Page 1

Infusion Series

Platinum Edition

ITCB DV, ITCB Twin,

ITCB HV, ITCB HV Twin

®

RECIPE

DECAF

GUATEMALA

SELECT RECIPE

ETHIOPIA

KENYA

COSTA RICA

RECIPE EDIT

VOLUME BYPASS PRE-INFUSE PULSE BREW

DRIP TIMESMARTWAVE REVIEWFRESHNESS

RECIPES MACHINE SETTINGS SERVICE

IMPORT / EXPORTCALIBRATIONS

SERVICE

EVENT LOG STATISTICS

ACCESS SERVICE MENU

ADVANCEDCARE & CLEANING

RECIPE EDIT

REGIONAL SETTINGS BREW SETTINGS

BREW SETTINGS

PROGRAMMING MANUAL

Bunn-O-Matic Corporation

Post Office Box 3227, Springfield, Illinois 62708-3227

Phone (217) 529-6601 | Fax (217) 529-6644

55503.0000 A 10/18 © 2018 Bunn-O-Matic Corporation

www.bunn.com

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1. Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCR/MCP/MCA single cup brewers,

thermal servers and ThermoFresh® servers (mechanical and digital) 1 year parts and 1 year labor.

2. All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labor for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts

and labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation

or operation, improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor

water quality, damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal

use including but not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the

Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or

by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective

equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from BUNN that the

defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make mod-

ifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such

individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive

option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during

the applicable parts and labor warranty periods specified above) to repair the defective components, provided that this

repair is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase

price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of

use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities

or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter,

BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN

with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench

design, Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice,

Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh,

savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard,

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (sylized logo), Velocity

Brew, Air Brew, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource,

Coffee At Its Best, Cyclonic Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing

Brews Like a BUNN, Picture Prompted Cleaning, Pouring Profits, Signature Series, Sure Tamp, Tea At Its Best, The

Horizontal Red Line, Ultra are either trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial

®

trifecta

brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

2

Page 3

TABLE OF CONTENTS

Warranty .................................................................................................................. 2

Operating Controls .................................................................................................. 4

Accessing Programming ......................................................................................... 4

Programming Lockout .............................................................................................. 5

Service Access Menu ............................................................................................. 5

Service Access Options .......................................................................................... 6

Advanced Menu ...................................................................................................... 7

Setting a Password ................................................................................................. 8

Recipes Parameters ............................................................................................... 9

Brew Lockout .......................................................................................................... 10

Modifying Recipes .................................................................................................. 10

Machine Settings .................................................................................................... 12

Recipe Review ........................................................................................................ 13

Transfer Recipes ..................................................................................................... 14

Set & Recipe Temperature ...................................................................................... 14

Screensaver ............................................................................................................ 15

Energy Saver .......................................................................................................... 17

Set Date & Time ...................................................................................................... 17

Freshness Time ...................................................................................................... 18

Updating Software .................................................................................................. 19

Machine Settings .................................................................................................... 20

Transfer Machine Settings ...................................................................................... 21

Flowrate Calibrations .............................................................................................. 22

Smart Funnel Events .............................................................................................. 23

Service Messages ................................................................................................... 24

3

Page 4

PROGRAMMING

Using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify various

brewing parameters such as brew temperatures, brew volumes, bypass, pulse brew, pre-infusion, SmartWAVE,

drip time and fresh time. The operator can customize the brewing process to their specifications, allowing for

the precise brewing of various flavors of coffee.

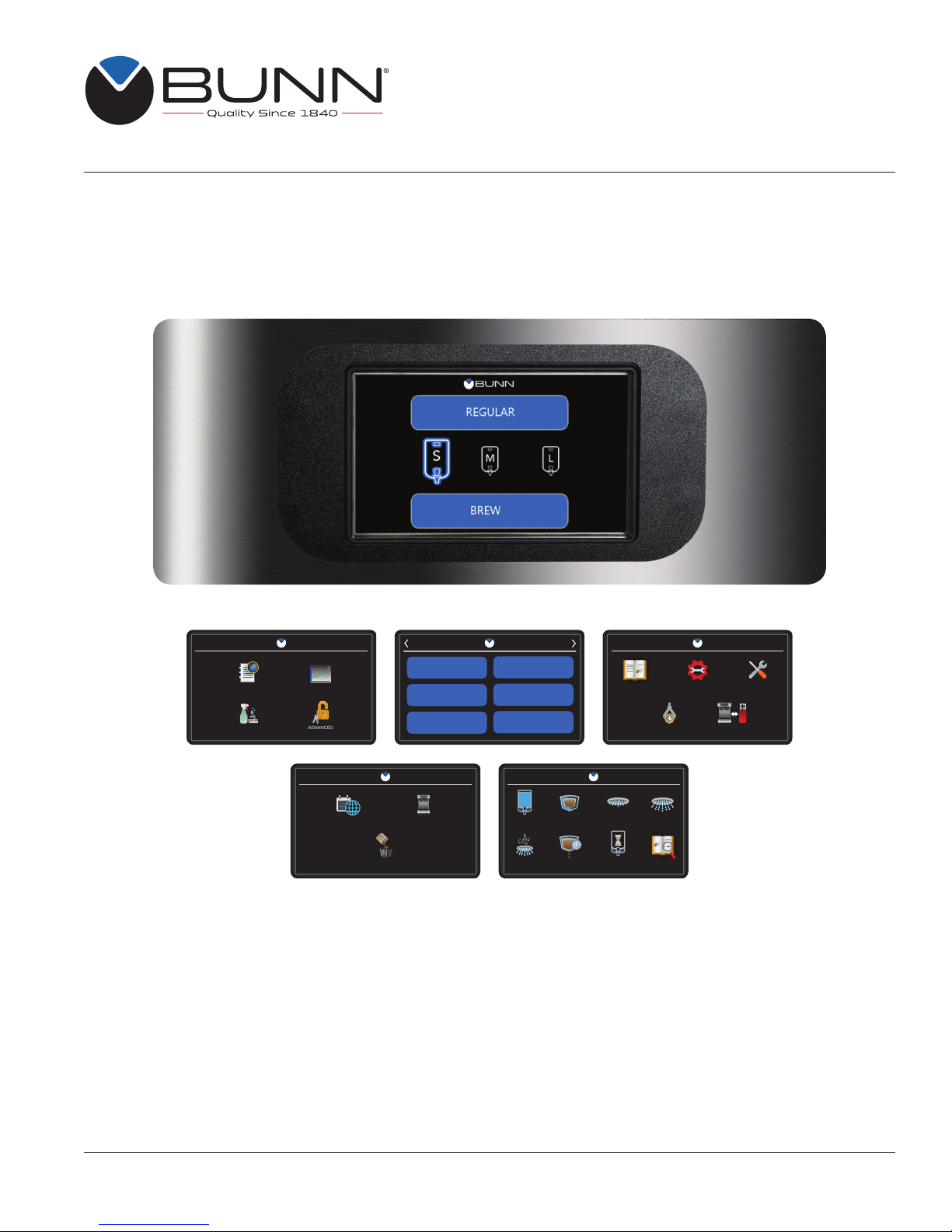

OPERATING CONTROLS

D

B

REGULAR

S S

M

L

BREW

Home Screen

A. BREW Left/Right

When the home screen is visible, select the BREW button to begin a brew cycle on the selected side.

D

DECAF

M

BREW

C

L

AA

B. PROGRAMMING

Touch the BUNN logo for 2 seconds to enter the programming.

C. BATCH SELECTOR SWITCHES

Selecting the icon corresponding to Small, Medium, and Large batch selects the amount of product

to be brewed on the selected side. The highlighting of the icon indicates the selected batch to brew.

D. RECIPE LIBRARY

Select the button to choose between any of the saved recipes stored in the Recipe Library. Use the arrows

at the top of the screen to scroll through the list of recipes available.

050718

4

Page 5

SERVICE

EVENT LOG STATISTICS

ADVANCEDCARE & CLEANING

ACCESS

PROGRAMMING (cont.)

Always remember to place a container and funnel under the sprayhead when operating the brewer during the

set-up of CALIBRATE FLOW, and testing the brew and bypass valves in SERVICE TOOLS/TEST OUTPUTS.

HOW TO ACCESS PROGRAMMING

To enter programming mode, the home screen must

be present on the display. Touch the BUNN logo at the

top of the display for 2 seconds. The SERVICE ACCESS

screen will appear on the display.

HOW TO EXIT PROGRAMMING

To exit the programming mode at any time, select the

BUNN logo at the top of the display. The display will

return to the home screen.

If there is no interaction with the touchscreen within a

5-minute period while in programming mode, the display

will automatically return to the home screen.

PROGRAMMING LOCKOUT

This switch is located on the graphics board located

under the top panel of the brewer. The switch can be

set to prevent access to the advanced programming

settings of the brewer. Once all the correct brew settings

are programmed, the operator can set the switch to

the “ON” position to prohibit anyone from viewing and

changing settings. The brewer must be powered down

when setting the switch.

Touch for 2 seconds

REGULAR

M

S S

BREW

L

DECAF

M

BREW

L

SERVICE ACCESS

To access this menu, touch the BUNN logo for 2 seconds

with the home screen present. This is the first screen that

will appear on the display when accessing programming

mode. If Programming Lockout is enabled, the advanced

icon will not appear until the feature is disabled. Select

any icon to access the sub-menus.

Touch for 2 seconds

050718

5

Page 6

PROGRAMMING (cont.)

SERVICE ACCESS OPTIONS

EVENT HISTORY - Select this icon to view current cycles, lifetime cycles, and the length/number of

times certain components are activated.

STATISTICS - Select this icon to view the amount of brew cycles per batch size. Twin models will

show separate numbers for left and right brew cycles. The second sub-screen within Statistics will

show model, display version and I/O version number.

CARE & CLEANING - Select this icon to view cleaning instructions. The instructional content featured

will have a picture with a short description of the action that should take place.

ADVANCED - Selecting this icon will display a password entry screen. By default, the password can

be bypassed by selecting ENTER. By default, entering 7738 on this screen will allow permission for

setting a password. Setting a password will prevent entry into the Service Menu.

PASSWORD ENTRY

The default password (0000) can be changed in REGIONAL SETTINGS. To prevent an override for this password,

refer to the "Programming Lockout Switch" to enable.

PASSWORD ENTRY

####

SHOW

PASSWORD

By selecting the "SHOW PASSWORD" check box, the entered password is revealed on the screen.

Enter

Cancel

123

1

1

456

4

4

789

7

7

Cancel

2

2

5

5

8

8

0

0

0

3

3

6

6

9

9

Enter

x

- Selecting "Enter" will attempt to advance the user to the Service Menu.

- Selecting "Cancel" will back the user out of the PASSWORD ENTRY screen.

SHOW

PASSWORD

PASSWORD ENTRY

123

1

1

456

4

4

789

7

7

Cancel

2

2

5

5

8

8

0

0

0

0000

3

3

6

6

9

9

Enter

x

- Selecting "Clear All" will remove all digits entered on the screen.

x

- Selecting "Clear" will remove the latter digit entered on the screen.

Passwords:

0000 - Default password that will gain access to the Service Menu unless reset.

3366 - Demo mode

7738 - Override for Service Screen password change

5020 - Override for Import/Export password change

050718

6

Page 7

PROGRAMMING (cont.)

SERVICE ACCESS OPTIONS

EVENT HISTORY - Select this icon to view current cycles, lifetime cycles, and the length/number of

times certain components are activated.

STATISTICS - Select this icon to view the amount of brew cycles per batch size. Twin models will

show separate numbers for left and right brew cycles. The second sub-screen within Statistics will

show model, display version and I/O version number.

CARE & CLEANING - Select this icon to view cleaning instructions. The instructional content featured

will have a picture with a short description of the action that should take place.

ADVANCED - Selecting this icon will display a password entry screen. By default, the password can

be bypassed by selecting ENTER. By default, entering 7738 on this screen will allow permission for

setting a password. Setting a password will prevent entry into the Service Menu.

ADVANCED MENU

To access this menu, select the ADVANCED icon while viewing the SERVICE ACCESS screen on the display. If

Programming Lockout is enabled, this menu cannot be accessed until the feature is disabled. Select any icon to

access the sub-menus.

ADVANCED MENU OPTIONS

RECIPES - Select this icon to disable, enable, add or modifying recipes.

MACHINE SETTINGS - Select this icon to adjust global settings on the brewer.

SERVICE - Select this icon to access high level diagnostic functions and service information.

ADVANCED MENU

RECIPES MACHINE SETTINGS SERVICE

IMPORT / EXPORTCALIBRATIONS

CALIBRATIONS - Select this icon to perform necessary adjustments to ensure accurate brewing.

IMPORT/EXPORT - Select this icon to import/export screen graphics or recipes.

050718

7

Page 8

PROGRAMMING (cont.)

SETTING A PASSWORD (ADVANCED)

The default password for accessing the Service Menu can be reset in

Regional Settings when using the password "7738" at the Password

Entry screen.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, enter the numbers: 7738.

4. Select ENTER.

5. At the SERVICE MENU screen, select the REGIONAL SETTINGS

icon.

6. Within REGIONAL SETTINGS, select PASSWORD.

7. Select the ADVANCED icon.

8. Enter "7738" into the first password text area on the screen. After the password is entered, the system will

notify the user if the password for resetting is accepted. If "INVALID" is shown on the screen, ensure you

entered the "7738" password when accessing the SERVICE MENU and repeat this steps 5 through 7.

9. Proceed to enter the "NEW PASSWORD" by selecting the second text area on the screen. A numeric pad

will appear; enter the new password and select ENTER when finished.

10. Confirm the new password by selecting the third text area and entering the same digits that

SETTING A PASSWORD (IMPORT/EXPORT)

The default password for importing and exporting files can be reset

in Regional Settings.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER

4. At the SERVICE MENU screen, select the REGIONAL

SETTINGS icon.

5. Within REGIONAL SETTINGS, select PASSWORD.

6. Select the IMPORT/EXPORT icon.

7. Proceed to enter the "NEW PASSWORD" by selecting the text area on the screen. If a password was

previously set for IMPORT/EXPORT, you will need to enter the current password first. A numeric pad will

appear; enter the new password and select ENTER when finished.

8. Confirm the new password by entering the same digits that were entered in Step 7 on the Numeric pad.

9. When finished, select "SAVE".

VIEWING ASSET, SERIAL & SERVICE NUMBER

1. Touch the BUNN logo for 2 seconds to enter the SERVICE

ACCESS screen.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password

is required, enter the code at this screen).

4. At the SERVICE MENU screen, select the SERVICE icon.

5. Select SERVICE NUMBERS to view the asset, serial and service numbers.

NOTE: The asset number will display if it has been setup in programming, otherwise it will not appear.

8

Page 9

PROGRAMMING (cont.)

COFFEE DEFAULT RECIPE PARAMETERS

(Regular, Decaf, Brazil, Colombia, Costa Rica, Ethiopia, Guatemala, Kenya, Peru, Sumatra)

Recipe Setting Small Batch

Medium Batch

(Disabled by Default)

Large Batch

Volume 64.0 OZ / 1.9 L 128 OZ / 3.8 L 128.0 OZ / 3.8 L

Bypass (ITCB HV only) 0% 20% 20%

Pre-Infusion Disabled Disabled Disabled

Pulse Brew Disabled Disabled Disabled

SmartWAVE 4 4 4

SmartWAVE Enabled

NO NO NO

Drip Time 1:00 (Min:Sec) 1:30 (Min:Sec) 1:30 (Min:Sec)

Freshness Time 1:00 (Hr:Min) 1:00 (Hr:Min) 1:00 (Hr:Min)

Total Brew Time 2:38 (Min:Sec) 3:39 (Min:Sec) 4:20 (Min:Sec)

TEA DEFAULT RECIPE PARAMETERS

Recipe Setting Small Batch

Medium Batch

(Disabled by Default)

Large Batch

Volume 38.0 OZ / 1.9 L 76.0 OZ / 2.2 L 76.0 OZ / 2.2 L

Dilution 160.0 OZ / 4.7 L 320.0 OZ / 9.4 L 320.0 OZ / 9.4 L

Dilution Delay 0:00 0:00 0:00

Pre-Infusion Disabled Disabled Disabled

Pulse Brew 0:15 ON / 0:15 PAUSE 0:15 ON / 0:15 PAUSE 0:15 ON / 0:15 PAUSE

SmartWAVE DISABLED DISABLED DISABLED

SmartWAVE Enabled

NO NO NO

Drip Time 0:55 (Min:Sec) 1:20 (Min:Sec) 1:20 (Min:Sec)

Freshness Time 8:00 (Hr:Min) 8:00 (Hr:Min) 8:00 (Hr:Min)

Total Brew Time 3:25 (Min:Sec) 6:20 (Min:Sec) 6:20 (Min:Sec)

9

Page 10

PROGRAMMING (cont.)

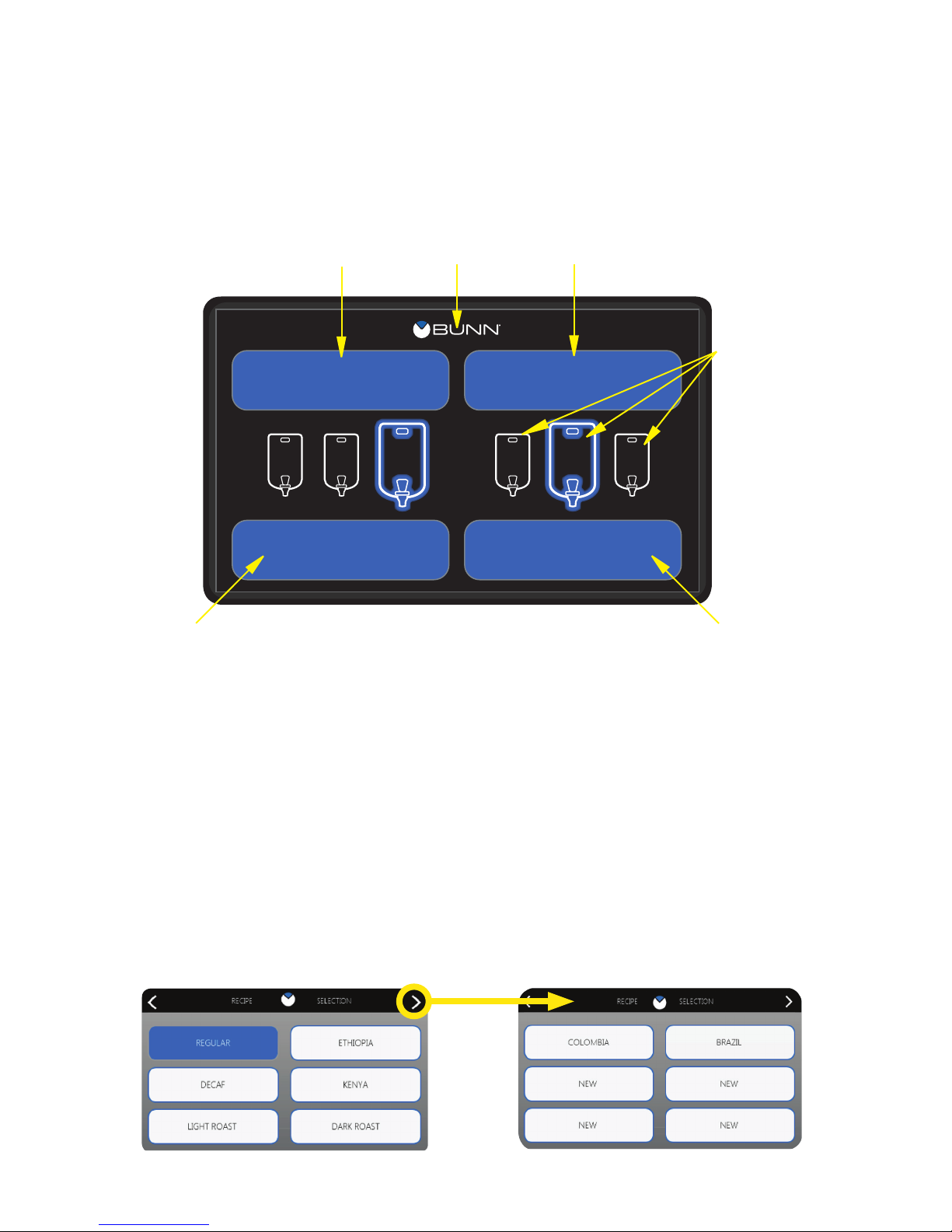

BREW LOCKOUT

This is a feature that allows the user to lock out all brewing functions until

the water in the tank has reached the specified READY TEMPERATURE.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is

required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. Select the BREW SETTINGS icon.

6. With the Temperature screen present, locate the BREW LOCKOUT feature on the bottom-left of the screen.

Select the white text area so that a green check mark appears.

7. Select the white text area across from READY TEMP. Enter the desired READY TEMP on the numeric pad.

Note: Ready temperature will allow brewing to occur when the tank temperature reaches that value.

MODIFYING RECIPES

By default, recipe settings are preset from the factory. The operator

RECIPE EDIT

has the choice of enabling, disabling and modifying any recipe

setting.

VOLUME

BYPASS

DILUTION

DILUTION DELAY

PRE-INFUSE

HOW TO ACCESS RECIPE SETTINGS

1. Touch the BUNN logo for 2 seconds to enter SERVICE

ACCESS.

PULSE BREW

SMARTWAVE

DRIP TIME

FRESHNESS

RECIPE REVIEW

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the ADVANCED MENU screen, select the RECIPES icon.

5. The RECIPE EDIT screen will appear on the display. If necessary, use the scroll arrow at the top of the

screen to navigate to the desired recipe name to edit. Select the recipe name.

6. Enable the batch size you wish to modify by selecting the white check box. If the batch size is already

enabled as indicated by the green check mark, proceed to the next step.

7. Select the batch icon next to the size you wish to modify (small, medium and large).

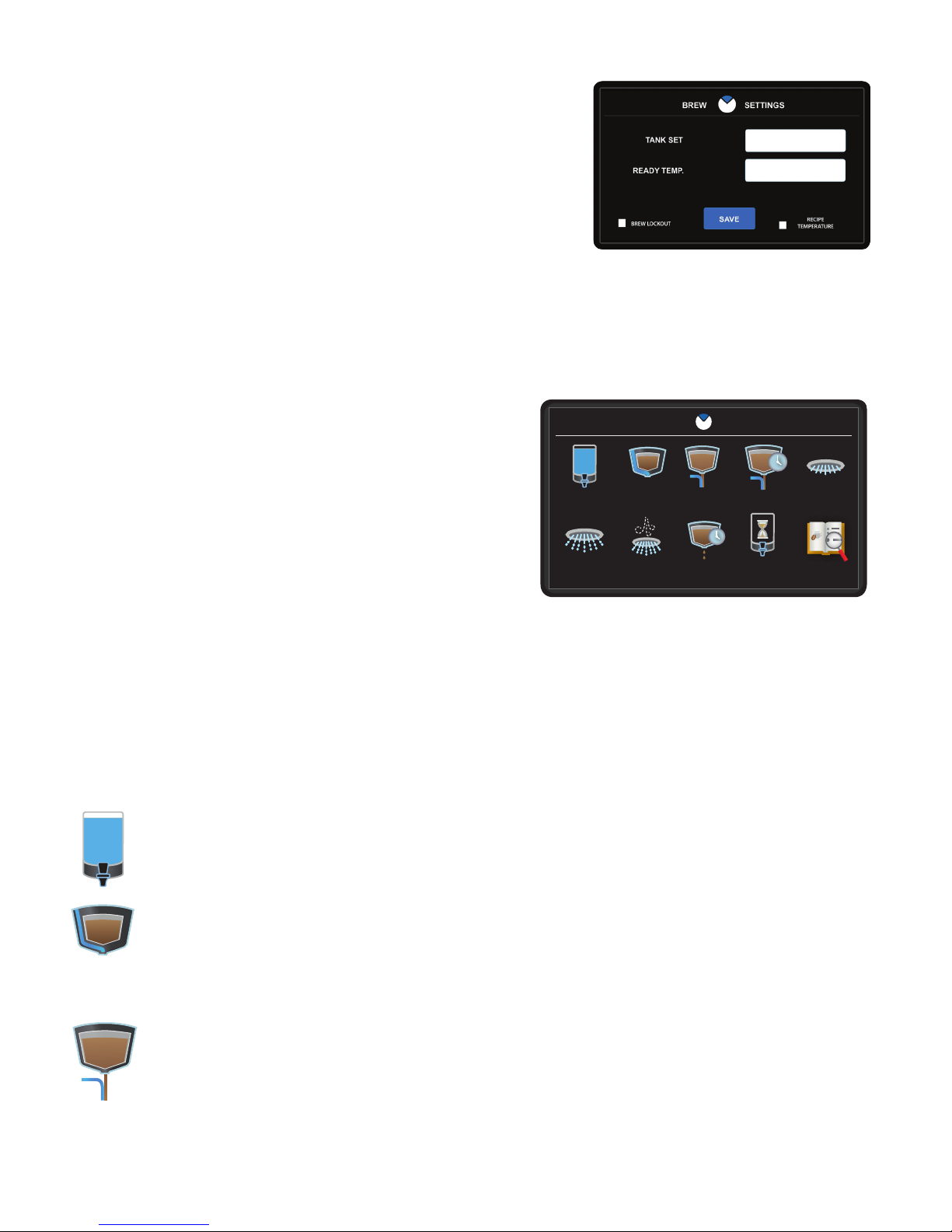

8. The screen that will appear has a menu of icons that represent settings you can enable, disable or modify.

VOLUME - This icon allows for volume adjustments. Each batch size, small, medium, and large will

have adjustable brew volume ranges to choose from. Pressing SAVE after the number has been

entered will confirm the change and exit back out to the recipe parameter screen.

BYPASS (ITCB HV Only)- This icon adjusts the bypass as a percentage of the total brew volume.

This means the set percentage will bypass the coffee grounds through the funnel to the server. If

bypass is used in a recipe, it will only turn on after 30 seconds of sprayhead time. The operator will

press SAVE to confirm their entry, which will exit them back to the recipe parameter screen.

DILUTION (Tea Recipes Only) - Dilution is used in tea brewing to dilute the concentrate of tea

brewed in the funnel. The user will set the amount desired in ounces or ml. The user can adjust

the volume by touching the text field and prompting the numeric keypad or use the plus or minus

butttons to increment or decrement the volume. Save confirms the change and exits the user back

to the recipe parameters screen. The arrow will just take user back to the recipe parameter screen.

10

Page 11

PROGRAMMING (cont.)

DILUTION DELAY (Tea Recipes Only)- This feature allows the user to set a time when the dilution

water should turn on after a brew cycle has been initiated. The user can adjust the time by touching

the text field and prompting the numeric keypad or use the plus or minus butttons to increment

or decrement the time. Save confirms the change and exits the user back to the recipe parameters

screen. The arrow will just take user back to the recipe parameter screen.

PRE-INFUSE - Pre-Infusion is defined as two parts; the first initial wetting of the coffee grounds

and the first initial “OFF” period before the rest of the brew cycle begins. The operator will have

the ability to brew with just pre-infusion only, if they prefer to do so. The operator must enable the

feature by selecting the checkbox. To set an “ON” time, the operator can select the text field. This

will prompt the numeric keypad to enter the desired time. To confirm a change, the operator must

press the SAVE button. The batch size icon in the upper right hand corner of the screen will allow

the operator to cycle between batch sizes. If the operator switches to a different batch size, those

parameters must be updated in the fields. Disabling the feature will gray out the white text fields.

The operator will not be able to adjust this setting unless the feature is enabled.

PULSE BREW - Pre-infusion and bypass settings will be taken into account if set already. The

operator will use the text fields to enter times. When entering the sprayhead on time, the ounces or

milliliters (depends on units set on the machine) being dispersed for that amount of time will display.

The quantity of water dispersed will be larger the longer the time is on. If the time is decreased, the

volume should lower as well. The volume displayed will be gathered from an average of both the

left and right sprayhead calibration settings. When setting the pause time, the operator is choosing

how long to turn the sprayhead off; this is not an accumulated time. This time is the length that the

sprayhead will turn off during the pulse routine then turn back on. Both on and off times will have

limits the operator is able to set depending on the parameters of the recipe. When configuring the

routine, the total brew time will change to be shorter or longer depending on the routine settings.

Longer pause times extend total brew time in most cases. The Auto calculate button will automatically set a routine based on the parameters for the recipe. Save will confirm and save the settings

for that recipes batch size. The batch size icon will cycle through the other enabled sizes to allow

the operator to set the pulse brew for a different size batch from this screen.

Reset - Creates an auto pulse brew is a set routine of 7 pulses that has been calculated by

parameters the operator has set. The operator must specify the batch volume, percentage of bypass,

pre-infusion time, and drip time. The pulse off time is calculated off a 60 second additional Brew

time for the 6 off pulses between the 7 on pulses. Off time = 10 sec / pulse = 60 sec / 6 pulses

Manual Pulse Brew - If a operator would like to adjust the brewing time which they have been

given in Auto pulse, they can change or make adjustments to the remaining on/off times. Doing this

can extend or shorten the brew time originally calculated for the Auto Pulse brew thus the operator

is now going to control what on and off times the brewer will use to make a pulse routine.

SMARTWAVE® - This is a brewing feature that alters the trajectory of water coming out of the

sprayhead in order to enhance uniformity of extraction. This is accomplished by activating the

air pump during the sprayhead on times only. When the sprayhead valve is on, the air pump will

activate and blow a pulse of air which will widen the pattern of water that hits the bed of coffee.

The operator will be able to set the SmartWAVE from 1-14. The plus/minus buttons will increment

and decrement by 1. Each number represents the air pump turning on twice during that brew cycle.

1 (2) - 14 (28). There will always be a blowout period of 5 seconds at the end of the brew. This will

evacuate water in the sprayhead to help avoid lime build up.

110618

11

Page 12

PROGRAMMING (cont.)

DRIP TIME - Drip time is the time allotted to allow for any excess coffee to drip from the funnel after

a brew has been completed. The operator will be able to add up to 5 minutes worth of time. If no

time is added the brew will complete and funnel locks will raise.

FRESHNESS - This time is used to help control beverage quality. An alert will pop-up full screen and

state that the recipe has expired. Once acknowledged, the operator can brew as normal.

REVIEW - Selecting this icon will give the operator another method of setting a recipe. This method

uses a table layout that shows the parameters and the values that are set. Selecting the white area

will take the operator directly to the edit page for that parameter. The operator can change the value,

SAVE, and exit back to the recipe review screen.

MACHINE SETTINGS

Selecting Brew Settings will take the user directly to the Set Temperature screen. This screen allows the setting of

the temperature that the tank attempts to heat to and maintain, and at what threshold the system allows brewing

to occur (if brew lockout is on). The tank set temp is the set point that the heater tries to control to, and the ready

temperature is how much below the set temp that the system allows brews to occur, depending on whether or

not the brew lockout (also known as temperature lockout) feature is active.

HOW TO ACCESS MACHINE SETTINGS

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is

required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. The MACHINE SETTINGS screen will appear on the display. There

will be a menu of icons that represent settings you can enable, disable or modify.

MACHINE SETTINGS

REGIONAL SETTINGS BREWER SETTINGS

BREW SETTINGS

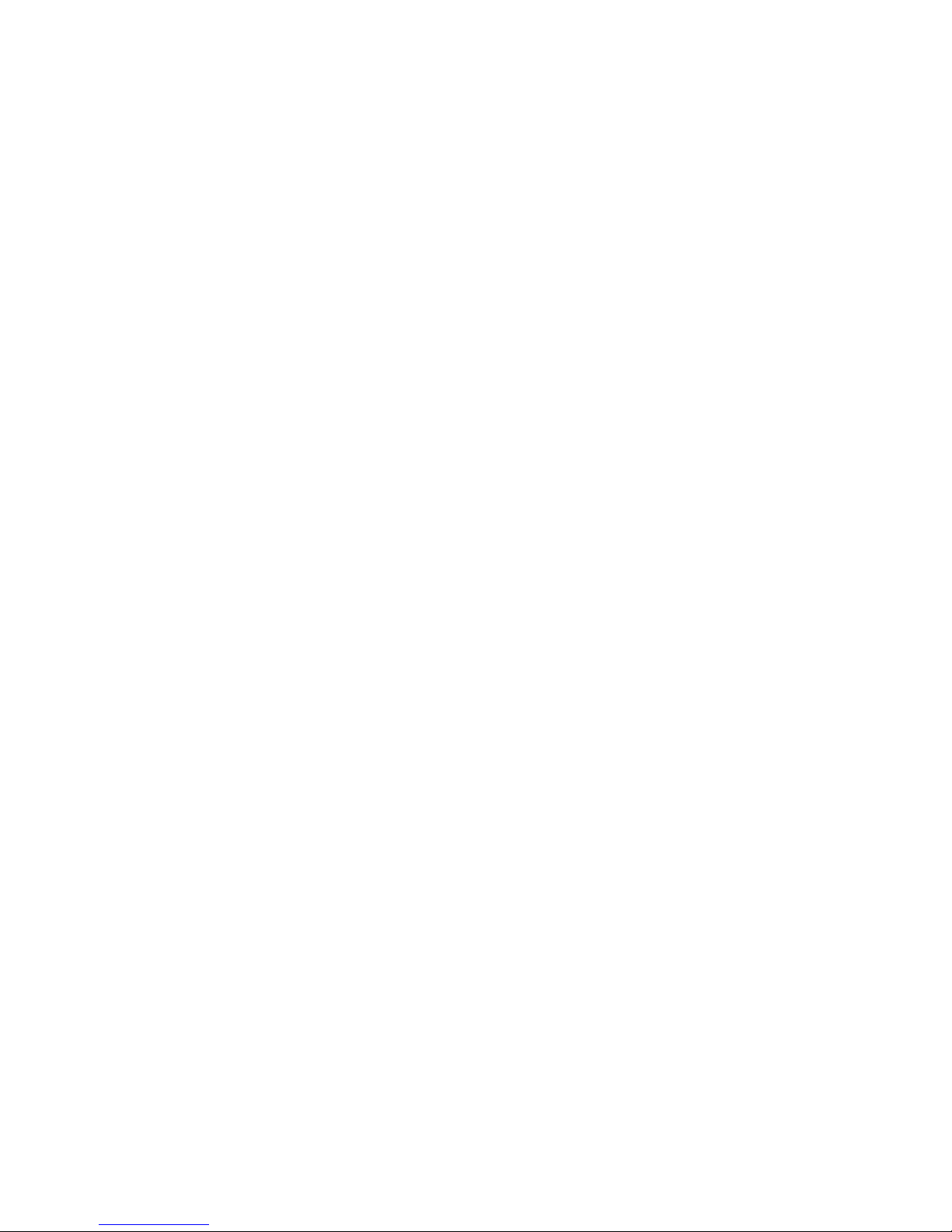

RENAMING A RECIPE

There are 5 pages containing 6 recipe names (30 total). By default, recipe names are preset from the factory.

The operator has the choice of renaming any recipe.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the RECIPE icon.

5. The RECIPE EDIT screen will appear on the display. If necessary, use the scroll arrow at the top of the

screen to navigate to the desired recipe name to edit. Select the recipe name.

NOTE:

selection list from the home screen. Grey-filled buttons represent recipes with all batch sizes disabled; these recipe

names will not appear in the recipe selection list from the home screen until a batch size is enabled.

Blue-filled buttons represent recipes with enabled batch sizes; these recipes will appear in the recipe

6. Select the white rectangle that contains the current name for the recipe.

7. Use the touchscreen to enter a new recipe name. Select ENTER when finished.

8. Select SAVE to store the new recipe name in programming.

050718

12

Page 13

PROGRAMMING (cont.)

ENABLING/DISABLING BATCH SIZES

The operator has the option to setup a recipe to include up to 3 batch sizes. Disabling all batch sizes for any given

recipe will remove it from the recipe selection list at the home screen.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the RECIPE icon.

5. The RECIPE EDIT screen will appear on the display. If necessary, use the scroll arrow at the top of the

screen to navigate to the desired recipe name to edit. Select the recipe name.

6. Select the desired batch sizes to be offered with the recipe by selecting the white check box next to each

batch size icon. Enabling the batch size without editing the batch recipe settings will automatically set

recipe parameters to default settings (volume, bypass, pre-infusion, etc).

7. Select SAVE to keep the changes made to the recipe.

RECIPE REVIEW

Recipe review is a feature that allows the user to quickly view and modify recipe settings. This method will provide

a table layout that shows the parameters and the values that are set for the recipe in review.

8. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

9. Select the ADVANCED icon.

10. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

11. In the SERVICE MENU screen, select the RECIPE icon.

12. The RECIPE EDIT screen will appear on the display. If necessary, use the scroll arrow at the top of the

screen to navigate to the desired recipe name to edit. Select the recipe name.

13. Select any Enabled batch size to review recipes.

14. Select the RECIPE REVIEW icon.

NOTE: You can toggle between enabled batch sizes by selecting the batch size icon on the top-right corner of

the screen.

15. Within Recipe Review, you will see a table layout containing recipe settings. Use the scroll arrow at the

top of the screen to navigate through the pages. You can edit each setting by selecting the corresponding

white text area and entering a new value before saving the changes.

13

Page 14

PROGRAMMING (cont.)

HOW TO TRANSFER RECIPES

The ability to transfer recipes from brewer to brewer is supported for Platinum Series Brewers. When choosing

a USB device for transferring and loading files, ensure to follow the proper USB formats.

1. Insert the USB device into the external US port on the right-side of the hood.

2. Ensure the brewer is plugged into a power source and powered On.

3. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

4. Select the ADVANCED icon.

5. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

6. In the SERVICE MENU screen, select the IMPORT/EXPORT icon.

7. Select EXPORT. The Export Menu will appear on the display.

8. Select the RECIPES icon.

9. Select YES. All recipes will be exported to the USB device.

10. Remove the USB device from the USB port and insert the USB device into a compatible Platinum

Series Brewer.

11. Repeat steps 2-6.

12. Select IMPORT. The import menu will appear on the display.

13. Select the RECIPES icon.

14. Select YES to import all recipes. Allow time for the import to finish.

15. Touch the BUNN logo at the top of the display to return to the home screen. Remove the USB

device and review the recipes for verification.

SET TEMPERATURE & RECIPE TEMPERATURE

The user has the ability to choose between SET TEMPERATURE and READY TEMPERATURE when deciding

the target temperature for water to reach before a brew cycle can occur. BREW LOCKOUT can be enabled

when either setting is selected.

SET TEMPERATURE

This is a global setting for the brewer to maintain water temperature for. The feature must first be enabled before it can be adjusted.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password

is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS

icon.

5. Select the BREW SETTINGS icon.

6. With the Temperature screen present, the RECIPE TEMPERATURE and SET TEMPERATURE option can be

toggled by selecting the white box next to RECIPE TEMPERATURE.

The READY TEMP is only available if BREW LOCKOUT is enabled, as indicated with a green check mark. To

enable SET TEMPERATURE, ensure RECIPE TEMPERATURE is disabled as indicated with an empty white box

next to the option.

14

Page 15

PROGRAMMING (cont.)

RECIPE TEMPERATURE

This feature allows the user to individually set target brewing temperatures for each recipe. Recipe Temperature must be enabled before the option appears in RECIPE EDIT.

How To Enable RECIPE TEMPERATURE

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. Select the BREW SETTINGS icon.

6. With the Temperature screen present, the RECIPE TEMPERATURE and SET TEMPERATURE option can be

toggled by selecting the white box next to RECIPE TEMPERATURE. The READY TEMP is only available if

BREW LOCKOUT is enabled, as indicated with a green check mark. To enable RECIPE TEMPERATURE, ensure

there’s a green check mark within the white box next to the option.

7. You will now see the RECIPE TEMPERATURE icon within the RECIPE EDIT screens for every recipe. Before

leaving the RECIPE TEMPERATURE screen, ensure the “READY WITHIN” Temperature is set (5ºF is the default) only when BREW LOCKOUT is enabled.

8. Individually set Recipe Temperatures by accessing

SCREENSAVER

A screensaver will appear after a period of inactivity with the touchscreen display. This feature is disabled by

default. The ability to load custom screen saver graphics is supported and the brewer comes with a set of

BUNN graphics loaded in the software.

HOW TO SET A DEFAULT SCREENSAVER

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. The MACHINE SETTINGS screen will appear on the display. Select BREWER SETTINGS.

6. Select SCREENSAVER.

7. Check the box next to BUNN DISABLED, the wording should then change to BUNN ENABLED.

8. Select the text area and input the amount of time before the screensaver appears on the numeric touch-

pad. The time entered on this screen must fall between 5 min - 24 min. By default, the screensaver is set

to 15 min. When enabled, the system will cycle through a series of BUNN graphics after the set amount of

time for the screensaver to appear.

15

Page 16

PROGRAMMING (cont.)

HOW TO SET A CUSTOM SCREENSAVER

Custom screensaver graphic(s) must be loaded into the software before it can be set as a screensaver. When

choosing a USB device for transferring and loading files, ensure to follow the proper formats and review size

restrictions.

Supported Graphic Type: .Jpg

Maximum Number of Images Supported: 10

Recommended Graphic Dimensions: 480 x 272 resolution

First Steps: Import Custom Graphics into the Brewer's Software

1. Load a USB device with custom screensaver graphics and eject the device from the computer when the

file transfer is complete.

2. Insert the USB device into the external US port on the right-side of the hood.

3. Ensure the brewer is plugged into a power source and powered On.

4. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

5. Select the ADVANCED icon.

6. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

7. In the SERVICE MENU screen, select the IMPORT/EXPORT icon.

8. Select IMPORT. The Import Menu will appear on the display.

9. Select the GRAPHICS icon. If the icon is grayed out on the display, remove and reinsert the USB

device into the USB port. If the graphic remains gray-out, ensure to follow the proper formats and

review size restrictions.

10. Select YES to import graphics. Allow time for the import to complete.

11. Touch the BUNN logo at the top of the display to return to the home screen.

Next Steps: Setting the Custom Graphic as Screensaver

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. The MACHINE SETTINGS screen will appear on the display. Select BREWER SETTINGS.

6. Select SCREENSAVER.

7. Check the box next to CUSTOM DISABLED, the wording

should then change to CUSTOM ENABLED.

8. Select the text area and input the amount of time before the

screensaver appears on the numeric touch-pad. The time

entered on this screen must fall between 5 min - 24 min.

By default, the screensaver is set to 15 min. When enabled,

HR:MIN

the custom graphic(s) will appear after the set amount of

time.

Note: The “CUSTOM ENABLED” feature is only available if graphics have been imported to the machine.

16

Page 17

PROGRAMMING (cont.)

SETTING ENERGY SAVER

When enabled, this setting will lower the tank temperature with 12 and 24 hour formats to save on energy consumption during idle periods. If energy saver has been enabled, the brew button(s) on the homes screen will

display ENERGY SAVER and be grayed-out. If a brew button is selected and brew lockout is disabled, the machine

will exit energy saver and begin to brew. If brew lockout is enabled and the energy save button is pressed, the

machine will exit the feature and begin to heat water to brewing temperature. After energy saver has been exited,

the machine will not enter this mode until the next scheduled time.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. The MACHINE SETTINGS screen will appear on the display. Select BREWER SETTINGS.

6. Select ENERGY SAVER.

7. Within the ENERGY SAVER screen, select the DISABLED

check box if the feature is not ENABLED.

8. Below TANK ACTION, choose between shutting off the

tank heater completely or reducing the water temperature

to 140 degrees Fahrenheit.

9. Below ENERGY SAVER ON, select the white text area.

Enter the time desired on the numeric touch pad. This

will be the time when the Energy Saver feature

becomes active.

10. Below ENERGY SAVER OFF, select the white text area. Enter the time desired on the numeric touch pad.

This will be the time when the Energy Saver feature becomes inactive and tank temperature will return to

normal operation (ready temperature for brewing).

SET DATE/TIME

The software has the ability to keep track of date and time. To set the time and date the user must select time &

date from the regional settings menu and also choose between 6 different display formats for Day/Month/Year.

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. The MACHINE SETTINGS screen will appear on the display. Select BREWER SETTINGS.

6. Select TIME & DATE.

7. Use the scroll arrow to navigate to TIME FORMAT. Choose the desired format for displaying Time and Date.

8. Use the scroll arrow to navigate back to TIME & DATE. Select each white text area and input the current

information as it relates to time and date. Select SAVE when finished.

17

Page 18

PROGRAMMING (cont.)

FRESHNESS TIME

This feature is used to help control beverage quality. An alert with a pop-up message that will state the recipe has

expired. The operator will have the ability to press OK to acknowledge the reminder event. Once acknowledged,

the operator can brew as normal.

HOW TO MODIFY FRESHNESS TIME

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the RECIPE icon.

5. The RECIPE EDIT screen will appear on the display. If necessary, use the scroll arrow at the top of the

screen to navigate to the desired recipe name to edit. Select the recipe name.

6. Select the batch icon next to the size you wish to modify (small, medium and large).

7. The screen that will appear has a menu of icons that represent settings you can enable, disable or modify.

Select the FRESHNESS TIME icon. Note: this is not a global setting and will need to be enabled and

adjusted for each batch size within a recipe if the feature is desired.

8. To enable the feature, ensure there is a green check mark next to ENABLED. Use the + and - buttons to

adjust the time in the white text area. Select SAVE when finished.

HR:MIN

18

Page 19

PROGRAMMING (cont.)

UPDATE SOFTWARE

Certain folder structure must exist on a USB drive with correct naming conventions in order for the software update

to be successful. In addition to folder structure, certain files are required to reside in folders within the directory.

Follow the instructions to ensure folder structure and files are present before proceeding with updating software.

1. Insert the USB drive that will be used for the software update into a computers USB port.

2. Access the USB drive (removable disk accessed from “My Computer” in Windows).

3. Verify folder structure is present and programming files exist.

Note: No folders should be zipped or compressed on the USB drive.

Graphics Board

I/O Board

Click on Folder

Root Directory Folder

Software Files

Folder: Platinum

Folder: Platinum_IO

4. Open the protective cover to the USB slot on the right-side of the hood. Insert the USB device with the loaded

software updates.

5. The display touchscreen will present options available for updating software. Select the component on the touchscreen display to begin the update.

6. Allow time for the update to complete. Repeat steps to complete all

software updates if necessary.

19

Page 20

PROGRAMMING (cont.)

MACHINE SETTINGS

Selecting Brew Settings will take the user directly to the Set Temperature screen. This screen allows the setting of

the temperature that the tank attempts to heat to and maintain, and at what threshold the system allows brewing

to occur (if brew lockout is on). The tank set temp is the set point that the heater tries to control to, and the ready

temperature is how much below the set temp that the system allows brews to occur, depending on whether or

not the brew lockout (also known as temperature lockout) feature is active.

HOW TO ACCESS MACHINE SETTINGS

1. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

2. Select the ADVANCED icon.

3. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

4. In the SERVICE MENU screen, select the MACHINE SETTINGS icon.

5. The MACHINE SETTINGS screen will appear on the display. There will be a menu of icons that represent

settings you can enable, disable or modify.

RECIPE EDIT

REGIONAL SETTINGS BREW SETTINGS

BREW SETTINGS

REGIONAL SETTINGS - Regional settings will allow the user to change the language, time & date,

units, and password for the brewer. Selecting each button will navigate the user to that respective

category. The BUNN programming button will navigate the user to the home screen.

BREWER SETTINGS - Machine settings allows the operator to make changes to energy saver, funnel

detect, and screen saver. The green check mark means the feature is enabled. Pressing the button

again will disable that feature and the check mark will go away to leave just an empty white box.

Once enabled if the feature has settings that must be set, the user will be taken directly to the set

up screens.

BREW SETTINGS - Users can press the temp set temperature number to go to a keypad entry

screen to change the value. The ready temperature will work similarly, but can only be accessed if

brew lockout is enabled. If brew lockout is disabled, then the ready temperature is grayed out and

the button will become inactive. Selecting the brew lockout check box will alternate states between

enabled and disabled. If the ready temperature is active, it allows a value to be entered in a range

of 2 to 20 degrees below the tank set temperature.

050718

20

Page 21

PROGRAMMING (cont.)

DEFAULT MACHINE SETTINGS

Setting Options Defaults

Language English / French / Spanish English

Time / Format 12 hrs / 24 hrs - 6 formats 12 hrs, MM-DD-YYYY

Units English / Metric English

Tank Set 185 - 205˚F 200˚

Ready Temp 180 - 203˚F 195 - 200˚F

Energy Saver Enabled / Disabled Disabled

Screen Saver Enabled / Disabled Disabled

Sprayhead Flowrate 10 - 200 oz / Min 39 oz / Min

Bypass Flowrate 10 - 200 oz / Min 41 oz / Min

Dilution Flowrate 10 - 200 oz / Min 64 oz / Min

Server Preheat Enabled / Disabled Enabled

Server Detect Enabled / Disabled Enabled

Smart Server Enabled / Disabled Disabled

Auto-Off Hrs/Min 0:00

HOW TO TRANSFER MACHINE SETTINGS

The ability to transfer machine settings from brewer to brewer is supported for Platinum Series Brewers. When

choosing a USB device for transferring and loading files, ensure to follow the proper USB formats.

1. Insert the USB device into the external US port on the right-side of the hood.

2. Ensure the brewer is plugged into a power source and powered On.

3. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

4. Select the ADVANCED icon.

5. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

6. In the SERVICE MENU screen, select the IMPORT/EXPORT icon.

7. Select EXPORT. The Export Menu will appear on the display.

8. Select the MACHINE SETTINGS icon.

9. Select YES. The machine settings will be exported to the USB device.

10. Remove the USB device from the USB port and insert the USB device into a Platinum Series Brewer.

11. Repeat steps 2-6.

12. Select IMPORT. The import menu will appear on the display.

13. Select the MACHINE SETTINGS icon.

14. Select YES to import machine settings. Allow time for the import to finish.

15. Touch the BUNN logo at the top of the display to return to the home screen. Remove the USB device and

review the machine settings for verification.

21

Page 22

PROGRAMMING (cont.)

HOW TO CALIBRATE SPRAYHEAD FLOW RATE

This function allows the operator to test and enter the actual flow rate of water coming out of the sprayhead(s).

The procedure includes a 1-minute dispense of water to determine the actual flow rate. Ensure that the brewer

is heated to brewing temperature before performing a sprayhead calibration.

1. Place a container, accurately graduated with a minimum capacity of 60 ounces, under the funnel.

2. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

3. Select the ADVANCED icon.

4. At the PASSWORD ENTRY screen, select ENTER. (If a password is required, enter the code at this screen).

5. At the SERVICE MENU screen, select the CALIBRATION icon.

6. For Single models, there is only 1 sprayhead to calibrate. For Twin models, there is a left and a right

sprayhead to calibrate. Ensure the container is under the correct sprayhead for calibration.

7. Select the START button to begin a 1-minute dispense of hot water from the sprayhead.

8. The display will show the time remaining for dispense along with the option to stop the dispense if

necessary. The 60-second timer on the display will count down to zero.

9. When the counter reaches zero, the display will change to allow the measured amount of water in the

container to be entered and saved in programming. Measure the amount of water in the container and

select the white text area on the screen to enter the value to match the amount in the container.

10. Select SAVE.

11. The display should now show the actual flow rate of the sprayhead.

12. Repeat steps 1-7 to calibrate the other side. (Twin models only)

HOW TO CALIBRATE BYPASS FLOW RATE (ITCB-HV Only)

This function allows the operator to test and enter the actual flow rate of water coming out of the bypass. The

procedure includes a 1-minute dispense of water to determine the actual flow rate. Ensure that the brewer is

heated to brewing temperature before performing a bypass calibration.

13. Place a container, accurately graduated with a minimum capacity of 60 ounces, under the funnel.

14. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

15. Select the ADVANCED icon.

16. At the PASSWORD ENTRY screen, select ENTER (If a password is required, enter the code at this screen).

17. At the SERVICE MENU screen, select the CALIBRATION icon.

18. For Single models, there is only 1 bypass to calibrate. For Twin models, there is a left and a right bypass

to calibrate. Ensure the container is under the correct brew station for calibration.

19. Select the START button to begin a 1-minute dispense of hot water from the bypass.

20. The display will show the time remaining for dispense along with the option to stop the dispense if necessary. The 60-second timer on the display will count down to zero.

21. When the counter reaches zero, the display will change to allow the measured amount of water in the

container to be entered and saved in programming. Measure the amount of water in the container and

select the white text area on the screen to enter the value to match the amount in the container.

22. Select Save.

23. The display should now show the actual flow rate of the bypass.

24. Repeat steps 13-23 calibrate other side. (Twin models only)

22

Page 23

PROGRAMMING (cont.)

HOW TO CALIBRATE DILUTION FLOW RATE

This function allows the operator to test and enter the actual flow rate of water coming out of the dilution nozzle.

The procedure includes a 1-minute dispense of water to determine the actual flow rate.

1. Place a container, accurately graduated with a min. capacity of 128 ounces, under the dilution nozzle.

2. Touch the BUNN logo for 2 seconds to enter SERVICE ACCESS.

3. Select the ADVANCED icon.

4. At the PASSWORD ENTRY screen, select ENTER. (If a password is required, enter the code at this screen).

5. At the SERVICE MENU screen, select the CALIBRATION icon.

6. Select the DILUTION icon to begin calibrating.

7. Select the START button to begin a 1-minute dispense of water from the dilution nozzle.

8. The display will show the time remaining for dispense along with the option to stop the dispense if necessary.

The 60-second timer on the display will count down to zero.

9. When the counter reaches zero, the display will change to allow the measured amount of water in the

container to be entered and saved in programming. Measure the amount of water in the container and select

the white text area on the screen to enter the value to match the amount in the container.

10. Select SAVE.

11. The display should now show the actual flow rate of the dilution.

12. Repeat steps 13-23 calibrate other side. (Twin models only)

CHECK GROUNDS IN FUNNEL: BREW ANYWAY?

Once a brew is complete, a message will appear prompting to remove

the funnel and discard the contents. This message will only display

for 3 seconds then return to the home screen. If the funnel has not

been removed since the last brew, the user will be prompted to check

grounds and brew anyway or be allowed to cancel and return to the

home screen.

SMART FUNNEL POP-UP EVENTS

The following are messages that can appear when FUNNEL DETECT

is Enabled.

SMART FUNNEL NOT PRESENT: BREW ANYWAY?

If "Funnel Detect" is enabled and the user selects the brew button, a

message will appear that warns the user a SMART Funnel is not present

(inserted into the funnel rail). The user as the ability to continue with

the brew by selecting "BREW".

NEW RECIPE HAS BEEN ADDED

When a SMART funnel is inserted and the recipe is not in the Recipe

library, the system will attempt to add the funnel recipe to the recipe

library. The system will add the recipe in the first available empty slot

in the library. When this occurs, a message will be shown to indicate

that a new recipe has been added to the library. It is recommended

that the user review the recipe parameters (see "How to Access Recipe

Settings").

23

Page 24

PROGRAMMING (cont.)

RECIPE LIST FULL

When attempting to brew a new recipe with a full recipe library (up to

30 recipes), the funnel recipe will be ignored. To avoid this message

from appearing in future brew cycles, a recipe must be deleted from the

recipe library to create storage for a new recipe (see “Delete Recipes”).

BATCH SIZE NOT ENABLED

If a recipe is in the library, but the batch size is not enabled, the recipe will be selected for brewing, but the

size selection will not be auto selected. A message will appear prompting the user to enable the batch size

for the recipe (see “ENABLING/DISABLING BATCH SIZES”). The system will not perform a brew cycle for the

selected recipe until the corresponding batch size is enabled.

SMALL BATCH SIZE

NOT ENABLED

MEDIUM BATCH SIZE

NOT ENABLED

LARGE BATCH SIZE

NOT ENABLED

SERVICE MESSAGES

When the system detects an event that requires attention, a message will appear on the display with supporting

information related to the event. Selecting the BUNN logo at the top of the display will exit the to the home screen

without resolving the event, but the message is recorded in "EVENT HISTORY".

FILL TIME TOO LONG

If the filling or refilling process for the hot water tank is taking too long,

this message will display. Refer to the information on the service message

as a general starting point for resolution.

HEATING TIME TOO LONG

If the heating process for the hot water tank is taking too long, this message

will display. Refer to the information on the service message as a general

starting point for resolution.

SOFTWARE UPGRADE NEEDED

In the event that a board was upgraded while the other was not, a message

will appear to let the user know there is an upgraded needed for the board

listed in the message. Pressing OK will clear the message for continued

use. The message will only clear once the software has been upgraded

(see "UPGRADE SOFTWARE").

24

Page 25

PROGRAMMING (cont.)

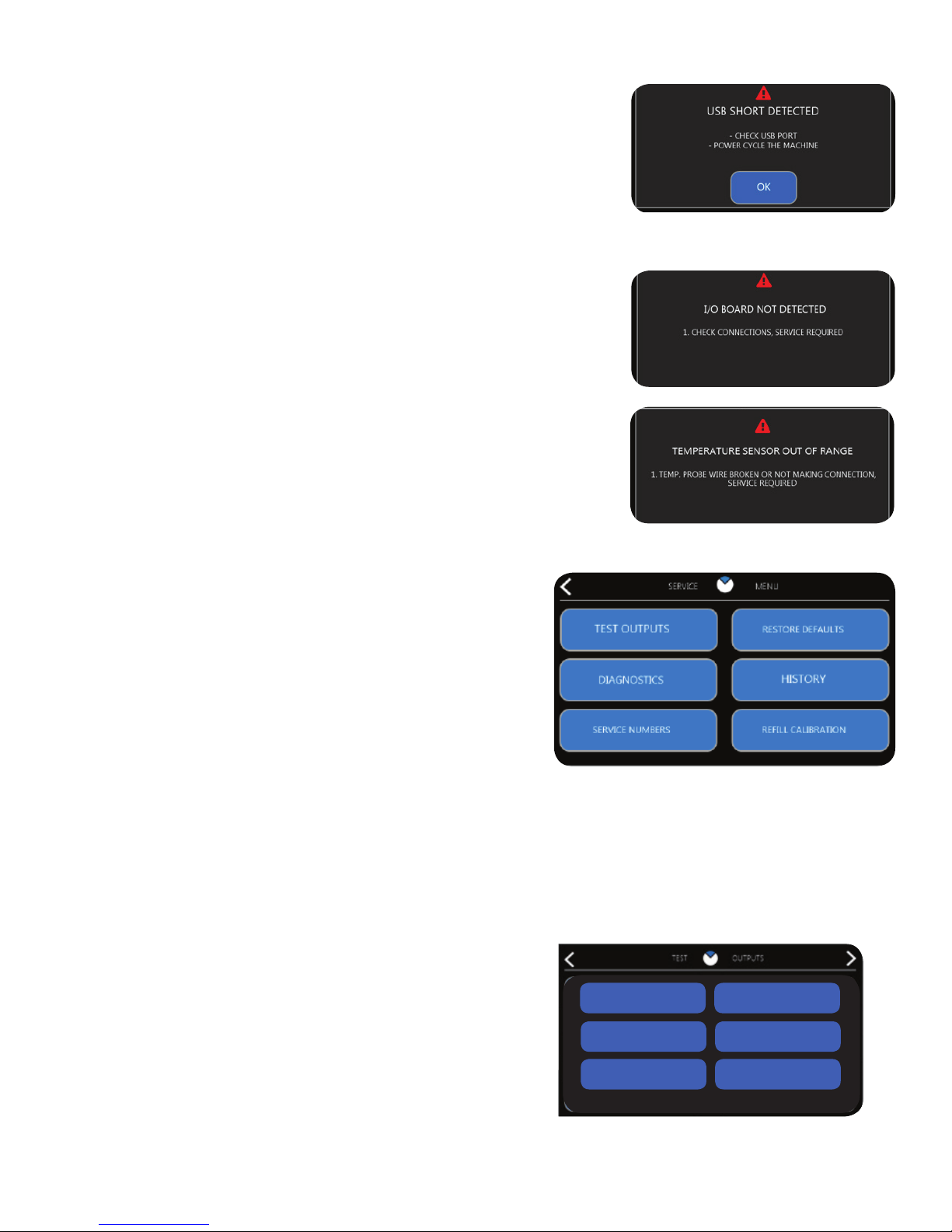

USB SHORT DETECTED

The USB drive is not intended to be used for anything other than machine

functions. In the event of a charger or another device being inserted, this

message will appear. When this message appears, the USB port will shut

down and the machine must be power cycled without any device connected

to the USB port to return USB functions back to normal. Pressing the ok

button will return the user to the home screen.

I/O BOARD NOT DETECTED

If the I/O board is not receiving the proper commands or a loss of communication occurs, this message will appear. Refer to the information on

the service message as a general starting point for resolution.

TEMPERATURE SENSOR OUT OF RANGE

If the temperature probe in the tank is not making a good connection, a

message will appear. There are two separate events related to the temperature probe that will result in a message to appear with a description.

DIAGNOSTICS

On entry to the Diagnostic screens, brews that are in process are

canceled, which turns off all of the outputs associated with brew

cycles, and the heaters are turned Off. Within the Diagnostics

menu, there are several options to choose from.

TEST OUTPUTS

This feature allows the user to manually turn On/Off individual

electrical components to check for functionality.

Each button corresponds to a specific action. For example,

selecting a brew or bypass valve will possibly dispense hot water out of the sprayhead; ensure that the brew

funnel is always in place when testing outputs.

Brew valve: For testing brew valves (ensure funnel is in place)

Bypass Valve: For testing bypass valve(s) - (ensure funnel is in place)

Dilution Valve: For testing dilution valve(s) - (ensure server or container is in place)

Funnel lock: For testing funnel lock(s)

Air Pump: For testing air pump(s)

Refill: For testing the refill circuit

BREW VALVE BYPASS VALVE

Tank Heater Triac: For testing tank heater(s)

FUNNEL LOCK AIR PUMP

REFILL TANK HEATER TRIAC

25

Page 26

Loading...

Loading...