Buderus Logamax plus GB142-24, Logamax plus GB142-30, Logamax plus GB142-45, Logamax plus GB142-60 Servicing Instructions

Servicing instructions

WARNING!

Improper installation, adjustment, alteration, service or maintenance can

cause injury, loss of life or property damage. Refer to this manual. For

assistance or additional information consult a qualified installer, service

agency or the gas supplier.

NOTICE!

In the Commonwealth of Massachusetts this boiler must be installed by a

licensed Plumber or Gas Fitter.

Notice:

This manual must be retained for future reference.

– Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other boiler.

– What to do if you smell gas

• Do not try to light any boiler

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

–

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Warning: If the information in these instructions is

not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Condensing gas boiler

Logamax plus

GB142-24/30/45/60

For installers

Please read thoroughly

before servicing

7214 9400 (11/2011) US/CA

Preface

About these instructions

These Servicing Instructions contain important information to

diagnose and resolve issues concerning the GB142 boiler with

capacities 24, 30, 45 and 60 kW.

These Servicing Instructions are intended for specialist installers, who have the necessary training and experience for working

on heating and gas systems.

Subject to technical changes!

Slight changes may be made to the illustrations, process steps

and technical data as a result of our policy of continuous

improvement.

Updating of documentation

Please contact us if you have any suggestions for improvements

or corrections.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!2

1 Safety and general instructions 4

1.1 Designated use 4

1.2 Hazard definitions 4

1.3 The following instructions must be observed 4

1.4 Observe these instructions for heating

system water 5

1.5 Tools, materials and additional equipment 5

1.6 Inspection 5

1.7 Disposal 5

1.8 Abbreviations 6

2 Regulations and guidelines 7

3 Product description 8

4 Operation 9

4.1 Operating the BC10 basic controller 9

4.1.1 General 9

4.2 Menu structure of the BC10 basic controller 9

4.2.1 "Flue gas test" menu 10

4.2.2 "Service Mode" menu 11

4.2.3 "Manual Operation" menu 12

4.2.4 "Adjustments" menu 12

5Function 14

5.1 General 14

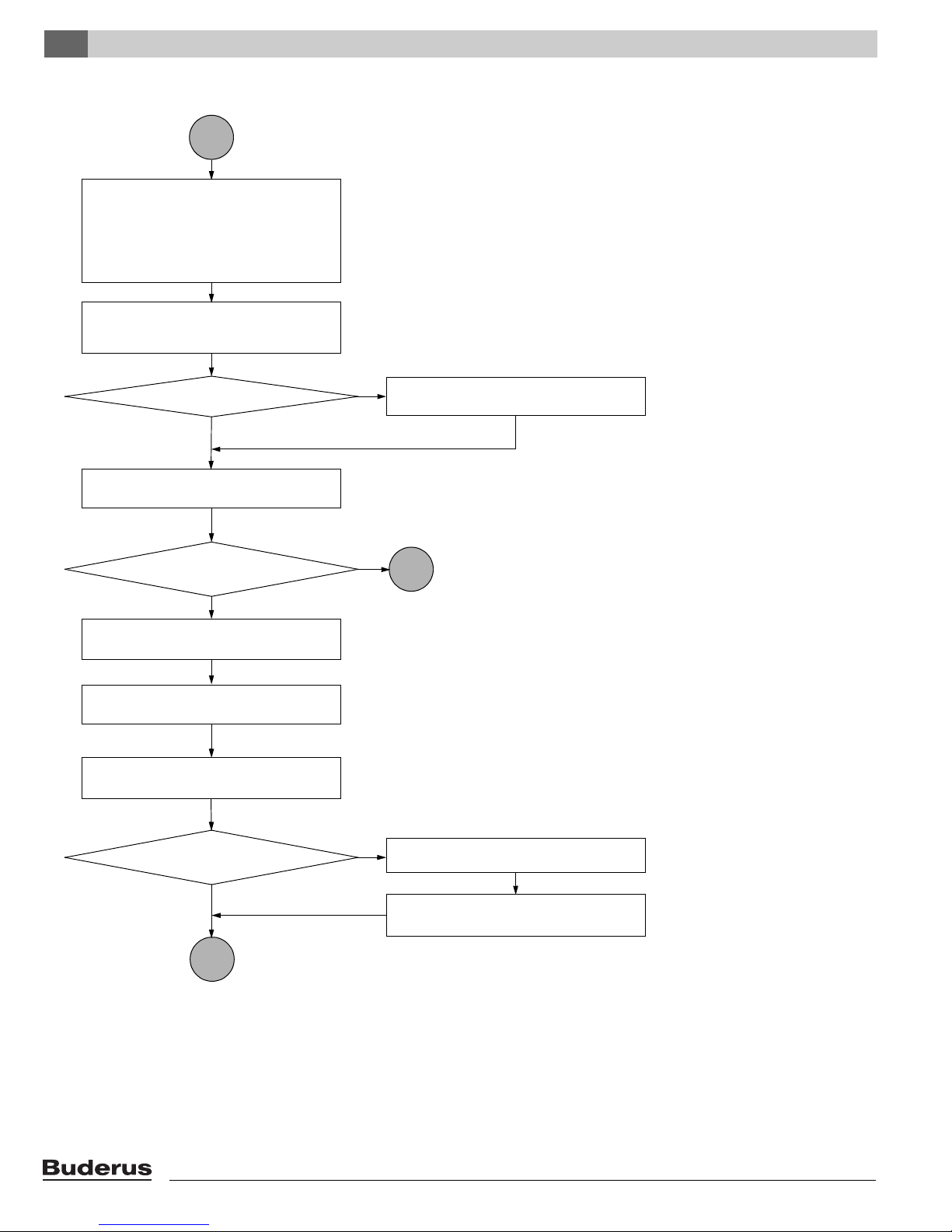

5.2 Structure diagram "Function" 15

Contents

8.1.7 Checking the supply/return/safety/hot-water

temperature sensors 89

8.1.9 Checking the hot-water temperature sensor 91

8.1.10 Checking the supply/return/safety sensors cable 92

8.1.11 Checking the hot surface ignitor; control 92

8.1.12 Checking the hot surface ignitor; resistance 93

8.1.13 Checking the hot surface ignitor; supply cord 93

8.1.15 Testing the ionization current 95

8.1.16 Checking the ionization electrode; cable 95

8.1.17 Checking the ionization electrode;

replace if necessary 96

8.1.18 Checking the gas control valve;

cable connections 98

8.1.20 Checking the gas control valve;

cable connection between gas control valve

and UBA 3 installation base 99

8.1.21 Ohming out the gas control valve 100

8.1.22 Replacing the gas control valve 101

8.1.23 Checking the control unit; connections

to the boiler 104

8.1.24 Bleed the gas supply pipe 106

8.1.25 Measuring the inlet gas pressure

(flow pressure) 107

8.1.26 Measure and adjust the gas/air ratio 108

8.1.27 Measuring the carbon monoxide content (CO) 109

8.1.28 Transformer; replacing 109

8.1.29 Automatic air purging system; replacing 111

8.1.30 Burner; replacing 113

8.1.31 Sight glass; replacing 115

8.1.32 Condensate trap; replacing 116

8.1.33 Pressure sensor; replacing 116

8.1.34 Heat exchanger; replacing 117

8.1.35 UBA 3; replacing 125

6Symptoms 20

6.1.1 General 20

6.1.3 Display codes on the display of the BC10

basic controller 20

6.2 LED on the UBA 3 26

7 Diagnosis 27

7.1 Faults without a fault code 27

7.2 Faults with a fault code 46

8 Actions 84

8.1 Testing, measuring, adjusting and replacing

various components 84

8.1.1 Checking the UBA 3 fuse; replace if necessary 84

8.1.2 External connection board fuse 85

8.1.3 Checking the fan unit; 120 VAC control 86

8.1.4 Checking the fan unit; supply cord (120V AC) 87

8.1.5 Checking the fan unit; tacho cable 88

8.1.6 Replacing the fan unit 88

9 Appendix 126

10 Spare parts 128

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 3

Safety and general instructions1

1 Safety and general instructions

Please observe these instructions in the interest of your own

safety.

1.1 Designated use

The boiler was designed for heating water for a space heating

system and generating hot water e.g. for domestic purposes.

The boiler is delivered with a BC10 basic controller and the

"Universal Automatic Burner Control Unit 3" (UBA 3) preinstalled.

The boiler can be fitted with a modulating outdoor reset control

AM10 (scope of delivery) and an On/Off thermostat or relay

panel end switch (24 V) (accessories).

1.2 Hazard definitions

The following defined terms are used throughout the documentation to bring attention to the presence of hazards of various risk

levels. Notices give important information concerning the life of

the product.

DANGER:

Indicates the presence of hazards that can

cause severe personal injury, death or substantial property damage.

WARNING:

Indicates the presence of hazards that can

cause severe personal injury, death or substantial property damage.

CAUTION:

Indicates presence of hazards that can cause

minor personal injury or property damage.

CAUTION:

Risk of electric shock.

Indicates presence of hazards due to electric

shock.

NOTICE:

Indicates special instructions on installation,

operation or maintenance that are important but

not related to personal injury or property

damage.

1.3 The following instructions must be

observed

– The boiler must only be used for its designated purpose,

observing the Installation Instructions.

– Only use the boiler in the combinations and with the accesso-

ries and spares listed.

– Other combinations, accessories and consumables must

only be used if they are specifically designed for the intended

application and do not affect the system performance and the

safety requirements.

– Maintenance and repairs must only be carried out by autho-

rized professionals.

– You must report the installation of a condensing gas boiler to

the relevant gas utility company and have it approved.

– You are only allowed to operate the condensing gas boiler

with the combustion air/flue gas system that has been specifically designed and approved for this type of boiler.

– Please note that local permission for the flue system and the

condensate water connection to the public sewer system

may be required.

– You must also observe:

– the local building regulations stipulating the installation rules.

– the local building regulations concerning the air intake and

outlet systems and the chimney connection.

– the regulations for the power supply connection.

– the technical rules laid down by the gas utility company con-

cerning the connection of the gas burner fitting to the local

gas main.

– the instructions and standards concerning the safety equip-

ment for the water/space heating system.

– the Installation Instructions for building heating systems.

– The boiler must be located in an area where leakage of the

tank or connections will not result in damage to the area adja-

cent to the boiler or to lower floors of the structure. When

such locations cannot be avoided, it is recommended that a

suitable drain pan, adequately drained, be installed under the

boiler. The pan must not restrict combustion air flow.

– The boiler must be installed such that the gas ignition system

components are protected from water (dripping, spraying,

rain etc.) during boiler operation and service.

– The boiler must not be installed on carpeting.

– Do not restrict or seal any air intake or outlet openings.

– If you find any defects, you must inform the owner of the sys-

tem of the defect and the associated hazard in writing.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!4

Safety and general instructions 1

DANGER

if flammable gas explodes.

Beware if you smell gas: there may be an

explosion hazard!

Warning: If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage,

personal injury or death.

Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other boiler.

What to do if you smell gas

Do not try to light any boiler.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

1.4 Observe these instructions for heating

system water

– Thoroughly flush the system prior to filling.

Only use untreated main water to fill and top off the system.

– Do not use salt bedding exchangers to soften the water.

– Do not use inhibitors or other additives!

– No Toxic chemicals such as used for boiler treatment, shall

be introduced into the heating water used for space heating.

– The maximum permissible flow rate of the GB142-24/30 this

is 11 GPM (gal./min.), for the GB142-45 is 15 GPM and for

the GB142-60 is 20 GPM.

– When using oxygen-permeable pipes, e. g. for floor heating

systems, you must separate the system using heat exchang-

ers. Unsuitable heating system water promotes the formation

of sludge and corrosion.

This may damage the heat exchanger or affect its operation.

1.6 Inspection

We advise you to offer your customer an annual inspection and

maintenance contract. If inspection reveals that maintenance

work is necessary you can carry this out as required in the Installation instruction of the boiler.

Installation

CAUTION:

– Check and clean the heating system at least

once a year.

– Carry out a maintenance overhaul if neces-

sary. Immediately repair defects to avoid

damage to the heating system!

– Periodically examine the venting systems and cleaning of the

screens in the vent terminal.

– Also periodically inspect the low water cutoffs, including

flushing of float types.

– And periodically inspect the burner flames (see page 8, fig. 1,

pos. 10).

– Check the neutralization unit if present.

– Check to see if there are no obstructions to the flow combus-

tion and ventilation air.

– For direct vent boilers, proper reassembly and resealing of

the vent-air intake system is required.

Maintenance

– Cleaning the heat exchanger, the burner and the condensate

trap (see installation instructions, Maintenance).

– Checking the ionization signal (par. 8.1.15, page 95)

– Checking and adjusting the gas/air ratio (par. 8.1.26,

page 108).

1.7 Disposal

– Dispose of the boiler packaging in an environmentally sound

manner.

– Dispose of components of the heating system

(e. g. boiler or control device), that must be replaced, by

handing them in to an authorized recycling facility.

– Keep boiler area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

1.5 Tools, materials and additional equipment

For the installation and maintenance of the boiler you will need

the standard tools for central heating, gas and water fitting.

In addition, a handtruck with a fastening belt is very useful.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 5

Safety and general instructions1

1.8 Abbreviations

AM10 = Outdoor reset module

AS = System fault code

AV = Air Vent

BC = Operating code

BC10 = Control panel (on the boiler)

BCT = Boulter Buderus cylinder thermostat

BDV = Boulter Buderus diverter valve

BKS = Blocking boiler fault code

CB = Connection Block

CH = Central Heating

CHF = Central Heating Supply

CHR = Central Heating Return

CM10 = Cascade module

CT = Cylinder Thermostat

CWDO = Condensate water drainage outlet

CM10 = Cascade module

DHW = Domestic Hot Water

DV = Diverter Valve

E=Earth

EM10 = External control module

EMS = Energy management system

FA = Outdoor sensor

HK1 or HK2 = Central Heating line

KIM = Boiler identification module

L = Live Line

LED = Light Emitting Diode

LSV = Lock Shield Valve

MCW = Mains Cold Water

MM10 = Controler for HK2, second Central Heating line module.

N = Neutal

PE = Ground

PL = Permanent hot line

Prog = Programmer

RT or RC = Room Thermostat

SC = Service code

T=Timer

TRV = Thermostatic Radiator Valve

ÜC = Other display codes

UBA 3 = Universal automatic burner control unit 3

VKS = Locking boiler fault code

WC = Wiring Centre

WM10 = Controler for HK1, first Central Heating line

ZV = Two Port Zone Valve

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!6

2 Regulations and guidelines

Regulations and guidelines 2

The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to the

latest edition of the National Fuel Gas Code, ANSI Z223.1. In

Canada, installation must be in accordance with the requirements of CAN/CSA B149.1, Natural Gas and Propane Installation Code.

Where required by the authority having jurisdiction, the installation must conform to the Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

Install CO detectors per local regulations. The boiler requires

yearly maintenance, see maintenance section see chapter

„8.1.27 Measuring the carbon monoxide content (CO)“ on

page 109.

Operating Limits of the boiler:

Max. boiler temperature: 220 °F (105 °C)

Max. operating pressure: 44 psi (3 bar)

The hot water distribution system must comply with all

applicable codes and regulations. When replacing an existing

boiler, it is important to check the condition of the entire hot water

distribution system to ensure safe operation.

Massachusetts Installations Only:

For direct- vent boilers, mechanical-vent heating boilers or

domestic hot water equipment, where the bottom of the vent

terminal and the intake is installed below four feet above grade

the following requirements must be satisfied:

1) If there is not one already present, a carbon monoxide

detector and alarm shall be placed in a living area outside

the bedrooms. The carbon monoxide detector and alarm

shall comply with NFPA 720 (2005 Edition).

2) A carbon Monoxide detector and alarm shall be located in

the room that houses the boiler or equipment and shall:

a) Be powered by in series on the same electrical circuit as

the boiler or equipment:

b) Have battery back-up power:

c) Meet ANSI/UL 2034 Standards and comply with

NFPA 720 (2005 Edition):

d) Have been approved and listed by a Nationally

Recognized Testing Lab:

3) A product-approved vent terminal must be used, and if

applicable, a Product approved air intake must be used.

Installation shall be in strict compliance with the

manufacturer's instructions. A copy of the installation.

4) A metal or plastic identification plate shall be mounted at the

exterior of the building, four feet directly above the location

of vent terminal. The plate shall be of sufficient size to be

easily read from a distance of eight feet away, and read "Gas

Vent Directly Below".

b) For direct-vent boilers mechanical-vent heating boilers

or domestic hot water equipment where the bottom of

the vent terminal and the intake is installed four feet or

above grade the following requirements must be

satisfied:

1) If there is not one already present, a carbon monoxide

detector and alarm shall be placed in the living area

outside the bedrooms, The carbon monoxide detector

and alarm shall comply with NFPA 720 (2005 Edition).

2) A carbon monoxide detector shall:

a) Be located inn the area where the boiler or

equipment is located:

b) Have battery back-up power:

c) Be a minimum comply with NFPA 720

(2005 Edition).

3) A product-approved vent terminal must be used, and if

applicable, a product-approved air intake must be used.

Installation shall be in strict compliance with the

manufacturer's instructions. A copy of the installation

instructions shall remain with the boiler or equipment at

the completion of the installation.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 7

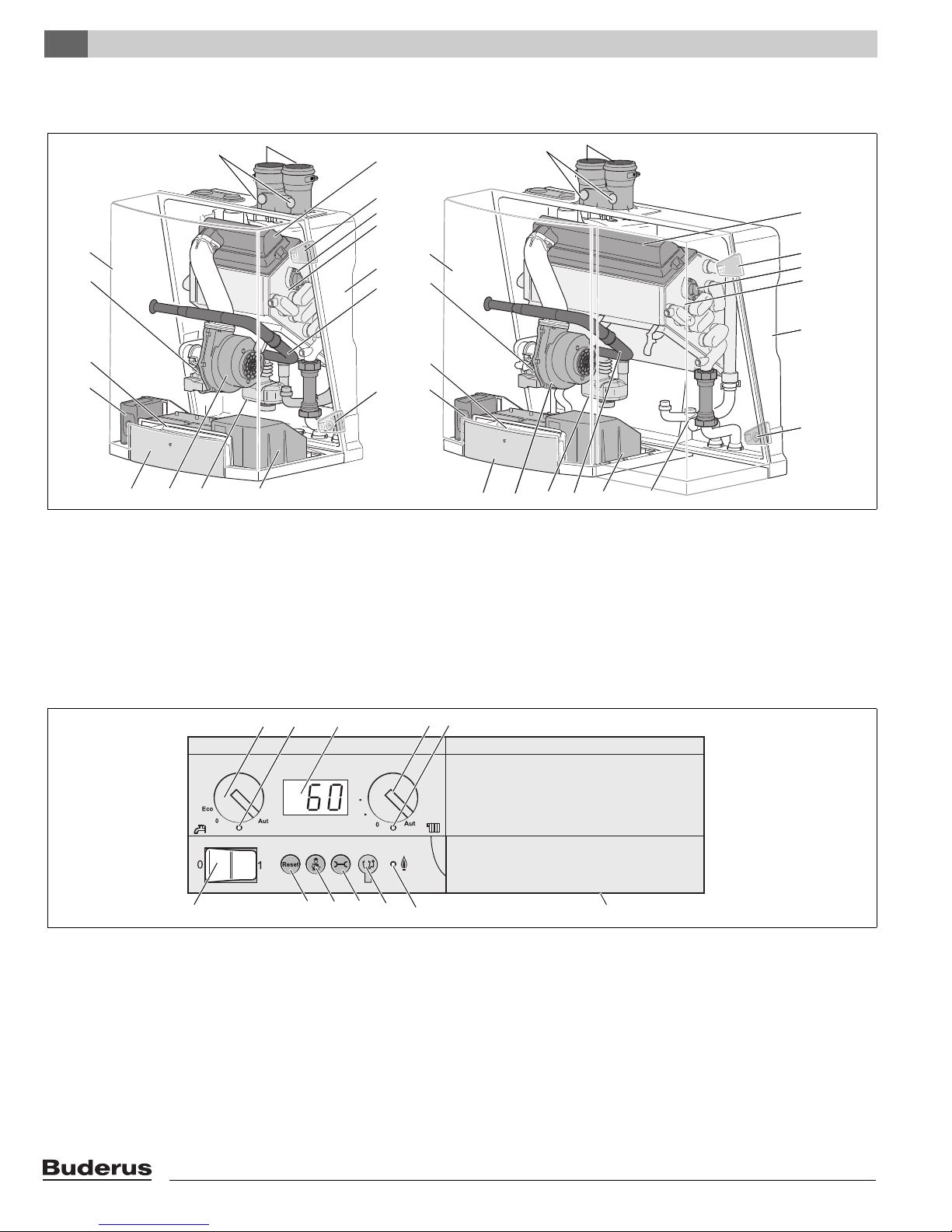

Product description3

1

2

3

6

9

11

13

14

9

16

15

7

5

8

1

4

10

12

13

14

2

3

5

4

6

7

9

11

9

8

10

12

161517

190

170

150

130

90

110

140

130

120

90

100

110

4

7

2

1

5

812

1011

3 6

9

3 Product description

fig. 1 Logamax plus GB142-24/30 (left) and GB142-45/60 (right)

pos. 1: Drawer with control unit

pos. 2: Universal Burner Automat (UBA 3)

pos. 3: Control unit BC10

pos. 4: Gas valve

pos. 5: Cover

pos. 6: Flue measuring points

pos. 7: Parallel flue

pos. 8: Burner

pos. 9: Latches of which two have locks

pos. 10: Sighting glass

pos. 11: Heat exchanger

pos. 12: Back cover

pos. 13: Air intake for the fan

pos. 14: Fan

pos. 15: Condensate trap and internal condensate drain flue

gas pipe

pos. 16: External Connection Board (under the cover)

pos. 17: Pressure sensor

fig. 2 Basic Controller Logamatic BC10

pos. 1: Main switch

pos. 2: DHW temperature knob

pos. 3: LED "DHW status"

pos. 4: Display

pos. 5: Space heating water temperature knob

1)

pos. 6: LED "Heating system status"

1)

ECO mode means that the temperature inside the hot water tank is 140 °F (60 °C), with a hysteresis (ΔT) of 18 °F instead of 9 °F

pos. 7: Under the cover a RC system controller can be installed.

pos. 8: LED "Burner Operation"

pos. 9: Service Tool connector

pos. 10: "Service"

pos. 11: "Chimney sweep"

pos. 12: "Reset"

e button

c button

d button

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!8

4 Operation

4.1 Operating the BC10 basic controller

4.1.1 General

The boiler is equipped with an control unit, the basic controller

BC10. The BC10 allows you to operate the boiler.

Briefly press on the control panel cover to open it

(see fig. 3).

The basic controller BC10 (see fig. 2) is located on the left side in

the drawer.

On the right side of the drawer there’s space for a RC control unit.

4.1.2 Switching the heating system on and off

Switching on the heating system

Set the main switch on the BC10 basic controller to position "1"

(On).

Switching off the heating system

Operation 4

fig. 3 Opening the control panel

Set the main switch on the BC10 basic controller to position "0"

(Off).

4.2 Menu structure of the BC10 basic controller

The menu structure of the boiler can be viewed on the BC10 using

the "Reset"

fig. 2, pos. 9, 10 and 11) buttons and the display indication (see

fig. 2, pos. 4).

The menu structure consists of 4 menus, schematically

represented on the following pages using structure diagrams:

– "Flue gas test" menu (page 10)

– "Service Mode" menu (page 11)

– "Manual Operation" menu (page 12)

– "Settings" menu (page 12).

c, "Chimney sweep d" and "Service e" (see

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 9

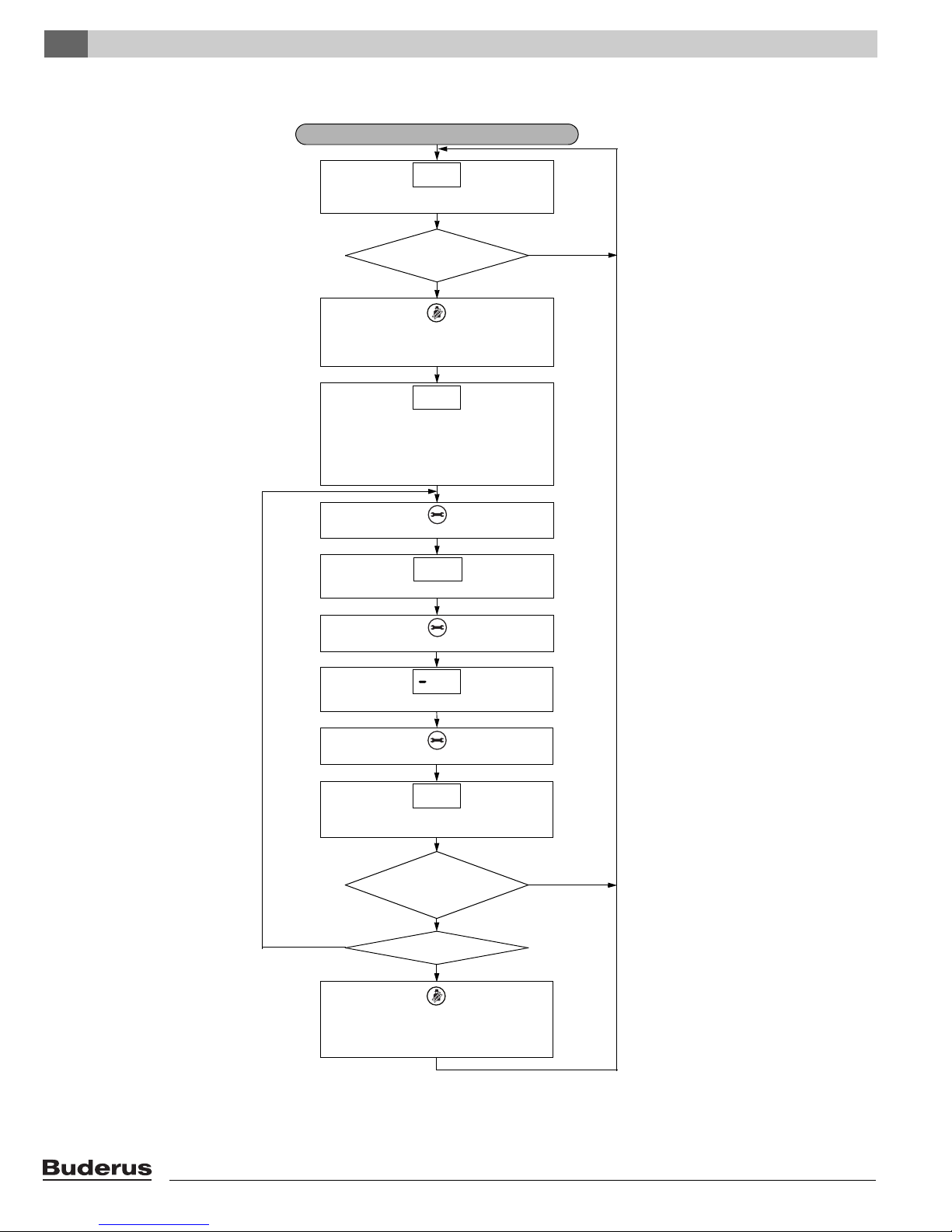

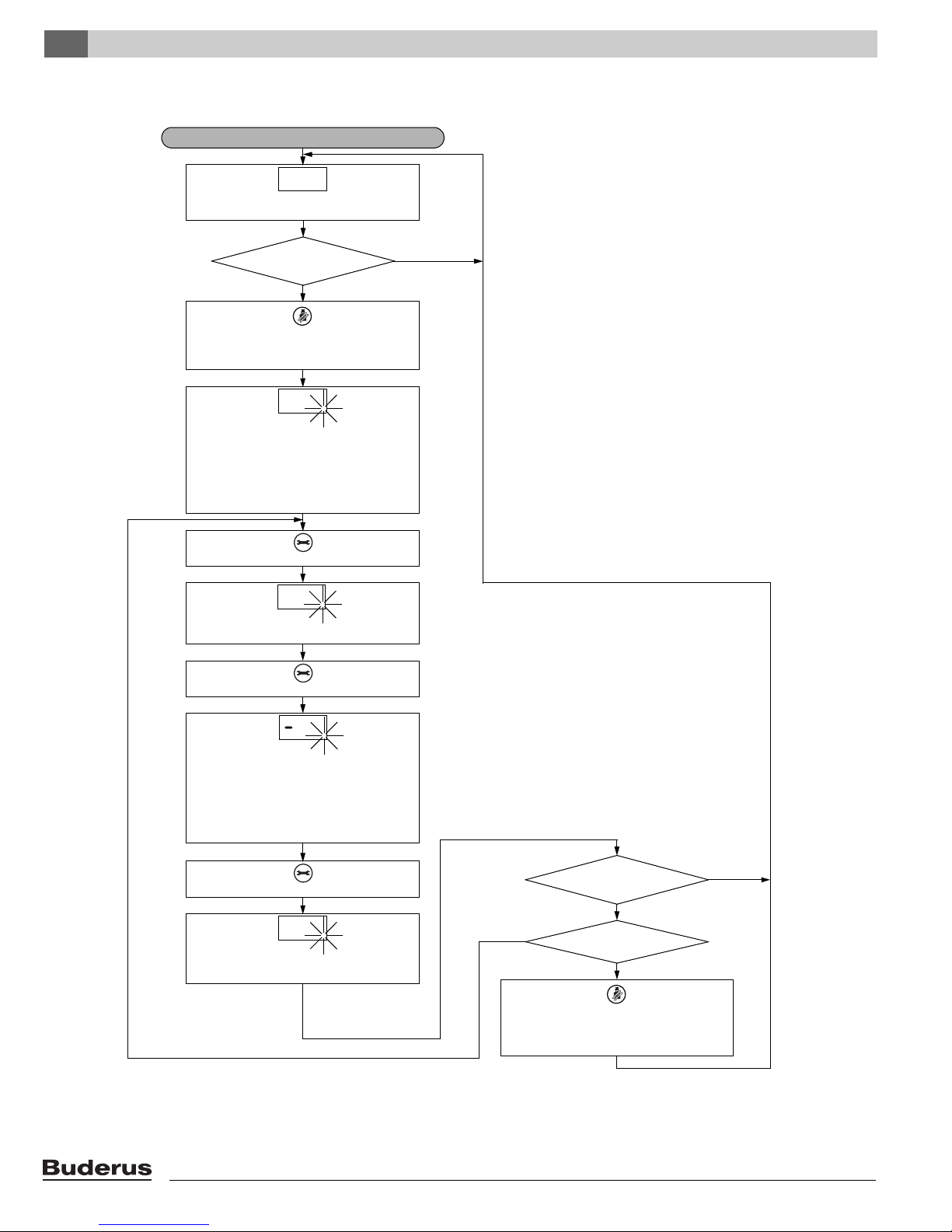

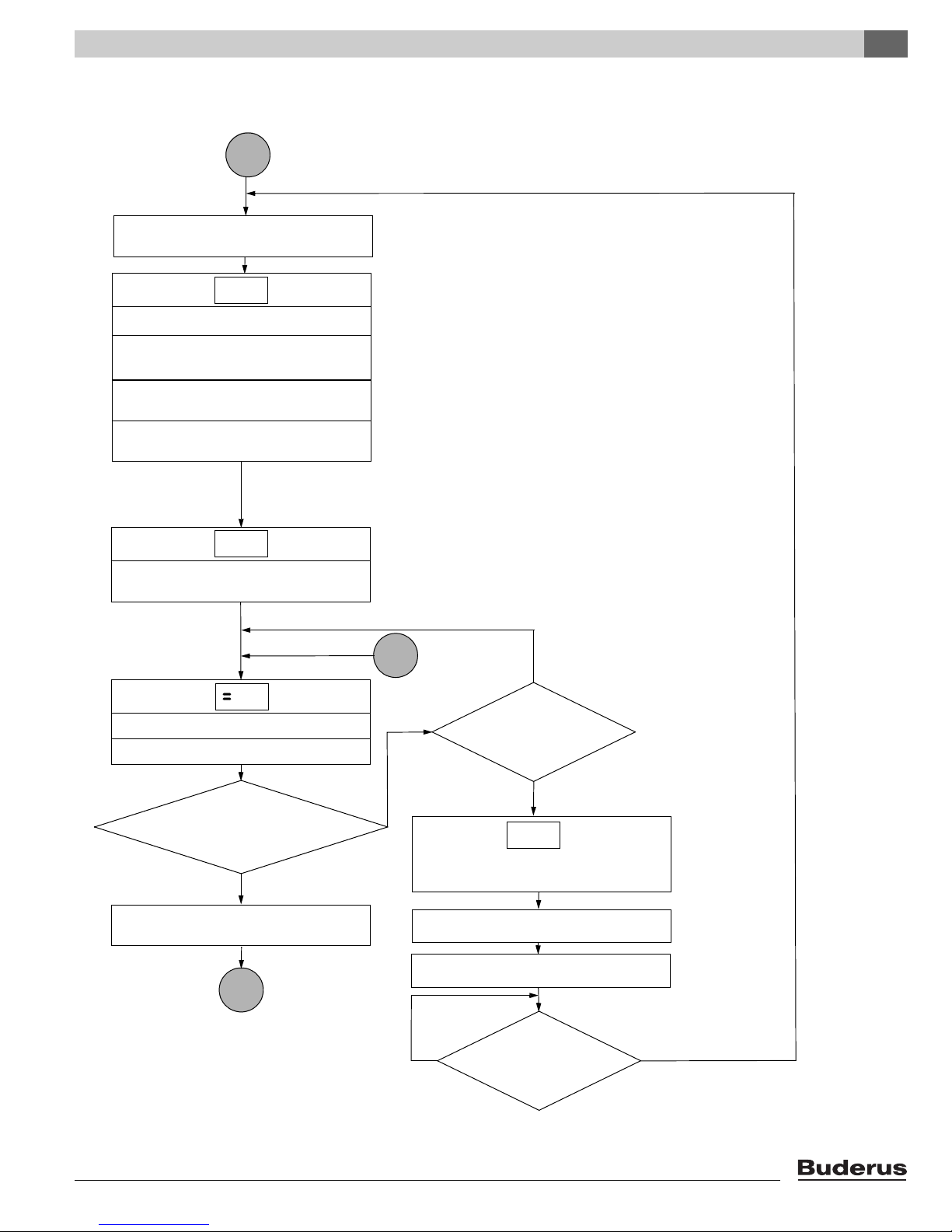

Operation4

"FLUE GAS TEST" MENU

no

yes

Press the service button.

psi

Current heating system pressure. See page 20.

Operating code. See page 21.

Activate

flue gas test?

Press the service button.

no

Activate flue gas test:

Press and hold the chimney sweep button

2 to 5 seconds.

The flue gas test is activated as soon as a dot is

visible in the lower right hand corner of the

display. This means that the boiler runs in

heating mode at 100 % for 30 minutes. The

maximum boiler water temperature as set on

the BC10 basic controller applies here.

A

.

27

.

Press the service button.

Current supply temperature 0 ... 199 °F

(-18 .. 93 °C). See page 20.

2

7

.

Deactivate

flue gas test?

Deactivate flue gas test:

Press and hold the chimney sweep button for

more than 2 seconds, until the decimal point

has disappeared.

yes

no

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

27

yes

Have

30 min. passed or

was the power

interrupted?

9P

2

.

4.2.1 "Flue gas test" menu

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!10

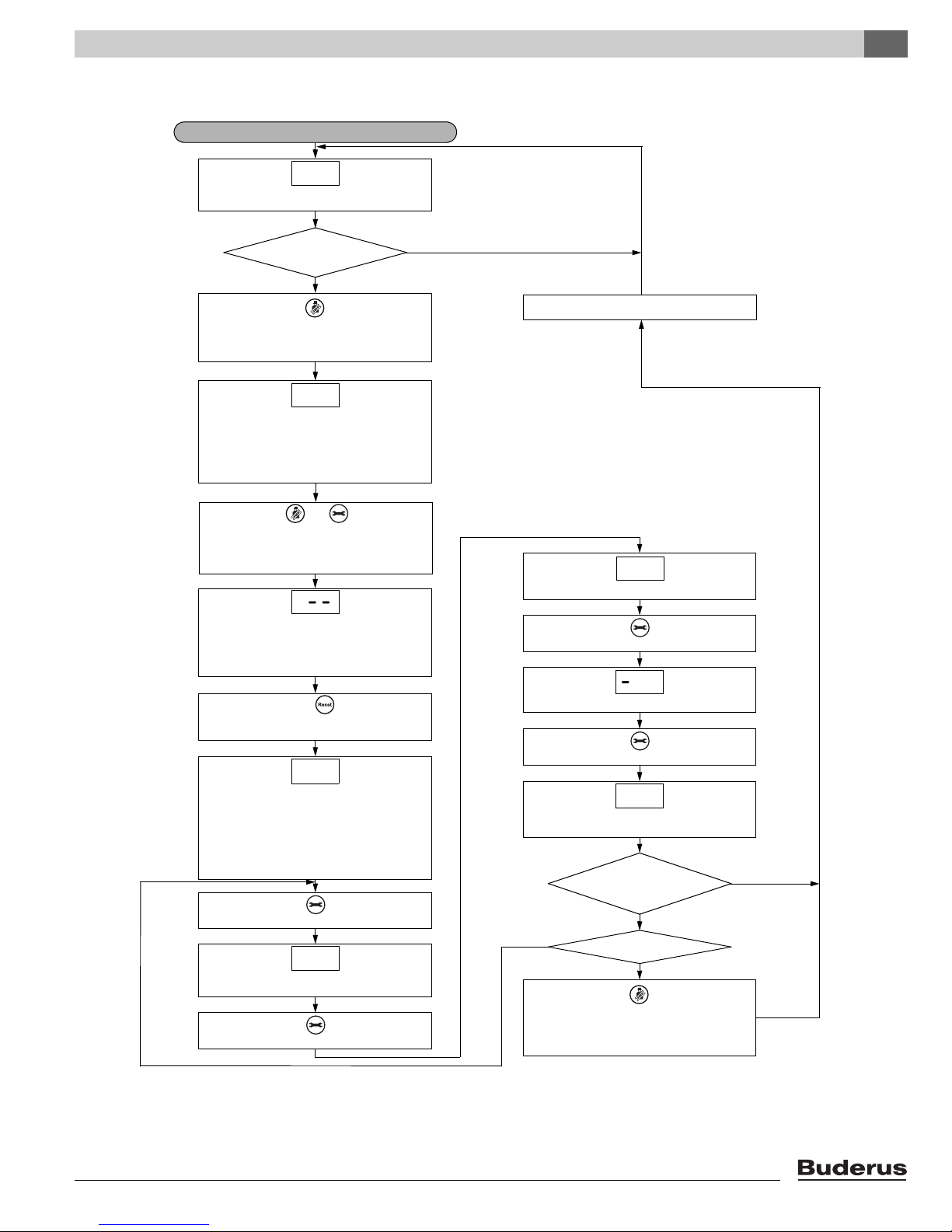

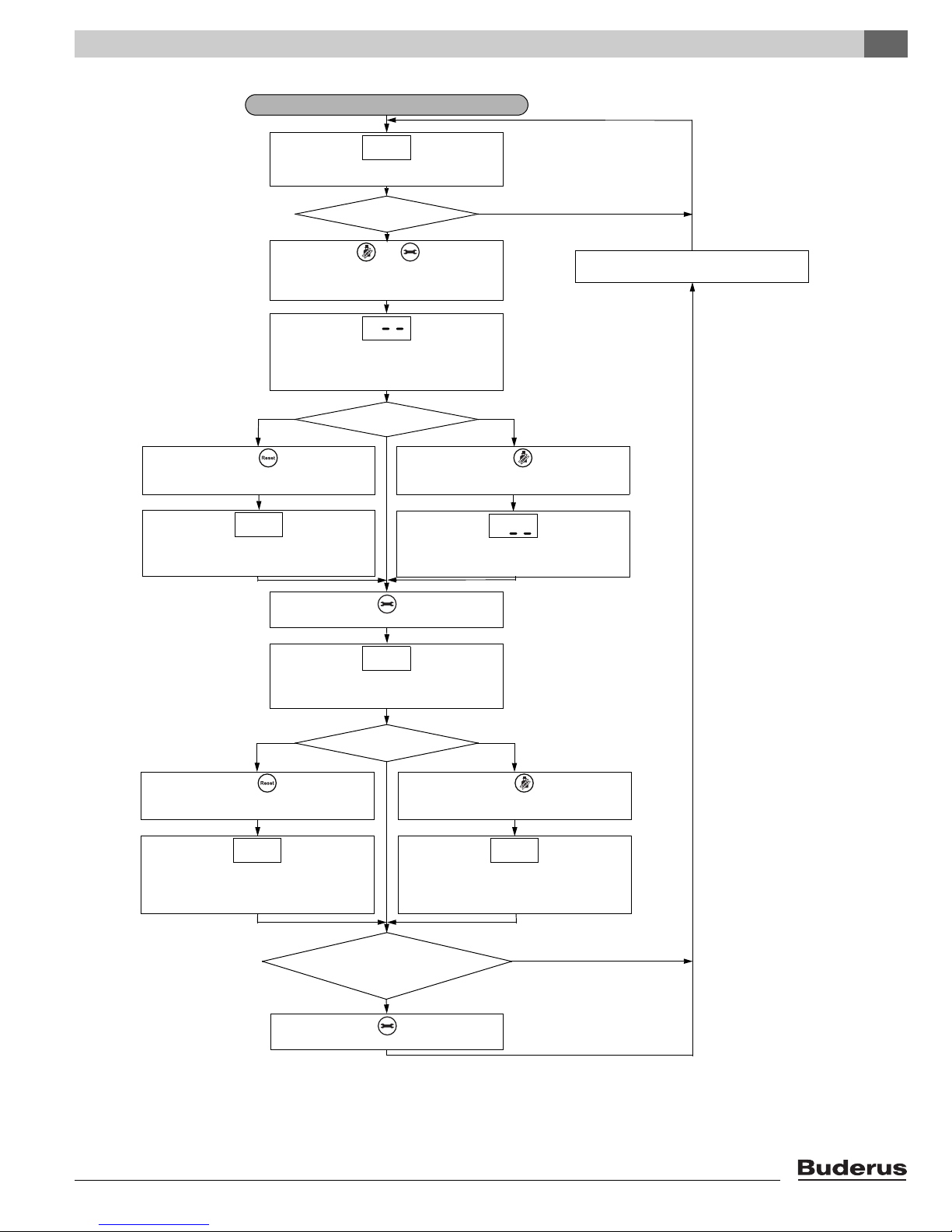

4.2.2 "Service Mode" menu

psi

Current heating system pressure. See page 20.

"SERVICE MODE" MENU

Activate service mode 2nd step:

Simultaneously press and hold the "Chimney

sweep" and "Service" buttons for more than

2 seconds.

Activate

service mode?

no

Activate service mode 1st step:

Press and hold the "Chimney sweep" button

for 2 to 5 seconds.

As soon as a non-flashing dot is shown in the

right-hand bottom corner of the display, the

boiler will run in heating mode at 100 % load for

30 minutes. The maximum boiler water

temperature set on the BC10 basic controller

applies.

27

.

Boiler load in line with "Settings" menu.

+

Current boiler load. See page 20.

Service mode activated.

You can now temporarily lower the boiler load

to partial load to check, and if relevant set the

gas/air ratio or the ionization current.

L

.

Press and hold the "Reset" button until the

display shows "L30."

-

Press the "Service" button.

Press the "Service" button.

Current boiler load. See page 20.

The boiler will reduce its load to 30 % within a

couple of seconds. The maximum boiler water

temperature as set on the BC10 basic controller

applies. Check the gas/air ratio (see page 108)

or the ionization current (see page 95) and

adjust the gas/air ratio if necessary.

03L .

Have 30 min.

passed or was the

power interrupted?

Operating code. See page 46.

Press the "Service" button.

.

Press the "Service" button.

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

27

.

Deactivate

service mode?

Deactivate service mode:

Press and hold the "Chimney sweep" button for

more than 2 seconds until the decimal point

has disappeared.

no

yes

yes

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

27

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

no

27

.

yes

9P

2

.

A

Operation 4

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 11

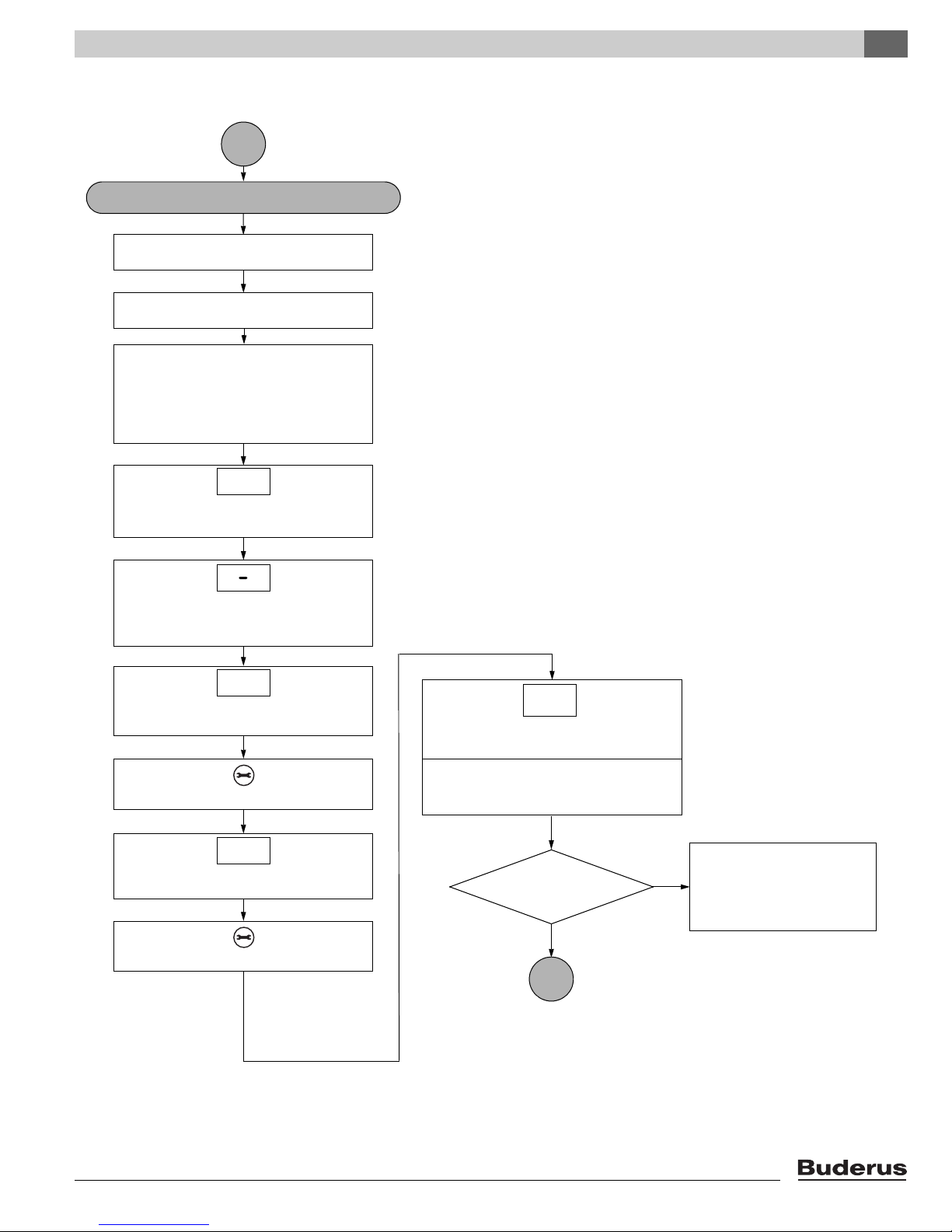

Operation4

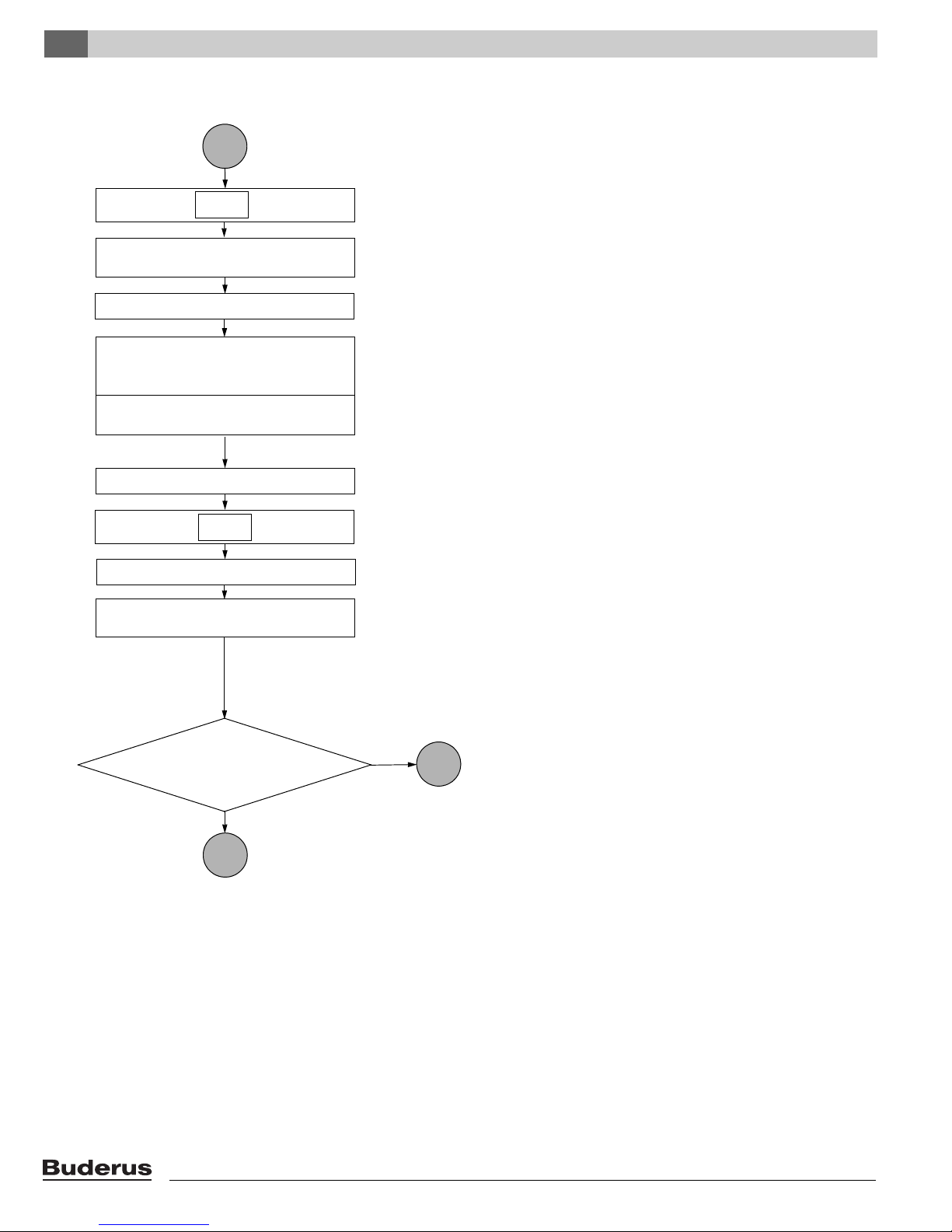

"MANUAL OPERATION" MENU

yes

Power

interrupted?

Press the "Service" button.

psi

Current heating system pressure. See page 20.

Operating code. See page 20.

During manual operation the "Adjustments"

menu on page 12 can be used to temporarily

change the required boiler load in case of an

emergency.

Activate manual

operation?

Press the "Service" button.

no

To activate manual operation:

Press and hold the "Chimney sweep" button for

more than 5 seconds.

As soon as a flashing dot is shown in the right-

hand bottom corner of the display, manual

operation is active. The means that the boiler is

permanently in heating mode. The maximum

boiler water temperature as set on the BC10

basic controller now applies. The "Heat

request" LED is lit.

Press the "Service" button.

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

Deactivate manual

operation?

no

2

7

.

9P

2

.

27

.

Deactivate manual operation:

Press and hold the "Chimney sweep" button for

more than 2 seconds until the flashing decimal

point has disappeared.

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

27

H

.

no

yes

yes

4.2.3 "Manual Operation" menu

4.2.4 "Adjustments" menu

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!12

"ADJUSTMENTS" MENU

Open programming mode: Simultaneously

press and hold the "Chimney sweep" and

"Service" buttons for more than 2 seconds.

Open the

“Adjustments” menu?

no

Boiler load and pump post purge

time settings confirmed.

+

As soon as the display shows "L--", the

programming mode is open. The first

parameter shown on the display is used to set

the boiler load for heating operation.

Adjust the boiler load with

the "Reset" button.

-

Press the "Service" button.

Have at least

5 min. passed without a button being

pressed or was the power supply

interrupted ?

As soon as the display shows "F ", the second

parameter can be set. This parameter

indicates the pump post purge time.

no

L

Adjust boiler load?

Adjust the boiler load with

the "Chimney sweep" button.

+

The setting "L30" means that the

heating load is lowered to 30 %.

„L__“ is the maximum

heating load setting of 100 %.

Factory default setting: "L " = 100 %.

03L

L

yes, higher

yes, lower

5F

Adjust pump post

purge time?

"F00" is the minimum pump post purge time

setting in minutes. "F60" is the maximum

pump post purge time setting in minutes.

"F1d" is the maximum

pump post purge time setting for one day.

Factory default setting "F 5" = 5 minutes.

no

yes, higher

yes, lower

Adjust the pump post purge time with

the "Reset" button.

-

Adjust the pump post purge time with the

"Chimney sweep" button.

+

00F 1dF

Press the "Service" button.

yes

no

yes

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

27

Operation 4

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 13

Function5

5Function

5.1 General

To clarify the operation of the Logamax plus GB142-24/30/45/60

thermal power gas boilers under normal operating conditions, the

work steps are schematically represented in the structure diagrams

on the following pages of this chapter.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!14

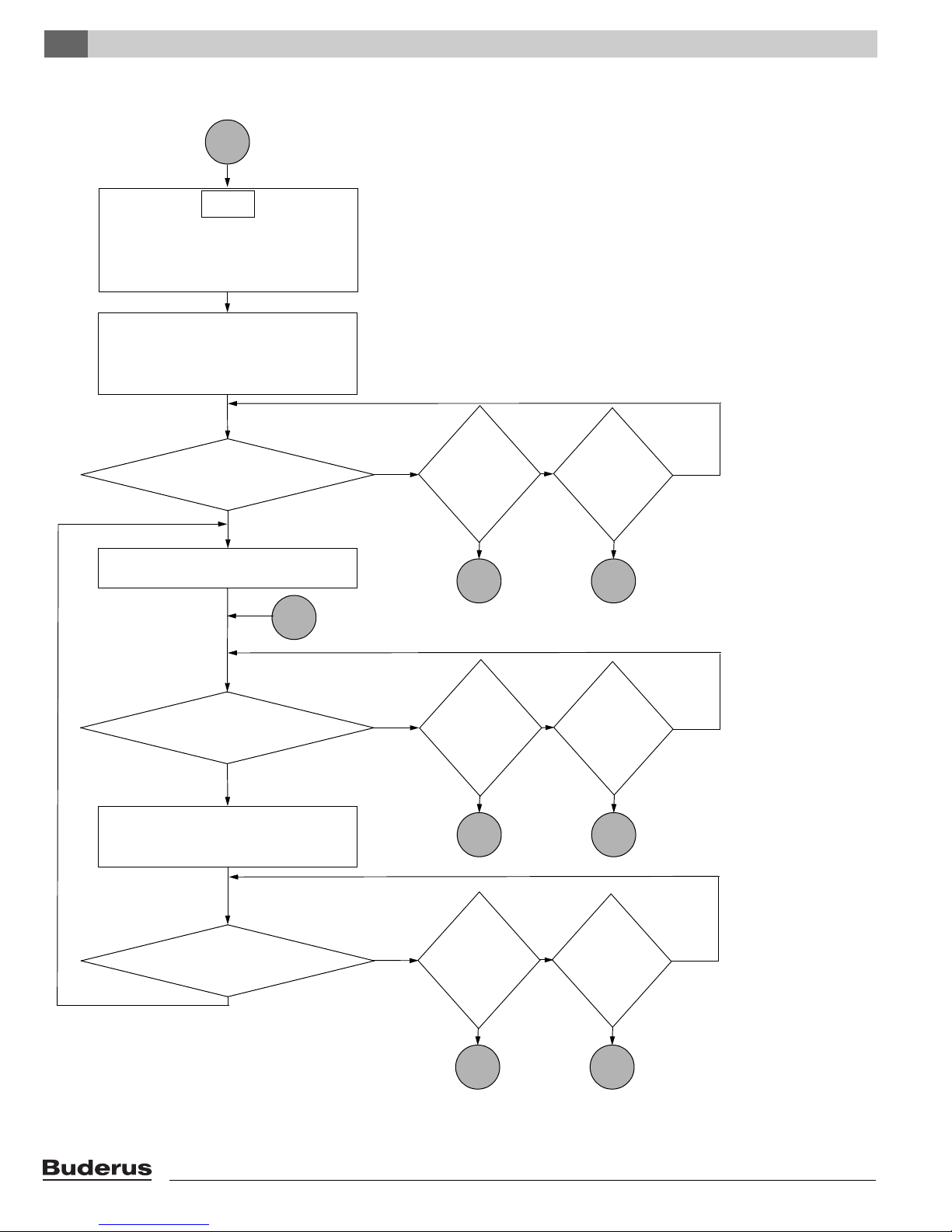

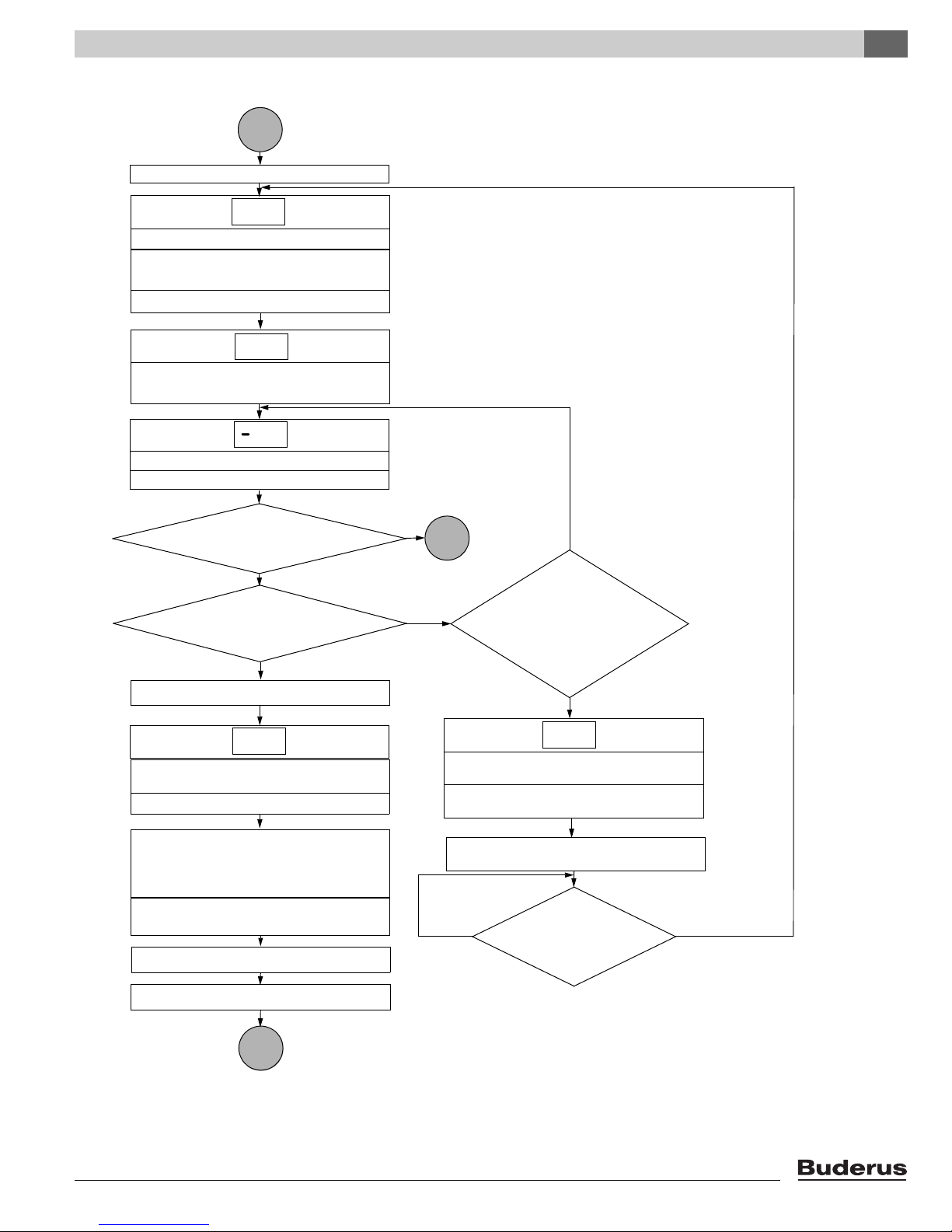

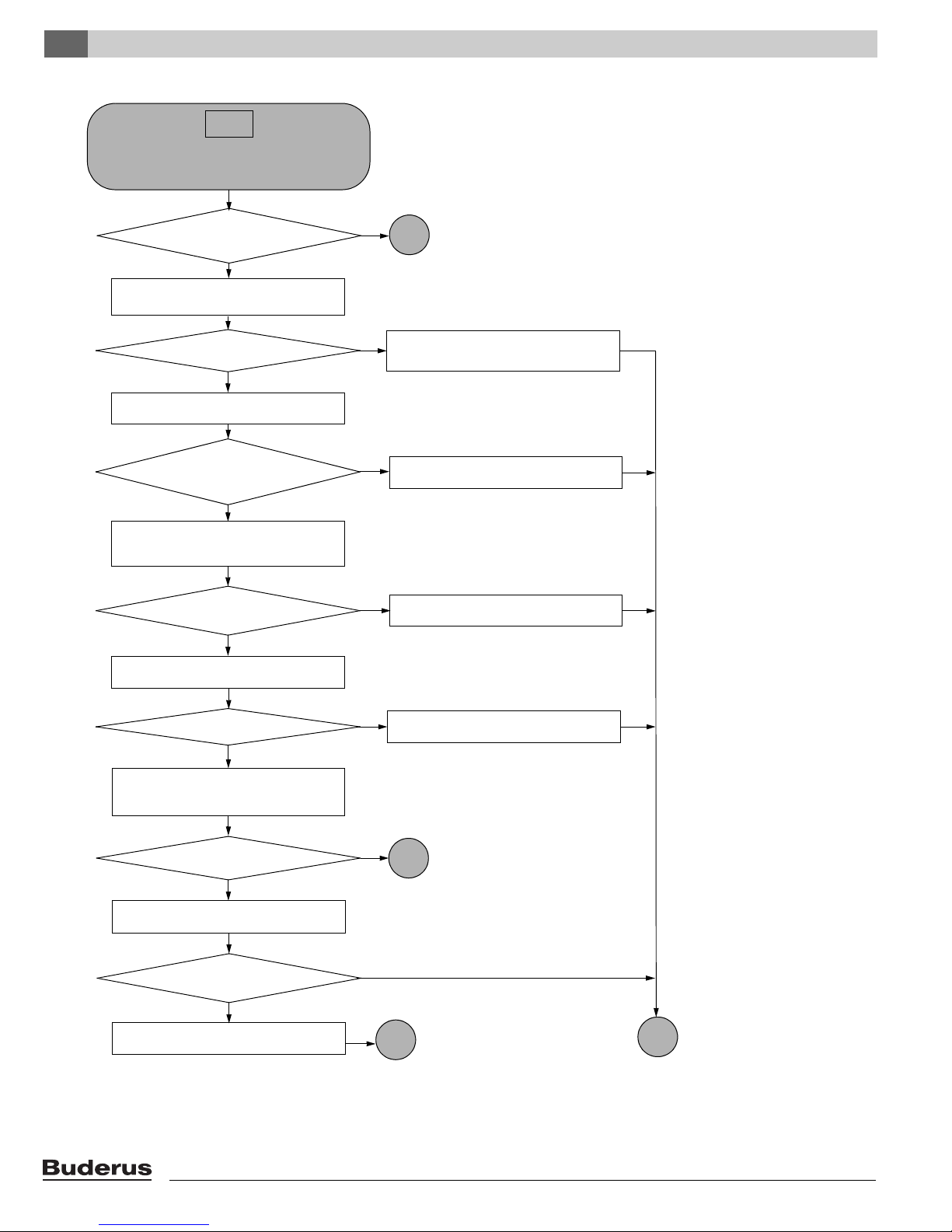

5.2 Structure diagram "Function"

1

Start up

Connect the heating system to the power grid

by turning the circuit breaker ON.

Turn the main switch on the BC10 to

position “1” (ON), see page 8, fig. 2.

A display check is carried out

(for max. 1 second).

888 ...

Flashes twice for 2 seconds until

communication between the UBA 3 and the

BC10 has been established.

Press the "Service" button.

Current heating system pressure.

See page 20.

Press the "Service" button.

Operating code.

The heating boiler is started.

U0

Is the

air purging phase

okay?

Unit will show an error code.

Fault must be fixed before

proceeding.

See chapter 6, 7 and 7.2.

no

2

yes

Current supply temperature 0 ... 199 °F

(-18 ... 93 °C). See page 20.

27

page 16

Start of air-side pre-flushing phase.

The blower runs for < 20 seconds at

approx. 60 % of the maximum speed.

The LED of the UBA 3 lights for 1 second.

This means that the UBA 3 is reading the

KIM. If a new KIM or UBA 3 has been

installed, the LED will flash at a high

frequency for max. 10 sec. while data is being

exchanged.

9P

2

psi

Function 5

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 15

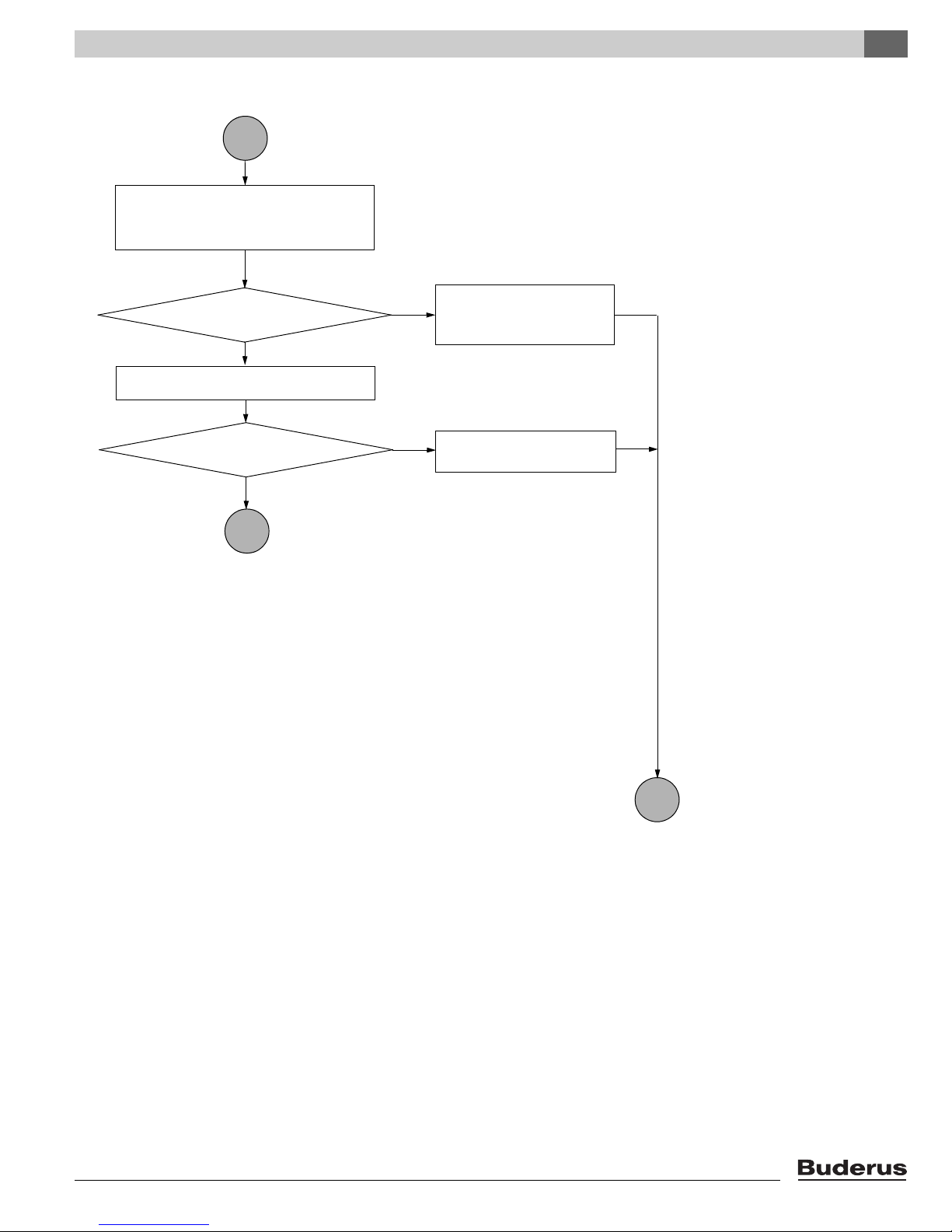

Function5

2

Has the pump post

purge time expired?

yes

yes

Have ten seconds

passed or was the power supply

interrupted?

yes

no

Operating code.

The boiler is in ready mode,

there is no heat request.

H

0

Start of pump post purge time via the heating

system. Pump post purge time in line with

"Settings" menu.

See page 12 and page 20.

Factory default setting: 5 minutes.

The primary circulation pump stops.

The primary circulation pump is run for

10 seconds to prevent it from seizing up.

no

page 15

3

page 17

no

Is

there a heat

request from the

room or outdoor

temperature-

dependent

regulator?

no

Is

the

temperature

in the hot water

tank at least

9 °F (5 K)lower than the

temperature set

on the BC10

or RC?

6

page 19

5

yes

yes

no

3

page 17

Is

there a heat

request from the

room or outdoor

temperature-

dependent

regulator?

Is

the

temperature

in the hot water

tank at least

9 °F (5 K) lower than

the temperature set

on the BC10

or RC?

6

page 19

yes

yes

no

3

page 17

Is

there a heat

request from the

room or outdoor

temperature-

dependent

regulator?

Is

the

temperature

in the hot water

tank at least

9 °F (5 K) lower than

the temperature set

on the BC10

or RC?

6

page 19

yes

yes

no

no

no

page 18

Has the primary

circulation pump been off for

more than 24 hours?

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!16

4

7

page 18

3

yes

Is the temperature

in the hot water tank higher

than the hot water temperature setting

in the BC10 or RC control

device?

no

H

L0

C0

The blower is started up.

The tank filling pump

is activated.

The hot surface ignitor is activated

for seven seconds.

The primary circulation pump

is started.

Ignition phase:

The gas valve is opened.

GB142 is in the hot water mode.

The "Burner" LED is lit.

The "Hot water mode" LED on the

BC10 is lit.

The "Hot water mode" LED

goes off.

yes

no

yes

no

page 16

The gas valve is closed,

the burner is shut down.

The "Burner" LED goes off.

The blower stops.

Is

the supply

temperature 82.8 K

higher than the hot water

temperature setting

or higher than

200 °F (93 °C)?

Is

the supply

temperature lower

than the preset

hot water temperature

plus 63 °F (35 K)?

page 19

Y0

Function 5

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 17

Function5

5

Is there a

heat request from the room or

outdoor temperature-dependent

regulator?

yes

4

page 18

A0

The gas valve is closed,

the burner is shut down.

The "Burner" LED goes off.

Start the pump over-run time through the hot

water tank at least 30 seconds,

max. 1 minute, if there is a heat request.

Air-side after-purging by blower

for 30 seconds.

The blower stops.

The primary circulation pump stops.

The tank filling pump

is stopped.

no

6

page 19

page 16

H0

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!18

Is the

temperature in the hot water

at least 9 °F (5 K) lower than the temperature

set on the BC10 or RC?

6

Is the

room or outdoor temperature-

dependent regulator in the request

position?

no

yes

The GB142 enters heating mode.

The "Burner" LED is lit.

H

The "Heat request" LED goes off.

Is

the supply

temperature

11 °F (6 K) higher than

the target value? (The target value

is calculated by the outdoor

temperature-dependent regulator

or is set - in the event of room

temperature-dependent

regulation- on the

BC10)

5

H0

The gas valve is closed,

the burner is shut down.

The "Burner" LED goes off.

Start of pump post purge time via the heating

system. Pump post purge time in line with

"Settings" menu. See page 12 and page 20.

Factory default setting: 5 minutes.

Air-side after-purging by blower for

30 seconds.

The primary circulation pump stops.

page 16

The blower stops.

page 17

7

yes

no

The gas valve is closed,

the burner is shut down.

The "Burner" LED goes off.

The blower stops.

Is

the supply

temperature 11 °F (6 K)

lower than the

target value?

no yes

L0

C0

The blower is started up.

The hot surface ignitor is activated for

seven seconds.

The circulation pump is started up.

Ignition phase:

The gas valve is opened.

The "Heat request" LED is lit.

page 16, page 18

Yes

no

Y0

Function 5

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 19

Symptoms6

6 Symptoms

6.1 Display indication on the BC10 basic controller

6.1.1 General

A display value or code is shown on the display of the BC 10 basic controller (see page 8, fig. 2).

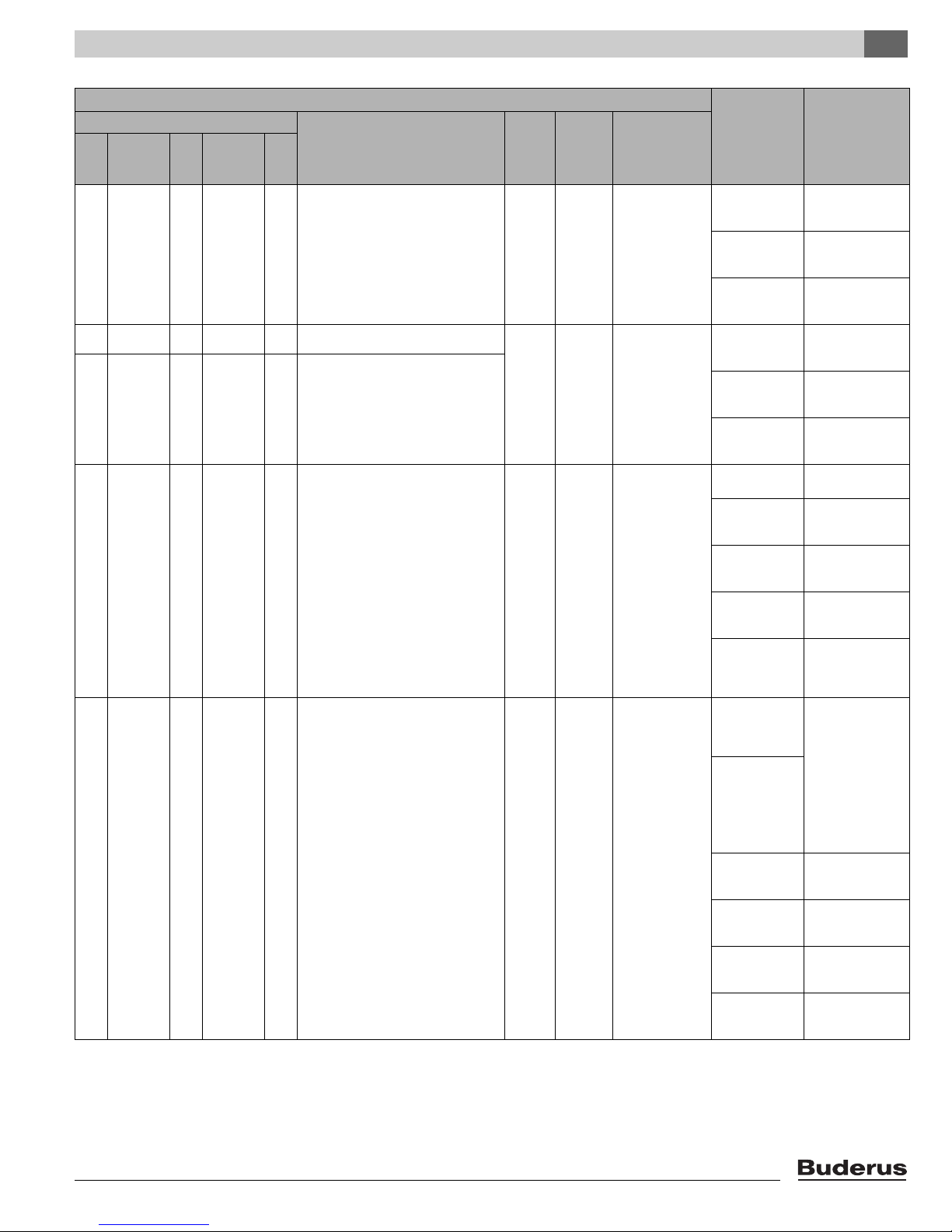

6.1.2 Display values on the display of the BC10 basic controller

The display value is shown automatically or can be called up by pressing the "Chimney sweep

page 10 and 12.

The following display values can be shown on the display of the BC10 basic controller:

Display

value

[\/7/2|

[p/2/9|

[l/9/9|

[f/\/5|

table 1 Display values on the BC10 basic controller

6.1.3 Display codes on the display of the BC10 basic

A display code shows the current status of the Logamax plus

GB142.

The display value is shown automatically or can be called up by

pressing the "Service

Two display codes (see table 2 level 3 and level 4) are shown.

After the first display code (level 3) is displayed, the second one

(level 4) can be called up by pushing the “Service

the BC10 basic controller level 4 can only be called up in the event

of a fault code.

Under normal operating conditions it is only possible to call up level

4 using the RC control device or a service tool.

Type of display value Unit Range

Current supply temperature °F

°C

Current heating system pressure psi

Configured target load %

Configured target pump post purge time min

controller

e" button.

e“ button. On

[\/\/0|

[-/1/8|

[p/0/0|

[l/3/0|

[f/0/0|

If the display code is a fault code, this fault code either flashes

(locked fault code) in the display or it is shown permanently

(blocking fault code). A boiler reset is only necessary with a

locking fault code (flashing) (see 8, fig. 2). The cause of the

fault must be remedied first. The cause has to be remedied

and the boiler resumes regular operation.

In the event of a locking boiler fault code both the display

value and the display code flash.

If there are more than once display codes at the same time,

the display codes will be shown in turn. And if one of these

display codes is a locking display code, the blocking display

codes shown will also flash.

–

[l/9/9|

–

–

–

–

d" or "Service e" button (see

Factory

default

setting

1)

/

[\/9/3|

[p/2/9|

[l/9/9|

[f/6/0|

/

/

[l/?/?| [l/?/?|

/

[f/1/d| [f/\/5|

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!20

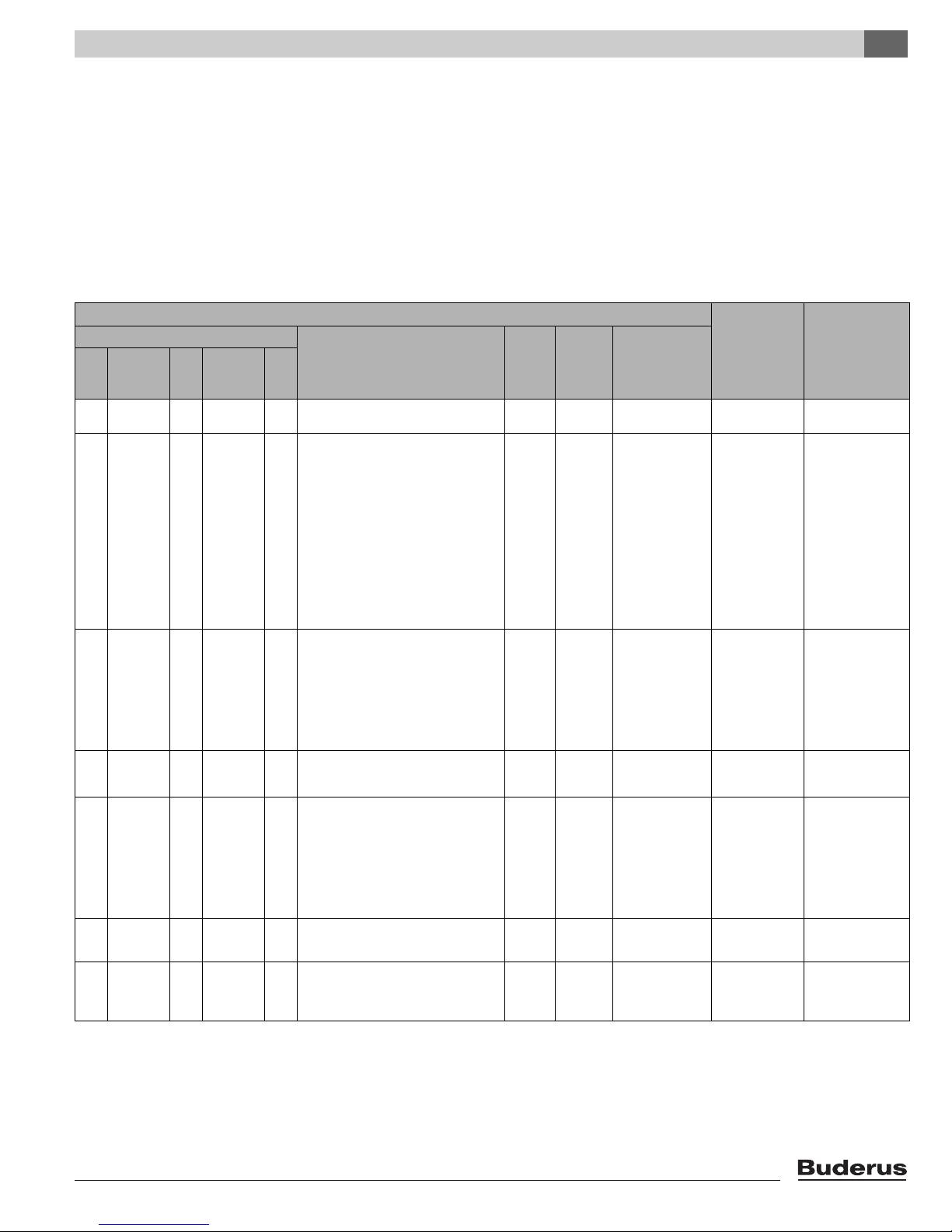

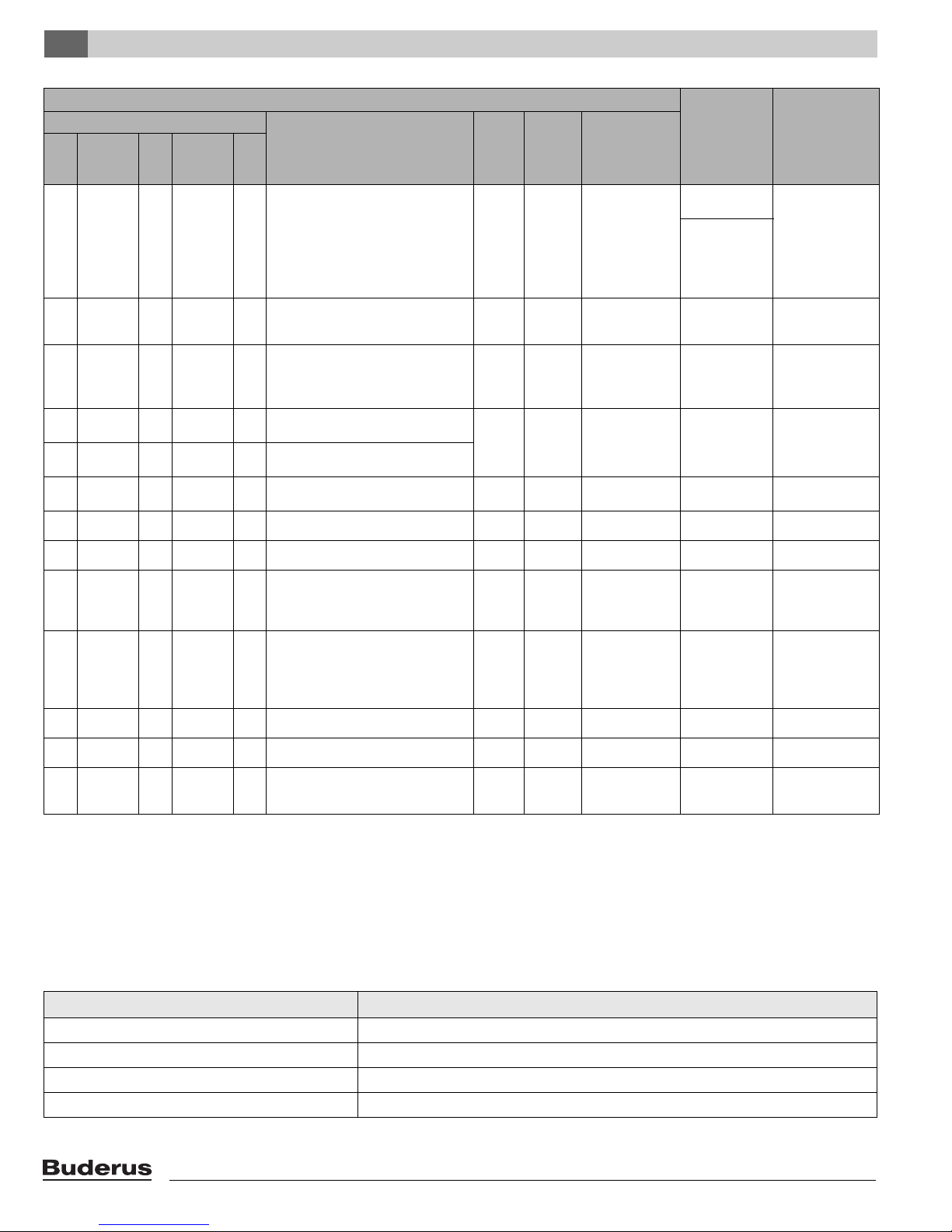

The following display values can be shown on the display of

the BC10 basic controller:

Abbreviations used in table 2:

Type of display code:

BC - Operating code

SC – Service code

BKS – Blocking boiler fault code

VKS – Locking boiler fault code (flashing)

AS – System fault code

ÜC – Other display codes

Symptoms

Display code

z

Main

display

code

z

Sub-

display

code

Key to display code

z

[\/\/\| [\/\/\|

[\/-/\|

e [-/a/\]

or any other

indication

with a

permanent

dot in the

bottom

right-hand

corner.

[2/0/8|

1)

e [-/h/\| e [2/0/0|

1)

e [-/h/}

any other

indication

with a

flashing dot

in the

bottom

right-hand

corner.

e [2/0/0|

1)

e [=/h/\| e [2/0/1|

1)

e [0/a/\| e [3/0/5|

1)

Communication test while starting up.

This code flashes 2 x 2 seconds while

starting up to indicate that the

communication between the UBA 3 and

the BC10 basic controller is being tested.

If a new UBA 3 or a new KIM was fitted,

this code will flash for

max. 10 seconds. If this code continues

to flash on the display, there is a fault in

the communication between the UBA 3

and the BC10 basic controller.

See page 46.

This fault code will also appear when

connecting a thermostat to the RC

terminals.

The boiler is in the flue gas test mode or

in service mode.

The boiler is in heating mode. BC

The boiler is in manual operation mode. BC The room

The boiler is in hot water mode. BC

The boiler has switched off. Start the

pump over-run time via the tank for at

least 30 seconds and maximum

1 minute.

table 2 Display indications on the BC10 basic controller

1)

only visible using the service tool

2)

is being carried out

Type of

display

code

ÜC No heating

BC page 10 or

BC

Reset

required

?

Other

symptoms

No indication in

display.

operation and no

hot water.

temperature is too

high.

Diagnosis Remedy

page 28 page 28

page 11

page 12 page 12

Symptoms 6

page 10 or page 11

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 21

Symptoms6

Symptoms

Display code

Main

display

z

code

z

e [0/a/\| e [2/0/2|

e [0/c/\| e [2/8/3|

e [0/e/\| e [2/6/5|

e [0/h/\| e [2/0/3|

e [0/l/\| e [2/8/4|

e [0/u/\| e [2/7/0|

e [0/y/\| e [2/0/4|

e [0/y/\| e [2/7/6| e

e [0/y/\| e [2/7/7| e

e [0/y/\| e [2/8/5| e

table 2 Display indications on the BC10 basic controller

1)

only visible using the service tool

2)

is being carried out

Sub-

display

code

1)

1)

1)

1)

1)

1)

1)

Key to display code

z

Operating phase:

The switch optimization program is

activated.

This program is activated if there is more

than one burner firing requests from an

RC or ON/OFF regulator within 10

minutes.

This means that the boiler cannot be

restarted until at least ten minutes have

elapsed since initial startup of the burner.

The burner is started.

Readiness for operation:

The boiler is in ready mode.

The time-proportional program is

activated.

The time-proportional program is

activated as soon the load requested by

the modulating room controller is lower

than the lower limit of the boiler load.

During the time-proportional program the

burner is switched on and off repeatedly.

The period in which the burner is

switched on depends on the difference

between the load required by the

modulating room controller and the lower

limit of the boiler load. As soon as the

burner is switched on, the device is

operating at minimum load. As soon as

the burner is switched off, the display

code [0/e/\|

display of the BC10.

The time-proportional program is

deactivated automatically as soon as the

load required by the modulating room

controller is higher than the lower limit of

the boiler load.

The boiler is in ready mode, there is no

heat request.

The gas valve is opened.

Power Up.

Boiler is starting up after a reset or after

the main power is switched on.

This display code will be displayed for 4

minutes maximum.

The boiler switches off, the temperature

is higher than the target temperature.

The supply sensor has measured

a temperature higher than 203 °F

(95 °C).

The safety sensor has measured

a temperature higher than

203 °F (95 °C).

The return sensor has measured

a temperature higher than

203 °F (95 °C).

e [2/6/5| is indicated in the

Type of

display

code

BC Possibly no

BKS no

BKS no

BKS no

BC

BC

BC

BC

BC

BC

Reset

required

?

Other

symptoms

heating operation.

Diagnosis Remedy

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!22

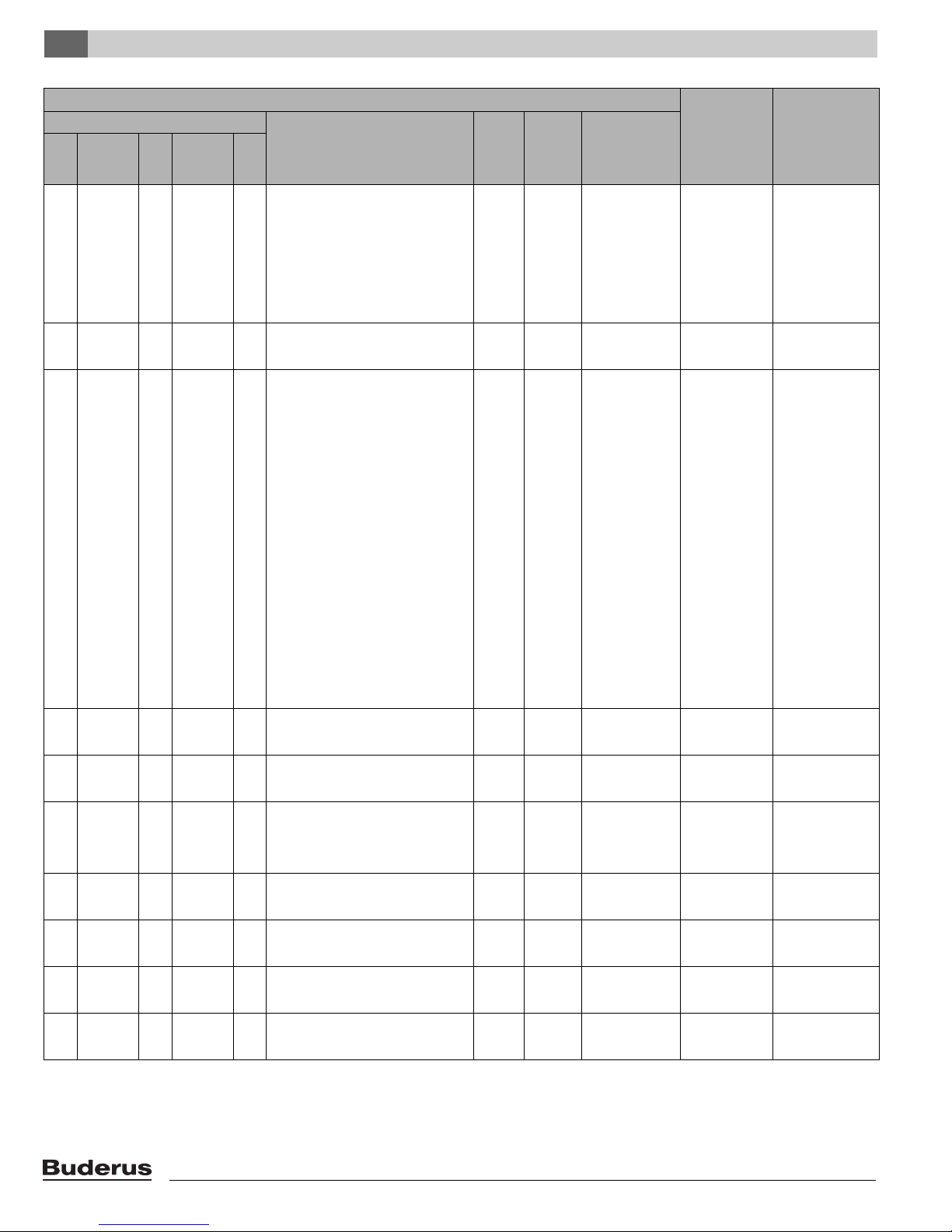

Symptoms

Display code

Main

display

z

code

z

e [1/c/\| e [2/1/0| e

e [1/l/\| e [2/1/1| e

e [2/e/\| e [2/0/7| e

e [2/f/\| e [2/6/0|

e [2/f/\| e [2/7/1| e

e [2/l/\| e [2/6/6| e

e [2/p/\| e [2/1/2|

e [2/u/\| e [2/1/3|

e [3/a/\| e [2/6/4| e

e [3/f/\| e [2/7/3| e

e [3/l/\| e [2/1/4| e

e [3/p/\| e [2/1/6| e

e [3/y/\| e [2/1/5| e

e [4/a/\| e [2/1/8| e

e [4/c/\| e [2/2/4| e

e [4/e/\| e [2/7/8| e

e [4/l/\| e [2/2/0| e

e [4/p/\| e [2/2/1| e

e [4/u/\| e [2/2/2| e

Sub-

display

code

1)

1)

1)

Key to display code

z

Flue gas sensor is activated

(not available).

The UBA 3 does not register any

connections to the unused contacts 78

and 50.

The system pressure is too low.

No temperature increase after burner

start or the temperature difference

between the supply and safety sensors is

more than 27 °F (15 K).

The temperature difference between the

supply and safety sensors is more than

27 °F (15 K).

The primary circulation pump does not

generate a pressure difference.

Temperature increase of supply sensor

or safety sensor is more than 9 °F/sec

(5 K/sec).

The temperature difference between the

supply and return sensors is more than

90 °F (50 K).

The air flow by the blower has failed

during the operating phase.

The blower is switched off during the

safety test.

The blower is switched off during the

safety test.

The blower is running too slowly.

The blower is running too fast.

The supply sensor has measured a

temperature higher than 221 °F (105 °C).

The UBA 3 does not register the short cut

bestween the unused contacts 22 and

24.

The sensor test has failed.

The safety sensor is shorted or

measures temperatures higher than 266

°F (130 °C).

The safety sensor contact

is interrupted.

The supply sensor is shorted.

table 2 Display indications on the BC10 basic controller

1)

only visible using the service tool

2)

is being carried out

Type of

display

required

code

BKS no

BKS no

BKS no

BC

BKS no

VKS yes

BC

BC

BKS no

BKS no

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

Reset

?

Other

symptoms

Flue gas sensor

has measured a

flue gas temperature higher than

221 °F (105 °C)

No heating

operation and no

hot water.

No heating

operation and no

hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and no

hot water.

Symptoms 6

Diagnosis Remedy

page 48 page 48

page 48 page 48

page 49 page 49

page 49 page 49

page 50 page 50

page 52 page 52

page 53 page 53

page 54 page 54

page 55 page 55

page 56 page 56

page 57 page 57

page 58 page 58

page 59 page 59

page 60 page 60

page 60 page 60

page 61 page 61

page 62 page 62

page 63 page 63

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 23

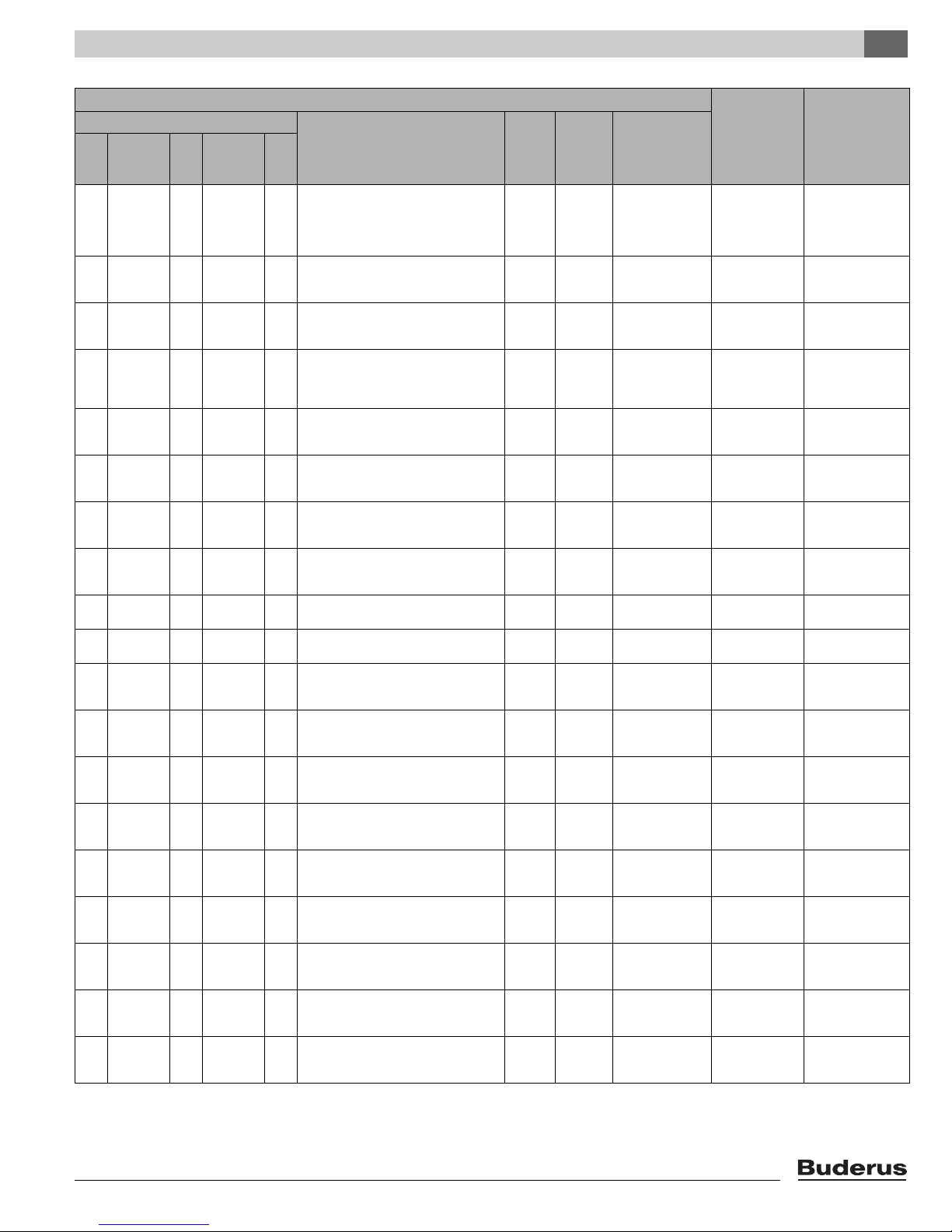

Symptoms6

Symptoms

Display code

Main

display

z

code

z

e [4/y/\| e [2/2/3| e

e [6/a/\| e [2/2/7| e

e [6/a/\| e [2/2/7| e

e [6/c/\| e [2/2/8| e

e [6/c/\| e [3/0/6| e

e [6/l/\| e [2/2/9| e

e [6/p/\| e [2/6/9| e

e [7/c/\| e [2/3/1| e

e [7/l/\| e [2/6/1| e

e [7/l/\| e [2/8/0| e

e [8/y/\| e [2/3/2|

[8.8.8]

e [9/a/\| e [2/3/5| e

e [9/h/\| e [2/3/7| e

e [9/h/\| e [2/6/7| e

e [9/h/\| e [2/7/2| e

e [9/l/\| e [2/3/4| e

e [9/l/\| e [2/3/8| e

e [9/p/\| e [2/3/9| e

e [9/u/\| e [2/3/3| e

table 2 Display indications on the BC10 basic controller

1)

only visible using the service tool

2)

is being carried out

Sub-

display

code

1)

Key to display code

z

The supply sensor contact is interrupted.

No ionization after ignition.

After four startup attempts, a locking

boiler fault follows [6/a/\|.

No ionization after four startup attempts.

An ionization current was measured

before the burner start.

An ionization current was measured after

the burner switch-off.

Ionization fails during the operating

phase.

The hot surface ignitor activates too long.

The power supply was interrupted and

switched on again after a fault message.

The UBA 3 is defective.

The UBA 3 is defective.

The external switch contact is activated.

Display test while starting up. This code

is displayed for a maximum of 1 second.

KIM or UBA 3 is defective.

KIM or UBA 3 is defective.

The UBA 3 is defective.

The UBA 3 is defective.

The gas valve coil or the wiring to the gas

valve is defective.

The UBA 3 is defective.

KIM or UBA 3 is defective.

KIM or UBA 3 is defective.

Type of

display

required

code

VKS yes

BKS no

VKS yes

VKS yes

VKS yes

BKS no

VKS yes

VKS yes

VKS yes

VKS yes

BC

ÜC

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

VKS yes

Reset

?

Other

symptoms

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

Diagnosis Remedy

page 64 page 64

page 65 page 65

page 65 page 65

page 72 page 72

page 72 page 72

page 73 page 73

page 78 page 78

page 78 page 78

page 78 page 78

page 79 page 79

page 80 page 80

page 80 page 80

page 81 page 81

page 80 page 80

page 80 page 80

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!24

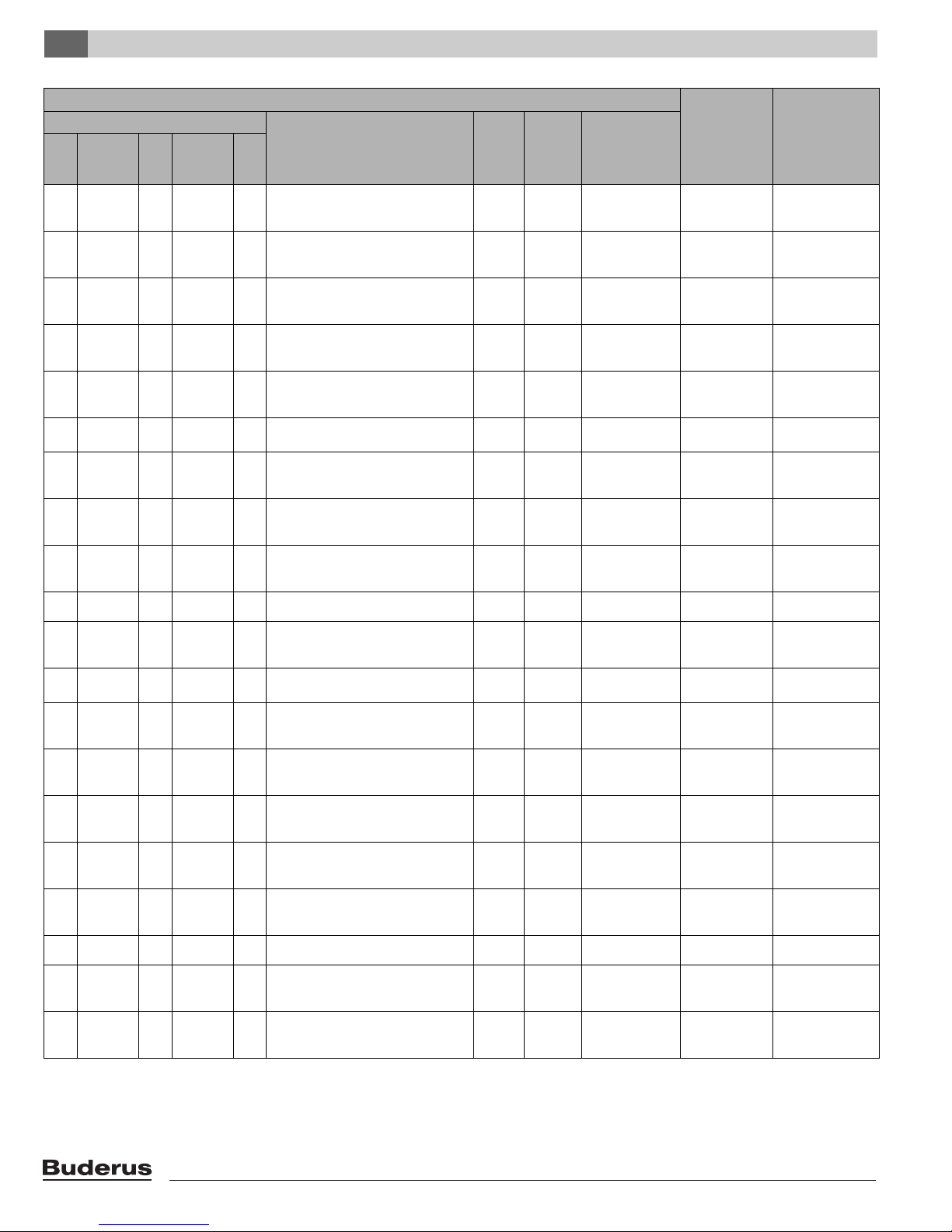

Symptoms

Display code

Main

display

z

code

z

e [a/0/1| e [8/0/0| e

e [a/0/1| e [8/0/8| e

e [a/0/1| e [8/0/9| e

e [a/0/1| e [8/1/0| e

e [a/0/1| e [8/1/1| e

Sub-

display

code

Key to display code

z

Outdoor sensor

Hot water temperature sensor

Hot water temperature sensor 2

Hot water remains cold.

Thermal disinfection.

table 2 Display indications on the BC10 basic controller

1)

only visible using the service tool

2)

is being carried out

Type of

display

code

AS

AS

AS

AS

Reset

required

?

Other

symptoms

The minimum

outdoor

temperature is

assumed.

No water is

heated any more.

The system

constantly tries to

heat the hot water

tank to the hot

water target value

setting.

The hot water

priority is

cancelled when

the fault message

appears.

Thermal

disinfection was

interrupted.

Symptoms 6

Diagnosis Remedy

Sensor

connected or

fitted incorrectly.

Sensor wire

broken or

shorted.

The sensor is

defective.

Sensor

connected or

fitted incorrectly.

Sensor wire

broken or

shorted.

The sensor is

defective.

Permanent

tapping or leak.

Sensor

connected or

fitted incorrectly.

Sensor wire

broken or

shorted.

The sensor is

defective.

Fill pump

connected

incorrectly or

defective.

Tap flow rate too

great during

disinfection

period.

Boiler load too

low for

simultaneous

heat use by

other connected

loads (e. g. 2nd

heating circuit).

Sensor

connected or

fitted incorrectly.

Sensor wire

broken or

shorted.

The sensor is

defective.

Fill pump

defective

Check the sensor

connection and the

sensor wire.

Check the sensor

installation.

Compare the

resistance value to

the sensor graph.

Check the sensor

connection and the

sensor wire.

Check the sensor

installation on the

hot water tank.

Compare the

resistance value to

the sensor graph.

Remedy the leak if

relevant.

Check the sensor

connection and the

sensor wire.

Check the sensor

installation on the

hot water tank.

Compare the

resistance value to

the sensor graph.

Test the fill pump

operation e. g.

using a relay test.

Choose the time for

thermal disinfection

so that no

additional heat

request occurs at

this time.

Check the sensor

connection and the

sensor wire.

Check the sensor

installation on the

hot water tank.

Compare the

resistance value to

the sensor graph.

Test the fill pump

operation e. g.

using a relay test.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 25

Symptoms6

Symptoms

Display code

Main

display

z

code

z

e [a/0/1| e [8/1/6| e

e [a/0/1| e [8/2/8| e

e [a/0/2| e [8/1/6| e

e [c/0/\| e [2/8/8| e

e [c/0/\| e [2/8/9| e

e [c/a/\| e [2/8/6| e

e [c/u/\| e [2/4/0| e

e [c/y/\| e [2/4/1| e

e [e/\/\|

+ any digit

or letter

e [e/\/\|

+ any digit

or letter

[h/\/7|

e [2/9/0| e

e [2/4/2|

e [h/\/7| e

[r/e/\|

table 2 Display indications on the BC10 basic controller

1)

only visible using the service tool

2)

is being carried out

Sub-

display

code

to

[2/8/7|

Key to display code

z

No communication with EMS.

Water pressure sensor.

No communication with BC10.

The UBA 3 has no connection to the

pressure sensor or there is a short circuit.

Short circuit in connection to pressure

sensor.

The return sensor has measured a

temperature higher than 221 °F (105 °C).

The return sensor is shorted.

The return sensor contact is interrupted.

The UBA 3 is defective.

KIM or UBA 3 is defective.

e

The heating system pressure is too low.

The heating system pressure is too low.

Reset is carried out. After pressing the

"Reset" button this code is displayed for

5 seconds.

Type of

display

required

code

AS

AS

AS

VKS yes

VKS yes

VKS yes

VKS yes

BKS no

VKS yes

SC

SC

ÜC

Reset

?

2)

Other

symptoms

The boiler no

longer gets heat

requests; the

heating system no

longer heats.

BC10 settings are

no longer taken

over by RCxx

devices.

No heating

operation and no

hot water.

No heating

operation and

no hot water.

No heating

operation and

no hot water.

Diagnosis Remedy

EMS bus system

is overloaded.

UBA 3/MC10 is

defective.

The digital water

pressure sensor

is defective.

Contact problem

at BC10 or BC10

is defective.

page 82 page 82

page 80 page 80

page 80 page 80

page 78 page 80

page 78 page 80

Reset by switching

the heating system

on and off.

Inform the

BUDERUS

customer service

department if

necessary.

Replace the digital

water pressure

sensor.

Check the BC10

connection.

Replace the BC10

if necessary.

6.2 LED on the UBA 3

In addition to the display indication on the BC10 basic controller, there is a red LED on the UBA 3.

The meaning of this LED is explained in see table 3.

LED Meaning

Off Normal operation

Flashing slowly (1 Hz) There is a boiler fault (locking fault).

Flashing fast (10 seconds) During startup after replacing the KIM or the UBA 3.

On During a fault in the UBA 3 or if the KIM is not recognized.

table 3 LED on the UBA 3

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!26

7 Diagnosis

7.1 Faults without a fault code

Hot water request

Although the UBA 3 indicates that the system is ready for

operation, it is possible that in the event of a hot water request no

hot water is made available, or it is only made available for a short

time.

Structure diagram for troubleshooting, see page 33.

Heating mode

Although the UBA 3 shows that the system is ready for operation

and the room temperature has not reached the preset value, the

Logamax plus GB142 does not enter the heating mode.

Structure diagram for troubleshooting: page 44.

Diagnosis 7

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 27

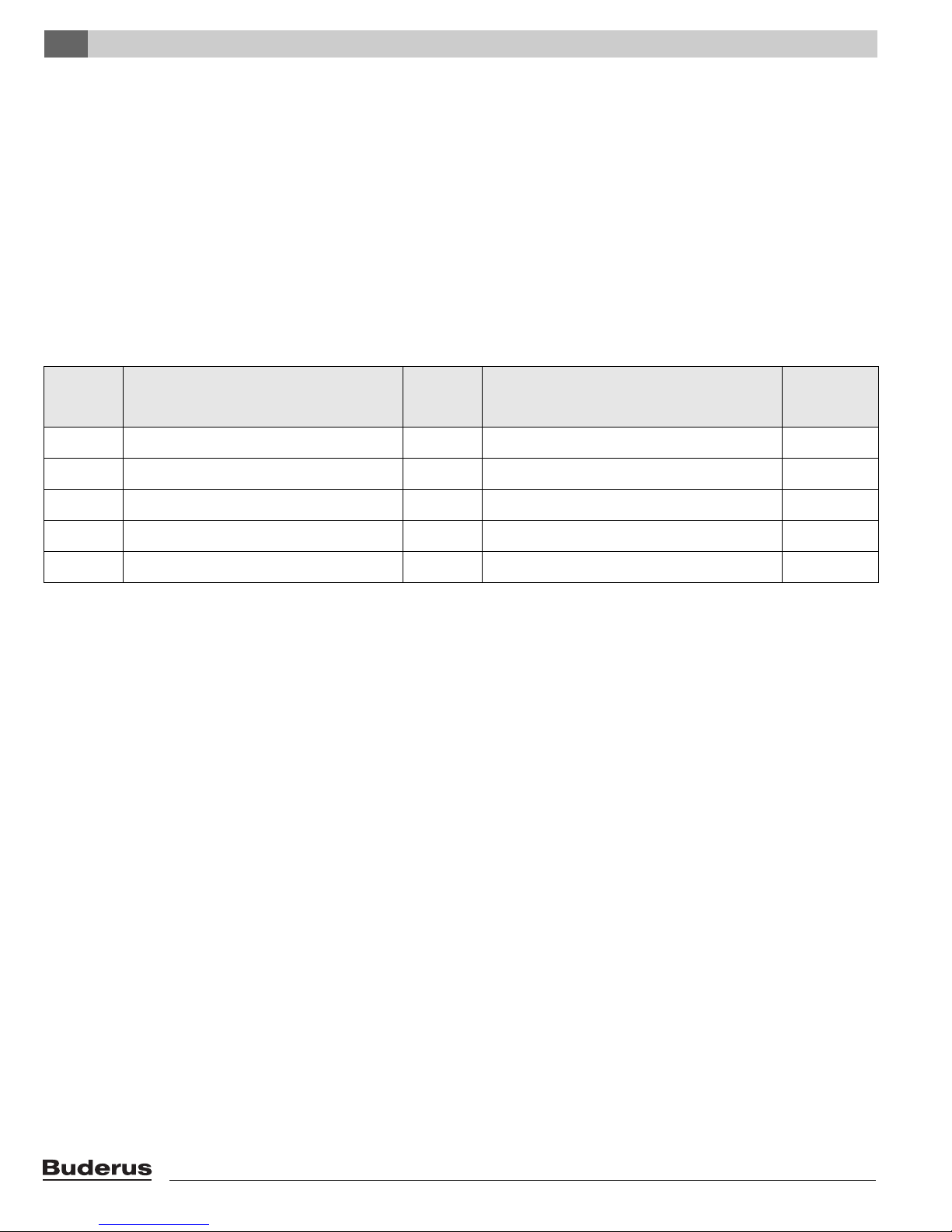

No display

8

page 31

yes

no

no

no

yes

Is the mains power

switch ON?

No indication in display.

no

yes

7

page 30

Switch on the mains power switch.

Check that the operating switch is in

position “1” (ON). See page 9.

yes

no

Is the

operating switch on the BC 10 in

position “1” (ON)?

Turn the operating switch on the BC 10 to

position “1” (ON). See page 9 (fig. 2).

Is the 120V AC cord okay?

Check that there is a 120V AC power

supply at the mains power switch.

yes

Is there a voltage at the

mains power switch?

Measure the resistance of the 120V AC

supply cord.

Check the fuse on the rear of the UBA 3

using a volt-ohm-multimeter.

See page 84.

Is the fuse okay?

44

page 83

Is there any indication on the

BC10 display?

Replace the fuse.

See page 84.

Deal with any problem in the electrical

system.

yes

no

Replace the cable loom (or the affected

part thereof.

Check that the mains power switch

is ON.

No

yes

Do the other

functions of the device work

normally?

19

page 29

Turn the operating switch on the BC10 to

position “0” (OFF). See page 9, par. 4.2.

Diagnosis7

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!28

44

page 83

Measure the relevant part of the cable loom.

See page 126.

Yes

Is the cable loom okay?

8

page 31

Check that there is between 7.8 and 15.2

VDC on both contacts 1 and 2 of the BC10.

See page 126.

No

No

Is there a voltage?

19

page 28

Replace the BC10.

See the fitting instructions of

the BC10.

Yes

Replace the cable loom or the

affected part thereof.

Diagnosis 7

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 29

Diagnosis7

Replace the fuse again.

See page 84.

No

No

Yes

7

Disconnect the following boiler components

from the electrical power supply:

- the blower, see page 86,

- the primary circulation pump,

see page 126.

No

Yes

Is the fuse okay?

Is there any indication on the

BC10 display?

Connect the external primary

circulation pump.

10

page 31

Turn the operating switch on the BC 10 to

position “1” (ON). See page 9, par. 4.2.

Turn the operating switch

to “0” (OFF).

Is there any indication on the

BC10 display?

Turn the operating switch on the BC10 to

position “1” (ON). See page 9, par. 4.2.

Replace the external primary

circulation pump.

Replace the fuse again.

See page 84.

9

page 32

Check the fuse on the rear of the UBA 3

again using a volt-ohm-multimeter.

See page 84.

Yes

page 28

No display, part 2

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!30

Loading...

Loading...