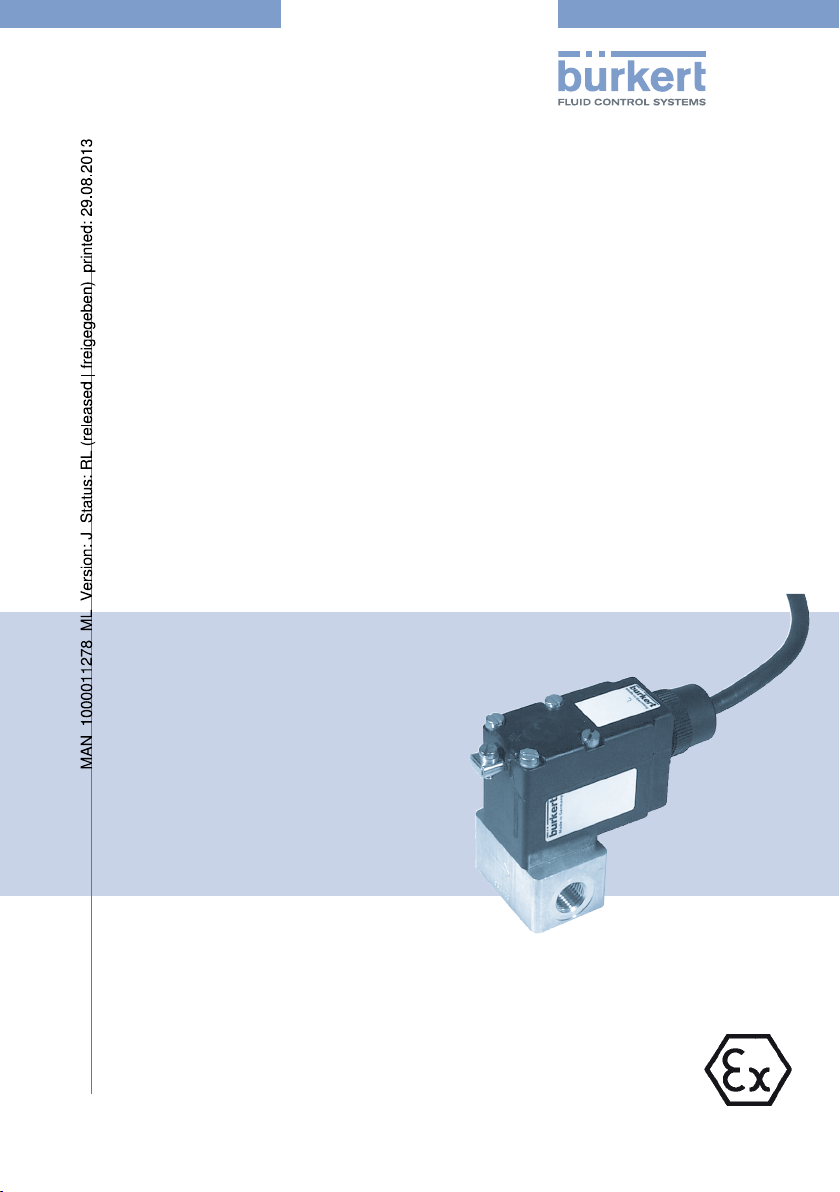

Page 1

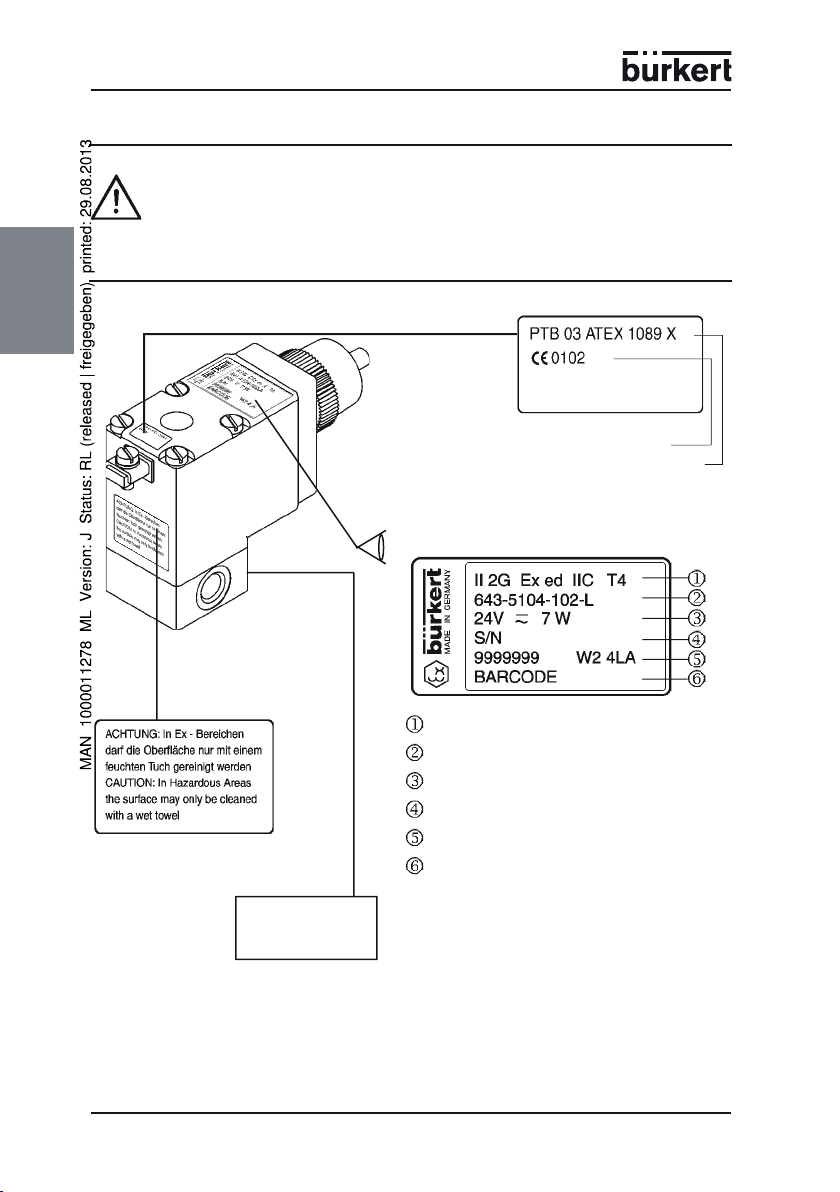

PTB 03 ATEX 1089 X

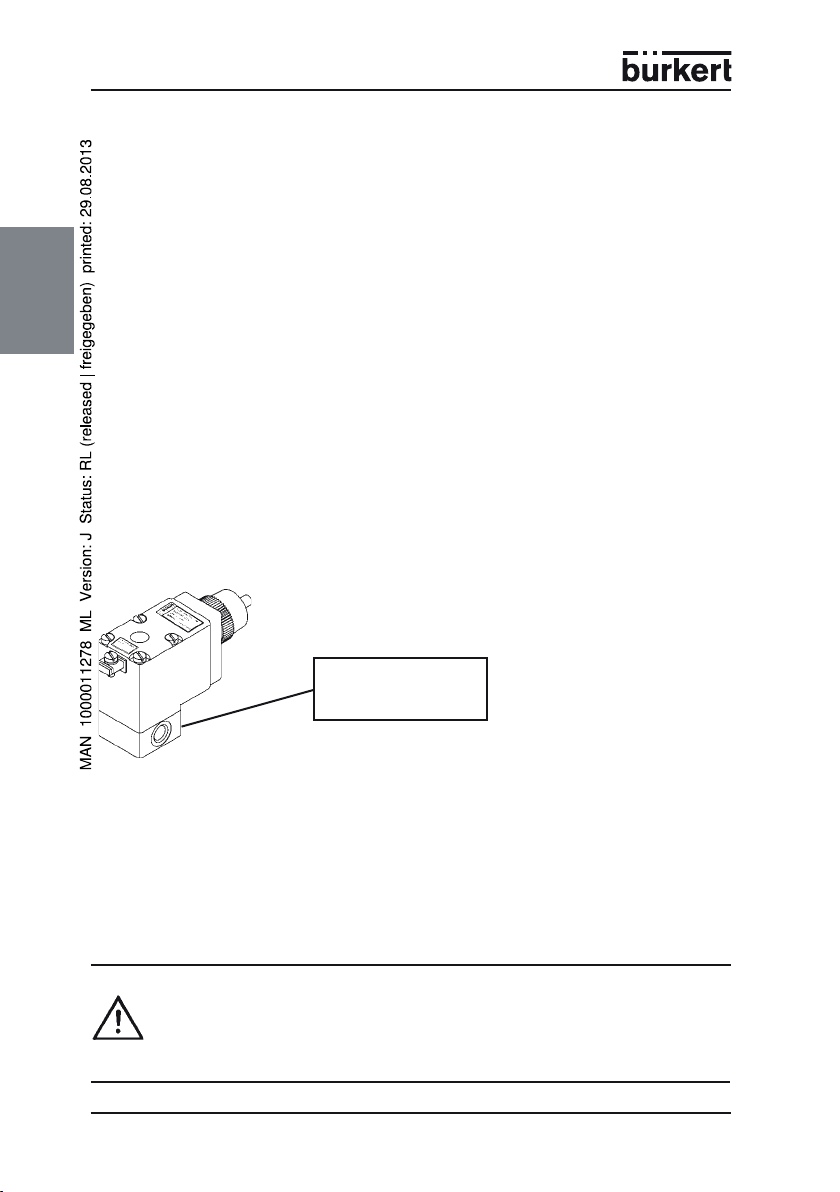

Example: Type 0641

Device with II 2G Ex ed IIC T4 or T5 / II 2G Ex edm IIC T4 or T5-approval

Geräte mit II 2G Ex ed IIC T4 bzw. T5 / II 2G Ex edm IIC T4 bzw. T5-Zulassung

Appareils avec mode de protection II 2G Ex ed IIC T4 ou

T5 / II 2G Ex edm IIC T4 ou T5

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2003 _ 2011 Bürkert Werke GmbH

Operating Instructions 1112/09_EU-ML_ _00804761 / Original DE

Page 3

DEVICE WITH II 2G EX ED IIC T4 OR T5 AND

II 2G EX EDM IIC T4 OR T5-APPROVAL

PTB 03 ATEX 1089 X

CONTENT:

1. GENERAL INFORMATION ........................................................................................................4

1.1. The operating instructions .........................................................................................4

1.2. Symbols ......................................................................................................................... 4

1.3. Intended use ................................................................................................................. 5

1.4. General safety instructions ....................................................................................... 6

1.5. General information .................................................................................................... 7

2. OPERATIN CONDITIONS FOR THE DEVICES .............................................................. 8

2.1. Special conditions ......................................................................................................8

3. TECHNICAL DATA ......................................................................................................................12

3.1. Electrical data.............................................................................................................13

4. INSTALLATION AND COMMISSIONING .........................................................................14

4.1. Montage ......................................................................................................................15

4.2. Commissioning ..........................................................................................................15

5. MAINTENANCE AND FAULTS ..............................................................................................16

5.1. Faults ............................................................................................................................16

6. ACCESSORIES ............................................................................................................................17

english

7. PACKING AND TRANSPORT ................................................................................................17

8. STORAGE .......................................................................................................................................17

9. DISPOSAL ......................................................................................................................................17

03 ATEX1089 X - 3

Page 4

1. GENERAL INFORMATION

1.1. The operating instructions

The operating manual describes the whole life cycle of the appliance. Store this

manual in such a way that is easily accessible to every user and is available to every

new owner of the appliance.

WARNING!

The operating manual must be read and understood.

• Read the operating manual carefully.

english

• Pay particular attention to the chapter Intended use and General safety

instructions!

1.2. Symbols

The following symbols are used throughout this manual:

DANGER!

High risk

• Serious or fatal injuries if the safety precautions are not observed.

WARNING!

Middle risk

• Injuries or serious equipment damage if the safety precautions are not

observed.

CAUTION!

Low risk

• Equipment damage if the safety precautions are not observed.

NOTES!

Draws attention to important additional information, tips and recommendations vital to your safety and the proper function of the equipment.

NOTES!

refers to information in this operating manual or in other

documents.

indicates a work step which you must carry out.

4 - 03 ATEX1089 X

Page 5

1.3. Intended use

The device may only be used for the applications indicated in the chapter Operating conditions for the devices, and only in connection with third-party devices or

components recommended or approved by Bürkert. Observe the instructions in this

operating manual, as well as the conditions of use and permissible data specified in

the chapter Operating conditions for the devices.

The proper and safe function of the system depends on proper transport, storage

and installation, and on careful operation and maintenance.

• The device serves exclusively as a solenoid valve for the media stated in the data

sheet and for use in Explosion Group II, Category 2G and Temperature Class T4

or T5 (see data on the Ex approval plate).

• The types of explosion protection used are flameproof enclosure „d“ with

increased safety „e“. The fuse incorporated in version K is executed in explosion

protection encapsulation type „m“. The composition of the ignition protection

symbol is aligned to the type of ignition protection of the respective components

used.

• Any other utilisation, or a utilisation going beyond this use will be regarded as

improper. Bürkert will accept no liability for any damage resulting from such use.

The user must bear all the risk alone.

english

03 ATEX1089 X - 5

Page 6

1.4. General safety instructions

DANGER!

Risk of explosion if the device is opened!

• The device is a sealed system. It must not be opened.

DANGER!

Electrical power supply in the system!

Acute risk of injury from hazardous structure-borne voltage!

english

Risk of damage to the device due to short circuit!

• Work on the electrical system may only be carried out by qualified

electricians.

• Before starting work, switch off the power supply and secure to

prevent it being switched on again!

• Observe the applicable accident prevention and safety regulations for

electrical devices!

WARNING!

Pressurised system!

Interventions in the pneumatic system represent an acute risk of injury.

• Work on the pneumatic system may only be carried out by qualified and

instructed personnel using appropriate tools.

• First switch off pressure before disconnecting lines and valves.

• Observe the flow direction during installation!

• Observe the applicable accident prevention and safety regulations for

pneumatic systems!

WARNING!

General hazards!

Hazards can lead to precarious situations.

• Unintentional operation or impermissible damage can lead to generally

dangerous situations including physical injury. Take appropriate measures to prevent unintentional operation or impermissible damage!

• The generally recognised safety engineering rules apply for the

planning and operation of the device. These rules must be observed.

NOTES!

The device has been developed in accordance with the acknowledged

safety engineering rules and corresponds to the state of the art. However,

risks may arise. Operate the device only in a proper and safe state and in

accordance with the operating manual.

6 - 03 ATEX1089 X

Page 7

1.5. General information

1.5.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed operating

instructions.

And also on the Internet under: www.burkert.com

1.5.2. Information on the internet

Operating instructions and data sheets for type 0641 (064../065..) may be found

on the Internet under: www.burkert.com

1.5.3. Warranty

The warranty is only valid if the device is used as intended in accordance with the

specified application conditions.

english

1.5.4. Approvals

The EC Qualification Test Certificate PTB 03 ATEX 1089 X has been drawn up by

the

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig

who also audited the manufacture (CE0102).

1.5.5. Conformity

In accordance with the EC Declaration of conformity, Type 064.-....-...-. / 65.-....-...-.

is compliant with the EC Directives.

1.5.6. Standards

Conformity with the EC Directives is verified by the following standards.

EN50014, EN50018, 50019, 50028 see also chapter „2.1.3. Types of explosion

protection“

03 ATEX1089 X - 7

Page 8

2. OPERATIN CONDITIONS FOR THE DEVICES

2.1. Special conditions

2.1.1. Short-circuit protection

As a short-circuit protection, each magnet must be connected in series with a

fuse corresponding to its rated current (max. 3 x I

or a motor protector switch with a fast-acting short-circuit and thermal trip (set to

the rated current). For very small rated currents for the magnets, the fuse with the

smallest current value according to the above-mentioned IEC standard will suffice.

This fuse may be mounted in the associated supply unit or must be connected in

english

series separately. The rated voltage of the fuse must be equal to or larger than the

quoted nominal voltage of the magnet. The switch-off capability of the fuse cartridge must be equal to or greater than the maximum theoretical short-circuit current

at the installation location (normally 1500 A).

In the case of versions A and L of the solenoid, short-circuit protection must

be assured by the operator. In the case of version K of the solenoid, the fuse is

installed in the terminal box of the device. More detailed descriptions of versions A,

L and K are to be found in the section Technical Data.

Fuse ... A

according to IEC 60127-2-1)

b

2.1.2. Operation with associated valve body

The solenoids coil type 64.-....-...-. / 65.-....-...-. may only be operated with

a matching valve body as a complete device, complying with the following

requirements:

• Materials with single and block assembly:

metal (brass, aluminium, stainless steel) or plastics (e,g, polyamide PA 6 GV ...)

DANGER!

Risk of explosion!

• When using the devices in petrol pumps for the control of petrol in

category 2, a valve body made of metal (brass, aluminium or stainless

steel) must be employed!

8 - 03 ATEX1089 X

Page 9

• Minimum dimensions of the valve bodies:

32 mm x 32 mm x 10 mm (L x W x H)

A larger valve body with better heat conductance may be attached at any time.

2.1.3. Types of explosion protection

• Solenoid Type 6..-...-...-.. in version with or without terminal box:

- Flameproof enclosure „d“ to EN 50 014 and EN 50 018 as well as

- Increased safety „e“ to EN 50 014 and EN 50 019

• Fuse protection (to separate Design Inspection Certficate)

- Encapsulation type „m“ to EN 50 014 and EN 50 028

The composition of the ignition protection symbol is aligned to the type of ignition

protection of the respective components used.

Solenoid with or without terminal box:

II 2G Ex ed IIC T4 or T5

Solenoid with or without terminal box:

II 2G Ex edm IIC T4 or T5

2.1.4. Dimensions

Connection type Length (mm) Width (mm) Height (mm)

Electrical connection A 96 32 59

Electrical connections L&K 112 60 113

2.1.5. Type of protection

IP65 to EN 60529 (DIN VDE 0470 Part 1)

2.1.6. Operational temperature range

Please note the operational temperature range listed for each type in the Electrical

Data!

english

03 ATEX1089 X - 9

Page 10

2.1.7. Maximum permissible ambient temperature

range

Please observe the maximum permissible ambient temperature range given under

Operating conditions of the coils for each type!

Version Installation Maximum permissible ambient

temperature range

64.-....-...-. Individual assembly -40 °C ... +60 °C

Block assembly -40 °C ... +45 °C

english

65.-....-...-. Individual assembly -40 °C ... +50 °C

Block assembly -40 °C ... +40 °C

2.1.8. Use in petrol pumps

DANGER!

Risk of explosion if the device is opened!

• The valves may only be dismantled by the manufacturer. The always

represent a closed system!

DANGER!

Risk of explosion!

• When using the devices in petrol pumps for the control of petrol in

category 2, a valve body made of metal (brass, aluminium or stainless

steel) must be employed!

The devices may also be used for the control of petrol in Category 2 when no air

and no oxygen are present in the closed system.

This also applies during start-up and shut-down of the system.

screwed as a block plugged-on

10 - 03 ATEX1089 X

Page 11

The solenoid coils are mounted on the armature either with 4 stud screws M4x59

(flange version) or central fixing G 1/8 (plugged-on version).

They may be disassembled only by the manufacturer!

The valves always represent a closed system.

2.1.9. Special version solenoid Type 655-1.5.-...-.

• Rated voltage UC 12 ... 240 V

• Max. permissible voltage tolerance ±20 %

• Rated current 0.42 ... 0.025 A

• Limiting power consumption in equilibrium 5 W

• Temperature class T5

• Ambient temperature -40 °C ... +40 °C

• Permissible installation individual assembly only

With these devices, a voltage tolerance of ±20 % is permissible.

They may only be installed in individual assembly.

2.1.10. Model with a terminal box

DANGER!

Risk of explosion!

• Only permanently laid cables and wiring may be inserted.

• The operator must provide suitable stress relief.

• Wires with an outside diameter of 6 to 13 mm may be used. Observe

the maximum thermal loading of the cables or wires to be inserted.

• The inserted break-off seal must be matched to the diameter of the

cable or wire.

• The rated cross-section of the cable or wire strands must be at least

0.75 mm² and may not exceed 2.5 mm².

• The screws for fixing the cover of the terminal box must be tightened

with a torque of 100 Ncm (±5%).

english

The solenoid coils may also be executed with a terminal box, with or without fuse/

contactor (to separate Design Inspection Certificate) as desired.

For protection against inadvertent opening of the cover, the latter bears the marking:

Open only when the voltage is switched off!

03 ATEX1089 X - 11

Page 12

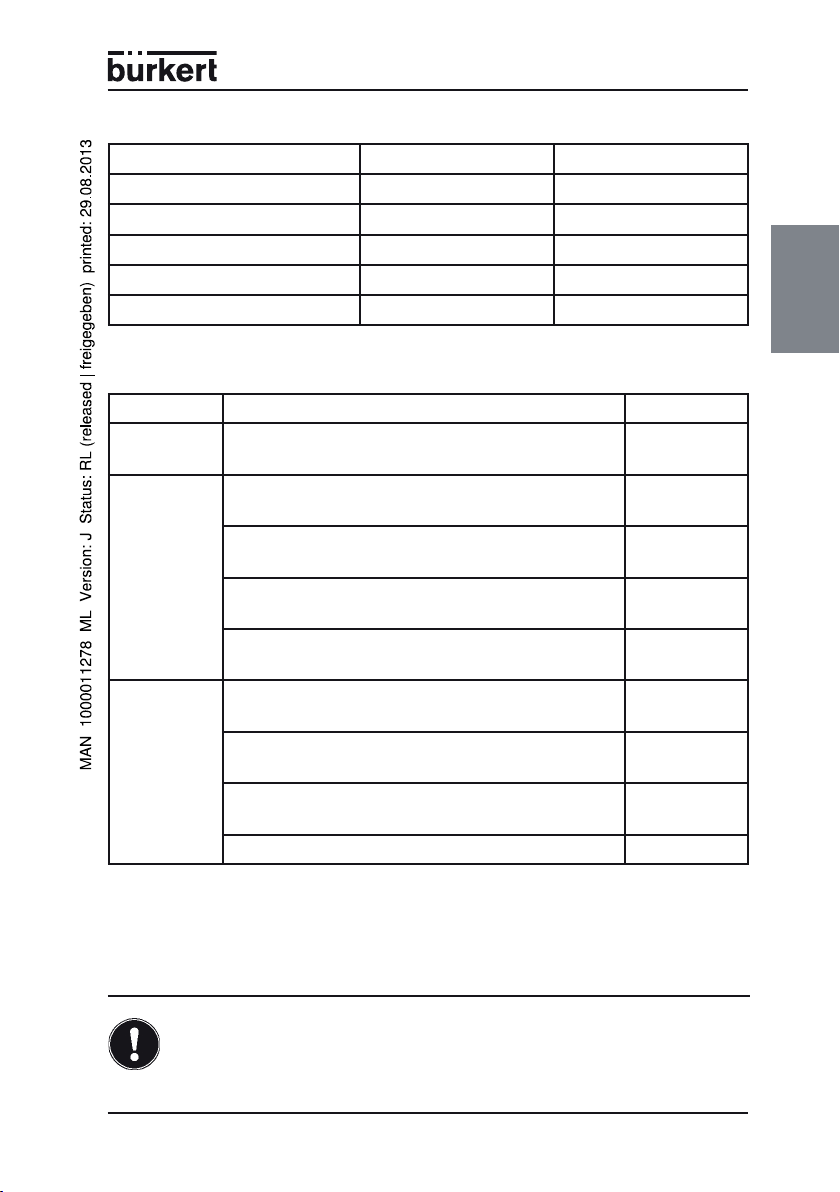

3. TECHNICAL DATA

DANGER!

Risk of explosion!

Exceeding the technical data indicated on the rating plate increases the

explosion risk!

Never exceed the technical data indicated on the rating plate!

english

CE designation

PTB certification No

Example

12 - 03 ATEX1089 X

Mode of protection / temperature code

Coil type - port size for fluid part - coil size

Voltage (±10 %) - power rating

Serial no. of the coil

Ident. no / date of production

Space for barcode

Sicherung/Fuse

... A

Page 13

3.1. Electrical data

Type

Temperature class

Type of current

Rated voltage

Rated current

Holding power

64.-....-...-. 65.-....-...-.

T4 T5

universal universal

12 ... 240 V 12 ... 240 V

0.58 ... 0.034 A 0.42 ... 0.025 A

7 W 5 W

3.1.1. Electrical connection

Marking Execution Internal code

A * Permanently installed rubber sheathed cable of

Type H05 RN-F3G0.75

** Terminal box with cable bushing M20 x

1.5, without fuse

Terminal box with threaded nipple M20 x 1.5,

L

K ***

without fuse

Terminal box with threaded nipple NPT 1/2,

without fuse

Terminal box with threaded nipple G 1/2, without

fuse

** Terminal box with cable bushing M20 x

1.5 and fuse

Terminal box with threaded nipple M20 x 1.5 and

fuse

Terminal box with threaded nipple NPT 1/2 and

fuse

Terminal box with threaded nipple G 1/2 and fuse JA07

none

JA02

JA08

JA09

JA10

JA01

JA05

JA06

english

* The connecting cable of solenoid Type 6..- must be laid permanently

such that it is adequately protected from mechanical damage

** Cable bushing to separate Design Inspection Certificate

*** Fuse/contactor to separate Design Inspection Certificate

NOTES!

The minimum rated cross-section of the conductor strands is

0.75 mm2.

03 ATEX1089 X - 13

Page 14

4. INSTALLATION AND COMMISSIONING

DANGER!

Danger of explosion!

• The device is a sealed system. The unit must not be dismantled!

The following safety regulations must be observed:

The surface of the device may develop an electrostatic charge.

•

In areas with an explosion hazard, the surface of the units may only be

cleaned with a damp cloth!

english

• Only permanently laid cables and wiring may be inserted.

• The operator must provide suitable stress relief.

• Wires with an outside diameter of 6 to 13 mm may be used. Observe

the maximum thermal loading of the cables or wires to be inserted.

• The inserted break-off seal must be matched to the diameter of the

cable or wire.

• The rated cross-section of the cable or wire strands must be at least

0.75 mm² and may not exceed 2.5 mm².

• The screws for fixing the cover of the terminal box must be tightened

with a torque of 100 Ncm (±5%).

DANGER!

High voltage!

Acute risk of injury from hazardous structure-borne voltage!

Risk of damage to the device due to short circuit!

• Work on the electrical system may only be carried out by qualified

electricians.

• Before starting work, switch off the power supply and secure to

prevent it being switched on again!

• Live terminals in the terminal box can cause electric shock, short circuit

or explosion. Switch off the power supply before opening the terminal

box.

• The connecting cables to the electromagnets must be secure, and be

laid so that they are adequately protected from mechanical damage.

• Observe the applicable accident prevention and safety regulations for

electrical devices!

14 - 03 ATEX1089 X

Page 15

WARNING!

Pressurised system!

Interventions in the pneumatic system represent an acute risk of injury.

• Work on the pneumatic system may only be carried out by qualified and

instructed personnel using appropriate tools.

• First switch off pressure before disconnecting lines and valves.

• Observe the flow direction during installation!

• Observe the applicable accident prevention and safety regulations for

pneumatic systems!

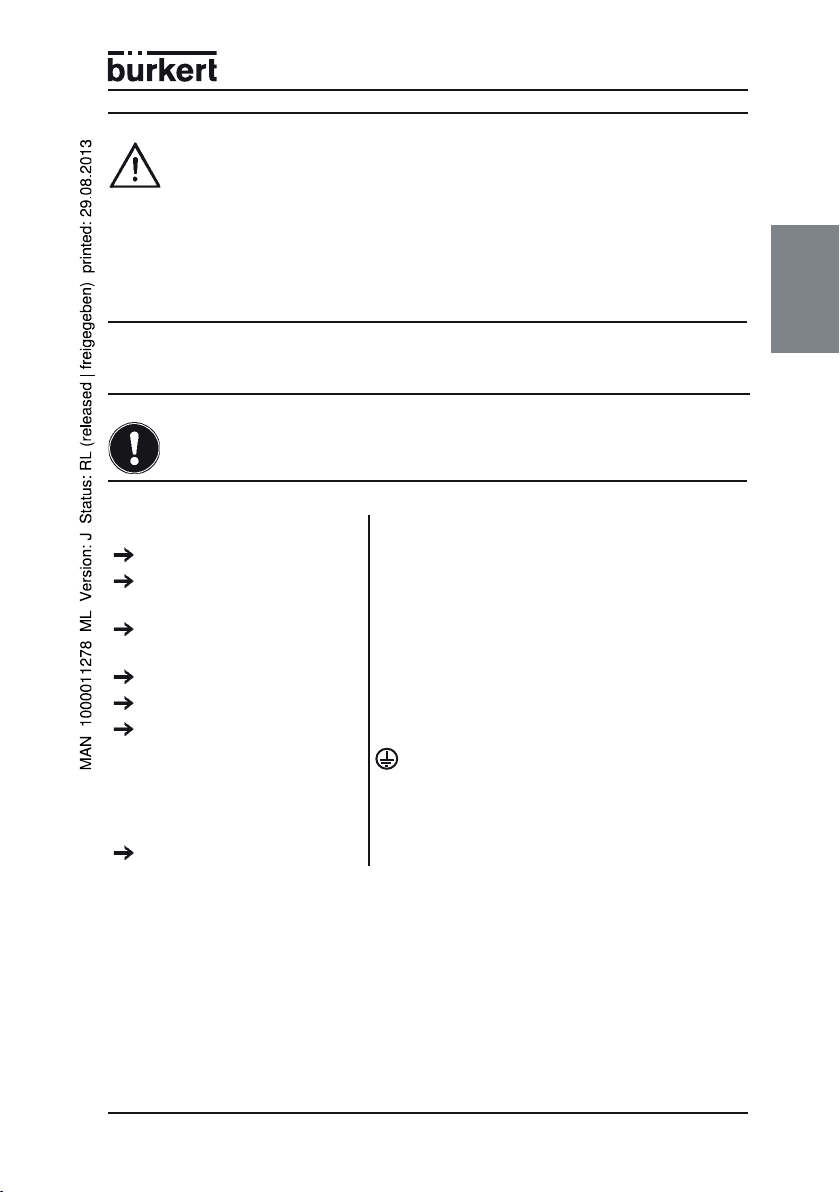

4.1. Montage

NOTES!

Installation in any position.

Preferably with solenoid system mounted at the top

Activity Notes

Clean the pipe runs

Installation in any position Preferred direction with drive mounted at the

top

Connect a dirt-trap

(strainer) upstream

Seal PTFE

Screwing on the pipe run Note the direction of flow!

Installation / Dismounting

Make electrical connections

Note the direction of flow!

Note

Always connect the earth conductor!

Note for units with connecting cable

The connecting cable and the coil are moduled

together. They must not be dismantled!

english

4.2. Commissioning

Before commissioning, ensure that

• The device has been correctly installed,

• The connections have been correctly made,

• The device is not damaged,

• All bolts are securely tightened.

03 ATEX1089 X - 15

Page 16

5. MAINTENANCE AND FAULTS

DANGER!

Hazards due to improper service, repair and maintenance work.

• Service and maintenance work on the device may only be carried out

by authorised and suitably qualified personnel.

• Repair work may only be carried out by the manufacturer!

• When carrying out repair or maintenance work on the system, the

valve must not be opened and the earth connection must not be

english

When operated under the conditions described in these instructions, the units are

maintenance-free.

disconnected!

5.1. Faults

In the event of faults, ensure that

• The device has been correctly installed,

• The connections have been correctly made,

• The device is not damaged,

• All bolts are securely tightened.

• The electric and pneumatic power supplies are connected,

• All pipework is free.

16 - 03 ATEX1089 X

Page 17

6. ACCESSORIES

For electromagnet models with terminal boxes, fuses of the Type 1058 with

approval PTB 01 ATEX 2064 U can be used in Temperature Class T4.

Fuse type 1058 Order No.

0.063 A 153717

0.080 A 153745

0.100 A 153718

0.125 A 153719

0.160 A 153720

0.200 A 153731

0.315 A 153733

0.400 A 153734

0.500 A 153735

0.630 A 153736

0.800 A 153737

1.000 A 153738

1.250 A 153739

1.600 A 153746

2.000 A 153740

3.150 A 153742

7. PACKING AND TRANSPORT

Pack and transport the device in its original packaging or in a suitable

other packaging to protect it from moisture and soiling.

english

8. STORAGE

Store the unit dry and free of dust and under atmospheric conditions!

Storage temperature: -40 ... +55 °C.

9. DISPOSAL

Observe the national standards for refuse disposal!

Dispose of the device in an environmentally responsible manner.

03 ATEX1089 X - 17

Page 18

english

18 - 03 ATEX1089 X

Page 19

GERÄTE MIT II 2G EX ED IIC T4 BZW.- T5 ODER II

2G EX EDM IIC T4 BZW. T5-ZULASSUNG

PTB 03 ATEX 1089 X

INHALT:

1. ALLGEMEINES ............................................................................................................................ 20

1.1. Die Bedienungsanleitung ........................................................................................20

1.2. Darstellungsmittel ......................................................................................................20

1.3. Bestimmungsgemäße Verwendung ......................................................................21

1.4. Allgemeine Sicherheitshinweise ............................................................................22

1.5. Allgemeine Hinweise ................................................................................................23

2. EINSATZBEDINGUNGEN DER GERÄTE........................................................................ 24

2.1. Besondere Bedingungen ........................................................................................24

3. TECHNISCHE DATEN ............................................................................................................. 28

3.1. Elektrische Daten ......................................................................................................29

4. MONTAGE / INBETRIEBNAHME ....................................................................................... 30

4.1. Montage ......................................................................................................................31

4.2. Inbetriebnahme ..........................................................................................................31

5. WARTUNG UND FEHLERBEHEBUNG............................................................................ 32

5.1. Fehlerbehebung .........................................................................................................32

6. ZUBEHÖR ..................................................................................................................................... 33

deutsch

7. VERPACKUNG UND TRANSPORT ................................................................................... 33

8. LAGERUNG ................................................................................................................................... 33

9. ENTSORGUNG ........................................................................................................................... 33

03 ATEX1089 X - 19

Page 20

1. ALLGEMEINES

1.1. Die Bedienungsanleitung

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus des Gerätes.

Bewahren Sie diese Anleitung so auf, dass sie für jeden Benutzer gut zugänglich ist

und jedem neuen Eigentümer des Gerätes wieder zur Verfügung steht.

WARNUNG!

Die Bedienungsanleitung muss gelesen und verstanden werden

• Bedienungsanleitung sorgfältig lesen.

• Die Kapitel Bestimmungsgemäße Verwendung und Allgemeine Sicher-

heitshinweise beachten!

1.2. Darstellungsmittel

In dieser Anleitung werden folgende Darstellungsmittel verwendet:

deutsch

GEFAHR!

hohes Risiko

• Tödliche Gefahren, schwere Verletzungen - wenn die Sicherheitsbestimmungen nicht beachtet werden.

WARNUNG!

mittleres Risiko

• Verletzungen, schwere Sachschäden - wenn die Sicherheitsbestimmungen nicht beachtet werden.

VORSICHT!

geringes Risiko

• Sachschäden - wenn die Sicherheitsbestimmungen nicht beachtet

werden.

HINWEIS!

bezeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen, die für

Ihre Sicherheit und die einwandfreie Funktion des Gerätes wichtig sind.

HINWEIS!

verweist auf Informationen in dieser Bedienungsanleitung oder in anderen

Dokumentationen.

markiert einen Arbeitsschritt, den Sie ausführen müssen.

20 - 03 ATEX1089 X

Page 21

1.3. Bestimmungsgemäße Verwendung

Das Gerät darf nur für die im Kapitel Einsatzbedingungen der Geräte vorgesehenen

Einsatzfälle und nur in Verbindung mit von Bürkert empfohlenen bzw. zugelassenen

Fremdgeräten und -komponenten verwendet werden.

Beachten Sie die Hinweise dieser Bedienungsanleitung sowie die Einsatzbedingungen und zulässigen Daten, die im Kapitel Einsatzbedingungen der Geräte spezifiziert sind. Der einwandfreie und sichere Betrieb des Systems setzt sachgemäßen

Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und

Instandhaltung voraus.

• Das Gerät dient ausschließlich als Magnetventil für die lt. Datenblatt zulässigen

Medien und für den Einsatz in Explosionsgruppe II, Kategorie 2G und Temperaturklasse T4 oder T5 (siehe Angaben auf dem Ex-Zulassungsschild).

• Die angewendten Zündschutzarten sind die Druckfeste Kapselung „d“ mit

Erhöhter Sicherheit „e“. Die Sicherung die bei Ausführung K eingebaut ist, ist im

Zündschutzart Vergusskapselung „m“ ausgeführt. Die Zusammen-setzung des

Zündschutzartenkennzeichens richtet sich nach den Zünd-schutzarten der jeweils

verwendeten Komponenten.

• Eine andere oder darüber hinausgehende Benutzung gilt als nicht bestim-

mungsgemäß. Für hieraus resultierende Schäden haftet Bürkert nicht. Das

Risiko trägt allein der Anwender.

deutsch

03 ATEX1089 X - 21

Page 22

1.4. Allgemeine Sicherheitshinweise

GEFAHR!

Explosionsgefahr durch Öffnen des Gerätes!

• Das Gerät ist ein geschlossenes System. Es darf nicht demontiert werden.

GEFAHR!

Elektrische Spannung im System!

Akute Verletzungsgefahr durchgefährliche Körperspannung!

Gefahr der Beschädigung des Gerätes durch Kurzschluss!

• Arbeiten am elektrischen System dürfen nur von ausgebildeten Elektrofachkräften durchgeführt werden!

• Vor Beginn der Arbeiten Spannung abschalten und vor Wiedereinschalten sichern!

• Geltende Unfallverhütungs- und Sicherheitsbestimmungen für elekt-

deutsch

WARNUNG!

rische Geräte beachten!

Druck im System!

Bei Eingriffen in das pneumatische System besteht akute

Verletzungsgefahr.

• Arbeiten am pneumatischen System dürfen nur durch fachkundiges

und unterwiesenes Personal und mit geeignetem Werkzeug erfolgen.

• Zuerst Druck abschalten, dann Leitungen und Ventile lösen!

• Beim Einbau Durchflussrichtung beachten!

• Geltende Unfallverhütungs- und Sicherheitsbestimmungen für pneumatische Geräte beachten!

WARNUNG!

Allgemeine Gefährdungen!

Gefährdungen können zu Gefahrensituationen führen.

• Unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung können

zu allgemeinen Gefahrensituationen bis hin zur Körperverletzung führen.

Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen

oder unzulässige Beeinträchtigung auszuschließen!

• Für die Einsatzplanung und den Betrieb des Gerätes gelten die einschlägigen allgemeinen anerkannten sicherheitstechnischen Regeln!

Diese Regeln müssen eingehalten werden!

HINWEIS!

Das Gerät wurde unter Einbeziehung der anerkannten sicherheitstechnischen Regeln entwickelt und entspricht dem Stand der Technik. Trotzdem

können Gefahren entstehen. Betreiben Sie das Gerät nur in einwandfreiem

Zustand und unter Beachtung der Bedienungsanleitung.

22 - 03 ATEX1089 X

Page 23

1.5. Allgemeine Hinweise

1.5.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten

Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

1.5.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des

Gerätes unter Beachtung der spezifizierten Einsatzbedingungen.

1.5.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 0641 (064../065..) finden Sie im

Internet unter: www.buerkert.de

deutsch

1.5.4. Zulassungen

Die EG-Baumusterprüfbescheinigung PTB 03 ATEX 1089 X wurde von der

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig

ausgestellt, die auch die Fertigung auditiert (CE0102).

1.5.5. Konformität

Der Typ 064.-....-...-. / 65.-....-...-. ist konform zu den EG Richtlinien entsprechend

der EG-Konformitätserklärung.

1.5.6. Normen

Durch folgende Normen wird die Konformität des mit den EG-Richtlinien erfüllt:

EN50014, EN50018, 50019, 50028 siehe auch Kapitel „2.1.3. Zündschutzarten“

03 ATEX1089 X - 23

Page 24

2. EINSATZBEDINGUNGEN DER GERÄTE

2.1. Besondere Bedingungen

2.1.1. Kurzschlussschutz

Jedem Magneten muss als Kurzschlussschutz eine seinem Bemessungsstrom

entsprechende Sicherung (max. 3 x I

schalter mit Kurzschluss- und thermischer Schnellauslösung (Einstellung auf

Bemessungsstrom) vorgeschaltet werden. Bei sehr kleinen Bemessungsströmen

des Magneten ist die Sicherung mit dem kleinsten Stromwert nach der genannten

IEC-Norm ausreichend. Diese Sicherung darf im zugehörigen Versorgungsgerät

untergebracht sein oder muss separat vorgeschaltet werden. Die SicherungsBemessungsspannung muss gleich oder größer als die angegebene Nennspannung des Magneten sein. Das Ausschaltvermögen des Sicherungseinsatzes

muss gleich oder größer als der maximal anzunehmende Kurzschlussstrom am

Einbauort (üblicherweise 1500 A) sein.

Bei der Ausführung A und L des Elektromagneten muss der Kurzschlussschutz

deutsch

durch den Betreiber gewährleistet werden. Bei Ausführung K des Elektromagneten

ist die Sicherung im Klemmkasten des Geräts eingebaut.

Nähere Beschreibung der Ausführungen A, L und K finden Sie im Abschnitt Tech-

nische Daten.

nach IEC 60127-2-1) bzw. ein Motorschutz-

b

Sicherung ... A

2.1.2. Betrieb nur mit zugehörigem Ventil

Die Magnetspulen Typ 64.-....-...-. / 65.-....-...-. dürfen nur mit einem zugehörigen

Ventilkörper als Komplettgerät betrieben werden, der folgenden Forderungen

entspricht:

• Werkstoffe bei Einzel- und Blockmontage:

Metall (Messing, Aluminium, Edelstahl) oder Kunststoff (z.B. Polyamid PA 6 GV ...)

GEFAHR!

Explosionsgefahr!

• Bei Einsatz der Geräte in Tanksäulen zur Steuerung von Benzin als

Kategorie-2-Gerät muss ein Ventilkörper aus Metall (Messing, Aluminium oder Edelstahl) verwendet werden!

24 - 03 ATEX1089 X

Page 25

• Mindestabmessungen der Ventilkörper:

32 mm x 32 mm x 10 mm (L x B x H)

Ein größerer Ventilkörper mit besserer Wärmeleitfähigkeit darf jeder Zeit angebaut

werden.

2.1.3. Zündschutzarten

• Elektromagnet Typ 6..-...-...-.. in Ausführung mit oder ohne Klemmkasten:

Druckfeste Kapselung „d“ nach EN 50 014 und EN 50018 sowie

Erhöhte Sicherheit „e“ nach EN 50014 und EN 50019

• Sicherung (nach getrennter Baumusterprüfbescheinigung)

Vergussverkapselung „m“ nach EN 50014 und EN 50028

Die Zusammensetzung des Zündschutzartenkennzeichens richtet sich nach den

Zündschutzarten der jeweils verwendeten Komponenten.

Elektromagnet mit oder ohne Klemmkasten:

II 2G Ex ed IIC T4 oder T5

Elektromagnet mit Klemmkasten und Sicherung:

II 2G Ex edm IIC T4 oder T5

2.1.4. Abmessungen

Anschlussart Länge (mm) Breite (mm) Höhe (mm)

Elektrischer Anschluss A 96 32 59

Elektrischer Anschluss L&K 112 60 113

deutsch

2.1.5. Schutzart

IP65 nach EN 60529 (DIN VDE 0470 Teil 1)

2.1.6. Einsatztemperaturbereich

Beachten Sie für jeden Typ den bei den Elektrischen Daten aufgeführten

Einsatztemperaturbereich!

03 ATEX1089 X - 25

Page 26

2.1.7. Maximal zulässiger

Umgebungstemperaturbereich

Bitte beachten Sie für jeden Typ den unter Einsatzbedingungen der Spule angegebenen, maximal zulässigen Umgebungstemperaturbereich!

Ausführung Installation Maximal zulässiger

Umgebungstemperaturbereich

64.-....-...-. Einzelmontage -40 °C ... +60 °C

Blockmotage -40 °C ... +45 °C

65.-....-...-. Einzelmontage -40 °C ... +50 °C

Blockmotage -40 °C ... +40 °C

2.1.8. Einsatz in Tanksäulen

deutsch

GEFAHR!

Explosionsgefahr durch Öffnen des Gerätes!

• Das Gerät ist ein geschlossenes System. Es darf nicht demontiert

werden.

GEFAHR!

Explosionsgefahr!

• Bei Einsatz der Geräte in Tanksäulen zur Steuerung von Benzin als

Kategorie-2-Gerät muss ein Ventilkörper aus Metall (Messing, Aluminium oder Edelstahl) verwendet werden!

Die Geräte dürfen auch zur Steuerung von Benzin in Kategorie 2 eingesetzt werden,

wenn in dem geschlossenen System keine Luft und kein Sauerstoff vorhanden ist.

Dies gilt auch beim Anfahren und Abschalten des Systems.

blockverschraubt übergesteckt

26 - 03 ATEX1089 X

Page 27

Die Magnetspulen werden entweder mit 4 Zylinderschrauben M4x59 (Flanschausführung) oder Zentralbefestigung G1/8 (Übersteckausführung) auf die Armatur

montiert.

Sie dürfen nur vom Hersteller demontiert werden!

Die Ventile stellen immer ein geschlossenes System dar.

2.1.9. Sonderausführung Elektromagnet Typ

655-1.5.-...-.

• Nennspannung UC 12 ... 240 V

• Max. zulässige Spannungstoleranz ±20 %

• Bemessungsstrom 0,42 ... 0,025 A

• Grenzleistung im Beharrungszustand 5 W

• Temperaturklasse T5

• Umgebungstemperatur -40 °C ... +40 °C

• Zulässige Installation nur Einzelmontage

Bei diesen Geräten ist eine Spannungstoleranz von ±20 % zulässig.

Sie dürfen nur in Einzelmontage aufgebaut werden.

2.1.10. Ausführung mit einem Klemmenkasten

GEFAHR!

Explosionsgefahr!

• Nur festgelegte Kabel und Leitungen dürfen eingeführt werden.

• Der Betreiber muss eine entsprechende Zugentlastung gewährleisten.

• Es können Leitungen mit Außendurchmeser von 6 mm bis 13 mm verwendet werden. Beachten Sie die maximale thermische Belastung der

eingeführten Kabel bzw. Leitungen.

• Die eingelegte, ausbrechbare Dichtung muss dem Durchmesser des

Kabels/Leitung angepasst werden.

• Der Bemessungsquerschnitt der Kabel/Leitungsadern muss mindestens 0,75 mm² betragen und darf 2,5 mm² nicht überschreiten.

• Die Schrauben zur Befestigung des Deckels des Klemmenkastens

müssen mit einem Drehmoment von 100 Ncm (±5 %) angezogen

werden.

deutsch

Die Magnetspulen können mit einem Klemmenkasten (wahlweise mit

/ ohne Sicherung) ausgeführt werden (Sicherung nach getrennter

Baumusterprüfbescheinigung).

Als Schutz gegen unbeabsichtigtes Öffnen des Deckels trägt dieser die Aufschrift:

Nur spannungsfrei öffnen!

03 ATEX1089 X - 27

Page 28

3. TECHNISCHE DATEN

GEFAHR!

Explosionsgefahr!

Überschreitung der auf dem Typschild angegebenen technischen Daten

führt zu hohem Risiko!

Auf dem Typschild angegebenen technischen Daten keinesfalls

überschreiten!

deutsch

CE-Kennzeichnung

PTB-Zulassungsnummer

Beispiel

28 - 03 ATEX1089 X

Schutzart/Temperaturklasse

Spulentyp - Anschlussgröße für

Fluidteil -Spulengröße

Spannung (±10 %) - Leistung

Serien-Nr. der Spule

Ident-Nr. der Spule - Herstelldaten

Platz für Barcode

Sicherung/Fuse

... A

Page 29

3.1. Elektrische Daten

Typ

Temperaturklasse

Stromart

Nennspannung

Bemessungsstrom

Grenzleistung im

Beharrungszustand

64.-....-...-. 65.-....-...-.

T4 T5

Allstrom Allstrom

12 ... 240 V 12 ... 240 V

0,58 ... 0,034 A 0,42 ... 0,025 A

7 W 5 W

3.1.1. Elektrischer Anschluss

Kennzeichnung.

A * Fest eingebaute Gummischlauchleitung des Typs

L

K ***

Ausführung Interner Code

H05 RN-F3G0,75

** Klemmenkasten mit Kabelverschraubung

M20 x 1,5, ohne Sicherung

Klemmenkasten mit Gewindenippel M20 x 1,5,

ohne Sicherung

Klemmenkasten mit Gewindenippel NPT 1/2, ohne

Sicherung

Klemmenkasten mit Gewindenippel G 1/2, ohne

Sicherung

** Klemmenkasten mit Kabelverschraubung

M20 x 1,5 und Sicherung

Klemmenkasten mit Gewindenippel M20 x 1,5 und

Sicherung

Klemmenkasten mit Gewindenippel NPT 1/2 und

Sicherung

Klemmenkasten mit Gewindenippel G 1/2 und

Sicherung

ohne

Angabe

JA02

JA08

JA09

JA10

JA01

JA05

JA06

JA07

deutsch

* Die Anschlussleitung des Elektromagneten Typ 6..- muss fest und so verlegt

werden, dass sie vor mechanischen Beschädigungen hinreichend geschützt ist.

** Kabelverschraubung nach getrennter Baumusterprüfbescheinigung

*** Sicherung nach getrennter Baumusterprüfbescheinigung

HINWEIS!

Der Mindestbemessungsquerschnitt der Leistungsadern beträgt

0,75 mm2.

03 ATEX1089 X - 29

Page 30

4. MONTAGE / INBETRIEBNAHME

GEFAHR!

Explosionsgefahr!

• Das Gerät ist ein geschlossenes System. Es darf nicht demontiert

werden.

Folgende Sicherheitsfestlegungen sind einzuhalten:

Die Oberfläche des Gerätes kann sich elektrostatisch aufladen.

•

In explosionsgefährdeten Bereichen darf die Oberfläche der Geräte nur

mit einem feuchten Tuch gereinigt werden!

• Nur festgelegte Kabel und Leitungen dürfen eingeführt werden.

• Der Betreiber muss eine entsprechende Zugentlastung gewährleisten.

• Leitungen mit Außendurchmeser von 6 mm ... 13 mm können verwendet werden. Beachten Sie die maximale thermische Belastung der

eingeführten Kabel bzw. Leitungen.

deutsch

• Die eingelegte, ausbrechbare Dichtung muss dem Durchmesser des

Kabels/Leitung angepasst werden.

• Der Bemessungsquerschnitt der Kabel/Leitungsadern muss mindestens 0,75 mm² betragen und darf 2,5 mm² nicht überschreiten.

• Die Schrauben zur Befestigung des Deckels des Klemmenkastens

müssen mit einem Drehmomont von 100 Ncm (±5 %) angezogen

werden.

GEFAHR!

Elektrische Spannung!

Akute Verletzungsgefahr durch gefährliche Körperspannung!

Gefahr der Beschädigung des Gerätes durch Kurzschluss!

• Arbeiten am elektrischen System dürfen nur von ausgebildeten Elektrofachkräften durchgeführt werden!

• Vor Beginn der Arbeiten Spannung abschalten und vor Wiedereinschalten sichern!

• Spannungsführende Klemmen im Klemmenkasten können Stromschlag,

Kurzschluss oder Explosion verursachen. Spannung abschalten. Erst

dann den Klemmenkasten öffnen.

• Die Anschlussleitungen der Elektromagneten müssen fest und so

verlegt werden, dass sie vor mechanischen Beschädigungen hinreichend geschützt sind.

• Geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

30 - 03 ATEX1089 X

Page 31

WARNUNG!

Druck im System!

Bei Eingriffen in das pneumatische System besteht akute

Verletzungsgefahr.

• Arbeiten am pneumatischen System dürfen nur durch fachkundiges

und unterwiesenes Personal und mit geeignetem Werkzeug erfolgen.

• Zuerst Druck abschalten, dann Leitungen und Ventile lösen!

• Beim Einbau Durchflussrichtung beachten!

• Geltende Unfallverhütungs- und Sicherheitsbestimmungen für pneumatische Geräte beachten!

4.1. Montage

HINWEIS!

Einbaulage beliebig.

Vorzugsweise mit Magnetsystem oben.

Tätigkeit Bemerkungen

Rohrleitungen reinigen

Einbaulage beliebig Vorzugsrichtung mit Antrieb oben

Schmutzfänger vorschalten Durchflussrichtung beachten!

Abdichtung PTFE

Rohrleitungen einschrauben Durchflussrichtung beachten!

Montieren / Demontieren

Elektrisch anschließen

Hinweis

Schutzleiter immer anschließen!

Hinweis für Geräte mit

Anschlusskabel

Anschlusskabel und Spule sind vergossen. Sie

dürfen nicht demontiert werden!

deutsch

4.2. Inbetriebnahme

Stellen Sie vor Inbetriebnahme sicher, dass

• das Gerät vorschriftmäßig installiert wurde,

• der Anschluss ordnungsgemäß ausgeführt wurde,

• das Gerät nicht beschädigt ist,

• alle Schrauben fest angezogen sind.

03 ATEX1089 X - 31

Page 32

5. WARTUNG UND FEHLERBEHEBUNG

GEFAHR!

Gefahr durch unsachgemäße Wartungs-, Reparatur- und

Instandhaltungsarbeiten!

• Wartungs- und Instandhaltungsarbeiten am Gerät dürfen nur von

dazu befugtem und entsprechend geschultem Personal durchgeführt

werden.

• Reparaturen am Gerät dürfen nur vom Hersteller durchgeführt werden!

• Bei Reparatur- oder Wartungsarbeiten an der Anlage darf das Ventil

nicht geöffnet und die Schutzleiterverbindung nicht getrennt werden!

Die Geräte sind beim Betrieb unter den in dieser Anleitung beschriebenen Bedingungen wartungsfrei.

deutsch

5.1. Fehlerbehebung

Stellen Sie bei Sörungen sicher, dass

• das Gerät vorschriftmäßig installiert wurde,

• der Anschluss ordnungsgemäß ausgeführt wurde,

• das Gerät nicht beschädigt ist,

• alle Schrauben fest angezogen sind.

• Spannung und Druck anliegen,

• die Rohrleitungen frei sind.

32 - 03 ATEX1089 X

Page 33

6. ZUBEHÖR

Bei Ausführung der Geräte mit Klemmkasten kann in Temperaturklasse T4, die

Sicherung des Typs 1058 mit Zulassung PTB 01 ATEX 2064 U eingesetzt werden.

Sicherung Typ 1058 Bestell.-Nr.

0,063 A 153717

0,080 A 153745

0,100 A 153718

0,125 A 153719

0,160 A 153720

0,200 A 153731

0,315 A 153733

0,400 A 153734

0,500 A 153735

0,630 A 153736

0,800 A 153737

1,000 A 153738

1,250 A 153739

1,600 A 153746

2,000 A 153740

3,150 A 153742

7. VERPACKUNG UND TRANSPORT

Verpacken und transportieren Sie das Gerät vor Nässe und Schmutz

gesichert in der Originalverpackung oder einer entsprechend schützen den Verpackung,

deutsch

8. LAGERUNG

Lagern Sie das Gerät trocken, staubfrei und unter atmosphärischen

Bedingungen!

Lagertemperatur: -40 ... +55 °C.

9. ENTSORGUNG

Beachten Sie die nationalen Abfallbeseitigungsvorschriften.

Entsorgen Sie das Gerät umweltgerecht.

03 ATEX1089 X - 33

Page 34

deutsch

34 - 03 ATEX1089 X

Page 35

APPAREILS AVEC L‘HOMOLOGATION

II 2G EX ED IIC T4 OU T5 OU

II 2G EX EDM IIC T4 OU T5

PTB 03 ATEX 1089 X

TABLE DES MATIÈRES:

1. INDICATIONS GENERALES ..................................................................................................36

1.1. Les consignes d‘utilisation .....................................................................................36

1.2. Symboles.....................................................................................................................36

1.3. Usage conforme a la destination ...........................................................................37

1.4. Consignes générales de sécurité ..........................................................................38

1.5. Indications générales ...............................................................................................39

2. CONDITIONS D‘EMPLOI DES APPAREILS ...................................................................40

2.1. Conditions Particulieres...........................................................................................40

3. CARACTERISTIQUES TECHNIQUES ..............................................................................44

3.1. Caractéristiques électriques ...................................................................................45

4. MONTAGE ET MISE EN SERVICE .....................................................................................46

4.1. Montage ......................................................................................................................47

4.2. Mise en service ..........................................................................................................47

5. MAINTENANCE ET DERANGEMENTS ............................................................................48

5.1. Derangements ............................................................................................................48

6. ACCESSOIRES ............................................................................................................................49

français

7. EMBALLAGE ET TRANSPORT .............................................................................................49

8. STOCKAGE ....................................................................................................................................49

9. ÉLIMINATION ................................................................................................................................49

03 ATEX1089 X - 35

Page 36

1. INDICATIONS GENERALES

1.1. Les consignes d‘utilisation

Les consignes d’utilisation décrivent l’ensemble du cycle de vie de l’appareil.

Veuillez conserver ces consignes de telle sorte qu’elles soient facilement accessibles à tous les utilisateurs et puissent être mises à la disposition de tout nouveau

propriétaire de l’appareil.

Les présentes consignes d’utilisation doivent être lues et comprises.

• Lire attentivement les consignes d’utilisation.

• Respecter les chapitres Usage conforme a la destination et Consignes

générales de sécurité!

1.2. Symboles

Les symboles suivants sont utilisés dans ces consignes:

français

DANGER!

Risque élevé

• Danger de mort, de blessures graves – si les consignes de sécurité ne

sont pas respectées.

AVERTISSEMENT!

Risque moyen

• Blessures, dommages matériels graves – si les consignes de sécurité

ne sont pas respectées.

ATTENZION!

Risque faible

• Dommages matériels – si les consignes de sécurité ne sont pas

respectées.

REMARQUE!

signale des informations complémentaires, des astuces et des recommandations importantes pour votre sécurité et pour le parfait fonctionnement

de l’appareil.

REMARQUE!

renvoie à des informations dans les présentes consignes ou dans d’autres

documentations.

désigne une opération que vous devez effectuer.

36 - 03 ATEX1089 X

Page 37

1.3. Usage conforme a la destination

L‘appareil doit uniquement être utilisé pour les applications prévues au chapitre

Conditions d’emploi des appareils et seulement en association avec des appareils

et composants étrangers recommandés ou homologués par Bürkert. Veuillez respecter les dispositions des présentes consignes d’utilisation ainsi que les conditions d’emploi et caractéristiques autorisées visées au chapitre Conditions d’emploi

des appareils. Le fonctionnement parfait et sûr du système suppose un transport,

un stockage et une installation corrects ainsi qu‘une conduite et un entretien

soigneux.

• L‘appareil sert exclusivement d‘électrovanne pour les fluides autorisés d‘après

la fiche technique et pour l‘emploi dans un groupe déflagrant II, catégorie 2G et

classe de température T4 ou T5 (voir indications sur la plaque d‘homologation

Ex).

• Les modes de protection allumage sont l’encapsulage résistant à la pression „d“

avec sécurité augmentée „e“. Le fusible incorporé dans la version K, est réalisé

en mode de protection allumage par enrobage „m“. La composition du marquage

indiquant le mode de protection, dépend du mode de protection des composant

utilisés.

• Un autre usage ou un emploi dépassant ce cadre est considéré comme non

conforme à la destination. Bürkert décline alors toute responsabilité pour les

dégâts susceptibles d’en résulter. Le risque est à la charge de l’utilisateur seul.

français

03 ATEX1089 X - 37

Page 38

1.4. Consignes générales de sécurité

DANGER!

Risque d’explosion en cas d’ouverture de l’appareil!

• L’appareil est un système fermé. Il ne doit pas être démonté.

DANGER!

Tension électrique dans le système!

Risque de blessure grave en raison d’une tension corporelle dangereuse!

Risque de dommages matériels (appareil) en cas de court-circuit!

• Les interventions sur le système électrique ne peuvent être réalisées

que par un électricien qualifié!

• Avant de commencer une intervention, couper la tension et assurer une

protection contre la remise en marche de l’appareil!

• Respecter les règles de prévention des accidents et de sécurité en

vigueur pour les appareils électriques!

français

AVERTISSEMENT!

Pression dans le système!

Des risques considérables de blessure existent en cas d’intervention sur le

système pneumatique.

• Les interventions sur le système pneumatique ne peuvent être réalisées

que par un personnel spécialisé et formé à cet effet, et à l’aide des

outils appropriés.

• Couper d’abord la pression, puis détacher les câbles et les vannes!

• Tenir compte du sens d’écoulement lors du montage!

• Respecter les règles de prévention des accidents et de sécurité en

vigueur pour les appareils pneumatiques!

AVERTISSEMENT!

Risques d’ordre général!

Les risques peuvent induire des situations dangereuses.

• Tout actionnement involontaire ou influence néfaste inadmissible peut

induire une situation dangereuse générale, allant jusqu’à des risques

de blessures corporelles. Prenez des mesures appropriées pour

exclure un actionnement involontaire ou des influences inadmissibles!

• Les règles techniques de sécurité généralement reconnues pertinentes

s’appliquent pour la planification de l’utilisation et l’exploitation de l’appareil ! Ces règles doivent impérativement être respectées!

REMARQUE!

L’appareil a été développé conformément aux règles techniques de

sécurité reconnues et est conforme à l’état de la technique. Toutefois, tous

les risques ne peuvent être exclus. N’utilisez cet appareil que s’il est en

parfait état et respectez toujours les consignes d’utilisation.

38 - 03 ATEX1089 X

Page 39

1.5. Indications générales

1.5.1. Adresses

Allemagne

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages de ces instructions de service

imprimées.

Egalement sur internet sous : www.burkert.com

1.5.2. Garantie légale

La condition pour bénéficier de la garantie est l‘utilisation conforme de l‘appareil

dans le respect des conditions d‘utilisation spécifiée.

1.5.3. Informations dans Internet

Vous trouverez dans Internet les instructions de service et les fiches techniques du

type 0641 (064../065..) sous : www.buerkert.fr

français

1.5.4. Homologations

Le certificat d’essai de modèle CE PTB 03 ATEX 1089 X a été établi par le

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig

qui a également auditionné la fabrication (CE0102).

1.5.5. Conformité

Le type 064.-....-...-. / 65.-....-...-. est conforme aux directives CE sur la base de la

déclaration de conformité CE.

1.5.6. Normes

La conformité avec les directives CE est satisfaite avec

les normes suivantes : EN50014, EN50018, 50019, 50028 voir chapitre „2.1.3.

Modes de protection d‘allumage“

03 ATEX1089 X - 39

Page 40

2. CONDITIONS D‘EMPLOI DES APPAREILS

2.1. Conditions Particulieres

2.1.1. Protection contre les courts-circuits

Un fusible correspondant au courant de calcul (max. 3 x Ib selon CEI 60127-2-1)

ou un disjoncteur de court-circuit et thermique à déclenchement rapide (réglage

au courant de calcul) doit être monté en amont de chaque aimant. En cas de très

faibles courants de calcul de l’aimant, le fusible du courant le plus faible selon la

norme dite CEI suffit. Ce fusible peut être placé dans l’appareil d’alimentation s’y

rattachant ou doit être branché séparément en amont. La tension de calcul du

fusible doit être égale ou supérieure à la tension nominale indiquée de l’aiment. Le

pouvoir de coupure de la cartouche doit être égal ou supérieur au courant de courtcircuit supposé au lieu de montage (habituelle-ment 1500 A).

Dans les versions A et L de l‘électro-aimant, la protection contre les courts-circuits

doit être assurée par l‘exploitant. Dans la version K de l‘électro-aimant, le fusible est

monté dans la boîte de connexions de l‘appareil.

français

Vous trouverez une description plus détaillée des versions A, L et K au chapitre

Caractéristiques techniques.

Fusible ... A

2.1.2. Fonctionnement avec corps de soupape s‘y

rattachant

Les bobines magnétiques de type 64.-....-...-. / 65.-....-...-. ne doivent être mises en

service qu‘avec un corps de vanne s‘y rattachant en tant qu‘appareil complet correspondant aux exigences suivantes:

• Matière première en cas de montage individuel et en bloc:

Métal (laiton, aluminium, acier inoxydable) ou matière synthétique (p. ex. polyamide PA 6 GV ...)

DANGER!

Risque d‘explosion!

• Lors de l‘utilisation des appareils dans des distributeurs de carburants

pour commander l‘essence, le corps de vanne doit être en métal (laiton,

aluminium ou acier inoxydable) en tant qu‘appareil de catégorie 2!

40 - 03 ATEX1089 X

Page 41

• Cotes minimales du corps de vanne:

32 mm x 32 mm x 10 mm (L x I x H)

Un corps de vanne plus grand ayant une meilleure conductibilité thermique peut

toujours être monté.

2.1.3. Modes de protection d‘allumage

• Electro-aimant type 6..-...-...-.. en version avec ou sans coffret à bornes:

- Encapsulage résistant à la pression „d“ elon EN 50 014 et EN 50 018

même que

- Sécuritéaugmentée „e“ selon EN 50 014 et EN 50 019

• Fusible (selon certificat déssai de type séparé)

- Enrobage „m“ selon EN 50 014 et EN 50 028

La composition du marquage indiquant le mode de protection, dépend du mode de

protection des composant utilisés.

Electro-aimant avec ou sans coffret à bornes:

II 2G Ex ed IIC T4 ou T5

Electro-aimant avec ou sans coffret à bornes:

II 2G Ex edm IIC T4 ou T5

2.1.4. Dimensions

français

Mode de

raccordement

Raccordement électrique A

Raccordement électrique L&K

Longueur

(mm)

96 32 59

112 60 113

Largeur

(mm)

Hauteur

(mm)

2.1.5. Mode de protection

IP65 selon EN 60529 (DIN VDE 0470 partie 1)

2.1.6. Plage de température de service

Tenir compte pour chaque type de la plage de température de service figurant dans

les Caractéristiques électriques!

03 ATEX1089 X - 41

Page 42

2.1.7. Plage de température ambiante maximale

admissible

Veuillez noter pour chaque types dans Conditions d‘emploi des bobines la plage de

température ambiante maximale admissible!

Version Installation Plage de température ambiante

maximale admissible

64.-....-...-. Montage isolé -40 °C ... +60 °C

Montage bloc -40 °C ... +45 °C

65.-....-...-. Montage isolé -40 °C ... +50 °C

Montage bloc -40 °C ... +40 °C

2.1.8. Mise en œuvre dans les distributeurs de

français

DANGER!

DANGER!

carburant

Risque d’explosion en cas d’ouverture de l’appareil!

• Les vannes ne doivent être démontées que par le fabricant. Elles

constituent toujours un système fermé.

Risque d‘explosion!

• Lors de l‘utilisation des appareils dans des distributeurs de carburants

pour commander l‘essence, le corps de vanne doit être en métal (laiton,

aluminium ou acier inoxydable) en tant qu‘appareil de catégorie 2!

Les appareils peuvent être également utilisés pour commander l’essence en catégorie 2 si dans le système fermé, il n’y a ni air, ni oxygène.

Ceci vaut également au démarrage et à la mise hors circuit du système.

vissée en bloc montée en saillie

42 - 03 ATEX1089 X

Page 43

Les bobines sont montées sur l‘armature, soit avec 4 vis à tête cylindrique M4x59

(version à bride), soit par une fixation centrale G 1/8 (version en saillie).

Elles ne doivent être démontées que par le constructeur !

Les vannes doivent toujours constituer un système fermé.

2.1.9. Version spéciale Électro-Aimant de type

655-1.5.-...-.

• Tension nominale UC 12 ... 240 V

• Tolérance de tension maximale admissible ±20 %

• Courant de calcul 0,42 ... 0,025 A

• Puissance limite en état stationnaire 5 W

• Classe de température T5

• Température ambiante -40 °C ... +40 °C

• Installation admise seulement montage isolé

Chez ces appareils, une tolérance de ±20 % est admise.

Ils doivent être installés qu‘en montage isolé.

2.1.10. Exécution avec boîte à bornes

DANGER!

Risque d‘explosion!

• Uniquement des câbles et des lignes déterminés doivent être

introduits.

• L‘exploitant doit assurer une décharge de traction correspondante.

• Des lignes ayant un diamètre extérieur de 6 mm à 13 mm peuvent être

utilisées. Tenir compte de la charge thermique maximale es câbles ou

des lignes introduits.

• Le joint qui peut s‘arracher doit être adapté au diamètre du câble/de la

ligne.

• La section de référence des conducteurs du câble/de la ligne doit

mesurer au moins 0,75 mm² et ne doit pas dépasser 2,5 mm².

• Les vis pour fixer le couvercle de la boîte de connexions doivent être

serrées à un couple de 100 Ncm (±5 %).

français

Les bobines magnétiques peuvent être aussi réalisées avec une boîte de

connexions (au choix avec ou sans fusible) (fusible selon certificat d’essai de type

séparé).

Comme protection contre toute ouverture involontaire du couvercle, ce dernier

porte l‘inscription:

à n‘ouvrir qu‘en absence de tension!

03 ATEX1089 X - 43

Page 44

3. CARACTERISTIQUES TECHNIQUES

DANGER!

Risque d‘explosion!

Le non-respect des caractéristiques techniques visées sur la plaque signalétique induit des risques graves!

Toujours respecter les caractéristiques techniques figurant sur la plaque

signalétique!

français

Dans les atmosphéres

explosives la surface des

appareils ne doit être

nettoyée qu‘á l´aide d´un

chiffon humide!

Fusible

Identification CE

No. d‘agrément PTB

Exemple

Bobine suivant dessin

Type de bobine - grandeurs de branchement

pour partie fluide - taille de bobine

Tension (±10 %) - puissance

N° de série de la bobine

No. d‘identification - date de production

Place pour Code

Sicherung/Fuse

... A

44 - 03 ATEX1089 X

Page 45

3.1. Caractéristiques électriques

Type

Classe de température

Type de courant

Tension nominale

Courant de calcul

Puissance limite en état

stationnaire

64.-....-...-. 65.-....-...-.

T4 T5

tous courants tous courants

12 ... 240 V 12 ... 240 V

0,58 ... 0,034 A 0,42 ... 0,025 A

7 W 5 W

3.1.1. Raccordement électrique

Repère Version Code interne

A * Conduite flexible en caoutchouc montée fixe du

type H05 RN-F3G0,75

** Boîte de connexions avec passe câble à

vis M20 x 1,5 sans fusible

Boîte de connexions avec raccord fileté M20 x 1,5

L

K ***

sans fusible

Boîte de connexions avec raccord fileté NPT 1/2,

sans fusible

Boîte de connexions avec raccord fileté G 1/2,

sans fusible

** Boîte de connexions avec passe câble à

vis M20 c 1,5 et fusible

Boîte de connexions avec raccord fileté M20 x 1,5

et fusible

Boîte de connexions avec raccord fileté NPT 1/2

et fusible

Boîte de connexions avec raccord fileté G 1/2 et

fusible

sans

indication

JA02

JA08

JA09

JA10

JA01

JA05

JA06

JA07

français

* La ligne de raccordement de l‘électro-aimant Type 6..- doit être posée fixe et de

manière à ce qu‘elle soit suffisamment à l‘abri de détériorations mécanique.

** Passe câble à vis selon certificat d‘essai de type séparé

*** Fusible d‘après certificat d‘essai de type séparé

REMARQUE!

La section minimale de dimensionnement des conducteurs de ligne est de

0,75 mm2.

03 ATEX1089 X - 45

Page 46

4. MONTAGE ET MISE EN SERVICE

DANGER!

Danger d‘explosion!

• L’appareil est un système fermé. L‘appareil ne doit pas être démonté!

Il faut respecter les prescriptions de sécurité suivantes:

La surface de l’appareil peut emmagasiner une charge électrostatique.

•

Dans les zones à risques de déflagration, la surface des appareils ne

doit être nettoyée qu’avec un linge humide!

• Uniquement des câbles et des lignes déterminés doivent être

introduits.

• L‘exploitant doit assurer une décharge de traction correspondante.

• Des lignes ayant un diamètre extérieur de 6 mm à 13 mm peuvent être

utilisées. Tenir compte de la charge thermique maximale es câbles ou

des lignes introduits.

français

• Le joint qui peut s‘arracher doit être adapté au diamètre du câble/de la

ligne.

• La section de référence des conducteurs du câble/de la ligne doit

mesurer au moins 0,75 mm² et ne doit pas dépasser 2,5 mm².

• Les vis pour fixer le couvercle de la boîte de connexions doivent être

serrées à un couple de 100 Ncm (±5 %).

DANGER!

Tension électrique!

Risque de blessure grave en raison d’une tension corporelle dangereuse!

Risque de dommages matériels (appareil) en cas de court-circuit!

• Les interventions sur le système électrique ne peuvent être réalisées

que par un électricien qualifié!

• Avant de commencer une intervention, couper la tension et assurer une

protection contre la remise en marche de l’appareil!

• Les bornes conductrices de tension de la boîte de bornes peuvent

causer des décharges électriques, des courts-circuits ou des explosions. Il convient de toujours couper la tension avant d’ouvrir la boîte

de bornes.

• Les lignes de raccordement des électro-aimants doivent solides et

posées de manière à être suffisamment protégées contre des dommages d’origine mécanique.

• Respecter les règles de prévention des accidents et de sécurité en

vigueur pour les appareils électriques!

46 - 03 ATEX1089 X

Page 47

AVERTISSEMENT!

Pression dans le système!

Des risques considérables de blessure existent en cas d’intervention sur le

système pneumatique.

• Les interventions sur le système pneumatique ne peuvent être réalisées

que par un personnel spécialisé et formé à cet effet, et à l’aide des

outils appropriés.

• Couper d’abord la pression, puis détacher les câbles et les vannes!

• Tenir compte du sens d’écoulement lors du montage!

• Respecter les règles de prévention des accidents et de sécurité en

vigueur pour les appareils pneumatiques!

4.1. Montage

REMARQUE!

Montage quelconque.

De préférence, placer le système aimanté sur le dessus.

Opération Remarque

Nettoyage des tuyauteries

Montage quelconque De préférence, placer l’entraînement sur le

dessus.

Monter collecteur d‘impuretés en amont

Etanchéité PTFE

Vissage des tuyauteries Tenir compte du snes de débit!

Montage / Démontage

Réaliser les branchements

électriques

Tenir compte du snes de débit!

Directive

Toujours connecter le conducteur de

protection!

Appareils avec câble de raccordement

Le câble de raccordement et la bobine sont

scellés. Ils ne doivent pas être démontés!

français

4.2. Mise en service

Avant la mise en service, assurez-vous que :

• l’appareil a été installé de manière conforme,

• le branchement a été réalisé comme il convient,

• l’appareil n’est pas endommagé,

• toutes les vis sont convenablement serrées.

03 ATEX1089 X - 47

Page 48

5. MAINTENANCE ET DERANGEMENTS

DANGER!

Risques induits par les travaux de maintenance, de réparation et de

remise en état non conformes!

• Les travaux de maintenance et de remise en état sur l’appareil ne

peuvent être exécutés que par un personnel habilité et formé à cette

fin.

• Les réparations ne doivent être exécutées que par le fabricant!

• Lors de travaux de réparation ou de maintenance sur l’installation, la

vanne ne doit pas être ouverte et la connexion du conducteur de protection ne doit pas être débranchée!

Les appareils en service dans les conditions décrites dans ces instructions sont

exempts d’entretien.

français

5.1. Derangements

En cas de dérangement, assurez-vous que :

• l’appareil a été installé de manière conforme,

• le branchement a été réalisé comme il convient,

• l’appareil n’est pas endommagé,

• toutes les vis sont convenablement serrées,

• la tension et la pression requises sont présentes,

• les conduites sont bien dégagées (aucune obstruction).

48 - 03 ATEX1089 X

Page 49

6. ACCESSOIRES

Dans la version des électro-aimants avec boîte de bornes, le fusible de type 1058

avec homologation PTB 01 ATEX 2064 U peut être utilisé en classe de

température T4.

Type de fusible 1058 N° de commande.

0,063 A 153717

0,080 A 153745

0,100 A 153718

0,125 A 153719

0,160 A 153720

0,200 A 153731

0,315 A 153733

0,400 A 153734

0,500 A 153735

0,630 A 153736

0,800 A 153737

1,000 A 153738

1,250 A 153739

1,600 A 153746

2,000 A 153740

3,150 A 153742

français

7. EMBALLAGE ET TRANSPORT

Emballer et transporter l’appareil en le protégeant contre l’humidité et les

salissures, dans son emballage d’origine ou dans un emballage offrant

une protection équivalente.

8. STOCKAGE

Stocker l’appareil au sec, à l’abri de la poussière et dans des conditions

atmosphériques!

Température de stockage: -40 ... +55 °C.

9. ÉLIMINATION

Respectez les normes nationales relatives à l’élimination des déchets!

Éliminez l’appareil de manière écologique!

03 ATEX1089 X - 49

Page 50

français

50 - 03 ATEX1089 X

Page 51

Page 52

www.burkert.com

Loading...

Loading...