Page 1

BUFFALO FILTER

Smoke Evacuation Systems

SERVICE MANUAL

PlumeSafe® Whisper

TM

602

Smoke Evacuation System

SM9600 $5.00

April 15,1999

Page 2

BUFFALO FILTER

Smoke Evacuation Systems

Buffalo Filter

595 Commerce Drive

Buffalo, NY 14228

(716) 835-7000 • (800)323-2324

FAX: (716) 835-3414

Email: info@buffalofilter.com

Web: www.buffalofilter.com

Page 3

BUFFALO FILTER

Smoke Evacuation Systems

Table of Contents

Mode of Operation ………………………………………………………………..2

Section A.

Cleaning & Mainten ance ...................................................................................... 3

Section B.

Regulations and Compliance................................................................................. .4

Section C.

Periodic Inspection ............................................................................................... 6

Section D.

Calibration & Adjustments..................................................................................... 7

Section E.

Troubleshooting................................................................................................... 8

Section F.

System Operation & Instructions ........................................................................... 9

Section G.

System Diagram..................................................................................................16

Section H.

Electrical Schematics ...........................................................................................19

Section I.

Disassembly/Assembly Instructions.......................................................................22

Section J.

Systems Specifications.........................................................................................24

Section K.

Ordering Parts ....................................................................................................24

Section L.

Replacement Parts List ........................................................................................25

Section M.

Terms & Warranty...............................................................................................30

Page 4

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

2

Mode of Operation

The PlumeSafe Whisper 602 Smoke Evacuation Filtration System is designed to remove smoke

and noxious odors from the smoke plume generated while performing laser and electrosurgical

procedures.

These evacuation systems are designed with high suction and high flow rate centrifugal action

pumps. The ultra-quiet motor is used to draw the smoke plume from the surgical site through the

vacuum tubing and into the ViroSafe® filter where the smoke plume is purified by a series of

filters and carbon. A single disposable filter is used to simplify the installation and removal during

filter changes. This filter is completely enclosed to further protect the healthcare personnel from

potential contamination. The ViroSafe® filter contains four different filter stages within a single

housing to decontaminate the smoke plume.

The ViroSafe® filter is used with the PlumeSafe Whisper 602 Smoke Evacuation System.

The first stage of filtration is a pre-filter whose function is to trap and remove gross particulate

and casual fluid, while capturing some micro-organisms.

The second stage of filtration is a VLSI (Very Large-Scale Integrated) grade ULPA (Ultra Low

Penetration Air) high-tech, patented1 filter designed to capture particulate and micro-organisms

down to 0.01µm at an efficiency of 99.99995%. Each ULPA filter is pre-tested and certified

before use and is impregnated with a chemical agent.

The third stage of filtration uses virgin coal grade activated carbon for the removal and

adsorption of odors and toxic gases produced by the burning of tissue. These harmful gases are

a health hazard to those healthcare workers who breathe them. For this reason, the highest

quality virgin coal grade activated carbon is used. This activated carbon preferentially removes

toxic organic gases rather than water vapor.

The fourth stage of filtration is an expanded foam and filtration media, both of which are also

impregnated with a chemical agent, used to trap activated carbon fines from migrating out of the

filter.

1

U.S. Patent: #5,874,052

Page 5

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

3

Section A.

Cleaning & Maintenance

The procedure for cleaning and maintenance of the PlumeSafe Whisper 602 is as follows:

1. Clean the entire surface of the system with an appropriate surface disinfectant after each

procedure. (Please avoid abrasive cleaners)

2. Clean the filter housing with an appropriate surface disinfectant after each procedure. (Please

avoid abrasive cleaners)

3. Replug filter after each use.

4. Dispose the vacuum hose and all 'single' use disposable parts after each procedure. Dispose

of in the appropriate manner for your locale.

5. Change the ViroSafe® filter at the prescribed number of hours for the filter being used.

Failure to change the filter will affect the performance of the system.

Page 6

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

4

Section B.

Regulations and Compliance

The operational information contained in this section is intended for the customer review of

compliance issues. The information pertains to the use of Buffalo Filter products both

domestically and internationally:

1. The PlumeSafe Whisper 602 complies with IEC601.1 electrical specifications in the following

systems: PlumeSafe Whisper 602 - 120V/60Hz, 100V/50Hz & 60Hz , 220V/50 Hz,

240V/50Hz

2. The PlumeSafe Whisper 602 Smoke Evacuation System(s) has a classification under the

UL2601-1, Clause 5.1 of : CLASS 1 Equipment

3. The PlumeSafe Whisper 602 Smoke Evacuation System(s) has an identification under the

UL2601-1, Clause 5.2 according to the degree of protection against electric shock: Type B

Equipment

4. The PlumeSafe Whisper 602 Smoke Evacuation System(s) has an identification under the

UL2601-1, Clause 5.3 according to the degree of protection against harmful ingress of water:

Ordinary Equipment (enclosed equipment without protection against ingress of

water)

5. The PlumeSafe Whisper 602 Smoke Evacuation System(s) has a classification under the

UL2601-1, Clause 5.4 according to the method of sterilization or disinfection recommended by

BUFFALO FILTER: Unplug System. Wipe system with a damp cloth containing mild

surface disinfectant solution, or soapy water. Wipe dry with a clean cloth. Do not

steam sterilize or autoclave.

6. The PlumeSafe Whisper 602 Smoke Evacuation System(s) has a classification under the

UL2601-1, Clause 5.5 according to the degree of safety of application in the presence of

flammable anesthetic mixture with air or with oxygen or nitrous oxide: Equipment not

suitable for use in the presence of Flammable Anesthetic mixture with air or with

oxygen or nitrous oxide.

7. The PlumeSafe Whisper 602 Smoke Evacuation System has a classification under the UL26011, Clause 5.6 according to the mode of operation: Continuous Operation

8. The fuses used on the circuit board are to be serviced by an authorized Buffalo Filter

technician as follows: 120V/60Hz, 100V/50 Hz & 60 Hz, 220V/50Hz and 240V/50Hz

use a 0.0625A/250V fuse

9. The PlumeSafe Whisper 602 Smoke Evacuation System and all filters and accessories are not

intended for contact with patients.

10. The PlumeSafe Whisper 602 Smoke Evacuation System is in full compliance with the Medical

Devices Directive II, Council Directive 93/42/EEC of 14 June 1993

11. The PlumeSafe Whisper 602 Smoke Evacuation System complies with the City of Los

Angeles Electrical Codes.

Page 7

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

5

Cautions and Warnings

Please note that all Cautions and Warnings should be read and understood prior to any operation

of this equipment. Only personnel who have been properly trained in its operation should operate

the PlumeSafe Whisper 602 Smoke Evacuation System.

A "Warning" is a situation in which improper operation of the system could adversely affect the

operator of the equipment or the patient.

A "Caution" is a situation in which the PlumeSafe Whisper 602 or other equipment could be

damaged by improper operation.

WARNINGS:

• The ViroSafe

accordance with your local codes or regulations. These filters may be disposed or incinerated

whichever is appropriate for your locale.

• The ViroSafe

used with the PlumeSafe Whisper 602 system, should not be used for more than is prescribed

in the filter instructions. Failure to change these filters may result in decreased filter efficiency

and contamination of the electric motor, vacuum pump, and sound absorbing components

within the system.

• If casual fluid is expected to be introduced into the ViroSafe

Whisper 602 system, fluid collection devices must be installed with the vacuum hose

assembly. Failure to install a fluid collection device could cause filter blockage and electrical

damage.

CAUTIONS:

®

filters are completely disposable. Please handle these disposable filters in

®

filter should be changed according to the instructions. The ViroSafe® filter,

®

filter and/or the PlumeSafe

• Using any other filters or accessories not manufactured by Buffalo Filter may cause damage

to the system and will be cause for voiding the warranty.

• DO NOT block either the tubing or the filter. If either becomes clogged or occluded, or if the

airflow through either is significantly restricted, the motor/blower could overheat and cause

the system to fail. The failure may be only a blown circuit but could cause complete motor

failure.

• When suctioning fluids into the fluid collection container with any system, it is recommended

that a 1/4" or smaller wand or silicone/PVC tubing be used at the patient end. Using anything

larger than 1/4" tubing may offer flow rates that are too high for suctioning fluids in and

around the surgical area.

• Care must be exercised in the installation of all hoses, adapters and suction canisters. Failure

to follow the procedures outlined in this manual may result in overheating of the motor and

be cause for voiding the warranty. Wear protective equipment and use "Universal

Precautions" when handling used equipment.

Page 8

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

6

Special Note:

Use "Universal Precautions" procedure whenever

Section C.

Periodic Inspection

The PlumeSafe Whisper 602 Smoke Evacuation System is engineered to provide the end user

with many years of trouble free service. In order to maintain the system in top operating order

the system should be inspected according to the following schedule:

AFTER EACH USE:

1. Check filter life indicator, anticipate filter replacement.

2. The system should be inspected for signs of physical damage and fluid or solid contamination

after each use.

3. The filter should be inspected for physical damage, fluid or solid contamination, and filter life

after each use. Please replace the filter if filter life has been expended.

ONCE A WEEK:

1. Check the "Service" light on the membrane keypad. If the light is lit, contact Buffalo Filter for

service instructions.

2. Check the filter for physical damage, fluid or solid contamination, and filter life. If filter life

has been expended, please replace the filter.

3. Examine the entire system for physical damage. Contact your local distributor or Buffalo Filter

for service instructions if damaged.

YEARLY INSPECTIONS:

1. Check the "Service" light on the membrane keypad. If the light is lit, contact Buffalo Filter for

service instructions.

handling contaminated filters or smoke evacuation

equipment.

Page 9

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

7

Section D.

Calibration & Adjustments

The PlumeSafe Whisper 602 Smoke Evacuation System is completely adjusted at the time of

manufacture so that no additional adjustment to the system is necessary.

There is no need to calibrate any part of the PlumeSafe Whisper 602 Smoke Evacuation System,

all calibration is performed at the factory.

If the "Service" light is illuminated at any time, contact your local distributor or Buffalo Filter for

service instructions.

Page 10

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

8

Section E.

Troubleshooting

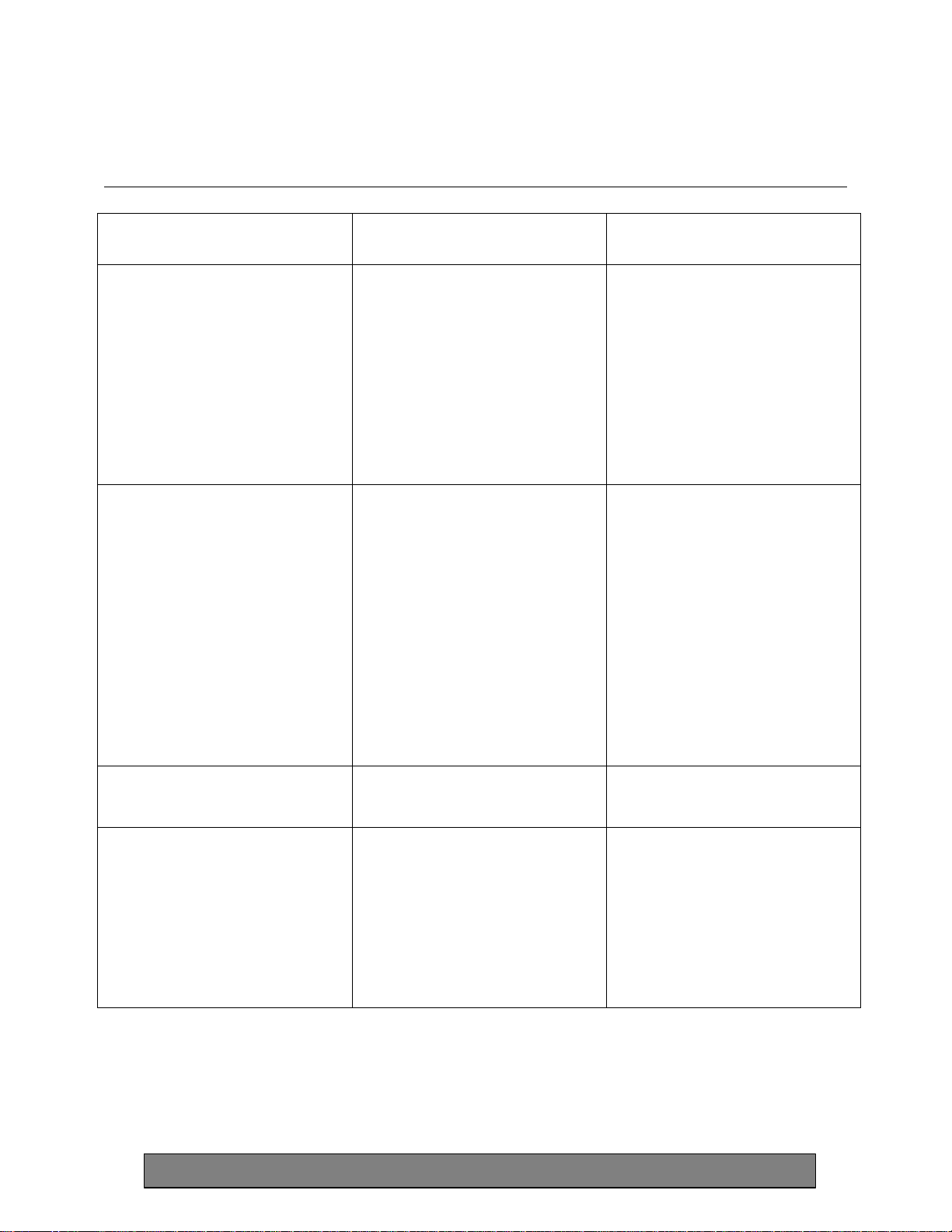

Problem Potential Cause Corrective Action

1. Smoke Evacuation System

is operational but suction is

minimal or none.

1. Smoke Evacuator System

does not function even

though "ON" button is

pressed.

1. Filter not seated completely

2. Filter clogged

3. Vacuum hose clogged

4. Motor/Blower obstructed

1. Not plugged into electrical

outlet or system not

powered up with switch

2. Circuit breaker(s) tripped

3. Footswitch/Remote Switch

plugged in

4. Electronic system failure

1. Re-install ViroSafe® filter,

press firmly into place and

inspect for obstructions

2. Replace ViroSafe® filter

3. Check or replace hose

4. Contact your local

distributor or Buffalo Filter

1. Check power outlet or

check to be sure system is

powered up with switch on

side

2. Reset circuit breaker(s) on

back of system

3. Unplug footswitch or

remote switch

4. Contact your local

distributor or Buffalo Filter

2. "Service" light is lit. 1. Motor/Blower needs

3. Motor/Blower operated

intermittently.

servicing.

1. Incorrect power to system

2. Electronic system failure

1. Contact your local

distributor or Buffalo Filter

1. Check the wall socket to be

sure the correct power is

supplied to system.

2. Contact your local

distributor or Buffalo Filter

Page 11

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

9

Section F.

System Operation & Instructions

Operation of the PlumeSafe Whisper 602 Smoke Evacuation Filtration System is as follows:

1. Remove the Smoke Evacuator from the packaging and inspect for any damage that may have

occurred during shipment. If any damage is present, please notify carrier immediately for

damage assessment.

2. Inspect the filter section of the system to insure that no packing debris has fallen into the

filter chamber. Remove any debris.

3. Install a ViroSafe® filter per the directions enclosed in the filter box.

4. Connect any adapters, hoses, tubing, electrosurgical pencils, etc. to complete the installation.

5. Electrically connect the system into a grounded 120V/60Hz electrical outlet. (If international,

use appropriate voltage/frequency and a grounded connection.)

6. Press the ON/OFF rocker switch on the side of the system to the ON position.

7. Press the ON/OFF button on the membrane key panel to activate the motor.

8. Press the suction control UP ARROW button to 100%, then press the vacuum adjust DOWN

ARROW button to 20%. Repeat to assure smooth operation.

9. Press the UP or DOWN ARROW buttons on the suction adjust again, both up or down, to

verify the smooth operation of the motor speed from high to low speed and back again.

WARNING: If casual fluid is expected to be introduced into the ViroSafe® Filter or

PlumeSafe Whisper 602 system, fluid collection devices must be

installed with the vacuum hose assembly. Failure to install a fluid

collection device could cause filter blockage and electrical damage.

Page 12

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

10

Note:

Please make certain to read these instructions before installing or operating

this equipment. Failure to do so could result in improper usage, damage to

FILTER LIFE REMAINING

Electronic System Controls

100%

FOOT

SWITCH

80%

60%

40%

SUCTION

CONTROL

100% 80% 60%

40%

20% 0%

REPLACE NEW

20%

Electronic system controls on the PlumeSafe Whisper 602 products are easy to understand and

simple to use. The membrane control panel on the front of the smoke evacuation filtration

system is identical for domestic and international systems. The membrane control panel is used

to control the power, motor speed and the filter life indicator.

the system, and/or personal injury.

The following are descriptions of the membrane panel controls for the PlumeSafe Whisper 602

system:

• POWER

There are two ON/OFF switches on each system. The ON/OFF switch that disables the

electrical power to the system is located on the side of the system. The ON/OFF switch for

the electronic membrane control panel is located on the front of the systems.

To turn the system electrical power on, press the rocker switch on the side of the system to

the ON position. To turn the system electrical power OFF press the rocker switch to the OFF

position.

To turn the system motor ON, press the ON/OFF button on the membrane panel until the

motor is running. To turn the system motor OFF, press the ON/OFF button again.

POWER

ON

OFF

FILTER LIFE

RESET

SERVICE

Page 13

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

11

Note:

On any Buffalo Filter smoke evacuator, there are two circuit breakers for the "hot"

• SUCTION CONTROL

The SUCTION CONTROL for air suction is adjusted by way of the internal speed

microprocessor controller. The control UP ARROW button can be pressed to increase the air

suction and DOWN ARROW button can be pressed to decrease the air suction. Control of the

air suction can be done at any time with or without the motor running. Setting the air suction

control at the lowest setting that still removes the smoke plume will lower the system noise.

Each time either arrow is pressed the air suction will increase or decrease by 10%. When two

lights are lit on the flow control panel the actual airflow is the percentage between the two lit

numbers.

• FOOTSWITCH/REMOTE SWITCH

A footswitch or remote switch can be added to the system by simply plugging in a Buffalo

Filter footswitch (P/N FS10003) or a Buffalo Filter Remote Switch Activator (P/N RSA1002)

into the electrical jack on the side of the system.

When the footswitch is plugged in, the system may be turned on or off by pressing the

footswitch pedal once for each operation. When not using the footswitch, please unplug and

store away. For footswitch operation the power switch needs to be in the ON position. When

the footswitch is plugged in, the light on the membrane control panel entitled

FOOTSWITCH/REMOTE SWITCH will light to let the operator know the footswitch or remote

switch is active.

When using the remote switch activator, please refer to the instruction sheet that

accompanies that product.

• CIRCUIT BREAKER

Two (2) 15 AMP for domestic or two (2) 8 AMP for international circuit breakers are installed

as standard on each system to electrically protect both the system and the operator from

damage or injury. If the system is overheated or if there is an electrical surge in the system

the circuit breaker(s) will "trip" and the system will not operate. In order to re-start the

system press the circuit breaker button into its original position.

and "common" wires. Both circuit breakers act in the same manner. If either circuit

breaker is tripped, press the circuit breaker button back into its original position.

• FILTER LIFE REMAINING INDICATOR

The filter life indicator on the membrane control panel allows the operator to know the status

of the life of the filter being used The filter life indicator for the PlumeSafe Whisper 602

system is factory set for 6 hours. These settings correspond to the actual filter life of the

ViroSafe® filter for any system. After any filter is changed, the RESET button must be fully

reset for the next filter. Pressing, and holding down the reset button for 5 seconds, can

accomplish this. If the reset button is accidentally pressed at any time, the filter life indicator

will not reset unless the button is held down for 5 seconds.

Page 14

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

12

Ø PlumeSafe Whisper 602:

The filter life indicator button labeled ‘RESET HOLD’ must be pressed and held for 5

seconds for the filter life indicator to fully reset. Install a ViroSafe® filter into the

PlumeSafe Whisper 602 system per the installation instruction contained in this

operator's manual. When the PlumeSafe Whisper 602 system is turned on, the filter

life indicator will light up all the GREEN, AMBER and RED LEDs indicating that there is

still adequate life in the filter. When the filter has been used for 4 hours, the AMBER

and RED lights will be illuminated to indicate that the ViroSafe® filter is nearing the

end of its useful life. After 6 full hours have elapsed, the RED light will start blinking to

indicate that the filter has expended it useful life and needs to be changed. At this

time the ViroSafe® filter should be changed according to the removal instructions

included in the operator's manual included with your PlumeSafe Whisper 602.

• SERVICE LIGHT INDICATOR

The RED service light indicator on the front membrane panel will illuminate after 500 hours of

operation. When this occurs, all non-essential membrane panel functions except the on/off

switch and the motor speed control for continuing the system operation will become nonoperational until servicing can be completed.

WHEN THE SERVICE LIGHT COMES ON, PLEASE CONTACT YOUR LOCAL

DISTRIBUTOR OR BUFFALO FILTER FOR SERVICE INSTRUCTIONS ON THE

SYSTEM.

Page 15

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

13

10 Foot Power

Footswitch

Footswitch Installation/Operation

71mm(2.80")

27mm(1.86")

1. Remove the Footswitch from the packaging and inspect for any damage that may have

occurred during shipping.

2. Turn system off before installing Footswitch.

3. Connect the plug to the outlet on the system labeled "Footswitch". The PlumeSafe Whisper

602 system has a Footswitch inlet jack on the side of the system.

4. Turn the system ON to activate the Footswitch. The footswitch pedal will automatically

become active once the plug is inserted into the footswitch socket on the system, and the

light on the membrane control panel will become illuminated.

5. Press the footswitch pedal once to activate the system.

6. Press the UP or DOWN ARROWS of the vacuum adjust to the desired air suction.

7. Press the footswitch again to deactivate the system.

If the footswitch is not in use, remove the footswitch and store away until needed again.

96mm(3.78")

Page 16

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

14

Remote Switch Activator Installation/Operation

The Buffalo Filter Remote Switch Activator (RSA1002) is designed for use with any brand of

Electrosurgical Generator (ESU) that incorporates a Buffalo Filter Smoke Evacuation System. The

RSA1002 operates essentially in the same manner as a footswitch; the smoke evacuator is turned

on and off by pressing the "CUT" or "COAG" button on the ESU pencil.

The RSA1002 uses a patent pending2 technology to sense the harmonic vibrations emitted by all

electrosurgical generator units. These vibrations are recognized by the RSA1002, and will activate

the smoke evacuator when the vibrations are present. Other operating room noises, tones,

vibrations, beeps and personal loud noises should not activate the RSA1002.

Instruction Overview

1. Remove RSA1002 from the package, check for damage.

2. Clean area on ESU with alcohol (apply caution when using flammable liquids) before

installing RSA1002. Remove adhesive backing and place on ESU according to ESU "diagram"

for your particular ESU generator.

3. Turn on Smoke Evacuation and adjust suction control to 50%, turn on ESU and adjust

speaker volume to 50%.

4. Plug in the RSA1002 into jack labeled "Footswitch" or "Remote Switch" on the smoke

evacuator.

5. Adjust the RSA1002 for both "CUT" & "COAG"; see Adjustment Instructions that come with

the remote switch activator.

6. Operate the smoke evacuator remotely with the ESU hand control pencil by pressing either

"CUT" or "COAG" button.

Refer to the instructions that accompany the Remote Switch Activator for additional

installation instructions and detailed placement of the Remote Switch.

If the Remote Switch Activator is not in use, remove the Remote Switch Activator and store away

until needed again.

2

U.S. Patent Pending: #08/909,902

Page 17

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

15

SYSTEM OPERATION

1. Please follow the instructions for the proper and safe installation of the filter system before

proceeding with the operation of the system. The installation of the disposable ViroSafe®

filter is described in the Operators Manual that accompanied the product.

2. Once the system is properly installed and operating according to the above instructions, the

operator may choose to increase or decrease the amount of suction. Pressing the UP or

DOWN ARROW buttons on the membrane keypad will selection of a higher or lower setting.

The 20% setting is the lowest suction strength and the 100% setting is the highest suction

strength. Any setting in between can be used in order to remove smoke, fumes and toxic

gases from the surgical site. Each pressing of either arrow increases or decreases the suction

setting by 10%.

Note: For the most efficient use of the virgin coal grade activated carbon, please use

the lowest vacuum setting possible. This vacuum setting should be the lowest setting

that clears the surgical field of smoke plume.

3. At any time during the operation of the smoke evacuator, the vacuum can be adjusted to the

desired setting. After setting the suction adjust to the highest setting, if you are still not

clearing the field, this is an indication to change the disposable ViroSafe® filter.

4. When the filter life indicator FLASHES RED, this is an indication that the ViroSafe® filter has

reached the end of its useful life and needs to be changed. Please refer to the instructions

in the operator's manual provided with your Porta PlumeSafe Whisper 602 to properly change

the filter.

If any problems occur during in-service, please refer to Section E - Troubleshooting.

Page 18

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

16

Airflow through the PlumeSafe Whisper 602

Section G.

System Diagram

Page 19

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

17

PlumeSafe Whisper 602 Explosion View

PER

Circuit

Breaker

F

O

O

T

J

A

C

K

234

10111213141516

Plu

meS

a

f

e

1

8

9

6

5

POWER

FOOT

SWITCH

SUCTION

CONTROL

FILTER LIFE REMAINING

FILTER LIFE

100% 80% 60% 40% 20% 0%

RESET

REPLACE

SERVICE

1

SMOKE EVACUATION SYSTEM

S

I

H

W

7

15

1

4

Page 20

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

18

PlumeSafe Whisper 602 Shell Insulation

Page 21

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

19

Section H.

Electrical Schematics

Page 22

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

20

NOTE: Before performing any work on the PlumeSafe Whisper 602 make certain the

system is turned off and the electrical plug has been disconnected from the wall

power outlet.

WARNING: If fluid is expected to be introduced into the ViroSafe® Filter and/or the PlumeSafe

Whisper 602 system, fluid collection devices must be installed with the vacuum

hose assembly. Failure to install a fluid collection device could cause filter blockage

and electrical damage.

CAUTION: Using any other filter or accessory not manufactured by Buffalo Filter may cause

damage to the system and will be cause for voiding the warranty.

Page 23

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

21

Section I.

Disassembly/Assembly Instructions

WARNING: ELECTRICAL SHOCK HAZARD!

Before performing any work on the PlumeSafe Whisper 602 make certain the

system is turned off and the electrical plug has been disconnected from the wall

power outlet.

Please refer to the PlumeSafe Whisper 602 System diagram in the previous section

for details.

DISASSEMBLY INSTRUCTIONS

In order to field service the Buffalo Filter PlumeSafe Whisper 602 Smoke Evacuation System, the

system will need to be disassembled. Read the instructions below before attempting to service

the system.

The disassembly of the PlumeSafe Whisper 602 Smoke Evacuation System is as follows:

1. Turn the system upside down as to expose the base where the four (4) wheels are

mounted.

2. Spaced equally around the inside perimeter of the hexagonal base are six (6) button head

fasteners. Using a 1/8” Allen Wrench remove all six (6) and the base will separate from

the rest of the system.

NOTE: Some earlier systems had six (6) button head fasteners around the outside

perimeter of the shell which will require a 5/32” Allen Wrench.

3. Remove the acoustical insulation from the shell and stack each piece on top of each other

keeping the orientation of each piece the same as inside the system.

NOTE: When reinstalling the insulation it is very important to reinstall in the same way it

was removed. Remember that the insulation not only dampens noise but also has

openings that aid in two critical airflow pathways, cool air in and hot air out. Refer to the

explosion view of the insulation for additional help in reinstalling the insulation.

4. When removing the insulation, some connecting wires to the power entry module on the

back of the system will have to be removed first.

5. The circuit breaker can be removed by first removing the two (2) wires from the back of

the circuit breaker. The removal of the circuit breaker can be accomplished by pressing

the tabs on either side of the breaker and pushing the breaker to the outside of the shell.

Note: The international systems require the removal of two (2) circuit breakers.

6. To remove the power entry module, press the small tabs on the back of the component

and remove from the back of the system.

7. Disconnect all electrical motor leads and using a 1/8” Allen Wrench remove the bolts

holding the motor to the filter basket assembly.

8. Carefully remove the motor from its mount. Next remove the motor mount gasket.

NOTE: The direction of the exhaust airport is critical because during reinstallation it must

Page 24

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

22

point toward the front of the system. The front of the system is where the controller

board is mounted.

9. Using a 3/8” socket with a long extension remove the four (4) nuts that hold the filter

basket in place.

10. Remove the filter basket from the top of the system.

11. Remove the Footswitch/Remote Switch inlet jack by removing the nut on the outside of

the shell with a 1/2" wrench turning counterclockwise. Note: Do not attempt to

disconnect the footswitch wiring from printed circuit board (PCB), as the entire footswitch

jack assembly will be removed with the PCB.

12. For this step, you will need to be electrically grounded. Remove the 5 bolts, type 6-32,

from the circuit board using a #2 Phillips screwdriver or a flat screwdriver for some earlier

production models. Carefully remove the circuit board and place in an anti-static holder.

NOTE: You must be grounded before servicing any part of the controller board

or removing it from the shell. Failure to be grounded when removing the PCB

could cause permanent electrical damage.

13. If the microprocessor needs to be replaced on the controller board you must be grounded

prior to servicing the controller board. Locate the microprocessor on the controller board.

If necessary, using a chip puller, remove the microprocessor from the circuit board.

NOTE: No other components should be removed from the circuit board other

than the microprocessor.

14. If necessary the fuse can be replaced on the controller board by using a fuse puller to

remove the 0.0625 amp fuse from the circuit board. (This is only applicable on newer

models where the circuit board has quick disconnect fuse clips. This is not applicable to

older models where the fuse is soldered to the board).

NOTE: No other components should be removed from the circuit board other

than the fuse.

15. If necessary on all international systems, remove the RFI filter by unscrewing the two (2)

Phillips head fasteners and removing the wires connections.

16. If any of the wheels need to be serviced they can be easily removed as follows: Using a

3/8” nut driver or open end wrench, remove the four (4) nuts from the base of the wheel.

17. Note: Refer to the explosion view of all the components in this Service Manual to correctly

guide you through all of the disassembly/assembly steps.

REASSEMBLY INSTRUCTIONS

For reassembly of the PlumeSafe Whisper 602 Smoke Evacuation System, please

follow the above instructions in reverse order.

Note: Refer to the Electrical Schematic in Section H for the correct wire terminations during

assembly.

Page 25

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

23

Section J.

Systems Specifications

Specifications PlumeSafe

Whisper 602

Buffalo Filter

Part Number

Flow Rate MAX. CFM (LPM)

Motor Rating-CFM

(LPM)

Motor Stages 3 2 2 3

PSW0602 PSW0602/220 PSW0602/240 PSW0602/100

1 1/4" = 40(1133)

7/8" = 33(935)

Buffalo Filter ESU

Pencil = 4.4(125)

110 (3115) 111 (3144) 111 (3144) 110 (3115)

PlumeSafe

Whisper

602/220

1 1/4" = 59(1671)

7/8" = 42(1189)

Buffalo Filter ESU

Pencil = 5(142)

PlumeSafe

Whisper

602/240

1 1/4" = 60(1699)

7/8" = 43(1217)

Buffalo Filter ESU

Pencil = 5(142)

PlumeSafe

Whisper

602/100

1 1/4" = 40(1133)

7/8" = 33(935)

Buffalo Filter ESU

Pencil = 4.4(125)

Static Suction,

inches H2O (mbar)

Electrical Power:

AMPS 5.4 8.0 8.0 5.4

Volts 120 220 240 100

Frequency (Hz) 50 & 60 50 & 60 50 & 60 50 & 60

Dimensions:

Height cm) 20” (50.8) 20” (50.8) 20” (50.8) 20” (50.8)

Width (cm) 14” (35.6) 14” (35.6) 14” (35.6) 14” (35.6)

Length (cm) 14” (35.6) 14” (35.6) 14”(35.6) 14” (35.6)

Weight, lbs. (kg) 28.5 (13.0) 28.5 (13.0) 28.5 (13.0) 28.5 (13.0)

Filter ViroSafe® ViroSafe® ViroSafe® ViroSafe®

Filtration Efficiency 99.99995% 99.99995% 99.99995% 99.99995%

Filtration Rating

75" H2O

(187)

0.01µm 0.01µm 0.01µm 0.01µm

95.2" H2O

(231)

95.2" H2O

(231)

75" H2O

(187)

Page 26

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

24

Section K.

Ordering Parts

Please order all parts, accessories and replacement filters for the PlumeSafe Whisper 602 by

contacting your local distributor or Buffalo Filter directly at:

1-800-343-2324 (US only)

Or

716-835-7000

(If calling internationally, use International Dialing Codes)

FAX: 716-835-3414

E-mail: info@buffalofilter.com

Web Site: http://www.buffalofilter.com

Page 27

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

25

Section L.

Replacement Parts List

PlumeSafe Whisper 602

120V / 50 & 60Hz

# Quantity Part Number Description

1 1

2 1

3 1

4 1

5 1

6 1

7 2

8 1

9 1

10 1

11 1

12 1

13 2

14 1

15 1

16 1

17 1

18 1

19 5

20 1

21 6

22 5

23 2

24 4

25 2

26 24

27 1

28 4

29 1

30 1

31 8

32 1

HOUSING 602W Whisper 602 Housing

MOTOR 120 DC DC Brushless Motor

GSKT MM WSP Gasket for Motor, SC-42 Closed Cell

HANDLEWHISPR Handle For Whisper 602

HANDLE FOAM Foam for Whisper 602 handle

CORD WRAP Cord Wrap for Whisper 602

CIRCUIT 15 US – 15Amp Circuit Breaker

PWR EN MD.08 Power Entry Module (.080")

PCB-DB26 ASY Whisper 602 PCB w/26" jack

CHP W6 Chip W6

PLUG/CORD602 Plug/Cord 12' AEC60, AEC250

WIRE ASSBLY Wire Assembly for Whisper 602 – Complete w/E-Terms

GASKET LED LED Gasket

LBL WHIS S/N Label Kit for Whisper 602

LBL CITY LA Label for City of LA Approval

BOX WHISPER Box for Whisper 602 System

KEYPADBFGRFX Buffalo Filter Membrane Switch Graphics

MEMBRANEBLNK Membrane Blank

BOLT10-32 .5 Bolt 10-32 0.5" SS

BOLT10-32.75 Bolt 10-32 0.75" Long

BOLT6-32 .5" Bolt 6-32 0.5" Long -PAN HD

WASHER #6S Star washer #6 electrical

WASHER 1/4"L Lock Washer 1/4" split ring

WASHER #10F Flat washer #10

NUT JAM10-32 Jam Nut 10-32, Zinc

NUT 10-32 10-32 Lock Nuts S/S

WALL PLATE Wall Plate Suction Canister

WHEELS 2" Whisper 602 Wheels

RUBBER FEET Cylindrical Isolator

INSULKIT WSP Insulation Kit for Whisper 602

ISOLATORS Motor Isolators

MANUAL602/12 602/1202/Whisper/TURBO Operator’s Manual

Page 28

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

26

PlumeSafe Whisper 602

220V / 50 & 60Hz

# Quantity Part Number Description

1 1 HOUSING 602W Whisper 602 Housing

2 1 MOTOR 220/240 Motor 220/240V International

3 1 GSKT MM WSP Gasket for Motor, SC-42 Closed Cell

4 1 HANDLEWHISPR Handle For Whisper 602

5 1 HANDLE FOAM Foam for Whisper 602 handle

6 1 CORD WRAP Cord Wrap for Whisper 602

7 2 CIRCUIT 8 Euro – 8Amp Circuit Breaker

8 1 PWR EN MD.08 Power Entry Module (.080")

9 1 PCB-AC26 ASY Whisper 602 PCB w/26" jack

10 1 CHPW220/50/6 Chip W220/50/6

11 1 PLUG/CORD602 Plug/Cord 12' AEC60, AEC250

12 1 WIRE ASSBLY Wire Assembly for Whisper 602 – Complete w/E-Terms

13 2 GASKET LED LED Gasket

14 1 LBL WSP KIT Label Kit for Whisper 602

15 1 LBL CITY LA Label for City of LA Approval

16 1 BOX WHISPER Box for Whisper 602 System

17 1 KEYPADBFGRFX Buffalo Filter Membrane Switch Graphics

18 1 MEMBRANEBLNK Membrane Blank

19 8 BOLT10-32 .5 Bolt 10-32 0.5" SS

20 1 BOLT10-32.75 Bolt 10-32 0.75" Long

21 5 BOLT6-32 .5" Bolt 6-32 0.5" Long -PAN HD

22 5 WASHER #6S Star washer #6 electrical

23 2 WASHER 1/4"L Lock Washer 1/4" split ring

24 4 WASHER #10F Flat washer #10

25 2 NUT JAM10-32 Jam Nut 10-32, Zinc

26 26 NUT 10-32 10-32 Lock Nuts S/S

27 1 WALL PLATE Wall Plate Suction Canister

28 4 WHEELS 2" Whisper 602 Wheels

29 1 RUBBER FEET Cylindrical Isolator

30 1 INSULKIT WSP Insulation Kit for Whisper 602

31 8 ISOLATORS Motor Isolators

32 1 MANUAL602/12 602/1202/Whisper/TURBO Operator’s Manual

33 1 REF6EHT1 PN#6EHT1

34 1 LBL CE SMALL CE Label Small

Page 29

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

27

PlumeSafe Whisper 602

240V / 50 & 60Hz

# Quantity Part Number Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1 HOUSING 602W Whisper 602 Housing

1 MOTOR 220/240 Motor 220/240V International

1 GSKT MM WSP Gasket for Motor, SC-42 Closed Cell

1 HANDLEWHISPR Handle For Whisper 602

1 HANDLE FOAM Foam for Whisper 602 handle

1 CORD WRAP Cord Wrap for Whisper 602

2 CIRCUIT 8 Euro – 8Amp Circuit Breaker

1 PWR EN MD.08 Power Entry Module (.080")

1 PCB-AC26 ASY Whisper 602 PCB w/26" jack

1 CHP W240/50/6 Chip W240/50/6

1 PLUG/CORD602 Plug/Cord 12' AEC60, AEC250

1 WIRE ASSBLY Wire Assembly for Whisper 602 – Complete w/E-Terms

2 GASKET LED LED Gasket

1 LBL WSP KIT Label Kit for Whisper 602

1 LBL CITY LA Label for City of LA Approval

1 BOX WHISPER Box for Whisper 602 System

1 KEYPADBFGRFX Buffalo Filter Membrane Switch Graphics

1 MEMBRANEBLNK Membrane Blank

8 BOLT10-32 .5 Bolt 10-32 0.5" SS

1 BOLT10-32.75 Bolt 10-32 0.75" Long

5 BOLT6-32 .5" Bolt 6-32 0.5" Long -PAN HD

5 WASHER #6S Star washer #6 electrical

2 WASHER 1/4"L Lock Washer 1/4" split ring

4 WASHER #10F Flat washer #10

2 NUT JAM10-32 Jam Nut 10-32, Zinc

26 NUT 10-32 10-32 Lock Nuts S/S

1 WALL PLATE Wall Plate Suction Canister

4 WHEELS 2" Whisper 602 Wheels

1 RUBBER FEET Cylindrical Isolator

1 INSULKIT WSP Insulation Kit for Whisper 602

8 ISOLATORS Motor Isolators

1 MANUAL602/12 602/1202/Whisper/TURBO Operator’s Manual

1 REF6EHT1 PN#6EHT1

1 LBL CE SMALL CE Label Small

Page 30

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

28

PlumeSafe Whisper 602

100V / 50 & 60Hz

# Quantity Part Number Description

1 1 HOUSING 602W Whisper 602 Housing

2 1 MOTOR 120 DC DC Brushless Motor

3 1 GSKT MM WSP Gasket for Motor, SC-42 Closed Cell

4 1 HANDLEWHISPR Handle For Whisper 602

5 1 HANDLE FOAM Foam for Whisper 602 handle

6 1 CORD WRAP Cord Wrap for Whisper 602

7 2 CIRCUIT 15 US – 15Amp Circuit Breaker

8 1 PWR EN MD.08 Power Entry Module (.080")

9 1 PCB-DB26 ASY Whisper 602 PCB w/26" jack

10 1 CHP W6 Chip W6

11 1 PLUG/CORD602 Plug/Cord 12' AEC60, AEC250

12 1 WIRE ASSBLY Wire Assembly for Whisper 602 – Complete w/E-Terms

13 2 GASKET LED LED Gasket

14 1 LBL WHIS S/N Label Kit for Whisper 602

15 1 LBL CITY LA Label for City of LA Approval

16 1 BOX WHISPER Box for Whisper 602 System

17 1 KEYPADBFGRFX Buffalo Filter Membrane Switch Graphics

18 1 MEMBRANEBLNK Membrane Blank

19 8 BOLT10-32 .5 Bolt 10-32 0.5" SS

20 1 BOLT10-32.75 Bolt 10-32 0.75" Long

21 5 BOLT6-32 .5" Bolt 6-32 0.5" Long -PAN HD

22 5 WASHER #6S Star washer #6 electrical

23 2 WASHER 1/4"L Lock Washer 1/4" split ring

24 4 WASHER #10F Flat washer #10

25 2 NUT JAM10-32 Jam Nut 10-32, Zinc

26 26 NUT 10-32 10-32 Lock Nuts S/S

27 1 WALL PLATE Wall Plate Suction Canister

28 4 WHEELS 2" Whisper 602 Wheels

29 1 RUBBER FEET Cylindrical Isolator

30 1 INSULKIT WSP Insulation Kit for Whisper 602

31 8 ISOLATORS Motor Isolators

32 1 MANUAL602/12 602/1202/Whisper/TURBO Operator’s Manual

33 1 REF10EHT1 PN#10EHT1

Page 31

BUFFALO FILTER

Smoke Evacuation Systems

PlumeSafe® Whisper 602 Service Manual

29

Section M.

Terms & Warranty

SPECIFICATIONS. All product specifications are subject to change without notice.

SHIPMENT OF ORDER. Buffalo Filter will try to accommodate individual customer requests for shipping method. Buffalo Filter

reserves the right to decide shipping method on prepaid orders. Care is exercised in the checking and packaging of all merchandise

to avoid error, but should discrepancies arise, claims should be made within 24 hours after delivery.

All products are shipped F.O.B Buffalo Filter's facilities, and risk of loss transfers to the purchaser upon tender of delivery to the

carrier at our dock. If the merchandise is damaged after risk of loss has transferred, a claim must be made to the carrier involved.

Buffalo Filter will provide reasonable assistance to customers in pursuing these claims.

RETURN OF MATERIAL. In the event of an error by Buffalo Filter, products may be returned to Buffalo Filter for correction of such

error. In all other cases, returns will only be accepted with the prior consent of Buffalo Filter, in its sole discretion, and will be

accepted only in exchange for merchandise of an equivalent dollar value, less a reasonable restocking and handling charge.

In all cases, returns will not be accepted unless a pre-authorized return number is obtained from Buffalo Filter in advance. This

number must be clearly marked on the exterior of the packaging before returning products to Buffalo Filter. All transportation costs

must be prepaid by the shipper and all risks of loss and damage of goods are the responsibility of the shipper. Unauthorized returns

will be refused. Include a copy of the packing papers and/or invoice with the return. Buffalo Filter shall have no obligation to refund

the purchase price of any returned merchandise.

ENTIRE AGREEMENT. By acceptance of products from Buffalo Filter, Purchaser acknowledges and agrees to all of the terms and

conditions contained herein. No additional or different terms or conditions shall apply unless expressly accepted by Buffalo Filter in

writing in advance. All matters involving the validity, interpretation and application of this agreement shall be controlled by the laws

of New York State without regard to conflicts of laws rules..

JURISDICTION. Purchaser hereby consents to the jurisdiction of the New York Courts with respect to any controversy or dispute

arising out of this agreement or the merchandise sold hereunder.

LIMITED WARRANTY. Buffalo Filter will replace without charge, or at its option, refund the purchase price of, any goods which

Buffalo Filter determines to have contained a defect in material or workmanship as of the date of shipment for a period of three (3)

years from the date of delivery for P/N PSWTURBO and for a period of one (1) year from the date of delivery for all other goods,

provided, however, that Buffalo Filter is promptly notified of any suspected defect and is given the opportunity to inspect the goods in

question and the installation and use thereof. Using any filter not manufactured by Buffalo Filter may cause damage to the system

which will not be covered by this warranty.

THE FORGOING WARRANTY IS THE ONLY WARRANTY MADE BY BUFFALO FILTER AND IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. ALL WARRANTIES IMPLIED BY ANY COURSE OF

DEALING OR USAGE BETWEEN THE PARTIES ARE EXPRESSLY EXCLUDED AND NO PROMISE OR AFFIRMATION OF

FACT MADE BY ANY AGENT OR REPRESENTATIVE OF BUFFALO FILTER SHALL GIVE RISE TO ANY LIABILITY OR

OBLIGATION.

LIMITATION OF LIABILITY AND INDEMNIFICATION BY PURCHASER. BUFFALO FILTER SHALL NOT BE LIABLE IN ANY CASE

FOR SPECIAL, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES OF ANY KIND. IN NO CASE SHALL BUFFALO

FILTER'S LIABILITY EXCEED THE AMOUNT PAID BUFFALO FILTER BY PURCHASER FOR THE SPECIFIC SYSTEM

GIVING RISE TO THE LIABILITY. PURCHASER AGREES TO INDEMNIFY AND HOLD BUFFALO FILTER HARMLESS FROM

AND AGAINST ALL LIABILITIES, CLAIMS, AND DEMANDS OF THIRD PARTIES OF ANY KIND RELATING TO THE USE OF

PRODUCTS PURCHASED HEREUNDER.

CONFIDENTIAL INFORMATION. Any information, drawings, plans, or specifications furnished by Buffalo Filter have been developed

at Buffalo Filter's expense, are confidential and proprietary to Buffalo Filter. Recipients are granted a limited license to use such items

to install, operate, and maintain the products with which they are supplied and are not permitted to disclose such items or to use

them for any other purpose.

Loading...

Loading...