶sales▶offices▶are▶available▶on▶the▶

internet▶at:▶www.burkert.com

4.2 Warranty conditions

The▶condition▶governing▶the▶legal▶warranty▶is▶the▶conforming▶use▶of▶

the▶device▶in▶observance▶of▶the▶operating▶conditions▶specified▶in▶this▶

manual.

4.3 Information on the Internet

You▶can▶find▶the▶user▶manuals▶and▶technical▶data▶sheets▶regarding▶

the▶type▶8025▶at:▶www.burkert.com

English

5

Page 6

Type 8025 UNIVERSAL

1

35

4

2

Description

5 DESCRIPTION

5.1 Area of application

The▶transmitter▶8025▶Universal▶can▶be▶connected▶to▶a▶remote▶flow▶

sensor▶which▶emits▶a▶frequency▶signal.▶The▶specifications▶of▶the▶flow▶

sensor▶which▶can▶be▶connected▶to▶the▶transmitter▶are▶described▶in▶

chapter▶„6▶Technical▶data“.

When▶connected▶to▶a▶ flow▶ sensor,▶ the▶device▶makes▶it▶ possible▶ to▶

switch▶a▶solenoid▶valve,▶activate▶an▶alarm▶or▶generate▶a▶flow▶rate▶proportional▶frequency,▶thanks▶to▶a▶transistor▶output▶and,▶for▶some▶versions,▶

by▶means▶of▶two▶relay▶outputs,▶fully▶configurable,▶and▶to▶establish▶a▶

control▶loop▶thanks▶to▶a▶4-20▶mA▶current▶output.

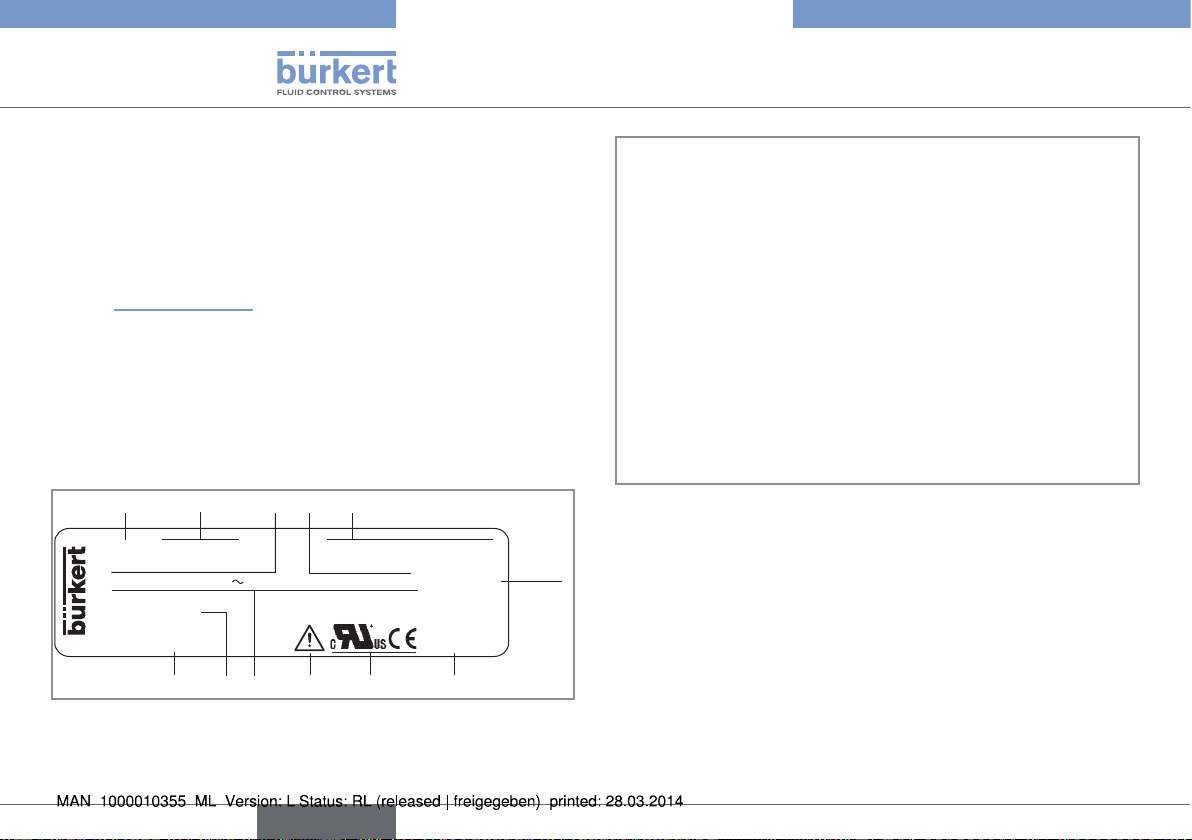

5.2 Description of the name plate

LFLOW 8025 PANEL SUPPLY: 12-36V= 210 mA

DO1: 5-36V= 100mA AO1:4-20mA

DO2&3: 2xRelay 30 and 42V peak or 60V... max. IP20

S/N 20 000

Made in France

00564417 W46MA

10

9

781112

6

1.▶ Measured▶value

2.▶ Type▶of▶the▶device,▶housing

3.▶ Specifications▶of▶the▶transistor▶output▶DO1

4.▶ Specifications▶of▶the▶analogue▶output▶AO1▶

5.▶ Supply▶voltage▶and▶max.▶current▶consumption

6.▶ Protection▶class▶of▶the▶device

7.▶ Manufacturing▶code

8.▶ Conformity▶logos

9.▶ Warning:▶Before▶using▶the▶device,▶take▶into▶account▶the▶technical▶specifications▶described▶in▶these▶operating▶instructions.

10.▶Specifications▶of▶the▶relay▶outputs▶DO2▶and▶DO3

11.▶Serial▶number

12.▶Order▶code

Fig. 1: Name plate of transmitter 8025 Universal (example)

6

English

Page 7

Type 8025 UNIVERSAL

Technical data

6 TECHNICAL DATA

6.1 Conditions of use

Ambient▶temperature -10▶to▶+60▶°C

Air▶humidity <▶80▶%,▶non▶condensated

Height▶above▶sea▶level max.▶2000▶m

Installation▶class Class▶I▶acc.▶to▶UL▶61010-1

Degree▶of▶pollution Degree▶2▶acc.▶to▶EN▶61010-1

Protection▶rating

•▶ wall-mounted▶version▶

▶

▶

▶

•▶ panel▶version

6.2 Conformity to standards and

directives

The▶device▶conforms▶to▶the▶EC▶directives▶through▶the▶following▶

standards:

•▶ EMC:▶EN▶61000-6-2,▶EN▶61000-6-3

•▶ LVD:▶EN▶61010-1

•▶ Environnemental▶testing:

acc.▶to▶EN▶60529

•▶ IP65,▶device▶wired,▶cable▶glands▶

tightened,▶cover▶lid▶screwed▶tight▶and▶

entry▶item▶nuts▶of▶the▶cable▶glands▶

tightened▶at▶a▶screwing▶torque▶of▶

1.5▶Nm.

•▶ front▶side▶IP65,▶rear▶side▶IP20

▶- Vibration:▶EN▶60068-2-6,

▶- Shock:▶EN▶60068-2-27.

The▶UL▶devices▶with▶PU01▶variable▶key▶comply▶with▶the▶following▶

standards:

•▶ UL▶61010-1

•▶ CAN/CSA-C22.2▶n°▶61010-1

6.3 Mechanical data

Part Material

Housing▶and▶cover,▶wall-mounted▶version ABS

Cable▶glands,▶wall-mounted▶version PA

Open▶housing,▶panel▶version PC

Foil polyester

4▶screws Stainless▶steel

Cable▶clips PA

English

7

Page 8

Type 8025 UNIVERSAL

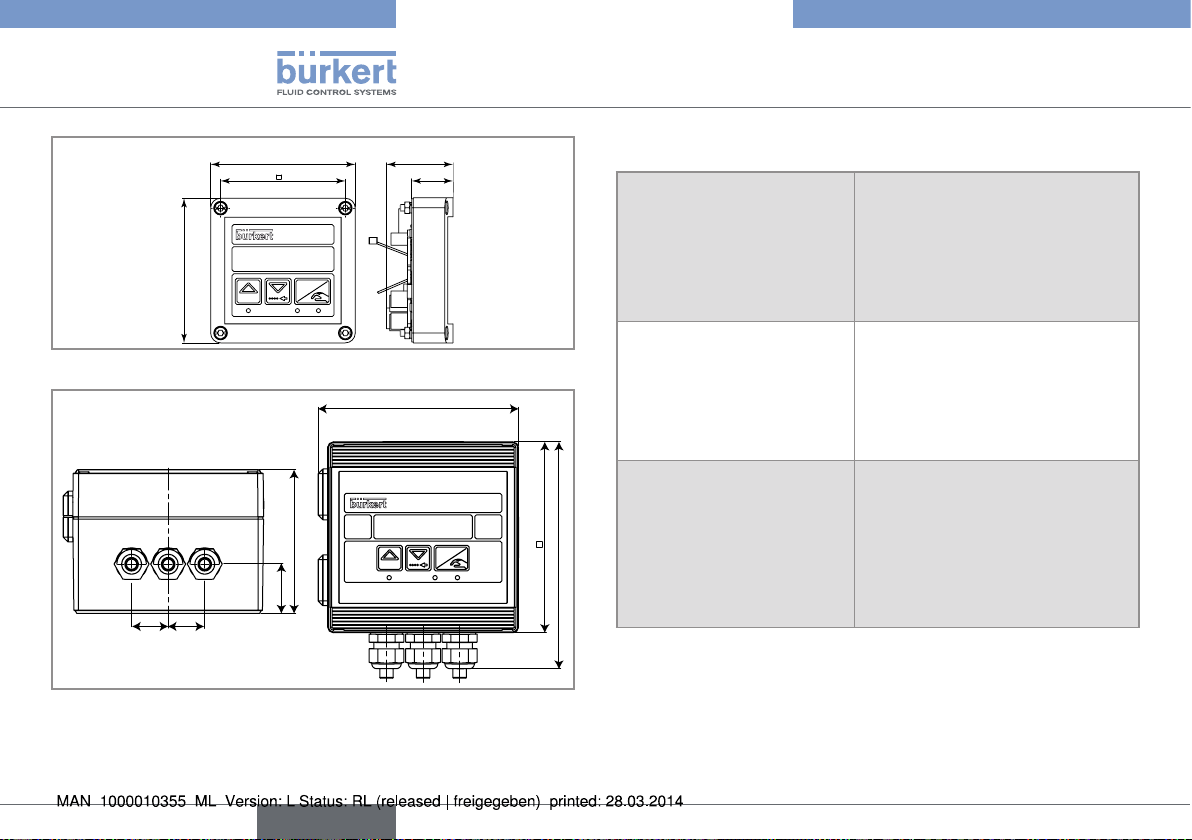

126

Technical data

88

76

FLOW

88

ENTER

0....9

40

25

Fig. 2: Dimensions of transmitter 8025 Universal, panel version [mm]

FLOW

120

23

23

90

31.50

0....9

ENTER

Fig. 3: Dimensions of transmitter 8025 Universal, wall-mounted

version [mm]

6.4 Electrical data

Power▶supply▶12-36▶V▶DC •▶ filtered▶and▶regulated

Power▶source▶(not▶provided) •▶ Source▶with▶limited▶power▶in▶

Power▶supply▶115/230▶V▶AC

•▶ frequency

•▶ supplied▶voltage

143

•▶ current

•▶ integrated▶protection

•▶ power

•▶ SELV▶circuit,▶with▶a▶safe▶energy▶

level

•▶ max.▶tolerance▶12▶V▶DC:▶-5▶%▶or▶

+10%

•▶ max.▶tolerance▶36▶V▶DC:▶±10▶%

accordance▶with▶§▶9.3▶of▶the▶

EN▶61010-1▶standard

•▶ or▶class▶2▶source▶in▶accordance▶

with▶the▶UL▶1310/1585▶and▶

EN▶60950-1▶standards

•▶ 50/60▶Hz

•▶ 27▶V▶DC,▶regulated

•▶ max.▶250▶mA

•▶ 250▶mA▶time▶delay▶fuse

•▶ 6▶VA

8

English

Page 9

Type 8025 UNIVERSAL

Technical data

Current▶consumption▶

(without▶the▶consumption▶of▶

the▶4-20▶mA▶output)

•▶ version▶without▶

relays,▶energized▶with▶

12-36▶V▶DC

•▶ version▶with▶relays,▶energized▶with▶12-36▶V▶DC

•▶ version▶without▶

relays,▶energized▶with▶

115/230▶V▶AC

•▶ version▶with▶relays,▶energized▶with▶115/230▶V▶AC

▶

▶

•▶ 60▶mA▶(at▶12▶V▶DC)▶and▶30▶mA▶

(at▶36▶V▶DC)▶

•▶ 90▶mA▶(at▶12▶V▶DC)▶and▶45▶mA▶

(at▶36▶V▶DC)

•▶ 40▶mA▶

▶

•▶ 55▶mA

Transistor output DO1

•▶ type

•▶ function▶

•▶ frequency▶(f)

•▶ Electrical▶data▶

▶

•▶ duty▶cycle▶if▶

0,6▶<▶f▶<▶300▶Hz

•▶ duty▶cycle▶if▶

300▶<▶f▶<▶1500▶Hz

•▶ duty▶cycle▶if▶

1500▶<▶f▶<▶2200▶Hz

•▶ protection

polarized,▶potential-free

•▶ NPN▶/▶PNP▶(wiring▶dependent)

•▶ pulse▶output▶(by▶default),▶user▶

configurable

•▶ 0,6-2200▶Hz

•▶ 5-36▶V▶DC,▶100▶mA▶max.,▶

voltage▶drop▶2,7▶V▶DC▶at▶

100▶mA

•▶ >▶0.45▶

•▶ >▶0.4▶

•▶ <▶0.4▶

•▶ galvanically▶isolated,▶and▶

protected▶against▶overvoltages,▶polarity▶reversals▶and▶

short-circuits

English

9

Page 10

Type 8025 UNIVERSAL

Technical data

Relay outputs (DO2 and

DO3)

•▶ operating▶

•▶ electrical▶data▶of▶the▶load▶

(non▶UL▶devices)

•▶ electrical▶data▶of▶the▶load▶

(UL▶devices)

•▶ max.▶breaking▶capacity

•▶ life▶span

Current output AO1

•▶ specification▶

▶

•▶ max.▶loop▶impedance▶if▶the▶

device▶is▶energized▶with▶

12-36▶V▶DC▶

•▶ max.▶loop▶impedance▶if▶the▶

device▶is▶energized▶with▶

115/230▶V▶AC

▶

•▶ hysteresis▶(by▶default),▶user▶configurable,▶normally▶open

•▶ 230▶V▶AC▶/▶3▶A▶or▶

40▶V▶DC▶/▶3▶A

•▶ max.▶30▶V▶AC▶and▶42▶V▶peak▶or▶

max.▶60▶V▶DC,▶3▶A

•▶ 750▶VA▶(resistive▶load)

•▶ ▶min.▶100000▶cycles

•▶ 4-20▶mA,▶sink▶or▶source▶(wiring▶

dependent),▶22▶mA▶to▶indicate▶a▶

fault▶(can▶be▶activated)

•▶ 1300W▶at▶36▶V▶DC,▶1000W▶at▶

30▶V▶DC,▶750W▶at▶24▶V▶DC,▶

300W▶at▶15▶V▶DC,▶200W▶at▶

12▶V▶DC

•▶ 900W

6.5 Specifications of the connected

flow sensor

Signal▶originating▶from▶the▶

remote▶sensor

•▶ type▶

▶

▶

•▶ frequency

•▶ max.▶voltage

Input▶impedance

Power▶supply supplied▶by▶the▶transmitter▶depending▶

▶

•▶ pulse,▶sine-wave▶(typical▶sensitivity▶50▶mV▶peak-to-peak▶at▶250▶

Hz),▶"on/off",▶or▶standard▶voltage▶

0-5▶V▶DC

•▶ 0,6▶Hz▶to▶2,2▶kHz,▶can▶be▶adjusted

•▶ 36▶V▶DC

depends▶on▶the▶position▶of▶selector▶

"LOAD"▶on▶the▶electronic▶board▶of▶the▶

8025.▶See▶chap.▶„7.4.10“

on▶the▶position▶of▶selector▶"SENSOR▶

SUPPLY"▶of▶the▶8025,▶either:

•▶ 5▶V▶DC,▶30▶mA▶max.

•▶ (L+)-12V:▶supply▶voltage▶(L+)▶of▶the▶

transmitter▶minus▶12▶V▶DC▶(minus▶

12,5▶V▶DC▶max.),▶80▶mA▶max.

•▶ L+:▶supply▶voltage▶(L+)▶of▶the▶

transmitter▶(minus▶1,5▶V▶DC▶max.),▶

140▶mA▶max.▶(if▶the▶device▶is▶energized▶with▶12-36▶V▶DC),▶80▶mA▶

max.▶(if▶the▶device▶is▶energized▶with▶

115/230▶V▶AC)

10

English

Page 11

Type 8025 UNIVERSAL

Installation and wiring

6.6 Electrical connection

Type▶of▶connection on▶the▶terminal▶blocks▶of▶the▶

electronics▶(and▶through▶cable▶

glands▶M16x1,5,▶for▶the▶wallmounted▶versions)

Cable▶specifications

•▶ cable▶type

•▶ Cross▶section▶of▶wires

•▶ Diameter▶of▶each▶cable▶(for▶

the▶cable▶glands▶M16x1,5▶of▶

the▶wall-mounted▶version)

•▶ shielded

•▶ 0.2▶to▶1.5▶mm

•▶ 4▶to▶8▶mm

2

7 INSTALLATION AND WIRING

7.1 Safety instructions

danger

Risk of injury due to electrical voltage.

▶▶ Shut▶down▶the▶electrical▶power▶source▶of▶all▶the▶conductors▶and▶

isolate▶it▶before▶carrying▶out▶work▶on▶the▶system.

▶▶ Observe▶all▶applicable▶accident▶protection▶and▶safety▶regula-

tions▶for▶electrical▶equipment.

Warning

Risk of injury due to non-conforming installation.

▶▶ The▶electrical▶installation▶can▶only▶be▶carried▶out▶by▶qualified▶

and▶skilled▶staff▶with▶the▶appropriate▶tools.

▶▶ Install▶appropriate▶safety▶devices▶(correctly▶rated▶fuse▶and/or▶

circuit-breaker);▶For▶the▶versions▶with▶a▶115/230▶V▶AC▶supply▶voltage,▶insert▶a▶safety▶device▶between▶the▶phase▶and▶the▶

neutral▶conductor.

▶▶ Respect▶standard▶NF▶C▶15-100▶/▶IEC▶60364.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶▶ Take▶appropriate▶measures▶to▶avoid▶unintentional▶activation▶of▶

the▶installation.

▶▶ Guarantee▶a▶set▶or▶controlled▶restarting▶of▶the▶process▶subse-

quent▶to▶any▶intervention▶on▶the▶device.

English

11

Page 12

Type 8025 UNIVERSAL

Installation and wiring

Protect▶this▶device▶against▶electromagnetic▶interference,▶

ultraviolet▶rays▶and,▶when▶installed▶outdoors,▶the▶effects▶of▶

the▶climatic▶conditions.

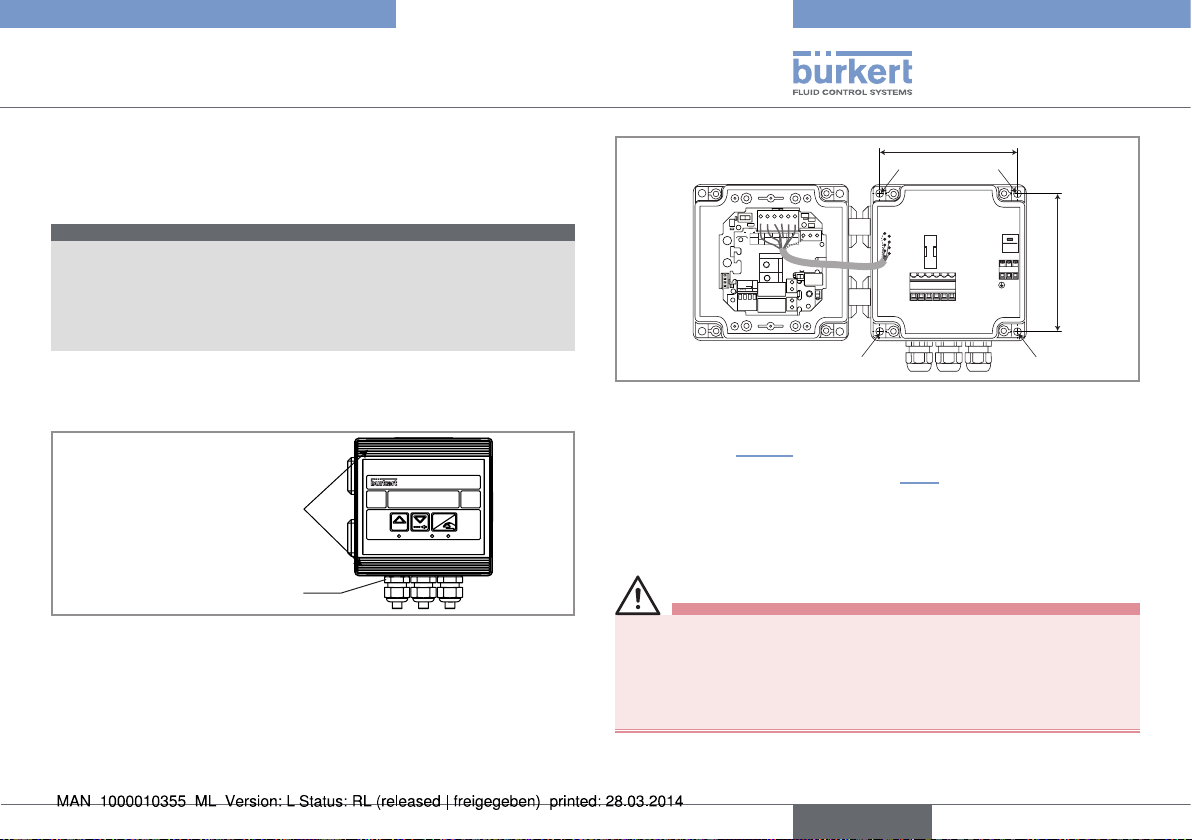

7.2 Installation of a panel version

Install▶the▶panel▶version▶of▶the▶device▶in▶a▶cabinet▶with▶a▶

protection▶class▶at▶least▶IP54▶to▶ensure▶a▶degree▶of▶pollution▶2▶inside▶the▶cabinet.

▶→ To▶cut▶the▶opening▶in▶the▶cabinet▶door,▶use▶the▶supplied▶drilling▶

jig,▶respecting▶the▶dimensions▶indicated▶in▶„Fig.▶4“.

95

80

76

50

95

80

76

50

Fig. 4: Dimensions of the drilling jig [mm]

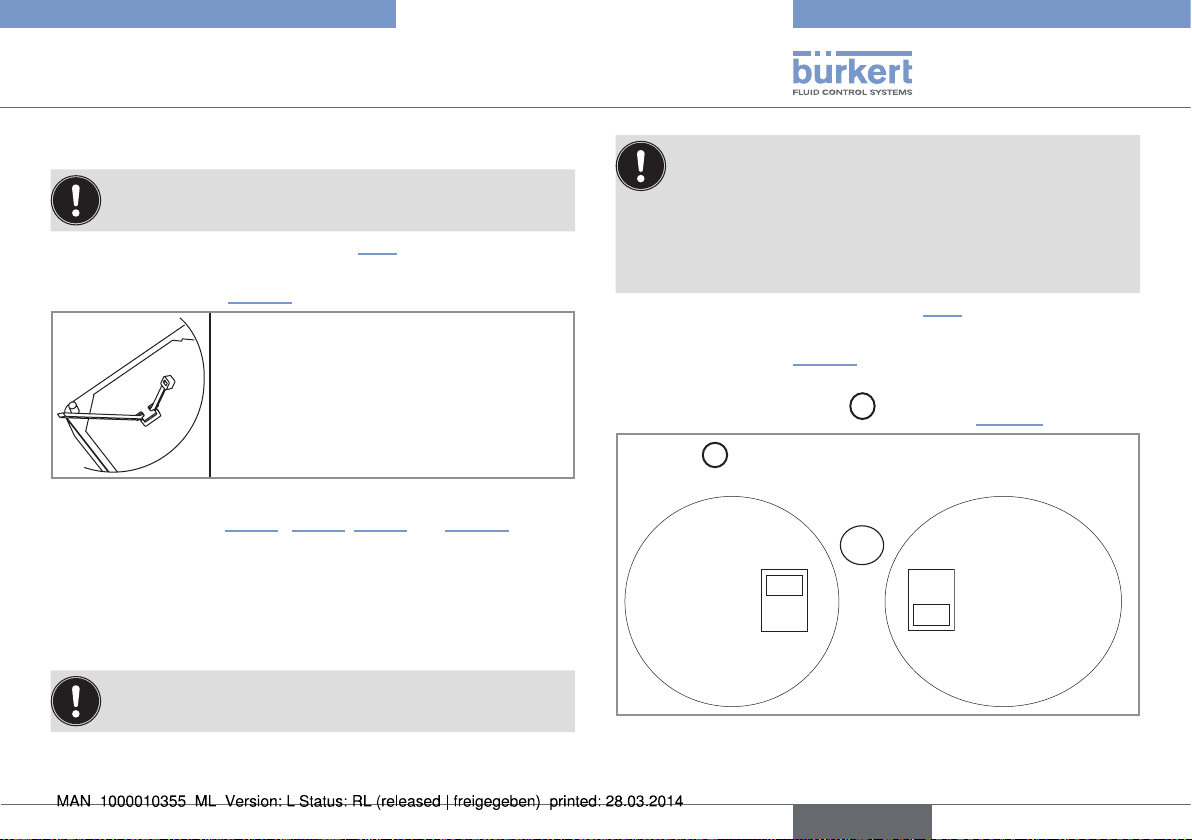

▶→ Insert▶the▶4▶screws▶in▶the▶housing▶(from▶the▶front).

▶→ Insert▶the▶seal▶on▶the▶external▶threads▶of▶the▶4▶screws▶(rear▶of▶

the▶housing).

▶→ Put▶the▶assembly▶on▶the▶cutout,▶electronics▶turned▶to▶the▶inside▶

of▶the▶cabinet.

▶→ Put▶the▶4▶washers▶on▶the▶4▶screws.

▶→ Put▶a▶nut▶on▶each▶of▶the▶4▶screws▶and▶tighten▶the▶nuts▶to▶secure▶

the▶device▶to▶the▶cabinet.

Screws

Washer

Nut

Cable▶clip

Seal

Fig. 5: Installation of a 8025, panel version

12

English

Page 13

Type 8025 UNIVERSAL

11

Installation and wiring

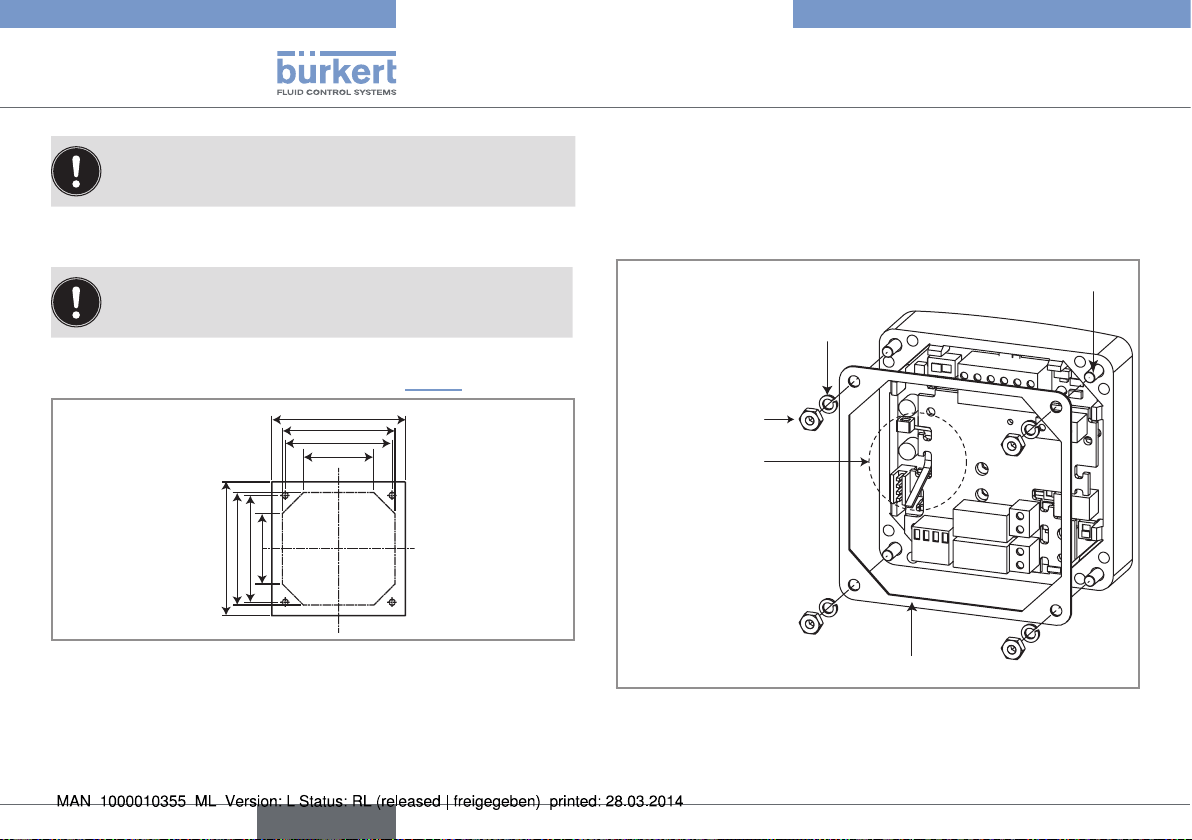

7.3 Installation of a wall-mounted

version

note

Risk of material damage if the cable glands are not tightly

screwed on the housing

▶▶ Before▶installing▶the▶wall-mounted▶housing▶on▶its▶support,▶

tighten▶the▶nuts▶of▶the▶entry▶item▶of▶the▶cables▶glands▶at▶a▶torque▶

of▶1.5▶Nm.

The▶flow▶transmitter▶in▶a▶wall-mounted▶version▶has▶4▶holes▶in▶the▶

bottom▶of▶the▶housing.

▶→ Remove▶the▶blanking▶strips▶covering▶the▶screws.

FLOW

Blanking▶strips

Nut▶of▶the▶entry▶item

▶→ Loosen▶the▶4▶screws▶and▶open▶the▶cover▶to▶get▶access▶to▶the▶holes▶[1].

ENTER

0....9

106 mm

SOURCE SINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

PULSE

Supply

Batch

DO1

12..36Vdc

NC

PE

ISOG

DO4

DI4

DI3

DI2

DI1

INPUT

PULSE

FLOW

SENSOR

PE PEPE

SENSOR

+5V

L+

SENSOR TYPE

SUPPLY

(L+)-12V

COIL NPN/PNP

COIL/PNP

470

2.2K

39K

LOAD

SUPPLY

+-

NC

COIL

213PE

OFFON

NPN/PNP

DO2

DO3

T 250 mA

56789 10

230V

230V

230V

106 mm

LN

LN

1 1

Fig. 6: Installation of a wall-mounted version

▶→ Secure▶the▶housing▶to▶the▶support▶respecting▶the▶dimensions▶

indicated▶in▶„Fig.▶6“.

▶→ Wire▶acc.▶to▶instructions▶in▶chap.▶„7.4“.

▶→ Close▶the▶housing▶and▶tighten▶the▶4▶screws▶of▶the▶cover.

7.4 Wiring

danger

Risk of injury due to electrical voltage.

▶▶ Shut▶down▶the▶electrical▶power▶source▶of▶all▶the▶conductors▶and▶

isolate▶it▶before▶carrying▶out▶work▶on▶the▶system.

▶▶ Observe▶all▶applicable▶accident▶protection▶and▶safety▶regula-

tions▶for▶electrical▶equipment.

English

13

Page 14

Type 8025 UNIVERSAL

Installation and wiring

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶

glands▶of▶a▶wall-mounted▶version▶to▶ensure▶the▶tightness▶of▶

the▶device.

Only▶move▶the▶selectors▶when▶the▶power▶supply▶is▶off.

•▶ Use▶a▶filtered▶and▶regulated▶12-36▶V▶DC▶power▶supply.

•▶ Make▶sure▶the▶installation▶is▶equipotential.▶See▶chap.▶

„7.4.1“.

•▶ Use▶shielded▶cables▶with▶a▶temperature▶limit▶of▶80▶°C▶

minimum.

•▶ Do▶not▶install▶the▶cables▶near▶high▶voltage▶or▶high▶frequency▶cables;▶If▶this▶cannot▶be▶avoided,▶observe▶a▶min.▶

distance▶of▶30▶cm.

•▶ Protect▶the▶device▶power▶supply▶by▶means▶of▶a▶300▶mA▶

fuse▶and▶a▶switch.

•▶ Protect▶the▶power▶supply▶of▶each▶transistor▶output▶by▶

means▶of▶a▶125▶mA▶fuse.

•▶ Protect▶the▶relays▶by▶means▶of▶a▶max.▶3▶A▶fuse▶and▶a▶

circuit▶breaker▶(depending▶on▶the▶process).

•▶ Do▶not▶apply▶both▶a▶dangerous▶voltage▶and▶a▶safety▶extralow▶voltage▶to▶the▶relays.

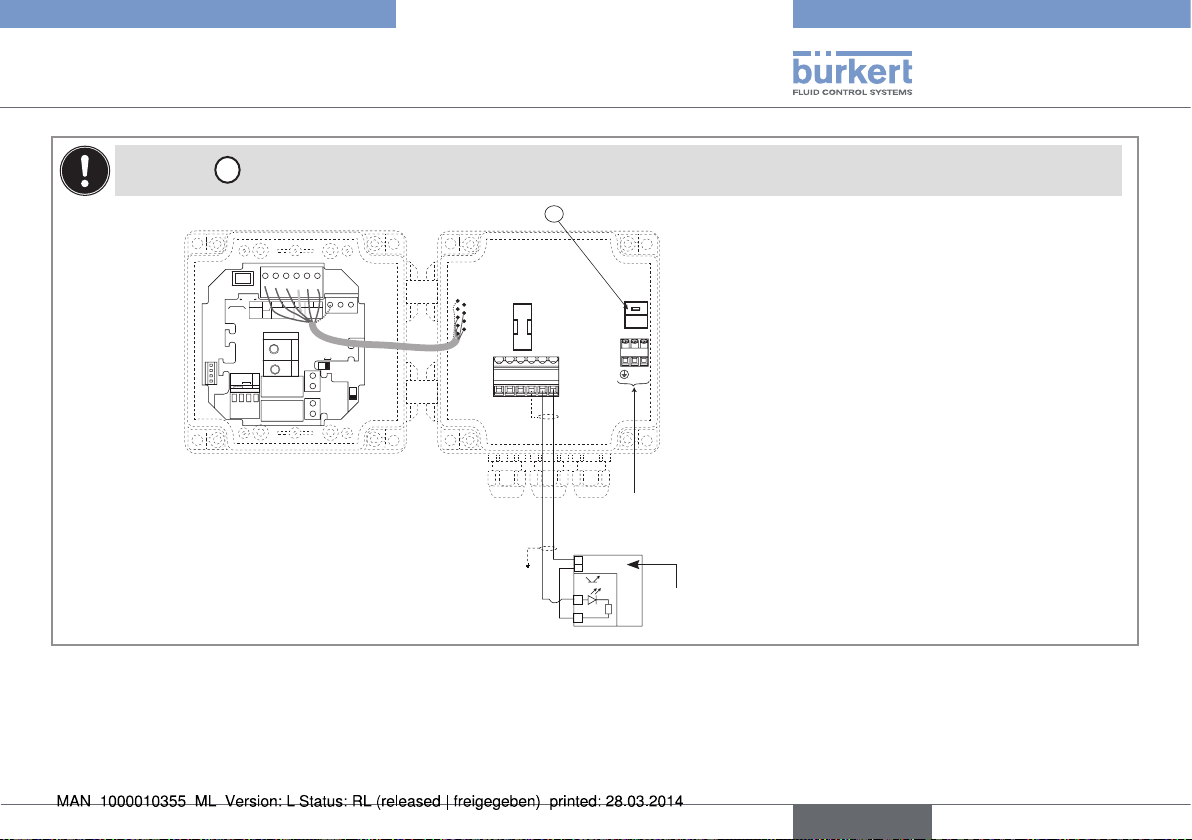

7.4.1 Equipotentiality of the installation

To▶ensure▶the▶equipotentiality▶of▶the▶installation▶(power▶supply▶-▶

device▶-▶fluid):

▶→ Connect▶together▶the▶various▶earth▶spots▶in▶the▶installation▶to▶

eliminate▶the▶potential▶differences▶that▶may▶occur▶between▶different▶earthes.

▶→ Observe▶faultless▶earthing▶of▶the▶shield▶of▶the▶power▶supply▶

cable,▶at▶both▶ends.

▶→ Connect▶the▶negative▶power▶supply▶terminal▶to▶the▶earth▶to▶sup-

press▶the▶effects▶of▶common▶mode▶currents.▶If▶this▶connection▶

cannot▶be▶made▶directly,▶a▶100▶nF/50▶V▶capacitor▶can▶be▶fitted▶

between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth.▶

▶→ Special▶attention▶has▶to▶be▶paid▶if▶the▶device▶is▶installed▶on▶

plastic▶pipes▶because▶there▶is▶no▶direct▶earthing▶possible.▶

Proper▶earthing▶is▶performed▶by▶earthing▶together▶the▶metallic▶

instruments▶such▶as▶pumps▶or▶valves,▶that▶are▶as▶close▶as▶possible▶to▶the▶device.▶If▶no▶such▶instrument▶is▶near▶the▶device,▶

insert▶metallic▶earth▶rings▶inside▶the▶plastic▶pipes▶upstream▶and▶

downstream▶the▶device▶and▶connect▶these▶parts▶to▶the▶same▶

earth.▶The▶earthing▶rings▶must▶be▶in▶contact▶with▶the▶fluid.

14

English

Page 15

Type 8025 UNIVERSAL

Installation and wiring

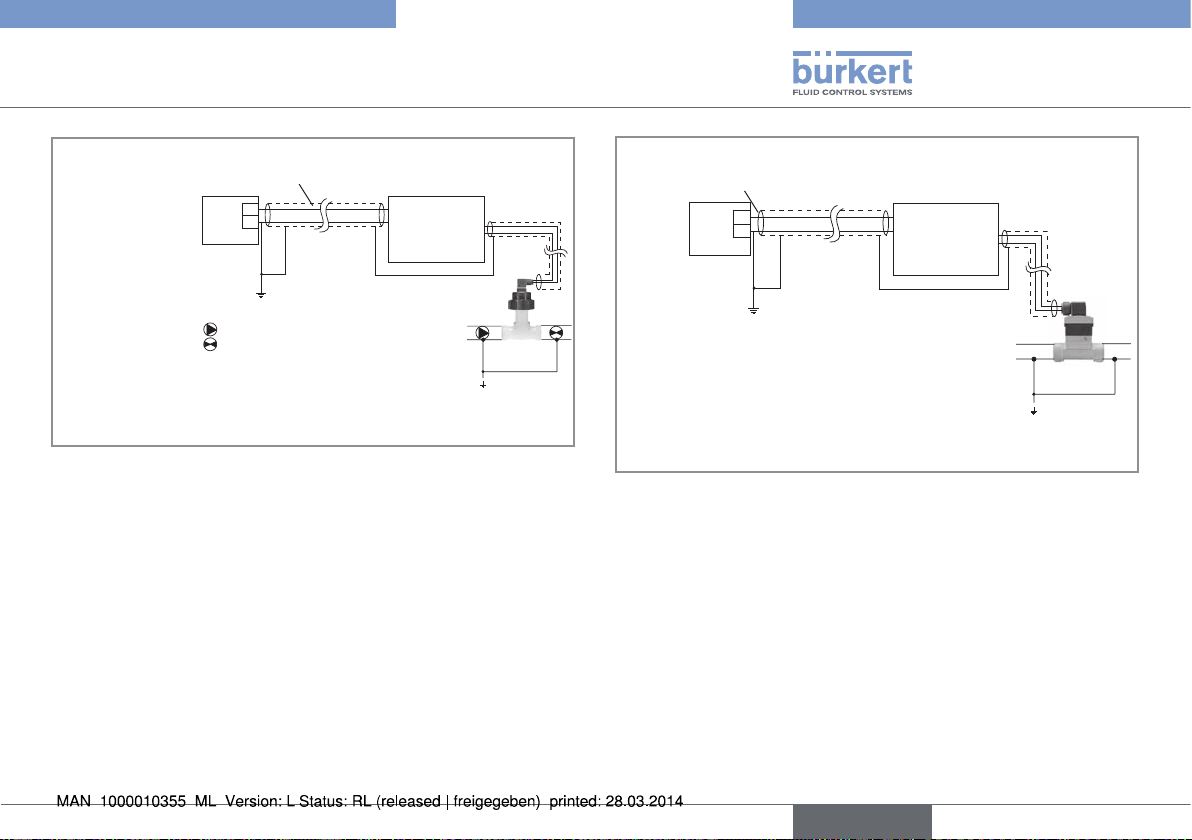

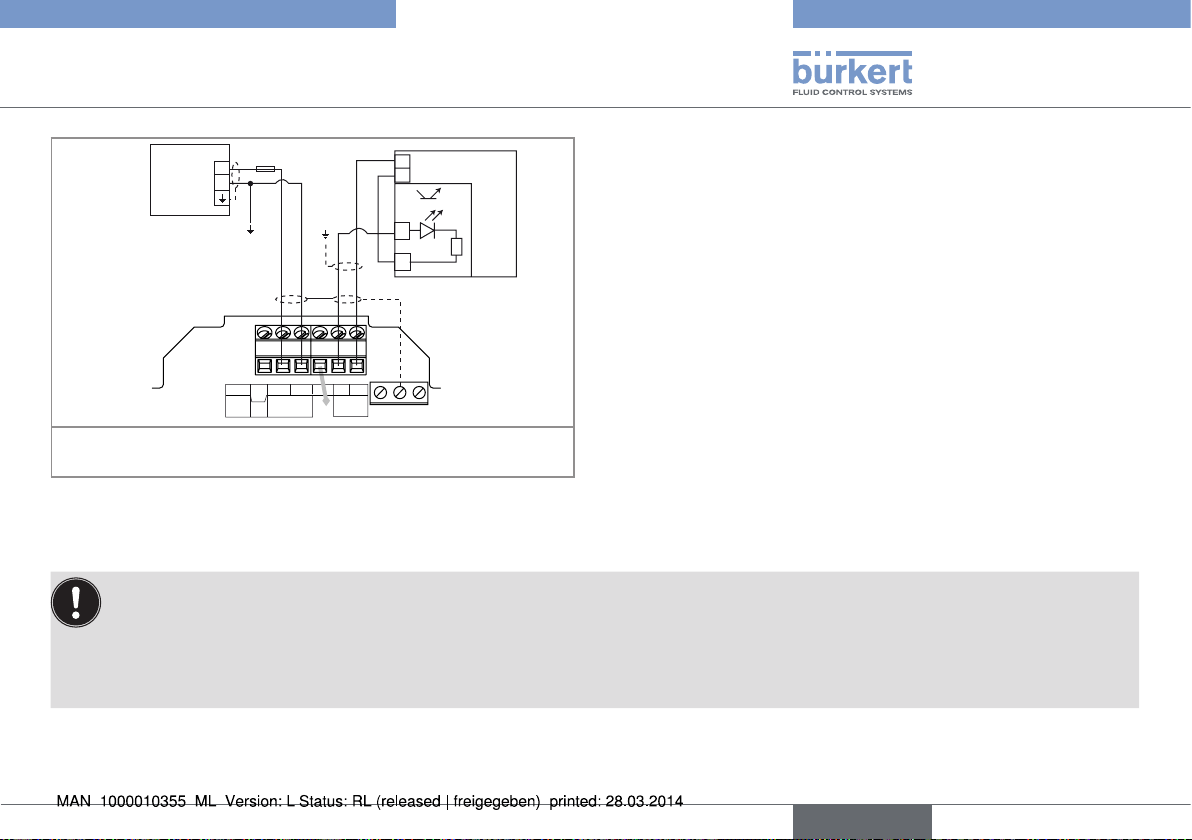

Power▶cable▶shield

+

-

Power▶supply

Valve,▶pump,...▶(or▶earth▶

rings,▶not▶provided,▶

inserted▶into▶the▶pipe)▶

(*)▶

If▶a▶direct▶earth▶connection▶is▶not▶possible,▶fit▶a▶100▶nF▶/▶50▶V▶capacitor▶

(*)

8025▶Universal

Flow▶sensor

Plastic▶pipe

between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth.

Fig. 7: Equipotentiality skeleton diagram with pipes in plastic

Power▶cable▶shield

+

-

Power▶supply

(*)▶

If▶a▶direct▶earth▶connection▶is▶not▶possible,▶fit▶a▶100▶nF▶/▶50▶V▶capacitor▶

(*)

8025▶Universal

Flow▶sensor

Metal▶pipe

between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth.

Fig. 8: Equipotentiality skeleton diagram with pipes in metal

English

15

Page 16

Type 8025 UNIVERSAL

1

Installation and wiring

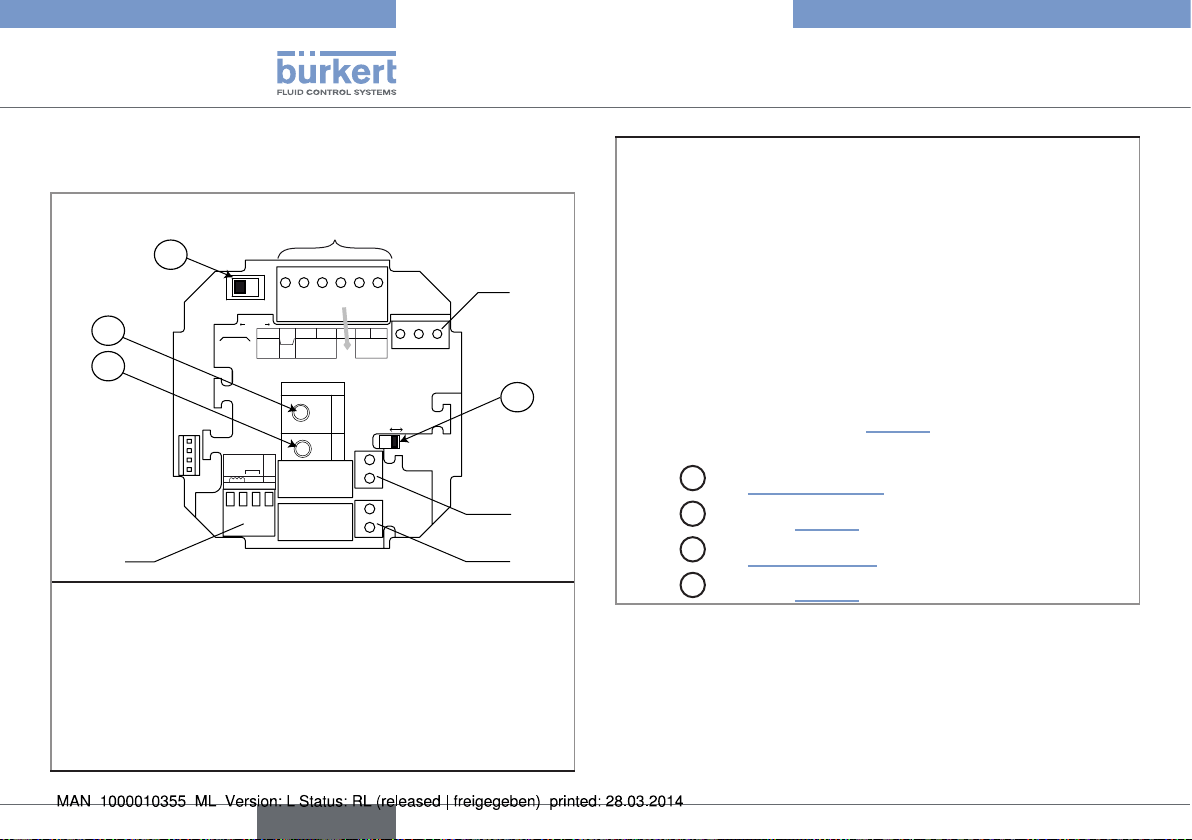

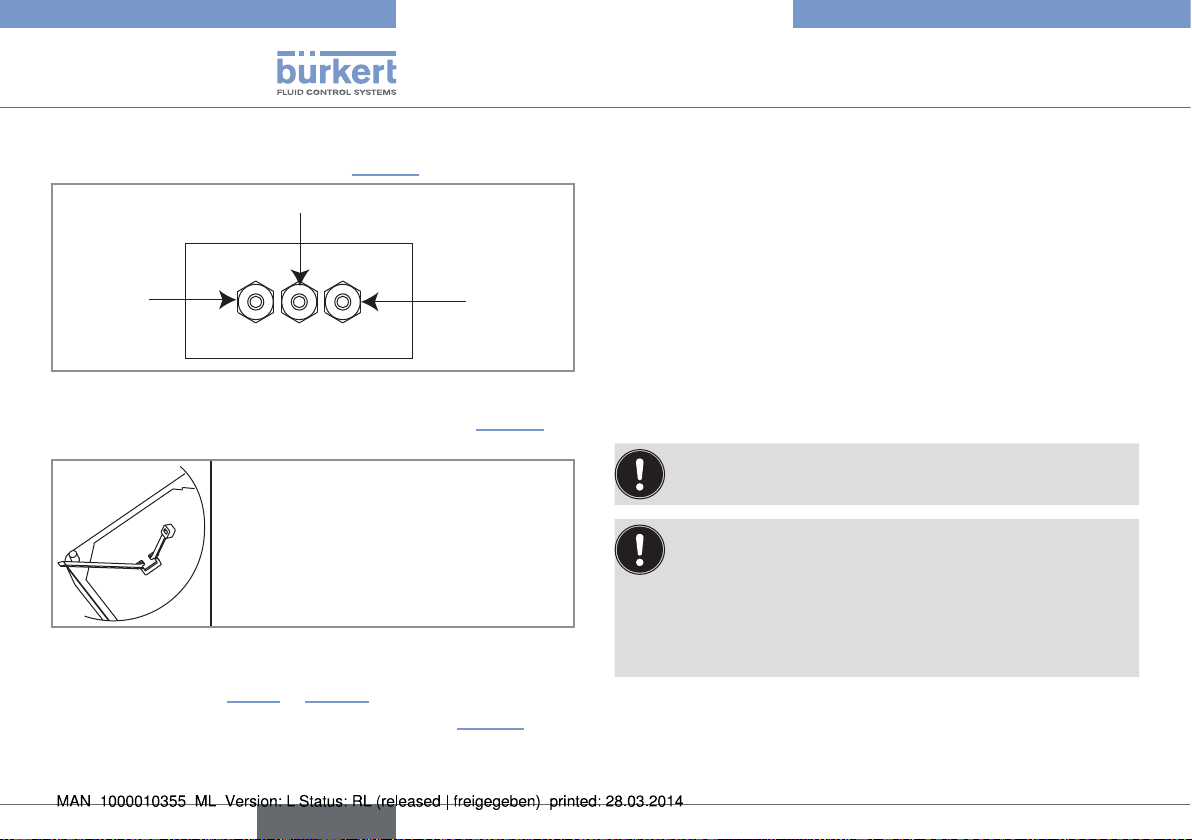

7.4.2 Terminal assignment and use of the

selectors

A

2

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

FLOW

PULSE

PE

ISOG

DO4

DI4

DI3

DI2

DI1

INPUT

Univ

Batch

SUPPLY

+-

NC

213PE

COIL

(AO1)

NC

L+

2.2K

NPN/PNP

Supply

12..36Vdc

SENSOR

+5V

(L+)-12V

470

39K

SUPPLY

COIL/PNP

LOAD

PULSE

DO1

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

PE PEPE

D

OFF ON

3

4

B

C

SENSOR

5

Terminal block 1

•▶ Iout:▶4-20▶mA▶output▶(AO1)

•▶ L+:▶V+▶(positive▶voltage)

•▶ L-:▶0V▶(power▶supply▶ground)

•▶ PE:▶protective▶earth,▶factory▶wired

•▶ P-:▶Negative▶transistor▶output▶(DO1)

•▶ P+:▶Positive▶transistor▶output▶(DO1)

Terminal block 2

PE:▶Shieldings▶of▶both▶the▶power▶supply▶cable▶and▶the▶AO1▶and▶

DO1▶output▶cables

Terminal block 3:▶Wiring▶of▶the▶relay▶output▶DO2▶(if▶the▶device▶

has▶relays).

Terminal block 4:▶Wiring▶of▶the▶relay▶output▶DO3▶(if▶the▶device▶

has▶relays).

Terminal block 5 "FLOW SENSOR": Wiring▶the▶remote▶flow▶

sensor.▶The▶wiring▶depends▶on▶the▶type▶of▶output▶signal▶originating▶

from▶the▶flow▶sensor:▶see▶chap.▶„7.4.10“.

Switch▶

Switch▶

Switch▶

Switch▶

A

:▶see▶„Fig.▶15“▶page▶21

B

:▶see▶chap.▶„7.4.10“

C

:▶see▶„Tab.▶1“▶page▶29

D

:▶see▶chap.▶„7.4.10“

Fig. 9: Terminal assignment of a panel version or a wall-mounted

version, 12-36 V DC

16

English

Page 17

Type 8025 UNIVERSAL

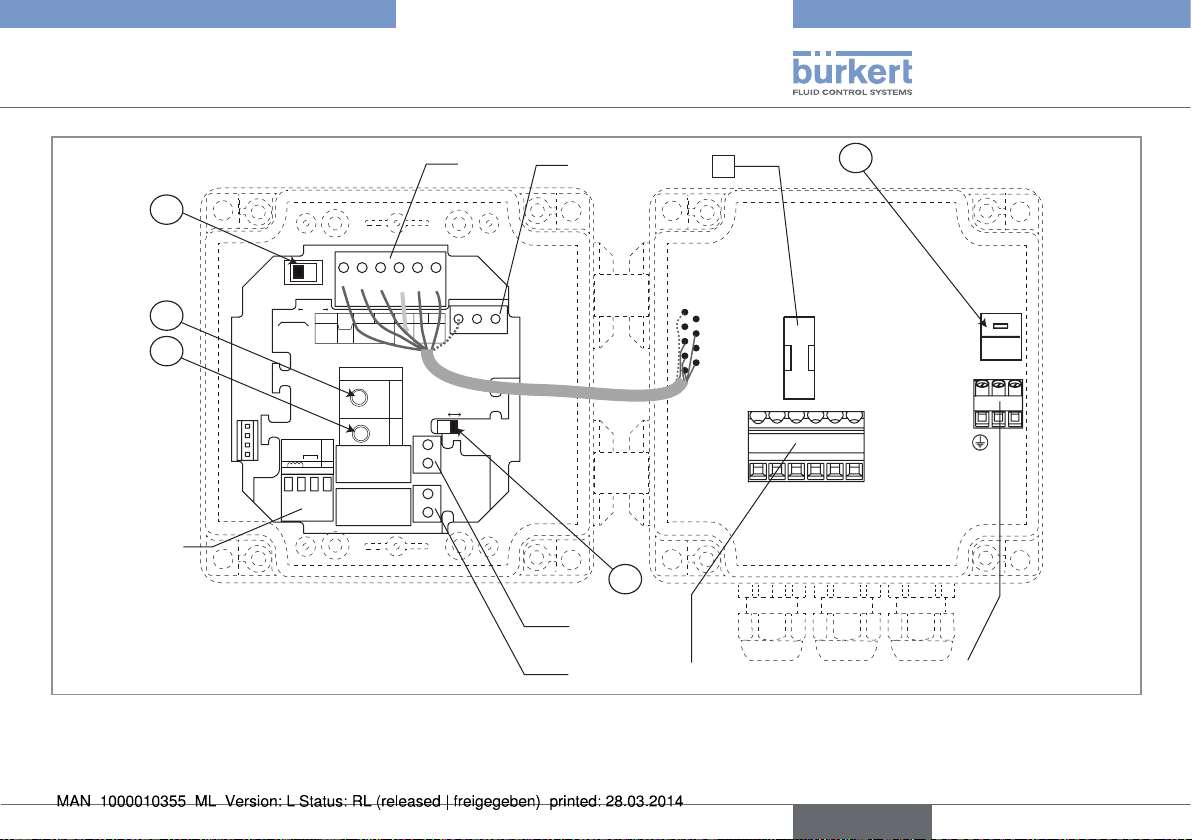

Installation and wiring

2

1

8

E

A

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

FLOW

PULSE

PE

ISOG

DO4

DI4

DI3

DI2

DI1

INPUT

SUPPLY

+-

NC

213PE

Univ

Batch

COIL

(AO1)

NC

L+

2.2K

NPN/PNP

Supply

12..36Vdc

SENSOR

+5V

(L+)-12V

470

39K

SUPPLY

COIL/PNP

LOAD

PULSE

DO1

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

PE PEPE

230V

230V

230V

T 250 mA

LN

OFF ON

56789 10

LN

B

C

SENSOR

3

D

4

5

6 7

English

17

Page 18

Type 8025 UNIVERSAL

Installation and wiring

Terminal block 1

PE:▶factory▶wired▶shield.

Terminal block 2

•▶ Iout:▶4-20▶mA▶output▶(green▶wire,▶factory▶wired)

•▶ L+:▶V+▶(red▶wire,▶factory▶wired)

•▶ L-:▶0V▶(black▶wire,▶factory▶wired)

•▶ PE:▶protective▶earth,▶factory▶wired

•▶ P-:▶negative▶transistor▶output▶(brown▶wire,▶factory▶wired)

•▶ P+:▶positive▶transistor▶output▶(white▶wire,▶factory▶wired)

Terminal block 3 "FLOW SENSOR": Wiring▶the▶remote▶flow▶sensor.▶

The▶wiring▶depends▶on▶the▶type▶of▶output▶signal▶originating▶from▶the▶

flow▶sensor:▶see▶chap.▶„7.4.10“.

Switch▶

Switch▶

Switch▶

Switch▶

Switch▶

Fig. 10: Terminal assignment of a wall-mounted version, 115/230 V AC

A

:▶see▶„Fig.▶15“▶page▶21

B

:▶see▶chap.▶„7.4.10“

C

:▶see▶„Tab.▶1“▶page▶29

D

:▶see▶chap.▶„7.4.10“

E

:▶see▶chap.▶„7.4.4“

Terminal block 4:▶Wiring▶of▶the▶relay▶output▶DO2▶(if▶the▶device▶has▶

relays).

Terminal block 5:▶Wiring▶of▶the▶relay▶output▶DO3▶(if▶the▶device▶has▶

relays).

Terminal block 6

•▶ Terminal▶5:▶4-20▶mA▶output▶(AO1)

•▶ Terminal▶6:▶positive▶27▶V▶DC▶power▶supply,▶available▶to▶energize▶an▶

external▶instrument

•▶ Terminal▶7:▶0V▶(earth▶of▶the▶power▶supply▶available▶to▶energize▶an▶

external▶instrument)

•▶ Terminal▶8:▶protective▶earth:▶shields▶of▶the▶AO1▶and▶DO1▶output▶

cables

•▶ Terminal▶9:▶Negative▶transistor▶output▶(DO1)

•▶ Terminal▶10:▶Positive▶transistor▶output▶(DO1)

Terminal block 7:▶Wiring▶of▶the▶115/230▶V▶AC▶power▶supply▶

8

Mark▶

:▶time-delay▶fuse▶to▶protect▶the▶115/230▶V▶AC▶power▶supply

18

English

Page 19

Type 8025 UNIVERSAL

Installation and wiring

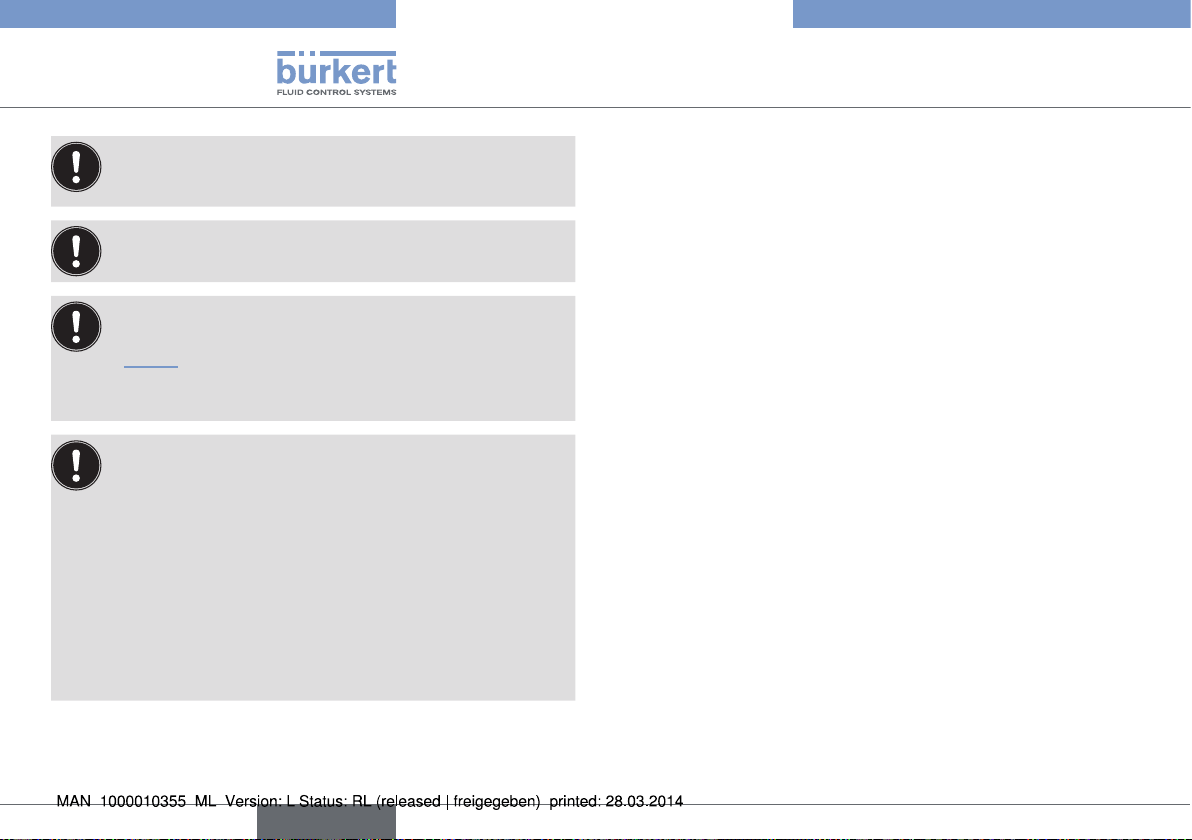

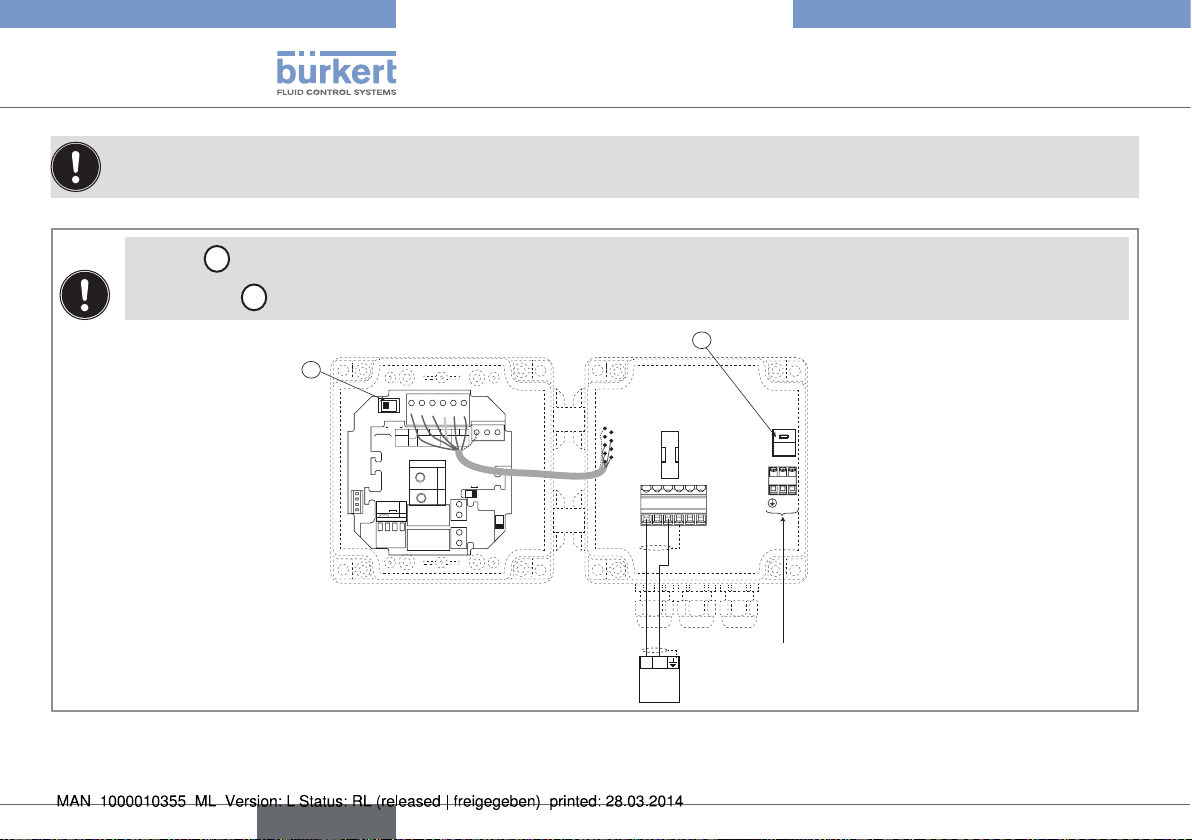

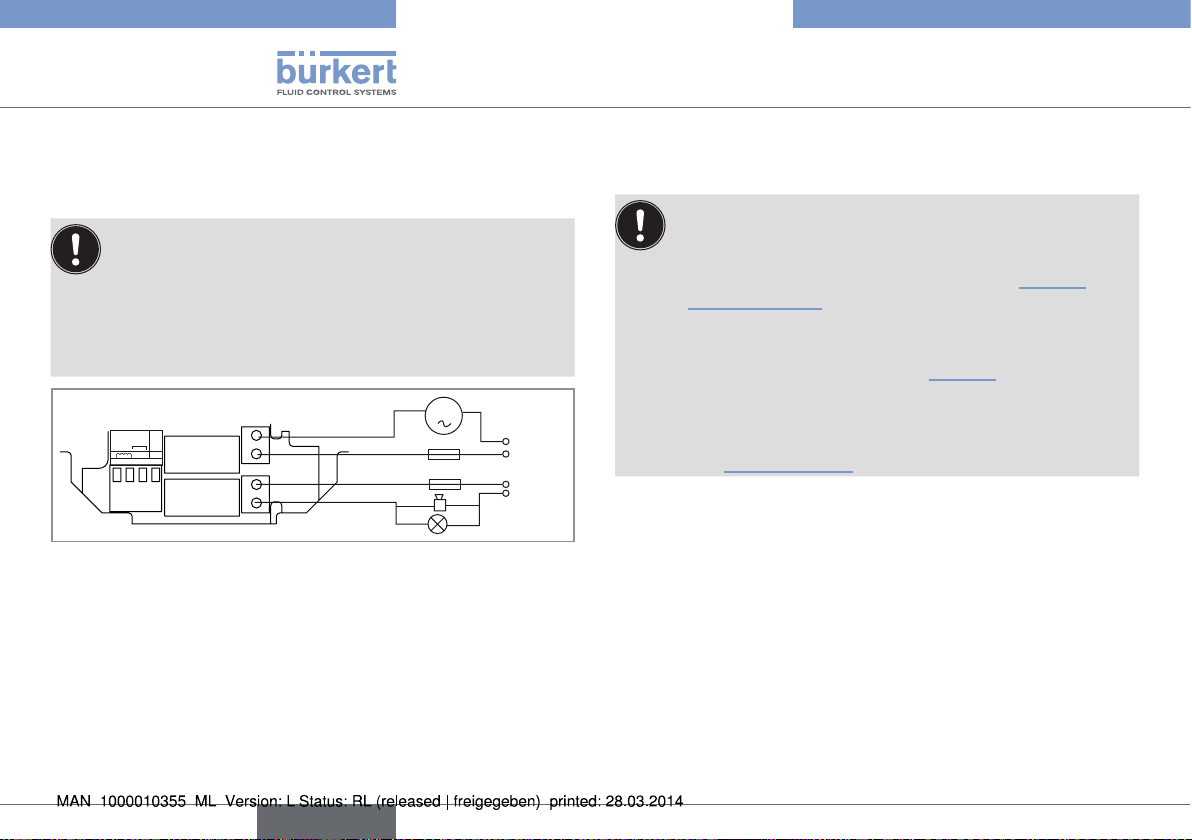

7.4.3 Wiring a panel version

Only▶move▶the▶selectors▶when▶the▶power▶supply▶is▶off.

▶→ Install▶the▶device▶as▶described▶in▶chap.▶„7.2“.

▶→ Set▶the▶selectors▶"SENSOR▶TYPE",▶"SENSOR▶SUPPLY"▶and▶

"LOAD":▶see▶chap.▶„7.4.10“.

▶→ Before▶wiring▶the▶device▶insert▶the▶sup-

plied▶cable▶clips▶into▶the▶slots▶of▶the▶electronic▶board.

Fig. 11: Inserting the cable clips

▶→ Wire▶acc.▶to▶chap.▶„7.4.5“▶,▶„7.4.6“,▶„7.4.9“▶and▶„7.4.10“.▶

▶→ Secure▶the▶power▶supply▶cable,▶the▶flow▶sensor▶connection▶

cable▶and,▶depending▶on▶the▶version,▶the▶relay▶connection▶

cables,▶with▶the▶cable▶clips.

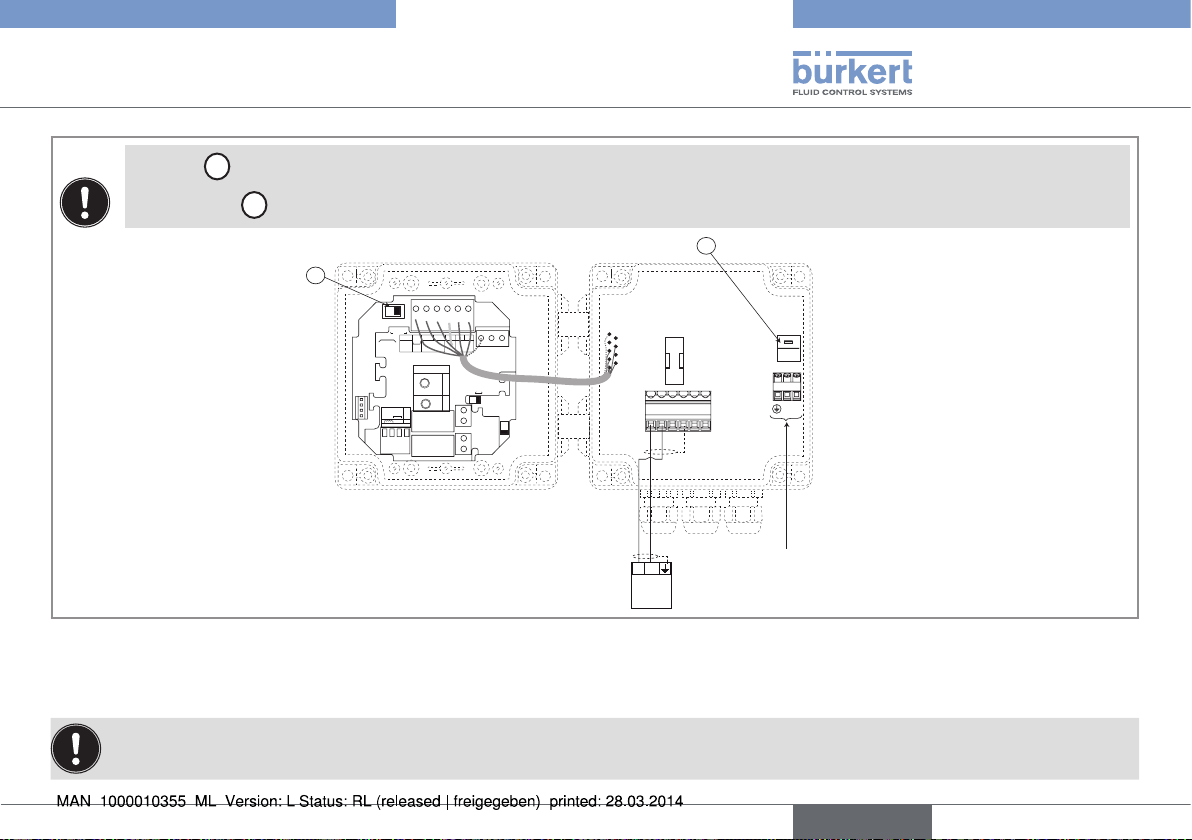

7.4.4 Wiring a wall-mounted version

Only▶move▶the▶selectors▶when▶the▶power▶supply▶is▶off.

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶

glands▶to▶ensure▶the▶tightness▶of▶the▶device.

•▶ Unscrew▶the▶unused▶cable▶gland.

•▶ Remove▶the▶transparent▶disk.

•▶ Insert▶the▶supplied▶stopper▶gasket.

•▶ Screw▶the▶nut▶of▶the▶cable▶gland.

▶→ Install▶the▶device▶as▶described▶in▶chap.▶„7.3“.

▶→ Set▶the▶selectors▶"SENSOR▶TYPE",▶"SENSOR▶SUPPLY"▶and▶

"LOAD":▶see▶chap.▶„7.4.10“.

▶→ If▶the▶wall-mounted▶version▶is▶energized▶with▶a▶115/230▶V▶AC▶

E

power▶supply,▶set▶selector▶

E

Selector▶

▶makes▶it▶possible▶to▶configure▶the▶supply▶volt-

▶as▶shown▶in▶„Fig.▶12“.

age▶of▶the▶device▶in▶a▶115/230▶V▶AC▶version.

E

▶→ Energize▶the▶

device▶with▶

a▶230▶V▶AC▶

voltage.

Fig. 12: Selector of the supply voltage on a 115/230 V AC version

230V

▶→ Loosen▶the▶nuts▶of▶the▶cable▶glands.

▶→ Energize▶the▶

115V

device▶with▶

a▶115▶V▶AC▶

voltage.

English

19

Page 20

Type 8025 UNIVERSAL

Installation and wiring

▶→ Insert▶each▶cable▶through▶a▶nut▶than▶through▶the▶cable▶gland,▶

using▶the▶cable▶glands▶as▶shown▶in▶„Fig.▶13“.

Cables▶of▶the▶outputs

Flow▶sensor▶cable

Fig. 13: Using the cable glands

Power▶supply▶cable▶

12-36▶V▶DC▶or▶

115/230▶V▶AC

▶→ Remove▶the▶two▶terminal▶blocks▶(marked▶6▶and▶7▶in▶„Fig.▶10“)▶

from▶the▶housing.

▶→ Before▶wiring▶the▶device▶insert▶the▶sup-

plied▶cable▶clips▶into▶the▶slots▶of▶the▶electronic▶board▶and▶of▶the▶115/230▶V▶AC▶

power▶supply▶board▶if▶the▶device▶has▶such▶

a▶board.

Fig. 14: Inserting the cable clips

▶→ Depending▶on▶the▶operating▶voltage▶of▶the▶device,▶wire▶

according▶to▶chap.▶„7.4.5“▶to▶„7.4.10“.

▶→ Insert▶the▶two▶terminal▶blocks▶(marked▶6▶and▶7▶in▶„Fig.▶10“)▶into▶

their▶original▶position.

▶→ Letting▶the▶housing▶stay▶completely▶open,▶secure▶the▶power▶

supply▶cable,▶the▶flow▶sensor▶connection▶cable▶and,▶depending▶

on▶the▶version,▶the▶relay▶connection▶cables,▶with▶the▶cable▶clips.

▶→ Tighten▶the▶cable▶glands▶making▶sure▶the▶cable▶in▶the▶housing▶is▶

long▶enough▶to▶allow▶complete▶opening▶of▶the▶housing.

▶→ Close▶the▶cover.

▶→ Tighten▶the▶4▶screws.

▶→ Put▶the▶blanking▶strips▶on▶the▶housing.

7.4.5 Wiring the AO1 current output of a

panel version or a wall-mounted

version, 12-36 V DC

Only▶move▶the▶selectors▶when▶the▶power▶supply▶is▶off.

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶

glands▶to▶ensure▶the▶tightness▶of▶the▶device.

•▶ Unscrew▶the▶unused▶cable▶gland.

•▶ Remove▶the▶transparent▶disk.

•▶ Insert▶the▶supplied▶stopper▶gasket.

•▶ Screw▶the▶nut▶of▶the▶cable▶gland.

The▶4-20▶mA▶output▶can▶be▶wired▶in▶either▶sourcing▶or▶sinking▶

mode.

20

English

Page 21

Type 8025 UNIVERSAL

12-36 V DC

Installation and wiring

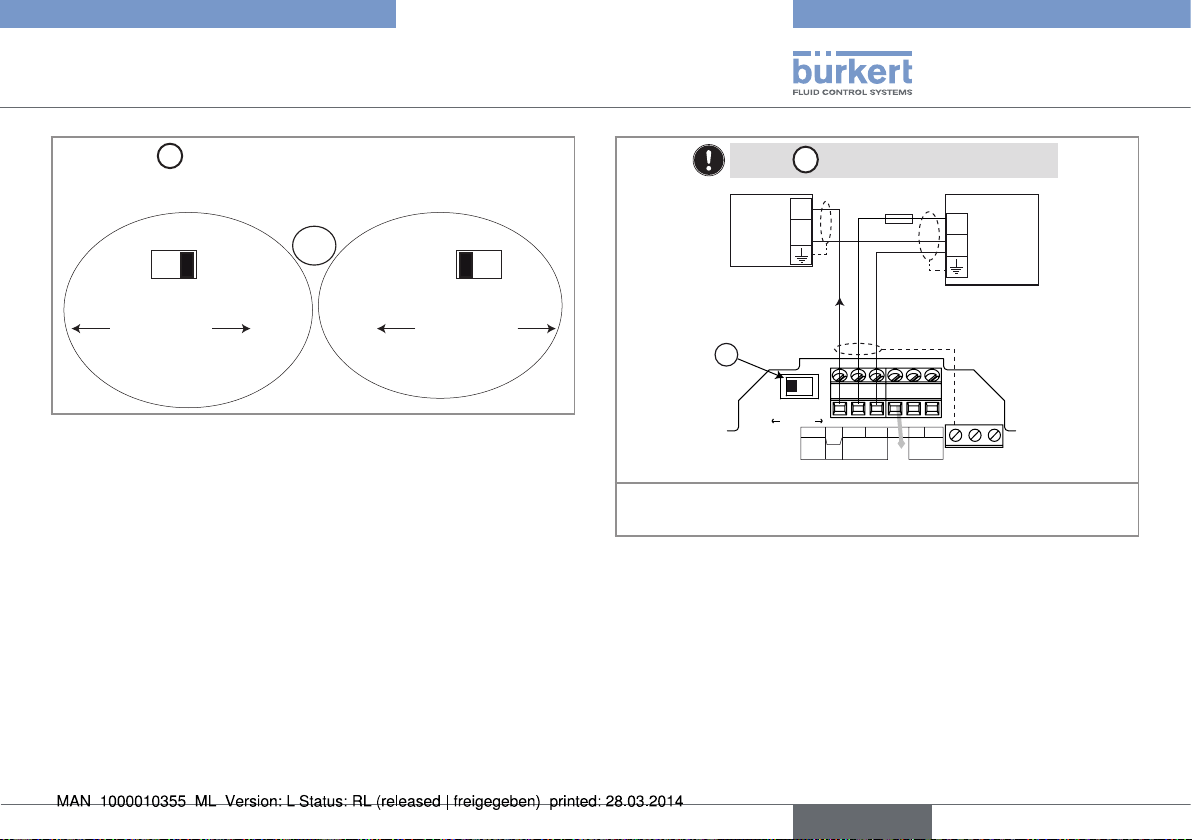

A

Use▶switch▶

▶to▶configure▶the▶wiring▶of▶the▶4-20▶mA▶cur-

rent▶output▶in▶sinking▶or▶sourcing▶mode.

A

SOURCE SINK

CURRENT

▶→ Wire▶the▶current▶output▶in▶

sinking▶mode.

Fig. 15: Using the sink/source switch

▶→ Wire▶the▶current▶output▶

in▶sourcing▶mode.

SOURCE SINK

CURRENT

Set▶the▶A▶switch▶on▶the▶left.▶

300 mA

I

Iout

L+ L- PE P- P+

(AO1)

Supply

12..36Vdc

NC

(*)

PULSE

DO1

+

-

Power▶supply

PE PEPE

4-20mA▶input▶at▶external▶

A

instrument

SOURCESINK

CURRENT

+

-

Univ

Batch

*)▶If▶a▶direct▶earth▶connection▶is▶not▶possible,▶fit▶a▶100▶nF/50▶V▶

capacitor▶between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth

Fig. 16: Wiring of the 4-20 mA output (AO1) in sourcing mode

English

21

Page 22

Set▶the▶A▶switch▶on▶the▶right.

4-20mA▶input▶at▶external▶

instrument

A

Type 8025 UNIVERSAL

Installation and wiring

7.4.6 Wiring the DO1 transistor output of

a panel version or a wall-mounted

+

300 mA

-

I

12-36 V DC

+

-

(*)

Power▶supply

version, 12-36 V DC

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶

glands▶to▶ensure▶the▶tightness▶of▶the▶device.

•▶ Unscrew▶the▶unused▶cable▶gland.

•▶ Remove▶the▶transparent▶disk.

•▶ Insert▶the▶supplied▶stopper▶gasket.

•▶ Screw▶the▶nut▶of▶the▶cable▶gland.

SOURCESINK

CURRENT

Iout

L+ L- PE P- P+

Univ

Batch

(AO1)

NC

Supply

12..36Vdc

PULSE

DO1

PE PEPE

*)▶If▶a▶direct▶earth▶connection▶is▶not▶possible,▶fit▶a▶100▶nF/50▶V▶

capacitor▶between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth

Fig. 17: Wiring of the 4-20 mA output (AO1) in sinking mode

22

English

12-36 V DC

Power▶supply▶of▶

the▶device

300 mA

+

-

(*)

+

5-36 VDC

-

+

-

PLC

Iout

L+ L- PE P- P+

Univ

Batch

(AO1)

NC

12..36Vdc

Supply

PULSE

DO1

PE PEPE

*)▶If▶a▶direct▶earth▶connection▶is▶not▶possible,▶fit▶a▶100▶nF/50▶V▶

capacitor▶between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth

Fig. 18: NPN wiring of the DO1 transistor output

Page 23

Type 8025 UNIVERSAL

Installation and wiring

12-36 V DC

Power▶supply▶of▶

the▶device

+

-

(*)

Univ

Batch

300 mA

Iout

L+ L- PE P- P+

(AO1)

Supply

12..36Vdc

NC

PULSE

DO1

PE PEPE

+

5-36 VDC

-

+

-

PLC

*)▶If▶a▶direct▶earth▶connection▶is▶not▶possible,▶fit▶a▶100▶nF/50▶V▶

capacitor▶between▶the▶negative▶power▶supply▶terminal▶and▶the▶earth

Fig. 19: PNP wiring of the DO1 transistor output

7.4.7 Wiring the AO1 current output of a wall-mounted version, 115/230 V AC

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶glands▶to▶ensure▶the▶tightness▶of▶the▶device.

•▶ Unscrew▶the▶unused▶cable▶gland.

•▶ Remove▶the▶transparent▶disk.

•▶ Insert▶the▶supplied▶stopper▶gasket.

•▶ Screw▶the▶nut▶of▶the▶cable▶gland.

English

23

Page 24

Only▶move▶the▶selectors▶when▶the▶power▶supply▶is▶off.

230V

LN

230V

T 250 mA

56789 10

LN

230V

A

CURRENT

SOURCESINK

BINARY

PE PEPE

PE

DI1

DI2

DI3

DI4

DO4

ISOG

FLOW

SENSOR

L+ L- PE P- P+

NC

Iout

PULSE

DO1

Supply

12..36Vdc

Univ

Batch

(AO1)

SUPPLY

NC

COIL

PULSE

INPUT

NPN/PNP

213PE

+-

SENSOR

SUPPLY

LOAD

+5V

L+

(L+)-12V

COIL/PNP

39K

470

2.2K

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

OFFON

E

+

-

The▶4-20▶mA▶output▶can▶be▶wired▶in▶either▶sourcing▶or▶sinking▶mode.

•▶ Set▶the▶A▶switch▶on▶the▶left.

E

•▶ Set▶selector▶

▶▶▶

▶depending▶on▶the▶value▶of▶the▶power▶supply.

4-20mA▶input▶at▶external▶instrument

Type 8025 UNIVERSAL

Installation and wiring

Connection▶of▶the▶power▶

supply▶for▶the▶8025

Fig. 20: Wiring of the 4-20 mA output (AO1) of a wall-mounted version, 115/230 V AC, in sourcing mode

24

English

Page 25

Type 8025 UNIVERSAL

230V

LN

230V

T 250 mA

56789 10

LN

230V

A

CURRENT

SOURCESINK

BINARY

PE PEPE

PE

DI1

DI2

DI3

DI4

DO4

ISOG

FLOW

SENSOR

L+ L- PE P- P+

NC

Iout

PULSE

DO1

Supply

12..36Vdc

Univ

Batch

(AO1)

SUPPLY

NC

COIL

PULSE

INPUT

NPN/PNP

213PE

+-

SENSOR

SUPPLY

LOAD

+5V

L+

(L+)-12V

COIL/PNP

39K

470

2.2K

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

OFFON

E

+

-

Installation and wiring

•▶ Set▶the▶A▶switch▶on▶the▶right.

E

•▶ Set▶selector▶

▶▶▶

▶depending▶on▶the▶value▶of▶the▶power▶supply.

Fig. 21: Wiring of the 4-20 mA output (AO1) of a wall-mounted version, 115/230 V AC, in sinking mode

4-20mA▶input▶at▶external▶instrument

Connection▶of▶the▶power▶

supply▶for▶the▶8025

7.4.8 Wiring the DO1 transistor output of a wall-mounted version, 115/230 V AC

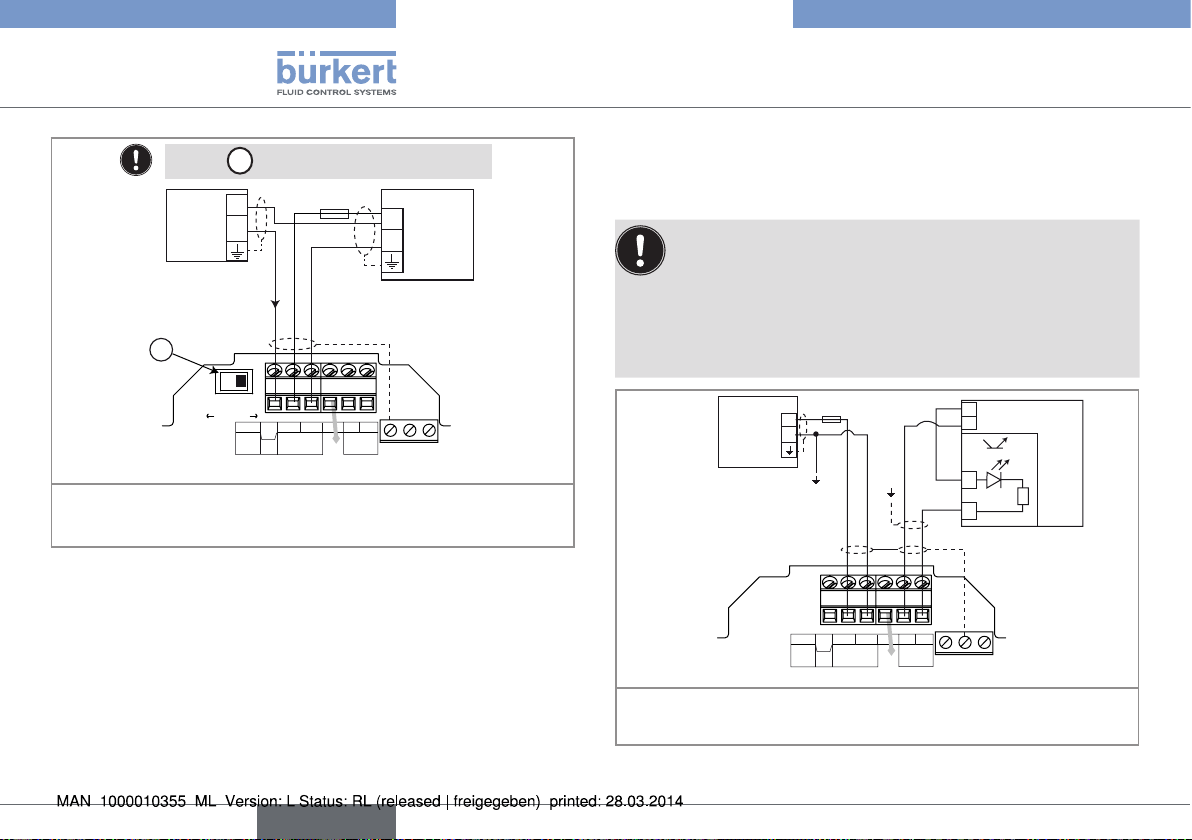

Only▶move▶the▶selectors▶when▶the▶power▶supply▶is▶off.

English

25

Page 26

Type 8025 UNIVERSAL

Installation and wiring

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶glands▶to▶ensure▶the▶tightness▶of▶the▶device.

•▶ Unscrew▶the▶unused▶cable▶gland.

•▶ Remove▶the▶transparent▶disk.

•▶ Insert▶the▶supplied▶stopper▶gasket.

•▶ Screw▶the▶nut▶of▶the▶cable▶gland.

Set▶of▶selector▶E▶depending▶on▶the▶value▶of▶the▶power▶supply.

▶

E

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

PULSE

Supply

Batch

DO1

12..36Vdc

SENSOR

NC

PE

ISOG

DO4

DI4

DI3

L+

DI2

DI1

2.2K

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

213PE

FLOW

SENSOR

+5V

(L+)-12V

470

PE PEPE

SENSOR TYPE

SUPPLY

COIL NPN/PNP

COIL/PNP

39K

LOAD

OFFON

DO2

DO3

T 250 mA

56789 10

230V

230V

230V

LN

LN

Connection▶of▶the▶power▶supply▶for▶the▶8025

PLC

+

5-36 VDC

-

+

-

Power▶supply▶for▶the▶PLC

Fig. 22: NPN wiring of the DO1 transistor output of a wall-mounted version, 115/230 V AC

26

English

Page 27

Type 8025 UNIVERSAL

Installation and wiring

Set▶selector▶E▶depending▶on▶the▶value▶of▶the▶power▶supply.

▶

E

SOURCESINK

CURRENT

BINARY

Iout

L+ L- PE P- P+

Univ

(AO1)

PULSE

Supply

Batch

DO1

12..36Vdc

FLOW

SENSOR

NC

PE

ISOG

DO4

DI4

DI3

L+

DI2

DI1

2.2K

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

213PE

SENSOR

+5V

(L+)-12V

470

39K

COIL/PNP

SUPPLY

LOAD

PE PEPE

SENSOR TYPE

COIL NPN/PNP

DO2

DO3

T 250 mA

OFF ON

56789 10

230V

230V

230V

LN

LN

Connection▶of▶the▶power▶supply▶for▶the▶8025

PLC

+

5-36 VDC

-

+

-

Power▶supply▶for▶the▶PLC

Fig. 23: PNP wiring of the DO1 transistor output of a wall-mounted version, 115/230 V AC

English

27

Page 28

Type 8025 UNIVERSAL

Installation and wiring

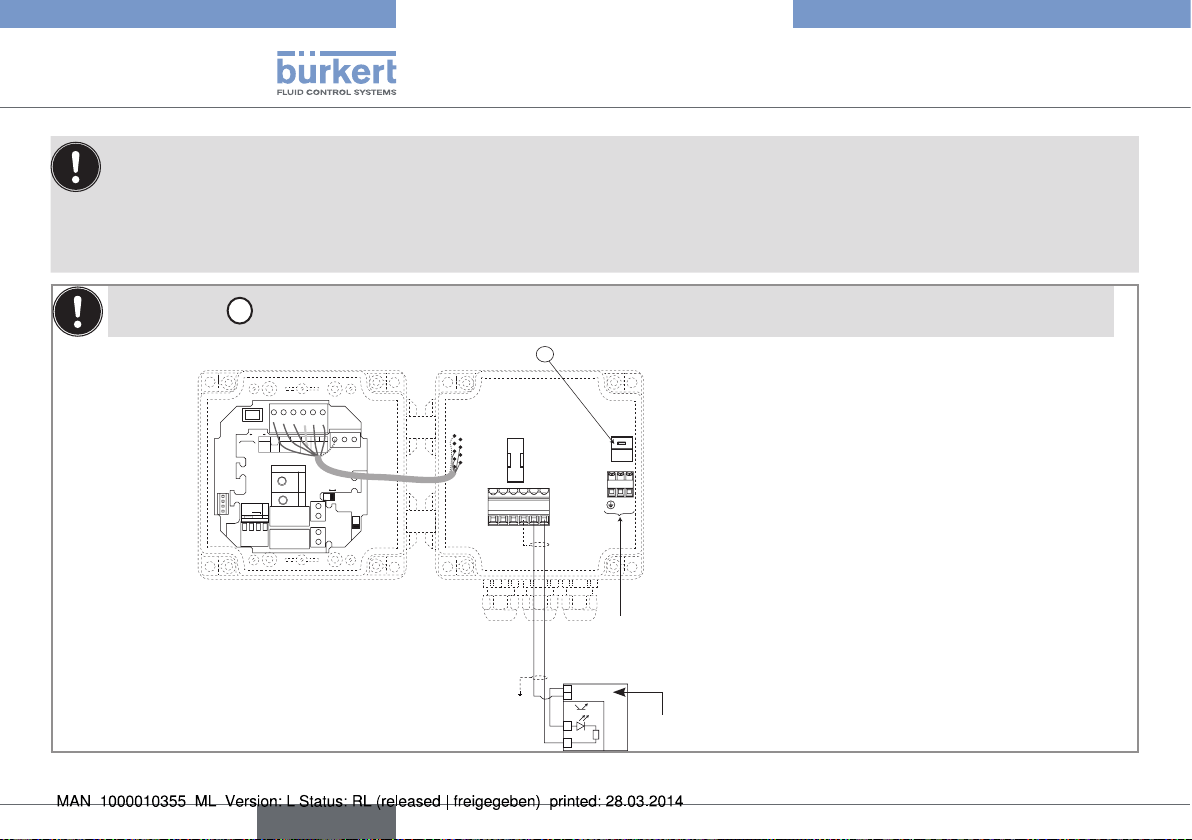

7.4.9 Wiring the relay outputs DO2 and

DO3 of the panel or a wall-mounted

version

Insert▶the▶supplied▶stopper▶gaskets▶into▶the▶unused▶cable▶

glands▶to▶ensure▶the▶tightness▶of▶the▶device.

•▶ Unscrew▶the▶unused▶cable▶gland.

•▶ Remove▶the▶transparent▶disk.

•▶ Insert▶the▶supplied▶stopper▶gasket.

•▶ Screw▶the▶nut▶of▶the▶cable▶gland.

m

FLOW

SENSOR

PULSE

INPUT

SUPPLY

+-

NC

213PE

NPN/PNP

COIL

DO2

DO3

OFFON

Fig. 24: Wiring of the DO2 and DO3 relay outputs

3 A

3 A

230 V AC

230 V AC

7.4.10 Connecting the flow sensor to the

transmitter

Before▶connecting▶the▶flow▶sensor▶to▶the▶transmitter▶8025▶

UNIVERSAL:

•▶ set▶selector▶"SENSOR▶TYPE"▶depending▶on▶the▶output▶

signal▶providing▶from▶▶the▶flow▶sensor.▶See▶„Fig.▶25“▶and▶

„Tab.▶1“▶page▶29.

•▶ if▶the▶selector▶"SENSOR▶TYPE"▶is▶set▶on▶"NPN/PNP",▶

set▶the▶selector▶"SENSOR▶SUPPLY"▶depending▶on▶the▶

transmitter▶supply▶voltage.▶See▶„Fig.▶26“.

•▶ set▶selector▶"LOAD"▶depending▶on▶the▶type▶of▶signal▶sent▶

out▶by▶the▶flow▶sensor▶and▶on▶the▶load▶wanted▶on▶terminal▶

1▶"PULSE▶INPUT"▶of▶terminal▶block▶"FLOW▶SENSOR".▶

See▶„Tab.▶1“▶page▶29.

28

English

Page 29

Type 8025 UNIVERSAL

SENSOR

Installation and wiring

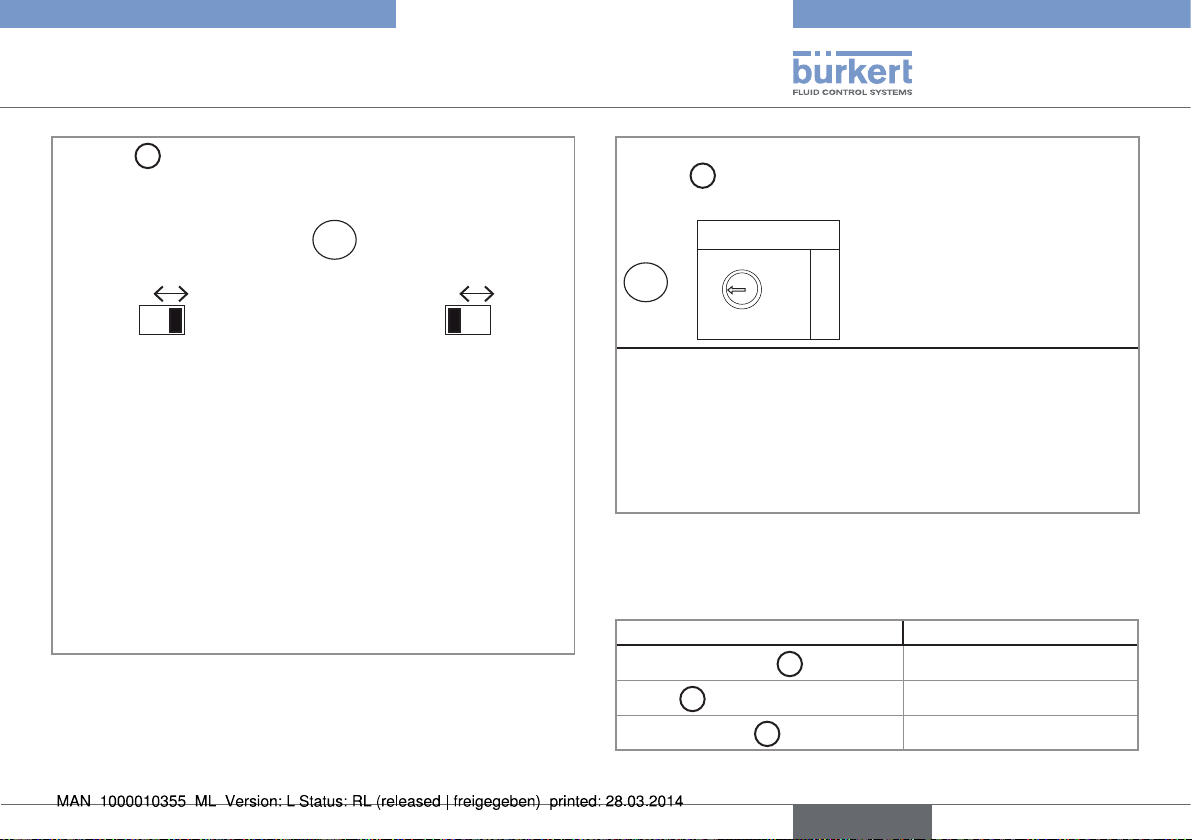

D

Selector▶

▶makes▶it▶possible▶to▶configure▶the▶type▶of▶sig-

nal▶the▶8025▶Universal▶receives▶from▶the▶flow▶sensor.

D

SENSOR TYPE

COIL NPN/PNP

▶→ Set▶the▶selector▶on▶the▶right▶

(default▶position)▶when▶the▶

signal▶from▶the▶flow▶sensor▶

which▶is▶connected▶to▶the▶▶

8025▶Universal▶is▶either:

•▶ a▶pulse▶signal,▶NPN▶or▶PNP

•▶ an▶"on/off"▶signal▶(Reed▶relay▶for▶

example)

•▶ a▶0-5▶V▶DC▶standard▶voltage▶

signal▶(TTL,▶for▶example)

Fig. 25: Using selector "SENSOR TYPE"

SENSOR TYPE

COIL NPN/PNP

▶→ Set▶the▶selector▶on▶the▶

left▶when▶the▶signal▶

from▶the▶flow▶sensor▶

which▶is▶connected▶to▶

the▶▶8025▶Universal▶is▶a▶

sine-wave▶signal▶(coil).

When▶selector▶"SENSOR▶TYPE"▶above▶is▶set▶on▶"NPN/PNP",▶

B

selector▶

the▶flow▶sensor.

▶▶makes▶it▶possible▶to▶configure▶the▶supply▶voltage▶for▶

+5V

B

L+

(L+)-12V

SUPPLY

▶→ If▶the▶8025▶Universal▶is▶energized▶with▶a▶115/230▶V▶AC▶power▶

supply,▶set▶selector▶"SENSOR▶SUPPLY"▶on▶"L+"▶(default▶

position).

▶→ If▶the▶8025▶Universal▶is▶energized▶with▶a▶12-36▶V▶DC▶

power▶supply,▶set▶the▶voltage▶selector▶"SENSOR▶SUPPLY"▶

depending▶on▶the▶voltage▶supply▶needed▶by▶the▶remote▶flow▶

sensor:▶"+5V",▶"L+"▶or▶"(L+)-12V"▶(default▶position).

Fig. 26: Using selector "SENSOR SUPPLY"

Tab. 1: Default positions of selectors "SENSOR SUPPLY",

"LOAD" and "SENSOR TYPE"

Selector Default▶position

SENSOR▶SUPPLY▶(

LOAD▶(

SENSOR▶TYPE▶(D)

C

)

B

)▶

L+

2.2KOhms

NPN/PNP

English

29

Page 30

Type 8025 UNIVERSAL

13

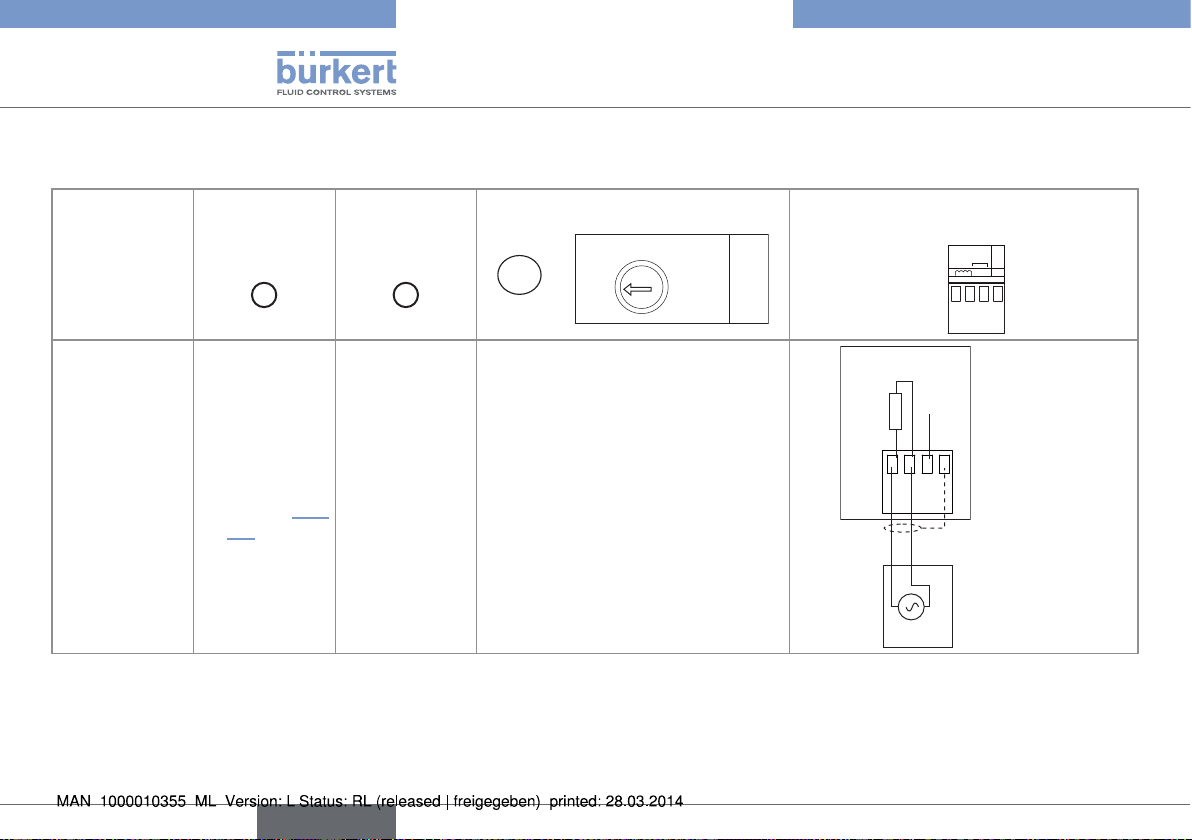

Installation and wiring

Tab. 2: Position of selectors "SENSOR TYPE" and "LOAD" and terminal assignment of terminal block "FLOW SENSOR" depending on the

signal emitted by the flow sensor

Type▶of▶signal▶

emitted▶by▶the▶

flow▶sensor

sine-wave▶(coil)

Selector▶

"SENSOR▶

TYPE"▶

D

)

(

▶→ Set▶the▶

selector▶on▶

"COIL"▶(„Fig.▶

25“)

Selector▶

"SENSOR▶

SUPPLY"▶

(B)▶

▶→ Any▶position.

Selector▶"LOAD"

COIL/PNP

470

C

2.2K

39K

▶→ Set▶selector▶"LOAD"▶on▶"39K":▶

the▶input▶impedance▶on▶terminals▶

1▶and▶2▶of▶terminal▶block▶"FLOW▶

SENSOR"▶will▶then▶be▶39▶kW

LOAD

Terminal▶assignment▶of▶terminal▶block▶

"FLOW▶SENSOR"

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

2

FLOW

SENSOR

PE

8025

39 kΩ

NC

213PE

Flow▶sensor

30

English

Page 31

Type 8025 UNIVERSAL

13

Installation and wiring

Type▶of▶signal▶

emitted▶by▶the▶

flow▶sensor

pulse,▶PNP

Selector▶

"SENSOR▶

TYPE"▶

D

)

(

▶→ Set▶the▶

selector▶on▶

"NPN/PNP"▶

(„Fig.▶25“)

Selector▶

"SENSOR▶

SUPPLY"▶

(B)▶

▶→ Set▶the▶

selector▶as▶

shown▶in▶

„Fig.▶26“.

Selector▶"LOAD"

COIL/PNP

470

C

2.2K

39K

▶→ Set▶selector▶"LOAD"▶on▶"39K":▶

the▶input▶impedance▶on▶terminals▶

1▶and▶2▶of▶terminal▶block▶"FLOW▶

SENSOR"▶will▶then▶be▶39▶kW

LOAD

Terminal▶assignment▶of▶terminal▶block▶

"FLOW▶SENSOR"

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

2

FLOW

SENSOR

PE

8025

39 kΩ

213PE

Flow▶sensor

English

31

Page 32

Type 8025 UNIVERSAL

13

Installation and wiring

Type▶of▶signal▶

emitted▶by▶the▶

flow▶sensor

0-5▶V▶DC▶

standard▶voltage▶

signal▶(TTL,▶for▶

example)

Selector▶

"SENSOR▶

TYPE"▶

D

)

(

▶→ Set▶the▶

selector▶on▶

"NPN/PNP"▶

(„Fig.▶25“)

Selector▶

"SENSOR▶

SUPPLY"▶

(B)▶

▶→ Set▶the▶

selector▶as▶

shown▶in▶

„Fig.▶26“.

Selector▶"LOAD"

COIL/PNP

470

C

2.2K

39K

▶→ Set▶selector▶"LOAD"▶on▶"39K":▶

the▶input▶impedance▶on▶terminals▶

1▶and▶2▶of▶terminal▶block▶"FLOW▶

SENSOR"▶will▶then▶be▶39▶kW

LOAD

Terminal▶assignment▶of▶terminal▶block▶

"FLOW▶SENSOR"

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

2

FLOW

SENSOR

PE

8025

39 kΩ

213PE

Flow▶sensor

32

English

Page 33

Type 8025 UNIVERSAL

13

8025

Installation and wiring

Type▶of▶signal▶

emitted▶by▶the▶

flow▶sensor

pulse,▶NPN

Selector▶

"SENSOR▶

TYPE"▶

D

)

(

▶→ Set▶the▶

selector▶on▶

"NPN/PNP"▶

(„Fig.▶25“)

Selector▶

"SENSOR▶

SUPPLY"▶

(B)▶

▶→ Set▶the▶

selector▶as▶

shown▶in▶

„Fig.▶26“.

Selector▶"LOAD"

COIL/PNP

470

C

2.2K

39K

LOAD

▶→ Set▶selector▶"LOAD":

•▶ either▶on▶"2.2k":▶the▶load▶resistance▶

R▶is▶then▶2,2▶kW

•▶ either▶on▶"470":▶the▶load▶resistance▶

R▶is▶then▶470▶W

Terminal▶assignment▶of▶terminal▶block▶

"FLOW▶SENSOR"

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

2

FLOW

SENSOR

PE

+3 V

R

213PE

Flow▶sensor

English

33

Page 34

Type 8025 UNIVERSAL

13

Installation and wiring

Type▶of▶signal▶

emitted▶by▶the▶

flow▶sensor

"on/off"▶signal▶

(Reed▶relay▶for▶

example)

Selector▶

"SENSOR▶

TYPE"▶

D

)

(

▶→ Set▶the▶

selector▶on▶

"NPN/PNP"▶

(„Fig.▶25“)

Selector▶

"SENSOR▶

SUPPLY"▶

(B)▶

▶→ Set▶the▶

selector▶as▶

shown▶in▶

„Fig.▶26“.

Selector▶"LOAD"

COIL/PNP

470

C

2.2K

39K

LOAD

▶→ Set▶selector▶"LOAD":

•▶ either▶on▶"2.2k":▶the▶load▶resistance▶

R▶is▶then▶2,2▶kW

•▶ either▶on▶"470":▶the▶load▶resistance▶

R▶is▶then▶470▶W

Terminal▶assignment▶of▶terminal▶block▶

"FLOW▶SENSOR"

SUPPLY

INPUT

+-

NPN/PNP

PULSE

NC

COIL

2

FLOW

SENSOR

PE

8025

+3 V

R

213PE

...

Flow▶sensor

34

English

Page 35

Type 8025 UNIVERSAL

Adjustment and commissioning

8 ADJUSTMENT AND

COMMISSIONING

8.1 Safety instructions

Warning

Risk of injury due to nonconforming operating.

Nonconforming▶operating▶could▶lead▶to▶injuries▶and▶damage▶the▶

device▶and▶its▶surroundings.

▶▶ The▶operators▶in▶charge▶of▶operating▶must▶have▶read▶and▶under-

stood▶the▶contents▶of▶this▶manual.

▶▶ In▶particular,▶observe▶the▶safety▶recommendations▶and▶intended▶use.

▶▶ The▶device/installation▶must▶only▶be▶operated▶by▶suitably▶trained▶

staff.

Warning

Danger due to nonconforming commissioning.

Nonconforming▶commissioning▶could▶lead▶to▶injuries▶and▶damage▶

the▶device▶and▶its▶surroundings.▶

▶▶ Before▶commissioning,▶make▶sure▶that▶the▶staff▶in▶charge▶have▶read▶

and▶fully▶understood▶the▶contents▶of▶the▶operating▶instructions.

▶▶ In▶particular,▶observe▶the▶safety▶recommendations▶and▶intended▶use.

▶▶ The▶device▶/▶the▶installation▶must▶only▶be▶commissioned▶by▶suit-

ably▶trained▶staff.

▶▶ Before▶commissioning▶the▶device,▶enter▶the▶K▶factor▶of▶the▶fitting▶

used.▶See▶chap.▶„8.7▶Entering▶the▶K▶factor▶of▶the▶fitting▶used“.

8.2 Operating levels of the device

The▶device▶has▶two▶operating▶levels:▶the▶Process▶level▶and▶the▶Configuration▶level.

Tab. 3: Default settings of the device

Function Default▶value

LANGUAGE English

UNIT▶of▶the▶flow▶rate l/min.

UNIT▶of▶the▶totalizers litre

OUTPUT▶AO1 4mA=▶0.000

20mA=▶0.000

ERR.▶22mA▶disabled

OUTPUT▶DO1 pulse

PU=▶0.00▶litre

OUTPUTS▶DO2▶and▶

DO3

K▶FACTOR

FILTER

CUT-OFF

BACKLIGHT level▶9,▶activated▶for▶30s

FLOW-WARNING W-▶=▶W+▶=▶0.000

VOLUME-WARNING 000000

Hysteresis,▶not▶inverted

2-▶=▶3-▶=▶0.000

2+▶=▶3+▶=▶0.000

time▶delays▶2▶and▶3▶=▶0

1

2,▶fast

0.000

English

35

Page 36

Type 8025 UNIVERSAL

Adjustment and commissioning

Process▶level

12.6 L/MiN

16.45 MA

0......9

87654 L

231 L.

+

0......9

>▶2▶s

To▶reset▶the▶daily▶totalizer▶(identified▶by▶a▶dot▶after▶the▶volume▶

units).

>▶5▶s

Parameters▶menu

ENTER

0......9

>▶5▶s

0......9

LANGUAGE

UNit

K-FACtOR

OUtPUt

FiLtER

tOtAL

CUt-OFF

BACKLit

Configuration▶level

ENTER

0......9

>▶2▶s

Test▶Menu

CAL AO1

FREQUENC.

FLOw

wARNiNG

END

Information▶menu▶

MEAS. OVF

DiSP. OVF

AO1 LOSt

0......9

END

ENTER

1)

1)

▶Accessible▶when▶the▶device▶status▶LED▶is▶orange▶or▶red.

36

English

END

SAVE N/Y

Process▶level

Page 37

Type 8025 UNIVERSAL

Adjustment and commissioning

8.3 Description of the navigation keys and the status LEDs

•▶ Scrolling▶up▶the▶

parameters

•▶ Incrementing▶the▶figure▶

selected

Device▶status▶LED:▶see▶following▶table.

•▶ Selecting▶the▶displayed▶parameter

•▶ Confirming▶the▶settings

Status▶LED▶of▶relay▶DO3▶(LED▶ON▶=▶

contact▶closed)

Status▶LED▶of▶relay▶DO2▶(LED▶ON▶=▶

contact▶closed)

•▶ Reading▶the▶messages▶

•▶ Scrolling▶through▶the▶parameters

•▶ Selecting▶the▶figure▶on▶the▶left

English

37

Page 38

Type 8025 UNIVERSAL

Adjustment and commissioning

Device status LED Status of the device

Green The▶device▶operates▶correctly.

Orange A▶warning▶message▶is▶generated.

▶→ Press▶the▶ ▶key▶for▶2▶seconds▶in▶the▶Process▶level▶to▶access▶the▶message.▶See▶the▶complete▶

operating▶instructions▶for▶the▶meaning.

Furthermore,▶a▶relay▶output▶(DO2▶or▶DO3)▶or▶the▶transistor▶output▶DO1▶switches▶if▶it▶is▶configured▶in▶

the▶"WARNING"▶mode▶(see▶the▶complete▶operating▶instructions▶)

Red An▶error▶message▶has▶been▶generated▶and▶the▶current▶output▶sends▶out▶a▶22▶mA▶current▶(if▶

parameter▶"ERR.▶22mA"▶is▶set▶to▶"ENABLED".▶See▶the▶complete▶operating▶instructions.

▶→ Press▶the▶ ▶key▶for▶2▶seconds▶in▶the▶Process▶level▶to▶access▶the▶message.▶See▶the▶complete▶

operating▶instructions▶for▶the▶meaning.

Blinking,▶whatever▶the▶colour A▶check▶for▶the▶correct▶behaviour▶of▶the▶outputs▶is▶running▶(see▶the▶complete▶operating▶instructions).

8.4 Using the navigation keys

You want to... Press...

move▶between▶parameters▶within▶a▶level▶or▶a▶menu.

▶to▶go▶to▶the▶next▶parameter.▶

•▶

access▶the▶Parameters▶menu.

38

English

▶to▶go▶to▶the▶previous▶parameter.

•▶

0......9

ENTER

▶+▶ ▶simultaneously▶for▶5▶s,▶in▶the▶Process▶level

Page 39

Type 8025 UNIVERSAL

Adjustment and commissioning

You want to... Press...

access▶the▶Test▶menu.

0......9

▶+▶ ▶+▶

access▶the▶Information▶menu.

▶for▶2▶s,▶in▶the▶Process▶level,▶when▶the▶device▶status▶LED▶is▶orange▶or▶red.

ENTER

▶simultaneously▶for▶5▶s,▶in▶the▶Process▶level

reset▶the▶daily▶totalizer.

select▶the▶displayed▶parameter.

confirm▶the▶displayed▶value.

modify▶a▶numerical▶value.

0......9

▶+▶ ▶simultaneously▶for▶2▶s,▶when▶the▶daily▶totalizer▶is▶displayed▶in▶the▶

Process▶level

ENTER

ENTER

▶to▶increase▶the▶blinking▶digit.

•▶

0......9

▶to▶select▶the▶digit▶at▶the▶left▶of▶the▶blinking▶digit.

•▶

0......9

▶+▶ ▶to▶move▶the▶decimal▶point.

•▶

English

39

Page 40

8.5 Details of the Process level

This▶level▶is▶active▶by▶default▶when▶the▶device▶is▶energized.

12.6 L/MiN

0......9

16.45 MA

or

Value▶of▶the▶measured▶flow▶rate,▶displayed▶in▶the▶unit▶chosen▶in▶the▶"UNIT"▶parameter▶of▶the▶

Parameters▶menu.

Value▶of▶the▶current▶output,▶proportional▶to▶the▶measured▶flow▶rate.

0 L/MiN.

Type 8025 UNIVERSAL

Adjustment and commissioning

The▶displayed▶flow▶rate▶is▶set▶to▶0▶(a▶dot▶is▶displayed▶after▶the▶flow▶rate▶

units▶when▶the▶function▶CUT-OFF▶is▶active)▶because▶the▶measured▶flow▶

rate▶is▶below▶the▶threshold▶value▶defined▶in▶the▶"CUT-OFF"▶parameter▶

of▶the▶Parameters▶menu.

40

87654 L

231 L.

Value▶of▶the▶main▶totalizer,▶volume▶of▶fluid▶counted▶by▶the▶device▶since▶the▶last▶reset.

Value▶of▶the▶daily▶totalizer▶(identified▶by▶a▶dot▶after▶the▶volume▶units),▶volume▶of▶fluid▶counted▶by▶

the▶device▶since▶the▶last▶reset.

0......9

+

>▶2▶s

Resetting▶the▶daily▶totalizer.

English

Page 41

Type 8025 UNIVERSAL

Adjustment and commissioning

8.6 Details of the Parameters menu

0......9

LANGUAGE

UNit

K-FACtOR

OUtPUt

FiLtER

tOtAL

CUt-OFF

BACKLit

END

Choosing▶the▶display▶language.

Choosing▶the▶flow▶rate▶unit,▶the▶number▶of▶decimals▶and▶the▶unit▶the▶totalizers▶are▶displayed▶in.

Entering▶the▶K▶factor▶of▶the▶fitting▶used▶or▶having▶it▶defined▶through▶a▶Teach-In▶procedure.▶

Parameterizing▶the▶4-20▶mA▶current▶output▶(AO1)▶and▶configuring▶the▶transistor▶output▶(DO1)▶

and,▶if▶the▶device▶is▶equipped▶with,▶the▶2▶relay▶outputs▶(DO2▶and▶DO3).

Choosing▶the▶filter▶level▶of▶the▶measured▶flow▶rate,▶on▶the▶displayed▶flow▶rate▶and▶the▶AO1▶

current▶output.

Resetting▶both▶totalizers.

Entering▶the▶measured▶flow▶rate▶value▶below▶which▶the▶device▶sets▶the▶measured▶flow▶rate▶to▶0▶

with▶effect▶on▶the▶display,▶the▶outputs▶and▶the▶totalizers.

Setting▶the▶brightness▶of▶the▶display▶and▶how▶long▶it▶stays▶ON,▶or▶deactivating▶the▶backlight.

SAVE N/Y

Saving▶the▶changes▶made▶within▶the▶Parameters▶menu▶or▶

not.▶If▶the▶changes▶are▶saved,▶the▶device▶operates▶with▶

the▶new▶settings.

12.6 L/MiN

Process▶level

English

41

Page 42

Type 8025 UNIVERSAL

Adjustment and commissioning

8.7 Entering the K factor of the fitting used

The▶device▶determines▶the▶flow▶rate▶in▶the▶pipe▶using▶the▶fitting▶K▶factor.

The▶K▶factor▶of▶the▶fitting▶used▶can▶be▶entered▶here.▶The▶device▶may▶also▶determine▶the▶K▶factor▶using▶a▶Teach-In▶procedure:▶See▶the▶com-

plete▶operating▶instructions.

The▶device▶will▶use▶the▶new▶K▶factor▶as▶soon▶as▶"SAVE▶YES"▶is▶confirmed▶when▶leaving▶the▶Parameters▶menu.

The▶K▶factor▶of▶the▶fitting▶used▶is▶in▶the▶operating▶instructions▶of▶the▶fitting.

The▶operating▶instructions▶of▶the▶Bürkert▶fittings▶can▶be▶found▶on▶the▶CD▶delivered▶with▶the▶device▶or▶on▶the▶internet▶at▶

www.burkert.com.

K-FACtOR K=10.000

The▶display▶shows▶the▶K▶factor▶of▶the▶

fitting,▶last▶entered▶or▶determined▶using▶

a▶Teach-In▶procedure.

K=2.8500

▶→ Enter▶the▶K▶factor▶(value▶between▶0.01▶and▶

99999.9)▶of▶the▶fitting▶used.

▶→ Confirm▶the▶displayed▶value.

▶→ Edit▶the▶parameter.

OUtPUt VALiD N/Y

REtURN

Is▶only▶displayed▶if▶the▶K▶factor▶has▶been▶changed.

▶→ Confirm▶the▶entered▶K▶factor▶or▶not.

Fig. 27: Entering the K factor of the fitting used

42

English

Page 43

Type 8025 UNIVERSAL

Adjustment and commissioning

8.8 Details of the Test menu

0......9

CAL AO1

FREQUENC.

FLOw

wARNiNG

END

Adjusting▶the▶4-20▶mA▶output.

Reading▶the▶rotational▶frequency▶of▶the▶paddle▶wheel.

Simulating▶a▶flow▶rate▶to▶check▶the▶correct▶operating▶of▶the▶outputs.

FLOw-w.

0......9

VOLUME-w.

Setting▶the▶flow▶rate▶threshold▶values▶for▶which▶a▶warning▶message▶is▶

generated.

Setting▶a▶threshold▶value▶of▶the▶daily▶totalizer,▶for▶which▶a▶warning▶message▶

is▶generated.

REtURN

SAVE N/Y

Saving▶the▶changes▶made▶within▶the▶Test▶menu▶or▶not.▶If▶

the▶changes▶are▶saved,▶the▶device▶operates▶with▶the▶new▶

settings.

12.6 L/MiN

Process▶level

English

43

Page 44

Type 8025 UNIVERSAL

Packaging, Transport

9 PACKAGING, TRANSPORT

note▶

Damage due to transport

Transport▶may▶damage▶an▶insufficiently▶protected▶device.

▶▶ Transport▶the▶device▶in▶shock-resistant▶packaging▶and▶away▶

from▶humidity▶and▶dirt.

▶▶ Do▶not▶expose▶the▶device▶to▶temperatures▶that▶may▶exceed▶the▶

admissible▶storage▶temperature▶range.

▶▶ Protect▶the▶electrical▶interfaces▶using▶protective▶plugs.▶

1. STORAGE

note▶

Poor storage can damage the device.

▶▶ Store▶the▶device▶in▶a▶dry▶place▶away▶from▶dust.

▶▶ Storage▶temperature▶of▶the▶device:▶-10▶to▶+60▶°C.

10 DISPOSAL OF THE PRODUCT

▶→

Dispose▶of▶the▶device▶and▶its▶packaging▶in▶an▶environmentallyfriendly▶way.

note

Comply▶with▶the▶national▶and/or▶local▶regulations▶which▶

concern▶the▶area▶of▶waste▶disposal.

44

English

Page 45

Typ 8025 UNIVERSAL

Inhaltsverzeichnis

1 ÜBER DEN QUICKSTART ........................................................................2

2 BESTIMMUNGSGEMÄSSE VERWENDUNG...................................3

3 GRUNDLEGENDE SICHERHEITSHINWEISE .................................3

4 ALLGEMEINE HINWEISE ..........................................................................4

5 BESCHREIBUNG ..........................................................................................5

6 TECHNISCHE DATEN ................................................................................6

7 INSTALLATION, VERKABELUNG ...........................................................10

8 BEDIENUNG, INBETRIEBNAHME ....................................................................... 34

9 VERPACKUNG, TRANSPORT .............................................................. 44

10 LAGERUNG ...................................................................................................44

11 ENTSORGUNG DES GERÄTES ......................................................... 44

deutsch

1

Page 46

Typ 8025 UNIVERSAL

Warnt vor Sachschäden!

Über den Quickstart

1 ÜBER DEN QUICKSTART

Der▶Quickstart▶beschreibt▶den▶gesamten▶Lebenszyklus▶des▶Gerätes.▶

Bewahren▶Sie▶ diese▶ Anleitung▶ so▶ auf,▶ dass▶ sie▶ für▶ jeden▶ Benutzer▶

zugänglich▶ist▶und▶jedem▶neuen▶Eigentümer▶des▶Gerätes▶wieder▶zur▶

Verfügung▶steht.

Wichtige Informationen zur Sicherheit!

Lesen▶Sie▶den▶Quickstart▶sorgfältig▶durch.▶Beachten▶Sie▶vor▶allem▶

die▶Kapitel▶Grundlegende▶Sicherheitshinweise▶und▶Bestimmungsgemäße▶Verwendung.

▶▶ Der▶Quickstart▶muss▶gelesen▶und▶verstanden▶werden.

Der▶Quickstart▶erläutert▶beispielhaft▶die▶Montage▶und▶Inbetriebnahme▶des▶Gerätes.

Die▶ausführliche▶Beschreibung▶des▶Gerätes▶finden▶Sie▶in▶der▶entsprechenden▶Bedienungsanleitung▶auf▶der▶mitgelieferten▶CD.

1.1 Darstellungsmittel

GefaHR!

Warnt vor einer unmittelbaren Gefahr!

▶▶ Bei▶Nichteinhaltung▶sind▶Tod▶oder▶schwere▶Verletzungen▶die▶

Folge.

waRnunG!

Warnt vor einer möglicherweise gefährlichen Situation!

▶▶ Bei▶Nichteinhaltung▶drohen▶schwere▶Verletzungen▶oder▶Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

▶▶ Nichtbeachtung▶kann▶mittelschwere▶oder▶leichte▶Verletzungen▶

zur▶Folge▶haben.▶

HInweIS!

▶▶ Bei▶Nichtbeachtung▶kann▶das▶Gerät▶oder▶die▶Anlage▶beschädigt▶

werden.

bezeichnet▶wichtige▶Zusatzinformationen,▶Tipps▶und▶

Empfehlungen.

verweist▶auf▶Informationen▶in▶dieser▶Bedienungsanleitung▶

oder▶in▶anderen▶Dokumentationen.

▶→ markiert▶einen▶Arbeitsschritt,▶den▶Sie▶ausführen▶müssen.

1.2 Begriffsdefinition "Gerät"

Der▶in▶dieser▶Anleitung▶verwendete▶Begriff▶"Gerät"▶steht▶immer▶für▶

den▶Transmitter▶Typ▶8025▶Universal▶mit▶einer▶Serien-Nummer▶größer▶

oder▶gleich▶20▶000.

2

deutsch

Page 47

Typ 8025 UNIVERSAL

Bestimmungsgemässe Verwendung

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz dieses Gerätes

können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

▶▶ Der▶Transmitter▶Typ▶8025▶Universal▶ist▶für▶die▶Bearbeitung▶eines▶

Frequenzsignals,▶das▶er▶vom▶angeschlossenen▶DurchflussSensor▶aufnimmt,▶bestimmt.

▶▶ Schützen▶Sie▶das▶Gerät▶vor▶elektromagnetischen▶Stö-

rungen,▶U.V.-Bestrahlung▶und▶bei▶Außenanwendung▶vor▶

Witterungseinflüssen.

▶▶ Für▶den▶Einsatz▶sind▶die▶in▶den▶Vertragsdokumenten▶und▶der▶

Bedienungsanleitung▶spezifizierten▶zulässigen▶Daten,▶Betriebs-▶

und▶Einsatzbedingungen▶zu▶beachten.

▶▶ Zum▶sicheren▶und▶problemlosen▶Einsatz▶des▶Gerätes▶müssen▶

Transport,▶Lagerung▶und▶Installation▶ordnungsgemäß▶erfolgen,▶

außerdem▶müssen▶Betrieb▶und▶Wartung▶sorgfältig▶durchgeführt▶

werden.

▶▶ Achten▶Sie▶immer▶darauf,▶dieses▶Gerät▶auf▶ordnungsgemäße▶

Weise▶zu▶verwenden.

▶▶ Beachten▶Sie▶bei▶der▶Ausfuhr▶des▶Gerätes▶gegebenenfalls▶beste-

hende▶Beschränkungen.

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese▶Sicherheitshinweise▶berücksichtigen▶keine▶

•▶ Zufälligkeiten▶und▶Ereignisse,▶die▶bei▶Montage,▶Betrieb▶und▶

Wartung▶der▶Geräte▶auftreten▶können.

•▶ Ortsbezogenen▶Sicherheitsbestimmungen,▶für▶deren▶Einhaltung,▶auch▶

in▶Bezug▶auf▶das▶Installations-▶und▶Wartungspersonal,▶der▶Betreiber▶

verantwortlich▶ist.

Gefahr durch elektrische Spannung!

▶▶ Schalten▶Sie▶vor▶Beginn▶der▶Arbeiten▶in▶jedem▶Fall▶alle▶existieren-

den▶am▶ Gerät▶angeschlossenen▶ Spannungs-Versorgungen▶ab,▶

und▶sichern▶Sie▶diese▶vor▶unbeabsichtigtem▶Wiedereinschalten!

▶▶ Beachten▶Sie▶geltende▶Unfallverhütungs-▶und▶Sicherheitsbestim-

mungen▶für▶elektrische▶Geräte!

Allgemeine Gefahrensituationen.

Zum▶Schutz▶vor▶Verletzungen▶ist▶zu▶beachten

▶▶ Dieses▶Gerät▶nicht▶in▶explosionsgefährdeten▶Bereichen▶

einsetzen.

▶▶ Dieses▶Gerät▶nicht▶in▶einer▶Umgebung▶verwenden,▶die▶mit▶den▶

Materialien,▶aus▶denen▶es▶besteht,▶inkompatibel▶ist.

▶▶ Belasten▶Sie▶das▶Gerät▶nicht▶mechanisch▶(z.▶B.▶durch▶Ablage▶

von▶Gegenständen▶oder▶als▶Trittstufe).

deutsch

3

Page 48

Typ 8025 UNIVERSAL

Allgemeine Hinweise

4 ALLGEMEINE HINWEISE

Allgemeine Gefahrensituationen.

Zum▶Schutz▶vor▶Verletzungen▶ist▶zu▶beachten

▶▶ Nehmen▶Sie▶keine▶äußerlichen▶oder▶innerlichen▶Veränderungen▶

am▶Gerät▶vor.

▶▶ Dass▶die▶Anlage▶nicht▶unbeabsichtigt▶betätigt▶werden▶kann.

▶▶ Installations-▶und▶Instandhaltungsarbeiten▶dürfen▶nur▶von▶autorisier-

tem▶Fachpersonal▶mit▶geeignetem▶Werkzeug▶ausgeführt▶werden.

▶▶ Nach▶einer▶Unterbrechung▶der▶elektrischen▶Versorgung▶ist▶ein▶

definierter▶oder▶kontrollierter▶Wiederanlauf▶des▶Prozesses▶zu▶

gewährleisten.

▶▶ Betreiben▶Sie▶das▶Gerät▶nur▶in▶einwandfreiem▶Zustand▶und▶

unter▶Beachtung▶der▶Bedienungsanleitung.

▶▶ Bei▶der▶Einsatzplanung▶und▶dem▶Betrieb▶des▶Gerätes▶die▶allge-

meinen▶Regeln▶der▶Technik▶einhalten.

HInweIS!▶

Elektrostatisch gefährdete Bauelemente / Baugruppen!

▶▶ Das▶Gerät▶enthält▶elektronische▶Bauelemente,▶die▶gegen▶

elektrostatische▶Entladung▶empfindlich▶reagieren.▶Berührung▶

mit▶elektrostatisch▶aufgeladenen▶Personen▶oder▶Gegenständen▶

gefährdet▶diese▶Bauelemente.▶Im▶schlimmsten▶Fall▶werden▶sie▶

sofort▶zerstört▶oder▶fallen▶nach▶der▶Inbetriebnahme▶aus.

▶▶ Beachten▶Sie▶die▶Anforderungen▶nach▶EN▶61340▶-5-1▶und▶5-2,▶

um▶die▶Möglichkeit▶eines▶Schadens▶durch▶schlagartige▶elektro-

statische▶Entladung▶zu▶minimieren▶bzw.▶zu▶vermeiden!

▶▶ Achten▶Sie▶ebenso▶darauf,▶dass▶Sie▶elektronische▶Bauelemente▶

nicht▶bei▶anliegender▶Versorgungsspannung▶berühren!▶

4.1 Herstelleradresse und

internationale Kontaktadressen

Sie▶können▶mit▶dem▶Hersteller▶des▶Gerätes▶unter▶folgender▶Adresse▶

Kontakt▶aufnehmen:

Bürkert▶SAS

Rue▶du▶Giessen

BP▶21

F-67220▶TRIEMBACH-AU-VAL

oder▶wenden▶Sie▶sich▶an▶Ihr▶lokal▶zuständiges▶Vertriebsbüro▶von▶

Bürkert.

Die▶internationalen▶Kontaktadressen▶finden▶Sie▶im▶Internet▶unter:▶

www.burkert.com

4.2 Gewährleistung

Voraussetzung▶für▶die▶Gewährleistung▶ist▶der▶bestimmungsgemäße▶

Gebrauch▶des▶Gerätes▶unter▶Beachtung▶der▶in▶der▶vorliegenden▶

Bedienungsanleitung▶spezifizierten▶Einsatzbedingungen.

4.3 Informationen im Internet

Bedienungsanleitungen▶und▶Datenblätter▶zum▶Typ▶8025▶finden▶Sie▶

im▶Internet▶unter:▶www.buerkert.de

4

deutsch

Page 49

Typ 8025 UNIVERSAL

1

35

4

2

Beschreibung

5 BESCHREIBUNG

5.1 Vorgesehener Einsatzbereich

Der▶Transmitter▶Typ▶8025▶Universal▶kann▶an▶einen▶abgesetzten▶Durchfluss-Sensor,▶der▶ein▶Frequenzsignal▶ausgibt,▶angeschlossen▶werden.▶

Die▶vorgeschriebenen▶ technischen▶Daten▶ des▶angeschlossenen▶

Durchfluss-Sensors▶sind▶im▶Kapitel▶„6▶Technische▶Daten“▶beschrieben.

Wenn▶das▶ Gerät▶ an▶ einem▶ Durchfluss-Sensor▶ angeschlossen▶ ist,▶

ermöglichen▶die▶ einstellbaren▶ Transistor-▶und,▶ bei▶einigen▶ Ausführungen,▶die▶beiden▶Relaisausgänge▶dem▶Gerät,▶ein▶Magnetventil▶zu▶

schalten,▶einen▶ Alarm▶ zu▶ aktivieren▶ oder▶ eine▶ dem▶ Durchfluss▶ proportionale▶Frequenz▶ zu▶ erzeugen,▶ und▶ der▶4-20▶ mA▶ Stromausgang▶

ermöglicht▶einen▶Regelkreise▶aufzubauen.

5.2 Beschreibung des Typenschilds

▶

LFLOW 8025 PANEL SUPPLY: 12-36V= 210 mA

DO1: 5-36V= 100mA AO1:4-20mA

DO2&3: 2xRelay 30 and 42V peak or 60V... max. IP20

S/N 20 000

Made in France

00564417 W46MA

10

9

781112

6

1.▶ Messgröße

2.▶ Typ▶des▶Gerätes,▶Gehäuse

3.▶ Daten▶des▶Transistorausgangs▶DO1

4.▶ Daten▶des▶Analogausgangs▶AO1▶

5.▶ Betriebsspannung▶und▶max.▶Stromverbrauch▶

6.▶ Schutzart▶des▶Gerätes

7.▶ Herstellungscode▶Konformitäts-Logos

8.▶ Warnung:▶Bevor▶das▶Gerät▶benutzt▶wird,▶die▶in▶der▶

Bedienungsanleitung▶beschriebenen▶technischen▶Daten▶▶

berücksichtigen.

9.▶ Daten▶der▶Relais-Ausgänge▶DO2▶und▶DO3

10.▶Seriennummer

11.▶Bestellnummer

Bild 1: Typenschild des Transmitters 8025 Universal (Beispiel)

deutsch

5

Page 50

Typ 8025 UNIVERSAL

Technische Daten

6 TECHNISCHE DATEN

6.1 Betriebsbedingungen

Temperaturbereich -10▶bis▶+60▶°C

Luftfeuchtigkeit <▶80▶%,▶nicht▶kondensierend

Höhe▶über▶Meeresspiegel 2000▶m.▶max.

Einbaukategorie Kategorie▶I▶nach▶UL▶61010-1

Verschmutzungsgrad Grad▶2▶nach▶EN▶61010-1

Schutzart

•▶ Wandmontage-Ausführung▶

▶

▶

▶

▶

•▶ Schaltschrank-Ausführung

6.2 Einhaltung von Normen und

Richtlinien

Durch▶folgende▶Normen▶wird▶die▶Konformität▶mit▶den▶EG-Richtlinien▶

erfüllt:

•▶ EMV:▶EN▶61000-6-2,▶EN▶61000-6-3

nach▶EN▶60529

•▶ IP65,▶mit▶angeschlossenem▶Gerät,▶

festgeschraubten▶Kabelverschraubungen,▶festgeschraubtem▶Deckel▶

und▶mit▶einem▶Drehmoment▶von▶

1.5▶Nm▶am▶Gehäuse▶festgeschraubten▶Zwischenstutzen▶der▶

Kabelverschraubungen.

•▶ außerhalb▶des▶Schaltschranks▶

IP65,▶innerhalb▶des▶Schranks▶IP20

•▶ Niederspannungsrichtlinie:▶EN▶61010-1

•▶ Prüfung▶Umgebungseinfluss:

▶- Vibration:▶EN▶60068-2-6,

▶- Schock:▶EN▶60068-2-27.

Die▶UL-Geräte▶mit▶variablem▶Schlüssel▶PU01▶entsprechen▶den▶folgenden▶Normen:

•▶ UL▶61010-1

•▶ CAN/CSA-C22.2▶n°▶61010-1

6.3 Mechanische Daten

Teil Werkstoff

Gehäuse▶und▶Deckel,▶

Wandmontage-Ausführung

Kabelverschraubungen,▶

Wandmontage-Ausführung

Schaltschrank-Gehäuse PC

Folie Polyester

4▶Schrauben Edelstahl

Kabelschellen PA

ABS

PA

6

deutsch

Page 51

Typ 8025 UNIVERSAL

Technische Daten

88

76

FLOW

88

ENTER

0....9

40

25

Bild 2: Abmessungen des Transmitters 8025 Universal,

Schaltschrank-Ausführung [mm]

126

FLOW

23

90

31.50

23

0....9

ENTER

Bild 3: Abmessungen des Transmitters 8025 Universal,

Wandmontage-Ausführung [mm]

120

6.4 Elektrische Daten

12-36▶V▶DC-VersorgungsSpannung

Spannungsquelle▶(nicht▶

mitgeliefert)

115/230▶V▶AC-Versorgungs-

143

Spannung

•▶ Frequenz

•▶ Gelieferte▶Spannung

•▶ Strom

•▶ Integrierter▶Schutz

•▶ Leistung

•▶ Gefiltert▶und▶geregelt

•▶ Stromkreis▶mit▶SicherheitsKleinspannung▶und▶nicht▶

gefährlichem▶Energieniveau

•▶ Max.▶Toleranz▶für▶12▶V▶DC:▶

-5▶%▶oder▶+10%

•▶ Max.▶Toleranz▶für▶36▶V▶DC:▶

±10▶%

•▶ Quelle▶mit▶begrenzter▶

Leistung▶gemäß▶Kap.▶9.3▶der▶

Norm▶EN▶61010-1

•▶ oder▶Quelle▶der▶Klasse▶

2▶gemäß▶den▶Normen▶▶

UL▶1310/1585▶und▶

EN▶60950-1

▶

•▶ 50/60▶Hz

•▶ 27▶V▶DC,▶geregelt

•▶ Max.▶250▶mA

•▶ 250▶mA-Zeitsicherung

•▶ 6▶VA

deutsch

7

Page 52

Typ 8025 UNIVERSAL

Technische Daten

Eigenverbrauch▶(ohne▶den▶Verbrauch▶des▶4-20▶mA-Ausgangs)

•▶ Ausführung▶ohne▶Relais,▶

12-36▶V▶DC-Versorgungsspannung

•▶ Ausführung▶mit▶Relais,▶

12-36▶V▶DC-Versorgungsspannung

•▶ Ausführung▶ohne▶Relais,▶

115/230▶V▶AC-Versorgungsspannung

•▶ Ausführung▶mit▶Relais,▶

115/230▶V▶AC-Versorgungsspannung

▶

•▶ 60▶mA▶(bei▶12▶V▶DC)▶und▶

30▶mA▶(bei▶36▶V▶DC)▶

•▶ 90▶mA▶(bei▶12▶V▶DC)▶und▶

45▶mA▶(bei▶36▶V▶DC)▶

•▶ 40▶mA▶

▶

•▶ 55▶mA

Transistorausgang DO1

•▶ Typ ▶

•▶ Funktion▶

•▶ Frequenz▶(f)

•▶ Elektrische▶Daten▶

▶

•▶ Taktverhältnis▶bei▶

0,6▶<▶f▶<▶300▶Hz

•▶ Taktverhältnis▶bei▶

300▶<▶f▶<▶1500▶Hz

•▶ Taktverhältnis▶bei▶

1500▶<▶f▶<▶2200▶Hz

•▶ Schutz

Polarisiert,▶potentialfrei

•▶ NPN▶/▶PNP▶(je▶nach▶

Verkabelung)

•▶ Pulsausgang▶(Grundeinstellung),▶einstellbar

•▶ 0,6-2200▶Hz

•▶ 5-36▶V▶DC,▶100▶mA▶max.,▶

Spannungsabfall▶von▶

2,7▶V▶DC▶bei▶100▶mA

•▶ >▶0,45▶

•▶ >▶0,4▶

•▶ <▶0,4▶

•▶ Galvanisch▶getrennt;▶Schutz▶

gegen▶Überspannung,▶Verpolung▶und▶Kurzschluss

8

deutsch

Page 53

Typ 8025 UNIVERSAL

Technische Daten

Relais-Ausgänge DO2 und

DO3

•▶ Umschaltbetrieb▶

•▶ Elektrische▶Daten▶der▶Last▶

(nicht▶UL-Geräte)

•▶ Elektrische▶Daten▶der▶Last▶

(UL-Geräte)

•▶ Max.▶Schaltvermögen

•▶ Lebensdauer

Stromausgang AO1

•▶ Daten▶

▶

▶

•▶ Schleifenimpedanz▶max.▶bei▶

einem▶mit▶12-36▶V▶DC▶versorgtem▶Gerät▶

•▶ Schleifenimpedanz▶max.▶bei▶

einem▶mit▶115/230▶V▶AC▶

versorgtem▶Gerät

▶

•▶ Hysterese▶(Grundeinstellung),▶

einstellbar,▶stromlos▶geöffnet

•▶ 230▶V▶AC▶/▶3▶A▶oder▶40▶V▶DC▶

/▶3▶A

•▶ max.▶30▶V▶AC▶und▶42▶V▶Spitze▶

oder▶max.▶60▶V▶DC,▶3▶A

•▶ 750▶VA▶(ohmsche▶Last)

•▶ ▶min.▶100000▶Zyklen

•▶ 4-20▶mA,▶Senke▶oder▶Quelle▶

(je▶nach▶Verkabelung),▶

22▶mA▶zur▶Fehlermeldung▶

(aktivierbar)

•▶ 1300W▶bei▶36▶V▶DC,▶1000W▶

bei▶30▶V▶DC,▶750W▶bei▶

24▶V▶DC,▶300W▶bei▶15▶V▶DC,▶

200W▶bei▶12▶V▶DC

•▶ 900W

6.5 Daten des angeschlossenen

Durchfluss-Sensors

Signal▶vom▶abgesetzten▶Sensor

•▶ Typ ▶

▶

▶

•▶ Frequenz

•▶ max.▶Spannung

Eingangsimpedanz

Betriebsspannung durch▶den▶Transmitter▶je▶nach▶Stelle▶des▶

▶

•▶ Pulssignal,▶sinusförmiges▶Signal▶(Empfindlichkeit:▶typisch▶50▶mV▶Spitze-Spitze▶bei▶

250▶Hz),▶On/Off-Signal,▶oder▶genormter▶

0-5▶V▶DC▶Spannungssignal

•▶ 0,6▶Hz▶bis▶2,2▶kHz,▶einstellbar

•▶ 36▶V▶DC

je▶nach▶Stelle▶des▶Auswahlschalters▶"LOAD"▶

auf▶der▶Elektronikplatine▶des▶8025.▶Siehe▶

Kap.▶„7.4.10“

Auswahlschalters▶"SENSOR▶SUPPLY"▶des▶

8025▶geliefert:

•▶ 5▶V▶DC,▶30▶mA▶max.

•▶ (L+)-12V:▶Versorgungsspannung▶(L+)▶

des▶Transmitters▶minus▶12▶V▶DC▶(minus▶

12,5▶V▶DC▶max.),▶80▶mA▶max.

•▶ L+:▶Versorgungsspannung▶(L+)▶des▶

Transmitters▶(minus▶1,5▶V▶DC▶max.),▶

140▶mA▶max.(bei▶einem▶Gerät▶mit▶

12-36▶V▶DC-Versorgungsspannung),▶

80▶mA▶max.▶(bei▶einem▶Gerät▶mit▶

115/230▶V▶AC-Versorgungsspannung)

deutsch

9

Page 54

Typ 8025 UNIVERSAL

Installation, Verkabelung

6.6 Elektrischer Anschluss

Anschluss-Typ über▶Schraubklemmleisten▶

auf▶der▶Elektronikplatine▶

(und▶über▶M16x1,5-Kabelverschraubungen▶bei▶den▶

Wandmontage-Ausführungen)

Kabel-Daten

•▶ Kabeltyp

•▶ Querschnitt▶der▶Ader

•▶ Durchschnitt▶des▶Kabels▶

(für▶die▶M16x1,5-Kabelverschraubungen▶der▶

Wandmontage-Ausführungen)

•▶ abgeschirmt

•▶ 0,2▶bis▶1,5▶mm

•▶ 4▶bis▶8▶mm

2

7 INSTALLATION, VERKABELUNG

7.1 Sicherheitshinweise

GefaHR!

Verletzungsgefahr durch Stromschlag!

▶▶ Schalten▶Sie▶vor▶Beginn▶der▶Arbeiten▶in▶jedem▶Fall▶alle▶existierenden▶

am▶Gerät▶angeschlossenen▶Spannungs-Versorgungen▶ab,▶und▶

sichern▶Sie▶diese▶vor▶unbeabsichtigtem▶Wiedereinschalten!

▶▶ Beachten▶Sie▶geltende▶Unfallverhütungs-▶und▶Sicherheitsbe-

stimmungen▶für▶elektrische▶Geräte!

waRnunG!

Verletzungsgefahr bei unsachgemäßer Installation!

▶▶ Elektrische▶Installation▶darf▶nur▶durch▶autorisiertes▶Fachpersonal▶

und▶mit▶geeignetem▶Werkzeug▶durchgeführt▶werden!

▶▶ Verwenden▶Sie▶unbedingt▶geeignete▶Sicherheitsvorrichtungen▶

(ordnungsgemäß▶dimensionierte▶Sicherungen▶und/oder▶Schutzschalter);▶Bei▶Geräten▶mit▶115/230▶V▶AC-Betriebsspannung▶

eine▶Sicherheitsvorrichtung▶zwischen▶den▶Außenleiter▶und▶den▶

Neutralleiter▶schalten.

▶▶ Die▶Norm▶NF▶C▶15-100▶/▶IEC▶60364▶beachten.

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

▶▶ Anlage▶vor▶unbeabsichtigtem▶Betätigen▶sichern.

▶▶ Nach▶jedem▶Eingriff▶an▶dem▶Gerät▶einen▶kontrollierten▶Wieder-

anlauf▶gewährleisten.

10

deutsch

Page 55

Typ 8025 UNIVERSAL

Installation, Verkabelung

Schützen▶Sie▶das▶Gerät▶vor▶elektromagnetischen▶Störungen,▶U.V.-Bestrahlung▶und▶bei▶Außenanwendung▶vor▶

Witterungseinflüssen.

7.2 Installation einer

Schaltschrank-Ausführung

Die▶Schaltschrank-Ausführung▶in▶ einen▶Schaltschrank▶ mit▶

minimaler▶Schutzart▶IP54▶ installieren,▶um▶einen▶Verschmutzungsgrad▶2▶innerhalb▶des▶Schaltschranks▶zu▶gewährleisten.

▶→ Die▶mitgelieferte▶Ausschneidschablone▶verwenden,▶dabei▶die▶

in▶„Bild▶4“▶angegebenen▶Maße▶für▶den▶Ausschnitt▶des▶Schaltschranks▶berücksichtigen.

95

80

76

50

95

80

76

50

Bild 4: Abmessungen der Ausschneidschablone [mm]

▶→ Die▶4▶Schrauben▶von▶vorne▶in▶das▶Gehäuse▶einsetzen.

▶→ Die▶Dichtung▶von▶hinten▶auf▶die▶Außengewinde▶der▶4▶Schrauben▶

setzen.

▶→ Die▶Montage▶von▶vorne▶auf▶den▶Ausschnitt▶plazieren,▶dabei▶die▶

Elektronik▶nach▶innen▶des▶Schaltschranks▶richten.

▶→ Die▶4▶Scheiben▶auf▶die▶4▶Schrauben▶setzen.

▶→ Das▶Gerät▶an▶den▶Schaltschrank▶mittels▶den▶4▶Überwurfmuttern▶

befestigen.

Schrauben

Scheibe

Überwurfmutter

Kabelklemme

Dichtung

Bild 5: Installation des 8025 in der Schaltschrank-Ausführung

deutsch

11

Page 56

Typ 8025 UNIVERSAL

11

Installation, Verkabelung

7.3 Installation einer

Wandmontage-Ausführung

HInweIS!

Gefahr vor Sachschäden, wenn die Kabelverschraubungen

nicht am Gehäuse befestigt sind

▶▶ Vor▶der▶Montage▶des▶Wandmontage-Gehäuses▶die▶Zwischen-