Page 1

INSTRUCTIONS

AND

PARTS MANUAL

STEPPER MODULE

BUG-9870 120 VAC

BUG-9872 240 VAC

BUG-9874 42 VAC

Please record your equipment identication information below for future reference. This information can be

found on your machine nameplate.

Model Number:

Serial Number:

Date of Purchase:

Whenever you request replacement parts or information on this equipment, always supply the information

you have recorded above.

LIT-STPR-IPM-0415

Bug-O Systems is guided by honesty, integrity and

ethics in service to our customers and in all we do.

A DIVISION OF WELD TOOLING CORPORATION

280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA 15317-9564 USA

PHONE: 412-331-1776 http://www.bugo.com FAX: 412-331- 0383

Page 2

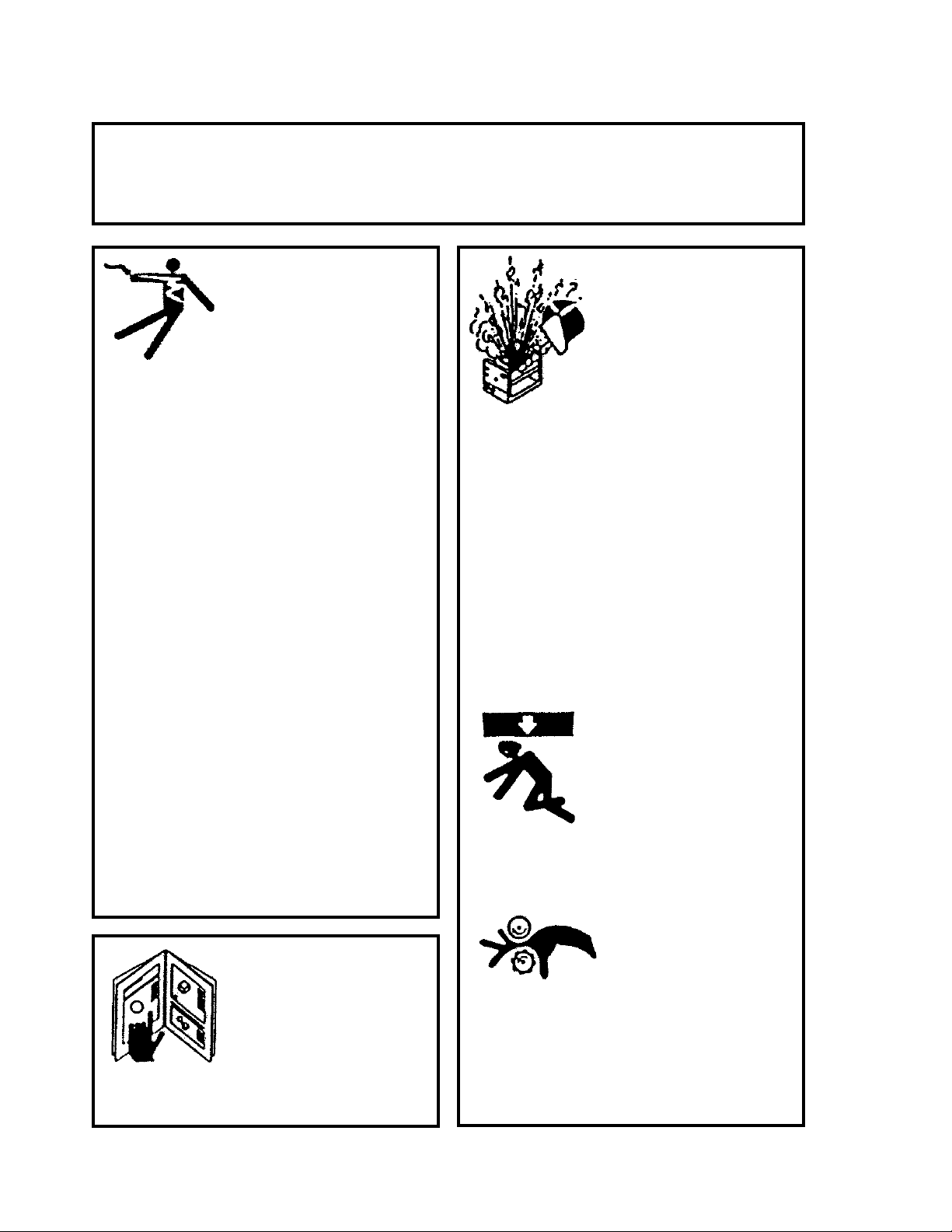

SAFETY

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY

ELECTRIC SHOCK can kill.

1) The equipment is not waterproof.

Using the unit in a wet environ-

ment may result in serious injury.

Do not touch equipment when wet

or standing in a wet location.

2) The unused connectors have

power on them. Always keep the

unused connectors covered with

the supplied protective panels.

Operation of the machine without

the protective panels may result in

injury.

QUALIFIED INDIVIDUALS.

EQUIPMENT DAMAGE

POSSIBLE.

1) Do not plug in the power cord without

rstverifyingtheequipmentisOFF

and the cord input voltage is the same

as required by the machine or serious

damage may result.

2) Always verity both the pinion and

wheels are fully engaged before apply ing power or equipment damage may

occur.

3) Never open the equipment without

rstunpluggingthepowercordor

serious injury may result.

4) Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

5) Never remove or bypass the equip ment power cord ground. Verify the

equipment is grounded in accor dance with all applicable local and

national electrical safety codes. If

none exist, use International Electric

Code (IEC) 950.

READ INSTRUCTIONS.

3) Do not leave the equipment

unattended.

4) Remove from the work site and store in

a safe location when not in use.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faultyorcarelessuserinstallationis

possible. As a result, never stand or

walk underneath equipment.

MOVING PARTS can

cause serious injury.

1) Never try to stop the pinion from mov ing except by removing power or by

using the STOP control.

Read the instruction manual before

installing and using the equipment.

2

2) Do not remove any protective panels,

covers or guards and operate equip ment.

Page 3

HIGH FREQUENCY WARNINGS

SPECIAL PRECAUTIONS ARE REQUIRED WHEN USING PLASMA,

TIG OR ANY WELDING PROCESS THAT USES HIGH FREQUENCY

TO STRIKE AN ARC.

WARNING: HIGH FREQUENCY CAN EFFECT MACHINE

OPERATION AND THEREFORE, WELD QUALITY.

Read the precautions below before installing and using the equipment.

PRECAUTIONS:

1) Some plasma or welding cables are strong sources of high frequency interference.

NEVER lay a plasma or welding cable across the controls of the machine.

2) Always physically separate the plasma or welding cable leads from the

machinecables.Forexample,theplasmaorweldingcableleadsshould

NEVER be bundled with a pendant cable or the machine power cord. Maximize

the separation between any machine cables and the plasma or welding cables.

3) Strictlyfollowthegroundingproceduresspeciedfortheplasmaorwelding

unit. NOTE: Some plasma and welding units produce exceptionally large

amounts of high frequency noise. They may require a grounding rod be

driven into the earth within six feet (2 meters) of the plasma or welding unit to

become compatible with an automatic cutting or welding process.

4) If the high frequency is produced using a spark gap, adjust the points so the

gap is as small as possible. The larger the gap, the higher the voltage and

the higher the interference.

5) Some plasma or welding units will inject high frequency interference into the

AC power line. Use separate power line branches whenever possible to power

the plasma or welding source and the machine. Do not plug them into the

same outlet box.

6) High frequency noise may enter the machine through the plasma or welding

supply remote contactor leads. Some plasma and welding sources can

produce noise spikes of up to several thousand volts. These sources are not

compatible with automated cutting and welding equipment. It is recommended

that the remote contactor leads on these plasma or welding sources not be

connected to the machine. An alternate solution is to purchase a separate

remote contactor isolation box.

3

Page 4

STEPPER MODULE

BUG-9870 120 VAC

BUG-9872 240 VAC

BUG-9874 42 VAC

INSTRUCTIONS AND PARTS MANUAL

TABLE OF CONTENTS

PAGE

5.............. Introduction / Technical Data / Items Supplied / Specications

6.............. Setup

6.............. BUG-9875 Stepper Module Switch Assembly / Parts List / Wiring Diagram

7.............. Operating Instructions

8.............. BUG-987X Stepper Module / Exploded View

9.............. BUG-987X Stepper Module / Parts List

10............ Wiring Diagram / Electrical Component Chart

11 ............ Troubleshooting

12............ Warranty

4

Page 5

INTRODUCTION

The BUG-O Stepper Module is an adjustable, timed output, power control, that is typically used to

overlay the surface of a shaft mounted in a lathe or on turning rolls where a weld bead is continuously

laid down, side by side, with each revolution.

Advance of the weld bead is a function of how long the BUG-O, or other tractor, is powered by the

Stepper Module when limit switch is activated and the speed of the BUG-O.

TECHNICAL DATA

Voltages: BUG-9870 120/VAC/50-60Hz/1Ph

BUG-9872 240/VAC/50-60Hz/1Ph

BUG-9874 42/VAC/50-60Hz/1Ph

Output Current

Capacity: 3.25 AMPs

Net Weight: 3.5 lbs. (1.5 kg)

L W H

Dimensions: 5.75" x 5.75" x 3.5"

(147 mm x 147 mm x 89.3 mm)

Timer range: 0.1 to 9.9 seconds

ITEMS SUPPLIED

Complete Stepper Module Assembly including one (1) BUG-9875 Stepper Module Switch Assembly

with 8' (2.4 m) long cable.

SPECIFICATIONS

Set time is displayed digitally as #.# and ranged from a minimum setting of 0.1 to a maximum setting of

9.9 seconds.

The Limit Stitch must be securely mounted in-line with a trip mechanism (such as a weld bead, screw

head or ag) that will actuate the limit switch once per revolution of the part. This trip mechanism

actuates the limit stitch and powers the BUG-O to move. Based on the Stepper Module’s set time and

the speed setting on the BUG-O tractor, the BUG-O will move and stop, advancing the weld. Welding

does not stop when the BUG-O moves.

This sequence continues until the operator manually stops the BUG-O and/or the welding process.

NOTE: Limit Switch must be “released” to reset for the next sequence. If the limit switch is not

“released”, the BUG-O will not advance. Check setup and conrm the limit switch resets.

5

Page 6

SETUP

Mount Stepper module to the BUG-O tractor using two (2) ¼-20 x screws, hex head, socket head or

cap screws (not supplied), using the mounting holes on the BUG-O carriage.

Mount Limit Switch to work where a trip mechanism will actuate the limit switch with each revolution of

the work piece. “Trip” can be a screw head, ag, spot weld or any other item that will activate the limit

switch / BUG-O. Mounting brackets used to install the Limit Switch are of your own make or purchase

that is appropriate to the specic application.

Plug power cord of Stepper Module into main power supply.

BUG-9875 STEPPER MODULE SWITCH ASSEMBLY / PARTS LIST / WIRING DIAGRAM

PART NO. QTY DESCRIPTION

900-4-001 96" Power Cord, SJO 18/2-250,

300V

BUG-1417 1 Cross Roller Plunger Actuated

BUG-9217-P 1 Cord Grip

BUG-9857 1 Cable Connector, 2-7, M

6

Page 7

OPERATING INSTRUCTIONS

Now that limit switch is mounted, screw the amphenol end of the limit switch cable into the amphenol

connector on the Stepper Module. The Stepper Module is mounted to the BUG-O tractor, BUG-O tractor is plugged into the power cable of Stepper Module. Input power is connected to Stepper Module. It

is time to test set-up.

Turn timer adjustment to display 3 seconds (3.0), this is an arbitrary value for this testing. Without turning your lathe or turning rolls on, manually trigger the limit switch, make sure to completely release the

limit switch (see “NOTE” below). The BUG-O should move until the relay completes the timed cycle,

then stops. Now, trigger the limit switch a second time, the BUG-O should move the same distance and

stop. Timer adjustment can now be set to desired time.

Timer Adjustment

Display

NOTE: If the limit switch is not completely released, the

timer will not reset. If not completely released activating

the limit switch will not result in the BUG-O moving.

Make certain that the limit switch mount will allow the

limit switch to completely reset. Revise the mounting or

adjust the limit so that the limit switch resets.

7

Page 8

BUG-987X STEPPER MODULE / EXPLODED VIEW

7

1

2

14

31

27

28

32

9

21

23

29

30

4

33

11

24

30

8

23

17

18

34

19

5

3

13

15

16

22

11

26

20

29

22

35

25

10

36

8

Page 9

BUG-987X STEPPER MODULE / PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 18" 900-4-019 16/3 SJTOW 300V, Pvc

2 1 BUG-2924 Reset Seal, Transparent

3 1 BUG-2929 Circuit Breaker 4 A

4 1 BUG-9216 Cord Grip

5 1 BUG-9453 V-Lock Power Inlet

6* 1 See pg. 10 V-Lock Power Cord

7 1 See pg. 10 Receptacle

8 1 BUG-9856 Panel Connector, 2-T, F

9 1 BUG-1338 Nameplate

10 1 BUG-9866 Stepper Base Plate

11 1 BUG-9871 Stepper Mod Enclosure

12 1 BUG-9875 Stepper Module Switch Assembly

13 4 FAS-0104 4-40 x 3/8 Pan Head, Black

14 2 FAS-0235 Rnd Hd Scr 10-24 x 1/2

15 1 MDS-1011 Display Bezel

16 1 MDS-1013 Display Filter

17 1 MDS-1018 Knob Straight Knurl, Black

18 1 MDS-1046 Knob Seal (Black)

19 1 MDS-1052 10K Potentiometer

20 4 MET-0143-SS Pan Hd Phil Scr M3 x 10

21 1 MET-0559-SS Soc Hd Cap Scr M4 x 20

22 6 MET-0943 Flt Hd Soc M3 x 10

23 6 MET-1340-SS M3 Hex Nut

24 1 MET-1350-SS M4 Hex Nut

25 1 See Chart Digital Stepper Module

26 4 SCF-1001 4-40 Self-Clinching Nut

27 2 WAS-0230 #10 Sae Flat Washer

28 2 Was-0232 #10 Split Lock Washer

29 6 WAS-5540-SS M3 Washer

30 6 WAS-5541-SS M3 Lock Washer

31 1 WAS-5550-SS M4 Washer

32 1 WAS-5551-SS M4 Lock Washer

33 2 See Chart Voltage Label

34 1 BUG-2005 Label, Bug-O

35 2 FAS-0559 Soc Hd Cap 1/4- 20 x 1

36 2

FAS-1351 Hex Nut 1/4- 20

* = Not Shown

9

Page 10

BUG-987X STEPPER MODULE / WIRING DIAGRAM

ELECTRICAL COMPONENT CHART

ITEM* DESCRIPTION BUG-9870 120

6 V-Lock Power Cord BUG-9454 BUG-9454-240 BUG-9454-42

7 Receptacle BUG-2847 BUG-9594 BUG-2847

25 Digital Stepper Module PCB-1219 PCB-1219 PCB-1219-42

33 Voltage Label BUG-9234 BUG-9233 BUG-9492

3 Circuit Breaker BUG-2929

5 V-Lock Power Inlet

8 Panel Connector BUG-9856

12 Limit Switch in BUG-9875

Stepper Module Switch Assembly

19 Potentiometer MDS-1052

* See Exploded View for Item Number relations

10

VAC

BUG-9872

240 VAC

BUG-9453

BUG-9454

BUG-1417

BUG-9874

42 VAC

Page 11

TROUBLESHOOTING

PROBLEM

Unit will not

move.

Weld beads

are spaced

too far

apart.

POSSIBLE CAUSE TEST BASE SYSTEM TEST PROCEDURE / REMEDY

Mechanical checks: A1

A2

A3

Electrical checks: B1

B2

B3

B4

B5

Stepper Module checks: C1

C2

Tractor speed

Timer settingD1D2

Make certain that there are no obstructions preventing

movement.

Make certain that wheels of carriage are properly installed

on BUG-O Rail.

Make certain that Pinion and Rack are properly engaged

and locked in place.

Proper Power is supplied to BUG-O.

BUG-O is turned “ON.”

BUG-O direction switch is set to move and in proper

direction.

Display on Stepper Module is illuminated.

Reset BUG-O Circuit Breaker.

Make certain that “FLAG” is actuating limit switch and that

limit switch has room to reset.

With welder off, turn speed of BUG-O to mid range and set

Timer to display 1.0 (1 second) and activate limit switch.

Slow speed of BUG-O.

Reduce Timer setting. This bring beads closer together.

Weld bead

is not

spaced far

enough

apart.

Tractor speed

Timer settingE1E2

Increase speed of BUG-O.

Increase Timer setting. This will move weld bead further.

11

Page 12

WARRANTY

Model _____________________________

Limited 3-Year Warranty

For a period ending one (1) year from the date of invoice, Manufacturer warrants that any new machine or part

is free from defects in materials and workmanship and Manufacturer agrees to repair or replace at its option, any

defective part or machine. HOWEVER, if the invoiced customer registers the Product Warranty by returning the

Warranty Registration Card supplied with the product within 90 days of the invoice date, or by registering on-line at

www.bugo.com, Manufacturer will extend the warranty period an additional two (2) years which will provide three

(3) total years from the date of original invoice to customer. This warranty does not apply to machines which, after

Manufacture’s inspection are determined by Manufacturer to have been damaged due to neglect, abuse, overloading, accident or improper usage. All shipping and handling charges will be paid by the customer.

The foregoing express warranty is exclusive and Manufacturer makes no representation or warranty (either express or implied) other than as set forth expressly in the preceding sentence. Specifically, Manufacturer makes

no express or implied warranty of merchantability or fitness for any particular purpose with respect to any goods.

Manufacturer shall not be subject to any other obligations or liabilities whatsoever with respect to machines or parts

furnished by Manufacturer.

Manufacturer shall not in any event be liable to Distributor or any customer for any loss of profits, incidental or consequential damages or special damages of any kind. Distributor’s or customer’s sole and exclusive remedy against

Manufacturer for any breach of warranty, negligence, strict liability or any other claim relating to goods delivered

pursuant hereto shall be for repair or replacement (at Manufacturer’s option) of the machines or parts affected by

such breach.

Serial No. __________________________

Date Purchased: ____________________

Where Purchased:___________________

Distributor’s Warranty:

In no event shall Manufacturer be liable to Distributor or to any customer thereof for any warranties, representations or promises, express or implied, extended by Distributor without the advance written consent of Manufacturer,

including but not limited to any and all warranties of merchantability or fitness for a particular purpose and all warranties, representations or promises which exceed or are different from the express limited warranty set forth above.

Distributor agrees to indemnify and hold Manufacturer harmless from any claim by a customer based upon any

express or implied warranty by Distributor which exceeds or differs from Manufacturer’s express limited warranty

set forth above.

HOW TO OBTAIN SERVICE:

If you think this machine is not operating properly, re-read the instruction manual carefully, then call your

Authorized BUG-O dealer/distributor. If they cannot give you the necessary service, write or phone us to

tell us exactly what difculty you have experienced. BE SURE to mention the MODEL and SERIAL numbers.

12

Loading...

Loading...