Page 1

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

Type 0255 / 0355

2/2- and 3/2-way solenoid valve

2/2- und 3/2-Wege-Magnetventil

Électrovanne 2/2 et 3/2 voies

www.burkert.com

International address

www.burkert.com

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Manuel d'utilisation et fiches techniques sur Internet : www.buerkert.fr

© Bürker t Werke GmbH , 2014

Operating Instr uctions 1404/04_EU-ML_00893044 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 2

2

1 OPERATING INSTRUCTIONS

The operating instructions contain important information.

▶▶ Read▶the▶operating▶instructions▶carefully▶and▶follow▶the▶safety▶instruc-

tions▶in▶particular,▶and▶also▶observe▶the▶operating▶conditions.

▶▶ Operating▶instructions▶must▶be▶available▶to▶each▶user.

▶▶ The▶liability▶and▶warranty▶for▶the▶device▶are▶void▶if▶the▶operating▶instruc-

tions▶are▶not▶followed.

1.1 Symbols

▶▶ Designates▶an▶instruction▶to▶prevent▶risks.

▶→ designates▶a▶procedure▶which▶you▶must▶carry▶out.

Warning of injuries:

Danger!

Imminent▶danger!▶Serious▶or▶fatal▶injuries.

Warning!

Potential▶danger!▶Serious▶or▶fatal▶injuries.

Caution!

Danger!▶Minor▶or▶moderately▶severe▶injuries.

Warns of damage to property:

note!

2 INTENDED USE

Incorrect use of the solenoid valve Type 0255 / 0355 can be

dangerous to people, nearby equipment and the environment.

▶▶ The▶device▶is▶designed▶to▶control,▶shut▶off▶and▶meter▶neutral▶media▶up▶

to▶a▶viscosity▶of▶21▶mm

2

/s.

▶▶ Provided▶the▶cable▶plug▶is▶connected▶and▶installed▶correctly,▶e.g.▶Bürk-

ert▶Type▶2508,▶the▶device▶satisfies▶protection▶class▶IP65▶in▶accordance▶

with▶DIN▶EN▶60529▶/▶IEC▶60529.

▶▶ Use▶according▶ to▶the▶permitted▶data,▶operating▶conditions▶and▶con-

ditions▶of▶ use▶specified▶ in▶the▶ contract▶documents▶ and▶operating▶

instructions.

▶▶ Correct▶transportation,▶correct▶storage▶and▶installation▶and▶careful▶use▶

and▶maintenance▶are▶essential▶for▶reliable▶and▶problem-free▶operation.

▶▶ Use▶the▶device▶only▶as▶intended.

2.1 Definition of term

In▶these▶ operating▶ instructions,▶the▶term▶ “device”▶always▶ refers▶ to▶the▶

solenoid▶valve▶Type▶0255▶and▶0355.▶

english

3

Risk of injury due to malfunction of valves with alternating

current (AC)!

Sticking▶core▶causes▶coil▶to▶overheat,▶resulting▶in▶a▶malfunction.

▶▶ Monitor▶process▶to▶ensure▶function▶is▶in▶perfect▶working▶order!

Risk of short-circuit/escape of media through leaking screw joints!

▶▶ Ensure▶seals▶are▶seated▶correctly.

▶▶ Carefully▶screw▶valve▶and▶connection▶lines▶together.

General hazardous situations.

To▶prevent▶injury,▶ensure▶that:

▶▶ Do▶not▶make▶any▶internal▶or▶external▶changes.▶Ensure▶that▶the▶system▶

cannot▶be▶activated▶unintentionally.

▶▶ Installation▶and▶repair▶work▶may▶be▶carried▶out▶by▶authorized▶techni-

cians▶only▶and▶with▶the▶appropriate▶tools.

▶▶ After▶an▶interruption▶in▶the▶power▶supply▶or▶pneumatic▶supply,▶ensure▶

that▶the▶process▶is▶restarted▶in▶a▶defined▶or▶controlled▶manner.

▶▶ Do▶not▶put▶any▶loads▶on▶the▶body.

▶▶ The▶general▶rules▶of▶technology▶apply▶to▶application▶planning▶and▶

operation▶of▶the▶device.

3 BASIC SAFETY INSTRUCTIONS

These▶safety▶ instructions▶do▶ not▶ make▶ allowance▶ for▶ any▶ contingencies▶▶

and▶events▶which▶may▶arise▶during▶installation,▶operation▶and▶maintenance.

Danger – high pressure!

▶▶ Before▶loosening▶the▶lines▶and▶valves,▶turn▶off▶the▶pressure▶and▶vent▶

the▶lines.

Risk of electric shock!

▶▶ Before▶reaching▶into▶the▶system,▶switch▶off▶the▶power▶supply▶and▶

secure▶to▶prevent▶reactivation!

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶for▶

electrical▶equipment!

Risk of burns/Risk of fire if used continuously through hot device

surface!

▶▶ Keep▶the▶device▶away▶from▶highly▶flammable▶substances▶and▶media▶

and▶do▶not▶touch▶with▶bare▶hands.▶

english

4

3.1 Warranty

The▶warranty▶is▶only▶valid▶if▶the▶device▶is▶used▶as▶intended▶in▶accordance▶

with▶the▶specified▶application▶conditions.

3.2 Information on the internet

The▶operating▶instructions▶and▶data▶sheets▶for▶type▶0255▶/▶0355▶can▶be▶

found▶on▶the▶internet▶at:

www.burkert.com▶▶

▶Type▶0255,▶0355

4 TECHNICAL DATA

4.1 Operating conditions

The▶following▶values▶are▶indicated▶on▶the▶type▶label:

•▶Voltage▶(Tolerance▶±▶10▶%)▶/▶Current▶type

•▶Coil▶power▶consumption▶(active▶power▶in▶W▶-▶at▶operating▶

temperature)

•▶Pressure▶range

•▶Body▶material:▶Brass▶(MS),▶Stainless▶steel▶(VA)

•▶Sealing▶material:▶FKM,▶EPDM,▶NBR,▶PTFE,▶Steel

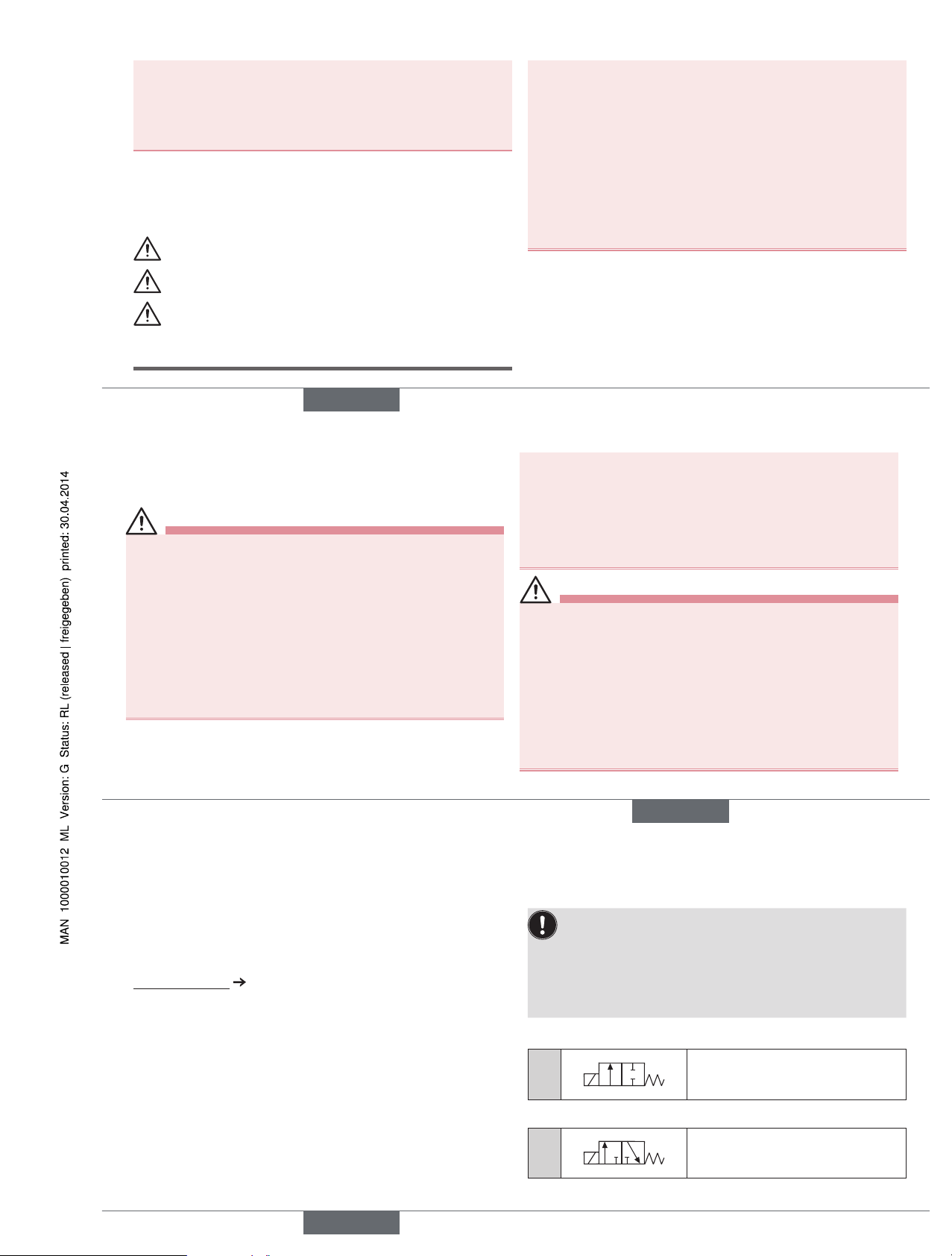

Circuit function Type 0255:

A

A

P

2/2-way▶valve;▶closed▶in▶rest▶position

Circuit function Type 0355:

C

A

P

R

3/2-way▶valve;▶closed▶in▶rest▶position,▶

output▶A▶unloaded

english

Type 0255 / 0355

Page 3

5

D

A

P

R

3/2-way▶valve;▶in▶rest▶position▶output▶A▶

pressurized

E

A

P1

P2

3/2-way▶valve;▶in▶rest▶position,▶

pressure▶connection▶P2▶connected▶to▶

output▶A.▶P1▶closed

4.2 Application conditions

Ambient▶temperature▶ ▶ ▶Standard:▶max.▶+55▶°C▶

High▶temperature:▶max.▶+250▶°C

Protection▶class▶ ▶ ▶ ▶IP65▶in▶accordance▶with▶DIN▶EN▶60529▶/▶

IEC▶60529▶with▶cable▶plug,▶e.g.▶Bürkert▶Type▶

2508▶or▶cable▶design

Operating▶duration▶ ▶ ▶Unless▶otherwise▶indicated▶on▶the▶type▶label,▶

the▶solenoid▶system▶is▶suitable▶for▶continuous▶operation

Important▶information▶for▶functional▶reliability▶during▶continuous▶

operation:▶If▶standstill▶for▶a▶long▶period▶at▶least▶1-2▶activations▶

per▶day▶are▶recommended.

Service▶life▶▶ ▶ ▶ ▶▶High▶switching▶frequency▶and▶high▶pressures▶

reduce▶the▶service▶life

4.2.1 Permitted temperature

Permitted▶temperature▶depending▶on▶coil▶material▶and▶sealing▶material:

Coil material Sealing material Medium

temperature

Epoxy,▶▶

Metal

1)

NBR -10▶-▶+90▶°C

FKM -10▶-▶+130▶°C

EPDM -40▶-▶+130▶°C

PTFE -40▶-▶+180▶°C

Steel -40▶-▶+180▶°C

Metal

2)

Steel -40▶-▶+250▶°C

Coil▶with▶electronic

3)

max.▶+90▶°C

1)

Coil with metal housing and copper wire winding

2)

Coil with metal housing and aluminum wire winding

3)

Switching frequency: max. 6 switching operations/min

english

6

4.2.2 Permitted media

Permitted▶media▶depending▶on▶sealing▶material

Sealing

material

Permitted media

NBR Neutral▶media,▶such▶as▶compressed▶air,▶

water,▶hydraulic▶fluid,▶oils▶and▶greases▶without▶

additives

FKM Oxygen

4)

,▶hot▶air,▶hot▶oils,▶oils▶with▶additives,▶

per▶solutions

EPDM Oil▶and▶grease-free▶media,▶e.g.▶hot▶water,▶

alkaline▶suds▶and▶bleaching▶lyes

PTFE,▶Steel Water,▶steam,▶organic▶solvents,▶oils,▶fuel,▶

alcohol,▶hydraulic▶substances

4)

for special design only

4.3 Conformity

In▶accordance▶with▶the▶EC▶Declaration▶of▶conformity,▶Type▶0255▶/▶0355▶

is▶compliant▶with▶the▶EC▶Directives.

4.4 Standards

The▶applied▶ standards,▶which▶verify▶conformity▶with▶ the▶EC▶Directives,▶

can▶be▶ found▶ on▶the▶EC-Type▶ Examination▶Certificate▶and▶/▶or▶the▶EC▶

Declaration▶of▶Conformity.

4.5 Type label

Typ e

Circuit▶

▶function

Orifice

Sealing▶material

Body▶material

Id.-Number

Manufacturer▶code

Voltage,▶Frequency,▶▶

Power▶consumption

Connection▶thread,▶Operating▶

pressure

0255 A 4,0 FKM MS

Made in Germany

00135952

W12MN

230V 50 Hz 10 W

G1/4 P

N 0 - 10 bar

english

7

5 INSTALLATION

5.1 Safety instructions

Danger!

Risk of injury from high pressure in the equipment!

▶▶ Before▶loosening▶the▶pipes▶and▶valves,▶turn▶off▶the▶pressure▶and▶vent▶

the▶lines.

Risk of injury due to electrical shock!

▶▶ Before▶reaching▶into▶the▶device▶or▶the▶equipment,▶switch▶off▶the▶power▶

supply▶and▶secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶for▶

electrical▶equipment.

Warning!

Risk of injury from improper installation!

▶▶ Installation▶may▶be▶carried▶out▶by▶authorized▶technicians▶only▶and▶with▶

the▶appropriate▶tools.

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶▶ Secure▶system▶from▶unintentional▶activation.

▶▶ Following▶assembly,▶ensure▶a▶controlled▶restart.

5.2 Before installation

Installation▶position:▶any,▶actuator▶preferably▶upwards.

Procedure:

▶→ Check▶pipelines▶for▶dirt▶and▶clean.

▶→ Install▶a▶dirt▶filter▶before▶the▶valve▶inlet▶(≤▶500▶µm).

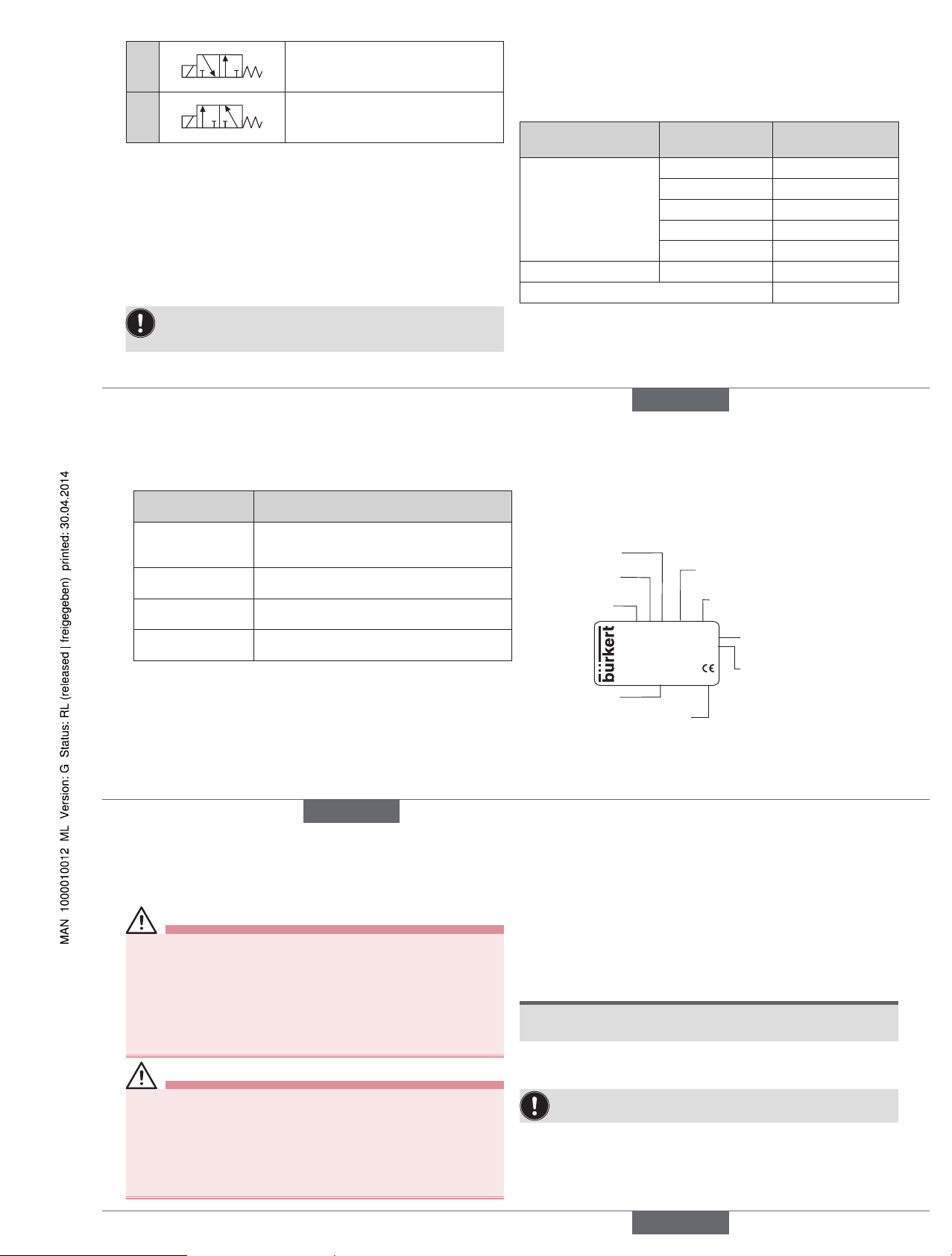

5.3 Installation

note!

Caution risk of breakage!

•▶Do▶not▶use▶the▶coil▶as▶a▶lever▶arm.

▶→ Hold▶the▶device▶with▶a▶open-end▶wrench▶on▶the▶body▶and▶screw▶

into▶the▶pipeline.

Valve▶body▶must▶not▶be▶installed▶under▶tension.

▶→ Observe▶direction▶of▶flow:▶

The▶arrow▶on▶the▶body▶indicates▶the▶direction▶of▶flow.

english

Type 0255 / 0355

Page 4

8

5.4 Electrical connection of the cable plug

Warning!

Risk of injury due to electrical shock!

▶▶ Before▶reaching▶into▶the▶system,▶switch▶off▶the▶power▶supply▶and▶

secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶for▶

electrical▶equipment.

If▶the▶protective▶conductor▶is▶not▶connected,▶there▶is▶a▶risk▶of▶electric▶

shock!

▶▶ Always▶connect▶protective▶conductor▶and▶check▶electrical▶continuity.

Note▶the▶voltage▶and▶current▶type▶as▶specified▶on▶the▶label.

Procedure:

▶→ Tighten▶cable▶ plug▶(for▶permitted▶types▶see▶ data▶sheet),▶observing▶

max.▶torque▶1▶Nm.

▶→ Check▶that▶seal▶is▶fitted▶correctly.

▶→ Connect▶protective▶conductor▶and▶check▶electrical▶continuity.

Seal▶▶

(ensure▶position▶

is▶correct)

max.▶1▶Nm

Authorized▶cable▶plug▶▶

e.g.▶Type▶2508▶or▶other▶suitable▶

cable▶plug▶in▶accordance▶with▶▶

DIN▶EN▶175301-803▶Form▶A

english

9

6 MAINTENANCE, TROUBLESHOOTING

6.1 Safety instructions

Warning!

Risk of injury from improper maintenance!

▶▶ Maintenance▶may▶be▶carried▶out▶by▶authorized▶technicians▶only▶and▶

with▶the▶appropriate▶tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶▶ Secure▶system▶from▶unintentional▶activation.

▶▶ Following▶maintenance,▶ensure▶a▶controlled▶restart.

6.2 Malfunctions

If malfunctions occur, check whether:

•▶

the

▶device▶has▶been▶installed▶according▶to▶the▶instructions,

•▶the▶electrical▶and▶fluid▶connections▶are▶correct,

•▶the▶device▶is▶not▶damaged,

•▶all▶screws▶have▶been▶tightened,

•▶the▶voltage▶and▶pressure▶have▶been▶switched▶on,

•▶the▶pipelines▶are▶clean,

•▶adequately▶high▶power▶supply▶is▶applied.

Malfunction Possible cause

Valve▶does▶not▶switch

Short-circuit▶or▶coil▶interrupted

Inadequate▶power▶supply

Core▶/▶core▶area▶is▶dirty

Medium▶pressure▶outside▶the▶permitted▶

pressure▶range

Valve▶does▶not▶close Internal▶space▶of▶the▶valve▶is▶dirty

english

10

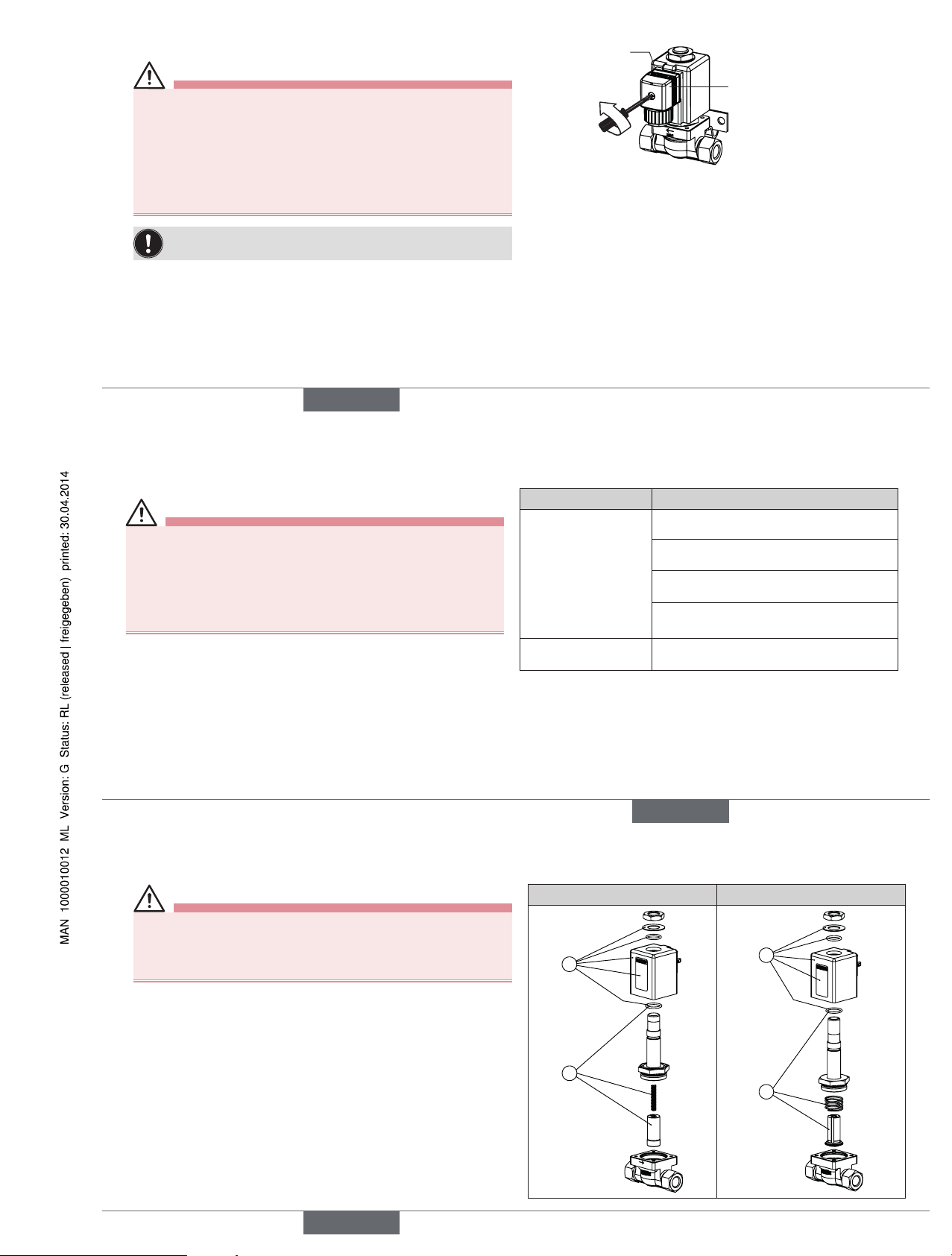

7 SPARE PARTS

Caution!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect▶accessories▶and▶unsuitable▶spare▶parts▶may▶cause▶injuries▶and▶

damage▶the▶device▶and▶the▶surrounding▶area.

▶▶ Use▶only▶original▶accessories▶and▶original▶spare▶parts▶from▶Bürkert.

7.1 Ordering spare parts

Order▶the▶spare-part▶sets▶specifying▶the▶positions▶(Pos.▶1:▶Coil▶set,▶

Pos.▶2:▶Wearing▶parts▶set)▶and▶the▶identification▶number▶of▶the▶device.

7.2 Overview of spare parts

Type 0255 Type 0355

2

1

1

2

english

Type 0255 / 0355

Page 5

11

8 TRANSPORT, STORAGE, DISPOSAL

note!

Transport damages!

Inadequately▶protected▶equipment▶may▶be▶damaged▶during▶

transport.

•▶During▶transportation▶protect▶the▶device▶against▶wet▶and▶dirt▶in▶

shock-resistant▶packaging.▶

•▶Avoid▶exceeding▶or▶dropping▶below▶the▶allowable▶storage▶

temperature.

Incorrect storage may damage the device.

•▶Store▶the▶device▶in▶a▶dry▶and▶dust-free▶location!

•▶Storage▶temperature▶-40▶-▶+80▶°C.

Damage to the environment caused by device components contaminated with media.

•▶Dispose▶of▶the▶device▶and▶packaging▶in▶an▶environmentally▶friendly▶

manner.

•▶Observe▶applicable▶regulations▶on▶disposal▶and▶the▶environment.

english

Type 0255 / 0355

Page 6

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

Type 0255 / 0355

2/2- and 3/2-way solenoid valve

2/2- und 3/2-Wege-Magnetventil

Électrovanne 2/2 et 3/2 voies

www.burkert.com

International address

www.burkert.com

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Manuel d'utilisation et fiches techniques sur Internet : www.buerkert.fr

© Bürker t Werke GmbH , 2014

Operating Instr uctions 1404/04_EU-ML_00893044 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 7

12

1 DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

▶▶ Bedienungsanleitung▶sorgfältig▶ lesen▶ und▶ Hinweise▶ zur▶ Sicherheit▶

beachten.▶

▶▶ Bedienungsanleitung▶muss▶jedem▶Benutzer▶zur▶Verfügung▶stehen.

▶▶ Haftung▶und▶Gewährleistung▶für▶das▶Gerät▶entfällt,▶wenn▶die▶Anwei-

sungen▶der▶Bedienungsanleitung▶nicht▶beachtet▶werden.

1.1 Darstellungsmittel

▶▶ markiert▶eine▶Anweisung▶zur▶Gefahrenvermeidung.

▶→ markiert▶einen▶Arbeitsschritt,▶den▶Sie▶ausführen▶müssen.

Warnung vor Verletzungen:

Gefahr!

Unmittelbare▶Gefahr!▶Schwere▶oder▶tödliche▶Verletzungen.

WarnunG!

Mögliche▶Gefahr!▶Schwere▶oder▶tödliche▶Verletzungen.

Vorsicht!

Gefahr!▶Leichte▶oder▶mittelschwere▶Verletzungen.

Warnung vor Sachschäden:

hinWeis!

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Typs 0255 und 0355

können Gefahren für Personen, Anlagen in der Umgebung und die

Umwelt entstehen.

▶▶ Das▶

Gerät▶ist▶zum▶Steuern,▶Absperren▶und▶Dosieren▶von▶Medien▶bis▶

zu▶einer▶Viskosität▶von▶21▶mm²/s▶konzipiert.

▶▶ Mit▶einer▶sachgemäß▶angeschlossenen▶und▶montierten▶Gerätesteck-

dose,▶

z.▶B.▶Bürkert▶T

yp▶

2508▶erfüllt▶das▶Gerät▶die▶Schutzart▶IP65▶nach▶

DIN▶EN▶60529▶/▶IEC▶60529.

▶▶ Für▶den▶Einsatz▶die▶in▶den▶Vertragsdokumenten▶und▶der▶Bedienungs-

anleitung▶spezifizierten▶ zulässigen▶ Daten,▶ Betriebs-▶ und▶ Einsatzbedingungen▶beachten.▶

▶▶ Voraussetzungen▶für▶ den▶ sicheren▶ und▶ einwandfreien▶ Betrieb▶ sind▶

sachgemäßer▶Transport,▶sachgemäße▶Lagerung▶und▶Installation▶sowie▶

sorgfältige▶Bedienung▶und▶Instandhaltung.

▶▶ Das▶Gerät▶nur▶bestimmungsgemäß▶einsetzen.

2.1 Begriffsdefinition

Der▶verwendete▶Begriff▶„Gerät“▶steht▶immer▶für▶Typ▶0255▶und▶0355.▶

deutsch

13

Verletzungsgefahr durch Funktionsausfall bei Ventilen mit

Wechselspannung (AC)!

Festsitzender▶Kern▶bewirkt▶Spulenüberhitzung,▶die▶zu▶Funktionsausfall▶

führt.

▶▶ Arbeitsprozess▶auf▶einwandfreie▶Funktion▶überwachen.

Kurzschlussgefahr/Austritt von Medium durch undichte

Verschraubungen!

▶▶ Auf▶einwandfreien▶Sitz▶der▶Dichtungen▶achten.

▶▶ Ventil▶und▶Anschlussleitungen▶sorgfältig▶verschrauben.

Allgemeine Gefahrensituationen.

Zum▶Schutz▶vor▶Verletzungen▶ist▶zu▶beachten:

▶▶ Keine▶inneren▶oder▶äußeren▶Veränderungen▶vornehmen.▶Anlage/Gerät▶

vor▶unbeabsichtigter▶Betätigung▶sichern.

▶▶ Installations-▶und▶Instandhaltungsarbeiten▶dürfen▶nur▶von▶autorisiertem▶

Fachpersonal▶mit▶geeignetem▶Werkzeug▶ausgeführt▶werden.

▶▶ Nach▶einer▶Unterbrechung▶der▶elektrischen▶oder▶fluidischen▶Versor-

gung▶ist▶ein▶definierter▶oder▶kontrollierter▶Wiederanlauf▶des▶Prozesses▶

zu▶gewährleisten.

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese▶Sicherheitshinweise▶ berücksichtigen▶ keine▶ Zufälligkeiten▶ und▶

Ereignisse,▶die▶bei▶Montage,▶Betrieb▶und▶Wartung▶auftreten▶können.

Gefahr durch hohen Druck!

▶▶ Vor▶dem▶ Lösen▶von▶Leitungen▶und▶ Ventilen▶den▶ Druck▶ abschalten▶

und▶Leitungen▶entlüften.

Gefahr durch elektrische Spannung!

▶▶ Vor▶Eingriffen▶in▶das▶Gerät▶oder▶die▶Anlage▶Spannung▶abschalten▶

und▶vor▶Wiedereinschalten▶sichern.

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶für▶

elektrische▶Geräte▶beachten.

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch heiße

Geräteoberfläche!

▶▶ Das▶Gerät▶von▶leicht▶brennbaren▶Stoffen▶und▶Medien▶fernhalten▶und▶

nicht▶mit▶bloßen▶Händen▶berühren.▶

deutsch

14

▶▶ Gehäuse▶nicht▶mechanisch▶belasten.

▶▶ Die▶allgemeinen▶Regeln▶der▶Technik▶einhalten.

3.1 Gewährleistung

Voraussetzung▶für▶die▶Gewährleistung▶ist▶der▶bestimmungsgemäße▶Gebrauch▶des▶Geräts▶unter▶Beachtung▶der▶spezifizierten▶

Einsatzbedingungen.

3.2 Informationen im Internet

Bedienungsanleitungen▶und▶Datenblätter▶zum▶Typ▶0255▶und▶0355▶finden▶

Sie▶im▶Internet▶unter:

www.buerkert.de▶▶

▶Typ▶0255,▶0355

4 TECHNISCHE DATEN

4.1 Betriebsbedingungen

Folgende▶Werte▶sind▶auf▶dem▶Typschild▶angegeben:

•▶Spannung▶(Toleranz▶±▶10▶%)▶/▶Stromart

•▶Spulenleistung▶(Wirkleistung▶in▶W▶-▶betriebswarm)

•▶Druckbereich

•▶Gehäusewerkstoff:▶Messing▶(MS) ,▶Edelstahl▶(VA)

•▶Dichtungswerkstoff:▶FKM,▶EPDM,▶NBR,▶PTFE,▶Stahl

Wirkungsweise Typ 0255:

A

A

P

2/2-Wege-Ventil,▶in▶Ruhestellung▶

geschlossen

Wirkungsweise Typ 0355:

C

A

P

R

3/2-Wege-Ventil,▶in▶Ruhestellung▶

geschlossen,▶Ausgang▶A▶entlastet

deutsch

Typ 0255 / 0355

Page 8

15

D

A

P

R

3/2-Wege-Ventil,▶in▶Ruhestellung▶

Ausgang▶A▶druckbeaufschlagt

E

A

P1

P2

3/2-Wege-Ventil,▶in▶Ruhestellung▶

Druckanschluss▶P2▶mit▶Ausgang▶A▶

verbunden.▶P1▶geschlossen

4.2 Einsatzbedingungen

Umgebungstemperatur▶ ▶Standard:▶max.▶+55▶°C▶

Hochtemperatur:▶max.▶+250▶°C

Schutzart▶ ▶ ▶ ▶ ▶ ▶IP65▶nach▶DIN▶EN▶60529▶/▶IEC▶60529▶mit▶

Gerätesteckdose,▶z.▶B.▶Bürkert▶Typ▶2508▶

oder▶Kabelausführung

Betriebsdauer▶▶ ▶ ▶ ▶Wenn▶auf▶dem▶Typschild▶nicht▶anders▶ange-

geben,▶ist▶das▶Magnetsystem▶für▶Dauerbetrieb▶geeignet

Wichtiger▶Hinweis▶für▶die▶Funktionssicherheit▶bei▶ Dauerbetrieb!▶

Bei▶langem▶Stillstand▶wird▶ eine▶ Betätigung▶von▶mindestens▶1-2▶

Schaltungen▶pro▶Tag▶empfohlen.

Lebensdauer▶ ▶ ▶ ▶ ▶Hohe▶Schaltfrequenz▶und▶hohe▶Drücke▶ver-

ringern▶die▶Lebensdauer

4.2.1 Zulässige Temperatur

Zulässige▶Mediumstemperatur▶in▶Abhängigkeit▶von▶Spulenwerkstoff▶

und▶Dichtungswerkstoff:

Spulenwerkstoff Dichtungswerkstoff Mediumstemperatur

Epoxid,▶▶

Metall

1)

NBR -10▶...▶+90▶°C

FKM -10▶...▶+130▶°C

EPDM -40▶...▶+130▶°C

PTFE -40▶...▶+180▶°C

Stahl -40▶...▶+180▶°C

Metall

2)

Stahl -40▶...▶+250▶°C

Spule▶mit▶Elektronik

3)

max.▶+90▶°C

1)

Spule mit Metallgehäuse und Kupferdraht-Wicklung

2)

Spule mit Metallgehäuse und Aluminiumdraht-Wicklung

3)

Schalthäufigkeit: max. 6 Schaltungen/min

deutsch

16

4.2.2 Zulässige Medien

Zulässige▶Medien▶in▶Abhängigkeit▶vom▶Dichtungswerkstoff:

Dichtungswerk-

stoff

Zulässige Medien

NBR Neutrale▶Medien▶wie▶Druckluft,▶Wasser,▶▶

Hydrauliköl,▶Öle▶und▶Fette▶ohne▶Additive

FKM Sauerstoff▶

4)

,▶Heißluft,▶heiße▶Öle,▶Öle▶mit▶▶

Additiven,▶Per-Lösungen

EPDM Öl-▶und▶fettfreie▶Medien,▶z.B.▶Heißwasser,▶▶

alkalische▶Wasch-▶und▶Bleichlaugen

PTFE,▶Stahl Wasser,▶Dampf,▶org.▶Lösungsmittel,▶Öle,▶▶

Treibstoff,▶Alkohole,▶Hydraulikstoffe

4)

nur für Sonderausführung

4.3 Konformität

Das▶Magnetventil,▶Typ▶0255▶und▶0355▶ist▶konform▶zu▶den▶EG-Richtlinien▶entsprechend▶der▶EG-Konformitätserklärung.

4.4 Normen

Die▶angewandten▶Normen,▶mit▶denen▶die▶Konformität▶mit▶den▶EG-Richtlinien▶nachgewiesen▶wird,▶sind▶in▶der▶EG-Baumusterprüfbescheinigung▶

und/oder▶der▶EG-Konformitätserklärung▶nachzulesen.

4.5 Typschild

Typ

Wirkungsweise

Nennweite

Dichtungswerkstoff

Gehäusewerkstoff

Identnummer

Hersteller-Code

Spannung,▶Frequenz,▶Leistung

Anschlussart,▶Betriebsdruck

0255 A 4,0 FKM MS

Made in Germany

00135952

W12MN

230V 50 Hz 10 W

G1/4 P

N 0 - 10 bar

deutsch

17

5 MONTAGE

5.1 Sicherheitshinweise

Gefahr!

Verletzungsgefahr durch hohen Druck in der Anlage!

▶▶ Vor▶dem▶Lösen▶von▶Leitungen▶oder▶Ventilen▶den▶Druck▶abschalten▶

und▶Leitungen▶entlüften.

Verletzungsgefahr durch Stromschlag!

▶▶ Vor▶Eingriffen▶in▶das▶Gerät▶oder▶die▶Anlage▶Spannung▶abschalten▶

und▶vor▶Wiedereinschalten▶sichern!

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶für▶

elektrische▶Geräte▶beachten!

WarnunG!

Verletzungsgefahr bei unsachgemäßer Montage!

▶▶ Die▶Montage▶darf▶nur▶autorisiertes▶Fachpersonal▶mit▶geeignetem▶

Werkzeug▶durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

▶▶ Anlage▶vor▶unbeabsichtigtem▶Betätigen▶sichern.

▶▶ Nach▶der▶Montage▶einen▶kontrollierten▶Wiederanlauf▶gewährleisten.

5.2 Vor dem Einbau

Einbaulage:▶ beliebig,▶vorzugsweise▶Antrieb▶oben.

Vorgehensweise:

▶→ Rohrleitungen▶von▶eventuellen▶Verschmutzungen▶säubern.

▶→ Vor▶dem▶Ventileingang▶einen▶Schmutzfilter▶einbauen▶(≤▶500▶µm).

5.3 Einbau

hinWeis!

Vorsicht Bruchgefahr!

•▶Spule▶nicht▶als▶Hebelarm▶benutzen.

▶→ Das▶Gerät▶mit▶einem▶Gabelschlüssel▶am▶Gehäuse▶festhalten▶und▶in▶

die▶Rohrleitung▶einschrauben.

Ventilgehäuse▶darf▶nicht▶verspannt▶eingebaut▶werden.

▶→ Durchflussrichtung▶beachten:▶▶

Der▶Pfeil▶auf▶dem▶Gehäuse▶kennzeichnet▶die▶Durchflussrichtung.

deutsch

Typ 0255 / 0355

Page 9

18

5.4 Elektrischer Anschluss der

Gerätesteckdose

WarnunG!

Verletzungsgefahr durch Stromschlag!

▶▶ Vor▶Eingriffen▶in▶das▶Gerät▶oder▶die▶Anlage,▶Spannung▶abschalten▶

und▶vor▶Wiedereinschalten▶sichern!

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶für▶

elektrische▶Geräte▶beachten!

Bei▶nicht▶angeschlossenem▶Schutzleiter▶besteht▶die▶Gefahr▶des▶

Stromschlags!

▶▶ Schutzleiter▶immer▶anschließen▶und▶elektrischer▶Durchgang▶prüfen.

Spannung▶und▶Stromart▶laut▶Typschild▶beachten.

Vorgehensweise:

▶→ Gerätesteckdose▶(zugelassene▶Typen▶siehe▶Datenblatt)▶fest-

schrauben,▶dabei▶maximales▶Drehmoment▶1▶Nm▶beachten.

▶→ Korrekten▶Sitz▶der▶Dichtung▶überprüfen.

▶→ Schutzleiter▶anschließen▶und▶elektrischer▶Durchgang▶prüfen.

Dichtung▶▶

(auf▶richtige▶Lage▶

achten)

max.▶1▶Nm

Zugelassene▶Gerätesteckdose▶

z.▶B.▶Typ▶2508▶oder▶andere▶

geeignete▶Gerätesteckdose▶nach▶

DIN▶EN▶175301-803▶Form▶A

deutsch

19

6 WARTUNG, FEHLERBEHEBUNG

6.1 Sicherheitshinweise

WarnunG!

Verletzungsgefahr bei unsachgemäßen Wartungsarbeiten!

▶▶ Die▶Wartung▶darf▶ nur▶ autorisiertes▶ Fachpersonal▶ mit▶ geeignetem▶

Werkzeug▶durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage und

unkontrollierten Wiederanlauf!

▶▶ Anlage▶vor▶unbeabsichtigtem▶Betätigen▶sichern.

▶▶ Nach▶der▶Wartung▶einen▶kontrollierten▶Wiederanlauf▶gewährleisten.

6.2 Störungen

Überprüfen Sie bei Störungen ob:

•▶das▶Gerät▶vorschriftsmäßig▶installiert▶ist,

•▶der▶elektrische▶und▶fluidische▶Anschluss▶ordnungsgemäß▶ausgeführt▶

ist,

•▶das▶Gerät▶nicht▶beschädigt▶ist,

•▶alle▶Schrauben▶fest▶angezogen▶sind,

•▶Spannung▶und▶Druck▶anliegen,

•▶die▶Rohrleitungen▶schmutzfrei▶sind,

•▶ausreichend▶starke▶Stromversorgung▶anliegt.

Störung Mögliche Ursache

Ventil▶schaltet▶nicht

Kurzschluss▶oder▶Spulenunterbrechung

Nicht▶ausreichende▶Stromversorgung

Kern▶oder▶Kernraum▶verschmutzt

Mediumsdruck▶außerhalb▶des▶zulässigen▶

Druckbereichs

Ventil▶schließt▶nicht Innenraum▶des▶Ventils▶verschmutzt

deutsch

20

7 ERSATZTEILE

Vorsicht!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches▶Zubehör▶und▶ungeeignete▶Ersatzteile▶können▶Verletzungen▶

und▶Schäden▶am▶Gerät▶und▶dessen▶Umgebung▶verursachen.

▶▶ Nur▶Originalzubehör▶sowie▶Originalersatzteile▶der▶Firma▶Bürkert▶

verwenden.

7.1 Ersatzteile bestellen

Bestellen▶Sie▶die▶Ersatzteilsätze▶unter▶Angabe▶der▶Positionen▶▶

(Pos.▶1:▶Spulensatz,▶Pos.▶2:▶Verschleißteilsatz)▶und▶der▶Identnummer▶

des▶Geräts.

7.2 Übersicht Ersatzteile

Typ 0255 Typ 0355

2

1

1

2

deutsch

Typ 0255 / 0355

Page 10

21

8 TRANSPORT, LAGERUNG,

ENTSORGUNG

hinWeis!

Transportschäden!

Unzureichend▶geschützte▶Geräte▶können▶durch▶den▶Transport▶

beschädigt▶werden.

•▶Gerät▶vor▶Nässe▶und▶Schmutz▶geschützt▶in▶einer▶stoßfesten▶Verpackung▶transportieren.▶

•▶Eine▶Über-▶bzw.▶Unterschreitung▶der▶zulässigen▶Lagertemperatur▶

vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

•▶Gerät▶trocken▶und▶staubfrei▶lagern.

•▶Lagertemperatur:▶-40▶°C▶...▶+80▶°C

Umweltschäden durch von Medien kontaminierte Geräteteile.

•▶Geltende▶Entsorgungsvorschriften▶und▶Umweltbestimmungen▶

einhalten.

•▶Nationale▶Abfallbeseitigungsvorschriften▶beachten.

deutsch

Typ 0255 / 0355

Page 11

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

Type 0255 / 0355

2/2- and 3/2-way solenoid valve

2/2- und 3/2-Wege-Magnetventil

Électrovanne 2/2 et 3/2 voies

www.burkert.com

International address

www.burkert.com

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Manuel d'utilisation et fiches techniques sur Internet : www.buerkert.fr

© Bürker t Werke GmbH , 2014

Operating Instr uctions 1404/04_EU-ML_00893044 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 12

22

1 LE MANUEL D’UTILISATION

Manuel d’utilisation contiennent des informations importantes.

▶▶ Lire▶attentivement▶ce▶manuel▶d’utilisation▶et▶respecter▶les▶consignes▶

de▶sécurité.

▶▶ Le▶manuel▶d’utilisation▶doit▶être▶à▶disposition▶de▶chaque▶utilisateur.

▶▶ Nous▶déclinons▶toute▶responsabilité▶et▶n’accordons▶aucune▶garantie▶

légale▶pour▶l’appareil▶en▶cas▶de▶non-respect▶des▶instructions▶figurant▶

dans▶ce▶manuel▶d’utilisation.

1.1 Symboles

▶▶ Identifie▶une▶instruction▶visant▶à▶éviter▶un▶danger.

▶→ identifie▶une▶opération▶que▶vous▶effectuer.

Mise en garde contre les blessures :

Danger !

Danger▶imminent▶!▶Les▶blessures▶graves▶ou▶mortelles.

avertissement !

Danger▶possible▶!▶Les▶blessures▶graves▶ou▶mortelles.

attention !

Danger▶!▶Les▶blessures▶légères▶ou▶moyennement▶graves.

Met en garde contre des dommages matériels :

remarque !

2 UTILISATION CONFORME

L’utilisation non-conforme du type 0255 / 0355 peut présenter

des dangers pour les personnes, les installations avoisinantes et

l’environnement.

▶▶ L’appareil▶ est▶ conçu▶ pour▶ commander,▶arrêter▶ et▶ doser▶des▶ fluides▶

neutres▶jusqu’à▶une▶viscosité▶de▶21▶mm

2

/s.

▶▶ Avec▶le▶connecteur▶adéquat,▶par▶ex.▶le▶type▶2508▶de▶Bürkert,▶connectée▶

et▶montée▶de▶manière▶conforme,▶l’appareil▶est▶conforme▶au▶type▶de▶

protection▶IP65▶selon▶DIN▶EN▶60529▶/▶IEC▶60529.

▶▶ Lors▶de▶l’utilisation,▶il▶convient▶de▶respecter▶les▶données▶et▶conditions▶

d’utilisation▶et▶d’exploitation▶admissibles▶spécifiées▶dans▶les▶instructions▶de▶service▶et▶dans▶les▶documents▶contractuels.

▶▶ Les▶ conditions▶ pour▶ l’utilisation▶sûre▶et▶parfaite▶ sont▶ un▶ transport,▶un▶

stockage▶et▶une▶installation▶dans▶les▶règles▶ainsi▶qu’une▶parfaite▶utilisation▶et▶maintenance.

▶▶ Veillez▶à▶ce▶que▶l’utilisation▶de▶l’appareil▶soit▶toujours▶conforme

.

2.1 Définition du terme

Le▶terme▶«▶appareil»▶utilisé▶dans▶ce▶manuel▶désigne▶toujours▶l’électrovanne▶

type▶0255▶et▶0355.▶

français

23

Risque de blessure dû à une panne pour les vannes avec tension

alternative (AC).

Un▶noyau▶bloqué▶provoque▶la▶surchauffe▶de▶la▶bobine▶et▶donc▶une▶panne.

▶▶ Surveiller▶le▶bon▶fonctionnement▶du▶processus▶de▶travail.

Risque de court-circuit / de sortie du fluide en présence de

vissages non étanches.

▶▶ Veiller▶à▶l’installation▶correcte▶des▶joints.

▶▶ Visser▶soigneusement▶la▶vanne▶et▶les▶raccords▶de▶la▶tuyauterie.

Situations dangereuses d’ordre général.

Pour▶prévenir▶les▶blessures,▶respectez▶ce▶qui▶suit▶:

▶▶ N’apportez▶pas▶de▶modifications▶à▶l’extérieur▶et▶l’intérieur▶de▶l’appareil.▶

L’installation▶ne▶peut▶pas▶être▶actionnée▶par▶inadvertance.

▶▶ Les▶travaux▶d’installation▶et▶de▶ maintenance▶ doivent▶ être▶effectués▶

uniquement▶par▶des▶techniciens▶qualifiés▶et▶habilités▶disposant▶de▶

l’outillage▶approprié

▶▶ Après▶une▶interruption▶de▶l’alimentation▶électrique▶ou▶pneumatique,▶

un

▶redémarrage▶défini▶ou▶contrôlé▶du▶processus▶doit▶être▶garanti.

3 CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces▶consignes▶de▶sécurité▶ne▶tiennent▶pas▶compte▶des▶hasards▶et▶des▶

événements▶pouvant▶survenir▶lors▶du▶montage,▶de▶l’exploitation▶et▶de▶

l’entretien.

Danger avec haute pression.

▶▶ Avant▶de▶desserrer▶les▶tuyauteries▶et▶les▶vannes,▶coupez▶la▶pression▶

et▶purgez▶les▶conduites.

Danger présenté par la tension électrique.

▶▶ Avant▶d’intervenir▶dans▶l’appareil▶ou▶l’installation,▶coupez▶la▶tension▶et▶

empêchez▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appareils▶

électriques▶en▶matière▶de▶prévention▶des▶accidents▶ainsi▶qu’en▶matière▶

de▶sécurité.

Risque de brûlures / d’incendie lors d’une durée de fonctionnement

prolongée dû à la surface brûlante de l’appareil.

▶▶ Tenez▶les▶substances▶et▶les▶fluides▶facilement▶inflammables▶à▶l’écart▶de▶

l’appareil▶et▶ne▶touchez▶pas▶ce▶dernier▶à▶mains▶nues.▶

français

24

▶▶ Ne▶soumettez▶pas▶le▶corps▶à▶des▶contraintes▶mécaniques.

▶▶ Les▶règles▶générales▶de▶la▶technique▶sont▶à▶appliquer▶pour▶l’opéra-

tionnel▶et▶l’utilisation▶de▶l’appareil.

3.1 Garantie légale

La▶condition▶pour▶bénéficier▶de▶la▶garantie▶légale▶est▶l’utilisation▶conforme▶

de▶l’appareil▶dans▶le▶respect▶des▶conditions▶d’utilisation▶spécifiées.

3.2 Informations sur Internet

Vous▶trouverez▶sur▶Internet▶les▶instructions▶de▶service▶et▶fiches▶techniques▶

relatives▶au▶type▶:

www.buerkert.fr▶▶

▶Type▶0255,▶0355

4 CARACTÉRISTIQUES TECHNIQUES

4.1 Conditions d’exploitation

Les▶valeurs▶suivantes▶sont▶indiquées▶sur▶la▶plaque▶signalétique▶:

•▶Tension▶(Tolérance▶±▶10▶%)▶/▶Type▶de▶courant

•▶Puissance▶de▶bobine▶(Puissance▶active▶en▶W▶-▶à▶l’état▶chaud)

•▶Plage▶de▶pression

•▶Matériau▶du▶corps▶:▶Laiton▶(MS),▶Acier▶inoxydable▶(VA)

•▶Matériau▶du▶joint▶:▶FKM,▶EPDM,▶NBR,▶PTFE,▶Acier

Fonction Type 0255 :

A

A

P

Vanne▶2/2▶voies,▶fermée▶en▶position▶

de▶repos

Fonction Type 0355 :

C

A

P

R

Vanne▶3/2▶voies,▶fermée▶en▶position▶de▶

repos,▶sortie▶A▶ouverte

français

Type 0255 / 0355

Page 13

25

D

A

P

R

Vanne▶3/2▶voies,▶en▶position▶de▶repos,▶

pression▶appliquée▶à▶la▶sortie▶A

E

A

P1

P2

Vanne▶3/2▶voies,▶en▶position▶de▶repos,▶

raccord▶de▶pression▶P2▶relié▶à▶la▶sortie▶

A.▶P1▶fermé

4.2 Conditions d’utilisation

Température▶ambiante▶ ▶ ▶Standard▶:▶max.▶+55▶°C▶

Haute▶température▶:▶max.▶+250▶°C

Type▶de▶protection▶ ▶ ▶ ▶IP65▶selon▶DIN▶EN▶60529▶/▶IEC▶60529▶

avec▶le▶connecteur,▶par▶le▶type▶2508▶de▶

Bürkert▶ou▶version▶avec▶câble

Durée▶de▶fonctionnement▶ ▶ ▶Si▶aucune▶information▶contraire▶ne▶figure▶

sur▶la▶plaque▶signalétique,▶le▶système▶

magnétique▶est▶adapté▶à▶un▶fonctionnement▶continu

Remarque▶importante▶ pour▶la▶ sécurité▶de▶ fonctionnement▶lors▶

d’un▶fonctionnement▶continu▶!▶Dans▶le▶cas▶d’un▶fonctionnement▶

de▶longue▶durée,▶il▶est▶recommandé▶de▶procéder▶à▶1▶-▶2▶commutations▶minimum▶par▶jour.

Durée▶de▶vie▶ ▶ ▶ ▶ ▶▶Une▶fréquence▶élevée▶de▶commutation▶ainsi▶

que▶des▶pressions▶élevées▶réduisent▶la▶durée▶

de▶vie

4.2.1 Température admissible

Température▶admissible▶du▶fluide▶en▶fonction▶du▶matériau▶du▶bobine▶et▶

matériau▶du▶joint▶:

Matériau du bobine Matériau du joint Température du fluide

Époxide,▶▶

Métal

1)

NBR -10▶...▶+90▶°C

FKM -10▶...▶+130▶°C

EPDM -40▶...▶+130▶°C

PTFE -40▶...▶+180▶°C

Acier -40▶...▶+180▶°C

Métal

2)

Acier -40▶...▶+250▶°C

Bobine▶avec▶électronique

3)

max.▶+90▶°C

1)

Bobine avec corps métallique et enroulement en fil de cuivre

2)

Bobine avec corps métallique et enroulement en fil d’aluminium

3)

Fréquence de commutation : 6 commutations/min max

français

26

4.2.2 Fluides admissibles

Fluides▶admissibles▶en▶fonction▶du▶matériau▶du▶joint▶:

Matériau

du joint

Fluides admissibles

NBR Fluides▶neutres▶tels▶que▶l’air▶comprimé,▶l’eau,▶

l’huile▶hydraulique,▶les▶huiles▶et▶les▶graisses▶sans▶

additifs

FKM Oxygène

4)

,▶air▶chaud,▶huiles▶chaudes,▶huiles▶avec▶

additifs,▶solutions▶Per

EPDM Fluides▶sans▶huile▶et▶sans▶graisse,▶par▶exemple▶

eau▶chaude,▶agents▶de▶nettoyage▶et▶de▶▶

blanchiment▶alcalins▶

PTFE,▶Acier Eau,▶vapeur,▶solvants▶organiques,▶huiles,▶▶

carburant,▶alcools,▶liquides▶hydrauliques▶

4)

uniquement pour version spéciale

4.3 Conformité

Le▶type▶0255▶/▶0355▶est▶conforme▶aux▶directives▶CE▶sur▶la▶base▶de▶la▶

déclaration▶de▶conformité▶CE.

4.4 Normes

Les▶normes▶appliquées▶justifiant▶la▶conformité▶aux▶directives▶CE▶

peuvent▶être▶consultées▶dans▶le▶certificat▶d’essai▶de▶modèle▶type▶CE▶et▶

/▶ou▶la▶déclaration▶de▶Conformité▶CE.

4.5 Plaque signalétique

Typ e

Fonction

Diamètre▶

nominal

Matériau▶du▶joint

Matériau▶du▶corps

N°▶d’identification

Code▶fabricant

Tension,▶Fréquence,▶

Puissance

Raccordement,▶Pres sion▶de▶

service

0255 A 4,0 FKM MS

Made in Germany

00135952

W12MN

230V 50 Hz 10 W

G1/4 P

N 0 - 10 bar

français

27

5 INSTALLATION

5.1 Consignes de sécurité

Danger !

Risque de blessures avec présence de haute pression dans

l’installation.

▶▶ Avant▶de▶desserrer▶les▶tuyauteries▶et▶les▶vannes,▶coupez▶la▶pression▶

et

▶purgez▶les▶conduites.

Risque de choc électrique.

▶▶ Avant▶d’intervenir▶dans▶l’appareil▶ou▶l’installation,▶

coupez

▶la▶tension▶et▶

empêchez

▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶

respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appareils▶

électriques▶en▶matière▶de▶prévention▶des▶accidents▶ainsi▶qu’en▶matière▶

de

▶sécurité.

avertissement !

Risque de blessures pour montage non conforme.

▶▶ Le▶montage▶doit▶être▶effectué▶uniquement▶par▶un▶personnel▶qualifié▶

et

▶habilité▶disposant▶de▶l’outillage▶approprié.

Risque de blessures dû à la mise en marche involontaire de

l’installation et le redémarrage non contrôlé.

▶▶ Empêchez▶tout▶actionnement▶involontaire▶de▶l’installation.

▶▶ Garantissez▶un▶redémarrage▶contrôlé▶après▶le▶montage.

5.2 Avant le montage

Position▶de▶montage▶:▶▶au▶choix,▶de▶préférence▶avec▶l’actionneur▶vers▶le▶

haut.

Procédure :

▶→ Contrôler▶les▶tuyauteries▶pour▶encrassement▶et▶les▶nettoyer.

▶→ Installer▶un▶filtre▶à▶saleté▶devant▶l’entrée▶de▶vanne▶(≤▶500▶µm).

5.3 Montage

remarque !

Attention risque de rupture.

•▶La▶bobine▶ne▶doit▶pas▶être▶utilisée▶comme▶levier.

▶→ Maintenez▶l’appareil▶sur▶le▶corps▶à▶l’aide▶d’un▶outil▶approprié▶(clé▶à▶

fourche)▶et▶vissez-le▶dans▶la▶tuyauterie.

Le▶corps▶de▶vanne▶ne▶doit▶pas▶être▶monté▶sous▶tension.

▶→ Respectez▶le▶sens▶du▶débit▶:▶▶

La▶flèche▶sur▶le▶corps▶indique▶le▶sens▶du▶débit.

français

Type 0255 / 0355

Page 14

28

5.4 Raccordement électrique du

connecteur

Danger !

Risque de choc électrique.

▶▶ Avant▶d’intervenir▶dans▶l’appareil▶ou▶l’installation,▶coupez▶la▶tension▶

et▶empêchez▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appareils▶

électriques▶en▶matière▶de▶prévention▶des▶accidents▶ainsi▶qu’en▶

matière▶de▶sécurité.

Il▶y▶a▶ risque▶ de▶ choc▶électrique▶si▶le▶conducteur▶de▶protection▶n’est▶

pas▶raccordé.

▶▶ Toujours▶raccorder▶le▶conducteur▶de▶protection▶et▶contrôler▶le▶pas-

sage▶du▶courant.

Respectez▶la▶tension▶et▶le▶type▶de▶courant▶selon▶la▶plaque▶

signalétique.

Procédure :

▶→ Visser▶le▶ connecteur▶(types▶ admissibles,▶voir▶ fiche▶ technique)▶ en▶

respectant▶le▶couple▶max.▶de▶1▶Nm.

▶→ Vérifier▶le▶bon▶positionnement▶du▶joint.

▶→ Raccorder▶le▶ conducteur▶de▶ protection▶ et▶ vérifier▶ le▶ passage▶ du▶

courant.

Joint▶▶

(veiller▶au▶bon▶

positionnement)

max.▶1▶Nm

Connecteur▶autorisé▶▶

par▶ex.▶type▶2508▶ou▶autres▶

connecteurs▶adéquates▶selon▶▶

DIN▶EN▶175301-803▶forme▶A

français

29

6 MAINTENANCE, DÉPANNAGE

6.1 Consignes de sécurité

avertissement !

Risque de blessures dû à des travaux de maintenance non conformes.

▶▶ La▶maintenance▶doit▶être▶effectué▶uniquement▶par▶un▶personnel▶qualifié▶

et▶habilité▶disposant▶de▶l’outillage▶approprié.

Risque de blessures dû à la mise en marche involontaire de l’installation et le redémarrage non contrôlé.

▶▶ Empêchez▶tout▶actionnement▶involontaire▶de▶l’installation.

▶▶ Garantissez▶un▶redémarrage▶contrôlé▶après▶la▶maintenance

.

6.2 Pannes

En présence de pannes, vérifiez :

•▶si▶l’appareil▶est▶installé▶dans▶les▶règles,

•▶si▶le▶raccord▶électrique▶et▶fluide▶est▶correct,

•▶si▶l’appareil▶n’est▶pas▶endommagé,

•▶si▶toutes▶les▶vis▶sont▶bien▶serrées,

•▶si▶la▶tension▶et▶la▶pression▶sont▶disponibles,

•▶si▶les▶tuyauteries▶sont▶propres,

•▶si▶l’alimentation▶électrique▶est▶suffisante.

Pannes Cause possible

La▶vanne▶▶

ne▶s’enclenche▶pas

Court-circuit▶ou▶coupure▶de▶la▶bobine

Alimentation▶électrique▶insuffisante

Le▶noyau▶ou▶l’espace▶du▶noyau▶est▶encrassé

Pression▶du▶fluide▶hors▶de▶la▶plage▶de▶

pression▶autorisée

La▶vanne▶ne▶se▶ferme▶

pas

Intérieur▶de▶la▶vanne▶encrassé

français

30

7 PIÈCES DE RECHANGE

attention !

Risque de blessures, de dommages matériels dus à de mauvaises

pièces.

De▶mauvais▶ accessoires▶ou▶ des▶pièces▶ de▶rechange▶ inadaptées▶

peuvent▶provoquer▶ des▶ blessures▶et▶ endommager▶ l’appareil▶ou▶ son▶

environnement.

▶▶ Utiliser▶uniquement▶ des▶ accessoires▶ et▶ des▶ pièces▶ de▶ rechange▶

d’origine▶de▶la▶société▶Bürkert.

7.1 Commander des pièces de rechange

Veuillez▶commander▶les▶jeux▶de▶pièces▶de▶rechange▶en▶indiquant▶les▶

positions▶(pos.▶1▶:▶jeu▶de▶bobines,▶pos.▶2▶:▶jeu▶de▶pièces▶d’usure)▶et▶le▶

numéro▶d’identification▶de▶l’appareil.

7.2 Aperçu de pièces de rechange

Type 0255 Type 0355

2

1

1

2

français

Type 0255 / 0355

Page 15

31

8 TRANSPORT, STOCKAGE,

ÉLIMINATION

remarque !

Dommages dus au transport.

Les▶appareils▶insuffisamment▶protégés▶peuvent▶être▶endommagés▶

pendant▶le▶transport.

•▶Transportez▶l’appareil▶à▶l’abri▶de▶l’humidité▶et▶des▶impuretés▶et▶dans▶

un▶emballage▶résistant▶aux▶chocs.▶

•▶Évitez▶le▶dépassement▶vers▶le▶haut▶ou▶le▶bas▶de▶la▶température▶de▶

stockage▶admissible.

Un mauvais stockage peut endommager l’appareil.

•▶Stockez▶l’appareil▶au▶sec▶et▶à▶l’abri▶des▶poussières.

•▶Température▶de▶stockage▶:▶-40▶…▶+80▶°C.

Dommages à l’environnement causés par des pièces d’appareil

contaminées par des fluides.

•▶Éliminez▶l’appareil▶et▶l’emballage▶dans▶le▶respect▶de▶

l’environnement.

•▶Respectez▶les▶prescriptions▶en▶matière▶d’élimination▶des▶déchets▶et▶

de▶protection▶de▶l’environnement▶en▶vigueur.

français

Type 0255 / 0355

Loading...

Loading...