Page 1

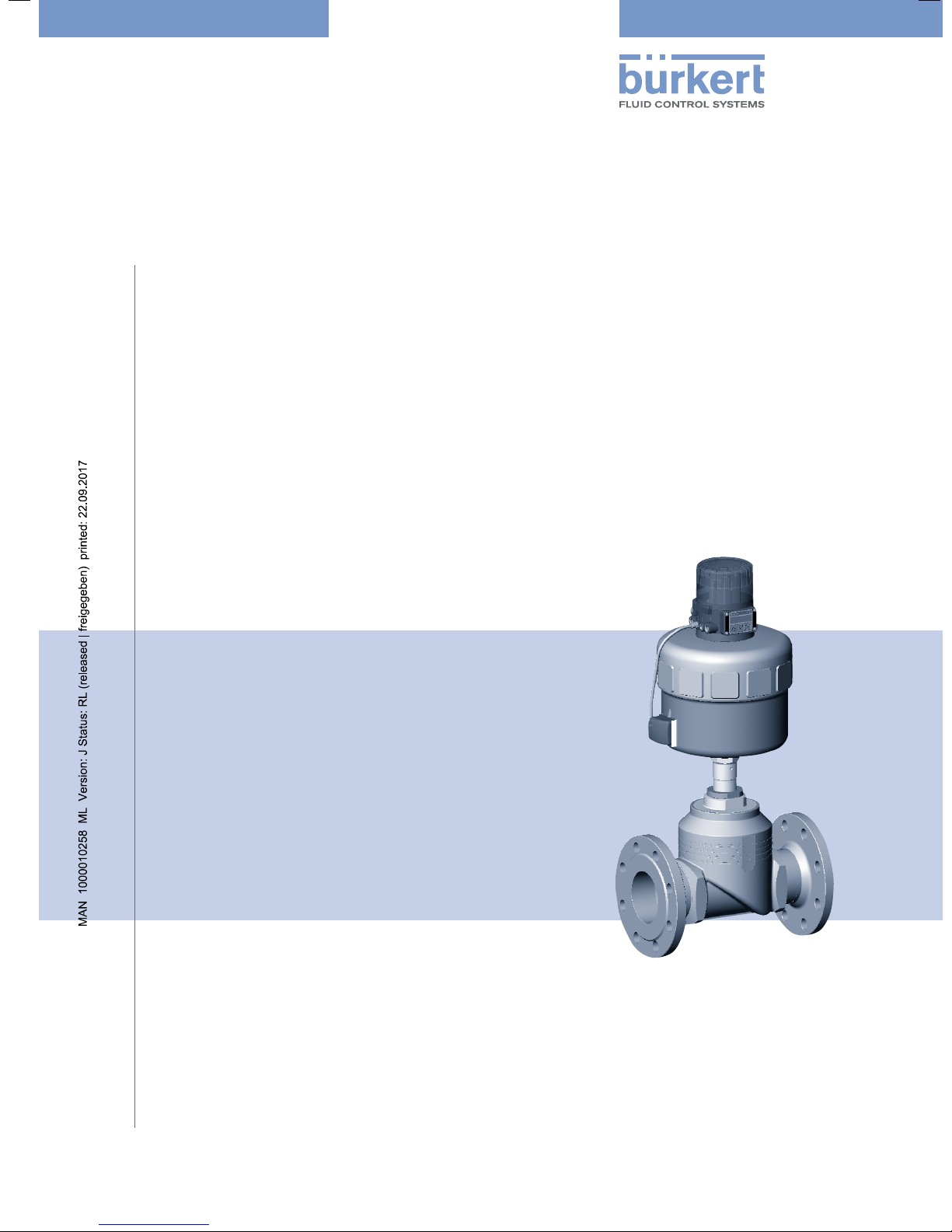

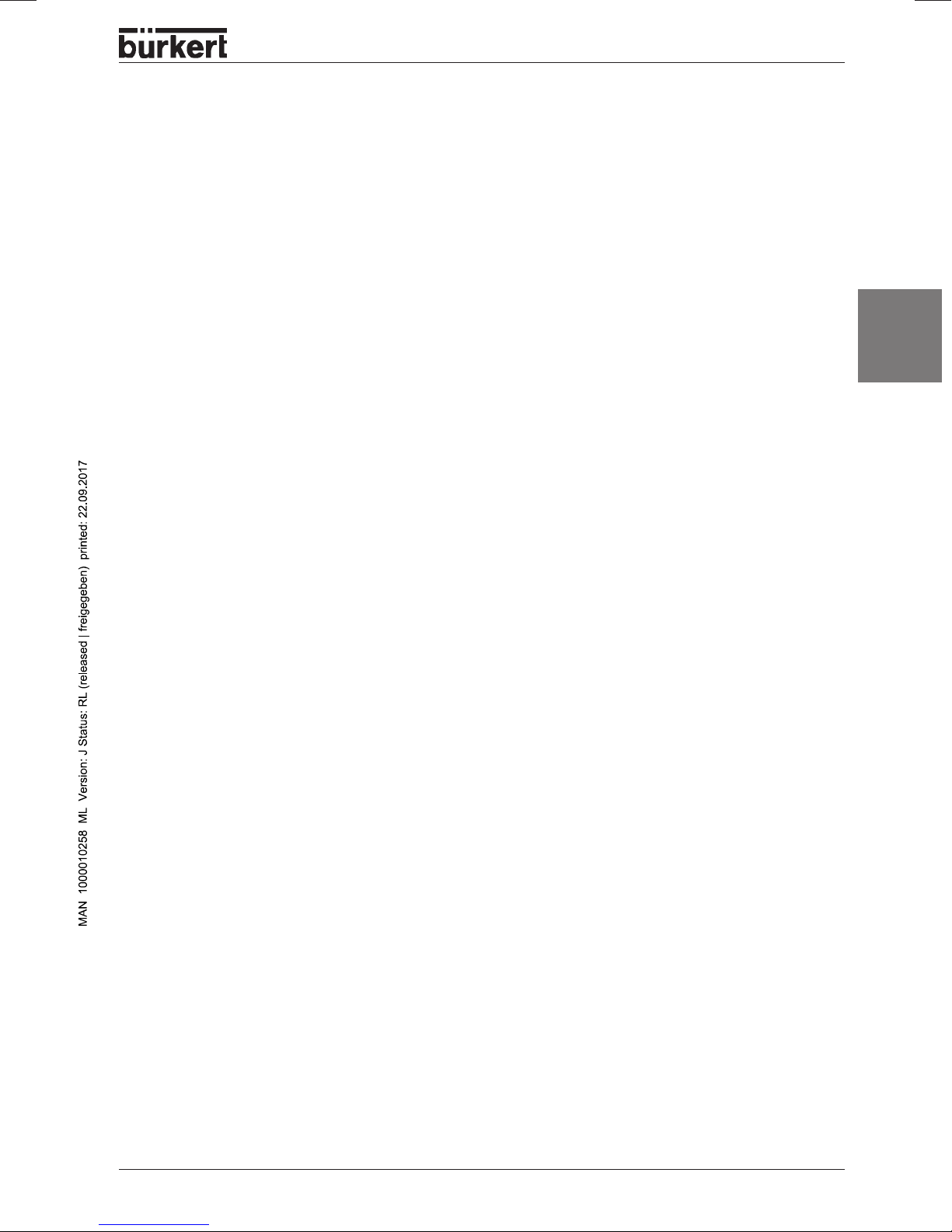

Type 2712

Piston controlled flat-seat valve

Kolbengesteuertes Geradsitzventil

Soupape à tête droite commandée par piston

Actuator sizes 175 mm - 225 mm

Nominal diameters DN 65, DN 80, DN 100

Antriebsgrößen 175 mm - 225 mm

Nennweiten DN 65, DN 80, DN 100

Tailles de mécanisme 175 mm - 225 mm

Diamètre nominal DN 65, DN 80, DN 100

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürker t Werke GmbH & Co. KG, 200 - 2017

Operating Instructions 1706/_EU-EN_008 / Original DE

Page 3

C

ONTENTS

Contents of the

overall operating instructions for the

Piston controlled flat-seat valve

Actuator sizes 175 - 225 mm

Nominal diameters DN 65, DN 80, DN 100

GENERAL NOTES ............................................................................................................................................................................................................................... 3

Symbols .................................................................................................................................................................................................................................................. 4

Safety information ................................................................................................................................................................................................................... 4

Scope of delivery....................................................................................................................................................................................................................... 4

Warranty conditions.............................................................................................................................................................................................................. 4

TECHNICAL DATA ............................................................................................................................................................................................................................. 5

Construction of the control valve ..................................................................................................................................................................... 6

Media ........................................................................................................................................................................................................................................................... 6

COMISSIONING........................................................................................................................................................................................................................................ 7

Installation........................................................................................................................................................................................................................................... 8

MAINTENANCE AND SERVICING ........................................................................................................................................................................... 9

english

Malfunctions................................................................................................................................................................................................................................. 10

Replacing the control cone..................................................................................................................................................................................... 10

Replacement of valve seat ....................................................................................................................................................................................... 12

Spare parts sets for standard valves ....................................................................................................................................................... 13

2712 big - 1

Page 4

C

ONTENTS

english

2 - 2712 big

Page 5

GENERAL

NOTES

GENERAL NOTES

english

Symbols

Safety notes

Scope of delivery

Warranty conditions

..................................................................................................................................................................................................................................................

......................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................

..............................................................................................................................................................................................................

4

4

4

4

2712 big - 3

Page 6

GENERAL NOTES

Symbols

The following symbols are used in these operating instructions:

marks a work step thet you must carry out.

ATTENTION!

NOTE

hsilgne

Safety notes

Please observe the notes in these operating instructions together with the conditions of use and permitted

data that are specified in the data sheets for the pneumatically actuated valve and for the Top

order that the device will function perfectly and remain operable for a long time:

• Keep to standard engineering rules in planning the use of and operating the device!

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Observe the current regulations on accident prevention and safety for electrical devices during

operation and maintenance of the device!

• Switch off the supply voltage in all cases before intervening in the system!

• Note that in systems under pressure, piping and valves may not be loosened!

• Take suitable precautions to prevent inadvertent operation or damage by unauthorized action!

• Make sure that after an interruption to the electrical or pneumatic supply, the process starts up again in

a well-defined, controlled manner!

• Read the safety notes for the electrical part in the operating instructions for the Top

• On non-observance of these notes and unauthorized interference with the device, we will refuse all

liability and the warranty on device and accessories will become void!

marks notes on whose non-observance your health or the functioning of the device will

be endangered.

marks important additional information, tips and recommendations.

Control

Control

.

, in

Scope of delivery

Immediately after receipt of a shipment, make sure that the contents are undamaged and match the

scope of delivery stated on the packing slip.

If there are discrepancies, please contact immediately our customer service:

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: +49 (0) 7940 - 10 91 111

Fax: +49 (0) 7940 - 10 91 448

E-Mail: info@de.buerkert.com

Warranty conditions

This document contains no warranty statements. In this connection we refer to our general sales and

business conditions. A prerequisite for validity of the warranty is use of the device as intended with

observance of the specified conditions of use.

ATTENTION!

The warranty covers only faultless condition of the valve Type 2712 with pneumatic

actuator and the TopControl. No liability will be accepted for consequential damage of

any kind that may arise from failure or malfunctioning of the device.

4 - 2712 big

Page 7

TECHNICAL

DATA

TECHNICAL DATA

english

Construction of the control valve

Media

...........................................................................................................................................................................................................................................................

.....................................................................................................................................................................

6

6

2712 big - 5

Page 8

TECHNICAL DATA

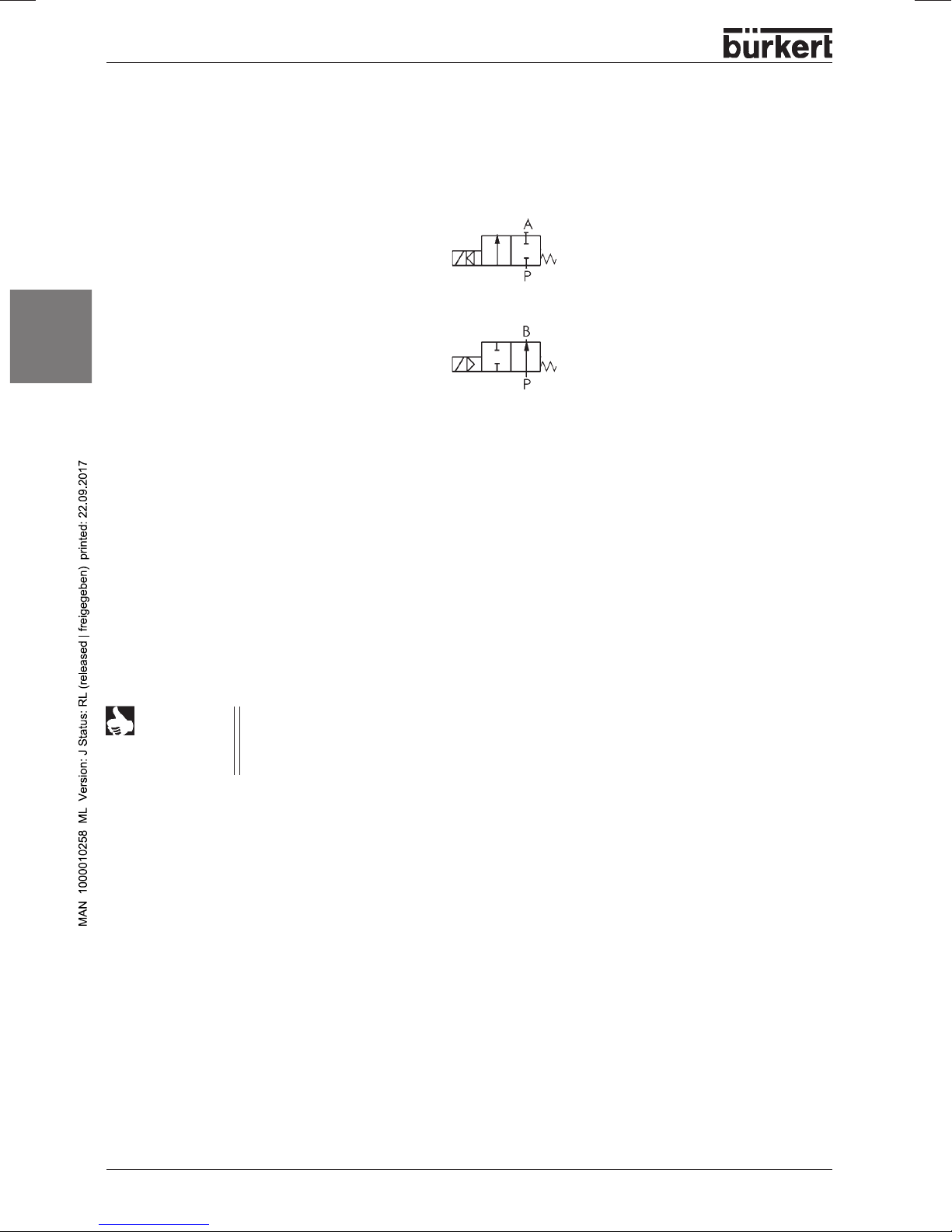

Construction of the control valve

2/2-way piston controlled valv e with control cone and Y-housing.

Control function A

(closed by spring force in rest position)

Control function B

(open in rest position)

english

Actuator material: P A (polyamide)

Housing material: stainless steel 316L

Seal materials: steel/steel (1.4571) or PTFE/steel

Media

Liquid and gaseous media are suitable that do not attack the housing and seal materials.

Control medium: instrument air , Class 3 to DIN ISO 8573-1

NOTE

The approved operating pressures and media temperatures are to be taken from the data

sheet or rating plate. With regard to the permissible seat leakage r ate, the v alues specified

in DIN EN 1349 are complied with, whereby for the steel/steel seal, leakage class IV

applies, and for the PTFE/steel seal, leakage class VI applies.

6 - 2712 big

Page 9

COMMISSIONING

COMMISSIONING

english

Installation of the valve

.........................................................................................................................................................................................................

8

2712 big - 7

Page 10

COMMISSIONING

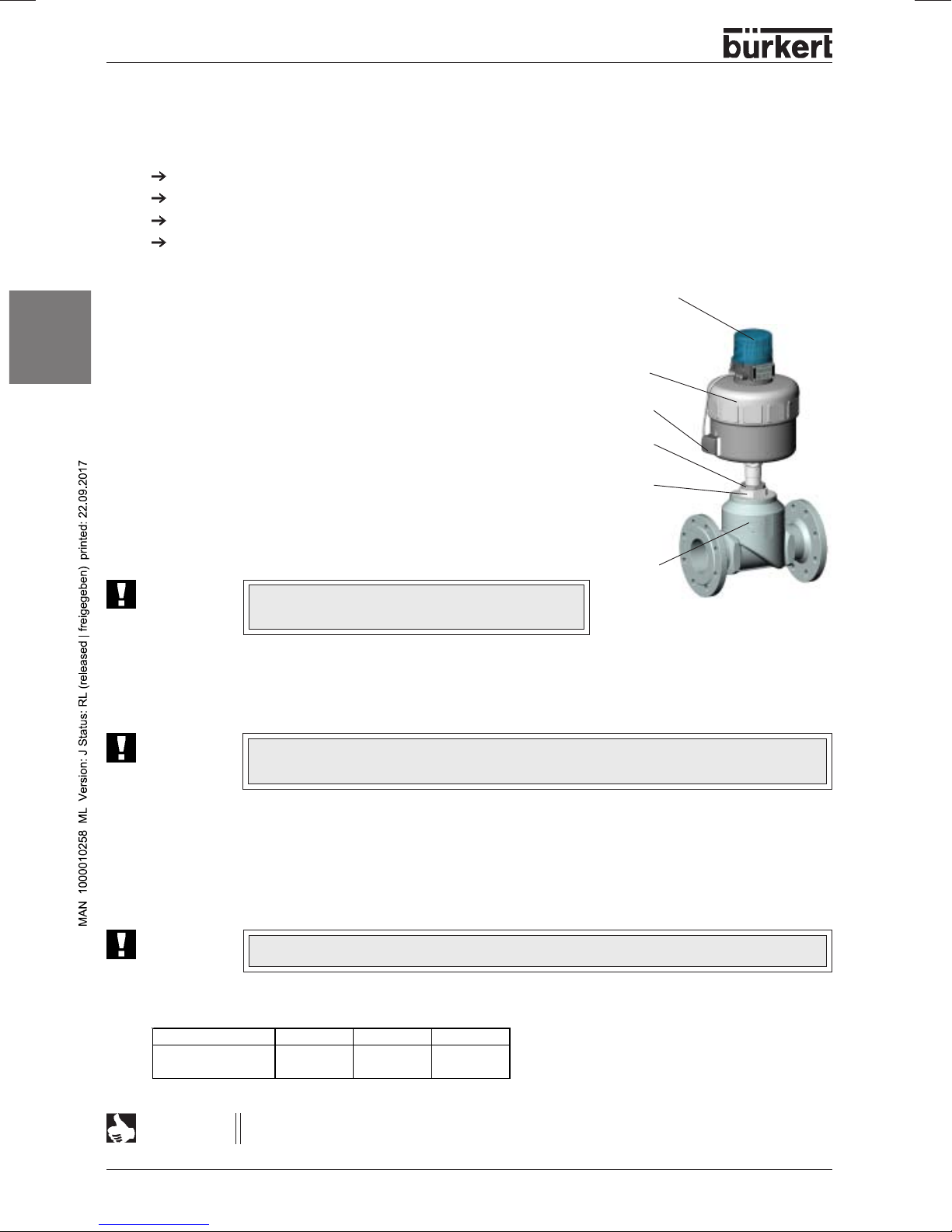

Installation of the valve

Installation in any orientation, but preferably with the actuator above.

Observe the direction of flow: with control valves the general rule is: inlet under seat!

Clean piping from contamination!

Before attaching the valve housing, make sure the piping is aligned!

If the housing is to be welded on, make absolutely sure that the drive unit is removed beforehand.

Procedure:

1. Remove the electrical and pneumatic supplies from the

Top

Control

2. Pull off the pneumatic hose between Top

english

at the control port of the latter.

3.

Control function A:

Pressurize the lower control port of the actuator with

compressed air (6 bar), so that the control cone is lifted from

the valve seat and is not damaged.

Control function B:

With control function B, no compressed air m ust be applied

for this purpose.

4. Remove the actuator in the open valve position by

unscrewing the threaded nipple (SW70) from the housing.

A TTENTION!

.

Do

not

loosen the screw (SW65) above the

threaded nipple!

Control

and actuator

Top

Control

actuator

lower

control port

screw

(SW65)

threaded nipple

(SW70)

housing

5. Before reinstalling the actuator (in the open valve position), grease the nipple thread with

stainless steel lubricant, e.g. Klüberpaste UH1 96-402 from Messrs. Klüber and replace

the graphite seal.

A TTENTION!

For special applications such as for oxygen and analysis, use only the approved

lubricants.

6 . After tightening the threaded nipple (observe torque), the actuator can be aligned as required.

For this purpose, unscrew the screw (SW65) above the threaded nipple ca. a half-turn and bring the

actuator into the desired position.

Then retighten the screw with a torque of 100 ± 5 Nm.

A TTENTION!

During this operation, the valve must also be in the open position.

Tightening torques for the threaded nipple (SW70)

DN 65 80 100

Tight eni ng torque

[Nm]

100 ± 5 120 ± 5 150 ± 5

NOTE

For applications in aggressive media, we recommaend attaching all free pneumatic

connections to a pneumatic hose whose other end lies in a neutral atmosphere.

8 - 2712 big

Page 11

MAINTENANCE AND SERVICING

MAINTENANCE AND

SERVICING

Malfunctions

Replacing the control cone

Replacement of valve seat

Spare parts sets

.................................................................................................................................................................................................................................

......................................................................................................................................................................................................................

.....................................................................................................................................................................................

.......................................................................................................................................................................................

english

10

10

12

13

2712 big - 9

Page 12

MAINTENANCE AND SERVICING

Malfunctions

Possible malfunctions concerning the actuator are listed in the operatinginstructions for the Top

ATTENTION!

Repairs to the actuator may only be carried out in the factory. Contact your Bürkert

branch or our Customer Service directly:

hsilgne

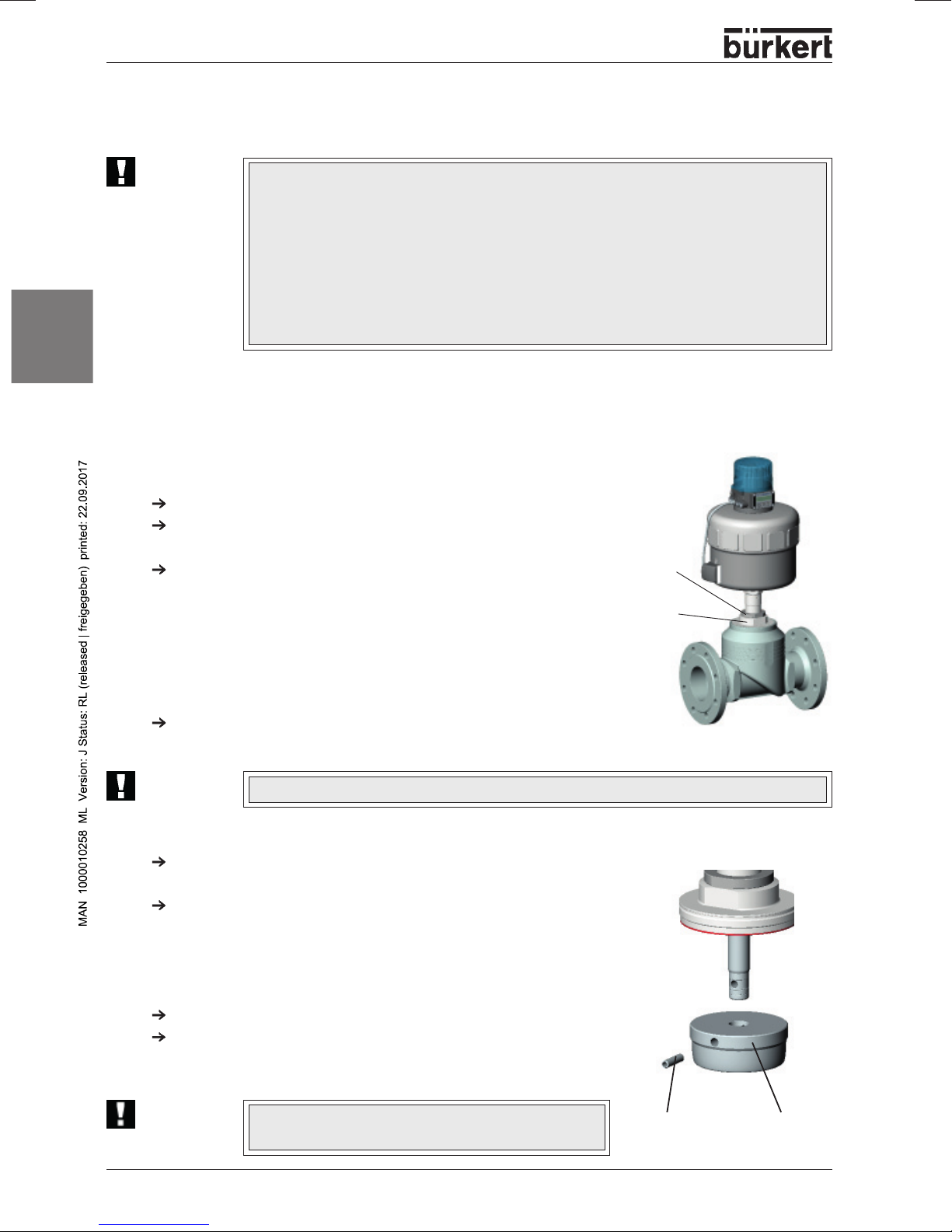

Replacing the control cone

On the fluidic side, the control cone can be replaced in case of wear or damage. For this purpose, the

actuator must be disassembled from the housing.

Disassembly

Remove the electrical and pneumatic supplies from the Top

Pull off the pneumatic hose between Top

control port of the latter.

Control function A:

Pressurize the lower control port of the actuator with compressed

air (6 bar), so that the control cone is liftet from the valve seat and

is not damaged.

Control function B:

With control function B, no compressed air must be applied for this

purpose.

Remove the actuator in the open valve position by unscrewing the

threaded nipple (SW70) from the housing.

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: +49 (0) 7940 - 10 91 111

Fax: +49 (0) 7940 - 10 91 448

E-Mail: info@de.buerkert.com

Control

Control

and actuator at the

.

screw

(SW65)

threaded nipple

(SW70)

Control

.

ATTENTION!

Do

not

loosen the screw (SW65) above the threaded nipple!

Replacing the control cone:

Knock out the dowel pin with a suitable driver.

Driver diameter Ø 8 mm

Pull off the control cone with the aid of two metal strips of equal

height that are clamped to the left and right of the spindle between

the control cone and the threaded nipple of the actuator. To pull off

the control cone, apply compressed air (approx. 6 bar) to the lower

control connection of the actuator.

Place the new control cone onto the end of the spindle.

Align the bores to each other.

ATTENTION!

10 - 2712 big

Do not damage the sealing surface or the control

contour!

dowel pin control

cone

Page 13

MAINTENANCE AND SERVICING

Assembly

Support the control cone at ists cylindrical part with the aid of a V-block or the lik e.

Place the dowel pin in postion and carefully knock in with a hammer .

Bring the dowel pin into a central position relative to the spindle axis (knock it in up to the end of the

recess).

Before reinstalling the actuator (in the open valve position), grease the nipple thread with stainless

steel lubricant, e.g. Klüberpaste UH1 96-402 from Messrs. Klüber and replace the graphite seal.

A TTENTION!

After tightening the threaded nipple (SW70) (observe torque), the actuator can be aligned as required.

For this purpose, unscrew the screw (SW65) above the threaded nipple ca. a half-turn and bring the

actuator into the desired position.

Then retighten the screw with a torque of 100 ± 5 Nm an.

A TTENTION!

For special applications such as for oxygen and analysis, use only the approved

lubricants.

During this operation, the valve must also be in the open position.

english

2712 big - 11

Page 14

MAINTENANCE AND SERVICING

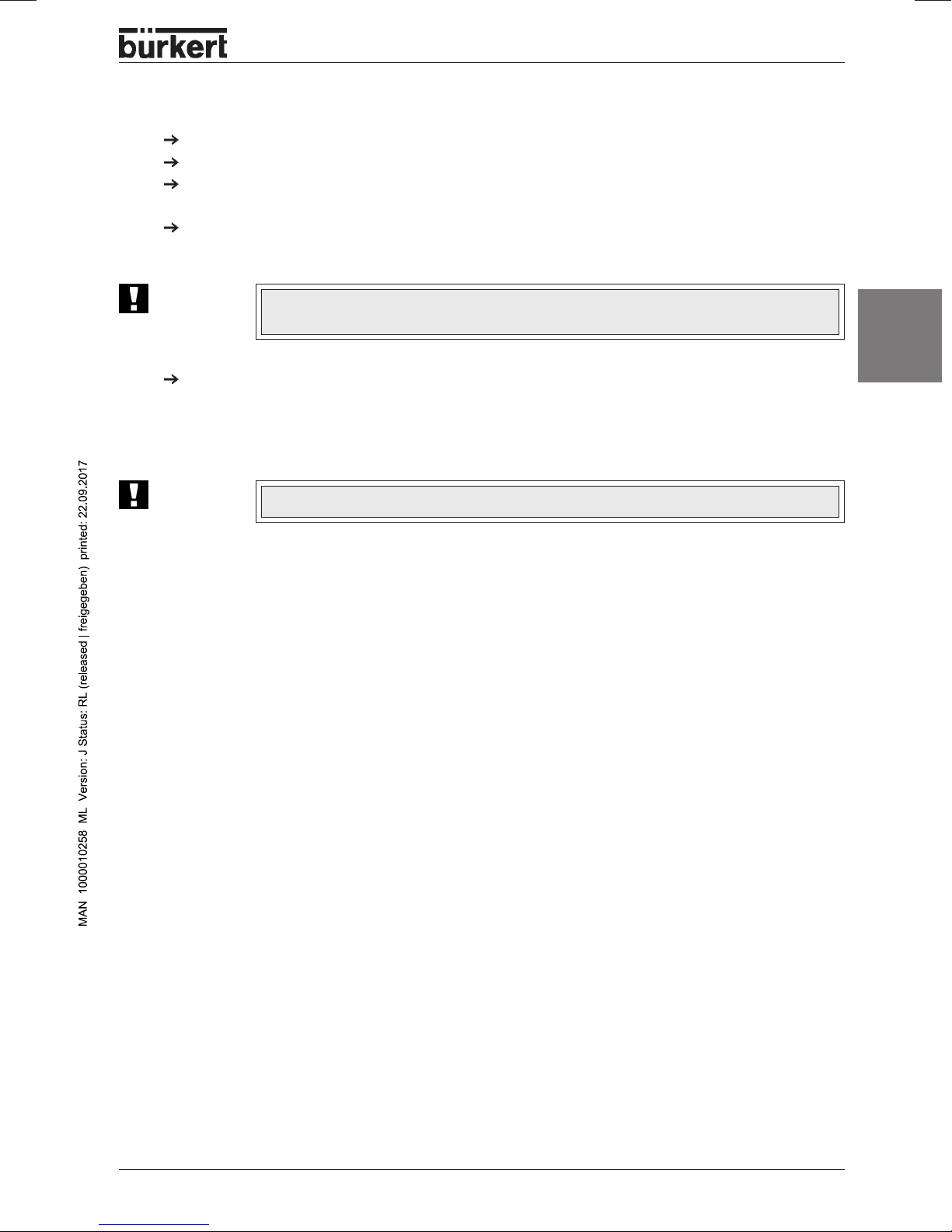

Replacement of valve seat

To replace the valv e seat, the actuator must be disassemb led from the housing. F or disassemb ly and

assembly, see "Replacing the control cone".

Unscrew the old housing seat using the assembly tool and a

spanner.

Clean thread and sealing surface in the housing with compressed

air.

Select a tool insert and screw it into the assembly tool.

Push the new seat onto the assembly tool, grease the thread with

stainless steel lubricant, e.g. Klüberpaste UH1 96-402 from

Messrs. Klüber.

english

A TTENTION!

Place the attached seat by hand into the housing thread and

screw it in.

Tighten the seat with a torque wrench to the torque specified.

For special applications such as for oxygen and

analysis, use only the approved lubricants.

assembly tool

tool insert

(to match the nominal

diameter of seat)

valve seat

NOTE

On installing a valve seat with a different nominal

diameter, the order number f or the valve changes!

Tightening torques for seat assembly

Seat assembly tools

Housing DN Order no.

DN Torque

[Nm]

65 150

80 180

100 220

+10

+10

+10

15 652 604

20 652 605

25 652 606

12 - 2712 big

32 652 607

40 652 608

50 652 609

Page 15

MAINTENANCE AND SERVICING

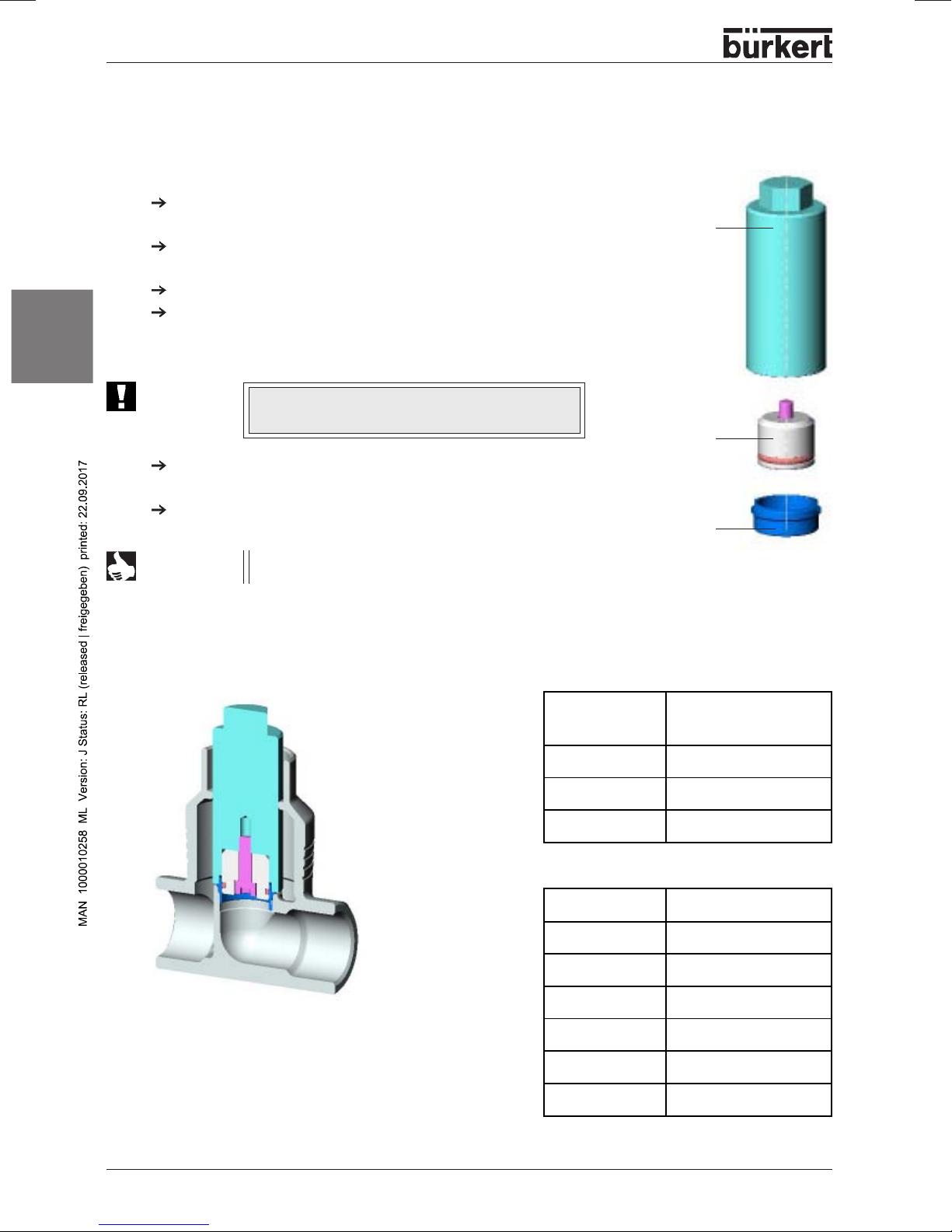

Spare parts sets for standard valves

A control cone set, a control fittings set and a set of seals (packed gland) are av ailab le as spares. To

disassemble the actuator fromt he housing or reassemble it, proceed as under installation.

NOTE

Before disassembling or opening the device,

release the pressure in the piping system.

screw SW 65

threaded nipple SW 70

control cone set

SET 6

always

interrupt the supply of medium and

set of seals

(packed gland)

SET 5

control fittings set

SET 6

actuator

english

NOTE

Spare parts sets for special versions are availab le on

request (e.g. oxygen or analysis versions, etc.)

2712 big - 13

Page 16

MAINTENANCE AND SERVICING

Control cone set

hsilgne

Valve seat set

DN

housing

65 40 Ø175 155 625 155 637

65 50 Ø175 155 627 155 639

65 65 Ø175 155 630 155 642

80 50 Ø225 155 628 155 640

80 65 Ø225 155 631 155 643

80 80 Ø225 155 633 155 645

100 65 Ø225 155 632 155 644

100 80 Ø225 155 634 155 646

100 100 Ø225 155.635 155 647

Contains:

Control cone, dowel pin, graphite seal

DN DN

Housing Seat Order no.

65 40 262 202

65 50 262 203

65 65 262 204

80 50 262 205

80 65 262 206

80 80 262 207

100 65 262 208

100 80 262 209

100 100 262 210

Contains: Valve seat, O-ring,

DN

seat

graphite seal

Actuator

size

Steel/Steel PTFE/steel

Order no. Order no.

NOTE

Valve seat sets are available on request, please contact your

Set of seals

(packed gland)

14 - 2712 big

DN housing Order no.

65 155 483

80 155 484

100 155 485

Contains:

packed gland module, housing seals

Page 17

INHALT

Inhaltsverzeichnis der

Gesamtbedienungsanleitung des

kolbengesteuerten Geradsitzregelventils

mit Antriebsgrößen 175 mm und 225 mm

und Nennweiten DN 65, DN 80, DN 100

ALLGEMEINE HINWEISE

Darstellungsmittel

Sicherheitshinweise

Lieferumfang

..................................................................................................................................................................................................................................

Garantiebestimmungen

TECHNISCHE DATEN

Aufbau des Regelventils

Medien

.....................................................................................................................................................................................................................................................

INBETRIEBNAHME

Einbau

....................................................................................................................................................................................................................................................

....................................................................................................................................................................................................

................................................................................................................................................................................................................

..........................................................................................................................................................................................................

...............................................................................................................................................................................................

..............................................................................................................................................................................................................

.............................................................................................................................................................................................

.......................................................................................................................................................................................................................

INSTANDHALTUNG UND WARTUNG

...........................................................................................................................................................

17

18

18

18

18

19

20

20

21

22

23

deutsch

Störungen

........................................................................................................................................................................................................................................

Austausch des Regelkegels

Austausch des Ventilsitzes

Ersatzteilsätze für Standardventile

....................................................................................................................................................................................

.....................................................................................................................................................................................

............................................................................................................................................................

2712 big - 15

24

24

26

27

Page 18

INHALT

deutsch

16 - 2712 big

Page 19

ALLGEMEINE HINWEISE

ALLGEMEINE

HINWEISE

deutsch

Darstellungsmittel

Sicherheitshinweise

Lieferumfang

Garantiebestimmungen

................................................................................................................................................................................................................

............................................................................................................................................................................................................

................................................................................................................................................................................................................................

...............................................................................................................................................................................................

18

18

18

18

2712 big - 17

Page 20

ALLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes gefährdet ist

kennzeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen

Sicherheitshinweise

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen

hcstued

Daten, die in den Datenblättern des Ventils mit pneumatischem Antrieb und des Top

sind, damit das Gerät einwandfrei funktioniert und lange einsatzfähig bleibt:

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der

Technik!

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte

während des Betriebes und der Wartung des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Beachten Sie, daß in Systemen, die unter Druck stehen, Leitungen und Ventile nicht gelöst werden dürfen!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung

auszuschließen!

• Gewährleisten Sie nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung einen

definierten und kontrollierten Wiederanlauf des Prozesses!

• Entnehmen Sie die Sicherheitshinweise zum elektrischen Teil der Bedienungsanleitung des Top

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung

unsererseits, ebenso erlischt die Garantie auf Geräte und Zubehörteile!

Control

spezifiziert

Control

Lieferumfang

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, daß der Inhalt nicht beschädigt ist und mit

dem auf dem beigelegten Packzettel angegebenen Lieferumfang übereinstimmt.

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an unseren Kundenservice:

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: +49 (0) 7940 - 10 91 111

Fax: +49 (0) 7940 - 10 91 448

E-Mail: info@de.buerkert.com

Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf unsere allgemeinen Verkaufsund Geschäftsbedingungen. Voraussetzung für die Garantie ist der bestimmungsgemäße Gebrauch des

Gerätes unter Beachtung der spezifizierten Einsatzbedingungen.

ACHTUNG!

18 - 2712 big

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit des Ventils Typ 2712 mit pneumatischem Antrieb und des Top

schäden jeglicher Art, die durch Ausfall oder Fehlfunktion des Gerätes entstehen könnten.

Control

. Es wird jedoch keine Haftung übernommen für Folge-

Page 21

TECHNISCHE DATEN DES VENTILS

TECHNISCHE

DATEN

deutsch

Aufbau des Regelventils

Medien

...................................................................................................................................................................................................................................................

.............................................................................................................................................................................................

20

20

2712 big - 19

Page 22

TECHNISCHE DATEN DES VENTILS

Aufbau des Regelventils

2/2-Wege-K olbensteuerventil mit Regelkegel und Schrägsitzgehäuse

Steuerfunktion A

(in Ruhestellung durch Federkraft geschlossen)

Steuerfunktion B

(in Ruhestellung geöffnet)

Antriebswerkstoff: P A (P olyamid)

Gehäusewerkstoff: Edelstahl 316L

Dichtwerkstoffe: Stahl/Stahl (1.4571) oder PTFE/Stahl

deutsch

Medien

Flüssige u. gasförmige Medien, die den Gehäuse- und Dichtwerkstoff nicht angreifen.

Steuermedium: Instrumentenluft, Klasse 3 nach DIN ISO 8573-1

HINWEIS

Die zugelassenen Betriebsdrücke und Medientemperaturen sind dem Datenblatt bzw . dem

T ypschild zu entnehmen. Hinsichtlich der zulässigen Sitzleckage werden die in der DIN EN

1349 angegebenen Werte eingehalten, wobei für die Stahl/Stahl-Abdichtung die Leckageklasse IV und für die PTFE/Stahl-Adichtung die Leckageklasse VI zutrifft.

20 - 2712 big

Page 23

INBETRIEBNAHME DES VENTILS

INBETRIEBNAHME

deutsch

Einbau des Ventils

.....................................................................................................................................................................................................................

22

2712 big - 21

Page 24

INBETRIEBNAHME DES VENTILS

Einbau des Ventils

Einbaulage beliebig, bevorzugt Antrieb nach oben.

Beachten Sie die Durchflußrichtung, bei Regelventilen gilt generell: Anströmung unter Sitz!

Säubern Sie die Rohrleitungen von V erunreinigungen!

Achten Sie vor Anschluß des Ventilgehäuses auf fluchtende Rohrleitungen!

Entfernen Sie bei Schweißgehäusen den Antrieb unbedingt vor dem Einschweißen des Gehäuses.

Vorgehensweise:

1. Entfernen Sie die elektrische u. pneumatische V ersorgung

deutsch

ACHTUNG!

vom T op

2. Ziehen Sie den Pneumatikschlauch zwischen Top

Antrieb am Steueranschluß desAntriebes ab.

3.

Steuerfunktion A:

Beaufschlagen Sie den unteren Steueranschluß des

Antriebes mit Druckluft (6 bar), damit der Regelkegel vom

V entilsitz abhebt und nicht beschädigt wird.

Steuerfunktion B:

Bei Steuerfunktion B muss hierzu keine Druckluft angelegt

werden.

4. Entfernen Sie den Antrieb in offener Ventilstellung durch Losschrauben des Gewindenippels (SW70) vom Gehäuse.

Control

Lösen Sie

Gewindenippels!

.

nicht

die Schraube (SW65) oberhalb des

Control

und

Top

Control

Antrieb

unterer

Steueranschluss

Schraube

(SW65)

Gewindenippel

(SW70)

Gehäuse

5. Fetten Sie vor Wiedereinbau des Antriebes (in off ener V entilstellung) das Nippelge winde mit

Edelstahlschmierstoff ein, z.B. Klüberpaste UH1 96 - 402 der Firma Klüber und erneuern Sie die

Graphitdichtung.

ACHTUNG!

V erwenden Sie bei spezifischen Anwendungen, z.B. Sauerstoff-, Analyseanwendungen

nur zugelassene Schmierstoffe

6 . Nach dem Festziehen des Gewindenippels (Drehmomente beachten), kann der Antrieb bei Bedarf

ausgerichtet werden.

Hierfür lösen Sie die Schraube (SW65) oberhalb des Gewindenippels ca. eine

halbe Drehung und bringen den Antrieb in die gewünschte Position.

Ziehen Sie danach die Schraube wieder mit 100 ± 5 Nm an.

ACHTUNG!

Das Ventil muss sich hierzu ebenf alls in der geöffneten Stellung befinden.

Anzugsmomente für den Gewindenippel (SW70)

DN 65 80 100

Anzugs moment

[Nm]

100 ± 5 120 ± 5 150 ± 5

HINWEIS

Bei Einsatz in aggressiver Umgebung empf ehlen wir, sämtliche freien Pneumatikanschlüsse

mit Hilfe eines Pneumatikschlauches in neutrale Atmosphäre abzuleiten.

22 - 2712 big

Page 25

INSTANDHALTUNG UND WARTUNG DES VENTILS

INSTANDHALTUNG

UND

WARTUNG

deutsch

Störungen

Austausch des Regelkegels

Austausch des Ventilsitzes

Ersatzteilsätze für Standardventile

........................................................................................................................................................................................................................................

..................................................................................................................................................................................

.....................................................................................................................................................................................

............................................................................................................................................................

24

24

26

27

2712 big - 23

Page 26

INSTANDHALTUNG UND WARTUNG DES VENTILS

Störungen

Mögliche Störungen seitens der Ansteuerung sind in der Bedienungsanleitung des T op

ACHTUNG!

Reparaturen am Antrieb dürfen nur im Werk durchgeführt werden. Wenden Sie sich hierzu

an Ihre Bürkert Niederlassung oder direkt an unseren Kundenservice:

Austausch des Regelkegels

hcstued

Auf der fluidischen Seite besteht die Möglichkeit bei Verschleiß oder bei Beschädigung den Regelkegel zu

tauschen. Hierzu muß der Antrieb vom Gehäuse demontiert werden.

Demontage

Entfernen Sie die elektrische u. pneumatische Versorgung vom

.

Control

Top

Ziehen Sie den Pneumatikschlauch zwischen Top

trieb am Steueranschluß des Antriebes ab.

Steuerfunktion A:

Beaufschlagen Sie den unteren Steueranschluß des Antriebes mit

Druckluft (6 bar), damit der Regelkegel vom Ventilsitz abhebt und

nicht beschädigt wird.

Steuerfunktion B:

Bei Steuerfunktion B muss hierzu keine Druckluft angelegt werden.

Entfernen Sie den Antrieb in offener Ventilstellung durch Losschrauben des Gewindenippels (SW70) vom Gehäuse.

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: + 49 (0) 7940 - 10 91 111

Fax: + 49 (0) 7940 - 10 91 448

E-Mail: info@de.buerkert.com

Control

und An-

Schraube

(SW65)

Gewindenippel

(SW70)

Control

aufgeführt.

ACHTUNG!

Lösen Sie

nicht

Regelkegel tauschen:

Klopfen Sie den Spannstift mit einem passenden Splinttreiber

heraus.

Durchmesser des Splinttreibers Ø 8 mm

Ziehen Sie den Regelkegel mit Hilfe zweier gleich hoher Metalleisten ab, die links und rechts der Spindel zwischen den Regelkegel und den Gewindenippel des Antriebes geklemmt werden.

Geben Sie zum Abziehen des Regelkegels auf den unteren Steueranschluß des Antriebes Druckluft (6 bar).

Stecken Sie den neuen Regelkegel auf das Spindelende.

Richten Sie die Bohrungen zueinander aus.

ACHTUNG!

24 - 2712 big

Dichtfläche und Regelkontur des Regelkegels dürfen

nicht beschädigt werden!

die Schraube (SW65) oberhalb des Gewindenippels!

Spannstift Regelkegel

Page 27

INSTANDHALTUNG UND WARTUNG DES VENTILS

Montage

Stützen Sie den Regelkegel an seinem zylindrischen Teil mit Hilfe eines Prismas oder ähnlichem ab.

Setzen Sie den Spannstift an und klopfen Sie ihn vorsichtig mit dem Hammer ein.

Bringen Sie den Spannstift in zur Spindelachse gesehen mittige Lage (klopfen Sie ihn bis zum Ende

der Ansenkung ein).

Fetten Sie vor Wiedereinbau des Antriebes (in offener V entilstellung) das Nippelgewinde mit Edelstahlschmierstoff ein, z.B. Klüberpaste UH1 96-402 der Firma Klüber , und erneuern Sie die Graphitdichtung.

ACHTUNG!

Nach dem Festziehen des Gewindenippels (SW70) (Drehmomente beachten), kann der Antrieb bei

Bedarf ausgerichtet werden. Hierfür lösen Sie die Schraube (SW65) oberhalb des Gewindenippels ca.

eine halbe Drehung und bringen den Antrieb in die gewünschte Position. Ziehen Sie danach die Schraube wieder mit 100 ± 5 Nm an.

ACHTUNG!

V erwenden Sie bei spezifischen Anwendungen, z.B. Sauerstoff-, Analyseanwendungen,

nur zugelassene Schmierstoffe

Das Ventil muss sich hierzu ebenf alls in der geöffneten Stellung befinden.

deutsch

2712 big - 25

Page 28

INSTANDHALTUNG UND WARTUNG DES VENTILS

Austausch des Ventilsitzes

Zum Austausch des V entilsitzes muß der Antrieb vom Gehäuse demontiert werden. Demontage und Montage siehe "Austausch des Regelkegels"

Schrauben Sie den alten Gehäusesitz mit Hilfe des

Montagewerkzeuges und einem Schraubenschlüssel aus.

Säubern Sie Gewinde und Dichtfläche im Gehäuse mit Preßluft.

Wählen Sie einen W erkzeugeinsatz aus und schrauben Sie ihn

in das Montagewerkzeug ein.

Stecken Sie den neuen Sitz auf das Montagewerkzeug, fetten

Sie das Gewinde mit Edelstahlschmierstoff ein, z.B.

Klüberpaste UH1 96 - 402 der Firma Klüber.

Montagewerkzeug

ACHTUNG!

deutsch

HINWEIS

V erwenden Sie bei spezifischen Anwendungen,

z.B. Sauerstoff-, Analyseanwendungen, nur zugelassene Schmierstoffe

Setzen Sie den aufgesteckten Sitz von Hand in das Gehäusegewinde und schrauben Sie ihn ein.

Ziehen Sie den Sitz mit Hilfe eines Drehmomentschlüssels auf

das angegebene Drehmoment an.

Bei Einbau eines V entilsitz es mit anderer Nennweite,

ändert sich die Bestellnummer für das V entil!

Anzugsmomente für die Sitzmontage

Werkzeugeinsatz

(je nach Sitz-

nennweite)

Ventilsitz

DN Anzugsmoment

[Nm]

65 150

80 180

100 220

+10

+10

+10

26 - 2712 big

Sitzmontagewerkzeuge

Gehäuse-DN Best.-Nr.

65 655 562

80 655 563

100 655 564

Page 29

INSTANDHALTUNG UND WARTUNG DES VENTILS

Ersatzteilsätze für Standardventile

Als Ersatzteile steht ein Regelkegelsatz, eine Regelgarnitur und ein Dichtungssatz Stopfbuchse zur

V erfügung. Zur Demontage bzw . Montage des Antriebes vom Gehäuse gehen Sie wie unter dem Punkt

Einbau beschrieben vor.

HINWEIS

Unterbrechen Sie vor dem Ausbau oder dem Öffnen des Gerätes

und bauen Sie den Druck im Leitunssystem ab.

Antrieb

Schraube SW 65

Gewindenippel SW 70

immer

die Mediumszufuhr

deutsch

HINWEIS

Ersatzteilsätze für Sonderausführungen erhalten Sie auf Anfrage

(z. B . Sauerstoff-, Analyseausfürungen usw .).

2712 big - 27

Page 30

INSTANDHALTUNG UND WARTUNG DES VENTILS

hcstued

Regelkegelsatz

Ventilsitzsatz

DN

Gehäuse

65 40 Ø175 155 625 155 637

65 50 Ø175 155 627 155 639

65 65 Ø175 155 630 155 642

80 50 Ø225 155 628 155 640

80 65 Ø225 155 631 155 643

80 80 Ø225 155 633 155 645

100 65 Ø225 155 632 155 644

100 80 Ø225 155 634 155 646

100 100 Ø225 155.635 155 647

Beinhaltet:

Regelkegel, Spannstift, Graphitdichtung

DN DN

Gehäuse Sitz Best-Nr.

65 40 262 202

65 50 262 203

65 65 262 204

80 50 262 205

80 65 262 206

80 80 262 207

100 65 262 208

100 80 262 209

100 100 262 210

Beinhaltet: Ventilsitz, O-Ring,

DN Sitz Antriebs-

Graphitdichtung

Stahl/Stahl PTFE/Stahl

größe

Best.-Nr. Best.-Nr.

HINWEIS

Ventilsitzsätze erhalten Sie auf Anfrage über Ihre Bürkert-Vertriebsniederlassung.

Dichtungssatz

Stopfbuchse

28 - 2712 big

DN Gehäuse Bestell-Nr.

65 155 483

80 155 484

100 155 485

Beinhaltet:

Modul Stopfbuchse, Gehäusedichtungen

Page 31

TABLE DES MATIÈRES

Table des matières des instructions

de service complètes de la soupape à tête

droite commandée par piston

Tailles de mécanisme 175 mm et 225 mm

Diamètre nominal DN 65, DN 80, DN 100

REMARQUES GENERALES

Représentation

.........................................................................................................................................................................................................................

..........................................................................................................................................................................................

Consignes générales de sécurité

Fourniture

Clauses de garantie

........................................................................................................................................................................................................................................

...........................................................................................................................................................................................................

CARACTÉRISTIQUES TECHNIQUES

Structure de la soupape de réglage

Fluides

MISE EN SERVICE

Montage

MAINTENANCE ET ENTRETIEN

...................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................

...........................................................................................................................................................................

....................................................................................................................................................................

............................................................................................................................................................

.............................................................................................................................................................

31

32

32

32

32

33

34

34

35

36

37

français

Pannes

..................................................................................................................................................................................................................................................

Echange du pointeau de réglage

Echange du siège de la soupape

Jeux de pièces de rechange

....................................................................................................................................................................

....................................................................................................................................................................

..................................................................................................................................................................................

2712 big - 29

38

38

40

41

Page 32

TABLE DES MATIÈRES

français

30 - 2712 big

Page 33

REMARQUES GENERALES

REMARQUES

GENERALES

Représentation

Consignes générales de sécurité

Fourniture

Clauses de garantie

.........................................................................................................................................................................................................................

........................................................................................................................................................................................................................................

...........................................................................................................................................................................................................

..................................................................................................................................................................

32

32

32

32

français

2712 big - 31

Page 34

REMARQUES GENERALES

Représentation

Les symboles de représentation suivants sont utilisés dans cette notice de service:

marque une étape de travail devant être exécutée

ATTENTION!

REMARQUE

caractérise des instructions dont l'inobservation entraîne des risques pour votre santé

ou met en cause la fonctionnalité de l'appareil.

caractérise des informations supplémentaires imprtantes, des conseils et des

recommandations.

Consignes de sécurité

Veuillez tenir compte des consignes de cette notice de service de même que des conditions d'emploi et

données admissibles spécifiées dans les fiches techniques de la soupape à mécanisme pneumatique et

du TopControl afin que l'appareil fonctionne parfaitement et reste longtemps opérationnel.

• S'en tenir aux règles techniques généralement reconnues lors du projet de mise en oeuvre et du

service de l'appareil.

• L'installation et les interventions nécessitées par la maintenance ne doivent être effectuées que par un

siaçnarf

personnel qualifié équipé des outils adéquats.

• Respecter les dispositions en vigueur de prévention des accidents et de sécurité pour appareils

électriques pen

• Toujours couper la tension d'alimentation avant toute intervention dans le système.

• Tenir compte que dans les systèmes sous pression, les conduites et soupapes ne doivent pas être

desserrées.

• Pendre les mesures qui s'imposent pour éviter un actionnement par inadvertance de l'appareil ou une

mise en cause inadmissible de son fonctionnement.

• Assurer un redémarrage défini et contrôlé du processus après une interruption de l'alimentation

électrique ou pneumatique.

• Se référer aux consignes de sécurité de la partie électrique des instructions de service du Top

• En cas d'inobservation de ces consignes et d'interventions non autorisées dans l'appareil, nous

déclinons toute responsabilité de même qu'elles entraînent l'annulation de la garantie sur l'appareil et

les pièces accessoires!

dant le service, la maintenance de l'appareil.

Control

.

Fourniture

Contrôler dès réception de l'envoi que le contenu n'a subi aucun dommage et qu'il correspond bien à la

fourniture figurant sur le bordereau d'envoi.

En cas de non concordance, s'adresser immédiatement à votre succursale Bürkert ou à notre service

après vente:

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: + 49 (0) 7940 - 10 91 111

Fax: + 49 (0) 7940 - 10 91 448

Clauses de garantie

Ce document ne constitue aucun engagement de garantie. Nous vous renvoyons à cet effet à nos

conditions générales de vente et comerciales. La condition préalable au consentement de la garantie est

l'utilisation conforme de l'appareil à l'usage auquel il est destiné, compte tenu de l'observation des

conditions d'emploi spécifiées.

ATTENTION!

32 - 2712 big

Les prestations de garantie ne s'étendent qu'à l'absence de défaut de la soupape type

2012 à mécanisme pneumatique et au Top

responsabilité pour des dégâts consécutifs de toute nature susceptibles de survenir par

suite de défaillance ou de disfonctionnement de l'appareil.

E-Mail: info@de.buerkert.com

Control

. Nous déclinons, par contre, toute

Page 35

CARACTERISTIQUES TECHNIQUES

CARACTERISTIQUES

TECHNIQUES

Structure de la soupape de réglage

Fluides

...................................................................................................................................................................................................................................................

...........................................................................................................................................................

34

34

français

2712 big - 33

Page 36

CARACTERISTIQUES TECHNIQUES

Structure de la soupape de réglage

Soupape 2/2 voies commandée par piston avec pointeau de réglage et boîtier incliné

Fonction de commande A

(fermée en position de repos par effet de ressort)

Fonction de commande B

(ouverte en position de repos)

Matière du mécanisme: P A (poly amide)

Matière du boîtier: Acier fin 316L

Matières d'étanchéité: Acier/Acier (1.4571) ou PTFE/Acier

Fluides

français

Fluides liquides ou gazeux qui n'attaquent pas la matière du boîtier et celle d'étanchéité

Fluide de commande: air instrumental, classe 3 selon DIN ISO 8573-1

REMARQUE

Les pressions de service et les températures de fluide admises figurent sur la plaque

signalétique. Concernant les fuites admises du siège, les valeurs indiquées dans la norme

DIN EN 1349 sont respectées, compte tenu que pour le joint étanche acier/acier la classe

IV de fuite s'applique et pour le joint PTFE/acier, la classe VI.

34 - 2712 big

Page 37

MISE EN SERVICE

MISE EN SERVICE

Montage de la soupape

......................................................................................................................................................................................................

36

français

2712 big - 35

Page 38

MISE EN SERVICE

Montage de la soupape

Position de montage quelconque , de préférence, mécanisme vers le haut.

T enir compte du sens du débit, pour les soupapes de réglage , l'écoulement a lieu en général sous le

siège!

Nettoyer les tuyauteries des impuretés!

Av ant de raccorder le boîtier de la soupape, v eiller à l'alignement des conduites!

Enlever impérativement le mécanisme avant de souder le boîtier (boîtier à souder).

Mode opératoire:

1. Enlever l'alimentation pneumatique et électrique du

Top

Control

2. Ôter en tirant le tuyau souple pneumatique entre le Top

et le mécanisme au raccord de commande de ce dernier.

3.

Fonction de commande A:

Charger d'air comprimé (6 bars) le raccord inférieur de

commande du mécanisme afin que le pointeau de réglage se

soulève du siège et ne soit pas endommagé.

Fonction de commande B:

Pas de chargement d'air comprimé ne doit être fait pour la

fonction B.

4. Enlever le mécanisme en position ouverte de la soupape, en

français

dévissant le raccord à vis (SW70) du boîtier.

A TTENTION!

.

Ne

desserrer pas la vis (SW65) au-dessus du

raccord à vis.

Control

Top

Control

Mécanisme

Raccord de commande

inférieur

Vis

(SW65)

Raccord à vis

(SW70)

Boîtier

5. Avant de remoter le mécansime (en position ouv erte de la soupape), graisser le raccord à vis av ec

un lubrifiant pour acier fin, p. ex. pâte Klüber UH1 96-402 de la maison Klüber , et renouv eler le joint

graphite.

A TTENTION!

Dans le cas d'applications spécifiques p.ex. applications d'analyse, d'oxygène, utiliser

uniquement des lubrifiants agrées.

6 . Aligner le mécanisme, si nécessaire, après avoir serré à fond le raccord à vis (veiller au couple de

serrage).

A cet effet, desserrer la vis (SW65) au-dessus du raccord à vis d'environ un demi-tour et placer le

mécanisme dans la position souhaitée.

Resserrer ensuite la vis à 100 ± 5 Nm.

A TTENTION!

La soupape doit également se trouver à cet effet en position ouv erte.

Couples de serrage pour le raccord à vis (SW70)

DN 65 80 100

Couple de serrage

[Nm]

REMARQUE

100 ± 5 120 ± 5 150 ± 5

En cas d'utilisation dans un environnement agressif, nous recommandons de dévier tous

les raccordements pneumatiques libres dans une atmosphère neutre à l'aide d'un tuyau

flexible pneumatique.

36 - 2712 big

Page 39

MAINTENANCE ET ENTRETIEN

MAINTENANCE ET

ENTRETIEN

Pannes

Echange du pointeau de réglage

Echange du siège de la soupape

Jeux de pièces de rechange

..................................................................................................................................................................................................................................................

..................................................................................................................................................................................

....................................................................................................................................................................

....................................................................................................................................................................

français

38

38

40

41

2712 big - 37

Page 40

MAINTENANCE ET ENTRETIEN

Pannes

Les pannes susceptibles de survenir du côté de l'excitation figurent dans les instructions de service du

Top

ATTENTION!

Echange du pointeau de réglage

Du côté fluide, il est possible de changer le pointeau de régalge en cas d'usure ou d'endommagement. A

cet effet, le mécanisme doit être démonté du boîtier.

Démontage

Control

.

Les réparations du mécanisme ne doivent être faites qu'en usine. S'adresser à cet effet

à votre succursale Bürkert ou directement à notre service clientèle.

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: + 49 (0) 7940 - 10 91 111

Fax: + 49 (0) 7940 - 10 91 448

E-Mail: info@de.buerkert.com

siaçnarf

Enlever l'alimentation pneumatique et électrique du T op

Ôther en tirant le tuyau souple pneumatique entre le T op

Control

Control

.

et le

mécanisme au raccord de commande de ce dernier.

Fonction de commande A:

Charger d'air comprimé (6bars) le raccord inférieur de commande du

mécanisme afin que le pointeau de réglage se soulève du siège et

ne soit pas endommagé.

vis

(SW65)

Raccord à vis

(SW70)

Fonction de commande B:

Pas de chargement d'air comprimé ne doit être fait pour la fonction B

Enlever le mécanisme en position ouverte de la soupape, en

dévissant le raccord à vis (SW70) du boîtier.

ATTENTION!

dresserer pas la vis (SW65) au-desus du raccord à vis.

Ne

Echange du pointeau de réglage:

Extraire la goupille à l'aide d'un chasse-goupille adéquat

Diamètre du chasse-goupille Ø 8 mm

Tirer le pointeau à l'aide de deux baguettes métalliques d'égale

longueur à coincer à gauche et à droite de la tige entre le pointeau

et la raccord à vis du mécanisme. Pour tirer le pointeau utiliser de

l'air comprimé (6 bars) sur le raccord inférieur de commande du

mécanisme.

Mettre le nouveau pointeau en place sur le bout de la tige.

Aligner les perçages les uns par rapport aux autres.

ATTENTION!

La surface d'étanchéité et le contour de réglage du

pointeau ne doivent pas être endommagés.

38 - 2712 big

Goupille

élastique

Pointeau de

réglage

Page 41

MAINTENANCE ET ENTRETIEN

Montage

Etayer le pointeau de réglage à sa partie cylindrique à l'aide d'un prisme ou objet similaire.

Mettre la goupille et l'insérer en la tapant prudemment avec le marteau.

Enfoncer la goupille en position médiane regardant l'axe de la broche (l'enfoncer jusqu'au bout du

chanfrein)

Avant de remoter le mécanisme (en position ouv erte de la soupape), graisser le raccord à vis av ec un

lubrifiant pour acier fin, p.ex. pâte Klüber UH1 96-402 de la maison Klüber , et renouveler le joint

graphite en cas de besoin.

A TTENTION!

Le mécanisme peut être aligné, si nécessaire, après avoir serré à fond le raccord à vis (SW70) (veiller

au couple de serrage).

A cet effet, desserrer la vis (SW65) au-dessus du raccord à vis d'environ un demi-tour et mettre le

mécanisme dans la position souhaité. Resserrer ensuite la vis à 100 ± 5 Nm.

A TTENTION!

Dans le cas d'applications spécifiques p.ex. applications d'analyse, d'oxygène, utiliser

uniquement des lubrifiants agrées.

La soupape doit également se trouver à cet effet en position ouv erte.

français

2712 big - 39

Page 42

MAINTENANCE ET ENTRETIEN

Echange du siège de soupape

Pour changer le siège de la soupape, le mécanisme de commande doit être démonté du boîtier . P our le

démontage, voir "Echange du pointeau de réglage".

Dévisser l'ancien siège de boîtier à l'aide de l'outil de montage

et d'une clé à vis.

Nettoyer le pas de vis et la surface d'étanchéité dans le boîtier

à l'air comprimé.

Choisir l'embout d'outil et le visser dans l'outil de montage.

Mettre en place le nouveau siège sur l'outil de montage,

graisser le filetage avec un lubrifiant, p. ex. pâte Klüber UH1

96 - 402 de la maison Klüber.

Outil de montage

A TTENTION!

français

REMARQUE

Dans le cas d'applications spécifiques p. ex.

applications d'analyse, d'oxygène, utiliser

uniquement des lubrifiants agrées.

Introduire le siège monté à la main dans le filet du boîtier et le

visser.

Serrer le siège à l'aide d'une clé dynamométrique au couple

indiqué.

En cas de montage d'un siège de soupape ayant un

autre diamètre nominal, le numéro de commande de

la soupape change!

Couple de serrage pour le montage du siège

Embout d'outil

(suivant diamètre

nominal du siège)

Siège de

soupape

DN Couple de serrage

[Nm]

65 150

80 180

100 220

+10

+10

+10

40 - 2712 big

Outils de montage de siège

DN boitier No. de cde

15 652 604

20 652 605

25 652 606

32 652 607

40 652 608

50 652 609

Page 43

MAINTENANCE ET ENTRETIEN

Jeux de pièces de rechange pour soupapes standard

Sont disponibles comme pièces de rechange, un jeu de pointeaux, une garniture de réglage et un jeu de

joints presse-étoupe. Pour démonter ou monter le mécanisme du boîtier , il f aut procéder comme décrit

dans Montage de la soupape.

REMARQUE

Av ant de démonter ou ouvrir l'appareil, couper impérativement l'arrivée de fluide et

supprimer la pression dans le système de conduites.

Mécanisme

Vis SW 65

Raccord à vis SW 70

Jeu de joints d'étanchéité

Jeu de pointeau

de réglage

SET 6

Presse-étoupe

SET 6

Garniture de réglage

SET 6

français

REMARQUE

V ous recevrez sur demande les jeux de pièces de rechange pour les v ersions spéciales

(p.ex. versions pour analyse, oxygène etc.).

2712 big - 41

Page 44

MAINTENANCE ET ENTRETIEN

Jeu de pointeau de réglage

Boîtier DN SiègeDNTaille du

mécanis-

me

acier/acier PTFE/acier

o

cde. No cde.

N

65 40 Ø175 155 625 155 637

65 50 Ø175 155 627 155 639

65 65 Ø175 155 630 155 642

80 50 Ø225 155 628 155 640

80 65 Ø225 155 631 155 643

80 80 Ø225 155 633 155 645

100 65 Ø225 155 632 155 644

100 80 Ø225 155 634 155 646

100 100 Ø225 155.635 155 647

Contient:

siaçnarf

Jeu de vannes

pointeau de réglage, goupille élastique, joint de graphite

DN DN

Boîtier Siège N

o

cde.

65 40 262 202

65 50 262 203

65 65 262 204

80 50 262 205

80 65 262 206

80 80 262 207

100 65 262 208

100 80 262 209

100 100 262 210

Contient: Siège de vanne, joint,

joint graphite

REMARQUE

Jeu de vannes sont disponibles sur demande. Si vous avez des

Jeu de joint

Presse-étoupe

42 - 2712 big

Boîtier DN No de commande

65 155 483

80 155 484

100 155 485

Contient:

Tête de soupape oscillante, joint de boîte

Page 45

Page 46

www.burkert.com

Loading...

Loading...