Page 1

ULTRA-1

ULTRA-2

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

41084.0000F 08/16 ©2009 Bunn-O-Matic Corporation

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCR/MCP/MCA single cup brewers, thermal servers and ThermoFresh® servers (mechanical and digital) 1 year parts and 1 year labor.

2) All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labor for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts and

labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured

by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation,

improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor water quality,

damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal use including but

not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the Buyer 1) giving BUNN

prompt notice of

any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office Box

3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an authorized

BUNN service location; and 3) receiving prior authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make

modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such

individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the

applicable parts and labor warranty periods specified above) to repair the defective components, provided that this repair

is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for

the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of

use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities

or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with

the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design,

Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet

Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment

Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com,

Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in

Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (sylized logo), Velocity Brew, Air Brew, Beverage

Bar Creator, Beverage Profit Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource, Coffee At Its Best, Cyclonic

Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Picture

Prompted Cleaning, Pouring Profits, Signature Series, Sure Tamp, Tea At Its Best, The Horizontal Red Line, Ultra are either

trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

2

41084 031314

Page 3

CONTENTS

Warranty ...................................................................................................................................2

User Notices .............................................................................................................................3

Site Preparation .......................................................................................................................3

Introduction ..............................................................................................................................4

Operating Controls .................................................................................................................... 6

Preventive Maintenance

Recommended Cleaning ....................................................................................................8

Auto-fill Cleaning Instructions ........................................................................................... 10

Preventive Maintenance Schedule ..................................................................................... 11

Troubleshooting ................................................................................................................ 14

Service

Access Panels ................................................................................................................... 22

Auger Motors .................................................................................................................... 23

Auger Motor Capacitors .................................................................................................... 24

Auger Shaft Assembly ....................................................................................................... 25

Circuit Breaker ..................................................................................................................27

Compressor ......................................................................................................28,31,38,41

Relay (or Contactor on Early Models) ...............................................................................43

Control Board .................................................................................................................... 44

Cooling Drum Alignment ................................................................................................... 45

Fan ............................................................................................................................... 46,47

Hot Gas Sensor ................................................................................................................. 48

Lamp Cord Assembly ........................................................................................................ 49

Lamp Cord Connector ....................................................................................................... 50

Lamp Holder/Socket Assembly .........................................................................................51

LED Lamps .......................................................................................................................52

Lamp Relay ....................................................................................................................... 53

Membrane Switch ........................................................................................................ 54,55

Solenoids .......................................................................................................................... 56

Temperature Sensor Assembly .........................................................................................57

Torque Sensor Circuit Board .............................................................................................58

Transformer .....................................................................................................................59

Auto Fill Systems .........................................................................................................60,62

Coolant Schematics ...........................................................................................................64,65

Electrical Schematics ..............................................................................................................66

USER NOTICES

All notices on this equipment are written for your protection. All notices are to be kept in good condition.

Replace any unreadable or damaged labels.

SITE PREPARATION

The dispenser must have at least four inches of space behind it. This space is needed for airflow, air filter

removal, and cleaning. Minimal clearance is required between the dispenser sides and the wall or another appliance. The dispenser performs better if not placed near any heating appliance. Leave some space so the dispenser

can be moved for cleaning.

3

41084 081216

Page 4

INTRODUCTION

Safety first!

To avoid electrical shock, unplug dispenser from power source before servicing inside.

WARNING: When powered, the condenser cooling fan will turn on every 30 minutes to aid cooling the entire

unit, even when not in the ICE or CHILL modes. KEEP HANDS AWAY FROM FAN!

Basic Maintenance

In order to maintain proper machine operation, the shaft seals and bushings need to be replaced as a Preventative Maintenance measure. A reminder message will appear every 6 months. Worn/dirty shaft seals/bushings

will have a direct effect on torque sensing and prevent complete freezing in “ICE” mode.

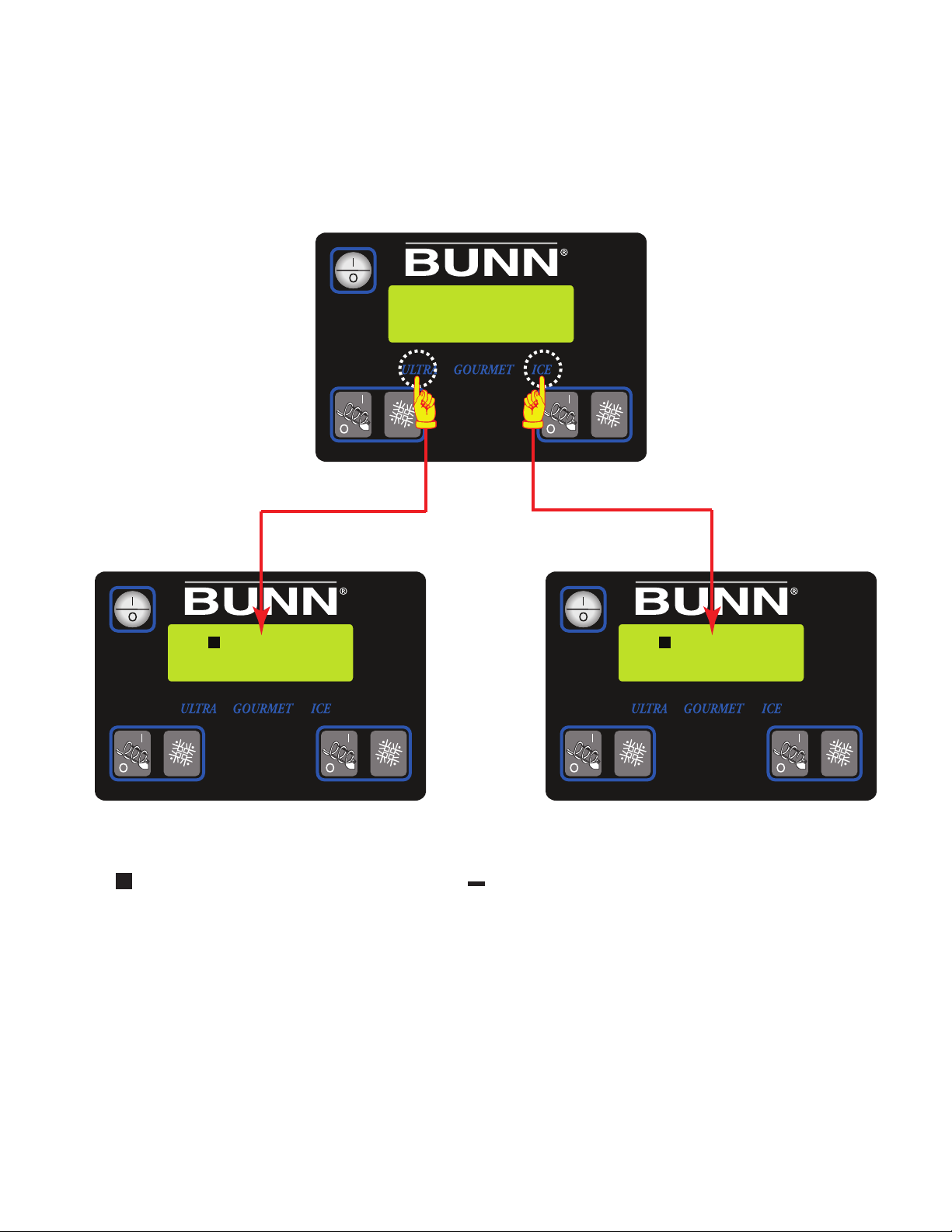

“UPPER” case vs “lower” case

Before beginning the process of troubleshooting, verify simple operating modes, ie; “CHILL” mode will not

freeze the product, but “ICE” mode will. You should also observe the letter case size in either mode. UPPER case

means the solenoid valve for that side is open, lower case, solenoid is closed.

JULY 4, 2002

Valve open Valve closed

ICEIce

Fault codes

To aid in troubleshooting, fault codes are now incorporated into the display. See “Troubleshooting”.

4

41084 102709

Page 5

TEMP & TORQUE SCREEN

Press and hold for five seconds the ULTRA and ICE hidden switches to display the TEMP & TORQUE. The

temperature of each cooling drum and the hot gas temperature will toggle back and forth. The auger torque is

displayed continuously. Press and release the ULTRA and ICE hidden switches to return to HOME SCREEN. The

TEMP & TORQUE mode is typically used for service.

DISPLAY

TEMP & TORQUE

30 25

161 161°h

-

30 25-

27 28°b

NOTICE: While in the TEMP & TORQUE screen, the UPPER/lower case will be replaced by symbols.

The indicates the solenoid valve is open, and the indicates that solenoid is closed.

5

41084 102709

Page 6

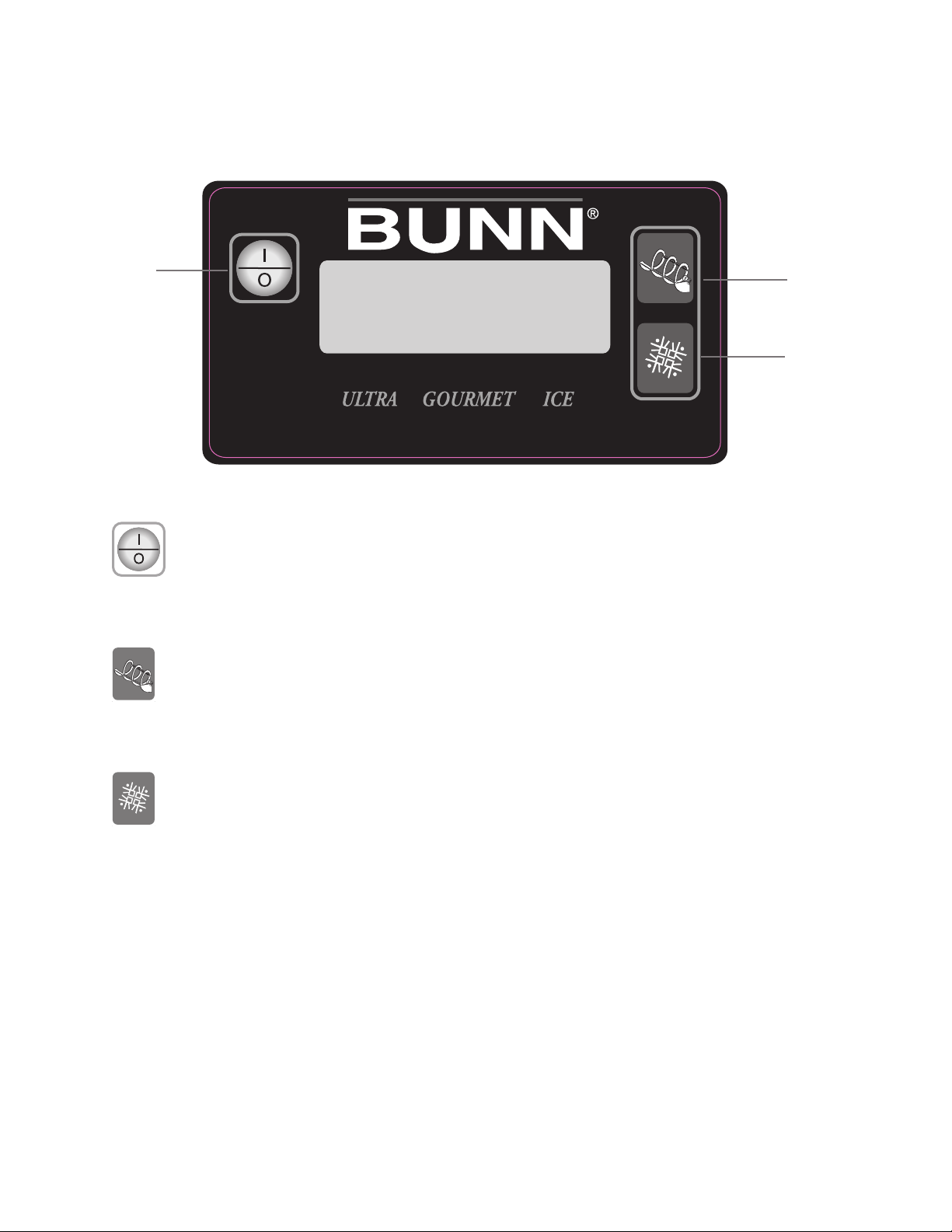

OPERATING CONTROLS

ULTRA-1

There are three of these switches that will be used for the operation of the dispenser.

1

2

3

P3932

1. switch (upper left corner of the control pad)

This switch is the ON/OFF toggle switch which powers up the dispenser and the LCD display. When ON

the Date and Time toggle back and forth continously except during programming.

2. (upper right corner)

This is used to turn the auger motor to AUGER ON, AUGER OFF or AUGER REFILL ON. (Refill only ap-

plicable when installed) (See *NOTE)

3. (lower right corner)

This is used to turn the ice control to OFF, ICE or CHILL.

*NOTE: Refill system includes a “Maximum Fill Time” in the software. If the time to fill the hopper exceeds this

limit, the hopper lights will flash and a “Refill Fault” will be displayed on the screen. If this accurs, check the

product supply to ensure the BIB is not empty. (Change BIB if empty). Then press the “ULTRA” button for 3

seconds to clear the fault and restart the refill system.

6

41084 102709

Page 7

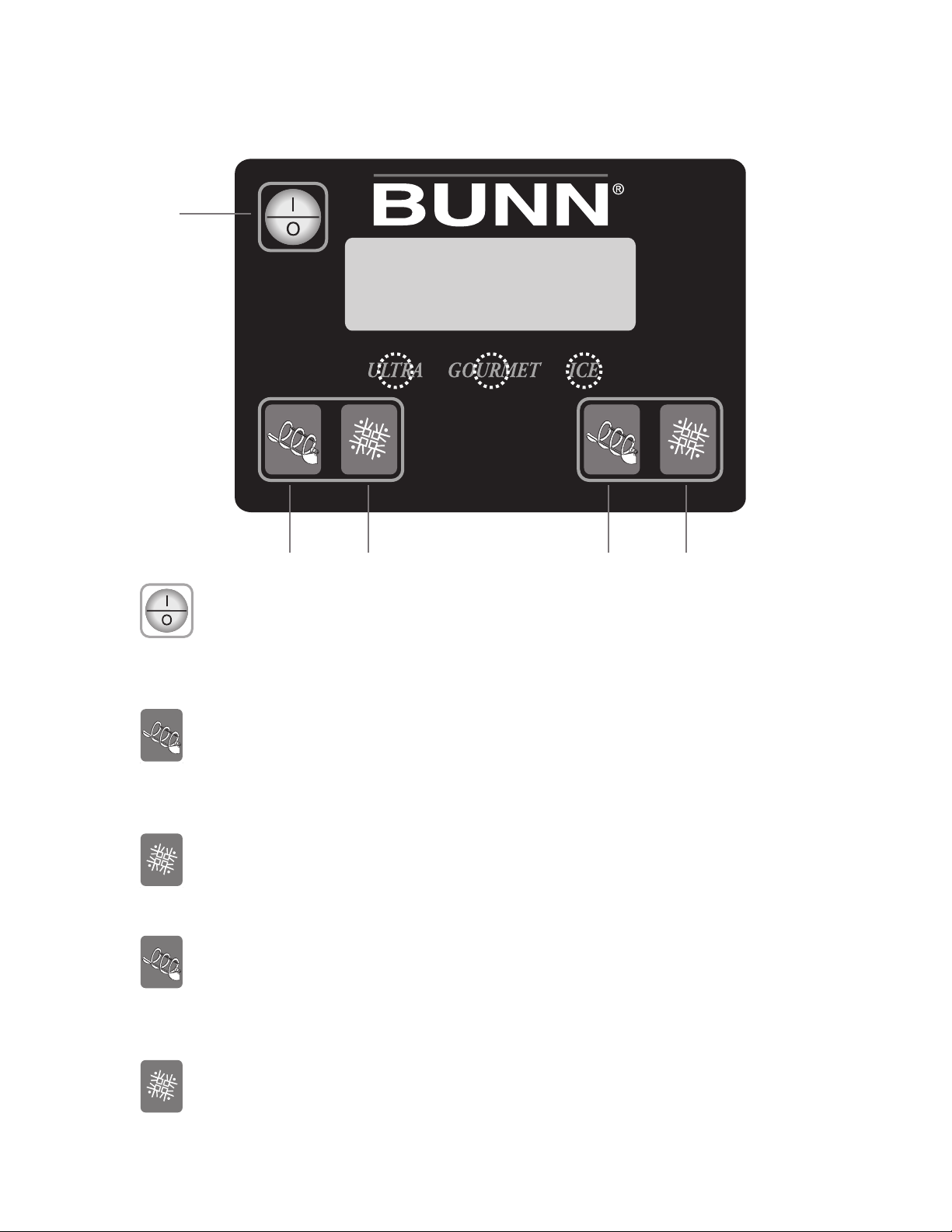

OPERATING CONTROLS

ULTRA-2

There are five of these switches that will be used for the operation of the dispenser.

1

P3677

2 3 4 5

1. switch (upper left corner of the control pad)

This switch is the ON/OFF toggle switch which powers up the dispenser and the LCD display. When ON

the Date and Time toggle back and forth continously except during programming.

2. (bottom left corner)

This is used to turn the left side auger motor to AUGER ON, AUGER OFF or AUGER REFILL ON. (Refill

only applicable when installed) (See *NOTE)

3. (bottom left corner)

This is used to turn the left side ice control to OFF, ICE or CHILL.

4. (bottom right corner)

This is used to turn the right side auger motor AUGER ON, AUGER OFF or AUGER REFILL ON. (Refill only

applicable when installed) (See *NOTE)

5. (bottom right corner)

This is used to turn the right side ice control to OFF, ICE or CHILL.

7

41084 102709

Page 8

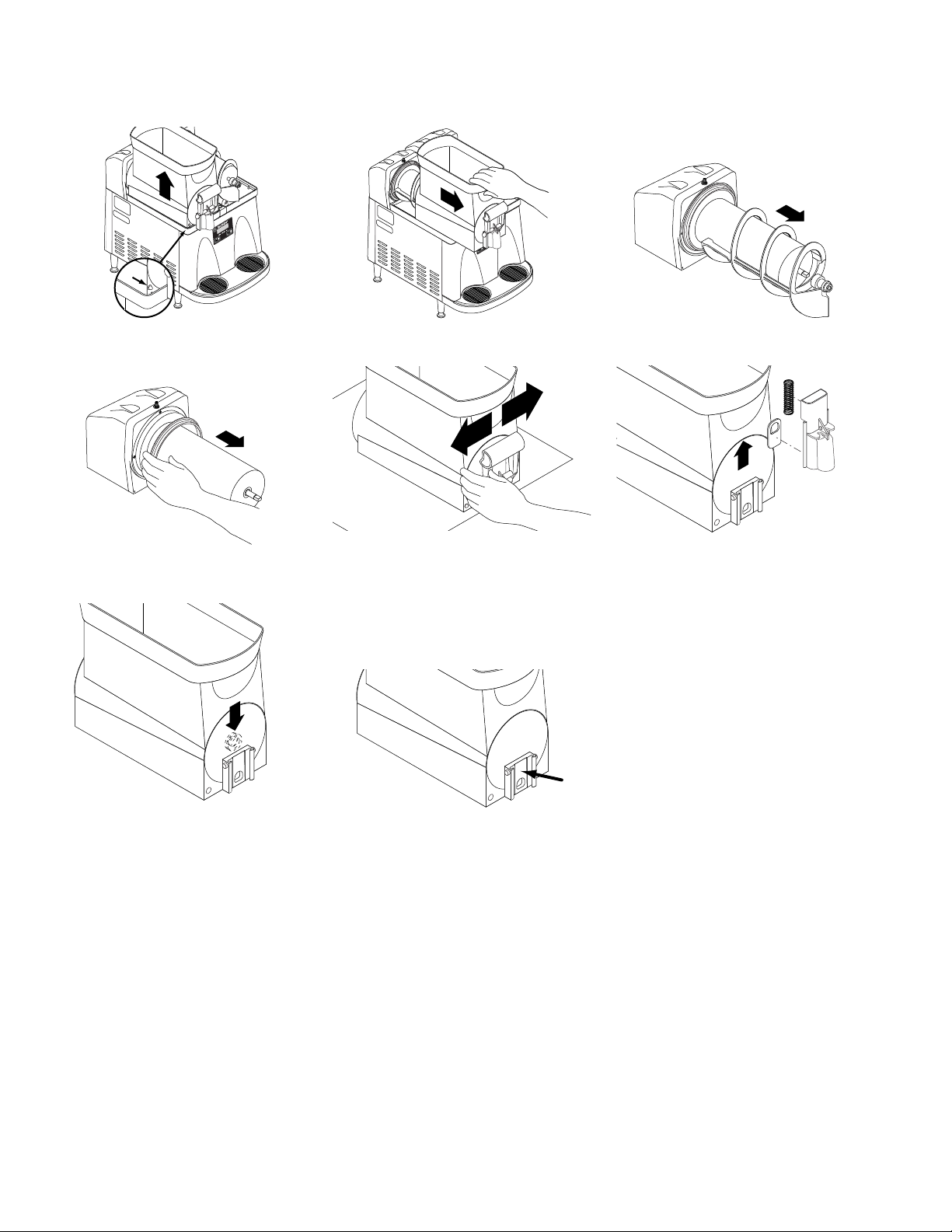

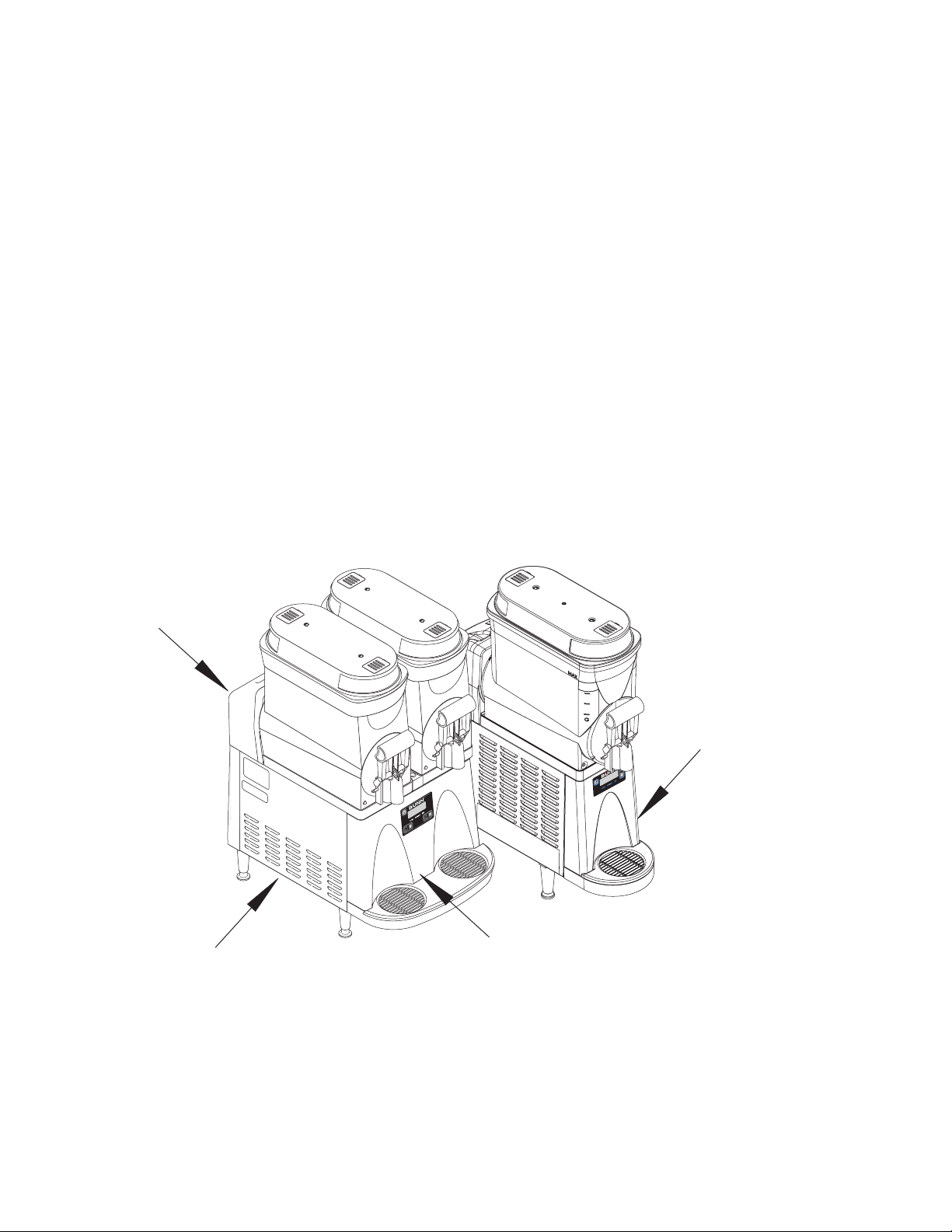

RECOMMENDED DAILY CLEANING (ULTRA-2 shown)

NOTE – Turn the power OFF to the dispenser before proceeding.

1. Empty all product from the hopper(s). Disconnect the hopper lid lamp cord(s) and remove the lids.

2. Depress the hopper lock plung-

er. Lift the hopper up slightly.

5. Remove the cooling drum seal

from the rear of the drum.

3. Pull forward to remove.

6. Caution: The faucet valve is

under spring tension. Spread

one side of the handle first, then

the other and disconnect from

the hopper.

4. Pull the auger from the cooling

drum.

7. Carefully slide the faucet valve

up to remove the spring and

faucet seal. Extra care should

be taken when handling the

seal to prevent damage. Do not

fold the seal as this will cause

damage to the Teflon® sealing

surface.

8. Remove the auger nose bush-

ing from inside the hopper.

9. Care must be taken to ensure this surface does not get scratched dur-

ing cleaning. Deep scratches could cause leakage around the seal.

10. Place all parts in a clean sink with mild hot water (120°F) and sanitizer solution. Allow all parts to soak for at

least 5 minutes. Carefully wash all components with a clean wash cloth in the hot water and sanitizer solution. Use a clean, soft bristle brush as needed for the smaller components and tight areas. Do not immerse

hopper lids. Use a commercial sanitizer that has 100 ppm of available chlorine with a concentration level

of at least 3% available chlorine (KAY-5 Sanitizer). Follow the sanitizer’s mixing instructions to ensure 100

ppm of available chlorine.

11. Wash the drums, hopper drip trays, top covers, and outer enclosure using a clean wash cloth that has been

dampened in the hot water and sanitizer solution. Pay particular attention to the shaft area and make sure

it is thoroughly cleaned and sanitized.

12. Thoroughly rinse all surfaces with a clean wash cloth that has been dampened with hot water. Wipe dry with

a clean dry wash cloth before reassembling the dispenser.

NOTE – Although most parts are dishwasher safe, they may be affected by the chemicals in some commercial

sanitizing agents. Do not place the hopper nor hopper lids in a dishwasher. Rinse thoroughly before assembly.

8

41084 102709

Page 9

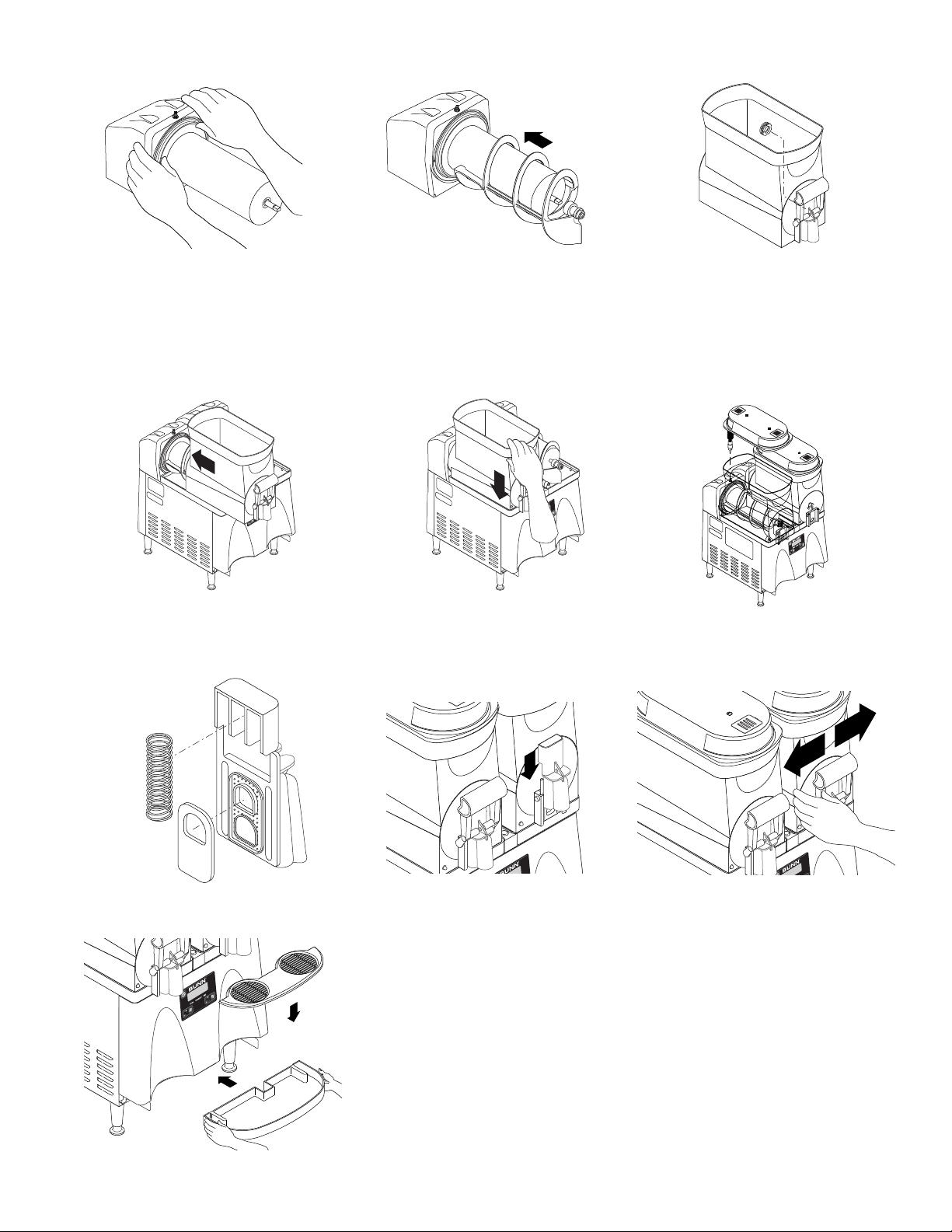

RECOMMENDED DAILY CLEANING (Continued)

1. Install the seal(s) over the

flange at the rear of the cooling

drum(s) and press the seal(s)

firmly into place as shown.

4. Thoroughly rinse the hopper(s)

and install over the auger(s)

and cooling drum(s).

2. Align the auger shaft(s) with the

auger(s). Push the auger(s) as

far as they will go and rotate so

the flat face of the auger shaft

is aligned with the flat face of

the auger nose.

5. Slide into place and push down

until the hopper lock plunger(s)

snap into place.

3. Install auger nose bushing into

inside front of hopper.

6. Set the lids on the hopper(s)

and plug in the hopper lid lamp

cord(s).

7. Position the faucet seal and re-

turn spring in the faucet valve.

10. Assemble the drip tray.

8. Slide the faucet valve assembly

into place on the hopper.

9

9. Press down on the valve to

compress the spring. Position

the faucet handle over the faucet valve one side at a time and

snap into place on the hopper.

41084 102709

Page 10

Auto-fill Cleaning Instructions

(With Brixing Pump Installed)

Materials required

1. Non-sudsing liquid detergent (such as common household automatic dishwasher liquid detergent).

2. Household bleach (Sodium chloride solution: 5.25%) or equivalent.

3. Clean five (5) gallon bucket.

4. Measuring Cup

5. An adaptor is needed to hold the Q.C.D. (Quick Connect/Disconnect) fitting on the concentrate suction line

open. A connector from an empty bag will work.

Sanitizing Procedure

1. Fill bucket with 4 gallons of warm water (120-180 deg. F).

2. Measure 4 ounces (1/2 cup) of the liquid detergent and add to the water.

3. Measure 2 ounces (1/4 cup) of bleach and add to the water, then stir, mixing evenly.

4. Ensure that the refill for the Ultra hopper is turned off.

5. Empty all product from the Ultra hopper

6. Disconnect the concentrate line from the B-I-B and install adaptor on the quick disconnect so the line is

open to the sanitizing solution. Place concentrate inlet line into the bucket so that the Q.C.D. will stay at the

bottom.

7. Press the auger button to turn on the “Auger Refill On” feature.

8. Allow system to run until the hopper is about 1/4 full then turn off refill.

9. Switch three way sanitize valve to the Sanitize postion.

10. Turn refill system back on and let run until the hopper is almost full then turn off refill.

11. Allow sanitizer to sit in system for 10 minutes.

12. Drain sanitizer from hopper and remove the Q.C.D. from the sanitizer bucket.

13. Empty remaining sanitizer and refill bucket with about 2 gallons of warm (120-180 deg. F) rinse water.

14. Turn sanitize valve back to dispense position.

15. Place Q.C.D. into rinse water and turn on refill system.

16. Run until hopper is about 1/4 full.

17. Turn off refill system and drain hoppers.

18. Refer to the Recommended Daily Cleaning instructions and follow these steps to clean the hopper, lid and

other dispense parts.

10

41084 040110

Page 11

DAMAGED/CORRODED AUGER SHAF

DIRTY OR DAMAGED TORQUE SENSOR BOARD

MISSING TORQUE SENSOR PINS

PREVENTIVE MAINTENANCE

A common problem occurs when the proper preventive maintenance procedures are not followed. Failure to

perform these procedures may result in damaged equipment and may not be covered by warranty.

Please check the following items before assuming a refrigeration fault.

When the product does not freeze, there are several possibilities other than a failure in the refrigeration system.

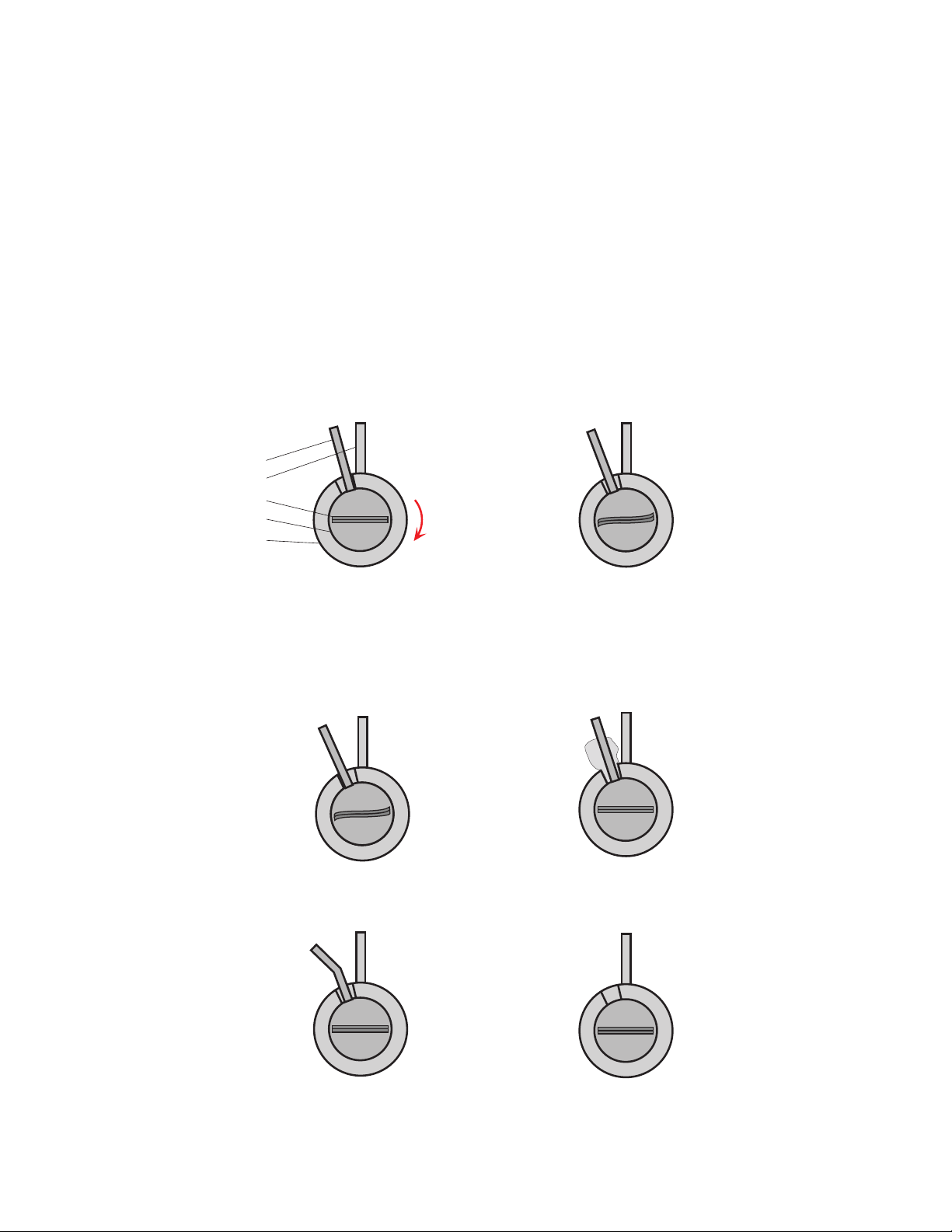

The torque between the auger motor and the frozen product is contolled by the torque sensor board measuring the distance between the pins on the coupler and shaft. When the distance between the pins reaches the

maximum allowable distance, the compressor shuts off. The machine thinks the product thickness has reach

the maximum and shuts off the compressor. The illustration below shows some of the other possible causes for

a false reading from the torque sensor board.

Proper inspection and preventive maintenance (including daily cleaning) will avoid expensive repairs and costly

down time.

NORMAL OPERATION

A

B

C

D

E

CHILL MODE

A. MOTOR SHAFT TORQUE SENSOR PIN

B. AUGER SHAFT TORQUE SENSOR PIN

C. TORSION SPRINGS

D. AUGER SHAFT

E. AUGER MOTOR COUPLING

POSSIBLE CAUSES FOR FALSE READINGS

WEAK TORSION SPRINGS

DAMAGED/WORN BUSHINGS/SEALS

ICE MODE

TOO MUCH KRYTOX GREASE

T

BENT TORQUE SENSOR PINS

11

41084 102709

Page 12

REQUIRED REGULAR MAINTENANCE:

Semi Annual:

Bunn Kit #34245.0002 is required for ULTRA-1 and

#34245.0000 & #34245.0001 is required for ULTRA-2,

to perform the semi annual Preventive maintenance:

Note: Service caused by failure to perform required

maintenance is not covered by warranty.

The following instructions apply to one hopper only;

repeat each step for all hoppers.

Kit Contents

Inventory this kit for completeness before proceeding.

* 34245.0003 PM Kit, ULTRA-2 PAF w/ LEDs

** 34245.0001 PM Kit, ULTRA-2

*** 34245.0002 PM Kit, ULTRA-1

Part Number Qty. Description

* ** ***

26781.0000 2 3 1 Auger Shaft Bushing (Blue)

37593.0000 2 3 1 Cooling Drum Seal

32079.0000 2 3 1 Hopper/Drum Seal

32268.1000 2 3 1 Seal Kit, Faucet (Clear)

29563.0000 - - - Lubricant (“Krytox”)

28395.0000 1 1 1 Seal Insertion Tool

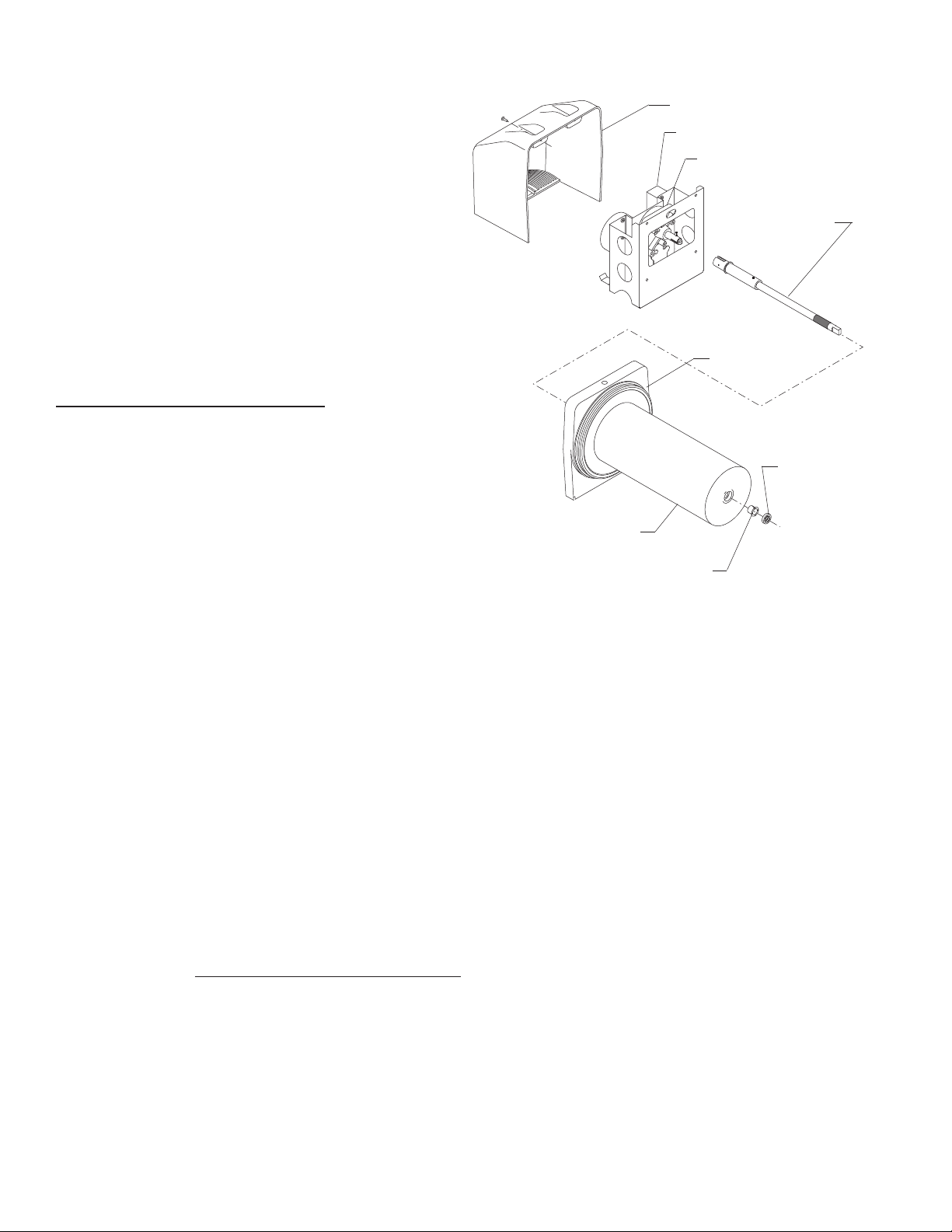

Cooling Drum

Auger Shaft Bushing

Auger Motor Cover

Run Capacitor

Auger Motor Assy

Auger Shaft Assy

Hopper/Drum Seal

Cooling Drum

Seal

P2528

FIG 1

INSTRUCTIONS

WARNING - Disconnect the dispenser from the power source before the removal of any panel or the replacement

of any component.

1. Drain, remove and clean hopper; refer to the Recommended Daily Cleaning instructions for proper cleaning

procedures. Discard the hopper/drum seal and faucet seal.

2. Remove the #8 locking screws securing auger motor cover to the cooling drum mount assembly; remove

cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right side (viewed from front) of the auger motor mounting bracket

securing the auger motor run capacitor. Set capacitor aside with wires attached.

4. Disconnect the auger motor terminal from the terminal on the main wiring harness.

5. Remove the remaining #8 locking screws securing the cooling drum mounting bracket. Remove motor with

mounting bracket.

NOTE: When removing or installing motor and shaft assembies, be sure the motor and shaft pins are turned to

a position that will clear the torque sensor circuit board.

12

41084 052112

Page 13

REQUIRED REGULAR MAINTENANCE (Continued)

6. Pull the auger shaft assembly straight out of cooling drum.

Inspect the shaft for abnormal wear.

7. From the front of dispenser, remove the seal and blue bushing

from cooling drum and discard them.

8. Inspect inside of the coling drum from the rear for product

leakage and clean thoroughly with an extended bristle brush

(Bunn part no. 40500.1068) and warm sanitize solution, rinse

and dry with a towel. Clean the front seal/bushing area of the

cooling drum thoroughly with the bristle brush. Refer to Fig. 4

for areas to be cleaned.

9. Refer to FIG 1, and slip new blue bushing into cooling drum.

10. Place seal on insertion tool #28395.0000 as shown in FIG 2.

Make sure open face of seal is toward cooling drum.

11. Apply a small amount of food grade lubricant (Bunn

#M2568.1001) to inside diameter of seal. Push seal into bore

until it is firmly seated; remove tool.

12. Place a small amount of #29563.0000 “Krytox” lubricant

(provided in kit in a plastic cap) on the end of the motor shaft

(about 1 1/2”) and a thin film in the groove. Install auger shaft

assembly onto the motor shaft. See FIG 3. Do not use too much

“Krytox” lubricant. Dirt or grease on pins will cause “optical”

misreading by torque sensors.

NOTE: This is the only place “Krytox” lubricant is used.

13. Assemble motor/shaft assembly as shown in FIG 3, then install

assembly into cooling drum. Make sure the pins do not hit the

sensor board and cooling drum seal is not dislodged as the

shaft passes through.

14. Secure motor and capacitor to the cooling drum mounting

bracket. Install rear motor cover.

15. Refer to the hopper assembly and installation procedures. Install

new hopper/drum seals and faucet seals included in the kit. See

FIG 1 & 5.

16. Remove and clean condenser air filter. See FIG 6.

17. Refer to the Programming Manual, “Menu Function Index”.

Scroll to menu “PM Complete?” and answer “YES” to reset

the reminder message “PM Due”.

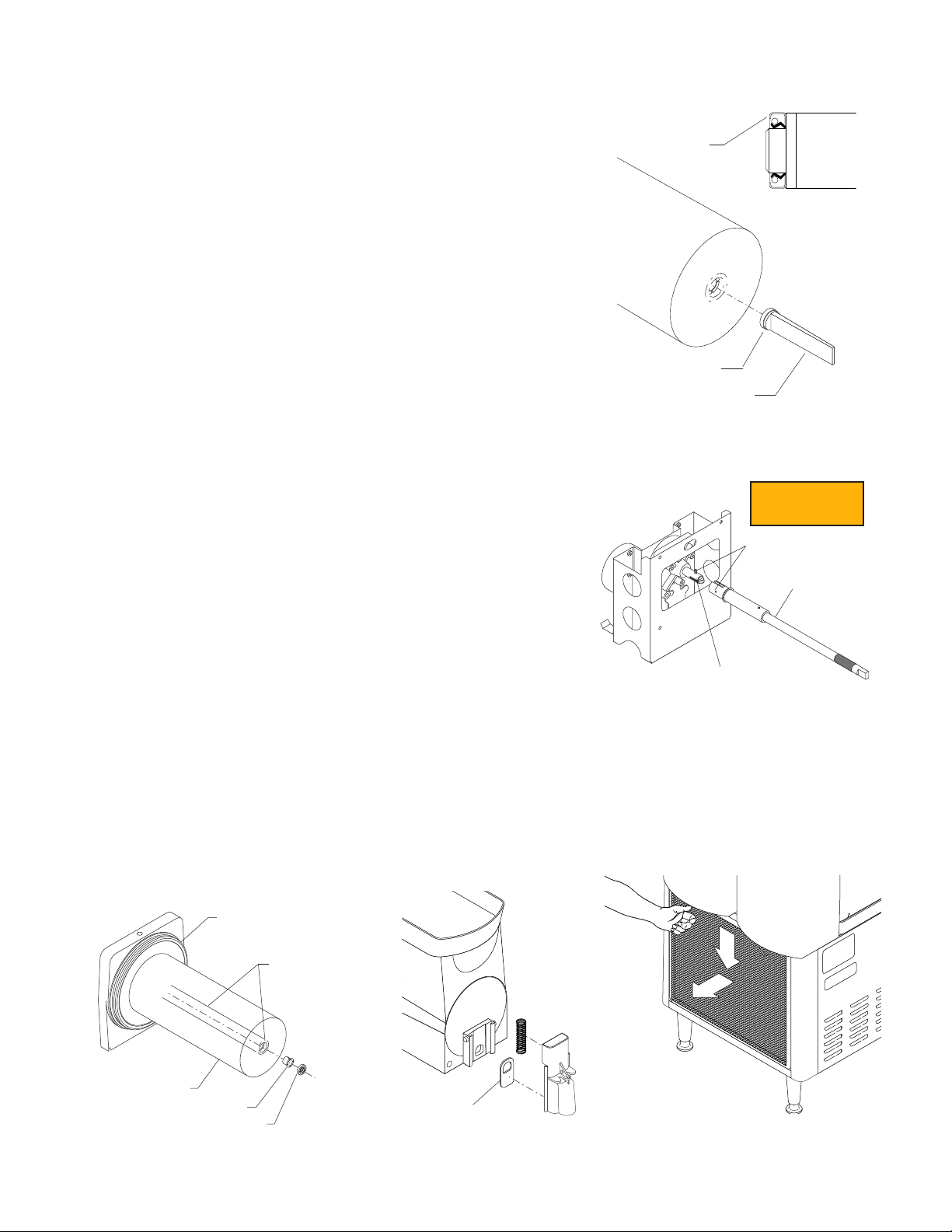

Open face of seal

away from tool

Cooling Drum Seal

Seal Insertion Tool

P1760

FIG 2

Check for weak

torsion springs

Pins

Auger Shaft Assy

Lube about 1 1/2” of shaft and in the

groove with #29563.0000 “Krytox”

Lubricant

P2529

FIG 3

Cooling Drum

Auger Shaft Bushing

Cooling Drum Seal

FIG 4

Hopper/Drum Seal

Inspect & Clean

Faucet Seal

FIG 5

13

P3695

P3682

FIG 6

41084 052112

Page 14

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

• All electronic components have 120 volt ac and/or low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If

an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Keep away from combustibles.

WARNING – • Exercise extreme caution when servicing electrical equipment.

• Unplug the dispenser when servicing, except when electrical tests are specified.

• Follow recommended service procedures

• Replace all protective shields or safety notices

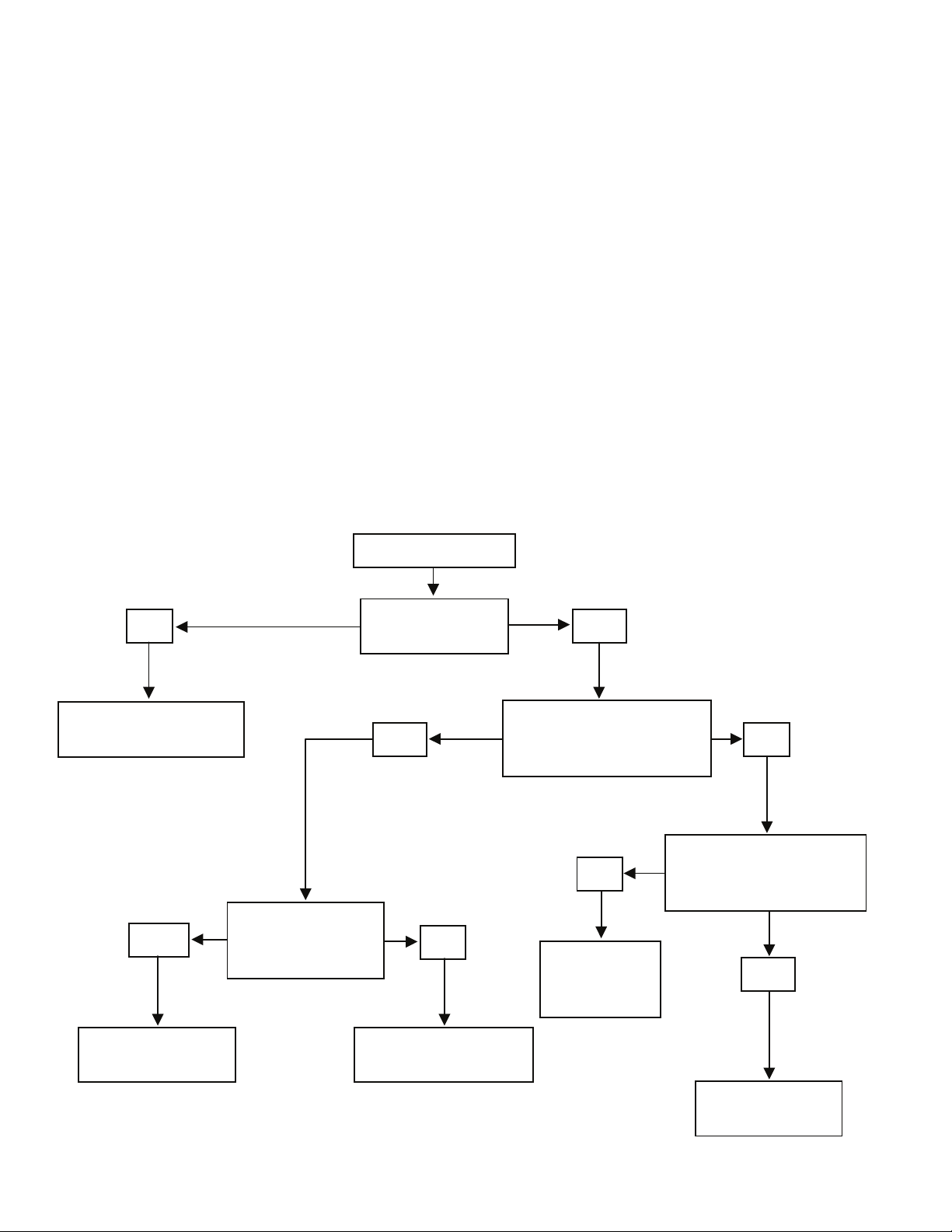

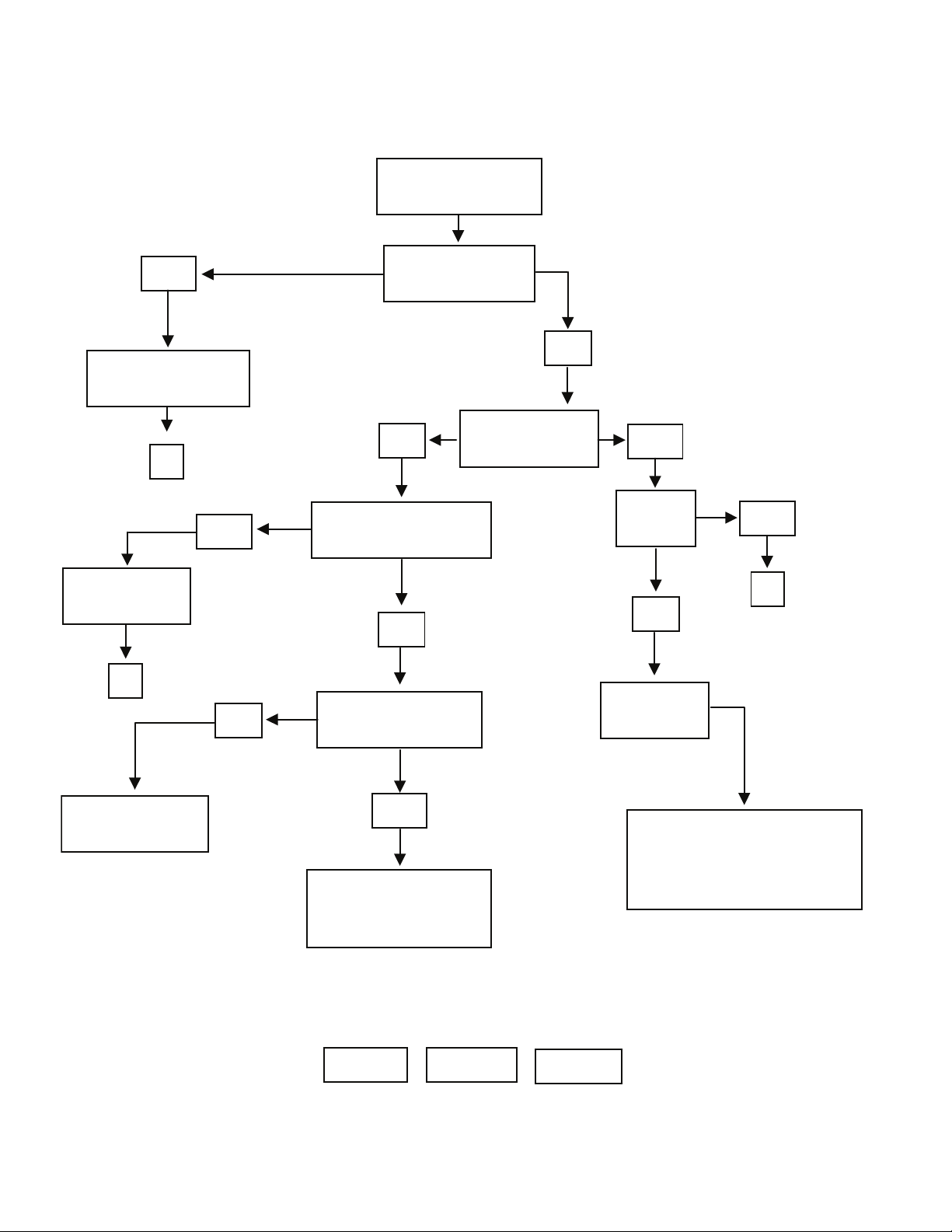

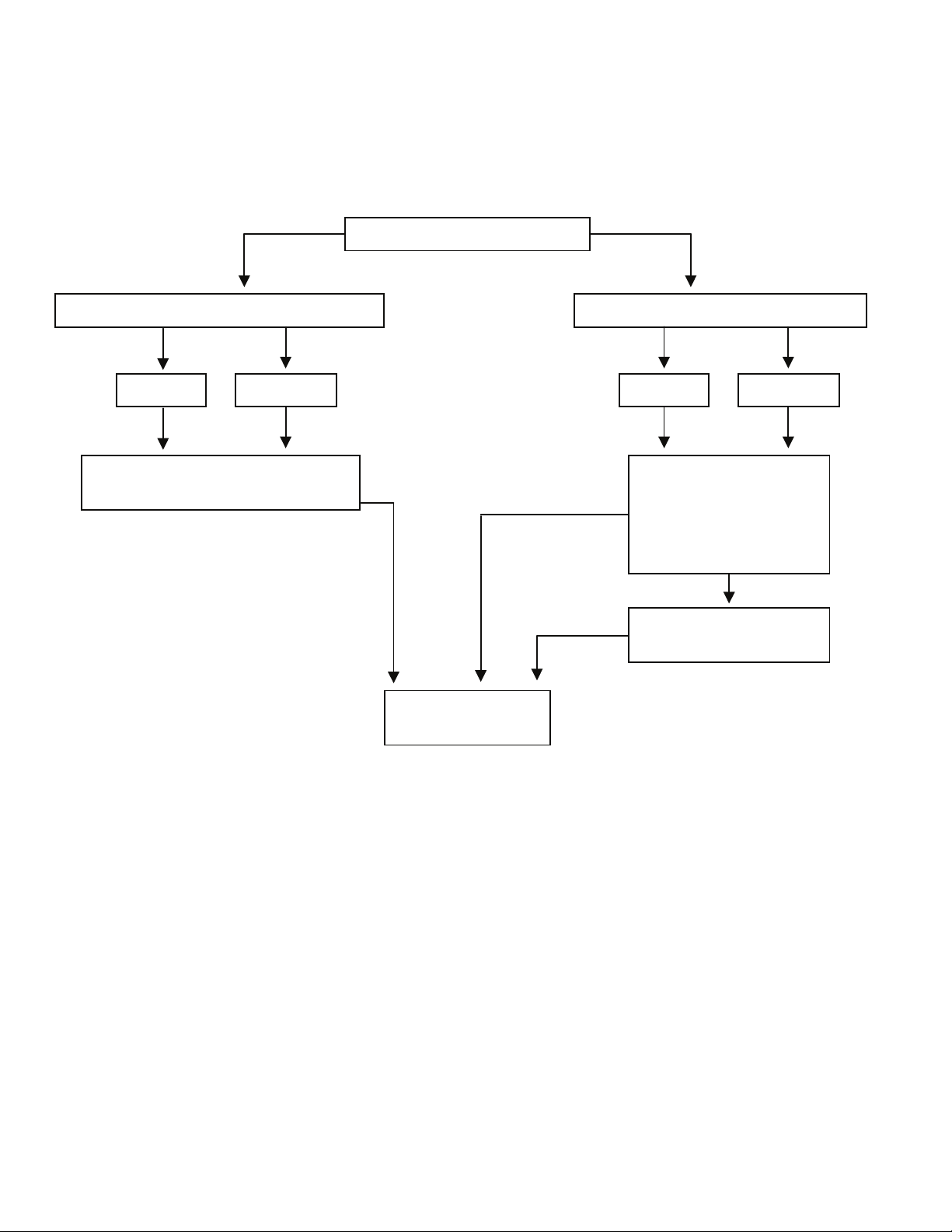

No Yes

Call licensed

electrician for repair

Yes

Does Membrane

Switch test ok?

No Power

Correct voltage

at outlet?

12vac to Control Board

Yes No

at J5-8 & J5-20?

12vac from secondary

No

of transformer?

No

Replace

Transformer

Yes

Replace Control

Board

Replace Membrane

Switch

14

Check main

wiring harness

41084 102709

Page 15

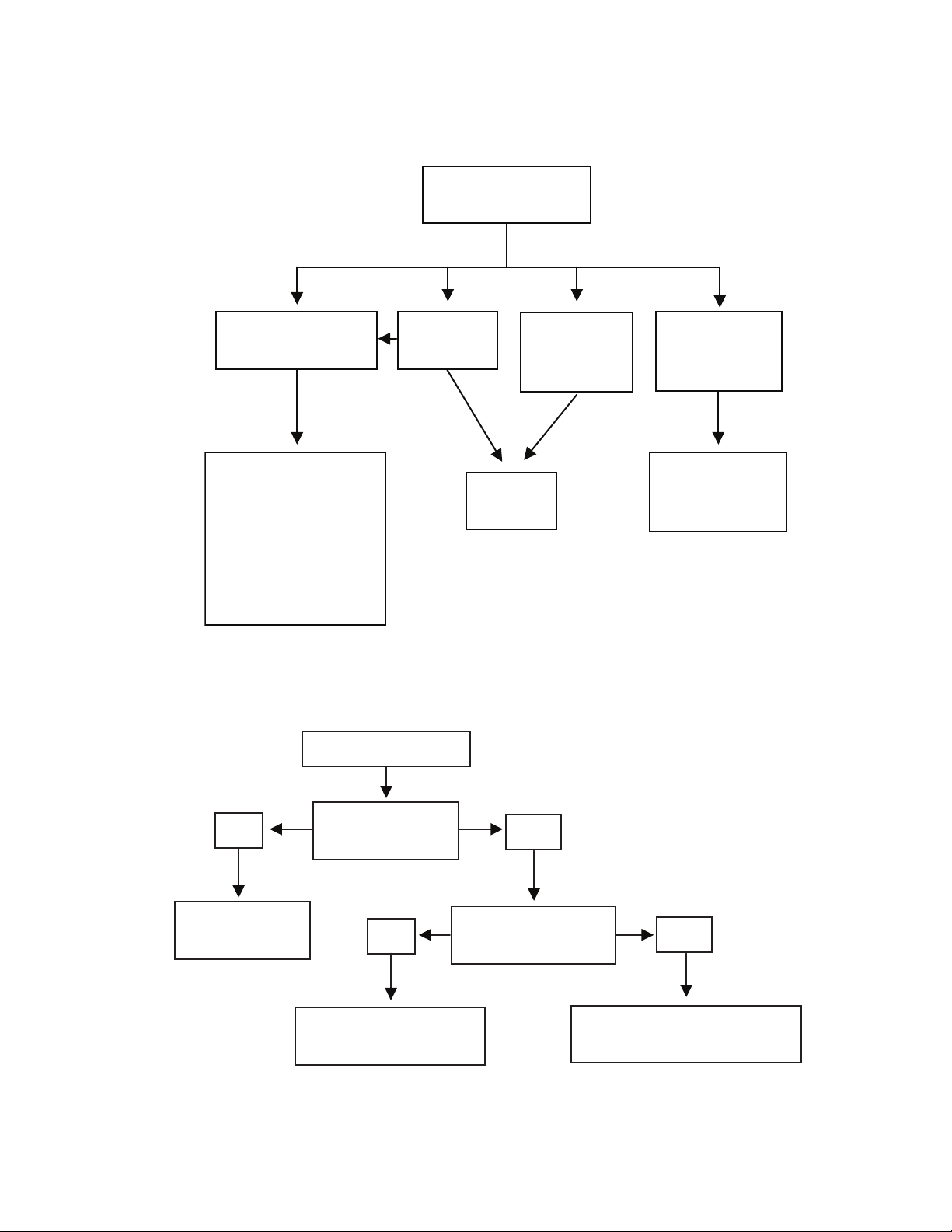

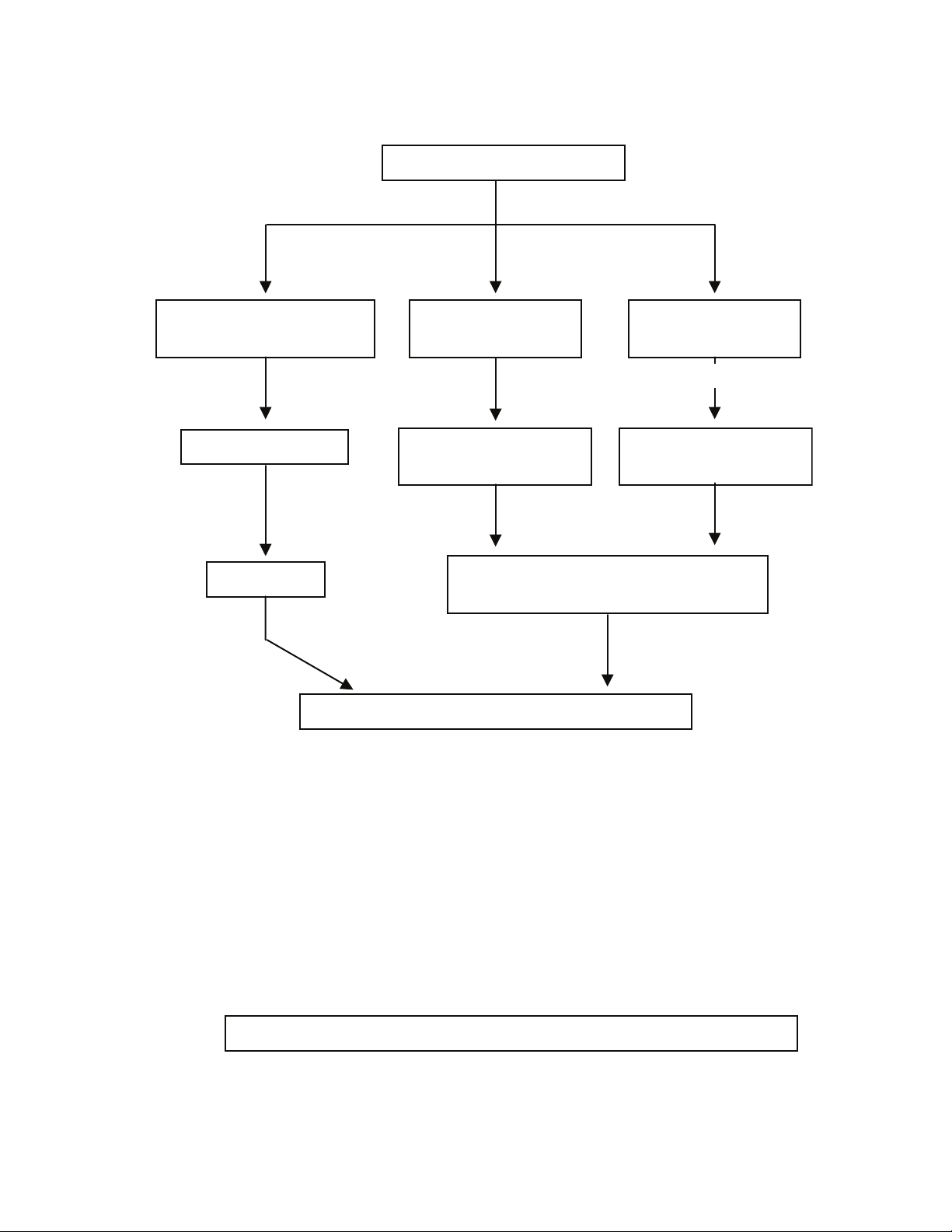

TROUBLESHOOTING (cont.)

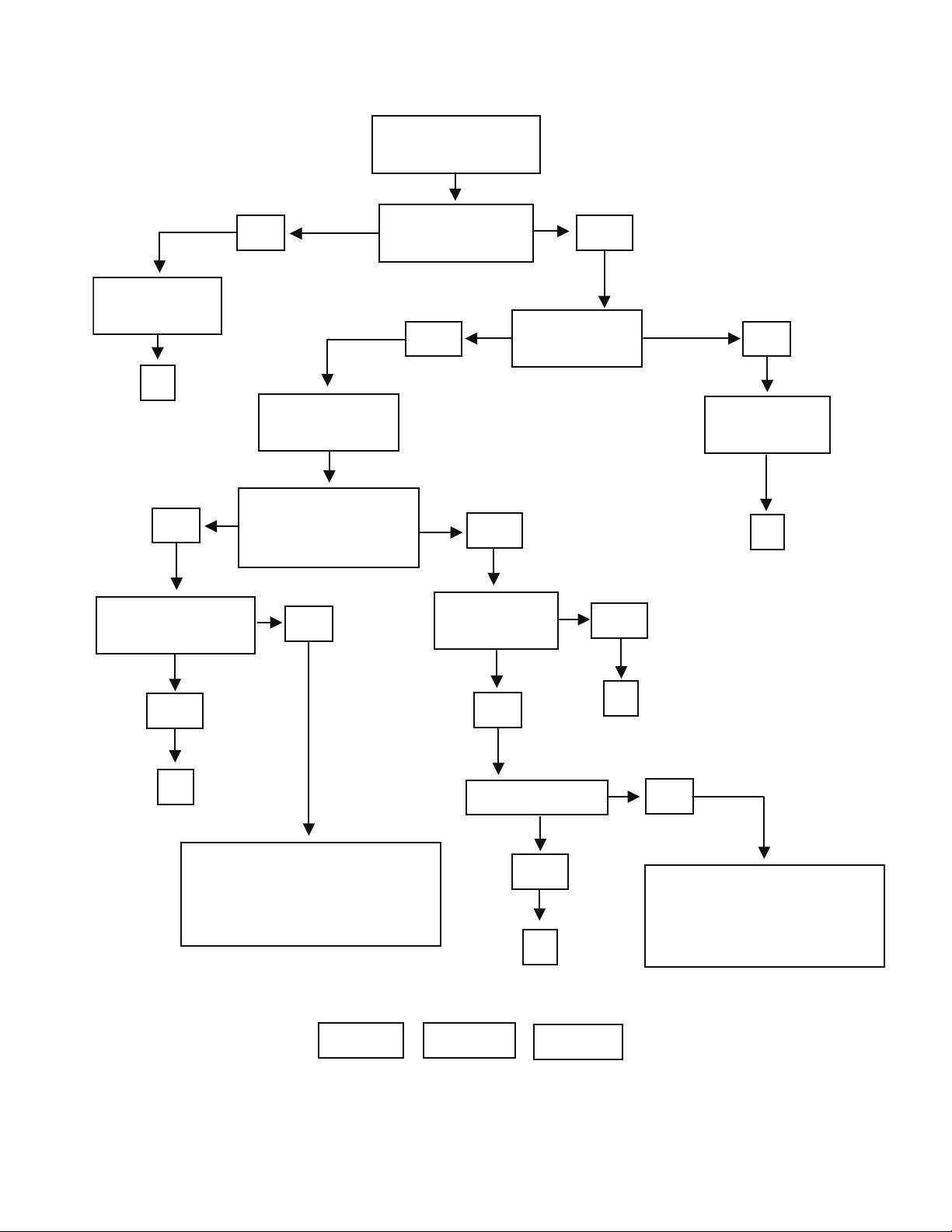

Chills but

won’t freeze

Set into

“DAY” mode

1

No

Is Thickness

screen set low?

Verify augers

are turned on

Is display showing

UPPER CASE

“ICE” mode?

No

Dispenser in

“DAY” mode?

Yes

Yes

Is Brix

level high?

YesNo

Dispenser in

“ICE” mode?

Yes

No

Set into

“ICE” mode

1

Yes

2

Inspect auger drive shafts

for weak torsion springs or

damaged pins. Check for dirty

or worn seals and bushings.

1- Done

No

Is Filter dirty?

2- Adjust

Yes

3

3- Clean

2

No

Have a certified

refrigeration technician

check for low refrigerant

or blockage.

15

41084 102709

Page 16

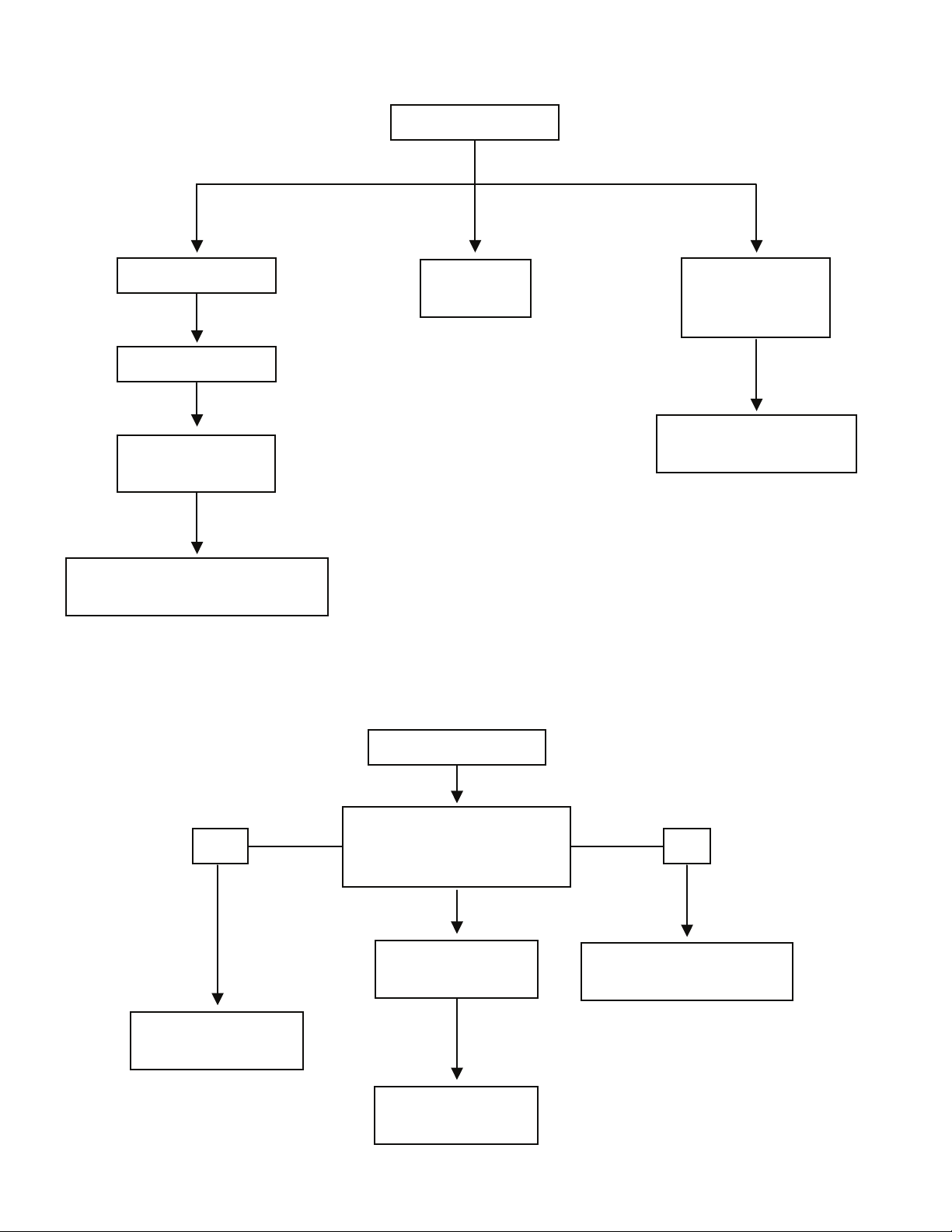

TROUBLESHOOTING (cont.)

No cooling

at all

Yes

Set into “ICE” or

“CHILL” mode

1

Plug directly

inti outlet

1

Yes

No

Is ICE/CHILL

set to off?

No

Is Dispenser on

an extension cord?

No

Is there correct

voltage at outlet?

No

Is compressor

running?

Yes

Is filter

dirty?

No

Check fan

Yes

3

Call a licensed

electrician

Yes

Follow compressor

circuit checks.

1- Done

2- Adjust

16

Have a certified

refrigeration technician

check for low refrigerant

or blockage.

3- Clean

41084 102709

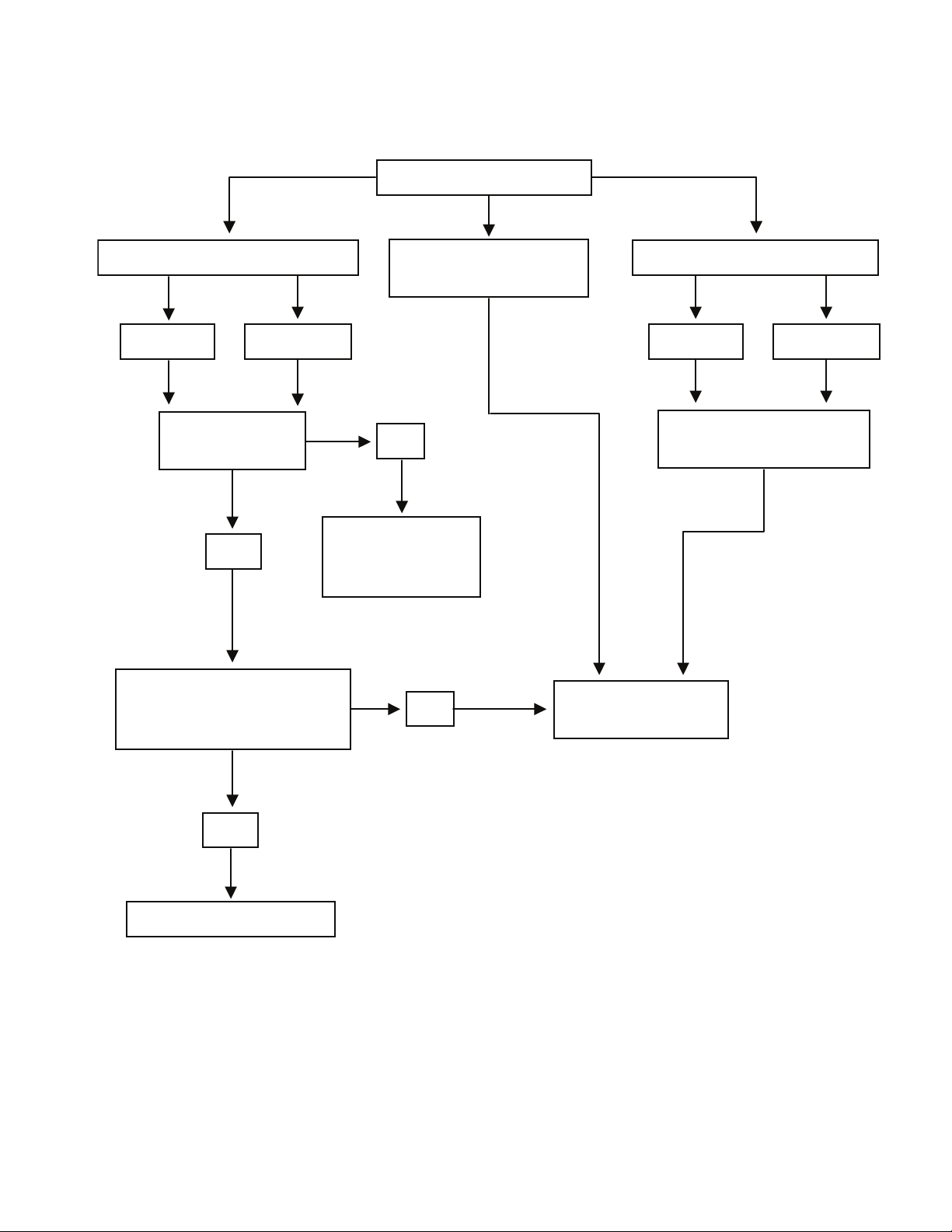

Page 17

TROUBLESHOOTING (cont.)

Freezes, but not

thick enough

Adjust thickness

screen higher

Check for slightly

bent auger shaft

pins and/or weak

torsion springs.

Check for dirty

or worn seals and

bushings.

No hood lamps

Brix ratio

too high

Adjust

product

Too much

alcohol in

product

Ambient

temperature

too hot

Recommended

for indoor

use only

No

Set into

“DAY” mode

Is dispenser in

“DAY” mode?

No

Check lamp circuit

Yes

Is circuit breaker

tripped?

17

Yes

Verify all 4 bulbs are 912

series & reset breaker

41084 102709

Page 18

TROUBLESHOOTING (cont.)

Noise

Auger jumping

Lower brix ratio

Drum alignment

Check auger shaft bushings

Check fan

Using auger

assembly from

CDS 2 or 3?

Replace with ULTRA

p/n 32106.1000

Yes

Check membrane

switch

Auger won’t turn

Do they turn during

“AUGER MOTOR TEST”

mode?

One direction,

but not the other

Replace control

board

18

No

Auger motor/capacitor

checks

41084 102709

Page 19

TROUBLESHOOTING (cont.)

Torque Sensor Error

TORQUE SENSOR ERROR

Left side

Right side

Are augers

turning?

Yes

Are augers shaft pins

damaged or missing?

TORQUE SENSOR

No

Go to motor

troubleshooting

No

SHORTED

TORQUE SENSOR OPEN

Left side

Check sensor

circuit

Right side

Sensor unplugged or

break in wiring

Yes

Replace as necessary

19

41084 102709

Page 20

TROUBLESHOOTING (cont.)

Temperature Sensor Error

TEMPERATURE SENSOR SHORTED

Left side

Right side

Check wiring harness between

thermistor and control board

Check thermistor

circuit

TEMPERATURE SENSOR OPEN

Left side

Right side

Product not covering

back end of drum.

Drum temperature

falls below 9° F.

Replenish product

Thermistor unplugged

or break in wiring

20

41084 102709

Page 21

TROUBLESHOOTING (cont.)

Clean Filter Messages

“MONTHLY FILTER

CLEAN REQUIRED”

Monthly reminder

Clean filter

“FILTER NEEDS

CLEANING”

Freezing is Disabled

Hot gas thermistor

sensing over 220° F

sensing over 250° F

Dirty filter; air flow blockage;

wrong refrigerant or over charged

Hold ULTRA button for 3 seconds to reset. *

“FILTER NEEDS

!!!CLEANING!!!”

Hot gas thermistor

* Early units have to reset to factory defaults in order to reset

21

41084 102709

Page 22

SERVICE

This section provides procedures for testing and replacing various major components used in this dispenser

should service become necessary. Refer to Troubleshooting for assistance in determining the cause of any

problem.

WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified service

personnel. The dispenser should be disconnected from the power source when servicing, except when electrical

tests are required and the test procedure specifically states to connect the dispenser to the power source.

COMPONENT ACCESS PANELS

WARNING - Disconnect the dispenser from the power source before the removal of any panel or the replacement

of any component.

All components are accessible by removal of the auger motor cover, lower drip tray, front cover and the left

and right side covers.

Refer to the contents listing for component location.

22

P3930.30

41084 102709

Page 23

SERVICE(CONT.)

oil

J1-3 Common

AUGER MOTORS

ULTRA-2 shown

FIG. 1 AUGER MOTORS

Location

The auger motors are located at the upper rear of the

dispenser chassis inside the auger motor covers.

Test Procedures

1. Remove the hopper from the same side as the motor

to be tested.

2. Turn “ON” the appropriate auger switch.

3. Nudge the auger to start it turning.

P1341

Removal and Replacement

1. Remove the two #8 locking screws securing the auger

motor cover to the cooling drum mount assembly.

2. Remove the cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right side of

the auger motor mounting bracket securing the auger

motor run capacitor. Set capacitor aside with wires attached.

4. Disconnect the auger motor terminal from the terminal

on the main wiring harness.

5. Remove the three remaining #8 locking screws securing the auger motor mounting bracket to cooling drum

mounting bracket.

6. Remove motor with mounting bracket, drip tray, split

pin and torsion spring bearing as an assembly.

NOTE: When removing or installing the motor be sure the

split pin in the motor shaft is turned to a position that will

clear the torque sensor circuit board.

7. Install new motor with mounting bracket, drip tray, split

pin and torsion spring bearing using three #8 locking

screws onto the cooling drum bracket.

8. Install the auger motor capacitor on the lower right side

of the auger mounting bracket, using the remaining #8

locking screw.

9. Connect the auger motor terminal to the terminal on the

main wiring harness.

10. Refer to Fig. 2 when reconnecting the wires.

If the auger doesn’t turn, replace the motor.

If auger starts to turn, replace the start capacitor.

WARNING: The compressor start capacitor must be properly

discharged before removing. This is most commonly done

on low voltage capacitors by shorting across the terminals

with a screwdriver.

ULTRA-2 LEFT AUGER MOTOR

J1-1 BRN/WHI to Left Auger Motor Capacitor

J1-2 BRN/BLK to J5-3 of Control Board

J1-3 WHI to Main Harness

ULTRA-2 RIGHT AUGER MOTOR

J1-1 WHI/RED to Right Auger Motor Capacitor

J1-1 Boost C

J1-2 Run Coil

J1-2 RED/BLK to J5-1 of Control Board

J1-1 BRN/WHI to Auger Motor Capacitor

J1-2 BRN/BLK to J10-9 of Control Board

J1-3 WHI to Main Harness

ULTRA-1 AUGER MOTOR

J1-3 WHI to Main Harness

FIG. 2 AUGER MOTOR TERMINALS

MOTOR COIL RESISTANCE

J1-3 to:

WHITE

J1-1 = 58 ohms

BLACK

J1-2 = 58 ohms

RED

23

41084 102709

Page 24

SERVICE (CONT.)

AUGER MOTOR CAPACITOR

ULTRA-2 shown

Removal and Replacement

1. Remove the two #8 locking screws securing the auger

motor cover to the cooling drum mount assy.

2. Remove the cover and set aside for reassembly.

3. Disconnect the wires from the auger motor capacitor

terminals.

4. Remove the #8 locking screw on the lower right side of

the auger motor mounting bracket securing the auger

motor capacitor.

5. Install a new capacitor on the lower right side of the

auger mounting bracket and secure with a #8 locking

screw.

6. Reconnect the wires to the capacitor terminals.

7. Refer to Fig. 4 when reconnecting the wires.

FIG. 3 AUGER MOTOR CAPACITORS

P1341

Location:

The auger motor capacitor(s) are located on the lower

right side of the auger motor mounting bracket inside the

auger motor cover(s).

Test Procedures

1. Remove the hopper from the same side as the motor

to be tested.

2. Turn “ON” the appropriate auger switch.

3. Nudge the auger to start it turning.

If the auger doesn’t turn, replace the motor.

If auger starts to turn, replace the start capacitor.

WARNING: The compressor start capacitor must be properly

discharged before removing. This is most commonly done

on low voltage capacitors by shorting across the terminals

with a screwdriver.

ULTRA-2 LEFT MOTOR CAPACITOR

BRN/WHI to Left Auger Motor J13-2

BRN/BLK to Control Board J13-3

ULTRA-2 RIGHT MOTOR CAPACITOR

WHI/RED to Right Auger Motor J13-13

RED/BLK to Control Board J13-1

ULTRA-1 AUGER MOTOR CAPACITOR

BRN/WHI to Auger Motor J10-8

BRN/BLK to Control Board J10-9

FIG. 4 AUGER MOTOR CAPACITOR TERMINALS

24

41084 102709

Page 25

SERVICE (cont.)

AUGER SHAFT ASSEMBLY

Auger Motor Cover

Run Capacitor

Auger Motor Assy

Hopper Drum Seal

Cooling Drum

FIG. 5 AUGER SHAFT ASSEMBLY

Auger Shaft Assy

Ceramic Coating

Auger Shaft Bushing

Cooling Drum Seal

7. Pull the auger shaft assembly straight out of cooling drum. Inspect the shaft for abnormal wear or

scoring.

8. From the front of dispenser, remove the seal and

blue bushing from cooling drum and discard

them.

9. Clean seal and bushing surfaces of the cooling

drum very thoroughly.

10. Refer to Fig 6 and slip new blue bushing into cooling

drum.

Blue bushing

P1758

Location:

The Auger Shaft Assembly is located in each of the

cooling drums.

Removal and Replacement:

1. Drain, remove and clean hopper; refer to the Rec-

ommended Daily Weekly Cleaning Section of this

manual, for proper cleaning procedures. Discard

the hopper/drum seal and faucet seal.

2. Remove the #8 locking screws securing auger

motor cover to the cooling drum mount assembly;

remove cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right side

(viewed from front) of the auger motor mounting

bracket securing the auger motor run capacitor. Set

capacitor aside with wires attached.

4. Disconnect the auger motor terminal from the

terminal on the main wiring harness.

5. Remove the remaining #8 locking screws securing

the auger motor mounting bracket to cooling drum

mounting bracket.

6. Remove motor with mounting bracket, split pin and

torsion spring bearing as an assembly.

Do NOT get any Lube on this surface

(between Drum and Bushings/Seals)

P1759

FIG. 6 AUGER SHAFT BUSHING

11. Place seal on insertion tool #28395.0000, as shown

in Fig. 7. Make sure open face of seal is toward

cooling drum.

12. Push seal into bore until it is firmly seated; remove

tool.

13. Place a small amount of #29563.0000 “Krytox”

lubricant (provided in kit in a plastic cap) on the

end of the motor shaft (about 1 1/2”) and a thin

film in the groove. Install auger shaft assembly onto

the motor shaft. See Fig. 8. Do not use too much

“Krytox” lubricant.

NOTE - This is the only place “Krytox” lubricant is

used.

NOTE - When removing or installing motor and shaft

assemblies, be sure the split pins are turned to a position that will clear the torque sensor circuit board.

25

41084 102709

Page 26

SERVICE (cont.)

AUGER SHAFT ASSEMBLY(cont.)

Open face of seal away

from tool

Cooling Drum Seal

Seal Insertion Tool

FIG. 7 COOLING DRUM SEAL

16. Refer to Hopper Installation for hopper assembly

and installation procedures. Be sure to use new

hopper/drum seal and faucet seals

P1760

14. Assemble motor/shaft assembly as shown in Fig.

8, then install assembly into cooling drum. Make

sure the pins do not hit the sensor board and cooling drum seal is not dislodged as the shaft passes

through.

Lube about 1 1/2” of shaft and

in the groove with #29563.0000

“Krytox” Lubricant

Auger Shaft Assy

P1761

FIG. 8 MOTOR/SHAFT ASSEMBLY

15. Secure motor and capacitor to the cooling drum

mounting bracket. Install rear motor cover.

FIG 9

17. Remove and clean condenser air filter, Fig. 10.

18. Refer to the Programming Manual, “Menu Function

Index”. Scroll to menu “PM Complete?” and answer

“YES” to reset the reminder message “PM Due”.

ULTRA-2 shown

P3682

FIG 10

26

41084 102709

Page 27

SERVICE (cont.)

CIRCUIT BREAKER

R

FIG. 11 CIRCUIT BREAKER (ULTRA-2)

Location:

The circuit breaker is located inside the dispenser

on the front right frame post on ULTRA-2 models; and

under the Auger Motor cover on ULTRA-1 models.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Remove the wires from the circuit breaker.

3. Check for continuity between the terminals. Conti-

nuity must be present between the terminals.

If continuity is present as described the circuit breaker

is functioning properly.

If continuity is not present as described, press the reset

button and repeat step #3, if continuity is not present

as described, replace the circuit breaker.

Removal and Replacement:

1. Remove the right side panel on ULTRA-2 models;

or remove the Auger Motor cover on ULTRA-1

models.

2. Remove the wires from the circuit breaker.

3. Compress the clips on the back side of the com-

ponent bracket and gently push the circuit breaker

through the opening in the bracket.

4. Push the new circuit breaker into the opening in

the bracket until the clips snap into position.

5. Reconnect the wires to the circuit breaker.

6. Refer to Fig. 13 when reconnecting the wires.

FIG. 12 CIRCUIT BREAKER (ULTRA-1)

WHI/BLU from Transformer

WHI/YEL to Lamp Relay (ULTRA-2)

RED to Lamp Relay (ULTRA-1)

FIG. 13 CIRCUIT BREAKER TERMINALS

27

41084 102709

Page 28

SERVICE (cont.)

230V COMPRESSORS

COMPRESSOR (AMERICOLD) (ULTRA-2)

FIG. 14 COMPRESSOR ASSY

Location:

The compressor assy is located inside the front of

the dispenser chassis.

Test Procedures:

WARNING: The compressor start capacitor must be properly

discharged before proceeding. This is most commonly done

on low voltage capacitors by shorting across the terminals

with a screwdriver.

Compressor Start Relay: Refer to FIG. 15

1. Disconnect the dispenser from the power source.

2. Remove compressor terminal cover retainer (5) and

compressor terminal cover (4).

3. Connect a voltmeter across the white wire and the white/

orange wire. Connect the dispenser to the power source.

Verify the dispenser is in “ICE” or “CHILL” mode.

The indication must be:

(a) 120 volts ac for two wire 120 volt models or

(b) 230 volts ac for two wire 230 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to the following

test procedures.

If voltage is not present as described, refer to the Relay and

check the relay.

1

23

4 5

120V COMPRESSORS

13

2

4 5

6

FIG. 15 COMPRESSOR ELECTRICAL COMPONENTS

1. Compressor Start Relay

2. Thermal Overload Protector

3. Overload Protector Retainer

4. Compressor Terminal Cover

5. Terminal Cover Retainer

6. Compressor Run Capacitor

6. Disconnect the two black wires from the compressor

start relay.

7. Remove relay from the compressor.

8. Check for continuity across the upper left terminal and

the right pin socket on the rear of the relay.

If continuity is present as described, the compressor start

relay is operating properly.

If continuity is not present as described, replace relay.

Compressor:

1. With the compressor start relay (1) removed, disconnect

the black wire from the compressor.

2. Check for continuity across the terminal on the compressor and the left pin on the compressor.

If continuity is present as described, the electrical part of

the compressor is operating properly.

If continuity is not present as described, replace the compressor.

Thermal Overload Protector:

1. Check for continuity across the terminals on the thermal

overload protector (2).

If continuity is present as described, the thermal overload

protector is operating properly.

If continuity is not present as described, replace the thermal

overload protector.

28

41084 102709

Page 29

SERVICE (cont.)

COMPRESSOR (AMERICOLD) (ULTRA-2) (cont.)

Removal and Replacement:

Compressor Start Relay: Refer to FIG. 15

1. Remove the terminal cover retainer (5) and the terminal

cover (4)

2. Disconnect the wires from the compressor start relay.

3. Pull relay (1) off of the compressor pins and discard.

4. Push new relay onto the compressor pins.

5. Refer to Fig. 16 and reconnect the wires.

6. Reinstall terminal cover (4) and cover retainer (5).

6. Install retainer (3) on new overload protector (2).

7. Install retainer (3) and overload protector (2) on the

compressor terminal bracket.

8. Refer to Fig. 17 and reconnect the thermal overload

protector wires.

9. Reinstall terminal cover (4) and cover retainer (5).

WHI/ORN from

Main Harness

White from Main Harness

Plug directly to two lower

terminals on Compressor

120V DISPENSERS

Black from Run Capacitor

White from Main Harness

Plug directly to two lower

terminals on Compressor

230V DISPENSERS

P1338

FIG. 16 COMPRESSOR START RELAY

TERMINALS

Compressor Thermal Overload Protector: Refer to FIG. 15

1. Remove terminal cover retainer (5) and terminal cover

(4).

2. Disconnect the WHI/ORN wire of the harness from the

thermal overload protector.

3. Disconnect the BLK wire from the Compressor’s upper

terminal.

4. Remove overload protector retainer (3) and thermal

overload protector (2) as an assembly.

5. Remove retainer (3) from overload protector (2) and

discard overload protector.

BLK to Compressor

FIG. 17 THERMAL OVERLOAD PROTECTOR

TERMINALS

Compressor Run Capacitor (230V Dispensers Only): Refer

to FIG. 15

1. Remove terminal cover retainer (5) and terminal cover

(4).

2. Disconnect the run capacitor leads.

3. Remove the #6 crimptite screw securing the run capacitor to the rear of the component bracket.

4. Remove run capacitor and discard.

5. Place new run capacitor on the rear of component bracket

and secure with #6 crimptite screw.

6. Refer to Fig. 18 and reconnect the wires.

BLK to Start Relay T1

BLK to Start Relay T3

P1816

FIG. 18 COMPRESSOR RUN CAPACITOR

TERMINALS

29

41084 102709

Page 30

SERVICE (cont.)

COMPRESSOR (AMERICOLD) (ULTRA-2) (cont.)

Removal and Replacement:

Compressor Assy:

NOTE: Before removal of any refrigeration component the

refrigerant in the system must be reclaimed by a licensed

refrigeration repair person.

NOTE: When replacing the compressor it is recommended

that the dryer also be replaced.

1. Disconnect the tubes from the condenser and the accumulator.

2. Disconnect the compressor wiring harness from the

dispenser main wiring harness.

3. Remove the four .25-20 keps nuts and washers securing

the compressor to the chassis. Set nuts and washers

aside for reassembly.

4. Disconnect and remove the transformer.

5. From the right side of the dispenser lift the compressor

assembly over the four studs in the chassis and remove

compressor.

6. Install new compressor over the four studs in the dispenser chassis with the fill valve to the left side of the

dispenser.

7. Secure compressor to the dispenser chassis using four

.25-20 keps nuts and washers.

8. Reconnect tubes from the condenser and the accumulator to the compressor.

9. Reinstall transformer.

10. Evacuate the system.

11. Recharge 120V system with 10 oz. of Type 404A refrigerant. Design Pressures: High 240 - Low 34

Recharge 230V system with 9.5 oz. of Type 404A re-

frigerant. Design Pressures: High 215 - Low 40

NOTE: The charging of the system must be done by a licensed refrigeration repair person.

NOTE: Refer to Wiring Diagrams when reconnecting wires

to Compressor, Thermal Overload Protector, Start Relay,

and Run Capacitor.

30

41084 102709

Page 31

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2)

FIG. 19 COMPRESSOR ASSY

Location:

The compressor assy is located inside the front of

the dispenser chassis.

Model T-2155

Test Procedures:

WARNING: The compressor start capacitor must be properly

discharged before proceeding. This is most commonly done

on low voltage capacitors by shorting across the terminals

with a screwdriver.

Compressor Start Relay: Refer to FIG. 20

1. Disconnect the dispenser from the power source.

2. Remove compressor terminal cover retainer (5) and

compressor terminal cover (4).

3. Connect a voltmeter across the white wire and the white/

orange wire. Connect the dispenser to the power source.

Verify the dispenser is in “ICE” or “CHILL” mode.

The indication must be:

(a) 120 volts ac for two wire 120 volt models or

(b) 230 volts ac for two wire 230 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to the following

test procedures.

6

If voltage is not present as described, refer to the Relay and

check the relay.

5

4

3

1

2

6. Disconnect the two black wires from the compressor

start relay.

7. Remove relay from the compressor.

8. Check for continuity across the upper left terminal and

the right pin socket on the rear of the relay.

Model T-2168

5

4

3

1

2

6

FIG. 20 COMPRESSOR ELECTRICAL COMPONENTS

1. Compressor Start Relay

2. Thermal Overload Protector

3. Overload Protector Retainer

4. Compressor Terminal Cover

5. Terminal Cover Retainer

6. Compressor Run Capacitor

If continuity is present as described, the compressor start

relay is operating properly.

If continuity is not present as described, replace relay.

Compressor:

1. With the compressor start relay (1) removed, disconnect

the black wire from the compressor.

2. Check for continuity across the terminal on the compres-

sor and the left pin on the compressor.

If continuity is present as described, the electrical part of

the compressor is operating properly.

If continuity is not present as described, replace the compressor.

Thermal Overload Protector:

1. Check for continuity across the terminals on the thermal

overload protector (2).

If continuity is present as described, the thermal overload

protector is operating properly.

If continuity is not present as described, replace the thermal

overload protector.

31

41084 102709

Page 32

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2) (cont.)

Removal and Replacement:

Compressor Start Relay: Refer to FIG. 20

1. Disconnect the wires from the compressor start relay.

3. Pull relay (1) off of the compressor pins and discard.

4. Push new relay onto the compressor pins.

5. Refer to Fig. 21 and reconnect the wires.

6. Reinstall terminal cover (4) and cover retainer (5).

White from Main Harness

6. Install retainer (3) on new overload protector (2).

7. Install retainer (3) and overload protector (2) on the

compressor terminal bracket.

8. Refer to Fig. 22 and reconnect the thermal overload

protector wires.

9. Reinstall terminal cover (4) and cover retainer (5).

WHI/ORN from

Main Harness

BLK to Compressor

Plug directly to two lower

terminals on Compressor

Model T-2155

Black from Run Capacitor

White from Main Harness

Black from Run Capacitor

White from Main Harness

P1338

Model T-2168

FIG. 21 COMPRESSOR START RELAY

TERMINALS

Compressor Thermal Overload Protector: Refer to FIG. 20

1. Remove terminal cover retainer (5) and terminal cover

(4).

2. Disconnect the WHI/ORN wire of the harness from the

thermal overload protector.

3. Disconnect the BLK wire from the Compressor’s upper

terminal.

4. Remove overload protector retainer (3) and thermal

overload protector (2) as an assembly.

5. Remove retainer (3) from overload protector (2) and

discard overload protector.

P1339

FIG. 22 THERMAL OVERLOAD

PROTECTOR TERMINALS

Compressor Run Capacitor: Refer to FIG. 20

1. Disconnect the run capacitor leads.

2. Remove the nut securing the run capacitor to the capacitor mounting bracket.

3. Remove run capacitor and discard.

4. Place new run capacitor on capacitor mounting bracket

and secure nut.

5. Refer to Fig. 23 and reconnect the wires.

BLK to Start Relay T1

BLK to Start Relay T3

P1816

FIG. 23 COMPRESSOR RUN CAPACITOR

TERMINALS

32

41084 102709

Page 33

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2) (cont.)

Removal and Replacement:

Compressor Assy:

NOTE: Before removal of any refrigeration component the

refrigerant in the system must be reclaimed by a licensed

refrigeration repair person.

NOTE: When replacing the compressor it is recommended

that the dryer also be replaced.

1. Disconnect the tubes from the condenser and the accumulator.

2. Disconnect the compressor wiring harness from the

dispenser main wiring harness.

3. Remove the four .25-20 keps nuts and washers securing

the compressor to the chassis. Set nuts and washers

aside for reassembly.

4. Disconnect and remove the transformer.

5. From the right side of the dispenser lift the compressor

assembly over the four studs in the chassis and remove

compressor.

6. Install new compressor over the four studs in the dispenser chassis with the fill valve to the left side of the

dispenser.

7. Secure compressor to the dispenser chassis using four

.25-20 keps nuts and washers.

8. Reconnect tubes from the condenser and the accumulator to the compressor.

9. Reinstall transformer.

10. Evacuate the system.

11. Recharge 120V system with 10 oz. of Type 404A refrigerant. Design Pressures: High 430 - Low 80

Recharge 230V system with 9.5 oz. of Type 404A re-

frigerant. Design Pressures: High 215 - Low 40

NOTE: The charging of the system must be done by a licensed refrigeration repair person.

NOTE: Refer to Wiring Diagrams when reconnecting wires

to Compressor, Thermal Overload Protector, Start Relay,

and Run Capacitor.

33

41084 102709

Page 34

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2)

Compressor Model:

EMBRACO/NT2168GK, 115V 60HZ/100V 50HZ

Compressor Specification:

Commercial Designation: ¾ HP

Nominal Voltage:

115VAC 60 HZ 1 PH / 100VAC 50 HZ 1 PH

Electrical Rating: 115VAC 60 HZ: 8 RLA (Rated Load

Amps), 54.5 LRA (Locked Rotor Amps)

Start Winding Resistance: 2.66 OHMS

Run Winding Resistance: 0.43 OHMS

Displacement: 0.885 CU IN

Refrigerant: R-404A

Oil Type: ESTER/IS022

Oil Charge: 15.22 FL. Oz.

Electrtic Motor Type: The type of motor being used

in the ULTRA-2 HP dispenser is known as CSR motor

(Capacitive Start & Run).

The CSR version uses a start and run capacitor with

an external thermal protector. The start capacitor is

in series with the compressor motor start winding. A

potential starting relay coil is wired across the start

winding which can sense change in voltage. The starting winding voltage will increase along with motor

speed. When the voltage has reached a point, the relay contacts will open, de-energizing the start winding

capacitor.

Capacitor Ratings:

Start Capacitor: 243-292 MFD 165V 50/60HZ

Run Capacitor: 35 +/-5% MFD 425V 50/60HZ

Refrigerant Charge:

Type: R404A

Amount: 11 oz.

Design Pressure: High 430 & Low 80

CSR Motor Wiring Diagram:

34

Page 35

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2)

Important Safeguards:

• Trained service personnel with the knowledge of servicing and troubleshooting refrigeration systems or

related components should be used.

• Always be alert of smell and sounds (arching, popping and humming) coming from the compressor. Disconnect power or unplug immediately and get away.

• Always ensure main power is disconnected before any removal of a protective cover.

• Compressor oil and refrigerant being vented can create a hazardous condition of chemical burn, frostbite or

fire.

• Never reset a breaker or replace a blown fuse without checking the compressor or related components for a

short circuit or ground fault condition first.

• Always wear and use the appropriate safety gear when servicing a refrigeration system. Protective gloves,

eyewear, shoes, clothes and tools.

• If compressor ground fault condition exists, keep power off, disconnect power leads, mark or tag compressor to indicate ground fault or defective compressor before replacing with a new compressor.

Compressor Wiring Diagram:

35

Page 36

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2)

Compressor Windings & Related Component Testing:

Testing Compressor Windings/Insulation with a Megger

A megger is a preferred test over using a typical ohm

meter for testing the compressor windings. The megger checks the insulation factor of a winding making

sure it is actually insulated and not leaking current

(Ground Fault). An ohm meter usually produce a low

voltage for reading resistance verses a megger uses

higher direct voltage source to measure insulation resistance to detect a breakdown in the motor winding

insulation.

Step 1: Disconnect all electrical power to the BUNN

ULTRA-2 HP.

Step 2: Access compressor terminal pins and disconnect the wire leads going to the compressor pins.

Note: Measure the resistance (ohms) between terminal pins C&S and C&R around ambient temperature

of 77° F. Add the resistance between C & S and C & R.

The sum should equal the resistance found between S

& R. A 10% deviation is acceptable.

Continuity must be present between C & S and C & R.

If there is no continuity on start or run winding, there

is an interruption within that winding.

Check the C (common) compressor winding to compressor ground terminal/housing. If continuity is

present, one of the compressor windings is shorted

to ground.

Check Compressor Windings for Ground Fault:

Upon removal of the protective terminal cover, if evidence is shown by any lead or terminal being overheated, it is a good indication that a compressor winding problem may exist. Follow the recommended step

below to check the compressor winding insulation. If

a ground fault is detected with the compressor, keep

the power off, thermal protector and potential relay

disconnected. A licensed certified refrigerant technician will need to replace a defective compressor.

Step 3: Set the megger to the compressor applicable

voltage rating. If the megger you are using only has

a few specific voltage ranges, select the next highest

voltage above your compressor volt range.

Step 4: Connect one lead of the megger to the copper

suction line or housing. Connect the other lead to one

of the compressor terminal pins (winding).

Step 5: Repeat the procedure for the two remaining

terminal pins. If the instrument indicates any resistance less than 2 megohms between any pin and the

housing (copper suction line), a ground fault exists.

Replace compressor.

36

Page 37

SERVICE (cont.)

COMPRESSOR (EMBRACO) (ULTRA-2)

External Thermal Protector

Check for continuity across the thermal protector terminals. Before testing the external thermal protector,

ensure the thermal protector had enough time to cool

off and reset. If no continuity is present across the

terminals, replace the thermal protector.

Start Capacitor

Start Capacitor: BUNN P/N# 39804.0004

Rating: 243-292 MFD 165V 50/60HZ

Disconnect the start capacitor from the system. Remove the bleed resistor. Use a capacitance

meter to measure the capacitance. The capacitance

value should be the rated value

minus 0% to plus 20%. If it is outside of this range,

then the start capacitor needs to be

replaced.

Run Capacitior

Run Capacitior: BUNN P/N# 44820.0004

Run Capacitor: 35 +/-5% MFD 425V 50/60HZ

Note: Use a 20,000 ohm resistor set-up to discharge

the capacitor before removing from the machine. By

doing this, will avoid possible damage to the capacitior, measuring device and risk of electrical shock.

Once the capacitor is properly discharged, use a capacitance meter to check the capacitance value. The

value should be within 5% range of the marked capacitior value.

Potential Start Relay Mounting Position

Always check the relay for correct mounting position

before continuing with the following continuity check.

• Relay terminal 2 and 5: No continuity, broken coil,

replace relay.

• Relay terminal 1 and 2: No continuity, contacts are

open, replace relay.

37

Page 38

SERVICE (cont.)

COMPRESSOR (APPLIANCES) (ULTRA-1)

FIG. 24 COMPRESSOR &

COMPONENT LOCATIONS

Location:

The compressor assy is located inside the front of the

dispenser chassis.

2 4

Test Procedures:

Compressor Start Relay: Refer to FIG. 25

WARNING: The compressor capacitor must be properly

discharged before proceeding. This is most commonly done

on low voltage capacitors by shorting across the terminals

with a screwdriver.

1. Disconnect the dispenser from the power source.

2. Remove compressor terminal cover retainer (4).

3. Connect a voltmeter across the white wire and the white/

orange wire. Connect the dispenser to the power source.

Verify the dispenser is in “ICE” or “CHILL” mode.

The indication must be:

(a) 120 volts ac for two wire 120 volt models or

(b) 230 volts ac for two wire 230 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to the following

test procedures.

If voltage is not present as described, refer to the Contactor

and check the contactor.

6. Disconnect the two black wires from the compressor

start relay.

7. Remove relay from the compressor.

8. Check for continuity across the upper left terminal and

the right pin socket on the rear of the relay.

If continuity is present as described, the compressor start

relay is operating properly.

If continuity is not present as described, replace relay.

3 1

FIG. 25 COMPRESSOR THERMAL

OVERLOAD PROTECTOR LOCATION

1. Compressor Start Relay

2. Compressor Run Capacitor

3. Thermal Overload Protector

4. Compressor Terminal Cover

Compressor:

1. With the compressor start relay (1) removed, disconnect

the black wire from the compressor.

2. Check for continuity across the terminal on the compressor and the left pin on the compressor.

If continuity is present as described, the electrical part of

the compressor is operating properly.

If continuity is not present as described, replace the compressor.

Thermal Overload Protector:

1. Check for continuity across the terminals on the thermal

overload protector (3).

If continuity is present as described, the thermal overload

protector is operating properly.

If continuity is not present as described, replace the thermal

overload protector.

38

41084 102709

Page 39

SERVICE (cont.)

COMPRESSOR (APPLIANCES) (ULTRA-1) (cont.)

Removal and Replacement:

Compressor Start Relay: Refer to FIG. 25

1. Remove the terminal cover (4)

2. Disconnect the wires from the compressor start relay.

3. Pull relay (1) off of the compressor pins and discard.

4. Push new relay onto the compressor pins.

5. Refer to Fig. 26 and reconnect the wires.

6. Reinstall terminal cover (4).

Compressor Thermal Overload Protector: Refer to FIG. 25

1. Remove terminal cover (4).

2. Disconnect the WHI/ORN wire of the harness from the

thermal overload protector.

3. Disconnect the BLK wire from the Compressor’s upper

terminal.

4. Remove overload protector (3) and start relay as an

assembly.

5. Remove overload protector (3) and discard overload

protector.

6. Install new overload protector (3) on to the relay (1).

7. Install relay (1) and overload protector (2) on the compressor terminal bracket.

8. Refer to Fig. 27 and reconnect the thermal overload

protector wires.

9. Reinstall terminal cover (4).

Compressor Run Capacitor: Refer to FIG. 25

1. Remove terminal cover (4).

2. Disconnect the run capacitor leads.

3. Remove the #8-32 screw securing the run capacitor to

the top of the dispenser chassis.

4. Remove run capacitor and discard.

5. Place new run capacitor on the top of the dispenser

chassis and secure with #8-32 screw.

6. Refer to Fig. 28 and reconnect the wires.

WHI/ORN

GRN

WHI

BRN/WHI (120V)

BRN (230V)

BLU

FIG. 26 RELAY TERMINALS

Plugs into Relay

FIG. 27 THERMAL OVERLOAD PROTECTOR

TERMINALS

BRN/WHI (120V) to Relay

BRN (230V) to Relay

BLU to Relay

FIG. 28 COMPRESSOR CAPACITOR TERMINALS

39

41084 102709

Page 40

SERVICE (cont.)

COMPRESSOR (APPLIANCES) (ULTRA-1) (cont.)

Compressor Assy:

NOTE: Before removal of any refrigeration component the

refrigerant in the system must be reclaimed by a licensed

refrigeration repair person.

NOTE: When replacing the compressor it is recommended

that the dryer also be replaced.

1. Disconnect the tubes from the condenser and the accumulator.

2. Disconnect the compressor wiring harness from the

dispenser main wiring harness.

3. Remove the four .25-20 keps nuts and washers securing

the compressor to the chassis. Set nuts and washers

aside for reassembly.

4. Disconnect and remove the transformer.

5. From the right side of the dispenser lift the compressor

assembly over the four studs in the chassis and remove

compressor.

6. Install new compressor over the four studs in the dispenser chassis with the fill valve to the right side of the

dispenser.

7. Secure compressor to the dispenser chassis using four

.25-20 keps nuts and washers.

8. Reconnect tubes from the condenser and the accumulator to the compressor.

9. Reinstall transformer.

10. Evacuate the system.

11. Recharge 120V and 230V system with 6 oz. of Type

404A refrigerant.

Design Pressures: High 330 - Low 60

NOTE: The charging of the system must be done by a li-

censed refrigeration repair person.

NOTE: Refer to Wiring Diagrams when reconnecting wires

to Compressor, Thermal Overload Protector, Start Relay,

and Run Capacitor.

40

41084 021710

Page 41

SERVICE (cont.)

COMPRESSOR (DANFOSS) (ULTRA-1B) (cont.)

FIG. 29 COMPRESSOR &

COMPONENT LOCATIONS

Location:

The compressor assy is located inside the front of the

dispenser chassis.

6. Disconnect the two black wires from the compressor

start relay.

7. Remove relay from the compressor.

8. Check for continuity across the upper left terminal and

the right pin socket on the rear of the relay.

If continuity is present as described, the compressor start

relay is operating properly.

If continuity is not present as described, replace relay.

Compressor:

1. With the compressor start relay (1) removed, disconnect

the black wire from the compressor.

2. Check for continuity across the terminal on the compres-

sor and the left pin on the compressor.

If continuity is present as described, the electrical part of

the compressor is operating properly.

If continuity is not present as described, replace the compressor.

Test Procedures:

Compressor Start Relay: Refer to FIG. 30

WARNING: The compressor capacitor must be properly

discharged before proceeding. This is most commonly done

on low voltage capacitors by shorting across the terminals

with a screwdriver.

1. Disconnect the dispenser from the power source.

2. Remove compressor terminal cover retainer (4).

3. Connect a voltmeter across the white wire and the white/

orange wire. Connect the dispenser to the power source.

Verify the dispenser is in “ICE” or “CHILL” mode.

The indication must be:

(a) 100 volts ac for two wire 100 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to the following

test procedures.

If voltage is not present as described, refer to the Relay and

check the relay.

41

41084 102709

Page 42

SERVICE (cont.)

COMPRESSOR (DANFOSS) (ULTRA-1B) (cont.)

Removal and Replacement:

Compressor Start Relay: Refer to FIG. 30

1. Remove the terminal cover (4)

2. Disconnect the wires from the compressor start relay.

3. Pull relay (1) off of the compressor pins and discard.

4. Push new relay onto the compressor pins.

5. Refer to Fig. 30 and reconnect the wires.

6. Reinstall terminal cover (4).

GRN

WHI

WHI/ORN to

Overload

Protector

FIG. 30 RELAY TERMINALS

Compressor Run Capacitor: Refer to FIG. 31

1. Remove terminal cover (4).

2. Disconnect the run capacitor leads.

3. Disconnect the run capacitor from the mounting bracket

located at the front of the dispenser chassis.

4. Remove run capacitor and discard.

5. Snap new run capacitor on the mounting bracket located

at the front of the dispenser chassis.

6. Refer to Fig. 31 and reconnect the wires.

BLK to Compressor

Relay

Compressor Assy:

NOTE: Before removal of any refrigeration component the

refrigerant in the system must be reclaimed by a licensed

refrigeration repair person.

NOTE: When replacing the compressor it is recommended

that the dryer also be replaced.

1. Disconnect the tubes from the condenser and the accumulator.

2. Disconnect the compressor wiring harness from the

dispenser main wiring harness.

3. Remove the four .25-20 keps nuts and washers securing

the compressor to the chassis. Set nuts and washers

aside for reassembly.

4. Disconnect and remove the transformer.

5. From the right side of the dispenser lift the compressor

assembly over the four studs in the chassis and remove

compressor.

6. Install new compressor over the four studs in the dispenser chassis with the fill valve to the right side of the

dispenser.

7. Secure compressor to the dispenser chassis using four

.25-20 keps nuts and washers.

8. Reconnect tubes from the condenser and the accumulator to the compressor.

9. Reinstall transformer.

10. Evacuate the system.

11. Recharge the 100V system with 6 oz. of Type 404A

refrigerant.

Design Pressures: High 330 - Low 60

NOTE: The charging of the system must be done by a li-

censed refrigeration repair person.

NOTE: Refer to Wiring Diagrams when reconnecting wires

to Compressor, Thermal Overload Protector, Start Relay,

and Run Capacitor.

BLK to Compressor

Relay

FIG. 31 COMPRESSOR CAPACITOR TERMINALS

42

41084 021710

Page 43

SERVICE (cont.)

RELAY (or CONTACTOR on Early Models)

ULTRA-2 shown

R

FIG. 32 RELAY

Location:

The relay (or contactor) is located inside the dispenser chassis on the lower outside of the component

bracket.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Remove the right side panel.

3. Connect the dispenser to the power source.

4. Turn on power (I/O) switch. Verify UPPER case

“ICE” or “CHILL” mode.

5. With a voltmeter, check the voltage across the white

wire and the orange wire.

The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt models.

6. Disconnect the dispenser from the power source.

If continuity is present as described, disconnect the

dispenser from power source and reconnect wires to

terminals #6 and #8, the relay is working.

If continuity is not present as described, do the same

continuity test across terminals #2 and #4. If continuity is present between terminals #2 and #4, reconnecr

wires to terminals #2 and #4 instead of #6 and #8.

If continuity is not present as described, replace the

relay.

Removal and Replacement:

1. Disconnect the wires from the relay.

2. Remove the two #8-32 locking screws securing the

relay to the chassis. Remove and discard relay.

3. Install the new relay on the chassis using two #8-32

locking screws.

4. Refer to Fig. 33 and 34 to reconnect the wires.

Early Model ULTRA-2

Terminal #4

Terminal #2

Terminal #6

BLK from Main

Harness/Power Cord

Terminal #8

WHI/ORN from

Compressor Harness

Terminal #0

WHI from Main Harness

Terminal #1

ORN from

Control Board

P1333

FIG. 33 CONTACTOR TERMINALS

Late Model ULTRA-2 & ULTRA-1

Terminal #0

WHI from

Main Harness

Terminal #1

ORN from

Main Harness

If voltage is present as described, proceed to #7.

If voltage is not present as described, refer to the Wir-

ing Diagram and check the dispenser wiring harness.

If harness has continuity, replace Control Board.

7. Disconnect the black wire and the WHI/ORN wires

from relay terminals #6 and #8.

8. Connect the dispenser to the power source.

9. Turn on power (I/O) switch. Verify UPPER case

“ICE” or “CHILL” and check for continuity across

terminals on relay.

43

Terminal #8

BLK from

Main Harness

Terminal #2

Terminal #4

Terminal #6

WHI/ORN from

Main Harness

FIG. 34 RELAY TERMINALS

41084 102709

Page 44

SERVICE (cont.)