Page 1

®

POWDER

BUNN

AUTO FILL

For ULTRA-2

™

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

29793.0001B 08/02 ©2002 Bunn-O-Matic Corporation

www.bunnomatic.com

Page 2

INTRODUCTION

This equipment supplies a liquid mix to the hoppers on the ULTRA-2 dispenser. It is for indoor use only on a

sturdy counter or shelf.

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis: parts

and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will

be commercially free of defects in material and workmanship existing at the time of manufacture and appearing

within the applicable warranty period. This warranty does not apply to any equipment, component or part that was

not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper

installation or operation, improper maintenance or repair, damage or casualty. This warranty is conditioned on the

Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601

or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the

defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from

BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are

not authorized to make modifications to this warranty or to make additional warranties that are binding on BUNN.

Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not

be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/

or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

2

29793.1 080102

Page 3

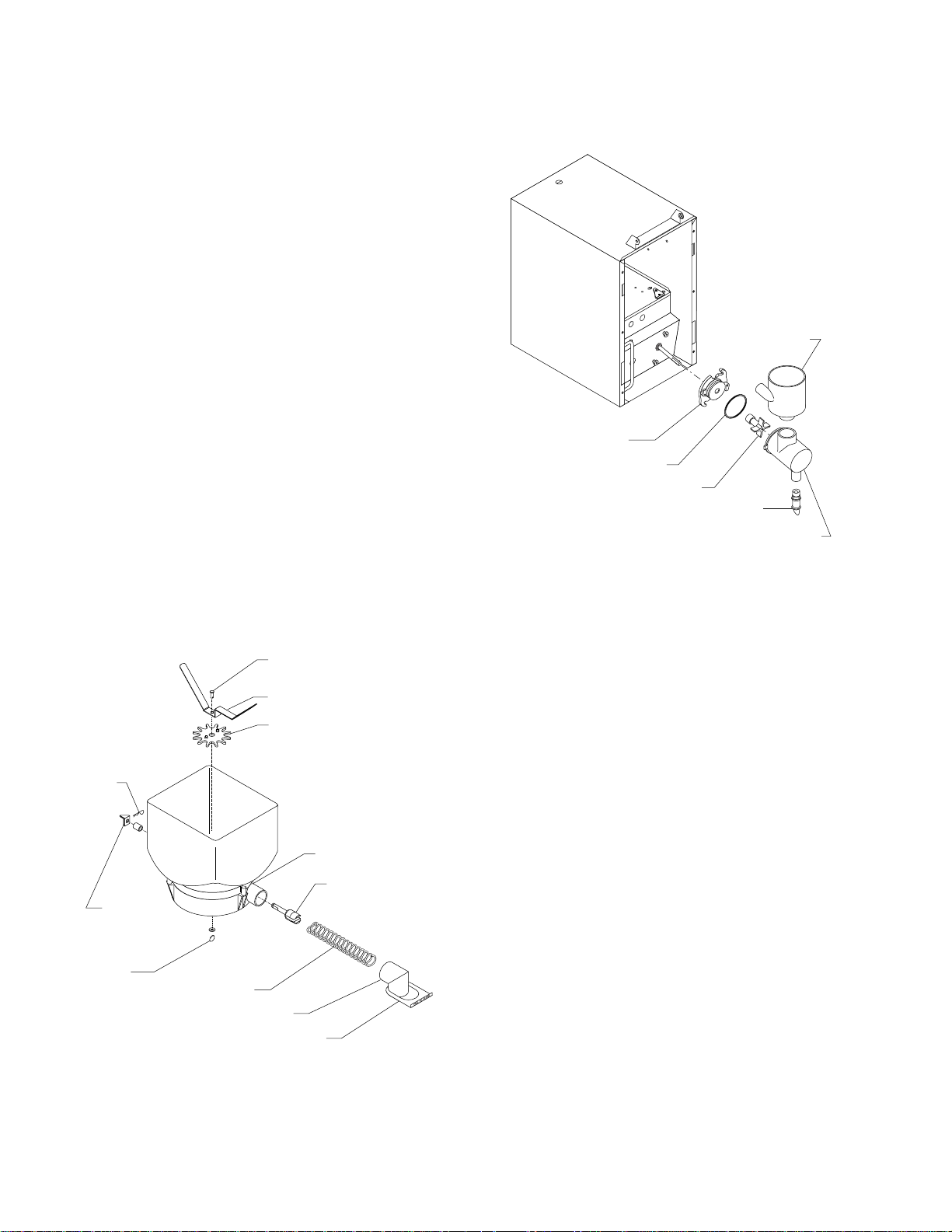

INITIAL SET-UP

1. Loosen auger motor cover screws.

2. Remove rear plastic plug from trim strip between hopper drip trays.

3. Install support rod into hole in trim strip.

4. Place PAF platform assembly on top of motor covers.

5. Tighten support rod from top of platform.

6. Retighten motor cover screws.

7. Plug RCA cord into ULTRA base unit.

8. Install hopper seal and press firmly into place on the flange of the cooling drum.

9. Align the auger shaft with the flat fin of the auger. Push the augers as far as they will go and rotate them so

the flat fin is facing up.

10. Place level probes in notch in rim of hoppers and install hoppers.

10. Install PAF units onto hoppers and platform.

11. Plug PAF power cord into rear of platform.

12. Plug PAF platform power cord into proper electrical outlet.

13. Attach a flexible water line to the .25" flare fitting on the back panel of the Powder Auto-Fill.

NOTE: A water strainer assembly (BUNN-O-MATIC #23820.1000) should be installed in line prior to the flexible

water line.

USER NOTICES

Carefully read and follow all notices on the equipment and in this manual. They were written for your protection.

All notices are to be kept in good condition. Replace any unreadable or damaged labels.

00656.0000

00986.0000

Push back until fully latched

before removing or manually

filling chilled product hopper.

34561.0000

3

29793.1 080102

Page 4

OPERATING INSTRUCTIONS

1. On the Ultra touch pad, make the following settings:

a) POWER- "ON"

b) DAY/NIGHT- "DAY"

2. Pull the Powder Auto-Fill fully forward on its support rails and open the door.

3. Fill the Powder Auto-Fill product hopper as follows:

a) Pull the slide gate closed on the Powder Auto-Fill

product hopper elbow and remove the hopper from

the Powder Auto-Fill.

b) Remove the lid from the product hopper and fill

the hopper with a powdered granita mix.

c) Install the product hopper into the Powder AutoFill. Insure hopper is fully seated behind retainer

plates.

d) Push the slide gate on the hopper ejector elbow

to the open position.

4. Place the ON/OFF switch at the Powder Auto-Fill

whipper panel to "ON".

5. After allowing 5 seconds for the Powder Auto-Fill to

initialize, observe the door lamp. The door lamp

should not be lit. If the door lamp is lit, consult the

fault list located on the decal placed on the back of

the door. Clear the fault before proceeding.

NOTE: If the Powder Auto-Fill is being used for the first

time with the selected granita mix, perform an adjustment as described in ADJUSTMENTS.

6. Close the Powder Auto-Fill door and observe the

following:

a) The door lamp lights steadily.

b) The Powder Auto-Fill begins dispensing liquid

granita product.

7. The Powder Auto-Fill will continue to fill the ULTRA

product hopper until the liquid level in the ULTRA

hopper reaches the product level probe or for 5

minutes, which ever occurs first.

8. If the Powder Auto-Fill fails to fill the ULTRA hopper

in 5 minutes, the following will occur:

a) The Powder Auto-Fill will stop dispensing product.

b) The door lamp will flash 4 times about every 2

seconds.

9. After checking the ULTRA and Powder Auto-Fill setup, the 5 minute refill fault may be cleared by simply

opening and closing the Powder Auto-Fill door.

10. Once the product level in the ULTRA covers the

auger, make the following switch settings at the

ULTRA control panel:

a) AUGER - "1".

b) ICE/OFF/CHILL - "ICE" or "CHILL" as appropriate

for the granita product.

11. From this point onward, the Powder Auto-Fill will

continue to automatically refill the ULTRA hopper,

maintaining the ULTRA product at an approximate

2 gallon level.

12. When the Powder Auto-Fill powder level falls low,

the door lamp will cycle ON and OFF, but will

continue to dispense product for a preset period.

When this period expires, the Powder Auto-Fill will

continue to cycle the door lamp ON and OFF and will

stop dispensing product.

13. To clear the low product fault, simply refill the

powder as follows:

a) Open the Powder Auto-Fill door.

b) Close the hopper slide gate.

c) Remove the product hopper.

d) Refill the product hopper with powdered granita

mix.

e) Replace the hopper.

f) Push the slide gate on the hopper ejector elbow

to the OPEN position.

g) Close the Powder Auto-Fill door.

4

29793.1 021202

Page 5

ADJUSTMENTS

When using the Powder Auto-Fill with a new powdered granita mix, follow the procedure outlined below to

adjust the Powder Auto-Fill to produce the correct recipe.

1. Determine the mix ratio of powdered granita mix.

Convert the recipe so that it is expressed in terms

of weight units [grams (g), dry ounces (oz), or

pounds (lbs)] of powdered granita mix to fluid

ounces (fl.oz.) of water [1 gallon (gal) = 128 fl.oz.;

1 liter (l) = 33.8 fl.oz.].

2. The delivery rate of the water ingredient is factory

preset to 1 fl.oz. per second. Therefore, it is only

necessary to adjust the delivery rate of the powdered granita mix. Adjustment is accomplished as

follows:

a) Place the Powder Auto-Fill on top of a fully

assembled ULTRA taking care to align the Powder

Auto-Fill guide rails over the rollers on the platform

guide rails.

b) Connect the Powder Auto-Fill power cord to the

outlet located on the ULTRA auger motor cover.

c) Attach a flexible water line to the .25" flare fitting

on the back panel of the Powder Auto-Fill.

NOTE: A water strainer assembly (BUNN-O-MATIC

#23820.1000) should be installed in line prior to the

flexible water line.

d) On the ULTRA touch pad, make the following

settings:

i) POWER- "ON"

ii) DAY/NIGHT- "DAY"

e) Pull the Powder Auto-Fill fully forward on its

support rails

f) Fill the Powder Auto-Fill product hopper as follows:

i) Pull the slide gate closed on the Powder AutoFill product hopper elbow and remove the product

hopper from the Powder Auto-Fill.

ii) Remove the lid from the product hopper and

fill the hopper with a powdered granita mix.

iii) Install the product hopper into the Powder

Auto-Fill.

g) Place the ON/OFF switch at the Powder Auto-Fill

whipper panel to "ON".

h) After allowing 5 seconds for the Powder Auto-Fill

to initialize, observe the door lamp on the whipper

panel. The door lamp should not be lit. If the door

lamp is lit, consult the fault list and clear the fault

before proceeding.

i) Remove the hole plug on the whipper panel.

Using a screwdriver, set potentiometer to approximately mid range.

j) Remove the mixing chamber from the Powder

Auto-Fill and place a small container, such as a cup,

under the product hopper ejector elbow.

k) Push the slide gate on the product hopper ejector

elbow to the OPEN position.

l) Momentarily set the TEST/SERVICE switch on the

whipper panel to the TEST position.

m) The hopper motor will run and dispense powdered granita mix for 10 seconds.

n) After the Powder Auto-Fill has finished the 10

second throw test, weigh the dispensed product.

o) Determine the dispense rate of the powdered

product (weight units per second) by dividing the

measured weight by 10.

p) Compare the measured dispense rate with the

mix ratio in step 1.

q) Adjust the MIN/MAX control clockwise to increase the dispense rate or counterclockwise to

decrease the dispense rate of the powdered granita

mix.

r) Repeat steps l through q as necessary until

proper mix ratio is achieved.

s) Replace the mixing chamber removed in step j.

Replace hole plug.

3. Once the mix ratio has been adjusted, the Powder

Auto-Fill can be run with the door open to allow the

user to catch dispensed product for brix testing as

follows:

a) Hold a container under the dispense tip of the

Powder Auto-Fill.

b) Hold the TEST/SERVICE switch on the whipper

panel to the SERVICE position.

c) When the container is filled to the desired level,

release the TEST/SERVICE switch.

d) Measure the brix using the appropriate measuring device.

e) Remove the hole plug. Using a screwdriver,

adjust the potentiometer clockwise to increase the

brix or counterclockwise to decrease the brix of the

product. Replace the hole plug.

5

29793.1 021202

Page 6

CLEANING

RECOMMENDED DAILY CLEANING AND MAINTENANCE TIPS

This should be done in conjunction with the recommended weekly cleaning of your ULTRA-2 machine.

Removing and cleaning the whipper chamber

(once a day):

1. Open the cabinet door.

2. Pull the mixing chamber out of the whipper chamber.

3. Twist the whipper chamber clockwise and pull it off

the whipper chamber receptacle.

4. Pull the frother off the motor shaft. Notice the flat

keyway on the shaft and the matching keyway

inside the frother. It is important that these two

keyways are lined up when reassembling.

5. Twist the whipper chamber receptacle clockwise

and pull it off the motor shaft.

6. Slip the O-ring off the whipper chamber receptacle.

7. Wash components in a mild solution of dish detergent using a bristle brush.

8. Rinse thoroughly and allow to dry before reinstalling in the machine.

Whipper Chamber

Receptacle

O-ring

Frother

Mixing Chamber

Dispense Tip

Whipper Chamber

Thorough cleaning of the hopper

Wiper Blade

Shaft

Wiper Blade

Wiper Drive Gear

(once a week):

1. Open the cabinet door.

2. Remove the hopper/base assembly from the cabinet, remove the cover and empty the contents.

Retaining

Clip

3. Pull the ejector elbow off the hopper base; remove

the slide gate from the ejector elbow.

4. Remove the wiper blade and drive gear by removing

the retaining ring from the wiper blade shaft.

5. Remove the auger by pulling it out of the front

hopper base.

6. Remove the auger drive shaft by removing the

retaining clip from the auger drive shaft.

7. Wash components in a mild solution of dish detergent using a bristle brush when needed.

8. Rinse and dry each item thoroughly before reassembling.

Auger Drive

Bracket

Retaining

Ring

Hopper Base

Auger Drive

Shaft

Auger

Ejector Elbow

Slide Gate

NOTICE

The cleaning instructions noted above are for nondairy sugar based food products. When dispensing any other

food product, the cleaning cycle for the whipping chamber assembly and ejector elbow must be performed daily.

6

29793.1 021202

Page 7

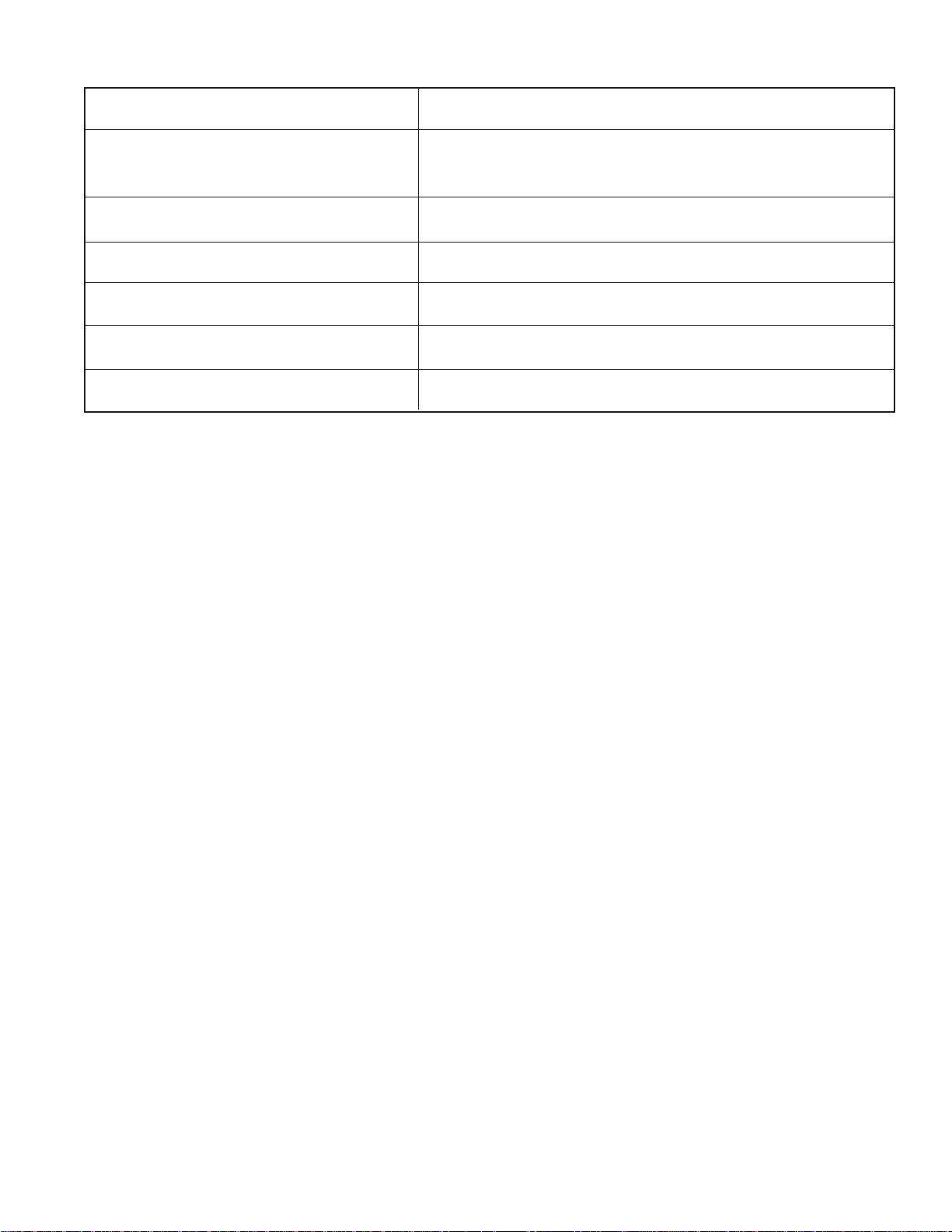

FAULT LIST

Door Lamp Fault

ON Normal operation - Powder Auto-Fill ready to

dispense

Flashes ON/OFF at 50% duty cycle Low product level in Powder Auto-Fill hopper

Two flashes about every 2 seconds ULTRA/Powder Auto-Fill probe circuit open

Three flashes about every 2 seconds Powder Auto-Fill hopper not in place

Four flashes about every 2 seconds ULTRA refill exceeded 5 minutes

OFF Door not closed

7

29793.1 021202

Page 8

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

• All electronic components have 120 volt ac and low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If an

intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will help

to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• Keep away from combustibles.

WARNING – • Exercise extreme caution when servicing electrical equipment.

• Unplug the dispenser when servicing, except when electrical tests are specified.

• Follow recommended service procedures

• Replace all protective shields or safety notices

PROBLEM

ULTRA and Powder Auto-Fill do not

run - Main power on ULTRA is OFF

Product level in ULTRA is lower than

level Probe - ULTRA running; Powder Auto-Fill door lamp is OFF

Product level in ULTRA is lower than

level Probe - ULTRA running; Powder Auto-Fill door lamp flashes ON

and OFF

PROBABLE CAUSE

1. ULTRA power cord disconnected

or main power switch in ON position.

1. The ULTRA DAY/NIGHT setting is

in the NIGHT mode.

2. Powder Auto-Fill power cord disconnected.

3. Powder Auto-Fill main power

switch in OFF position.

5. Powder Auto-Fill door is open.

1. Low product in Powder Auto-Fill.

REMEDY

Check that the power cord is connected to proper electrical source

and that the ULTRA main power

switch is in the ON position.

1. The ULTRA DAY/NIGHT setting

should be in the DAY mode.

2. Check that the Powder Auto-Fill is

plugged into the top of the ULTRA

auger motor cover.

3. Select the ON position of the main

power switch.

5. The Powder Auto-Fill door should

be closed securely.

Remove hopper and fill with powdered mix.

8

29793.1 021202

Page 9

TROUBLESHOOTING (cont.)

PROBABLE CAUSE REMEDYPROBLEM

Product level in ULTRA is lower than

level Probe - ULTRA running; Pow-

der Auto-Fill door lamp flashes two

times

Product level in ULTRA is lower than

level Probe - ULTRA running; Pow-

der Auto-Fill door lamp flashes three

times

Product level in ULTRA is lower than

level Probe - ULTRA running; Pow-

der Auto-Fill door lamp flashes four

times

1. Powder Auto-Fill not pulled completely forward.

2. ULTRA level probe misaligned.

1. Powder Auto-Fill hopper not installed properly.

1. Refill time exceeded five minutes.

1. Check that the Powder Auto-Fill is

pulled completely forward until the

guide rails roll into the indented position.

2. Position the ULTRA level probe so

that it is located in the notch of the

ULTRA hopper and touching the contact protruding from the front of the

PAF platform.

1. Properly position the Powder

Auto-Fill hopper.

.

Check that the SERVICE switch is

released or reset by opening and

closing the Powder Auto-Fill door.

The ULTRA product tastes "watery"

or "sugary"

Powder Auto-Fill dispenses dry prod-

uct only - dry powder build-up in

mixing and whipper chambers

1. Improper adjustment of product

mix ratio.

1. Powder Auto-Fill not connected to

water source.

2. Water source turned off.

3. Water line obstructed.

Adjust the product mix ratio per instructions in Powder Auto-Fill Adjustment. See page 5.

1. Connect the Powder Auto-Fill to a

20 to 90 psi (138 to 620 kPa)water

source.

2. Turn water source on.

3. Remove obstruction.

9

29793.1 021202

Page 10

TROUBLESHOOTING (cont.)

PROBABLE CAUSE REMEDYPROBLEM

Powder Auto-Fill will not dispense

product

1. No water

2. No power or incorrect voltage to

the dispenser.

3. Dispense Solenoid Valve

4. Control Board and Probe

5. Auger Drive

6. Transformer

Water lines and valves to the dispenser must be open and free of

obstructions.

Check that the power cord is connected to the ULTRA dispenser and

for voltage from the ULTRA dispenser.

Refer to Service- Dispense Solenoid

Valve for testing procedures. See

page 32

Refer to Service- Control Board and

Probe for testing procedures. See

page 18

Refer to Service- Auger Drive for

testing procedures. See page 13

Refer to Service- Transformer for

testing procedures. See page 26

Dripping from dispense tip

Water flows continuously

7. Water Strainer (Optional)

1. Dispense Solenoid Valve

1. Control Board and Probe

2. Dispense Solenoid Valve

A) Direction of flow arrow must be

pointing towards dispenser.

B) Remove the strainer and check

for obstructions. Clear or replace.

Remove dispense valve and clear

any obstructions. Rebuild or replace

the valve if necessary. Seepage 32

Refer to Service- Control Board and

Probe for testing procedures. See

page 18

Refer to Service- Dispense Solenoid

Valve for testing procedures. See

page 32

10

29793.1 021202

Page 11

TROUBLESHOOTING (cont.)

PROBABLE CAUSE REMEDYPROBLEM

Product overflows ULTRA hopper

Weak product

1. Control Board and Probe

2. Dispense Solenoid Valve

1. Whipper Motor

2. Frother

3. Dispense Solenoid Valve

4. Auger Drive

Refer to Service- Control Board and

Probe for testing procedures. See

page 18

Refer to Service- Dispense Solenoid

Valve for testing procedures. See

page 32

Refer to Service- Whipper Motor for

testing procedures. See page 16

Refer to Service- Frother for testing

procedures. See page 15

Refer to Service- Dispense Solenoid

Valve for testing procedures. See

page 32

Refer to Service- Auger Drive for

testing procedures. See page 13

Dispenser is making unusual noises

5. Auger Spring

6. Auger Motor

7. Improper adjustment of product

mix ratio

1. Plumbing lines

2. Water supply

Refer to Service- Auger Spring for

testing procedures. See page 13

Refer to Service- Auger Motor for

testing procedures. See page 14

Set the product mix ratio per Adjustments. See page 5

Plumbing lines should not be resting on the counter top.

A) The dispenser must be connected

to a cold water line.

B) Water pressure to the dispenser

must not exceed 90 psi (620 kPa).

Install a regulator if necessary to

lower the working pressure to approximately 50 psi (345 kPa).

Display not lit

1. Lamp

2. Lamp Holder

11

Refer to Service- Lamp for testing

procedures. See page 25

Refer to Service- Lamp Holder for

testing procedures. See page 25

29793.1 021202

Page 12

SERVICE

This section provides procedures for testing and

replacing various major components used in this dispenser should service become necessary. Refer to

Troubleshooting

of any problem.

WARNING - Inspection, testing, and repair of electrical

equipment should be performed only by qualified service personnel. The dispenser should be unplugged

when servicing, except when electrical tests are required and the test procedure specifically states to

plug-in the dispenser.

COMPONENT ACCESS

WARNING - Disconnect the dispenser from the power

source before the removal of any panel or the replacement of any component.

All components are accessible by opening the door,

removal of the door panel, removal of the dispenser

rear panel, hopper, hopper support plate and top wraparound cover. Refer to Fig. 1

for assistance in determining the cause

P1891

FIG. 1 COMPONENT LOCATIONS

Contents

Auger Drive Components...................................... 13

Auger Motor ......................................................... 14

Frother and Mixing/Whipper Chamber .................. 15

Whipper Motor ..................................................... 16

Control Board and Level Probes ........................... 18

TEST/SERVICE Switch .......................................... 21

Main Power ON/OFF Switch .................................. 22

Door Panel Assembly

Lamp Cord Assembly ..................................... 23

Lamp Cord Connector.....................................24

Lamp Holder/Socket .......................................25

Transformer ..........................................................26

Potentiometer ....................................................... 27

Hopper Level Indicator ......................................... 28

Hopper Switch ...................................................... 29

Door Switch .......................................................... 30

Pressure Regulator and Needle Valve ...................31

Dispense Solenoid ................................................32

Wiring Diagrams................................................... 33

12

29793.1 021202

Page 13

SERVICE (cont.)

AUGER DRIVE COMPONENTS

P1922

FIG. 2 AUGER DRIVE COMPONENTS

Location

The auger drive components are located in the bottom of the hopper assembly.

Removal, Cleaning and Replacement

1. Open the dispenser door.

2. Lift the hopper assembly over the retainer plates

(16) on hopper support plate (12) and slide hopper

assembly out the front of the dispenser.

3. Remove hopper lid (1) and empty product.

4. Pull off the ejector elbow (15) and remove the slide

gate (21).

5. Remove retainer ring (11) and washer (10) from

the bottom of the hopper base (9).

6. Remove wiper shaft (3), wiper blade (4) and wiper

drive gear (5) from the hopper base (9).

7. Remove auger wire (14) by pulling it out the front

of the hopper base (9).

8. Remove auger drive shaft (13) by removing the

retaining clip (6) from auger drive shaft.

9. Slide spacer (8) and auger drive shaft bracket (7)

off of the auger drive shaft (13).

10. Remove auger drive shaft (13) from hopper base

(9).

11. Wash components in a mild solution of dish detergent using a bristle brush when needed.

12. Rinse and dry each item thoroughly.

13. Check for damaged or broken components, replace any if necessary and reassemble hopper

assembly.

14. Install hopper assembly in the dispenser by sliding

hopper assy on the hopper support plate (12) until

the hopper base (9) seats firmly behind the retainer plates (16) on the hopper support plate (12).

1

2

3

4

5

6

7

8

9

10

11

17

18

19

13

14

20

15

21

16

12

P1894

FIG. 3 AUGER DRIVE & HOPPER ASSEMBLY

1. Hopper Lid

2. Hopper

3. Wiper Shaft

4. Wiper Blade

5. Wiper Drive Gear

6. Retainer Clip

7. Auger Drive Bracket

8. Spacer

9. Hopper Base

10. Washer

11. Retainer Ring

12. Hopper Support Plate

13. Auger Drive Shaft

14. Auger Wire

15. Ejector Elbow

16. Hopper Retainer Plates

17. Auger Motor Bracket

18. Auger Motor

19. Dust Seal

20. Auger Motor Mounting

panel

21. Slide gate

13

29793.1 021202

Page 14

SERVICE (cont.)

AUGER DRIVE MOTOR

FIG. 4 AUGER MOTOR

Location:

The auger motor is located on the right rear of the

motor assembly mounting panel.

P1922

Removal and Replacement:

1. Remove hopper assembly and set aside for reassembly.

2. Remove six #8-32 screws securing the rear cover

and remove the rear cover.

3. Remove the four #8-32 screws located inside the

dispenser housing on the lower right front of the

auger motor mounting panel, securing the auger

motor mounting bracket and auger motor to the

rear of the auger motor mounting panel.

4 Disconnect the wires from the auger drive motor.

5. Remove the auger motor mounting bracket, auger

motor and dust seal as an assembly.

6. Remove the dust seal from the auger motor and

discard the motor.

7. Install dust seal on the new auger motor shaft and

align the notch in the seal with the motor casting.

8. Connect the wires from the auger motor to the

terminals in the main wiring harness. See Fig. 5.

9. Using four #8-32 screws, install the auger motor,

dust seal and mounting bracket to the rear of the

auger motor mounting panel.

10. Install the hopper assembly.

11. Install the rear cover with six #8-32 screws.

Test procedures:

1. Disconnect the dispenser from the power source.

2. Check the voltage across the positive (red wire)

terminal and the negative (black wire) terminal on

the auger motor with a voltmeter. With the dispenser door open and the product level in the

ULTRA hopper lower than the probe, press and

hold the SERVICE switch. Connect the dispenser to

the power supply. The indication must be 4.0 to

26.5 volts dc.

If voltage is present as described, the auger motor

drive is operating properly. If auger does not turn,

replace the auger motor.

If voltage is not present as described, refer to wiring

diagrams and check wiring harness.

RED to Control

Board (J1-1)

BLK to GRN Wire

Main Harness to

Control Board (J1-7)

14

P1902

FIG. 5 AUGER MOTOR TERMINALS

29793.1 021202

Page 15

SERVICE (cont.)

FROTHER AND MIXING/WHIPPER CHAMBER

FIG. 6 FROTHER AND

MIXING/WHIPPER CHAMBER

Location:

The frother is located behind the dispenser door,

mounted on the front panel and inside the whipper

chamber.

P1923

10. Slide whipper chamber receptacle with seal (6) and

O-ring (4) on to the motor shaft.

11. Rotate the receptacle with seal (6) counterclockwise until it snaps into place on the motor mounting

nuts (7).

12. Push frother (5) onto the motor shaft, making sure

the flat in the frother (5) lines up with the flat on the

motor shaft.

13. Install whipper chamber (3) on the whipper chamber receptacle (6) by twisting counterclockwise

until tabs on the whipper chamber (3) lock with the

tabs on the whipper chamber receptacle (6). Be

sure dispense port is pointing down.

14. Install dispense tip (2) into the bottom of the

whipper chamber (3).

15. Slip the mixing chamber (1) onto the mixing chamber water inlet tube far enough so the mixing

chamber (1) will seat inside the whipper chamber

(3).

16. Install hopper assembly in the dispenser by sliding

hopper firmly behind the retainer plates on the

hopper support panel.

Removal, Cleaning and Replacement:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and lift the front edge of

the hopper over the retainer plates on the hopper

support panel and slide the hopper assembly out

the front of the dispenser.

3. Pull the mixing chamber (1) out of the whipper

chamber (3).

4. Remove the dispense tip (2) and twist the whipper

chamber (3) clockwise and pull it off the whipper

chamber receptacle (6).

5. Pull the frother (5) off the motor shaft. Notice the

flat side on the shaft and the matching flat inside the

frother. It is important that these two flats are lined

up when reassembling.

6. Slip the O-ring (4) off the whipper chamber receptacle (6).

7. Remove the receptacle by rotating clockwise until

the receptacle clears the nuts (7) and slide off the

motor shaft.

8. Wash components in a mild solution of dish detergent using a bristle brush.

9. Rinse thoroughly and allow to dry before reinstalling in the dispenser.

9 8 7 6 5 4 1 3 2

FIG. 7 MIXING/WHIPPER CHAMBER

COMPONENTS

1. Mixing Chamber

2. Dispense Tip

3. Whipper Chamber

4. O-Ring

5. Frother

P1895

6. Receptacle w/Seal

7. Nut

8. Slinger

9. Motor Assembly

15

29793.1 021202

Page 16

SERVICE (cont.)

WHIPPER MOTOR

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and remove the hopper

assembly out the front of the dispenser.

3. Remove the four #8-32 screws securing the hopper

support panel to the auger motor mounting panel

and the whipper motor mounting panel.

4. Slowly lift the hopper support panel up and disconnect the red/black and green wires from the hopper

switch.

5. Pull the mixing chamber out of the whipper chamber.

6. Twist the whipper chamber clockwise and pull it off

the whipper chamber receptacle.

7. Pull the frother off the motor shaft. Notice the flat

side on the shaft and the matching flat inside the

frother. It is important that these two flats are lined

up when reassembling.

8. Slide the receptacle with seal off of the motor shaft.

P1924

FIG. 8 WHIPPER MOTOR

Location:

The whipper motor is located on the back side of the

whipper motor mounting panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the white/red and white/brown wires of

the main wiring harness from the black leads of the

whipper motor.

3. With the ULTRA hopper level lower than the probe,

press and hold the SERVICE switch and check the

voltage across the disconnected harness wires

with a voltmeter. Connect the dispenser to the

power source. The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt CE models.

4. Disconnect the dispenser from the power source.

NOTE: To remove the receptacle only, rotate clockwise

until the receptacle clears the nuts and slide off of the

motor shaft.

9. Slide the slinger off of the motor shaft.

10. Remove the two nuts securing the whipper chamber receptacle and whipper motor to the front

panel.

11. Disconnect the black leads on the motor from the

white/red and white/brown wires of the main wiring

harness and remove the motor.

12. Install new motor on rear of front panel and secure

with two nuts. Connect the black leads from the

motor to the main wiring harness. Refer to Fig. 9

when reconnecting wires.

If voltage is present as described, replace the motor.

If voltage is not present as described, refer to the wiring

diagrams and check the dispenser wiring harness.

16

29793.1 021202

Page 17

SERVICE (cont.)

WHIPPER MOTOR (cont.)

13. Slide the slinger onto the motor shaft flush against

the front panel.

14. Wash whipper chamber components in a mild

solution of dish detergent using a bristle brush.

15. Rinse thoroughly and allow to dry before reinstalling in the dispenser.

16. Slide whipper chamber receptacle with seal and Oring onto the motor shaft.

17. Rotate the receptacle with seal counterclockwise

until it snaps into place on the motor mounting

nuts.

18. Push frother onto the motor shaft, making sure the

flat in the frother lines up with the flat on the motor

shaft.

19. Connect the red/black and green wires to the hopper switch, Fig.10 and install the hopper support

panel using the four #8-32 screws.

20. Install whipper chamber on the whipper chamber

receptacle by twisting counterclockwise until tabs

on the whipper chamber lock with the tabs on the

whipper chamber receptacle. Be sure dispense port

is pointing down.

21. Install dispense tip into the bottom of the whipper

chamber.

22. Slip the mixing chamber onto the mixing chamber

water inlet tube far enough so the mixing chamber

will seat inside the whipper chamber.

23. Install hopper assembly in the dispenser by sliding

hopper assembly on the hopper support panel until

the slot in the bottom rear of the hopper seats

against the pin and retainer plates on the hopper

support panel.

GRN to Control Boad (J1-8)

BLK

WHI/RED to Control Board (J7-2)

WHI/BRN to Control Board (J7-4)

FIG. 9 WHIPPER MOTOR TERMINALS

RED/BLK to Control Board (J1-10)

P1904

FIG. 10 HOPPER SWITCH TERMINALS

P1903

17

29793.1 021202

Page 18

SERVICE (cont.)

CONTROL BOARD and LEVEL PROBE

8. Select the "OFF" position of the main power switch

and disconnect the dispenser from the power source.

If voltage is present as described, proceed to #9.

If voltage is not present as described refer to the wiring

diagram and check the dispenser wiring harness.

9. Reconnect the four pin connector to the control

board (J7).

10. Disconnect the twelve pin connector (J1) from the

control board.

11. Measure the resistance between pins 8 & 12 of the

twelve pin connector on the wiring harness using

an ohmmeter. The indication must be between

298k ohms and 304k ohms.

P1925

FIG. 11 CONTROL BOARD

Location:

The control board is located behind the rear panel,

mounted on the back side of the hopper motor mounting panel.

Test Procedure:

Liquid Level Control

1. Disconnect the dispenser from the power source.

2. Disconnect the twelve pin connector (J1) from the

control board.

3. Check the voltage across pins 2 & 3 of the twelve pin

connector on the wiring harness with a voltmeter.

Connect the dispenser to the power source and

select the "ON" position of the main power switch.

The indication must be 24 volts ac.

4. Select the "OFF" position of the main power switch

and disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the wiring

diagram and check the dispenser wiring harness.

5. Reconnect the twelve pin connector to the control

board (J1).

6. Disconnect the four pin connector (J7) from the

control board.

7. Check the voltage across pins 1 & 3 of the four pin

connector on the wiring harness with a voltmeter.

Connect the dispenser to the power source and

select the "ON" position of the main power switch.

The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt CE models.

If the resistance measures as described, proceed to

#12.

If the resistance does not measure as described, refer

to the wiring diagram and check the dispenser wiring

harness.

12. Carefully connect a piece of insulated jumper wire

to the level probe contact pin (pink wire) located at

the lower left rear of the dispenser.

13. Check the voltage across the terminals, first of the

dispense solenoid and then of the hopper motor

with a voltmeter. Connect the dispenser to the

power source and select the "ON" position of the

main power switch. The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt CE models.

at the dispense solenoid and between 4 and 26 volts

dc at the hopper motor after a delay of approximately 10 seconds.

14. Touch the free end of the jumper wire to the

dispenser housing. The indication must be 0 (zero)

after a delay of up to 5 seconds.

15. Move the jumper wire away from the housing. The

indication must again be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt CE models.

at the dispense valve solenoid and between 4 and

26 volts dc at the hopper motor after a delay of up

to 5 seconds.

16. Disconnect the dispenser from the power source,

remove the jumper wire, and select the "OFF" position on the main power switch.

If voltage is present as described, The liquid level

control circuitry is operating properly.

If voltage is not present as described, replace the

control board.

18

29793.1 021202

Page 19

SERVICE (cont.)

CONTROL BOARD and LEVEL PROBE (cont.)

Test Procedure:

Low Product Detect

1. Disconnect the dispenser from the power source.

2. Disconnect the twelve pin connector (J1) from the

control board.

3. Check the voltage across pins 2 & 3 of the twelve pin

connector on the wiring harness with a voltmeter.

Connect the dispenser to the power source and

select the "ON" position of the main power switch.

The indication must be 24 volts ac.

4. Select the "OFF" position of the main power switch

and disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the wiring

diagram and check the dispenser wiring harness.

5. Reconnect the twelve pin connector to the control

board (J1).

6. Disconnect the four pin connector (J6) from the

control board.

7. Check the voltage across pins 1 (positive) & 3

(negative) of the four pin connector on the control

board with a voltmeter. Connect the dispenser to

the power source and select the "ON" position of the

main power switch. The indication must be +5 volts

dc.

8. Select the "OFF" position of the main power switch

and disconnect the dispenser from the power source.

If voltage is present as described, proceed to #12.

If voltage is not present as described, replace the photo

transistor.

12. Check the voltage across pins 1 (positive) & 3

(negative) of the four pin connector on the control

board with a voltmeter. Remove the hopper from

the dispenser, connect the dispenser to the power

source and select the "ON" position of the main

power switch. Shine a flashlight on the photo

transistor (left side panel). The indication must be

less than 1 volt dc.

13. Disconnect the dispenser from the power source

and select the "OFF" position on the main power

switch.

If voltage is present as described, proceed to #14.

If voltage is not present as described, replace the photo

transistor.

14. Disconnect the two pin connector (J2) from the

control board.

15. Check the voltage across pins 1 (positive) & 2

(negative) of the two pin connector on the control

board with a voltmeter. Connect the dispenser to

the power source and select the "ON" position of the

main power switch. The indication must be +1.5

volts dc.

16. Select the "OFF" position of the main power switch

and disconnect the dispenser from the power source.

If voltage is present as described, proceed to #9.

If voltage is not present as described, replace the

control board.

9. Reconnect the four pin connector to the control

board (J6).

10. Check the voltage across pins 1 (positive) & 3

(negative) of the four pin connector on the control

board with a voltmeter. Place a full hopper in the

dispenser, connect the dispenser to the power

source, select the "ON" position on the main power

switch, and close the dispenser door. The indication must be +5 volts dc.

11. Disconnect the dispenser from the power source,

remove the jumper wire, and select the "OFF" position on the main power switch.

If voltage is present as described, proceed to #17.

If voltage is not present as described, replace the

control board.

17. Check the photo LED forward and reverse bias

using a diode tester. The photo LED must be

forward biased with positive applied to pin 1 of the

two pin connector and negative applied to pin 2 of

the two pin connector. The photo LED must be

reverse biased with negative applied to pin 1 of the

two pin connector and positive applied to pin 2 of

the two in connector.

If the photo LED biasing checks as described, the low

level detect circuitry is operating properly.

If the photo LED biasing does not check as described,

replace the photo LED.

NOTE: The photo LED lights in the infrared spectrum

and is not visible to the human eye.

19

29793.1 021202

Page 20

SERVICE (cont.)

CONTROL BOARD and LEVEL PROBE (cont.)

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Remove the two plugs (J1 and J7) from the main

wiring harness, the potentiometer plug (J3), the

photo transistor plug (J6), and the photo LED plug

(J2) from the control board.

3. Remove the four #6-32 keps nuts securing the

control board to the hopper motor mounting panel.

4. Remove the control board.

5. Remove the four spacers from the old control board

and install them into the new control board.

6. Instal the new control board using the four #6-32

keps nuts.

7. Reconnect the two plugs (J1 and J7) from the main

wiring harness, the potentiometer plug (J3), the

photo transistor plug (J6), and the photo LED plug

(J2) to the control board. Refer to Fig. 12.

J1

J3

J2

J6

FIG. 12 CONTROL BOARD WIRING

J7

P1905

20

29793.1 021202

Page 21

SERVICE (cont.)

TEST/SERVICE SWITCH

P1923

FIG. 13 TEST/SERVICE SWITCH

Location:

The TEST/SERVICE switch is located on the

left front of the whipper motor mounting panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the switch terminals.

3. Check for continuity between the center terminal

and upper terminal with switch in the SERVICE

position (lower). Check for continuity between the

center terminal and the lower terminal with the

switch in the TEST position (upper). Continuity

must not be present when the switch is in the

center position.

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and remove the hopper

assembly out the front of the dispenser.

3. Remove the four #8-32 screws securing the hopper

support panel to the auger motor mounting panel

and the whipper motor mounting panel.

4. Slowly lift the hopper support panel up and disconnect the red/black and green wires from the hopper

switch.

5. Remove the facenut securing the TEST/SERVICE

switch the whipper motor mounting panel.

6. Remove switch with wires attached from the back

side of the whipper motor mounting panel.

7. Disconnect the wires from the switch and discard

the switch.

8. Refer to Fig. 14 when connecting the wires to the

new switch.

9. Install new switch with wires attached through the

hole in the whipper mounting panel and secure with

facenut.

10. Connect the red/black and green wires to the hopper switch. See Fig. 10 on page 17.

11. Install the hopper support panel to the auger motor

mounting panel and the whipper motor mounting

panel using the four #8-32 screws.

12. Install the hopper assembly.

WHI/ORN from Control

Board J1-6

GRN from Control

Board J1-8

BLU/BLK from Control

Board J1-11

If continuity is present as described, the switch is

operating properly.

If continuity is not present as described, replace the

switch.

21

FIG. 14 TEST/SERVICE SWITCH

TERMINALS

P1906

29793.1 021202

Page 22

SERVICE (cont.)

MAIN POWER ON/OFF SWITCH

P1923

FIG. 15 MAIN POWER ON/OFF SWITCH

Location:

The main power switch is located inside the dispenser on the right of the whipper motor mounting

panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the black wires from the main wiring

harness.

3. With the switch in the ON (lower) position check for

continuity between the center and the upper termi-

nal. With the switch in the OFF (upper) position no

continuity should be present between center and

upper terminals.

If continuity is present as described, the main power

switch is operating properly.

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and remove the hopper

assembly out the front of the dispenser.

3. Remove the four #8-32 screws securing the hopper

support panel to the auger motor mounting panel

and the whipper motor mounting panel.

4. Slowly lift the hopper support panel up and disconnect the red/black and green wires from the hopper

switch.

5. Remove the switch mounting nut on the front of the

whipper motor mounting panel.

6. Remove switch with wires attached from the rear of

the whipper motor mounting panel.

7. Remove the wires from the switch terminals and

discard switch.

8. Connect the wires to the new switch, refer to Fig. 16.

9. Push new switch through hole in the whipper motor

mounting panel and secure with face nut.

10. Connect the red/black and green wires to the hopper switch. See Fig. 10 on page 17.

11. Install the hopper support panel to the auger motor

mounting panel and the whipper motor mounting

panel using the four #8-32 screws.

12. Install the hopper assembly.

BLK from Power

Cord

BLK from Main

Harness

FIG. 16 MAIN POWER ON/OFF

P1907

SWITCH TERMINALS

22

29793.1 021202

Page 23

SERVICE (cont.)

LAMP CORD ASSEMBLY

FIG. 17 LAMP CORD ASSY

Location:

The lamp cord assembly is located in the top of the

dispenser.

P1891

Removal and Replacement:

1. Disconnect the lamp cord assembly from the lamp

cord connector assembly in the top of the dispenser.

2. Open the dispenser door and remove the five screws

securing the rear cover to the door.

3. Disconnect the lamp cord assembly from the lamp

holder/socket assembly and set the rear panel

aside.

4. Cut the terminals off of the lamp cord assembly.

5. Remove lamp cord assembly from the door assem-

bly and discard.

6. Push new lamp cord wires through the holes on the

top of the door assembly.

7. Strip the wires from the new lamp cord approxi-

mately .281".

8. Using the two terminals supplied, crimp the new

terminals to the lamp cord assembly and connect

them to the lamp holder/socket assembly wires.

9. Reinstall the rear panel to the door assembly.

10. Close the door.

11. Plug-in the new lamp cord assembly to the lamp

cord connector assembly on top of the dispenser.

12. Refer to Fig. 18 when reconnecting the wires.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Unplug the lamp cord assembly from lamp cord

connector assembly.

3. Check for continuity across the tip of the cord

assembly and the housing. Continuity must not be

present when the lamp is removed.

If continuity is present as described, the cord assembly is operating properly.

If continuity is not present as described, replace the

cord assembly.

BLK to WHI

at Lamp Holder

BLK to BLK

at Lamp Holder

P1926

FIG. 18 LAMP CORD WIRES

23

29793.1 021202

Page 24

SERVICE (cont.)

LAMP CORD CONNECTOR If continuity is present as described, the lamp cord

connector is operating properly.

If continuity is not present as described, replace the

lamp cord connector.

Removal and Replacement:

1. Disconnect the lamp cord assembly from the lamp

cord connector.

2. Remove the six #8-32 screws securing the rear

cover to the dispenser.

3. Disconnect the lamp cord connector wires from

the dispenser main wiring harness.

4. Remove nut and washer securing the lamp cord

connector to the dispenser. Remove and set aside

the insulating washers and discard nut, washer

P1923

FIG. 19 LAMP CORD CONNECTOR

Location:

The lamp cord connector is located on top of the

dispenser.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the lamp cord from the lamp cord

connector.

3. Disconnect the plug on the dispenser main harness

from the connector from the lamp cord connector.

4. Check the voltage across the two pin holes on the

main harness plug with a voltmeter and Day/Night

switch in the "DAY" position and the "ON/OFF"

switch in the "ON" position. Verify that the dispenser

hopper is full and in place, the platform probe

contact is making contact with the ULTRA liquid

level probe, and the dispenser door is closed.

Connect the dispenser to the power source. The

indication must be approximately 12.6 volts ac.

5. Disconnect the dispenser from the power source.

and lamp cord connector.

5. Remove new nut and washer from new lamp cord

connector.

6. Install the insulating washers to the hole in the top

of the dispenser. Push new lamp cord connector

through the holes in the insulating washers and

secure with the new nut and washer.

7. Reconnect the wires on the cord connector to the

dispenser main wiring harness.

8. Connect the lamp cord to the lamp cord connector.

9. Install the rear cover to the dispenser and secure

with six #8-32 screws.

If voltage is present as described, proceed to #6.

If voltage is not present as described, refer to the wir-

ing diagram and check the dispenser main wiring harness.

6. Check for continuity between pin 1 (red) of the lamp

cord connector and the center terminal of the lamp

cord connector. Check for continuity between pin 2

(black) of the lamp cord connector plug and the

lamp cord connector body. Check for continuity

between pins 1 & 2 of the lamp cord connector plug.

Continuity must not be present between pins 1 & 2.

24

To Main Harness

FIG. 20 LAMP CORD CONNECTOR

P1928

29793.1 021202

Page 25

SERVICE (cont.)

LAMP HOLDER/SOCKET ASSEMBLY

P1927

FIG. 21 LAMP HOLDER/SOCKET ASSEMBLY

Location:

The lamp holder/socket assembly is located inside

the dispenser door.

Test Procedures:

1. Disconnect the lamp cord from the lamp cord

connector.

2. Remove the lamp from the lamp holder/socket

assembly.

3. Check the voltage across the two pin holes on the

lamp holder/socket assembly with a voltmeter and

Day/Night switch in the "DAY" position and the ON/

OFF switch in the "ON" position. Verify that the

dispenser hopper is full and in place, the dispenser

probe contact is making contact with the ULTRA

liquid level probe, and the dispenser door is closed.

Reconnect the lamp cord to the lamp cord connector. The indication must be approximately 12.6

volts ac.

4. Disconnect the lamp cord from the lamp cord

connector.

If continuity is present as described, the lamp is operating properly.

If continuity is not present as described, replace the

lamp.

Removal and Replacement:

1. Disconnect the lamp cord assembly from the lamp

cord connector assembly in the top of the dispenser.

2. Remove the display graphic from the dispenser

door.

3. Open the dispenser door.

4. Remove the five #6-32 screws securing the rear door

cover to the door.

5. Carefully lower the rear door cover and disconnect

the lamp holder/socket assembly from the lamp

cord terminals.

6. Remove the lamp.

7. Remove #2-56 screw and elastic lock nut securing

the lamp holder/socket assembly to the mounting

bracket. Remove the lamp holder/socket assembly

and discard.

8. Install new lamp holder/socket assembly on mounting bracket using the #2-56 screw and lock nut.

9. Reinstall lamp.

10. Connect the new lamp holder/socket assembly to

the lamp cord terminals.

11. Reinstall the rear door cover to the dispenser door.

Make sure wires are located in notch in door flange.

12. Close the dispenser door.

13. Plug-in the lamp cord assembly to the lamp cord

connector assembly on top of the dispenser.

14. Refer to Fig. 22 when reconnecting the wires.

WHI to BLK

at Lamp Cord

BLK to BLK

at Lamp Cord

If voltage is present as described, the lamp holder/

socket assembly is operating properly.

If voltage is not present as described, replace the lamp

holder/socket assembly

5. Check for continuity across the terminals on the

lamps.

25

P1929

FIG. 22 LAMP HOLDER/SOCKET

ASSEMBLY WIRES

29793.1 021202

Page 26

SERVICE (cont.)

TRANSFORMER

P1930

FIG. 23 TRANSFORMER

Location:

The transformer is located under the hopper sup-

port panel mounted to the left of the whipper motor.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the four pin connector from the main

wiring harness from the four pin connector on the

transformer.

3. Check the voltage across the black wire (pin 1) and

the white wire (pin 2) on the plug from the main

wiring harness. Connect the dispenser to the power

source. The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt CE models.

4. Disconnect the dispenser from the power source.

5. Check the voltage between J1-2 and J1-3 on the

twelve pin connector at the control board. Connect

the dispenser to the power source. The indication

must be 24 volts ac.

If voltage is present as described, the transformer is

operating properly.

If voltage is not present as described, replace the

transformer.

Removal and Replacement:

1. Remove the hopper from the dispenser.

2. Remove the four #8-32 screws securing the hopper

support panel to the dispenser.

3. Disconnect the red/black and green wires from the

hopper switch and set the hopper support panel

aside.

4. Disconnect the transformer four pin connector

from the four pin plug on the main wiring harness.

5. Remove the two #6-32 keps nuts securing the

transformer to the dispenser base. Remove and

discard the transformer.

6. Install the new transformer on the dispenser base

and secure with two #6-32 keps nuts.

7. Connect the four pin connector on the transformer

to the four pin plug on the main wiring harness.

8. Reconnect the red/black and green wires to the

hopper switch. See Fig. 10 on page 17.

9. Install the hopper support panel and secure with

four #8-32 screws.

10. Install the hopper assembly.

If voltage is present as described, reconnect the plug

and the connector and proceed to #5.

If voltage is not present as described, refer to the wiring

diagrams and check the main wiring harness.

26

29793.1 021202

Page 27

SERVICE (cont.)

POTENTIOMETER

If the resistance measures as described, proceed to #7.

If resistance does not measure as described, replace

the potentiometer assembly.

7. Adjust the potentiometer fully counterclockwise.

8. Check resistance between pins 1 & 2 of the poten-

tiometer connector with an ohmmeter. The indication must be between 800 and 1200 ohms. Check

the resistance between pins 2 & 3 of the potentiometer connector with an ohmmeter. The indication

must be less than 20 ohms.

If the resistance measures as described, the potentiometer is operating properly.

If resistance does not measure as described, replace

the potentiometer assembly.

P1931

FIG. 24 POTENTIOMETER

Location:

The potentiometer is located under the hopper

support panel mounted to the left of the whipper motor

and mounted on a bracket. Adjustments can be made

by removing the 0.50" plug located on the whipper

motor mounting panel.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Remove the six #8-32 screws securing the rear

cover to the dispenser housing.

3. Disconnect the three pin connector (J3) from the

control board.

4. Check the resistance between pins 1 & 3 of the

potentiometer connector using an ohmmeter. The

indication must be between 800 and 1200 ohms.

If the resistance measures as described, proceed to #5.

If resistance does not measure as described, replace

the potentiometer assembly.

5. Adjust the potentiometer fully clockwise.

6. Check resistance between pins 2 & 3 of the poten-

tiometer connector with an ohmmeter. The indica-

tion must be between 800 and 1200 ohms. Check

the resistance between pins 1 & 2 of the potentiom-

eter connector with an ohmmeter. The indication

must be less than 20 ohms.

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Remove the six #8-32 screws securing the rear

panel to the dispenser.

3. Disconnect the three pin connector (J3) from the

control board.

4. Open the dispenser door and remove the #8-32

screw securing the potentiometer mounting bracket

to the whipper motor mounting panel.

5. Remove the potentiometer and mounting bracket

as an assembly.

6. Remove the facenut and locking washer securing

the potentiometer to the bracket.

7. Install the new potentiometer to the mounting

bracket using the locking washer and facenut.

8. Install the potentiometer and bracket assembly to

the whipper motor panel and secure with #8-32

screw.

9. Connect the three pin connector (J3) to the control

board.

10. Install the rear panel to the housing and secure with

six #8-32 screws.

27

29793.1 021202

Page 28

SERVICE (cont.)

HOPPER LEVEL INDICATOR

Photo LED

Photo Transistor

P1932

FIG. 25 HOPPER LEVEL INDICATOR

Location:

The photo transistor and LED are located on the

hopper side panels mounted just below the hopper

guide rails.

Test Procedures:

Refer to the section

PROBE

for test procedures.

CONTROL BOARD and LEVEL

7. Remove the six #8-32 round head screws securing

the front of the housing to the side panels.

8. Remove the six #8-32 truss head screws securing

the back of the housing to the side panels.

9. Carefully lift and spread the housing to remove it

from the rest of the dispenser.

10. Disconnect the photo transistor (J6) or LED (J2)

plug from the control board.

11. Cut the cable tie securing the cable assembly to the

cable tie mount.

12. Gently pull the photo transistor or LED from its

mounting lens.

13. Pull the photo transistor or LED through the grommet and free of the dispenser.

14. Snap the photo transistor or LED into the mounting

lens and feed the cable end through the grommet.

15. Gently bend the cable flush to the cable tie mount

and secure with new cable tie. Cut away excess

cable tie.

16. Connect the photo transistor (J6) or LED (J2) plug

to the control board.

17. Reassemble the dispenser top housing, rear panel,

and door assembly to the dispenser.

18. Reconnect the dispenser to the power source and

the water supply.

Removal and Replacement:

1. Disconnect the dispenser from the power source

and the water supply.

2. Remove the dispenser from the ULTRA machine

and place it on a flat work surface.

3. Disconnect the door lamp cord from the lamp

connector.

4. Remove the two #8-32 screws securing the door

hinge to the dispenser housing.

5. Carefully pull the door forward until the door support arms come completely out of the dispenser

housing and set aside.

6. Remove the six #8-32 truss head screws securing

the rear cover to the dispenser housing.

28

29793.1 021202

Page 29

SERVICE (cont.)

HOPPER SWITCH

P1933

FIG. 26 HOPPER SWITCH

Location:

The hopper switch is located under the hopper

support panel.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and remove the hopper.

3. Manually engage and release the hopper switch

actuator. The actuator must operate smoothly without binding at either end of its travel and an audible

click must be detected near the mid point of travel.

If the actuator operates as described, proceed to #4.

If the actuator does not operate as described, loosen

the hopper switch mounting screws, realign the switch,

and repeat the process. If the audible click cannot be

detected, proceed to #4.

4. Disconnect the twelve pin connector (J1) from the

control board.

5. Check continuity between pins 8 & 10 on the

harness using an ohmmeter. Continuity must be

present when the hopper is correctly installed.

Continuity must not be present when the hopper is

removed.

6. Reconnect the twelve pin connector (J1) to the

control board.

If continuity is present as described, the hopper switch

is operating properly.

If continuity is not present as described, proceed to #7.

7. Disconnect the wires from the hopper switch.

8. Check continuity between the N.O. and COM. terminals of the hopper switch using an ohmmeter.

Continuity must be present when the actuator is

engaged. Continuity must not be present when

actuator is released.

If continuity is present as described, refer to wiring

diagram and check the dispenser wiring harness.

If continuity is not present as described, replace the

hopper switch.

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and remove the hopper.

3. Remove the four #8-32 screws securing the hopper

support panel.

4. Carefully lift the hopper support panel, remove the

wires from the hopper switch, and remove the

hopper support panel.

5. Noting the orientation of the switch, remove the two

#4-40 screws, lockwashers and nuts securing the

switch to the panel.

6. Attach the new switch to the panel taking care to

orient it properly and secure with two #4-40 screws,

lockwashers and nuts.

7. Manually engage and release the hopper switch

actuator. The actuator must operate smoothly without binding at either end of its travel. If the actuator

operates as described, proceed to #8. If the actuator does not operate as described, loosen the two

screws and realign the switch and repeat the process.

8. Refer to Fig. 27 and reconnect the wires.

9. Install the hopper support panel and secure with

four #8-32 screws.

GRN to Control Boad (J1-8)

RED/BLK to Control Board (J1-10)

FIG. 27 HOPPER SWITCH TERMINALS

29

29793.1 021202

P1904

Page 30

SERVICE (cont.)

DOOR SWITCH

P1934

FIG. 28 DOOR SWITCH

Location:

The door switch is located on the right side panel

under the housing top cover.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the twelve pin connector (J1) from the

control board.

3. Check continuity between pins 8 & 9 on the wiring

harness using an ohmmeter. Continuity must be

present when the door is closed. Continuity must

not be present when the door is open.

4. Reconnect the twelve pin connector to the control

board.

5. Gain access to the door switch using steps listed in

Removal and Replacement

6. Disconnect the wires from the door switch.

7. Check continuity between the N.O. and COM. terminals of the switch using an ohmmeter. Continuity

must be present when the actuator is engaged.

Continuity must not be present when the actuator is

released.

.

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Remove the hopper assembly from the dispenser.

3. Remove the dispenser from the CDS machine and

place it on a flat work surface.

4. Disconnect the door lamp cord from the lamp

connector.

5. Remove the two #8-32 screws securing the door

hinge to the dispenser housing.

6. Carefully pull the door forward until the door support arms come completely out of the dispenser

housing and set aside.

7. Remove the six #8-32 truss head screws securing

the rear cover to the dispenser housing.

8. Remove the six #8-32 round head screws securing

the front of the housing to the side panels.

9. Remove the six #8-32 truss head screws securing

the back of the housing to the side panels.

10. Carefully lift and spread the housing to remove it

from the rest of the dispenser.

11. Remove the door switch actuator from the nylon

standoff.

12. Noting the orientation of the door switch, remove

the two #6-32 screws and the nylon standoff securing the switch mounting bracket to the dispenser

housing. Remove the switch.

13. Attach the new door switch taking care to orient the

switch correctly in the mounting bracket and secure in place with two #6-32 screws and nylon

standoff.

14. Reconnect the wires to the door switch. Refer to

Fig. 29.

15. Install the door switch actuator orienting the notched

side against the right side housing panel. Refer to

Fig. 28.

16. Reassemble the dispenser top housing, rear panel,

and door assembly to the dispenser.

ORA to Control

Board (J1-9)

GRN to Control

Board (J1-8)

If continuity is present as described, refer to wiring

diagram and check the dispenser wiring harness.

If continuity is not present s described, replace the door

switch.

30

P1908

FIG. 29 DOOR SWITCH TERMINALS

29793.1 021202

Page 31

SERVICE (cont.)

PRESSURE REGULATOR and NEEDLE VALVE

P1935

FIG. 30 PRESSURE REGULATOR

and NEEDLE VALVE

Location:

The pressure regulator and needle valve are located

inside the rear panel at the bottom of the dispenser.

Adjustments:

The water pressure regulator is preset at the factory

to produce 15 psi (103 kPa) of water pressure at the

regulator outlet with inlet pressures ranging from 20

psi to 90 psi (138 to 620 kPa). No field adjustments of

the pressure regulator should ever be necessary.

The needle valve is preset at the factory to dispense

1 fluid ounce of water per second. The dispenser is

designed to accommodate various product mix ratios

by adjusting the product dispense rate (see Initial

Setup). Should a readjustment of the water dispense

rate become necessary, proceed as follows:

1. Disconnect the dispenser from the power source.

2. Remove the six #8-32 screws securing the rear

panel to the dispenser housing.

3. Turn the needle valve adjustment screw counter-

clockwise to increase the water flow rate, and

clockwise to decrease the water flow rate.

Removal and Replacement:

Pressure Regulator

1. Disconnect the dispenser from the power source

and the water supply.

2. Remove the six #8-32 screws securing the rear

panel to the dispenser housing.

3. Disconnect the .25" copper tube from the outlet of

the pressure regulator.

4. Loosen the nut securing the bulkhead fitting to the

dispenser.

5. Remove the bulkhead fitting from the inlet to the

pressure regulator.

6. Remove the pressure regulator assembly.

7. Attach the regulator to the bulkhead fitting making

sure that the copper bushing is seated properly in

the regulator and tighten securely.

8. Tighten the nut securing the bulkhead fitting to the

dispenser housing.

9. Attach the .25" copper tube to the regulator assembly and tighten securely.

10. Connect the dispenser to the water source and

check for leaks. Tighten any leaking connections

before installing rear panel.

Removal and Replacement:

Needle Valve

1. Disconnect the dispenser from the power source

and the water supply.

2. Remove the six #8-32 screws securing the rear

panel to the dispenser housing.

3. Disconnect the .25" copper tube from the inlet

fitting on the needle valve.

4. Disconnect the water outlet from the solenoid valve.

5. Remove the solenoid valve and needle valve as

described in section-

Dispense Solenoid Valve

6. Remove the needle valve assembly. Remove the

fitting from the inlet port of the needle valve.

7. Install the fitting removed from the old needle valve

onto the new needle valve using pipe thread sealant

(BOM #M2526.0000).

8. Attach the needle valve to the fitting on the dispense

solenoid valve using pipe thread sealant (BOM

#M2526.0000) and tighten securely.

9. Install the solenoid valve and needle valve as described in section-

Dispense Solenoid Valve

10. Attach water inlet and outlet lines and tighten securely.

11. Connect the dispenser to the water source and

check for leaks. Tighten any leaking connections

before installing rear panel.

31

29793.1 021202

.

.

Page 32

SERVICE (cont.)

DISPENSE SOLENOID VALVE

P1935

FIG. 31 DISPENSE SOLENOID VALVE

Location:

The dispense solenoid valve is located on the left

side of the dispenser base inside of the rear cover.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the white/red and white/brown wires

from the solenoid valve.

3. Check the voltage across the white/red and white/

brown wires with a voltmeter. Connect the dispenser to the power source. The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt CE models.

4. Disconnect the dispenser from the power source.

7. Disconnect the dispenser from the power source.

If the sound is heard as described and water will not

pass through the solenoid valve, there may be a blockage in the water line before the solenoid valve or, the

solenoid valve may require inspection for wear and the

removal of waterborne particles.

If the sound is not heard as described, replace the

solenoid valve.

Removal and Replacement:

1. Disconnect the dispenser from the power source

and the water supply.

2. Remove the six #8-32 screws securing the rear

panel to the dispenser.

3. Remove the white/red and white/brown wires from

the solenoid valve.

4. Disconnect the water lines to and from the solenoid

valve.

5. Remove the two #8-32 nuts securing the solenoid

mounting bracket to the dispenser base. Remove

the solenoid and bracket assembly.

6. Remove the two #10-32 screws and lockwashers

securing the solenoid valve to the bracket.

7. Install a new solenoid valve to the bracket using two

#10-32 screws and lockwashers.

8. Install the solenoid and bracket to the base and

secure with two #8-32 nuts.

9. Install the water lines to and from the solenoid valve

using pipe thread sealant (BOM #M2526.0000) and

tighten securely.

10. Refer to Fig. 32 when reconnecting the wires.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to wiring

diagrams and check the dispenser wiring harness.

5. Check for continuity across the solenoid valve coil

terminals.

If continuity is present as described, reconnect the

white/red and white/brown wires to the solenoid.