Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

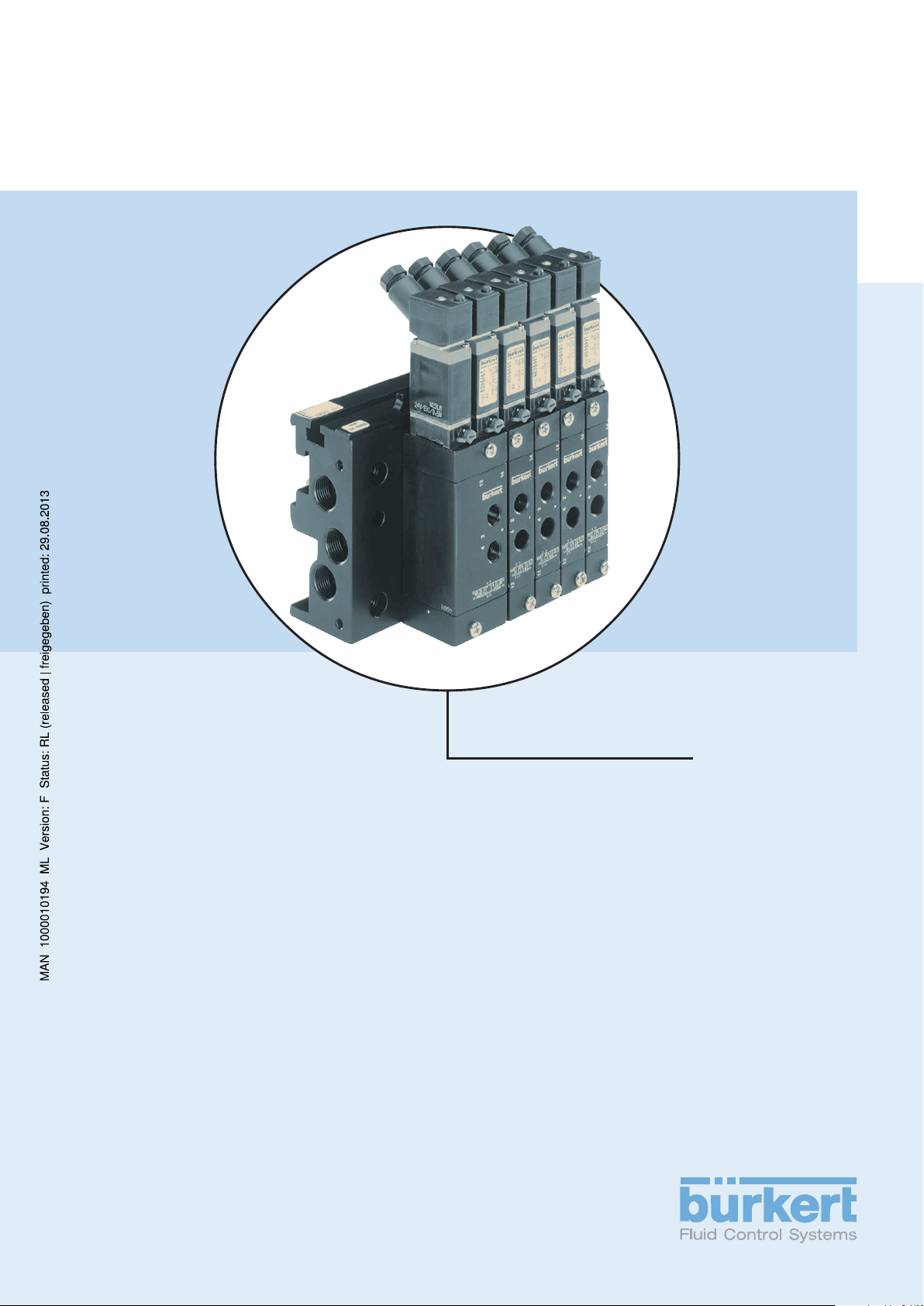

Type 0450

Block Assembly

Aluminium baseplate Type MP05

Mehrfachblock

Aluminiumgrundplatte Type MP05

bloc multiple

Plaque de montage en aluminium Type MP05

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2000 Bürkert Werke GmbH & Co. KG

Operating Instructions 0507/04_EU-ML_00803843

Page 3

C

ONTENTS

Block assembly Type 0450

Aluminium baseplate Type MP05

Contents:

GENERAL NOTES.................................................................................................................................................................................................................................... 3

Symbols ...................................................................................................................................................................................................................................................... 4

Safety notes............................................................................................................................................................................................................................................. 4

Scope of delivery ........................................................................................................................................................................................................................... 5

Warranty conditions.................................................................................................................................................................................................................. 5

english

TECHNICAL DATA ................................................................................................................................................................................................................................... 7

Valve construction........................................................................................................................................................................................................................ 8

Method of functioning of valves Type 0450 ............................................................................................................................................. 8

Media ............................................................................................................................................................................................................................................................... 8

Electrical connection ............................................................................................................................................................................................................... 9

ASSEMBLY AND COMMISSIONING...................................................................................................................................................................... 11

Measures to be taken before commissioning.................................................................................................................................. 12

Assembly and commissioning .............................................................................................................................................................................. 12

Construction of block assemblies with aluminium baseplate MP 05.............................................................. 13

Assembly of valve Type 04540 on the aluminium baseplate ...................................................................................... 14

Disassembly of valve Type 04540 from the aluminium baseplate ........................................................................ 14

Fixing the valve block to a standard rail.................................................................................................................................................. 14

Fixing the valve block to the wall

MAINTENANCE AND TROUBLE SHOOTING............................................................................................................................................ 15

Maintenance...................................................................................................................................................................................................................................... 16

Trouble shooting ........................................................................................................................................................................................................................ 16

......................................................................................................................................................................... 14

8640-0450 - 1

Page 4

C

ONTENTS

english

2 - 8640-0450

Page 5

G

ENERAL NOTES

GENERAL NOTES

english

Symbols ....................................................................................................................................................................................................................................................................... 4

Safety notes ........................................................................................................................................................................................................................................................... 4

Scope of delivery............................................................................................................................................................................................................................................ 5

Warranty conditions................................................................................................................................................................................................................................. 5

8640-0450 - 3

Page 6

G

ENERAL NOTES

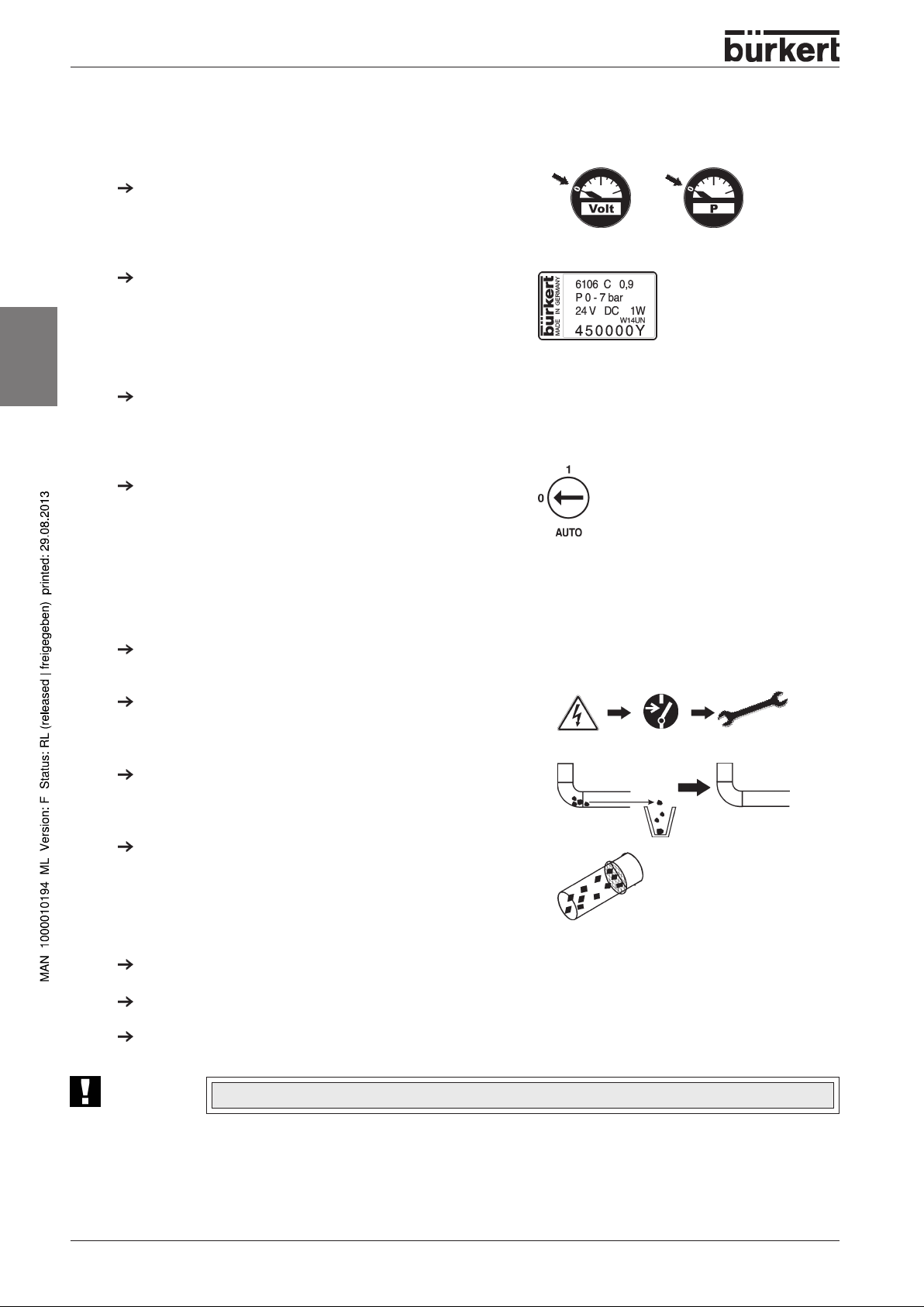

Symbols

The following symbols are used in these operating instructions:

marks a work step that you must carry out

ATTENTION!

NOTE

english

Safety notes

Please observe the notes in these operating instructions together with the conditions of use and permitted data that are specified

in the data sheets of the Block Assembly Type 0450 with Aluminium Baseplate Type MP05, in order that the device will function

perfectly and remain operable for a long time:

• Keep to standard engineering rules in planning the use of and operating the device!

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Observe the current regulations on accident prevention and safety for electrical devices during operation and maintenance of

• Before interfering with the system, always switch off the voltage supply!

• Beachten Sie, daß in Systemen, die unter Druck stehen, Leitungen und Ventile nicht gelöst werden dürfen!

marks notes on whose non-observance your health or the functioning of the device will be

endangered

marks important additional information, tips and recommendations

the device!

• Take suitable precautions to prevent unintentional operation or damage by unauthorized action!

• After interruption of the electrical or pneumatic supply, make sure the process is restarted in a well-defined, controlled

manner!

• On non-observance of these notes and unauthorized interference with the device, we will refuse all liability and the warranty

on device and accessories will become void!

NOTE

Approvals such as Ex, UL, UR, CSA, DVGW, etc. are marked on the nameplate or with a special sticker.

4 - 8640-0450

Page 7

Scope of delivery

Immediately after receipt of a shipment, make sure that the contents are undamaged and match the scope of delivery stated on

the packing slip. In general this consists of:

• Block Assembly Type 0450 with Aluminium Baseplate Type MP05

• Operating Instructions for Block Assembly Type 0450 with Aluminium Baseplate Type MP05

• Operating instructions for Pilot Valve 6106

If there are discrepancies, please contact immediately your Bürkert subsidiary or our customer service:

Warranty conditions

Bürkert Steuer- und Regelungstechnik

Chr.-Bürkert-Str. 13-17

Service-Department

D-76453 Ingelfingen

Ph.: (07940) 10-111

Fax: (07940) 10-448

E-mail: info@de.buerkert.com

G

ENERAL NOTES

english

This document contains no warranty statements. In this connection we refer to our general sales and business conditions. A

prerequisite for validity of the warranty is use of the device as intended with observance of the specified conditions of use.

ATTENTION!

The warranty covers only faultless condition of the Block Assembly Type 0450 with Aluminium Baseplate

Type MP05. No liability will be accepted for consequent damage of any kind that may arise from failure or

malfunctioning of the device.

8640-0450 - 5

Page 8

G

ENERAL NOTES

english

6 - 8640-0450

Page 9

T

ECHNICAL DATA

TECHNICAL DATA

english

Valve construction........................................................................................................................................................................................................................................ 8

Method of functioning of valves Type 0450 .............................................................................................................................................................. 8

Media ................................................................................................................................................................................................................................................................................ 8

Electrical connection ................................................................................................................................................................................................................................ 9

8640-0450 - 7

Page 10

T

ECHNICAL DATA

Valve construction

• 5/2 or 5/3-way valve with 3/2-way pilot valve Type 6106 (standard and impulse versions)

• 5/2-impulse or 5/3-way valves have double width and occupy 2 valve spaces

• Valve housing aluminium, black anodized, piston slide valve, service connections

• Service connections 2 (B) / 4 (A), supply and vent connection 1 (P) / 3 (R) / 5 (S) with interior thread G 1/8 G 1/8

• The valve can be assembled to a valve block on Aluminium Baseplate Type MP05

• Any orientation, but preferably with magnet system above

• Manual override knob for manual operating of the valve

english

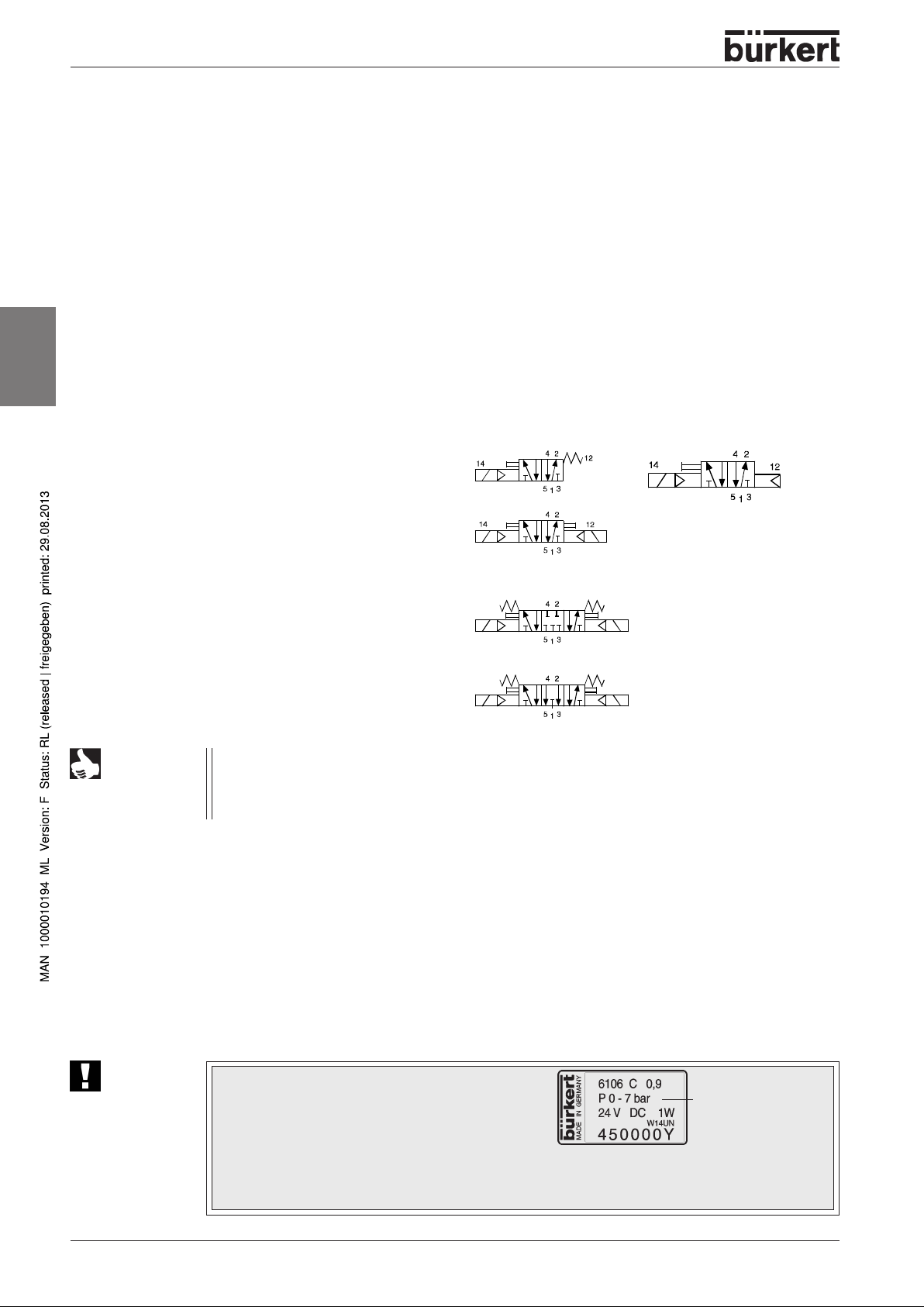

Circuit functions of valves Type 0450

H 5/2-way valve:

pilot control, de-energized, output port 2 exhausted,

various reset modes including impulse valve

Media

L 5/3-way valve:

pilot control, in middle position all connections blocked

N 5/3-way valve:

pilot control, in middle position outputs ports 2 and 4

exhausted

NOTE By sealing a service connection, the 5/2-way valve may be simply converted into a 3/2-way valve:

Service connection 2 => Circuit function C

Service connection 4 => Circuit function D

• Compressed air, lubricated, unlubricated

• Sealing material POM/NBR

• Permissible temperature range

Medium - 10 to + 70 °C

Ambient - 10 to + 55 °C

• Operating pressure range 2 - 8 bar or 2 - 10 bar

ATTENTION!

8 - 8640-0450

Observe the permissible pressure range on the nameplate!

Pressure difference between connections 1 and 3

At temperatures below 0 °C, operation is limited to dried air.

≥≥

≥ 2 bar

≥≥

Example

permissible pressure

Page 11

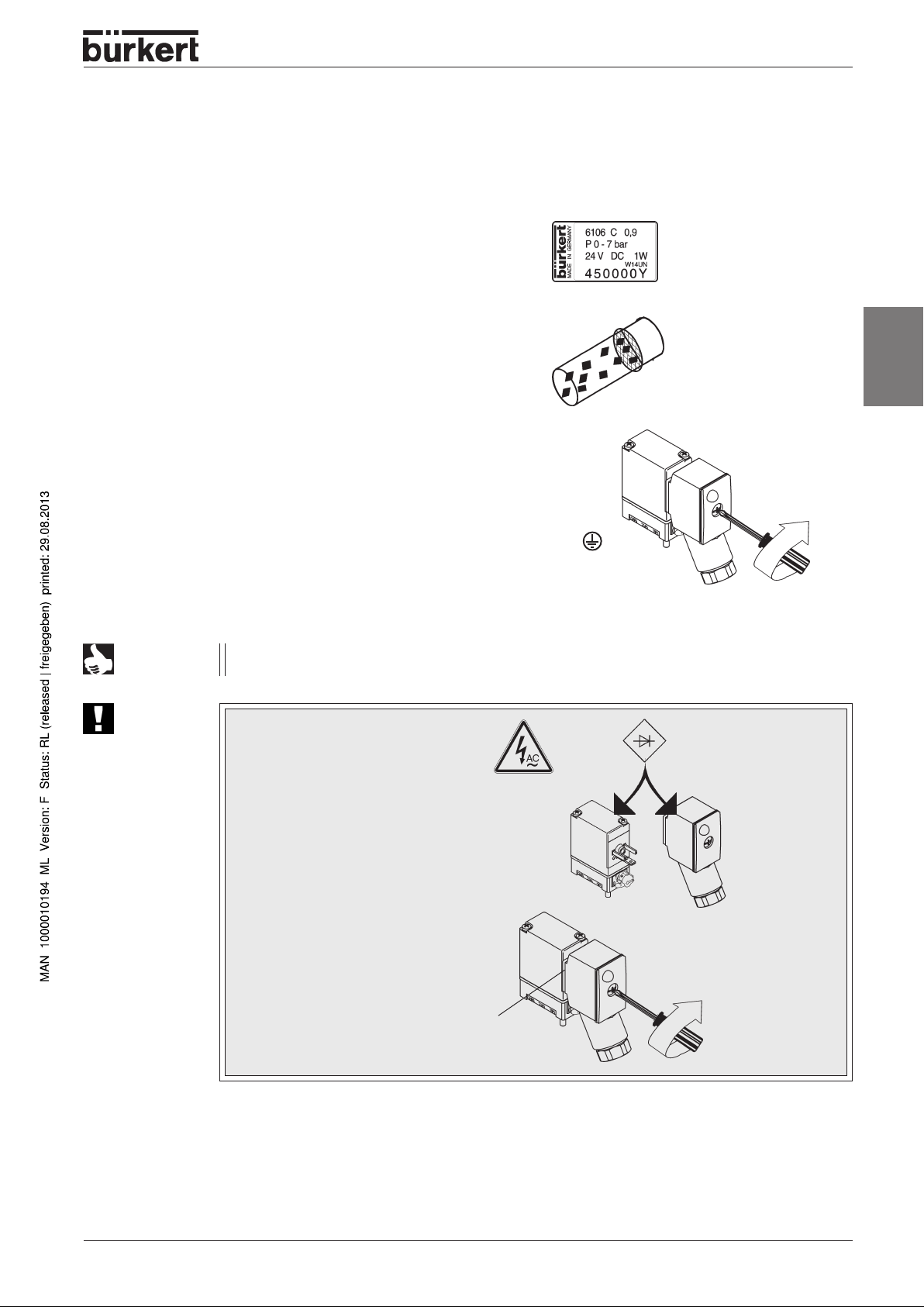

Electrical connection

Pilot valve Type 6106:

• Read the voltage, power rating and type of protection and current

from the nameplate!

• Voltage tolerance: ±10 %

• Use 10 mm filter to assure a long service life of the pilot valve!

Example

T

ECHNICAL DATA

• Electrical connection: cable connector Type 2506 onto the plug

connector of the coil (fixing torque: 0.4 Nm)

• Protection Type IP65 (only in connection with cable connector Type

2506).

• The cable connector may be mounted turned by 180° to suit the cable

direction.

NOTE

ATTENTION!

The coil heats up in operation!

Observe the voltage: with AC be sure to

use the cable connector Type 2506 or

connect a rectifier between!

10 µm

Alwys connect the

protective conductor!

english

0,4 Nm

On screwing the cable connector to the

coil, make sure the flat seal is properly

seated!

Type 2506

flat seal

8640-0450 - 9

Page 12

T

ECHNICAL DATA

english

10 - 8640-0450

Page 13

A

SSEMBLY AND COMMISSIONING

ASSEMBLY AND

COMMISSIONING

Measures to be taken before commissioning ................................................................................................................................ 12

Assembly and commissioning ............................................................................................................................................................................. 12

Construction of block assemblies with aluminium baseplate MP 05........................................................... 13

Assembly of valve Type 04540 on the aluminium baseplate..................................................................................... 14

Disassembly of valve Type 04540 from the aluminium baseplate ..................................................................... 14

Fixing the valve block to a standard rail................................................................................................................................................. 14

Fixing the valve block to the wall...................................................................................................................................................................... 14

english

8640-0450 - 11

Page 14

A

SSEMBLY AND COMMISSIONING

Measures to be taken before commissioning

Check connections, voltage and operating pressure!

0 bar, psi, kPa

Make sure that the max. operating data (see nameplate) are

not exceeded!

english

Check that configuration of connections 1 and 3 is according

to instructions; under no circumstances may they be

exchanged!

With electrical operation, turn the manual override knob to

automatic (0)!

Assembly and commissioning

Interventions shall be carried out only by specialist

personnel using suitable tools!

Before intervening in the system, always switch off the

voltage supply!

Example

Clean the piping before assembling the valve!

If necessary, install a dirt trap upstream to avoid

malfunctions.

In no case use the coil as a lever when screwing in connections!

Make sure operating conditions match the performance data of the device!

Avoid backpressure in the exhaust air channels by using large-volume silencers!

ATTENTION!

Lines and valves shall not be loosened in systems under pressure!

12 - 8640-0450

Page 15

Manual operation

For manual operation of the valve, turn

manual override knob by 90° in the

direction of the arrow (1).

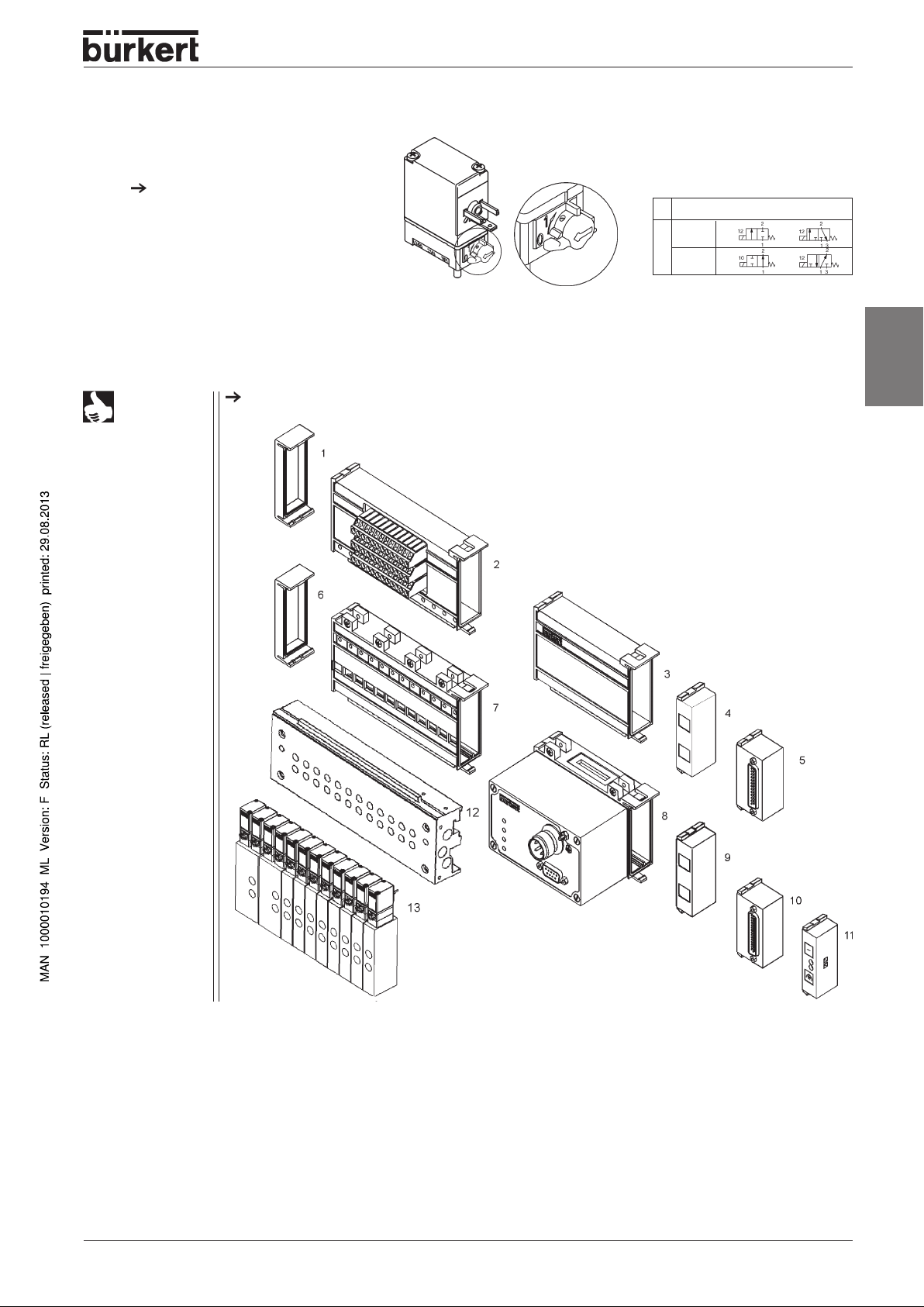

Building up block assemblies with aluminium baseplate MP 05

A

SSEMBLY AND COMMISSIONING

0AUTO

1

1/P ➜ 2/A

2/A ➜ 3/R

A

B

C

D

NOTE

It is expedient to begin assembly with the left-hand connection module.

english

8640-0450 - 13

Page 16

A

SSEMBLY AND COMMISSIONING

Assembly of valve Type 04540 on the aluminium baseplate

Place the 3 O-rings in the recess in the back of the valve. Make sure they are seated exactly!

english

ATTENTION!

Fix the valves with 2 screws each to the aluminium baseplate (tightening torque max. 0.5 Nm).

Mount the complete valve block on the wall or the standard rail.

Connect the supply and working lines.

Make the electrical connections to the pilot valves; observe the data on the nameplate!

Squeezing the O-rings will result in a leaky block!

Disassembly of valve Type 04540 from the aluminium baseplate

Unscrew the 2 screws at the valve from the aluminium baseplate.

Remove the valve in the forward direction.

Take care of the O-rings.

Fixing the valve block to a standard rail

Assembly

Hook the valve block with the upper groove in the standard rail.

Engage the lower clamps in the standard rail.

Tighten the screws on the clamps.

Disassembly

Loosen the clamping screws (approx. 4 turns).

Remove the block upwards from the standard rail.

Fixing the valve block to the wall

Fix the valve block with M6 screws directly to the wall.

14 - 8640-0450

Page 17

M

AINTENANCE AND TROUBLE SHOOTING

MAINTENANCE AND

TROUBLE SHOOTING

english

Maintenance................................................................................................................................................................................................................................................. 16

Trouble shooting ................................................................................................................................................................................................................................... 16

8640-0450 - 15

Page 18

M

AINTENANCE AND TROUBLE SHOOTING

Maintenance

The valves work without maintenance, even when running dry.

Trouble shooting

Fault Possible cause Remedy

english

Valves do not switch Operating voltage not present or

insufficient

Manual override knob not in neutral

position

Pressure supply insufficient or not present Execute pressure supply with as large a

Valves switch with

delay or blow out at

the vent connections

Pressure supply insufficient or not present Execute pressure supply with as large a

Venting of exhaust air channels insufficient

because silencers are too small or

contaminated (backpressure)

Check the electrical connection

Provide operating voltage acc. to nameplate

Turn knob to zero position

volume as possible (also for upstream

devices such as pressure controllers,

maintenance units, shut-off valves, etc)

Minimum operating pressure > 2 bar

volume as possible (also for upstream

devices such as pressure controllers,

maintenance units, shut-off valves, etc)

Minimum operating pressure > 2 bar

Use matching, large-sized silencers or

expansion vessels.

Clean the contaminated silencers.

Contamination or foreign bodies in pilot or

main valve

Leaky valve blocks Flat seals missing or wrongly positioned

between valve and baseplate

Pressurized the exhaust air channels in

pulses to blow out contamination

Install a new pilot or main valve if pulses of

compressed air bring no result.

Insert missing seals or replace damaged

seals.

16 - 8640-0450

Page 19

I

NHALT

Mehrfachblock Typ 0450

Aluminiumgrundplatte Typ MP05

Inhalt:

ALLGEMEINE HINWEISE .......................................................................................................................................................................................................... 19

Darstellungsmittel .................................................................................................................................................................................................................... 20

Sicherheitshinweise ................................................................................................................................................................................................................ 20

Lieferumfang .................................................................................................................................................................................................................................... 21

Garantiebestimmungen.................................................................................................................................................................................................... 21

TECHNISCHE DATEN ....................................................................................................................................................................................................................... 23

Aufbau des Ventils ................................................................................................................................................................................................................... 24

Wirkungsweisen der Ventile Typ 0450 ......................................................................................................................................................... 24

Medien ....................................................................................................................................................................................................................................................... 24

Elektrischer Anschluß........................................................................................................................................................................................................ 25

MONTAGE UND INBETRIEBNAHME ...................................................................................................................................................................... 27

Maßnahmen vor der Inbetriebnahme............................................................................................................................................................ 28

Montage und Inbetriebnahme ................................................................................................................................................................................. 28

Aufbau von Mehrfachblöcken mit der Aluminiumgrundplatte MP 05................................................................ 29

Montage des Ventils Typ 0450 auf die Aluminiumgrundplatte ................................................................................. 30

deutsch

Demontage des Ventils Typ 0450 von der Aluminiumgrundplatte...................................................................... 30

Befestigung des Ventilblocks an einer Normschiene ........................................................................................................... 30

Befestigung des Ventilblocks an der Wand

INSTANDHALTUNG UND WARTUNG .................................................................................................................................................................... 31

Wartung ................................................................................................................................................................................................................................................... 32

Störungsbeseitigung............................................................................................................................................................................................................ 32

........................................................................................................................................... 30

8640-0450 - 17

Page 20

deutsch

I

NHALT

18 - 8640-0450

Page 21

A

LLGEMEINE HINWEISE

ALLGEMEINE

HINWEISE

deutsch

Darstellungsmittel .............................................................................................................................................................................................................. 20

Sicherheitshinweise ........................................................................................................................................................................................................ 20

Lieferumfang .................................................................................................................................................................................................................................. 21

Garantiebestimmungen.............................................................................................................................................................................................. 21

8640-0450 - 19

Page 22

A

LLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes

gefährdet ist

kennzeichnet wichtige Zusatzinformationen, Tips und Empfehlungen

Sicherheitshinweise

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten, die im Datenblatt

des Mehrfachblocks Typ 0450 mit der Aluminiumgrundplatte MP05 spezifiziert sind, damit das Gerät einwandfrei funktioniert und

lange einsatzfähig bleibt:

deutsch

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der Technik!

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte während des Betriebes

und der Wartung des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Beachten Sie, daß in Systemen, die unter Druck stehen, Leitungen und Ventile nicht gelöst werden dürfen!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung auszuschließen!

• Gewährleisten Sie nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung einen definierten und

kontrollierten Wiederanlauf des Prozesses!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung unsererseits, ebenso

erlischt die Garantie auf Geräte und Zubehörteile!

HINWEIS

Zulassungen wie Ex, UL, UR, CSA, DVGW usw. werden auf dem Typenschild oder durch einen besonderen

Aufkleber gekennzeichnet.

20 - 8640-0450

Page 23

Lieferumfang

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, daß der Inhalt nicht beschädigt ist und mit dem auf dem beigelegten

Packzettel angegebenen Lieferumfang übereinstimmt. Generell besteht dieser aus:

• dem Mehrfachblock Typ 0450 mit Aluminiumgrundplatte MP05

• der Bedienungsanleitung für Typ 0450 mit Aluminiumgrundplatte MP05

• der Bedienungsanleitung des Vorsteuerventils 6106

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an an Ihre Bürkert-Niederlassung oder an unseren Kundenservice:

Bürkert Steuer- und Regelungstechnik

Chr.-Bürkert-Str. 13-17

Service-Abteilung

D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

E-mail: info@de.buerkert.com

A

LLGEMEINE HINWEISE

Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf unsere allgemeinen Verkaufs- und Geschäftsbedingungen. Voraussetzung für die Garantie ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten

Einsatzbedingungen.

ACHTUNG!

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit des Mehrfachblocks Typ 0450 mit Aluminiumgrundplatte MP05. Es wird jedoch keine Haftung übernommen für Folgeschäden jeglicher Art, die durch

Ausfall oder Fehlfunktion des Gerätes entstehen könnten.

deutsch

8640-0450 - 21

Page 24

A

LLGEMEINE HINWEISE

deutsch

22 - 8640-0450

Page 25

T

ECHNISCHE DATEN DES VENTILS

TECHNISCHE DATEN

deutsch

Aufbau des Ventils................................................................................................................................................................................................................................... 24

Wirkungsweisen der Ventile Typ 0450 ......................................................................................................................................................................... 24

Medien .............................................................................................................................................................................................................................................................. 24

Elektrischer Anschluß........................................................................................................................................................................................................................ 25

8640-0450 - 23

Page 26

T

ECHNISCHE DATEN DES VENTILS

Aufbau des Ventils

• 5/2- bzw. 5/3-Wegeventil mit 3/2-Wege-Vorsteuerventil Typ 6106 (Standard- und Impulsausführung)

• 5/2-Impuls bzw. 5/3-Wegeventil haben doppelte Baubreite, sie belegen 2 Ventilplätze

• Ventilgehäuse Aluminium schwarz eloxiert, Kolbenschieberventil, Arbeitsanschlüsse

• Arbeitsanschlüsse 2 (B) / 4 (A) sowie Versorgungs- und Entlüftungsanschluß 1 (P) / 3 (R) / 5 (S) mit Innengewinde G 1/8

• die Ventile können auf den Aluminiumplatten Typ MP05 zu Ventilblöcken montiert werden

• beliebige Einbaulage, vorzugsweise mit Magnetsystem oben

• Handbetätigung für manuelles Betätigen des Ventils

Wirkungsweisen der Ventile Typ 0450

H 5/2-Wege-Ventil:

deutsch

vorgesteuert, stromlos Ausgang 2 druckentlüftet,

verschiedene Rückstellarten einschließlich Impulsventil

Medien

L 5/3-Wege-Ventil:

vorgesteuert, in Mittelstellung alle Anschlüsse gespert

N 5/3-Wege-Ventil:

vorgesteuert, in Mittelstellung Ausgänge 2 und 4 entlüftet

HINWEIS Durch Verschließen eines Arbeitsanschlusses ist ein einfacher Umbau des 5/2-Wegeventils in ein 3/2-Wege-

ventil möglich:

Arbeitsanschluß 2 => Wirkungsweise C

Arbeitsanschluß 4 => Wirkungsweise D

• Druckluft geölt und ungeölt

• Dichtwerkstoff POM/NBR

• zulässige Temperatur

Medium - 10 bis + 70 °C

Umgebung - 10 bis + 55 °C

• Betriebsdruckbereich 2 - 8 bar bzw. 2 - 10 bar

ACHTUNG!

24 - 8640-0450

Beachten Sie den zulässigen Druckbereich

auf dem Typenschild!

Druckdifferenz zwischen Anschluß 1 und 3

Bei Temperaturen unter 0 ° C ist der Betrieb auf getrocknete Luft beschränkt.

≥ ≥

≥ 2 bar

≥ ≥

Beispiel:

zulässiger Druckbereich

Page 27

Elektrischer Anschluß

Vorsteuerventil Typ 6106:

• Entnehmen Sie Spannung, elektrische Leistung, Schutz- und

Stromart dem Typenschild!

• Spannungstoleranz: ±10 %

• Sorgen Sie durch 10 µ-Filterung für eine lange Lebensdauer des

Vorsteuerventils!

• Elektrischer Anschluß: Gerätesteckdose Typ 2506 an den Anschlußsteckerfahnen der Spule (Drehmoment zur Befestigung: 0,4 Nm)

• Schutzart IP65 (nur in Verbindung mit der Gerätesteckdose Typ 2506)

T

ECHNISCHE DATEN DES VENTILS

Beispiel

10 µm

deutsch

0,4 Nm

• Die Gerätesteckdose ist zur Wahl der Kabelganges um 180° versetzt

montierbar

HINWEIS

ACHTUNG!

Die Spule erwärmt sich im Betrieb!

Beachten Sie die Spannung, verwenden

Sie bei Wechselspannung unbedingt die

Gerätesteckdose Typ 2506 oder schalten

Sie einen Gleichrichter vor!

Achten Sie beim Verschrauben der

Gerätesteckdose mit der Spule auf einwandfreien Sitz der Flachdichtung!

Schutzleiter immer

anschließen!

Type 2506

Dichtung

8640-0450 - 25

Page 28

T

ECHNISCHE DATEN DES VENTILS

deutsch

26 - 8640-0450

Page 29

M

ONTAGE UND INBETRIEBNAHME

MONTAGE UND

INBETRIEBNAHME

deutsch

Maßnahmen vor der Inbetriebnahme ............................................................................................................................................................ 28

Montage und Inbetriebnahme ................................................................................................................................................................................ 28

Aufbau von Mehrfachblöcken mit der Aluminiumgrundplatte MP 05 .......................................................... 29

Montage des Ventils Typ 0450 auf die Aluminiumgrundplatte .............................................................................. 30

Demontage des Ventils Typ 0450 von der Aluminiumgrundplatte..................................................................... 30

Befestigung des Ventilblocks an einer Normschiene .......................................................................................................... 30

Befestigung des Ventilblocks an der Wand ........................................................................................................................................ 30

8640-0450 - 27

Page 30

M

ONTAGE UND INBETRIEBNAHME

Maßnahmen vor der Inbetriebnahme

Überprüfen Sie Anschlüsse, Spannung und Betriebsdruck!

0 bar, psi, kPa

Beachten Sie, daß max. Betriebsdaten (siehe Typenschild)

nicht überschritten werden!

Überprüfen Sie die vorschriftsmäßige Belegung der

Anschlüsse 1 und 3, diese dürfen auf keinen Fall vertauscht

werden!

deutsch

Stellen Sie die Handbetätigung bei elektrischem Betrieb auf

Automatik (0) um!

Montage und Inbetriebnahme

Eingriffe dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen!

Schalten Sie vor Eingriffen in das System in jedem Fall die

Spannung ab!

Beispiel

Säubern Sie vor Montage des Ventils die Rohrleitungen!

Schalten Sie gegebenenfalls zum Schutz vor Störungen

einen Schmutzfänger vor.

Verwenden Sie die Spule in keinem Fall als Hebel, wenn Sie die Anschlüsse einschrauben!

Achten Sie auf Übereinstimmung der Betriebsbedingungen mit den Leistungsdaten des Gerätes!

Vermeiden Sie Staudrücke in den Abluftkanälen durch großvolumige Schalldämpfer!

ACHTUNG!

In Systemen, die unter Druck stehen, dürfen Leitungen oder Ventile nicht gelöst werden!

28 - 8640-0450

Page 31

M

ONTAGE UND INBETRIEBNAHME

Handbetätigung

Drehen Sie zur manuellen Betätigung des

Ventils die Handbetätigung um 90° in

Pfeilrichtung (1).

Aufbau von Mehrfachblöcken mit der Aluminiumgrundplatte MP 05

0AUTO

1/P ➜ 2/A

1

2/A ➜ 3/R

A

B

C

D

HINWEIS

Beginnen Sie den Aufbau zweckmäßig mit dem Anschlußmodul - links - .

deutsch

8640-0450 - 29

Page 32

M

ONTAGE UND INBETRIEBNAHME

Montage des Ventils Typ 0450 auf die Aluminiumgrundplatte

Legen Sie die 3 O-Ringe in die Aussparung auf der Rückseite des Ventils. Achten Sie dabei auf exakten Sitz der Dichtungen!

ACHTUNG!

Befestigen Sie die Ventile mit je 2 Schrauben auf der Aluminiumgrundplatte (Anzugsmoment max. 0,5 Nm).

Montieren Sie den kompletten Ventilblock an der Wand oder Normschiene.

Schließen Sie Versorgungs- und Arbeitsleitungen an.

Stellen Sie die elektrischen Anschlüsse zu den Pilotventilen her; beachten Sie dabei die Werte auf dem Typenschild!

Gequetschte O-Ringe haben Undichtheit des Blocks zur Folge!

Demontage des Ventils Typ 0450 von der Aluminiumgrundplatte

deutsch

Lösen sie die 2 Schrauben am Ventil von der Aluminiumgrundplatte

Ziehen Sie das Ventil nach vorne ab

Achten Sie auf die O-Ringe

Befestigung des Ventilblocks an einer Normschiene

Montage

Hängen Sie den Ventilblock mit der oberen Nut in die Normschiene ein.

Rasten Sie die unteren Klemmstücke in die Normschiene ein.

Ziehen Sie die Schrauben an den Klemmstücken fest.

Demontage

Lösen Sie die Klemmschrauben (ca. 4 Umdrehungen).

Entnehmen Sie den Block nach oben von der Normschiene.

Befestigung des Ventilblocks an der Wand

Befestigen Sie den Ventilblock mit M6-Schrauben direkt an der Wand.

30 - 8640-0450

Page 33

I

NSTANDHALTUNG UND WARTUNG

INSTANDHALTUNG

UND WARTUNG

deutsch

Wartung ......................................................................................................................................................................................................................................................... 32

Störungsbeseitigung ........................................................................................................................................................................................................................ 32

8640-0450 - 31

Page 34

I

NSTANDHALTUNG UND WARTUNG

Wartung

Die Ventile arbeiten wartungsfrei, auch bei Trockenlauf.

Störungsbeseitigung

Störungen mögliche Ursache Behebung

deutsch

Ventile schalten nicht keine oder nicht ausreichende

Betriebsspannung

Handbetätigung nicht in neutraler

Stellung

Druckversorgung nicht ausreichend

oder nicht vorhanden

Ventile schalten verzögert oder blasen

an den Entlüftungsanschlüssen ab

Druckversorgung nicht ausreichend

oder nicht vorhanden

keine ausreichende Entlüftung der

Abluftkanäle durch zu kleine oder

verschmutzte Geräuschdämpfer

(Rückdrücke)

Überprüfen Sie den elektrischen Anschluß

Stellen Sie die Betriebsspannung laut

Typenschild sicher

Bringen Sie die Handbetätigung in NullStellung

Führen Sie die Druckversorgung möglichst

großvolumig aus (auch bei vorgeschalteten

Geräten wie Druckreglern,

Wartungseinheiten, Absperrventilen usw.)

Mindestbetriebsdruck > 2 bar

Führen Sie die Druckversorgung möglichst

großvolumig aus (auch bei vorgeschalteten

Geräten wie Druckreglern,

Wartungseinheiten, Absperrventilen usw.)

Mindestbetriebsdruck > 2 bar

Verwenden Sie entsprechend groß

dimensionierte Geräuschdämpfer bzw.

Expansionsgefäße.

Undichte Ventilblöcke Fehlende oder falsch positionierte

32 - 8640-0450

Verunreinigungen bzw. Fremdkörper

im Vorsteuer- oder Hauptventil

Flachdichtungen zwischen Ventil und

Grundplatte.

Reinigen Sie verschmutzte

Geräuschdämpfer

Beaufschlagen Sie die Abluftkanäle mit

impulsartigem Druck, um die

Verunreinigungen auszublasen

Bauen Sie ein neues Vorsteuer- bzw.

Hauptventil ein, wenn die impulsartige

Druckbeaufschlagung keinen Erfolg bringt

Setzen Sie fehlende Dichtungen ein oder

erneuern Sie beschädigte Dichtungen

Page 35

C

ONTENU

Multibloc type 0450

Plaque de montage en aluminium type MP05

Contenu:

REMARQUES GENERALES ................................................................................................................................................................................................. 35

Représentation.............................................................................................................................................................................................................................. 36

Consignes générales de sécurité ...................................................................................................................................................................... 36

Fourniture............................................................................................................................................................................................................................................. 37

Dispositions de garantie................................................................................................................................................................................................. 37

CARACTERISTIQUES TECHNIQUES .................................................................................................................................................................. 39

Structure de la soupape .................................................................................................................................................................................................... 40

Mode de fonctionnement de la soupape type 0450 ................................................................................................................... 40

Fluides....................................................................................................................................................................................................................................................... 40

Raccordement électrique............................................................................................................................................................................................... 41

MONTAGE ET MISE EN SERVICE............................................................................................................................................................................. 43

Mesures à prendre avant la mise en service....................................................................................................................................... 44

Montage et mise en service ......................................................................................................................................................................................... 44

Montage des multiblocs avec la plaque de montage en aluminium type MP 05........................... 45

Montage de la soupape type 0450 de la plaque de montage en aluminium ........................................ 46

Démontage de la soupape type 0450 de la plaque de montage en

aluminium MP 05........................................................................................................................................................................................................................ 46

français

Fixation du bloc de distribution et régulation sur un rail normalisé .............................................................. 46

Fixation du bloc de distribution et de régulation au mur

MAINTENANCE ET ENTRETIEN.................................................................................................................................................................................. 47

Entretien ................................................................................................................................................................................................................................................. 48

Dépannage .......................................................................................................................................................................................................................................... 48

................................................................................................ 46

8640-0450 - 33

Page 36

C

ONTENU

français

34 - 8640-0450

Page 37

R

EMARQUES GENERALES

REMARQUES

GENERALES

Représentation........................................................................................................................................................................................................................ 36

Consignes générales de sécurité ................................................................................................................................................................ 36

Fourniture......................................................................................................................................................................................................................................... 37

Dispositions de garantie........................................................................................................................................................................................... 37

français

8640-0450 - 35

Page 38

R

EMARQUES GENERALES

Symboles de représentation

Les symboles de représentation suivants sont utilisés dans cette notice de service:

marque une étape de travail devant être exécutée

ATTENTION!

REMARQUE

caractérise des instructions dont l’inobservation entraîne des risques pour votre santé ou met en cause la

fonctionnalité de l’appareil

caractérise des informations supplémentaires importantes, des conseils et des recommandations

Consignes de sécurité

Veuillez tenir compte des consignes de cette notice de service de même que des conditions d’emploi et données admissibles

spécifiées dans les fiches techniques du multibloc type 0450 avec la plaque de montage en aluminium type MP 05 afin que

l’appareil fonctionne parfaitement et reste longtemps opérationnel:

• S’en tenir aux règles techniques généralement reconnues lors du projet de mise en œuvre et du service de l’appareil!

• L’installation et les interventions nécessitées par la maintenance ne doivent être effectuées que par un personnel qualifié

équipé des outils adéquats!

français

• Respecter les dispositions en vigueur de prévention des accidents et de sécurité pour appareils électriques pendant le

service, la maintenance de l’appareil!

• Toujours couper la tension avant d’intervenir dans le système!

• Observer que les conduites et les vannes des systèmes se trouvant sous pression ne doivent pas être démontées!

• Prendre les mesures qui s’imposent pour éviter un actionnement par inadvertance de l’appareil ou une mise en cause

inadmissible de son fonctionnement

• Assurer un redémarrage défini et contrôlé du processus après une panne de l’alimentation électrique ou pneumatique!

• En cas d’inobservation de ces consignes et d’interventions non autorisées dans l’appareil, nous déclinons toute

responsabilité de même qu’elles entraînent l’annulation de la garantie sur l’appareil et les pièces accessoires!

REMARQUE

Les homologations telles que Ex, UL, UR, CSA, DVGW etc. figurent sur la plaque signalétique ou sur une

étiquette collante spéciale.

36 - 8640-0450

Page 39

Fourniture

Contrôler dès réception de l’envoi que le contenu n’a subi aucun dommage et qu’il correspond bien à la fourniture figurant sur le

bordereau d’envoi. Ce dernier comprend généralement:

• le multibloc type 0450 avec la plaque de montage en aluminium type MP 05

• la notice de service pour le type 0450 avec plaque de montage en aluminium type MP 05

• la notice de service de la soupape pilote 6106

En cas de non concordance, s’adresser immédiatement à votre succursale Bürkert ou à notre service après vente:

Dispositions de garantie

Bürkert Steuer- und Regelungstechnik

Chr.-Bürkert-Str. 13-17

Service-Abteilung

D-76453 Ingelfingen

Tel.: (07940) 10-111

Fax: (07940) 10-448

E-mail: info@de.buerkert.com

R

EMARQUES GENERALES

Ce document ne constitue aucun assentiment de garantie. Nous vous renvoyons à cet effet à nos conditions générales de vente

et commerciales. La condition préalable au consentement de la garantie est l’utilisation conforme de l’appareil à l’usage auquel il

est destiné, compte tenu de l’observation des conditions d’emploi spécifiées.

ATTENTION!

Les prestations de garantie ne s’étendent qu’à l’absence de défaut du Multibloc type 0450 avec la plaque

de montage en aluminium type MP 05. Nous déclinons, par contre, toute responsabilité pour des dégâts

consécutifs de toute nature susceptibles de survenir par suite de défaillance ou défaut de fonctionnement

de l’appareil.

français

8640-0450 - 37

Page 40

R

EMARQUES GENERALES

français

38 - 8640-0450

Page 41

C

ARACTÉRISTIQUES TECHNIQUES

CARACTERISTIQUES

TECHNIQUES

Structure de la soupape .................................................................................................................................................................................................................. 40

Mode de service de la soupape type 0450............................................................................................................................................................ 40

Fluides ............................................................................................................................................................................................................................................................ 40

Raccordement électrique .............................................................................................................................................................................................................. 41

français

8640-0450 - 39

Page 42

C

ARACTÉRISTIQUES TECHNIQUES

Structure de la soupape

• Soupape 5/2 ou 5/3 voies avec soupape pilote 3/2 voies type 6106 (version standard et à impulsions)

• Les soupapes à impulsions 5/2 ou 5/3 voies ont une largeur double, elles occupent deux places de soupape

• Boîtier de soupape en aluminium noir anodisé, soupape à coulisse à piston, raccords de travail

• Raccords de travail 2 (B) / 4 (A) de même que raccord d’alimentation et de purge 1 (P) / 3 (R) / 5 (S) avec taraudage G 1/8

• Les soupapes peuvent être montées comme blocs de distribution et de régulation sur les plaques en aluminium type MP 05

• Position de montage quelconque de préférence avec système magnétique en haut

• Actionnement à la main pour manœuvre manuelle de la soupape

Mode de fonctionnement de la soupape type 0450

H soupape 5/2 voies:

pilotée, sans courant, sortie 2 purgée sous pression,

différents modes de rappel, y compris soupape à impulsions

français

L soupape 5/3 voies:

pilotée, en position moyenne tous les raccords bloqués

N soupape 5/3 voies:

pilotée, en position moyenne sorties 2 et 4 purgées

REMARQUE En fermant un raccord de travail, on transforme simplement la soupape 5/2 voies en une soupape 3/2 voies:

Fluides

• Air comprimé huilé et non huilé

• Matière étanche POM/NBR

• Température admissible

• Plage de pression de service 2 - 8 bar ou 2 - 10 bar

Raccord de travail 2 => mode d’action C

Raccord de travail 4 => mode d’action D

Fluide - 10 à + 70 °C

Ambiance - 10 à + 55 °C

ATTENTION!

40 - 8640-0450

Tenir compte de la plage de pression admissible sur

la plaque signalétique!

Différence de pression entre raccord 1 et 3

À des températures inférieures à 0°C, le service est limité à l’air sec.

≥ ≥

≥ 2 bars

≥ ≥

Exemple:

Plage de température

admissible

Page 43

Raccordement électrique

Soupape pilote type 6106:

• Tension, puissance électrique, protection et genre de courant figurent

sur la plaque signalétique!

• Tolérance de tension: ±10 %

• Assurer une grande longévité à la soupape pilote avec un filtrage de

10 µ!

• Raccordement électrique: prise mobile de connecteur type 2506 aux

cosses à fiches de branchement de la bobine (couple de serrage 0,4

Nm)

Exemple

C

ARACTÉRISTIQUES TECHNIQUES

10 µm

• Type de protection IP65 (seulement en liaison avec la prise mobile de

connecteur type 2506)

• La prise mobile de connecteur se monte, décalée de 180°, pour le

choix de l’entrée de câble

REMARQUE

ATTENTION!

La bobine s’échauffe en service!

Faire attention à la tension. Utiliser

impérativement une prise mobile type

2506 en courant alternatif, autrement

monter un redresseur en amont!

Veiller en vis sant la prise mobile avec la

bobine à ce que le joint plat soit bien en

place!

Toujours brancher la

prise de terre!

0,4 Nm

français

Type 2506

Joint

8640-0450 - 41

Page 44

C

ARACTÉRISTIQUES TECHNIQUES

français

42 - 8640-0450

Page 45

M

ONTAGE ET MISE EN SERVICE

MONTAGE ET MISE

EN SERVICE

Mesures à prendre avant la mise en service.................................................................................................................................... 44

Montage et mise en service ...................................................................................................................................................................................... 44

Montage des multiblocs avec la plaque de montage en aluminium

type MP 05 ............................................................................................................................................................................................................................................ 45

Montage de la soupape type 0450 de la plaque de montage en aluminium....................................... 46

Démontage de la soupape type 0450 de la plaque de montage en

aluminium MP 05 ...................................................................................................................................................................................................................... 46

Fixation du bloc de distribution et régulation sur un rail normalisé............................................................. 46

Fixation du bloc de distribution et de régulation au mur............................................................................................... 46

français

8640-0450 - 43

Page 46

M

ONTAGE ET MISE EN SERVICE

Mesures à prendre avant la mise en service

Vérifier les raccordements, la tension et la pression de

service!

Veiller à ce que les caractéristiques opérationnelles ne

soient pas dépassées (voir plaque signalétique)!

Vérifier si l’occupation des raccords 1 et 3 est conforme aux

prescriptions. Ils ne doivent en aucun cas être interchangés!

Commuter la commande manuelle en service électrique sur

Automatique (0)!

0 bar, psi, kPa

Exemple

français

Montage et mise en service

Les interventions ne doivent être effectuées que par un

personnel qualifié, équipé de l’outillage adéquat!

Couper chaque fois la tension avant d’intervenir dans le

système!

Nettoyer la tuyauterie avant de monter la soupape!

Monter, le cas échéant, un collecteur de saletés pour se

mettre à l’abri de pannes.

Ne jamais utiliser .la bobine comme levier pour visser les raccords!

Veiller à ce que les conditions de service concordent avec les données de puissance de l’appareil!

Eviter les pressions de retenue dans les canaux d’échappement d’air par des silencieux de grand volume!

ATTENTION!

44 - 8640-0450

Dans les systèmes sous pression, les conduites ou soupapes ne doivent pas être desserrées!

Page 47

M

ONTAGE ET MISE EN SERVICE

Manœuvre manuelle

Tourner la commande à main dans le sens

de la flèche (1) de 90° pour manœuvrer

manuellement la soupape.

0AUTO

1/P ➜ 2/A

1

2/A ➜ 3/R

Montage des multiblocs avec la plaque de montage en aluminium type MP 05

A

B

C

D

REMARQUE

Commencer le montage de manière appropriée par le module de raccordement – gauche - .

français

8640-0450 - 45

Page 48

M

ONTAGE ET MISE EN SERVICE

Montage de la soupape type 0450 de la plaque de montage en aluminium

Mettre les 3 joints toriques dans l’évidement au dos de la soupape. Veiller ce faisant à ce que les joint soient bien en place!

ATTENTION!

Fixer chacune des soupapes avec 2 vis sur la plaque de montage en aluminium (couple de serrage 0,5 Nm).

Monter le bloc complet de distribution et de régulation au mur ou sur un rail normalisé.

Raccorder l’alimentation et les conduites de travail.

Brancher les raccords électriques aux soupapes pilotes, tenir compte des valeurs figurant sur la plaque signalétique!

Des joints toriques écrasés ont pour conséquence un bloc non étanche!

Démontage de la soupape type 0450 de la plaque de montage en aluminium MP 05

Desserrer les 2 vis de la soupape de la plaque en aluminium

Tirer la soupape vers l’avant

français

Faire attention aux joints toriques

Fixation du bloc de distribution et régulation sur un rail normalisé

Montage

Accrocher le bloc par la rainure supérieure dans le rail normalisé.

Encliqueter les pièces de calage inférieures dans le rail normalisé.

Bien serrer les vis des pièces de calage.

Démontage

Desserrer les vis de calage (environ 4 tours).

Retirer le bloc vers le haut du rail normalisé.

Fixation du bloc de distribution et de régulation au mur

Fixer le bloc directement au mur avec des vis M6.

46 - 8640-0450

Page 49

M

AINTENANCE ET ENTRETIEN

MAINTENANCE ET

ENTRETIEN

Entretien ....................................................................................................................................................................................................................................................... 48

Dépannage ..................................................................................................................................................................................................................................................... 48

français

8640-0450 - 47

Page 50

M

AINTENANCE ET ENTRETIEN

Entretien

Les soupapes travaillent sans entretien, aussi en marche à sec.

Dépannage

Pannes Cause possible Remède

français

Soupapes ne

commutent pas

Soupapes commutent avec retard ou

lâchen taux raccords

de purge

Tension d’alimentation absente ou

insuffisante

Commande à main n’est pas en

position neutre

Alimentation en pression insuffisante

ou absente

Alimentation en pression insuffisante

ou absente

Purge insuffisante des canaux

d’échappement d’air par des silencieux

trop petits ou encrassés

(rétropressions)

Vérifier le raccordement électrique

Assurer la tension de service selon la

plaquette signalétique

Mettre la commande à main sur zéro

Réaliser l’alimentation en pression au volume

maximal (même avec des appareils montés

en amont, tels que manostats, unité

d’entretien, soupape d’arrêt etc.)

Pression de service minimale: > 2 bars

Réaliser l’alimentation en pression au volume

maximal (même avec des appareils montés

en amont, tels que manostats, unité

d’entretien, soupape d’arrêt etc.)

Pression de service minimale: > 2 bars

Utiliser des silencieux ou des vases

d’expansion dimensionnés en conséquence

Nettoyer les silencieux encrassés

Blocs de distribution

et de régulation non

étanches

Impuretés ou corps étrangers dans la

soupape pilote ou soupape principale

Joints plats manquants ou mal

disposés entre soupape et plaque de

montage

Curer les canaux d’air d’échappement par jets

de pression pour expulser les impuretés

Monter une nouvelle soupape pilote ou

soupape principale si les jets de pression

restent sans effet

Insérer les joints manquants ou remplacer les

joints défectueux

48 - 8640-0450

Page 51

Bürkert Company Locations

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Page 52

The smart choice

of Fluid Control Systems

www.buerkert.com

Loading...

Loading...