Page 1

Type 8022

Flow Transmitter / Pulse divider

Durchflusstransmitter / Impulsteiler

Transmetteur de débit / Diviseur d’impulsions

Operating Instructions (from device Version 2)

Bedienungsanleitung (ab Geräte-Version 2)

Manuel d‘utilisation (à partir de la version 2 de l'appareil)

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2011-2016

Operating Instructions 1603/03_EU-ML 00809506 Original FR

Page 3

Type 8022

1 OPERATING INSTRUCTIONS ........................................................................................................................................................3

1.1 Symbols used ..........................................................................................................................................................................3

1.2 Definition of the term "device" ........................................................................................................................................3

2 INTENDED USE ....................................................................................................................................................................................4

3 BASIC SAFETY INSTRUCTIONS .................................................................................................................................................5

4 GENERAL INFORMATION ................................................................................................................................................................6

4.1 Manufacturer’s address and international contact addresses ......................................................................6

4.2 Warranty conditions ..............................................................................................................................................................6

4.3 Information on the Internet ...............................................................................................................................................6

5 DESCRIPTION .......................................................................................................................................................................................7

5.1 General description ..............................................................................................................................................................7

5.2 Combined sensor ..................................................................................................................................................................7

5.3 Description of the name plate ........................................................................................................................................7

6 TECHNICAL DATA ................................................................................................................................................................................8

6.1 Conformity to standards and directives ....................................................................................................................8

6.2 Operating conditions ...........................................................................................................................................................8

6.3 Mechanical data ......................................................................................................................................................................8

6.4 Electrical data ..........................................................................................................................................................................9

7 ASSEMBLY, INSTALLATION ........................................................................................................................................................10

7.1 Assembly of the device ...................................................................................................................................................10

7.2 Electrical wiring ....................................................................................................................................................................11

7.2.1 Connection as a flow transmitter ....................................................................................................11

7.2.2 Connection as a pulse divider .........................................................................................................12

8 COMMISSIONING ............................................................................................................................................................................12

9 ADJUSTMENT .....................................................................................................................................................................................13

9.1 Display and control keys .................................................................................................................................................13

9.2 Control key functions ........................................................................................................................................................13

9.3 Operation as a flow transmitter ..................................................................................................................................14

English

1

Page 4

Type 8022

9.4 Operation as a pulse divider .........................................................................................................................................14

9.5 Operating levels ...................................................................................................................................................................14

9.5.1 Switching between the operating levels ......................................................................................15

9.6 Main menu of the configuration level ......................................................................................................................16

9.6.1 Unit – Setting the unit for the flow rate ....................................................................................16

9.6.2 InP (Input) – Entering the K factor of the fitting or selecting a preset K factor ...........17

9.6.3 Out (Output) – Setting the output signal ............................................................................19

9.6.4 dAtA (Data) – Uploading and downloading the device settings ....................................20

10 MAINTENANCE, TROUBLESHOOTING .................................................................................................................................21

10.1 Maintenance work ..............................................................................................................................................................21

10.2 Error messages ...................................................................................................................................................................21

10.3 Default values .......................................................................................................................................................................21

11 SPARE PARTS / ACCESSORIES .............................................................................................................................................22

12 PACKAGING AND TRANSPORT ...............................................................................................................................................22

13 STORAGE ..............................................................................................................................................................................................22

14 DISPOSAL ............................................................................................................................................................................................22

2

English

Page 5

Type 8022

Operating Instructions

1 OPERATING INSTRUCTIONS

The Operating Instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available to every new owner of the device.

The Operating Instructions manual contains important safety information.

Read the complete Operating Instructions. Pay special attention to the chapters Basic Safety Instructions and

Intended Use.

▶ Read the complete Operating Instructions.

1.1 Symbols used

Caution!

Warns of a possible danger!

▶ Failure to observe this warning may result in a moderate or minor injury.

notE

Warns of damage to property!

▶ Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

refers to information in these Operating Instructions or in other documentation.

▶ Indicates an instruction to be carried out to avoid a danger, a warning or a possible risk.

→ Indicates a procedure to be carried out.

Indicates the result of a specific instruction.

1.2 Definition of the term "device"

In these Operating Instructions, the term "device" always refers to the flow transmitter type 8022 or the pulse

divider type 8022.

English

3

Page 6

Type 8022

Intended Use

2 INTENDED USE

Use of this device that does not comply with the Operating Instructions could present risks to people,

nearby installations and the environment.

The flow transmitter type 8022, associated to a Bürkert flow sensor, converts the frequency signal generated by the flow sensor into an analogue 4-20 mA current signal.

The pulse divider type 8022, associated to a Bürkert flow sensor, converts the frequency signal generated by the flow sensor into an adjustable frequency signal.

▶ The device is designed for use in industrial environments.

▶ Use the device in compliance with the characteristics and commissioning and use conditions specified in the

contractual documents and in the Operating Instructions.

▶ Do not use the device for security applications.

▶ Do not use the device outdoors.

▶ Protect the device against electromagnetic interference and ultraviolet rays.

▶ Use the device only if in perfect working order.

▶ Requirements for the safe and proper operation of the device are proper transport, storage and installation, as

well as careful operation and maintenance.

▶ Only use the device as intended.

4

English

Page 7

Type 8022

Basic Safety Instructions

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation, operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

Various dangerous situations

To avoid injury take care:

▶ not to use the device in explosive atmospheres.

▶ not to use the device in an environment incompatible with the materials it is made of.

▶ not to subject the device to mechanical loads (e.g. by placing objects on top of it or by using it as a step).

▶ not to make any modifications to the device.

▶ to prevent any unintentional power supply switch-on.

▶ to ensure that installation and maintenance work are carried out by qualified, authorised personnel in posses-

sion of the appropriate tools.

▶ to guarantee a defined or controlled restarting of the process, after a power supply interruption.

▶ to observe the general technical rules when installing and using the device.

notE

Electrostatic sensitive components/modules!

The device contains electronic components, which react sensitively to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects is hazardous to these components. In the worst case scenario,

they will be destroyed immediately or will fail after start-up.

▶ Observe the requirements in accordance with EN 61340-5-1 to minimize and even avoid the possibility of

damage caused by a sudden electrostatic discharge!

▶ Also, ensure that you do not touch electronic components when the power supply voltage is present!

English

5

Page 8

Type 8022

General Information

4 GENERAL INFORMATION

4.1 Manufacturer’s address and international contact

addresses

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the internet at: www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of the device in observance of the operating conditions specified in this manual.

4.3 Information on the Internet

The Operating Instructions and data sheets for type 8022 can be found on the Internet at: www.burkert.com

6

English

Page 9

12

1112 10 9

3 54

Type 8022

Description

5 DESCRIPTION

5.1 General description

The device, when it is combined with a flow sensor, operates either as a flow transmitter thanks to a 4-20 mA current

output, or as a pulse divider thanks to a transistor output. By default, the device operates as a flow transmitter.

• When operating as a flow transmitter, the 8022 converts the frequency signal generated by the combined

Bürkert flow sensor into an analogue 4-20 mA current signal (2-wire connection).

• When operating as a pulse divider, the 8022 converts the frequency signal generated by the combined Bürkert

flow sensor into an adjustable frequency signal (3-wire connection).

The device may be fitted with a display and configuration unit. The display and configuration unit makes it possible to:

• change the operating mode into pulse divider.

• configure the device.

5.2 Combined sensor

• The flow transmitter type 8022 must be combined to a Bürkert flow sensor with a transistor output, in the Low

Power version of the following types: 8020, 8030, 8070, SE30.

• The pulse divider type 8022 must be combined to a Bürkert flow sensor with a transistor output of the types

8020, 8030, 8070, SE30.

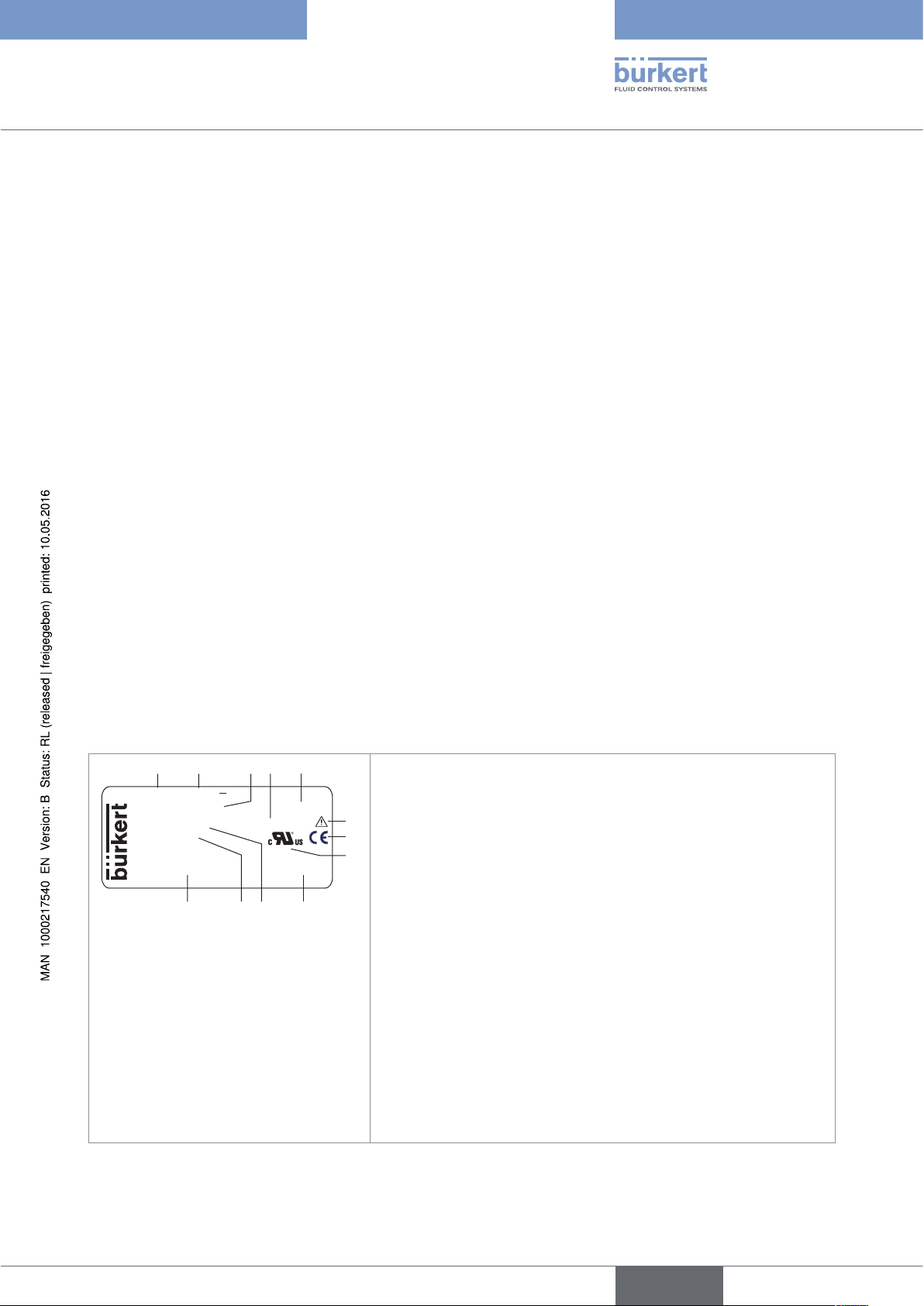

5.3 Description of the name plate

1. Type of the device

8022 12-30V...

4-20mA/Pulse Vers. 2

Tamb -10°...+60°C Pmax. 3.2W

S-N:2000

00563223 W49MG

Made in France

2. Operating voltage

6

3. Available outputs

7

8

4. Maximum power consumption

5. Version of the device

6. Warning: Before using the device, take into account the technical

specifications described in these Operating Instructions

7. Conformity

8. Certification

Fig. 1 : Example of a 8022 name plate

9. Construction code

10. Ambient operating temperature

11. Serial number

12. Order code

7

English

Page 10

Type 8022

Technical Data

6 TECHNICAL DATA

6.1 Conformity to standards and directives

The device conforms to the CE directives through the following standards:

• EMC: EN 61000-6-1, EN 61000-6-3

The UL devices (identified by the logo

lowing standards:

• UL 61010-1

• CAN/CSA-C22.2 n° 61010-1

), for the United States and Canada, also comply with the fol-

6.2 Operating conditions

Ambient temperature (operating) -10...+60 °C

Protection class IP65 according to EN 60529, if the following conditions are respected:

• Cable gland wired or blanked-off, or female connector plugged-in and

tightened

• Nut of the cable gland tightened with a torque of 1 N·m ± 20 %

(0,74 lbf·ft ± 20 %).

• Housing closed and screw tightened with a torque of 0,3 N·m ± 20 %

(0,22 lbf·ft ± 20 %), or display and configuration unit plugged on

the device and screw tightened with a torque of 0,3 N·m ± 20 %

(0,22 lbf·ft ± 20 %) at the factory.

Combined flow sensor

• Flow transmitter

• Bürkert flow sensor with a transistor output, in the Low Power version of

the types 8020, 8030, 8070, SE30.

• Pulse divider

• Bürkert flow sensor with a transistor output, of the types 8020, 8030,

8070, SE30.

6.3 Mechanical data

Fastening

• device without display and configuration unit

• device with display and configuration unit

Housing material polyamide/polycarbonate

Material of the seals

• seal for the sensor fixed connector

• seal for the cover

8

English

• 1 M3 x 35 screw

• 1 M3 x 45 screw

• NBR

• EPDM

Page 11

Type 8022

Technical Data

6.4 Electrical data

Electrical connection

• 4-pin terminal strip, 1.5 mm

2

max. wire section, 6 - 7 mm

cable diameter

• M12 male fixed connector

Voltage supply, 12...+30 V DC • filtered and regulated

• SELV circuit at a non dangerous energy level

• tolerance : ±10%

• residual ripple : < 5%

Frequency input 1-600 Hz, sensor supply voltage approximately V+ - 1 V

4-20 mA output

• Uncertainty of the output value

• Min. voltage drop at the device terminals

• Loop impedance

• ±1,5% of the full scale

• < 10 V at 20 mA

• max. 100 W at 12 VDC, max. 700 W at 24 VDC, max. 1000 W

at 30 VDC

Transistor output

• Uncertainty of the output value

NPN or PNP, 50 mA max. current, frequency up to 600 Hz

• ±1% of the measured value

Maximum power consumption

• Operating as a flow transmitter (4-20 mA

• 0,6 W

output in a 2-wire system)

• Operating as a pulse divider (NPN/PNP

output in a 3-wire system)

• 3,2 W, from which

- 0,2 W for the device,

- max. 1,5 W for the flow sensor,

- max. 1,5 W for the NPN/PNP output

English

9

Page 12

Type 8022

Assembly, Installation

7 ASSEMBLY, INSTALLATION

7.1 Assembly of the device

Fig. 1 shows how the device is screwed to the sensor.

notE

For the fault-free operation of the device observe the following during installation:

▶ When screwing to the sensor, ensure the seal is seated correctly.

▶ Torque the screw to a value between 0.2 and 0.3 N·m (between 0,15 and 0,22 lbf·ft), in order not to damage

the housing. With a damaged housing, correct operation of the device cannot be guaranteed.

10

Fig. 2 : Installing the device on the sensor

English

Page 13

Type 8022

Assembly, Installation

7.2 Electrical wiring

The electrical connection of the device is made on a terminal strip via cable gland, or an M12 male fixed connector.

Terminal assignment

NPN

1

PNP

2

12 - 30 V DC

3

GND

4

Fig. 3 : Terminal assignment of a version with cable gland

Pin assignment

12 - 30 V DC

1

NPN

2

GND

3

PNP

4

Fig. 4 : Pin assignment of the M12 male fixed connector

→ Wire:

• either the current output for an operation as a flow transmitter,

• or the transistor output for an operation as a pulse divider.

7.2.1 Connection as a flow transmitter

For an operation as a flow transmitter, wire the 4-20 mA current output with 2 wires, as described in Fig. 5.

8022

12 - 30 V DC

12 - 30 V DC

GND

Fig. 5 : Connection of the 4-20 mA current output of the flow transmitter

4 - 20 mA

11

English

Page 14

Type 8022

Assembly, Installation

7.2.2 Connection as a pulse divider

For an operation as a pulse divider, wire the transistor output with 3 wires, as described in Fig. 6.

The transistor output can be wired in NPN or in PNP mode with 3 wires.

Connection in NPN mode

Connection in NPN mode

12 - 30 V DC

NPN

GND

12 - 30 V DC

PNP

8022

8022

e.g. PLC

V+

IN

GND

e.g. PLC

V+

IN

12

GND

Fig. 6 : Connection of the transistor output of the pulse divider

8 COMMISSIONING

notE

▶ Only power on the device when the cover is closed.

▶ Switch off the device before removing the display and configuration unit.

GND

English

Page 15

Type 8022

Adjustment

9 ADJUSTMENT

9.1 Display and control keys

notE

The device is not tight when the display and configuration unit is removed.

▶ Screw the cover with order code 670549 on the device as soon as the display and configuration unit is

removed.

The display and configuration unit is only required to indicate the flow rate or to configure the device. It

can be removed after the settings have been made if you do not want to display the measured flow rate.

Status display:

with check mark = active

without check mark = not active

Process Value

Control keys:

selection, input and confirmation

(see chapter 9.2 Control key

Fig. 7 : Display and control keys

functions)

K factor

Keys for

LC display

Unit of flow rate

Unit of output value

Upper/Lower limit (High/Low)

4-character display

9.2 Control key functions

Their function with regards to the operating level is described in the following table.

Operating level

(see chapter 9.5

Operating levels)

Level 1:

Read level

Switching over the display value from:

• PV ProcessValue in set flow rate unit

Press and hold for 3 s:

Change to the configuration level

• PV ProcessValue in mA

• PV ProcessValue in Hz (frequency of sensor)

Level 2:

Configuration

level

Tab. 1 : Control keys

Scroll up (select). Scroll down (select). Confirm parameter, change between

Increase numerical

value by one value.

Enter values

Change by one

position to the left.

parameters.

Select and deselect parameter, confirm set

values.

Change to Read level when End is shown

13

English

Page 16

Type 8022

Adjustment

9.3 Operation as a flow transmitter

When operating as a flow transmitter, the frequency value of the sensor is converted into a 4-20 mA signal.

Setting:

→ Set the K factor of the fitting used (see Operating Instructions of the fitting used).

→ Always set the K factor in the pulse/liter unit.

→ Associate the 4-20 mA signal with a flow rate range using the upper and lower limits.

9.4 Operation as a pulse divider

When operating as a pulse divider, a pulse is sent out on the transistor output each time the set volume has been

counted.

The frequency value of the sensor is converted via the K factor and the volume set for a pulse.

Setting:

→ Set the K factor of the fitting used (see Operating Instructions of the fitting used).

→ Set the volume for each pulse sent out on the NPN and PNP outputs.

The K factor is always set in the unit pulse/liter whatever the setting in the parameter Unit.

9.5 Operating levels

For operating the flow transmitter / pulse divider there are 2 levels available: the Read level and the configuration level.

Level 1: Read level

When the device is switched on, it is at the Read level. The flow rate measured by the connected sensor is indicated.

At this level use the arrow keys to successively read different values and define which of them stays displayed. The

values differ depending whether the device is operating as a flow transmitter or a pulse divider.

Flow transmitter Pulse divider

l / m

PV

25.5

PV Hz

25.5

PV mA

12.3

Flow rate in liters/minute

Input frequency of the flow rate

sensor [Hz]

Output current [mA]

l / m

PV

Flow rate in liters/minute

25.5

PV Hz

25.5

Input frequency of the flow rate

sensor [Hz]

14

Fig. 8 : Level 1: Display options when operating as a flow transmitter or a pulse divider

English

Page 17

Type 8022

Adjustment

Level 2: Configuration level

At this level, the settings for the device are made.

Unit = set the unit for the flow rate

InP / Input = set the K factor of the fitting used

Out / Output = set the output signal

dAtA / Data = transfer of data from/to display and configuration unit

End = end configuration

Go back to Read level

Fig. 9 : Level 2: Define the settings

9.5.1 Switching between the operating levels

When the device is switched on, it is at the Read level.

→ Press and hold the ENTER key (3 seconds) to switch to the configuration level.

→ Confirm End in the main menu loop using the ENTER key to return to the Read level.

Level 2: Configuration levelLevel 1: Read level

l / m

PV

> 3 s (long)

25.5

Hz

mA

Unit

InP

Out

dAtA

End

Fig. 10 : Switching between the operating levels

15

English

Page 18

Type 8022

Adjustment

9.6 Main menu of the configuration level

→ Press and hold the ENTER key (3 s) to access the configuration level.

The following settings are possible:

Unit = set the unit for the flow rate, see chapter 9.6.1

InP / Input = set the K factor of the fitting used, see chapter 9.6.2

Out / Output = set the output signal, see chapter 9.6.3

dAtA / Data = transfer of data from/to the display and configuration unit, see chapter 9.6.4

Leaving the configuration level:

End = end the settings and go back to the Read level by pressing the ENTER key when End is

displayed.

9.6.1 Unit – Setting the unit for the flow rate

In this parameter, set the unit the measured flow rate is displayed in and in which the limits of the flow rate range

associated to the 4-20 mA output are defined.

When changing the unit (e.g. from liters to gallons), also change the current output limits.

Setting in the parameter:

16

l / s

l / m

l / h

m3 / m

m3 / h

g / s

g / m

g / s

End

Liters/second

Liters/minute

Liters/hour

Cubic meters/minute

Cubic meters/hour

US gallons/second

US gallons/minute

US gallons/hour

Status display changes to "active".

The selected unit is shown on the

display.

Fig. 11 : Unit – Setting the display for the flow rate unit

English

Page 19

Type 8022

Adjustment

9.6.2 InP (Input) – Entering the K factor of the fitting or selecting

a preset K factor

Entering the value of the K factor:

→ Go to the InP parameter and confirm.

→ Go to the FrEE parameter and confirm.

→ Enter the K factor of the fitting used, in pulses/liter. Refer to the Operating Instructions of the fitting used for

the value of the K factor (for example type S020, S030, S070 or S077).

→ Confirm the set K factor: the device uses the entered K factor.

Selecting a preset K factor (available from “Version 2” of the device. Refer to the name plate):

The K factor values of the fittings S020, S030, S070 and S077 are preset in the device.

If you use Instructions for selecting the correct preset K factor

• a fitting type S020 with a sensor

type 8020

→ Go to the InP parameter and confirm.

→ Go to the menu 8020 and confirm.

• a fitting type S030 with a sensor

type 8030 or SE30

• a fitting type S070 or a fitting type

S077, with a sensor type SE30

→ Go to the fitting model, for example SAdd if you use a saddle, and

confirm.

→ Go to the material the fitting is made of and confirm.

→ Go to the DN of the fitting. Confirm: the preset K factor is displayed.

Check that the displayed K factor is the same as the one indicated in

the Operating Instructions of the fitting used.

→ Confirm. The status display changes to “active”.

The preset K factor is used by the device.

→ Go to the InP parameter and confirm.

→ Go to the menu 8030 and confirm.

→ Go to the material the fitting is made of and confirm.

→ Go to the DN of the fitting. Confirm: the preset K factor is displayed.

Check that the displayed K factor is the same as the one indicated in

the Operating Instructions of the fitting used.

→ Confirm. The status display changes to “active”.

The preset K factor is used by the device.

→ Go to the InP parameter and confirm.

→ Go to the menu 8070 and confirm.

→ Go to the DN of the fitting. Confirm: the preset K factor is displayed.

Check that the displayed K factor is the same as the one indicated in

the Operating Instructions of the fitting used.

→ Confirm. The status display changes to “active”.

The preset K factor is used by the device.

English

17

Page 20

Type 8022

Adjustment

Parameters available from a “Version 2” of the device. Refer to the name plate of the device.

Enter the K factor *

Order of value input:

1. Select the decimal point place (each time

the key is pressed: one position to the left)

2. Set numerical values

K factor, see Operating instructions of the fitting used

If you use a fitting

*

S020 (with a

sensor 8020)

Select fitting model

T-fitting

If you use a

fitting S030

(with a sensor

8030 or SE30)

If you use a fitting

S070 or S077

(with a sensor

8070 or SE30)

Saddle

Welding tab or fusion spigot

Screw-on

Select material

Metal (stainless steel or brass)

PVC

PP

PVDF

Select fitting diameter **

DN06

** The display depends on the selected

sensor.

18

DN400

K factor is shown

KF

Status display

changes to „active“

Fig. 12 : Input – Setting the K factor

English

Page 21

Type 8022

Adjustment

9.6.3 Out (Output) – Setting the output signal

In this parameter, define whether the device is to work as a flow transmitter or a pulse divider.

Setting as flow transmitter (4 - 20 mA):

When changing the unit (e.g. from liters to gallons) the limit values for the current output are not converted automatically

→ Set the lower and upper limit values for the flow rate range associated to the 4-20 mA output, in the unit set

within the UNIT parameter.

The lower limit value is marked by an L (low) on the display and the upper limit value by an H (high).

Setting as pulse divider (Freq):

→ Set the volume, in the displayed unit, for each pulse emitted on the NPN and PNP outputs.

Setting in the parameter:

Status display changes to "active"

Select

Set the flow rate range *

flow

transmitter

mA

Lower limit value Upper limit value

L = low H = high

Select

pulse divider

Set the volume pro pulse, in the displayed unit *

L

* Order of value input:

1. Select the decimal point place

(each time the key is pressed: one position to

the left)

2. Set numerical values

Fig. 13 : Out – Setting the output; operation as flow transmitter or pulse divider

19

English

Page 22

Type 8022

Adjustment

9.6.4 dAtA (Data) – Uploading and downloading the device

settings

This function is available from the "Version 2" of the device. Refer to the name plate of the device.

The parameter makes it possible to transfer the device settings from one device to another by means of the display

and configuration unit.

Access the parameter:

Transfer from the device

to the display and configuration unit

Cancel

rdy = data has been

Confirm

Transfer from the display

and configuration unit to

the device

Fig. 14 : Data – Transfer of data from/to display and configuration unit

Upload (uPLd):

When uploading, the device settings are transferred to the display and configuration unit.

After the data has been transferred, "ready" (rdy) is displayed.

If the data could not be transferred to the display and configuration unit, the error message “Err” is displayed.

Download (dnLd):

When downloading, the device settings previously uploaded in the display and configuration unit are transferred

to another device type 8022.

After the data has been transferred, "ready" (rdy) is indicated on the display.

If the data could not be transferred to the device type 8022, the error message “Err” is displayed.

transferred

or

Err = data transfer not

possible

20

English

Page 23

Type 8022

Maintenance, Troubleshooting

10 MAINTENANCE, TROUBLESHOOTING

10.1 Maintenance work

The device is maintenance-free when operated according to these Operating Instructions.

10.2 Error messages

Error messages are only displayed at the Read level. They are shown alternately (flashing) with the process value.

Error Cause Troubleshooting

ERR1 Value cannot be displayed

(e.g. value too high).

ERR2 Input frequency of sensor higher than 600 Hz. • Use a suitable sensor.

ERR3 Calculated output current not within range of

4-20 mA or K factor = 0.

• Change the fow rate unit

(see chapter 9.6.1 Unit – Setting the unit for

the flow rate).

• Correctly set the flow rate range associated to

the 4-20 mA current output.

ERR4 Limit values of the flow rate range associated to

the 4-20 mA current output not correct (Low >

High).

ERR5 The K factor times the set volume (converted in

liters) pro pulse is < 1.

Tab. 2 : Error messages

10.3 Default values

Upon delivery, the following default values are saved:

Parameter Value

Unit

K factor (of fitting used)

Volume pro pulse 1 liter

Output signal (OUT) 4-20 mA

Lower flow rate limit

Upper flow rate limit

Liters/second [l/s]

1 pulse/liter [imp/l]

0 liters/second [l/s]

250 liters/second [l/s]

• Use a different sensor and/or correctly set the

K factor of the fitting used.

Correctly set the values.

• Check the set K factor.

• If the K factor is correct, enter a higher volume

pro pulse so that the K factor times the set

volume (converted in liters) pro pulse is equal

to or higher than 1.

Tab. 3 : Default values

21

English

Page 24

Type 8022

Spare parts / Accessories

11 SPARE PARTS / ACCESSORIES

Spare part /accessory Order code

Display and configuration unit

Transparent cover, with screw and seal (for operating without display and configuration

unit)

4-pin M12 female right-angle connector

4-pin M12 female connector moulded on 5-m long cable

Tab. 4 : Ordering table of spare parts and accessories

562 876

670 549

784 301

918 038

12 PACKAGING AND TRANSPORT

notE

Transport damage!

Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against moisture and dirt in shock-resistant packaging.

• Do not allow the temperature to exceed or drop below the permitted storage temperature.

13 STORAGE

notE

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -20 … 65 °C.

14 DISPOSAL

22

→ Dispose of the device and packaging in an environmentally friendly manner.

Observe national waste disposal regulations.

English

Page 25

Type 8022

English

23

Page 26

Type 8022

Spare parts / Accessories

24

English

Page 27

Page 28

www.burkert.com

Loading...

Loading...