Bunn Titan SingleCanada Owner's Manual

TITAN SINGLE™

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION OF CANADA

280 INDUSTRIAL PARKWAY SOUTH,

AURORA, ONTARIO, L4G 3T9

PHONE: (905) 841-2866 FAX: (905) 841-2775

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit

the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain

the latest catalog and manual updates. Contact Bunn-O-Matic Corporation at 1-800-263-2256 to obtain a

paper copy of the required Illustrated Parts Catalog mailed via Canada Post.

40885.7000E 5/12 ©2008 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corporation of Canada (“Bunn”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCP/MCA pod brewers

thermal servers and Thermofresh servers (mechanical and digital) - 1 year parts and 1 year labour.

2) All other equipment - 2 years parts and 1 year labour plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labour for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labour.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve

analysis - parts and labour for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation. Bunn warrants that the equipment manufactured

by it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component

or part that was not manufactured by Bunn or that, in Bunn’s judgement, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, non periodic cleaning and descaling,

equipment failures related to poor water quality, damage or casualty. In addition, the warranty does not apply to

replacement of items subject to normal use including but not limited to user replaceable parts such as seals and

gaskets. This warranty is conditioned on the Buyer 1) giving Bunn prompt notice of any claim to be made under

this warranty by telephone at (905) 841-2866 or by writing to 280 Industrial Parkway South, Aurora, Ontario, L4G

3T9. 2) if requested by Bunn, shipping the defective equipment prepaid to an authorized Bunn service location;

and 3) receiving prior authorization from Bunn that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, CONDITION,

WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY

OF EITHER MERCHANTABILITY, MERCHANTABLE QUALITY OR FITNESS FOR A PARTICULAR PURPOSE.The

agents, dealers or employees of Bunn are not authorized to make modifications to this warranty or to make

additional warranties that are binding on Bunn. Accordingly, statements by such individuals, whether oral or

written, do not constitute warranties and should not be relied upon.

If Bunn determines in its sole discretion that the defective equipment is covered by warranty, Bunn, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labour (during the applicable parts and labour warranty periods specified above) to repair the defective

components, provided that this repair is done by a Bunn Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE

SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT

BUNN’S SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost

sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental, consequential or punitive damages.

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family

Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic,

BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew,

PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design,

Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard,

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, Velocity Brew, A Partner You Can Count On, Air

Brew, Air Infusion, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic

Heating System, Daypart, Digital Brewer Control, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Tea At Its Best, The

Horizontal Red Line, Ultra are either trademarks or registered trademarks of Bunn-O-Matic Corporation.

INTRODUCTION

This equipment will brew coffee into an awaiting server or airpot. The brewer may have an auxillary hot water

faucet. It is only for indoor use on a sturdy and level counter or shelf. Please install in an area where there are

no water jet devices.

This brewer can be programmed to adjust different functions of the brewing process, such as brew temperature, brew volumes, bypass percentages, pulse brew, etc. Other features are Energy Savings mode, Freshness

Timer and Clean Alert.

Page 2

40885 030912

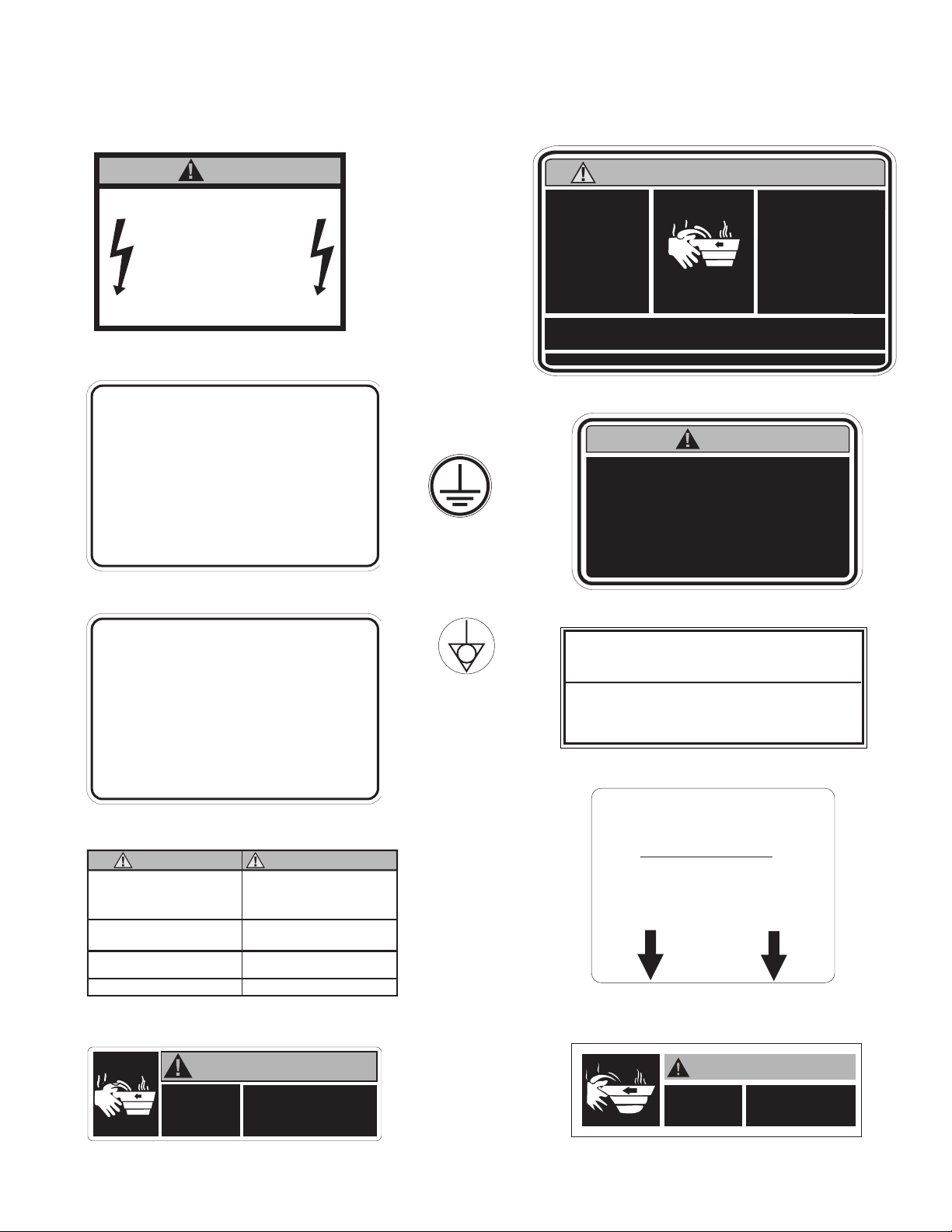

USER NOTICES

29710.7015

29710.7019

Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should be

kept in good condition. Replace any unreadable or damaged labels.

WARNING AVERTISSEMENT

HAZARDOUS VOLTAGE

TENSION DANGEREUSE

DISCONNECT FROM POWER

SOURCE BEFORE REMOVING!

DÉCONNECTER DE LA

SOURCE D'ALIMENTATION

AVANT D’ENLEVER !

12559.7103

Optional Field Wiring

120/208V

40.1 A, 8200 W

1PH, 3-Wire + GND, 60HZ

Branchement électrique optionnel

120/208V, 40.1 A,

8200 W, Monophasé,

3-fils relié à la terre, 60HZ

29710.7015

00824.0002

WARNING / AVERTISSEMENT

DISCARD DECANTER

IF:

• CRACKED

• SCRATCHED

• BOILED DRY

• HEATED WHEN EMPTY

• USED ON HIGH FLAME

OR EXPOSED ELECTRIC

ELEMENTS

READ THE ENTIRE OPERATING MANUAL BEFORE USING THIS PRODUCT.

VEUILLEZ LIRE LE MANUEL D’EMPLOI AVANT D’UTILISER CE PRODUIT.

L’INOBSERVATION DE CES CONSEILS PEUT ENTRAÎNER DES RISQUES DE BLESSURE.

PN: 00658.7000G 02/10 © 1985 BUNN-O-MATIC CORPORATION OF CANADA

WARNING AVERTISSEMENT

To reduce the risk of electric shock, do not remove or

open cover. No user-serviceable parts inside.

Authorized service personnel only. Disconnect power

before servicing.

Afin d’éviter un risque d’électrocution, ne pas ouvrir ou

enlever le panneau. Aucune pièce utile pour

l’opérateur à l’intérieur. Seulement le personnel

autorisé peut effectuer les réparations. Débrancher de la

source de courant avant d’effectuer une réparation.

FUNNEL CONTENTS

ARE HOT

LE CONTENU

DE L’ENTONNOIR

EST CHAUD

FAILURE TO COMPLY RISKS INJURY.

#00658.7000

#37881.7000

JETER LA CARAFE :

• SI ELLE EST FISSURÉE

• SI ELLE EST RAYÉE

• SI ON A LAISSÉ DE L’EAU

S’ÉVAPORER PAR

ÉBULLITION

• SI ELLE A ÉTÉ CHAUFFÉE À VIDE

• SI ELLE A ÉTÉ UTILISÉE SUR

UNE FLAMME VIVE OU SUR

DES ÉLÉMENTS ÉLECTRIQUES

DÉCOUVERTS

Optional Field Wiring

120/240V,

35.0A, 8200 W,

1PH, 3-Wire + GND, 60HZ

Branchement électrique optionnel

120/240V, 35.0A,

8200 W, Monophasé,

3-fils relie à la terre, 60HZ

29710.7019

WARNING

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL

ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE OPERATING MANUAL INCLUDING

THE LIMIT OF WARRANTY AND LIABILITY BEFORE

BUYING OR USING THIS PRODUCT.

THIS EQUIPMENT IS ENERGIZED AT ALL TIMES UNLESS

ELECTRICALLY DISCONNECTED.

00986.7000B 01/10 ©2007 Bunn-O-Matic Corporation

AVERTISSEMENT

• NE PAS SURCHARGER LE CIRCUIT.

• TOUJOURS METTRE LE BOÎTIER À LA MASSE.

• NE PAS DÉFORMER LA FICHE OU LE CORDON.

• SE CONFORMER AUX CODES NATIONAL OU

LOCAL D'ÉLECTRICITÉ.

• GARDER LES PRODUITS COMBUSTIBLES À

DISTANCE.

TOUT MANQUEMENT À SE CONFORMER À CES

DIRECTIVES PEUT ENTRAINER DES DOMMAGES

À L'ÉQUIPEMENT OU PRODUIRE DES DANGERS

D'INCENDIE OU D'ÉLECTROCUTION.

VEUILLEZ LIRE LE MANUEL DE FONCTIONEMENT EN

ENTIER, Y COMPRIS LES LIMITES DE GARANTIES ET

RESPONSABILITÉS,AVANT D’ACHETER OU

D'UTILISER LE PRÉSENT PRODUIT.

L' ÉQUIPEMENT EST TOUJOURS SOUS TENSION LORSQU'IL

N'EST PAS DÉBRANCHÉ.

#00986.7000

WARNING/AVERTISSEMENT

REMOVE

FUNNEL

SLOWLY

RETIRER

L’ENTONNOIR

LENTEMENT

00824.0001

This equipment must be installed to comply with Canadian

Plumbing Codes and applicable health and safety regulations.

For models installed outside Canada, comply with the

applicable Plumbing /Sanitation Code.

Cet équipement doit être installé conformément au code

Canadien de plomberie et aux règlements de santé et de

sécurité qui s’ appliquent. Les modèles destinés à être

installés ailleurs qu’au Canada doivent respecter les codes de

plomberie et d’hygiène de la localité.

#00656.7000

MAIN ON/OFF

SWITCH

INTERRUPTEUR

PRINCIPAL

39803.7000

WARNING /AVERTISSEMENT

HOT

LIQUID

LIQUIDE

CHAUD

03408.7000

Page 3

03409.7003

40885 112611

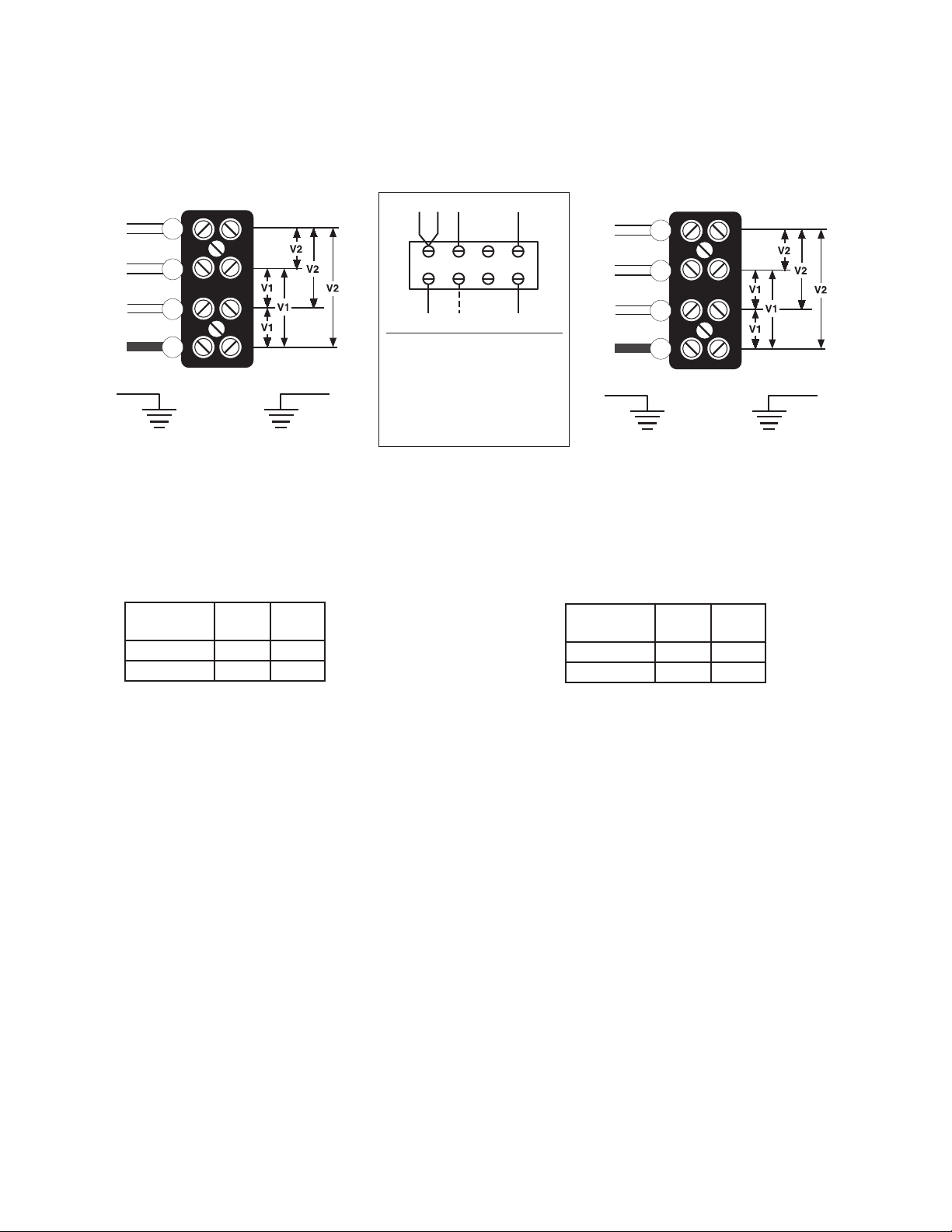

ELECTRICAL REQUIREMENTS

WARNING - If the power cord is ever damaged, it must be replaced by the manufacturer or its service agent with

a special cord available from the manufacturer or its service agent in order to avoid a hazard.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

WHI

N

BLU

L3

RED

L2

BLK

L1

GREEN GREEN

120/208 and 120/240 volt ac

three phase, 50/60 Hz models

Note: This electrical service consists of 4 current carrying conductors (Neutral, L1, L2 and

L3) and a separate conductor for earth ground.

SYSTEM

VOLTAGE V1 V2

208 208 120

240 240 120

TO MACHINE

BLU

BLK

RED

L1 L2 L3 N

FROM POWER SOURCE

FOR SINGLE PHASE OPERATION

MOVE BLU WIRE INTO TERMINAL

BLOCK WITH BLACK WIRE.

CONNECT INPUT WIRING TO:

L1, L2 & N FOR 120/208V &

120/240V MODELS,

L1 & N for 230V MODELS.

WHI

Note: This electrical service consists of 4 current carrying conductors (Neutral, L1, L2 and

L3) and a separate conductor for earth ground.

WHI

N

BLU

L3

RED

L2

BLK

L1

GREEN GREEN

400/230V volt ac three phase,

50/60 Hz models

SYSTEM

VOLTAGE V1 V2

400 400 230

230 230

L1, L2, L3, are the 3 phases

V1 = Phase to phase voltage, between any 2 phases.

V2 = Phase to neutral voltage, L1 to neutral must be 120V.

L1, L2, L3, are the 3 phases

V1 = Phase to phase voltage, between any 2 phases.

V2 = Phase to neutral voltage, L1 to neutral must be 230V.

ELECTRICAL HOOK-UP

CAUTION – Improper electrical installation will damage electronic components. Damage caused by incorrect

electrical connections is not covered by warranty.

1. An electrician must provide electrical service as specified in conformance with all local, state and federal

electrical codes.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

NOTE - The brewer is shipped without a plug on the power cord. Qualified service personnel must select

and install the proper UL listed grounding type attachment plug specified on the rear of the brewer.

3. Install the specified plug on the attached power cord.

4. Remove the front access panel to gain access to the terminal block.

5. Connect the brewer to the power source and verify the voltage at the terminal block before proceeding.

6. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked up, the brewer is ready for Initial Set-Up.

Page 4

40885 080108

CE REQUIREMENTS

• This appliance must be installed in locations where it can be overseen by trained personnel.

• For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C.

• Appliance shall not be tilted more than 10° for safe operation.

• An electrician must provide electrical service as specied in conformance with all local and national codes.

• This appliance must not be cleaned by water jet.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given instructions concerning use of

this appliance by a person responsible for its safety.

• Children should be supervised to ensure they do not play with the appliance.

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with

a special cord available from the manufacturer or its authorized service personnel in order to avoid a hazard.

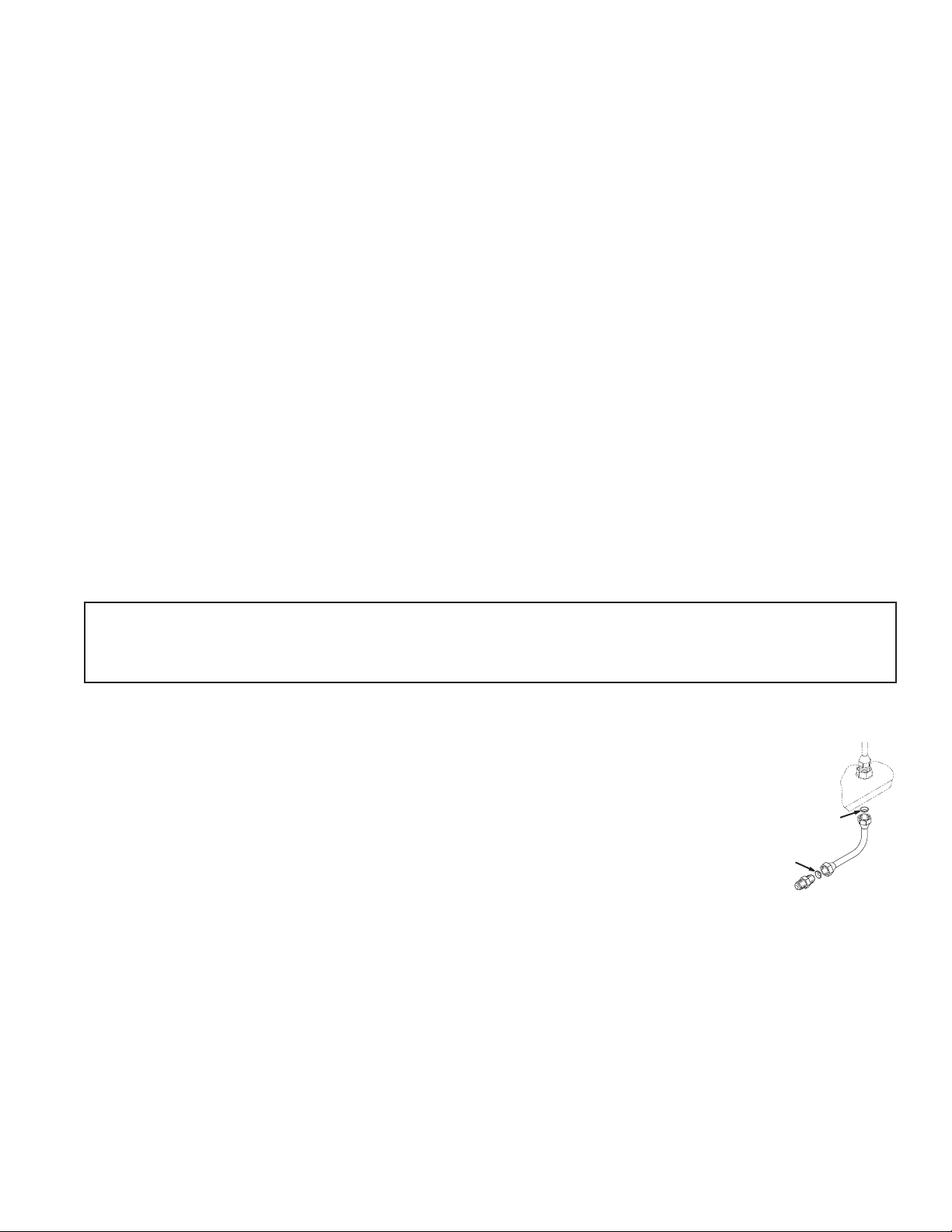

PLUMBING REQUIREMENTS

This brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138

and 620 kPa) with a minimum of 4.0 gpm from a 1⁄2" or larger supply line. A shut-off valve should be installed

in the line before the brewer. Install a regulator in the line when pressure is greater than 90 psi (620 kPa) to

reduce it to 50 psi (345 kPa). The water inlet fitting is 3⁄8" flare.

NOTE - Bunn-O-Matic recommends 3⁄8" copper tubing for all installations from the 1⁄2" water supply line. A tight

coil of copper tubing in the water line will facilitate moving the brewer to clean the counter top. Bunn-O-Matic

does not recommend the use of a saddle valve to install the brewer. The size and shape of the hole made in the

supply line by this type of device may restrict water flow.

This equipment must be installed to comply with the National Plumbing Code of Canada and the Canadian

Food Inspection Agency. For models installed outside Canada, you must comply with the applicable

Plumbing/Sanitation Code for your area.

PLUMBING HOOK UP

NOTE - If a backflow preventer is required by code, a shock arrestor should be installed between

backflow preventer and dispenser. Installing the shock arrestor as close to dispenser as possible

will provide best results.

1. Remove the shipping cap from the fitting on the bottom of the brewer.

2. Attach the flare tube assembly (supplied separately with the brewer) to the fitting using the

copper flare gaskets on each end as shown in illustration.

3. Flush the water line and securely attach it to the flare elbow fitting.

P4290

4. Turn on the water supply.

TANK DRAIN

1. Remove screws that secure the front access panel. Remove the panel.

2. Unfasten the hose clamp at the end of the drain hose. Remove the plug.

3. Place the end of the drain hose in a drain or in a container that has a minimum capacity of 10.0 gallons

(37.85 liters).

4. Release the white clamp to drain water from the tank.

5. When tank is empty, close the white clamp, replace the plug, and tighten the clamp at the end of the drain

hose.

6. Replace the front panel and tighten screws.

Page 5

40885 020112

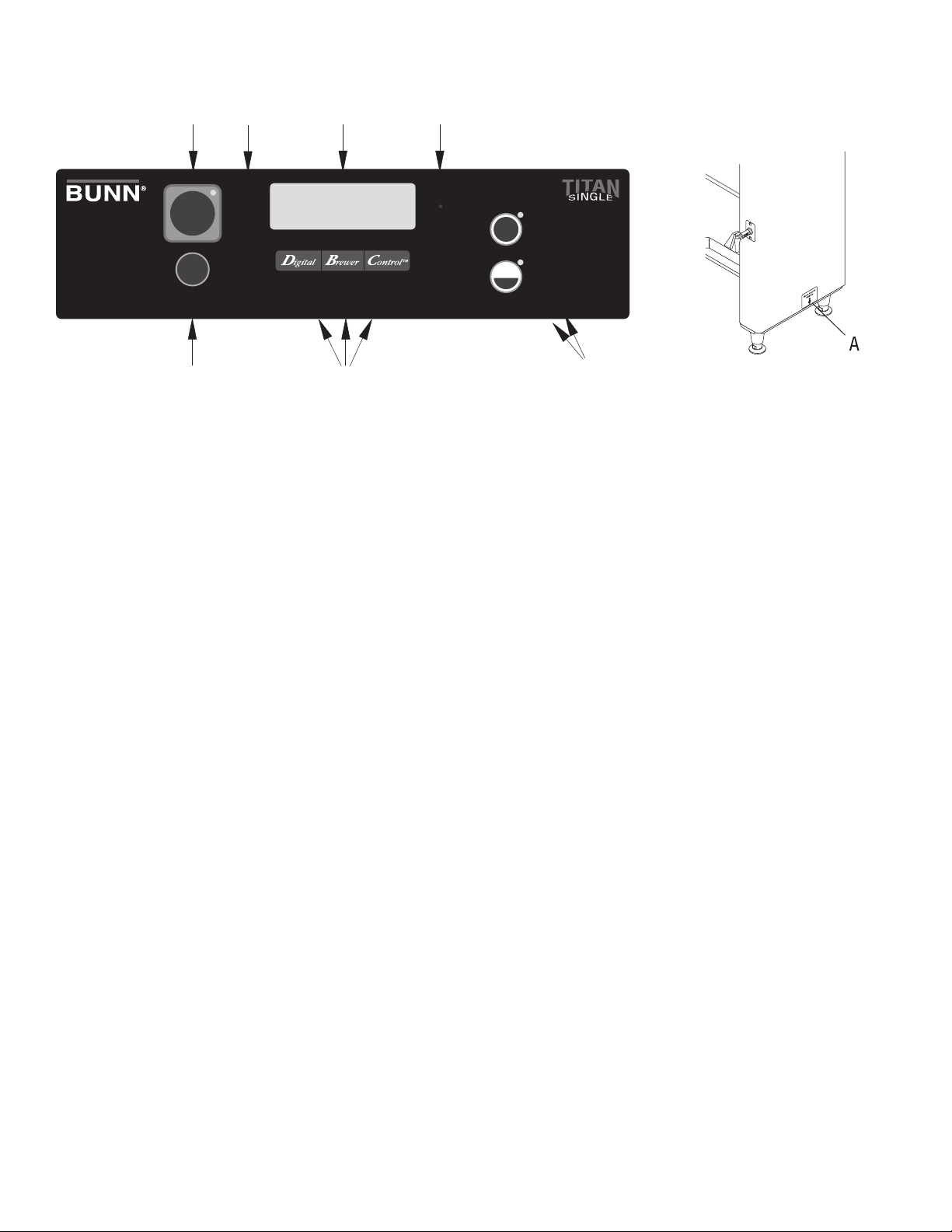

OPERATING CONTROLS

B

ENABLE

ON / OFF

BREW

BREW

D

C

READY TO BREW

WATER TEMP: 200°

G

H

E

LARGE

SMALL

F

P3894

A. MAIN ON/OFF SWITCH

This switch, located under the brewer in front of the right rear leg, turns power on and off to all components

in the brewer.

B. ON/OFF SWITCH (ENABLE BREW)

Pressing the "ON/OFF" switch will alternately turn the brew components on and off. Pressing this switch during

the brew cycle will interrupt the brew cycle, stopping the flow of water. Pressing this switch during programming

of the brewer will exit the setup and return to the main screen.

C. PROGRAMMING (left)

This hidden switch can be used to scroll backwards through the function list while in programming mode.

D. BREW

When the ON/OFF (Enable Brew) switch is ON and the main screen is visible, momentarily pressing and

releasing this switch will begin a brew cycle.

E. PROGRAMMING (right)

Pressing and holding this switch allows entry into the programming menus. Pressing and releasing the switch

steps through each function screen while in the programming mode.

F. BATCH SELECTOR SWITCHES

Pressing the switch corresponding to the Half or Full batch selects the amount of product to be brewed.

Pressing a different switch after a brew cycle has been initiated does not change the brew batch in progress.

Light indicates the selected batch to brew. Also used in programming to adjust settings on both batch sizes.

G. FUNCTION SCREEN

This is the display which shows the various functions of the brewer and allows the programming to be accomplished.

H. FUNCTION SCREEN SWITCHES

These are hidden switches which are used to program the brewer when in the programming mode.

Page 6

40885 080108

Loading...

Loading...