Page 1

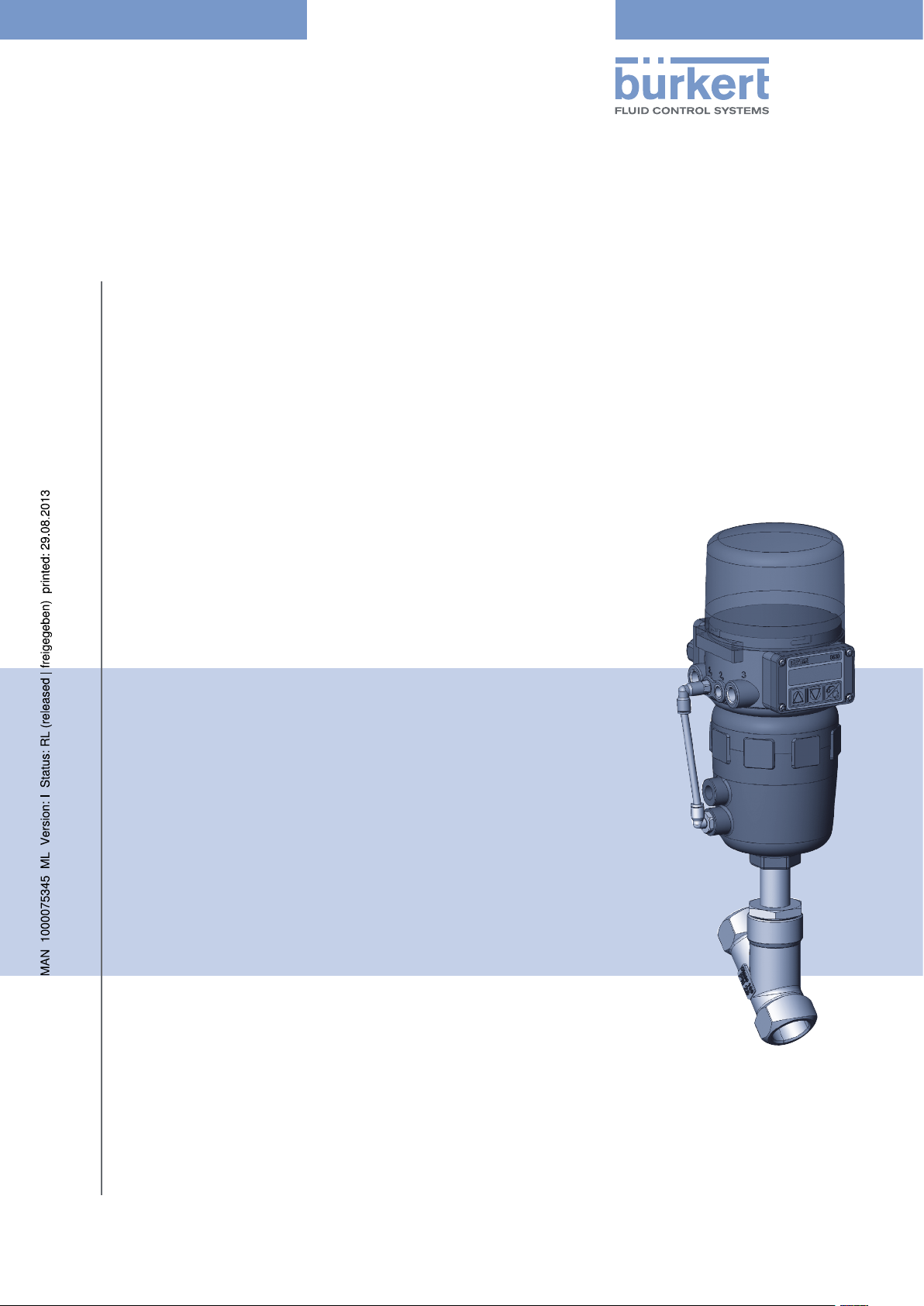

Type 2702

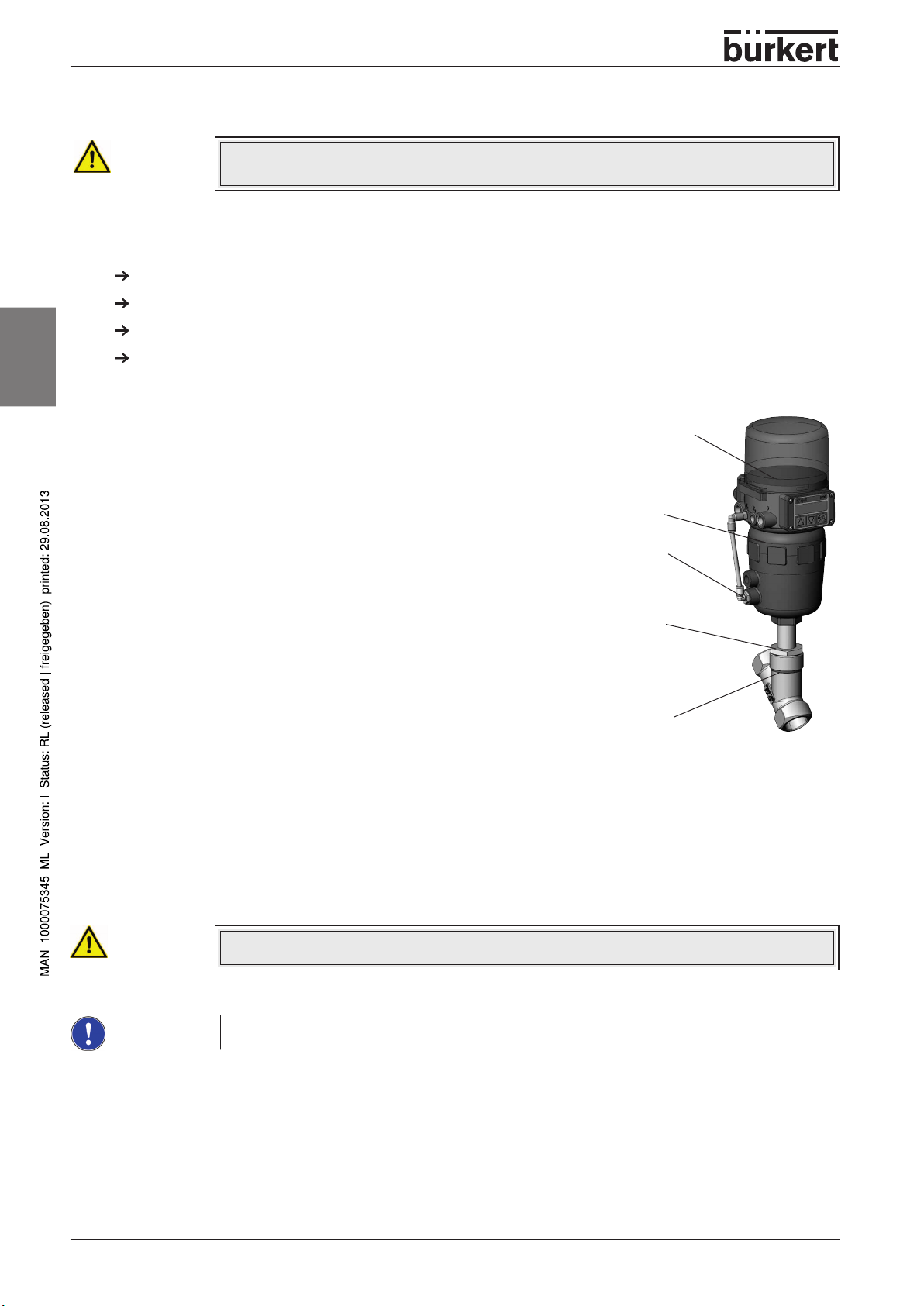

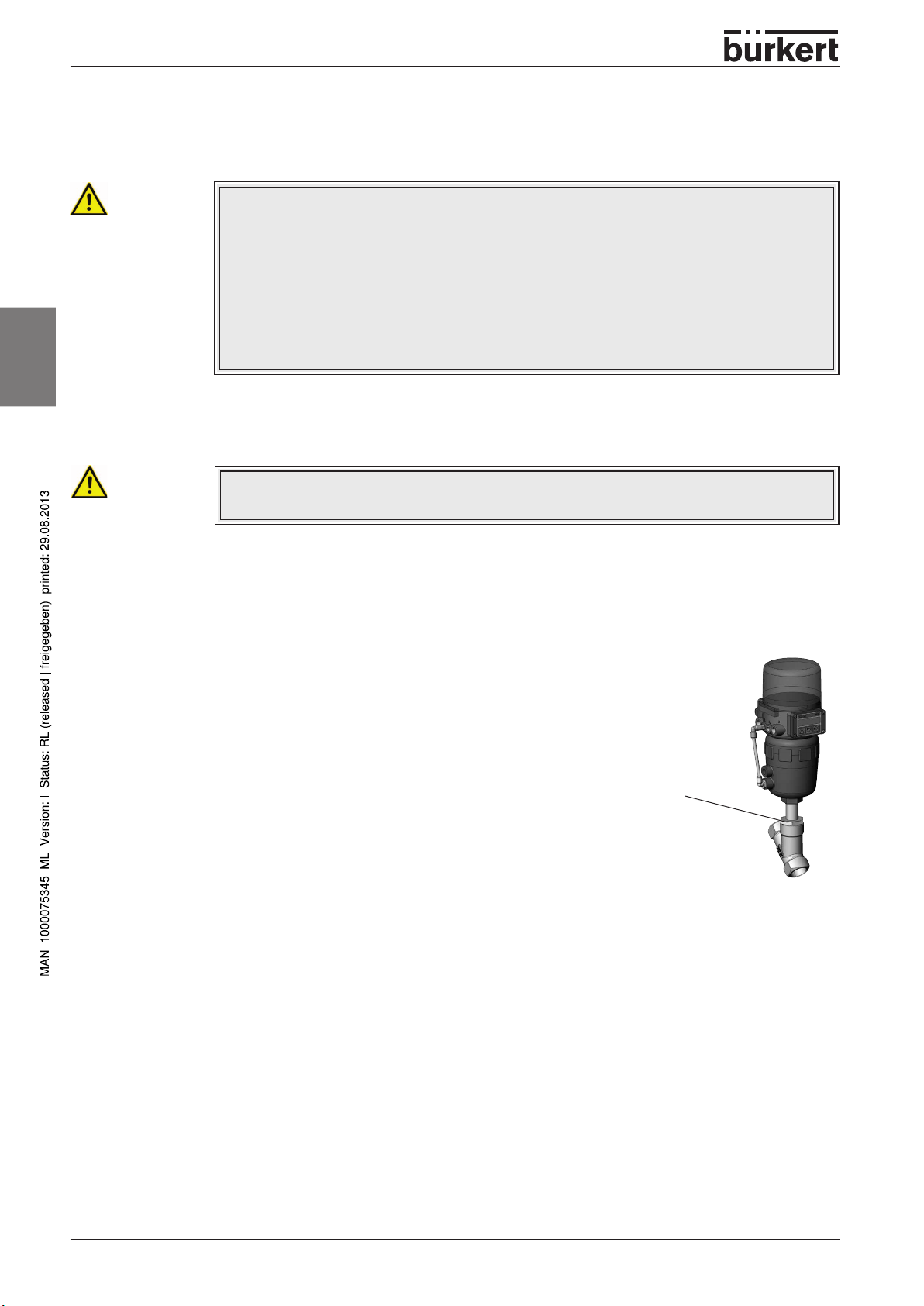

Piston actuated angle seat valve

Kolbengesteuertes Schrägsitzventil

Soupape de réglage à tête inclinée commandée par piston

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modification techniques.

© Bürkert Werke GmbH, 2005 - 2013

Operating Instructions 1308/06_EU-ML_00804367 / Original DE

Page 3

Contents

List of content Type

Generales notes .................................................................................................................................................5

Symbols............................................................................................................................................................................. 6

Intended use .................................................................................................................................................................... 6

General safety notes ...................................................................................................................................................... 6

Contact addresses ......................................................................................................................................................... 7

Warranty ............................................................................................................................................................................ 7

Transport , storage .......................................................................................................................................................... 7

english

Disposal ............................................................................................................................................................................ 8

Information in internet .................................................................................................................................................... 8

technical Data .......................................................................................................................................................9

Construction of the control valve ..............................................................................................................................10

Media ...............................................................................................................................................................................10

Kv values .........................................................................................................................................................................11

commissioninG .................................................................................................................................................... 13

Installation of the valve .................................................................................................................................................14

Procedure for TopControl Type 8630...........................................................................................................14

Procedure for SideControl Type 1067 .........................................................................................................15

Pneumatic installation for TopControl Type 8630 ................................................................................................17

Fluid connections of the TopControl Continuous ......................................................................................17

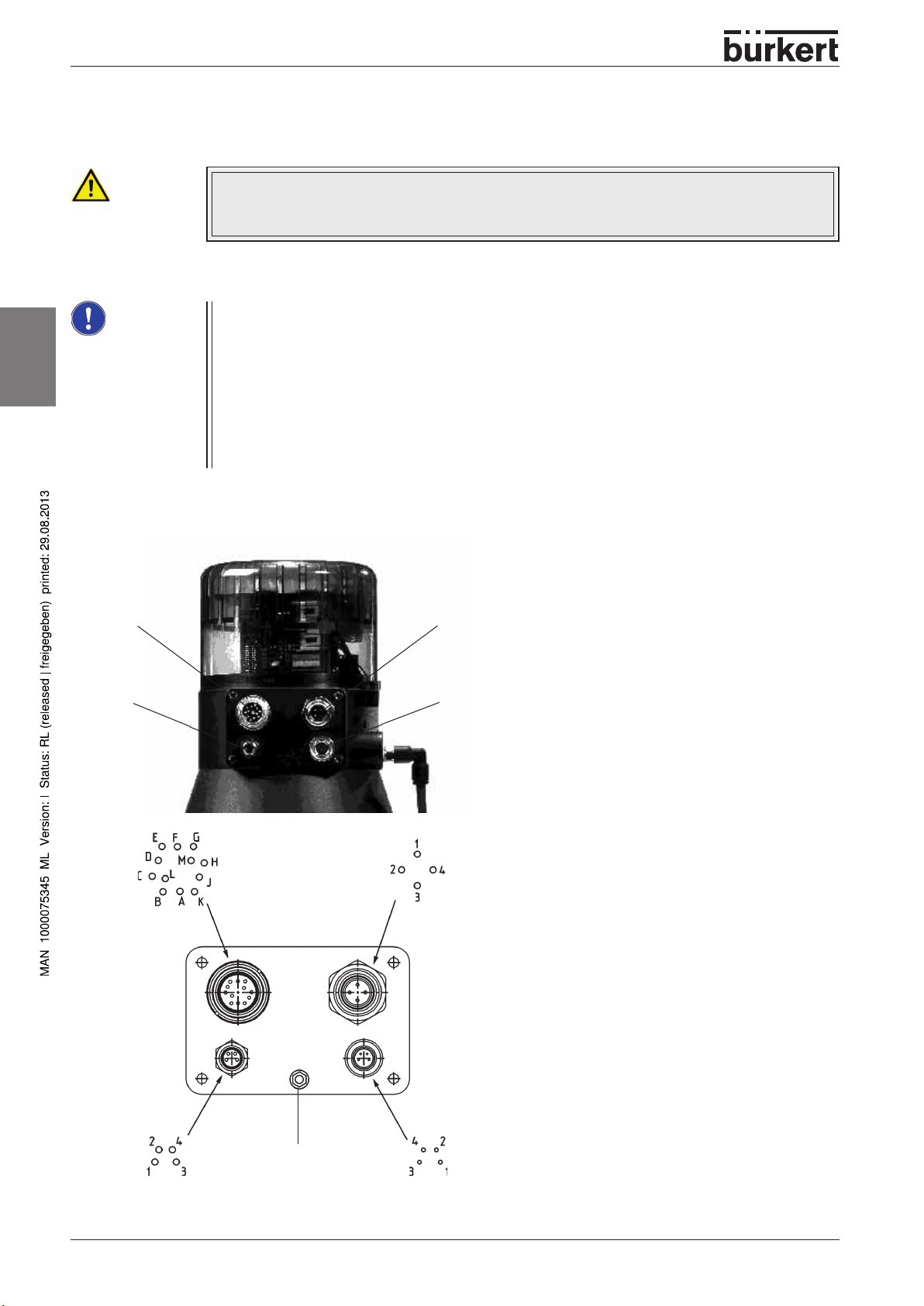

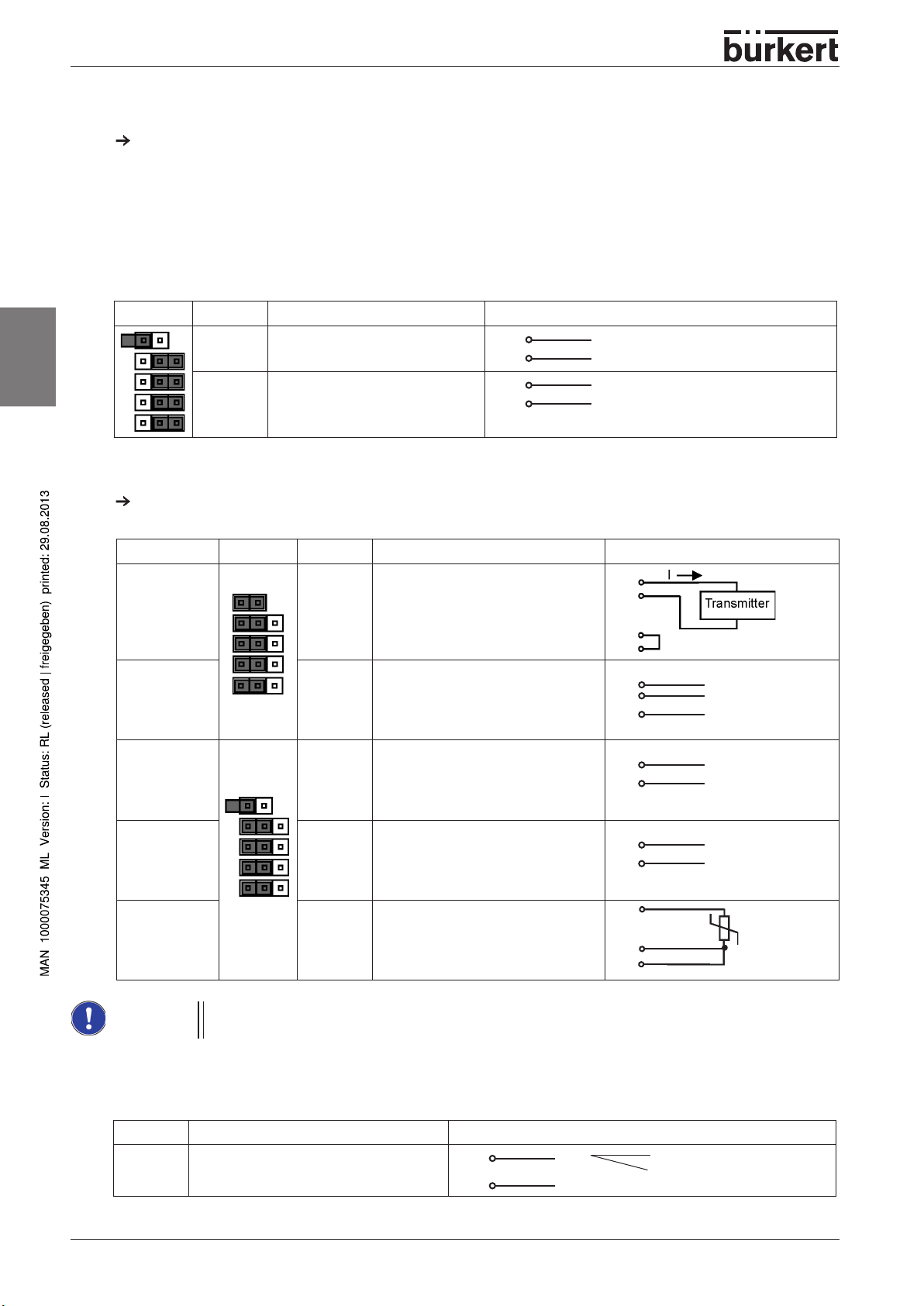

Electrical connection - multipole connectors (TopControl Type 8630) ...........................................................18

Marking of the multipole plugs or sockets and the contacts ...................................................................18

Output signals for SPS (circular plug M 16) ..............................................................................................19

Operating voltage (circular plug M 12) ........................................................................................................19

Inductive proximity switches (circular socket M8) .....................................................................................19

Process value (circular plug M 8) ..................................................................................................................20

2702 - 3

Page 4

Contents

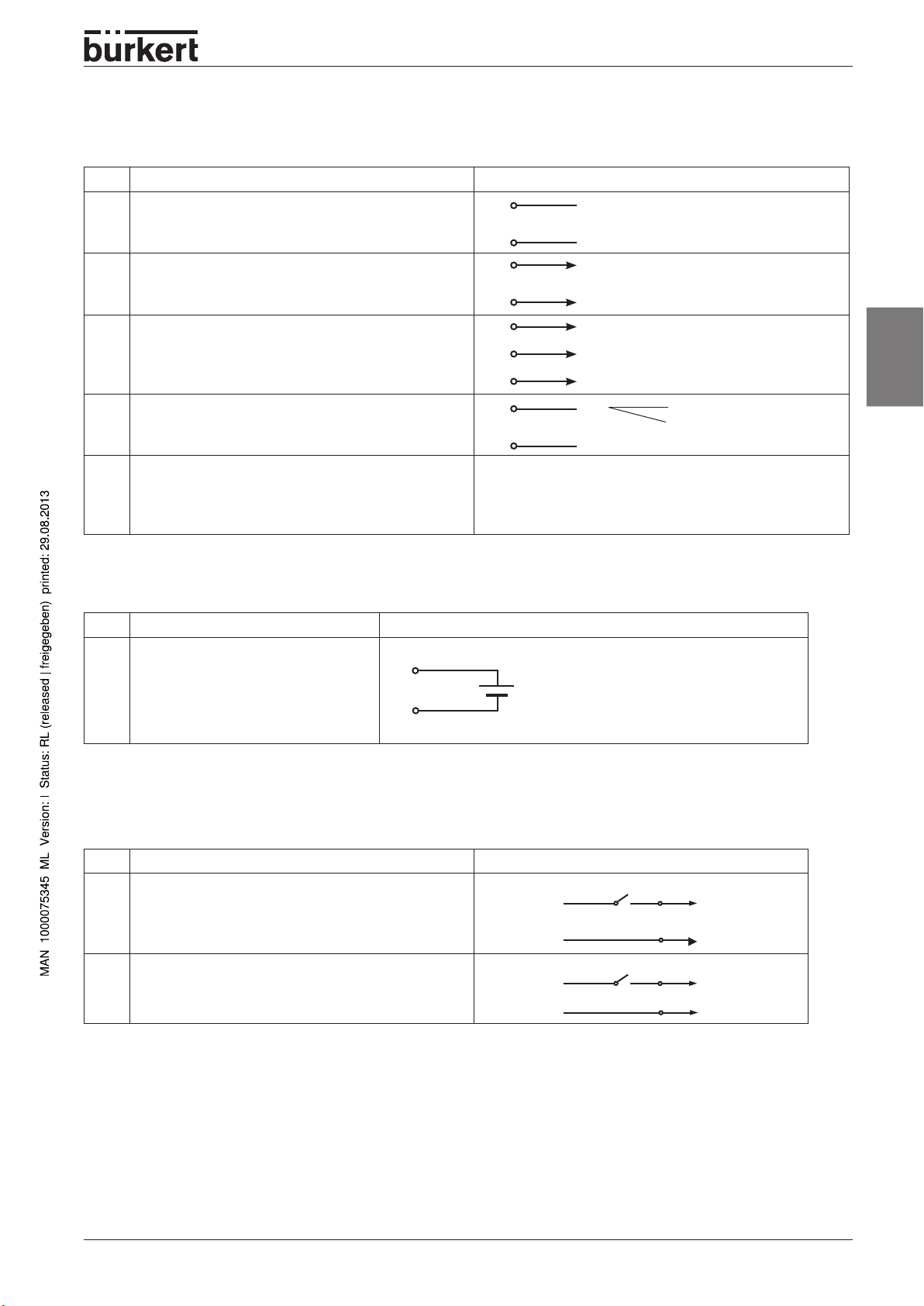

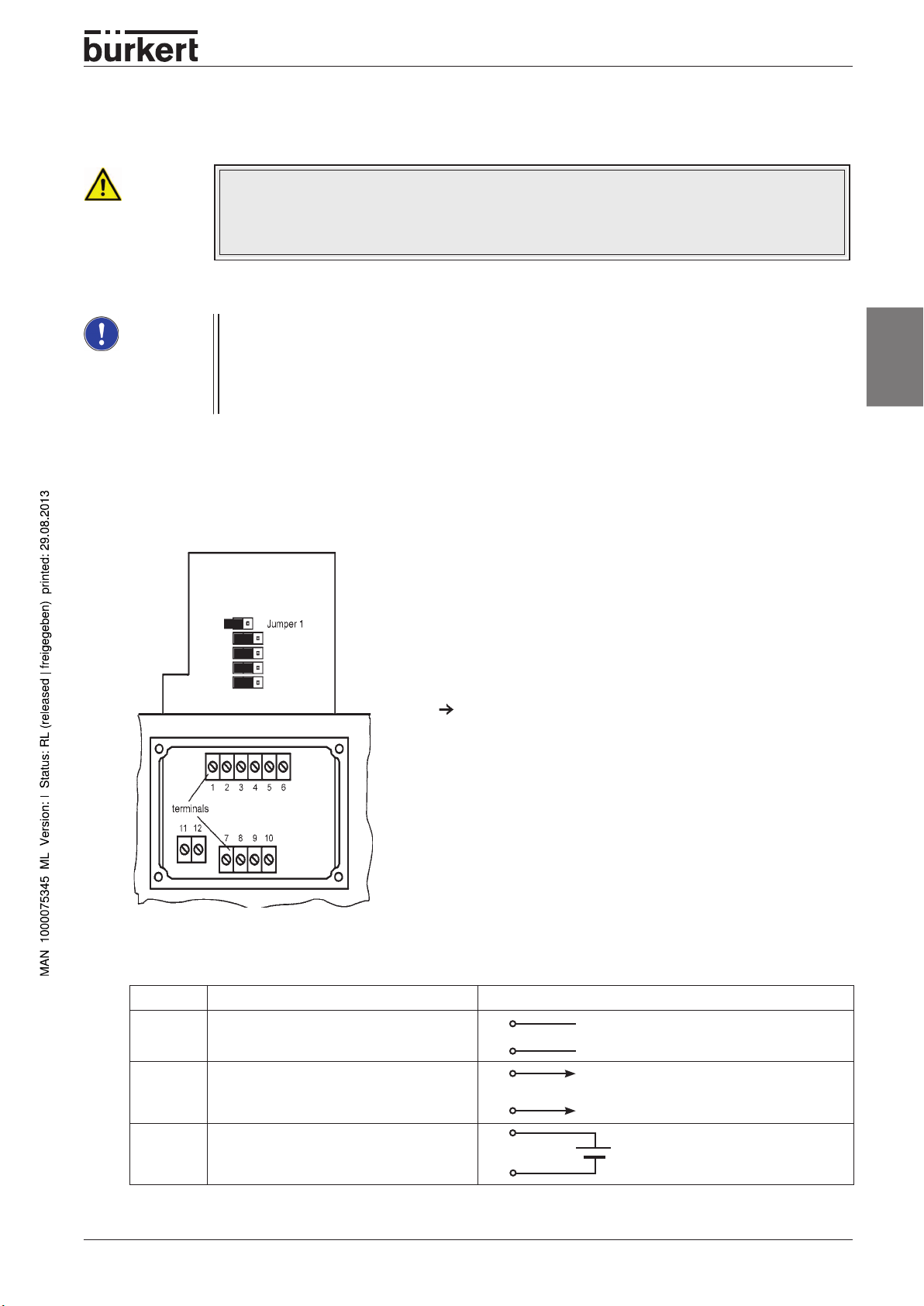

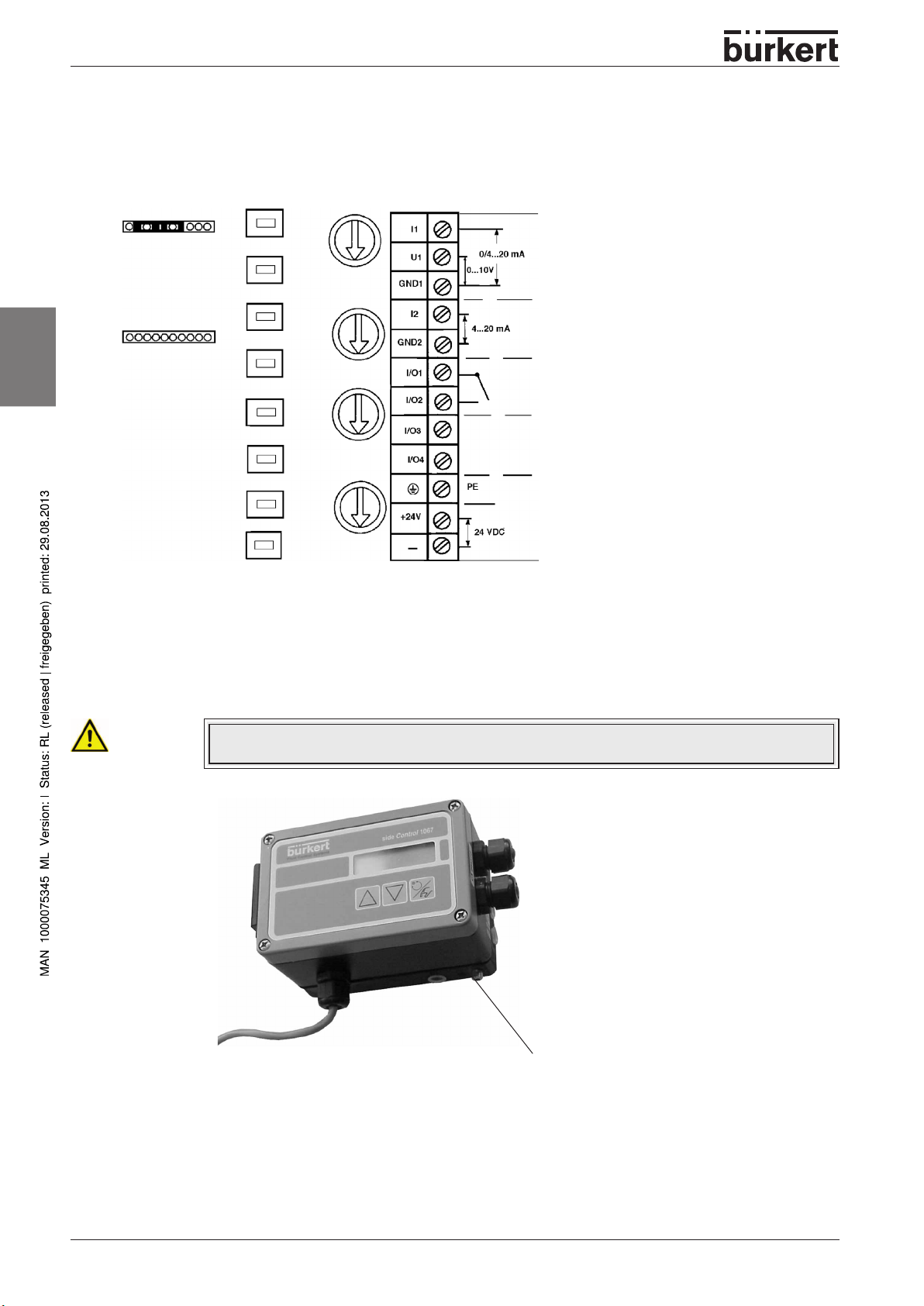

Electrical connection - terminals for cable bushing (TopControl Type 8630) ...............................................21

Connection PCB of the TOPControl Continuous with screw terminals and jumpers ......................21

Terminal configuration with cable bushings.................................................................................................21

Choice of binary outputs or process value input........................................................................................22

Setting the inductive proximity switches (option for TopControlTyp 8630) ...................................................23

Opening the hosing of the TOPControl Continuous .................................................................................23

Positioning the inductive proximity switches ...............................................................................................23

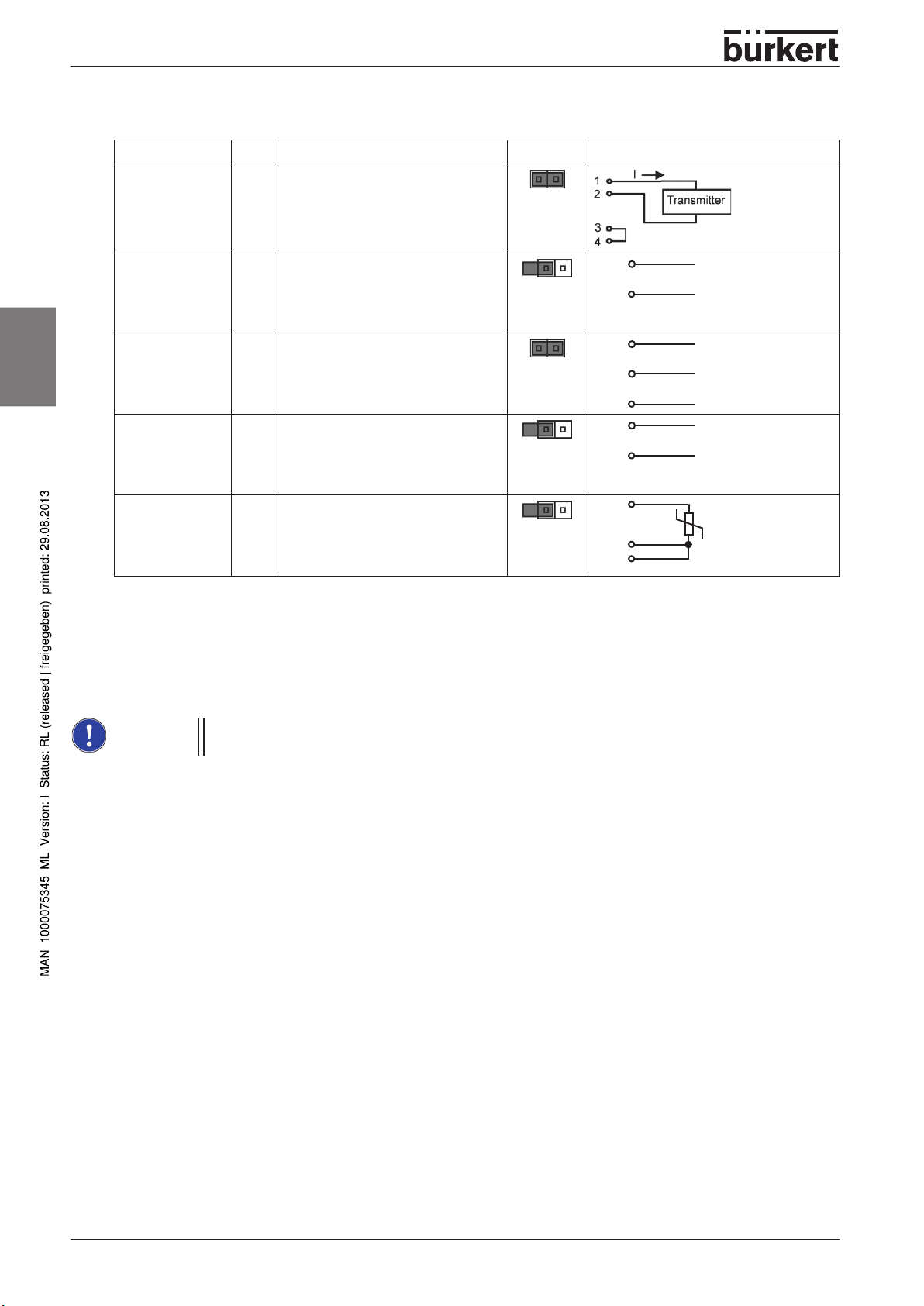

Electrical connection - terminal for cable bushing (SideControl Type 1067) ................................................24

english

Pin assignment ...................................................................................................................................................24

maintenance anD servicinG of the valve .................................................................................. 25

Faults ...............................................................................................................................................................................26

Replacement of the control plug with TopControl Typ 8630 .............................................................................26

Demounting the actuator .................................................................................................................................26

Replacement of the control plug ....................................................................................................................27

Mounting the actuator.......................................................................................................................................27

Replacement of the control plug wtih SideControl Typ 1067 ...........................................................................28

Demounting the actuator .................................................................................................................................28

Replacement of the control plug ....................................................................................................................29

Mounting the actuator.......................................................................................................................................30

Spare parts sets type 2702 .......................................................................................................................................31

4 - 2702

Page 5

General notes

General Notes

SYMBOLS ........................................................................................................................................................................6

INTENDED USE ............................................................................................................................................................6

GENERAL SAFETY NOTES .................................................................................................................................... 6

CONTACT ADDRESSES .........................................................................................................................................7

english

WARRANTY .....................................................................................................................................................................7

TRANSPORT, STORAGE .......................................................................................................................................... 7

DISPOSAL .......................................................................................................................................................................8

INFORMATION IN INTERNET ................................................................................................................................ 8

2702 - 5

Page 6

General notes

SYMBOLS

The following symbols are used in these operating instructions:

marks a word step that you must carry out.

DANGER!

WARNING!

english

CAUTION!

ATTENTION!

NOTE

INTENDED USE

means an immediate danger. If it is not avoided, death or serious injury (maiming)

will result.

means a possibly dangerous situation. If it is not avoided, death or serious injury may

result.

means a possibly dangerous situation. If it is not avoided, light injury may result. May also

be used for warnings regarding property damage.

means a possibly damaging situation. If it is not avoided, the product or its surroundings

may be damaged.

marks important additional information, tips and recommendations.

This device may only be used in combination with third-party devices and components recommended or

approved by Bürkert.

The proper function and safe operation of this product depends on professional transportation, professional

storage, installation, and mounting, as well as on careful operation and maintenance.

In order for the device to function perfectly and have a long service life, you must observe the information given in these operating instructions and comply with the operating conditions and the permissible data which

is specified in the „Technical Data“ chapter of these instructions.

On non-observances of these notes and unauthorized interference with the device, we will refuse all liability

and the warranty on device and accessories will become void!

The device is only to be used as a process regulation valve. Any other use is not considered the intended

use. Bürkert is not responsible for any damages resulting from such use. The user bears all risk.

GENERAL SAFETY NOTES

DANGER!

WARNING!

• Switch off the supply voltage in all cases before intervening in the system!

• Note that in systems under pressure, piping and valves may not be loosened!

• Observe the current regulations on accident prevention and safety during operation and

maintenance of the device!

6 - 2702

Page 7

General notes

ATTENTION!

• Keep to standard engineering rules in planning the use of and operating the device!

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Take suitable precautions to prevent inadvertent operation or damage by unauthorized

action!

• Make sure that after an interruption to the electrical or pneumatic supply, the process

starts up again ina well-defined, controlled manner!

• For the electrical part, observe the safety instructions in the operating manual of the

TopControl, SideControls.

• Failure to observe this operating manual and its operating instructions as well as unauthorized tampering with the device release us from any liability and also invalidate the

warranty covering the devices and accessories!

CONTACT ADDRESSES

Germany

Bürkert Fluid Control System

Sales Center

english

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: +49 (0) 7940 10 91-111

Fax: +49 (0) 7940 10 91 -448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of these printed operating instructions.

And also on the internet at: www.burkert.com

WARRANTY

The warranty is only valid if the device is used as intended in accordance with the specified application conditions.

ATTENTION!

The warranty extends only to defects in the delivered Type 2702 valve with pneumatic drive

and the TopControl or SideControl. We accept no liability for any kind of collateral damage

which can occur due to failure or malfunction of the device.

TRANSPORT, STORAGE

NOTE

Transportation and storage of the product should only be done in the original packing.

Storage temperature -10 °C ... +60 °C

2702 - 7

Page 8

General notes

DISPOSAL

CAUTION!

Environmental danger!

When disponsing of the appliance, observe the national standards for refuse disposal.

INFORMATION IN INTERNET

All Operating manuals and Datasheets for the Type 2702 you can find under: www.burkert.com - Technical

data

english

www.burkert.com → Documentation

8 - 2702

Page 9

Technical data

Technical DaTa

CONSTRUCTION OF THE CONTROL VALVE ............................................................................................ 10

MEDIA ............................................................................................................................................................................. 10

KV VALUE .................................................................................................................................................................... 11

english

2702 - 9

Page 10

TECHNICAL DATA

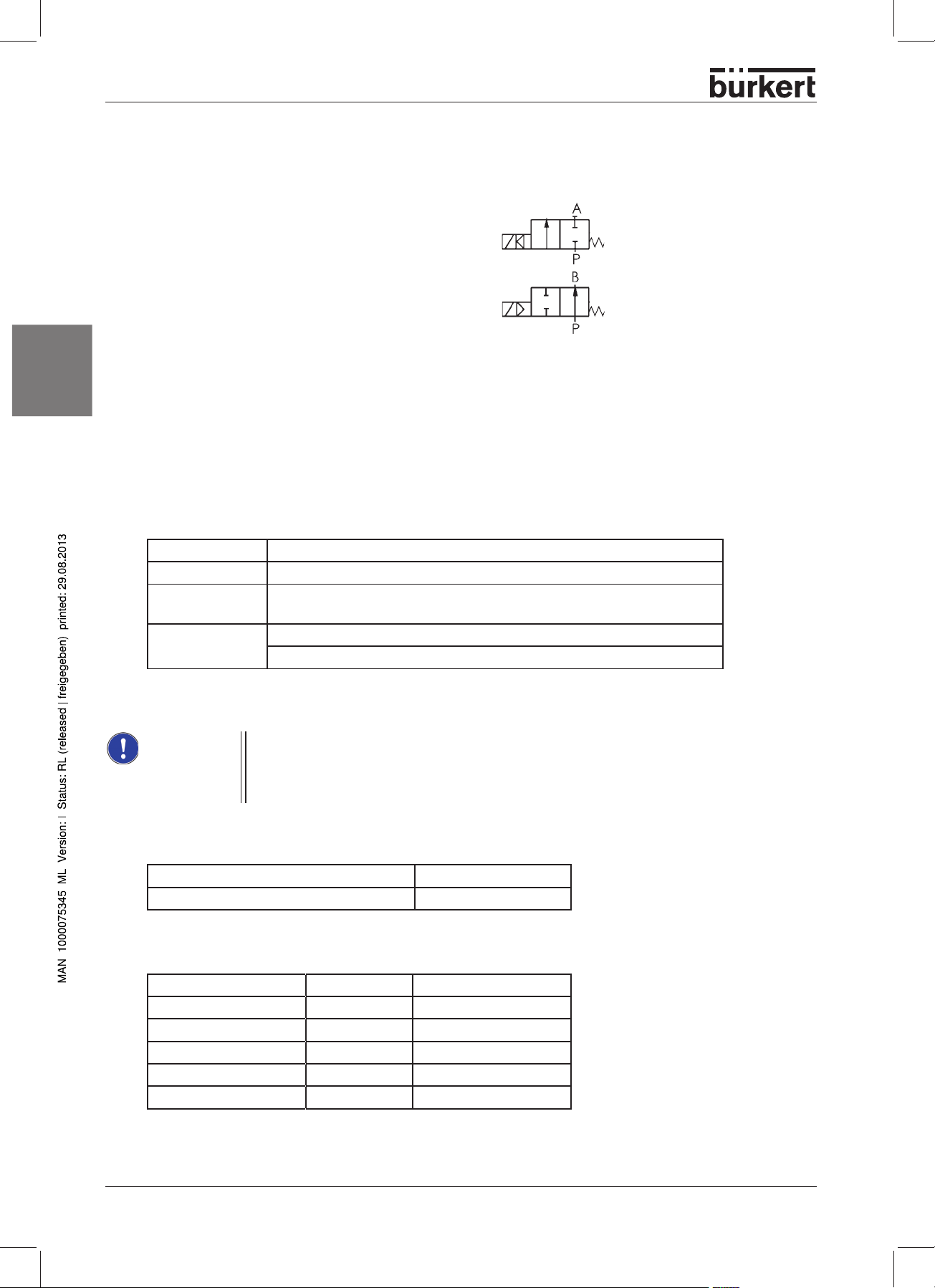

CONSTRUCTION OF THE CONTROL VALVE

2/2-way piston actuated valve with control plug and angle seat body

Control function A (closed by spring force)

Normally close

Control function B (open in rest position)

Normally open

hsilgne

Actuator material: PA (polyamide) or PPS

Body material: stainless steel 316L

Seal materials: steel/steel (1.4571) or PTFE/steel

MEDIA

Liquid and gaseous media that do not attack the body and seal materials.

Control medium Quality classes according to DIN ISO 8573-1

Dust content Class 5: Max. particle size 40 µm; max. particle density 10 mg/m

Water content Class 3: Max. pressure dew point -20 °C or min. 10 degrees below the

lowest operating temperature

3

Oil content Class 5: Max. 25 mg/m

Class 3: Max. 1 mg/m

Note: Higher demands placed on the positioner must be observed!

NOTE

Pilot pressure

Actuator size 80 (F) 5.5 - 10 bar

Actuator size 100 (G) 5.5 - 7 bar

The permitted operating pressure and temperature of the medium are listed on the rating

plate and in the following tables. With regard to the permissible seat leakage, the values

given in DIN EN 1349 are complied with,whereby for the steel/steel seal, leakage class IV

and for the PTFE/steel leakage class VI apply.

in conjunction with Bürkert positioners

3

in conjunction with SIDE Control Type 8635

3

Fluid pressure

10 - 2702

Actuator size F DN 15 0 - 16 bar

Actuator size F DN 20 0 - 16 bar

Actuator size F DN 25 0 - 16 bar

Actuator size F DN 32 0 - 15 bar

Actuator size G DN 40 0 - 12,5 bar

Actuator size G DN 50 0 - 7,2 bar

Page 11

KV VALUE

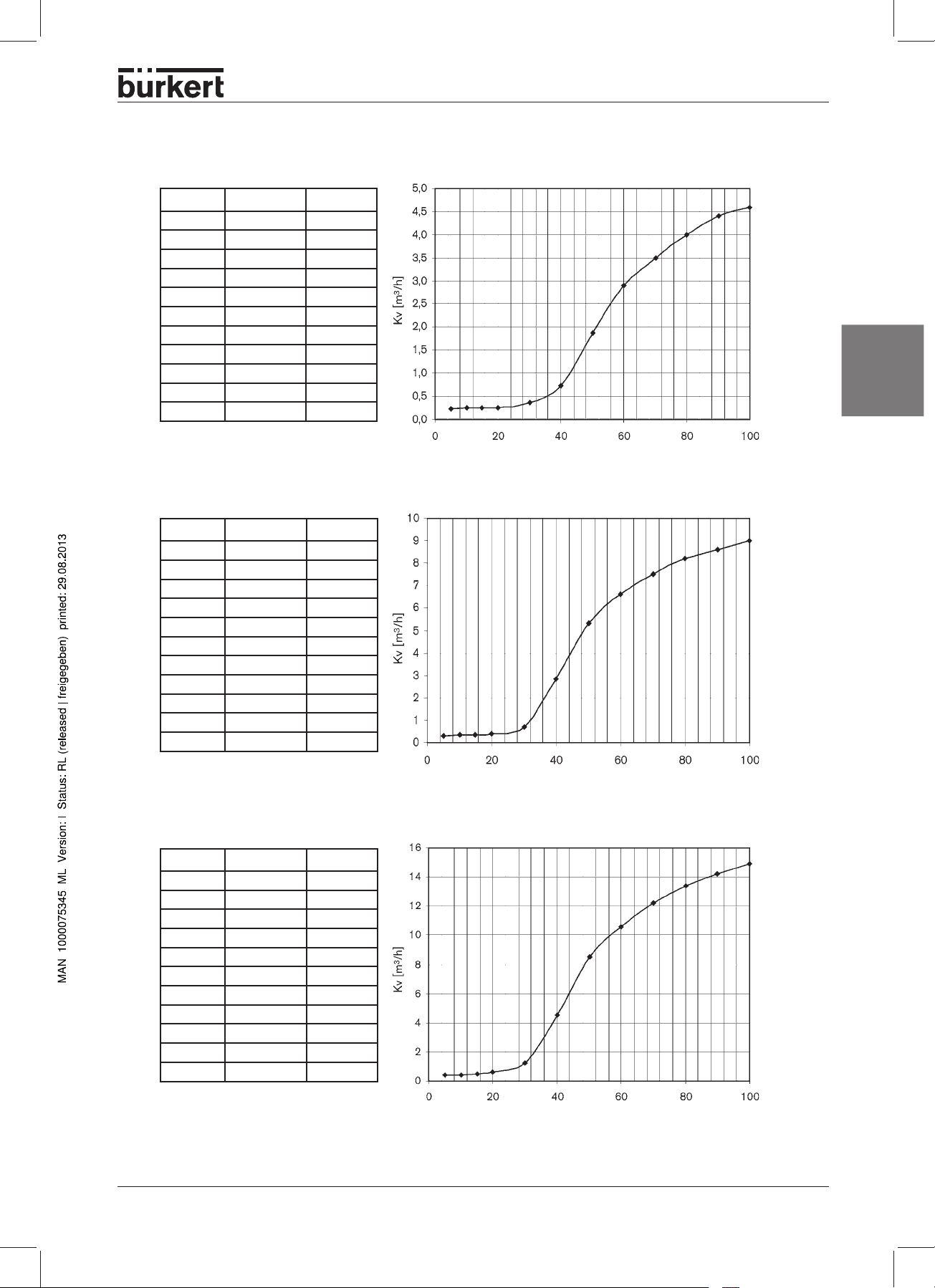

Type 2702 DN 15

Stroke % Stroke [mm] Kv [m3/h]

5 0.6 0.23

10 1.2 0.24

20 2.4 0.26

30 3.6 0.35

40 4.8 0.7

50 6.0 1.85

60 7.2 2.9

70 8.4 3.5

80 9.6 4.0

90 10.8 4.3

100 12.0 4.5

Type 2702 DN 20

TECHNICAL DATA

english

Stroke %

Stroke % Stroke [mm] Kv [m3/h]

5 0.9 0.30

10 1.8 0.33

20 3.6 0.42

30 5.4 0.7

40 7.2 2.85

50 9.0 5.3

60 10.8 6.6

70 12.6 7.5

80 14.4 8.2

90 16.2 8.6

100 18.0 9.0

Type 2702 DN 25

Stroke % Stroke [mm] Kv [m3/h]

5 1.0 0.39

10 2.0 0.41

20 4.0 0.60

30 6.0 1.25

40 8.0 4.5

50 10.0 8.5

60 12.0 10.5

70 14.0 12.2

80 16.0 13.5

90 18.0 14.2

100 20.0 15.0

Stroke %

Stroke %

2702 - 11

Page 12

Technical DaTa

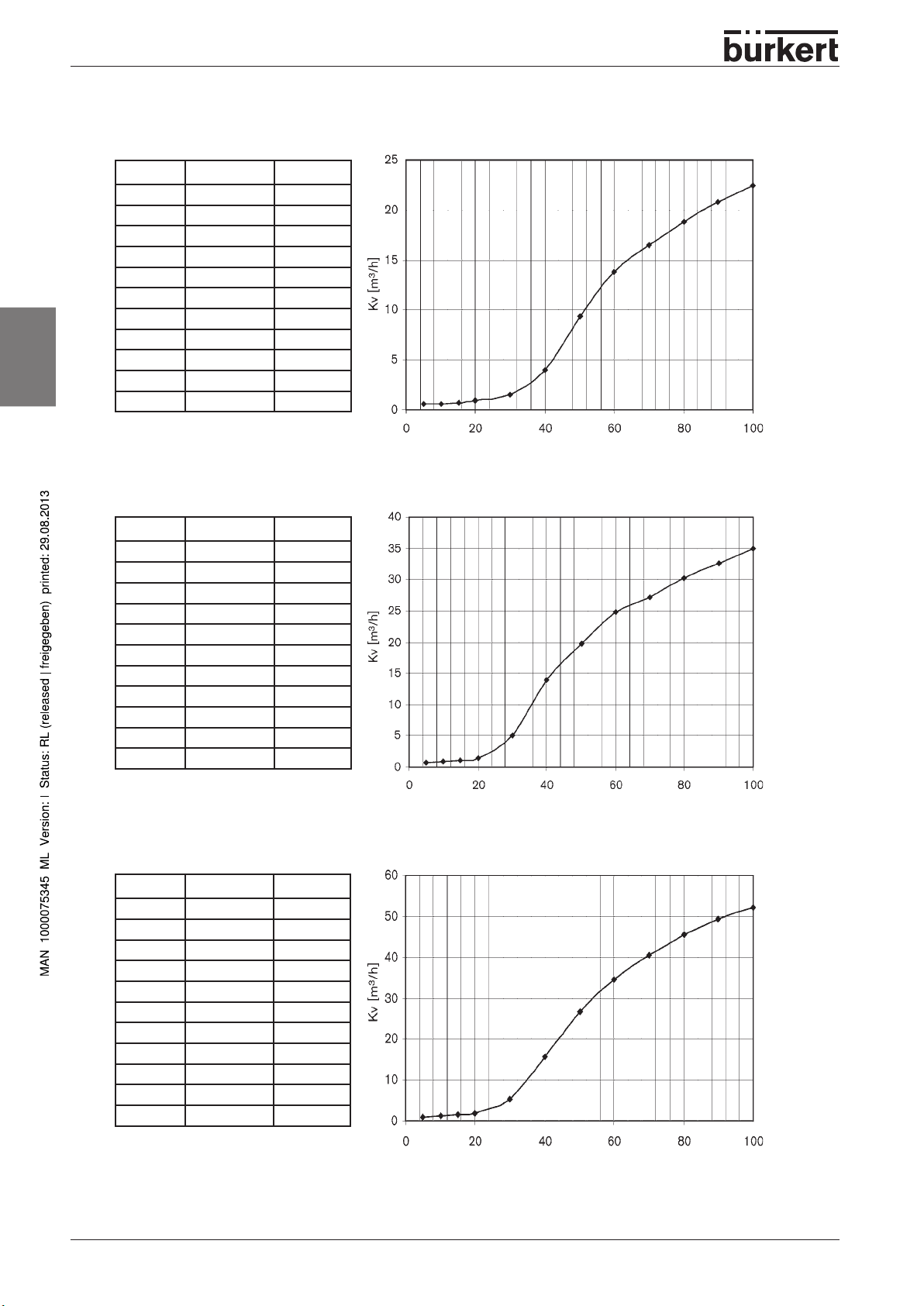

Type 2702 DN 32

Stroke % Stroke [mm] Kv [m3/h]

5 1.0 0.55

10 2.0 0.65

20 4.0 0.95

30 6.0 1.5

40 8.0 4.0

50 10.0 9.3

60 12.0 13.8

70 14.0 16.5

80 16.0 18.8

english

90 18.0 21.0

100 20.0 23.0

Type 2702 DN 40

Stroke %

Stroke % Stroke [mm] Kv [m3/h]

5 1.3 0.65

10 2.6 0.85

20 5.2 1.5

30 7.8 5.0

40 10.4 14.0

50 13.0 20.0

60 15.6 25.0

70 18.2 27.0

80 20.8 30.0

90 23.4 33.0

100 26.0 35.0

Type 2702 DN 50

Stroke % Stroke [mm] Kv [m3/h]

5 1.3 1.0

10 2.6 1.3

20 5.2 2.0

30 7.8 5.0

40 10.4 16.0

50 13.0 27. 0

60 15.6 34.0

70 18.2 41.0

80 20.8 45.0

90 23.4 49.0

100 26.0 53.0

Stroke %

12 - 2702

Stroke %

Page 13

Commissioning

Commissioning

INSTALLATION OF THE VALVE ......................................................................................................................... 14

Procedure for TopControl Type 8630 ......................................................................................................................14

Procedure for SideControl Type 1067 ....................................................................................................................15

PNEUMATIC INSTALLATION FOR TOPCONTROL TYPE 8630 ...................................................17

Fluid connections of the TopControl Continuous .................................................................................................17

ELECTRICAL CONNECTION - MULTIPOLE CONNECTORS

(TOPCONTROL TYPE 8630)................................................................................................................................ 18

english

Marking of the multipole plugs or sockets and the contacts ..............................................................................18

Output signals for SPS (circular plug M 16) ..........................................................................................................19

Operating voltage (circular plug M 12) ...................................................................................................................19

Inductive proximity switches (circular socket M8) .................................................................................................19

Process value (circular plug M 8) .............................................................................................................................20

ELECTRICAL CONNECTION - TERMINALS FOR CABLE BUSHING

(TOPCONTROL TYPE 8630)................................................................................................................................ 21

Connection PCB of the TOPControl Continuous with screw terminals and jumpers ..................................21

Terminal configuration with cable bushings ............................................................................................................21

Choice of binary outputs or process value input ...................................................................................................22

SETTING THE INDUCTIVE PROXIMITY SWITCHES

(OPTION FOR TOPCONTROL TYPE 8630) ................................................................................................. 23

Opening the housing of the TOPControl Continuous..........................................................................................23

Positioning the inductive proximity switches ..........................................................................................................23

ELECTRICAL CONNECTION - TERMINAL FOR CABLE BUSHING

(SIDECONTROL TYPE 1067) .............................................................................................................................. 24

Pin assignment ..............................................................................................................................................................24

2702 - 13

Page 14

Commissioning

INSTALLATION OF THE VALVE

CAUTION!

Use of the incorrect lubricant causes contamination!

For special applications such as for oxygen and analysis, use only the approved lubricants.

May be installed in any position, but preferably with the actuator above.

Observe the flow direction - general rule for control valves: flow direction: Below seat

Clean the piping of contamination!

Before connecting the valve body, take care that piping is aligned!

In the case of weld-end bodies, be sure to remove the actuator before welding.

english

Procedure for TopControl Type 8630

1. Remove the electrical and pneumatic supplies from the TopControl.

2. Pull off the pneumatic hose between TopControl and actuator at

control connection of actuator.

3. Control function A:

Pressurize the lower pilot air port of the actuator with compressed air

(6 bar),

so that the plug is lifted from the valve seat and is not damaged.

Control function B:

With control function B, no compressed air must beapplied for this

purpose.

Top Control

actuator

lower

pilot air

port

threaded

nipple

4. Remove the actuator in the open valve position by unscrewing the

nipple from the valve body.

5. Before reinstalling the actuator (in the open valve position), grease the

nipple thread with stainless steel lubricant,

e. g. Klüberpaste UH1 96-402 from company Klüber.

6. Replace the graphite seal.

7. After tightening the threaded nipple, align the pilot air ports by turning

the actuator.

ATTENTION!

NOTE

The valve must be for this in the opened position.

When using in an aggressive environment, you are advised to connect pneumatic hoses to all

free control connections and place their other ends in a neutral atmosphere.

valve body

14 - 2702

Page 15

Commissioning

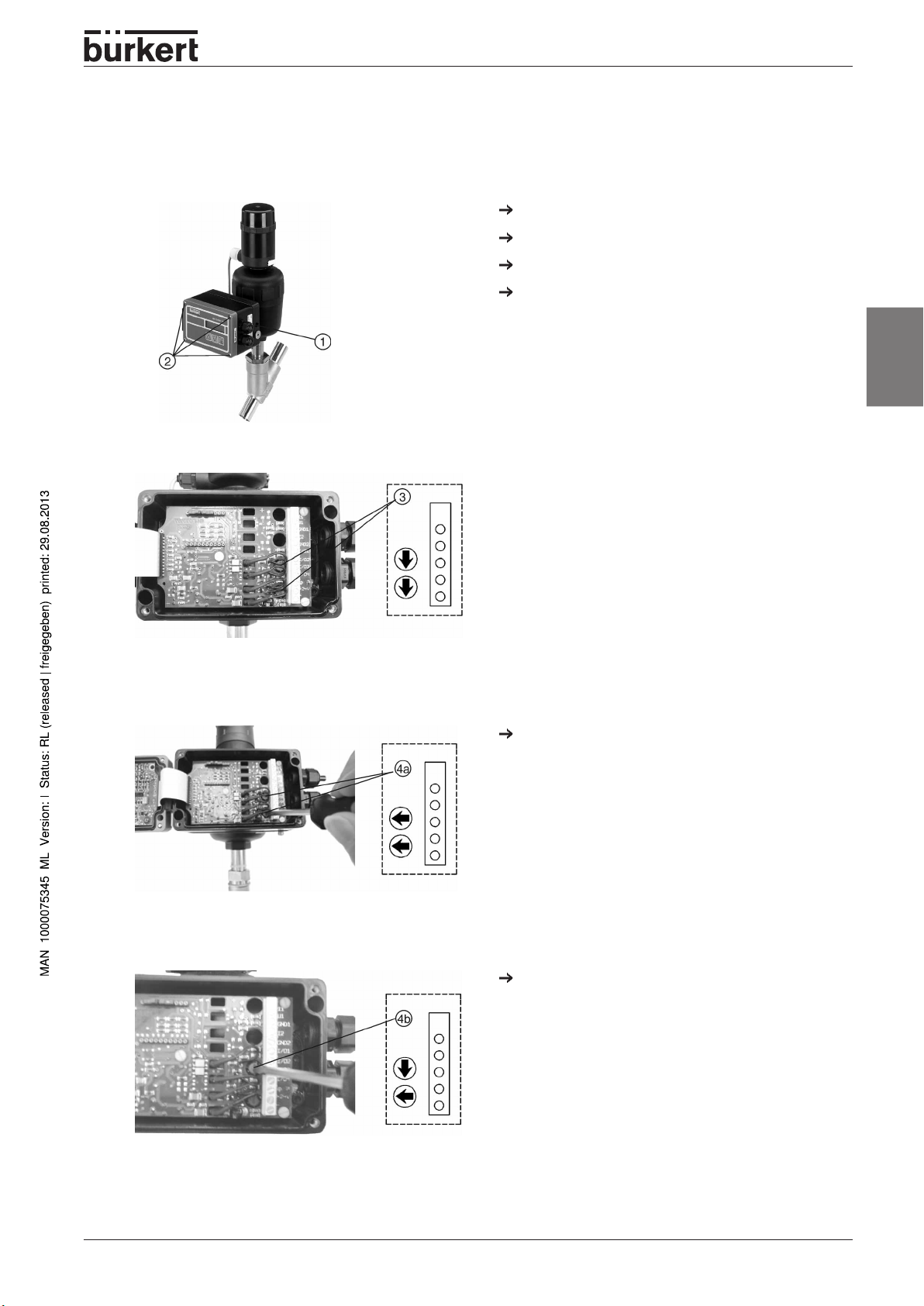

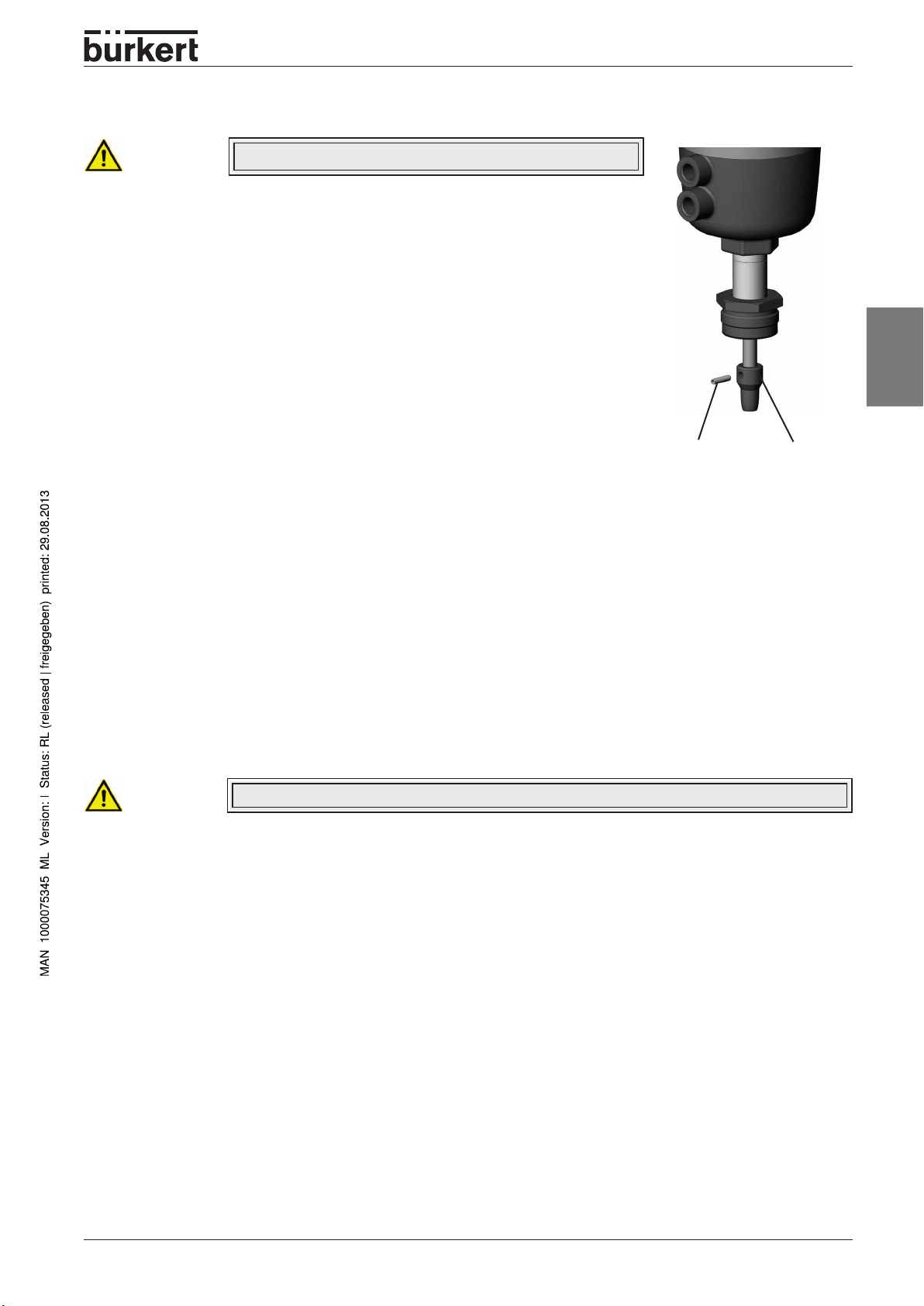

Procedure for SideControl Type 1067

Dismount the piston actuator as described below. You will avoid damage to the gaskets because the piston

will be brought into the upper position.

Connect compressed air at 4.5 to 6 bar to P (1).

Remove the blowout mouthpiece.

Unscrew the 4 screws.

Open the cover (2).

The 2 red switches for emergency manual actuation

(3) are located next to the terminal strip.

english

They are in the idle position when the arrow is parallel to the terminal strip.

Turn the 2 switches carefully 90 degrees in the

clockwise direction (in either order) (4a).

The piston moves into the upper position and the

plug is separated from the valve seat.

Turn only the upper switch to the idle position

(4b).

The piston stays in the upper position even after the

compressed air is switched off.

2702 - 15

Page 16

Commissioning

english

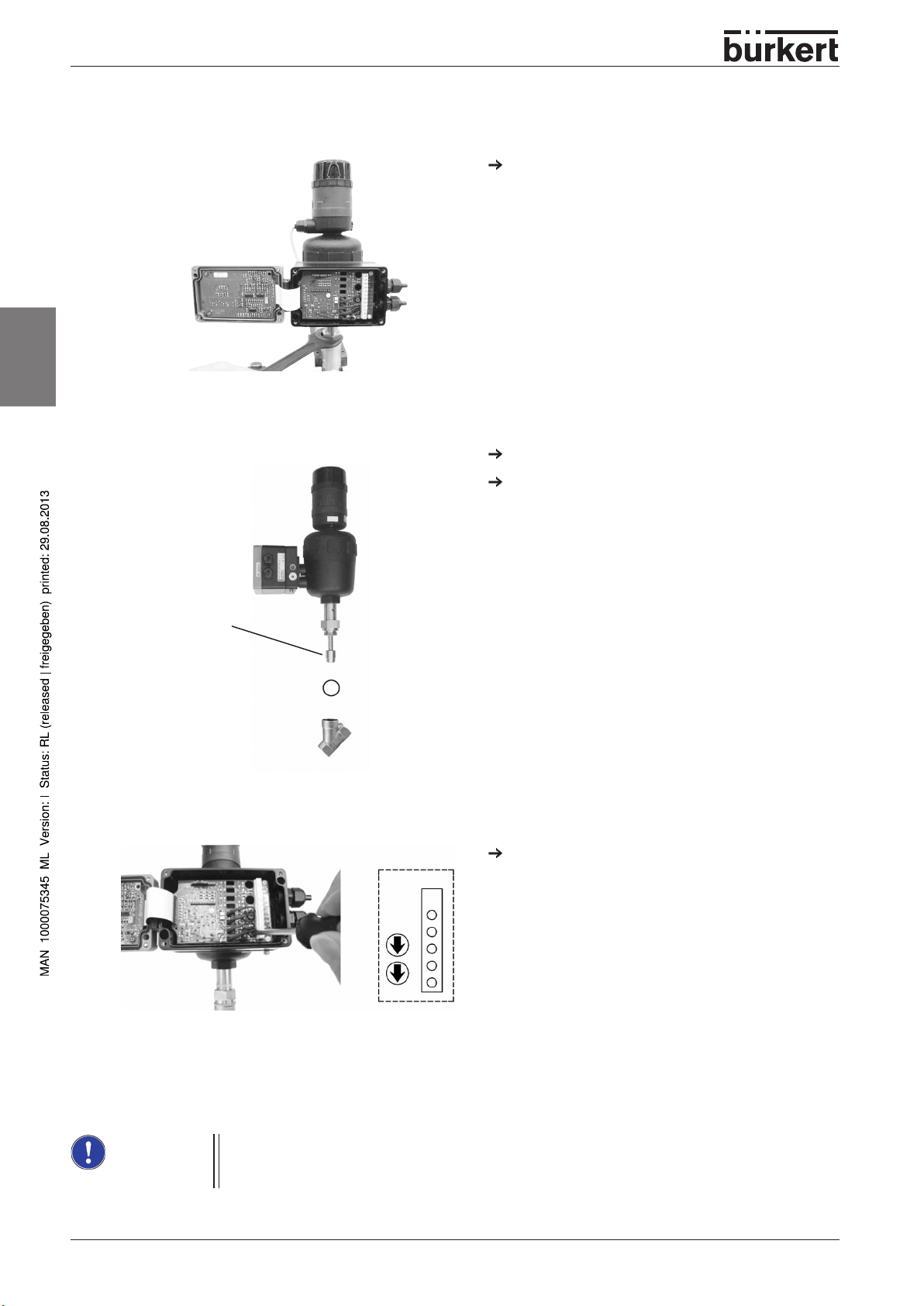

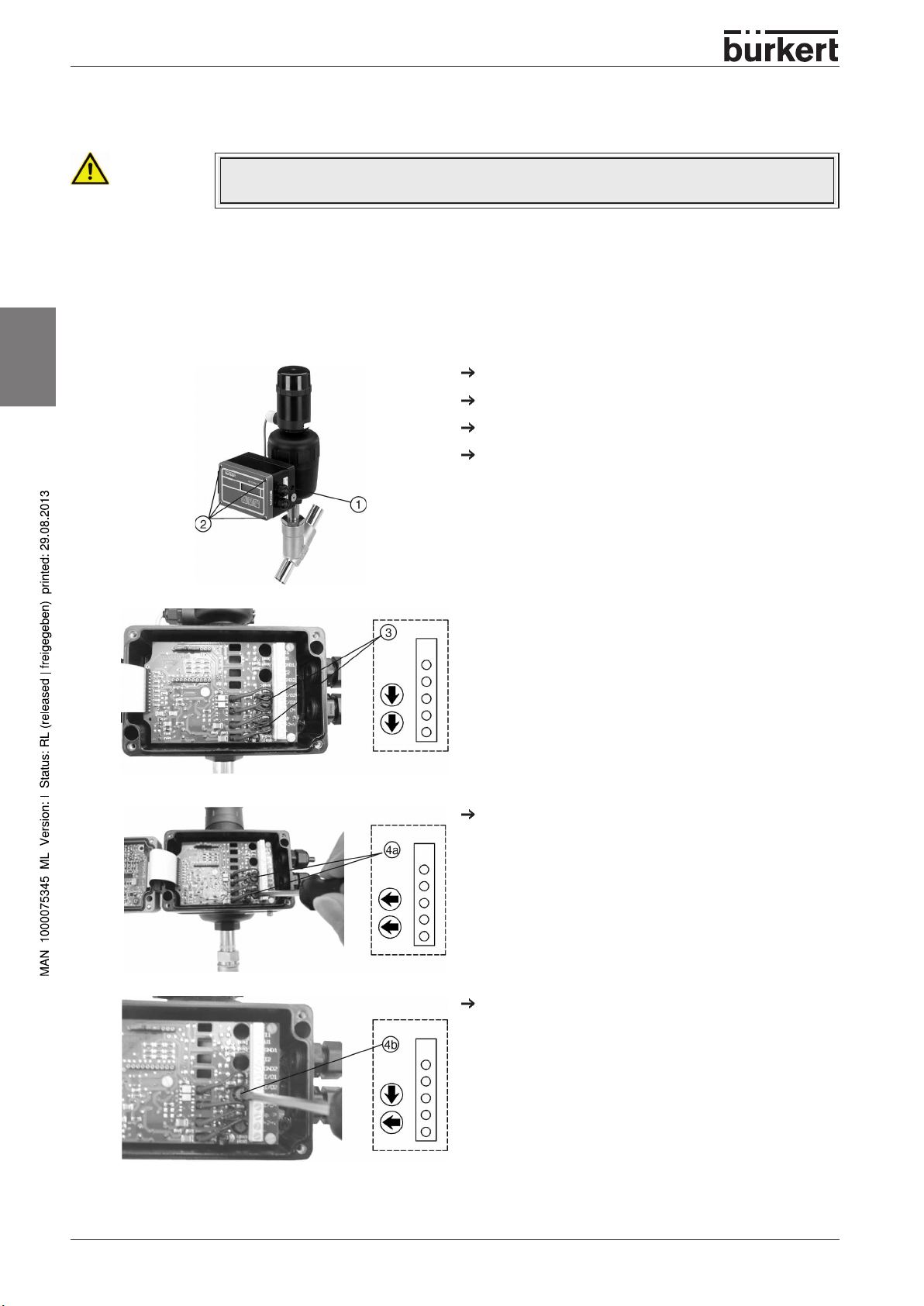

Remove the valve body from the piston actuator.

The plug is now in the upper position.

This means the gasket will not be damaged.

Weld the valve body.

Clean the valve body carefully.

plug

RECOMMENDATION

Mount the valve body with a new sealing ring between the valve body and the piston actuator.

Turn the lower switch back into the idle position.

The piston actuator is bled and the spring closes the

valve.

NOTE

16 - 2702

This procedure causes air to be trapped under the spring-loaded piston.

Normally the air will escape slowly.

After 10 hours, however, this procedure should be completed.

Page 17

PNEUMATIC INSTALLATION FOR TOPCONTROL TYPE 8630

The control valve is driven by compressed air via the TopControl.

Remove the protective caps from the connectors on the TopControl and the valve.

Apply the supply pressure to port ”1”.

The supply pressure necessary for complete opening or closing of the valve may lie between the minimum

values of 3 and 6 bar, depending on the actuator. The permissible maximum value for the control pressure is

7 bar. The values for the pressure supply are given under p

Attach the exhaust line or silencer to port ”3”.

on the rating plate of each control valve.

Pilot

Commissioning

Control medium: instrument air, class 3 to DIN ISO 8573-1

Fluid connections of the TopControl Continuous

Remove the protective caps from the valve

and the TOPControl Continuous.

Apply the supply pressure to connection “1“

(3..7 bar, instrument air, free from oil, water

and dust)

Attach the exhaust line or silencer to

connection „3“

english

NOTE

Maintain the applied supply pressure, without fail, at least 0.5 - 1 bar over that required to

bring the pneumatic actuator into the end position. This assures that the control behaviour in

the upper region of the stroke will not be significantly affected negatively if the pressure difference is too small.

Keep variations in the supply pressure as low as possible during operation (max. ± 10%).

With larger variations, the controller parameters calibrated with the AUTOTUNE function will

not be optimal.

2702 - 17

Page 18

Commissioning

ELECTRICAL CONNECTION - MULTIPOLE CONNECTORS

(TOPCONTROL TYPE 8630)

ATTENTION!

NOTE

english

For connection to the technical earth (ground) (TE), a threaded stud with nut is provided on

the connection module. To assure electromagnetic compatibility (EMC), connect this stud to

a suitable earthing (grounding) point using as short a cable as possible (max. 30 cm).

Use of the 4 - 20 mA setpoint input

If the voltage supply of a TOPControl device fails in a row of such devices connected in

series, the input of the failed device will become high-impedance. This will cause the 4 -

20 mA standard signal to fail. If this occurs, please contact Bürkert Service directly.

With Profibus DP or DeviceNet:

The markings of the multipole plugs and sockets, and the contacts are to be found in the

respective chapters.

Marking of the multipole plugs or sockets and the contacts

M16

M12

M8

Output signals

to SPS

M8

Operating voltage

18 - 2702

TE

Process value Initiators (inductive proximity switches)

Page 19

Output signals for SPS (circular plug M 16)

PIN Allocation External connection/signal level

A

Setpoint GND

B

Setpoint + (0/4..20 mA or 0..5/10 V)

C

Analog position feedback +

D

Analog position feedback GND

E

Binary output 1

F

Binary output 2

G

Binary output GND

H

Binary input +

J

Binary input GND

K

not connected

L

not connected

B

A

C

D

E

F

G

H

J

+ (0/4...20 mA or 0..5/10 V)

completely isolated electrically

GND

+ (0/4...20 mA or 0...5/10 V)

completely isolated electrically

GND

24 V / 0 V

24 V / 0 V

24 V / 0 V

+ 0 ... 5 V (log. 0)

10 ... 30 V (log. 1)

GND

Commissioning

english

M

not connected

Operating voltage (circular plug M 12)

PIN Allocation External connection

1

2

3

4

+ 24 V

not connected

GND

not connected

1

3

24 V DC ± 10 %

max. residual ripple 10 %

Inductive proximity switches (circular socket M8)

PIN Allocation Signal level

1

Proximity switch 1 +(NO)

2

Proximity switch 1 GND

3

Proximity switch 2 +(NO)

4

Proximity switch 2 GND

+24 V DC

GND

+24 V DC

GND

S1

1

2

open / 24 V

GND

S2

3

4

open / 24 V

GND

2702 - 19

Page 20

Commissioning

Process value (circular plug M 8)

Input type * PIN Allocation Jumper ** External connection

4 ... 20 mA

- internal

supply

1

+ 24 V supply transmitter

2

Output transmitter

3

GND

4

bridge to GND

english

4 ... 20 mA

- external

supply

Frequency

- internal

supply

Frequency

- external

supply

Pt-100

(see note

below)

1

not connected

2

Process actual +

3

not connected

4

Process actual -

1

+ 24 V - supply sensor

2

Clock input +

3

Clock input - (GND)

4

not connected

1

not connected

2

Clock input +

3

Clock input -

4

not connected

1

not connected

2

process actual 1 (current supply)

3

process actual 3 (GND)

4

process actual 2 (compensation)

2

4

1

2

3

2

3

2

3

4

4 ... 20 mA

GND

+24 V

Clock +

Clock -

Clock +

Clock -

Pt 100

* May be set via software (section Procedure for specifying the basic settings)

** The jumper is situated on the connection board of the TOPControl Continuous (see next

page)

NOTE

For line compensation reasons, connect sensor Pt-100 via 3 conductors. PIN 3 and PIN 4 must

be bridged at the sensor.

20 - 2702

Page 21

Commissioning

ELECTRICAL CONNECTION - TERMINALS FOR CABLE BUSHING

(TOPCONTROL TYPE 8630)

ATTENTION!

NOTE

For connection to the technical earth (ground) (TE), a threaded stud with nut is provided

on the connection module. To assure electromagnetic compatibility (EMC), connect this

stud to a suitable earthing (grounding) point using as short a cable as possible

(max. 30 cm).

Use of the 4 - 20 mA setpoint input

If the voltage supply of a TOPControl Continuous device fails in a row of such devices connected in series, the input of the failed device will become high-impedance. This will cause the

4 - 20 mA standard signal to fail. If this occurs, please contact Bürkert Service directly.

Connection PCB of the TOPControl Continuous with screw terminals and

jumpers

english

Remove the cover with the cable bushings to gain access

to the screw terminals. This is done by unscrewing the

4 self-tapping screws.

Terminal configuration with cable bushings

Terminal Allocation External connection

1

2

3

4

5

6

Setpoint +

Setpoint GND

Analog position feedback +

Analog position feedback GND

Operating voltage +

Operating voltage GND

1

2

3

4

5

6

+ (0/4 ... 20 mA or 0 ... 5/10 V)

GND

+ (0/4 ... 20 mA or 0 ... 5/10 V)

completely isolated electrically

GND

24 V DC ± 10 %

max. residual ripple 10 %

2702 - 21

Page 22

Commissioning

Choice of binary outputs or process value input

Select using the jumpers:

2 binary outputs (see terminal Allocation when binary outputs selected) or

Process value input (see terminal Allocation when process value input selected)

Terminals 7 to 10 are connected to the corresponding signals.

Terminal allocation on selection of binary outputs

Jumper Terminal Allocation External connection

english

7

8

9

10

Terminal allocation on selection of process value input:

The input type is set via the configuration menu (see Procedure for specifying the basic settings).

Binary output 1

Binary output 1

Binary output 2

Binary output 2

10

7

8

9

24 V / 0 V NC / NO

GND

24 V / 0 V NC / NO

GND

Input type* Jumper Termianl Allocation External connection

10

10

10

7

8

9

7

8

9

8

9

8

8

9

4 ... 20 mA

internal

supply

Frequency

internal

supply

4 ... 20 mA

external

supply

Frequency

external

supply

Pt-100

(see

note

below)

10

10

10

10

10

7

8

9

7

8

9

7

8

9

7

8

9

7

8

9

+ 24 V input transmitter

Output transmitter

Brigde to GND

GND

+ 24 V supply sensor

Clock input +

not connected

Clock input - (GND)

not connected

Process actual +

Process actual not connected

not connected

Clock input +

not connected

Clock input -

not connected

Process actual 1 (current supply)

Process actual 2 (compensation)

Process actual 3 (GND)

+24 V

Clock +

Clock - (GND)

+ (4 ... 20 mA)

Clock - (GND)

Clock +

Clock - (GND)

Pt-100

NOTE

For reasons of line compensation, connect the Pt 100 sensor over 3 conductors.

Be sure to bridge terminals 9 and 10 at the sensor.

Terminal allocation with binary outputs

Terminal Allocation External connection

11 12Binary input +

Binary input GND

22 - 2702

11

12

+ 0 ... 5 V (log. 0)

10 ... 30 V (log. 1)

GND

Page 23

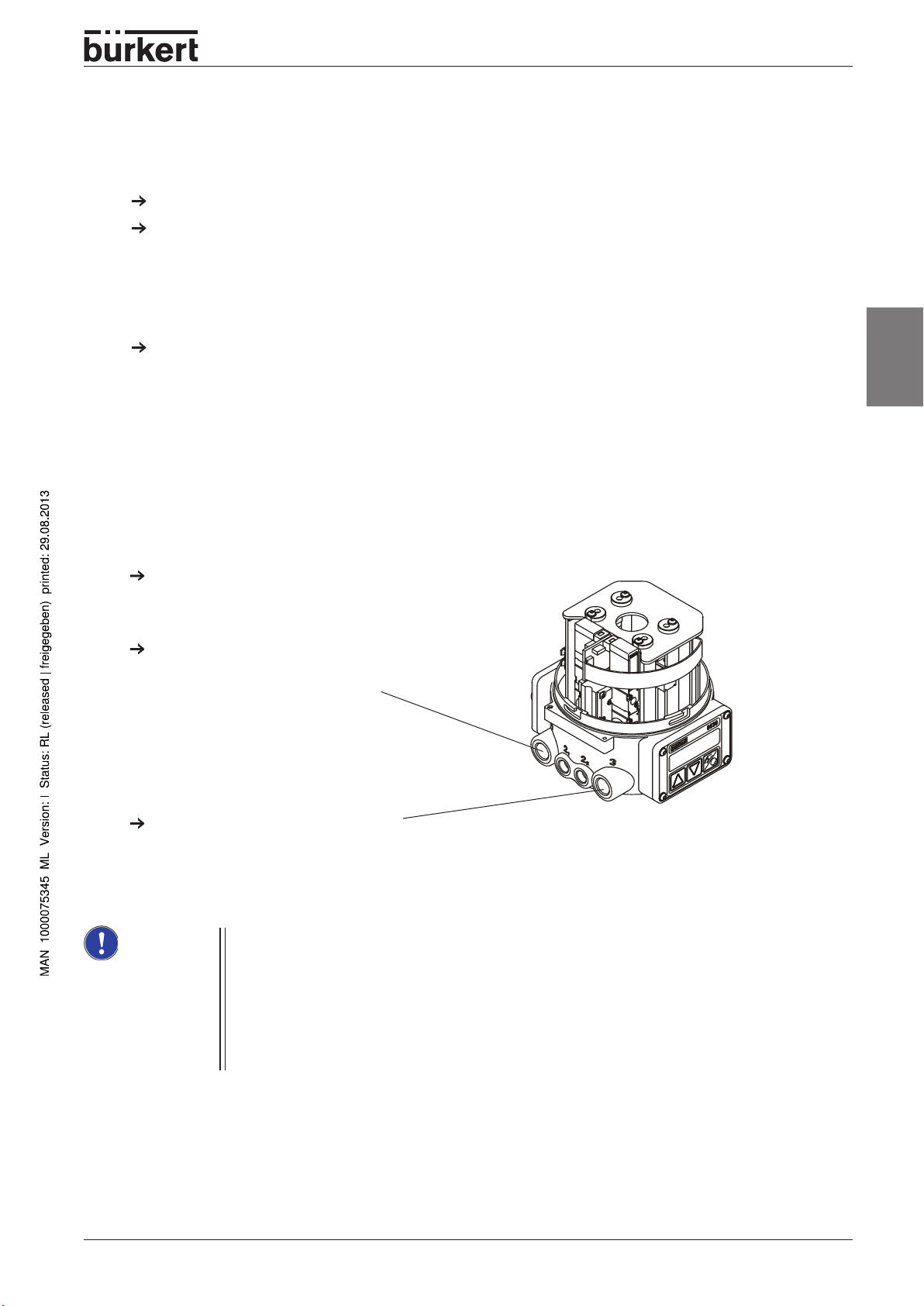

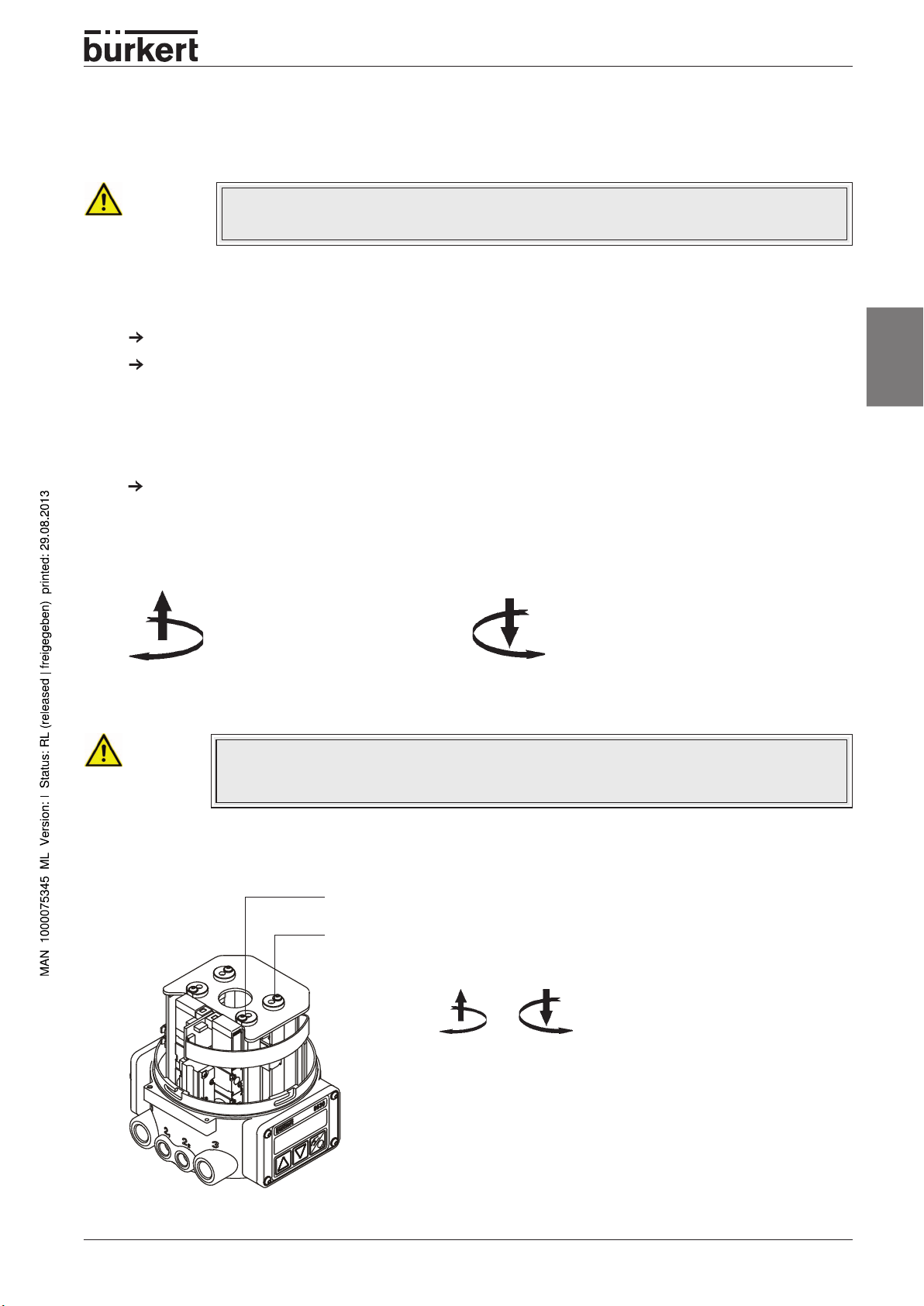

SETTING THE INDUCTIVE PROXIMITY SWITCHES

(OPTION FOR TOPCONTROL TYPE 8630)

Commissioning

CAUTION!

Danger of injury from electrical voltage in the open TopControl.

Switch the operating power off to the TopControl before opening!

Opening the housing of the TOPControl Continuous

Remove any lead seals or fastenings present between cover and housing.

Turn the cover anticlockwise and lift it off.

Positioning the inductive proximity switches

The inductive proximity switches are positioned vertically with one adjusting screw each:

Turning clockwise

causes upward adjustment

Turning anticlockwise

causes downward adjustment

english

CAUTION!

Caution! Plug connectors may be damaged or loosened.

Plug connectors may be damaged or loosened.

On adjusting the height of the inductive proximity switches, make sure that adjacent flexes

are not pulled (e.g. by getting hooked in the proximity switches).

Screw to adjust the lower proximity switch

Screw to adjust the upper proximity switch

2702 - 23

Page 24

Commissioning

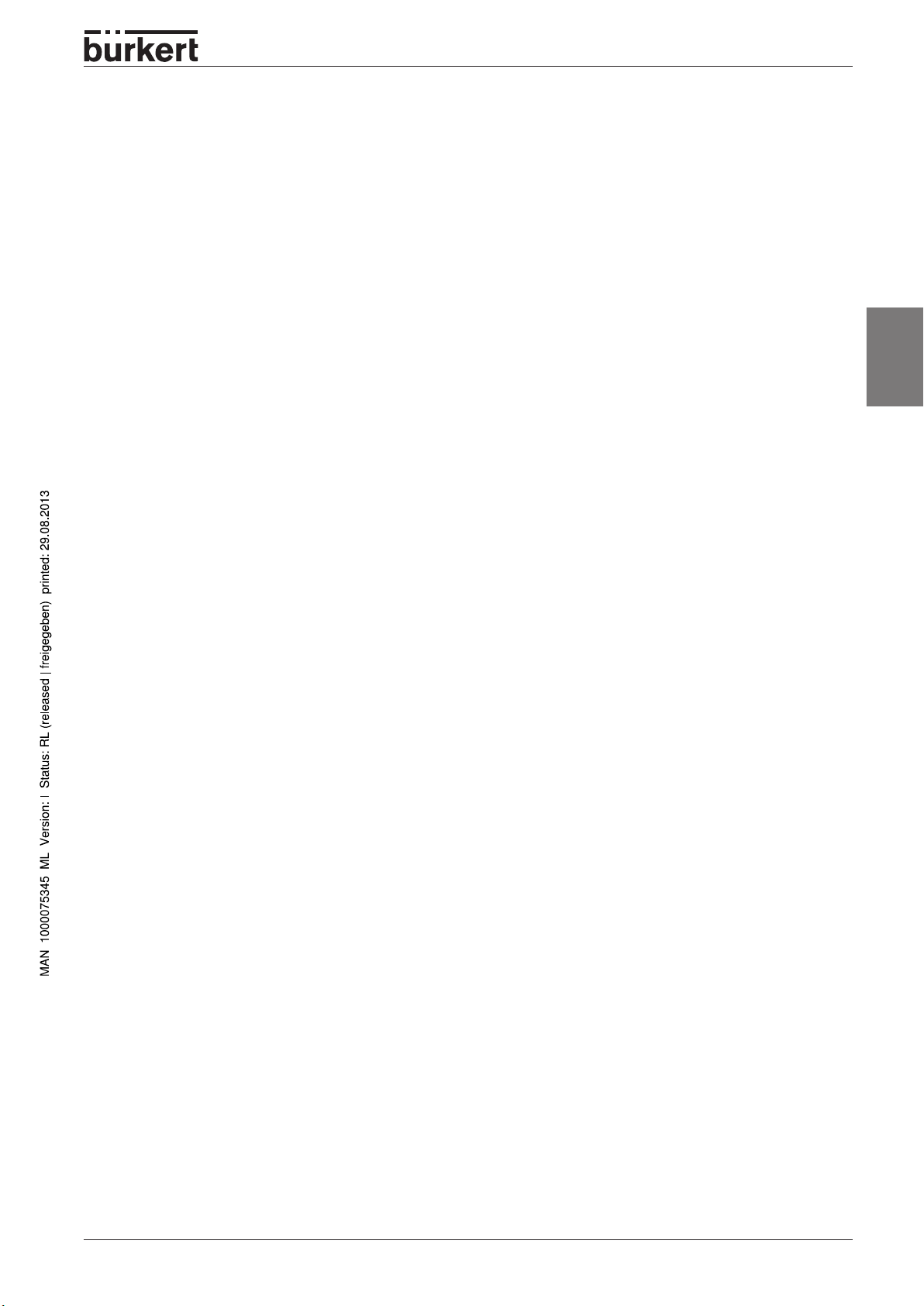

ELECTRICAL CONNECTION - TERMINAL FOR CABLE BUSHING

(SIDECONTROL TYPE 1067)

Pin assignment

Signal input

Jumper position

english

- either for target position

(operation as positional control)

- or for process target value

(operation as process controller)

- input for actual process value

Binary input

Contact

Output

(Option)

Suppply voltage

Input U1 (Unit signal 0 ... 10 V) Input impedance 200 kW

Input I1 (Unit signal 0/4 ... 20 mA) Input impedance > 175 W

Input I2 (Unit signal 4 ... 20 mA) Input impedance > 175 W

ATTENTION!

To ensure electromagnetic compatibility (EMC resistance), the interior M4 threading of the

armature must be connected to ground with the shortest possible cable.

24 - 2702

M4-internal thread

Page 25

Maintenance and Servicing of the valve

Maintenance and servicing of the valve

FAULTS .......................................................................................................................................................................... 26

REPLACEMENT OF THE PLUG WITH TOPControl TYPE 8630 .................................................. 26

Demounting the actuator .............................................................................................................................................26

Replacement of the plug .............................................................................................................................................27

Mounting the actuator ..................................................................................................................................................27

REPLACEMENT OF THE PLUG WITH SIDEControl TYPE 1067 ................................................ 28

Demounting the actuator .............................................................................................................................................28

Replacement of the plug .............................................................................................................................................29

Mounting the actuator ..................................................................................................................................................30

SPARE PARTS SETS TYPE 2702 ..................................................................................................................... 31

english

2702 - 25

Page 26

Maintenance and Servicing of the valve

FAULTS

Possible problems with control are listed in the operating manual of the TopControl.

ATTENTION!

Repairs to the actuator may only be carried out in the factory. Contact your Bürkert branch

or ourCustomer Service directly:

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: +49 (07940) 10 91-111

Fax: +49 (07940) 10 91-448

E-Mail: info@de.buerkert.com

english

REPLACEMENT OF THE PLUG WITH TOPControl TYPE 8630

CAUTION!

On the fluidic side is it possible to exchange the plug if it becomes worn or damaged. For this purpose the

actuator must be disassembled from the valve body.

Use of the incorrect lubricant causes contamination!

For special applications such as for oxygen and analysis, use only the approved lubricants.

Demounting the actuator

→ Remove the electrical and pneumatic supplies from the TopControl.

→ Pull off the pneumatic hose between TopControl and actuator at control

connection of actuator

Control function A:

→ Pressurize the lower pilot air of the actuator with compressed air

(6 bar), so that the plug is lifted from the valve seat and is not

damaged.

Control function B:

→ With control function B, no compressed air must be applied for this

purpose.

→ Remove the actuator in the open valve position by unscrewing the nipple

from the valve body.

threaded nipple

26 - 2702

Page 27

Replacement of the plug

Maintenance and Servicing of the valve

ATTENTION!

→ Knock out the dowel pin with a suitable driver.

Driver diameter:

up to DN 32 ∅ 4 mm

from DN 40 ∅ 5 mm

→ Pull off the plug with aid of two metal strips of equal height that are clam-

ped to the left and right of the spindle between the plug and the threaded

nipple of the actuator. To pull off the plug, apply compressed air (approx. 6

bar) to the lower pilot air port of the actuator.

→ Push the new plug over the end of the spindle.

→ Align the bores.

Do not damage the sealing surface or the control contour!

Mounting the actuator

→ Support the plug at its cylindrical part with the aid of a V-block or the like.

→ Carefully knock the dowel pin into the bore with a hammer.

Dowel pin

english

Plug

→ Bring the dowel pin into a central position relative to the spindle axis (knock in as far as the end of the

recess).

→ Before reinstalling the actuator, grease the nipple thread with stainless steel lubricant, e.g.Klüberpaste

UH1 96-402 from company Klüber and replace the graphite seal.*

→ After tightening the threaded nipple, orient the control connection by turning the actuator.*

ATTENTION!

* The valve must be for this in the opened position.

2702 - 27

Page 28

Maintenance and Servicing of the valve

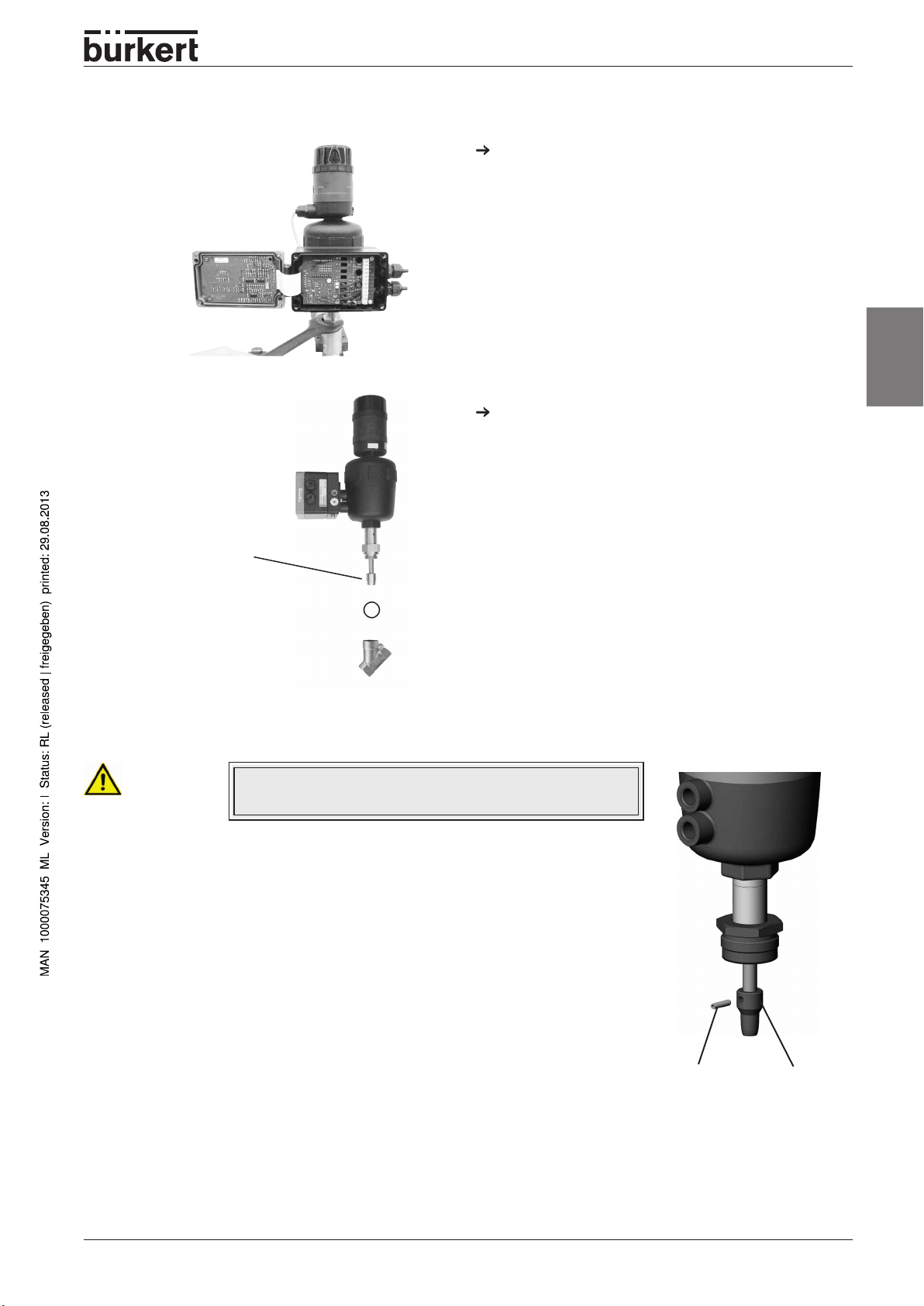

REPLACEMENT OF THE PLUG WITH SIDEControl TYPE 1067

CAUTION!

Use of the incorrect lubricant causes contamination!

For special applications such as for oxygen and analysis, use only the approved lubricants.

Demounting the actuator

Dismount the piston actuator as described below. You will avoid damage to the gaskets because the piston

will be brought into the upper position.

english

Connect compressed air at 4.5 to 6 bar to P (1).

Remove the blowout mouthpiece.

Unscrew the 4 screws.

Open the cover (2).

The 2 red switches for emergency manual actuation (3)

are located next to the terminal strip.

They are in the idle position when the arrow is parallel to

the terminal strip.

Turn the 2 switches carefully 90 degrees in the

clockwise direction (in either order) (4a).

The piston moves into the upper position and the plug is

separated from the valve seat.

Turn only the upper switch to the idle position (4b).

The piston stays in the upper position even after the

compressed air is switched off.

28 - 2702

Page 29

Maintenance and Servicing of the valve

Remove the valve body from the piston actuator.

The plug is now in the upper position.

This means the gasket will not be damaged.

Weld the valve body.

english

Plug

Replacement of the plug

ATTENTION!

→ Knock out the dowel pin with a suitable driver.

Driver diameter:

up to DN 32 ∅ 4 mm

from DN 40 ∅ 5 mm

→ Pull off the plug with aid of two metal strips of equal height that are clam-

ped to the left and right of the spindle between the plug and the threaded

nipple of the actuator. To pull off the plug, apply compressed air (approx. 6

bar) to the lower pilot air port of the actuator.

Do not damage the sealing surface or the control contour

at the plug!

→ Push the new plug over the end of the spindle.

→ Align the bores.

Dowel pin

Plug

2702 - 29

Page 30

Maintenance and Servicing of the valve

Mounting the actuator

Mount the valve body with a new sealing ring bet-

ween the valve body and the piston

actuator.

english

NOTE

plug

Turn the lower switch back into the idle position.

The piston actuator is bled and the spring closes the

valve.

This procedure causes air to be trapped under the spring-loaded piston.

Normally the air will escape slowly.

After 10 hours, however, this procedure should be completed.

30 - 2702

Page 31

MAINTENANCE AND SERVICING OF THE VALVE

SPARE PART SETS FOR TYPE 2702 STANDARD VERSION

Angle seat control valve

Plug set

english

WARNING!

Plug set 6

Contains: Plug, dowel pin, graphite seal, lubricant

Danger due to spraying of fluids under high pressure!

Always interrupt the medium flow before disassembling or opening the device, and let off

the pressure in the hose system.

DN PTFE - steel

15 170315 170322

20 170316 170323

25 170318 170324

32 170319 170325

40 170320 170326

50 170321 170327

Order no.

steel - steel

Order no.

2702 - 31

Page 32

Maintenance and Servicing of the valve

NOTE

english

Spare parts sets for special versions are available on request

(e.g. oxygen or analysis versions, etc.).

32 - 2702

Page 33

Inhalt

Inhaltsverzeichnis Typ 2702

Allgemeine Hinweise ...................................................................................................................................... 35

Darstellungsmittel .........................................................................................................................................................36

Bestimmungsgemäßer Gebrauch .............................................................................................................................36

Allgemeine Sicherheitshinweise ................................................................................................................................36

Kontaktadressen ............................................................................................................................................................37

Gewährleistung .............................................................................................................................................................37

Transport und Lagerung ..............................................................................................................................................37

Entsorgung .....................................................................................................................................................................38

deutsch

Informationen im Internet .............................................................................................................................................38

TecHniscHe DATen ............................................................................................................................................ 39

Aufbau des Regelventils ..............................................................................................................................................40

Medien .............................................................................................................................................................................40

Kv-Werte ........................................................................................................................................................................41

inbeTriebnAHme .................................................................................................................................................. 43

Einbau des Ventils ........................................................................................................................................................44

Vorgehensweise bei TopConrol Typ 8630 ..................................................................................................44

Vorgehensweise bei SideControl Typ 1067 ...............................................................................................45

Pneumatische Installation bei TopControl Typ 8630 ..........................................................................................47

Fluidische Anschlüsse des TopControl Continuous ................................................................................47

Elektrischer Anschluss - Multipolstecker (TopControl Typ 8630) ....................................................................48

Bezeichnung der Multipolstecker bzw. -buchsen und der Kontakte .....................................................48

Ausgangssignale zur SPS ( Rundstecker M 16) ........................................................................................49

Betriebsspannung (Rundstecker M 12) .......................................................................................................49

Induktive Näherungsschalter (Buchse rund M 8) .......................................................................................49

Prozess-Istwert (Rundstecker M 8) ...............................................................................................................50

2702 - 33

Page 34

Inhalt

Elektrischer Anschluss - Klemmen für Kabelverschraubung (TopControl Typ 8630) ..................................51

Anschlussplatine des TOP Control Continuous mit Schraubklemmen und Jumpern .......................51

Klemmenbelegung bei Kabelverschraubung ...............................................................................................51

Auswahl zwischen binären Ausgängen und Prozess-Istwert-Eingang .................................................52

Einstellen der induktiven Näherungsschalter (Option bei TopControlTyp 8630) ..........................................53

Öffnen des TOP Control Continuous-Gehäuses .......................................................................................53

Positionieren der induktiven Näherungsschalter ........................................................................................53

Elektrischer Anschluss - Klemmen für Kabelverschraubung (SideControl Typ 1067) ................................54

Anschlussbelegung ...........................................................................................................................................54

insTAnDHAlTung unD wArTung Des VenTils ............................................................................. 55

deutsch

Störungen .......................................................................................................................................................................56

Austausch des Regelkegels bei TopControl Typ 8630 .......................................................................................56

Demontage des Antriebs .................................................................................................................................56

Austausch des Regelkegels ............................................................................................................................57

Montage des Antriebs ......................................................................................................................................57

Austausch des Regelkegels bei SideControl Typ 1067 .....................................................................................58

Demontage des Antriebs .................................................................................................................................58

Austausch des Regelkegels ............................................................................................................................59

Montage des Antriebs ......................................................................................................................................60

Ersatzteilsätze für Standardgeräte Typ 2702 .........................................................................................................61

34 - 2702

Page 35

Allgemeine Hinweise

Allgemeine Hinweise

DARSTELLUNGSMITTEL ...................................................................................................................................... 36

BESTIMMUNGSGEMÄSSER GEBRAUCH .................................................................................................. 36

ALLGEMEINE SICHERHEITSHINWEISE ....................................................................................................... 36

KONTAKTADRESSEN ............................................................................................................................................. 37

deutsch

GEWÄHRLEISTUNG ................................................................................................................................................ 37

TRANSPORT UND LAGERUNG ......................................................................................................................... 37

ENTSORGUNG .......................................................................................................................................................... 38

INFORMATIONEN IM INTERNET ...................................................................................................................... 38

2702 - 35

Page 36

Allgemeine Hinweise

DARSTELLUNGSMITTEL

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen

GEFAHR!

WARNUNG!

VORSICHT!

deutsch

ACHTUNG!

HINWEIS

bezeichnet eine unmittelbare drohende Gefahr. Wenn sie nicht gemieden wird, sind Tod

oder schwerste Verletzungen (Verkrüppelung) die Folge.

bezeichnet eine möglicherweise gefährliche Situation. Wenn sie nicht gemieden wird, können Tod oder schwerste Verletzungen die Folge sein.

bezeichnet eine möglicherweise gefährliche Situation. Wenn sie nicht gemieden wird, können leichte oder geringfügige Verletzungen die Folge sein. Darf auch für Warnungen vor

Sachschäden verwendet werden.

bezeichnet eine möglicherweise schädliche Situation. Wenn sie nicht gemieden wird, kann

das Produkt oder etwas in seiner Umgebung beschädigt werden.

bezeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen

BESTIMMUNGSGEMÄSSER GEBRAUCH

Das Gerät darf nur in Verbindung mit von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten und

–komponenten verwendet werden.

Der einwandfreie und sichere Betrieb des Produktes setzt sachgemäßen Transport, sachgemäße Lagerung,

Aufstellung und Montage sowie sorgfältige Bedienung und Instandhaltung voraus.

Bitte beachten Sie die Hinweise dieser Anleitung sowie die Einsatzbedingungen und zulässigen Daten, die

im Kapitel "Technische Daten" spezifiziert sind, damit das Gerät einwandfrei funktioniert und lange einsatzfähig bleibt.

Bei Nichtbeachtung dieser Hinweise sowie bei unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung

unsererseits, ebenso erlischt die Garantie auf Geräte u. Zubehörteile!

Das Gerät dient ausschließlich als Prozessregelventil. Eine andere oder darüber hinausgehende Benutzung

gilt als nicht bestimmungsgemäß. Für hieraus resultierende Schäden haftet Bürkert nicht. Das Risiko trägt

allein der Anwender.

ALLGEMEINE SICHERHEITSHINWEISE

GEFAHR!

WARNUNG!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Beachten Sie, dass in Systemen, die unter Druck stehen, Leitungen und Ventile nicht

gelöst werden dürfen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen während

des Betriebs, der Wartung und der Reparatur des Gerätes!

36 - 2702

Page 37

Allgemeine Hinweise

ACHTUNG!

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen

Regeln der Technik!

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem

Werkzeug erfolgen!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige

Beeinträchtigung auszuschließen!

• Gewährleisten Sie nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung einen definierten und kontrollierten Wiederanlauf des Prozesses!

• Beachten Sie zum elektrischen Teil die Sicherheitshinweise in der Bedienungsanleitung

des TopControl, SideControl.

• Bei Nichtbeachtung dieser Bedinungsanleitung und ihrer Hinweise sowie bei unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die

Garantie auf Geräte und Zubehörteile!

KONTAKTADRESSEN

Deutschland

Bürkert Fluid Control System

Sales Center

deutsch

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: +49 (0) 7940 10 91-111

Fax: +49 (0) 7940 10 91-448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.buerkert.com

GEWÄHRLEISTUNG

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung

der spezifizierten Einsatzbedingungen.

ACHTUNG!

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit des gelieferten Ventils Typ

2702 mit pneumatischem Antrieb und des TopControl oder SideControl. Für Folgeschäden jeglicher Art, die durch Ausfall oder Fehlfunktion des Gerätes entstehen könnten, wird

keine Haftung übernommen.

TRANSPORT UND LAGERUNG

HINWEIS

Transportieren und lagern Sie das Gerät nur in der Originalverpackung.

Lagertemperatur -10 °C ... +60 °C

2702 - 37

Page 38

Allgemeine Hinweise

ENTSORGUNG

VORSICHT!

Gefahr für die Umwelt!

Beachten Sie bei der Entsorgung des Gerätes die nationalen Abfallbeseitigungsvorschriften.

INFORMATIONEN IM INTERNET

Bedienungsanleitungen und Datenblätter zum Typ 2702 finden Sie im Internet unter:

www.buerkert.com → Dokumentation

deutsch

38 - 2702

Page 39

Technische DaTen

Technische Daten

AufbAu des Regelventils .......................................................................................................................... 40

Medien ......................................................................................................................................................................... 40

Kv-WeRte .................................................................................................................................................................. 41

deutsch

2702 - 39

Page 40

TECHNISCHE DATEN

AUFBAU DES REGELVENTILS

2/2-Wege-Kolbensteuerventil mit Regelkegel und Schrägsitzgehäuse

Steuerfunktion A

(in Ruhestellung durch Federkraft geschlossen)

Steuerfunktion B (in Ruhestellung geöffnet)

Antriebswerkstoff: PA (Polyamid) oder PPS

Gehäusewerkstoff: Edelstahl 316L

hcstued

MEDIEN

Dichtwerkstoffe: Stahl/Stahl (1.4571) oder PTFE/Stahl

Flüssige und gasförmige Medien, die den Gehäuse- und Dichtwerkstoff nicht angreifen.

Steuermedium Qualitätsklassen nach DIN ISO 8573-1

Staubgehalt Klasse 5: Max. Teilchengröße 40 µm; max. Teilchendichte 10 mg/m

Wassergehalt Klasse 3: Max. Drucktaupunkt -20 °C, oder min. 10 Grad unterhalb

der niedrigsten Betriebstemperatur

3

Ölgehalt Klasse 5: Max. 25 mg/m

Klasse 3: Max. 1 mg/m

Hinweis: Bei höheren Anforderungen des Positioners sind diese zu beachten!

HINWEIS

Den zugelassenen Betriebsdruck und die Mediumstemperatur entnehmen Sie dem Typschild

und den folgenden Tabellen. Hinsichtlich der zulässigen Sitzleckage werden die in der DIN

EN 1349 angegebenen Werte eingehalten, wobei für die Stahl/Stahl-Abdichtung die Leckageklasse IV und für die PTFE/Stahl-Adichtung die Leckageklasse VI zutrifft.

in Verbindung mit Bürkert Positionern

3

in Verbindung mit SIDE Control Typ 8635

3

Steuerdruck

Mediumsdruck

40 - 2702

Antriebsgröße 80 (F) 5,5 - 10 bar

Antriebsgröße 100 (G) 5,5 - 7 bar

Antriebsgröße F DN 15 0 - 16 bar

Antriebsgröße F DN 20 0 - 16 bar

Antriebsgröße F DN 25 0 - 16 bar

Antriebsgröße F DN 32 0 - 15 bar

Antriebsgröße G DN 40 0 - 12,5 bar

Antriebsgröße G DN 50 0 - 7,2 bar

Page 41

KV-WERTE

Typ 2702 DN 15

Hub % Hub [mm] Kv [m3/h]

5 0,6 0,23

10 1,2 0,24

20 2,4 0,26

30 3,6 0,35

40 4,8 0,7

50 6,0 1,85

60 7,2 2,9

70 8,4 3,5

80 9,6 4,0

90 10,8 4,3

100 12,0 4,5

TECHNISCHE DATEN

Hub %

Typ 2702 DN 20

Hub % Hub [mm] Kv [m3/h]

5 0,9 0,30

10 1,8 0,33

20 3,6 0,42

30 5,4 0,7

40 7,2 2,85

50 9,0 5,3

60 10,8 6,6

70 12,6 7,5

80 14,4 8,2

90 16,2 8,6

100 18,0 9,0

Typ 2702 DN 25

Hub % Hub [mm] Kv [m3/h]

5 1,0 0,39

10 2,0 0,41

20 4,0 0,60

30 6,0 1,25

40 8,0 4,5

50 10,0 8,5

60 12,0 10,5

70 14,0 12,2

80 16,0 13,5

90 18,0 14,2

100 20,0 15,0

deutsch

Hub %

Hub %

2702 - 41

Page 42

Technische DaTen

typ 2702 dn 32

Hub % Hub [mm] Kv [m3/h]

5 1,0 0,55

10 2,0 0,65

20 4,0 0,95

30 6,0 1,5

40 8,0 4,0

50 10,0 9,3

60 12,0 13,8

70 14,0 16,5

80 16,0 18,8

90 18,0 21,0

100 20,0 23,0

Hub %

deutsch

typ 2702 dn 40

Hub % Hub [mm] Kv [m3/h]

typ 2702 dn 50

Hub % Hub [mm] Kv [m3/h]

5 1,3 0,65

10 2,6 0,85

20 5,2 1,5

30 7, 8 5,0

40 10,4 14,0

50 13,0 20,0

60 15,6 25,0

70 18,2 27,0

80 20,8 30,0

90 23,4 33,0

100 26,0 35,0

Hub %

5 1,3 1,0

10 2,6 1,3

20 5,2 2,0

30 7, 8 5,0

40 10,4 16,0

50 13,0 27,0

60 15,6 34,0

70 18,2 41,0

80 20,8 45,0

90 23,4 49,0

100 26,0 53,0

42 - 2702

Hub %

Page 43

InbetrIebnahme

Inbetriebnahme

EINBAU DES VENTILS .......................................................................................................................................... 44

Vorgehensweise bei TopConrol Typ 8630 .............................................................................................................44

Vorgehensweise bei SideControl Typ 1067 ..........................................................................................................45

PNEUMATISCHE INSTALLATION BEI TOPCONTROL TYP 8630 ...............................................47

Fluidische Anschlüsse des TopControl Continuous ...........................................................................................47

ELEKTRISCHER ANSCHLUSS - MULTIPOLSTECKER (TOPCONTROL TYP 8630) ............... 48

Bezeichnung der Multipolstecker bzw. -buchsen und der Kontakte .................................................................48

Ausgangssignale zur SPS ( Rundstecker M 16) ...................................................................................................49

Betriebsspannung (Rundstecker M 12) ..................................................................................................................49

Induktive Näherungsschalter (Buchse rund M 8) ..................................................................................................49

Prozess-Istwert (Rundstecker M 8) ..........................................................................................................................50

ELEKTRISCHER ANSCHLUSS - KLEMMEN FÜR KABELVERSCHRAUBUNG

(TOPCONTROL TYP 8630)................................................................................................................................... 51

Anschlussplatine des TOPControl Continuous mit Schraubklemmen und Jumpern ....................................51

Klemmenbelegung bei Kabelverschraubung ..........................................................................................................51

Auswahl zwischen binären Ausgängen und Prozess-Istwert-Eingang ............................................................52

EINSTELLEN DER INDUKTIVEN NÄHERUNGSSCHALTER

(OPTION BEI TOPCONTROLTYP 8630) ....................................................................................................... 53

Öffnen des TOP Control Continuous-Gehäuses ..................................................................................................53

deutsch

Positionieren der induktiven Näherungsschalter....................................................................................................53

ELEKTRISCHER ANSCHLUSS - KLEMMEN FÜR KABELVERSCHRAUBUNG

(SIDECONTROL TYP 1067) ................................................................................................................................. 54

Anschlussbelegung ......................................................................................................................................................54

2702 - 43

Page 44

InbetrIebnahme

EINBAU DES VENTILS

VORSICHT!

Einbaulage beliebig, bevorzugt Antrieb nach oben.

Beachten Sie die Durchflußrichtung! Bei Regelventilen gilt generell: Anströmung unter Sitz!

Säubern Sie die Rohrleitungen von Verunreinigungen!

Achten Sie vor Anschluß des Ventilgehäuses auf fluchtende Rohrleitungen!

Entfernen Sie bei Schweißgehäusen den Antrieb unbedingt vor dem Einschweißen des Gehäuses.

Falscher Schmierstoff verursacht Verunreinigungen!

Verwenden Sie bei spezifischen Anwendungen, z.B. Sauerstoff- oder Analyseanwendungen nur zugelassene Schmierstoffe.

Vorgehensweise bei TopControl Typ 8630

1. Entfernen Sie die elektrische u. pneumatische Versorgung

vom TopControl.

deutsch

2. Ziehen Sie den Pneumatikschlauch zwischen TopControl

und Antrieb am Steueranschluß des Antriebes ab.

3. Steuerfunktion A:

Beaufschlagen Sie den unteren Steueranschluß des Antrie-

bes mit Druckluft (6 bar), damit der Regelkegel vom Ventil-

sitz abhebt und nicht beschädigt wird.

Top Control

Antrieb

unterer

Steueranschluss

GewindeNippel

Steuerfunktion B:

Bei Steuerfunktion B muss keine Druckluft angelegt werden.

4. Entfernen Sie den Antrieb in offener Ventilstellung durch Los-

schrauben des Nippels vom Gehäuse.

5. Fetten Sie vor Wiedereinbau des Antriebes (in offener Ventil-

stellung) das Nippelgewinde mit Edelstahlschmierstoff ein,

z.B. Klüberpaste UH1 96 - 402 der Firma Klüber.

6. Erneuern Sie die Graphitdichtung.

7. Richten Sie nach Festziehen des Gewindenippels die Steueranschlüsse durch Verdrehen des Antriebes aus.

ACHTUNG!

HINWEIS

Das Ventil muss sich in der geöffneten Stellung befinden.

Bei Einsatz in aggressiver Umgebung empfehlen wir, sämtliche freien Pneumatikanschlüsse

mit Hilfe eines Pneumatikschlauches in neutrale Atmosphäre abzuleiten.

Gehäuse

44 - 2702

Page 45

InbetrIebnahme

Vorgehensweise bei SideControl Typ 1067

Demontieren Sie den Kolbenantrieb wie nachfolgend beschrieben. Sie vermeiden Schäden an den Dichtflächen, weil der Kolben in die obere Stellung gebracht wird.

Schließen Sie Druckluft 4,5 bis 6 bar an

P an (1).

Nehmen Sie das Ausblasemundstück heraus.

Drehen Sie die 4 Schrauben heraus.

Öffnen Sie den Deckel (2).

Die 2 roten Schalter für die Handnotbetätigung (3)

befinden sich neben der Klemmenleiste.

Sie sind in der Ruhelage, wenn der Pfeil parallell zur

Klemmenleiste liegt.

Drehen Sie die 2 Schalter vorsichtig im Uhrzei-

gersinn um 90 Grad (Reihenfolge beliebig) (4a).

Der Kolben bewegt sich daraufhin in die obere Lage

und der Regelkegel wird vom Ventilsitz getrennt.

deutsch

Drehen Sie nur den oberen Schalter bis zur Ru-

helage (4b).

Der Kolben bleibt in der oberen Lage, auch wenn

die Druckluft abgeschaltet wird.

2702 - 45

Page 46

InbetrIebnahme

Trennen Sie das Ventilgehäuse vom Kolbenan-

trieb.

Der Regelkegel befindet sich nun in der oberen

Lage. Dadurch wird die Dichtungsfläche nicht beschädigt.

deutsch

Schweißen Sie das Ventilgehäuse

Reinigen Sie das Ventilgehäuse sorgfältig.

EMPFEHLUNG

Montieren Sie das Ventilgehäuse mit einem neuen

Dichtungsring zwischen Ventilgehäuse und Kolbenantrieb.

Regelkegel

Drehen Sie den unteren Schalter in die Ruhelage

zurück.

Der Kolbenantrieb wird entlüftet und die Feder

schliesst das Ventil.

HINWEIS

46 - 2702

Durch diese Vorgehensweise wird Luft unter dem federbelasteten Kolben eingeschlossen.

Normalerweise entweicht die Luft langsam. Nach 10 Stunden sollte dieser Vorgang jedoch

abgeschlossen sein.

Page 47

PNEUMATISCHE INSTALLATION BEI TOPCONTROL TYP 8630

Das Regelventil wird über das TopControl mit Druckluft angesteuert.

Entfernen Sie die Schutzkappen von den Anschlüssen am TopControl und am Ventil

Legen Sie den Versorgungsdruck an Anschluss ”1”

Der für das vollständige Öffnen bzw. Schließen des Ventils erforderliche Versorgungsdruck kann je nach Antrieb, zwischen den Minimalwerten von 3 bar bis 6 bar liegen. Der zulässige Maximalwert für den Steuerdruck

beträgt 7 bar. Die Werte für die Druckversorgung sind unter p

tils angegeben.

Montieren Sie Abluftleitung oder Schalldämpfer an Anschluss ”3”.

Steuermedium: Instrumentenluft, Klasse 3 nach DIN ISO 8573-1

auf dem Typschild des jeweiligen Regelven-

Pilot

InbetrIebnahme

deutsch

Fluidische Anschlüsse des TopControl Continuous

Entfernen Sie die Schutzkappen am Ventil

und am TOPControl Continuous.

Legen Sie den Versorgungsdruck an An-

schluss ”1” (3 ... 7 bar; Instrumentenluft,

öl-, wasser- und staubfrei).

Montieren Sie Abluftleitung oder Schall-

dämpfer an Anschluss ”3”.

HINWEIS

Halten Sie den anliegenden Versorgungsdruck unbedingt mindestens 0,5 ... 1 bar über dem

Druck, der notwendig ist, den pneumatischen Antrieb in seine Endstellung zu bringen. Sie

gewährleisten dadurch, dass das Regelverhalten im oberen Hubbereich aufgrund zu kleiner

Druckdifferenz nicht stark negativ beeinflusst wird.

Halten Sie die Schwankungen des Versorgungsdrucks während des Betriebs möglichst gering (max. ±10 %). Bei größeren Schwankungen sind die mit der Funktion Autotune eingemessenen Reglerparameter nicht optimal.

2702 - 47

Page 48

InbetrIebnahme

ELEKTRISCHER ANSCHLUSS - MULTIPOLSTECKER

(TOPCONTROL TYP 8630)

ACHTUNG!

HINWEIS

deutsch

Bezeichnung der Multipolstecker bzw. -buchsen und der Kontakte

M16

Zum Anschluss der Technischen Erde (TE) befindet sich am Anschlussmodul ein Gewindestift mit Mutter. Verbinden Sie zur Gewährleistung der elektromagnetischen Verträglichkeit

(EMV) diesen Gewindestift über ein einem möglichst kurzes Kabel (max. 30 cm) mit einem

geeigneten Erdungspunkt.

Verwendung des 4 - 20 mA-Sollwerteingangs

Fällt in einer Reihenschaltung mehrerer Geräte die Betriebsspannung eines TOPControl Con-

tinuous-Gerätes in dieser Reihenschaltung aus, wird der Eingang des ausgefallenen

TOPControl Continuous-Gerätes hochohmig. Dadurch fällt das 4 - 20 mA-Normsignal aus.

Wenden Sie sich in diesem Fall bitte direkt an den Bürkert-Service.

Bei Profibus DP oder DeviceNet:

Die Bezeichnung der Multipolstecker bzw. -buchsen und der Kontakte finden Sie in den jeweiligen Kapiteln.

M12

M8

Ausgangssignale

zur SPS

M8

Betriebsspannung

48 - 2702

TE

Prozess-Istwert Initiatoren (Induktive Näherungsschalter)

Page 49

Ausgangssignale zur SPS ( Rundstecker M 16)

PIN Belegung äußere Beschaltung / Signalpegel

A

Sollwert GND

B

Sollwert + (0/4..20 mA oder 0..5/10 V)

C

Analoge Stellungsrückmeldung +

D

Analoge Stellungsrückmeldung GND

E

Binärer Ausgang 1

F

Binärer Ausgang 2

G

Binäre Ausgänge GND

H

Binärer Eingang +

J

Binärer Eingang GND

K

nicht belegt

L

nicht belegt

M

nicht belegt

B

A

C

D

E

F

G

H

J

+ (0/4...20 mA oder 0..5/10 V)

komplett galvanisch getrennt

GND

+ (0/4...20 mA oder 0...5/10 V)

komplett galvanisch getrennt

GND

24 V / 0 V

24 V / 0 V

24 V / 0 V

+ 0 ... 5 V (log. 0)

10 ... 30 V (log. 1)

GND

InbetrIebnahme

deutsch

Betriebsspannung (Rundstecker M 12)

PIN Belegung äußere Beschaltung

1

2

3

4

+ 24 V

nicht belegt

GND

nicht belegt

1

3

24 V DC ± 10 %

max. Restwelligkeit 10 %

Induktive Näherungsschalter (Buchse rund M 8)

PIN Belegung Signalpegel

1

Näherungsschalter 1 +(NO)

2

Näherungsschalter 1 GND

3

Näherungsschalter 2 +(NO)

4

Näherungsschalter 2 GND

+24 V DC

GND

+24 V DC

GND

S1

1

2

offen / 24 V

GND

S2

3

4

offen / 24 V

GND

2702 - 49

Page 50

InbetrIebnahme

Prozess-Istwert (Rundstecker M 8)

Eingangstyp * PIN Belegung Jumper ** äußere Beschaltung

4 ... 20 mA

- intern

versorgt

1

+ 24 V Eingang Transmitter

2

Ausgang Transmitter

3

GND

4

Brücke nach GND

4 ... 20 mA

- extern

versorgt

Frequenz

- intern

versorgt

Frequenz

- extern

versorgt

deutsch

Pt-100

(siehe Hinweis

unten)

* Über Software einstellbar (siehe Kapitel Vorgehensweise zum Festlegen der Grundeinstellungen)

** Der Jumper befindet sich auf der Anschlussplatine des TOPControl Continuous (s. nächste Seite)

1

nicht belegt

2

Prozess-Ist +

3

nicht belegt

4

Prozess-Ist -

1

+ 24 V - Versorgung Sensor

2

Takt-Eingang +

3

Takt-Eingang - (GND)

4

nicht belegt

1

nicht belegt

2

Takt-Eingang +

3

Takt-Eingang -

4

nicht belegt

1

nicht belegt

2

Prozess-Ist 1 (Stromspeisung)

3

Prozess-Ist 3 (GND)

4

Prozess-Ist 2 (Kompensation)

2

4

1

2

3

2

3

2

3

4

4 ... 20 mA

GND

+24 V

Takt +

Takt -

Takt +

Takt -

Pt 100

HINWEIS

Sensor Pt-100 aus Leitungskompensationsgründen über 3 Leitungen anschließen.

PIN 3 und PIN 4 unbedingt am Sensor brücken.

50 - 2702

Page 51

InbetrIebnahme

ELEKTRISCHER ANSCHLUSS - KLEMMEN FÜR KABELVERSCHRAUBUNG

(TOPCONTROL TYP 8630)

ACHTUNG!

HINWEIS

Zum Anschluss der Technischen Erde (TE) befindet sich am Anschlussmodul ein Gewindestift mit Mutter. Verbinden Sie zur Gewährleistung der elektromagnetischen Verträglichkeit (EMV) diesen Gewindestift über ein einem möglichst kurzes Kabel (max. 30 cm)

mit einem geeigneten Erdungspunkt.

Verwendung des 4 - 20 mA-Sollwerteingangs

Fällt in einer Reihenschaltung mehrerer Geräte die Betriebsspannung eines TOPControl Continuous-Gerätes in dieser Reihenschaltung aus, wird der Eingang des ausgefallenen TOPControl

Continuous-Gerätes hochohmig. Dadurch fällt das 4 - 20 mA-Normsignal aus. Wenden Sie

sich in diesem Fall bitte direkt an den Bürkert-Service.

Anschlussplatine des TOPControl Continuous mit Schraubklemmen und

Jumpern

deutsch

Machen Sie die Anschlussklemmen durch Lösen des

Deckels mit den Kabelverschraubungen zugänglich.

Drehen Sie dazu die 4 selbstschneidenden Schrauben

heraus.

Klemmenbelegung bei Kabelverschraubung

Klemme Belegung äußere Beschaltung

1

2

3

4

5

6

Sollwert +

Sollwert GND

Analoge Stellungsrückmeldung +

Analoge Stellungsrückmeldung GND

Betriebsspannung +

Betriebsspannung GND

1

2

3

4

5

6

+ (0/4 ... 20 mA oder 0 ... 5/10 V)

GND

+ (0/4 ... 20 mA oder 0 ... 5/10 V)

komplett galvanisch getrennt

GND

24 V DC ± 10 %

max. Restwelligkeit 10 %

2702 - 51

Page 52

InbetrIebnahme

Auswahl zwischen binären Ausgängen und Prozess-Istwert-Eingang

Wählen Sie über die Jumper:

2 binäre Ausgänge (siehe Tabelle Klemmenbelegung bei Wahl der binären Ausgänge) oder

Prozess-Istwert-Eingang (siehe Tabelle Klemmenbelegung bei Wahl des Prozess-Istwert-Eingangs).

Die Klemmen 7 bis 10 werden mit den entsprechenden Signalen belegt.

Klemmenbelegung bei Wahl der binären Ausgänge

Jumper Klemme Belegung äußere Beschaltung

Klemmenbelegung bei Wahl des Prozess-Istwert-Eingangs

deutsch

7

8

9

10

Binärer Ausgang 1

Binärer Ausgang 1

Binärer Ausgang 2

Binärer Ausgang 2

7

8

9

10

Den Eingangstyp stellen Sie über das Konfiguriermenü ein (siehe Vorgehensweise zum Festlegen

der Grundeinstellungen).

24 V / 0 V NC / NO

GND

24 V / 0 V NC / NO

GND

Eingangstyp Jumper Klemme Belegung äußere Beschaltung

10

10

10

7

8

9

7

8

9

8

9

8

8

9

4 ... 20 mA

intern

versorgt

Frequenz

intern

versorgt